Page 1

OWNER'S MANUAL

grilled

thicknesses of buns. The buns are discharged onto a product

slide at the bottom of the unit. The system is high speed and

allowing operators to produce the hottest buns in the shortest

MODEL HST13 - VERTICAL TOASTER

Supplier Name:

Address:

Serial #:

Date Received:

Date Installed:

Telephone #: 704-525-6230

Toll Free #: 800-722-3474 Customer Service

Fax #: 704-525-6229

Service Referral #: 800-722-3474

Local Service Name:

Local Service #:

Conveyor Speed

Setting:

MARSHALL AIR SYSTEMS, INC.

419 Peachtree Drive South

Charlotte, NC 28217

MANUFACTURER'S INTRODUCTION GENERAL SPECIFICATIONS

Height: 23.250"

The Marshall High Speed Vertical Toaster produces a

effect on the cut side of sandwich buns. The buns are

inserted at the top of the unit and are pressed against a

heated platen surface, which is covered by a replaceable

toaster platen sheet. The spacing between the heated grill

and the conveyor is adjustable to accommodate different

also variable in speed. Additionally, the heat controls are preset at factory, which eliminates unauthorized tampering with

heat settings. The flexibility of this toaster is unmatched

time.

Width: 19.875"

Depth: 15.250"

Electrical:

Power Cord:

Weight:

208V Single Phase 18.5 Amps

240V Single Phase 18.5 Amps

6 ft. 3 wire including ground,

with NEMA L6 -20P Plug

(Plug furnished by others on

international units.)

130 lbs.

135168CH7 RV100599

Copyright © 1999 Marshall Air Systems, Inc.

All Rights Reserved.

Page 2

OWNER'S MANUAL

MODEL HST13 - VERTICAL TOASTER

TABLE OF CONTENTS

INSTALLATION 1 -2

OPERATION 2

PREVENTIVE MAINTENANCE 2-4

TROUBLESHOOTING GUIDE 4-5

BROILER & TOASTER LIMITED WARRANTY 6

BROILER & TOASTER WARRANTY RETURN PROCEDURES 7

ILLUSTRATIONS

OVERALL DIMENSIONS FIGURE 1,2

HANG-ON PARTS FIGURE 3

SWITCHES AND TOASTER PLATEN SHEET FIGURE 4

BELT TENSION PARTS AND ADJUSTMENT MECHANISM FIGURE 5

INTERNAL PARTS AND DRIVE COMPONENTS FIGURE 6

ADJUSTMENT LEVER OPERATION FIGURE 7

BELT REMOVAL INSTRUCTIONS FIGURE 8

TOASTER BELT ORIENTATION FIGURE 9

CONTROL CABINET ACCESS INSTRUCTIONS FIGURE 10

TOASTER TENSION INSTRUCTIONS FIGURE 11

WIRING SCHEMATIC (208V, 50/60HZ, 1PH) #135169

WIRING SCHEMATIC (240V, 50/60HZ, 1PH) #135817

135168CH7 RV100599

Copyright © 1999 Marshall Air Systems, Inc.

All Rights Reserved.

Page 3

These screws are located inside the left side panel (switch side). After uncrating unit, remove the side panel and

is installed from

er operation, insert heels on the side of the

ance of the toasted

age

OWNER'S MANUAL

MODEL HST1 3 -VERTICAL TOASTER

INSTALLATION

35168CH7 RV100599 1

Copyright © 1999 Marshall Air Systems, Inc.

All Rights Reserved.

PRE-INSTALLATION

The toaster is packaged to minimize the risk of shipping damage. Immediately upon receipt, make certain to

1.

inspect the unit for damage. FILE ALL CLAIMS WITH THE FREIGHT CARRIER.

Before installation and operation of the toaster, it is necessary to remove two (2) shipping screws from the unit.

2.

This toaster is shipped completely wired and ready to plug into a grounded NEMA L6-20R amp receptacle. (208

3.

Volt Single Phase, 3 wire including the ground circuit). Check receptacle for proper voltage and phase. Units

FINAL INSTALLATION

Place toaster on level metal surface. The unit should be caulked to the countertop as required by local health

1.

department codes.

