Page 1

2 A-PLUS 2

SC

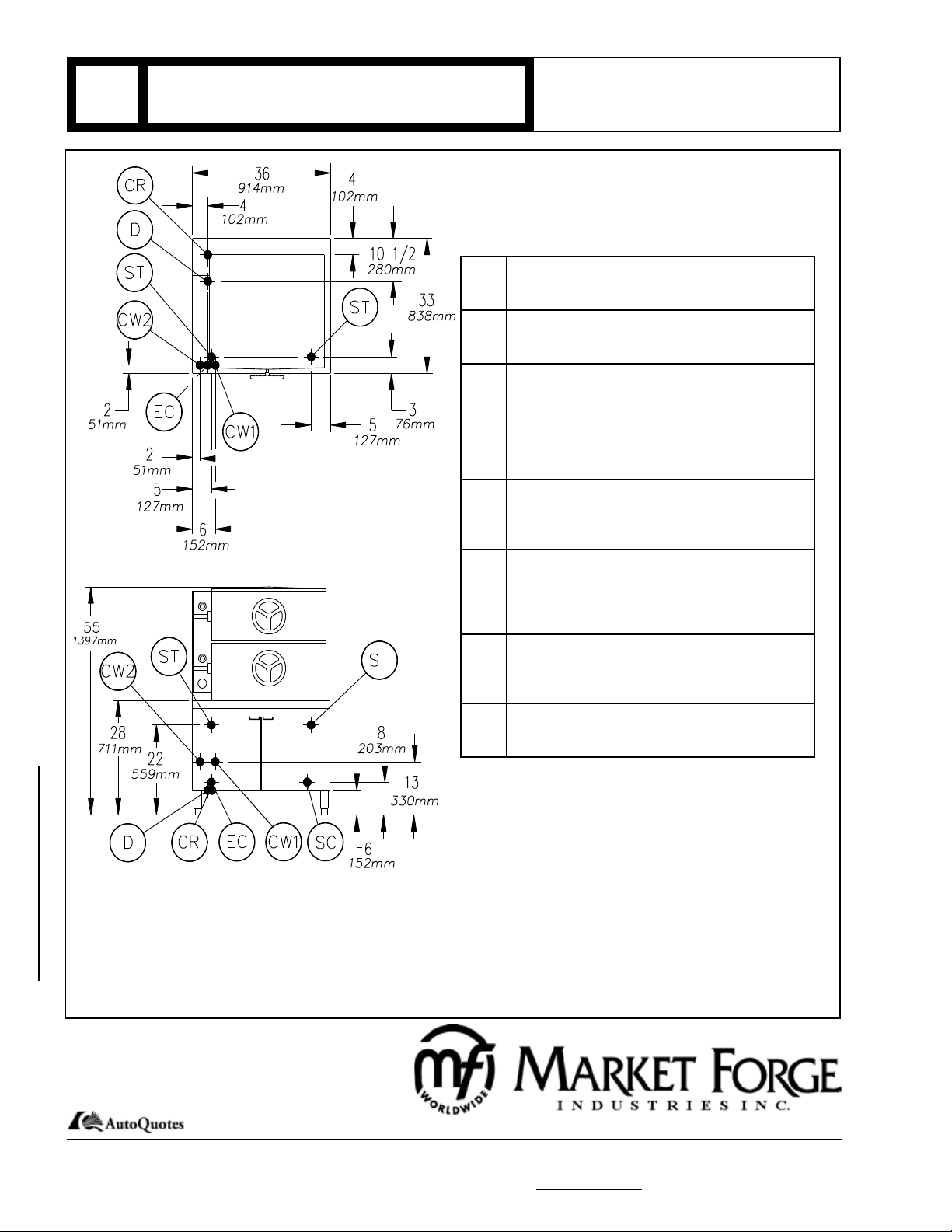

MODEL: • 2 A-PLUS 2 SC

SIZE: 36” Wide x 33” Front-to-Back

(914mm Wide x 838mm Front-to-Back

DESCRIPTION:

Will be a Market Forge Model 2 A-Plus 2 SC steam cooker

with stainless steel cooking compartments. Both compartments shall have pressure and pressureless steam controls,

and shall provide operator selection of either 5 PSI (0.35kg/

cm2) pressure steam cooking or free-vented, pressureless

steam cooking. Center and/or bottom compartment shall operate as a pressure steam cooker at 5 PSI (0.35kg/cm2).

Cooking compartments shall have double-door construction.

Inner door shall be of cast aluminum with stainless steel facing, and shall be removable for cleaning without the use of

tools. Door wheel screw shall be Acme type with replaceable

bushing and all threads concealed. Compartment doors shall

be self-latching, and shall open automatically approximately

15° when primary latch is released. Upper cooking compartment shall be equipped with lift-out pan supports. Center and/

or bottom compartment shall include lift-out four-track shelf

uprights and three pullout shelves.

Cooking compartments shall be automatically and independently controlled.

WITH STEAM COIL GENERATOR

)

JOB NAME: ________________________

ITEM NO.: _________________________

NO. REQUIRED: ____________________

OPERATION WILL BE BY: Stainless steel steam coil boiler,

ASME constructed, National Board Registered, UL approved

15 PSI (1kg/cm2) equipped for operation with incoming steam

at 40-50 PSI (2.8-3.5kg/cm2) with a ow of 300 lbs. per hour

(135kg/hr.) equipped for operation of A-Plus at either 0 PSI

(pressureless mode) or 5 PSI (0.4kg/cm2) through a pressure reducing valve (pressure mode).

SPEC SHEET: S-2403C

07/08

UPPER COMPARTMENT - PRESSURELESS MODE:

15-Minute timer is set. Steam ow will automatically be interrupted when compartment door is opened during cooking

cycle. At end of cooking cycle, indicator light will turn off, and

a continuous audible signal will sound.

