Marshall Air FR15BG Service Manual

This document contains the installation and operating instructions for:

MODEL: FR15BG AUTOBROIL™

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

INSTRUCTIONS TO PURCHASER:

1. ANSI Z83.11 STANDARDS REQUIRE THAT YOU POST IN A PROMINENT

LOCATION THE PROCEDURES TO FOLLOW IN THE EVENT THE USER

SMELLS GAS. THIS INFORMATION SHALL BE OBTAINED FROM THE

LOCAL GAS SUPPLIER.

2. THIS MANUAL NEEDS TO BE RETAINED FOR FUTURE REFERENCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATION AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

114272 RV121598

Copyright© 1994 Marshall Air Systems, Inc.

All Rights Reserved.

MODEL FR15BG

TABLE OF CONTENTS

I. MACHINE SETTINGS (Quick Reference)............................................................................... 2

II. MACHINE INSTALLATION..................................................................................................... 3

III. OPERATING INSTRUCTIONS............................................................................................... 6

IV. SCHEDULED MAINTENANCE............................................................................................... 8

V. TROUBLESHOOTING.......................................................................................................... 10-14

VI. ASSEMBLY & DISASSEMBLY INSTRUCTIONS.................................................................... 14

VII. REPLACEMENT PARTS....................................................................................................... 14-19

Pre-lnstallation ....................................................................................................................... 3

Appliance Location................................................................................................................. 3

Electrical Information.............................................................................................................. 4

Gas Piping To Appliance ........................................................................................................ 4

Pre-Operation Check.............................................................................................................. 4-5

Lighting and Shut-Off Instructions........................................................................................... 5

Performance Criteria .............................................................................................................. 5-6

Broiler and Toaster Adjustment-Daily...................................................................................... 6-7

Setting Temperature Controller For Proper High/Low Operation-Weekly .............................. 7

Setting Holding Temperature-Weekly..................................................................................... 7-8

Daily Cleaning Procedures...................................................................................................... 8

Monthly Cleaning Procedures.................................................................................................

Quarterly Cleaning Procedures and Preventive Maintenance .............................................. 10

PAGE

9-10

LIMITED WARRANTY............................................................................................................ i

WARRANTY PROCEDURES................................................................................................. ii

ILLUSTRATIONS

FR15BG Dimensions...............................................................……………………... Figure 1

Exploded View..........................................................................……………………… Figure 2

Hamburger Slide.......................................................................……………………. Figure 3

Burner Assembly ......................................................................……………………… Figure 4

Gas Distribution System ...........................................................…………………….. Figure 5

Conveyor..................................................................................……………………….. Figure 6

Axle Scraper.............................................................................……………………… Figure 6

Restraining Device ...................................................................……………………… Figure 7

Burner Shield Installation..........................................................……………………… Figure 8

Kit, Broiler Extension 15"..........................................................……………………… Figure 9

Drive Sprocket Asby Set-up......................................................……………………. Figure 10

Schematic................................................................................……………………… #114558, 114559, 117003

