Page 1

OWNER’S MANUAL

MODEL VT18 AUTOTOAST™ VERTICAL TOASTER

Supplier Name: MARSHALL AIR SYSTEMS, INC.

Address: 419 Peachtree Drive South

Charlotte, NC 28217

Model #: ______________________

Fax #: 704-525-6229

Model VT18

PRODUCT DESCRIPTION

The Marshall Model VT18 Vertical Toaster

produces caramelized buns hot and fast for building

sandwiches to customer orders. This model has a

slim vertical footprint. Buns are loaded at the top

and released onto a product slide at the bottom.

The variable speed drive ranges from 20 seconds

to 2 minutes. Heat controls are fully adjustable from

200- 565F. Left and right side toasting

temperatures can be zoned for flexibility.

All controls are located inside a secured cabinet,

eliminating unauthorized tampering. The toaster is

adjustable for various crown and heel bread

thickness. The multi-control feature options of this

toaster produce and deliver the hottest buns in the

shortest time. The optional Bun Loader allows the

user to load up to 6 buns for toasting.

Serial #’: ______________________

Date Received: ______________________

Date Installed: ______________________

Telephone #: 704-525-6230

Service Referral #: 800-722-3474

Local Service: ______________________

Local Service #: ______________________

GENERAL SPECIFICATIONS

Model: VT18 Vertical Contact Toaster

Height: 22.000”, 29.500” with Optional

Loader

Width: 26.125”

Depth: 13.375, 16.000” with Optional Butter

Wheel

Options: Bun Loader

Butter Wheel

Electrical: 208 VAC, 60Hz, 16 Amps

240 VAC, 50/60 HZ, 19 Amps

Power Cord: 8.0 ft 3 wire ground type UL rated

Plug furnished by others on

International units)

Weight: 103 lbs.

Approvals: ETL/CETL, CSA, CE and NSF

148665 RV012615

Copyright 2013 Marshall Air Systems, Inc.

All Rights Reserved.

Page 2

OWNER’S MANUAL

quip

MODEL VT18 AUTOTOAST™ VERTICAL TOASTER

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE

Ne pas entreposer ni utiliser de l’essence ni d’autres vapeurs ou liquides inflammables dans

le voisinage de cet appareil, ni de tout autre appareil.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATION AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

AVERTISSEMENT: Une installation, un ajustement, une altération, un service ou un entretien

non conforme aux normes peut causer des dommages à la propriété, des blessures ou la mort.

Lisez attentivement les directives d’installation et d’opération et d’entretien avant de faire

l’installation ou l’entretien de cet é

KEEP THIS MANUAL IN A SAFE PLACE AND RETAIN FOR FUTURE USE.

Toaster area must be kept free of combustible materials and the flow of ventilation air

must not be obstructed. Operating personnel must not perform any maintenance or

repair functions. Contact your Qualified Service Company.

FOR YOUR SAFETY

AVERTISSEMENT

ement

148665 RV032114

Copyright 2013 Marshall Air Systems, Inc.

All Rights Reserved.

Page 3

OWNER’S MANUAL

MODEL VT18 - VERTICAL CONTACT TOASTER

TABLE OF CONTENTS

PRE INSTALLATION ....................................................................................................................................1

INSTALLATION.............................................................................................................................................1

DAILY CLEANING.........................................................................................................................................2

WEEKLY MAINTENANCE............................................................................................................................3

MONTHLY MAINTENANCE..........................................................................................................................3

QUARTERLY MAINTENANCE.....................................................................................................................3

ANNUAL MAINTENANCE ........................................................................................................................... .4

TOASTER CONTROL DESIGNATION.........................................................................................................4

TROUBLESHOOTING GUIDE...................................................................................................................4-7

REPLACEMENT PARTS ..............................................................................................................................8

CONTROL GENERATION 1 ELECTRICAL REPLACEMENT PARTS.........................................................9

CONTROL GENERATION 2 ELECTRICAL REPLACEMENT PARTS.......................................................10

ILLUSTRATIONS

OVERALL DIMENSIONS-VT18..................................................................................................FIGURE 1, 2

HANG-ON PARTS-VT18.................................................................................................................FIGURE 3

TOASTER PLATEN SHEET-VTI8 ..................................................................................................FIGURE 4

CARRIAGE ASSEMBLY -VT18......................................................................................................FIGURE 5

DRIVE MOTOR ASSEMBLY-VT18.................................................................................................FIGURE 6

SCHEMATICS CONTROL GENERATION 1 (SEE PAGE 4)

VT18 WIRING SCHEMATIC (208V 60HZ, 1PH) VARIABLE SPEED………………………….DWG# 148302

VT18 WIRING SCHEMATIC (240V 50/60HZ, 1PH) VARIABLE SPEED…………………….. DWG# 150218

VT18 (MM2FINTLCE) WIRING SCHEMATIC (240V 50/60HZ, 1PH) ………………….…….. DWG# 157401

148665 RV032114

Copyright 2011 Marshall Air Systems, Inc.

