This document contains the installation and operating instructions for:

MODEL: FR24BG AUTOBROIL™ (BC5)

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE.

INSTRUCTIONS TO PURCHASER:

1. ANSI Z83.11 STANDARDS REQUIRE THAT YOU POST IN A

PROMINENT LOCATION THE PROCEDURES TO FOLLOW IN THE EVENT THE

USER SMELLS GAS. THIS INFORMATION SHALL BE OBTAINED FROM THE

LOCAL GAS SUPPLIER.

2. THIS MANUAL NEEDS TO BE RETAINED FOR FUTURE

REFERENCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATION AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

123718 RV051099

Copyright© 1994 Marshall Air Systems, Inc.

All Rights Reserved.

MODEL FR24BG

TABLE OF CONTENTS

I. MACHINE SETTINGS (Quick Reference) ..................................................................... 2

II. MACHINE INSTALLATION............................................................................................ 3

Pre-Installation................................................................................................................ 3

Appliance Location......................................................................................................... 3-4

Electrical Information...................................................................................................... 4

Gas Piping To Appliance................................................................................................ 4

Pre-Operation Check...................................................................................................... 4-5

Lighting and Shut-Off Instructions.................................................................................. 5

Performance Criteria...................................................................................................... 6

III. OPERATING INSTRUCTIONS...................................................................................... 7

Daily Broiler Adjustment................................................................................................. 7

Setting Temperature Controller For Proper High/Low Operation-Weekly..................... 7-8

IV. SCHEDULED MAINTENANCE...................................................................................... 8

Daily Cleaning Procedures............................................................................................. 8

Monthly Cleaning Procedures........................................................................................ 9

Quarterly Cleaning Procedures and Preventive Maintenance....................................... 10

V. TROUBLESHOOTING.................................................................................................. 10-13

VI. ASSEMBLY & DISASSEMBLY INSTRUCTIONS.......................................................... 13-14

VII. REPLACEMENT PARTS ............................................................................................... 14-19

BROILER LIMITED WARRANTY................................................................................... i

BROILER WARRANTY PROCEDURES ...................................................................... ii

ILLUSTRATIONS

MODEL FR24BG

Overall Dimension....................................................................................................................... Figure 1

Exploded View - Removable Parts.............................................................................................. Figure 2

Exploded View - Internal Parts.................................................................................................... Figure 3

Exploded View - Drive System.................................................................................................... Figure 4

Gas Distribution System.............................................................................................................. Figure 5

Pilot System................................................................................................................................. Figure 6

Conveyor- Axle Scraper............................................................................................................. Figure 7

Restraining Device...................................................................................................................... Figure 8

Control Panel............................................................................................................................... Figure 9

Burner Construction .................................................................................................................... Figure 10

Hot Surface Pilot Operation......................................................................................................... Figure 11

Hot Surface Pilot Trouble Shooting............................................................................................. Figure 12

Autocat™ Catalytic Converter (Natural Gas Only)...................................................................... Figure 13

Lower Burner Support Asby........................................................................................................ Figure 14

Autocat™ Catalytic Converter 9.5" Arms(LP Gas Only)............................................................. Figure 15

Autocat™ Catalytic Converter 3" Arms(LP Gas Only)................................................................. Figure 16

Heated Holding Asby-120V........................................................................................................ Figure 17

Heated Holding Asby-240V........................................................................................................ Figure 18

AutoLoader™............................................................................................................................... Figure 19

Wiring Schematic..............................................…....(120V, 1PH, 60HZ, 13Amps) Drawing #1231713 (BC5)

Wiring Schematic..........................…….. (220V-240V, 1PH, 50HZ, 7Amps) Drawing #123830 (BC5BKINTL)

Wiring Schematic............................…........................(120V, 1PH, 60Hz, 4Amps) Drawing #124557 (BC5A)

I. MACHINE SETTINGS

AUTOBROIL™

MODEL: FR24BG

SERIAL NUMBER: _____________________________________________________________________

TYPE OF GAS: ________________________________________________________________________

ELECTRICAL SUPPLY: _________________________________________________________________

BROILER HIGH/LOW TEMPERATURE SETTING: ____________________________________________

GAS PRESSURE: HIGH _________________ LOW ____________________

BROILER SPEED SELECTOR SETTING: ___________________________________________________

START-UP TECHNICAIN: _______________________________________________________________

START-UP DATE: _____________________________________________________________________

COMMENTS: _________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

2

II. MACHINE INSTALLATION

PRE-INSTALLATION

1. After uncrating the Autobroil™ unit, inspect for shipping damage. Check that all control knobs are intact on

the electrical cabinet front. Contact the factory if there are obvious problems. Set the unit in place and

leave the plastic wrapping on to protect it from the debris and trash of building construction. DO NOT

remove plug from gas inlet pipe. Leave this for the Qualified Service Company. Check that machine has

not been dented or damaged by the carrier. Notify your freight carrier immediately to file a concealed

damage claim, following the instructions attached to the outside of the shipping crate. Your warranty will

not cover freight damage.

2. Installation must be performed by a Qualified Service Company. The term "Qualified Service Company"

means any individual, firm, corporation or company which is either engaged in and is responsible for the

installation or replacement of gas piping on the outlet side of the meter, or the service regulator when a

meter is not provided, or the connection, installation or repair of gas appliances, who is experienced in

such work, familiar with all precautions required, and has complied with all the requirements of the

authority having jurisdiction.

3. A remote gas shut-off valve must be provided and interlocked to the exhaust fire protection system.

A gas shut-off control is located on the top of the gas safety valve (behind the right side panel) for

emergency shut-off of gas supply to this appliance.

4. Because this unit is power fan exhausted, it is necessary to provide adequate make up air equal to the

amount removed. In addition to this, any other exhausts, flues, or air removal systems must be taken into

consideration. Examples of this are heat removal fans or hot water heater flues.

5. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1/2 psig (3.45 kPa).

6. The appliance must be isolated from the gas supply piping system by closing its individual shutoff valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig

(3.45 kPa).

APPLIANCE LOCATION

WARNING: IF NOT INSTALLED, OPERATED AND MAINTAINED IN ACCORDANCE WITH THE MANUFACTURER'S

INSTRUCTIONS, THIS PRODUCT COULD EXPOSE YOU TO SUBSTANCES IN FUEL OR FROM FUEL COMBUSTION

WHICH CAN CAUSE DEATH OR SERIOUS ILLNESS AND WHICH ARE KNOWN TO THE STATE OF CALIFORNIA TO

CAUSE CANCER, BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

1. Position Autobroil™ to properly align with exhaust hood (refer to equipment plan).

2. The hood/ventilator for the appliance should be located in accordance with the National Fire Protection

Association Standard #96, "Removal of Smoke and Grease-Laden Vapors from Commercial Cooking

Equipment" and any local applicable requirements.

