Page 1

WATERFORD SYSTEMS

HIGH RATE SAND FILTER SYSTEM

For Above Ground Swimming Pools

O W N E R’S M A N U A L

INSTALLATION, OPERATION & PARTS

This manual should be given to the end user of this system.

Pentair Water Pool and Spa, Inc.

© 2007 Pentair Water Pool and Spa, Inc. All rights reserved.

1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 553-5000

Pentair Water Pool and Spa logo are trademarks of Pentair Water Pool and Spa, Inc. Other trademarks and trade names may be used in

this document to refer to either the entities claiming the marks and names or their products. Pentair Water Pool and Spa Inc. disclaims proprietary interest in marks and names of others.

Printed in U.S.A.

04/18/2007

S260 (Rev. C)

839 0494

Page 2

2

HIGH-RATE SAND FILTER SYSTEM

To avoid unneeded service calls, prevent possible injuries, and get the most out

of your filter, READ THIS MANUAL CAREFULLY!

The High Rate Sand Filter System:

• Is designed to circulate and filter water in above ground swimming pools.

• Offers quiet, efficient performance and is durable, reliable.

• With a 3’ cord or no cord, use with permanently installed pools ONLY

(see CAUTION #7, below).

• With a 25’ cord, use with storable pools ONLY (see CAUTION #8, below).

Table of Contents

Safety Instructions.......................................................................................... ...........3

Specifications/Dimensional Data..............................................................................4

General Information .................................................................................................5

Installation ............................................................................................................5-7

Filter Mount/Piping................................................................................................5

Filter Set-up ..........................................................................................................6

Loading Sand Media.............................................................................................6

Valve Installation ...............................................................................................6-7

Electrical ..................................................................................................................7

Startup/Operation/Backwash ................................................................................8-9

Maintenance ............................................................................................................9

Storage/Winterizing................................................................................................10

Multi-Port Valve Service.........................................................................................11

Valve Removal.......................................................................................................11

Pump Service ...................................................................................................11-12

Troubleshooting Guide...........................................................................................13

Repair Parts List ...............................................................................................14-17

Warranty ................................................................................................................18

IMPORTANT SAFETY INSTRUCTIONS

When installing and using electrical equipment, basic safety precautions should always be followed,

including the following:

SAVE THESE INSTRUCTIONS

1. READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

2. To reduce the risk of injury, do not permit children to use this product unless they are closely supervised at

all times.

3. Risk of electrical shock. Connect only to a

grounding type receptacle protected by a ground-fault circuit-interrupter (GFCI). Contact a qualified electrician if you

cannot verify that the receptacle is protected by a GFCI.

4. Do not bury cord. Locate cord to minimize abuse from lawn

mowers, hedge trimmers, and other equipment.

5. To reduce the risk of electrical shock,

replace a damaged cord immediately.

6.

To reduce the risk of electrical shock, do not

use an extension cord to connect unit to electrical supply; provide a properly located outlet.

7. Permanent pumps are for use with permanently installed pools and may also be used with hot tubs and

spas if so marked. Do not use with storable pools. A permanently installed pool is constructed in or on the ground or in a

building such that it cannot be readily disassembled for storage. A storable pool is constructed so that it may be readily

disassembled for storage and reassembled to its original integrity.

8. Storable pool pumps are for use with storable

pools only. Do not use with permanently installed pools. A

storable pool is constructed so that it is capable of being

readily disassembled for storage and reassembled to its original integrity. A permanently installed pool is constructed in

or on the ground, or in a building, such that it cannot be readily disassembled for storage.

Page 3

3

This is the safety-alert symbol. When you see

this symbol on your valve or in this manual,

look for one of the following signal words and be

alert to the potential for personal injury.

warns about hazards that will cause

serious personal injury, death or major

property damage if ignored.

warns about hazards that can cause

serious personal injury, death or major

property damage if ignored.

warns about hazards that will or can

cause minor personal injury or property

damage if ignored.

The label NOTICE indicates special instructions

which are important but not related to hazards.

