Page 1

OWNER’S MANUAL

UNIVERSE PLUS ELECTRIC SKILLET

MODELS:

30P-STEL 30P-STEM 40P-STEL 40P-STEM

WARNING:

Improper installation, adjustment,

alteration, service or maintenance can cause damage, injury

or death. Read the installation,

operating & maintenance instructions thoroughly before installing

or servicing the equipment.

FOR YOUR SAFETY:

Do not store or use gasoline or

other ammable vapors or liquids

in the vicinity of this or any other

appliance.

Form No.: S-6004 Rev. D 06/08

PRINTED IN

USA

An Employee Owned Company

35 Garvey Street • Everett • MA • 02149-4403

Tel: (617) 387-4100 • Toll Free: (866) 698-3188

Fax: (617) 387-4456 • Outside MA Fax: (800) 227-2659

E-Mail: custserv@mi.com • Website: www.mi.com

Page 2

TABLE OF CONTENTS

SPEC SHEET INFORMATION ...................................

INSTALLATION ...........................................................

OPERATION ...............................................................

TEST KITCHEN BULLETIN ........................................

TROUBLE-SHOOTING ...............................................

MAINTENANCE ..........................................................

WIRING .......................................................................

PARTS ........................................................................

1

3

4

5

7

7

8

11-19

INTRODUCTION

NOTICE:

THE FOLLOWING FAYCETS ARE THE ONLY ONES APPROVED BY THE MASSACHUSETTS

BOARD OF REGISTRATION OF PLUMBERS AND GAS FITTERS FOR INSTALLATION ON

THIS EQUIPMENT.

SINGLE PANTRY FAUCET MANUFACTURED BY T & S BRASS AND BRONZE WORKS, INC.

MODEL # B-0305 OR CONCEALED MIXING FAUCET WITH 4-ARM HANDLES MANUFACTURED BY T & S BRASS AND BRONZE WORKS, INC. MODEL # B-0512.

IMPORTANT:

INSTALLING, OPERATING AND SERVICE PERSONNEL:

•

INSTALLATION OF THE EQUIPMENT SHOULD BE PERFORMED BY QUALIFIED, CERTIFIED, LICENSED

•

AND/OR

AUTHORIZED PERSONNEL WHO ARE FAMILIAR WITH AND EXPERIENCED IN STATE/LOCAL INSTALLA-

•

TION CODES.

OPERATION OF THE EQUIPMENT SHOULD BE PERFORMED BY QUALIFIED OR AUTHORIZED PERSON-

•

NEL WHO HAVE READ THIS MANUAL AND ARE FAMILIAR WITH THE FUNCTIONS OF THE EQUIPMENT.

INSTALLING, OPERATING AND SERVICE PERSONNEL:

•

SERVICE OF THE EQUIPMENT SHOULD BE PERFORMED BY AN AUTHORIZED MARKET FORGE SERVICE

•

AGENT.

•

SHIPPING DAMAGE CLAIM PROCEDURE:

THE EQUIPMENT IS INSPECTED & CRAFTED CAREFULLY BY SKILLED PERSONNEL BEFORE LEAVING FACTORY. THE TRANSPORTATION COMPANY ASSUMES FULL RESPONSIBILITY FOR SAFE DELIVERY UPON

ACCEPTANCE OF THIS EQUIPMENT.

IF SHIPMENT ARRIVES DAMAGED:

VISIBLE LOSS OR DAMAGE: NOTE ON FREIGHT BILL OR EXPRESS DELIVERY AND HAVE SIGNED BY

1.

THE PERSON MAKING DELIVERY.

FILE CLAIM OR DAMAGES IMMEDIATELY REGARDLESS OF THE EXTENT OF DAMAGES.

2.

CONCEALED LOSS OR DAMAGE: IF DAMAGE IS NOTICED AFTER UNPACKING, NOTIFY THE TRANSPOR-

3.

TATION COMPANY IMMEDIATELY AND FILE ‘CONCEALED DAMAGE’ CLAIM WITH THEM. THIS SHOULD

BE DONE WITHIN FIFTEEN DAYS FROM THE DATE DELIVERY IS MADE TO YOU. RETAIN CONTAINER FOR

INSPECTION.

