Page 1

OWNER'S MANUAL

Important: Keep in safe, easy-to-find location.

TM

Autobroil

Model 713BG

Marshall Air Systems, Inc.

419 Peachtree Drive South

Charlotte, North Carolina USA 28217

704-525-6230

704-525-6229 FAX

Sales and Service

1-800-722-3474

Page 2

Page 3

OWNER’S MANUAL

quip

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

INSTRUCTIONS TO PURCHASER:

1. ANSI Z83.11 STANDARDS REQUIRE THAT YOU POST IN A

PROMINENT LOCATION THE PROCEDURES TO FOLLOW IN THE

EVENT THE USER SMELLS GAS. THIS INFORMATION SHALL BE

OBTAINED FROM THE LOCAL GAS SUPPLIER.

2. KEEP THIS MANUAL IN A SAFE PLACE AND RETAIN FOR FUTURE

REFERENCE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE

AVERTISSEMENT

AVERTISSEMENT

Ne pas entreposer ni utiliser de l’essence ni d’autres vapeurs ou liquids inflammables dans le

Ne pas entreposer ni utiliser de l'essence ni d'autres vapeurs ou liquides inflammables dans le voisinage

voisinage de cet appareil, ni de tout autre appareil.

de cet appareil, ni de tout autre appareil.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATION AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

FOR YOUR SAFETY

AVERTISSEMENT: Une installation, un ajustement, une aleration,un service ou un entretien

non conforme aux norms peut casuer des dommages a la propriete, de blessures ou la mort.

Lisez attentivement les directives d’installation et d’operation et d’entretien avant de faire

l’installation ou l’entretien de cet e’

ement

Broiler area must be kept free of combustible materials, and the flow of combustion and

ventilation air must not be obstructed. Operating personnel must not perform any maintenance

or repair functions. Contact your Qualified Service Company.

146267 RV050911

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

Page 4

Page 5

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

TABLE OF CONTENTS

I. BROILER SETTINGS (Quick Reference)............................................................................................. 1

II. BROILER INSTALLATION.................................................................................................................... 2

Pre-Installation ...................................................................................................................................... 2

Broiler Location .................................................................................................................................. 2-3

Electrical Information............................................................................................................................. 3

Gas Piping To Broiler.........................................................................................................................3-4

Pre-Operation Check..........................................................................................................................4-5

Performance Criteria..........................................................................................................................5-6

III. OPERATING INSTRUCTIONS............................................................................................................. 6

Broiler Adjustment-Daily..................................................................................................................... 6-7

Operation of 6-Button Control .......................................................................................................... 7-14

IV. SCHEDULED MAINTENANCE...........................................................................................................14

Cleaning During Operation.................................................................................................................. 14

Daily Cleaning Procedures.............................................................................................................14-16

Weekly Cleaning Procedures.........................................................................................................16-17

Monthly Cleaning Procedures............................................................................................................. 17

Quarterly Cleaning Procedures and Preventive Maintenance ....................................................... 17-18

Biannual Preventive Maintenance....................................................................................................... 18

Annual Preventive Maintenance.....................................................................................................18-19

V. MOTOR SPEED BOARDS .................................................................................................................19

VI. TROUBLESHOOTING...................................................................................................................19-25

VII. INSTRUCTION SHEET FOR CHARcat™ CATALYTIC CONVERTER............................................. 25

Pre-Installation .................................................................................................................................... 25

Installation........................................................................................................................................... 26

Operation............................................................................................................................................. 26

Cleaning.............................................................................................................................................. 26

VIII. REPLACEMENT PARTS............................................................................................................. 27–30

Warranty

ILLUSTRATIONS

Dimensional Drawing ................................................................................................................ Figure 1

External Removable Parts..........................................................................................................Figure 2

Internal Removable Parts...........................................................................................................Figure 3

Drive Assembly .......................................................................................................................... Figure 4

146267 RV050911

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

Page 6

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

Top Burner Assembly................................................................................................................. Figure 5

Hot Surface Pilot System ....................................................................................................... Figure 6, 7

6-Button Control User Interface.................................................................................................. Figure 8

Gas Distribution DB9L................................................................................................................ Figure 9

Loader Assembly ..................................................................................................................... Figure 10

Conveyor Re-tension Adjustment……………………………………………………………………Figure 11

Catalyst Equipped Model 2424G (DB9A)................................................................................. Figure 12

Gas Distribution DB9R ............................................................................................................. Figure 13

Removal of Drive Shaft Assembly for Cleaning ....................................................................... Figure 14

Daily/Weekly Cleaning Instructions .......................................................................................... Figure 15

Spare Parts Kit ......................................................................................................................... Figure 16

Regional Spare Parts Kit.......................................................................................................... Figure 17

Kit, 713BG, CM24 Preventative Maintenance................................................................... Dwg #149268

Control Panel Quick Guide............................................................................................... Dwg # 146269

WIRING SCHEMATICS

Wiring Schematic (713BG, 120V, 1Ph, 60Hz, 6-Button Control)(DB9)............................. Dwg #146203

146267 RV021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

Page 7

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

I. BROILER SETTINGS

MODEL:_______________________________________________________________________________

SERIAL NUMBER: ___________________________________________________________________

TYPE OF GAS: ___________________________________________________________________

ELECTRICAL SUPPLY: ______120 VOLT

SCHEMATIC NUMBER___________________ REV. _________

GAS PRESSURE SETTINGS : _SEE PAGE 5_

GAS PRESSURE UPPER BURNERS___________

GAS PRESSURE LOWER BURNERS:

MIN ___________ MAX __

MENU SETTINGS: GAS BROILER

GLOBAL TEMPERATURE

RECIPE BUTTON SPEED

1 __________ _________

2 __________

3 __________

4 __________

5 __________

6 __________

MARSHALL AIR SYTEMS REPRESENTATIVE CONTACT: 1-800 722-3474 _________________________

START-UP TECHNICIAN: ______________________ SERVICE AGENCY: _________________________

ADDRESS: __________________________________ CITY/STATE: __________________ ZIP: ________

TELEPHONE: ___________________ PAGER: ____________________ FAX: ______________________

START-UP DATE: ___________________________________________________________________

COMMENTS: ___________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________

AUTOBROIL™

_____________________________________________________

_________

146267 RV021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

1

Page 8

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

II. BROILER INSTALLATION

PRE-INSTALLATION

1. After uncrating the Autobroil™ (broiler), inspect for shipping damage. Check that all control knobs

are intact on the electrical cabinet front. Set the broiler in place and leave the plastic wrapping on to

protect it from the debris and trash of building construction. DO NOT remove plug from gas inlet

pipe. Check that broiler has not been dented or damaged by the carrier. To file a concealed damage

claim, follow the instructions attached to the outside of the shipping crate. Warranty does not cover

freight damage.

2. Installation must be performed by a Qualified Service Company

Company" means any individual, firm, corporation or company which is either engaged in and is

responsible for the installation or replacement of gas piping on the outlet side of the meter, or the

service regulator when a meter is not provided, or the connection, installation or repair of gas

appliances, who is experienced in such work, familiar with all precautions required, and has complied

with all the requirements of the authority having jurisdiction.

3. A remote gas shut-off valve must be provided and interlocked to the exhaust fire protection system.

4. This broiler is power fan exhausted, therefore it is necessary to provide adequate make up air equal

to the amount removed. In addition, any other exhausts, flues, or air removal systems must be taken

into consideration. Examples of this are heat removal fans or hot water heater flues.

5. The broiler must be isolated from the gas supply piping system during any pressure testing of the gas

supply piping system at test pressures equal to or less than ½ psig (3.45kPa).

BROILER LOCATION

WARNING: IF NOT INSTALLED, OPERATED AND MAINTAINED IN ACCORDANCE WITH THE

MANUFACTURER'S INSTRUCTIONS, THIS PRODUCT COULD EXPOSE YOU TO SUBSTANCES

IN FUEL OR FROM FUEL COMBUSTION WHICH CAN CAUSE DEATH OR SERIOUS ILLNESS

AND WHICH ARE KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH

DEFECTS OR OTHER REPRODUCTIVE HARM.

1. Position broiler to properly align with exhaust hood (refer to equipment plan). Note nameplate

clearance. The AutoBroil™ is shipped in either a Left to Right or Right to Left configuration based

upon customer designation and if needed can be converted to be opposite configuration. See Figure

8 for details. Attention should be paid to the location of a/c registers and hood makeup air. If air from

either blows into broiler area, cooking and broiler performance will be affected.

2. The exhaust hood/ventilator for the broiler should be located in accordance with the National Fire

Protection Association Standard #96, "Removal of Smoke and Grease-Laden Vapors from

Commercial Cooking Equipment" and any local applicable requirements.

3. For proper installation, the minimum clearance from combustible construction is 0" from sides and 18"

from food loading end and food delivery end.

4. Make sure broiler is level. The grease drainage and collection system may not function if broiler is

not level.

. The term "Qualified Service

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

2

Page 9

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

5. Adequate clearance should be maintained to allow easy access to loading and unloading areas of the

broiler.

6. For servicing, broiler must be moved two feet clear from all surrounding equipment.

CAUTION: KEEP THE BROILER AREA FREE AND CLEAR FROM COMBUSTIBLES.

ELECTRICAL INFORMATION

1. The broiler is furnished with a cord and plug. The broiler requires a 120 Volt A.C., 60 Hz, Single

Phase, 3 wire (including ground), 20 AMP circuit. Broiler must be electrically grounded in accordance

with local codes, or in the absence of local codes, with the National Electrical code ANSI/NFPA No.

70-latest edition.

2. There is a Wiring Diagram located in the Owner's Manual and inside the control cabinet.

WARNING: THIS BROILER IS NOT CAPABLE OF BEING SAFELY PLACED INTO

OPERATION DURING A POWER FAILURE AND NO ATTEMPT TO OPERATE

IT SHOULD BE MADE.

GAS PIPING TO BROILER

1. Installation of this broiler must conform with local codes, or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z-223.1-latest edition.

2. In Canada, this broiler is to be installed in accordance with Standard CGA B149.1 or B149.2

Installation Codes for gas burning appliances and equipment and any local applicable requirements.

3. The broiler is supplied with a 3/4" female pipe thread. The installer must make the pipe connection to

the broiler in accordance with the "National Fuel Gas Code," ANSI Z-223.1-latest edition. The gas

line connected to the 3/4" female pipe thread cannot be less than a 3/4" pipe. The gas pressure and

gas volume required by this broiler is shown on Page 5. Gas piping from source to broiler must be

adequate to satisfy these requirements when all other gas appliances in the restaurant are operating

at maximum demand.