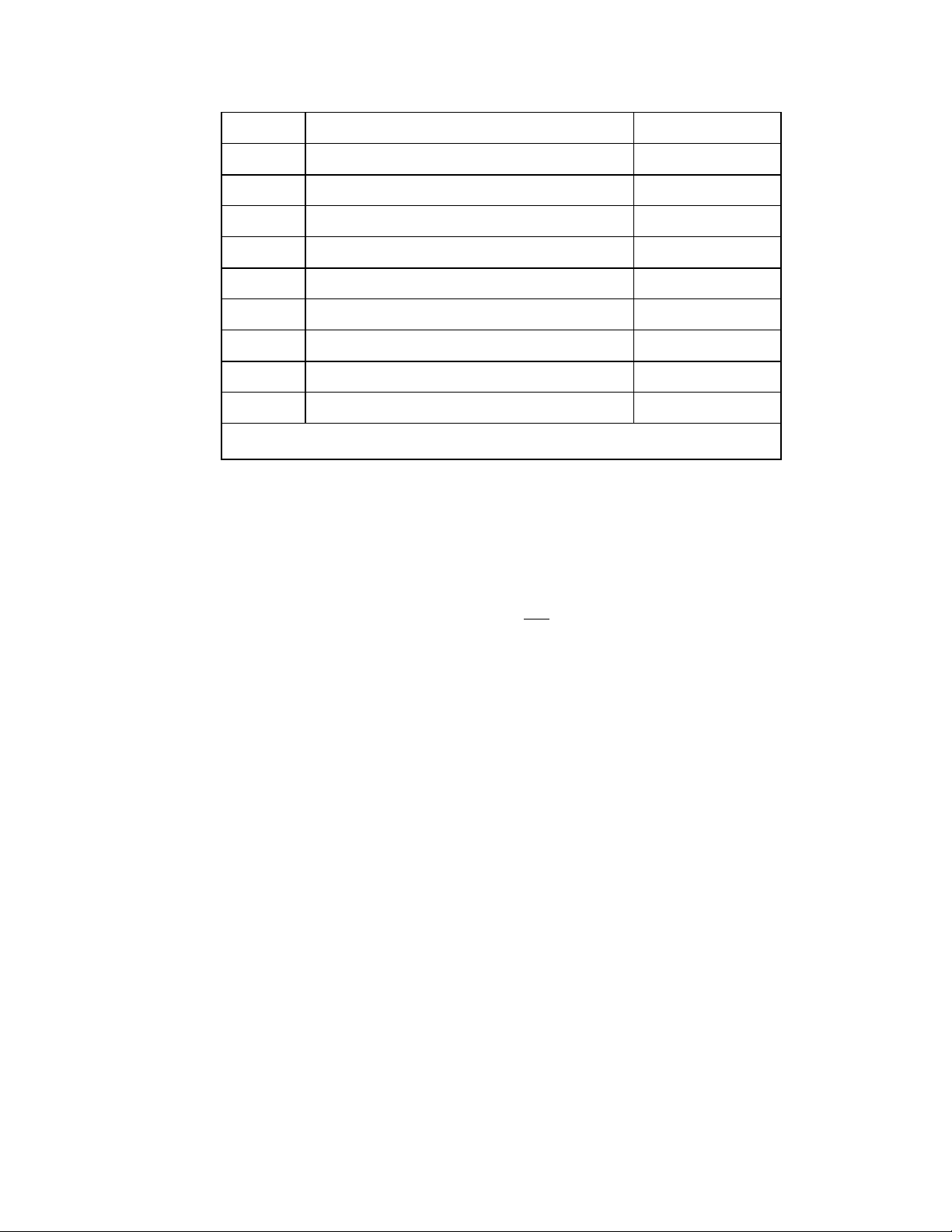

I. MACHINE SETTINGS

AUTOBROIL™

MODEL: FR15BG

SERIAL NUMBER: ___________________________________________________________

TYPE OF GAS: ______________________________________________________________

BROILER HIGH/LOW TEMPERATURE SETTING: __________________________________

GAS PRESSURE: HIGH ____________ LOW ______________

SPEED SELECTOR SETTING: _________________________________________________

PASS-THRU TIME: __________________________________________________________

HOLDING TEMPERATURE SETTING: ___________________________________________

START-UP TECHNICIAN: _____________________________________________________

START-UP DATE: ___________________________________________________________

COMMENTS: _______________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

2

II. MACHINE INSTALLATION

PRE-INSTALLATION

1. After uncrating the Autobroil™ unit, inspect for shipping damage. Check that all control knobs are intact on the

electrical cabinet front. Contact the factory if there are obvious problems. Set the unit in place and use the plastic

bag to protect it from the debris and trash of building construction. DO NOT remove plug from gas inlet pipe.

Leave this for the Qualified Service Company. Check that machine has not been dented or damaged by the

carrier. Notify your freight carrier immediately to file a concealed damage claim, following the instructions

attached to the outside of the shipping crate. Your warranty will not cover freight damage.