i

Page 3

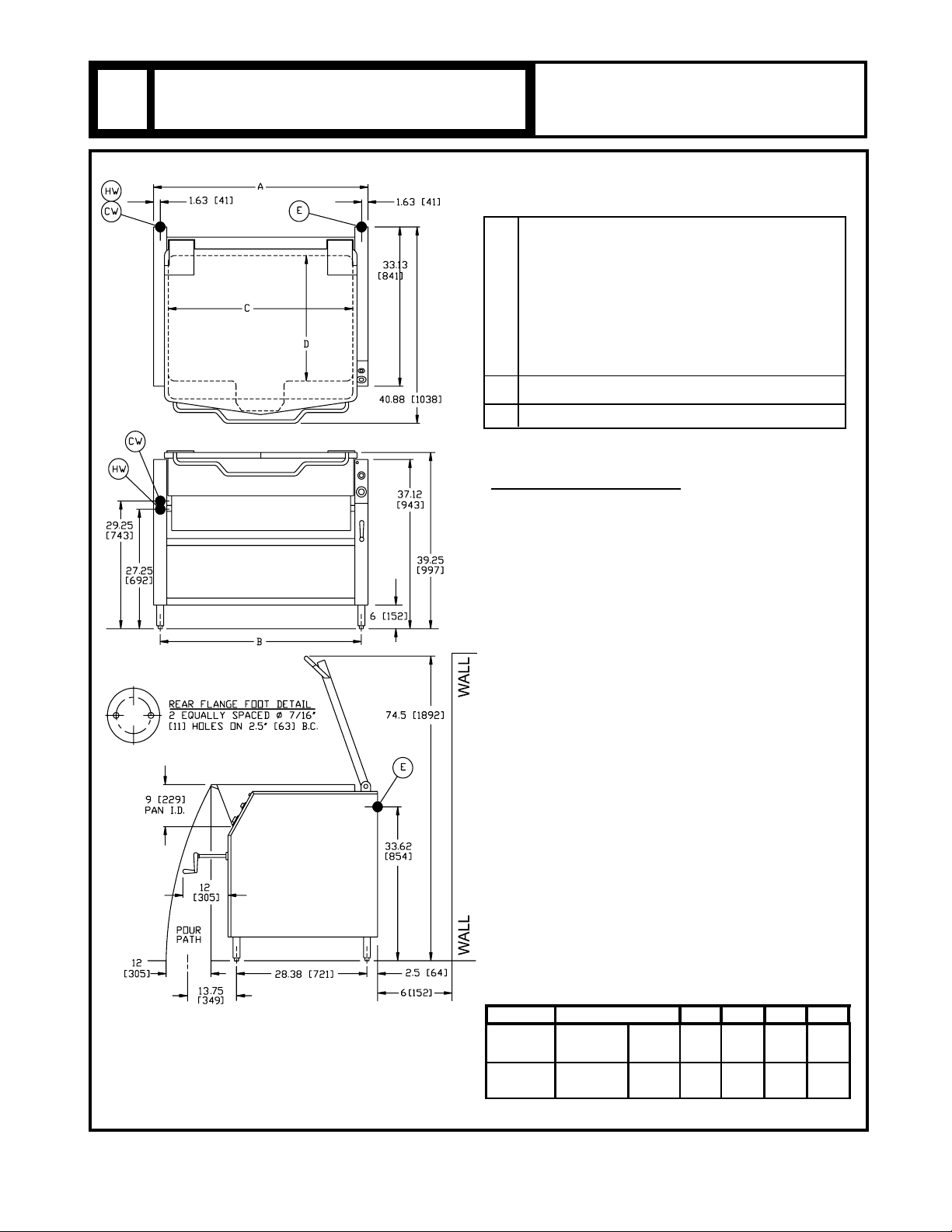

UNIVERSE PLUS

E

MODELS: ● 30P-STEL ●40P-STEL

● 30P-STEM ●40P-STEM

DESCRIPTION:

The Market Forge Electric Universe Plus Tilting Skillets

are available in 30-gallon (87-liter) and 40-gallon (114-li-

ter) pan bodies with 12kW and 18 kW inputs respectively.

Both models are available in open-leg and closed-base

frame assemblies with manual or power tilt capabilities.

The heavy duty construction of our Universe Plus Skil-

lets incorporates sides formed of 10 gauge stainless

steel and a 5/8” thick stainless steel clad plate that will

provide a rigid at cooking surface with improved heat

distribution. The balanced design of the pan allows the

operator to easily and quickly tilt to the desired posi-

tion. Our new power tilt operates smoothly, with manual

override that works easily when needed and without the

use of tools or drills as required by other manufacturers.

ELECTRIC TILTING SKILLET

JOB NAME: ___________________________

ITEM NO.: ____________________________

NO. REQUIRED: _______________________

CONSTRUCTION:

The Universe Plus Skillet has a fully polished stainless steel cooking surface that prevents food from adhering and helps to safely clean the equipment. Heat-

ers turn off automatically when the cooking pan is tilted

from the horizontal position. The skillet is provided with

a heavy-duty spring assisted cover with a condensate

vent. The cooking pan and cover are supported by

two consoles with a fully welded stainless steel tubular

frame system that provides stable support to the unit.

The consoles are completely covered with stainless

steel that provides protection to the controls and is also

easily cleanable and provides clear access for easy

oor cleaning. The closed-base model incorporates an

easily removable stainless steel front and rear panel.

The sloped front of the pan allows for complete draining of the pan when tilted to 70°. The tilting mecha-

nism includes a precision ground and polished worm

for smooth and long lasting tilt operation and positive

control with a collapsible hand crank. A power tilting option is available and is also supplied with the collaps-

ible handle for manual override operation if required.

TECHNICAL SPECIFICATIONS:

COOKING PAN:

The unitized cooking pan with integral clad plate cooking

surface is welded with full penetration to resist cracking due

to expansion and contraction. The polished cooking sur-

face resists product adherence and improves cleanup and

appearance. The pan incorporates an easy-pour lip and

30P-STEM Shown

5-gallon increment markings. The clad plate cooking surface has electric tubular elements attached to the bot-

tom of the pan for even and efcient heat transfer. An

interlock switch is provided to turn the heaters off when

the pan is tilted more than 10° from the normal horizon-

tal position. The spring assisted cover with integral vent,

condensate drip guide and full width handle affords ef-

fortless operation and will maintain an open position.

C

ONTROLS:

The skillet comes standard with a solid-state tempera-

ture control with a positive OFF position and 100°-450°

Fahrenheit scale, a pilot light to indicate when the elements are ON, and a 1 hour mechanical timer. The op-

tional power tilting mechanism also utilizes an UP/DOWN

rocker switch. The manual tilting mechanism uses a collapsible hand crank conveniently located below the con-

trol panel. The controls are resistant to dripping and light

splashing water (NEMA T-2).

OPERATION SHALL BE BY:

All UniVerse Plus Tilting Skillets models are available in

208VAC, 240VAC, eld convertible to 1 or 3 phase, or

480VAC 3 phase. 30 Gallon models are rated at 12 kW

and the 40 Gallon models are rated at 18 kW.

1

Page 4

E

UNIVERSE PLUS

ELECTRIC TILTING SKILLET

DETAILS & DIMENSION

Electrically Operated

SERVICE CONNECTIONS

E

Electrical Connection - Use wire suitable for 90oC. A

stepdown transformer provides power to the 120V control

circuit.

VOLTS AC

208

240

480 (3 pH Only)

Details of other electrical systems are available upon request.

Cold Water - 3/8" O.D. NPT to faucet (Optional).

CW

Hot Water - 3/8" O.D. NPT to faucet (Optional).

HW

40P-STEM &

40P-STEL

(18 kW)

1 pH

3 pH

87

50

75

43

--

22

30P-STEM &

30P-STEL

(12 kW)

1 pH

3 pH

58

33

50

29

--

14.5

OPTIONAL AT EXTRA COST:

● 2” Draw-Off Valve with Strainer.

● Modular Joining Kit.

● Pan Support.

● Pan Holder Inserts.

● Pouring Lip Strainer.

● Single Pantry Faucet.

● Posi-Set.

● 2” Tangent Draw-Off Valve with Drain Hose Assembly,

Includes:

○ 2” Tangent Draw-Off Valve with Strainer.

