Page 1

A SERIES

PRESSURE STEAM COOKERS

INSTALLATION - OPERATION - MAINTENANCE

MODELS

2AM36G, 2 compartment, modular base gas boiler

2AM36E, 2 compartment, modular base electric boiler

2AM36D, 2 compartment, modular base direct steam

3AM36G, 3 compartment, modular base gas boiler

3AM36E, 3 compartment, modular base electric boiler

3AM36D, 3 compartment, modular base direct steam

2A, 2 compartment, direct steam on legs

3A, 3 compartment, direct steam on legs

44 Lakeside Avenue, Burlington, Vermont 05401 USA

Telephone: (802) 658-6600 Fax: (802) 864-0183

www.mi.com PN 14-0297 Rev D (4/16)

© 2016 - Market Forge Industries Inc.

Page 2

Your Service Agency’s Address:

Model

Serial number

Steamer installed by

Installation checked by

Page 3

IMPORTANT

TABLE OF CONTENTS

WARNING: Improper installation, adjustment, alternation,

service or maintenance can

cause property damage, injury or death. Read the installation, operation and maintenance instructions thoroughly

before installing or servicing

this equipment.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE

USER SMELLS GAS MUST BE

POSTED IN A PROMINENT LOCATION. This information may

be obtained by contacting your

local gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or

other ammable vapors or liquids in the vicinity of this or any

other appliance.

INSTALLATION

Service Connections ..................................................... 2

PRV – Pressure Reducing Valve Maintenance and Adjustments .............. 6

OPERATION

Preheating .............................................................. 7

Basic Operating Instructions .............................................. 8

Cooking Tips ............................................................ 9

Suggested Steam Times ................................................. 10

MAINTENANCE

Preventative Maintenance ............................................... 13

Drain Screen Cleaning & Removal .................................... 13

Safety Valve Check .................................................. 13

Inner Door Removal & Cleaning ...................................... 14

Door Wheel Lubrication .............................................. 14

Replacing Worn or Damaged Door Gasket ............................ 14

Door Assembly Instructions .............................................. 15

The information contained in this

manual is important for the proper installation, use, and maintenance of this steamer. Adherence to these procedures and

instructions will result in satisfactory baking results and long,

trouble free service. Please

read this manual carefully and

retain it for future reference.

ERRORS: Descriptive, typographic or pictorial errors are

subject to correction. Specications are subject to change

without notice.

Page 4

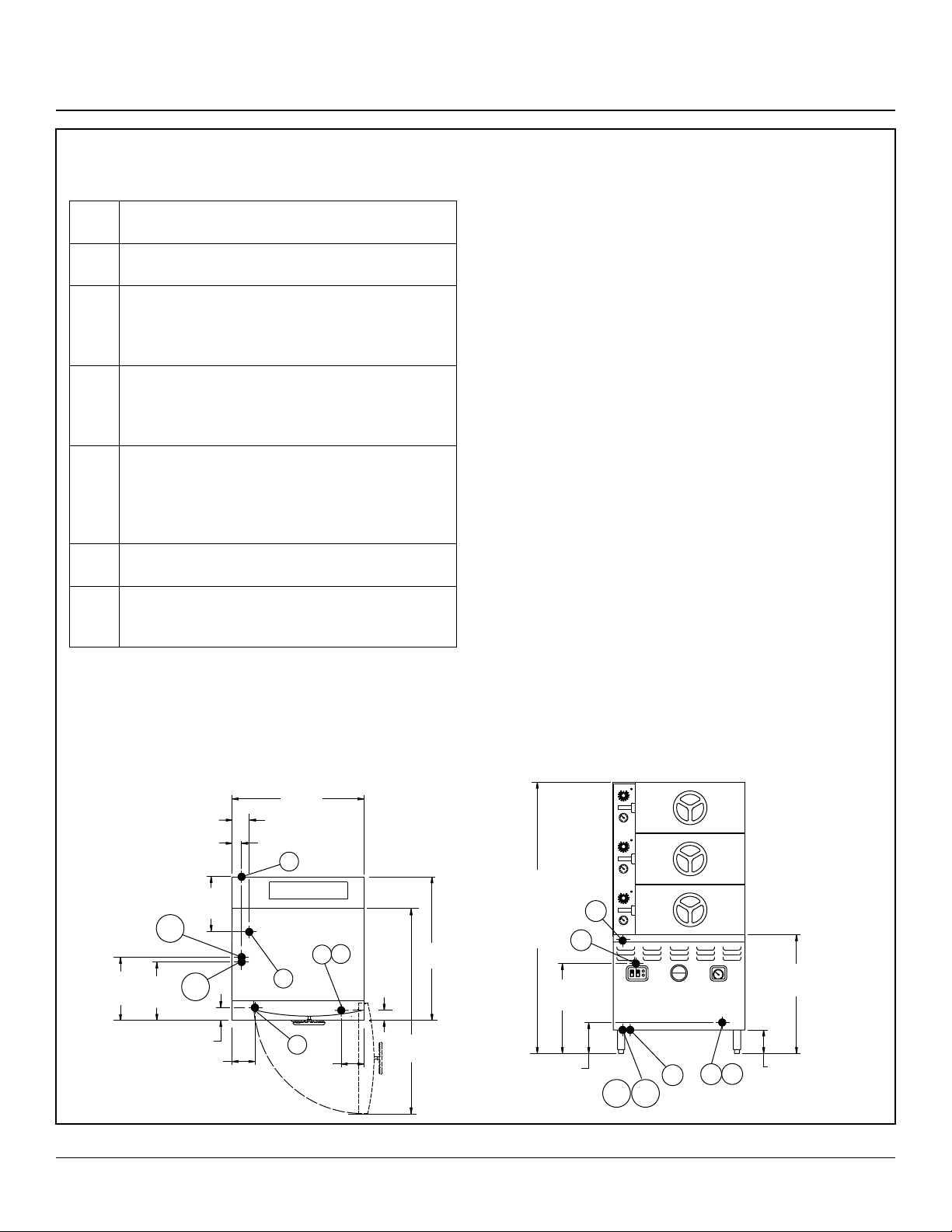

Service Connections

2AM36G & 3AM36G

SERVICE CONNECTIONS

G Gas Connection - 3/4” (19mm) N.P.T. female for

200,000 BTU boiler.

G1 Gas Connection - 1” (25mm) N.P.T. female for

300,000 BTU boiler.

CW1 Cold Water - 3/8” (10mm) NPT for cold water to

boiler. Cold water lines will have a maximum of

50 PSI (3.5kg/cw2) and a minimum of 25 PSI

(1.8 kg/cw2) water pressure.