Check that the two lift off side covers are in place on the toaster AND THE LEFT COVER IS SECURED WITH A

2.

SCREW AT THE BOTTOM.

Check that the toaster platen sheet is installed over the contact platen. The toaster platen sheet

3.

the top of the unit by lightly creasing it at the center, and directly hanging it on the center platen.

4. Install the bun guide/spacer on the toaster. (Figure 4)

5. Connect the toaster to the power supply.

6. Turn on the conveyor switch on the toaster and check for free movement of the two conveyor belts.

7. Turn on the heat switch. Allow 15 minutes for the toaster to warm up before toasting buns.

After warm up, drop buns into the toaster at the top of the unit. For prop

8.

toaster marked "Heel", and crown on the opposite side. THE CUT SIDES OF THE HEEL AND CROWN MUST

The toasted heel and crown will drop down onto the product slide together. Check the appear

9.

buns.

Adjust the gap settings using the two levers inside the right panel. (See Figure 7). The levers are labeled "Heel"

10.

gap and "Crown" gap. To adjust the gap, loosen the black adjustment knob (Figure 5), several turns to diseng

Page 4

d through the machine but instead are damaged or

th or towel and

OWNER'S MANUAL

MODEL HST13 - VERTICAL TOASTER

The speed control is located behind the left side cover. DISCONNECT (UNPLUG) THE POWER BEFORE

11.

OPENING THE SIDE COVER. The speed control can be adjusted to control the conveyor belt speed to lighten or

darken the toasted product. The toaster is shipped with the speed control set on 8, which is approximately a ten

second toast.

12.

OPERATION

1. The toaster is operated by turning on the conveyor switch (see Figure 4) and then the heat switch.

2. Allow the toaster to warm up for 15 minutes before toasting buns.

3. For proper operation, insert heels on the side of the toaster marked "HEEL" and crowns on the opposite side.

4. Turn both switches off at the end of the day to turn off the toaster.

5. Toaster Platen Sheet General Information:

Test at least 3 buns before putting the toaster into service. Uniform surface toasting and bun temperature are

achieved when the gap described in step 10 is set correctly.

A. The toaster is not designed for use with but tered buns.

B. Life of Toaster Platen Sheet - depends on usage and cleaning.

C. Sheet turning white - this is black pigment fading out of the sheet and does not mandate sheet replacement.

D. What triggers sheet replacement? When buns no longer fee

torn, the toaster platen sheet should be replaced. Replace ONLY with Marshall toaster platen sheet.

CAUTION: DO NOT REMOVE THE CONTROL PANEL COVER WITHOUT FIRST TURNING OFF THE

TOASTER AND UNPLUGGING THE TOASTER.

PREVENTIVE MAINTENANCE

1.

2. Rotate toaster platen sheet so the "heel" side is on "crown" side, opposite than the day before.

3. Re-install all parts after drying.

E. How to get maximum life? Rotate the sheet daily so the "HEEL" side is opposite from the day before.

DAILY:

Carefully remove the toaster platen sheet (Figure 4), lay it on a flat surface, and wipe with a soft clo

clean with soap and water. Use ONLY enough water to make the cloth damp. DO NOT USE ABRASIVES ON

THE TOASTER PLATEN SHEET.

135168CH7 RV100599

Copyright © 1999 Marshall Air Systems, Inc.

All Rights Reserved.

2

Page 5

n a widthwise, circular motion. The belt is

DO NOT POUR

Thoroughly rinse the belt by wiping with a clean, damp towel. Frequently rinse the wiping towel to remove the

Copyright

© 199

9

Marshall Air Systems, Inc.

OWNER'S MANUAL

MODEL HST13 - VERTICAL TOASTER

WEEKLY:

1. Turn toaster off and unplug power cord from wall receptacle.

2. Perform daily maintenance.

Remove the front and back covers (Figure 3), by lifting these covers off the toaster. Clean these covers with

3.

soap and water. Wipe the exposed metal parts with a damp soft cloth or towel.

