This document contains the installation and operating instructions for:

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

MODEL: FR15BS AUTOBROIL™

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

INSTRUCTIONS TO PURCHASER:

1. THIS MANUAL NEEDS TO BE RETAINED FOR FUTURE

REFERENCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATION AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

118719 RV111798

Copyright© 1994 Marshall Air Systems, Inc.

All Rights Reserved.

MODEL: FR15BS AUTOBROIL™

TABLE OF CONTENTS

I. MACHINE SETTINGS....................................................................................... ......................………………........ 1

II. MACHINE INSTALLATION ............................................................................... ......................…………….......... 2

III. OPERATING INSTRUCTIONS......................................................................... .......................…………….......... 3

IV. SCHEDULED MAINTENANCE......................................................................... ......................………………........ 4

V. TROUBLESHOOTING..................................................................................... .......................……………….... 5-7

VI. REPLACEMENT PARTS................................................................................... .....................……………...... 7-10

BROILER LIMITED WARRANTY...................................................................... .......................…………….......... i

BROILER WARRANTY PROCEDURES.......................................................... ...........................……………...... ii

ILLUSTRATIONS

Broiler Overall Dimensions.................................................................................................. Figure 1

Broiler Pans and Covers...................................................................................................... Figure 2

Broiler Components............................................................................................................. Figure 3

Broiler Electrical Components............................................................................................. Figure 4

Axle Scraper......................................................................................................................... Figure 5

Meat Stripper Adjustment.................................................................................................... Figure 6

Electrical Schematic (208V, 60Hz, 10, 39 Amps)............................................................. Drawing No. 118738

Electrical Schematic (220V, 50Hz, 10, 37 Amps)............................................................. Drawing No. 118513

Electrical Schematic (380V, 50Hz, 30, 13 Amps)............................................................. Drawing No. 118508

Electrical Schematic (240V, 50Hz, 10, 34 Amps)............................................................. Drawing No. 118740

Electrical Schematic (415V, 50Hz, 30,12 Amps)............................................................. Drawing No. 118512

Electrical Schematic (220V, 60Hz, 30, 25 Amps)............................................................. Drawing No. 124673

Electrical Schematic (240V, 50Hz, 10, 34 Amps)............................................................. Drawing No. 131685

Electrical Schematic (415V, 50Hz, 30, 12 Amps............................................................... Drawing No. 135837

118719 RV111798

Copyright© 1994 Marshall Air Systems, Inc.

All Rights Reserved.

I. MACHINE SETTINGS

MODEL: FR15BS AUTOBROIL™

SERIAL NUMBER: ___________________________________________________________________

VOLTAGE: _________________________________________________________________________

SPEED SELECTOR SETTING: _________________________________________________________

PASS-THRU TIME: __________________________________________________________________

BROILER HIGH/LOW TEMPERATURE SETTING: __________________________________________

START-UP TECHNICIAN: ____________________________________________________________

START-UP DATE: ___________________________________________________________________

COMMENTS: _______________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

118719 RV111798

Copyright© 1994 Marshall Air Systems, Inc.

All Rights Reserved.

1

II. MACHINE INSTALLATION

PRE-INSTALLATION

1. After uncrating the Autobroil™ unit, inspect for shipping damage. Check that the controller, switches, and

components are intact on the electrical cabinet front. Set the Autobroil™ in place and use the plastic bag to protect it

from the debris and trash of building construction. Check that sideskins have not been dented or damaged by the

carrier. If damaged, notify your freight carrier immediately to file a concealed damage claim, following the

instructions attached to the outside of the shipping crate. Your warranty will not cover freight damage.

2. Because this unit is required to be power fan exhausted, it is necessary to provide adequate make up air equal to

the amount of air removed. In addition to this, any other exhausts, flues, or air removal systems must be taken into

consideration. Examples of this are heat removal fans or hot water heater flues.

