Page 1

S CRIPT

TM

i

user’s manual

c l s e l e c t r o s t a t i c

M ARTIN L OGAN

®

Page 2

2 Contents & Introduction

CONTENTS &INTRODUCTION

Contents & Introduction . . . . . . . . . . . . . . . . . . . . . . . . .2

Contents

Introduction

Installation in Brief . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Low Voltage Power Connection

Signal Connection

Using Only One Power Supply . . . . . . . . . . . . . . . . . . .5

Break-In

Mounting the Script i On A Wall . . . . . . . . . . . . . . . . . .6

Changing the Direction of Rotation . . . . . . . . . . . . . .10

Room Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Your Room

Terminology

Rules of Thumb

Dipolar Speakers and Your Room

Dispersion Interactions . . . . . . . . . . . . . . . . . . . . . . . . .12

Controlled Horizontal Dispersion

Controlled Vertical Dispersion

Three Major Types of Dispersion

Home Theater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Electrostatic Advantages . . . . . . . . . . . . . . . . . . . . . . . .15

Full Range Operation . . . . . . . . . . . . . . . . . . . . . . . . .16

MartinLogan Exclusives . . . . . . . . . . . . . . . . . . . . . . . . .17

Curvilinear Line Source

MicroPerf Stator

Plasma Deposited Diaphragm

Transducer Integrity

Low Voltage Power

Electrostatic Loudspeaker History . . . . . . . . . . . . . . . .18

Frequently Asked Questions . . . . . . . . . . . . . . . . . . . . .20

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Specifications

Warranty and Registration

Service

Serial Numbers

Glossary of Audio Terms . . . . . . . . . . . . . . . . . . . . . . . .24

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Congratulations! You have invested in one of the world’s

premier loudspeaker systems.

The MartinLogan Script i represents the culmination of an

intensive, dedicated group research program directed

toward establishing a world class reference monitor

utilizing leading-edge technology, without compromising

durability, reliability, craftsmanship or aesthetic design.

The result of cumulative technology gleaned from previous

research and development projects, the Script i represents

the latest developments in electrostatic and hybrid loudspeaker technology.

Combining our proprietary curvilinear electrostatic transducer with a compact, but powerful woofer, we have designed

a product, in one package, that reproduces music with

uncomprimised electrostatic clarity.

The materials in your new Script i speakers are of the highest

quality and will provide years of enduring enjoyment

and

deepening respect. The cabinetry is constructed from

the highest quality composite material for acoustical integrity

and is finished with our attractive custom matte finish.

Through rigorous testing, the curvilinear electrostatic panel

has proven itself to be one of the most durable and reliable

transducers available today. Fabricated from a custom tool

punched high-grade steel, the patented panel is then coated

with a special polymer that is applied via a proprietary plasma

bonding process. This panel assembly houses a membrane

just 0.0005 of an inch thick. Ruggedly constructed and

insulated, as much as 150 watts of continuous power has

driven the Script i’s energized diaphragm into massive

excursions with no deleterious effects.

The other sections of your User’s Manual will explain in

detail the operation of your Script i’s and the philosophy

applied to their design. A clear understanding of your

speakers will insure that you obtain maximum performance and pleasure from this most exacting transducer. It

has been designed and constructed to give you years of

trouble-free listening enjoyment.

Page 3

Installation in Brief 3

INSTALLATION IN BRIEF

We know you are eager to hear your Script i loudspeakers,

so this section is provided to allow fast and easy set up.

Once you have them operational, please take the time to

read, in depth, the rest of the information in this manual.

It will give you perspective on how to attain the greatest

possible performance from this most exacting transducer.

If you should experience any difficulties in the setup or

operation of your Script i’s, please refer to the Installation

or Operation sections of this manual.

Should you encounter a persistent problem that cannot be

resolved, please contact your authorized MartinLogan

dealer. They will provide you with the appropriate technical

analysis to alleviate the situation.

WARNING!

•Hazardous voltages exist inside—do not

remove cover

•Refer servicing to a qualified technician

•To prevent fire or shock hazard, do not

expose this module to moisture

•Turn amplifier off and unplug speaker

should any abnormal conditions occur

•Do not operate if there is any visual

damage to the electrostatic panel element

•Do not over drive speaker beyond its rated power

Step 1: Unpacking

Remove your new Script i speakers from their packing.

Step 2: Mounting

Mount each Script i at its desired location on your front,

side, or back wall(s). Please see the Mounting the Script i

section (pages 6–10) of this manual for details on installation

and determining the proper mounting height.

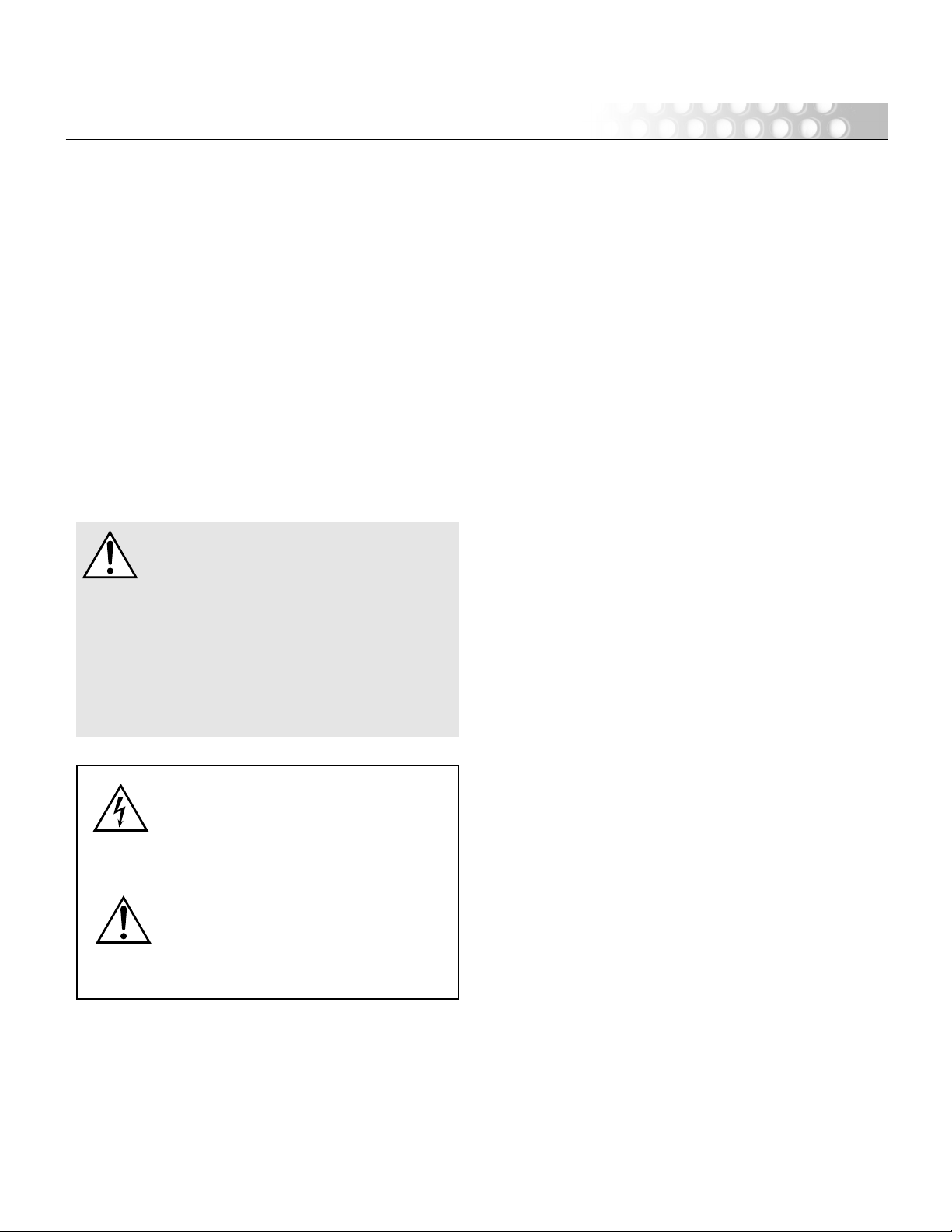

Step 3: Power Connection (see warning)

The Script i requires power to energize its electrostatic

panel. Plug the provided power supply first into the Power

In power receptacle on the rear panel of the speaker

,

making sure that you have made a firm

connection, and

then to a convenient wall outlet. Please see the Operations

section (pages 4–5) of this manual for more details.

Step 4: Signal Connection

Use the best speaker cables you can. Higher quality cables,

available from your specialty dealer, are recommended

and will give you superior performance. Spade connectors

are suggested for optimum contact and ease of installation.

Attach your speaker cables to the Signal Input section on

the rear panel. Be consistent when connecting speaker

leads to the terminals on the back of the Script i: take

great care to assign the same color to the (+) terminal on

both the left and right channels. If bass is nonexistent and

you cannot discern a tight, coherent image, you may need

to reverse the (+) and (-) leads on one side to bring the

system into proper polarity.

Please see the Operations section (pages 5) of this manual

for more details.

Step 5: Listen and Enjoy

Now, you may turn on your system and enjoy!

The lightning bolt flash with arrowhead symbol, within

an equilateral triangle, is intended to alert the user to

the presence of uninsulated “dangerous voltage” within the

product’s enclosure that may be of sufficient magnitude

to constitute a risk of electric shock.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in

the literature accompanying the appliance.

Page 4

Your Script i’s use external low-voltage power supplies to

energize their electrostatic panels. For this reason the proper

low-voltage power supplies are provided. A power supply

should be firmly inserted into the ‘Power In’ receptacle on

the rear connection panel of each speaker, then to any

convenient AC wall outlet. Your Script i’s integrate a signal

sensing circuit which will switch the Script i off after a few

minutes of no music signal, and requires less than two seconds to recharge the panels when a music signal is present.