Carefully read and follow all safety instructions in

this manual and on system.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

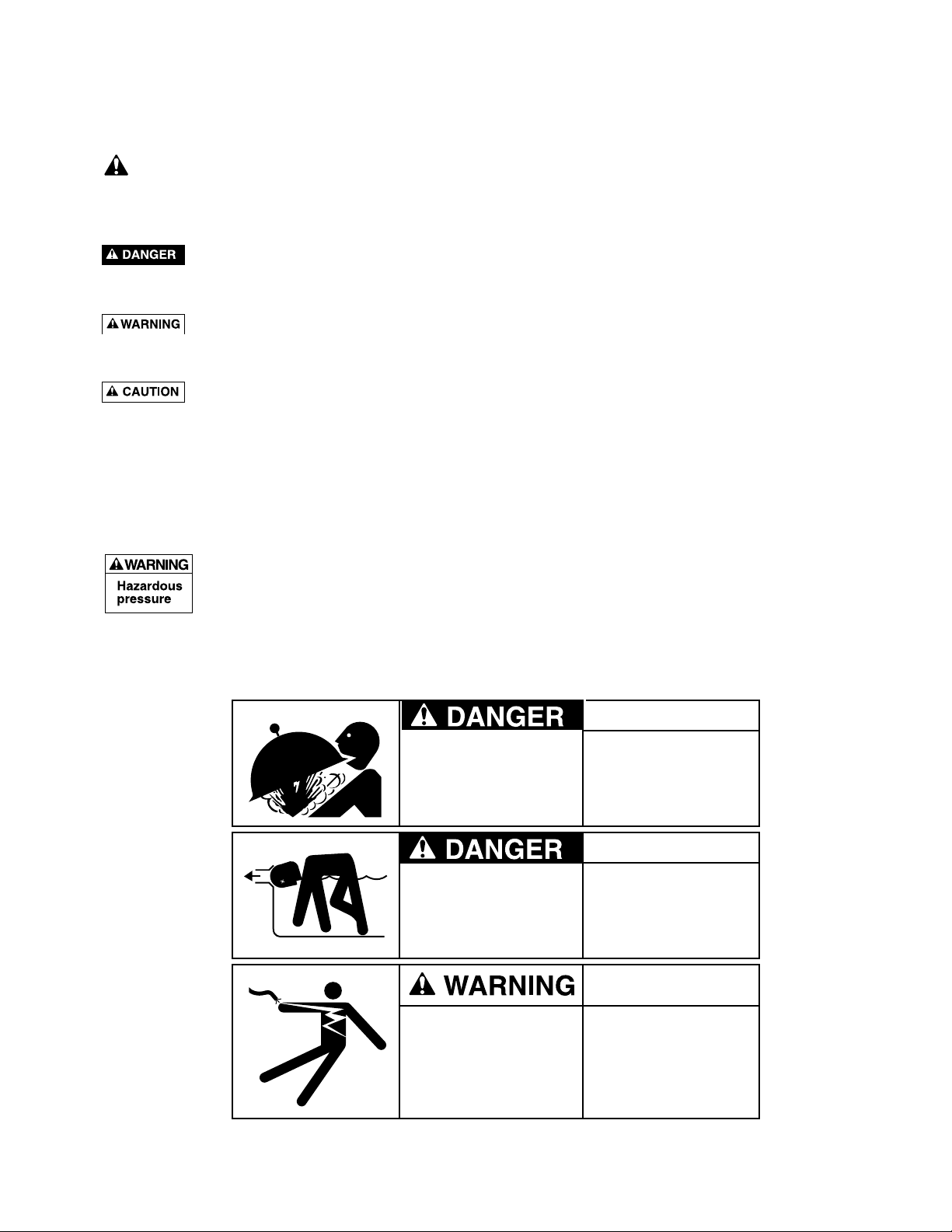

Incorrectly installed or tested equipment may fail, causing severe injury

or property damage. Read and follow

instructions in owner's manual when installing and

operating equipment. Have a trained pool profes-

sional perform all pressure tests.

1. Do not connect system to a high pressure or city

water system.

2. Use equipment only in a pool or spa installation.

3. Trapped air in system can cause explosion. BE

SURE all air is out of system before operating or

testing equipment.

Before pressure testing, make the following safety

checks:

• Check all clamps, bolts, lids, and system acces-

sories before testing.