All Rights Reserved.

Page 4

OWNER’S MANUAL

MODEL VT18 - VERTICAL CONTACT TOASTER

SCHEMATICS CONTROL GENERATION 2 (SEE PAGE 4)

VT18 WIRING SCHEMATIC (208V 60Hz 1PH)...................................................................... DWG# 163579

VT18 WIRING SCHEMATIC (220V OR 240V 1PH) .............................................................. DWG # 164071

VT18 WIRING SCHEMATIC (220V OR 240V 1PH) VARIABLE SPEED............................... DWG # 166247

148665 RV111914

Copyright 2011 Marshall Air Systems, Inc.

All Rights Reserved.

Page 5

OWNER’S MANUAL

MODEL VT18 - VERTICAL CONTACT TOASTER

PRE-INSTALLATION

1. The toaster is packaged to prevent the risk of shipping damage. Immediately upon receipt,

inspect the toaster for damage. FILE ALL CLAIMS WITH THE FREIGHT CARRIER.

2. Unpack toaster and remove all protective paper or plastic from metal parts.

FILE ANY CONCEALED DAMAGE CLAIMS WITH THE FREIGHT CARRIER.

3. INSPECTION, TESTING AND REPAIR OF ELECTRICAL EQUIPMENT SHOULD BE

PERFORMED BY QUALIFIED SERVICE PERSONNEL. THE TOASTER SHOULD BE

UNPLUGGED WHEN SERVICING, EXCEPT WHEN ELECTRICAL TEST ARE REQUIRED.

4. It is necessary to check your voltage at the receptacle. The toaster is factory-shipped set at

208V for domestic and 240V for international service. If voltage at receptacle does not match

rating label, it is necessary to simply change a jumper inside the toaster.

CAUTION: DO NOT REMOVE THE ELECTRICAL CONTROL PANEL COVER ON THE RIGHT

SIDE OF TOASTER WITHOUT FIRST TURNING OFF THE TOASTER AND UNPLUGGING

THE CORD.

INSTALLATION

1. Place toaster on a level surface.

2. Check that all panels and covers are in place on the toaster.

3. Check that the toaster platen sheet is installed over the contact platens. The toaster platen sheet

is installed by placing rods into arms of toaster. See Figure 4 .Make sure seam is against platens

(facing top of toaster). USE ONLY MARSHALL APPROVED PLATEN SHEETS OR TOASTER

WARRANTY IS VOID.

4. Check conveyor carriage making sure it is completely seated in saddles and on top pins.

5. Connect the toaster to the power supply.

6. Press and release the “I/O” button on the control. “Lo” will be displayed. Check for free movement

of the conveyor belt.

7. Toaster is ready to use in approximately 15 minutes. Control will display “rdy”.

8. After warm up, insert buns into the top of the toaster. For proper operation, insert heels on the

side of the toaster marked "Heel", and crown on the opposite side. THE CUT SIDES OF THE

HEEL AND CROWN MUST FACE THE TOASTER PLATEN SHEET.

9. The toasted heel and crown will return to the toaster front together. Check the quality of the

toasted buns.

10. Adjust the gap between the conveyor and the toaster heat platens using the two knobs on top of

the toaster (see Figure 1 for knob locations). Both must be lowered at the same time. The knobs

are labeled “HEEL” and “CROWN”. The height gauges in the front indicate whether you are

raising or lowering the platens.

11. The Adjustment Range is .625” – 1.438”.

Contact the factory for instructions.

148665 RV032114 1

Copyright 2012 Marshall Air Systems, Inc.

All Rights Reserved.

Page 6

OWNER’S MANUAL

MODEL VT18 - VERTICAL CONTACT TOASTER

12. The conveyor speed is preset at the factory for 65 seconds. MM2F models set at 45 seconds.

(Please note that the adjustable speed range is 9 to 105 seconds.)

13. Test at least 3 buns before putting the toaster into service. Uniform surface toasting and bun

temperature are achieved when the gap described in step 10 is set correctly.

14. If necessary, the speed of the conveyor can be changed. The speed control is located behind a

cover on the side of the toaster (see Figure 1 for location). Adjust as needed and reinstall cover.

DAILY OPERATION AND CLEANING GUIDE

1. Press and release the “I/O” Button of the control to turn toaster on. “Lo” will be displayed.

CAUTION: DO NOT OPERATE TOASTER WITHOUT ALL PANELS AND COVERS

INSTALLED.

The display of the control will show “Rdy” once the toaster is up to temperature. (Approximately

2.

15 minutes.)

3. For proper operation, insert heels cut side up on the side of the toaster marked "HEEL", and

crowns on the opposite side.