APPLIANCE LOCATION

1. Position Autobroil™ to properly align with exhaust hood. Note name plate clearance.

2. The hood/ventilator for the appliance should be located in accordance with the National Fire Protection Association

Standard #96, "Removal of Smoke and Grease-Laden Vapors from Commercial Cooking Equipment" and any local

applicable requirements.

3. For proper installation, the minimum clearance from combustible construction is 6" from sides and 6" from back.

4. Adequate clearance should be maintained to allow easy access to loading and unloading areas of the machine.

5. For servicing, unit must be moved 2' clear from all construction.

ELECTRICAL INFORMATION

1. The Electrical Schematic is inside the electrical cabinet, and a copy is also included at the back of this manual. Make

certain the supply voltage and number of supply conductors agrees with the Electrical Schematic. The load-carrying

conductors should be sized according to the loads shown on the Electrical Schematic and the National Electrical

Code. A grounding lug is attached inside the control cabinet. Safety precautions dictate this lug be used.

2. On a new electrical service - MAKE CERTAIN THAT VOLTAGE IS WITHIN 10% OF THE UNIT'S RATED

VOLTAGE AND THAT THE NEUTRAL IS IN FACT NEUTRAL. SERIOUS DAMAGE WILL OCCUR BY HAVING

VOLTAGE ON THE NEUTRAL. Appliance should be protected by a properly sized circuit breaker furnished from the

main building circuit panel.

3. There is an Electrical Schematic located in the Owner's Manual and also inside the electrical cabinet of the machine.

2

III. OPERATING INSTRUCTIONS

PRE-OPERATION CHECK

Before operating your Autobroil™, make a quick check of critical items as follows:

1. Check that no "binding" and resultant conveyor overloading is present. With the electrical connections

complete and with the electrical cabinet door secured shut, set the forward switch "ON" for the

conveyors. Adjust the speed control for mid-point speed. The conveyor should move forward in smooth

unaltered motion. Shut down immediately if there is any evidence of "binding" or other mechanical

blockage.

2. Proper conveyor operation is when the amperage draw in the white or black motor lead from the circuit

board (Figure 4) to the motor cord measures .15 DC amps or less. To check amperage the cabinet door

will need to be open. THIS PROCEDURE SHOULD ONLY BE PERFORMED BY A QUALIFIED

ELECTRICIAN.

3. The Autobroil™ was tested at the factory before shipping so excessive amperage will indicate conveyor

binding caused by shipping damage. Remove the roller chain (Figure 4) driving the conveyor in question

and move the conveyor by hand. Loosen the sprockets (Figure 4) that drive the various axles and

reposition them by 1/32" until the conveyor tightness is eliminated. Twenty -five inch pounds of torque is

required to drive a properly set up conveyor.

4. After the conveyor checkout is complete, turn on the heat switch. All heater elements should glow red

except for one top element. After the unit is up to temperature, this one element will cycle. For trouble

shooting problems, see Section V. CAUTION: NEVER RUN HEAT WITHOUT CONVEYOR ON.

5. Before first use, and after any special cleaning, it is necessary to "season" the BROILER chain. This is

done by bringing the broiler chain to operating temperature and applying liquid shortening from a

saturated cloth over the full width of the broiler chain while the chain makes five or six complete

revolutions.

BROILER ADJUSTMENT

The Autobroil™ requires 20 to 30 minutes to reach stable temperature. After this time lapse, the conveyor

speed can be set to properly cook the product.

SETTING TEMPERATURE CONTROLLER FOR PROPER HIGH/LOW OPERATION-WEEKLY

1. Follow the procedure below in order to set temperature control for 700°F (371 °C). After doing this, turn

on the broiler.

2. Observe the temperature displayed: push "SET" and release to view the "SET POINT." To change set

point push "SET" and, within three seconds, use the arrows to select a new set point. When setting the

High/Low for proper operation, make the set point 700°F (371 °C). Press the set button again to make

the change permanent. Broiler High/Low control is now set.