CW2 Cold Water - 3/8” (10mm) NPT for cold water to

condenser. Cold water lines will have a maximum of 50 PSI (3.5kg/cw2) and a minimum of

25 PSI (1.8 kg/cw2) water pressure.

D Drain - Pipe full 2” (50mm) NPT to ush oor

drain capable of receiving water owing at a

maximum rate of 5 gallons (19 liters) per minute. DO NOT MAKE SOLID CONNECTION TO

FLOOR DRAIN.

EC Electrical Connection - 120 Volts AC, 60 Hz, single

phase, and a 9 foot Power Cord/NEMA 5-15.

ST Steam Take-off - Connection for operations of

adjacent steam powered equipment. Requires

steam take-off kit (optional at extra cost).

DIMENSIONS ARE IN INCHES [MM]

OPERATION WILL BE BY

Gas red, A.S.M.E. constructed and National Board Reg-

2

istered, 15 PSI (1 kg/cm

) steam boiler rated at 200,000

BTU

Notes: If equipment is installed where elevation exceeds

2,000 feet (609.6 meters) above sea level, specify instal-

lation altitude so that proper gas orices can be provided.

The only available space to supply utilities to the gas

boiler is the 6” (152mm) space between the oor and the

cabinet.

Allow 3” (76mm) space from side wall and 6” (152mm)

from rear wall if adjoining walls are combustible.

PVC & CPVC PIPE ARE NOT ACCEPTABLE MATERIALS FOR DRAINS.

CAUTION: REMOTE KETTLE OPERATION If this boiler

is feeding a remote kettle that will be more than 5 feet

(1.5 meters) away, consult factory before ordering.

WATER SUPPLY

Good quality water feed is the responsibility of the owner.

Water quality must be within the following general guide-

lines.

TDS: 40-125 ppm Chlorides: <25 ppm

Silica: <13 ppm pH: 7.0 - 8.5

Chloramine: <0.2 ppm Chlorine: <0.2 ppm

Hardness: 35-100 ppm

The best defense against poor water quality is a water

treatment system designed to meet your water quality

conditions.

CW1

12.5

10.5

[318

[267]

INSTALLATION

4[102]

2.5 [64]

10.5

[267]

CW2

3 [76]

5 [127]

36 [914]

EC

FLUE

D

ST

5 [127]

68 [1730]

3AM36G

22

[559]

8 [203]

ST

EC

28

[711]

6 [152]

G1

G

D

CW1CW2

55 [1397]

G1

G

2.75

[70]

33

[838]

53

[1346]

2AM36G

Figure 1

2

Page 5

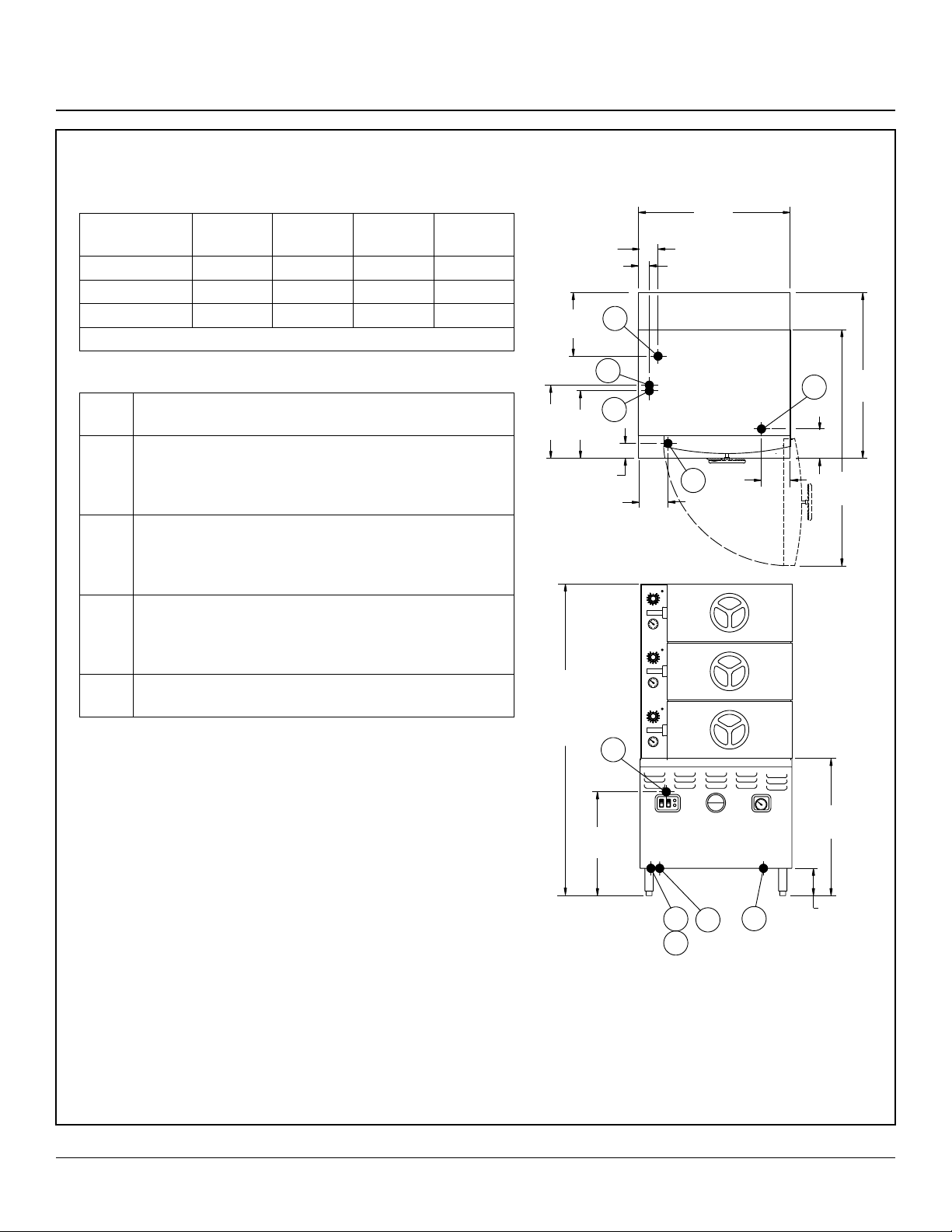

2AM36E & 3AM36E

Service Connections

ELECTRICAL REQUIREMENTS

24kW

3pH

36kW

3pH

42kW

3pH

48kW

3pH

208 (197-219) 66 100 117 --

240 (220-240) 58 87 -- 116

480 (360-500) 29 44 -- 58

Details of other electrical systems available upon request.

