Page 1

OWNER'S MANUAL

Width:

10"

BZ6A

- 6 Ft. 3 wire w/NEMA

5-15

MODELS BZ6, BZ6A, BZ6AINTL -THERMOGLO™ DOWNHEATER

Supplier Name: MARSHALL AIR SYSTEMS, INC.

Address: 419 Peachtree Drive South

Charlotte, NC 28217

Model#: ____________________

Serial #: ____________________

____________________

____________________

Date Received: ____________________

Date Installed: ____________________

Telephone #: 704-525-6230

Toll Free #: 800-722-3474 Customer Service

Fax #: 704-525-6229

Service Referral #: 800-722-3474

Local Service Name: ____________________

Local Service #: ____________________

MANUFACTURER'S INTRODUCTION

The Models BZ6, BZ6A, BZ6AINTL

ThermoGlo™ Downheater feature Marshall's

own ThermoGlo™ heating technology.

ThermoGlo™ offers maintenance free operation

since it does not rely on bulbs or parabolic

reflectors to achieve its even, gentle heat

pattern. Each model includes mounting

brackets, On/Off switch and an infinite

temperature controller. The Downheater mounts

on slide brackets built into the microwave and

suspended overshelf.

GENERAL SPECIFICATIONS

Models: BZ6, BZ6A, BZ6AINTL

Height:

Depth: 20.875"

Electrical:

Power Cord:

Weight:

Approvals: ETL and NSF

5.5"

BZ6 - 208 volts, 4.3 amps

BZ6A-120 volts, 7 amps

BZ6AINTL-240 volts, 3.5 amps

BZ6 - wire leads only

plug

BZ6AINTL - 6 Ft. 3 wire, no plug

15lbs.

130522BZ6 RV092899

Copyright 1999 Marshall Air Systems, Inc.

All Rights Reserved

Page 2

MODELS BZ6, BZ6A, BZ6AINTL -THERMOGLO™ DOWNHEATER

TABLE OF CONTENTS

INSTALLATION.........................................................................................................….... 1

THERMOGLO™ WITH ON/OFF SWITCH ...................................................................... 1

DAILY CHECKLIST AND CLEANING GUIDE......................................................…....1 - 2

MONTHLY MAINTENANCE......................................................................................….... 2

TROUBLESHOOTING................................................................................................….. 2

THERMOGLO™ & HEATED HOLDING CABINET LIMITED WARRANTY..................... 3

THERMOGLO™ & HEATED HOLDING CABINET WARRANTY RETURN

PROCEDURES...........................................................................................................…...4