3. For proper installation, the minimum clearance from combustible construction is 0" from sides and 18" from

food loading end and food delivery end.

3

4. Adequate clearance should be maintained to allow easy access to loading and unloading areas of the

machine.

5. For servicing, unit must be moved two feet clear from all construction.

CAUTION: KEEP THE APPLIANCE AREA FREE AND CLEAR FROM COMBUSTIBLES.

ELECTRICAL INFORMATION

1. The domestic appliance is furnished with a cord and plug; and requires a 120 volt, A.C., 60 HZ, Single

Phase, 3 wire (including ground), 20 AMP circuit. Appliance must be electrically grounded in accordance

with local codes, or in the absence of local codes, with the National Electrical code ANSI/NFPA No. 70latest edition.

2. The international appliance requires 220 volt or 240 volt, A.C., 50 Hz, Single Phase and is furnished with a

cord only - no plug.

3. There is a Wiring Diagram located in the Owner's Manual and under the right side skin. GAS

PIPING TO APPLIANCE

1. Installation of this appliance must conform with local codes, or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z-223.1 -latest edition.

2. In Canada, this appliance is to be installed in accordance with Standard CGA B149.1 or B149.2 Installation

Codes for gas burning appliances and equipment and any local applicable requirements.

3. The appliance is supplied with a 3/4" female pipe thread. The installer must make the pipe connection to

the unit in accordance with the "National Fuel Gas Code," ANSI Z-223.1-latest edition. The gas line

connected to the 3/4" female pipe thread cannot be less than a 3/4" pipe. The gas pressure and gas

volume required by this appliance is shown on Page 7. Gas piping from source to broiler must be adequate

to satisfy these requirements when all other gas appliances in the restaurant are operating at maximum

demand.

4. A flexible AGA approved gas line is available. Instructions are (1) the installation shall be made with a

connector that complies with the Standard for Connectors for Movable Gas Appliances, ANSI Z21.699latest edition, and Addenda, Z21.69a-latest edition, and a quick-disconnect device that complies with the

Standard for Quick-Disconnect Devices for Use With Gas Fuel, ANSI Z21.41-latest edition, and Addenda,

Z21.41a-latest edition and Z21.41b-latest edition, and (2) adequate means must be provided to limit the

movement of the appliance without depending on the connector and the quick-disconnect device or its

associated piping to limit the appliance movement. See Figure 8 for details.

5. See Page 3, Items 5 and 6, for instructions on gas supply line pressure testing.

CAUTION: DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND VENTILATION AIR.

PRE-OPERATION CHECK

Before lighting and operating your Autobroil™, make a quick check of critical items as follows:

1. Remove both side panels and check to see that all parts are in place and that none are damaged.

Particularly make sure all burners are in place and that the shields are in position on the bottom burners.

2. Start conveyor chains and check for proper operation. The conveyor chains should run free and not be

catching on anything.

3. The speed of the conveyor chains should be modulated from low to high, and back again without the chain

stopping.

4

4. Before first use, and after any special cleaning, it is necessary to "season" the broiler chain. This is done

by bringing the broiler to operating temperature and then (with burners still lit) applying liquid shortening

from a saturated cloth over the full width of the broiler chain while the chain makes 5 or 6 complete

revolutions.

5. Check that gas pressure at appliance is correct (see Performance Criteria on Page 7).

6. Check that broiler grease tray is in place under burners (Figure 2).

LIGHTING INSTRUCTIONS FOR ELECTRONIC IGNITION SYSTEM

1. Turn exhaust system on. (Some hoods are so powerful that the broiler must be lit before the exhaust is

turned on).

2. Make sure filters are in place in the hood.

3. Turn conveyor chain on and set speed at approximate mid-point.

4. Remove right side cover. (Same Side As Controls).

5. Turn gas control switch on top of Honeywell gas safety valve to "ON".

6. Turn on the broiler heat switch on the control panel and verify all burners have ignited. Ignition is

electronic (does not require manual lighting of pilot). Set broiler temperature controller on right side of the

broiler (behind the side panel) to 400°F (204°C) (see Item 3 of setting temperature controller on Page 9).