4. Reconnect the power cord.

5. Clean belts according to the Belt Cleaning Procedure below. Do not scrub belts with abrasive material.

6. Install the front and rear covers.

BELT CLEANING PROCEDURE

NOTE:

Supplies Needed:

A. Turn conveyor and heat switches off.

Put heat resistant gloves on your hands. IT IS IMPORTANT TO WEAR HEAT RESISTANT GLOVES TO

B.

AVOID BURNING HANDS.

C. Dispense Sizzle Plus agent onto a clean, damp No-Scratch Pad until the pad is nearly saturated.

Using the saturated pad, lightly rub the exposed surface of the belt i

not easy to wet so repeated rubbing may be needed to completely contact the soiled surface.

D.

SIZZLE PLUS ONTO THE BELT SURFACE.

E. Rotate the belt by turning the conveyor switch on. Turn switch off when new section of belt is exposed.

F. Repeat cleaning steps on new, exposed section of belt so that the entire surface of belt has agent applied.

TOASTER BELTS MUST BE CLEANED WHILE TOASTER IS STILL AT OPERATING

TEMPERATURE.

Kay Chemical #54238 Sizzle Plus Agent, No-Scratch Pad, #03574-018, Heat

Resistant Gloves (A 1qt. bottle of agent and 1 No-Scratch Pad are shipped with

the toaster to your restaurant. If you do not receive, contact your restaurant

supplies dealer or Kay Chemical Customer Service, 800-529-5458.)

G. Finish scrubbing entire belt by repeating the process of:

A. Turning the toaster conveyors on and off. B. Scrubbing the exposed surfaces of both crown and heel belts.

H.

accumulated soil and cleaner residue.

135168CH7 RV100599

All Rights Reserved.

3

Page 6

Replace all connections or components that have damaged terminals. Replace all damaged wiring with same or

Lay the unit on the right side. The bottom of the control cabinet will

135168CH7 RV1

00599

Copyright

© 1999

Marshall Air Systems, Inc.

All Rights Reserved.

4

OWNER'S MANUAL

MODEL HST13 - VERTICAL TOASTER

MONTHLY:

1. Perform Daily and Weekly Maintenance.

2. Replace any worn out toaster platen sheets or conveyor belts with Marshall parts.

TROUBLE SHOOTING GUIDE

SERVICE MUST BE PERFORMED BY A QUALIFIED SERVICE COMPANY. THE TERM

"QUALIFIED SERVICE COMPANY" MEANS ANY INDIVIDUAL, FIRM, CORPORATION OR

NOTE:

WARNING:

COMPANY WHICH IS EITHER ENGAGED IN AND IS RESPONSIBLE FOR THE INSTALLATION OR

REPLACEMENT OF ELECTRICAL COMPONENTS, OR THE CONNECTION, INSTALLATION OR

REPAIR OF ELECTRICAL APPLIANCES, WHO IS EXPERIENCED IN SUCH WORK, FAMILIAR

WITH ALL PRECAUTIONS REQUIRED, AND HAS COMPLIED WITH ALL THE REQUIREMENTS OF

THE AUTHORITY HAVING JURISDICTION.

INSPECTION, TESTING, AND REPAIR OF ELECTRICAL EQUIPMENT SHOULD BE PERFORMED

BY QUALIFIED SERVICE PERSONNEL. THE UNIT SHOULD BE UNPLUGGED WHEN SERVICING,

EXCEPT WHEN ELECTRICAL TESTS ARE REQUIRED.

USE EXTREME CARE DURING ELECTRICAL CIRCUIT TESTS. LIVE CIRCUITS WILL BE

DANGER:

PROBLEM:

1. No heat and conveyor belts do not move.

SOLUTION:

A. Check that toaster is plugged in.

B. Check that conveyor and heat switches are on.

C. Check that power is available at the receptacle. Check toaster nameplate for voltage.

PROBLEM:

2. Conveyor belts move but no heat.

WITH UNIT UNPLUGGED, check connections inside of plug. WITH UNIT UNPLUGGED, remove left side cover

screw at bottom of cover, and remove cover. Check electrical connections for bums, discoloration or arcing.

D.

a higher rated wire.

SOLUTION:

A. Check that the heat switch is on.

Turn off switches and unplug toaster. Remove left and right side covers. Remove ONE screw and loosen one

screw from each side as shown in Figure 10.