Your Script i speakers are provided with a power supply

for the power service supplied in the country of original

consumer sale. The AC power rating applicable to a particular unit is specified both on the packing carton and on

the power supply.

If you remove your Script i speakers from the country

of original sale, be certain that AC power supplied in any

subsequent location is suitable before connecting the lowvoltage power supply. Substantially impaired performance

or severe damage may occur to a Script i speaker if operation is attempted from an incorrect AC power source.

WARNING! The power supply should not be

installed, removed, or left detached from the speaker while connected to an AC power source.

Signal Connection

Use the best speaker cables you can. The length and type of

speaker cable used in your system will have an audible

effect. Under no circumstance should a wire of gauge higher

(thinner) than #16 be used. In general, the longer the length

used, the greater the necessity of a lower gauge, and the

lower the gauge, the better the sound, with diminishing

returns setting in around #8 to #12.

A variety of speaker cables are now available whose

manufacturers claim better performance over standard

heavy gauge wire. We have verified this in many cases, and

the improvements available are often more noticeable

than the differences between wires of different gauge. The

effects of cables may be masked if the equipment is not of

the highest quality.

We also recommend, if possible, that short runs of speaker

cable connect the power amplifier and speaker and that

high quality long interconnect cables be used to connect

the preamplifier and power amplifier. This results in the

power amplifiers being close to the speakers, which may

be practically or cosmetically difficult, but if the length of

the speaker cables can be reduced to a few meters, sonic

advantages may be obtained.

Connections are done at the Signal Input section on the

rear electronics panel of the Script i (see figure 1). Use spade

connectors for optimum contact. Make certain that all of

your connections are tight.

Be consistent when connecting speaker leads to the terminals

on the back of the Script i: take great care to assign the

same color to the (+) terminal on both the speaker and

the amplifier.

WARNING! Turn your amplifier off before making

or breaking any signal connections!

Low-Voltage Power Connection

4 Operation

OPERATION

Figure 1. Single-wire and power connection. One Channel shown.

Page 5

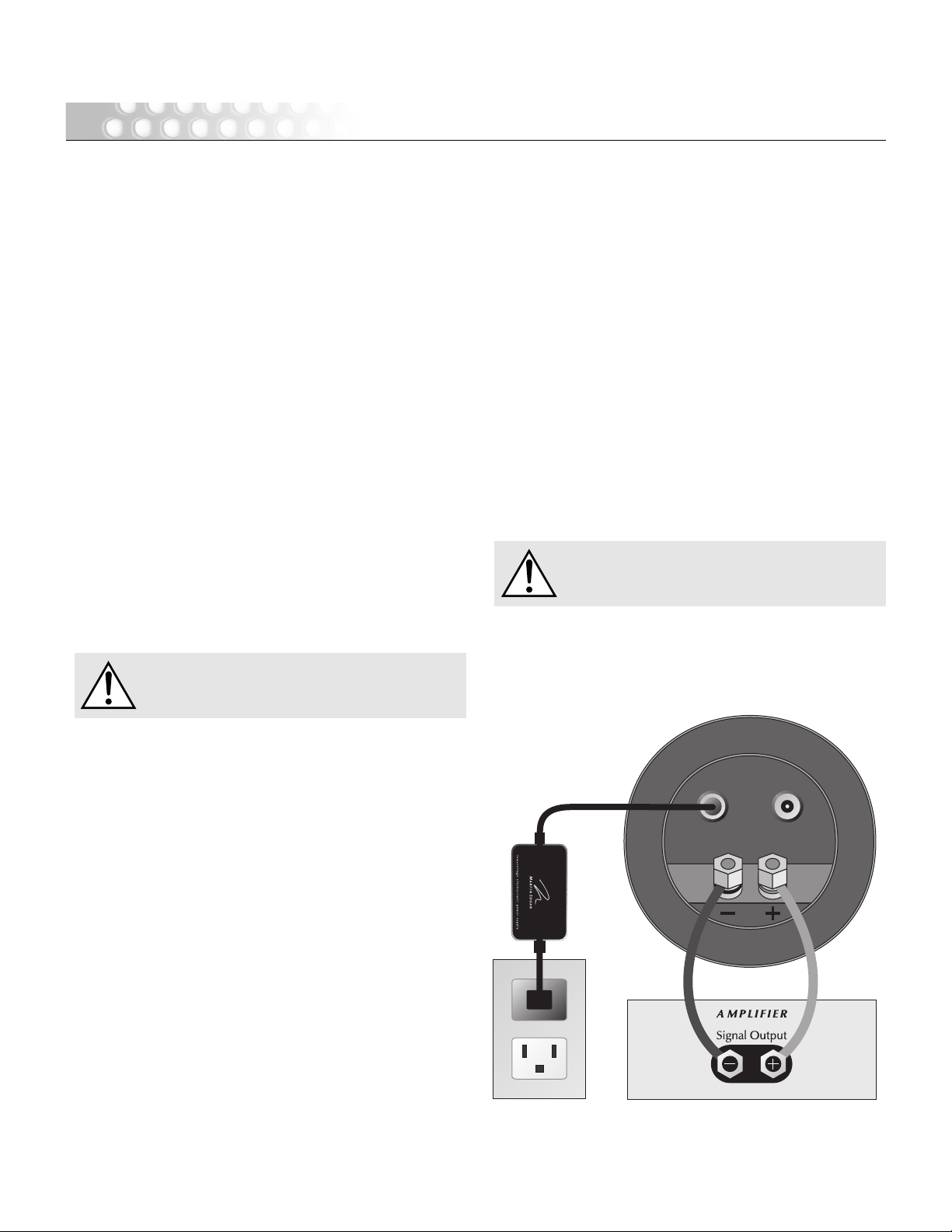

You may have noticed a connection on the back of your

Script i’s labeled ‘Power Out’. The use of this connection will

allow you to daisy-chain up to seven 16-volt MartinLogan

products and eliminate the need for multiple low-voltage

power supplies.

A variety of low voltage interconnect cables may be purchased at your local MartinLogan dealer. Please ask them

about options to fit your specific needs.

To use this connection option choose a primary speaker

(whichever speaker is most conveinent) and connect it as

instructed in the ‘Low-Voltage Power Connection’ section

on the previous page. To attach additional speakers, run a

low-voltage interconnect cable from the ‘Power Out’ to

the next speakers ‘Power In’ (see figure 2).

When you first begin to play your Script i speaker, it will

sound a bit bass shy. This is due to the high-quality, long-life

components used in our woofer. Our custom made, butyl

surround woofer requires at least 30 hours of break-in at

90 dB (moderate listening levels) before any critical listening.

The break-in requirements of the crossover components

(and, to a lesser degree, the electrostatic transducer) are equal.

Operation 5

Using Only One Power Supply Break-In

Figure 2. Connecting power to multiple speakers using one power supply.

Page 6

WARNING! Installing the Script i on a wall

requires only 1 person, but an assistant will

be helpful.

The stand shipped with the MartinLogan Script i

loudspeaker is designed for use only with the

Script i. Use with other appliances may result in

instability causing possible injury.

To prevent injury, this apparatus must be securely attached to the wall in accordance with the

installation instructions.

NOTE: These instructions describe how to mount the Script i

to a wall. MartinLogan recommends using 5 wall anchors

to secure each Script i to the wall. If any of the screws hit a

stud, it is recommended to screw directly into the stud.

NOTE: To assure that your Script is are safely wall mounted,

these instructions must be carefully followed. Study them

thoroughly before beginning to install your Script i’s.

NOTE: The following instructions assume the mounting

surface is of standard wood frame and standard sheet rock

construction. If you wish to mount the Script i to another

type of material, you should consult a bonded contractor.

Required hardware (included):

(10) wall anchors

(10) 1" Phillips head wood screws

6mm Allen tool

Required tools (not supplied):