7. If pilot flame or burners fail to light turn heat switch off and wait five minutes before attempting to relight.

SHUT-OFF INSTRUCTIONS

1. Turn heat switch off.

2. Wait 30 minutes.

3. Turn conveyor switch off.

4. Turn exhaust system off.

5

PERFORMANCE CRITERIA

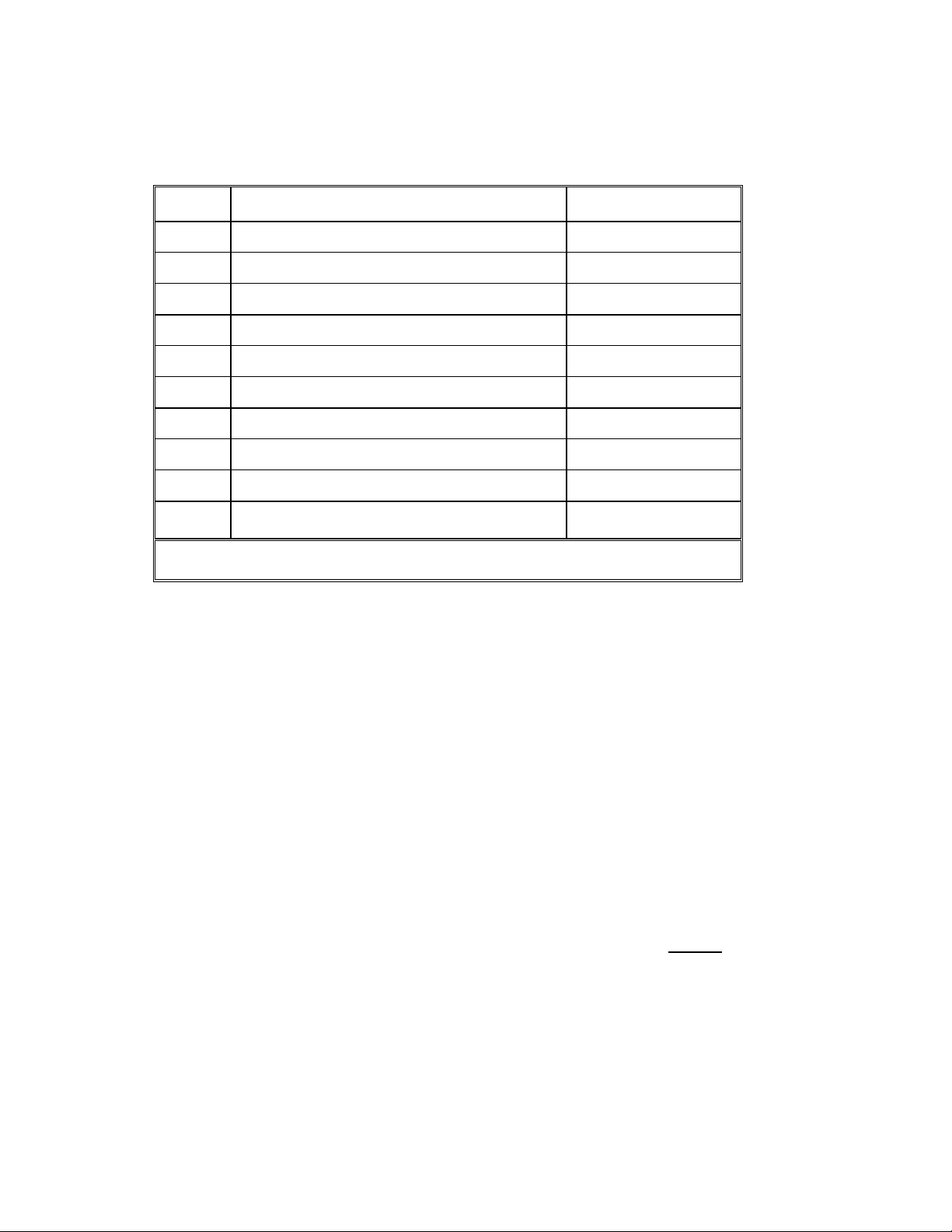

1. The manifold pressure for each burner and appliance inlet pressure and gas amount is listed below:

Type of Gas

Pressure at the Appliance

Manifold Pressure

Total Gas Amount

- Natural or Propane

- 6.0-10.0 IWC for Natural

- 11.0-14.0 IWC for Propane

- Low 8.0 IWC; High 10.0 IWC for

- Low 9.5 IWC; High 11.0 IWC for

- 97,000 BTUH @ 100% High Fire

LOW 4.0 IWC W/O CATALYST;

LOW 3.0 IWC W/CATALYST; High 5.0

IWC W/O Catalyst; High 5.0 IWC

W/Catalyst for Natural

Propane

Propane (LP Catalyst Only)

Manifold pressure is measured by a pressure gauge on the outlet side of the Honeywell gas valve. With

the unit on for at least twenty minutes and the broiler temperature controller set at 400°F (204°C) (see

Item 3 on Page 9), the pressure should be at 4.0 IWC w/o Catalyst; 3.0 IWC w/Catalyst (8.0 IWC for

propane); (9.5 IWC for LP Catalyst Only). With the broiler temperature controller set for 800°F (427°C)

the high fire pressure is 5.0 IWC (10.0 IWC for propane). High pressure is adjusted using the regulator in

the top of the Honeywell gas safety valve. Low fire is adjusted using the gas pressure regulator. See

Figure 5 for gas system layout.

2. The burners in the appliance are a special infrared type. All of the air for combustion must be injected

through the Venturis. This makes orifice design and alignment very critical. The orifice design, in

combination with the correct natural or propane gas pressure will result in adequate air aspiration and

mixing. There are no air shutters. No air adjustment is needed. The proper orifice part numbers are found in

Section VII - Replacement Parts.

CAUTION: DO NOT STACK BOXES OR IN ANY WAY BLOCK AREA IN IMMEDIATE VICINITY OF

VENTURIS OR IN ANY OTHER WAY OBSTRUCT FLOW OF COMBUSTION AIR.

3. Ignitor - sensor - pilot burner flame is adjustable with a small screwdriver. The cap screw behind the 1/4"

gas line exiting the valve should be removed. See Figure 5. The small adjusting screw is under the cap

screw. Turning the small adjusting screw inward (clockwise) will reduce the flame to the pilot. The pilot

flame should be uniform and just large enough to make a flame envelope around the end of the sensor and

ignitor.

4. All burners will be bright orange when burning properly. If a dull red is observed after 30 minutes of warmup with a blue flame above the burner face, the orifice may be dirty or damaged. "Popping," or burning back

at the orifice of the burner, is a result of the burner screen being loose or a faulty gasket under the burner

screen. LP machines may exhibit a light "popping" sound when the unit is turned off;

this is normal.

NOTE: IF BURNER SCREEN IS TORN OR HAS A HOLE, OR IF A GASKET IS LEAKING, THE

BURNER MUST BE REPAIRED. See Figure 10.

6

III. OPERATING INSTRUCTIONS

BROILER ADJUSTMENT- DAILY

LIGHTING INSTRUCTIONS FOR ELECTRONIC IGNITION SYSTEM

1. Turn exhaust system on.(Some hoods are so powerful that the broiler must be lit before the exhaust is

turned on.)

2. Make sure filters are in place in the hood.

3. Turn conveyor chain on and set speed at approximate mid-point.

4. Remove right side cover.

5. Turn gas control switch on top of Honeywell gas safety valve to "ON".

6. Turn on the broiler heat switch on the control panel and verify all of the burners have ignited. Ignition is

electronic. Set broiler temperature controller on right side of control cabinet to 400°F (204°C) (see Item 3

of setting temperature controller on Page 9).

7. If pilot flame or burners fail to light turn heat switch off and wait five minutes before attempting to relight.

SHUT-OFF INSTRUCTIONS

1. Turn heat switch off.

2. Wait 30 minutes.

3. Turn conveyor switch off.

4. Turn exhaust system off.

SETTING TEMPERATURE CONTROLLER FOR PROPER HIGH/LOW OPERATION - WEEKLY (This

Control Is Located Under The Right Broiler Side Cover)

1. Follow the procedure in Step 3 below in order to set temperature control for 400°F (204°C). After doing

this, turn on the burners.

2. Allow the broiler burners and conveyor chain to warm up for 60 minutes (with the chain at approximately

the correct speed).

3. Observe the temperature displayed: push "SET" and release to view the "SET POINT." To change set

point push "SET" and, within three (3) seconds, use the arrows to select a new set point. When setting the

High/Low for proper operation, make the set point THE SAME as the observed temperature made after the

sixty (60) minute warming period. Broiler High/Low control is now set. The setting should be approximately

700°F (371 °C). If not at least 650°F (343°C), the high and low gas pressures, as discussed on Page 7

under Performance Criteria, may require adjustment or the hood exhaust may be excessive. The broiler

will work but will cook slower.