2. Installation must be performed by a Qualified Service Company. The term "Qualified Service Company" means

any individual, firm, corporation or company which is either engaged in and is responsible for the installation or

replacement of gas piping on the outlet side of the meter, or the service regulator when a meter is not provided,

or the connection, installation or repair of gas appliances, who is experienced in such work, familiar with all

precautions required, and has complied with all the requirements of the authority having jurisdiction.

3. A remote gas shut-off valve must be provided and interlocked to exhaust system when in operation.

A gas shut-off control is located in the gas piping (behind the left side panel) for emergency shut-off of gas supply

to this appliance.

4. Because this unit is power fan exhausted, it is necessary to provide adequate make up air equal to the amount

removed. In addition to this, any other exhausts, flues, or air removal systems must be taken into consideration.

Examples of this are heat removal fans or hot water heater flues.

5. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/2 psig (3.45 kPa).

6. The appliance must be isolated from the gas supply piping system by closing its individual shutoff valve during

any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig (3.45 kPa).

APPLIANCE LOCATION

WARNING: IF NOT INSTALLED, OPERATED AND MAINTAINED IN ACCORDANCE WITH THE MANUFAC TURER'S

INSTRUCTIONS, THIS PRODUCT COULD EXPOSE YOU TO SUBSTANCES IN FUEL OR FROM FUEL

COMBUSTION WHICH CAN CAUSE DEATH OR SERIOUS ILLNESS AND WHICH ARE KNOWN TO THE STATE OF

CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

1. Position Autobroil™ to properly align with exhaust hood (refer to equipment plan).

2. The hood/ventilator for the appliance should be located in accordance with the National Fire Protection

Association Standard #96, "Removal of Smoke and Grease-Laden Vapors from Commercial Cooking Equipment"

and any local applicable requirements.

3. For proper installation, the minimum clearance from combustible construction is 6" from sides and 6" from back.

3

4. Adequate clearance should be maintained to allow easy access to loading and unloading areas of the machine.

5. For servicing, unit must be moved two feet clear from all construction.

CAUTION: KEEP THE APPLIANCE AREA FREE AND CLEAR FROM COMBUSTIBLES.

ELECTRICAL INFORMATION

1. The appliance is cord connected and requires a 120 volt, A.C., 60 HZ, Single Phase, 2 wire w/ground 15 AMP circuit

or a 240 volt, A.C., 50 HZ, Single Phase, 2 wire w/ground 10 AMP circuit. Appliance must be electrically grounded in

accordance with local codes, or in the absence of local codes, with the National Electrical code ANSI/NFPA No. 70latest edition.

2. There is a Wiring Diagram located in the Owner's Manual and under the left side skin.

GAS PIPING TO APPLIANCE

1. Installation of this appliance must conform with local codes, or in the absence of local codes, with the National Fuel

Gas Code, ANSI Z-223.1-latest edition.

2. In Canada, this appliance is to be installed in accordance with Standard CGA B149.1 or B149.2 Installation Codes

for gas burning appliances and equipment and any local applicable requirements.

3. The appliance is supplied with a 3/4" female pipe thread. The installer must make the pipe connection to the unit in

accordance with the "National Fuel Gas Code," ANSI Z-223.1-latest edition. The gas line connected to the 3/4"

female pipe thread cannot be less than a 3/4" pipe. The gas pressure and gas volume required by this appliance is

shown on Page 6. Gas piping from source to broiler must be adequate to satisfy these requirements when all other

gas appliances in the restaurant are operating at maximum demand.

4. A flexible AGA approved gas line is available. Instructions are (1) the installation shall be made with a connector that

complies with the Standard for Connectors for Movable Gas Appliances, ANSI Z21.699-latest edition, and Addenda,

Z21.69a-latest edition, and a quick-disconnect device that complies with the Standard for Quick-Disconnect Devices

for Use With Gas Fuel, ANSI Z21.41-latest edition, and Addenda, Z21.41a-latest edition and Z21.41b-latest edition,

and (2) adequate means must be provided to limit the movement of the appliance without depending on the

connector and the quick-disconnect device or its associated piping to limit the appliance movement. See Figure 7 for

details.

