Page 1

SERVICE & PARTS MANUAL

Ultra Steam® Convection Steamer

Models:

3005 CTE

3010 CTE

3015 CTE

Revision No. 1-284

Form Number S-2267A 2/84 Printed in USA

Market Forge Co.

35 Garvey Street Everett, MA02149 Tel. (617) 387-4100,

Telex 94-9414, Cable MAFORCO

Page 2

TABLE OF CONTENTS

Section

SECTION 1 INTRODUCTION

1.1 Description

1.2 Service

SECTION 2 TROUBLE-SHOOTING

2.1 General

2.2 Electrical Fault Isolation

Page

1-1

1-1

2-1

2-1

LIST OF ILLUSTRATIONS

Figure Page

SECTION 2 TROUBLE-SHOOTING

2.1 Schematic & Wiring Diagram, 60Hz. 2-4

2.2 Schematic & Wiring Diagram, 50Hz 2-5

LIST OF TABLES

Tables Page

SECTION 2 TROUBLE-SHOOTING

2.1 Trouble-Shooting Guide 2-1

2.2 Ultra Steam® Function 2-3

Section Page

SECTION 3 ILLUSTRATED PARTS LIST

3.1 General 3-1

3.2 Ordering Information 3-1

3.3 Index of Illustrated Parts 3-1

Figure Page

SECTION 3 ILLUSTRATED PARTS LIST

3.1 Base and Steamer Assembly 3-2

3.2 Electrical Assembly 3-4

3.3 Plumbing Assembly 3-6

3.4 Door Assembly 3-10

Tables Page

SECTION 3 ILLUSTRATED PARTS LIST

3.1 Parts List for Base and Steamer Assembly 3-3

3.2 Parts List for Electrical Assembly 3-5

3.3 Parts List for Plumbing Assembly 3-7

3.4 Parts List for Door Assembly 3-11

Page 3

SECTION 1 INTRODUCTION

Ultra Steam® Convection Steamers are electrically powered high-capacity cookers featuring improved energy

efficiency. These units are designed to reduce power consumption by jacketing the cooking compartment with

the steam generator. Because the cooking compartment and steam generator are joined to become a single unit,

the need for steam supply piping has been eliminated.

1.1 Description

The Ultra Steam® Convection Steamer was designed

and built to derive maximum value from energy

supplied. Jacketing of the steam generator around the

sides and bottom of the cooking compartment

produces an efficient cooker. Steam is directed into

the cooking chamber through supply jets.

For ease of maintenance, the steam generator is

accessed from the front through the clean-out port.

This access hole allows service personnel to inspect

interior of generator for evidence of Corrosion, buildup of sediment, or other conditions which may be

detrimental to operation of unit.

1.2 Service

Should repairs be required, a network of authorized

service agencies is available to assist with prompt

service. A current Directory of Authorized Service

Agencies and service assistance may be obtained by

contacting:

Product Service Department

Market Forge Company

35 Garvey Street

Everett, MA 02149

Telephone: (617) 387-4100

The model and serial numbers must be referenced

when corresponding with Market Forge.

1-1

Page 4

SECTION 2 TROUBLE-SHOOTING

PROBLEM

Clean or replace

2.1 General

This section contains trouble-shooting and

maintenance information to assist service personnel in

locating the general source of problems which may

occur with the Ultra Steam® Convection Steamer. It is

recommended that local authorized service be

obtained for assistance in. completing trouble-shooting

procedures.

Table 2-1 serves as a general guide to trouble

shooting. Before attempting to utilize this

information, service personnel should be thoroughly

familiar with the operating instructions and the function

of all controls in Operator's Manual, form number S-

2262.

2.2 Electrical Fault Isolation

Correction of an electrical failure first requires

isolation of the fault to a single circuit or component.

In most cases, the nature of the steamer will be

sufficient to isolate it to one or more circuit elements.