SERVICE CONNECTIONS

EP Power Supply - Use wire suitable for at least 90°C.

Nominal amp per line wire:

CW1 Cold Water - 3/8” (10mm) NPT for cold water to boil-

er. Cold water lines will have a maximum of 50 PSI

(3.5kg/cw2) and a minimum of 25 PSI (1.8 kg/cw2)

water pressure

CW2 Cold Water - 3/8” (10mm) NPT for cold water to con-

denser. Cold water lines will have a maximum of 50

PSI (3.5kg/cw2) and a minimum of 25 PSI (1.8 kg/

cw2) water pressure.

D Drain - Pipe full 2” (50mm) NPT to ush oor drain ca-

pable of receiving water owing at a maximum rate of

5 gallons (19 liters) per minute. DO NOT MAKE SOLID CONNECTION TO FLOOR DRAIN.

ST Steam Take-off - Connection for operation of adjacent

steam powered equipment.

OPERATION WILL BE BY:

Electrically powered, A.S.M.E. constructed and National Board

Registered, 15 PSI (1 kg/cm2) steam boiler rated at

24kW

NOTE: The only available space to supply utilities to the boiler is

the 6” (152mm) space between the oor and the cabinet base.

PVC & CPVC Pipe are not acceptable materials for drains.

CAUTION: REMOTE KETTLE OPERATION If this boiler is feeding a remote kettle that will be more than 5 feet (1.5 meters)

away, consult factory before ordering.

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water

quality must be within the following general guidelines.

DIMENSIONS ARE IN INCHES [MM]

4 [102]

2.5 [64]

10.5

[267]

12.5

[318]

68 [1730]

3AM36E

55 [1397]

2AM26E

10.5

[267]

D

CW1

CW2

3 [76]

5 [127]

ST

22

[559]

CW1

CW2

36 [914]

ST

D

6 [152]

EP

[152]

EP

33

[838]

6

56

[1346]

28

[711]

6 [152]

TDS: 40-125 ppm Hardness: 35-100 ppm Chlorine: <0.2 ppm

Silica: <13 ppm Chlorides: <25 ppm

Chloramine: <0.2 ppm pH: 7.0 - 8.5

The best defense against poor water quality is a water treatment

system designed to meet your water quality conditions.

Figure 2

3

INSTALLATION

Page 6

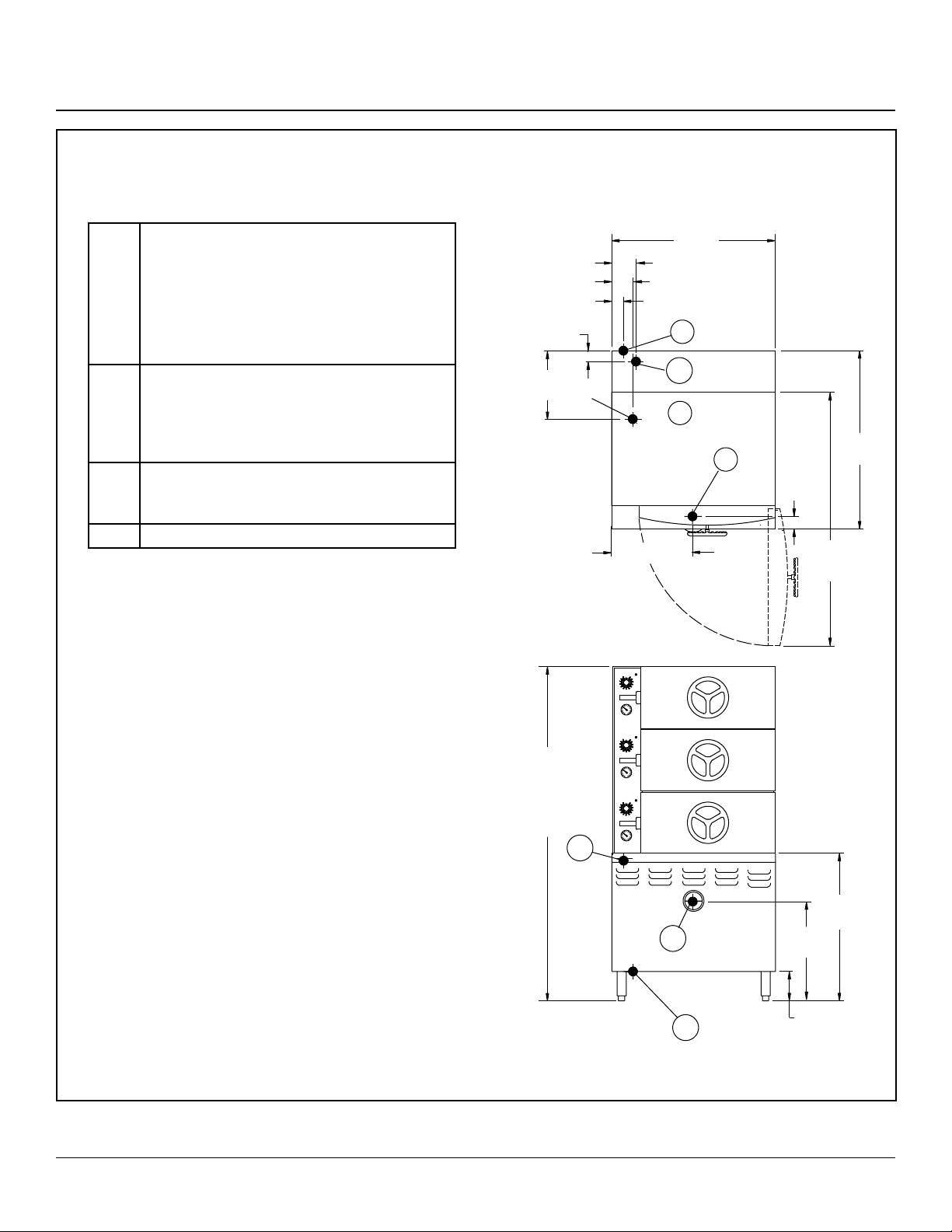

Service Connections

2AM36D & 3AM36D

SERVICE CONNECTIONS

S Steam Supply: 3/4” (19mm) NPT Shall have

a minimum incoming pressure of 15 PSI.

Pressure reducing valve will reduce incom-

ing pressure (up to 200 PSI) to required 5

PSI (0.4kg/cm2).

NOTE: Steam supply must be food grade

quality.