5. See Page 3, Items 5 and 6, for instructions on gas supply line pressure testing.

CAUTION: DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND VENTILATION AIR.

PRE-OPERATION CHECK

Before lighting and operating your Autobroil™, make a quick check of critical items as follows:

1. Remove both side panels and check to see that all parts are in place and that none are damaged.

2. Start conveyor chain and check for proper operation. The conveyor chain should run free and not be catching on

anything.

4

3. The speed of the conveyor chain should be modulated from low to high, and back again without the

chain stopping.

4. Before first use, and after any special cleaning, it is necessary to "season" the broiler chain. This is

done by bringing chain to operating temperature and then (with burner still lit) applying liquid

shortening from a saturated cloth over the full width of the broiler chain while the chain makes 5 or 6

complete revolutions.

5. Check that gas pressure at appliance is correct (see Performance Criteria on Page 6).

6. Check that grease pan is in place under unit (Figure 1).

7. Check that all parts are installed on the unit (see Figure 10).

LIGHTING INSTRUCTIONS FOR ELECTRONIC IGNITION SYSTEM

1. Turn exhaust system on.

2. Make sure filters are in place in the hood.

3. Turn conveyor chain on and set speed at approximate mid-point.

4. Remove left side cover.

5. Turn gas control switch on top of Honeywell valve to "ON".

6. The broiler heat switch on the control panel will now cycle the burners on and off. Set broiler temperature controller on left side of control cabinet to (204°C) 400°F (see Item 3 of setting temperature

controller on Page 7).

7. Turn on heat switch. Ignition is electronic (does not require manual lighting of pilot).

8. If pilot flame or burners fail to light turn heat switch off and wait five minutes before attempting to

relight.

SHUT-OFF INSTRUCTIONS

1. Turn heat switch off.

2. Wait 30 minutes.

3. Turn conveyor switch off.

4. Turn ventilator off.

PERFORMANCE CRITERIA

1. The manifold pressure for each burner and appliance inlet pressure and gas amount is listed below:

Type of Gas - Natural or Propane

Pressure at the Appliance - 6.0-10.0 IWC for Natural

- 11.0 IWC for Propane

5

Manifold Pressure - Low 4.0 IWC; High 5.0 IWC for Natural

- Low 7.0 IWC; High 10.3 IWC for Propane

Total Gas Amount ** - 61,000 BTUH @ 100% High Fire

Manifold pressure is measured by a pressure gauge on the outlet side of the Honeywell gas valve. With

the unit on for at least twenty minutes and the broiler temperature controller set at (204°C) 400°F (see

Item 3 on Page 7), the pressure should be at 4.0 IWC (7.0 IWC for propane). With the broiler

temperature controller set for (427°C) 800°F the high fire pressure is 5.0 !WC (10.3 IWC for propane).

High pressure is adjusted using the regulator in the top of the gas safety valve. Low fire is adjusted

using the gas pressure regulator. See Figure 5 for gas system layout.

2. The burners in the appliance are a special infrared type. All of the air for combustion must be injected

through the Venturis. This makes orifice design and alignment very critical. The orifice design, in

combination with the correct natural or propane gas pressure will result in adequate air aspiration and

mixing. There are no air shutters. No air adjustment is needed. The proper orifice part numbers are

found in Section VII - Replacement Parts.

CAUTION: DO NOT STACK BOXES OR IN ANY WAY BLOCK AREA IN IMMEDIATE VICINITY OF

VENTURIS OR IN ANY OTHER WAY OBSTRUCT FLOW OF COMBUSTION AIR.

3. Pilot burner flame is fixed and is not adjustable.

4. All burners will be bright orange when burning properly. If a dull red is observed after 30 minutes of

warm-up with a blue flame above the burner face, the orifice is not aligned properly. "Popping," or

burning back at the orifice of the burner, is a result of the burner screen being loose or a faulty gasket

under the burner screen. LP machines may exhibit a light "popping" sound when the unit is turned off;

this is normal.