4. A flexible AGA approved gas line is available (#500174 36” flex gas line with restraint). Instructions

are:

(1) The installation shall be made with a connector that complies with the Standard for

Connectors for Movable Gas Appliances, ANSI Z21.699-latest edition, and Addenda

Z21.69a-latest edition, and a quick-disconnect device that complies with the Standard for

Quick-Disconnect Devices for Use With Gas Fuel, ANSI Z21.41-latest edition, and Addenda,

Z21.41a-latest edition and Z21.41b-latest edition and Z21.41b-latest edition.

(2) Adequate means must be provided to limit the movement of the broiler without depending on

the connector and the quick-disconnect device or its associated piping to limit the broiler

movement.

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

3

Page 10

OWNER’S MANUAL

p

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

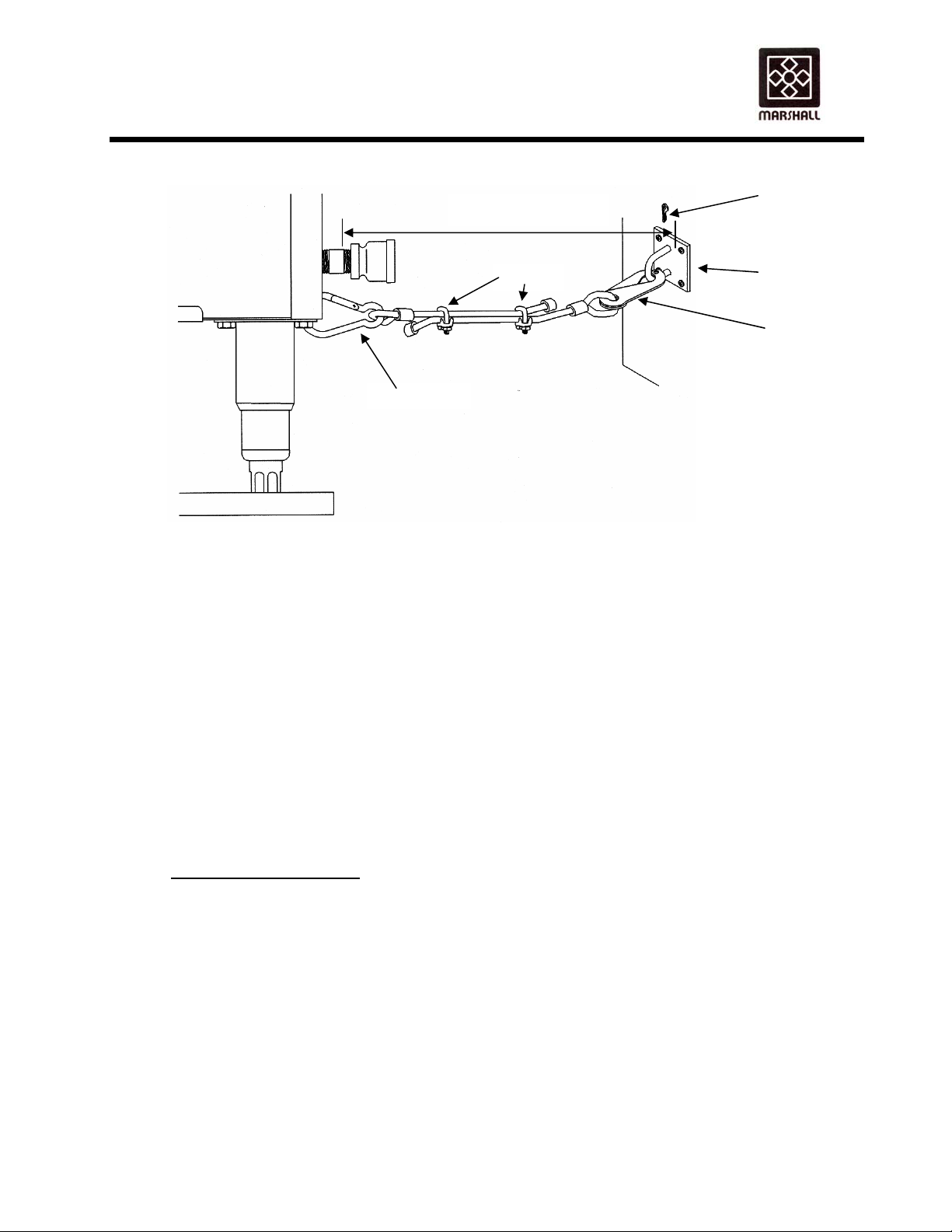

Overall Length

Cotter Pin

Clam

Spring Hook

Optional restraining device is available.

(3) The restraining device must always be connected when the broiler is in operation.

Disconnect for movement necessary for service and cleaning. Then reconnect the restraint

when the broiler has been returned to its normal position.

(4) The restraining device is a separate line and should be no less than 6 inches away from the

gas connector. It should also be in a parallel position to the floor. Using the adjustable

clamps, alter the length of the cable so that the overall length is 3 to 6 inches shorter than the

length of the gas connector including the fittings. Attach the wall bracket to an existing wall

or other architecturally sound surface. Attach scissor hook to the wall bracket and secure

with cotter pin. Finally, attach the spring hook to the gas broiler. Make certain that the

overall length of the line is 3 to 6 inches shorter then the gas connector at this point.

5. See Page 2,Pre-Installation Item 5 for instructions on gas supply line pressure testing.

CAUTION: DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND VENTILATION AIR.

PRE-OPERATION CHECK

Before lighting and operating your broiler, perform a check of critical items as follows:

1. Remove both side panels and check to see that all parts are in place and that none are

damaged. Particularly make sure all burners are in place and that the shields are in position on the

bottom burners.

IMPROPER INSTALLATION OF BURNERS CAN CAUSE FLAME / HEAT DAMAGE TO

COMPONENTS OR WIRING, FOR EXAMPLE THE PILOT WIRES.

2. Start conveyor chains and check for binding. The conveyor chains should run free and not be

catching on any parts.

Wall Bracket

Scissor Hook

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

4

Page 11

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

3. The speed of the conveyor chains should be changed from slow to fast, and back again without the

chain stopping.

4. Before first use, and after any special cleaning, it is necessary to "season" the broiler chain. This is

done by bringing the broiler to operating temperature and then (with burners still lit) applying liquid or

solid shortening from a saturated cloth over the full width of the broiler chain while the chain makes 5

or 6 complete revolutions.

5. Check that gas pressure at broiler gauges is correct (see Performance Criteria shown in chart below).

6. Check that broiler grease tray is in place under burners (see Figure 3).

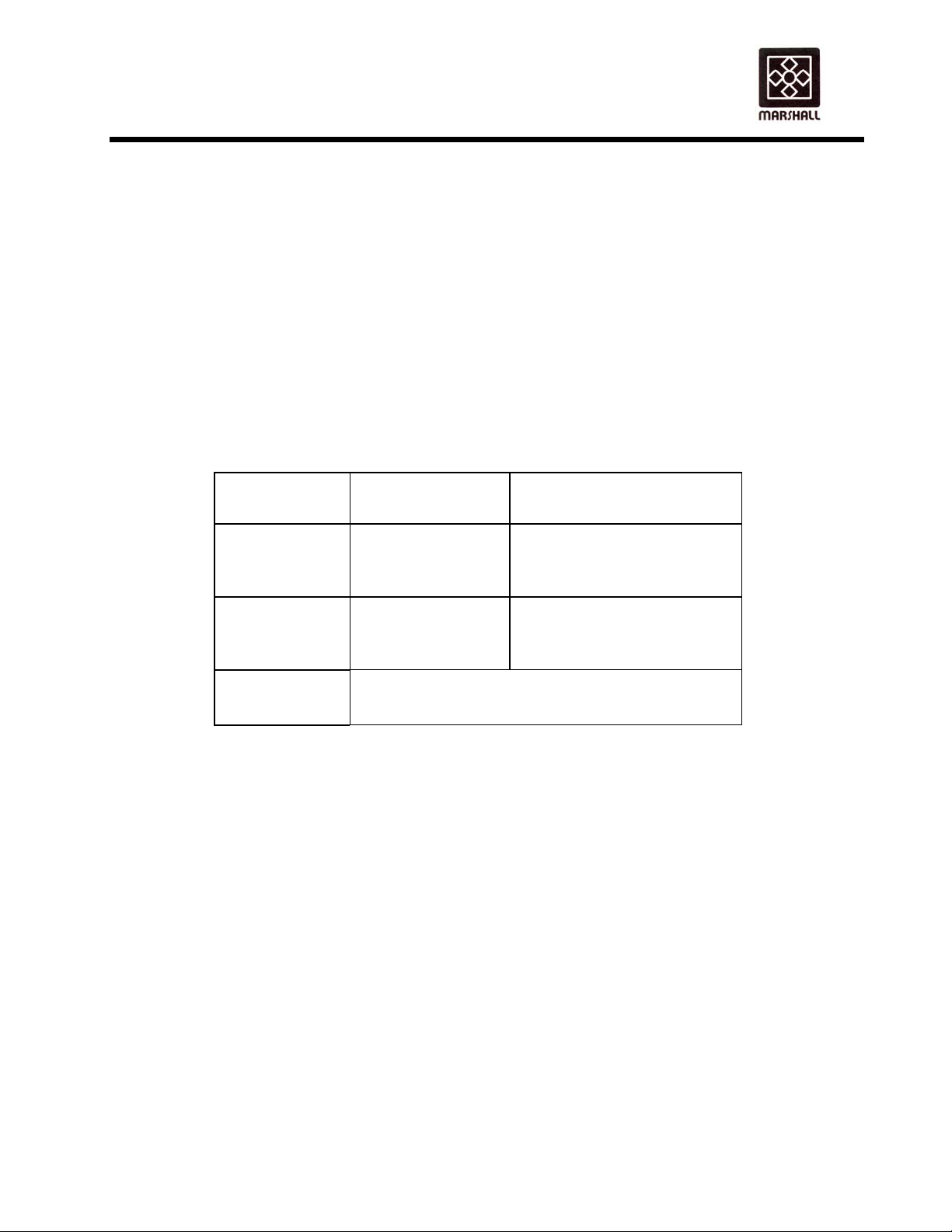

PERFORMANCE CRITERIA

1. The manifold pressure for each burner and broiler inlet pressure and gas amount is listed below:

Lower burner manifold pressure is measured by a pressure gauge attached to the lower manifold.