3. Place one meat patty on the broiler chain. Based on the appearance of the broiled patty, reset the Digital

Speed Control for the desired broiling quality. (Note: This single patty should be cooked to the maximum

degree of the Minimum/Maximum doneness tolerance.)

NOTE: THE HIGHER THE NUMERICAL VALUE SET ON THE DIGITAL SPEED CONTROL, THE

FASTER THE CONVEYOR CHAIN WILL RUN.

3

IV. SCHEDULED MAINTENANCE

DAILY CLEANING PROCEDURES

CAUTION: UNDER NO CIRCUMSTANCES SHOULD OVEN CLEANER EVER BE USED ON THIS APPLIANCE.

1. Scrape axles to remove daily grease buildup.

2. Remove the top heat shield (Figure 2) located above the meat conveyor and clean with wire brush.

3. Remove the meat stripper and wash with hot soapy water.

4. Wire brush the broiler conveyor and wipe with damp cloth.

5. Turn off the conveyor and remove the grease pan, product slide, product slide pan, meat stripper, and conveyor

wiper; clean with hot soapy water.

6. Remove the lower reflector, conveyor arm cover, and front deflector; clean with hot soapy water.

7. The tube bundle should be removed and wire brushed. Further cleaning is not necessary; however, make sure

carbon deposits are scraped from between the tubes with a tool such as a screwdriver.

8. Additional cleaning should exhibit good housekeeping and entail a general wiping of all exterior surfaces. DO NOT

GET WATER ON THE ELECTRICAL CABINET OR THE HEATING ELEMENTS. NEVER HOSE THE MACHINE.

Monthly Cleaning Procedures

1. Remove the broiler conveyor chain from the machine and steam clean or soak in detergent solution. The conveyor is

removed by taking the conveyor apart at the cutlinks. When the conveyor is removed, check all heating elements and

replace elements showing extreme corrosion. Check bearings for excessive wear and order replacements where

needed. (See Figure 5 for cutlink illustration.) Make certain conveyors are reinstalled going in the correct direction.

PLACING CHAIN ON BACKWARDS WILL CAUSE SEVERE BINDING PROBLEMS.

CAUSTIC FUMES CAUSE ELECTRICAL COMPONENT DAMAGE AND WILL CAUSE MANY

OTHER PROBLEMS IF USED TO CLEAN THIS BROILER. SEE FIGURES 2, 3, AND 5 FOR

CLEANING.

PREVENTIVE MAINTENANCE

Once Every Three Months

1. Lubricate the roller chain with a few drops of the oil.

2. Inspect all motor brushes and replace if less than 1/4" is left.

3. CAUTION: DISCONNECT POWER BEFORE OPENING PANEL. Retighten the screw lugs on the main power

wires at the main terminal block inside the control box. Check that other electrical connections are still tight.

4. INVENTORY THE SPARE PARTS KIT AND ORDER MISSING PARTS AS NEEDED. KEEP A COMPLETE SET

OF PARTS ON HAND AT ALL TIMES.

4

V. TROUBLESHOOTING

This section contains a list of imagined problems with your Autobroil™. By locating the problem in this section, you may

be able to make a quick repair. ALL ELECTRICAL TROUBLE SHOOTING INVOLVING ACCESS INTO THE MOTORS

OR ELECTRICAL ENCLOSURES MUST BE PERFORMED BY A QUALIFIED ELECTRICIAN.

1. MACHINE HAS POWER BUT ELEMENTS ARE OUT.

POSSIBLE CAUSE

A) Check to make sure broiler on-off switch is in "ON" position and that the right voltage is coming out of

switch (see Electrical Schematic).

B) Check that heat switch is in ON position.

C) Check that power is passing to and through the large mercury relay.

D) Check wiring to individual elements.

E) Check fuses to each element.

F) Check elements.

