Market Forge 3500M42MT6G Owner’s Manual

MT 6/10 GALLON SERIES

MODULAR BASE DIRECT STEAM TILTING KETTLES

INSTALLATION - OPERATION - MAINTENANCE

MODELS ON

CABINET BASE

MT6

MT10

MT6T6

MT10T6

MT10T10

Telephone: (802) 658-6600 Fax: (802) 864-0183

www.marketforge.com PN 14-0325 Rev F (11/17)

MODEL WITH

GAS BOILERS

MT6G

MT10G

MT6T6G

MT10T6G

MT10T10G

© 2017 - Market Forge

MODEL WITH

ELECTRIC BOILERS

MT6E

MT10E

MT6T6E

MT10T6E

MT10T10E

Your Service Agency’s Address:

Model

Serial number

Kettle installed by

Installation checked by

IMPORTANT

TABLE OF CONTENTS

WARNING: Improper installation, adjustment, alternation,

service or maintenance can

cause property damage, injury or death. Read the installation, operation and maintenance instructions thoroughly

before installing or servicing

this equipment.

FOR YOUR SAFETY

Do not store or use gasoline or

other ammable vapors or liquids in the vicinity of this or any

other appliance.

The information contained in this

manual is important for the proper installation, use, and maintenance of this kettle. Adherence

to these procedures and instructions will result in satisfactory

baking results and long, trouble free service. Please read

this manual carefully and retain

it for future reference.

INSTALLATION

Introduction .............................................................. 2

Service Connections - Cabinet Base Models ................................ 3

Service Connections - Gas Boiler Models .................................. 7

Service Connections - Electric Boiler Models .............................. 11

OPERATION

Operating & Cleaning Instructions ........................................ 15

ERRORS: Descriptive, typographic or pictorial errors are

subject to correction. Specications are subject to change

without notice.

Introduction

Market Forge MT6 and MT10 series tilting steam

jacketed kettles are mounted on a modular stainless steel cabinet, a gas boiler or an electric boiler.

Double wall construction around the lower half of

the kettle forms a surrounding chamber inot which

steam is introduced as a source of heat for cooking.

Steam input plumbing is equipped with a manual

control valve. Condensate is removed through a

steam trap connecting with the kettle drain plumbing assembly. A swing nozzle, hot-cold combination

faucet provides a source of water for addition to the

kettle for cooking and cleaning.

The 6 gallon kettle is mounted in a trunnion assembly to the modular base. The trunnion pivots include

steam input and return connections for the kettle.

Kettle tilting is accomplished manually by moving

the handle xed to the rim so as to rotate the kettle

in a trunnion.

CABINET BASE MODELS:

• MT6 - Single 6 gallon mounted on an 24”

(457mm) wide x 28” (711mm) tall cabinet base

equipped for direct connection to a remote

steam source

• MT10 - Single 10 gallon mounted on an 24”

(457mm) wide x 28” (711mm) tall cabinet base

equipped for direct connection to a remote

steam source

• MT6T6 - Two 6 gallon kettles mounted side by

side on an 36” (914mm) wide x 28” (711mm) tall

cabinet base equipped for direct connection to

a remote steam source.

• MT10T10 - Two 10 gallon kettles mounted side

by side on an 36” (914mm) wide x 28” (711mm)

tall cabinet base equipped for direct connection

to a remote steam source.

• MT10T6 - One 10 gallon and one 6 gallon kettle

mounted side by side on an 36” (914mm) wide

x 28” (711mm) tall cabinet base equipped for

direct connection to a remote steam source.

GAS BOILER BASE MODELS:

• MT6G - Single 6 gallon mounted on an 24”

(457mm) wide x 28” (711mm) tall gas boiler

• MT10G - Single 10 gallon mounted on an 24”

(457mm) wide x 28” (711mm) tall gas boiler

• MT6T6G - Two 6 gallon kettles mounted side by

side on an 36” (914mm) wide x 28” (711mm) tall

gas boiler

• MT10T10G - Two 10 gallon kettles mounted

side by side on an 36” (914mm) wide x 28”

(711mm) tall gas boiler

• MT10T6G - One 10 gallon and one 6 gallon

kettle mounted side by side on an 36” (914mm)

wide x 28” (711mm) tall gas boiler

ELECTRIC BOILER BASE MODELS:

• MT6E - Single 6 gallon mounted on an 24”

(457mm) wide x 28” (711mm) tall electric boiler

• MT10E - Single 10 gallon mounted on an 24”

(457mm) wide x 28” (711mm) tall electric boiler

• MT6T6E - Two 6 gallon kettles mounted side by

side on an 36” (914mm) wide x 28” (711mm) tall

electric boiler

• MT10T10E - Two 10 gallon kettles mounted

side by side on an 36” (914mm) wide x 28”

(711mm) tall electric boiler

• MT10T6E - One 10 gallon and one 6 gallon

kettle mounted side by side on an 36” (914mm)

wide x 28” (711mm) tall electric boiler

SERVICE:

Modular kettles are durable cooking equipment requiring a minimum of service other then routine

cleaning and preventive methods. Should repairs be

required, a network of authorized service agencies

is available to assist with prompt service. A current

directory of authorized service agencies is available

on our website, www.mi.com.

The model and/or serial numbers must be referenced when corresponding with Market Forge. The

data plate containing model and serial numbers per-

taining to the equipment is located inside the cabinet

door on the right vertical frame member.

INSTALLATION

2

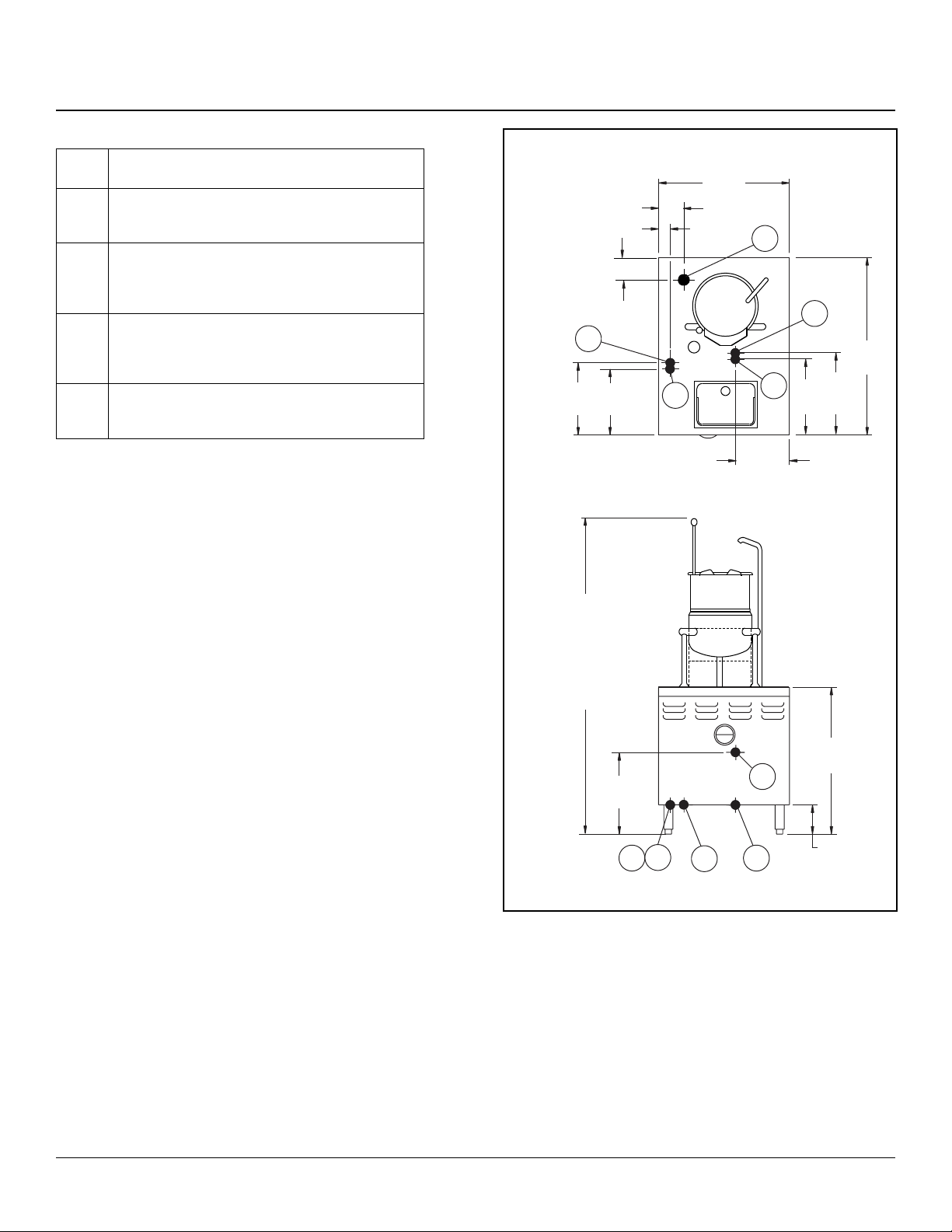

Service Connections - Cabinet Base Models

MT-6 & MT-10

S* Steam Supply - 1/2 (13mm) NPT for incoming steam

at 15-50 PSI (1.0-3.5kg/cm2).

D Drain - Pipe full 2” (50mm) NPT to flush floor drain.