With the broiler temperature set to 1000°F the high fire pressure is 5.0 IWC for Natural Gas or 9.0

IWC for LP Gas. High pressure is adjusted using the regulator in the top of the lower burners’ safety

gas valve. Low fire is adjusted using the modulating gas valve. See Figure 9 (DB9L) or Figure 13

(DB9R) for gas system layout. Reset the temperature to 830°F (443°C). Once the broiler reaches

830°F, the gas pressure is varied by the modulating valve to maintain 830°F. (NOTE: Broilers with

catalysts the temperature is set at 960°F.)

To check low pressure, set the temperature to 400°F and the modulating gas valve will drop the lower

burner gas pressure to 1.0 IWC for Natural Gas or 5.4 IWC for LP Gas in an effort to get down to

400°F. Adjust this pressure using the screw located under the plastic cap on the side of the

modulating valve. Figure 9 or 13 . With high and low pressures checked and set, reset the

temperature to 830°F (443°C) which is the correct cooking temperature.

2. The upper burners in the broiler operate at a fixed pressure and are a special infrared type. All of the

air for combustion must be injected through the venturis. This makes orifice design and alignment

very critical. The orifice design, in combination with the correct natural or propane gas pressure will

result in adequate air aspiration and mixing. There are no air shutters. No air adjustment is needed.

TYPE OF GAS:

Natural

LP

Total Gas

Amount

PRESSURE AT

THE BROILER

6.0 - 10.0 IWC

11.0 - 14.0 IWC

146,000 BTUH @ 100 % HIGH FIRE

MANIFOLD PRESSURE

Upper Burners 3.5 IWC

Lower Burners 1.0 IWC to

High 5.0 IWC

Upper Burners 6.4 IWC

Lower Burners 5.4 IWC to

High 9.0 IWC

98,000 BTUH @ IDLE

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

5

Page 12

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

CAUTION: DO NOT STACK BOXES OR IN ANY WAY BLOCK AREA IN IMMEDIATE

VICINITY OF VENTURIS OR IN ANY OTHER WAY OBSTRUCT FLOW OF

COMBUSTION AIR.

3. The flame rod igniter flame is adjustable with a small screwdriver. The cap screw behind the 1/4" gas

line exiting the valve should be removed. The small adjusting screw is under the cap screw. Turning

the small adjusting screw inward (clockwise) will reduce the flame to the igniter. The igniter flame

should be uniform and just large enough to make a flame envelope around the end of the sensor and

igniter.

4. The upper burners will be bright orange when burning properly. If a dull red is observed after 30

minutes of warm-up with a blue flame below the burner face, the orifice may be dirty, damaged, or

misaligned. "Popping," or burning back at the orifice of the burner, is a result of the burner screen

being loose or a faulty gasket under the burner screen. LP broilers may exhibit a light "popping"

sound when the broiler is turned off; this is normal. The lower burners are of a conventional blue

flame type.

NOTE: IF BURNER SCREEN IS TORN OR HAS A HOLE, OR IF A GASKET IS LEAKING,

THE BURNER MUST BE REPAIRED (See Figure 5).

III. OPERATING INSTRUCTIONS

BROILER ADJUSTMENT - DAILY

LIGHTING INSTRUCTIONS FOR ELECTRONIC IGNITION SYSTEM

1. Turn exhaust system on. (Some hoods are so powerful that the broiler must be lit before the exhaust

is turned on).

2. Make sure filters are in place in the hood.

3. Turn broiler on by pressing the On/Off button.

4. The upper burners light first followed by the lower burners 3 minutes later.

5. Verify all of the burners have ignited. Ignition is electronic.

6. If pilot flame or burners fail to light, press the On/Off button for 3 seconds and wait five minutes

before attempting to relight.

7. Allow the broiler burners and conveyor chain to warm up until the control displays “Ready” (with the

chain at approximately the correct speed).

8. Place one meat patty on the broiler chain. Based on the appearance of the broiled patty, reset the

cook time for the desired broiling quality. (Note: this single patty should be cooked to the maximum

degree of the Minimum/Maximum doneness tolerance.)

MANUAL LIGHTING INSTRUCTIONS

1. Remove manifold side cover.

2. Press the On/Off button and hold a flame up to the upper burner igniter.

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

6

Page 13

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

3. Once upper pilot has lit, wait 3 minutes and hold a flame to the lower burner igniter.

This procedure is in case the ignition surface part of the igniter (See Figures 9 & 13) were to break.

If the flame sensor part of the igniter (see Figures 9 & 13) were to break, the igniter must be replaced

immediately.

SHUT-OFF INSTRUCTIONS

1. Press the On/Off button for 3 seconds.

2. The control will display Hot and the conveyors will stop running in approximately 10 minutes.

WARNING: If the cool down waiting period is not observed, the conveyor chain may warp.

3. Turn exhaust system off.

NOTE: Note the gas control knob/slide switch on top of each safety gas valve is "ON". All safety gas

valves with a slide switch will have a clear sealant over the switch and connectors. The sealant

is to help keep water out of the valve. The switch will always be sealed in the “on” position.

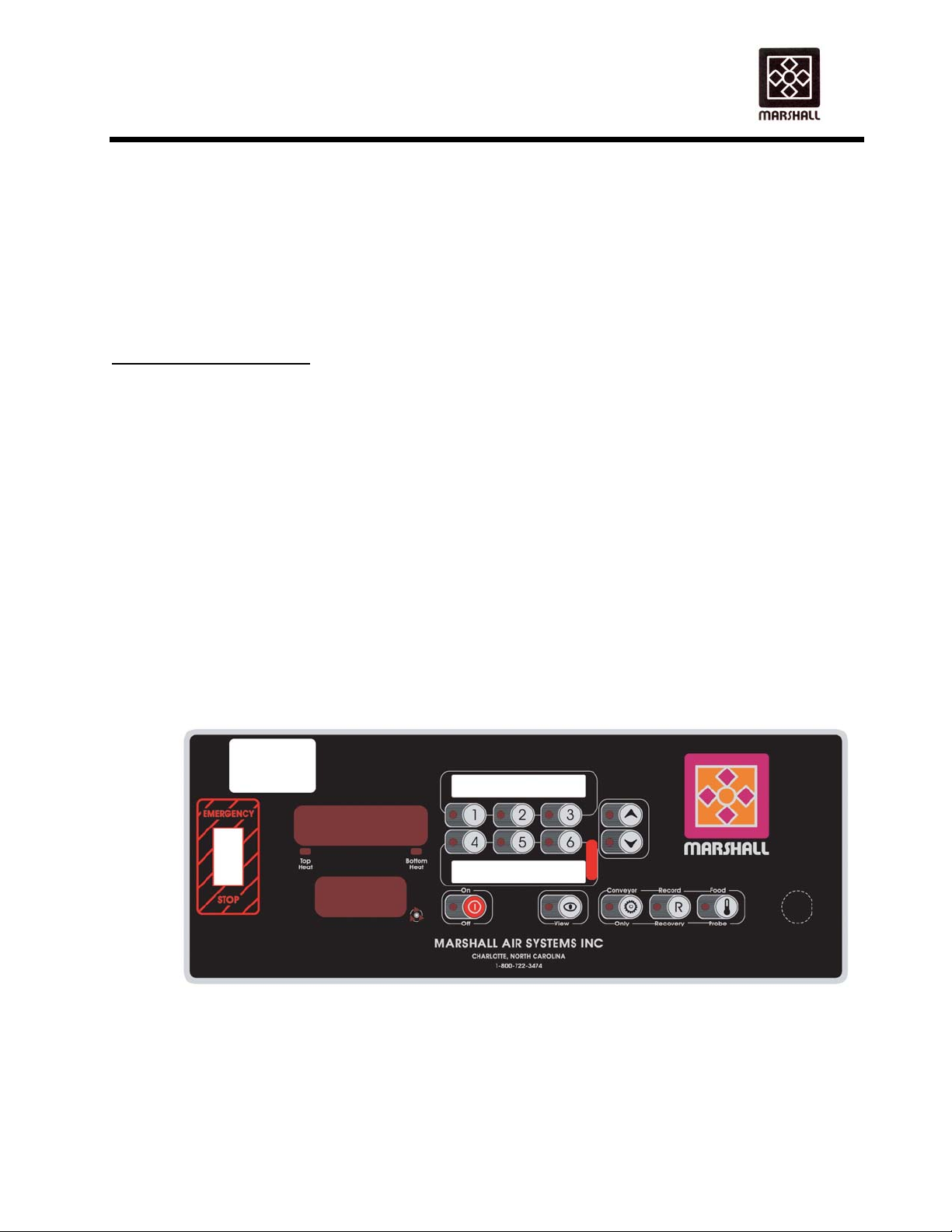

OPERATION OF 6-BUTTON CONTROL

1. USER INTERFACE

The following is the user interface layout.

The Control Panel illustration above shows a typical control interface layout. See Figure 8 for a

description of the buttons. You can also refer to the Control Panel Quick Guide at the end of this

manual.

TIME AND DATE SETUP

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

7

Page 14

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

When the controller is in Off mode, the system Time and Date can be adjusted by pressing the Off

Button for 10 seconds. The time is displayed on the 1

Down Buttons, the hours are changed. Pressing the View Button moves the “focus” to the MM. Use

the Up/Down Buttons to adjust. By pressing View Button again, HH:MM are replaced by DD/MM (or

MM/DD, depending on setting of temperature units) (1

travel from one setting to another, and use the Up/Down Buttons to modify. The View Button will

return to HH:MM. Pressing the Off Button again stores the new Time and Date, and returns to Off

mode.