2. CONVEYOR WILL NOT RUN.

POSSIBLE CAUSE:

A) Check rocker switch to make sure power is flowing through switch.

B) Check fuse in control wiring in electrical cabinet.

C) Make certain the conveyor is not mechanically jammed. The speed control will allow the motor to stall until

the binding or jamming is removed.

D) Check that set screws are tight in roller chain drive sprockets (Figure 4).

E) If everything works up to this point, unplug the motor cord from the speed control and plug it into a spare

speed control. If the motor works, there is a failed speed control board (Figure 4). If it does not work, then

the motor has failed.

3. MECHANICAL BINDING

POSSIBLE CAUSE:

A) Check roller chain tension for proper adjustment. Adjust motor if chain is too tight.

B) Inspect conveyor chain closely for bent or warped links that may be hanging up and causing a binding

condition. Also check that the chain links are not climbing out of the sprockets as the conveyor rotates. If

they are, then loosen conveyor sprockets and reposition.

C) Make sure the axle assembly is clean and free of grease and food residue to allow smooth movement of

the conveyor.

5

D) Check the axle assembly to make certain all set screws, bearings, etc. are properly positioned and secure.

E) Check that meat stripper is installed and positioned correctly (Figure 6).

F) Disassemble conveyor axle assembly and check condition of teflon bearing for excessive wear.

G) Visually inspect the motor drive chain assembly (Figure 3) for smooth rotation of chain and make certain

there is not binding or worn components.

4. THERE IS NO SPEED CONTROL ON THE CONVEYOR.

POSSIBLE CAUSE:

A) Attach the wires from the board (Figure 4) with no control into a spare circuit board. If there is still no

control, the potentiometer (Figure 4) for that conveyor has failed.

B) If attaching to the spare board makes it work, the circuit board has failed.

C) If neither of the above works, then the motor has failed.

5. MEAT DOES NOT COOK COMPLETELY.

POSSIBLE CAUSE:

A) Check to make sure tube bundle is clean.

B) Check to make sure the heat shield is installed (Figure 2).

C) Check to make sure all elements are working.

D) Check the speed of the conveyor.

E) Check refrigeration. Holding temperature of meat may be lower than 0°F.

F) Check for excessive exhaust by momentarily turning exhaust fan off.

G) Check setting on temperature controller

6. CANNOT MAINTAIN CONSISTENT DEGREE MEAT COOKING.

POSSIBLE CAUSE:

A) Check that tube bundles are being cleaned in accordance with Item 7 in Section IV.

B) Check store power supply for large voltage variation. A 5% swing in voltage will require more than a 5%

change in speed to counteract.

C) Meat of different temperatures is being used. (Frozen vs. partially thawed.)

D) Check for excessive exhaust by momentarily turning off exhaust fan.

E) Check to make sure the heat shield is installed (Figure 2).

6

7. MEAT OVERCOOKED ON OUTSIDE AND UNDERCOOKED ON INSIDE.

POSSIBLE CAUSE:

A) Check refrigeration. Holding temperature of meat may be lower than 0°F.

B) Check that tube bundles are being cleaned in accordance with Item 7 in Section IV.

8. MEAT NOT SLIDING INTO HAMBURGER CATCH AREA.

POSSIBLE CAUSE:

A) Meat stripper (Figure 3) needs cleaning.

B) Meat stripper needs adjustment (Figure 6).

C) Product slide (Figure 2) not installed properly.

D) No teflon sheet installed (Figure 2).