D Drain - Pipe full 1” (25mm) NPT to ush oor

drain capable of receiving water owing at

a maximum rate of 5 gallons (19 liters) per

minute. DO NOT MAKE SOLID CONNECTION TO FLOOR DRAIN.

EC Electrical Connection - 120 Volts AC, 60 Hz,

single phase, and a 9 foot Power Cord/

NEMA 5-15.

CR Condensate Return - Optional

NOTES: Allow 12” (305mm) spacing on left and 6”

(152mm) spacing on right if height of adjoining wall or

equipment exceeds 29” (737mm).

PVC and CPVC pipe are not acceptable materials for

drains.

DIMENSIONS ARE IN INCHES [MM]

4.3 [109]

4 [102]

2.5 [64]

2 [51]

10.5

[267]

17 [432]

36 [914]

EC

CR

D

33

S

3 [76]

[838]

53

[1346]

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water

quality must be within the following general guidelines.

TDS: 40-125 ppm Chlorides: <25 ppm

Silica: <13 ppm pH: 7.0 - 8.5

Chloramine: <0.2 ppm Chlorine: <0.2 ppm

Hardness: 35-100 ppm

The best defense against poor water quality is a water treatment

system designed to meet your water quality conditions.

Appliance to be installed with backflow protection according to

federal, state or local codes.

Figure 3

68 [1730]

3AM36D

55 [1397]

2AM26D

EC

28

[711]

S

D

17

[432]

6 [152]

INSTALLATION

4

Page 7

2A & 3A

Service Connections

SERVICE CONNECTIONS

S Steam Supply - 3/4” (19mm) NPT Shall have a

minimum incoming pressure of 15 PSI (1kg/

cm2). Pressure reducing valve will reduce in-

coming pressure (up to 200 PSI) to required

5 PSI (0.4kg/cm2). NOTE: STEAM SUPPLY

MUST BE FOOD GRADE QUALITY.

D Drain - Pipe full 1” (25mm) NPT to ush oor

drain capable of receiving water owing at a

maximum rate of 5 gallons (19 liters) per minute. DO NOT MAKE SOLID CONNECTION TO

FLOOR DRAIN.

EC Electrical Connection - 120 Volts AC, 60 Hz,

single phase, and a 9 foot Power Cord/NEMA

5-15.

NOTES: Allow 12” (305mm) spacing on left and 6”

(152mm) spacing on right if height of adjoining wall or

equipment exceeds 29” (737mm).

PVC and CPVC pipe are not acceptable materials for

drains.

One BHP is required per compartment.

WATER SUPPLY

Good quality water feed is the responsibility of the owner. Water

quality must be within the following general guidelines.

TDS: 40-125 ppm Chlorides: <25 ppm

Silica: <13 ppm pH: 7.0 - 8.5

Chloramine: <0.2 ppm Chlorine: <0.2 ppm

Hardness: 35-100 ppm

The best defense against poor water quality is a water treatment

system designed to meet your water quality conditions.

Appliance to be installed with backflow protection according to

federal, state or local codes.

DIMENSIONS ARE IN INCHES [MM]

6

7

[178]

Hold down flanges

from center line of leg

4 [102]

[152]

S

7.5 [191]

1.5 [38]

1.5 [38]

must be bolted

down within a

1-5/16” [33] Ø

2 [51]

EC

D

3 [76]

EC

D

34.5 [876]

32.5 [826]

1/2” [13] Ø 2 holes

for 3/8” [10] bolt

8

[203]

20.25

[514]

55 [1400] - 2A

58 [1480] - 3A

30 [762]

53 [1346]

Figure 4

5

28 [711] - 2A

18 [457] - 3A

S

20 [508] - 2A

10 [254] - 3A

22 [559] - 2A

12 [304] - 3A

INSTALLATION

Page 8

PRV – Pressure Reducing Valve Maintenance and Adjustments

WATTS PRESSURE REDUCING VALVE –

MARKET FORGE PART NUMBER 10 - 1033

To provide adequate steam pressure regulation, your

cooker / steamer may be equipped with a Watts Pressure

Reducing Valve ( PRV ). The ¾” PRV is designed to regulate an incoming Maximum pressure of 200 PSI down to

Operating pressures between 5 – 20 PSI. The PRV will

safely regulate the incoming steam to your type of unit.

The chart below indicates the required Incoming Pressure

for the following Market Forge Models.

Model Max. Operation

Pressure

A - cooker 5 PSI 200 PSI

Max. Incoming

Pressure

ADJUSTING WATTS ¾” PRESSURE REDUCING

VALVE

1. Release the locking wing nut (Item 1) and loosen the

adjusting screw spring (Item 2)

2. Turn the inlet steam supply to full open. Then turn

adjusting screw (Item 2) clockwise just enough to allow the valve to open slightly. Allow cooker / steamer

to operate in this manner for several minutes by pulling out the steam operating handle or turning on the

timer.

3. Turn adjusting screw (Item 2) down slowly at intervals

until reduced pressure reaches the desired set-point

per the chart below.

4. Tighten locking wing nut (Item 1)

5. If a chattering noise should occur, move adjusting lever or screw (Item 3 as shown) located in bottom half

of the valve body, clockwise or counter-clockwise, until chattering stops.

2

1

3

Figure 5

INSTALLATION

6

Page 9

Preheating

MODEL A COMPARTMENT STEAM COOKER:

1. Be sure that steam pressure is at the unit.

a. Direct Steam - Turn on external steam supply

valve.

b. All other Units - Follow steam boiler operating in-

structions on control box cover plate inside cabinet base.

c. Be sure that 115 volt connection has been made

to the unit.

PREHEATING-MANUAL CONTROLS:

1. Close compartment door engaging both door latches.

If door does not latch, turn door wheel counterclockwise until both latches are engaged.

2. Seal cooking compartment door by turning door

wheel clockwise until wheel is hand tight.

CAUTION

Do not wrench door wheel tight. This action

can cause needless damage to both the door

wheel and door gasket over a period of time.

3. Start preheating by pulling steam control lever out

and down.

NOTE: Always start one compartment at a time.

Each compartment has an individual steam

control and is operated independently.

4. Pull steam control lever out and down.

5. Compartment timer will sound to end preheating.

6. Release steam control valve by lifting lever.

7. Allow time for steam and condensate to leave the

compartment before opening the door.

8. Allow pressure to return to 0 PSI. Loosen door by

turning wheel counter clockwise. Push primary door

latch from door lip. Allow remaining steam to dissipate from the partially open door. Then lift secondary

latch, and open the door fully.