○ 90o Stainless Steel Elbow.

○ 8 Foot Long of 2” ID Hose (cut to required length).

○ Hose Clamp.

● Drain Cup Assembly, Includes:

○ Stainless Steel Cup Assembly.

○ 8 Foot Long of 2” ID Hose (cut to required length).

○ Hose Clamp.

● Drain Pan Assembly, Includes:

○ 6” x 12” x 20” Stainless Steel Solid Pan with Elbow.

○ 8 Foot Long of 2” ID Hose (cut to required length).

○ Hose Clamp.

● Double Pantry Faucet.

● Single Pantry Spray Hose.

● Double Pantry Spray Hose.

● Caster Kit w/Strain Relief.

● Correctional Package.

CLEARANCE:

Left Side

Right Side

Back

12 kW

0"

0"

6"

18 kW

0"

0"

6"

DIMENSIONS

MODEL CAPACITY A B C D

30P-STEL

30P-STEM

40P-STEL

40P-STEM

30 Gallon inches 36 34.63 30.5 25.75

114 liter mm 914 879 775 654

40 Gallon inches 46 44.63 40.5

152 liter mm 1168 1133 1029

2

25.75

654

Page 5

INSTALLATION

GENERAL INSTALLATION:

UNPACKING:

Immediately after unpacking, check for possible shipping damage. If the tilting universe plus electric skillet is found to be dam-

aged, save the packing material and contact the carrier within 15

days of delivery.

Before installing, verify that the electrical service agrees with the

specications on the rating plate located on the right side panel

as you face the front of the skillet. If the supply and equipment

requirements do not agree, contact your dealer.

LOCATION:

The installation location must allow adequate clearances for ser-

vicing and proper operation. A minimum front clearance of 36”,

and rear clearance of 6” is required.

INSTALLATION CODES AND STANDARDS:

Your Tilting Universe Plus Electric Skillet must be installed in ac-

cordance with:

1. Provincial and local codes, with: USA state and local codes,

or in the absence of local codes, with: The National Electri-

cal Code ANSI/NFPA-70 (Latest Edition), or in the absenceof local codes, with: Canada CSA C22.1 Canadian Electrical

Code, Part 1.

2. ANSI/NFPA Standard #96, “Vapor Removal from Cooking

Equipment”, (Latest Edition), available from Tha National Fire

Protection Association, Batterymarch Park, Quincy, Massa-

chusetts (MA) 02269.

LEVELING AND ANCHORING THE SKILLET:

1. Place the skillet in the desired location of installation.

2. Place a carpenter’s level on the top of the skillet pan and

turn the adjustable feet to level the skillet from side-to-side-

and front-to-back.

3. Mark hole locations on the oor through the anchoring

holes provided in the rear adjustable ange feet.

4. Remove the skillet from the anchoring holes marks that you

marked on the oor and drill a hole for each marking. After

all holes have been drilled, place the skillet back into original

position.

5. Check to make sure the skillet is still level. (See Step 2).

6. Bolt and anchor the skillet securly to the oor, then seal the

bolt sand anged feet with a silastic or equivalent compound.

7. If faucet is provided, connect water supply and check

operation.

8. Turn the power on and check for proper operation.

WARNING!:

Electrical and grounding connections must comply with

the appliance portions of The National Electrical Code

and/or other local codes.

ELECTRICAL CONNECTION:

NOTE!: Do not install in such a manner that a service person

cannot remove the control box cover.

• Connect unit to a branch circuit having a voltage and circuit

type specied on the name plate and of sufcient size to carry

load. The amps per line wire for the various voltage rating are

shown in table below.

NOTE!: Supply wires must be suitable for temperature of at

least 200

o

F (90oC). Additionally, all wiring must conform to

the requirements of local and national electric codes. Conduit

and ttings must be watertight.

• Connect ground wire from electrical service to ground lug.

• Ensure that skillet is rmly seated on fram before checking

connection and functioning of controls.

NOTE!: Unit is equipped with an interlock switch that shuts off

current to the heating elements when skillet pan is more

than (10

o

) above normal horizontal cooking position.

• Switch on current supply to unit. Check for proper fuctioning

of controls and heating elements (See page 4, Operating

Instructions).

SERVICE CONECTIONS:

• All Internal Wiring for the skillet is complete.

• Make service connections as indicated on page 2 and elec-

trical connections above.

• If a faucet is provided, connect the water supplies and check

for proper operation.

AMP PER LINE WIRE TABLE:

MODELS: 30P-STEL * 30P-STEM

EXPORT MODELS: 30P-STEL-LX * 30P-STEM-LX

12 kW 220/380 Volt 18.2 18 kW 220/380 Volt 27.0

12 kW 240/415 Volt 16.7 18 kW 240/415 Volt 25.0

208 Volt 57.7 57.7 18 kW 87.0 87.0

240 Volt 50.0 50.0 18 kW 75.0 75.0

208 Volt

240 Volt

480 Volt

3 pH, 4 Wire, 50Hz

Amps Per Line Wire

( EXPORT ONLY )

12 kW, 1 pH Unit, 60Hz

Amps Per Line

L # 1 L # 2 L # 1 L # 2

12 kW, 3 pH Unit, 60Hz

Amps Per Line

L # 1 L # 2 L # 3 L # 1 L # 2 L # 3

33.0 33.0 33.0 50.0 50.0 50.0

29.0 29.0 29.0 43.0 43.0 43.0

14.5 14.5 14.5 22.0 22.0 22.0

MODELS: 40P-STEL * 40P-STEM

EXPORT MODELS: 40P-STEL-LX * 40P-STEM-LX

3 pH, 4 Wire, 50Hz

Amps Per Line Wire

( EXPORT ONLY )

18 kW, 1 pH Unit, 60Hz

Amps Per Line

18 kW, 3 pH Unit, 60Hz

Amps Per Line

208 Volt

240 Volt

480 Volt

3

Page 6

OPERATION

WARNING!: The tilting skillet and its parts are hot. Use care

when operating, cleaning and servicing the tilting skillet.

BEFORE FIRST USE:

Using a non-corrosive, grease-dissolving commercail cleaner,

clean the protective metal oils from all surface parts and inte-

rior of the skillet. Follow the cleaner manufacturer’s directions.

