Page 1

SERVICE & PARTS

MANUAL

DUAL MATIC

STEAM COOKER

Model 3100

MARKET FORGE CANADA LTD.

Mississauga. Ontario, Canada

Form Number S2124 3/78 Printed in U.S.A.

Page 2

TABLE OF CONTENTS

1.2 Basic Functioning

1-1

2.2 Setting In Place

2-1

2.3 Mechanical Connections

2-1

2.4 Installation Check

-

Out

2-1 2.4.1 Initial Control Setting

2-1

2.4.2 Cooker

Check

-

Out 2-1

3.2.1 Generator Start

-Up 3-1 3.2.2 Preheating

3-1

3.2.3 Pressureless Steam Cooking

3-1

3.2.4 Pressure Cooking

3-1

3.2.5 Shut-Down Procedure

3-2

4.2 Steam Circuits

4-1 4.2.1 Steam Inlet Line

4-1

4.2.2 Steam Exhaust and Drain

Lines

4-1

4.2.3 Pressure Safety Line

4-1

4.2.4 Evacuation Line

4-2

4.2.5 Pressure Indicator Line

4-2 4.3 Electrical Circuits

4-2 4.3.1 Control Circuit Components

4-3 4.3.2 Pressure Cooking Operation

4-4 4.3.3 Pressureless Cooking Operation

4-4

5.2 Trouble

-

Shooting Guides

5-1

5.3 Electrical Fault Isolation

5-1

5.4 Electrical Trouble

-

Shooting Procedures

5-5

5.4.2 Electrical Inspection

5-5 5.4.3 Selector Switch

5-5

5.4.4 60-Minute Timer

5-5 5.4.5 10-Minute Timer

5-7 5.4.6 Push

-

Button Timer

5-7 5.4.7 Door Interlock Switch

5-8 5.4.8 Solenoid Valves

5-8

5.4.9 Buzzer

5-8

5.4.1.0

Indicator Light

5-8

6.2 Preventive Maintenance

6-1 6.2.1 Door Disassembly and Cleaning

6-1

6.2.2 Safety Valve Check

6-2

6.2.3 Door Fulcrum Cleaning

&

Lubrication

6-3

6.3.1 Door Assembly

6-3 6.3.2 Exterior Panel Removal

6-4

6.3.3 Control Panel Removal

6-4 6.3.4 Pressure Relief and Check Valve

6.3.5 Steam Trap Replacement

6-5

6.3.6 Jet Pipe Replacement

6-6

6.3.7 Inlet Solenoid Valve Replacement

6-6

7.2 Ordering Information

7-1

Paragraph Paragraph

SECTION 1 INTRODUCTION

1.1 Description 1-1

SECTION 5 TROUBLE-SHOOTING

5.1 General 5-1

1.3 Service 1-1

SECTION 2 INSTALLATION

2.1 Assembly 2-1

5.4.1 Incoming Power 5-5

2.4.3 Shut-Down Procedure 2-2

SECTION 3 OPERATION

3.1 Operating Controls and Indicators 3-1

3.2 Operating Procedures 3-1

5.4.1.1 Wiring 5-9

SECTIONS MAINTENANCE

6.1 General 6-1

3.3 Cleaning 3-2

SECTION 4 PRINCIPLES OF OPERATION

4.1 General 4-1

6.3 Repair and Replacement 6-3

Replacement 6-4

6.3.8 Exhaust Solenoid Valve Replacement 6-6

SECTION 7 ILLUSTRATED PARTS LIST

7.1 General 7-1

S2124

Page 3

LIST OF ILLUSTRATIONS

3-2

Pan Support Removal

3-2

Cooking Mode

5-1

Wiring Diagram, Dual Matic

5-6

Figure

SECTION 1 INTRODUCTION

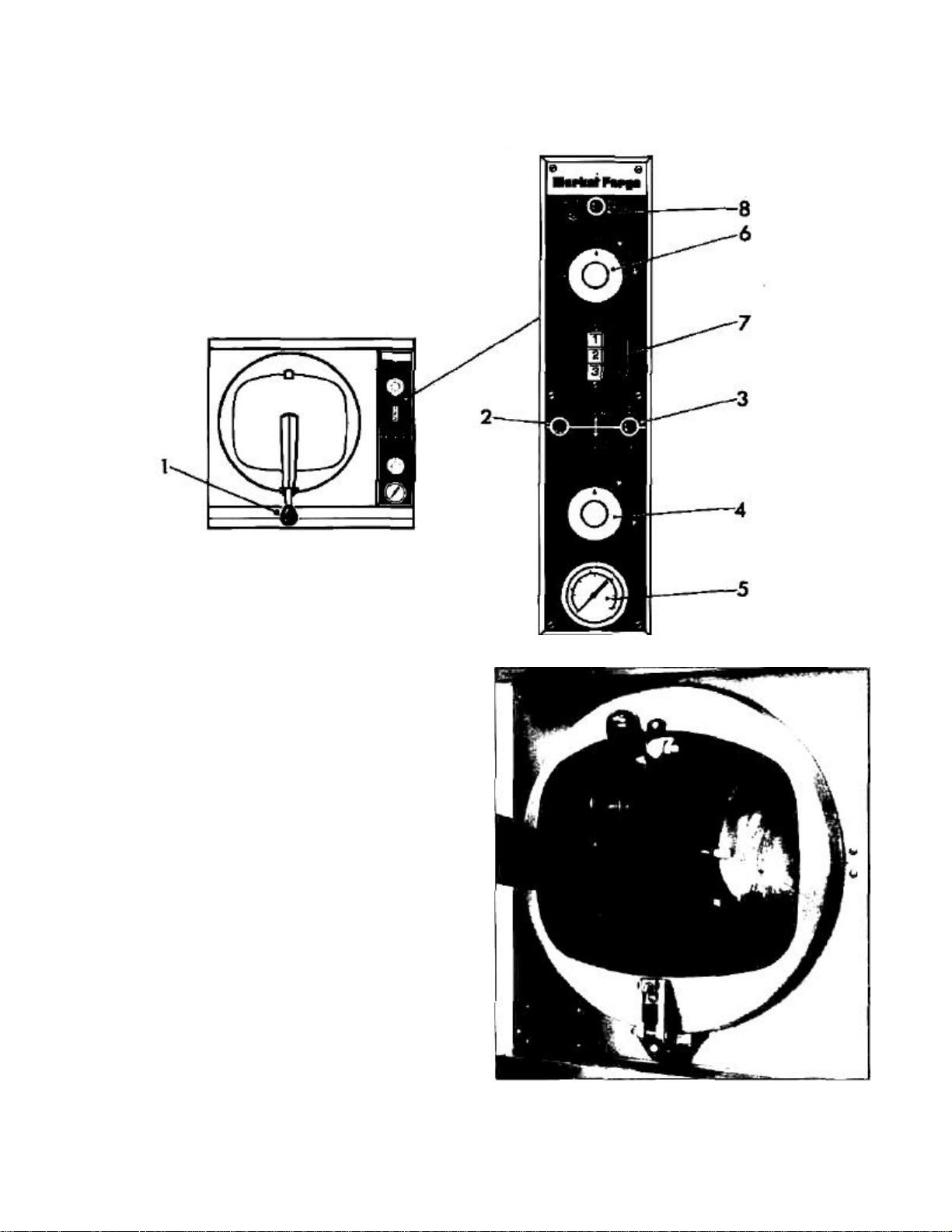

1-1 Model 3100 Dual Matic Steam Cooker 1-2

SECTION 3 OPERATION

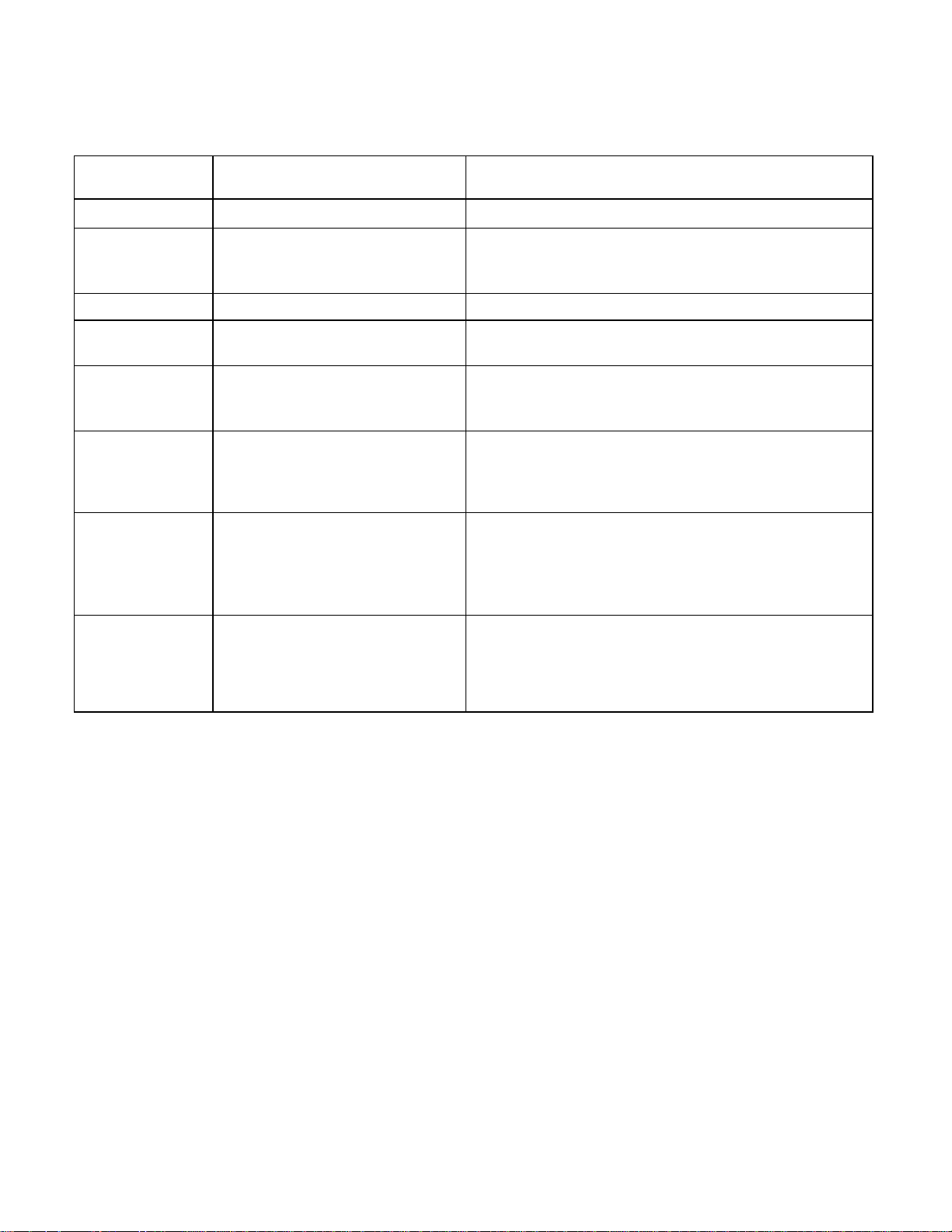

3-1 Dual Matic Controls and Indicator 3-2

SECTION 4 PRINCIPLES OF OPERATION

Page

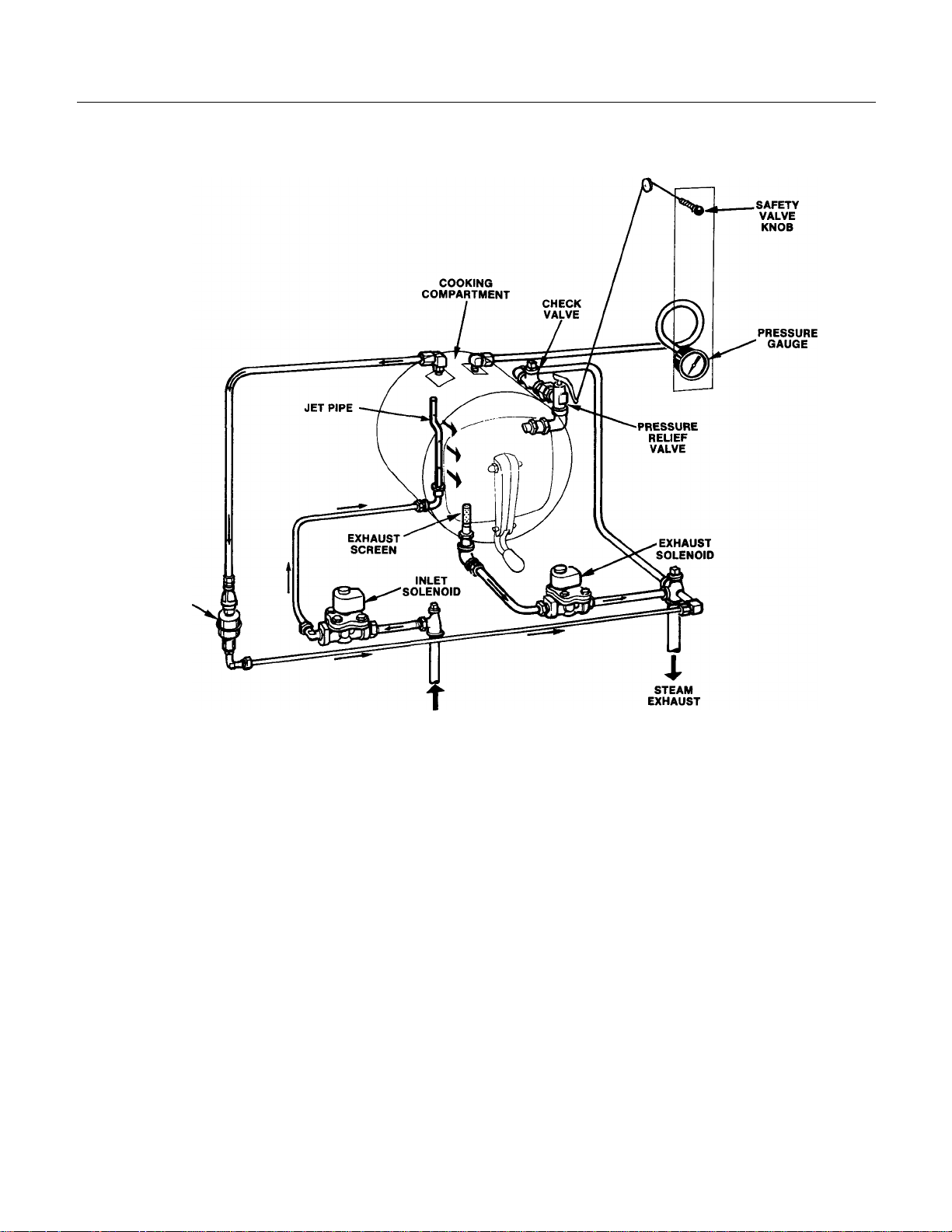

4-1 Pictorial Diagram — Steam Circuits 4-2

4-2 Pictorial Diagram, Electric Circuits, Pressure

4-3 Pictorial Diagram, Electric Circuits, Pressureless

Cooking Mode

SECTION 5 TROUBLE-SHOOTING

4-4

4-5

5-2 Schemat ic Diagram, Dual Matic 5-9

SECTION 6 MAINTENANCE

6-1 Door Spring Disengagement 6-2

List of Tables

SECTIONS 3 OPERATION

3-1 Controls and Indicators 3-3

SECTION 5 TROUBLESHO OTING

5-1 Operator’s Trouble-Shooting Guide 5-1

Figure

6-2 Door Removal 6-2

6-3 Gasket Removal 6-2

6-4 Door Seal Tension Adjustment 6-3

6-5 Control Panel Removal

6-6 Pressure Relief and Check Valve

Replacement 6-5

6-7 Steam Trap Replacement 6-5

6-8 Jet Pipe Alignment 6-6

6-9 Inlet Solenoid Valve Replacement

6-10

Exhaust Solenoid Valve Replacement 6-7

SECTION 7 ILLUSTRATED PARTS LIST

7-1 Cabinet & Frame Assembly 7-2

7-2 Cooking Compartment & Plumbing 7-4

7-3 Door Assembly 7-6

7-4 Door Latch