PREHEATING-AUTOMATIC CONTROLS:

1. Close compartment door engaging both door latches.

If door does not latch, turn door wheel counterclockwise until both latches are engaged.

2. Seal cooking compartment door by turning door

wheel clockwise until wheel is hand tight.

CAUTION

Do not wrench door wheel tight. This action

can cause needless damage to both the door

wheel and door gasket over a period of time.

3. Place automatic override switch in AUTO (down position).

4. When pressure gauge indicates a minimum of 3 PSI,

set timer at 5 minutes by going beyond 15 minutes

and back to 5 minutes for accurate timing.

5. Pull the operating handle out and down and allow it

to lock in this position. Pilot light next to the timer will

come on indicating that unit is operating.

6. The sound of the buzzer indicates the end of cycle

and that steam and condensate are being exhausted. Steam control lever will release automatically.

Time indicates 0 minutes.

7. Turn off buzzer by setting timer to OFF position from

0 minute setting.

8. Allow time for all steam and condensate to leave the

compartment before opening the door.

NOTE: If AUTOMATIC CONTROLS fail, place auto-

matic override switch in MANUAL (up position) and time all procedures manually.

9. Allow pressure to return to 0 PSI. Loosen door by

turning wheel counter-counter-clockwise. Push primary door latch from door lip. Allow remaining steam

to dissipate from the partially open door. Then lift secondary latch, and open the door fully.

7

OPERATION

Page 10

Basic Operating Instructions

BASIC OPERATING INSTRUCTIONS FOR AUTOMATIC CONTROLS:

1. Check to be sure the steam pressure gauge registers

between 4 and 5 pounds.

2. Place pans of food into the cooking compartment to

be used.

3. Close and latch the door.

4. Turning the door wheel clockwise to seal the cooking

compartment.

WARNING

Do not permit steam to leak. Set the door tight

enough to make a rm seal. Steam leakage

will cause undue wear to the gasket.

5. Turn timer pointed clockwise to the 60 minute mark,

and then to the desired cooking time.

6. Pull the operating handle out and down and allow it

to lock in this position. Pilot light next to the timer will

come on indicating that unit is operating.

7. The pilot light will signify this cooking compartment

is in operation. At the end of the cooking cycle the

AUTOMATIC controls will release the operating handle, shutting off the steam supply and exhausting the

steam from the cooking compartment. The pilot light

will turn off and the buzzer will signify that cooking

has been terminated.

BASIC OPERATING INSTRUCTIONS FOR MANUAL

CONTROLS:

1. Check to be sure the steam pressure gauge registers

between 4 and 5 pounds.

2. Place pans of food into the cooking compartment to

be used.

3. Close and latch the door.

4. Turning the door wheel clockwise to seal the cooking

compartment.

WARNING

Do not permit steam to leak. Set the door tight

enough to make a rm seal. Steam leakage

will cause undue wear to the gasket.

5. Pull the operating handle out and down and allow it to

lock in this position.

6. Turn timer pointed clockwise to the 60 minute mark,

and then to the desired cooking time.

7. Set timer. When bell rings, lift handle and push in to

shut off cooker.

8. To silence the buzzer, turn the TIMER KNOB to the

OFF position.

OPERATION

8

Page 11

Cooking Tips

HELPFUL HINTS

1. Always preheat compartments for satisfactory operation.

2. When all compartments are to be used at once, let

steam into each compartment separately (after food

is loaded) allowing pressure for one compartment to

recover to 3 pounds before letting steam into the next

compartment.

3. Should steam seep out and around compartment

door, check to see that the door wheel is adequately

hand tightened. If, after tightening the door wheel,

steam continues to seep around the door, the door

gasket should be replaced. It is a good procedure to

keep an extra door gasket on hand for this purpose.

4. If greasy foods have been cooked in the compartment steam cooker, steam should be passed through

the lines after the cooking period to help remove any

fat that might remain in the line. To do this, follow

the same procedure as preheating (Steps 3-8 under

PREHEATING-MANUAL CONTROLS).

5. To prolong gasket life, leave compartment doors

slightly ajar when unit is not in use. Under no circumstances, however, should all compartment doors be

left wide open at the same time.

6. Keep compartment door wheels free and easy to

turn by periodically removing inner door and applying

small amounts of door lubricant to acme type screw.

Be sure inner threads are also lubricated by turning

wheel a number of times. To remove, open door, turn

door wheel clockwise as far as possible, then lift inner

door up and pull out.

6. Food may be served from the same pan in which it

is steam cooked, thus reducing food breakage since

there is no extra handling or transferring of food from

cooking pan to serving pans. It also reduces pot

washing tasks.

7. Some important advantages of steam cooking are:

reduce fuel costs, decrease food cost, cut cooking

and clean up time, cook more food in less space and

increase employee productivity.

8. Rice and spaghetti products, if thoroughly wet at the

start of the cooking process are very easily prepared.

9. Foods such as potatoes, poultry, seafood and some

meats may be blanched in the steam cooker, thus reducing the total cooking time and grease absorption.

10. Fuel is used only when the steam cooking unit is in

operation.

11. The steam cooker will loosen foods burned on pans

making washing easier.

12. Solid pans are recommended when liquid is to be re-

tained and perforated pans when the liquid is not to

be retained.

13. Eggs may be cooked out of the shell if they are to be

chopped which eliminates peeling after steaming.

14. Frozen or stale bread may be readied for serving with

a small amount of steam.

15. The steam cooker can be opened during the cooking

period (by rst releasing the steam pressure) to add

or remove items. If any time is lost, an adjustment

may be made on the timer.

A COOKER FACTS ON PARADE

1. Many foods, except those requiring dry heat can be

cooked in a steam cooking unit.

2. Steam cooked foods have a greater nutritional value since more of their vitamins and minerals are retained.

3. Because foods are cooked faster by the higher temperatures of steam cooking, they can be prepared

closer to serving time, insuring maximum freshness.

4. Steam cooked food has a higher percent yield - more

portions per dollar spent.

5. The principle upon which the steam cooker is based

can be likened to the domestic pressure cooker.

16. All frozen foods must be thoroughly defrosted in order

to obtain the most satisfactory results.

17. Steam cooking information, including recommended

pan sizes and type, weight per pan, cooking times

and pan yields are given on the following pages of

this bulletin.