4. To turn off, press the “I/O” Button “Hi” will be displayed which means toaster is still too hot to

remove any parts. Once the toaster has cooled (approximately 30 minutes), the display will show

“Off.”

5. The LED Control will indicate important information:

A. To see temperature settings, press and release either the Heat 1(Left Platen) or the Heat 2

(Right Platen) Button, the pre-programmed temperature settings will flash. This will display

for 5 seconds or until another button is pressed.

B. To see the actual temperature of heaters, press and hold either the Heat 1(Left Platen) or

the Heat 2 (Right Platen) Button for 3 seconds, the actual platen temperatures will be

displayed. This will display until another button is pressed.

6. Definitions of various displays:

“Off” Toaster is off and not operating.

“Lo” Heater platens have not reached programmed set temperature.

“Rdy” Toaster has reached programmed set temperature and is ready to toast.

“Hi” Toaster is off and too hot to touch all removable parts.

“AL1” This is an alarm message that indicates the Left Platen Probe is disconnected or

defective. Toaster automatically shuts off.

“AL2” This is an alarm message that indicates the Right Platen Probe is disconnected

or defective. Toaster automatically shuts off.

“AL3” This is an alarm message that indicates the Left Platen is too hot. Toaster

automatically shuts off.

“AL4” This is an alarm message that indicates the Right Platen is too hot. Toaster

automatically shuts off.

148665 RV032114 2

Copyright 2012 Marshall Air Systems, Inc.

All Rights Reserved.

Page 7

OWNER’S MANUAL

MODEL VT18 - VERTICAL CONTACT TOASTER

DAILY CLEANING

1. Turn toaster off and cool for 30 minutes.

2. Remove conveyor carriage from toaster frame.

3. Take conveyor carriage to sink and spray with water.

4. Clean platen sheet three (3) times daily as listed below.

After lunch rush – Clean sheet in place using a damp cloth or non-abrasive pad. If sheet has

black butter buildup, it must be wiped off. Use Sizzle cleaner if necessary.

After dinner rush – Clean sheet in place using a damp cloth or non-abrasive pad. If sheet has

black butter buildup, it must be wiped off. Use Sizzle cleaner if necessary.

After closing – Remove sheet from toaster. Place on a flat surface and clean using a damp cloth

or non-abrasive pad. If sheet has black butter buildup, it must be wiped off. Make sure to install

sheet seam against platen (facing top of toaster).

5. Inspect platens for butter that has baked-on surface. Scrape off any buildup.

6. Wipe cooling fan louvers on side with a dry cloth or towel.

7. Reinstall all parts after drying.

WEEKLY MAINTENANCE

1. Review and perform Daily and Weekly Maintenance Procedures.

2. Replace any worn out toaster platen sheets with Marshall Part #503983 (4 pack). USE ONLY

MARSHALL APPROVED PLATEN SHEETS OR TOASTER WARRANTY IS VOID.

MONTHLY MAINTENANCE

1. Review and perform Daily and Weekly Maintenance Procedures.

QUARTERLY MAINTENANCE

1. Adjust Belt Tension by Loosing Tension Brackets and pushing toward end of Carriage as you

retighten screws. If tensioning brackets are at the end of adjustment, it is necessary to remove a

link. Tension bracket is shown on Figure 5, see Note for instructions.

2. Check set screws on gears and conveyor sprockets for tightness. Snug these if loose. DO NOT

OVERTIGHTEN.

3. Review and perform Daily, Weekly & Monthly Maintenance Procedures.

148665 RV032114 3

Copyright 2012 Marshall Air Systems, Inc.

All Rights Reserved.