7-5 Door Fulcrum & Switch 7-8

7-6 Control Panel 7-9

7-7 Electrical Component Panel 7-10

Page

6-4

6-7

7-7

5-2 General Trouble-Shooting Guide 5-2

5-3 Electrical Fault Isolation Guide 5-4

SECTION 6 MAINTENANCE

6-1 Preventive Maintenance 6-1

Page 4

SECTION 1 INTRODUCTION

1 -1

S2124

This service and parts manual contains general information, installation, operation, principles of

operation, trouble-shooting, and maintenance information for the Market Forge Dual Matic Steam

Cooker. Also included is a parts list in which each replaceable part is identified and shown in an

accompanying exploded view.

1.1 DESCRIPTION

The Market Forge model 3100 Dual Matic is a

dual-mode compartment cooker which may be used

as either a pressure steam cooker or a free-vented

pressureless steam cooker. It consists of a cooking

compartment fitted with electrically controlled steam

circuits for application of steam by the cooking method

and for the duration selected by the operator. The

cooking compartment and all control components are

enclosed within stainless steel cover panels with

operator controls displayed on a single front mounted

panel.

A separate steam source required for operation of

the Dual Matic is normally purchased with it, in which

case the cooker is factory mounted with all steam,

drain and electrical interconnections completed.

Figure 1-1 shows one Dual Matic/Generator

configuration with the cooker on a 24" 610 mm wide

cabinet base containing an electrically powered steam

generator, (model suffix E). Other applications include

the Dual Matic on a gas -fired generator, (model suffix

G), a steam coil generator (model suffix SO, or a

cabinet containing steam pressure controls for direct

connection to a remotely located generator (model

suffix D). The model 3100 may also be combined with

other cooking equipment or installed banked with a

second Dual Matic on a single larger cabinet base.

1.2 BASIC FUNCTIONING

The Dual Matic may be converted from a pres sure

steam cooker to a pressureless, free-vented steam

cooker simply by placing a mode selector switch in the

required position followed by use of simple electric

controls:

1. For pressure cooking the compartment is

automatically sealed by the closing of an

exhaust valve and evacuation of air through a

steam trap as steam is injected. The compart ment

remains at approximately 14 Ibs. steam pressure

until the operator-selected cooking duration ends.

Fresh foods, defrosted frozen foods and frozen

entrees are cooked in this mode.

2. For pressureless cooking the compartment remains

vented to the drain system while steam is injected.

In this manner a continuous flow of steam

circulates throughout the compartment and out the

exhaust for the cooking duration. This mode allows

frozen foods to be defrosted, or defrosted and

cooked in a single operation.

1.3 SERVICE

Required service, both preventive and corrective, is

explained in Section 6. Should repairs be required, a

network of authorized agencies is available to assist with

prompt service. A current Directory of Authorized Serv ice

Agencies may be obtained by contacting:

Product Service Department

Market Forge

35 Garvey Street

Everett, Massachusetts 02149

Telephone: (617)387-4100

Product Service Department

Market Forge Canada, Ltd.

1375 Aimco Blvd., Unit 5

Mississauga, Ontario Canada L4W 1B5

Telephone: (416)621-9252

The model and serial numbers must be referenced

when corresponding with Market Forge. The data plate

containing the serial number pertaining to the equipment is

located on the left end of the bottom front trim ledge.