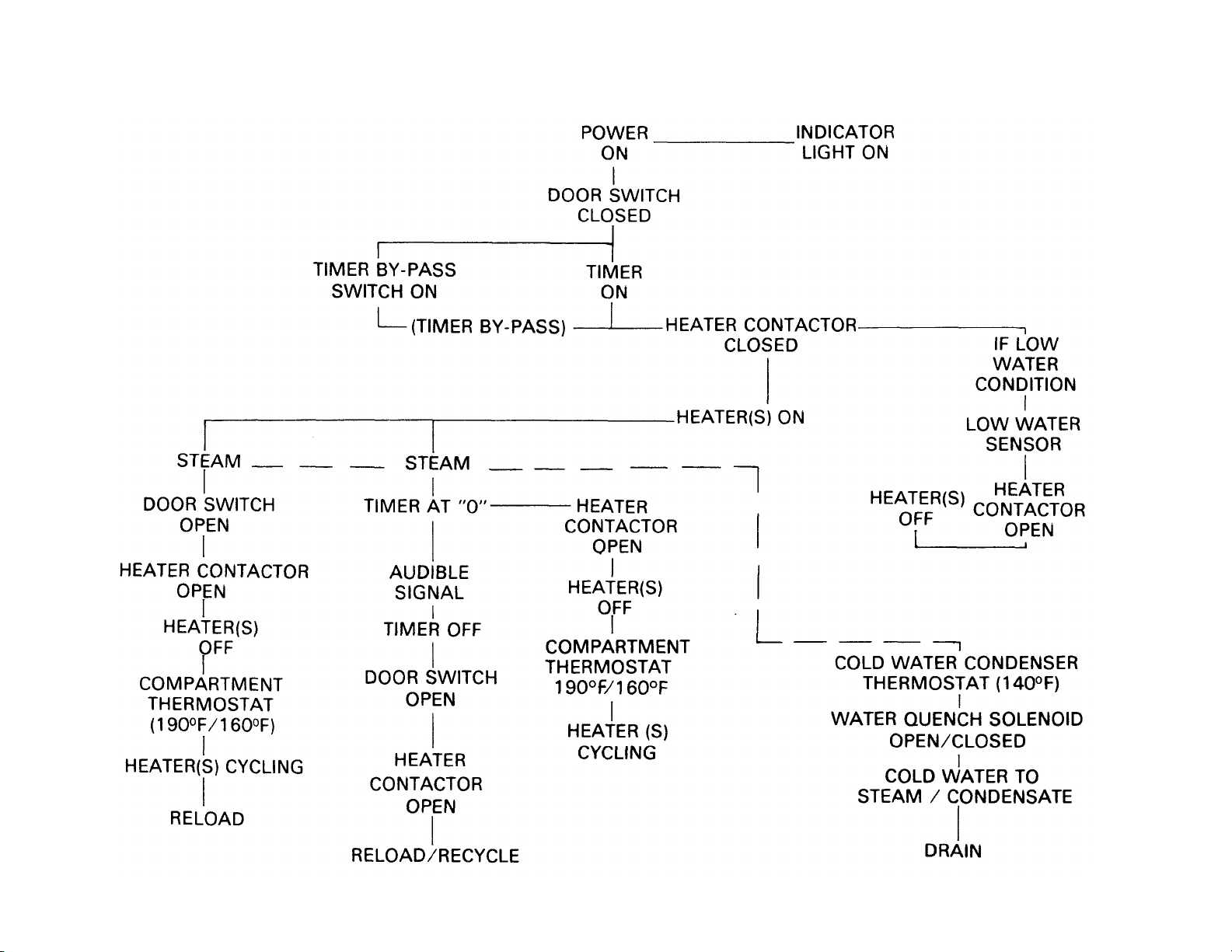

Table 2-2 is provided as a guide for isolating electrical

faults which may occur in operation of the cooker.

Wiring diagram and schematic diagram are provided

for locating the source of the electrical failures.

TROUBLE-SHOOTING GUIDE

This trouble-shooting guide lists some common difficulties which the operator may encounter in using the cooker,

together with possible solutions.

Probable Cause Remedy

SWITCH FAILS TO LIGHT WHEN POWER SWITCH IS PUSHED ON

a. Power to cooker is off

b. Burned out bulb-faulty switch

STEAM GENERATOR FAILS TO PRODUCE STEAM

a. Water supply valve closed

b. Purge/drain valve open

c. Faulty heating element(s)

d. Solenoid valve stuck closed

e. Water level sensor stuck

NO STEAM IN COOKER COMPARTMENT

a. Steam jets restricted

b. Door interlock switch faulty

c. Timer by -pass switch faulty

d. Thermostat faulty

DOOR LEAKS STEAM

a. Door out of adjustment

b. Drain line clogged

Locate external breaker and place it in ON position

Replace switch

Open valve

Close purge/drain valve

Replace heating elements)

a. Clean or replace valve

b. Replace coil

Clean jets with wire or replace

Replace interlock switch

Replace by -pass switch

Replace thermostat make sure proper thermostat

is used 190°F 88° C or 160°F 71°C

Adjust door catch

Clean drain line

Table 2-1 2-1

Page 5

TROUBLE-SHOOTING GUIDE (cont.)