A level

An electric drill and 1/4" and 1/8" drill bits

Phillips screwdriver

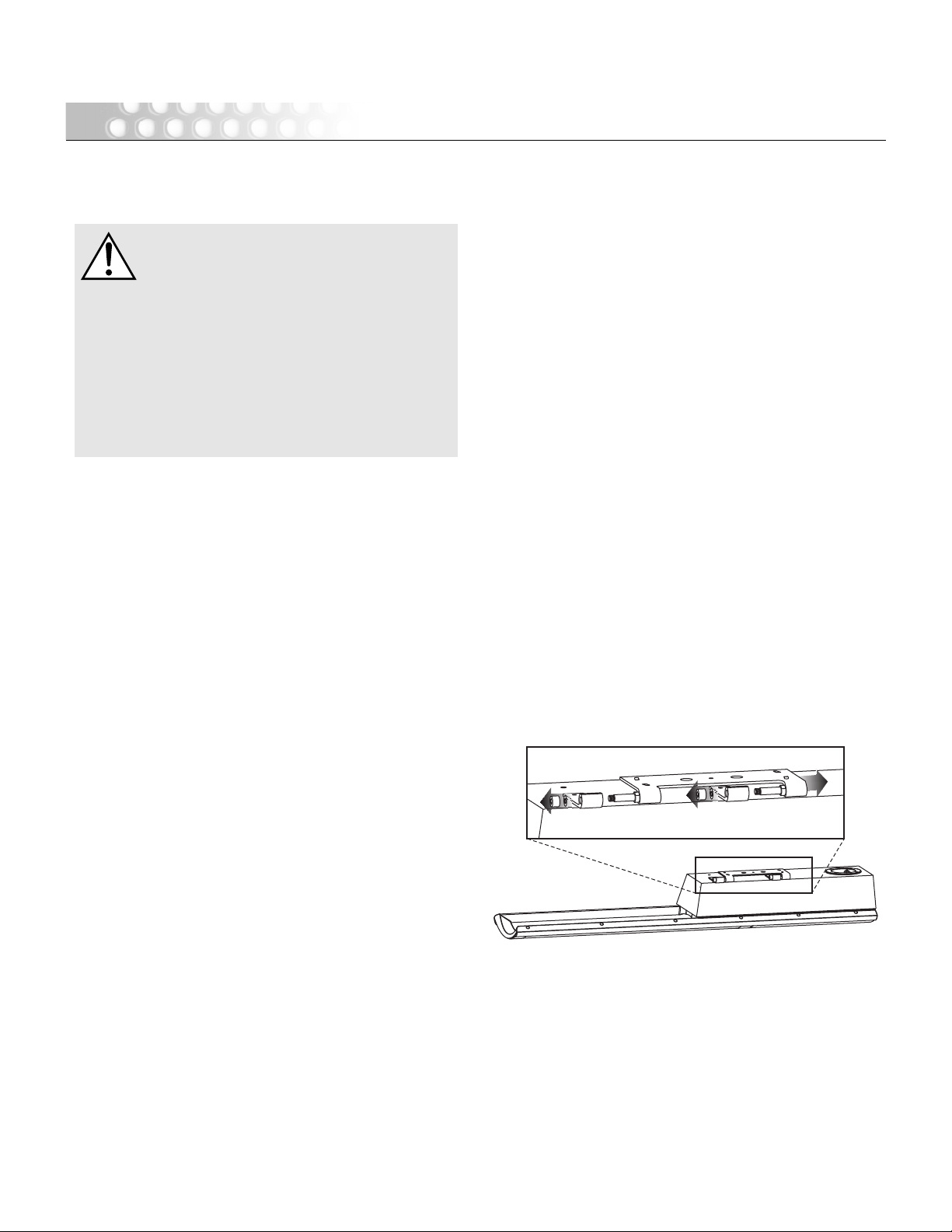

1 Your Script i loudspeakers ship from the factory with the

wall mounting brackets installed. You will notice that the

brackets are installed on opposite sides of each speaker.

This allows 1 speaker to pivot clockwise and the other

to pivot counterclockwise. Before beginning your installation, place a Script i near the desired installation location

and assure that the direction of rotation will allow you to

pivot the Script i towards your listening location. If the

direction of rotation causes your Script i to pivot away

from the listening location, try the other speaker. Leave

each Script i near it's desired installation location before

proceeding and only install one speaker at a time—this

will eliminate the chance of confusing the nearly identical

wall brackets as you install your new speakers.

2 Starting with one speaker, prepare a flat surface with

padding and sheets to protect the speaker as you work

on it. Carefully place the Script i face down on the work

surface, using books or pieces of cardboard to keep the

speaker from rocking. Using a 6mm Allen tool remove

the 2 cap nuts and washers located on top of the cylindrical hinges and place them aside (do not reinstall the cap

nuts). Carefully remove the wall bracket from the cabinet

by sliding it towards the bottom of the speaker. Please note

that the 2 long narrow cabinet brackets DO NOT need

to be removed from the Script i cabinet (see figure 3).

Figure 3. Removing the Script i wall bracket from the cabinet.

6 Mounting the Script i On A Wall

MOUNTING THE SCRIPT i On A Wall

Page 7

Mounting the Script i On A Wall 7

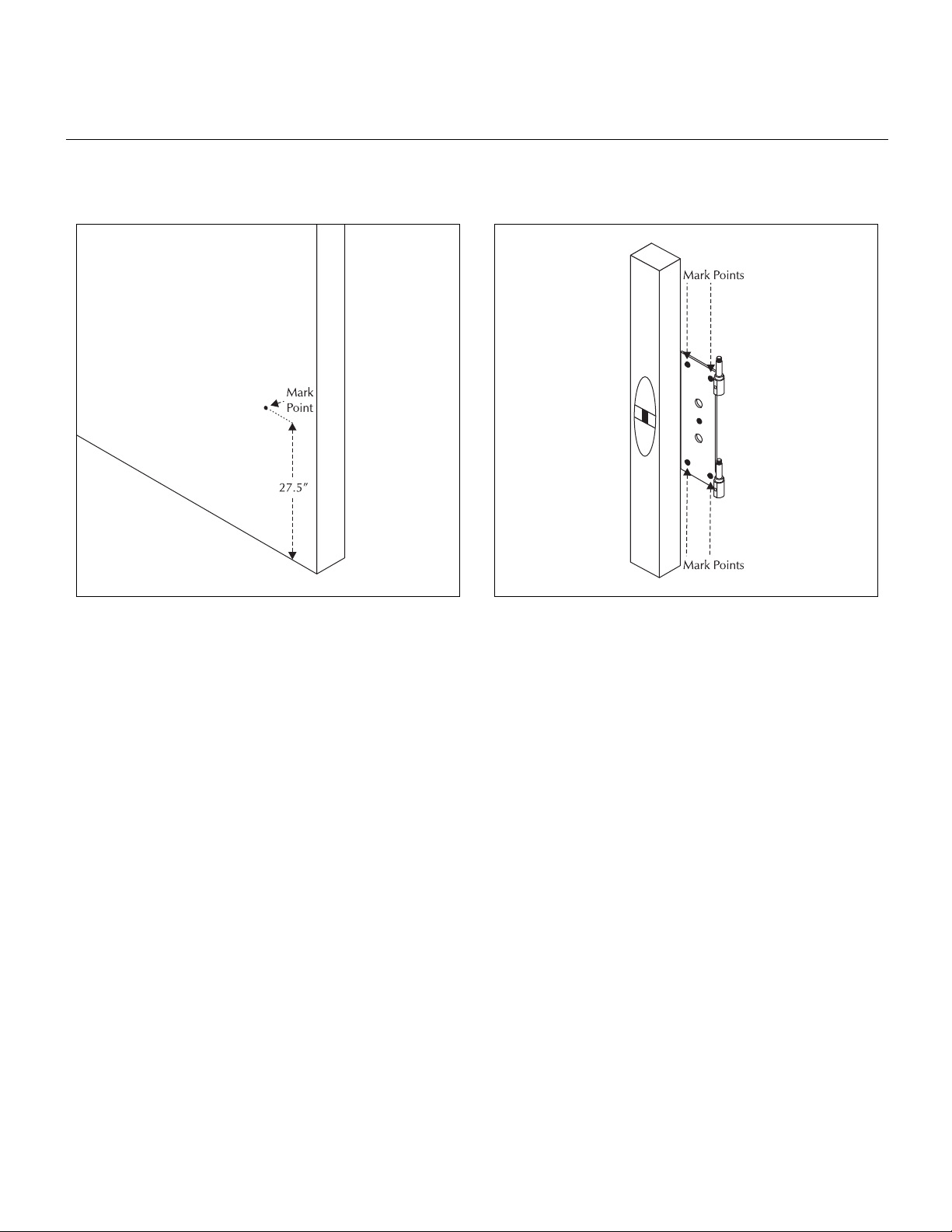

3 At the desired installation location, mark a point on your

wall 27.5 inches above the floor (see figure 4).

4 Using a level, square the wall bracket and hold it flush

against the wall with the wall bracket’s center hole over

the center point you just marked. The cylindrical hinges

on the wall bracket should point away from the wall

and the hinge pins should point upwards towards the

ceiling. Mark 4 points (2 each at the top and bottom of

the bracket) inside of the wall bracket’s arc shaped cut

outs (see figure 5).