DO NOT MAKE SOLID CONNECTION TO FLOOR

DRAIN.

HW Hot Water - 3/8” (10mm) NPT for hot water to faucet.

Hot water line will have a maximum of 50 PSI (3.5kg/

cw2) and a minimum of 25 PSI (1.8 kg/cw2) water

pressure (Water may be filtered).

CW Cold Water - 3/8” (10mm) NPT for cold water to

faucet. Cold water line will have a maximum of 50 PSI

(3.5kg/cw2) and a minimum of 25 PSI (1.8 kg/cw2)

water pressure.

CR** Condensate Return - 1/2 (13mm) NPT condensate

return from kettle may be connected to condensate

return line.

* Pressure reducing valve is required if incoming pressure exceeds

50 PSI (3.5kg/cm2).

** Optional at extra cost

NOTES:

PVC and CPVC pipe are not acceptable materials for drains.

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water quality must be within the following general guidelines.

TDS: 40-125 ppm Chlorides: <25 ppm

Silica: <13 ppm pH: 7.0 - 8.5

Chloramine: <0.2 ppm Chlorine: <0.2 ppm

Hardness: 35-100 ppm

DIMENSIONS ARE IN INCHES [MM]

4 [102]

CW

8.5

10.5

[267]

55.25

[1043]

MT6

[1473]

MT10

[216]

58

HW

24 [610]

4 [102]

2.5 [64]

CR

9 [229]

D

S

33

[838]

12

[305]14[356]

The best defense against poor water quality is a water treatment

system designed to meet your water quality conditions.

Appliance to be installed with backflow protection according to federal,

state or local codes.

28

[711]

6 [152]

18

[457]