WATER EXITING THROUGH STEAM JETS

a. Generator solenoid valve stuck open a. Clean or replace valve

b. Water level sensor stuck b. Replace coil

GENERATOR FAILS TO PURGE

a. Purge/drain valve clogged a. Clean purge/drain valve

b. Unit operating b. Push ON/OFF switch to OFF position

OPEN DRAIN LINE EMITS STEAM

a. Condenser solenoid valve stuck closed a. Clean or replace valve

b. Condensate thermostat faulty b. Replace coil Replace thermostat

c. Wat er supply to condenser off Open water inlet

TIMER DOES NOT FUNCTION

a. Timer faulty a. Turn timer past 10-minute mark to verify operation

b. Check electrical connections

c. Replace timer

b. Timer by -pass switch faulty a. Place by -pass switch in timer controlled (left) position

b. Replace by -pass switch

Page 6

Page 7

Page 8

Page 9

SECTION 3 ILLUSTRATED PARTS LIST

3.1 General

This section contains a complete listing of all

replaceable parts of the Ultra Steam® Convection

Steamer. For the purpose of parts identification, the

unit is broken down into functional assemblies, and

each assembly is shown in an exploded view which is

keyed to the accompanying parts list. Each parts list

contains the figure index number, the Market Forge

part number, and an abbreviated description.

3.2 Ordering Information

Orders for repair parts should be directed to the

nearest authorized parts distributor. For a current

Market Forge Authorized Parts Distributor List

contact:

Customer Service Department Market

Forge Company 35 Garvey Street

Everett, MA 02149 Telephone: (617)

387-4100

3.3 Index of Illustrated Parts

Figure

or

Table

F3-1 Base and Steamer Assembly

T3-1 Parts List for Base and

Steamer Compartment

F 3-2 Electrical Assembly

T3-2 Parts List for Electric Assembly

F3-3 Plumbing Assembly

T3-3 Parts List For Plumbing Assembly

F3-4 Door Assembly Complete

T3-4 Parts List for Door Assembly

3-1

Page

3-2

3-3

3-4

3-5

3-6

3-7

3-10

3-11

Page 10

Page 11

Parts List for Base Steamer Compartment

Item No. Part No. Description

1 91-7510 Panel, Outer, Left Side

2 91 -7070 Panel, Back

3 91 -7073 Cover, Box, Terminal

4 91 -7505 Panel, Outer, Right Side

5 91-7150 Assy., Top, Outer

6 91 -7501 Rack, Pan

7 91 -7508 Assy., Trough

8 91-7804 Screw, Orifice 5KW

9 91-7515 Screw, Orifice 10& 15KW

10 91-7880 Assembly, Weldment, Strainer & Clip

11 91 -7230 Assy., WIdmt., Base, Bezel & Compt/Boiler

12 91 -7405 Assy., Weldment, Hinge, Door

13 91 -7504 Catch, Door

14 91-7520* Bracket, Mounting, Thermostat

15 10-1764* Screw, Mach., Truss Hd., ST. ST., #10-32 x 1/2" Lg.

16 10-1959* Screw, Mach., Truss Hd., ST. ST., #10-24 x 3/8" Lg.

17 10-0100* Washer, Nylon, .040 Thk., 1/2" OD

18 10-2509* Lockwasher, Med. Series , #10, ST. ST. .062 Wd. x .047 Thk.

19 10-2338* Nut, Hex, ST. ST. #10-24

20 10-1761* Screw, Mach,, Truss Hd., ST. ST. #8-32 x 3/8" Lg.

21 91 -7885 Spacer, Hinge 3/8 OD x 1/2 Lg.

22 10-2413* Washer, Plain, ST. ST. #10

23 10-1956* Screw, Tapping-Truss Hd., #8 x 3/8 Lg.

24 91-7325 Stud, Pan Rack Support

*These parts may be purchased locally Table 3-1

3-3

Page 12

Figure 3-2. Electrical Assembly.

Page 13

Parts List for Electrical Assembly

Item No. Part No. Description

1 91 -7083 Panel, Control

2 10-4485 Knob, Buckeye

3 09-5243 Knob, Skirted with indicator arrow 2" Dia. D-Shaft-Right

4 09-6522 Switch, Push button w/lamp DPDT, reads POWER

5 10-6293 Timer, 60 Minute, 240V, 50/60 Hz

6 10-7903 Switch, Toggle, DPDT, 15 Amp/125VAC, 10 Amp/250VAC, .250 Spade Terminal

7 10-1739* Screw, Mach., Truss Hd., ST. ST., #8-32 x 1/2" Lg.

8 09-3856* Washer, Plain, Nylon, #8, 3/8 OD x 16" Thk.