Rinse throughly and drain the pan. Wipe dry with a soft clean

cloth.

CONTROLS:

Red Temperature Light Illuminates when heating elements

are supplying heat to the tilting skillet.

_________________________________________________

Thermostat Turns tilting skillet ON and maintains

set temperature by controlling power

supply. Temperature settings range

from 100oF to 450

Bulletin on page 6).

_________________________________________________

Hand Crank To raise and lower pan.

_________________________________________________

Tilt Switch (Optional) Push UP to raise pan; push DOWN to

lower tilting braising pan.

_________________________________________________

Timer 1 Hour mechanical timer (program

duration of cooking time).

_________________________________________________

START-UP PROCEDURE:

1. Ensure that the skillet pan is in the DOWN position.

o

F (See Test Kitchen

NOTE!: Electric power automatically shuts off when skillet is

tilted more than 10o above normal horizontal cooking position.

3. Set thermostat at desired temperature by turning thermostat

control knob clockwise. (refer to Test Kitchen Bulletin on

page 6)

4. Preheat to desired temperature by turning thermostat

control knob clockwise. (refer to Test Kitchen Bulletin on

page 6 )

NOTE!: For best results, allow unit to cycle ON/OFF once.

5. Ensure that cover is up for most types of cooking except for

simmering, or boiling. Cover has drip-lip at rear to direct con-

densate into skillet.

6. Remove cooked food immediately to prevent over-cooking.

Tilt skillet by turning hand crank clockwise or pushing tilt

switch.

7. Lower skillet by turning hand crank counterclockwise or

pushing tilt switch.

**********************************************************************

Turn thermostat control knob counterclockwise to OFF when

no further heating is desired.

2. Turn the THERMOSTAT dial to the desired temperature

(refer to Test Kitchen Bulletin on page 6). The RED TEM-

PERATURE light will come on.

3. When skillet pan has reached set temperature, the RED

TEMPERATURE light will go off and the heating elements

will shut off. The heating elements will cycle on and off there-

after to maintain set temperature. The RED TEMPERATURE

light will cycle on and off with the heating elements.

4. Preheat skillet pan and allow it to cycle to equalize heat

across the entire surface.

5. Water will boil faster with the lid down.

6.Turn THERMOSTAT to OFF whn skillet is not in use.

BASIC OPERATION:

1. Ensure that electric power connection has been made

correctly and that branch circuit breaker at building supply

box is ON.

2. Ensure that skillet is in full down position and clean before

using.

*********************************************************************

DAILY SHUTDOWN PROCEDURE:

To turn skillet OFF, turn the THERMOSTAT dial to OFF.

TILTING THE SKILLET:

1. DO NOT try to tilt skillet with lid down.

2. Make sure the receving pan is in place.

3. Turn hand crank clockwise or for power tilt, push and hold

TILT SWITCH in the ip mode until desired pan position has

been reached. The pan will empty when raised to the top tilt

position. When the braising pan is raised 10

o

or more, the

heating elements eill be turned off automatically.

4. Food is poured through the removable strainer into a food

receiving pan positioned under the lip of the pouring spout.

5. To lower pan, turn hand crank counterclockwise or push

and hold TILT SWITCH in the DOWN mode.