NOTE: IF BURNER SCREEN IS TORN OR HAS A HOLE, OR IF A GASKET IS LEAKING, THE

BURNER MUST BE REPAIRED. See Figure 4.

III. OPERATING INSTRUCTIONS

BROILER ADJUSTMENT - DAILY

LIGHTING INSTRUCTIONS FOR ELECTRONIC IGNITION SYSTEM

1. Turn exhaust system on.

2. Make sure filters are in place in the hood.

3. Turn conveyor chain on and set speed at approximate mid-point.

4. Remove left side cover.

5. Turn gas control switch on top of Honeywell valve to "ON".

6

6. The broiler heat switch on the control panel will now cycle the burners on and off. Set broiler temperature

controller on left side of control cabinet to (204°C) 400°F (see Item 3 of setting temperature controller on Page 7).

7. Turn on heat switch. Ignition is electronic.

8. If pilot flame or burners fail to light turn heat switch off and wait five minutes before attempting to relight.

SHUT-OFF INSTRUCTIONS

1. Turn heat switch off.

2. Wait 30 minutes.

3. Turn conveyor switch off.

4. Turn ventilator off.

SETTING TEMPERATURE CONTROLLER FOR PROPER HIGH/LOW OPERATION-WEEKLY

1. Follow the procedure in Step 3 on Page 7 in order to set temperature control for (204°C) 400°F. After doing this,

turn on the broiler.

2. Allow the broiler burners and conveyor chain to warm up for 60 minutes (with the chain at approximately the

correct speed).

3. Observe the temperature displayed: push "SET" and release to view the "SET POINT." To change set point push

"SET" and, within three seconds, use the arrows to select a new set point. When setting the High/Low for proper

operation, make the set point THE SAME as the observed temperature made after the sixty minute warming.

Broiler High/Low control is now set. The setting should be between (274°C) 525°F and (343°C) 650°F. If not at

least (274°C) 525°F, the high and low gas pressures, as discussed on Page 6 under Performance Criteria, may

require adjustment or the hood exhaust may be excessive. The broiler will work but will cook slower.

4. Place one meat patty on the broiler chain. Based on the appearance of the broiled patty, reset the Digital Speed

Control for the desired broiling quality. (Note: this single patty should be cooked to the maximum degree of the

Minimum/Maximum doneness tolerance.)

NOTE: THE HIGHER THE NUMERICAL VALUE SET ON THE DIGITAL SPEED CONTROL, THE FASTER

THE CONVEYOR CHAIN WILL RUN.

SETTING HOLDING TEMPERATURE-WEEKLY

1. The temperature controller on the front of the unit has been preset at (90°C) 195°F. Push and release the "SET"

button to observe the set point. If this setting has been inadvertently changed, it is necessary to reset the proper

value. This may be done using the arrows on the control within three seconds of pushing and releasing the "SET"

button. Afterwards the actual temperature is displayed.

7

IV. SCHEDULED MAINTENANCE

DAILY CLEANING PROCEDURES

CAUTION: Do not touch the broiler section immediately after appliance shut-down. The temperature inside enclosures

is in excess of (260°C) 500°F, which eliminates the need to clean any parts inside the enclosures for

sanitary purposes. Any grease that may build up on the exterior of the enclosures should be cleaned off

with a damp cloth and a minimum amount of detergent. Never use a large amount of water on the

enclosure or allow burner faces to get wet as this could cause premature burner or gasket failure.

Disconnect the power supply to the appliance before cleaning or servicing.

CAUTION: Under no circumstances should oven cleaner be used on this appliance. IT WILL EAT HOLES IN

THE ALUMINUM GAS VALVES AND GAS LINES, CAUSTIC FUMES CAUSE ELECTRICAL

COMPONENT DAMAGE, AND WILL CAUSE MANY OTHER PROBLEMS IF USED TO CLEAN THIS

BROILER.

CAUTION: KEEP THE APPLIANCE AREA FREE AND CLEAR FROM COMBUSTIBLES.