9

Flange (Part of Heat er Cartridge)

9A 91-7502 Plate, Cover, Blank, Heating Element

10 91-7521 Gasket, Heating Element

11 10-9276 Push Button Boot

12 10-6859 Microswitch

13 09-3424* Screw, Mach., Truss Hd., #10-32 1/4 Lg.

14 09-6484 Contactor, 60 Amp, 3 Pole, 208/240V, 50/60 Hz

14A 10-5476 Contactor, 40 Amp, 3 Pole, 208V, 50/60 Hz

14B 10-5943 Contactor, 40 Amp, 3 Pole, 240V, 50/60Hz

15 91-7128 Bracket, Mounting, Elect. Comp.

16 10-1764* Screw, Mach., Truss Hd., ST. ST., #10-32 x 1/2" Lg.

17 09-6516 Siren, Audio Alert, 120V

18

Knurled Nut (Part of Item 17)

19 10-1739* Screw, Mach., Truss Hd., ST. ST., #8-32 x 1/2" Lg.

20 10-2330* Nut, Hex, ST. ST., #8-32

21 10-2518* Lockwasher, Med. Series, ST. ST., #8, .055 wide, .040 Thk.

22 91-7115 Box, Terminal

23 10-5070 End Piece, Sectional Terminal Block

24 10-5503 Terminal Block

25 10-1959* Screw, Mach., Truss Hd., ST. ST., #10-24 x 3/8" Lg.

26 09-6575 Bushing, Snap, Nylon, 11/16 I.D.

27 10-5492 Ground Lug

28 10-5678 Clip, Cable, Cellulose, 7/16" Dia.

29 10-2509* Lockwasher, Med. Series. ST. ST. #10

30 10-2338* Nut, Hex, #10-24

31 09-6548 Thermostat, Snap Disc, Surface Mounting Type, 190°F 88°C

31A 09-6559 Thermostat, Snap Disc, Surface Mounting Type, for High Altitude 160°F 71°C

32 09-6557 Heater, Cartridge, 2 Wire, 208V (1pH)

32A 09-6553 Heater, Cartridge, 3 Wire, 208V (3pH)

32B 09-6558 Heater, Cartridge, 2 Wire, 240V (1pH)

32C 09-6554 Heater, Cartridge, 3 Wire, 240V (3pH)

32D 09-6556 Heater, Cartridge, 3 Wire, 380V (3pH)

32E 09-6555 Heater, Cartridge, 3 Wire, 415V (3pH)

These parts may be purchased locally Table 3-2

3-5

Page 14

Figure 3-3. Plumbing Assembly

Page 15

Item No. Part No. Description

3A

3B

4

6

7

8

9

10

11

12

13

14

15

16

20

21

22

23

24

25

26

27

28

30

31

32

33

34

35

36

37

Parts List for Plumbing Assembly

1 09-4878 *

2

3

10-2858 *

09-4862

10-8368

10-8369

10-4056 *

5

17

18

19

29

29A

38 91 -7457 Line, Ball Valve to Drain

10-2847 *

10-1120 *

10-2813 *

91-3791

10-2830 *

91-7456

10-3490 *

10-3320 *

09-6549

91-7147

10-2403 *

10-2508 *

10-2336 *

10-2837 *

91-7462

10-2813 *

91-7071

10-3644 *

10-3358 *

10-1055 *

91-7455

91-7072

91-7146

10-3628

10-0865

09-4902

91-7262

10-3357 *

09-4887

91-7451

09-4895 *

91-7216

91-7464

91-7463

Elbow, 90° Reducing, Ml 3/8 x 1/8

Elbow, 90° Comp., Brass, 1/ 4 OD x 1/8 IPS

Nozzle, Jet, Full Cone, 1/4 IPS Pipe Conn., .046 Dia. Orifice (Model

3005 CTE)

Nozzle, Jet, Full Cone, 1/4 IPS Pipe Conn., .062 Dia. Orifice (Model

3010 CTE)

Nozzle, Jet, Full Cone, 1/4 IPS Pipe Conn., .078 Dia. Orifice (Model

3015 CTE)

Bushing, Reducing, Outside Hex, Ml 3/4 IPS x 1/4 IPS

Nipple, Close, Bl, 3/4 IPS

Full Coupling, Steel, 3/4 IPS

Plug, Sq. Hd., Ci, 3/4 IPS (Models 3005 CTE and 3010 CTE only)

Vacuum Breaker, Rework (Model 3015 CTE only)