Page 8

OWNER’S MANUAL

MODEL VT18 - VERTICAL CONTACT TOASTER

ANNUAL MAINTENANCE

1. Replace motor brushes (Kit #148549 consists of 2).

2. Perform Quarterly Maintenance.

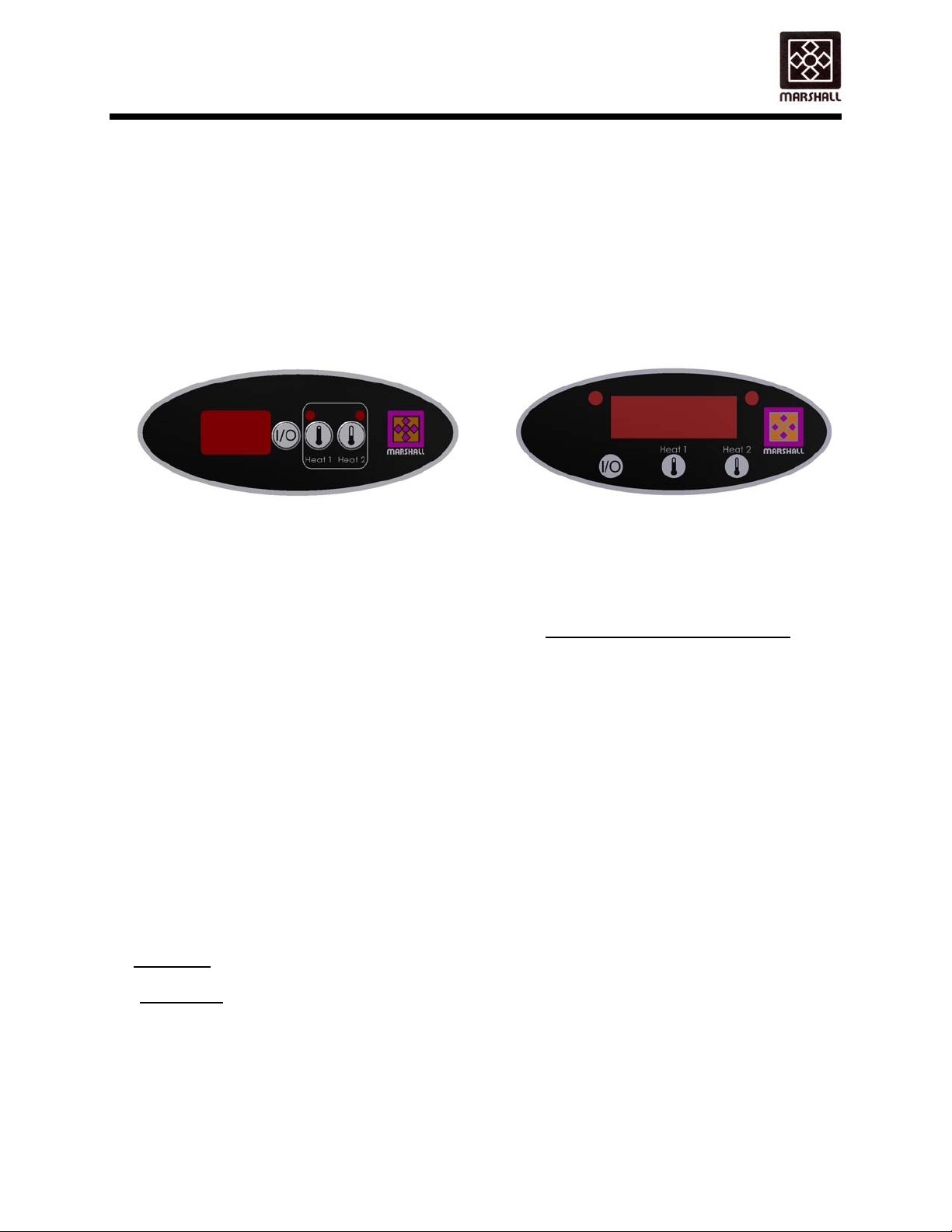

TOASTER CONTROL DESIGNATION

Before any troubleshooting or replacement parts are ordered, it is necessary to determine the

style of control that your toaster has. Generation 2 started in March 2014, but older toasters may

or may not have been field upgraded from Generation 1 to Generation 2.

Buttons to the right of the LED display. Buttons underneath the LED display.

TROUBLESHOOTING GUIDE

NOTE: SERVICE MUST BE PERFORMED BY A QUALIFIED SERVICE COMPANY. THE

WARNING: INSPECTION, TESTING, AND REPAIR OF ELECTRICAL EQUIPMENT SHOULD BE

DANGER: USE EXTREME CARE DURING ELECTRICAL CIRCUIT TESTS. LIVE CIRCUITS

1. PROBLEM: Toaster shuts off intermittently and/or no heat and conveyor belts do not move.

(Will not turn on)

SOLUTION:

A) Check that toaster is plugged in. Check condition of power cord and plug.

B) Check circuit breaker in main breaker panel. Reset if necessary.

C) Check for error message. “AL1” message is a defective left platen probe. “AL2” is a defective

right platen probe. “AL3” is high temperature error of the left platen. “AL4” is high temperature

error of the right platens. All alarms will turn toaster off requiring a service call.

GENERATION 1 GENERATION 2

TERM "QUALIFIED SERVICE COMPANY" MEANS ANY INDIVIDUAL, FIRM,

CORPORATION OR COMPANY WHICH IS EITHER ENGAGED IN AND IS

RESPONSIBLE FOR THE INSTALLATION OR REPLACEMENT OF ELECTRICAL

COMPONENTS, OR THE CONNECTION, INSTALLATION OR REPAIR OF

ELECTRICAL APPLIANCES, WHO IS EXPERIENCED IN SUCH WORK, FAMILIAR

WITH ALL PRECAUTIONS REQUIRED, AND HAS COMPLIED WITH ALL THE

REQUIREMENTS OF THE AUTHORITY HAVING JURISDICTION.

PERFORMED BY QUALIFIED SERVICE PERSONNEL. THE UNIT SHOULD BE

UNPLUGGED WHEN SERVICING, EXCEPT WHEN ELECTRICAL TESTS ARE

REQUIRED.