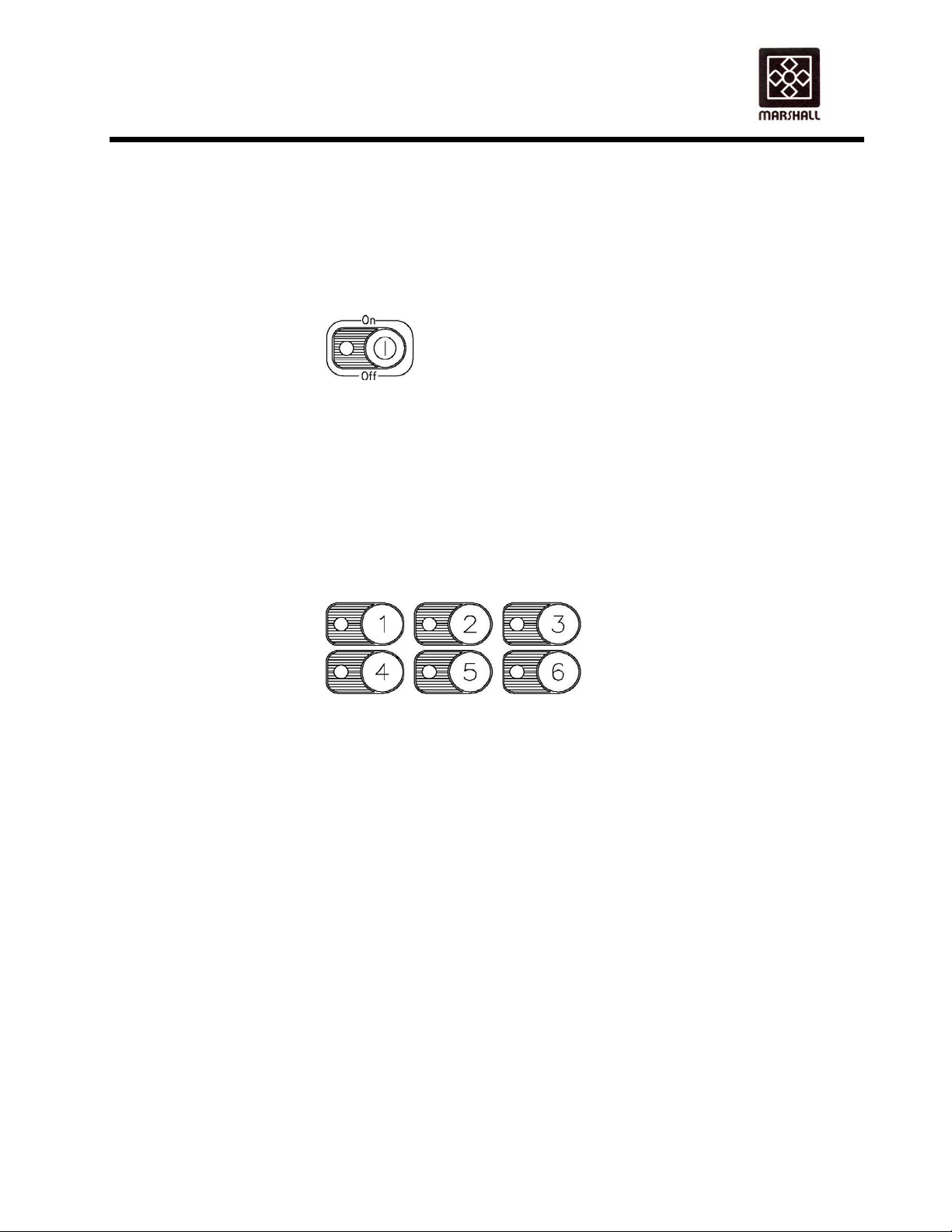

ON/OFF BUTTONS

A normal press of this button turns on the controller. This causes the broiler to start running the

motors at the slowest recipe speed found (overcooked food is safer than undercooked food). This

button also starts the gas ignition system and the burners should light. This recipe is selected (its

corresponding LED lights up) and the temperature set point is the one defined by this same recipe.

At any time in On mode, the user can change the selected recipe. When just turned On, the broiler

will scroll PREHEAT on the 1

st

line until the Soak Time has elapsed. After this time, broiler will display

either READY, LOW or HIGH, depending on the current temperature readings.

A 3-second long press of the On/Off button turns off the broiler. The 1st line will then blink HOT for

the Cool Down period (burners off, but the motors are still running, one at the fastest speed

supported by the broiler, one at the slowest speed supported by the broiler). At that point, the broiler

will then simply display OFF, and all outputs will be disabled.

RECIPE BUTTONS

Recipes, there are 6 of them, are defined by a time and a temperature. The time basically sets the

conveyor speed. All 6 recipes control the conveyor speed. The top three (3) recipe buttons are for

the left conveyor belt and the bottom three (3) buttons are for the right conveyor belt.

When the broiler is READY, a simple press of the recipe button will activate the selected recipe

speed and temperature (LOW and HIGH conditions may or may not be triggered).

When a specific recipe must be changed, keep its button pressed for 3 seconds, until the 1

parameter name scrolls on the 1

will also blink, indicating that they can be used. Pressing either Up or Down the 1

makes the display switch to the parameter’s value (preceded by an arrow, as in ►4.25, to indicate a

changeable value). Subsequent presses will then modify the parameter. If Up or Down are not

pressed for 5 seconds, the display resumes scrolling the parameter name.

Each recipe has 2 programmable parameters. To switch from one to the next, press the recipe

button. After the last parameter is programmed, the broiler resumes normal operation.

- SET COOK TIME,

- SET GAS TEMPERATURE.

Model 713BG Model 2424G

Factory Set Cook time: Button 1-3 =3:20, Factory Set: Button 1=3:15,

st

line SET COOK TIME. The recipe as well as the Up/Down LED’s

st

line, and the HH is blinking. Using the Up and

st

line) and YY (2nd line). Use the View Button to

st

st

time simply

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

8

Page 15

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

4-6 = 3:40 2=3:25,3=3:35,4=4:00,5=4:10,

Factory Set gas temperature: 830°F NAT 6=4:30

800°F LP Factory set gas temperature: 960°F

VIEW BUTTON

The View button allows a user to view actual or programmed system parameters. Changes cannot be

made just by using this button.

A simple press of the View button allows the user to see the current broiler temperatures and

conveyor speeds (when not in OFF.) Press the View button to scroll through the available viewable

parameters ( COOKTIME, GAS TEMPERATURE ) When the wanted parameter is displayed, the Up

button is used to toggle between the parameter name and current value. The Down arrow switches

between the current top and bottom recipe speeds (corresponding recipe LED lights up) Pressing the

View button one more time when the last parameter is displayed resumes normal operation. If the

broiler is in OFF mode, then cook times are not displayed. When they are displayed, they are shown

on the 2

Simply pressing the View button shows the current broiler parameters. However, if the View button is

pressed for 3 or more seconds, then the user may view (again, not change) the current recipe

programs. After the View button is pressed for 3 seconds, all recipe LEDs start flashing.

The user then selects the recipe they want to view. COOK TIME is the 1

followed by GAS TEMPERATURE.

Use the selected Recipe button to travel through the parameters. Again, the Up button is used

to see the parameter value. Keep in mind that these are actual recipe programs, and not

current broiler parameters. The blinking recipe LED indicates this. Also, there are no conveyor

speeds displayed on the 2

the broiler resumes normal operation.

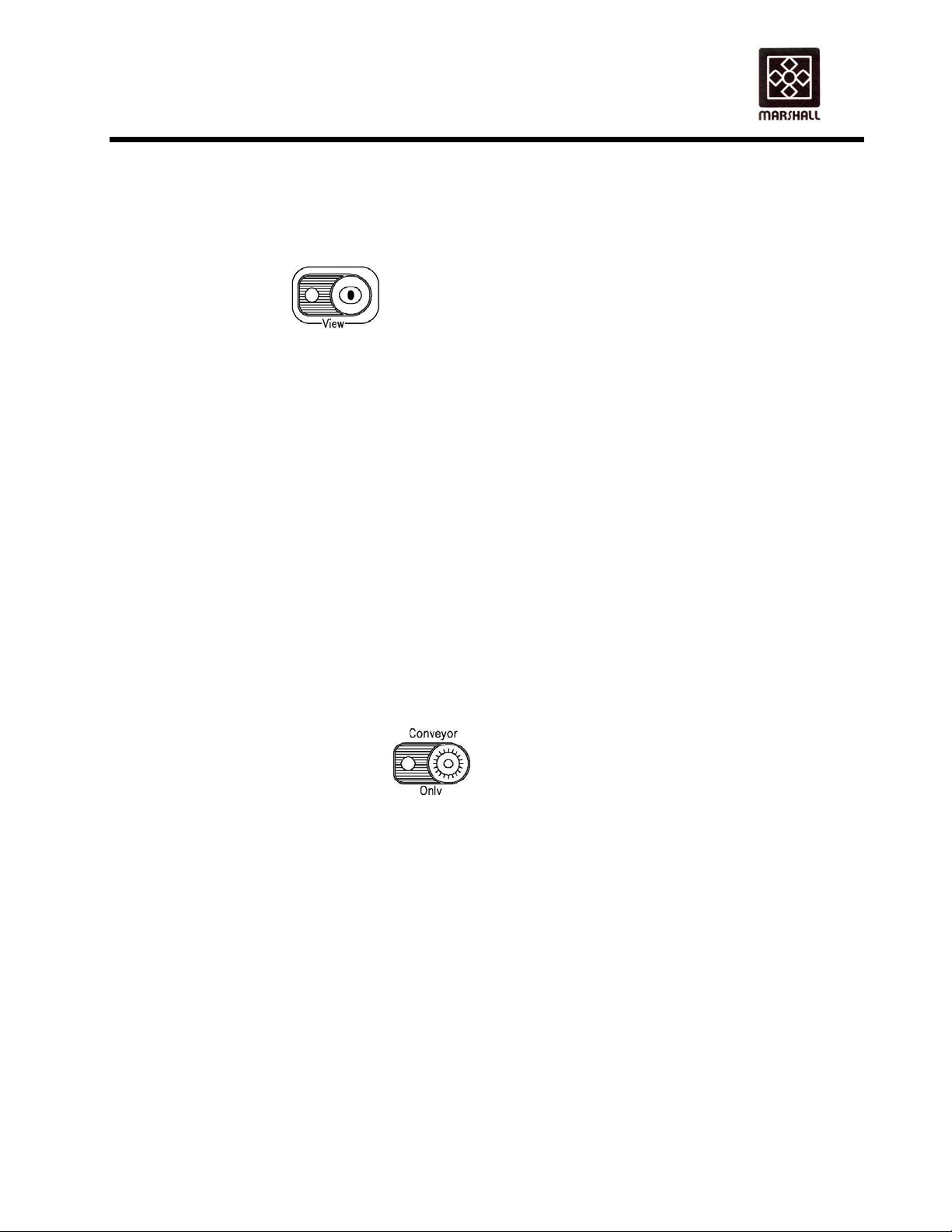

CONVEYOR ONLY BUTTON

The Conveyor Only mode allows the broiler user to run the conveyors without heating. This may be

for servicing purposes (such as finding the open link on the conveyor). This mode is accessible only

from the OFF mode. Upon power on of broiler (initialization), the display flashes the software revision

number for example 1.15,1.16 or 1.17. This revision must be known to determine the correct

operation of the Conveyor Only button.