Page 5

DUAL MATIC STEAM COOKER

Figure 1-1. Model 3100 Dual Mafic Steam Cooker

Page 6

SECTION 2 INSTALLATION

S2124

2.1 ASSEMBLY

The Dual Matic is factory mounted on a cabinet

base containing either a steam generator or direct

steam connections for the cooker. The assembled unit

is shipped bolted to a skid with cabinet feet in a

separate container. Steps required for assembly are as

follows:

1. Remove the four bolts which fasten the equipment

frame to the skid.

2. Install feet in threaded mounting locations of cabinet

frame.

3. Mount the two pan support racks on studs located

inside the cooking compartment.

4. Attach doors and panels. Detailed instruc tions are

enclosed with the panels.

2.2 SETTING IN PLACE

If possible a location should be selected under an

exhaust hood which will remove small amounts of

water vapor emitted when the cooker door is opened.

Level the unit in final location by turning the adjustable

feet. Using the cabinet top as a reference, obtain level

adjustment left -to-right and front-to-back.

NOTE: If unit is to be placed directly in front of

a wall which will eliminate rear access, remove

the four Phillips head screws which secure the

top to the back. With screws removed the top

can be lifted off for future servicing of internal

components.

2.3 MECHANICAL CONNECTIONS

Since the Dual Matic is interconnected at the

factory to the steam generator or direct steam

plumbing, no field connections are required to the

cooker. All electrical and plumbing connections are

routed to the steam generator cabinet through the 6"

752 mm high space between the floor and the bottom

edge of the cabinet frame. Connection locations for the

Dual Matic mounted on steam generators of electric,

gas, and steam coil utility and direct connected steam

are shown in separate Installation Instructions for each.

2.4 INSTALLATION CHECK-OUT

After the Dual Matic is completely assembled and

all mechanical connections made to its steam source

(steam generator or direct steam connection plumbing),

both steam source and cooker must be

given a thorough check-out before being put into

operation. Check-out procedure for the Dual Matic

mounted on steam generators of electric, gas and

steam coil utility or direct connected steam are

given in separate Installation Instructions for each.

Procedures for the Dual Matic Cooker only are included in subsection 2.4.2. If the Dual Matic fails to

perform as described, consult Table 5-1 and 5-2 of

the trouble-shooting guide for corrective action. If

difficulty arises with the generator, reference the

separate service and parts manual for that equipment.

Before making this check-out the operator must

be thoroughly familiar with the operating procedures

in Section 3, and with the function of each control

described in Table 3-1. Reference Figure 3-1 for

identification of controls required in the following

procedures.

2.4.1 Initial Control Settings

Before beginning the start -up procedures for the

Dual Matic the instruction plate and service manual

for the steam generator must be consulted and all

start-up procedures completed to supply 15 psi

steam to the steam inlet circuit for the cooker.

1. All steam generator controls are in the operating

mode and 15 psi steam is applied to the Dual

Matic inlet plumbing.

2. Both cooker timers (Figure 3-1; 4, 6) are in the

OFF position.

3. Cooker compartment is empty of all information

materials and the door is open.

2.4.2 Cooker Check-Out

2.4.2.1 Pressure Cooking Mode (Figure 3-1)

1. Close cooker compartment door, being certain

latch handle (1) is securely engaged.

2. Place selector switch (2) in PRESSURE COOKING (down) position.

3. Set 60-MINUTE Ti mer dial (4) at "4-minute"

position. Indicator light (3) will turn on. Operation

is correct if operating pressure (13-15 psi

indicated on gauge) is attained before 4-minute

time elapses. Indicator light will turn off and

buzzer will sound at end of 4-minute period.

2-1

Page 7

2-2 DUAL MATIC STEAM COOKER

4. Turn timer dial (4) to OFF. Buzzer will shut off.

5. Open cooking compartment door.

4. Repeat #3 to check 2-Pan operation at 4 1/2

minute duration and 3-Pan operation at 5 1/2

minute duration. (Timer accuracy ± 5%)

2.4.2.2 Safety Valve (Figure 3-1)

5. Open cooking compartment door.

1. Close cooker compartment door, being certain

latch handle (1) is securely engaged.

2. Place selector switch (2) in PRESSURE (down)

position.

3. Set 60-MINUTE Timer dial (4) to "4-minute"

setting. Pressure gauge (5) will indicate a pres sure rise.

4. Pull out on SAFETY VALVE knob (8). If safety

valve is operating correctly, the pressure will drop

sharply in response to release of steam from

compartment.

5. Release SAFETY VALVE knob (8). Safety valve

should close allowing pressure to rise again.

6. Turn 60-MINUTE Timer dial (4) to OFF position.

7. Open cooking compartment door.

2.4.2.3 Pressureless Cooking Mode (Figure 3-1)

1. Close cooking compartment door, being certain

latch handle (1) is securely engaged.

2. Place selector switch (2) in PRESSURELESS

COOKING (up) position.

3. Set 10-MINUTE Timer dial (6) to "1-minute" and

press 1-PAN push button (7). Operation is correct

if indicator light (3) lights and steam is passed

into cooker and continuously exhausted for a

period of 3^ minutes. At end of cycle buzzer will

sound and indicator light will turn off. (Timer

accuracy ± 5%)

2.4.2.4 Door Shut-Off Switch (Figure 3-1)

1. Close cooking compartment door, being certain

latch handle (1) is securely engaged.

2. Place selector switch (2) in PRESSURELESS

COOKING (up) position.

3. Set 10-MINUTE Timer dial (6) to "1-minute" and

press 1-PAN push button (7). Inlet valve will

open allowing steam to pass through cooking

compartment.

4. With cooker in operation lift door handle (1) and

open door slightly. If operation is correct, inlet

valve will close stopping steam flow into cooker.

Timer will continue to run with indicator light on.

5. Close door and secure latch. Inlet valve will open

for remainder of timed cycle.

6. Return 10-MINUTE Timer dial (6) to OFF

position and open cooker door.

2.4.3 Shut-Down Procedure

No shut-down procedure is required for the Dual

Matic except to check that both timer dials (4, 6) are

in the OFF position and the compartment door is

open. Consult the steam generator instruction plate

and complete the generator shut down procedure.

NOTE

Before final check-off of the Dual Matic/

Generator system for use in cooking, generator

start-up and shut -down must be completed two

more times to insure cleanliness and proper

operation.

S2124

Page 8

SECTION 3 OPERATION

3.1 OPERATING CONTROLS AND INDICATORS

All of the controls required to operate the Dual

Matic are listed in Table 3-1, together with a short

functional description of each. Figure 3-1 shows the

physical location of each control and indicator.

3.2 OPERATING PROCEDURES

The Dual Matic may be used as either a pres sureless steam cooker which defrosts and cooks

frozen food, or as a steam pressure cooker to cook

fresh and defrosted foods. Instructions for operation

in either cooking mode are included in this section.

Consult Test Kitchen Bulletin #54 for detailed

cooking information.

3.2.1 Steam Source Operation

The Dual Matic is supplied mounted on a cabinet

containing either a steam generator or controls for

direct connected steam. Manual controls are ac cessed by opening the cabinet door. Start up procedure for the steam source is completed once

before each daily operating period of the cooker. (For

steam generators see instruction plate.)

3.2.2 Preheating

Before each initial operation of the cooker, and at

any other time when the cooking compartment is

cold, a 3-minute preheating period is required. To

preheat the cooker put steam source into operation

and proceed as follows:

1. Close cooking compartment door and lock

securely in place by pressing down on latch

handled).

2. Place cooking mode selector switch (2) in the

PRESSURE COOKING position.

3. Set 60-MINUTE timer (4) to "3-minute" setting.

4. Turn off buzzer which sounds to indicate

cooking is complete by setting 60-MINUTE

timer dial (4) to OFF position.

5. Allow pressure to return to "0-PSI" (5). Open

door by pulling up on latch handle (1). Allow

remaining vapor to escape before raising door

to full open position.

3.2.3 Pressureless Steam Cooking

Before loading the cooker, be sure compartment

is hot. See 3.2.2 for preheating instructions.

1. Slide pans of food into cooking compartment pan

supports.

2. Close cooking compartment door and push down

on latch handle (1) to engage lock.

3. Place cooking mode selector switch (2) in

PRESSURELESS COOKING (up) position.

4. Set 10-MINUTE timer (6) to required cooking

time.

5. Press pan selector button 1, 2 or 3 (7) coinciding

with the number of pans loaded in cooker.

NOTE To activate control circuit, the timer must be

set first, then the pan selector button pushed.

6. Turn off buzzer which sounds to indicate cooking

is complete by setting timer dial (6) to the OFF

position.

7. Open door by pulling up on latch handle (1).

8. Unload by sliding pans of food from pan supports,

taking care to avoid hitting compartment opening.

3.2.4 Pressure Cooking

Before loading the cooker be sure compartment

is hot. See 3.2.2 for preheating instructions.

1. Slide pans of food into cooking compartment pan

supports.

2. Close cooking compartment door and push down

on latch handle (1) to engage lock.

3. Place cooking mode selector switch (2) in

PRESSURE COOKING (down) position.

4. Set 60-MINUTE Timer (4) to required cooking

time.

5. Turn off buzzer which sounds to indicate cooking

is complete by setting 60-Minute timer dial to the

OFF position.

6. Allow pressure to return to "0-PSI" (5). Open door

by pulling up on latch handle (1). Allow remaining

vapor to escape before raising door to full open

position.

3-1 S2124

Page 9

3-2 DUAL MATIC STEAM COOKER

7.

Unload by sliding pans of food from pan sup

ports,

Figure

3-2.

Pan Support Removal

Figure 3-1. Dual Mafic Controls and Indicators

taking care to avoid hitting compartment opening.

3.2.5 Shut-Down Procedure

No shut -down procedure is required for the Dual

Matic except to check that both timer dials (4, 6) are in

the OFF position, and the compart ment door is open.

When all cooking has been completed for the day the

steam source must be shut off. (For steam generators

see instruction plate.)

3.3 CLEANING

After each period of daily operation (more

frequently as required to maintain cleanliness), the Dual

Matic should be thoroughly cleaned by completing the

following steps.