WILL BE EXPOSED. WHERE TESTING INDICATES "WITH POWER OFF", BE

SURE THAT THE TOASTER IS UNPLUGGED.

148665 RV032114 4

Copyright 2012 Marshall Air Systems, Inc.

All Rights Reserved.

Page 9

OWNER’S MANUAL

MODEL VT18 - VERTICAL CONTACT TOASTER

QUALIFIED SERVICE TECHNICIAN CHECK:

A) Check that there is power at receptacle. Verify voltage is correct based upon the voltage listed on

the toaster nameplate.

B) WITH POWER OFF check connections inside of plug. Remove right side panel and check wiring.

Any wires or terminals with burns or discoloration from arcing should be replaced. All wiring, if

replaced, should be same or higher rated wire.

C) Check sensors to see if ohm readings correct. At room temperature (70˚F), should be nominal

1.09K ohms.

D) With toaster off, check for continuity across the solid state relay terminals #1 and #2. Normal

readings are in megohm range. If reading ohms, relay has failed closed and will not cycle.

E) Control Generation 2 if no LED on display, check for .5 amp transformer fuses. If fuses good,

check for 208 volts on terminals 1 and 6, then 18 Vac on 11 and 12. If 208 volts is present and no

18 Vac output, replace transformer.

2. PROBLEM: Conveyor belts move but no heat.

SOLUTION:

QUALIFIED SERVICE TECHNICIAN CHECK:

A) Check that there is power at receptacle. Verify voltage is correct based upon the voltage listed on

the toaster nameplate.

B) Check for loose connections at terminal strip and temperature terminals (see schematic).

C) Verify that the heater and sensor wires are connected to the controller.

D) Replace all connections or components that have damaged terminals. Replace any damaged

wiring with same or higher rated wire.

E) Check the resistance of the sensor(s). If sensor is open, replace. At room temperature (70˚F),

should be nominal 1.09K ohms.

F) Check voltage into solid-state relays. The voltage input from module should be approximately

5Vdc. Voltage to heater should be 208 or 240Vac.

G) Check the resistance of the heater platens: 24 ohms at room temperature.

H) Control Generation 2 – Check for 24Vdc to the heater relay (R1, R2) from the control board. If

getting 24Vdc from the control board, check for 208 volts on output side of relay. If no 208 volts

then replace relay. If there is 208 volts, then possible solid state relay problem.

3. PROBLEM: Heater platens are hot, control says LO or RDY, conveyor belts do not move.

SOLUTION:

A) Make sure carriage is seated in saddles and top slots are around locator pins.

B) Remove conveyor carriage and turn conveyors by hand and determine there is no binding due to

dropping carriage.

C) Make sure all setscrews on gears are tight.

D) Check motor to make sure it is turning with carriage removed.

E) Increase belt tensioning by loosening tension bracket screws, push toward end as you retighten

screws. If bracket is at the end of adjustment, it is necessary to remove one conveyor link. See

Figure 5.

F) Conveyor carriage has been dropped, bent. Replace carriage.

QUALIFIED SERVICE TECHNICIAN CHECK:

A) Check that there is power at receptacle. Verify voltage is correct based upon the voltage listed on

the toaster nameplate.

148665 RV092314 5

Copyright 2012 Marshall Air Systems, Inc.

All Rights Reserved.

Page 10

OWNER’S MANUAL

MODEL VT18 - VERTICAL CONTACT TOASTER

B) Check the fuses inside the right panel. Replace with type AGC 1.5 amp fuse if necessary.

C) Check for voltage to speed control board. Check for voltage to the motor.

D) Check for red light on the speed board. If red light is lit, the motor is working too hard or in a

stalled state.

E) Some speed boards have a green light. If green light is lit then power is going to the board.

F) Make sure each voltage slide switch of the speed board is set at 230V and 90V as labeled on

the speed board.

G) Check for DC voltage out of board to motor.

H) Check all wiring to motor for loose connectors.

4. PROBLEM: Variable Speed Motor Not Operating

SOLUTION:

QUALIFIED SERVICE TECHNICIAN CHECK:

A) Verify correct voltage to toaster and motor.

B) Check 1.5-amp fuses (#500061) inside right control panel. Replace if necessary.

C) Check for DC voltage to motor out of board (90VDC Motor).

D) If red light on board is on, disconnect load from motor by removing conveyor carriage. If it

goes out, look for conveyor or motor binding. If it stays lit, replace motor – there is probably a

gearbox problem.

E) Check DC amp draw to motor by putting meter in series with motor. (Pull wire from A1 on

board, put one lead to A1, other to wire pulled from A1.) When red LED on board is on, DC

amp reading should be .3 amps approximately.

F) If green LED is on and red is not, make sure that there is varying DC voltage out of board to

motor (terminals A1 & A2 on board) as speed control knob is increased or decreased.