9

OPERATION

Page 12

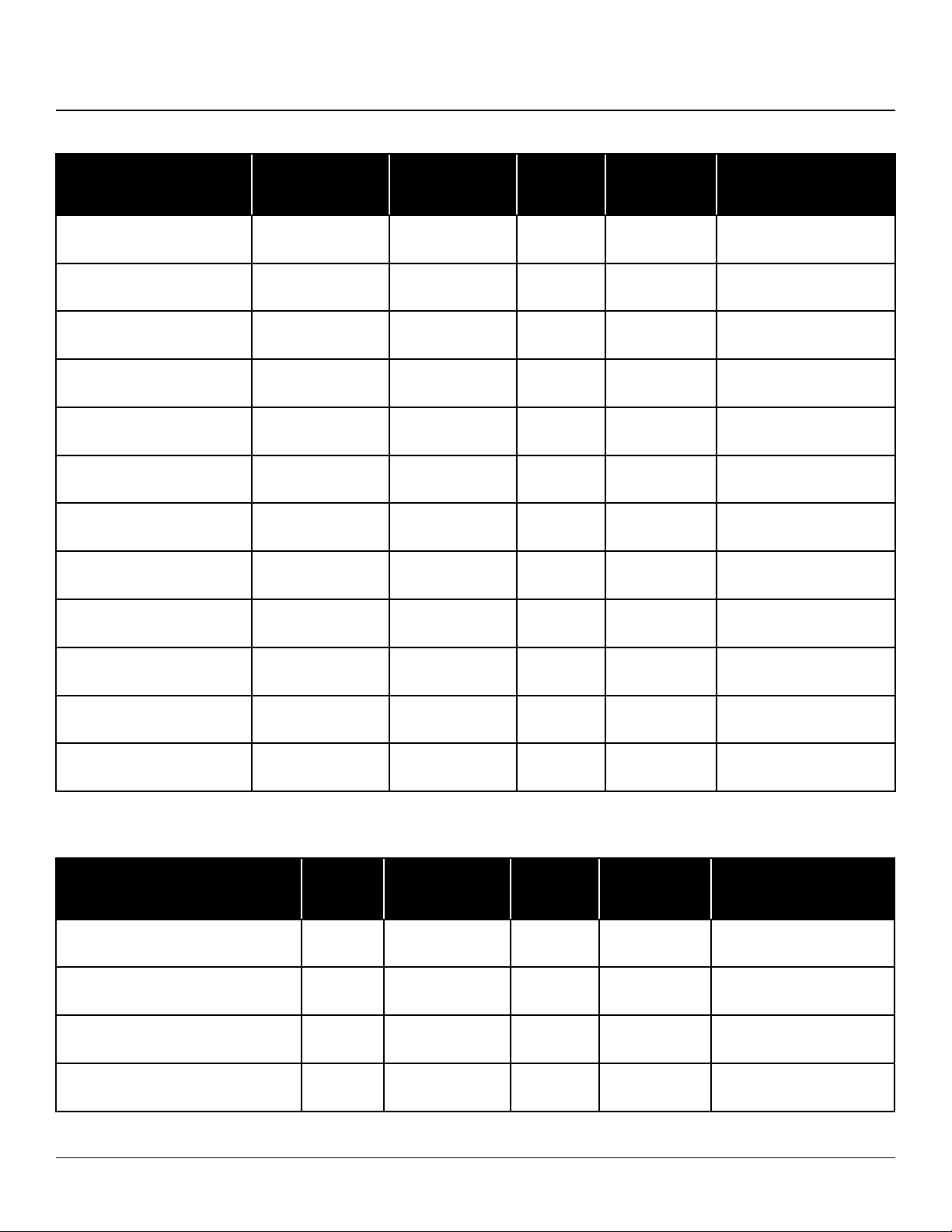

Suggested Steam Times

The steam cooker compartment is a pressure cooker which operates at 5 PSI (0.33kg/cm2). This enables the cook to prepare foods nearer to the time of service. The gures given below are timer settings and should be set on a pre-heated compartment either with manual or automatic controls. If a large or cold load is put in, it will be necessary to set the timers after

a minimum of three pounds pressure shows on the compartment steam gauge. On the manual units the timer will sound

and the steam must be manually exhauster, where as it is automatically exhausted on the others, thus stopping the cooking

cycle. Six 12” x 20” x 21/2” or Four 12” x 20” x 4” pans may be used in each compartment. Suggested pan sizes for various

foods are give below and on the next two pages.

FROZEN VEGETABLES, DEFROSTED

Six 12” x 20” x 21/2” pans of thoroughly defrosted vegetables may be done at once. For uniform results, it is recommended

that not more than 5# (2.3kg) of frozen vegetables be evenly distributed in a 12” x 20” x 21/2” perforated pan. Loosen pack

peas, corn and diced carrots may be cooked, once package per 12” x 20” x 21/2” pan, in the frozen state if time does not

allow for defrosting.

WEIGHT

ITEM

Asparagus, Spears

Beans,Green Regular

Beans,Green French Cut

Beans,Lima

Broccoli

Brussel Sprouts

Carrots,Diced

Caliower

Corn

Peas

* All portions are equivalent to approximately

PER PAN

5#

(2.3kg)

5#

(2.3kg)

5#

(2.3kg)

5#

(2.3kg)

6#

(2.7kg)

5#

(2.3kg)

5#

(2.3kg)

5#

(2.3kg)

5#

(2.3kg)

5#

(2.3kg)

SIZE OF PAN

PERFORATED

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

1

/2 cup cooked.

NUMBER

OF PANS

1-3

4-8

1-3

4-8

1-3

4-8

1-3

4-8

1-3

4-8

1-3

4-8

1-3

4-8

1-3

4-8

1-3

4-8

1-3

4-8

TIMER

SETTINGS IN

MINUTES

10-12

13-15

10-12

13-15

10-12

13-15

10-12

13-15

8-10

10-12

10-12

13-15

9-10

11-13

11-12

13-15

9-10

11-13

6-7

8-9

NO. OF COOKED

PORTIONS PER PAN*

3 oz. (65g)

23-25

23-25

23-25

23-25

18-20

23-25

23-25

23-25

23-25

23-25

VEGETABLES, CANNED

WEIGHT

ITEM

Canned, Vegetables

* All portions are equivalent to approximately

PER PAN

71/2 #

(3.4kg)

OPERATION

SIZE OF PAN

PERFORATED

12” x 20” x 21/2”

1

/2 cup cooked.