1. Remove left and right side pan supports (Figure 3-2)

by lifting front up and forward to disengage from

mounting studs. Wash with detergent, rinse, and set

aside for reassembly.

S2124

Page 10

OPERATION 3-3

pressed.

set.

TABLE 3-1 CONTROLS AND

INDICATORS (See figure 3-1)

Figure 3-1 Ref. Description Function

1 Latch Handle Secures cooker door in closed position. Lift to open.

2

Selector Switch

PRESSURELESS

COOKING/PRESSURE

The cooking mode selector switch. Placed in up

position for pressureless cooking; down position for

pressure cooking.

3 Indicator Light (Red) Indicates when lit that cooker is in operation.

4

60-Minute Timer

(Pressure cooking)

5 Pressure Gauge

Controls pressure cooking mode cycle duration. Time

manually preset from 0-60 minutes.

Indicates steam pressure (psi/Kg/cm2) inside cooker

chamber during pressure cooking mode of operation.

Controls pressureless cooking mode cycle duration in

6

10-MinuteTimer

(Pressureless Cooking)

conjunction with pan selector buttons. Time manually

preset from 0-10 minutes before selector button

Compensates for cooking time differential between 1, 2

7

Pan Selector

Buttons

1/2/3

or 3 pans of food loaded into the compartment for

pressureless mode. Button coinciding with number of

pans loaded is pressed after the 10-MINUTE timer is

Steam release safety valve opens automatically in the

8

Pressure Release Knob

(Safety valve)

unlikely event that a malfunction causes ex cessive

steam pressure in compartment. Pull out on knob to

operate manually.

2. Wash cooking compartment interior using mild nonabrasive water. Rinse and dry thoroughly.

CAUTION

Failure to wash compartment may result in pitting

of the aluminum surfaces. Use only mild detergent

suitable for use with aluminum.

3. Replace pan supports in compartment and leave door

open.

S2124

Page 11

SECTION 4 PRINCIPLES OF OPERATION

4.1 GENERAL

The Dual Matic Steam Cooker consists of a

cooking compartment into which pans of food are

loaded through an inward opening door. The

compartment is fitted with electrically controlled

steam circuits to apply steam in either the pressure or

pressureless methods and for the duration selec ted

by the operator. The principles of operation in this

section include an explanation of steam and electrical

circuits as well as pressure cooking and pressureless

cooking operation.

4.2 STEAM CIRCUITS

The steam circuits consist of the piping, solenoid

valves, steam trap, and safety valve required to

provide controlled steam application to the cooking

compartment. A simplified diagram of these circuits is

shown in figure 4-1.

NOTE Figure 4-1 is strictly a pictorial schematic

diagram and is not intended to show the actual

configuration of the circuits. All components are

shown in correct relationship with each other.

However, the diagram does not show their actual

locations or position within the cooker.

As shown in the diagram, steam inlet and ex haust connections are normally connected at the

factory directly into a steam generator on which the

cooker is mounted. The generator is equipped to

supply constant, regulated steam at 14-15 psi. Steam

exhaust is directed into the generator drain system

where it is condensed to water prior to entry into the

building drain system.

Both steam inlet and exhaust lines are equipped

with solenoid valves which are operated by the

electrical control circuit. Both are two-position valves

— the inlet valve normally closed, the ex haust valve

normally open. The inlet valve is opened whenever

the control circuit is activated in either the pressure or

pressureless modes. The exhaust valve is closed

only when the control circuit is activated in the

pressure mode.

4.2.1 Steam Inlet Line

A steam supply line is plumbed from the

generator output to a 1/2" IPS elbow fitting con

nected to the input side of the steam inlet solenoid

valve. At all times when the cooker is not in operation the valve remains closed to prevent steam from

entering the inlet line. During operation the inlet

solenoid valve is opened by activation of the control

circuit. Steam at 15 psi enters the 1/2" line

connected to a coupling in the bottom rear of the

cooking compartment. A jet pipe mounted in the

coupling inside the compartment directs steam

uniformly throughout the interior. Steam continues to

enter the compartment in this manner until the

control circuit closes the solenoid valve.

4.2.2 Steam Exhaust and Drain Lines

Steam exhaust and compartment drainage are

drained from the cooking compartment by a single

line connecting with the steam generator drain

system. A perforated cylindrical strainer mounted inside the cooking compartment at the bottom allows

steam, condensation and cooking drainage to enter

the exhaust line. The line connects to the inlet side

of the exhaust solenoid valve. Except when the valve

is closed by the control circuit, activated in the pres sure mode, exhaust and drainage pass through the

valve into the 3/4" drain line to a waste outlet 'T.

Drainage passes from the cooker into the drain

system of the steam generator.

4.2.3 Pressure Safety Line

A branch of the drain and exhaust line provides

pressure overload protection for the cooking compartment in the unlikely event of equipment malfuntion. The inlet side of a pressure relief valve is

connected with the compartment through a coupling

in the right side. Pre-set to open automatically at

pressures in ex cess of 15 1/2 psi, the valve may

also be operated manually for test purposes by

pulling out on a knob mounted on the control panel.

The knob is connected by a steel cable and suitable

sheaves to the manual release lever at the top of the

valve. The lever is spring-loaded to return to the

closed position when the knob is released.

When the safety valve is opened, steam is allowed to pass into a 3/4" line connected to a sideoutlet T' fitting in the drain line. A check valve

mounted between the safety valve and the T' fitting

prevents back-flow from the drain line.

rev. 3/78 4-1 S2124

Page 12

4-2 DUAL MATIC STEAM COOKER

STEAM

TRAP

STEAM IN

Figure 4-1. Pictorial Diagram — Steam Circuits

4.2.4 Evacuation Line

A separate line between the cooking compart -

ment and the drain provides for evacuation of air

during cooking in the pressure mode. An elbow

fitting mounted into the top of the compartment is

connected through a 1/4" ID tubing line and suitable

fittings to the inlet side of a steam trap. The trap

functions as a chamber evacuator to eliminate air

which passes into it from the cooking compartment.

It is a thermostatically operated valve device preset

to open automatically when air, vapor, or

condensate at temperatures lower than 240° F

enters. The trap closes automatically when steam

above 240° F enters. Discharge from the trap

passes into a %" ID line connected to the waste

outlet "T" of the drain line.

S2124

4.2.5 Pressure Indicator Line

A pressure gauge mounted in the control panel

constantly monitors the steam pressure inside the

cooking compartment. Connection is made through a

1/8" IPS tubing connected to a compression fitting at

the top of the compartment.

4.3 ELECTRICAL CIRCUITS

The electrical circuits of the cooker control the

power to activate timer motors and energize solenoid

operated valves and circuits which in turn control

application of steam to the cooking compartment. The

cooker operates on 120V, 2 amp 60 Hz (50 Hz on

special order) electrical service connected to all

circuits from a 2-pole terminal block mounted to the

cooker frame inside the

Page 13

PRINCIPLES OF OPERATION

4-3

front cover panel. Power input to the terminal block is

connected at the factory from the elec trical circuits of

the steam generator on which the cooker is mounted.

Power is supplied to the control circuit at all times

when the shut -off device for the generator/cooker

system (supplied by the user) is in the ON position.

dial through a gear reduction and clutch mechanism.

The timer dial is manually set for any interval of

operation from 0 to 60-minutes as read on the calibrated dial face. The manual rotation of the dial

moves the common element of the timer switch from

the neutral position to the contact which connects with

pressure mode controls and energizes the timer

motor. When power is applied to the motor, the dial

4.3.1 Control Circuit Components

The control circuit is shown in pictorial diagrams in

figures 4-2 and 4-3. A brief description of the electrical

circuit elements follows.

rotates until the indicator dart coincides with "0minutes." At this point the common element of the

timer switch is transferred to a second contact,

interrupting the circuit to the timer motor, solenoid

valves and indicator light, and applying 120-volts to

the buzzer. Contact to the buzzer circuit remains

4.3.1.1 Selector Switch. The selector switch is a

double-pole, double-throw, two-position switch

(PRESSURELESS COOKING/PRESSURE COOKING). When the switch is in the PRESSURELESS

position those control circuits required for cooker

operation as a free vented system are connected.

Operation begins only after the 10-MINUTE timer dial

is set followed by pressing a pan selector push button.

When the switch is in the PRESSURE position those

circuits required for cooker operation as a pressure

system are connected. Operation begins when the 60MINUTE timer is set.

closed until the dial is manually turned to the OFFposition, returning the common element of the timer

switch to the neutral position.

4.3.1.5 10-Minute Timer. The timer operates in the

same manner as the 60-MINUTE timer but with a

maximum time setting of 10 minut es. The manual

motion of setting the timer dial moves the common

element of the timer switch from the neutral position

to the contact which connects with pressure-less

mode controls, the timer motor and the pan-selector

push-button switch. The timer motor is activated only

after the push button timer has "timed out." The

remainder of operation is the same as for the 60-

4.3.1.2. Indicator Light. The indicator light is

minute timer.

connected into both the pressure and pressureless

cooking mode circuits. It remains lighted (red) at all

times when either the 60-MINUTE timer, or the 10MINUTE timer and the push-button timer are set. It

turns off at the end of the timed cooking duration.

4.3.1.6 Push -Button Timer (pan selector). The

Timer is a three-button solid state capacitor discharge

timing device powered by a separately mounted

120V/36V step-down transformer. The switch

functions to compensate for the alteration in cooking

time associated with cooking 1-pan (2 1/2 minutes), 2-

4.3.1.3 Door Interlock Switch. The interlock switch is

a single pole, two-position, microswitch with normally

open contacts. The switch lever is operated by an

actuating pin mounted in the door latch assembly.

When the door is open the pin remains retracted with

the switch contacts in the normally open position.