4. The temperature displayed by the control at all times is the ACTUAL temperature, except for a few

seconds after depressing SET.

7

5. Place one meat patty on the broiler chain. Based on the appearance of the broiled patty, reset the Digital

Speed Control for the desired broiling quality. (Note: this single patty should be cooked to the maximum

degree of the Minimum/Maximum doneness tolerance.)

NOTE: THE NUMBERS DISPLAYED BY THE SPEED CONTROL ARE RELATIVE TO ONE

ANOTHER. THE LARGER THE NUMBER, THE FASTER THE CONVEYOR.

SETTING HOLDING TEMPERATURE - WEEKLY

1. The temperature controller on the front of the unit has been preset at 190°F (87°C). Push and

release the "SET" button to observe the set point. If this setting has been inadvertently changed, it is

necessary to reset the proper value. This may be done using the arrows on the control within three

seconds of pushing and releasing the "SET" button. Afterwards, the actual temperature is displayed.

IV. SCHEDULED MAINTENANCE

DAILY CLEANING PROCEDURES

CAUTION: Do not touch the broiler section immediately after appliance shut-down. The temperature

inside enclosures is in excess of 500°F (260°C), which eliminates the need to clean any parts

inside the enclosures for sanitary purposes. Any grease that may build up on the exterior of the

enclosures should be cleaned off with a damp cloth and a minimum amount of detergent. Never

use a large amount of water on the enclosure or allow burner faces to get wet as this could

cause premature burner or gasket failure. Disconnect the power supply to the appliance

before cleaning or servicing.

CAUTION: Under no circumstances should oven cleaner be used on this appliance. IT WILL EAT

HOLES IN THE ALUMINUM GAS VALVES, GAS LINES, AND THE LOWER PLATEN (HOLDING

AREA). CAUSTIC FUMES CAUSE ELECTRICAL COMPONENT DAMAGE, AND WILL CAUSE

MANY OTHER PROBLEMS IF USED TO CLEAN THIS BROILER.

CAUTION: KEEP THE APPLIANCE AREA FREE AND CLEAR FROM COMBUSTIBLES.

1. Allow broiler burners and chain to operate for 30 minutes after cooking last patty to burn off excess grease

on broiler components. Then turn the unit off and allow to cool. (This applies every time a meat chain is

turned off - regardless of what time of day meat chain is shut down - and regardless of how few patties were

broiled in the last 30 minutes, last hour, etc.) This will clean some parts of the cooking chamber. Failure to

perform this procedure daily will result in poor cooking times.

2. Remove all exterior panels except those which are attached with screws. Be careful not to touch any hot

internal broiler components.

3. Remove burners from left side of unit and shake all debris off burners after they cool. Both top and

bottom burners may be slid out through the side of the machine. DO NOT WASH BURNER AS IT

WILL DESTROY GASKET. Brush surface of burner mesh with soft brush.

4. Remove lower burners and shields. Brush or scrape residue off shield.

WARNING: THE BURNER AND REVERBERATING SCREENS (LOCATED UNDER THE TOP BURNERS), ARE

MADE FROM INCONEL METAL MESH. THIS MATERIAL DETERIORATES WITH USE. INSPECT

THESE SCREENS DAILY AND REPLACE IF SCREEN IS SEVERELY CORRODED. FAILURE TO

DO SO CAN RESULT IN METAL PARTICLES BEING SERVED TO YOUR CUSTOMERS.

8

5. Remove the following items and wash with hot soapy water.

Front Tunnel Guard Figure 2

Tunnel Closure Figure 2

Tunnel Fillers Figure 2

Drip Tray (Broiler Arm) Figure 2

Lower Discharge Tent Figure 3

* Broiler Grease Tray Figure 2

* Platen Lid Figure 2

Meat Stripper Figure 3

* Catch Pan & Insert Figure 2

* Product Slide Ramp & Teflon Sheet Figure 2

* Broiler Spatula Figure 2

* NOTE: these items may be removed during the 30 minute period.

6. With the conveyor switch ON and heat switch OFF, wire brush the broiler conveyor and, as it cools, wipe with

damp cloth.

7. Scrape deposits from the axles with the axle scraping tool, furnished with each machine as shown in Figure

7. * THIS IS IMPORTANT TO PREVENT GREASE FIRES AT THE REAR OF THE BROILER.

8. Remove grease and meat residue from any part of remaining broiler structure where visible. Use a damp

cloth with detergent and a putty knife for best results. * DO NOT SCRAPE THE LOWER PLATEN

(HOLDING AREA).

9. After cleaning all removable parts as noted, allow to dry and reassemble.

MONTHLY CLEANING PROCEDURES

1. Turn off gas switch on top of the safety valve and disconnect electricity.

2. Remove upper burners, reverberating screens, lower burners, and shields to check for wear. These parts

are illustrated in Figure 3.

3. If the conveyor chain has been removed, make certain it is not on backward and CLOSE open links to

match other links. (Figure 7)

4. Using a damp cloth, wipe the inside of each burner venturi.

5. Reinstall burner screens, lower burner shields, and burners.

6. Remove spark guard and wipe out. (Figure 2)

9

7. PROCEDURE FOR CLEANING OPTIONAL MARSHALL CHARBROILER CATALYSTS:

Marshall recommends that the restaurant soak the catalyst in a solution of commercial degreaser and

warm water for twenty minutes once a month. It is important to note that the catalyst may flake off the

metal honeycomb substrate if it is impacted by a high-pressure water stream. Therefore, we recommend

that the restaurant personnel first prepare the degreaser-and-water bath, and then place the catalyst in

the bath. We want to emphasize that the cleaning procedure involves a soak, rather than a scrubbing or

hosing procedure. After soaking for twenty minutes, rinse the catalyst either by soaking again in cold

water or by rinsing in a gentle stream of cold water. Following the rinse, shake the catalyst to remove all

excess water, and allow to dry at room temperature before returning it to service. A large fan may be used

to move room air more quickly over the catalyst to expedite the drying step.

QUARTERLY CLEANING PROCEDURES & PREVENTIVE MAINTENANCE

1. If required, remove conveyor and soak in hot soapy water overnight. The chain is removed by lifting axle up

to produce slack and separating as described in Figure 7. When replacing chain, make certain the conveyor

is installed properly. PLACING CHAIN ON BACKWARD WILL CAUSE SEVERE BINDING PROBLEMS.