10

NUMBER

OF PANS

1-3

4-8

TIMER

SETTINGS IN

MINUTES

4-5

5-8

NO. OF COOKED

PORTIONS PER PAN*

3 oz. (65g)

26-30

Page 13

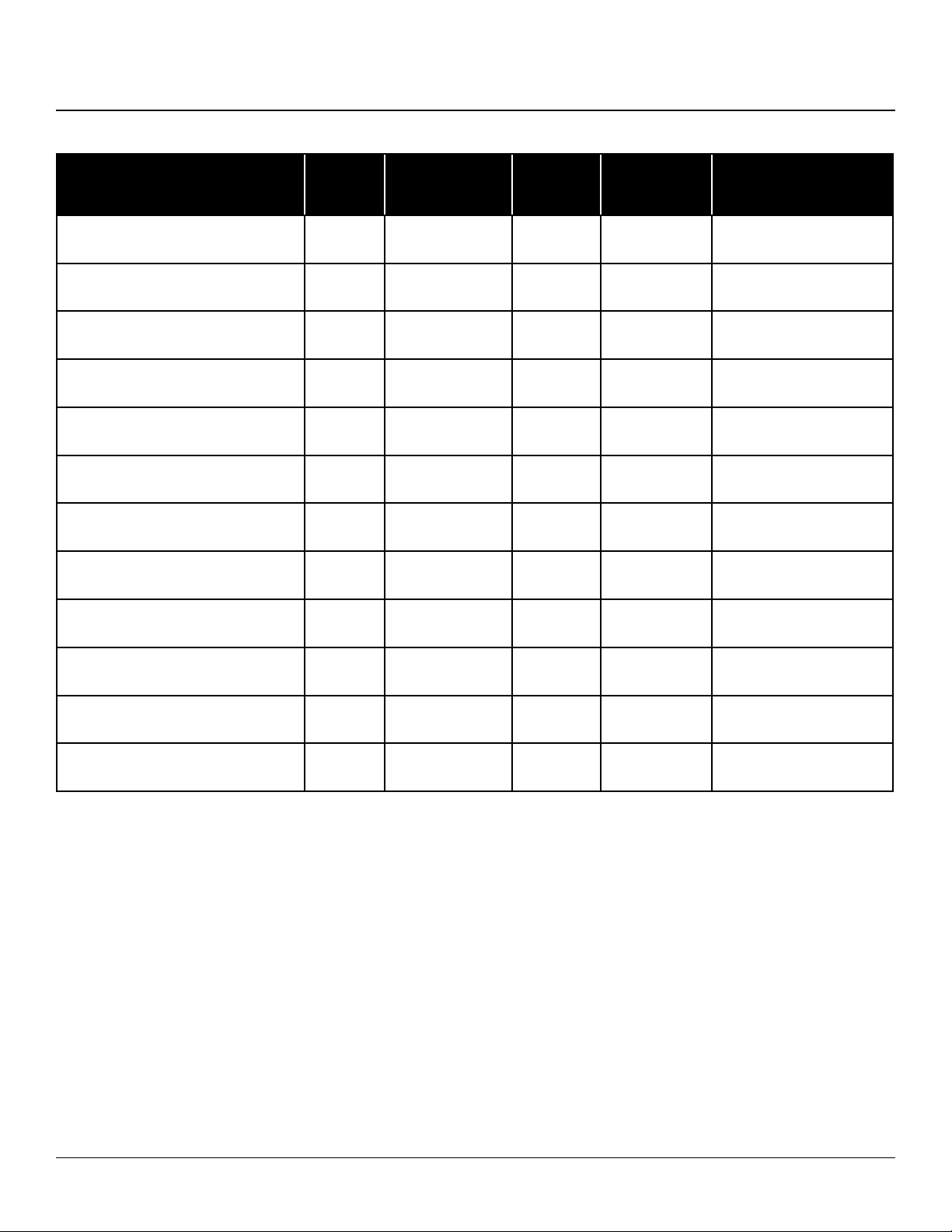

VEGETABLES, FRESH

Suggested Steam Times

WEIGHT

ITEM

Green Beans, Wax

Broccoli, 1/2” - 3/4” , Stalks

Cabbage , Cored - 1/4

1/6 of Head

Carrots, Sliced

Cauliower

Con on the Cob, Husked 1 Doz. 12” x 20” x 21/2”

Potatoes, French Fry Cut

Potatoes, Regular Cut

Spinach, Cut and Cleaned

Squash, Summer,

1” Slices

Squash, Winter, Diced

Turnip, Diced

* All portions are equivalent to approximately

PER PAN

6#

(2.7kg)

6#

(2.7kg)

5#

(2.3kg)

9#

(4kg)

6#

(2.7kg)

10#

(4.5kg)

10#

(4.5kg)

3#

(1.4kg)

7#

(3.2kg)

9#

(4kg)

5#

(2.3kg)

SIZE OF PAN

PERFORATED

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 4”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

1

/2 cup cooked.

NUMBER

OF PANS

1-3

4-8

1-3

4-8

1-3

4-8

1-3

4-8

1-3

4-8

1-3

4-8

1-3

4-8

1-3

4-8

1-2

3-4

1-3

4-8

1-3

4-8

1-3

4-8

TIMER

SETTINGS IN

MINUTES

15-20

20-25

10-15

15-20

14-16

16-20

18-21

21-25

10-15

15-20

10-12

12-15

15-18

18-20

25-30

30-35

3-5

4-8

8-12

12-15

15-20

20-25

25-30

30-35

NO. OF COOKED

PORTIONS PER PAN*

3 oz. (65g)

30-35

25-30

12-20

25-40

30-35

12

50

50

10-12

30-35

30-35

20-25

MISCELLANEOUS

WEIGHT

ITEM

Eggs, in Shell

Eggs, out of Shell

Rice, 1 Gallon of Water 4# 12” x 20” x 4”

Spagetti, 1

* All portions are equivalent to approximately 1/2 cup cooked.

1

/2 - 2 Gallons Water 3# 12” x 20” x 4”

PER PAN

3 doz.

4 doz.

SIZE OF PAN

SOLID

12” x 20” x 21/2”

PERFORATED

12” x 20” x 21/2”

11

NUMBER

OF PANS

1-3

4-8

1-3

4-8

1-2

3-4

1-2

3-4

TIMER

SETTINGS IN

MINUTES

8-9

9-10

6-7

7-8

22-24

25-27

20-22

23-26

NO. OF COOKED

PORTIONS PER PAN*

2 oz. (55g)

36

48

60

3 oz. (85g) Portions

40-45

4 oz. (110g) Portions

OPERATION

Page 14

Suggested Steam Times

MEAT - POULTRY - FISH

WEIGHT

ITEM

Chicken, Cut Up, Blanched

Chicken, Whole

Fish, Fillets

Fowl %# or More, Whole

Fankforts

Hamburgers, 3 ounce

Meatballs, ** 1 Ounce

Meatloaf **

Pork Chops, Loin,

4 Ounces with Bone 6#

Sausages, 10 Per Pound

Turkey, on Carcass

Turkey, off Carcass

* All portions are equivalent to approximately

PER PAN

8#

(3.6kg)

three 4#

(1.8kg)

3#

(1.4kg)

two 5#

(2.3kg)

5#

(2.3kg)

5#

(2.3kg)

6#

(2.7kg)

15#

(6.8kg)

6#

20-22#

10-12#

SIZE OF PAN

SOLID

12” x 20” x 21/2”

12” x 20” x 4”

12” x 20” x 21/2”

12” x 20” x 4”

12” x 20” x 21/2”

PERFORATED

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 21/2”

12” x 20” x 4”

12” x 20” x 21/2”

1

/2 cup cooked.