When the door latch is engaged to secure the door,

the actuating pin is moved against the switch lever to

pans (3 1/2 minutes), or 3-pans (4 1/2 minutes) of

food in the pressureless mode. When a button is

pressed a light inside is lit and the button is held in the

depressed position by a latching device. Contacts to

externally controlled circuits are closed and internal

timer circuits energized. At the end of the timed

duration (plus the 10-MINUTE timer setting) a

solenoid operates to release the latching device.

close the contacts. Connected into the circuit with the

steam inlet valve, the door switch acts as a protective

device to interrupt valve operation unless the door is

closed.

4.3.1.7 Buzzer. The buzzer is an alarm device which

operates by oscillation of a striker against the core of

an electromagnet. When either the 60-MINUTE or 10-

MINUTE timer dials reach "0-minutes" the buzzer coil

is energized to sound the buzzer. Movement of either

4.3.1.4 60-Minute Timer. The timer contains a 120volt synchronous motor which drives a timing

timer dial to the OFF position opens the contact to the

buzzer coil to shut it off.

S2124

Page 14

4-4 DUAL MATIC STEAM COOKER

4.3.2 Pressure Cooking Operation

When the mode selector switch is placed in the

PRESSURE COOKING position one set of contacts

closes to connect the circuit to the open switch

contacts of the 60-MINUTE timer. A second set of

selector switch contacts close to connect a circuit to

the indicator light and the door interlock switch. The

compartment door is shut, closing the normally open

contacts of the door interlock switch, to connect the

circuit to the coil of the steam inlet va lve. At this

point the cooker is not operating, and all other

components in figure 4-2 are in the open position.

3. 120-volts is applied through the closed contacts

of the door interlock switch to the coil of the

normally closed steam inlet solenoid valve to

open it.

4. The circuit is completed to the indicator light

(red).

5. 120-volts appears across the primary windings

of the push button timer transformer even

though the 36-volt secondary current is not

required.

6. 60-MINUTE timer dial rotates until the indicator

dart coincides with the"0-minute" position. The

common element of the timer switch is tripped,

breaking the circuit to pressure mode

components and transferring it to a second

contact position (1-4). The timer motor is

opened to stop dial rotation.

7. 120-volts is removed from the exhaust valve and

inlet valve coils, and the indicator light.

8. 120-volts is applied to the buzzer coil to produce

an audible signal.

9. Timer dial is manually rotated to the OFF position by the operator. The common element of the

timer switch is transferred from the secondary

contact position to the neutral position, removing

120-volts from the buzzer coil. 10. The cooker

remains off until the 60-MINUTE timer dial is

reset.

4.3.3 Pressureless Cooking Operation

When the mode selector switch is placed in the

PRESSURELESS COOKING position a single set

of contacts close to connect the circuit to the open

TRANSFORMER

NOTE: All CONTROLS SHOWN IN OPERATING

POSITION FOR THE PRESSURE MODE

Figure 4-2. Pictorial Diagram, Electrical Circuits —

Pressure Cooking Mode

The dial of the 60-MINUTE timer is turned by the

operator to the required cooking interval, and the

following sequence of events occurs:

1. Switch (1-3) contacts of the 60-MINUTE timer

close to place 120-volts into the circuit for all

pressure mode electrical components. The timer

motor begins to operate for the set duration.

2. 120-volts is applied across the coil of the normally

open steam exhaust solenoid valve to close it.

S2124

switch contacts of the 10-MINUTE timer. The

operator rotates the 10-MINUTE timer dial to the

required cooking duration, completing the circuit (1-

3) to the timer motor and the push-button timer. The

compartment door is shut, closing the normally

open contacts of the door interlock switch to

connect the circuit to the coil of the steam inlet

solenoid. At this point the cooker is not operating

and all other components in figure 4-3 are in the

open position.

One of the three buttons of the push-button

timer is pressed by the operator and the following

sequence of events occurs:

1. The button is illuminated and held in the

depressed position. Contacts in the button close

the circuit to the internal timer circuits and apply

120-volts into the circuit for pres -sureless mode

electrical components and the transformer.

2. 120-volts is applied to the primary winding of the

120 V./36v. transformer to energize the timer

circuit.

Page 15

PRINCIPLES OF OPERATION 4.5

3. 120-volts is applied through the closed contacts of

the door interlock switch to the coil of the

normally closed steam inlet solenoid valve to

open it.

4. The circuit is completed to the indicator light (red).

5. The push-button timer completes the cycle of

operation for the button pressed, immediately

applying 120-volts to the 10-MINUTE timer motor.

6. Timer dial rotates until the indicator dart coincides

with "0-minute." The common element of the

timer switch is tripped breaking the circuit to

pressureless mode components and transferring

it to a second contact position (1-4). The timer

motor circuit is opened to stop dial rotation.

7. 120-volts is removed from the inlet valve coil and

the indicator light.

8. 120-volts is applied to the buzzer coil to produce

an audible signal. A separate circuit to the pushbutton timer applies a momentary impulse to an

internal solenoid coil to release the timer button,

NOTE: ALL CONTROLS SHOWN IN OPERATING

POSITION FOR THE PRESSURELESS MODE

Figure 4-3. Pictorial Diagram, Electrical Circuits Pressureless

Cooking Mode

open the circuit to the button lamp and to the 10MINUTE timer motor.

9. Timer dial is manually rotated to the OFF position

by the operator. The common element of the

timer switch is transferred from the secondary

contact position to the neutral position, removing

120-volts from the buzzer coil and the circuit to

the push-button timer.

10. The cooker remains off until the 10-MINUTE dial

is reset and a push-button pressed.

S2124

Page 16

SECTION 5 TROUBLE-SHOOTING

lector Switch in PRESSURELESS

5.1 GENERAL

The information in this section is intended to

assist both the operator and service personnel in

locating the general source of problems which may

occur with the Dual Matic. Before following any of

the procedures given in this section, the operator

should be thoroughly familiar with the operating

instructions and the function of all controls which

are described in Section 3. If the problem cannot

be readily corrected, the operator should contact

the nearest Market Forge service agency for

assistance.

5.2 TROUBLE-SHOOTING GUIDES

An operator's trouble-shooting guide for use

TABLE 5-1 OPERATOR'S TROUBLE-SHOOTING

by the Dual Matic operator is given in Table 5-1.

Table 5-2 gives additional, more extensive information for use by service personnel.

5.3 ELECTRI CAL FAULT ISOLATION

Correction of an electrical failure first requires

isolation of the fault to a single circuit or

component. In most cases the nature of the failure

and its effect upon the operation of the Dual Matic

will be sufficient to isolate it to one or more circuit

elements. Table 5-3 is provided as a guide for

isolating electrical faults.

GUIDE

PROBLEM

Probable Cause

1. INDICATOR LIGHT FAILS TO LIGHT

a. Power to Dual Matic off.

b. Se

COOKING position.

c. 60-Minute timer not set.

2. INDICATOR LIGHT FAILS TO LIGHT

a. Power to Dual Matic off.

b. Selector Switch in

PRESSURE COOKING

position.

c. 10-Minute timer not set.

d. Button of Push-Button timer not

depressed.

Remedy

IN PRESSURE COOKING MODE.

Locate external circuit breaker for incoming power and

place in ON position.

Place in PRESSURE COOKING position.

Set 60-Minute timer.

IN PRESSURELESS COOKING MODE.

Locate external circuit breaker for incoming power and

place in ON position.

Place in PRESSURELESS COOKING position.

Set 10-Minute timer (Before pressing pushbutton, d).

Press one of the three buttons (After setting 10-Minute

timer, c). NOTE: Cooker will not operate if push button

is depressed before setting 10-Minute timer.

5-1 S2124

Page 17

DUAL MATIC STEAM COOKER

Locate external circuit breaker for incoming

TABLE 5-1 (cont.)

PROBLEM Probable Cause Remedy

3. STEAM FAILS TO ENTER COMPARTMENT IN EITHER PRESSURE OR PRESSURE-LESS COOKING MODES

WITH INDICATOR LIGHT ON.

a. Compartment door not latched securely. Close door and engage handle in latch.

b. Steam not entering Dual Matic control Check steam supply generator for proper oper plumbing. tion.

TABLE 5-2

GENERAL TROUBLE-SHOOTING GUIDE

PROBLEM Probable Cause Remedy

1. INDICATOR LIGHT FAILS TO LIGHT WITH SELECTOR SWITCH IN PRESSURE COOKING POSITION

AND 60-MINUTE TIMER SET.

a. Power to Dual Matic off.

power and place in ON position.

b. Indicator light burned out. Replace light.

c. Faulty wiring. Inspect condition of wire, and tightness of all

connections. Correct as needed.

d. Faulty Selector Switch. Replace switch. See subsection 5.4.3.

e. 60-Minute timer contact faulty. Replace 60-Minute timer. See subsection 5.4.4 .

2. INDICATOR LIGHT FAILS TO LIGHT WITH SELECTOR SWITCH IN PRESSURELESS COOKING

POSITION AND BOTH 10-MINUTE TIMER AND PUSH-BUTTON TIMER SET.

a. Power to Dual Matic off. Locate external circuit breaker for incoming

power and place in ON position.

b. Indicator light burned out. Replace light.

c. Faulty wiring. Inspect condition of wire and tightness of all

connections. Correct as needed.

d. Faulty selector switch. Replace switch. See subsection 5.4.3.

e. 10-Minute timer contacts faulty. Replace 10-Minute timer. See subsection 5.4.5.

f. Push-Button timer contacts faulty. Replace Push-Button timer. See subsection 5.4.6.

3. PRESSURE COOKING MODE FAI LS TO STOP.

a. Defective 60-Minute timer motor Replace 60-Minute timer. See subsection or

contact. 5.4.4.

b. Defective steam exhaust solenoid Replace valve. See subsection 5.4.8. valve.

Page 18

TABLE 5-2 (cont.)

PROBLEM

Probable Cause

4. PRESSURELESS COOKING MODE FAI LS TO STOP.

a. Defective 10-Minute timer motor or contact. Replace 10-Minute timer. See subsection 5.4.5.

b. Defective Push -Button timer or transformer. Replace Push-Button timer. See subsection 5.4.6.

c. Defective steam inlet valve. Replace valve. See subsection 5.4.8.