HW

CW

CR

S

D

Figure 1

3

INSTALLATION

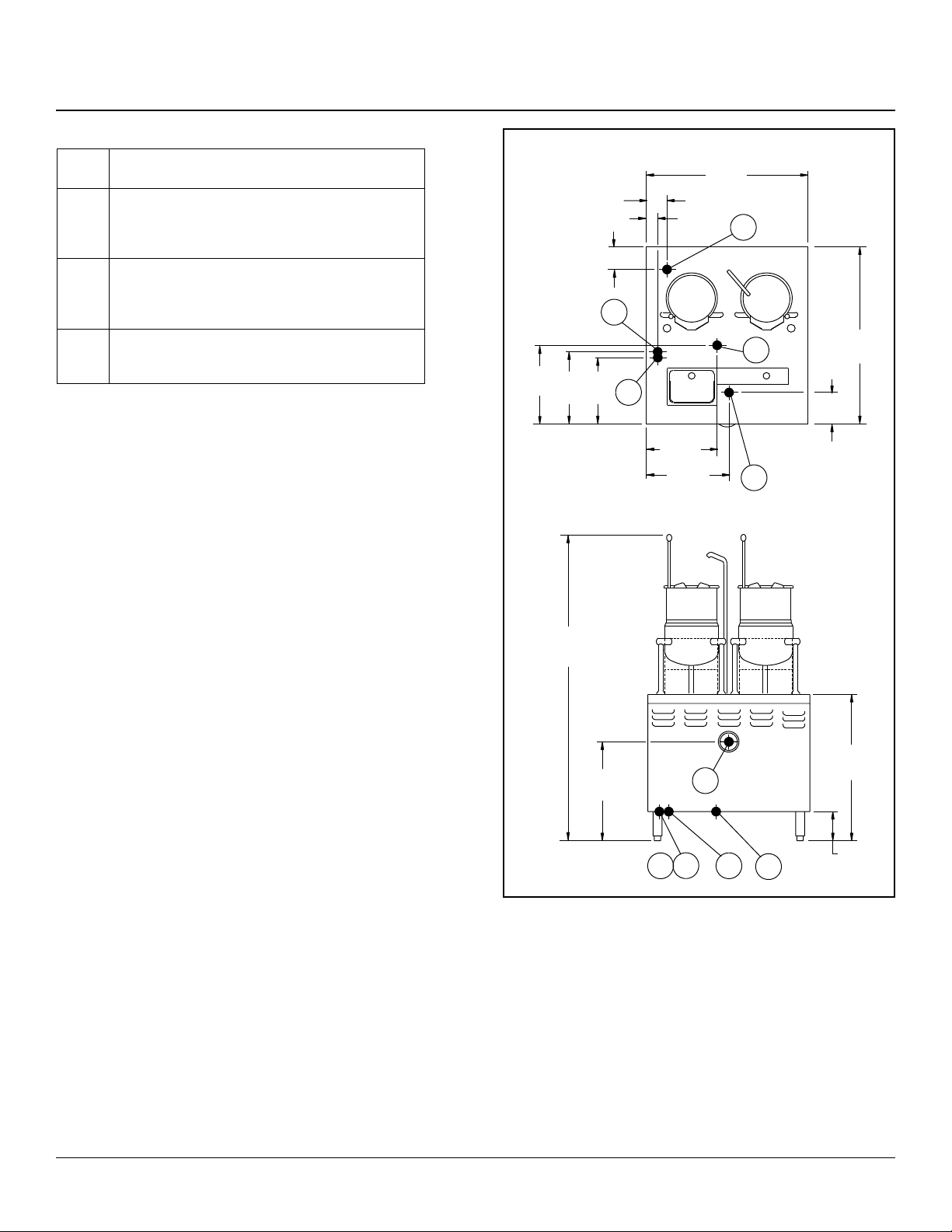

Service Connections - Cabinet Base Models

MT6T6

S* Steam Supply - 1/2 (13mm) NPT for incoming steam

at 15-50 PSI (1.0-3.5kg/cm2).

HW Hot Water - 3/8” (10mm) NPT for hot water to faucet.

Hot water line will have a maximum of 50 PSI (3.5kg/

cw2) and a minimum of 25 PSI (1.8 kg/cw2) water

pressure (Water may be filtered).

CW Cold Water - 3/8” (10mm) NPT for cold water to

faucet. Cold water line will have a maximum of 50 PSI

(3.5kg/cw2) and a minimum of 25 PSI (1.8 kg/cw2)

water pressure.

CR** Condensate Return - 1/2 (13mm) NPT condensate

return from kettle may be connected to condensate

return line.

* Pressure reducing valve is required if incoming pressure exceeds

50 PSI (3.5kg/cm2).

** Optional at extra cost

NOTES:

PVC and CPVC pipe are not acceptable materials for drains.

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water quality must be within the following general guidelines.

TDS: 40-125 ppm Chlorides: <25 ppm

Silica: <13 ppm pH: 7.0 - 8.5

Chloramine: <0.2 ppm Chlorine: <0.2 ppm

Hardness: 35-100 ppm

DIMENSIONS ARE IN INCHES [MM]

4 [102]

CW

12

10.5

[267]

55.25

[1403]

8.5

[216]

HW

15 [381]

18 [457]

[305]

4 [102]

2.5 [64]

36 [914]

CR

D

S

33

[838]

6 [152]

The best defense against poor water quality is a water treatment

system designed to meet your water quality conditions.

Appliance to be installed with backflow protection according to federal, state or local codes.

18

[457]

CW

HW

Figure 2

28

S

CR

D

[711]

6 [152]

INSTALLATION

4

Loading...

Loading...