Broilers with release 1.15 - When pressed,SPEED is displayed on the 1

the left belt will turn at 1 minute cook speed. Also the LED for recipe 1 will illuminate. Press VIEW

button 2 more times the right belt will turn at 1 minute. Cook speed and the LED for recipe 4 will

illuminate.

Continuing to press the VIEW button will cycle between the Left and Right belt. The Up/Down

buttons are used to change motor speeds. As soon as the Conveyor Only button is pressed

again, the conveyors stop and the broiler resumes OFF mode

Broilers with release 1.16 - When pressed,SPEED is displayed on the 1

minute cook speed. Also the UP/DOWN LED’s will flash as well as the VIEW LED.

nd

line.

st

parameter viewed,

nd

line in this view mode. As before, once the last parameter is displayed,

st

line. Press the VIEW and

st

line. Both belts turn at 1

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

9

Page 16

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

Continuing to press the VIEW button will cycle between the Left and Right belt. The Up/Down

buttons are used to change motor speeds. As soon as the Conveyor Only button is pressed

again, the conveyors stop and the broiler resumes OFF mode

Broilers with release 1.17 & 2.0- When pressed speed is displayed on the 1

1 minute cook speed. Also the Up/Down & View LED’S will flash.

Pressing the view button once, The LED for Recipe 1 will illuminate. The Left belt motor RPM will be

displayed on the 1

nd

the 2

line. Pressing the view button a second time will display the PWM full scale in the 1st line and

the RPM on the 2

will illuminate, The right belt RPM will be displayed on the 1

scale (17.8=1780) will be displayed on the 2

PWM in full scale will be displayed on the 1

st

line and the Left belt PWM in hundreds scale (17.8=1780) will be displayed on

nd

line for the left motor. A third press of the view button and the LED for Recipe 4

nd

line. A fourth press of the view button the right belt

st

line and the motor RPM will be displayed on the 2nd line.

st

line and the right belt PWM In hundreds

Pressing the view button a fifth time the speed is again displayed on the 1

buttons are illuminated. Any further pressing of the view button will continue this cycle. Pressing the

Up/Down buttons while in any of the Four view modes will increase or decrease the motor RPM for

that belt.

As soon as the conveyor only button is pressed again the conveyor stops and the broiler resumes

OFF mode.

RECORD/RECOVERY BUTTON

This button is available anytime. When pressed, the controller will list a log of the last 3 recovery

times.

A recovery time is the time required for the temperature to go from 200°F to 50°F below factory

set gas temp. This is useful for service and HACCP purposes.

When the Recovery Button is pressed, the controller will successively display GAS1, GAS2 and

GAS3 ramp times, “1” being the most recent ramp logged. To actually see logged time, press the

Up button.

FOOD PROBE BUTTON

This button is useable only when the broiler is On . It is accessible in 2 modes: automatic or manual.

In manual mode, it is up to the user to press the Food Probe button to initiate a log, whereas, the

automatic mode will remind the user (up to 6 times a day) to take a sample. Even in automatic mode,

the user still has the capability to log extra samples manually as he/she wishes.

To do a manual log, the user must first make sure the temperature probe is correctly connected, and

then press the Food Probe Button.

Step #1

This step prepares the controller for logging. It determines the equalization time that will be used

later on in the process.

st

line, Both belts turn at

st

line and no recipe

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

10

Page 17

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

Display: SELECT RECIPE TO LOG is scrolled and recipe LED’s blink.

Sound: None.

User Action: Select the Recipe corresponding to the sample that will be probed.

Step #2

This step starts the logging and gives the user time to set up for the sampling.

Display: Shows INSERT PROBE. Actual temperature can be seen when up button is

pressed. The up button and Record LED’s blink.

Sound: None.

User Action: Insert the Food Probe into the sample according to local sanitary codes and normal

restaurant procedures. Press up button.

Step #3

In this step the temperature continues to be shown to the user. Nothing is being logged yet. The

user must wait until certain temperature is reached (that depends on the specific restaurant

procedures.)

Display: The 1

button LED also blinks.

Sound: None

User Action: Keep Food Probe inserted. When temperature reaches a specific point (known to the

user), the user presses the Record button.

Step #4

In this last step, the actual log is written to memory. The temperature now displayed is logged.

Display: Last temperature read is displayed until Food Probe Button is pressed again. This exits

Food Probe.

Sound: None.

User Action: Remove probe, and press Food Probe Button to resume normal operation.

Data Logged

The following is logged each time a sample is taken (in Step #4):

Date/time stamp (MM/DD/YY if English (degree F), DD/MM/YY if Metric (degree C) as well as

HH:MM)

Recipe number (that was selected by user)

Cook chamber temperature

Food “Start temperature” (when user pressed Record)

Food “End temperature” (when temp was recorded)

NOTE: At the end of Step #4 the user can record another sample of same recipe by pressing Record

again instead of Food Probe, which clears display of previous samples. Display then shows probe’s

current temperature and Steps 3, and 4 are repeated.

UP AND DOWN BUTTONS

These buttons are used to adjust the various system parameters when required. Time is

incremented/decremented at 5-second intervals, and temperature at 5°F (2°C) intervals. These

buttons have a typematic feature associated with them. Keeping them pressed for more than 2

st

line displays the temperature currently measured by the Food Probe. The Record

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

11

Page 18

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

seconds causes the rate of change to accelerate to 25°F/10°C (temperature), or 20 seconds (time)

every 500 msec.

3. DISPLAY

GENERAL

In general, all messages are scrolled on the 1st line (about 2 characters per second), and

times are displayed on the 2

Some buttons have a LED, which is used to indicate various situations.

• On/Off LED: full on when broiler is On, otherwise Off.

• Up/Down LED’s: blink when Up/Down buttons are expected.

• Recipe LED’s: on when a recipe is active, blinking when programming or viewing recipes.

• Conveyor Only: blinking when feature is in use.

• Recovery: full on when feature is in use.

• View: full on when feature is in use.

• Conveyor: this is a group of 3 LED’s that simulate a rotating motion (about 2 changes per

second). This is active whenever the controller is receiving pulses from all installed

tachometers.

• Top and Bottom Heater LED’s: full on when the corresponding heaters are on, otherwise off.

Also, whenever the arrow symbol (X) is displayed with the data, this means that this is a parameter

being changed/adjusted.

TIME DISPLAY

All conveyor speeds are displayed on the 2

displayed as MM.SS, or HH:MM . For example, 9.59 is 9 minutes and 59 seconds, and 1:10 is 1

hour and 10 minutes.

3. SYSTEM STATES

There are several states of operation as follows:

POWER-UP MODE

When a power-up occurs, there is a lamp test, where all LED’s come on for 5 seconds (this includes

all LED’s in the two displays). Following the lamp test, the software number and revision are

displayed. These are useful for troubleshooting purposes when several versions exist in the field.

The first line shows the software number and the second line shows the revision in the format 1.15.

Normally, major release versions will be whole numbers (1.00, 2.00, etc.) and if a fraction occurs,

these are minor release versions.

Following this, the broiler falls automatically into Off mode.

OFF STATE

In this state, the heaters are disabled. Nothing is displayed, except for OFF on the 1

The motors may be used if the Conveyor Only function is used. Also the view and recovery buttons

may be used.

nd

.

nd

line, and are limited to 9.59. All other times are

st

line.

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

12

Page 19

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

ON STATE

This is the normal cooking state. Before displaying READY, the broiler will go through the PREHEAT

mode; The pre-heat mode lasts until the pre-heat Soak Time expires.

In the On mode, 2 extra conditions may exist: LOW and HIGH. Both depend on the current set point,

and the current temperature. If the difference between the set point and the current temperature

exceeds the programmable thresholds, then either the LOW or HIGH messages are displayed. This

warns the user to wait until the READY condition

conveyor. These conditions are likely to occur when a recipe calls for different temperatures.

HOT STATE

This state is active after the broiler is turned Off (or if an error occurs that causes the broiler to shutdown). This state is a cool down step between the On and Off states. The conveyors continue to turn

but the burners are off. The display continuously shows HOT until the Cool Down Time has elapsed,

at which point the OFF message reappears.

4. DIAGNOSTICS

This section describes the various diagnostics errors that are available.

BROILER TEMPERATURE PROBES

comes back before putting product onto the

All probes are type-K probes. All temperature readings normally associated with a type-K probe are

considered valid by the controller. However, if the probes become disconnected or otherwise open,

the controller will sound the buzzer

The defective probe number is displayed on the 2nd line: On the broiler controller, there are two

thermocouples connected together:

• 2 is temperature probes

Pressing any button shuts the buzzer off, but will not remove the error message. The only way to remove

the error message is to resolve the probe and/or connection problem.

and scroll HOT-PROBE ERROR on the 1st line of the display.

When this heater probe errors occurs, the broiler continues operation, at 100% heat. The operator will

most likely then have to adjust the recipe times, but at least the broiler can still operate. Due to

broiler construction, 100% heat for any amount of time is not a problem as the broiler will not “burn” or

otherwise ignite.

EXTERNAL DC ERROR

The DC I/O connector has a +5VDC supply. This supply is internally protected against over-currents.

Should this occur, the broiler will internally disconnect the supply and report HOT-EXTERNAL DC

ERROR. The broiler goes into shutdown (through HOT mode) and the only way to reset this is to

resolve the problem (most likely a short). Since the buzzer is powered through the same +5VDC

supply as the DC I/O connectors, the buzzer does not sound when this error occurs.

After the Cool Down delay, the error message becomes OFF-EXTERNAL DC ERROR instead of

HOT-EXTERNAL DC ERROR.

5. EMERGENCY STOP SWITCH

An emergency stop switch is on the front of the broiler as shown in Figure 8. This switch is for

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

13

Page 20

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

stopping the conveyors and shuts off the gas immediately in case of a conveyor jam or other problem

requiring the broiler to shut down.