Figure 4. Step 3 Figure 5. Step 4

Page 8

8 Mounting the Script i On A Wall

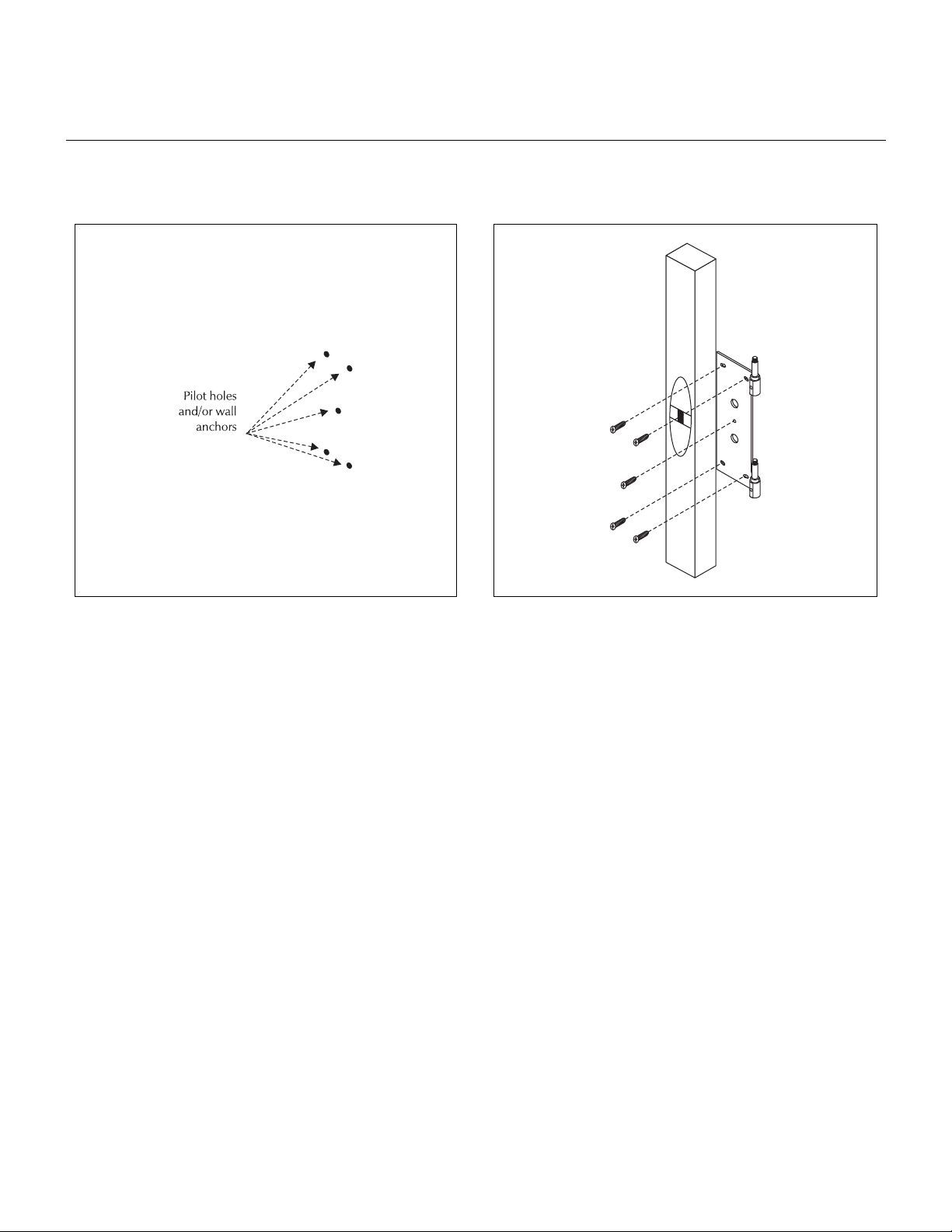

5 Set the wall bracket aside. Using a

1

/8" bit, drill a pilot

hole at all five points. If any of the pilot holes hit a stud

during this step, DO NOT widen the pilot hole and

install a wall anchor at that location. If a pilot hole does

not hit a stud, use a 1/4" bit to widen the pilot hole and

using a Phillips screwdriver install the wall anchors so

they are flush with the wall (see figure 6).

6 Mount the wall bracket to the center wall anchor (or

pilot hole) using a 1" Phillips head screw driven through

the wall brackets center point. Do not fully tighten the

screw—the bracket must be vertically leveled before

installing the remaining screws. The cylindrical hinges

on the wall bracket should point away from the wall

and the hinge pins should point upwards towards the

ceiling (see figure 7).

7 Using a level, square the bracket and drive the four

remaining 1" Phillips head screws into the upper and

lower wall anchors (or pilot holes). Do not fully tighten

the screws (see figure 7).

8 Using a level, make sure the bracket is level and tighten

all five screws (see figure 7).

Figure 6. Step 5 Figure 7. Steps 6–8

Page 9

Mounting the Script i On A Wall 9

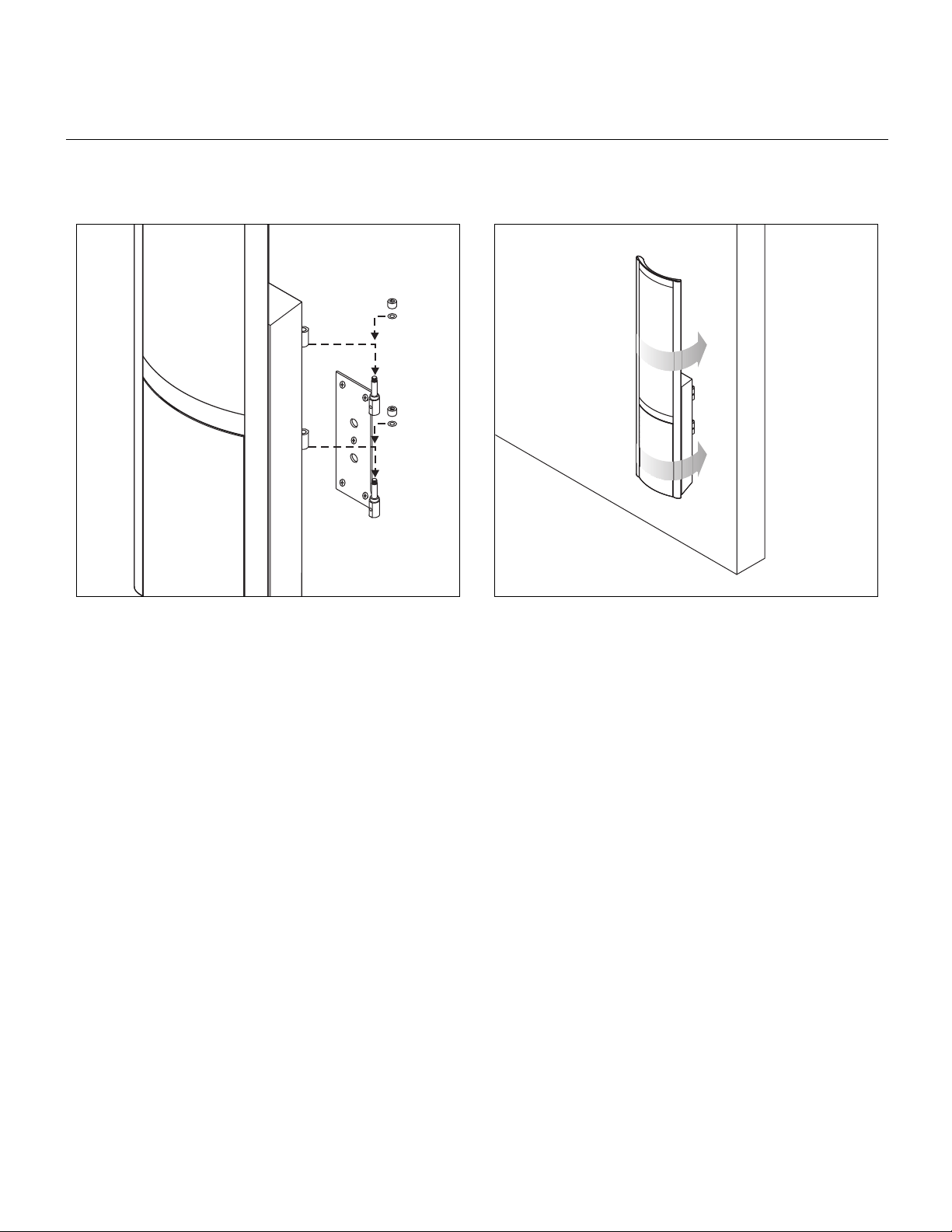

9 Place the Script i onto the wall bracket aligning the

cylindrical parts of the cabinet bracket hinges with the

upward pointing pins on the wall bracket. Carefully

lower the Script i into place (see figure 8).

10 Using a 6mm Allen tool, attach a cap nut and washer on

top of each pin, but do not fully tighten the cap nuts

(see figure 8).

11 Make signal connections from the amplifier and the AC

power connection (see Operations section, pages 4-5).

12 Rotate the Script i to point at the listening position and

tighten the cap nuts.

13 To install the other Script i, repeat steps 2-12.

Figure 8. Steps 9–10 Figure 9. Step 12

Page 10

10 Mounting the Script i On A Wall

NOTE: Your Script i’s ship from the factory with the brackets

installed on opposite sides of each speaker. This allows 1

speaker to pivot clockwise and the other to pivot counter-

clockwise. Most installations will not require any alteration

to the bracket.

NOTE: These instructions describe how to change the

Script i’s wall and cabinet brackets so that the speaker will

rotate in the oposite direction.

Required hardware (included):

2.5mm Allen tool

6mm Allen tool

Required tools (not supplied):

1

/8" Allen tool

1 Prepare a flat surface with padding and sheets to pro-

tect the speaker as you work on it. Carefully place the

Script i face down on the work surface, using books or

pieces of cardboard to keep the speaker from rocking.

Using a 6mm Allen tool remove the 2 cap nuts located

on top of the cylindrical hinges and place them aside.

Carefully remove the wall bracket from the cabinet by

sliding it towards the bottom of the speaker (see figure 3).

2 Using a 2.5mm Allen tool carefully loosen the 2 set screws

that hold the 2 hinge pins in place (see figure 10, step A).

3 Remove the 2 hinge pins (see figure 10, step B).

4 Rotate the wall bracket 180 degrees (see figure 10, step C).

5 Reinstall the 2 hinge pins (see figure 10, step D).

6 Using a 2.5mm Allen tool, reinstall the 2 set screws to

lock the hinge pins in place. Make sure the set screw

tightens against the flat surface of the pin (see figure 10,

step E).

7 Using a 1/8" Allen tool, remove 4 screws (2 each) from the

cabinet brackets (see figure 11).

8 Rotate the cabinet brackets 180 degrees and install them

on the oposite side of the cabinet (see figure 12).

Figure 10. Changing the pivot direction of the Script i wall bracket.

Changing the Direction of Rotation

Figure 11. Removing the Script i cabinet brackets.

Figure 12. Reinstalling the Script i cabinet brackets.

Page 11

Room Acoustics 11

Your room is actually a component and an important part of your

system. This component is a very large variable and can dramatically add to, or subtract from, a great musical experience.

All sound is composed of waves. Each note has its own wave

size, with the lower bass notes literally encompassing from 10’

feet to as much as 40’ feet. Your room participates in this wave

experience like a three dimensional pool with waves reflecting

and becoming enhanced depending on the size of the room and

the types of surfaces in the room.

Remember, your audio system can literally generate all of the

information required to recreate a musical event in time, space,

and tonal balance. The purpose of your room, ideally, is to not

contribute to that information. However, every room does contribute to the sound, and the better speaker manufacturers have

designed their systems to accommodate this phenomenon.