ILLUSTRATIONS

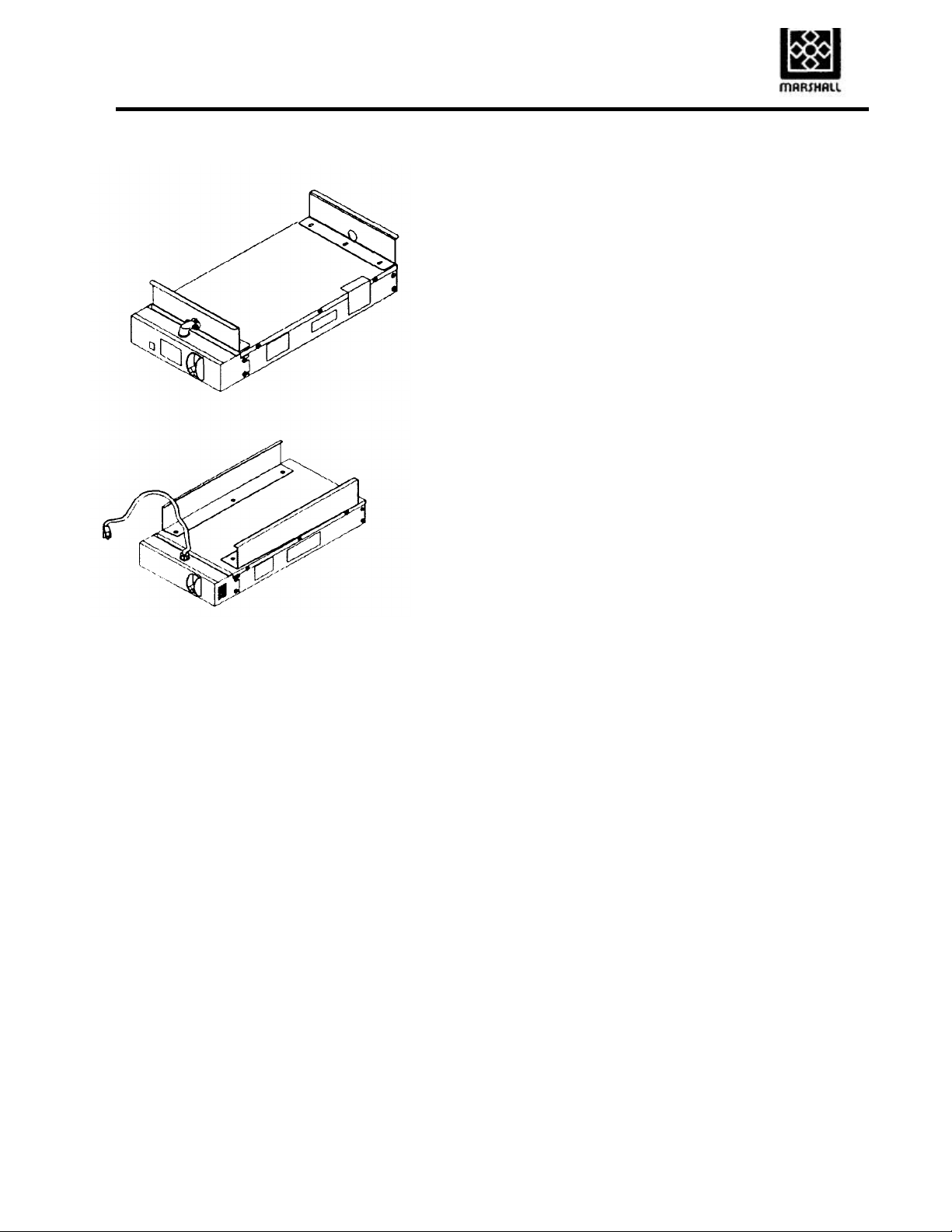

MODEL BZ6 DOWN HEATER (208V) .........................................................…...FIGURE 1

MODEL BZ6 DOWN HEATER REPLACEMENT PARTS (208V)...................….FIGURE 2

MODEL BZ6A DOWN HEATER (120V)........................................................…..FIGURE 3

MODEL BZ6A DOWN HEATER REPLACEMENT PARTS (120V) ............….....FIGURE 4

WIRING SCHEMATIC, BZ6 208V............................................................…. DWG 130016

WIRING SCHEMATIC, BZ6A 120V..........................................................…. DWG 134140

WIRING SCHEMATIC, BZ6AINTL 240V..................................................…. DWG 137462

130522BZ6 RV092899

Copyright 1999 Marshall Air Systems, Inc.

All Rights Reserved

Page 3

MODELS BZ6, BZ6A, BZ6AINTL -THERMOGLO™ DOWNHEATER

INSTALLATION

PRE-INSTALLATION

The ThermoGlo™ Downheater has been packaged to minimize the risk of shipping damage. Immediately

upon receipt, make certain to inspect the unit for any evidence of damage that might have occurred through

rough handling in shipment. FILE ALL CLAIMS WITH THE FREIGHT CARRIER.

FINAL INSTALLATION

1. Unpack unit and remove all protective paper or plastic covering from metal part s.

2. This unit is designed to slide under the shelf system on a rail track. If it is not going to be used with

this rail track system, the brackets must have holes drilled in the flanges to mount the

ThermoGlo™.

3. The wires should to be connected to a power source and routed through flex conduit for the Model

BZ6. A power cord is provided on the Model BZ6A for connection to a 120V receptacle. The plug

on this cord is NEMA #5-15. The BZ6AINTL is provided with a 3-wire power cord only;

no plug is provided. THE HEATER WILL BE DESTROYED IF CONNECTED TO IMPROPER

SUPPLY VOLTAGE.

4. This equipment should be installed, adjusted, and serviced by qualified electrical maintenance

personnel familiar with the construction and operation of electrical equipment and the hazards involved.

It is the responsibility of the individual installing the ThermoGlo™ to take diligent care to mount and

connect the electrical wiring so that it complies with the National Electrical Codes and Occupational

Safety and Health Act (OSHA ).