Do not use this switch for normal shut downs at the end of the day. Use it if the conveyor jams or you

need to stop the broiler immediately .This switch stops the conveyors and turns off the burners and

turns off power to the control panels. When you turn the Emergency Stop Switch back on, the control

panels will cycle through an initialization, then display OFF. From here you can start as normal.

IV. SCHEDULED MAINTENANCE

CLEANING DURING OPERATION

Grease and Ash removal from Grease Tray.

Use caution when removing the Grease Tray as it will be extremely HOT. DO NOT clean

the Grease Tray in cold water, as cold water will warp the hot Tray. To avoid cooling the

broiler down during cleaning, replace the used Grease Tray with a clean one immediately

after removing the used one. One spare Grease Tray is included with the Broiler.

DAILY CLEANING PROCEDURES

CAUTION: Do not touch the broiler section immediately after broiler shut-down. The temperature

inside enclosures is in excess of 500°F (260°C), which eliminates the need to clean any

parts inside the enclosures for sanitary purposes. Any grease that may build up on the

exterior of the enclosures should be cleaned off with a damp cloth and a minimum

amount of detergent. Never use water on the enclosure or allow burner faces to get

wet as this could cause premature burner or gasket failure. Disconnect the power

supply to the broiler before cleaning or servicing.

CAUTION: UNDER NO CIRCUMSTANCES SHOULD OVEN CLEANER BE USED ON THIS

BROILER. OVEN CLEANER WILL EAT HOLES IN THE ALUMINUM GAS VALVES

AND GAS LINES, CAUSTIC FUMES CAUSE ELECTRICAL COMPONENT DAMAGE,

AND WILL CAUSE MANY OTHER PROBLEMS IF USED TO CLEAN THIS BROILER.

CAUTION: DO NOT ALLOW WATER TO CONTACT THE (3) COOLING FANS. DOING SO MAY

CAUSE THE BROILER TO TRIP THE GROUND FAULT RECEPTACLES AND NOT

OPERATE. PLEASE COVER THE FANS WITH PLASTIC OR OTHER TO PREVENT.

CAUTION: KEEP THE BROILER AREA FREE AND CLEAR FROM COMBUSTIBLES.

1. Allow broiler burners and chain to operate until the control goes from HOT to OFF after cooking last

patty to burn off excess grease on broiler components. (This applies every time a meat chain is

turned off -- regardless of what time of day meat chain is shut down -- and regardless of how few

patties were broiled in the last 30 minutes, last hour, etc.) This will clean some parts of the cooking

chamber. Failure to perform this procedure daily will result in poor cooking times.

2. Turn off broiler, wait 30 minutes and disconnect electricity.

3. Remove all exterior panels except those which are attached with screws. Be careful not to touch

any hot internal broiler components.

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

14

Page 21

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

4. Remove upper burners and reverberators. To remove burners, lift slightly on burner housing and

slide towards the venturi opening in side frame, tilt the burner up and lift out. Shake off all debris.

Hold burners with mesh facing the floor. Brush burner mesh with soft brush. Brush off

reverberators, making sure all debris is removed from all of the openings. Lightly brush out venturi.

DO NOT WASH UPPER BURNERS AS IT WILL DESTROY THE GASKET.

WARNING: THE UPPER BURNER SCREENS (LOCATED UNDER THE TOP BURNERS), ARE MADE

FROM INCONEL METAL MESH. THIS MATERIAL DETERIORATES WITH USE. INSPECT

THESE SCREENS DAILY AND REPLACE IF SCREEN IS SEVERLY CORRODED. FAILURE

TO DO SO CAN RESULT IN METAL PARTICLES BEING SERVED TO YOUR CUSTOMER.

5. Remove lower burners and shields. To remove burners, lift burner positioning end up off of support

and twist burner 90 degrees, tilt burner towards either end of broiler and slide out. Hold burners with

ports facing the floor. Brush burner ports with soft brush. Wash burner shields. Lower burners can

be rinsed.

6. Using a damp cloth, wipe the inside of each burner venturi.

7. Remove the following items and wash with soapy water when they are cool enough to touch with

bare hand. All items can be run through a dish washer.

Cooling Fan Plenum Asby

*

Grease Catch Tray Asby

Grease Pan Asby

*

Product Catch Pan Asby

*

Product Catch Trays

*† Auto Loader Carriage

Entrance Hanging Cover

Hang On Shields (Entrance, Exit)

Loader Arm Cover

Lower Burner Shields (3)

*

Meat Strippers

Shield Entrance, Lower Burner Asby

*

Tunnel Covers (Entrance, Exit)

Tunnel Fillers (2 each)(1Entrance,1Exit)

* NOTE: These items may be removed during the 30 minute cooling period.

† NOTE: Clean items with a green scrub pad.

Figure 3, Item 10

Figure 3, Item 5

Figure 2,Item 9

Figure 2,Item 7

Figure 2, Item 5

Figure 2, Item 1

Figure 2, Item 3

Figure 3, Items 4,6

Figure 2,Item 4

Figure 3,Item 7

Figure 2,Item 6

Figure 3, Item 8

Figure 2 ,Items 2,8

Figure 3,Items 3,11

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

15

Page 22

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

8. Using the conveyor only button on the control which turns the conveyor ON and leaves the heat OFF,

brush the broiler conveyor and, as it cools, wipe with damp cloth.

9. Scrape deposits from the axles with the axle scraping tool, furnished with each machine as shown

below. *THIS IS IMPORTANT TO PREVENT GREASE FIRES AT REAR OF THE BROILER.

Axle Scraper Part Number 100367

The axle scraper provided with the broiler is a handy tool for cleaning the dirt and grime off of the axles. To

insert, place end of scraper in between conveyor and turn scraper as shown in the illustration. Scrape the

axle back and forth. One end of the scraper is made to scrape a ¾” diameter shaft. The other end of the

scraper is made to scrape a 1 1/16” diameter shaft.

10. Remove grease and meat residue from any part of remaining broiler structure where visible. Use a

damp cloth with detergent and a putty knife for best results.

11. After cleaning all removable parts as noted, allow to dry and reassemble.

WEEKLY CLEANING PROCEDURES

1. Perform daily cleaning procedures.

2. Inspect igniters for ash and debris buildup (Figure 9, Item 5).

3. Using a small wire brush or sand paper, lightly clean sensor rod and inside of hood only. Use caution

the sensor rod and glow plug will break easily!

4. Blow loose debris from igniter area.

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

16

Page 23

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

5. If sensor rod or glow plug does break, the igniter must be replaced. Attempt to light manually, then

call service agency.

6. Using a small wire brush and some pressure, brush clean the upper and lower flame runners (Figure

9, Items 2 and 3).

7. Make sure that when cleaning the small ports on the flame runners that all are cleared of any debris

buildup.

8. Remove any loose debris from flame runner area.

9. Remove conveyor and soak in hot soapy water overnight. To remove conveyor, lift front axle up to

produce slack in the conveyor and separate conveyor at the open link. Using the conveyor only

button may be required to locate the open link. If necessary open link with chain pliers (part #500033)

to separate conveyor. When replacing the conveyor, make certain the conveyor is installed properly.

Make reference to the orientation of the conveyor links and the conveyor direction before

reassembly. See Figure 11. PLACING CONVEYOR ON BACKWARD WILL CAUSE SEVERE

BINDING PROBLEMS. CLOSE all open links with pliers to match other links.

10. Remove the Drive Shaft Assembly and clean. (See Figure 14)

11. Clean gas orifices:

a) Orifices are passageways directing gas flow into burners. Uneven gas flow or poor air to gas

ratio is caused by dirty or damaged orifices.

b) Orifices are made of brass. Use special care in cleaning--don't gouge or make gas holes

bigger.

c) To reach orifices, remove burners.

d) Use a chenille stem (similar to a pipe cleaner) or small orifice brush dipped in rubbing alcohol

to clean orifices. Swab until clean; free of carbon build-up. Do not use drill bit; this will

damage the orifices. Chenille stems are available in the craft section of your local

department store or craft store.

MONTHLY CLEANING PROCEDURES

1. Turn off broiler, wait 30 minutes and disconnect electricity.

2. Perform daily & weekly cleaning procedures.

3. Remove roller (drive) chain covers on each side of broiler at exit end. Clean any grease

accumulations.

QUARTERLY CLEANING PROCEDURES & PREVENTIVE MAINTENANCE

1. Perform daily, weekly, and monthly cleaning procedures.

2. Lubricate the roller (drive) chain with a few drops of any grade motor or machine oil.

3. Remove and inspect all motor brushes and replace if less than 1/4" is left.

4. Do not remove internal gas lines for cleaning.

5. Blow out all six (6) burners through the venturi opening with a low

pressure air source.

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

17

Page 24

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

CAUTION: Do not drop burners or get wet the upper burners as this may add to premature

burner failure.

6. Re-tension Conveyor. Refer to Figure 11 for instructions.

7. INVENTORY THE SPARE PARTS KIT AND ORDER MISSING PARTS AS NEEDED. KEEP A

COMPLETE SET OF PARTS ON HAND AT ALL TIMES.

BIANNUAL PREVENTIVE MAINTENANCE

1. Perform daily, weekly, monthly, and quarterly cleaning procedures.

2. Replace lower burner shields with new ones (see Figure 3 ) if excessive corrosion is evident or if they

are cracked or broken.

ANNUAL PREVENTIVE MAINTENANCE

1. Perform daily, weekly, monthly, quarterly and biannual cleaning procedures.

2. Replace upper burner reverberators (see Figure 3) if existing have burn through.

3. Replace lower burner shields (see Figure 3) if existing are cracked or broken.

4. Replace upper flame runner (see Figure 9). Included in Annual parts kit #149268.

5. Replace lower flame runner (see Figure 9). Included in Annual parts kit #149268.

6. Inspect upper burners and replace or rebuild if necessary.

7. Replace Conveyor Bearings. (see Figure 4). Included in Annual parts kit #149268.

8. Replace overdrive tube assembly (see Figure 4). Included in Annual parts kit #149268.

9. Replace upper and lower pilots (igniters). Included in Annual parts kit #149268.

10. Replace burner orifices and flame runner orifices. Included in Annual parts kit #149268.

11. Replace motor brushes in both motors. Included in Annual parts kit #149268.

SPARE PARKS KIT

PART #

135031 CIRCUIT BOARD (SPEED CONTROL)(713BG) 1

146200 CONVEYOR OPEN LINK 7.437” (713BG) 1

146199 CONVEYOR OPEN LINK 13.375” (713BG) 1

146198 CONVEYOR OPEN LINK 24” (CM24) 1

127359 GAS VALVE (LP) 1

502203 GAS VALVE MODULATING (LP) 1

502868 GAS VALVE (NATURAL) 1

DESCRIPTION

QUANTITY

PER KIT

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

18

Page 25

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

PART #

502193 GAS VALVE, MODULATING (NATURAL) 1

154116 IGNITER/SENSOR PILOT (LP) 1

154115 IGNITER/SENSOR PILOT (NATURAL) 1

500083 LINK – HALF (DRIVE CHAIN) 1

500092 LINK – MASTER (DRIVE CHAIN) 1

500940 MOTOR (DRIVE) 1

500033 PLIERS CHAIN 1

501991 PICK - UP 1

148496 THERMOCOUPLE BROILER W/FITTING 1

500277 TIE PLASTIC CABLE 5

V. MOTOR SPEED BOARDS

DESCRIPTION

DC OUTPUT

VOLTAGE SWITCH

QUANTITY

PER KIT

AC SUPPLY

VOLTAGE SWITCH

It is necessary when installing replacement circuit boards, to check the settings of the AC input switches.