B.

now swivel open.

EXPOSED. WHERE TESTING INDICATES "WITH POWER OFF", BE SURE THAT THE CONVEYOR

AND HEAT SWITCHES ARE OFF AND TOASTER IS UNPLUGGED.

Page 7

D. Replace all connections or components that have damaged terminals. Replace all damaged wiring with same or a higher

OWNER'S MANUAL

MODEL HST13 - VERTICAL TOASTER

C. Check for loose connections at the temperature controllers and heating elements.

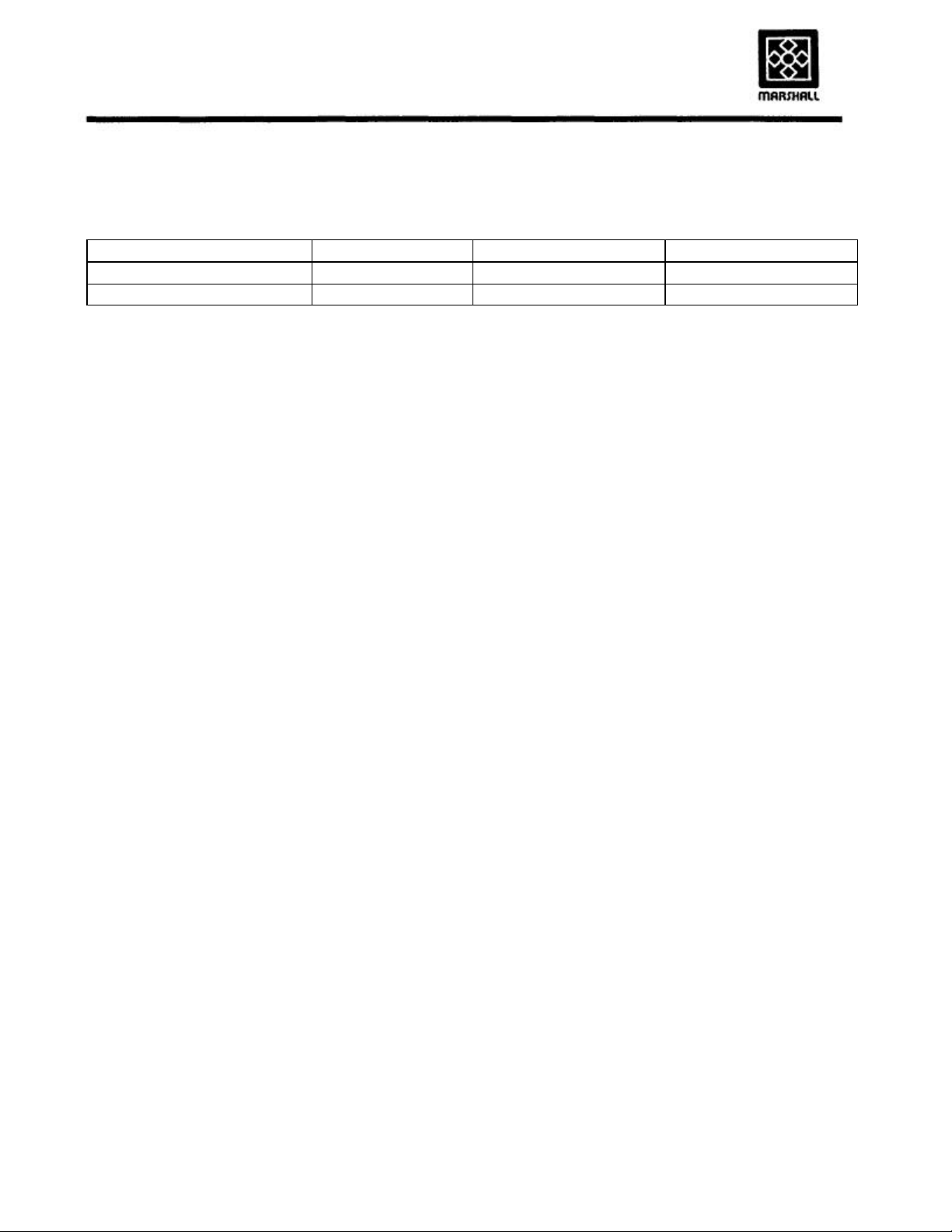

E. Check resistance of heating platens:

Center Platen Heel Platen Crown Platen

Schematic - 208V 135169 20 OHMS 52 OHMS 52 OHMS

Schematic - 240V 135817 25 OHMS 52 OHMS 52 OHMS

PROBLEM:

3. Grill is hot, but conveyor belts do not move.

SOLUTION:

A, Check that conveyor is on.