CLOSE open links to match other links. (Figure 7)

2. If required, spread conveyor links open with screwdriver or chain pliers (part #500033). Lift front axle up to

make slack in the conveyor belt, unhook conveyor chain and remove to gain access to lower cooking

chamber for cleaning side walls. Make reference to the orientation of the conveyor links and the conveyor

direction for reassembly. (Figure 7)

3. Lubricate the roller (drive) chain with a few drops of any grade motor or machine oil.

4. Remove and inspect all motor brushes and replace if less than 1/4" is left.

5. Do not remove internal gas lines for cleaning.

6. Clean gas orifices:

• Orifices are passageways directing gas flow into burner. Uneven gas flow or air to

gas ratio is caused by dirty or damaged orifices.

• Orifices are made of brass. Use special care in cleaning-don't gouge or make gas

holes bigger.

• To reach orifices, remove burners.

• Use a pipe cleaner dipped in rubbing alcohol to clean orifices. Swab until clean;

free of carbon build-up. Do not use drill bit; this will damage the orifices.

7. Blow out all six (6) burners through the venturi opening with a tow pressure air source. CAUTION: Do not

drop burners or get wet as this may break gasket or add to premature Burner failure.

8. INVENTORY THE SPARE PARTS KIT AND ORDER MISSING PARTS AS NEEDED. KEEP A COMPLETE SET

OF PARTS ON HAND AT ALL TIMES.

10

V. TROUBLESHOOTING

This section contains a list of possible problems with the Autobroil™ unit. ALL ELECTRICAL TROUBLE

SHOOTING INVOLVING ACCESS INTO THE MOTORS OR ELECTRICAL ENCLOSURES MUST BE

PERFORMED BY A QUALIFIED ELECTRICIAN. All items marked with asterisks (*) should be performed

by service agency qualified to perform service on gas fired appliances.

1. PROBLEM: BURNER BACKFIRES. Flashback, blue flame at entrance to burner makes motor-boating

sound like a blow torch. IMPORTANT: If burner backfires, turn it off. Continued operation will cause

damage to the entire burner.

POSSIBLE CAUSE:

* A) Burner screen failure (hole) or burner gasket. SOLUTION: Replace burner screen or gasket.

* B) Burner over-fired - manifold pressure too high. SOLUTION: Check and reset gas control

regulator to give rating plate value for manifold pressure (shown under Performance Criteria on

Page 7). Wait 5 minutes & relight. Flashback will not occur immediately unless a large opening in

or around the burner screen is evident. Wait an hour after relighting to check that problem is

solved. Figure 5 illustrates which regulator sets high and low gas pressures.

C) Check to ensure all screws holding the burner screen in place are snug. See Figure 10.

2. PROBLEM: FLAMES VISIBLE AT EXHAUST STACK OR IN CHAMBER.

POSSIBLE CAUSE:

* A) Low gas pressure. SOLUTION: Check and reset gas control regulator to give rating value for

manifold pressure (shown under Performance Criteria on Page 7. Figure 5 illustrates which

regulator sets high and low pressures.

3. PROBLEM: PILOT FLAME GOES OUT (STUDY FIGURE 11 & 12 FOR PILOT OPERATION).

POSSIBLE CAUSE:

* A) Pilot assembly dirty or bent. SOLUTION: Check for bent pilot gas line and/or dislodge debris.

* B) Low gas pressure. SOLUTION: Increase gas pressure to appliance (see Figure 5).

* C) Pilot orifice clogged. SOLUTION: Dislodge debris or replace orifice.

D) Wires from pilot assembly loose. SOLUTION: Trace wires to where they plug into gas valve and

check connection. (Figure 6)

* INSTRUCTIONS MARKED WITH ASTERISKS SHOULD BE PERFORMED BY AUTHORIZED

SERVICE PERSONNEL.

4. PROBLEM: BURNER WILL NOT LIGHT AT ALL.

POSSIBLE CAUSE:

A) Hot Surface Ignition. SOLUTION: Recycle heat switch. See Figure 11 and 12.

* B) Orifice. SOLUTION: Check that orifice is not plugged. (If it is necessary to change the orifices,

new ones must be ordered from the factory.)

11

C) Check that flame runner is fully lit (Figure 6). SOLUTION: If not, clean flame runner orifice or

remove and clean flame runner.

D) Pilot. SOLUTION: Pilot must light and stay lit in order for burner to light. Check pilot problem list

(see Item 3 on Page 13).

* E) Gas Solenoid. SOLUTION: Check that solenoid valve on main gas valve is working.

F) Pilot Solenoid. SOLUTION: Check that solenoid valve #501698 on Figure 5 is functioning. It opens

for 120 seconds during the ignition cycle and then closes with a delay-on-break timer in the control

cabinet.

G) Pilot Jumpers. SOLUTION: Check the short and long pilots shown at the top of Figure 6 to

make certain they are not plugged. They turn off after 120 seconds from activating heat switch.

5. PROBLEM: CONVEYOR CHAIN WILL NOT MOVE.

POSSIBLE CAUSE:

A) Check for object caught in conveyor, causing a jam. SOLUTION: Remove object.

* B) Check 1.5 amp fuse on top of the control cabinet (Figure 6) SOLUTION: Replace if blown and

recycle ON/OFF switch.

C) Check 10 amp fuse. SOLUTION: Replace if blown.

D) Check to see if motor shaft is moving. SOLUTION: Sprocket needs to be tightened.

* E) Check switch to make sure power is flowing through it. SOLUTION: Replace switch.

* F) Connect motor control leads to an operating motor speed control board. SOLUTION: If motor

runs, replace motor control board. If motor still does not run, replace motor.

6. PROBLEM: CONVEYOR RUNS BUT SPEED IS CONSTANT

POSSIBLE CAUSE:

* A) There are four parts to the motor system. They are the motor, the circuit board, the digital

speed control and the fuse mounted on the top of the control cabinet. The most likely problem

would be a blown fuse. SOLUTION: Using spare parts, replace one part at a time until the trouble

spot is identified.

* INSTRUCTIONS MARKED WITH ASTERISKS SHOULD BE PERFORMED BY AUTHORIZED

SERVICE PERSONNEL.

7. PROBLEM: REPEATED MECHANICAL BINDING.

POSSIBLE CAUSE:

A) Check to see that chain is not on backward. SOLUTION: See proper chain installation on Figure 7.

B) Inspect chain closely for bent or warped links that may be snagging and causing a binding

condition. Also check that the chain links are not climbing out of the sprockets as the conveyor

rotates. SOLUTION: Straighten or replace bad links.

C) Make sure the axle assembly is clean and free of grease and food residue to allow smooth

movement of the conveyor. SOLUTION: Clean axle. See Figure 7.

12

D) Check the axle assembly to make certain all set collars, bearings, etc. are properly positioned and

secure.

E) Disassemble conveyor axle assembly and check condition of bushings and bearings for excessive

wear. SOLUTION: Replace if worn or damaged.