*

4

Page 7

TEST KITCHEN BULLETIN

THERMOSTAT

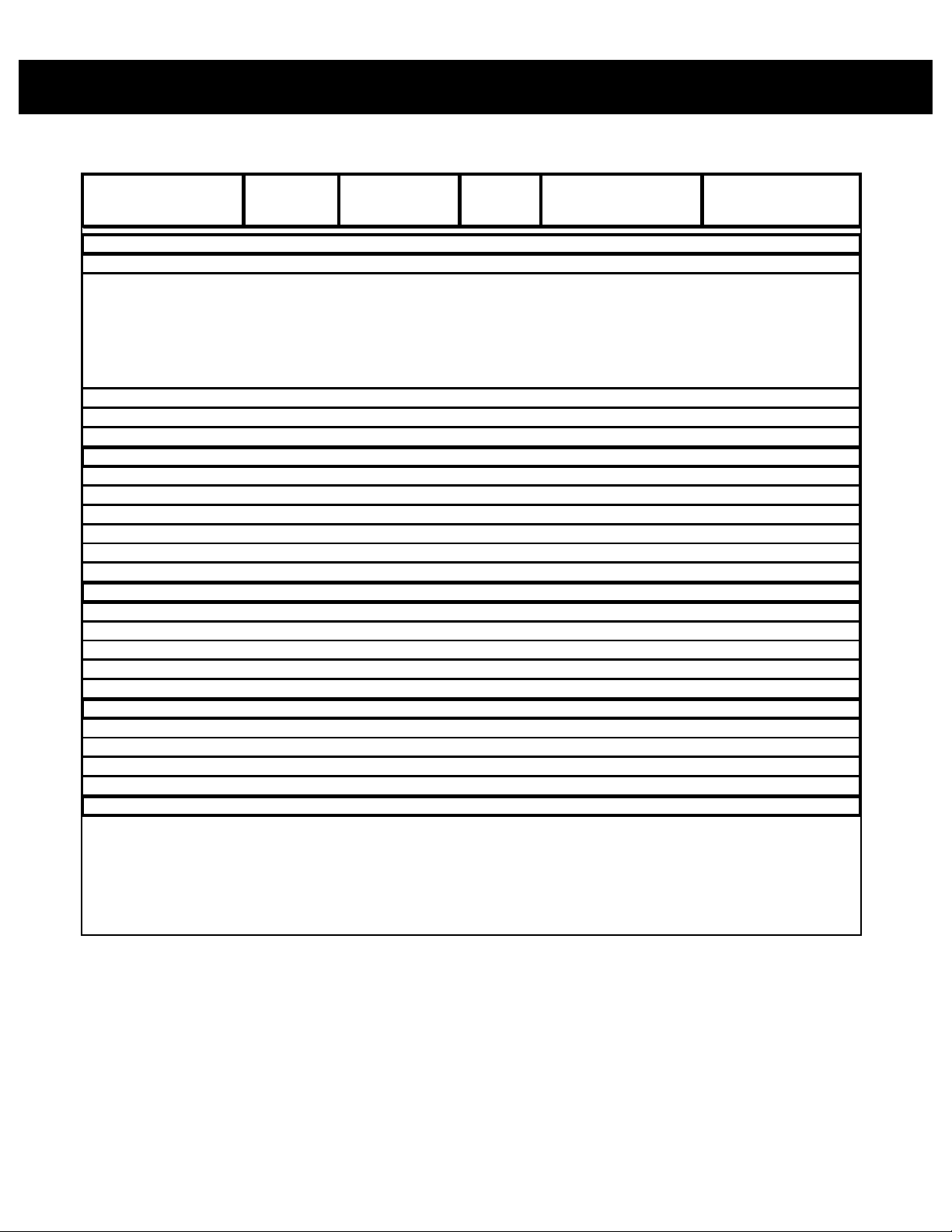

ITEM HOUR QTY. YIELD QTY. YIELD

SIZE

SETTING

BREAKFAST FOODS

Bacon 3 Slices 350

Eggs 1 Egg

Boiled-Hard 1 Egg 225

Boiled-Soft 1 Egg 225

Fried 1 Egg 400

Poached 1 Egg 225

Scrambled 1 1/2 Eggs 300

French Toast 3 Slices 450

Reqular Oatmeal 1/2 Cup 250

Pancakes 2 Each 400

FISH

Clams 1 pt. 400

Fish Cakes 2 oz. 400

Haddock Filet 4 oz. 400

Halibut Steak 5 oz. 450

Lobster 1-1 lb. 350

Swordfish 5 oz. 450

SAUCES, GRAVIES AND SOUPS

Brown Gravy 1 oz. 350

Cream Sauces 2 oz. 250

Cream Soups 6 oz. 200

French Onion Soup 6 oz. 225

Meat Sauce 4 oz. 350

MISCELLANEOUS

Grilled Cheese 1 sand 400

Macaroni & Cheese 8 oz. 200

Rice 4 oz. 350

Spaghetti

4 oz. 350

MEAT & POULTRY

Beef

American Chop Suey 6 oz. 400

Beef Stew 8 oz. 300

Corn Beef Hash 5 oz. 400

Cheeseburger 3 oz. 300

Hamburger 3 oz. 300

BATCHES

PER

o

o

o

o

o

o

200

o

o

o

o

o

o

o

o

o

o

200

o

175

o

o

o

200

o

o

o

225

o

225

o

225

o

o

o

o

12 2 lbs. 10 3 lbs. 15

5 50 50 75 75

8 50 50 75 75

4 30 30 45 45

5 36 36 60 60

o

1 18gal. 720 28gal. 1100

7 35 Slices 12 50 Slices 17

2 20 lbs. 500 40 lbs. 1000

10 30 each 15 50 each 25

10 10qts. 20 15qts. 30

5 70-3 oz. 35 110-3 oz. 55

4 60-4 oz. 60 90-4 oz. 90

3 60-4 oz. 60 90-4 oz. 90

4 20-1 lb. 20 30-1 lb. 30

3 50-5 oz. 50 75-5 oz. 75

o

o

2 18gal. 2300 35gal. 4500

1 18gal. 1150 35gal. 2250

1 18gal. 375 35gal. 725

1 18gal. 350 35gal. 700

o

1 18 gal. 575 35 gal. 1100

8 35 sand 35 40 sand 50

2 18gal. 300 35gal. 525

o

o

o

1 20 lb.raw 320 40 lb. 650

2 8 lb. 200 12 lb. 300

2 18gal. 350 35gal. 700

-- 18gal. 280 35gal. 560

5 16 lb. 50 25 lb. 75

12 7 lb. 35 10 lb. 50

15 7 lb. 35 10 lb. 50

30 Gallon 40 Gallon

PER LOAD

PER LOADPORTION

5

Page 8

TEST KITCHEN BULLETIN

Hamburger 3 oz. 300 15 7 lb. 35 10 lb. 50

Meatballs 1 oz. 400

o

225

o

3 12 lb. 65 18 lb. 100

Pot Roast 2 oz. 350

o

200

o

-- 120 lb. 500 180 lb. 750

Salisbury Steak 5 oz. 400

o

3 16 lb. 50 24 lb. 75

Sirloin Steak 6 oz. 400

o

5 15 lb. 40 22 1/2 lb. 60

Swiss Steak 4 oz. 300

o

200

o

1 25 lb. 100 40 lb. 160

Chicken

Pan-Fired 350 3 50 Pieces 25 80 Pieces 40

Whole 2 oz. 350 200

o

-- 16-5 lb. 200 24-5 lb. 265

Frankfurters

Grilled 2 oz. 300

o

8 22 lb. 176 33 lb. 264

Boiled 2 oz. 250

o

12 16 lb. 128 25 lb. 200

Ham Steak 3 oz. 400

o

8 10 lb. 50 15 lb. 75

Pork Chops 5 oz. 400

o

4 15 lb. 50 25 lb. 75

Sausage Links 3 links 350

o

7 30 lb. 120 45 lb. 180

2 1/4's

BATCHES

PER

ITEM HOUR QTY. YIELD QTY. YIELD

Turkey

Off Carcass 2 oz. 400