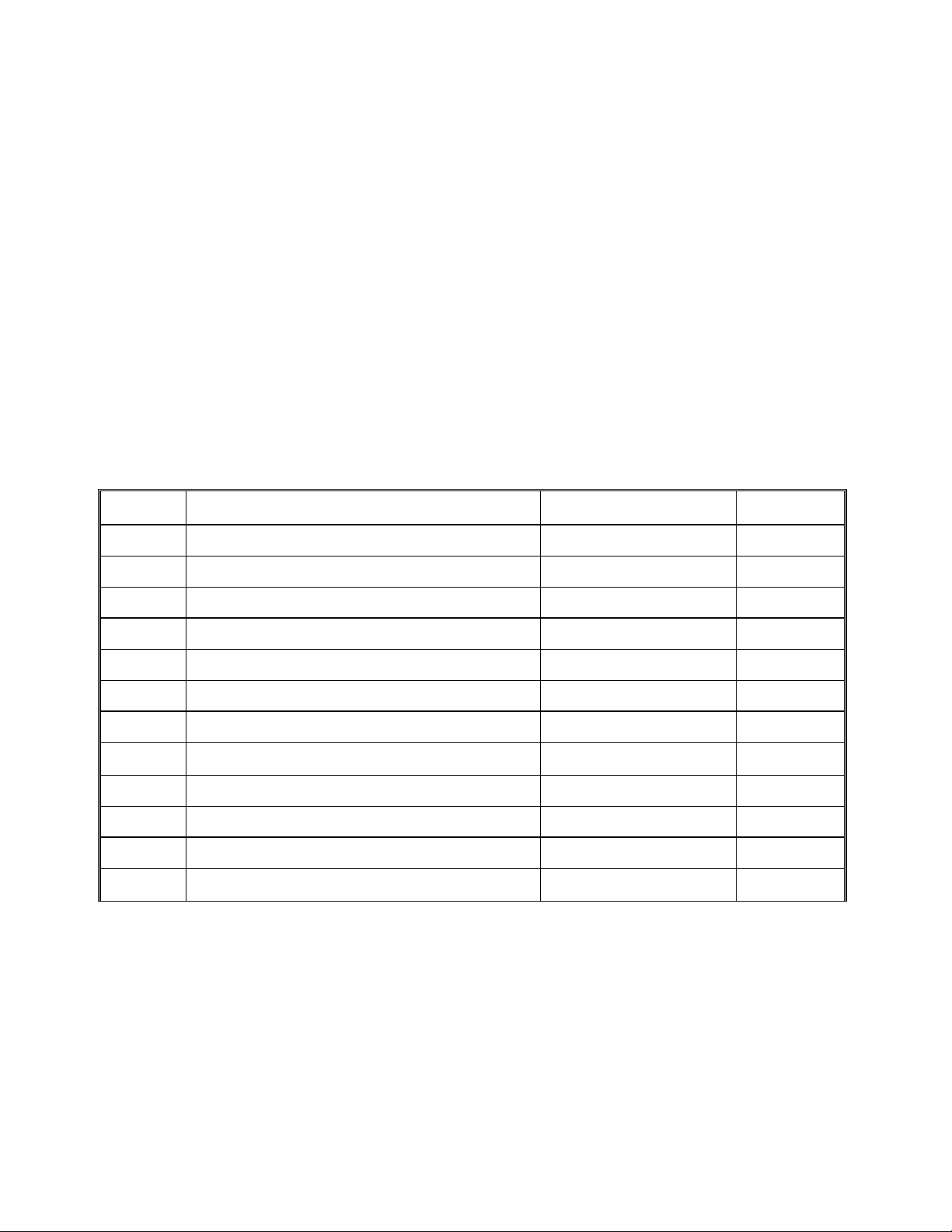

VI. REPLACEMENT PARTS

When ordering parts, make sure to specify the machine model number and serial number as shown by the label attached

to the right side cover.

