Page 1

COOKER CHECK-OUT

The cooker check-out procedure is as follows:

1. Set both 60 minute timers to the "4 minute" position. Observe that the indicator lights are off and

steam does not enter compartments.

2. Close the cooker compartment doors to be certain that latches are securely engaged. Observe

that indicator lights are on and steam can be heard entering the compartments.

3. Observe the boiler drain line for steam flow to the open floor drain. Correct steam condenser

operation is evidenced by the presence of water flowing from the drain.

4. Cooker operation is correct when, after a short preheat time delay the timer dials begin to move

toward "0". After the delay period plus the "4 minute" initial setting the timer dials will return to the

"0" position, the buzzer will sound and is silenced by turning the dial to the OFF position.

5. The steam cooker/generator start -up and shut-down must be completed a total of three times to

ensure cleanliness and proper operation before the final check-off.

Page 2

GENERAL

This section contains both preventive and corrective maintenance information. Preventive

maintenance may be performed by maintenance personnel at the establishment in which the

cooker is installed.It is recommended that user personnel never attempt to make repairs or

replacements to the equipment Assistance in service methods or a current directory of

authorized agencies may be obtained from Market Forge Co.

DAILY CLEANING

After each period of daily operation (more frequently as required to maintain cleanliness) the

cooker should be thoroughly cleaned by completing the following steps:

1. Remove all pan supports by lifting up and off mounting studs and remove the drain screen

from the lower left comer of each compartment Wash with warm water and detergent, rinse

and set aside for reassembly.

2. Wash cooking compartment interior using warm water and detergent rinse and dry

thoroughly.

3. Replace pan supports and drain screens, leave doors ajar.

4. Remov e wash and rinse drain trough.

PREVENTIVE MAINTENANCE

A good preventive maintenance program begins with the daily cleaning procedure

described above. Additional preventive maintenance operations are presented in

this section. In establishments which employ full-time maintenance personnel, the

tasks described can be assigned to them. For other installations tasks requiring

mechanical or electrical experience must be performed by an authorized service

agency. The following paragraphs set forth minimum preventive maintenance

procedures which must be completed periodically to assure continued trouble free

operation.

CAUTION

Under no circumstances should hardware (or parts) be replaced with a different size

or type other than as specified in the parts list. The hardware used in the cooker has

been selected or designed specifically for its application and the use of other

hardware may damage the equipment present a safety hazard and will void any

warranty.

DOOR ADJUSTMENT

This unit is equipped with a positive slam action type latch mechanism that is factory

set and permanently secured. In the event of a steam leak between the gasket and

the face of the cooker, the gasket should be adjusted to provide an air tight joint To

reset the gasket proceed as follows:

1. Close the door.

2. Pre-heat cooker compartment This will simulate actual cooking conditions. It is

recommended that this adjustment be made on a heated unit

3. Inspect the door and observe escaping steam.

4. Loosen the four adjustment screws located on the right and left ends of the door.

5. Press door against cooker body by maintaining moderate pressure against the

outer door. This will engage the gasket firmly with the face of the cooker. Tighten

the four adjustment screws -

If, after performing the described adjustment the seal is not tight replace the gasket

Note- Should the latch/striker mechanism become inoperative the component parts are

replaceable.