Terminology

Standing Waves – The parallel walls in your room will reinforce

certain notes to the point that they will sound louder than the rest

of the audio spectrum and cause “one note bass”, “boomy bass”

or “tubby bass”. For instance, 100Hz represents a 10 foot wavelength. Your room will reinforce that specific frequency if one of the

dominant dimensions is 10 feet. Large objects in the room such as

cabinetry or furniture can help to minimize this potential problem.

Some serious “audiophiles” will literally build a special room

with no parallel walls just to help eliminate this phenomenon.

Reflective Surfaces (near-field reflections) – The hard surfaces of

your room, particularly if close to your speaker system, will reflect

some waves back into the room over and over again, confusing

the clarity and imaging of your system. The smaller sound waves

are mostly affected here, and occur in the mid and high frequencies.

This is where voice and frequencies as high as the cymbals occur.

Resonant Surfaces and Objects – All of the surfaces and objects

in your room are subject to the frequencies generated by your

system. Much like an instrument, they will vibrate and “carry on”

in syncopation with the music, and contribute in a negative way

to the music. Ringing, boominess, and even brightness can occur

simply because they are “singing along” with your music.

Resonant Cavities – Small alcoves or closet type areas in your room

can be chambers that create their own “standing waves” and can

drum their own “one note” sounds.

Clap your hands. Can you hear an instant echo respond back?

You have near-field reflections. Stomp your foot on the floor.

Can you hear a “boom”? You have standing waves or large panel

resonances such as a poorly supported wall. Put your head in a

small cavity area and talk loudly. Can you hear a booming?

You’ve just experienced a cavity resonance.

Rules of Thumb

Hard vs. Soft Surfaces – If the front or back wall of your listening

room is soft, it might benefit you to have a hard or reflective wall

in opposition. The ceiling and floor should follow the same basic

guideline as well. However, the side walls should be roughly the

same in order to deliver a focused image.

This rule suggests that a little reflection is good. As a matter of fact,

some rooms can be so “over damped” with carpeting, drapes and

sound absorbers that the music system can sound dull and lifeless.

On the other hand, rooms can be so hard that the system can

sound like a gymnasium with too much reflection and brightness.

The point is that balance is the optimum environment.

Breakup Objects – Objects with complex shapes, such as book-

shelves, cabinetry and multiple shaped walls can help break up

those sonic gremlins and diffuse any dominant frequencies.

Dipolar Speakers and Your Room

MartinLogan electrostatic loudspeakers are known as dipolar

radiators. This means that they produce sound from both their

fronts and their backs. Consequently, musical information is

reflected by the wall behind them and may arrive, either in or

out of step, with the information produced by the front of the

speaker. The Script i was designed to minimize these rear wall

reflection interactions when it is mounted on a wall.

Now that you know about reflective surfaces and resonant objects,

you can see how midrange and high frequencies can be affected.

The timing of the initial wave as it radiates to your ears, and then

the reflected information as it arrives at your ears later in time, can

result in confusion of the precious timing information that carries

the clues to imaging. Consequently the result is blurred imaging

and excessive brightness. Soft walls, curtains, wall hangings, or

sound dampeners (your dealer can give you good information

here) can be effective if these negative conditions occur.

Your Room

ROOM ACOUSTICS

Page 12

12 Dispersion Interactions

Your Script i’s launch a 30 degree dispersion pattern when

viewed from above. This horizontal dispersion field gives a

choice of good seats for the performance while minimizing

interactions with side walls (see figure 13). Make sure both

speakers stand exactly at the same vertical angle, otherwise

the image can be skewed or poorly defined. The wave

launch of both speakers is extremely accurate in both the

time and spectral domain. Consequently, small refined

adjustments can result in noticeable sonic improvements.

Controlled Vertical Dispersion

As you can see from the illustrations, your Script i speakers

project a controlled dispersion pattern. Each Script i is a 26”

inch line source (see figure 14). This vertical dispersion

profile minimizes interactions with the floor and the ceiling.

In the field of loudspeaker design, it is a known fact that as

the sound wave becomes progressively smaller than the

transducer producing it, the dispersion of that wave

becomes more and more narrow, or directional. This fact

occurs as long as the transducer is a flat surface. Large flat

panel speakers exhibit venetian blind effects due to this

phenomenon. This is why most manufacturers opt for

small drivers (i.e. tweeters and midrange) to approximate

what is known as a point source wave launch.

Historically, most attempts to achieve smooth dispersion

from large flat panel transducers resulted in trade-offs.

After exhaustive testing of these different solution attempts,

we found an elegantly simple, yet very difficult to execute

solution. By curving the radiating surface, we create the

effect of a horizontal arc. This allows the engineers at

MartinLogan to control the high frequency dispersion

pattern of our transducers. That is why you see the gentle

curve on our products.

DISPERSION INTERACTIONS

Controlled Horizontal Dispersion Three Major Types of Dispersion

Figure 13. MartinLogan Script i’s deliver a 30 degree wave launch dispersion

pattern distributed horizontally.

Figure 14. Your Script i speaker is a 26” inch line source when viewed vertically.

Page 13

Dispersion Interactions 13

Figure 15–16. As can be seen here, point source

concepts invite a great deal of room interaction.

While delivering good frequency response to a

large listening audience, imaging is consequently

confused and blurred.

Figure 17–18. Even though they suffer from

“venetian blind” effect, angled multiple panel

speakers can deliver good imaging, but only

to specific spots in the listening area.

Figure 19–20. A controlled 30-degree cylindrical

wave-front, which is a MartinLogan exclusive,

offers optimal sound distribution with minimal

room interaction. The result is solid imaging with

a wide listening area.

Page 14

It had long been the practice of stereo buffs to connect their

television to the stereo system. The advantage was the use

of the larger speakers and more powerful amplifier of the

stereo system. Even though the sound was greatly improved, it

was still mono and limited by the broadcast signal.

In the late 1970’s and early ‘80’s two new home movie

formats became widely available to the public: VCR and

laser disc.

By 1985, both formats had developed into very high quality

audio/video sources. In fact, the sonic performance of some

video formats exceeded audio-only formats. Now, with

theater quality sound available at home, the only element

missing was the "surround sound" presentation found in

movie houses.

Fortunately, "Dolby” and “DTS" encoded movies (which

include almost all movies) have the same surround sound

information encoded on home releases as the theater films.

All that is required to retrieve this information is a decoder

and additional speakers and amps to reproduce it.

Home theater is a complex purchase and we recommend

that you consult your local MartinLogan dealer as they are

well versed in this subject

Each piece of a surround system can be purchased

separately. Take your time and buy quality. No one has

ever complained that the movie was too real. The following

list and descript iions will only give you a brief outline of

the responsibilities and demands placed on each speaker.

Front Left and Front Right

If these speakers will also be the same two used for your

stereo playback then they should be of very high quality

and able to play loud (over 102 dB) and reproduce bass

below 80 Hz.

Center Channel.

This is the most important speaker in a video system, as

almost all of the dialogue and a large portion of the front

speaker information is reproduced by the center channel.

It is important that the center speaker be designed by

the same manufacturer as the front speakers, and that it is

recommended for use as a center speaker. This is not the

place to cut corners.

Surround Speakers.

We recommend that the surround speakers play down

to 80 Hz or below. The surround speakers contain the

information that makes it appear that planes are flying over

your head. Some may suggest that this is the place to save

money and purchase a small inexpensive speaker. If you

choose to do so, be prepared to upgrade in the future as

discrete six channel digital encoding becomes available

and the demands on the surround speakers increase.

Subwoofer.

With any good surround system you will need a high-quality

subwoofer (the .1, in a 5.1 channel surround system). Most

movie soundtracks contain large amounts of bass information as part of the special effects. Good subwoofers will

provide a foundation for the rest of the system.

14 Home Theater

Figure 21. Ascent i speakers as front channels, Theater i as the center channel,

Script i speakers as side surround (effects) channels, and Depth subwoofers

as 0.1 (effects) channel.

HOME THEATER

Page 15

How can sound be reproduced by something that you are

able to see through? Electrostatic energy makes this possible.

Where the world of traditional loudspeaker technology

deals with cones, domes, diaphragms and ribbons that

are moved with magnetism, the world of electrostatic

loudspeakers deals with charged electrons attracting and

repelling each other.

To fully understand the electrostatic concept, some background

information will be helpful. Remember when you learned

in a science or physics class that like charges repel each

other and opposite charges attract each other? Well, this

principle is the foundation of the electrostatic concept.

An electrostatic transducer consists of three pieces: the stators,

the diaphragm and the spacers (see figure 22). The diaphragm

is what actually moves to excite the air and create music.

The stator’s job is to remain stationary, hence the word stator,

and to provide a reference point for the moving diaphragm.

The spacers provide the diaphragm with a fixed distance in

which to move between the stators.

As your amplifier sends music signals to an electrostatic

speaker, these signals are changed into two high-voltage

signals that are equal in strength but opposite in polarity.

These high voltage signals are then applied to the stators.

The resulting electrostatic field, created by the opposing

high voltage on the stators, works simultaneously with

and against the diaphragm, consequently moving it back

and forth, producing music. This technique is known as

push-pull operation and is a major contributor to the sonic

purity of the electrostatic concept due to its exceptional

linearity and low distortion.

Since the diaphragm of an electrostatic speaker is uniformly

driven over its entire area, it can be extremely light and

flexible. This allows it to be very responsive to transients,

thus perfectly tracing the music signal. As a result, great

delicacy, nuance and clarity is possible. When you look at

the problems of traditional electromagnetic drivers, you

can easily see why this is so beneficial. The cones and

domes which are used in traditional electromagnetic

drivers cannot be driven uniformly because of their design.

Cones are driven only at the apex. Domes are driven at

their perimeter. As a result, the rest of the cone or dome

is just “along for the ride”. The very concept of these

drivers requires that the cone or dome be perfectly rigid,

damped and massless. Unfortunately, these conditions are

not available in our world today.