PART# DESCRIPTION QUANTITY PER UNIT LOCATION

101037 Bundle Tube 1 Figure 2

101042 Conveyor Idler W/Meldin Bearing 2 Figure 3

101043 Conveyor Sprocket 2 Figure 3

101044 Conveyor Bearing 2 Figure 3

101363 Axle Scraper 1 Figure 5

104679 Link Cut Conveyor 15" 1 Figure 5

110042 Fan 1 Figure 4

115682 Conveyor Wiper Assembly 1 Figure 3

117228 Control Guard 1 Figure 4

117262 Product Slide Pan 1 Figure 2

117270 Thermocouple Wire Chase 1 Figure 4

117272 Product Slide Assembly with Teflon Sheet 1 Figure 2

7

117277 Conveyor Arm Cover 1

Figure 2

117285 Temperature Controller 1

117288 Teflon Sheet 1 Figure 2

117289 Reflector-Lower 1 Figure 2

117290 Heat Shield (Top) 1 Figure 2

118266 Deflector-Front 1 Figure 2

118527 Temperature Controller (CE ONLY) 1 Figure 4

118719 Owner's Manual FR15BS 1 N/A

118730 Vented Panel-Side Cover 2 Figure 2

118734 Spare Parts Kit 208V 1 N/A

118735 Spare Parts Kit 240V 1 N/A

120792 Product Slide without Teflon Sheet 1 Figure 2

120106 Front Deflector 1 Figure 2

121373 Heat Guard 1 Figure 2

123781 Meat Stripper 1

130657 Kit, Motor Reversing 1 N/A

Figure 4

Figure 3, 6

500010 Cable Ties N/A N/A

500026 Conveyor 15" 37.250" lg N/A

500033 Conveyor Chain Pliers 1 N/A

500035 Roller Chain #35 Riveted (Per Link) 35" Figure 3

500037 Sprocket Drive 3518 x 1/2" (conveyor) 1 Figure 3

500040 Sprocket Drive 3510 x 1/2" (motor) 1 Figure 3

500046 Elements-Broiler 895W for 120V * 9 Figure 4

500048 Elements-Broiler 895W for 240V * 9 Figure 4

500049 Elements-Broiler 895W for 220V * 9 Figure 4

500064 Fuse, Non 15 Amp 9 Figure 4

500065 Fuse Block 3-Pole 3 Figure 4

500067 Fuse Block (1-Pole) 1 Figure 4

8

500068 Fuse Holder 1 Figure 4

500083 Offset Link (Roller Chain) 1 N/A

500092 Master Link (Roller Chain) 1 Figure 3

500112 Digital Potentiometer 1 Figure 4

500204 Terminal Block (3-Pole) 1 Figure 4

500333 Fuse 2 Amp AGC 1 Figure 4

500334 Fuse, AGC 3 Amp 1 Figure 4

500518 1/4" Set Collar 2 Figure 4

500588 Terminal Block (4-Pole) 1 Figure 4

500589 Thermocouple Fitting 1 Figure 4

500732 Ground Lug 1 Figure 4

500935 Fuse, Non 5 Amp 1 Figure 4

500940 Motor 1 Figure 4

500941 Motor Brush for Motor ASPEC 29894G 2 Figure 4

500966 Terminal Strip 8-Pole 1 Figure 4

501624 Circuit Board #MM23011 C SPEC #185B 1 Schematic

501810 Mercury Relay, 120V Coil, 2-Pole 1 Figure 4

501835 Grease Pan 1 Figure 1

501864 Rocker Switch 2 Figure 4

501958 Transformer 240V to 120V (International) * 1 Figure 4

501971 Relay, 1-Pole 20A, 120V Coil 1 Figure 4

501999 Mercury Relay 240V Coil, 2-Pole (International) 1 Figure 4

502168 Transformer 240V to 12V (International) * 1 Figure 4

502197 Thermocouple 1 Figure 4

502248 Transformer 120V to 12V * 1 Figure 4

502625 Relay, 1-Pole 20A, 240V Coil 1 Figure 4

502630 Mercury Relay, 240V Coil, 3-Pole 1 Figure 4

502892 Rotary Speed Selector 1 Figure 4

9

503092 Transformer (CE Only) 1 Figure 4

503099 Fuse Holder (CE Only) 1 Figure 4

503104 Fan (CE Only) 1 Figure 4

503193 Fuse (CE Only) 1 Figure 4

503287 Brush Motor for Motor AType 24Y2FETM-D4" 2 N/A

503460 Cord 6/3 SO (CE Only) 1 Figure 4

503503 Kit, Control Temp. Faceplate REF: 132575 1 N/A

503574 Line Filter 1 Schematic

503575 Line Filter 1 schematic

* Customer must look at Electrical Schematic to determine which part is needed when ordering replacements.