THERMOGLO™ WITH ON/OFF SWITCH

1. This unit consists of a junction box and a switch designed to be mounted to the end of the heater. The

switch is rated for a maximum of 12 amps at 120 volts, 208 volts, or 240 volts.

2. Before operating the ThermoGlo™ Downheater, set heat control switches (infinite switches) to 10

position on dial.

DAILY CHECKLIST AND CLEANING GUIDE TO

USE THE DOWNHEATER

1. Turn on the power switch.

2. The unit is ready to use after a 15 minute preheat period.

130522BZ6 RV092899

Copyright 1999 Marshall Air Systems, Inc.

All Rights Reserved

1

Page 4

2

MODELS BZ6, BZ6A, BZ6AINTL -THERMOGLO™ DOWNHEATER

CLEANING CHECKLIST

1. Turn off the unit and allow it to cool for 30 minutes.

2. Clean unit with a damp cloth and cleaner degreaser.

ONLY CLEAN WHEN THERMOGLO™ HAS COOLED!

DO NOT IMMERSE UNIT IN WATER!

DO NOT SATURATE HEATER SURFACES WITH WATER!

DO NOT USE CAUSTIC, ABRASIVE OR CORROSIVE CHEMICAL CLEANERS!

DO NOT USE SHARP OBJECTS TO SCRAPE CLEAN!

3. The ThermoGlo™ Downheater is enclosed in a stainless steel wrap. This heater is constructed so that

heat expansion and cooling cycles may take place freely. Therefore, by no means is it water tight.

4. Allow sufficient drying time before attempting to use.

MONTHLY MAINTENANCE

1. Follow the Daily Checklist and Cleaning Guide. The only adjustments that can be made are the infinite

controllers (see Figure 2 or Figure 4).

2. With proper maintenance procedures and consideration to heater construction, the ThermoGlo™

Downheater will give years of trouble-free operation.

TROUBLESHOOTING

* DISASSEMBLING HEATER VOIDS WARRANTY *

Identify problem in the left column and look for probable cause and solution in right hand column. Probable

causes listed in the order they are most likely to happen. This sequence should be used to isolate the problem.

PROBLEM PROBABLE CAUSE SOLUTION

1. No Heat Unplugged Plug in

2. Low Product Temperature Infinite controller set too low Adjust to higher setting

Circuit breaker is tripped Reset breaker; call electrician if

tripped twice

Cord/plug defective Replace cord/plug

Controller "off' Turn knob "on" and to desired

position.

Defective infinite controller Replace infinite controller

Excessive Air Draft(s) Shield Draft(s)

130522BZ6 RV092899

Copyright 1999 Marshall Air Systems, Inc.

All Rights Reserved

Page 5

3

MODELS BZ6, BZ6A, BZ6AINTL -THERMOGLO™ DOWNHEATER

THERMOGLO™AND HEATED HOLDING CABINET LIMITED WARRANTY

MARSHALL AIR SYSTEMS, INC., ("Marshall") warrants to the first purchaser ("Purchaser") all new equipment of its manufacture to be

free of defects in material and factory workmanship for a period of one year from date of shipment provided that (i) the equipment is installed

in the Continental United States, Canada or Hawaii and operated according to the Owner's Manual while located at the original address of

installation, (ii) the warranty registration card has been completed and returned to the factory within fifteen (15) days after installation.

Marshall's obligation under this warranty is limited to the repair or replacement at its option of any defective part. It is understood that

Marshall's obligation with respect to equipment located outside the Continental United States, Canada or Hawaii is limited to replacement

parts only.

Because Marshall does not and cannot control Purchaser's installation, use, and maintenance of equipment manufactured by Marshall,

this warranty DOES NOT COVER:

1. Any equipment calibration.

2. Switches.

3. Plugs and cords.

4. Blown fuses or bulbs.

5. Any component disassembled in the field or that has broken seals.

6. Any replacement parts used on the equipment which are not purchased from Marshall.

7. Accessory components not installed and/or manufactured by Marshall.

8. Water or grease accumulation, which wilt cause electrical failures.

9. Labor, except that provided at Marshall's factory.

10. Damage due to improper or lack of cleaning, abuse and/or service.

SHIPPING DAMAGE must be reported to the carrier and is not covered under this warranty. Marshall will not be liable for damage as a

result of improper installation, misuse, abuse, alteration of original design, incorrect voltage, unauthorized service, breakage of fragile items,

or any other damage caused by an act out of Marshall's control.