1. Allow broiler burners and chain to operate for 30 minutes after cooking last patty to burn off excess grease on

broiler components. Then turn the unit off and allow to cool. (This applies every time a meat chain is turned off regardless of what time of day meat chain is shut down - and regardless of how few patties were broiled in the

last 30 minutes, last hour, etc.) This will clean some parts of the cooking chamber. Failure to perform this

procedure daily will result in poor cooking times.

2. Remove all exterior panels except those which are attached with screws. Be careful not to touch any hot internal

broiler components.

3. Remove burners from right side of unit and shake all debris off burners after they cool. DO NOT WASH BURNER

AS IT WILL DESTROY GASKET. Brush surface of burner mesh with soft brush.

4. Remove lower burner shields as shown in Figure 8. Brush or scrape residue.

WARNING: THE BURNER AND REVERBERATING SCREENS (LOCATED UNDER THE TOP BURNERS),

ARE MADE FROM INCONEL METAL MESH. THIS MATERIAL DETERIORATES WITH USE.

INSPECT THESE SCREENS DAILY AND REPLACE IF SCREEN IS SEVERELY CORRODED.

FAILURE TO DO SO CAN RESULT IN METAL PARTICLES BEING SERVED TO YOUR

CUSTOMERS.

5. Remove the following items and wash with hot soapy water.

Tunnel Guard Front

* Conveyor Cover Figure 2

8

Figure 2

Rear Tunnel Plate

Meat Stripper Figure 2

* Holding Lid Figure 2

Figure 2

* Broiler Spatula

* Make Up Tray Insert Figure 3

* Burger Tray & Stop Assembly Figure 3

Slide Insert Figure 3

* Wire Rack Figure 3

* Grease Pan

Conveyor Wiper Figure 2

* NOTE: these items may be removed during the 30 minute period.

Figure 3

Figure 1

6. With the conveyor switch ON and heat switch OFF, wire brush the broiler conveyor and, as it cools, wipe

with damp cloth.

7. Scrape deposits from the axles with the axle scraping tool, furnished with each machine as shown in Figure 6.

8. The slide surface (Figure 3) is covered with a teflon sheet. Daily cleaning is necessary. To clean:

Remove slide assembly, then remove teflon sheet by loosening (DO NOT REMOVE) thumb screws on slide (see

Figure 3). Gently wash and rinse sheet with warm water and a mild liquid detergent. Don't scrub sheet with

coarse materials. All washing should be done on a flush smooth surface, taking care not to fold, crease, or cut the

teflon sheet. DO NOT USE A DEGREASER ON THE TEFLON SHEET. THE TEFLON SHEETS' USEFUL LIFE

WILL BE GREATLY REDUCED IF A DEGREASER IS USED.

9. Remove grease and meat residue from any part of remaining broiler structure where visible. Use a damp cloth

with detergent and a putty knife for best results.

10. After cleaning all removable parts as noted, allow to dry and reassemble.

MONTHLY CLEANING PROCEDURES

1. Turn off gas control knob and disconnect electricity.

2. Remove upper burners, lower burners and screens (only used on natural gas units). These parts are illustrated in

Figure 2.

3. Spread conveyor links open with screwdriver or chain pliers (part #500033). Lift front axle up to make slack in the

conveyor belt, unhook conveyor chain and remove to gain access to lower cooking chamber for cleaning side

walls.

9

4. Remove and clean lower burner shields as shown in Figure 8. This can best be accomplished with a

scraper.

5 Blow out all four (4) burners through the venturi opening. CAUTION: Do not drop burners or get

wet as this may break gasket or add to premature burner failure.

6. Reassemble conveyor chain. Make certain it is not on backward (Figure 6) and CLOSE open links to

match other links.

7. Using a damp cloth, wipe the inside of each burner venturi.

8. Reinstall burner screens, lower burner shields, and burners.

QUARTERLY CLEANING PROCEDURES & PREVENTIVE MAINTENANCE

1. Remove conveyor and soak in hot soapy water overnight. The chain is removed by lifting axle up to

produce slack and separating as described in Item 3 above. When replacing chain, make certain the

conveyor is installed per Figure 6. PLACING CHAIN ON BACKWARD WILL CAUSE SEVERE

BINDING PROBLEMS. CLOSE open links to match other links.