1. The AC supply voltage switch must be set at 115.

2. The DC output voltage switch must be set at 180.

VI. TROUBLE SHOOTING

This section contains a list of possible problems with the broiler. ALL ELECTRICAL TROUBLE SHOOTING

INVOLVING ACCESS INTO THE MOTORS OR ELECTRICAL ENCLOSURES MUST BE PERFORMED BY

A QUALIFIED ELECTRICIAN. All items marked with asterisks (*) should be performed by qualified

service personnel certified to perform service on gas fired appliances.

1. PROBLEM

sound like a blowtorch. IMPORTANT: If burner backfires, turn it off. Continued operation will

cause damage to the entire burner.

POSSIBLE CAUSE

A) Burner screen failure (hole) or burner gasket. SOLUTION: Replace burner.

: BURNER BACKFIRES. Flashback, blue flame at entrance to burner makes motor-boating

:

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

19

Page 26

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

* B) Burner over-fired; manifold pressure too high. SOLUTION: Check and reset gas control

regulator to give rating plate/label value for manifold pressure (shown under Performance

Criteria on Page 5). Wait 5 minutes & relight. Flashback will not occur immediately unless a

large opening in or around the burner screen is evident. Wait an hour after relighting to check

that problem is solved. Figure 9 illustrates which regulator sets high and low gas pressures.

C) Check to ensure all screws holding the burner screen in place are snug, if your burner has

removable screens (see Figure 5).

2. PROBLEM

POSSIBLE CAUSE

* A) Low gas pressure. SOLUTION: Check and reset gas control regulator to give rating plate/label

3. PROBLEM

NOTE: ATTEMPT TO LIGHT MANUALLY, THEN CALL SERVICE AGENCY

POSSIBLE CAUSE

A) Wires from pilot assembly loose. SOLUTION: Trace wires to where they plug into gas valve

and check connection (see Figure 9).

B) Wires from pilot assembly damaged/ burned. SOLUTION: Trace wires. If damaged/ burned,

replace pilot. Check lower burners to make sure they are installed fully over orifice.

* C) Pilot assembly dirty or bent. SOLUTION: Check for bent pilot gas line and/or dislodge debris.

* D) Low gas pressure. SOLUTION: Increase gas pressure to broiler (see Figure 9).

* E) Pilot orifice clogged. SOLUTION: Dislodge debris or replace orifice.

F) Grease Pan, cover and or shield not in place. SOLUTION: Make sure all are in place

(see Figure 2&3).

4. PROBLEM

ORANGE WHEN BURNING PROPERLY.

POSSIBLE CAUSE

A) Check that flame runner is fully lit. SOLUTION: If not, clean flame runner orifice or remove and

B) Lower burners dirty. SOLUTION: Check ports are not plugged, clean with wire brush.

C) Lower burner shield bent/broken. SOLUTION: Replace shield.

D) Orifice. SOLUTION: Check that orifice is not plugged. (If it is necessary to change the orifices,

* INSTRUCTIONS MARKED WITH ASTERISKS SHOULD BE PERFORMED BY AUTHORIZED

SERVICE PERSONNEL.

: FLAMES VISIBLE AT EXHAUST STACK OR IN CHAMBER.

:

value for manifold pressure (shown under Performance Criteria on Page 5). Figure 9 illustrates

which regulator sets high and low pressures.

: PILOT FLAME GOES OUT (STUDY FIGURES 6 AND 7 FOR PILOT OPERATION).

:

: BURNER WILL NOT LIGHT AT ALL. NOTE: UPPER BURNERS WILL BE BRIGHT

: (IN ORDER MOST LIKELY TO LEAST LIKELY)

clean flame runner.

new ones must be ordered from the local parts distributor.)

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

20

Page 27

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

E) Hot Surface Ignition, pilot not lit. SOLUTION: Cycle On/Off button or replace igniter.

F) Pilot. SOLUTION: Pilot must light and stay lit in order for burner to light. Check pilot problem

list.

* G) Gas Solenoid. SOLUTION: Check that solenoid valve on main gas valve is working.

* H) Pilot Jumpers. SOLUTION: Check the pilots to make certain they are not plugged.

5. PROBLEM:

POSSIBLE CAUSE

A) Manual On/off switch on the top of the gas valve is turned off. SOLUTION: Turn switch to on

position.

* B) Failed igniter. SOLUTION: Replace igniter.

* C) Failed transformer. SOLUTION: Check for 120 Volts at the primary side of the transformer and

24 Volts on the secondary output. Replace transformer if necessary.

D) Loose connection at gas valve wiring harness. SOLUTION: Check to be sure connector is

securely plugged into the gas valve.

* E) Failed gas valve. SOLUTION: Replace valve and recaulk connectors and manual On/Off switch

in On position.

6. PROBLEM

POSSIBLE CAUSE

A) Check for object caught in conveyor, causing a jam. SOLUTION: Remove object.

B) Check to see if motor shaft is moving. SOLUTION: Sprocket set screw needs to be tightened.

C) Check 1.5 amp fuse on side of the control cabinet. SOLUTION: Turn broiler off, replace fuse,

D) Check 5 amp main power fuse. SOLUTION: Replace if blown.

* E) Connect motor control leads to an operating motor speed control board. SOLUTION: If motor

7. PROBLEM

POSSIBLE CAUSE

* A) Pickup bracket has loosened/Fallen off. SOLUTION: Secure brackets check pickup mounting

( See Figure 4.)

* INSTRUCTIONS MARKED WITH ASTERISKS SHOULD BE PERFORMED BY AUTHORIZED

SERVICE PERSONNEL.

MAIN GAS VALVE(S) DOES NOT WORK.

:

: CONVEYOR CHAIN WILL NOT MOVE.

:

turn broiler on.

runs, replace motor control board. If motor still does not run, replace motor.

: CONVEYOR RUNS BUT SPEED IS CONSTANT

:

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

21

Page 28

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

B) Drive tube is binding with shaft. SOLUTION: Program Left side belt to 1:00 cook time and Right

belt to 6:00 cook time. This may free grease build up.

* C) There are three parts to the motor system. They are the pick-up, the speed circuit board, and

the motor. The parts are listed in the order in which they are most likely to cause a problem.

SOLUTION: Using spare parts, replace one part at a time until the trouble spot is identified.

8. PROBLEM

POSSIBLE CAUSE

A) Tension conveyor- See details in Figure 11.

B) Check to see that chain is not on backward. SOLUTION: See proper chain installation in

Figure 11.

C) Inspect chain closely for bent or warped links that may be snagging and causing a binding

D) Make sure the axle assembly is clean and free of grease and food residue to allow smooth

movement of the conveyor. SOLUTION: Clean axle with axle scraper (see Page 15). Clean

overdrive tube.

E) Check the axle assembly to make certain all set collars, bearings, etc. are properly positioned

and secure. SOLUTION: Reposition set collars, bearings, etc. Tighten set collar set screws.

* F) Disassemble conveyor axle assembly and check condition of bushings and bearings for

excessive wear. SOLUTION: Replace if worn or damaged.

G) Visually inspect the motor drive chain assembly for smooth rotation of chain. SOLUTION:

H) Make sure conveyor is not catching on meat stripper. SOLUTION: Straighten bent stripper.

9. PROBLEM

POSSIBLE CAUSE

A) Meat stripper is dirty. SOLUTION: Clean stripper. (Figure 2)

* INSTRUCTIONS MARKED WITH ASTERISKS SHOULD BE PERFORMED BY AUTHORIZED

SERVICE PERSONNEL.

: REPEATED MECHANICAL BINDING.

:

condition. Also check that the chain links are not climbing out of the sprockets as the conveyor

rotates. SOLUTION: Straighten or replace bad links. Adjust sprockets.

Make certain there are no binding or worn components.

: HAMBURGERS WILL NOT FALL CORRECTLY.

:

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

22

Page 29

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

10. PROBLEM: GROUND FAULT RECEPTACLES TRIP.

POSSIBLE CAUSE

A) Water has seeped into cooling fans. SOLUTION: Turn off cooling fan reset switch located on

back of control cabinet on lower right as viewed when facing the broiler load end. See Figure 1.

It is a toggle switch with a soft rubber boot over the switch making it easy to feel. This will allow

broiler to operate. After one hour, cooling fan reset switch must be turned on.

B) Water has seeped into control cabinet. SOLUTION: Plug broiler into a non-ground fault

receptacle using an extension cord. This will allow broiler to operate and dry out.

11. PROBLEM

POSSIBLE CAUSE

A) Dirty grease pan. SOLUTION: Exchange grease pan with spare clean pan. (See Figure 3.)

B) Cooling fan reset switch turned off. SOLUTION: Turn on cooling fan switch underneath broiler.

12. PROBLEM

POSSIBLE CAUSE:

A) An object (most likely an order ticket) has been sucked into cooling fan. SOLUTION: Shut off

13. PROBLEM

HAS DECREASED OVER A PERIOD OF DAYS.

POSSIBLE CAUSE:

* A) Low gas pressure. SOLUTION: Check gas pressure gauges and correct gas pressures to

B) Hang on covers and burner shields not in place. SOLUTION: Install parts correctly.

C) Holes in the upper three (3) burner reverberators are obstructed. SOLUTION: Clean holes and

reverberators.