• BE SURE all air is out of system before testing.

• Tighten Sta-Rite trap lids to 30 ft. lbs. (4.1 kg-cm)

torque for testing.

• Water pressure for test must be less than 25 PSI

(172 kPa).

• Water temperature for test must be less than 95˚ F.

(35˚ C).

• Limit test to 24 hours. After test, visually check sys-

tem to be sure it is ready for operation. Remove

trap lid and retighten hand tight only.

NOTICE: These parameters apply to Sta-Rite equipment only. For non-Sta-Rite equipment, consult

manufacturer.

Hazardous Pressure!

Can cause tank

explosion.

WHEN USING SYSTEM:

Do not test with

compressed air

or operate above

rated pressure.

Hazardous voltage.

Can shock, burn,

or cause death.

BEFORE WORKING

ON PUMP OR MOTOR:

Unplug pump motor.

Hazardous suction.

Can trap or tear hair or

body parts, causing

severe injury or death.

WHEN USING SYSTEM:

Do not block pump

suction or pool main

drain.

READ AND FOLLOW SAFETY INSTRUCTIONS!

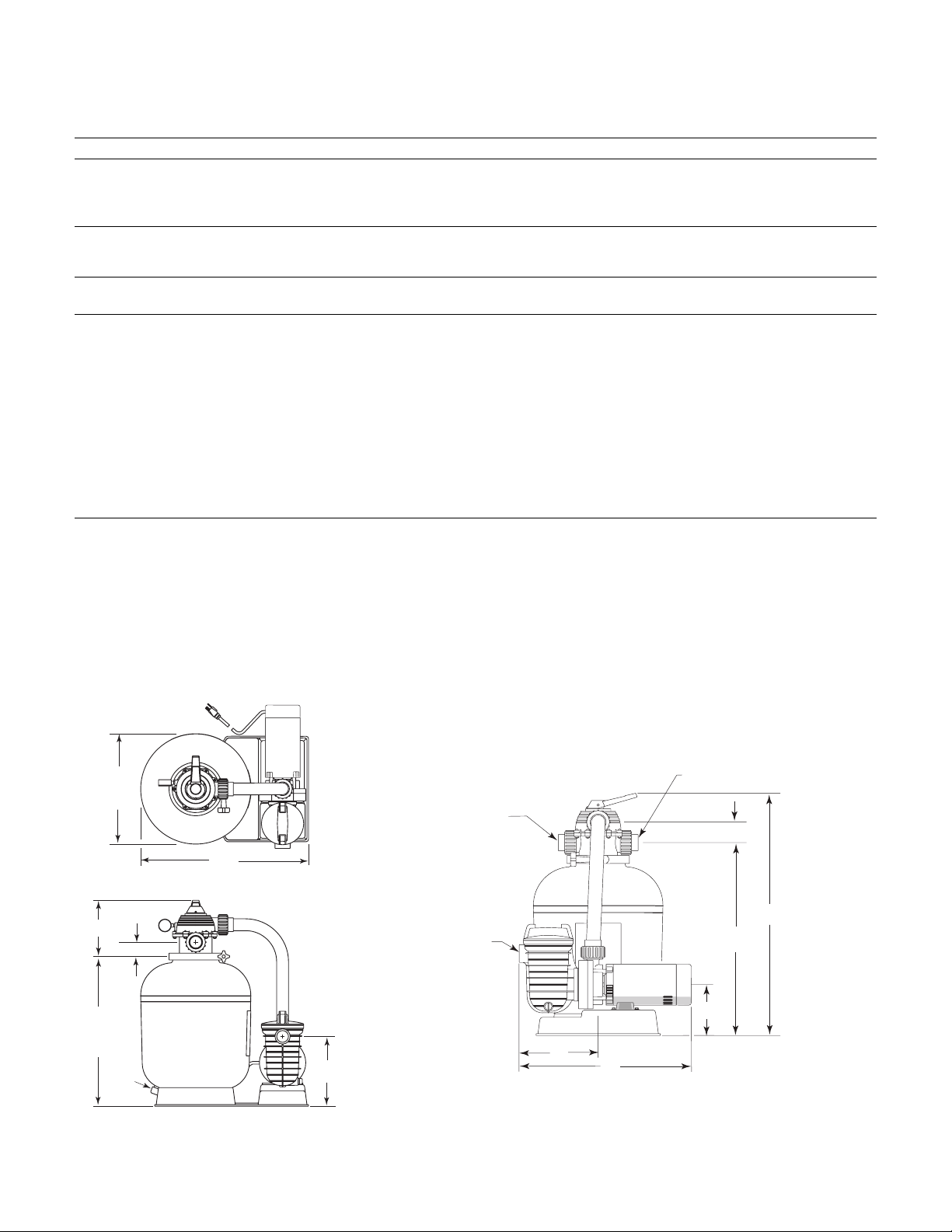

Page 4

1-1/2" NPT

Return to Pool

(Union Connection)

1-1/2" NPT

Suction

Connection

1-1/2" NPT

Waste Outlet

(Union Connection)

23

2-13/16

A

B

7

11

1278 0994

Drain

(To Tank

Flange)

D

2-5/16

9-1/16

11-1/4

Ta nk

Dia.

C

E

1279 0994

4

TABLE I - OUTLINE DIMENSIONS IN INCHES (mm)

Filter Model A B C D E

15”(406mm) Filters 24 (610) 30-7/8 (784) 15-3/4 (400) 21-11/16 (551) 26-1/16 (662)

18”(457mm) Filters 26-9/16 (675) 33-5/16 (846) 17-3/4 (451) 24-1/4 (616) 27-1/16 (692)

21” (508mm) Filters 28-11/16 (729) 34-7/16 (875) 20-3/4 (527) 26-3/8 (670) 28-9/16 (725)

TABLE ll - FILTER SPECIFICATIONS AND OPERATING INFORMATION

FILTER MODEL: 15” 18” 21”