G) Check for oil leaks on motor signifying bad seal or overheating that has taken place. In either

case, motor should be replaced.

H) Check ohm reading at motor cord plug (Range between 50-80 Ohms).

5. PROBLEM: Circuit Board not working properly. DO NOT ADJUST POTS ON BOARD!

SOLUTION:

QUALIFIED SERVICE TECHNICIAN CHECK:

A) Verify AC voltage to board and DC voltage to motor from board. If there is AC voltage in, but

no DC voltage out, replace board.

B) Check all connections on board and terminal strip.

C) Verify that board is wired correctly. (See schematic in Owner’s Manual.)

D) Make sure that one slide switch on board is in 230V position and other is in 90V position.

E) Make sure all wires are connected to potentiometer. A loose wire will make toaster run at

single uncontrolled speed.

F) Control Generation 2 – Check for 24 Vdc from control board to motor relay (R3). If relay is getting

24 Vdc, check for 208 volts on output side of relay. If no 208 volts, replace relay.

6. PROBLEM: Product is over or under toasted.

SOLUTION:

A) Check the gap settings. There must be compression of the bun as it feeds into the toaster.

Decreasing the gap will increase bun temperature and darken surface color. To lower

(decrease gap) turn knob counter-clockwise; to raise (increase gap) turn knob clockwise.

B) Check toast time. Time should be approximately 65 seconds nominal from start to finish.

148665 RV032114 6

Copyright 2012 Marshall Air Systems, Inc.

All Rights Reserved.

Page 11

OWNER’S MANUAL

MODEL VT18 - VERTICAL CONTACT TOASTER

C) Check conditions of toaster platen sheet and belts. Clean both as noted in this manual

D) Make sure conveyor belt is not binding.

E) Check drive system for loose sprockets.

QUALIFIED SERVICE TECHNICIAN CHECK:

A) Check that heaters are cycling. Do this by using an amp clamp on either of the wires from the

controller to the platen. You are looking for cycling. Also verify that the temperature controller

has power.

B) Check platen set temperatures by depressing each button briefly and then check actual

temperatures by holding each button in for 3 seconds.

C) Check that the 3 wires from the speed board are hooked to the speed control.

7. PROBLEM: Buns do not feed properly into toaster.

SOLUTION:

A) Check condition of the toaster platen sheet to be sure buns are not sticking. Clean sheet as

described in daily maintenance. Replace if needed. Sheet should be rotated daily so that the

end of the sheet that is at the bottom is at the top when re-installed.

B) Check toaster platen sheet installation.

C) Toaster gap set too close or too far. See instructions on Page 1, Number 10.

8. PROBLEM: Buns do not exit toaster.

SOLUTION:

A) Check condition of the toaster platen sheet to be sure buns are not sticking. Clean sheet as

described in daily maintenance. Replace if needed. Sheet should be rotated daily.

B) Check toaster platen sheet installation.

C) Toaster platen gap set too close.

9. PROBLEM: Gap setting knobs jammed.

SOLUTION:

A) Turn knobs counter-clockwise. Indicator is read using top

B) Turn both knobs at same time. Platen sheet could be interfering.

10. PROBLEM: Conveyors turning intermittently.

SOLUTION:

A) Make sure carriage is seated in saddles and top slots are around locating pins.

B) Check for bent parts on the carriage.

C) Bearings worn and need replacing.

11. PROBLEM: Motor noisy/chirping.

SOLUTION:

A) Remove motor brushes and inspect. If ¼” or less, replace with new.

B) If longer than ¼”, replace brushes and tighten cap. Do not overly tighten cap.

edge.

148665 RV032114 7

Copyright 2012 Marshall Air Systems, Inc.

All Rights Reserved.

Page 12

OWNER’S MANUAL

MODEL VT18 - VERTICAL CONTACT TOASTER

REPLACEMENT PARTS (See page 9 and 10 for electrical components)

When ordering parts, make sure to specify the model number and serial number as shown by the label

attached on the back of toaster. WARNING: Use of Non Marshall approved parts will void warranty.

It is necessary to determine control style before specifying any electrical components for replacement.

See page 9 and page 10 for information.