MAINTENANCE

2

Page 3

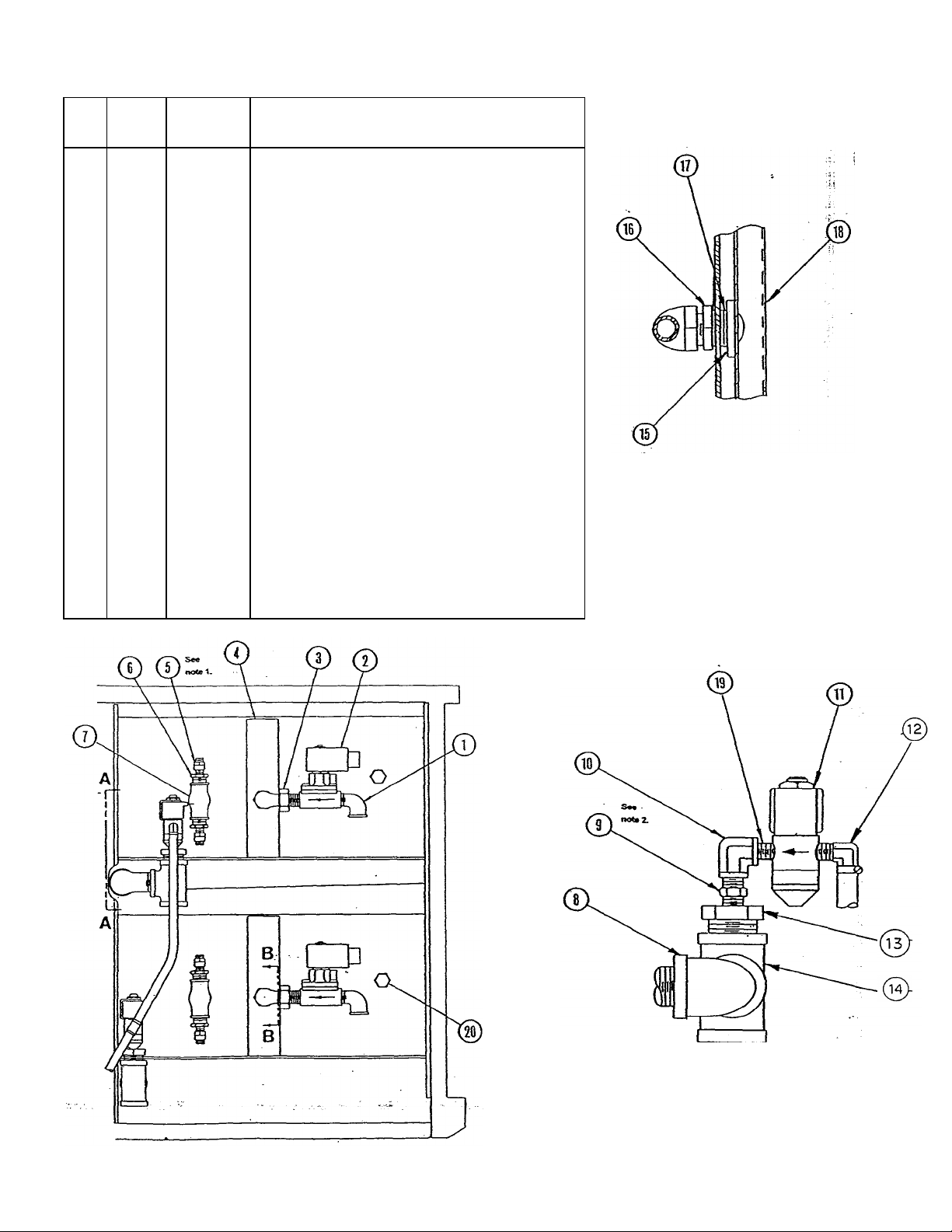

3500 - Control Side Plumbing

SECTION B

-B

NOTES:

SECTION A

-A

ITEM

QTY.

PER

COMP-

1 1 10-2811 STREET ELBOW. 1/2" IPS

2 1 10-5859 VALVE, SOL, 1/2" STM. ( 120 VOLT) 60 Hz

1 10-7340 VALVE, SOL. 1/2" STM. ( 240 VOLT) 60 Hz

3 1 10-4844 EL, UNION, 90 DEGREE, 1/2" IPS. BRASS

4 1 91-3430 CHANNEL

5 2 08-4874 VALVE, PRESSURE RELIEF

6 2 10-3324 BUSHING,REDUCING, 1/2" X 1/4" IPS

7 1 10-3442 TEE, BRASS. 1/2" X 1/2" X 3/4" IPS

8 1 08-4831 ELBOW, 90 DEGREE, B.I., 1" IPS, STREET

9 1 08-4866 NOZZLE, CONDENSER ( NEWER MODELS )

10 1 09-4817 EL, 90 DEGREE, REDUCING, 1/2" X 1/4" IPS.