Elbow, 90° Street, M l, 3/4 IPS

Line, Solenoid -Drain CWC

Tee, Side Outlet, Plain, Ml, 3/4 IPS

"Y" Branch, Ml, 3/4 IPS

Thermostat, Snap Disc, Probe Type

Clamp, Bracket, Cross

Washer, Plain, ST. ST., 1/4

Lockwasher, ST. ST., 1/4

Nut, Hex, ST. ST., 1/4-20

Elbow, 90° Comp., 5/8 OD x 1/2 IPS

Assy. Weldment, Tee, Side Outlet

Plug, Sq. Hd., Brass, 3/4 IPS

Bracket, Mounting, Tee

Plug, Sq. Hd., Brass, 3/8 IPS

Elbow, 90° Comp., 3/8 OD x 3/8 IPS

Tee, Brass, 3/8 IPS

Line, Water, Solenoid to Broiler

Bracket, Support, Tee

Bracket, Outlet, Drain Cross

Adaptor, Comp., Straight, Brass, 1/4 IPS x 3/8 OD

Valve, Solenoid, 240V, 50/60 Hz, 1/4 IPS-N.C.

Valve, Solenoid, 208V, 50/60 Hz, 1/4 IPS-N.C.

Bracket, Mounting, Solenoid

Elbow, 90° Comp., 3/8 OD x 1/4 IPS

Low Water Cutoff

Assembly, Elbow and Line, Broiler to Ball Valve

Valve, Ball, 1/2 IPS

Extension, Knob, Valve, Ball

Channel, Mounting, Drain, Valve, Ball

Clip, Holding, Drain, Valv e, Ball

*These parts may be purchased locally Table 3-3

3-7

Page 16

Table

3-3

(contJ

Parts List for Plumbing Assembly (Cont'd.)

Item No. Part No. Description

39 91 -7521 Gasket, Heating Element

40 91 -7502 Plate, Cover, Blank, Heating Element

41 91-7113 Plate, Cover, Boiler

42 91-7114 Gasket, Water Fill Cover

43 10-8102 Valve, Pressure Relief, 1/2 PSI 3/4 NPT Low Pressure

44 10-2160 * Screw, Mach., Truss Hd., #10-32 x 3/8 Lg.

45 10-2972 * Rivet, Pop, 1/8 Dia. x .232

46 10-1764 * Screw, Mach., Truss Hd., #10-32 x 1/2 Lg.

47 10-1953 * Screw, Mach., Pan Hd., #10-24 x 1/2 Lg.

48 09-3431 * Screw, Mach., Hex Hd., ST. ST., #3/8-16 x 3/4 Lg.

49 10-2507 * Lockwasher, ST. ST., 3/8

50 10-1739 * Screw, Mach.. Truss Hd., ST. ST., #8-32 x 1/2 Lg.

*These parts may be purchased locally

3-8

Page 17

Figure 3-4. Door Assembly (Part No. 91- 7040} 3-10

Page 18

Parts List for Door Assembly

Table

3-4

Item No. Part No. Description

1 91-7046 Door, Outer

2 91 -7045 Door, Inner, Cast Aluminum

3 91-7043 Panel, Door, Inner

4 91-7048 Connector, Door, Inner

5 91-7041 Handle, Door, Acrylic

6 91-7047 Pin, Hinge

7 09-1608 Striker, Casting, Latch, Door

8 91-7049 Spring, Door, Inner

9 09-4213 Gasket, Door, Silicone

10 91-7044+* Insulation, Door, Fiberglass Back, Foil Faced 8-78" x 11-1/16" x 3/8"

11 09-6542 Bearing, Bronze 1/4 ID x 1/2 Long

12 09-6543 Ring, Retaining, Crescent

13 10-2044* Screw, Mach., Hex, ST. ST., #10-24 x 1/2" Lg.

14 10-2526* Washer, Extrenal Tooth, ST. ST., #10

15 10-1768* Screw, Truss Hd., ST. ST., #10-32 x 1" Lg.

16 10-2550* Nut, Acorn, ST. ST., #8-32

17 10-1739* Screw, Truss Hd., ST. ST., #8-32 x 1/2" Lg.

18 10-2518* Lockwasher, ST. ST., #8

19 10-0795* Loctite

20 91-7050+* Insulation. Door, Fiberglass, Front, Foil Faced 11 -1/2 x 12-3/4" x 3/8"

21 10-0100* Washer, Flat, White Nylon

22 10-3522+ Sealant. Adhesive, Clear, #732 RTV

23 09-2610 Bearing, Bronze, 1/4 ID x 3/8 Lg.

*These parts may be purchased locally

+Not shown in exploded view

3-11

Loading...

Loading...