2. Lubricate the roller (drive) chain with a few drops of any grade motor or machine oil.

3. Remove and inspect all motor brushes and replace if less than 1/4" is left.

4. Do not remove internal gas lines for cleaning.

5. Clean gas orifices:

• Orifices are passageways directing gas flow into burner. Uneven gas

flow or air to gas ratio is caused by dirty or damaged orifices.

• Orifices are made of brass. Use special care in cleaning—don't gouge

or make gas holes bigger.

• To reach orifices, remove burners.

• Use a pipe cleaner dipped in rubbing alcohol to clean orifices. Swab

until clean; free of carbon build-up. Do not use drill bit; this damages

orifice.

6. INVENTORY THE SPARE PARTS KIT AND ORDER MISSING PARTS AS NEEDED. KEEP A

COMPLETE SET OF PARTS ON HAND AT ALL TIMES.

V. TROUBLESHOOTING

This section contains a list of possible problems with the Autobroil™ unit. ALL ELECTRICAL TROUBLE

SHOOTING INVOLVING ACCESS INTO THE MOTORS OR ELECTRICAL ENCLOSURES MUST BE PERFORMED

BY A QUALIFIED ELECTRICIAN. All items marked with asterisks (*) should be performed by service agency

qualified to perform service on gas fired appliances.

1. PROBLEM: BURNER BACKFIRES. Flashback, blue flame at entrance to burner makes motor-boating sound like

a blow torch. IMPORTANT: If burner backfires, turn it off. Continued operation will cause damage to the entire

burner.

POSSIBLE CAUSE:

10

* A) Burner screen failure (hole) or burner gasket. SOLUTION: Replace burner screen or gasket (Figure 4).

* B) Burner over-fired - manifold pressure too high. SOLUTION: Check and reset gas control regulator to give

2. PROBLEM: FLAMES VISIBLE AT EXHAUST STACK OR IN CHAMBER.

* A) Low gas pressure. SOLUTION: Check and reset gas control regulator to give rating value for manifold pressure

3. PROBLEM: PILOT FLAME GOES OUT AFTER 90 SECONDS OF IGNITION TRIAL.

* A) Pilot assembly dirty or bent. SOLUTION: Check for bent pilot gas line and/or dislodge debris.

* B) Low gas pressure. SOLUTION: Increase gas pressure to appliance (see Figure 5).

* C) Pilot orifice clogged. SOLUTION: Dislodge debris or replace orifice.

4. PROBLEM: BURNER WILL NOT LIGHT AT ALL.

* A) Orifice. SOLUTION: Check that orifice is not plugged. (If it is necessary to change the orifices, new ones must

rating plate value for manifold pressure (shown under Performance Criteria on Page 6). Wait 5 minutes &

relight. Flashback will not occur immediately unless a large opening in or around the burner screen is evident.

Wait an hour after relighting to check that problem is solved. Figure 5 illustrates which regulator sets high and

low gas pressures.

POSSIBLE CAUSE:

(shown under Performance Criteria on Page 6. Figure 5 illustrates which regulator sets high and low pressures.

POSSIBLE CAUSE:

POSSIBLE CAUSE:

be ordered from the factory.)

* INSTRUCTIONS MARKED WITH ASTERISKS SHOULD BE PERFORMED BY AUTHORIZED SERVICE

PERSONNEL.

B) Check that flame runner is fully lit. SOLUTION: If not, clean flame runner orifice or remove and clean

flame runner. Refer to Figure 2.

C) Pilot. SOLUTION: Pilot must light and stay lit in order for burner to light. Check pilot problem list (see Item 3 on

Page 11).

* D) Gas Solenoid. SOLUTION: Check that solenoid valve on main gas valve is working.

5. PROBLEM: CONVEYOR CHAIN WILL NOT MOVE.

POSSIBLE CAUSE:

A) Check 10 amp fuse. SOLUTION: Replace if blown.

11

Loading...

Loading...