10

BROILER LIMITED WARRANTY

MARSHALL AIR SYSTEMS, INC., ("Marshall") warrants to the first purchaser ("Purchaser") all new equipment of

its manufacture to be free of defects in material and factory workmanship for a period of one year" from date of shipment

provided that (i) the equipment is installed in the Continental United States, Canada or Hawaii and operated according to

the Owner's Manual while located at the original address of installation, (ii) the warranty registration card has been

completed and returned to the factory within fifteen (15) days after installation, and (iii) a post-installation start-up has

been performed by an authorized service representative (portable equipment not applicable). Marshall's obligation under

this warranty is limited to the repair or replacement at its option of any defective part. Under certain circumstances,

Marshall will reimburse Purchaser for limited labor costs in replacing parts during a period of not more than ninety (90)

days after date of shipment, provided that Labor Reimbursement instructions are followed and items i, ii, and iii above are

completed. See special provision for portable equipment. It is understood that Marshall's obligation with respect to

equipment located outside the Continental United States, Canada or Hawaii is limited to replacement parts only.

*The following broiler parts have a six month part warranty:

• Burner Shields and Screens

• Burner Grids

• Burner Gaskets

• Electric Broiler Elements

• Flame Runners

Because Marshall does not and cannot control Purchaser's installation, use, and maintenance of equipment

manufactured by Marshall, this warranty DOES NOT COVER:

Any equipment calibration;

Any component disassembled in the field;

Damage due to improper cleaning and/or abuse, i.e.. burner rotation, grease accumulation in electrical

components or plugs (hosing or "watering down" equipment will cause electrical failures not covered by warranty);

Blown fuses or bulbs, motor brushes and Teflon components;

Any replacement parts used on the equipment which are not purchased from Marshall;

Accessory components not installed or manufactured by Marshall.

Shipping damage must be reported to the carrier and is not covered under this warranty. Marshall will not be

liable for damage as a result of improper installation, misuse, abuse, alteration of original design, incorrect voltage,

unauthorized service, breakage of fragile items, or any other damage caused by an act out of Marshall's control.

The affect of corrosion, fire, and normal wear on the equipment or component parts is not covered by this

warranty. This warranty does not cover cooking performance, smoke capture or holding temperatures which is a function

of food types, textures, temperatures, equipment line ups and other variables chosen by the Purchaser and over which

Marshall has no control. This warranty does not apply to damage caused by accident or to damage caused by the

negligence of Purchaser or the employees of Purchaser or to damage caused by lightning generated electrical current or

any other Act of God whatsoever. This warranty does not apply to any equipment bearing a serial number which has been

tampered with or altered. Marshall reserves the right to accept or reject any such claim in whole or in part. Marshall will not

accept the return of any product without prior written approval from Marshall, and all such approved returns shall be made

at Purchaser's sole expense.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE

IMPLIED WARRANTY OF MERCHANTABILITY AND THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE, OR PATENT OR OTHER INTELLECTUAL PROPERTY RIGHT INFRINGEMENT, AND EXCEPT FOR THE