5. STEAM FAILS TO ENTER COMPARTMENT IN EITHER COOKING MODE (WITH INDICATOR LIGHT ON).

a. Compartment door not closed. Securely latch door closed.

b. No steam entering Dual Matic steam line. Check steam generator for proper operation.

c. Faulty door interlock switch. Replace switch. See subsection 5.4.7.

d. Faulty inlet solenoid valve. Replace valve. See subsection 5.4.8.

6. STEAM ENTERS COMPARTMENT AT ALL TIMES.

a. Ruptured inlet solenoid diaphragm. Replace valve.

b. Defective or jammed door interlock switch. Clean or replace switch. See subsection 5.4.7.

7. NO STEAM PRESSURE GAUGE READING IN PRESSURE COOKING MODE (WITH INDICATOR LIGHT ON).

a. Insufficient steam input from steam Check generator for 15 psi output and make

generator, necessary adjustment.

b. Faulty pressure gauge. Replace gauge.

c. Faulty steam exhaust solenoid valve. Replace valve. See subsection 5.4.8.

d. Faulty relief valve. Replace valve.

Remedy

8. BUZZER FAILS TO SOUND AT END OF PRESSURE COOKING DURATION (WITH INDICATOR LIGHT OFF).

a. Faulty 60-Minute timer contacts. Replace 60-Minute timer. See subsection 5.4.4.

b. Faulty buzzer. Replace buzzer. See subsection 5.4.9.

9. BUZZER FAILS TO SOUND AT END OF PRESSURELESS COOKING DURATION (WITH INDICATOR LIGHT OFF).

a. Faulty 10-Minute timer contacts. Replace 10-Minute timer. See subsection 5.4.5.

b. Faulty buzzer. Replace buzzer. See subsection 5.4.9.

10. PUSH-BUTTON REMAINS DEPRESSED WHEN BUZZER SOUNDS AT END OF PRESSURELESS COOKING

DURATION.

a. Faulty Push -Button timer solenoid. Replace Push-Button timer. See subsection 5.4.6.

11. IN PRESSURE COOKING MODE COOKING COMPARTMENT FAILS TO REACH COOKING TEMPERATURE.

a. Air in cooking compartment. Replace steam trap.

b. b. Low steam pressure. See item 7.

Page 19

TABLE 5-2 (cont.)

Buzzer fails to sound at end of either Pressure or

button timer fails to reset (button released)

DUAL MATIC STEAM COOKER

PROBLEM

Probable Cause

12. IN PRESSURE COOKING MODE PULL ING OUT

CAUSE PRESSURE DROP.

a. Valve knob cable dissengaged.

b. Defective relief valve.

TABLE 5-3 ELECTRICAL FAULT ISOLATION GUIDE

FAILURE FAULT LOCATION

1. Will not operate in either Pressure or

Pressureless Cooking mode.

2. Operates in Pressure mode but not in

Pressureless mode.

Remedy

ON SAFETY VALVE KNOB FAILS TO

Reconnect or replace cable.

Replace relief valve.

a. Incoming power

b. Selector Switch

c. Wiring

a. Selector Switch

b. Wiring

c. 10-Minute timer

d. Push -Button timer e. Transformer

3. Operates in Pressureless mode but not in

Pressure mode.

a. Selector Switch

b. Wiring

c. 60-Minute timer

4. Exhaust solenoid valve fails to close with

indicator light on in Pressure mode.

5. Indicator light off in either mode.

6. Inlet solenoid valve fails to open but indicator

light is on in either mode.

a. Exhaust solenoid valve coil

b. Wiring

a. Indicator light

b. Wiring

a. Door interlock switch

b. Inlet solenoid valve coil

c. Wiring

7.

Pressureless cooking.

8. Push at completion of Pressureless cooking.

a. 10-or 60-Minute timer contacts

b. Buzzer

c. Wiring

a. 10-Minute timer contacts

b. Push-Button timer

c. Wiring

9. Will not stop operating in Pressure mode. a. 60-Minute timer motor

10. Will not stop operating in Pressureless mode.

a. 10-Minute timer motor

b. Push -button timer

Page 20

TROUBLE -SHOOTING

5.5

5.4 ELECTRICAL TROUBLE-SHOOTING PROCEDURES

Before performing the trouble-shooting proce-

Pressure and Pressureless Cooking modes, or failure

to operate in one mode only. To check the Selector

Switch, proceed as follows:

dures in this section the serviceman must be

familiar with the function of all controls as

described in Section 3 and with the Principles of

Operation described in Section 4.

Electrical trouble-shooting procedures which

follow require access to components and terminals

of the electrical control panels shown in fig. 7-6 and

7-7. Electrical controls are reached by removing

the machine top, lower trim edge, and lower front

panel as described in subsection 6.3.2. Wiring and

terminal locations are shown in figure 5-1.

1. Turn off power to the Dual Matic at external

breaker.

2. Disconnect all five wires (1, 2. 3, 12, 19) from

Selector Switch terminals (figure 5-1).

3. Connect an ohmmeter between the middle

terminal and either one of the outer terminals (A,

B) for one pole of the switch.

4. Operate switch to obtain a reading of zero ohms

on meter when switch is in either PRESSURE

COOKING or PRESSURELESS COOKING

position. If a zero reading cannot be obtained,

5.4.1 Incoming Power

Before trouble-shooting any of the electrical parts

or assemblies, verify that power is being supplied to

the Dual Matic. Incoming power is connected at the

terminal block (figure 7-7,1). With power connected

to the Dual Matic an a-c volt-meter is used to

measure 120 Volts across terminals to lines coded

switch is defective and must be replaced.

5. Move ohmmeter leads to second pole of switch.

6. Repeat Step 4. If zero ohm reading cannot be

obtained, switch is defective and must be

replaced.

7. Remove ohmmeter and replace all five leads on

Selector Switch as shown in figure 5-1.

18 and 19. If power is not present, the connection

to the Dual Mat ic is faulty. If 120 volts is present,

and the cooker will not operate, the fault lies within

5.4.4 60-MINUTE Timer

the electrical circuits of the Dual Matic.

5.4.2 Electrical Inspection

The first step in any electrical trouble-shooting

procedure is a thorough physical inspection of all

wiring connections. To access electrical

components remove the control panel as explained

in subsection 6.3.3.

WARNING

Before removing control panel or checking connections and wiring be sure that the circuit

5.4.4.1. Timer Contacts. Defective timer contacts

will result in failure of the Dual Matic to operate in the

Pressure Cooking mode. If the cooker fails to operate

in the Pressure Cooking mode, but functions

correctly in the Pressureless Cooking mode, the fault

is with the 60-Minute timer contacts or it's wiring.

When this occurs, remove the control panel

(subsection 6.3.3), and proceed as follows:

breaker for incoming power to the Dual Matic is

OFF. When power is supplied all exposed

terminals of the control panel carry 120 volts.

Check all wiring connections by hand to assure

that both ends of all connection points are tightly

secured. Use a screwdriver to tighten connection

points if necessary. Visually inspect all quickdisconnect terminals for evidence or corrosion.

Terminals in this condition should be separated,

cleaned with emery cloth until shiny and tightly

reconnected.

CAUTION

Extreme care must be taken in removing or replacing connections on the push-button timer

P.C. board. Do not pull wires loose from quickdisconnect terminals.

5.4.3 Selector Switch

A defective Selector Switch may be the cause

1. Turn off power to the Dual Matic at external circuit

breaker.

2. Disconnect all four wires (1. 4, 6. 14) from timer

terminals. (See figure 5-1).

3. Connect an ohmmeter between terminal 1 and

terminal 3.

4. Rotate timer dial beyond the 0-MINUTE point (any

setting) to obtain a reading of zero ohms on the

ohmmeter. If zero reading cannot be obtained,

timer contacts are defective and the timer must

be replaced.

5. Move ohmmeter leads to terminals 1 and 4.

6. Rotate timer dial to 0-MINUTE position. (An

audible click indicates correct position). If zero

ohm reading cannot be obtained, the timer is

defective and must be replaced.

S2124

of failure of the Dual Matic to operate in both

rev. 3/78

Page 21

Figure 5-1. Wiring Diagram, Dual Matic

Page 22

TROUBLESHOOTING

5-7

7. Remove ohmmeter and replace all four leads on

timer terminals as shown in figure 5-1.

5.4.4.2 Timer Motor. A defective timer motor will

cause continuous operation in the pressure mode

with the timer dial failing to return to the 0-MIN-UTE

position. If the timer motor fails to turn proceed as

follows:

1. Carefully check motor wire leads (10 and 11) and

tighten loose connections.

WARNING

Use care while working with control panel.

Terminals carry 120 volts.

2. Turn on power to the Dual Mafic.

3. With Selector Switch in PRESSURE COOKING

position, set 60-MINUTE timer dial (any setting

beyond "0-minute"). If operation is correct the

motor will turn the dial dart through an arc toward

"0-minute". If the motor fails to operate, it is

defective and the entire timer must be replaced.

4. Shut off power to the Dual Matic.

5.4.5 10-MINUTE Timer

5.4.5.1 Timer Contacts. Defective timer contacts will

result in failure of the Dual Matic to operate in the

Pressureless Cooking mode. If the cooker fails to

operate in the Pressureless Cooking mode, but

functions correctly in the Pressure Cooking mode, the

fault may be in the 10-Minute timer or its wiring.

When this occurs check the timer contacts in the

same manner as explained for the 60-Minute timer in

paragraph 5.4.4.1. Use an ohm-meter to check

contacts between terminals 1 and 3 and between 1

and 4. Should a reading of zero ohms fail to be

obtained for either, the timer is defective and must be

replaced.