11 1 08-4821 VALVE, SOL. 1/4" WTR., (120 VOLT) 60 Hz

1 08-4810 VALVE, SOL, 1/4" WTR-, ( 240 VOLT) 50 Hz

12 1 08-4841 STEAM SUPPLY HOSE ( UPPER COMP.)

1 08-4842 STEAM SUPPLY HOSE ( LOWER COMP.)

13 1 08-4867 BUSHING, 1" NPT X 1/4" NPT

14 1 10-8045 TEE, M.I.1" NPT

15 1 08-4407 SPACER, RUBBER

16 1 10-3343 LOCKNUT, 1/2" IPS

17 3 91-6203 GASKET, .859 ID X 1-1/32 OD X 1/8" TK

18 1 91-3240 JET PIPE

19 1 09-4816 NIPPLE, CLOSE, BRASS, 1/8" NPT

20 1 10-8105 COMPARTMENT THERMOSTAT

PART

NUMBER

DESCRIPTION

1. Assemble item 5

2. Assemble item 9

Page 4

PER

NUMBER

1

6429

TRANS., STEP DN.

24

V

ITEM

QTY.

PER

1 1 10-9174

1 08-6343

1 10-9175

1 08-6344

2 1 08-6308

3 1 10-6291

1 10-6293

4 1 10-6682

1 10-6665

5 1 10-5859

1 10-7340

6 1 10-8105

7 1 08-4821

1 08-4810

8 1 10-5016

NUMBER

PART

3500 WIRING SCHEMATIC PARTS LIST

DESCRIPTION

RELAY, 120 VOLT

RELAY, 240 VOLT

SOCKET, RELAY 120 VOLT

SOCKET, RELAY 240 VOLT

REED SWITCH

60 MIN. TIMER 120 V

60 MIN. TIMER 240V

BUZZER, 120 VOLT

BUZZER, 240 VOLT

SOLENOID, STEAM 120 V

SOLENOID, STEAM 240 V

THERMOSTAT, 195 F

COND.. THERM.. 120V

COND., THERM., 240 V

PILOT LT. 120V

ITEM

OPTIONAL -NOT SHOWN

QTY.

1

PART

0808-6450

TIMER, DIGITAL

MODEL: 3500

DESCRIPTION

4

Page 5

ILLUSTRATED PARTS LIST - DOOR ASSEMBLY

QTY.

ITEM

1 1 91 - 6229 OUTER DOOR

2 1 91 - 6241 INNER DOOR

3 1 08-4400 DOOR GASKET

4 1 91 - 6237 GASKET RETAINING PLATE

5 4 10 - 2396 8 - 32 SELF LOCKING SCREW

6 4 08 - 4601 COMPRESSION SPRING

7 1 91 - 6228 DOOR HANDLE

8 4 09 - 3429 1/4-20 X 3/8 HX. HD. BOLT

9 4 10-2513 1/4" INTERNAL TOOTH WASHER

10 2 08-4600 COMPRESSION SPRING

11 2 10-2365 10 - 32 SELF LOCKING NUT

12 2 10-0369 HANDLE CAP

13 4 10 - 0100 1/2 O.D. NYLON WASHER

14 1 09 -1608 LATCH STRIKER CASTING

15 2 10 -1728 8 - 32 X 3/8" LG. FLATHEAD SCREW

16 2 08 - 2702 NYLON FLANGED BEARING

17 1 91-9216 MAGNET, DOOR - NOT SHOWN

PER

COMP.

PART

NUMBER

DESCRIPTION

5

Page 6

3500 - Drain Connection

6

Page 7

3500 CONTROL PANEL ASSEMBLY

QTY.

ITEM

PER

COMP.