B. Check conveyor speed control setting.

C. Check for power to speed control circuit board.

D. Check that belt is not slipping on roller. If so, check for tears and that the tension keeper lever is

engaged in the slot shown in Figure 5.

E. Check for loose chain, or sprockets, tighten set screw on flat of shaft if needed. Replace as

needed.

F. TURN OFF SWITCHES, UNPLUG TOASTER, and remove the right side cover. Check fuse.

Replace fuse if necessary with same type AGC 1.5 Amp.

G. Check for loose connections or wiring.

H. Check that circuit board 115/230 switch is at the 230V position.

I. Check for DC voltage of at least 25VDC at the motor.

PROBLEM:

4. Product is over or under toasted.

SOLUTION:

A. Check toasting speed. Good toasting will occur in 10 seconds from bun load to drop.

B. Check gap setting. There must be compression of the bun as it feeds into the toaster. Decreasing

the gap (per Page 1, Number 10) will increase bun temperature and darken surface color.

C. If buns are burned, the toaster platen sheet may be causing buns to get stuck in the toaster OR

the toaster thermostat may have failed in a closed condition making the center platen too hot.

Check that thermostat DOES cycle.

PROBLEM:

5. Buns do not feed properly into toaster.

SOLUTION:

A. Check condition of Toaster Platen Sheet to be sure buns are not sticking to cover. Replace

Toaster Platen Sheet if necessary.

B. Belts need washing as described under Weekly Maintenance on Page 3.

C. Toast er gap set too close. See Page 1, Number 10.

135168CH7 RV100599

Copyright © 1999 Marshall Air Systems, Inc.

All Rights Reserved.

5

Page 8

l and factory workmanship for a period of one year* from date of shipment provided that (i)

eriod

• Burner Shields and Scree

ns •

Burner Grids

• Burner Gaskets

• Electric Broiler Elements

• Flame Runners

ured by Marshall,

1.

Any equipment calibration.

2. Any component disassembled in the field.

3. Plugs and cords.

mulation in electrical

5.

Blown fuses or bulbs, motor brushes.

6.

Any replacement parts used on the equipment which are not purchased fr

om Marshall.

the equipment or component parts is not covered by this warranty.

This warranty does not cover cooking performance, smoke capture or holding temperatures which is a function of food types,

en by the Purchaser and over which Marshall has no

control. This warranty does not apply to damage caused by accident or to damage caused by the negligence of Purchaser or

whatsoever. This warranty does not apply to any equipment bearing a serial number which has been tampered with or altered.

cept the return of any

product without prior written approval from Marshall, and all such approved returns shall be made at Purchaser's sole

135168CH7 RV100599

6

Copyright

© 1999

Marshall Air Systems, Inc.

All

Rights Reserved.

OWNER'S MANUAL

MODEL HST13 - VERTICAL TOASTER

BROILER & TOASTER LIMITED WARRANTY

MARSHALL AIR SYSTEMS, INC., ("Marshall") warrants to the first purchaser ("Purchaser") all new equipment of its

manufacture to be free of defects in materia

the equipment is installed in the Continental United States, Canada or Hawaii and operated according to the Owner's Manual while

located at the original address of installation, (ii) the warranty registration card has been completed and returned to the factory within

fifteen (15) days after installation, and (iii) a post-installation start-up has been performed by an authorized service representative

(portable equipment not applicable). Marshall's obligation under this warranty is limited to the repair or replacement at its option of any

defective part. Under certain circumstances, Marshall will reimburse Purchaser for limited labor costs in replacing parts during a p

of not more than ninety (90) days after date of shipment, provided that Labor Reimbursement instructions are followed and items i, ii,

and iii above are completed. See special provision for portable equipment. It is understood that Marshall's obligation with respect to

equipment located outside the Continental United States, Canada or Hawaii is limited to replacement parts only.