o

200

o

-- 3-26-30 lb. 200 4-26-30 lb. 275

On Carcass 2 oz. 400

o

200

o

-- 4-16-20 lb. 175 6-16-20 lb. 265

Canned oz. 400

o

6 30 lb. 125 45 lb. 200

Fresh

Beans oz. 400

o

3 25 lb. 125 50 lb. 250

Beets oz. 400

o

1 30 lb. 125 60 lb. 300

Broccoli oz. 400

o

3 25 lb. 125 40 lb. 200

Cabbage oz. 400

o

5 20 lb. 80 30 lb. 125

Carrots oz. 400

o

2 35 lb. 150 70 lb. 300

Cauliflower oz. 250

o

5 15 lb. 75 25 lb. 125

Corn ear 400

o

8 50 ears 50 75 ears 75

Potatoes oz. 400

o

2 40 lb. 200 60 lb. 300

Spinach oz. 225

o

10 6 lb. 25 9 lb. 35

Turnips oz. 400

o

2 20 lb. 100 30 lb. 150

Frozen

Beans oz. 400

o

6 15 lb. 60 22 1/2 lb. 90

Lima Beans oz. 250

o

4 15 lb. 60 22 1/2 lb. 90

Broccoli oz. 400

o

8 12 lb. 50 18 lb. 75

Sliced Carrots oz. 250

o

6 15 lb. 60 22 1/2 lb. 90

Baby Carrots oz. 250 3 15 lb. 50 22 1/2 lb. 90

Corn oz. 250

o

18 15 lb. 50 22 1/2 lb. 90

Baby Onions oz. 250

o

7 15 lb. 50 22 1/2 lb. 90

Peas oz. 400

o

10 15 lb. 75 22 1/2 lb. 110

Spinach oz. 400

o

3 15 lb. 75 22 1/2 lb. 110

Butterscotch Sauce 1 oz. 200

o

1 18gal. 2330 35gal. 4500

Cherry Cobbler 3 oz. 200

o

1 19gal. 750 36gal. 1500

Chocolate Sauce 1 oz. 200

o

1 20gal. 2300 37gal. 4500

Cornstarch Pudding 4 oz. 200

o

1 21gal. 575 38gal. 1100

Fruit Gelatin 3 oz. 250

o

2 22gal. 750 39gal. 1500

VEGETABLES

DESSERT ITEMS

SIZE SETTING

MEAT & POULTRY

40 Gallon

PORTION THERMOSTAT PER LOAD PER LOAD

30 Gallon

6

Page 9

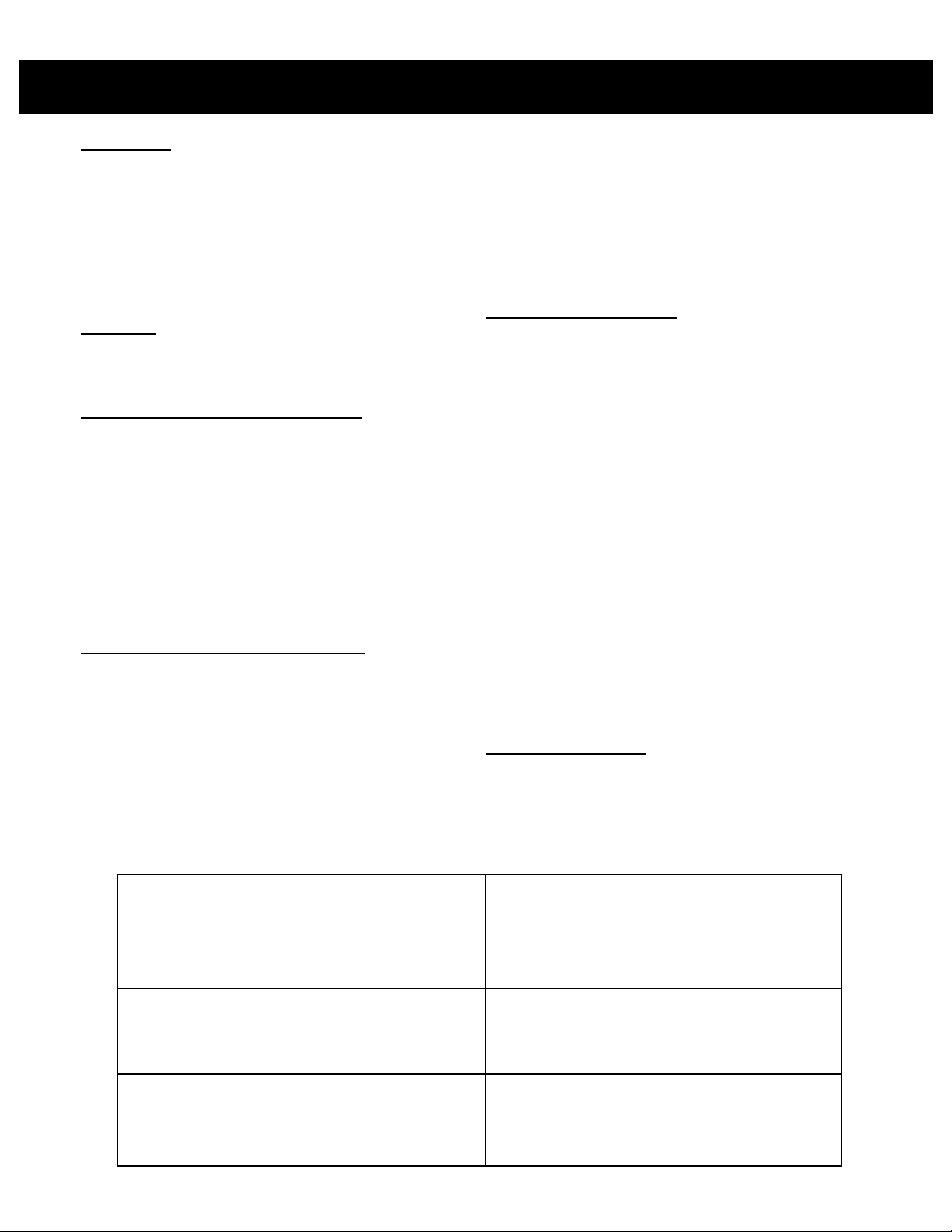

TROUBLE-SHOOTING

PROBLEM

Uneven Heating

Signal Light Out

Unit Fails to Heat

PROBABLE CAUSE

a. Defective element.

b. Uneven torque of element

clamp plate nuts.

c. Temperature control out of

calibration or defective.

a. Burnt out bulb.

b. Defective temperature control

or thermocouple.

c. Loose electrical connection.

a. Circuit breaker is off.

b. Malfunction of interlock

switch.

c. Contactor does not pull in.

d. Defective temperature control

or thermocouple.

REMEDY

a. Replace element.

b. Re-torque element clamp

plate nuts on bottom of skillet

(5’ pounds only/nut).

c. Calibrate or replace.

a. Replace.

b. Replace.

c. Repair.

a. Reset circuit breaker.

b. Adjust or replace.

c. Replace contactor.

d. Replace temperature control

or thermocouple.

MAINTENANCE

IMPORTANT!: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING.

DAILY CLEANING:

1. The skillet should be cleaned daily.

2. Wash the skillet with a mild detergent and hot water. If food is stuck to the surface of the skillet pan, soak it and use a

little heat to loosen the food. Then, wash with clean water and whip dry.