1 1 91 - 6350 CONTROL PANEL, 60Hz

2 1 10-5016 PILOT LIGHT

3 1 09 - 5259 KNOB, TIMER

4 1 10-6291 60 MIN. TIMER, 120 V

5 1 10-6682 BUZZER, 120 V

6 1 10-6005 TERMINAL BLOCK

PART

NUMBER

91 - 6351 CONTROL PANEL, 50 Hz

10-6293 60 MIN. TIMER, 240 V

08 - 6429 DIGITAL TIMER

10-6665 BUZZER, 240V

DESCRIPTION

CONTROL PANEL ASSEMBLY VIEW - FRONT & BACK

4

5

7

Page 8

TROUBLE SHOOTING GUIDE

GENERAL

The information In this section Is Intended to assist the operator, maintenance

and the service personnel in locating the source of problems which may occur

with the cooker. Before following any of the procedures given in this section,

the operator/maintenance person should be thoroughly familiar wfth the

operating instructions and the function of all controls as described in the

operating instructions section of this manual. If the problem cannot be readily

corrected without the use of tools the operator/maintenance person should

contact the nearest Market Forge service agency for assistance.

TROUBLES POSSIBLE CAUSE REMEDY

60 minute timer indicator light

fails to light when timer is set

Steam fails to enter cooking

compartment with indicator light

on.

Steam enters compartment

continuously. Timer dial not

turning.

1. Power to cooker is off 1. Locate external breaker and

place it in ON position

Door interlock switch contacts

not closed.

*3. Door interlock switch faulty. 3. Replace switch.

*4. Burned out bulb-faulty light 4. Replace light

*5. Faulty timer contacts. 5. Replace timer.

*6. Faulty selector switch. 6. Replace switch.

*7. Faulty wiring. 7. Inspect condition of wire and

*1. Faulty solenoid valve

*2. Faulty wiring.

*1- Faulty thermostatic switch.

*2. Faulty timer motor.

*3. Faulty steam solenoid valve- 3.Replace valve.

*4. Faulty wiring.

2. Shut cooker door to dose

switch contacts.

tightness of all connections.

Correct as needed.

1. Replace valve

2. Inspect condition of wire and

tightness of all connections.

Correct as needed.

1. Replace switch.

2. Replace timer.

4.Inspect condition of wire and

tightness of all connections.

Correct as needed.

Page 9

direct connect steam control)

TROUBLE SHOOTING GUIDE

TROUBLES POSSIBLE CAUSE REMEDY

Steam continues to flow into

compartment and/or buzzer

fails to sound at end of timer

setting

*1. Timer contacts faulty. 1. Replace timer.

*2. Buzzer faulty. 2. Replace buzzer

Steam flows continuously

from steam generator (or

drain line with cooker in

operation

. *2. Faulty condenser thermostat. 2. Replace thermostat.

*4. Faulty wiring. 3. Inspect condition of wire and

tightness of all connections.

Correct as needed.

1. Cold water not connected. 1. Turn on external shut off valve.

*3. Faulty cold water solenoid. 3. Replace Valve-

*4. Faulty wiring. 4. Inspect condition of wire and

tightness of all connections.

Correct as needed.

Page 10

ITEM PART# QTY REQUIRED DESCRIPTION

*14 10-2513 4 1/4"A" WASHER

*16 10-0369 2 CAP, HANDLE

**17 91-6242 REF. ONLY

ASSY DOOR

*18 08-4601 4 SPRING COMPRESSION BETWEEN

INNER AND OUTER DOOR.

21 10-2403 4 WASHER

1 91-6228 1 HANDLE, DOOR

2 91-6229 1 OUTER DOOR

3 10-0100 8 WASHER,NYLON

4 08-4601 4 SPRING COMPRESSION

5 09-1608 1 STRIKER, DOOR LATCH

6 10-2396 2 NUT, SELF—LOCKING

7 10-1728 2 SCREW, FLATHEAD

8 91-9297 1 LATCH

9 08-2700 2 BEARING

10 10-2396 2 NUT, SELF LOCKING

*11 91-6241 1 RETAINER ASSY, INNER DR

*12 08-4400 1 GASKET, DOOR

*13 08-3406 4 SCREW, BUTTON HEAD

*15 08-4600 2 SPRING, COMPRESSION

19 10-0369 2 END CAPS

20 08-3406 4 SCREW (ADJ)

22 10-2513 4 STARWASHER

*NOT SHOWN IN EXPLO DED VIEW

** To receive a complete door, please list above items with accompanying quantities. The exceptions to this are items

#1,8,9,&10

Door Assembly

10

Loading...

Loading...