*The following broiler/toaster parts are consumable items and not covered under warranty:

• Teflon Sheets and Belts

Because Marshall does not and cannot control Purchaser's installation, use, and maintenance of equipment manufact

this warranty DOES NOT COVER:

SHIPPING DAMAGE must be reported to the carrier and is not covered under this warranty. Marshall will not be liable for

damage as a result of improper installation, misuse, abuse, alteration of original design, incorrect voltage, unauthorized service,

breakage of fragile items, or any other damage caused by an act out of Marshall's control.

The effect of corrosion, fire, and normal wear on

textures, temperatures, equipment line ups and other variables chos

the employees of Purchaser or to damage caused by lightning generated electrical current or any other Act of God

Marshall reserves the right to accept or reject any such claim in whole or in part. Marshall will not ac

expense.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE IMPLIED

WARRANTY OF MERCHANTABILITY AND THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, OR

PATENT OR OTHER INTELLECTUAL PROPERTY RIGHT INFRINGEMENT, AND EXCEPT FOR THE EXPRESS WARRANTY

CONTAINED HEREIN, THE EQUIPMENT IS SOLD "AS IS." REMEDIES UNDER THIS WARRANTY AND UNDER ANY WARRANTY

THAT MAY SURVIVE THE DISCLAIMER OF WARRANTIES ARE LIMITED EXCLUSIVELY TO THOSE REMEDIES DESCRIBED

ABOVE. NO OTHER REMEDY IS AVAILABLE UNDER THIS WARRANTY OR ANY OTHER WARRANTY. NEITHER THIS

WARRANTY NOR ANY OTHER WARRANTY COVERS, AND MARSHALL WILL NOT BE RESPONSIBLE FOR, ANY INCIDENTAL

OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT LIMITED TO THE COST OF DISASSEMBLY AND SHIPMENT OF THE

EQUIPMENT, PRODUCTION OR PRODUCT LOSSES, INJURY TO OTHER PROPERTY, OR LOST PROFITS RESULTING FROM

THE USE OF OR INABILITY TO USE THE PRODUCTS OR FROM THE PRODUCTS BEING INCORPORATED IN OR BECOMING A

COMPONENT OF ANY OTHER PRODUCT OR GOODS, OR OTHER LOSSES. WHERE, DUE TO OPERATION OF LAW,

CONSEQUENTIAL AND INCIDENTAL DAMAGES CANNOT BE EXCLUDED, THEY ARE EXPRESSLY LIMITED IN AMOUNT TO

THE PURCHASE PRICE OF THE EQUIPMENT.

Damage due to improper or lack of cleaning, abuse, and/or service i.e. burner rotation, grease accu

4.

components or plugs (hosing or "watering down" equipment will cause electrical failures not covered by warranty).

7. Accessory components not installed or manufactured by Marshall.

FOR INTERNATIONAL INSTALLATIONS -- PLEASE CONTACT YOUR LOCAL MARSHALL AIR

SYSTEMS RECOGNIZED DISTRIBUTOR.

Page 9

restocking fee. In the event of an error by Marshall

Copyright

© 1999

Ma

rshall Air Systems, Inc.

OWNER'S MANUAL

MODEL HST1 3 -VERTICAL TOASTER

BROILER & TOASTER WARRANTY RETURN PROCEDURES

I. RETURN GOODS AUTHORIZATION FOR PARTS

For prompt warranty parts replacement and RGA processing, please call Marshall's Customer Service Department at

800-722-3474 or 704-525-6230 for assistance. In all cases, a Return Goods Authorization (RGA) number must be

issued by Marshall Air Systems, Inc. Unauthorized returns will not be processed.

Option #1:

Option #2:

Option #3: Purchaser may obtain replacement part(s) from recognized service agency.

Purchaser to return part(s) prepaid to Factory, Marshall to repair or replace at own expense if

defective, and ship part(s) back to Purchaser prepaid.

Marshall to furnish replacement part(s), freight prepaid, with or without requesting return of the

defective part(s).