3. Be sure to wash under the skillet cover and rinse with clean water.

4. Check the skillet pouring lip corners to be sure they are clean. Also, wash around the exterior of the skillet. Rinse with

clean water and air dry.

WARNING!: DO NOT GET WATER ON WIRING OR CONTROLS. BE SURE TO WASH INSIDE OF SKILLET PAN, INSIDE OF

COVER INCLUDING UNDER DRIP-LIP, AND POURING SPOUT AREA.

WARNING!: THE SKILLET PAN AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING, CLEANING AND SERVICING

THE TILT SKILLET.

WARNING!: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE DISCONNECT SWITCH TO INDICATE THAT YOU ARE WORKING ON THE CIRCUIT BEFORE PERFORMING ANY MAINTENANCE.

ADJUSTMENT NOTE!: ALL TILTING SKILLETS ARE ADJUSTED AT THE FACTORY. AT LEAST TWICE A YEAR HAVE AN

AUTHORIZED SERVICE PERSON CLEAN AND ADJUST THE TILTING SKILLET FOR MAXIMUM PERFORMANCE.

7

Page 10

WIRING: 208V/220V/240V

8

Page 11

WIRING: 220V/380V - 240V/415V

9

Page 12

WIRING: 480V

10

Page 13

PARTS

FIGURE NO. 1 Main Assembly

11

Page 14

PARTS

ITEM PART FIGURE NO. 1 30 40

NO. NO. DESCRIPTION GAL. GAL.

1 98-6031 PAN COVER ASSEMBLY 1

98-6032 PAN COVER ASSEMBLY 1

2 98-6033 LEFT HAND TRUNNION ASSEMBLY 1 1

3** 98-6034 FAUCET COVER PLATE 1 1

~NPN~ FAUCET MOUNTING PLATE PANTRY FAUCET 1 1

~NPN~ FAUCET MOUNTING PLATE DOUBLE FAUCET 1 1

4 98-6035 LEFT HAND CONSOLE TOP COVER 1 1

5 98-6036 LEFT HAND CONSOLE TILT SHAFT BEARING BRACKET 1 1

6 98-6037 LOWER CONSOLE SIDE PANEL LEFT HAND 1 1

7 98-6038 LEFT HAND CONSOLE FRONT COVER 1 1

8 97-5577 GRIP HANDLE 1 1

9 98-6040 CRANK SHAFT 1 1

10 98-6041 INPUT SHAFT ADAPTOR 1 1

11 98-6042 ADJUSTABLE BULLET FOOT 2 2

12 98-6043 RIGHT HAND FRONT CONSOLE COVER 1 1

13 98-6044 DECAL 1 1

14 98-6045 TIMER COMPLETE WITH DIAL 1 1

15 98-6046 THERMOSTAT DIAL 1 1

* 98-6047 ROTARY SHAFT SEAL 1 1

16 98-6048 PILOT LIGHT - TEMPERATURE, RED 1 1

17 98-6049 RIGHT HAND CONSOLE TOP COVER 1 1

18 98-6050 SPRING RETAINER 2 2

* 98-6051 Hx. BOLT 3/8-16 x 1 1/2 4 4

* 98-6052 WASHER 3/8 STAINLESS STEEL 4 4

* 98-6053 SPACER 4 4

19 98-6054 GEAR BOX ASSEMBLY 1 1

19A 97-6396 WORM GEAR

20 98-6055 FLANGE ADJUSTABLE FOOT 2 2

21 98-6056 LOWER CONSOLE SIDE PANEL RIGHT HAND 1 1

22 98-6057 TILT SHAFT 1

98-6058 TILT SHAFT 1

23 98-6059 TILT ARM EXTENSION 2 2

24 98-6060 ARM, LIFT 2 2

25 98-6061 ROLL PIN, 1/4 x 1 1/2 STAINLESS STEEL 2 2

98-6062 Hx. BOLT 1/4 x 1 1/2 STAINLESS STEEL 2 2

26 91-9145 SPRING, RIGHT HAND 1 1

91-9144 SPRING, LEFT HAND 1 1

27 98-6065 FLUE ASSEMBLY 1

12

Page 15

PARTS

ITEM PART FIGURE NO. 1 30 40

NO. NO. DESCRIPTION GAL. GAL.

27 98-6066 FLUE ASSEMBLY 1

98-6065 FLUE ASSEMBLY 1

98-6066 FLUE ASSEMBLY 1

28 98-6067 RIGHT HAND TRUNNION ASSEMBLY 1 1

98-6068 SWIVEL BRACKET 1 1

29 98-6069 LIQUID TIGHT CONNECTOR 1/2” 1 1

98-6070 LOCKNUT 1/2” 1 1

30 97-5702 CORD SET 1 1

31 98-6072 POST ASSEMBLY 2 2

32 97-5545 CAP SCREW 5/16-18 x 3/4 STAINLESS STEEL 8 8

33 97-5352 LOCK PIN 2 2

34 97-5343 END LOCK PIN 2 2

35 98-6073 STATIONARY DISC 2 2

36 98-6074 CORE 2 2

37 97-5160 SPRING 2 2

38 98-6076 ROTARY DISC 2 2

39 97-5356 END STOP PLATE 2 2

40 98-6078 FRONT COVER PANEL (MODULAR UNITS) 1

98-6079 FRONT COVER PANEL (MODULAR UNITS) 1

41 98-6080 BACK COVER PANEL (MODULAR UNITS) 1 1

98-6081 BACK COVER PANEL (MODULAR UNITS) 1

42 98-6082 VENT COVER 1 1

43 98-6083 SWIVEL SPACER 1 1

44 91-9262 ARM 1 1

45 98-6084 KNOB 1 1

46 98-6085 SWIVEL BASE 1 1

47 98-6086 WASHER 1/4 STAINLESS STEEL 1 1

48 98-6087 Hx. Hd. SCREW 1/4-20 x 3/8 STAINLESS STEEL 1 1

49* 98-6013 POUR LIP STRAINER 1 1

* NOT SHOWN

** SELECT AS REQUIRED

13

Page 16

PARTS

FIGURE NO. 3 Control Circuit Components

ITEM PART FIGURE NO. 3

NO. NO. DESCRIPTION QTY.