PART # DESCRIPTION FIGURE

144074 Arm, Front Tensioning 4

149404 Bar, Chain Support, Kit of 2 5

149278 Bearing, Shaft Rear, Front, Kit of 4 5

148105 Bracket, Motor Mounting 6

148549 Brush Replacement Kit, Motor Set of 2 Not Shown

150426 Butter Wheel (Optional) 3

150429 Butter Wheel Base (Optional) 3

150425 Butter Wheel Kit (Optional) 3

148120 Carriage, Conveyor Asby 3

504102 Conveyor, Toaster 5

148133 Cover, Front 3

150430 Cover, Front For Butter Wheel (Optional) 3

148119 Cover LH Side 3

148118

160837 Cover RH Side (MM2F Only) 3

149279 Gear, Toaster, Drive Kit of 2 5,6

148303 Guard, Heat 3

504016 Idler, 1.405 Dia. (2 Per) 5

161895 Kit, Toaster Foot for HT18 VT18 Toasters Not Shown

504009 Knob, Adjustment 3

502906 Knob, Clear Schematic

148142 Loader, (OPTIONAL) (MM2D Models) 3

131479 Loader, (MM2F Models) 3

144027 Plate, Cover 3

144402 Plate, Idler Tensioning (2 Per ) 5

161452 Ramp, Heated Bun (MM2F Only) 3

144077 Rod, Toaster Platen Sheet 18.250” (1 Per) 4

504018 Screw, #10-32 x 1.500” SS 5

148317 Shaft, Conveyor Drive 5

148318 Shaft, Idler 5

149280 Sheet, Toaster Platen Package of 4 4

148127 Slide, Product (MM2D, MM2DINTLCE & MM2FINTLCE) 3

151097 Spacer, Conveyor Kit (3 Spacers) 5

504046 Spring, Tension (2 Per) 5

144078 Sprocket, Conveyor Asby (2 Per) 5

Cover RH Side (MM2D, MM2DINTLCE &

MM2FINTLCE)

3

148665 RV032114 8

Copyright 2012 Marshall Air Systems, Inc.

All Rights Reserved.

Page 13

OWNER’S MANUAL

MODEL VT18 - VERTICAL CONTACT TOASTER

CONTROL GENERATION 1 ELECTRICAL REPLACEMENT PARTS

(NOTE BUTTON LAYOUT TO RIGHT OF DISPLAY)

PART # DESCRIPTION FIGURE

148150 Circuit Board 230V Schematic

143852 Control, 3 Digit (Control Type 1 Only) Schematic

148301 Control, Module (MM2D Only) (208V Units) Schematic

157400 Control, Module (MM2FINTLCE only) SCHEMATIC Schematic

150214 Control, Module (MM2D Intl, MM2FINTLCE) Schematic

151246 Control, Module (MM2F) Schematic

504011 Cord, 12/3 w/6-20 Plug (MM2D Only) Schematic

504237 Cord, 12/3 3 Wire (MM2FINTLCE, MM2GINTLCE) Schematic

504145 Cord, Set (MM2DINTL) Schematic

144139 Fan, Cooling 240 Vac Schematic

500069 Fuse Holder Schematic

500061 Fuse, 1.5 AMP Schematic

500392 Jumper Schematic

503985 Motor, Right Angle Drive 6,Schematic

503981 Platen, 9” X 12” (2 Per) 6,Schematic

502892 Potentiometer, Rotary Schematic

504313 Relay, Control Schematic

504023 Relay, Solid State Schematic

161003 Sensor, RTD (Note: 2 req’d per toaster) Schematic

502080 Strain Relief for Cord Not Shown

500340 Terminal Strip Schematic

148595 Wiring Harness Platens Not Shown

148665 RV041714 9

Copyright 2012 Marshall Air Systems, Inc.

All Rights Reserved.

Page 14

OWNER’S MANUAL

MODEL VT18 - VERTICAL CONTACT TOASTER

CONTROL GENERATION 2 ELECTRICAL REPLACEMENT PARTS

(NOTE BUTTON LAYOUT UNDER DISPLAY)

PART # DESCRIPTION FIGURE

148150 Circuit Board 230V Schematic

163975 Control Interface Board (LED Control) Schematic

163582 Control I/O Board (MM2F-NC, MM2D-NC) Schematic

164073 Control I/O Board (MM2FINTLCE-NC) Schematic

166249 Control I/O Board (MM2DINTL-NC, MM2DINTLCE-NC) Schematic

504011 Cord, 12/3 w/6-20 Plug (MM2D-NC Only) Schematic

504237

504145 Cord, Set (MM2DINTL-NC) Schematic

144139 Fan, Cooling 240 Vac Schematic

500069 Fuse Holder Schematic

501139 Fuse, .5 AMP Schematic

500061 Fuse, 1.5 AMP Schematic

500392 Jumper Schematic

503985 Motor, Right Angle Drive 6,Schematic

503981 Platen, 9” X 12” (2 Per) 6,Schematic

502892 Potentiometer, Rotary Schematic

504023 Relay, Solid State Schematic

163580 Sensor, RTD Schematic

502080 Strain Relief for Cord Not Shown

500340 Terminal Strip Schematic

504314 Transformer Schematic

148595 Wiring Harness Platens Not Shown

Cord, 12/3 3 Wire (MM2FINTLCE-NC, MM2GINTLCENC)

Schematic

148665 RV012615 10

Copyright 2012 Marshall Air Systems, Inc.

All Rights Reserved.