The effect of corrosion, fire, and normal wear on the equipment or component parts is not covered by this warranty. This warranty does

not cover cooking performance, smoke capture or holding temperatures which is a function of food types, textures, temperatures, equipm ent

line ups and other variables chosen by the Purchaser and over which Marshall has no control. This warranty does not apply to damage

caused by accident or to damage caused by the negligence of Purchaser or the employees of Purchaser or to damage caused by lightning

generated electrical current or any other Act of God whatsoever. This warranty does not apply to any equipment bearing a serial number

which has been tampered with or altered. Marshall reserves the right to accept or reject any such claim in whole or in part. Marshall will not

accept the return of any product without prior written approval from Marshall, and all such approved returns shall be made at Purchaser's

sole expense.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE IMPLIED WARRANTY OF

MERCHANTABILITY AND THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, OR PATENT OR OTHER

INTELLECTUAL PROPERTY RIGHT INFRINGEMENT, AND EXCEPT FOR THE EXPRESS WARRANTY CONTAINED HEREIN, THE

EQUIPMENT IS SOLD "AS IS." REMEDIES UNDER THIS WARRANTY AND UNDER ANY WARRANTY THAT MAY SURVIVE THE

DISCLAIMER OF WARRANTIES ARE LIMITED EXCLUSIVELY TO THOSE REMEDIES DESCRIBED ABOVE. NO OTHER REMEDY IS

AVAILABLE UNDER THIS WARRANTY OR ANY OTHER WARRANTY. NEITHER THIS WARRANTY NOR ANY OTHER WARRANTY

COVERS, AND MARSHALL WILL NOT BE RESPONSIBLE FOR, ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING

BUT NOT LIMITED TO THE COST OF DISASSEMBLY AND SHIPMENT OF THE EQUIPMENT, PRODUCTION OR PRODUCT LOSSES,

INJURY TO OTHER PROPERTY, OR LOST PROFITS RESULTING FROM THE USE OF OR INABILITY TO USE THE PRODUCTS OR

FROM THE PRODUCTS BEING INCORPORATED IN OR BECOMING A COMPONENT OF ANY OTHER PRODUCT OR GOODS, OR

OTHER LOSSES. WHERE, DUE TO OPERATION OF LAW, CONSEQUENTIAL AND INCIDENTAL DAMAGES CANNOT BE

EXCLUDED, THEY ARE EXPRESSLY LIMITED IN AMOUNT TO THE PURCHASE PRICE OF THE EQUIPMENT.

FOR INTERNATIONAL INSTALLATIONS - PLEASE CONTACT YOUR LOCAL MARSHALL AIR

SYSTEMS RECOGNIZED DISTRIBUTOR.

130522BZ6 RV092899

Copyright ©1999 Marshall Air Systems, Inc.

All Rights Reserved

Page 6

4

MODELS BZ6, BZ6A, BZ6AINTL -THERMOGLO™ DOWNHEATER

THERMOGLO™ AND HEATED HOLDING CABINET WARRANTY

RETURN PROCEDURES

I. RETURN GOODS AUTHORIZATION FOR PARTS

For prompt warranty parts replacement and RGA processing, please call Marshall's Customer

Service Department at 800-722-3474 or 704-525-6230 for assistance. In all cases, a Return Goods

Authorization (RGA) number must be issued by Marshall Air Systems, Inc. Unauthorized returns will

not be processed.

Option #1: Purchaser to return part(s) prepaid to Factory, Marshall to repair or replace at own

expense if defective, and ship part(s) back to Purchaser prepaid.

Option #2: Marshall to furnish replacement part(s) freight prepaid with or without requesting return

of the defective part(s).

Option #3: Purchaser may obtain replacement part(s) from recognized service agency.

II. NON-WARRANTY RETURNS:

All items returned for customer cancellations are subject to a 20% restocking fee. In the event of an

error by Marshall Air Systems, Inc., a Returned Goods Authorization will be issued for full credit.

Custom fabricated parts are not returnable.

FOR INTERNATIONAL INSTALLATIONS - PLEASE CONTACT YOUR LOCAL MARSHALL AIR

SYSTEMS RECOGNIZED DISTRIBUTOR.

130522BZ6 RV092899

Copyright ©1999 Marshall Air Systems, Inc.

All Rights Reserved

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Loading...

Loading...