1 98-6131 COMPONENT MOUNTING BOARD 1

2 97-5441 GROUND LUG 1

3 97-4617 TERMINAL BLOCK SECTION ASSEMBLY 3

4 98-6132 FUSE HOLDER 1

5** 97-5476 FUSE, 3A, 250V (120V UNIT) 1

98-6134 FUSE, 1A, 250V (220V UNIT) 1

6 98-6189 CONTACTOR 1

7 98-6190 TEMPERATURE CONTROL 1

8* 98-6138 TRANSFORMER, 220-120V, 100VA (220V UNIT) (NOT

SHOWN)

** SELECT AS REQUIRED

1

14

Page 17

PARTS

FIGURE NO. 4 Draw-Off Valve Assembly

ITEM PART FIGURE NO. 4

NO. NO. DESCRIPTION QTY.

98-6014 2” DRAW-OFF VALVE ASSEMBLY

1 98-6155 ACORN NUT 10-24 UNC 1

2 97-5413 HANDLE STAINLESS STEEL 1

3 97-5069 GLAND NUT 1

4 97-5072 BONNET 1

5 97-5078 “O” RING 1

6 97-5075A STEM ASSEMBLY 1

7 98-6156 VALVE BODY 1

8* 98-6010A DRAW-OFF STRAINER (OPTIONAL) 1

* NOT SHOWN

15

Page 18

PARTS

FIGURE NO. 5 Optional Motor Tilt Components (LX Models)

16

Page 19

PARTS

ITEM PART FIGURE NO. 5

NO. NO. DESCRIPTION QTY.

1 98-6139 TILT SWITCH 1

2 97-5793 SPRING TENSION PIN 3/16 x 1 1/4 LONG 1

3 98-6140 UNIVERSAL JOINT 1

4 98-6141 SET SCREW 5/16-18 x 3/8 2

5 98-6142 MOTOR MOUNTING BRACKET 1

6** 97-5351 Hx. SCREW 5/16-18 x 3/4 3

~NPN~ FLAT WASHER 5/16 3

~NPN~ LOCK WASHER 5/16 3

7 98-6144 MOTOR 1/20 HP 230V 1

8 98-6146 CAPACITOR 440 VAC 2.0 MFD (230V MOTOR) 1

9 98-6147 MOTOR ACCESS PANEL 1

10 98-6148 Hx. BOLT 1/4-20 x 1/2 2

11 98-6149 SWITCH MOUNTING BRACKET 1

12 98-6150 SCREW 6-32 x 1 4

13 97-5414 LIMIT SWITCH 2

14 98-6151 CAM ACTUATOR 1

15 98-6152 SET SCREW 1/4-20 x 1/2” 2

16 97-5642 HIGH LIMIT THERMOSTAT 1

17** 98-6153 FUSE 3/4 AMP TIME DELAY (120V MOTOR) (NOT SHOWN) 1

98-6154 FUSE 0.3A TIME DELAY 250V (230V MOTOR) (NOT SHOWN) 1

98-6132 FUSE HOLDER (NOT SHOWN) 1

** SELECT AS REQUIRED

17

Page 20

PARTS

FIGURE NO. 6 Heating Element Pan Assembly

18

Page 21

PARTS

ITEM PART FIGURE NO. 6 30 40

NO. NO. DESCRIPTION GAL. GAL.

1 98-6163 BOTTOM COVER 1

98-6164 BOTTOM COVER 1

2 98-6165 HEX HD. BOLT, 1/4 - 20 x 7/8 8 8

3 98-6166 LEFT HAND ELEMENT INSULATION SHIELD (30 Gal.) 1

98-6167 LEFT HAND ELEMENT INSULATION SHIELD (40 Gal.) 1

4 98-6168 RIGHT HAND ELEMENT INSULATION SHIELD (30 Gal.) 1

98-6169 RIGHT HAND ELEMENT INSULATION SHIELD (40 Gal.) 1

5 98-6170 HIGH LIMIT BULB ENCLOSURE 1 1

6 97-6629 THERMOCOUPLE 1 1

7 97-5642 HIGH LIMIT THERMOSTAT 1 1

**8 98-6171 ELEMENT ASSEMBLY, 208V, 4KW 3

98-6172 ELEMENT ASSEMBLY, 220V, 4KW 3

98-6173 ELEMENT ASSEMBLY, 240V, 4KW 3

98-6174 ELEMENT ASSEMBLY, 277V, 4KW

(USED ON 480 VOLT APPLICATION ONLY)

98-6175 ELEMENT ASSEMBLY, 347V, 4KW 3

98-6176 ELEMENT ASSEMBLY, 208V, 6KW 3

98-6177 ELEMENT ASSEMBLY, 220V, 6KW 3

98-6178 ELEMENT ASSEMBLY, 240V, 6KW 3

98-6179 ELEMENT ASSEMBLY, 277V, 6KW

(USED ON 480 VOLT APPLICATION ONLY)

98-6180 ELEMENT ASSEMBLY, 347V, 6KW 3

9 98-6181 ELEMENT CLAMP (30 Gal.) 9

98-6182 ELEMENT CLAMP (40 Gal.) 9

10 98-6183 HEX NUT, 1/4 - 20 29 29

** Select as required.

3

3

19

Page 22

An Employee Owned Company

35 Garvey Street, Everett, MA 02149, Tel: (617) 387-4100,

Toll Free (866) 698-3188, Fax: (617) 387-4456, Outside MA Fax: (800) 227-2659, custserv@mfii.com, www.mfii.com

UniVerse Plus Tilting Skillet

Pan Support 98-6006

The Correct Positioning of the

Skillet Pan Support

Form No.

98-6006

10/10

Page 1 of 2

Page 23

An Employee Owned Company

35 Garvey Street, Everett, MA 02149, Tel: (617) 387-4100,

Toll Free (866) 698-3188, Fax: (617) 387-4456, Outside MA Fax: (800) 227-2659, custserv@mfii.com, www.mfii.com

UniVerse Plus Tilting Skillet

Pan Support 98-6006

The Incorrect Positioning of the

Skillet Pan Support

Form No.

98-6006

10/10

Page 2 of 2

Loading...

Loading...