Page 15

22.000

PLATEN GAP

ADJUSTMENT KNOBS

A

17.000 BUN

LOADING AREA

25.375

DETAIL A

OPTIONAL

LOADER

SPEED CONTROL

IS LOCATED BEHIND

THIS COVER

WITH OPTIONAL

BUTTER WHEEL

MODEL:VT18

OVERALL DIMENSIONS

FIGURE 1

THIS EGDE TO BE USED

TO GAUGE SETTING

29.500

WITH OPTIONAL

LOADER

16.000"

PLATEN GAP

ADJUSTMENT GAUGE

VIEW WINDOW

HEEL LOADING AREA

REMOVABLE HEAT GUARD

NOTE:

UNIT SHOWN WITHOUT

OPTIONAL LOADER OR

OPTIONAL BUTTER WH E EL

THIS VIEW

CROWN LOADING AREA

11.625

13.375

NOTE:

UNITS POWER CORD HAS A

NEMA 6-20 PLUG.

BUN DISCHARGE AREA

MODEL:VT18

OVERALL UNIT ISOMETRIC VIEW

148665FIG1 RV081712

Copyright © 2006 Marshall Air Systems, Inc.

All rights reserved

FIGURE 2

Page 16

#150426

OPTIONAL

BUTTER WHEEL

OPTIONAL

#150425

COVER, RH SIDE

BUTTER WHEEL KIT

MODEL:VT18

HANG-ON PARTS

FIGURE 3

#148133

FRONT COVER

#148118 MM2D, MM2DINTLCE, MM2FINTLCE

#160837 MM2F

#150430

OPTIONAL

BUTTER WHEEL

FRONT COVER FOR

#1444027

COVER PLATE

#150429

OPTIONAL

BUTTER WHEEL BASE

SADDLES

CARRIAGE LOCATOR

PRODUCT SLIDE SINGLE PIECE

#148127 MM2D, MM2DINTLCE, MM2FINTLCE, SOME MM2F

TWO PIECE HEATED RAMP

#161452 MM2F, SOME MM2F

CARRIAGE LOCATOR PINS

#148303

HEAT GUARD

SEE DETAIL A

#504009

SPRING

#502199

ADJUSTMENT KNOB

148665FIG3

Copyright © 2006 Marshall Air Systems, Inc.

All rights reserved

SCALE 1:4

DETAIL A

NUT

#501549

WASHER

RV060413

#501358

COVER, LH SIDE

ASBY #148120

FURTHER DETAIL

SEE FIGURE 5 FOR

CARRIAGE CONVEYOR

#148119

MODEL MM2D

#148142 (SHOWN)

LOADER, OPTIONAL

MODEL MM2F #131479

THIS ROD TO

REST IN CARRIAGE

LOCATOR SADDLE

Page 17

ARM, FRONT TENSIONIN G

#144074

DETAIL A

ROD, TOASTER PLATEN SHEET 18.250"

#144077

A

TOASTER PLATENS

148665FIG4 RV060413

Copyright © 2006 Marshall Air Systems, Inc.

All rights reserved

SHEET, TOASTER PLATEN

#149280

MODEL:VT18

TOASTER PLATEN SHEET

FIGURE 4

Page 18

#149279

CONSISTS OF

(1) DRIVE GEAR

(1) TOASTER GEAR

GEAR, TOASTER KIT

BEARING, REAR, FRONT KIT

#149278

CONSISTS OF

(2) FRONT

(2) REAR

#148317

SHAFT, CONVEYOR DRIVE

#144078

SPROCKET, CONVEYOR ASBY

PLATE, IDLER TENSIONING

#144402

SHAFT, IDLER

#148318

#504046

SPRING, TENSION

NOTE: TO RETENSION CONVEYOR

1. LOOSEN SCREWS

2. PUSH PLATE TOWARD FRONT OF CARRIAGE

3. RETIGHTEN SCREWS

MODEL:VT18

FIGURE 5

#504102

CONVEYOR, TOASTER

IDLER

#504016

#504018

#151097

SCREW, 10-32X1.5

KIT, SPACER CONVEYOR

#149404

CONSISTS OF (2)

BAR, CHAIN SUPPORT KIT

CARRIAGE ASSEMBLY

148665FIG5

Copyright © 2006 Marshall Air Systems, Inc.

All rights reserved

RV060413

Page 19

PLATEN 9" X 12"

#503981

GEAR, DRIVE KIT

#149279

CONSISTS OF

TOASTER AND DRIVE GEAR

MOTOR BRACKET MOUNTING SCREWS

148665FIG6 RV011007

Copyright © 2006 Marshall Air Systems, Inc.

All rights reserved

MOTOR, RIGHT ANGLE DRIVE

#503985

MOTOR MOUNTING BRACKET

#148105

MOTOR MOUNTING SCREWS

MODEL:VT18

DRIVE MOTOR ASSEMBLY

FIGURE 6

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Loading...

Loading...