F) Visually inspect the motor drive chain assembly for smooth rotation of chain. SOLUTION:

Make certain there are no binding or worn components.

G) Make sure conveyor is not catching on meat stripper. SOLUTION: Straighten bent stripper.

8. PROBLEM: HIGH/LOW CONTROL DOES NOT WORK.

POSSIBLE CAUSE:

* A) Determine gas pressure by checking gas pressure gauge. SOLUTION: Adjust per instructions on

Page 7.

B) If unit stays in high or low, check that control is properly set for about 700°F (371 °C).

SOLUTION: Reset to proper temperature as shown in Item 3 on Page 9.

C) If control flashes "EEE" or "999", then inspect thermocouple for continuity. SOLUTION:

Check to be sure thermocouple leads are securely fastened to temperature controller. If so,

then replace thermocouple.

* INSTRUCTIONS MARKED WITH ASTERISKS SHOULD BE PERFORMED BY AUTHORIZED

SERVICE PERSONNEL.

9. PROBLEM: HOLDING TEMPERATURE WILL NOT REACH 190°F.

POSSIBLE CAUSE:

* A) Check that overhead ThermoGlo™ is hot. SOLUTION: Replace element after making sure

element is receiving power.

* B) Check element connections on bottom heating element.

* C) Using a surface thermometer on top of platen, check that temperature controller is allowing platens

to heat to the desired temperature.

* D) The temperature sensor attached to the bottom heated plate has failed. This condition

causes the controller to flash "EEE" or "999". SOLUTION: Check to be sure sensor leads are

securely fastened to temperature controller. If so, then replace sensor.

10. PROBLEM: HAMBURGERS WILL NOT FALL CORRECTLY.

POSSIBLE CAUSE:

A) Meat stripper is dirty or adjusted too far from conveyor. SOLUTION: Clean and reposition

near chain by moving brackets that hold stripper. See illustration on

Figure 3.

* INSTRUCTIONS MARKED WITH ASTERISKS SHOULD BE PERFORMED BY A QUALIFIED

SERVICE COMPANY.

13

QTY PER

VI. ASSEMBLY & DISASSEMBLY INSTRUCTIONS

1. The burner screen (Figure 10) may be replaced by removing all the screws from the burner housing and

frame. The assembly will then lift off. Remove all old gasketing and replace. Compress the new assembly

into the burner housing with hand pressure all around the outside of the burner housing.

2. Insert new screws and snug the screws in a staggered sequence. Do not over tighten screws. These

screws will keep the frame tight against the gasket.

3. The restraining device is a separate line and should be anchored no less than 6" away from the gas

connector and in a parallel position to the flexible line. The following instructions refer to Figure 8. By

using the adjusting clips (1) alter the length of the cable (2) so that the overall length (3) is 3" to 6" shorter

than the length of the flexible gas line including the fitting. Then attach staple (4) to an existing wall or

other structurally sound surface. Attach scissor hook (5) to staple and secure with cotter pin. Finally

attach spring hook (6) to gas appliance as shown in Figure 8. Make certain that the overall length of the

restraining line is shorter than the gas line so no strain is placed on the gas line or piping when moving

the unit.

4. When replacing the thermocouple which attaches to the hi/low temperature controller, make certain it is

inserted through side wall of machine into cooking chamber exactly one inch (1").

5. To remove and clean lower burner shields - remove left side skin and lower burner end cover (Figure 3),

slide burners out thru opening and lift off shields from burner pins. Scrape and wire brush shields.

6. To properly set the clearance between the meat stripper and the conveyor chain, the machine must be

HOT. Loosen the bolts holding the brackets to the sides of the unit and adjust their position until the top

edge of the stripper is within 1/16" of the hot conveyor. See Figure 3.

WARNING: THIS APPLIANCE IS NOT CAPABLE OF BEING SAFELY PLACED INTO OPERATION

DURING A POWER FAILURE AND NO ATTEMPT TO OPERATE IT SHOULD BE MADE.

VII. REPLACEMENT PARTS - FR24BG

When ordering parts, make sure to specify the machine model number, type of gas and serial number as shown

by the label attached to the right side cover.

PART# DESCRIPTION

100367 Scraper Axle 1 7

101357 Bearing, Teflon .750" Outer 2 4

110042 Fan 1 6,Schematic

115665 Burner, 24" 6 or 3* 3

115695 Broiler Spatula 1 2

115816 Top Burner End Cover 1 3

115856 Screen Mounting Clip 9 3

115857 Reverberating Screen 3 3

116084 Conveyor Support Tube 4 3

UNIT

FIGURE

• On LP units with catalyst the 3 upper burners are #131087. See Figure 15 & 16.

116126 Thermocouple Fitting 1 4

14

117213 Lower Burner End Cover 1 3

117228 Control Guard 1 4

117244 Meat Stripper 1 3

118040 Drive Axle 1 4

118425 Spark Guard 1 2

118532 Tunnel Closure 1 2

118537 Venturi Manifold Assembly 2 5

118538 Distribution Manifold Assembly 1 5

118548 Drip Tray (Broiler Arms) 1 2

118701 Front Tunnel Guard 1 2

118709 Burner Shield - Bottom 3 3

118930 Temperature Control (High/Low Gas) 1

119512 Burner, Lower 24" 3 3

119521 Lighter Arm Assembly 1 6

119530 Meat Stripper Hanger (Right) 1 3

119531 Meat Stripper Hanger (Left) 1 3

119538 Tunnel Filler 2 2

119539 Lower Discharge Tent 1 3

120029 Support Pin 4 4

120030 Conveyor Shaft (Idler) 1 4

120048 Wiper Blade 1 3

121696 Conveyor Wiper Assembly 1 3

122551 Idler 2 4

122639 Ignitor -Sensor -Pilot (LP) 1 6

122671 Insert Front Catch Pan 1 2

123145 Burner Gasket N/A 10

3

123702 Broiler Grease Tray 1 2

123710 Product Slide Ramp 1 2

123711 Cloth Mount 1 2

123713 Temp. Control (BC5INTL) 1 Schematic

123714 Temp. Control (BC5INTL) 1 Schematic

15

123717 Spare Parts Kit FR24BG 1 N/A

123718 Owner's Manual 1 N/A

123721 Temperature Control 1 4

123722 Temperature Control 1 6

123725 Platen Lid (Hold-up Latch) 2 3

123763 Platen Lid Assembly 1 2

123764 Catch Pan Assembly 1 2

123782 ThermoGlo™ Assembly 13" x 24.750" 1 Schematic

123832 Heat Guard Shield 1 2

123865 Burner Track, Open End 3 3

123866 Burner Track, Stop End 3 3

123867 Burner Track, Rails (Long) 3 3

124578 Broiler .500" Bearing Assembly 2 4

124596 Burner Track Rail (Short) 3 3

124630 Burner Screen Kit 6 10

124649 Heated Holding Assy -120V 1 17

124652 Burner Housing 6 10

124657 Burner Shield Mounting Kit 3 3

124724 24" Conveyor Cut Link (Per Link) 1 7

127359 Gas Valve (LP) 1 5

130203 Tglo Assembly 13" x 24.750" (240V) 1 Schematic

130657 Kit, Motor Reversing 1 N/A

130780 Kit, Patty Lid Latch Assembly 1 3

131396 Side Skin Assembly 2 2

131452 Lower Burner Support Assy 3 14

133570 Heated Holding Assy -240V 1 17

500027 24" Conveyor Belt SS (Per Foot)