D) Burner orifices clogged. SOLUTION: Clean the burner orifices using a chenille stem dipped in

alcohol. Chenille stems are available in the craft section of your local department store or at

your local craft store.

E) Air blowing into broiler chamber for A/C register or exhaust hood makeup air. SOLUTION:

* INSTRUCTIONS MARKED WITH ASTERISKS SHOULD BE PERFORMED BY AUTHORIZED

SERVICE PERSONNEL.

: EXCESSIVE GREASE PAN FIRES.

: CONTINUOUS TICKING SOUND

the fan reset switch located as described in #10. Reach under broiler and look for paper object.

The fan air intake is closest to the back of the electrical cabinet and can be reached from under

the broiler.

: COOK TIMES HAVE HAD TO BE CHANGED BECAUSE BROILER TEMPERATURE

machine settings.

Redirect air flow away from broiler chamber.

:

:

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

23

Page 30

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

F) Lower burner ports are clogged. SOLUTION: Remove burners and clean ports using soft

brush.

G) No item above solves situation. SOLUTION: Record recovery times using control and contact

Marshall Air Customer Service.

14. TROUBLE SHOOTING GUIDE FOR 6-RECIPE BUTTON CONTROLS

The following Error Messages are associated with the 6-Recipe Button controls:

ERROR MESSAGE PROBLEM SOLUTION

LOW

Indicates temperature is below the set point by the programmed amount.

Parts Not In Place Install parts correctly

Gas Valve Off Check Burner Position

Clean Orifices

Clean Flame Runner

Low Gas Pressure Check Gas Pressure

Pilot Burner Not Lit Recycle Heat Switch

Dirty Orifices Clean Orifices

Faculty Display Temperature Check Thermocouples

HIGH

Indicates temperature is above the set point by the programmed amount.

Parts Not In Place Install Parts Correctly

Set Point Set Too Low Check Set Point

Gas Pressure Set Too High Check Pressure

Modulating Valve Minimum Pressure Check Modulating

Set Too High Valve and Pressure

Faculty Display Temperature Check Thermocouples

TACH ERROR or HOT – TACH ERROR or OFF – TACH ERROR

Note: On the lower display window, the number 1 or 2 or 12 will be shown 1 indicates a single conveyor

problem, or a left conveyor problem on a dual conveyor broiler. 2 indicates a right conveyor problem.

When a problem occurs, the first message displayed is TACH ERROR, which almost immediately will cause

the broiler to shut down and display HOT – TACH ERROR. After the cool down period, the broiler will turn off

and display OFF – TACH ERROR

Jammed Conveyor Remove Items Preventing Conveyor From

Moving

Failed Fuse Replace Fuse

Loose Wire or Connector Check wire connections

Loose Pick-up Tighten Pick-Up

Damaged Pick-up Replace Pick-Up

Failed Speed Control Circuit Board Replace Circuit Board

Failed Motor Replace Motor

Failed Speed Module Replace Speed Module

NOTE: If the broiler has two conveyor belts, and you have a TACH ERROR on only one of the conveyors, as

a temporary work around to keep the one working conveyor running you can use the following procedure:

Turn on the broiler using the ON/OFF key. The broiler will start, and you will get a TACH ERROR. The broiler

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

24

Page 31

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

will go into the HOT mode. Press the ON/OFF key once and the tach error beep will stop, press the ON/OFF

key again and the broiler will start the one conveyor that does not have a TACH ERROR. During this

operation, the control will still display the TACH ERROR message, but the broiler will not shut down to the

HOT mode.

This procedure will allow the store operator to continue in operation until a service agency technician can get

to the store to fix the problem.

HOT – PROBE ERROR or OFF – PROBE ERROR

Note: The number on the second line of the control display indicates the thermocouple number.

For electric broilers, 1 indicates the top heater thermocouple, and 2 indicates the bottom heater

thermocouple.

For gas broilers, which have two thermocouples connected in parallel (which acts as one thermocouple to the

control), the display will indicate 2

When a problem occurs, the first message displayed is HOT - PROBE ERROR. After the cool down period,

the broiler will turn off and display OFF – PROBE ERROR.

Loose Thermocouple Fix wiring connection

Failed Thermocouple Replace Thermocouple

Depending on the 6-Recipe Button Control factory setting, some electric broilers will default to 100 percent

heater output to allow the broiler to continue to operate until the problem is fixed. In this case, the recipe cook

time should be temporarily adjusted to achieve the desired cooked product using the 100 percent heat. A

PROBE ERROR message will be displayed until the problem is fixed.

HOT – EXTERNAL DC ERROR or OFF – EXTERNAL DC ERROR

Check Wiring and Connectors For Short Repair Wiring

Failed Pick-up Replace Pick-up

Failed Speed Control Circuit Board Replace Circuit Board

Failed Speed Module Replace Module

Failed Gas Module Replace Module

Failed 6-Recipe Button Control Replace 6-Recipe Button Control

FOOD PROBE ERROR

Food Probe Not Connected Plug in Food Probe

Failed Food Probe Replace Food Probe

CLEAR LOG Log File almost full Clear Food Probe Log File

LOG FULL Log File is full Clear Food Probe Log File

VII. INSTRUCTION SHEET CHARCat™ CATALYTIC CONVERTER INSTALLATION

AND CLEANING

PRE-INSTALLATION

The catalytic converter (catalyst) is packaged to minimize the risk of shipping damage. Immediately upon

receipt, make certain to inspect the broiler for damage. FILE ALL CLAIMS WITH THE FREIGHT CARRIER.

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

25

Page 32

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

INSTALLATION

Prior to installation of a catalyst equipped conveyor broiler in an existing restaurant, your hood duct and fan

system should be cleaned by a professional commercial cleaning service. Refer to Figure 12 and make

certain that all parts related to the catalyst are properly installed.

OPERATION

The catalyst is activated by the exhaust heat from the broiler. There are no extra burners to be added or

electrical components to be connected in order for the catalyst to work. As long as all parts are properly

installed and the broiler calibrated, the catalyst will operate normally. (See broiler owner’s manual for broiler

calibration.)

CAUTION: DO NOT TOUCH THE CATALYST IMMEDIATELY AFTER BROILER SHUT DOWN. THE

TEMPERATURE OF THE CATALYST IS IN EXCESS OF 500°F (260°C), NEVER PUT

WATER ON CATALYST WHILE CATALYST IS HOT. USING WATER ON A HOT

CATALYST WILL CAUSE SEVERE WARPING AND MATERIAL DAMAGE.

CAUTION: UNDER NO CIRCUMSTANCES SHOULD SOAP, DEGREASER, OVEN CLEANER OR

ANY OTHER CLEANING AGENT BE USED ON THE CATALYST. CLEANERS WILL

CAUSE SEVERE DAMAGE.

CAUTION: DO NOT RUN THE CATALYST THROUGH A DISHWASHER.

CLEANING

The catalyst washing procedure is a simple three-step process. The vast majority of the fatty acids deposited

on the catalyst are water-soluble. Care must be taken to use only clean hot water. Soaps, detergents,

bleaches and antioxidants all contain substances which are considered catalyst poisons. In other words, they

will render the catalytic converter inoperable. Clean all foreign matter from the wash basin before starting the

catalyst washing process. The process is as follows:

1. Partially fill a clean wash basin with about 4” of clean hot water (100-130°F). Set the converter

module in the water so that it is completely covered. Let it soak for 15 minutes

2. Remove the module. Shake out the excess water. Drain and rinse the basin thoroughly; then

repeat step 1.

3. Remove the module and rinse through the catalyst with a large volume of hot water. The typical

restaurant rinse nozzle is ideal. Work the spray slowly over the entire surface of the catalyst. DO

NOT USE A HIGH PRESSURE HOSE. Shake the remaining water from the converter module

and allow to dry as time permits. Reinstall on the broiler. The converter is now ready for

normal operation.

4. Rotating the square catalyst from front to back of the broiler when reinstalling the catalyst will

extend the life of the catalyst. This means when it is placed on the broiler, the handles in front

should now be on the back side of the broiler.

Frequency for the above procedure should follow your normal restaurant procedure for cleaning and

sterilization of your food preparation and cooking surfaces but not less than once per week.

146267 021810

Copyright © 2010 Marshall Air Systems, Inc.

All Rights Reserved.

26

Page 33

OWNER’S MANUAL

MODEL 713BG(DB9L,DB9R)/2424G (DB9A) AUTOBROIL™

CATALYST WARRANTY

The catalyst will perform perfectly for a minimum of two (2) years provided the cleaning instructions are

followed. All warranty claims are the responsibility of Engelhard Corporation and subject to their inspection of

the alleged defective catalyst.

VIII. REPLACEMENT PARTS

When ordering parts, make sure to specify the machine model number, type of gas and serial number as

shown by the label attached to the right side cover.

WARNING: USE OF NON- MARSHALL APPROVED PARTS WILL VOID WARRANTY.

PART #

149015 ARM, LOADER ASBY 1 10

150245 BEARING, SLEEVE 1 4

146194 BEARING, TEFLON EXIT 1 4

146193 BEARING,TEFLON EXIT 1 4

503148 BOOT, SWITCH LONG 1 SCHEMATIC

148549 BRUSH, MOTOR KIT (2 BRUSHES) 2 4

115665 BURNER, 24” COMPLETE OPTIONAL 5

127000 BURNER, 24” DISPOSABLE G5B (COMES

WITH NEW BROILERS FOR THE TOP

BURNERS ONLY)

146936 BURNER,LOWER TUBULAR 3 3

152110 BURNER,LOWER TUBULAR LP 3 3

146260 CAP, OVERDRIVE SHAFT 1 4

145530 CARRIAGE, AUTO LOADER ASBY 1 2,10

148022 CATALYST CHARCAT 1 12

500035 CHAIN, ROLLER #35 (3.55 FT) 2 4

135031 CIRCUIT BOARD SET FOR 120V 2 SCHEMATIC

150432 COLLAR, BEARING LOCK 1 4

150433 COLLAR, IDLER 1.750” OD, .755” ID 2 4

500117 COLLAR, SET 0.505”ID X 0.875” OD 2 10

145871 CONTROL, 6 BUTTON HORIZONTAL 1 SCHEMATIC

145690 CONVEYOR, 6” MESH 1 10

145689 CONVEYOR, 12” MESH 1 10

503560 CONV BELT, 13.75 “ ROD , 7GA. (6FT) 1 11

503561 CONV BELT, 7.437” ROD, 7GA. (6FT) 1 11