II. WARRANTY LABOR REIMBURSEMENT THROUGH RECOGNIZED SERVICE AGENCIES

Normally, labor will be covered for 90 days under the start up fee. In the unlikely event this does not apply, consult

Marshall Air Systems, Inc. To be reimbursed for warranty labor costs, authorization must be given by Marshall Air

Systems, Inc. Unauthorized work will not be reimbursed. Work must be performed by a Marshall Air Systems

Recognized Service Agency within the service time allowance guidelines and must be submitted along with failed

parts (if applicable) to Marshall Air Systems (freight prepaid) within 30 days of the work being performed. Travel is

covered, but must not exceed 50 miles or 1 hour, whichever is greater. Call Marshall's Service Department at 800722-3474 or 704-525-6230 with any questions. Service is to be performed by recognized service agencies during

normal working hours. Owner to pay for all other charges including excessive travel or overtime charges.

DIAGNOSTIC LABOR CHARGES ARE INCLUDED IN SERVICE TIME ALLOWANCE GUIDELINES. All portable

equipment (under 90 pounds) shall be delivered by Purchaser, at Purchaser expense, to the nearest authorized

service agency for in-shop repair or, at Purchaser's discretion, Purchaser will pay all travel time and mileage

expenses for portable equipment.

III. NON-WARRANTY RETURNS:

FOR INTERNATIONAL INSTALLATIONS -- PLEASE CONTACT YOUR LOCAL MARSHALL AIR SYSTEMS RECOGNIZED

DISTRIBUTOR.

135168CH7 RV100599 7

All Rights Reserved.

All items returned for customer cancellations are subject to a 20%

Air Systems, Inc., a Returned Goods Authorization will be issued for full credit. Custom fabricated parts are not

returnable.

Page 10

135168FIG 1 RY042899

Copyright © 1999 Marshall Air Systems. Inc.

All rights reserved. -

Page 11

TOASTERS WITH SERIAL NUMBERS

0899181 AND ABOVE:

#503767 CLEATED BELT (HEEL AND CROWN SIDES ARE SAME BELT)

NOTE: TO CHANGE STITCHED BELTS TO CLEATED BELTS ON UNITS

0899180 AND BELOW. ORDER BELT REPLACEMENT KIT #137638

TOASTERS WITH SERIAL NUMBERS 0899180 AND BELOW,

HEEL SIDE - #5034998LKH CROWN SIDE - #503499BLKC

NOTE TO BELT INSTALLER: IF BOTH BELTS ARE BLACK,

NOTE THE DIFFERENCE BETWEEN THE TWO. THE SEWN

SEAM FOR THE HEEL BELT RUNS IN THE OPPOSITE

DIRECTION THAN THE CROWN SIDE BELT. REFER TO

FIGURE 9 FOR BELT/SEAM ORIENTATION.

HANG-ON PARTS

135168FIG 3 RY092999

Copyright © 1999 Marshall Air Systems. Inc.

All rights reserved

Page 12

135168FIG 4 RY042899

Copyright © 1999 Marshall Air Systems. Inc.

All rights reserved

Page 13

135168FIG 5 RY093099

Copyright © 1999 Marshall Air Systems. Inc.

All rights reserved

Page 14

DRIVE SIDE W/ COVER REMOVED

135168FIG 6 RY093099

Copyright © 1999 Marshall Air Systems. Inc.

All rights reserved

INTERNAL PARTS AND DRIVE COMPONENTS

Page 15

ADJUSTABLE GAP SETTING

135168FIG 7 RY093099

Copyright © 1999 Marshall Air Systems. Inc.