500033 Pliers Chain Conveyor 1 7

500035 Roller Chain #35 Riveted (Per Link) 35" 4

62" (3" Arms)

82" (9" Arms)

7

500040 Sprocket #3510 X .500" (Motor) 1 4

500061 Fuse 1.5 amp 2 6,Schematic

16

500063 Fuse 10 Amp 2 Schematic

500067 Fuse Block 1 Schematic

500070 Gas Gauge 1 5

500083 Link Half (Drive Chain) 1 4

500092 Link Master (Drive Chain) 1 4

500118 Set Collar 3/4" 4 3,4

500174 Gas Line Flex 36" With Restraint 1 8

500186 Gas Regulator VR-48 (Natural) 1 5

500187 Gas Regulator VR-48 (LP) 1 5

500336 Gas Line Restraining Device RD-36 1 8

500340 Terminal Strip 3 Pole 1 Schematic

50041.7 Nipple 1/2" x 1.500" 1 5

500419 Nipple 1/2" x 2.500" 1 5

500518 Collar, Set 1/4" ID Plated 1 3

500657 Bell Reducer 3/4"-1/2" 1 5

500811 Tool Box 1 N/A

500940 Drive Motor 1 4

500941 Motor Brushes for Motor "SPEC 29894G" 2 N/A

501012 Thumb Screw, 1/4"-20 x 3/4" 2 2

501163 Ell 90° 1 5

501624 Circuit Board #MM23011C SPEC #185B 1 Schematic

501698 Solenoid Valve 120 Volt Coil (Pilots) 1 5

501747 Transformer 120V-24V 1 Schematic

501748 Thumb Screw 2 Schematic

501864 Switch 2 4,Schematic

502197 Thermocouple Type K (Broiler Tunnel) 1 4

502248 Transformer 120V-12V 2 Schematic

502211 Cord 14/3 w/plug (9 foot) 1 6

502395 Sprocket #5010 x 3/4" 2 4

502450 Pilot, Long 2.250" Long 2 6

502451 Pilot, Short 1.500" Long 5 6

17

502531 Spring 1.250" x.375" Dia 1 3

502550 Ignitor -Sensor -Pilot (Natural) 1 6

502579 Timer 120 Sec. Delay Brake 1 Schematic

502611 Solenoid Valve 120 Volt Coil (High-Low Pressure) 1 5,Schematic

502631 Pipe Corrugated X 12" (5/8" DIA.) 4 5

502647 Kep Nuts N/A 10

502839 Sprocket #3524 X .750" (Broiler Drive) 1 4

502868 Gas Valve (Natural) 1 5

502892 Potentiometer - Rotary 1 9, Schematic

502906 Potentiometer - Knob 1 4

502978 Heater 450W-120V 1 3

502949 Teflon Sheet 1 2

502991 Burner Screw N/A 10

503081 Potentiometer Knob Lock 2 4

503287 Brush Motor for Motor "Type 24Y2FETM-D4" 2 N/A

503413 Kit, Control Temp. Faceplate REF: 132574 1 N/A

503503 Kit, Control Temp. Faceplate REF: 132575 1 N/A

NATURAL GAS ORIFICES

121668 Long & Short Pilot Orifice #68 7 6

502915 Orifice #BCR 18X (Ignitor-Sensor- Pilot Burner) 1 6

501718 Orifice #70 (Lighter Arm) 1 6

502713 Orifice #49 Button (Burners) 6 6

LP GAS ORIFICES

122640 Long & Short Pilot Orifice .018" (Upper) 4 6

500487 Long & Short Pilot Orifice .011" (Lower) 3 6

502924 Orifice .010" (Ignitor-Sensor Pilot Burner) 1 6

502766 Orifice #79 (Lighter Arm) 1 6

502863 Orifice #56 Button ( Burners) 6 6

INTERNATIONAL PARTS (50 Hz)

125713 Temp. Control (High/Low Gas) 1 Schematic

18

125714 Temp. Control (Holding) 1 Schematic

502168 Transformer 240V to 12V, 6VA 2 Schematic

502409 Transformer 240V to 120V, 30 VA 1 Schematic

502575 Gas Solenoid 1 Schematic

502868 Gas Valve 1 Schematic

502916 Transformer 240V to 24V, 56VA 1 Schematic

502978 Heater 400W-240V 1 Schematic

OPTIONAL CATALYTIC CONVERTER

123734 Broiler arms drip tray 1 13

123832 Heat Guard 1 13

125690 "V" Baffle insert, mount Assembly 1 13

502944 Catalyst 1 13

127554 Cover, Rear Catalyst 1 13

OPTIONAL CATALYTIC CONVERTER (LP ONLY)

127554 Cover, Rear Catalyst 1 15

131093 Burner Flame Deflector 1 15

131094 Catalyst Extension Assy 1 15

125702 Extended Arm Catalyst Cover(9.5" Arms) 1 15

131365 "SPL" Top Burners 1 15

123734 Broiler Arms Drip Tray (3" Arms) 1 16

OPTIONAL SPL ORIFICES FOR 6,000 FT ELEVATION

500927 Orifice, Flame Runner #80 1 N/A

502243 Orifice, Burner #62 Button 6 N/A

19

BROILER LIMITED WARRANTY

MARSHALL AIR SYSTEMS, INC., ("Marshall") warrants to the first purchaser ("Purchaser") all new equipment of its

manufacture to be free of defects in material and factory workmanship for a period of one year* from date of shipment provided that

(i) the equipment is installed in the Continental United States, Canada or Hawaii and operated according to the Owner's Manual while

located at the original address of installation, (ii) the warranty registration card has been completed and returned to the factory within

fifteen (15) days after installation, and (iii) a post-installation start-up has been performed by an authorized service representative

(portable equipment not applicable). Marshall's obligation under this warranty is limited to the repair or replacement at its option of

any defective part. Under certain circumstances, Marshall will reimburse Purchaser for limited labor costs in replacing parts during a

period of not more than ninety (90) days after date of shipment, provided that Labor Reimbursement instructions are followed and

items i, ii, and iii above are completed. See special provision for portable equipment. It is understood that Marshall's obligation with

respect to equipment located outside the Continental United States, Canada or Hawaii is limited to replacement parts only.