To make these cones and domes move, all electromagnetic

drivers must use voice coils wound on formers, spider

assemblies, and surrounds to keep the cone or dome in

position (see figure 23). These pieces, when combined

with the high mass of the cone or dome materials used,

make it an extremely complex unit with many weaknesses

and potential for failure. These faults contribute to the

high distortion products found in these drivers and is a

tremendous disadvantage when you are trying to change

motion as quickly and as accurately as a loudspeaker

must (40,000 times per second!).

Electrostatic Advantages 15

Figure 22. Cut away view of an electrostatic transducer.

Notice the simplicity due to minimal parts usage.

Figure 23. Cut away view of a typical moving coil driver.

Notice the complexity due to the high number of parts.

ELECTROSTATIC ADVANTAGES

Page 16

ESL

Panel

Critical Zone: 500Hz–20kHz

The most significant advantage of MartinLogan’s exclusive

transducer technology reveals itself when you look at

examples of other loudspeaker products on the market today.

The Script i uses no crossover networks above 500 Hz

because they are not needed. The Script i consists of a single,

seamless electrostatic membrane reproducing all frequencies above 500 Hz simultaneously. How is this possible?

First we must understand that music is not composed of

separate high, mid and low frequency pieces. In fact,

music is comprised of a single complex waveform with all

frequencies interacting simultaneously.

The electrostatic transducer of the Script i essentially acts

as an exact opposite of the microphones used to record

the original event. A microphone, which is a single working element, transforms acoustic energy into an electrical

signal that can be amplified or preserved by some type of

storage media. The Script i’s electrostatic transducer transforms electrical energy from your amplifier into acoustical

energy.

Due to the limitations of electromagnetic drivers, no

single unit can reproduce the full range of frequencies.

Instead, these drivers must be designed to operate within

narrow, fixed bandwidth of the frequency range, and then

combined electrically so that the sum of the parts equals

the total signal. While nice in theory, we must deal with

real-world conditions.

In order to use multiple drivers, a crossover network is

enlisted to attempt a division of the complex musical signal

into the separate pieces (usually highs, mids, and lows) that

each specific driver was designed to handle. Unfortunately,

due to the phase relationships that occur within all crossover

networks and during the acoustical recombination process,

nonlinearities and severe degradation of the music signal

take place in the ear’s most critical zone (See Figure 20).

The Script i’s electrostatic transducer can single-handedly

reproduce all frequencies above 500 Hz simultaneously.

You have in one transducer the ability to handle in elegant

simplicity the critical frequencies above 500 Hz.

The crossover phase aberrations that are associated with

traditional tweeter, midrange, and woofer systems are

eliminated. The result is a dramatic improvement in imaging

and staging performance, due to the minutely accurate

phase relationship of the full-range panel wave launch.

Tweeter

Midrange

Woofer

Conventional Loudspeaker MartinLogan Script i

Figure 24. This diagram illustrates how a conventional

speaker system must use multiple crossover networks

that have negative effects on the musical performance.

Full Range Operation

crossover point (2–5kHz)

crossover point (500Hz)

crossover point (100–500Hz)

Woofer

16 Electrostatic Advantages

Page 17

Since the beginning of audio, achieving smooth dispersion

has been a problem for all loudspeaker designers. Large

panel transducers present even more of a challenge because

the larger the panel, the more directional the dispersion

pattern becomes.

Full range electrostats have long been one of the most problematic transducers because they attain their full range

capabilities via a large surface area. It looked as if they were

in direct conflict to smooth dispersion and almost every

attempt to correct this resulted in either poor dispersion or

a serious compromise in sound quality.

After extensive research, MartinLogan engineers discovered

an elegantly simple solution to achieve a smooth pattern

of dispersion without degrading sound quality. By curving

the horizontal plane of the electrostatic transducer, a

controlled horizontal dispersion pattern could be achieved,

yet the purity of the almost massless electrostatic diaphragm

remained uncompromised. After creating this technology,

MartinLogan developed the production capability to bring it

out of the laboratory and into the market place.

You will find this proprietary MartinLogan technology used

in almost all of our products. It is one of the many reasons

behind our reputation for high quality sound with practical

usability. This is also why you see the unique “see through”

cylindrical shape of MartinLogan products.

MicroPerf Stator

The MicroPerf stator design reduces the size of individual

holes in a stator, allowing more openings per square inch

than a standard MartinLogan stator. This maximizes efficiency

and dispersion of small stat panels and also increases optical clarity. In addition, the tighter grid of holes permits the

MicroPerf stator to drive the diaphragm accurately.

The diaphragm in the Script i employs an extremely sophisticated conductive coating that has been applied to the

polymer surface at an atomic level using a plasma bonding

process. A proprietary compound is driven into the surface

of the polymer film in an oxygen free argon chamber. This

process allows extremely uniform surface resistivity characteristics, an optically transparent surface and adds no mass to

the diaphragm. This uniform surface resistivity controls the

electrostatic charge on the diaphragm surface and regulates

its migration. As a result, no discharging or “arcing” can occur.

Transducer Integrity

All MartinLogan transducers begin with two pieces of highgrade, cold rolled steel. These steel pieces are then custom

perforated and insulated with a unique composite coating.

This proprietary coating insulates the stator to three times

its actual needed working voltage and gives the Script i a

wide margin of safe operation. In addition to the electrical

insulation properties, this coating also provides the Script i

with a durable, attractive finish that dampens the steel to

prevent ringing. These pieces then sandwich a proprietary

diaphragm and spacers into a curved geometry, and bond

together with aerospace adhesives whose strength exceeds

that of welding.The result of these advanced technologies

is a transducer that is attractive, durable, highly rigid, well

dampened, and neutral.

Low Voltage Power

To eliminate the need for a traditional IEC power cord and

broaden ease of installation, especially for custom installers,

the Script i features a low-voltage power supply.

Curvilinear Line Source (CLSTM) Plasma Deposited Diaphragm

MartinLogan Exclusives 17

MARTINLOGAN EXCLUSIVES

Page 18

18 Electrostatic Loudspeaker History

In the late 1800s, any loudspeaker was considered exotic.

Today, most of us take the wonders of sound reproduction

for granted.

It was 1880 before Thomas Edison had invented the first

phonograph. This was a horn-loaded diaphragm that was

excited by a playback stylus. In 1898, Sir Oliver Lodge

invented a cone loudspeaker, which he referred to

as a “bellowing telephone”, that was very similar to the

conventional cone loudspeaker drivers that we know

today. However, Lodge had no intention for his device to

reproduce music because in 1898 there was no way to

amplify an electrical signal! As a result, his speaker had

nothing to offer over the acoustical gramophones of the

period. It was not until 1906 that Dr. Lee DeForrest invented the triode vacuum tube. Before this, an electrical signal

could not be amplified. The loudspeaker, as we know it

today, should have ensued then, but it did not. Amazingly,

it was almost twenty years before this would occur.

In 1921, the electrically cut phonograph record became a

reality. This method of recording was far superior to the

mechanically cut record and possessed almost 30 dB of

dynamic range. The acoustical gramophone couldn’t begin to reproduce all

of the information on this new disc. As

a result, further developments in loudspeakers were needed to cope with

this amazing new recording medium.

By 1923, Bell Telephone Laboratories made the decision to

develop a complete musical playback system consisting of an

electronic phonograph and a loudspeaker to take

advantage

of the new recording medium. Bell Labs

assigned the pro-

ject to two young engineers, C.W. Rice and E.W. Kellogg.

Rice and Kellogg had a well equipped laboratory at their

disposal. This lab possessed a vacuum tube amplifier with

an unheard of 200 watts, a large selection of the new

electrically cut phonograph records and a variety of

loudspeaker prototypes that Bell Labs had been collecting

over

the past decade. Among these were Lodge’s cone, a

speaker

that used compressed air, a corona discharge

(plasma) speaker, and an electrostatic speaker.

After a short time, Rice and Kellogg had narrowed the field

of “contestants” down to the cone and the electrostat. The

outcome would dictate the way that future generations

would refer to loudspeakers as being either “conventional”

or “exotic”.

Bell Laboratory’s electrostat was something to behold.

This enormous bipolar speaker was as big as a door. The

diaphragm, which was beginning to rot, was made of a

pig intestine that was covered with fine gold leaf to conduct the audio signal.

When Rice and Kellogg began playing the new electrically

cut records through the electrostat, they were shocked

and impressed. The electrostat performed splendidly.

They had never heard instrumental timbres reproduced

with such realism. This system sounded like real music

rather than the honking, squawking rendition of the

acoustic gramophone. Immediately, they knew they were

on to something big. The acoustic gramophone was destined to become obsolete.

Due to Rice and Kellogg’s enthusiasm, they devoted a

considerable amount of time researching the electrostatic

design. However, they soon encountered the same difficulties that even present designers face; planar speakers

require a very large surface area to

reproduce the lower frequencies of

the audio spectrum. Because the

management at Bell Labs considered

large speakers

unacceptable, Rice

and Kellogg’s

work on electrostatics

would never be put to use for a commercial product. Reluctantly, they advised the Bell

management to go with the cone. For the next 30 years,

the electrostatic design lay dormant.

During the Great Depression of the 1930s, consumer audio

almost died. The new electrically amplified loudspeaker

never gained acceptance, as most people continued to use

their old Victrola-style acoustic gramophones. Prior to the

end of World War II, consumer audio saw little, if any,

progress. However, during the late 1940s, audio experienced a great rebirth. Suddenly there was tremendous

interest in audio products, and with that, a great demand

for improved audio components. No sooner had the cone

become established than it was challenged by products

developed during this new rebirth.