NUMBER

OF PANS

1-3

4-6

1-2

3-4

1-3

4-6

1-2

3-4

1-3

4-6

1-3

4-6

1-3

4-6

1-3

4-6

1-3

4-6

1-3

4-6

1-2 100-120

1-3

4-6

SETTINGS IN

MINUTES

TIMER

18-25

25-30

45-55

55-65

8-12

10-15

50-65

60-75

3-4

4-5

12-14

15-18

18-22

22-25

40-45

45-50

25-30

30-35

18-21

22-25

50-60

60-75

NO. OF COOKED

PORTIONS PER PAN*

3 oz. (65g)

15-20

Protein

25-30

Protein

12-15

Protein

20-25

Protein

35-40

Protein

20-25

Protein

20-25

Protein

50-60

Protein

24

Protein

18-20

Protein

50-60

Protein

55-65

Protein

** Raw weight for meatballs and meatloaf includes hamburg and extenders and yields 2 ounces protein plus extenders, or

3 ounces total portion.

OPERATION

12

Page 15

Preventative Maintenance

CAUTION

DO NOT HOSE DOWN UNIT AS IT CONTAINS ELECTRICAL COMPONENTS.

GENERAL

This section contains both preventive and corrective maintenance information required for the A Cooker. Preventive maintenance may be performed by maintenance personnel at the establishment in which the cooker is installed. It is recommended

that user personnel never attempt to make repairs or replacements to the equipment without the assistance of authorized

service. Assistance in service methods or a current Directory of Authorized Service Agencies may be obtained from Market

Forge.

PREVENTIVE MAINTENANCE

A good preventive maintenance program begins with the daily cleaning procedure described in the table below. Additional

preventive maintenance operations are presented in this section.

FREQUENCY PROCEDURE

DAILY 1. CLEANING: Remove pan supports, shelves and shelf supports, and thoroughly wash and rinse

interior of both cooking compartments. Be sure the drain screen, located inside top compartment,

is clear of all food particles.

WEEKLY 1. SAFETY VALVE CHECK: With upper compartment in operation in the pressure cooking mode, lift

up on level of forward mounted safety valve. Repeat for rear mounted safety valve. Steam should

ow freely from outlet port, verifying proper functioning and clearing of accumulated deposits in

valves.

2. INNER DOOR CLEANING: Remove inner door from both compartments. Wash inner door and

inside of outer door with mild detergent, rinse and reassemble.

MONTHLY 1. DOOR WHEEL LUBRICATION: Check door hand wheel rotation for ease of motion. If wheel resists

rotation when door is unlatched, lubrication is required. Remove inner door and apply graphite lubrication to screw threads.

DRAIN SCREEN CLEANING & REMOVAL

The drain screen inside the top compartment is provided

to prevent blockage of the drain line. It must be kept clean

at all times by scrubbing daily with a stiff bristle brush.

WARNING

A plugged drain may cause compartment

ooding, resulting in overow of scalding

water when door is opened.

Should the drain screen require removal due to excessive

blockage or damage, the truss head screw is loosened

and the screen slipped out. The screen must be in position, completely covering the lower drain opening, prior to

reuse of the A Cooker.

SAFETY VALVE CHECK

The safety valves are protective devices which automatically relieve excessive pressure (above 8 PSI) in the un-

likely event of equipment malfunction. Manual opening of

the valves is also possible and should be done once a

week to assure valves are clear and mechanically sound.

1. Place upper cooker compartment into operation in

the pressure mode and allow pressure to build to

about 4 PSI.

2. Pull up on safety valve lever for forward-mounted

valve (closest to manifold box on left side of cooker).

Flow of steam from the valve outlet veries correct

manual valve function and clears exhaust passage.

NOTE: Steam is not present at relief valve until steam

trap has evacuated all air from the cooker

compartment. Presence of adequate steam

should be checked (4-5 psi on gauge) before

checking valve.

3. Repeat step 2 for rear-mounted valve.

13

MAINTENANCE

Page 16

Preventative Maintenance

INNER DOOR REMOVAL & CLEANING

The door assembly includes an outer door with mounted

hand wheel and an inner door with sealing gasket. The inner door parts should be cleaned weekly to ensure proper

sealing against compartment opening.

1. With door opened and hand wheel turned to full

clockwise position, grasp tabs and lift inner door up

and away from door.

Wash inner doors, gaskets and inside of outer door with

mild detergent, rinse and reassemble.

DOOR WHEEL LUBRICATION

The door wheel includes the externally mounted wheel

and built-in screw mechanism. Rotation of the door wheel

should be checked monthly for ease of motion. If the

wheel grinds or is difcult to turn, the screw should be

lubricated with graphite followed by rotation of the wheel

to transfer lubricant into threads in door.

REPLACING WORN OR DAMAGED DOOR GASKET

Remove the screws from the gasket of the inner door. Slip

out the old gasket. Clean the face of the inner door and

the gasket plate. Place the new gasket and gasket plate

in position and fasten the screws through the assembly

as illustrated below. Tighten the screws enough to make

a rm seal. It is recommended that a spare gasket be kept

on hand in event of an emergency. Replacement gaskets

may be obtained for your model by requesting MODEL

“A” DOOR GASKET #10-0433. Include the serial number

of your steam cooker with your order when ordering parts.

Figure 6

MAINTENANCE

14

Page 17

Door Assembly Instructions

1. Make sure the handle on the door is turned as far

clockwise as possible.

Figure 7

2. Take the inner door out of cavity. Remove packaging

and discard.

3. Line up the outer door pins (marked “A”) with the inner door holes (marked “B”). Set the door in place

and turn handle counter-clockwise until you bring the

inner door to the outer door.

Figure 9

Figure 8

15

MAINTENANCE

Loading...

Loading...