5.4.5.2 Timer Motor.

A defective timer motor will cause continuous

operation in the Pressureless Cooking mode with the

timer dial failing to return to the 0-MINUTE position. If

the timer motor fails to turn proceed as follows:

1. Connect a jumper wire between push-button

timer terminals 4 and 5.

rev. 3/78

2. Connect a jumper wire between terminal 3 on the 10Minute Timer and selector switch terminal connected

to wire 19.

WARNING

Use care while working with control panel. Terminals

carry 120 volts.

3. Set 10-Minute timer dial at 1-MINUTE position.

4. Touch second lead wire to Push -Button timer terminal

5. Motor should begin to operate, returning dial to 0MINUTE position. If not, motor is defective and entire

10-Minute timer must be replaced.

5. Turn off power to Dual Matic.

6. Remove jumper wires and reconnect wires to Push

Button timer terminals.

5.4.6 Push -Button Timer and Transformer

A defective Push -Button timer will result in failure of the

Dual Matic to operate in the Pressureless Cooking mode.

If the cooker fails to operate in the Pressureless mode

and the selector switch operates correctly, the fault may

be in the Push -Button timer or its wiring. When this

occurs consult one of the following paragraphs describing

the nature of the fault.

5.4.6.1 Timer Contacts. If Pressureless Cooking fails to

begin when all controls are set correctly, the fault may be

in the contacts of the Push -Button timer. Proceed as

follows:

1. Turn off power to the Dual Matic.

2. Disconnect the four wires (5, 3, 17, 13) to terminals 1

and 2 (See figure 5-1).

CAUTION

Extreme care must be taken in removing or replacing

connections on the push -button timer P.C. board. Do

not pull wires loose from quick-disconnect terminals.

3. Connect an ohmmeter between terminals 1 and 2.

4. Depress one of the three pan selector buttons to

obtain a reading of zero ohms on the meter. Depress

each of the other two buttons to obtain a zero ohm

reading for each. If a zero ohm reading cannot be

obtained for any button, the Push -Button timer is

defective and must be replaced.

5. Remove ohmme ter and replace all four leads on

terminals 1 and 2 as shown in figure 5-1.

5.4.6.2 Timer Circuit/Transformer.

Should the Pressureless Cooking mode fail to stop

once begun, the fault may be in the internal timer

circuits or

S2124

Page 23

5-8 DUAL MATIC STEAM COOKER

the transformer for the Push-button timer. When this

occurs proceed as follows:

WARNING

Use care while working on control panel.

Terminals carry 120 volts.

1. Turn on power to Dual Matic, place Selec tor

Switch in PRESSURELESS COOKING position,

set 10-Minute timer dial (any setting beyond "0-

minute"), and depress 3-PAN push-button.

2. Connect an a-c volt meter between secondary

terminals GR (green) and GR (green) of the

transformer to obtain a 36 volt reading on the

meter. If a reading of 36 volts cannot be obtained, the transformer is defective and must be

replaced.

3. Allow Push-button timer duration to elapse (3PAN button = 41/2 minutes), then proceed with

steps 4 and 5.

4. Disconnect 10-Minute timer motor lead (no

number) from terminal 4 of the Push-Button

timer.

5. Connect an a-c volt meter between terminals 1

and 4 of the Push-Button timer to obtain a 120

volt reading on the meter. If a reading cannot be

obtained, the Push-Button timer is defective and

must be replaced.

6. Turn off power to the Dual Matic.

5.4.6.3 Timer Solenoid Circuit. A defective PushButton timer solenoid will prevent the depressed

push-button from being released when the 10-Minute

timer has "timed-out" to 0-MINUTE. If the button fails

to release, proceed as follows:

WARNING

Use care while working on timer on control

panel. Terminals carry 120 volts.

1. Install a jumper wire from Push-button terminal 3

to the Selector Switch terminal connecting with

wire 2.

2. Place Selector Switch in PRESSURELESS

COOKING position.

3. Turn on power to the Dual Matic.

4. Depress the 1-PAN button and allow 1 1/2 minute

duration to elapse. Operation is correct if the

solenoid energizes to release the depressed 1PAN button. If not, Push-Button timer is

defective and must be replaced.

S2124

5. Disconnect power to Dual Matic and remove

jumper wire.

5.4.7 Door Interlock Switch

The only malfunction which results from a

defective cooker compartment door switch is

failure of the normally closed inlet solenoid valve to

open. If steam does not enter the compartment

when the door is closed, and the door latch is

securely engaged with all controls set for either

Pressure or Pressureless Cooking, the fault may

be in the door interlock switch. Proceed as follows:

1. Turn off power to the Dual Matic.

2. Disconnect the two wires to the door switch

terminals (See figure 5-1).

3. Connect an ohmmeter between the two terminals of the switch.

4. Depress the door latch plunger, closing the

normally open switch contacts to obtain a

reading of zero ohms on the meter. If a zero

reading cannot be obtained, the switch is

defective and must be replaced.

5. Remove the ohmmeter and replace the two

leads on switch terminals (See figure 5-1).

5.4.8 Solenoid Valves

When either the inlet or exhaust solenoid valves

fail to operate, the fault may be a defective coil. A

defective coil is found using an a-c volt meter to

check the voltage at the coil wire terminals, with

the Dual Matic operating in the Pressure Cooking

mode. If voltage of 120 volts is present the fault is

the coil. Defective valve coils are not separately

replaceable, requiring complete valve replacement.

5.4.9 Buzzer

If the buzzer does not sound at the termination of

either the Pressure or Pressureless Cooking

modes (timer dial returned to "0-Minute" position),

the fault may be a defective buzzer. Buzzer

operation is verified using an a-c volt meter at

buzzer coil connections (permanently soldered),

with input power on. Selector Switch in the

PRESSURE COOKING position and the 60-Minute

timer dial at the "0-minute" position. If voltage is

120 volts, the fault is in the buzzer which must be

replaced. If 120 volts is not present, the fault is in

the wiring or control components (60-Minute timer.

Selector Switch).

5.4.10 Indicator Light

If the Dual Matic functions correctly with the

single exception that the indicator light fails to

rev. 3/78

Page 24

TROUBLE-SHOOTING

light during operation, the fault is a defective indicator

light. A "burned-out" or defective light is verified by

using an a-c volt meter at the leads (terminal strip

terminals 1 and 7), with input power on. the Selector

Switch in the PRESSURE COOKING position and the

60-Minute timer dial set (any setting beyond "0minute"). If 120 volts is present the fault is in the

indicator light and requires replacement. If 120 volts is

not present the fault is in the wiring or control

components (Selector Switch, 60-Minute timer).

5.4.11 Wiring

All of the electrical components of the Dual Matic

(Selector Switch, 60-Minute timer, 10-Minute timer,

Push-Button timer/transformer, solenoid valves,

buzzer and indicator light) are connected to each ot her

by wiring shown in Figure 5-1. If all of the electrical

components are operating correctly (and the incoming

power has been checked), but the cooker fails to

operate in either the Pressure or Pressureless modes,

the fault lies in the wiring.

Figure 5-1 is a wiring diagram which shows all

terminals and interconnections within the electrical

circuits. All numbered terminals are identified and all

leads number coded as shown. Connections can be

easily removed. Figure 5-2 shows the same information schemat ically and is an aid in isolating

circuits for testing.

Using an ohmmeter, wiring continuity between the

connections shown on the wiring diagram (figure 5-1)

are readily verified. This is best done in stages,

removing only those wires required for each continuity

check. As each lead is replaced it should be checked

for evidence of corrosion and cleaned if necessary. All

leads must be tightly attached so as to provide a good

electrical connec tion.

Figure 5-2. Schematic Diagram, Dual

Matic

S2124

Page 25

SECTION 6 MAINTENANCE

6.1 GENERAL

This section contains both preventive and

corrective maintenance information. Preventive

maintenance may be performed by maintenance

personnel at the establishment in which the cooker

is installed. It is recommended that user personnel

never attempt to make repairs or replacements to

the equipment without the assistance of authorized

service. Assistance in service methods or a current

Directory of Authorized Service Agencies may be

obtained from Market Forge. (See subsection 1.3).

6.2 PREVENTIVE MAINTENANCE

A good preventive maintenance program begins

with the daily cleaning procedure described in

subsection 3.3. Additional preventive maintenance

operations are presented in this section. In establishments which employ full-time maintenance

personnel, the tasks described can be assigned to

them. For other installations, tasks requiring

mechanical or electrical experience should be

performed by an authorized service agency.

Table 6-1 sets forth minimum preventive maintenance procedures which must be completed

periodically to assure continued trouble-free

operation of the Dual Matic.

6.2.1 Door Disassembly and Cleaning

The door assembly must be removed from the

cooker compartment for weekly cleaning. Though

no tools are needed, care in following procedure is

necessary to insure that the door will pass through

the compartment opening.

1. With cooking compartment door open, lift pan

supports up and forward to dissengage from

mounting studs. Remove from compartment as

shown in figure 3-2.

TABLE 6-1 PREVENTIVE

MAINTENANCE

Frequency Procedure

Daily 1. Cleaning — Remove pan supports and thoroughly wash and rinse cooker compart ment

interior with mild soap or aluminum cleaner. Leave door open when cooker is not in use.

See subsection 3.3.

CAUTION: Do not use strong detergent or abrasive cleaners. Pitting of aluminum interior

will result.

Weekly 1. Door Assembly Cleaning — Remove cooker door assembly as explained in sub-

section 6.2.1 and wash thoroughly with detergent and water. Inspect door gasket and

replace if worn. Exercise care in reassembly and check for tight door sealing in closed

position.

NOTE: Care must be exercised in following disassembly instructions. Door passes

through compartment opening with ease when procedure is followed in

sequence.

2. Safety Valve Check — With Compartment under pressure pull out on safety valve

knob to allow steam to escape. Pressure shown on gauge will drop sharply in response to

valve opening as explained in subs ection 6.2.2.

6-1 S2124

Page 26

Figure

6-2.