All rights reserved

ADJUSTMENT LEVER OPERATION

Page 16

BEFORE PROCEEDING FURTHER, DISCONNECT POWER TO MACHINE

SET EACH ADJUSTMENT KNOB TO LOWEST POSITION. SEE ILLUSTRATION

SEN NUT ON

TOP OF BRACKET. NUTS SHOULD BE LOOSENED ENOUGH TO BE ABLE TO

REMOVE BELT FROM ROLLER. IF UNIT IS EQUIPPED WITH SPRINGS, PULL

LAY UNIT ON SIDE. SO THAT DRIVE SIDE IS FACING DOWN AGAINST

EACH CURVED ADJUSTMENT ARM SO THAT IT COMES LOOSE

FROM THE ROUND PIN ON EACH BRACKET. YOU MAY NEED TO HAVE ONE

E PLATEN. TOTAL OF (4) THIS WILL ALLOW

REMOVED. SEE ILLUSTRATION BELOW. DO NOT REMOVE BOLTS THAT ARE

IF BELTS HAVE A

STITCHED JOINT, MAKE SURE TO ORIENT AS SHOWN. IF NEW BELT HAS

THESE BELTS ARE SYMMETRICAL

G TENSION SETUP, INSTALL

TENSION KEEPER LEVERS BACK INTO SLOT. IF NO SPRINGS, TIGHTEN

DISTANCE BETWEEN UPPER AND LOWER SHAFTS MUST BE THE SAME ON

135168FIG 8 RY093099

Copyright © 1999 Marshall Air Systems. Inc.

All rights reserved

TOOLS NEEDED: 1/2" WRENCH

1. REMOVE FRONT, BACK AND SIDE COVERS

2.

BELOW.

LOOSEN NUT ON UNDERSIDE OF BEARING BRACKET THEN LOO

3.

OUT TENSION KEEPER LEVERS.

4.

TABLE.

PULL UP ON ON

5.

HAND ON ADJUSTMENT ARM WHILE WORKING THIS LOOSE. SWING

ADJUSTMENT ARM AWAY FROM ROUND PIN. SEE ILLUSTRATION BELOW.

REMOVE BOLTS ON EACH SID

THE PLATEN BRACKETS AND BEARING RETAINER BRACKETS TO BE

6.

IN THE CENTER.

7. SLIDE OLD BELTS OFF OF ROLLERS AND THRU CUTOUTS IN SIDE.

BEFORE SLIDING ON NEW BELTS. REFER TO FIGURE 9.

8.

CLEATS DO NOT REFER TO FIGURE 9.

AND CAN BE INSTALLED ON HEEL OR CROWN SIDE.

IF UNIT IS EQUIPPED WITH THE SPRIN

9.

NUTS SO THAT BELT WILL NOT SLIP ON ROLLERS.

10.

EACH SIDE OF UNIT. SEE FIGURE 11.

Page 17

135168FIG 9 RV050399

Copyright © 1999 Marshall Air Systems. Inc.

All rights reserved

Page 18

BOTTOM OF CONTROL CABINET SWINGS

1. TURN UNIT OFF AND UNPLUG

2. REMOVE BOTH SIDE COVERS

3. LOOSEN SCREW "A"

4. REMOVE SCREW "B"

5. LAY UNIT ON LEFT SIDE TO ALLOW

BOTTOM PANEL TO SWING OPEN

6.

DOWN GIVING ACCESS TO CONTROLS

135168FIG 10 RV093099

Copyright © 1999 Marshall Air Systems. Inc.

All rights reserved

7. REAR OF CABINET IS CAULKED,

ALONG LINE AT "C". DO NOT BREAK

THESE SEALS

Page 19

AFTER BELTS INSTALLED AND TENS[ON ING BOLTS ARE SET, MEASURE DISTANCES

MEASURE DISTANCE "A" ON DRIVE SIDE. MEASURE DISTANCE "A" ON ADJ. SIDE DISTANCE

MEASURE DISTANCE "B" ON DRIVE SIDE. MEASURE DISTANCE "B" ON ADJ. SIDE DISTANCE

135168FIG 11 RV093099

Copyright © 1999 Marshall Air Systems. Inc.

All rights reserved

BETWEEN TOP OF UPPER SHAFT AND TOP OF LOWER SHAFTS.

"A" SHOULD BE SAME ON BOTH SIDES. ADJUST IF NEEDED.

"B" SHOULD BE SAME ON BOTH SIDES. ADJUST IF NEEDED.

TOASTER TENSION INSTRUCTIONS

Page 20

Copyright © 1998 Marshall Air Systems. Inc.

All rights reserved

Page 21

Copyright © 1998 Marshall Air Systems. Inc.

All rights reserved

Loading...

Loading...