EXPRESS WARRANTY CONTAINED HEREIN, THE EQUIPMENT IS SOLD "AS IS." REMEDIES UNDER THIS

WARRANTY AND UNDER ANY WARRANTY THAT MAY SURVIVE THE DISCLAIMER OF WARRANTIES ARE

LIMITED EXCLUSIVELY TO THOSE REMEDIES DESCRIBED ABOVE. NO OTHER REMEDY IS AVAILABLE UNDER

THIS WARRANTY OR ANY OTHER WARRANTY. NEITHER THIS WARRANTY NOR ANY OTHER WARRANTY

COVERS, AND MARSHALL WILL NOT BE RESPONSIBLE FOR, ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES,

INCLUDING BUT NOT LIMITED TO THE COST OF DISASSEMBLY AND SHIPMENT OF THE EQUIPMENT,

PRODUCTION OR PRODUCT LOSSES, INJURY TO OTHER PROPERTY, OR LOST PROFITS RESULTING FROM

THE USE OF OR INABILITY TO USE THE PRODUCTS OR FROM THE PRODUCTS BEING INCORPORATED IN OR

BECOMING A COMPONENT OF ANY OTHER PRODUCT OR GOODS, OR OTHER LOSSES. WHERE, DUE TO

OPERATION OF LAW, CONSEQUENTIAL AND INCIDENTAL DAMAGES CANNOT BE EXCLUDED, THEY ARE

EXPRESSLY LIMITED IN AMOUNT TO THE PURCHASE PRICE OF THE EQUIPMENT.

FOR INTERNATIONAL INSTALLATIONS -- PLEASE CONTACT YOUR LOCAL

MARSHALL AIR SYSTEMS RECOGNIZED DISTRIBUTOR.

LIMITED.BRL.DOC

BROILER WARRANTY PROCEDURES

RETURN GOODS AUTHORIZATION FOR PARTS - FACTORY DIRECT

For prompt warranty parts replacement and RGA processing, please call Marshall's Customer Service

Department at 800-722-3474 or 704-525-6230 for assistance. In all cases, a Return Goods

Authorization (RGA) number must be issued by Marshall Air Systems, Inc. Unauthorized returns will

not be processed.

Option #1: Purchaser to return part prepaid to Factory, Marshal! to repair or replace at own

expense if defective, and ship part back to Purchaser prepaid.

Option #2: Marshall to furnish replacement part freight prepaid with or without requesting return of

the defective part.

WARRANTY LABOR REIMBURSEMENT AND/OR PARTS REPLACEMENT THROUGH

RECOGNIZED MAINTENANCE & REPAIR CENTERS

Normally, labor will be covered under the start up fee. In the unlikely event this does not apply, consult Marshall

Air Systems, Inc. To be reimbursed for warranty labor costs, authorization must be given by Marshall Air

Systems, Inc. Unauthorized work will not be reimbursed. Work must be performed by a Marshall Air Systems

Recognized Service Agency within the service time allowance guidelines and must be submitted along with failed

parts (if applicable) to Marshall Air Systems (freight prepaid) within 30 days of the work being performed. Travel is

covered, but must not exceed 50 miles or 1 hour, whichever is greater. Call Marshall's Service Department at

800-722-3474 or 704-525-6230 with any questions. Service is to be performed by recognized service agencies

during normal working hours. Owner to pay for all other charges including excessive travel or overtime charges.

DIAGNOSTIC LABOR CHARGES ARE INCLUDED IN SERVICE TIME ALLOWANCE GUIDELINES. All

portable equipment (under 90 pounds) shall be delivered by Purchaser, at his/her expense, to the nearest

authorized service agency for in-shop repair or at purchasers discretion he/she will pay all travel time and mileage

expenses for portable equipment.

NON-WARRANTY RETURNS:

All items returned for customer convenience are subject to a 20% restocking fee. In the event of an error by

Marshall Air Systems, Inc., a Returned Goods Authorization will be issued for full credit.

FOR INTERNATIONAL INSTALLATIONS -- PLEASE CONTACT YOUR

LOCAL MARSHALL AIR SYSTEMS RECOGNIZED DISTRIBUTOR.

PROCEDUR. BRL DOC

Loading...

Loading...