(JSAL15 Series) (JSAL180 Series) (JSAL210 Series)

Effective Filter Area 1.26 Ft.2(.117M2) 1.57 Ft.2(.223M2) 2.18 Ft.2(.203M2)

Max. Flow Rate 25.2 GPM(95 L/m) 31.5 GPM(123 L/m) 43.6 GPM(165 L/m)

Max. Operating Pressure 50 PSI(345 kPa) 50 PSI(345 kPa) 50 PSI(345 kPa)

Max. Operating Temperature 95° F(35°C) 95° F(35°C) 95° F(35°C)

Turnover in Hours:

6 Hours 9,070 Gal.(34 330 liters) 11,340 Gal.(42 922 liters) 15,700 Gal.(59 424 liters)

8 Hours 12,100 Gal.(45 799 liters) 15,120 Gal.(57 229 liters) 20,930 Gal.(79 220 liters)

10 Hours 15,120 Gal.(57 229 liters) 18,900 Gal.(71 536 liters) 26,160 Gal.(99 016 liters)

12 Hours 18,144 Gal.(68 675 liters) 22,680 Gal.(85 844 liters) 31,390 Gal.(118 811 liters)

Qty. of Media Required:

Cu. Ft. (cm

3

) 1(28 320cm3) 1.5(42 255cm3) 2(56 923cm3)

Weight in lbs.(kg) 100(45,4 kg) 150(68 kg) 200(90,7 kg)

NOTE: 1 cubic foot (28 320 cm3) of sand weighs approximately 100 lbs. (45,4kg). DO NOT use a finer grade of sand than recommended.

RECOMMENDED SAND GRADES:

Use only: #20 Silica Sand, Size Range .40-.55mm., Uniformity Coefficient less than 1.75.

NOTICE: Use of other sands will reduce filter performance, may damage pump, and will void warranty.

Recommended:

1. Wedron Silica/Best Sand Co., Sand Grade: Wedron .45-.55mm., Effective Size .46mm, Uniformity Coefficient

1.22.

2. U.S. Silica - Silurian Filter Sand, Sand Grade.45-.55 mm., Effective Size .48mm, Uniformity Coefficient 1.18.

Figure 1: Dimensions

Page 5

GENERAL INFORMATION

• Clean a new pool as well as possible before filling

pool and operating filter. Excess dirt and large particles of foreign matter in the system can cause serious damage to the filter and pump.