In 1947, Arthur Janszen, a young Naval engineer, took part in

a research project for the Navy. The Navy was interested

in

ELECTROSTATIC LOUDSPEAKER HISTORY

Rice and Kellogg had

narrowed the field of

“contestants” down to the

cone and the electrostat.

Page 19

Electrostatic Loudspeaker History 19

developing a better instrument for testing microphone

arrays. The test instrument needed an extremely accurate

speaker, but Janszen found that the cone speakers of the

period were too nonlinear in phase and amplitude response

to meet his criteria. Janszen believed that electrostats were

inherently more linear than cones, so he built a

model

using

a thin plastic diaphragm treated with a conductive coating.

This model confirmed Janszen’s beliefs, for it exhibited

remarkable phase and amplitude linearity.

Janszen was so excited with the results

that he continued research on the electrostatic speaker on his own time. He

soon thought of insulating the stators to

prevent the destructive effects of arcing.

By 1952, he had an electrostatic tweeter

element ready for commercial production. This new tweeter soon created a sensation among

American audio hobbyists. Since Janszen’s tweeter element

was limited to high frequency reproduction, it often found

itself used in conjunction with woofers—most notably,

those from Acoustic Research. These systems were highly

regarded by all audio enthusiasts.

As good as these systems were, they would soon be surpassed by another electrostatic speaker.

In 1955, Peter Walker published three articles regarding

electrostatic loudspeaker design in Wireless World, a

British magazine. In these articles, Walker demonstrated

the benefits of the electrostatic loudspeaker. He explained

that electrostatics permit the use of diaphragms that are

low in mass, large in area and uniformly driven over their

surfaces by electrostatic forces. Due to these characteristics,

electrostats have the inherent ability to produce a wide

bandwidth, flat frequency response with distortion products

being no greater than the electronics driving them.

By 1956, Walker backed up his articles by introducing a consumer product, the now famous Quad ESL. This speaker

immediately set a standard of performance for the audio

industry due to its incredible accuracy. However, in actual

use, the Quad had a few problems. It could not be played

very loud, it had poor bass performance, it presented a

difficult load that some amplifiers did not like, its dispersion

was very directional and its power handling was limited to

around 70 watts. As a result, many people continued to

use box speakers with cones.

In the early 1960s Arthur Janszen joined forces with the

KLH loudspeaker company, and together they introduced

the KLH 9. Due to the large size of the KLH 9, it did not

have as many limitations as the Quad. The KLH 9 could

play markedly louder and lower in frequency than the

Quad ESL. Thus a rivalry was born.

Janszen continued to develop electrostatic designs. He

was instrumental in the design of the Koss Model One, the

Acoustech and the Dennesen speakers. Roger West, the chief designer

of the Janszen Corporation, became

the president of Sound Lab.

When

Janszen Corporation was

sold, the

RTR loudspeaker company bought

half of the production tooling. This

tooling was used to make the

electrostatic panels for the Servostatic, a hybrid electrostatic

system that was Infinity’s first speaker product. Other

companies soon followed; each with their own unique

applications of the technology. These include Acoustat,

Audiostatic, Beverage, Dayton Wright, Sound Lab and Stax,

to name a few.

Electrostatic speakers have progressed and prospered

because they actually do what Peter Walker claimed they

would. The limitations and problems experienced in the

past were not inherent to the electrostatic concept. They

were related to the applications of these concepts.

Today, these limitations have been resolved. Advancements

in materials due to the U.S. space program give designers

the ability to harness the superiority of the electrostatic

principle. Today’s electrostats use advanced insulation

techniques or provide protection circuitry. The poor dispersion properties of early models have been addressed by

using delay lines, acoustical lenses, multiple panel arrays

or, as in our own products, by curving the diaphragm.

Power handling and sensitivity have also been increased.

These developments allow the consumer the opportunity

to own the highest performance loudspeaker products ever

built. It’s too bad Rice and Kellogg were never able to see

just how far the technology would be taken.

These developments allow

the consumer to own the

highest performance loud-

speaker products ever built.

Page 20

20 Frequently Asked Questions

FREQUENTLY ASKED QUESTIONS

How do I clean my speakers?

Just use a dust free cloth or a soft brush to remove the dust

from your speakers. We recommend a specialty cloth

(available at the Xtatic shop at www.martinlogan.com)

that cleans your speakers better than anything else we

have tried. Do not spray any kind of cleaning agent

on or in close proximity to the electrostatic element.

What is the advantage of ESL?

Since the diaphragm is uniformly driven over its entire

surface—unlike a tweeter that is only driven at its edges—

it is the only technology that can be made large enough to

play bass, yet is still light enough for high frequencies. This

unique property allows for the elimination of high frequency crossover points and their associated distortions.

What size amplifier should I use?

We recommend an amplifier with 100 to 200 watts per

channel for most applications. Probably less would be

adequate for our smaller hybrids or when used in home

theater where a subwoofer is employed. Our hybrid

designs will perform well with either a tube or transistorized amplifier, and will reveal the sonic character of

either type. However, it is important that the amplifier

be stable operating into varying impedance loads: a stable amplifier will be able to deliver twice its rated

wattage into 4 Ohms and should again double into 2

Ohms.

Could you suggest a list of suitable electronics and

cables that would be ideal for MartinLogan speakers?

The area of electronics and cable choice is probably the

most common type of question that we receive. It is also

the most subjective. We have repeatedly found that

brands that work well in one setup will drive someone

else nuts in another. We use many brands with great

success. Again, we have no favorites; we use electronics

and cables quite interchangeably. We would suggest listening to a number of brands—and above all else— trust

your ears. Dealers are always the best source for information when purchasing additional audio equipment.

Is there likely to be any interaction between my speakers

and the television in my Audio/Video system?

Actually, there is less interaction between a television

and an electrostatic speaker than between a television

and a conventional system. However, we do recommend

that you keep your speakers at least one foot away

from the television because of the dynamic woofer they

employ. In the case of our center channel speakers,

however, they are fully shielded and can go anywhere.

Will my electric bill go ‘sky high’ by leaving my speakers

plugged in all the time?

No. A pair of MartinLogans will draw about 5 watts maximum. There is circuitry to turn off the static charge when

not in use; however, actual consumption will remain close

to the same. The primary purpose of the sensing circuitry

is to prevent dust collection on the electrostatic element.

If the diaphragm is punctured with a pencil or similar

item, how extensive would the damage to the speaker be?

Our research department has literally punctured hundreds

of holes in a diaphragm, neither affecting the quality of

the sound nor causing the diaphragm to rip. However,

you will be able to see the actual puncture and it can

be a physical nuisance. If this is the case, replacing the

electrostatic transducer will be the only solution.

Will exposure to sunlight affect the life or performance

of my speakers?

We recommend that you not place any loudspeaker in

direct sunlight. The ultraviolet (UV) rays from the sun can

cause deterioration of grill cloth, speaker cones, etc. Small

exposures to UV will not cause a problem. In general,

the filtering of UV rays through glass will greatly reduce

the negative effects on the electrostatic membrane itself.

Page 21

Frequently Asked Questions 21

Will excessive smoke or dust cause any problems with

my electrostatic speakers?

Exposure to excessive contaminants such as smoke

or dust may potentially affect the performance of the

electrostatic membrane, and may cause discoloration

of the diaphragm membrane. When not in use for

extended periods, you should unplug the speakers and

cover them with the plastic bags in which the speakers

were originally packed. It is a good idea to vacuum the

electrostatic portion of each speaker once or twice a

year. See the vacuuming FAQ.

A problem has recently developed with my MartinLogan

speakers. The right speaker seems to be hissing even

when the amplifier and such are not connected. I was

wondering if this sounds like any problem you have

encountered previously and have a simple solution for

or might it be something which will need to be looked

into more carefully.

Your speakers are dusty. See the vacuuming FAQ. The

electrostatic charge on the element has attracted airborne

dust or pollen. Since 1993, all of our speakers have been

built with a charging circuit board that only charges the

electrostatic element when music plays. At other times

they are not charged and cannot collect dust. You can get

the same benefit by simply unplugging them whenever

they are not in use. A power strip is an easy way to do that.

Could my children, pets, or myself be shocked by the

high-voltage present in the electrostatic panel?

No. High voltage with low current is not dangerous. As a

matter of fact, the voltage in our speakers is 10 times

less than the static electricity that builds up on the surface

of your television screen.

How do MartinLogan speakers hold up over a long term

in the humidity of tropical climates?

We should tell you that MartinLogan indeed has a very

substantial number of customers in tropical regions of

the world. Our speakers have been serving them nicely for

many years. This concern may have come from our earlier

design of speakers, which were charged continuously.

Since 1993, all of our speakers have been designed so that

they only charge the panel while music is being played.

This improvement has made a tremendous difference

in the consistent performance of our product. There may

be a little more maintenance involved in humid regions

when not in an air conditioned environment. Simply

enough, the concern is to keep the electrostatic panels

dust free. Humidity will combine with any dust on the

panel to make it slightly conductive. This will result in a

slight pathway for the charge to leave the membrane of

the speaker. The solution is simple. They only require

occasional vacuuming with a strong vacuum hose.

How do I vacuum my MartinLogan speakers?

Vacuuming will be most effective if the speakers have

been unplugged for six hours or overnight. You need

not worry about the vacuum pressure damaging the

"delicate" membrane. It is extraordinarily durable

Dirt and dust may be vacuumed off with a brush attachment connected to your vacuum cleaner, or you may

blow them off with compressed air.

Should I unplug my speakers during a thunderstorm?

Yes, or before. It’s a good idea to disconnect all of your

audio/video components during stormy weather.

Page 22

22 Troubleshooting

TROUBLESHOOTING

No Output

• Check that all your system components are turned on.

• Check your speaker wires and connections.

• Check all interconnecting cables.

Weak Output from Electrostatic Panel, Loss of Highs

• Check the power cord. Is it properly connected to the

speaker and to the wall?