*The following broiler parts have a six month part warranty:

• Burner Shields and Screens

• Burner Grids

• Burner Gaskets

• Electric Broiler Elements

• Flame Runners

Because Marshall does not and cannot control Purchaser's installation, use, and maintenance of equipment manufactured by

Marshall, this warranty DOES NOT COVER:

Any equipment calibration;

Any component disassembled in the field;

Damage due to improper cleaning and/or abuse, i.e. burner rotation, grease accumulation in electrical components or plugs

(hosing or "watering down" equipment will cause electrical failures not covered by warranty);

Blown fuses or bulbs, motor brushes and Teflon components;

Any replacement parts used on the equipment which are not purchased from Marshall;

Accessory components not installed or manufactured by Marshall.

Shipping damage must be reported to the carrier and is not covered under this warranty. Marshall will not ba liable for

damage as a result of improper installation, misuse, abuse, alteration of original design, incorrect voltage, unauthorized service,

breakage of fragile items, or any other damage caused by an act out of Marshall's control.

The effect of corrosion, fire, and normal wear on the equipment or component parts is not covered by this warranty. This

warranty does not cover cooking performance, smoke capture or holding temperatures which is a function of food types, textures,

temperatures, equipment line ups and other variables chosen by the Purchaser and over which Marshall has no control. This warranty

does not apply to damage caused by accident or to damage caused by the negligence of Purchaser or the employees of Purchaser or to

damage caused by lightning generated electrical current or any other Act of God whatsoever. This warranty does not apply to any

equipment bearing a serial number which has been tampered with or altered. Marshall reserves the right to accept or reject any such

claim in whole or in part. Marshall will not accept the return of any product without prior written approval from Marshall, and all such

approved returns shall be made at Purchaser's sole expense.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE

IMPLIED WARRANTY OF MERCHANTABILITY AND THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE, OR PATENT OR OTHER INTELLECTUAL PROPERTY RIGHT INFRINGEMENT, AND EXCEPT FOR THE

EXPRESS WARRANTY CONTAINED HEREIN, THE EQUIPMENT IS SOLD "AS IS." REMEDIES UNDER THIS WARRANTY

AND UNDER ANY WARRANTY THAT MAY SURVIVE THE DISCLAIMER OF WARRANTIES ARE LIMITED

EXCLUSIVELY TO THOSE REMEDIES DESCRIBED ABOVE. NO OTHER REMEDY IS AVAILABLE UNDER THIS

WARRANTY OR ANY OTHER WARRANTY. NEITHER THIS WARRANTY NOR ANY OTHER WARRANTY COVERS, AND

MARSHALL WILL NOT BE RESPONSIBLE FOR, ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING BUT

NOT LIMITED TO THE COST OF DISASSEMBLY AND SHIPMENT OF THE EQUIPMENT, PRODUCTION OR PRODUCT

LOSSES, INJURY TO OTHER PROPERTY, OR LOST PROFITS RESULTING FROM THE USE OF OR INABILITY TO USE

THE PRODUCTS OR FROM THE PRODUCTS BEING INCORPORATED IN OR BECOMING A COMPONENT OF ANY

OTHER PRODUCT OR GOODS, OR OTHER LOSSES. WHERE, DUE TO OPERATION OF LAW, CONSEQUENTIAL AND

INCIDENTAL DAMAGES CANNOT BE EXCLUDED, THEY ARE EXPRESSLY LIMITED IN AMOUNT TO THE PURCHASE

PRICE OF THE EQUIPMENT.

FOR INTERNATIONAL INSTALLATIONS -- PLEASE CONTACT YOUR LOCAL

MARSHALL AIR SYSTEMS RECOGNIZED DISTRIBUTOR.

LIMITED.BRL.DOC

BROILER WARRANTY PROCEDURES

RETURN GOODS AUTHORIZATION FOR PARTS - FACTORY DIRECT

For prompt warranty parts replacement and RGA processing, please call Marshall's Customer Service

Department at 800-722-3474 or 704-525-6230 for assistance. In all cases, a Return Goods

Authorization (RGA) number must be issued by Marshall Air Systems, Inc. Unauthorized returns will

not be processed.

Option #1: Purchaser to return part prepaid to Factory, Marshall to repair or replace at own

expense if defective, and ship part back to Purchaser prepaid.

Option #2: Marshall to furnish replacement part freight prepaid with or without requesting return of

the defective part.

WARRANTY LABOR REIMBURSEMENT AND/OR PARTS REPLACEMENT THROUGH

RECOGNIZED MAINTENANCE & REPAIR CENTERS

Normally, labor will be covered under the start up fee. In the unlikely event this does not apply, consult Marshall

Air Systems, Inc. To be reimbursed for warranty labor costs, authorization must be given by Marshall Air

Systems, Inc, Unauthorized work will not be reimbursed. Work must be performed by a Marshall Air Systems

Recognized Service Agency within the service time allowance guidelines and must be submitted along with failed

parts (if applicable) to Marshall Air Systems (freight prepaid) within 30 days of the work being performed. Travel is

covered, but must not exceed 50 miles or 1 hour, whichever is greater. Call Marshall's Service Department at

800-722-3474 or 704-525-6230 with any questions. Service is to be performed by recognized service agencies

during normal working hours. Owner to pay for all other charges including excessive travel or overtime charges.

DIAGNOSTIC LABOR CHARGES ARE INCLUDED IN SERVICE TIME ALLOWANCE GUIDELINES. All portable

equipment (under 90 pounds) shall be delivered by Purchaser, at his/her expense, to the nearest authorized

service agency for in-shop repair or at purchaser's discretion he/she will pay all travel time and mileage expenses

for portable equipment.

NON-WARRANTY RETURNS:

All items returned for customer convenience are subject to a 20% restocking fee. In the event of an error by

Marshall Air Systems, Inc., a Returned Goods Authorization will be issued for full credit.

FOR INTERNATIONAL INSTALLATIONS - PLEASE CONTACT YOUR LOCAL

MARSHALL AIR SYSTEMS RECOGNIZED DISTRIBUTOR.

PROCEDUR.BRL.DOC

Loading...

Loading...