UPPER COMPARTMENT - PRESSURE MODE:

60 minute timer is set. Steam and pressure will ll the compartment automatically. At the end of cooking cycle steam

control handle shall release, turning off the indicator light,

exhausts steam and condensate from the cooking compartment, and sounds a continuous alarm.

LOWER COMPARTMENT:

Shall operate only as a pressure cooker in the same manner as described for the upper compartment in the pressure

mode.

Cabinet base will be of modular design to match other Market Forge cooking equipment and enclose the boiler. Base

with stainless steel frame will be equipped with 6” (152mm)

stainless steel legs and adjustable bullet feet, reinforced dieformed stainless steel marine edged counter top, and stainless steel lift-off front panel.

The manufacturer reserves the right to modify materials and specications without notice.

The steam generator shall have an automatic drain and cold

water condenser. Condenser shall automatically convert exhausted steam into water before it is discharged from the

drain.

COOKING CAPACITIES:

Upper Compartment (Pressure or Pressureless)

• (6) 12” x 20” x 2 1/2” pans.

• (4) 12” x 20” x 4” pans.

Lower Compartment (Pressure)

• (6) 12” x 20” x 2 1/2” pans.

• (4) 12” x 20” x 4” pans.

OPTIONAL AT EXTRA COST: (Indicate quantity in space provided)

• ____ Steam Take-Off Kit.

• ____ Spray and Rinse Hose.

• ____ M12 - 12” (305mm) Spacer Cabinet.

• ____ M6 - 6” (152mm) Spacer Cabinet.

• ____ Condensate Return Kit.

• ____ 12” x 20” x 2 1/2” perforated stainless steel pans.

• ____ 12” x 20” x 2 1/2” solid stainless steel pans.

• ____ 12” x 20” x 4” perforated stainless steel pans.

• ____ 12” x 20” x 4” solid stainless steel pans.

FOOD SERVICE EQUIPMENT

2 A-Plus 2 Cooker

An Employee Owned Company

35 Garvey Street • Everett • MA • 02149

Tel: (617) 387-47100 • Toll Free: (866) 698-3188 • Fax: (617) 387-4456 • Outside MA Fax: (800) 227-2659

E-Mail: custserv@mi.com • Website: w w w . m f i i . c o m

Page 2

SC

SPEC SHEET: S-2403C

07/08

2 A-PLUS 2

WITH STEAM COIL GENERATOR

Steam Coil Operated

SC Steam Supply - 1/2” (13mm) IPS incoming steam

CR Condensate Return - 1/2” 13mm IPS return from

CW1 Cold Water Only - 3/8” (10mm) IPS for cold water

CW2 Cold Water - 3/8” (10mm) NPT. tubing for cold

D Drain - Pipe full 2” (50mm) IPS to ush oor drain

EC Electrical Connection - 120 VAC, 60 Hz, 1/2”

ST Steam Take-off - Connection for operations of

DETAILS & DIMENSION

SERVICE CONNECTIONS

pressure must not be less then 40 PSI (2.8kg/

cm2) nor exceed 50 PSI (3.5kg/cm2).

generator may be connected to condensate return line (optional at extra cost).

to boiler. Cold water lines will have a maximum of

50 PSI (3.5 kg/cm2) and a minimum of 25 PSI (1.8

kg/cm2) water pressure. CAUTION: FILTER SYS-

TEM INSTALLATION INSTRUCTIONS MUST BE

ADHERED TO WHEN CONNECTING A FILTER

TO THIS LINE

water to boiler. Cold water line will have a maximum of 50 PSI (3.5 kg/cm2) and a minimum of 5

PSI (1.8 kg/cm2) water pressure.

capable of receiving water owing at a maximum rate of 5 gallons (19 liters) per minute. DO

NOT MAKE SOLID CONNECTION TO FLOOR

DRAIN. INSTALL NO ELBOWS IN DRAIN LINE.

(13mm) conduit connection or equivalent. Use

wire suitable for at least 90OC. Amp draw for

cooker and boiler controls: 6 Amps.

adjacent steam powered equipment. Requires

steam take-off kit (optional at extra cost).

NOTE: Allow 12” (305mm) spacing on left and 6” (152mm)

spacing on right if height of adjoining wall or equipment ex

ceeds 29” (737mm). Matching spacer cabinets 12” (305mm)

or 6” (152mm) wide are available and may be specied.

CAUTION: Before connecting water to this unit, have water

supply analyzed to make sure hardness os no greater than

2.0 grains and Ph level is within the range of 7.0 - 8.5. Water which fails to meet these standards should be treated

2 A-Plus 2 Cooker

by installation os water conditioner. EQUIPMENT FAILURE

CAUSED BY INADEQUATE WATER QUALITY IS NOT

COVERED UNDER WARRANTY.

FOOD SERVICE EQUIPMENT

It is our policy to build equipment which is design certied by U.L., A.S.M.E., N.S.F. and C.S.A. However, a continuing program of product improvement makes it necessary

An Employee Owned Company

PRINTED IN U. S. A. 35 Garvey Street • Everett • MA • 02149

to submit new models to the agencies as they are developed and consequently not all models bear the appropriate agency labels at all times.

Tel: (617) 387-47100 • Toll Free: (866) 698-3188 • Fax: (617) 387-4456 • Outside MA Fax: (800) 227-2659

PVC and CPVC pipe are not acceptable materials for

drains.

The only available space to supply utilities to the steam

boiler is the 6” (152mm) space between the oor and the

cabinet base.

E-Mail: custserv@mi.com • Website: w w w . m f i i . c o m

-

Loading...

Loading...