• Is the power cord connected to a switched outlet?

• Dirt and dust may need to be vacuumed off. Please see

the FAQ regarding vacuuming.

Popping and Ticking Sounds, Funny Noises

• These occasional noises are harmless and will not hurt

your audio system or your speakers. All electrostatic

speakers are guilty of making odd noises at one time or

another. It is the result of airborne contaminates (most

notably dust). Vacuuming is recommended.

• These noises may be caused by dirt and dust particles

collecting on the speaker, by high humidity.

• Dirt and dust may need to be vacuumed off. Please see

the FAQ regarding vacuuming.

Exaggerated Highs, Brightness

• Check the toe-in of the speakers. Read the Placement

section of this manual for more information.

Muddy Bass

• Check placement. Try moving the speakers closer to the

front and sidewalls.

• Check the type of feet that are being used. Try attaching

the coupling spikes.

• Possibly means low electrostatic panel output. See 'Weak

Output from Electrostatic Panel, Loss of Highs’.

Lack of Bass, No Bass

• Check your speaker wires. Is the polarity correct?

• Check your speaker wires. Are both woofers working?

• Check your speaker wires if bi-wiring.

Poor Imaging

• Check placement. Are both speakers the same distance

from the walls? Do they have the same amount of toein? Try moving the speakers away from the back and

sidewalls.

• Check the polarity of the speaker wires. Are they connected properly?

• Try switching the left speaker with the right.

Page 23

The Script i hybrid speaker system consists of a broadrange single element electrostatic transducer integrated

with a quick-response woofer. This approach takes advantage of the benefits that both technologies have to offer.

Dispersion is a controlled 30 degrees. This was achieved

by curving the electrostatic transducer element itself, an

elegantly simple solution.

System Frequency Response

70–20,000 Hz ± 3 dB

Dispersion

Horizontal: 30 Degrees

Vertical: 26” (66 cm) Line Source

Sensitivity

88 dB/2.83 volts/meter

Impedance

6 ohms, 3 ohms @ 20 kHz

Crossover Frequency

500 Hz

Components

Minimal straight path design, air core coils

Woofer Type

6.5" (16.5 cm) mineral filled poly-cone with high damping

rubber surround; non-resonant chamber format

Power Handling

150 watts per channel

Recommended Amplifier Power

80–150 watts per channel

Weight

25 lbs. each (11.3 kg)

Size (with wall mount bracket)

10.2” inches W × 6.8” inches D × 44” inches H

(25.9 cm W × 17.28 cm D × 111.8 cm H)

Your Script i speakers are provided with an automatic Limited

90 Day Warranty coverage. You have the option, at no addi-

tional charge, to receive a limited 5 year warranty coverage.

To obtain the limited 5 year warranty coverage you need to

complete and return the certificate of registration, included with your speakers, and provide a copy of your dealer

receipt, to MartinLogan within 30 days of purchase.

For your convenience MartinLogan also offers online warranty

registration at www.martinlogan.com.

MartinLogan may not honor warranty service claims unless

we have a completed warranty registration card on file!

If you did not receive a certificate of registration with your

new Script i speakers you cannot be assured of having

received new units. If this is the case, please contact your

authorized MartinLogan dealer.

Service

Should you be using your MartinLogan product in a country

other than the one in which it was originally purchased,

we ask that you note the following:

1 The appointed MartinLogan distributor for any given

country is responsible for warranty servicing only on

units distributed by or through it in that country in

accordance with its applicable warranty.

2 Should a MartinLogan product require servicing in a

country other than the one in which it was originally

purchased, the end user may seek to have repairs performed

by the nearest MartinLogan distributor, subject to that

distributor’s local servicing policies, but all cost of

repairs (parts, labor, transportation) must be born by the

owner of the MartinLogan product.

3 If, after owning your speakers for six months, you

relocate to a country other than the one in which

you purchased your speakers, your warranty may be

transferable. Contact MartinLogan for details.

Serial Numbers

The serial number for each of your Script i loudspeakers is

located behind the grille cloth and above the woofer. Each

individual speaker has a unique serial number.

General Information 23

GENERAL INFORMATION

Warranty and RegistrationSpecifications

Page 24

AC. Abbreviation for alternating current.

Active crossover. Uses active devices (transistors, ICs, tubes)

and some form of power supply to operate.

Amplitude. The extreme range of a signal. Usually measured

from the average to the extreme.

Arc. The visible sparks generated by an electrical discharge.

Bass. The lowest frequencies of sound.

Bi-Amplification. Uses an electronic crossover, or line-level

passive crossover, and separate power amplifiers for the

high and low frequency loudspeaker drivers.

Capacitance. That property of a capacitor which determines

how much charge can be stored in it for a given potential

difference between its terminals, measured in farads, by

the ratio of the charge stored to the potential difference.

Capacitor. A device consisting of two or more conducting

plates separated from one another by an insulating material

and used for storing an electrical charge. Sometimes called

a condenser.

Clipping. Distortion of a signal by its being chopped off. An

overload problem caused by pushing an amplifier beyond its

capabilities. The flat-topped signal has high levels of harmonic distortion which creates heat in a loudspeaker and is the

major cause of loudspeaker component failure.

Crossover. An electrical circuit that divides a full bandwidth

signal into the desired frequency bands for the loudspeaker

components.

dB (decibel). A numerical expression of the relative loud-

ness of a sound. The difference in decibels between two

sounds is ten times the Base 10 logarithm of the ratio of

their power levels.

DC. Abbreviation for direct current.

Diffraction. The breaking up of a sound wave caused by

some type of mechanical interference such as a cabinet

edge, grill frame or other similar object.

Diaphragm. A thin flexible membrane or cone that vibrates

in response to electrical signals to produce sound waves.

Distortion. Usually referred to in terms of total harmonic

distortion (THD) which is the percentage of unwanted

harmonics of the drive signal present with the wanted signal.

Generally used to mean any unwanted change introduced

by the device under question.

Driver. See transducer.

Dynamic Range. The range between the quietest and the

loudest sounds a device can handle (often quoted in dB).

Efficiency. The acoustic power delivered for a given electrical

input. Often expressed as decibels/watt/meter (dB/w/m).

ESL. Abbreviation for electrostatic loudspeaker.

Headroom. The difference, in decibels, between the peak

and RMS levels in program material.

Hybrid. A product created by the marriage of two different

technologies. Meant here as the combination of a dynamic

woofer with an electrostatic transducer.

Hz (Hertz). Unit of frequency equivalent to the number of

cycles per second.

Imaging. To make a representation or imitation of the original

sonic event.

Impedance. The total opposition offered by an electric circuit

to the flow of an alternating current of a single frequency. It

is a combination of resistance and reactance and is measured

in ohms. Remember that a speaker’s impedance changes

with frequency, it is not a constant value.

24 Glossary of Audio Terms

GLOSSARY OF AUDIO TERMS

Page 25

Inductance. The property of an electrical circuit by which a

varying current in it produces a varying magnetic field that

introduces voltages in the same circuit or in a nearby circuit.

It is measured in henrys.

Inductor. A device designed primarily to introduce inductance

into an electrical circuit. Sometimes called a choke or coil.

Linearity. The extent to which any signal handling process

is accomplished without amplitude distortion.

Midrange. The middle frequencies where the ear is the

most sensitive.

NAC. The abbreviation for natural ambience compensation.

Passive crossover. Uses no active components (transistors,

ICs, tubes) and needs no power supply (AC, DC, battery)

to operate. The crossover in a typical loudspeaker is of the

passive variety. Passive crossovers consist of capacitors,

inductors and resistors.

Phase. The amount by which one sine wave leads or lags a

second wave of the same frequency. The difference is

described by the term phase angle. Sine waves in phase

reinforce each other; those out of phase cancel.

Pink noise. A random noise used in measurements, as it

has the same amount of energy in each octave.

Polarity. The condition of being positive or negative with

respect to some reference point or object.

RMS. Abbreviation for root mean square. The effective value

of a given waveform is its RMS value. Acoustic power is

proportional to the square of the RMS sound pressure.

Resistance. That property of a conductor by which it opposes

the flow of electric current, resulting in the generation of

heat in the conducting material, usually expressed in ohms.

Resistor. A device used in a circuit to provide resistance.

Resonance. The effect produced when the natural vibra-

tion frequency of a body is greatly amplified by reinforcing

vibrations at the same or nearly the same frequency from

another body.

Sensitivity. The volume of sound delivered for a given elec-

trical input.

Stator. The fixed part forming the reference for the moving

diaphragm in a planar speaker.

THD. The abbreviation for total harmonic distortion. (See

Distortion)

TIM. The abbreviation for transient intermodulation distortion.

Transducer. Any of various devices that transmit energy from

one system to another, sometimes one that converts the

energy in form. Loudspeaker transducers convert electrical

energy into mechanical motion.

Transient. Applies to that which lasts or stays but a short

time. A change from one steady-state condition to another.

Tweeter. A small drive unit designed to reproduce only

high frequencies.

Wavelength. The distance measured in the direction of

progression of a wave, from any given point characterized

by the same phase.

White noise. A random noise used in measurements, as it

has the same amount of energy at each frequency.

Woofer. A drive unit operating in the bass frequencies only.

Drive units in two-way systems are not true woofers but

are more accurately described as being mid/bass drivers.

Glossary of Audio Terms 25

Page 26

26 Notes

NOTES

Page 27

Notes 27

Page 28

2101 Delaware Street, Lawrence, Kansas 66046, USA tel 785.749.0133 fax 785.749.5320 www.martinlogan.com

c l s e l e c t r o s t a t i c

M

ARTIN L OGAN

©2003 MartinLogan. All rights reserved. Rev. #041603

®

Loading...

Loading...