Door Removal

Disengage left and right ends of door seat spring by

counter-acting the force of the door lift spring with

one hand while disengaging studs with the other

hand (figure 6-1).

DUAL MATIC STEAM COOKER

5. Inspect door gasket for cleanliness and wear. If

food soil has become lodged behind the

gasket or the gasket is torn, push it off

perimeter of door and clean or replace as

needed (figure 6-3). A gasket which is stuck

to the door is easily removed by first soaking

the entire door in hot soapy water.

Figure 6-1. Door Spring Disengagement

Push door lift springs to the rear and off studs.

Rotate the door assembly out through the door

opening, door handle first, as shown in figure 6-2.

Figure 6-3. Gasket Removal

NOTE

To assure a pressure seal, the gasket

must be cleaned of soil and scale, and

be free of breaks.

6. Replace gasket on door and reassemble door

assembly in compartment. Open and close

door several times to check for correct

operation and tight seal of door in closed

position. See paragraph 6.3.1.2 to adjust door

seal tension.

6.2.2 Safety Valve Check

The safety valve is a protective device which

automatically relieves excessive pressure (above

15 1/2 psi, Ikg/cm2) in the unlikely event of equipment malfunction. Manual opening of the valve is

also possible and should be done once a week to

assure that the valve is clear and mechanically

sound.

1. Place cooker into operation in the pressure

mode (subsection 3.2.4) and allow pressure

to build up to about 15 psi.

2. Pull out on safety valve knob (figure 3-1, 8). A

sharp drop in pressure indicated by the

pressure gauge verifies correct manual valve

functioning and clears exhaust passage. If

pressure fails to drop, shut cooker off by

returning 60-Minute

Page 27

MAINTENANCE 6-3

timer dial to the OFF-position and consult

section 6.3.4 for replacement procedure.

NOTE

Steam emitted by valve is directed into the

drain and can neither be heard nor seen.

can be made pliable by first soaking it in hot soapy

water. Remounting the door in the compartment

completes the replacement.

NOTE

The critical function of the door seal makes it

imperative that the gasket be in good

3. Return 60-Minute Timer dial to the OFF-position.

condition. For this reason it is recommended

that at least one spare gasket be kept at all

6.2.3 Door Fulcrum Cleaning & Lubrication

times.

The door fulcrum assembly located under the

door opening includes the door latch anchor, the

door switch, switch actuating pin and the fulcrum

adjustment screw. These parts are shown in figure

7-5.

Periodic unscheduled cleaning of the actuating

pin (15) with detergent -water solution will ensure

trouble free operation. The actuating pin and its

guide must be free of food particles, with pin motion

easy and unrestricted.

The anchor is equipped with a bronze roller

bearing (7) which engages the hooked door latch.

The entire roller assembly is shown as item (10) in

figure 7-5. The roller must be cleaned periodically to

insure free-moving operation. Should accumulated

dirt or food interrupt normal rolling, detergent -water

solution should be used to free it. Cleaning should

be followed by lubrication using graphite or other

dry lubricant.

6.3.1.2 Door Seal Tension Adjustment. An

adjustment screw is built into the door anchor and

fulcrum assembly to allow compensation for

normal variation in gasket thickness caused by

wear. The adjustment screw is shown in figure 6-

4. If steam escapes from around the door, sealing

tension against the door opening can be increased

by loosening the 1/4-20 jam nut and turning the

socket head adjustment screw counterclockwise

with an allen wrench. Installation of a replacement

door gasket may result in excessive door latching

tension and require clockwise adjustment of the

screw. Trial and error will achieve the screw

adjustment which both seals the door against the

compartment opening yet allows door latching with

only moderate force applied to the handle. The

final position is set by holding the cap screw with

an allen wrench while tightening the 1/4-20 jam

nut.

6.3 REPAIR AND REPLACEMENT

Section 7 of this manual contains a listing of all

replaceable parts and associated exploded views of

the Dual Matic. In most cases disassembly procedures will be obvious from the exploded views.

Illustrated disassembly and assembly instructions

follow for procedures which are not readily

apparent.

6.3.1 Door Assembly

The door assembly consists of the door latch

and the latch fulcrum assembly. All parts are replaceable as shown in figures 7-3, door assembly;

Figure 7-4, door latch; and figure 7-5, door fulcrum

and switch.

6.3.1.1 Gasket Replacement. The door gasket

(figure 7-3, 5) is readily replaced by first removing

the door assembly from the cooking compartment

as explained in subsection 6.2.1. The worn gasket

is removed in the same manner as described for

cleaning and a replacement substituted. A new

gasket which is difficult to stretch onto the door

Figure 6-4. Door Seal Tension Adjustment

6.3.1.3 Door Lift Spring Replacement. Should

either spring bec ome damaged, it is necessary to

replace both left and right springs as a set (figure

7-3). The door assembly is removed from the

cooking compartment as explained in subsection

6.2.1. Springs are installed by removing spring

bearings (1), screws (3), and worn springs (2A,

2B) and mounting replacements. Springs are

marked

S2124

Page 28

6-4

DUAL MATIC STEAM COOKER

with tabs indicating the left and right side replacement springs for installation on the appropriate side

as viewed from the front of the compartment.

6.3.2 Exterior Panel Removal

Access to all internal plumbing assemblies is

from the top and front of the Dual Matic cabinet.

Whenever internal repairs or replacements are

required, the top panel and the front trim and lower

panel must first be removed. These parts are

shown in figure 7-1. The following procedure is

required for removal of exterior panels.

1. Raise the cooking compartment door.

2. Remove the three truss head screws (5) in the

lower front panel (4), and the two round head

screws (3) and washers (2) at each end of the

lower front trim assembly.

3. Loosen the pan head screws (7) on the left side

of the control panel and pull the trim assembly

out from under the lower front panel. The lower

panel can then be slid down from around the

cooking compartment.

4. Remove the four self-tapping screws (9) on the

rear edge of the top panel (8), the truss head

screw (5) in the top left corner of the front

panel (6) and the pan head screw (7) in the top

right corner of the control panel.

5. Lift the top panel off the cooker.

6.3.3 Control Panel Removal

Electrical components mounted on the control

panel are accessed by unfastening the panel from

the cooker cabinet and pulling it forward to the limit

of the free play in the wiring connections as shown

in figure 6-5. To accomplish this the top panel must

first be removed as explained in subsection 6.3.2,

steps 4 and 5 and the following procedure

completed:

1. Turn the panel knob (Figure 7-6, 3) for the

safety valve off the plunger (6) by holding the

plunger and spring with one hand while turning

the knob counter clockwise.

WARNING

Control panel terminals carry 120 volts. To

avoid electrical shock, shut off power to

the Dual Matic at the external circuit

breaker until panel has been removed and

positioned for testing.

2. Pull the plunger through the rear of the panel

and replace the knob to retain the spring.

3. Remove the five remaining pan head screws

(figure 7-1, 7) from the panel and pull the panel

forward about two inches.

S2124

Figure 6-5. Control Panel Removal

4. Disconnect the compression fitting at the rear of the

pressure gauge as shown in figure 6-5.

All panel components are readily accessed for

trouble shooting and replacement. For access to

separate electric component mounting plate the lower

front panel and trim must also be removed as

explained in subsection 6.3.2, steps 1, 2 and 3. The

component mounting plate assembly is included in

figures 6-5 and 6-9, and shown exploded in figure 7-7.

6.3.4 Pressure Relief and Check Valve

Replacement

The pressure relief valve and the check valve are

accessed for replacement by removing the top panel

as explained in subsection 6.3.2, steps 4 and 5.

Valves are shown exposed for replacement in figure

6-6.

Page 29

MAINTENANCE 6-5

Figure

6-7.

Steam Trap Replacement

WARNING

Figure 6-6. Pressure Relief & Check Valve Replacement

To avoid steam burn be certain that control timers

are in the OFF position, the pressure gauge reads

0 psi and the compartment door is open. Plumbing

contains 15 psi steam pressure when compartment

is under pressure.

Removal is completed by breaking the plumbing

assembly at the 3/4" union fitting and turning out the

defective valve from the threaded nipples.

Replacement valves must be sealed into the plumbing

assembly with silicon tape or equivalent high

temperature steam line sealant. Pressure relief valve

replacement requires cutting the relief valve cable and

substituting a new cable. All replacement parts are

identified in figure 7-2.

6.3.5 Steam Trap Replacement

The steam trap for the cooking compartment,

located in the lower left corner of the cabinet, is

accessed by removing the lower front panel and trim

as explained in subsection 6.3.2, steps 1, 2 and 3. The

exposed trap is shown in figure 6-7 and identified for

replacement in figure 7-2, item 31.

WARNING

To avoid steam burns be certain that control timers

are in the OFF position, the pressure gauge reads

0 psi and the compartment door is open. Plumbing

contains 15 psi steam pres sure when compartment

is under pressure.

S2124

Page 30

6-6 DUAL MATIC STEAM COOKER

S2124

rev.

3/78

Trap replacement is simplified by a twist -lock

connection at the inlet (top) end. To disengage the trap, the

body is turned clockwise and then pulled downward.

Removal is completed by using a wrench to turn counter

clockwise on the trap hex surface while using a second

wrench to hold the elbow fitting fast. Use of silicone tape or

equivalent high temperature steam line sealant is required

for installing the replacement trap. The locking collar need

not be replaced unless damaged.

6.3.7 Inlet Solenoid Valve Replacement

A replacement for the 1/2" inlet solenoid valve is

available from Market Forge Authorized Service

Agencies as a complete unit. It is therefore

necessary to replace the entire valve when either

the coil is faulty or the diaphragm ruptures. The

valve is accessed by removing the lower front panel

and trim strip as explained in subsection 6.3.2, steps

1, 2 and 3. The exposed valve is shown in figure 69, and identified for replacement in figure 7-2, item

20.

6.3.6 Jet Pipe Replacement

Should the steam jet pipe (figure 7-2, 22) require