NEVER test this filter with compressed air.

Do not operate filter at water temperatures

above 95°F (35°C).

NEVER operate this filter system at more than

50 pounds per square inch (50 PSI/345 kPa)

pressure!

Plug system into electrically isolated, Ground

Fault Circuit Interrupter protected circuit

ONLY!

• Clean a new pool as well as possible before filling

pool and operating filter. Excess dirt and large particles of foreign matter in the system can cause serious damage to the filter and pump.

• Keep pool water pH at recommended level (7.2 to

7.6) to avoid irritation to eyes and skin.

• The Hi-Rate Sand Filter System is designed for use

with above ground swimming pools only.

• Use only #20 Silica sand with a screen mesh of .45

to .55mm. Use of other sands will reduce filter

performance.

To reduce risk of electric shock, install

pump at least 10 feet from the inside wall of the pool.

Do not use an extension cord.

INSTALLATION

Trap to Pump Assembly:

Using four 5/16” cap screws, flat washers and lockwashers, mount trap to pump body; be sure to install gasket

between trap and pump body. Tighten cap screws to 80

inch-lbs

(92 cm-kg) torque; do not overtighten.

Filter Mount Must:

• Provide weather and freezing protection.

• Provide space and lighting for easy access for routine

maintenance. (See Table I and Figure 1, Page 4, for

space requirements.)

• Be on a reasonably level surface and provide ade-

quate drainage.

• Be as close to pool as possible to reduce line loss

from pipe friction.

• Be solid – level– rigid – vibration free.

• Be installed so that trap suction inlet is below pool

water level at all times. This allows pump to prime.

• Have adequate ventilation to prevent motor

overheating.

Piping:

• Use teflon tape or Plasto-Joint Stik1on all male connections of plastic pipe and fittings except unions.

DO NOT use pipe compounds on plastic pipe; it

will cause the pipe to crack. Do not use sealant or

tape on unions – assemble them dry and hand tight.

• Do not damage union sealing surfaces and “O” Rings.

• Support pipe independently to prevent strains on filter

and valve.

• Use 1-1/2 or 2" pipe to reduce pressure losses as

much as possible. If flex hose is used, use the type

with smooth internal walls.

• Fittings restrict flow; for best efficiency use fewest

possible fittings.

• Keep piping tight and free of leaks: pump suction line

leaks may cause trapped air in filter tank or loss of

prime at pump; pump discharge line leaks may show

up as dampness or jets of water.

• When unions are provided, use as follows for leak

free connections:

1. O-Ring and sealing surfaces must be clean.

2. Assemble hand tight only (no wrenches).

3. No pipe compound or teflon tape on unions.

Valves:

• For servicing filter system and for cleaning pump trap,

install ball or gate valves

A. Between pump trap and pool skimmer, and

B. Between selector valve and return pipe to pool.

• A check valve installed between filter and heater will

prevent hot water from backing up into filter and deforming internal components.

• Use care before assembly not to damage union sealing surfaces or O Ring.

Wastewater:

• Be sure all provisions for waste water disposal meet

applicable local, state or national codes. 100 gallons

(379 liters) or more of pool water will be discharged

during filter backwashing. Do not discharge where

water will cause flooding or damage.

1

Lake Chemical Co., Chicago, IL

5

Page 6

D. After all

laterals are

securely in

sockets,

position

assembly on

centering

boss in

bottom of

tank.

733 0294

Filter Setup

Assembly: See Figures 2 through 5 for filter assembly.

Loading Sand Media

1. To keep sand out of collector assembly, place plastic

sand shield over top of collector tube before pouring

sand into filter (See Figure 5).

2. To support laterals and prevent lateral breakage during loading, fill tank about half full of water before

loading sand.

3. Pour sand into filter tank. See “Recommended Sand

Grades”, Page 4, for correct type and quantity of

sand to use.

NOTICE: Make sure gasket area on top of tank is

free of sand before installing valve and clamp.

4. Before installing valve, double-check that correct

quantity of sand has been loaded (see Page 4).

5. Remove plastic sand loading shield and keep for future use.

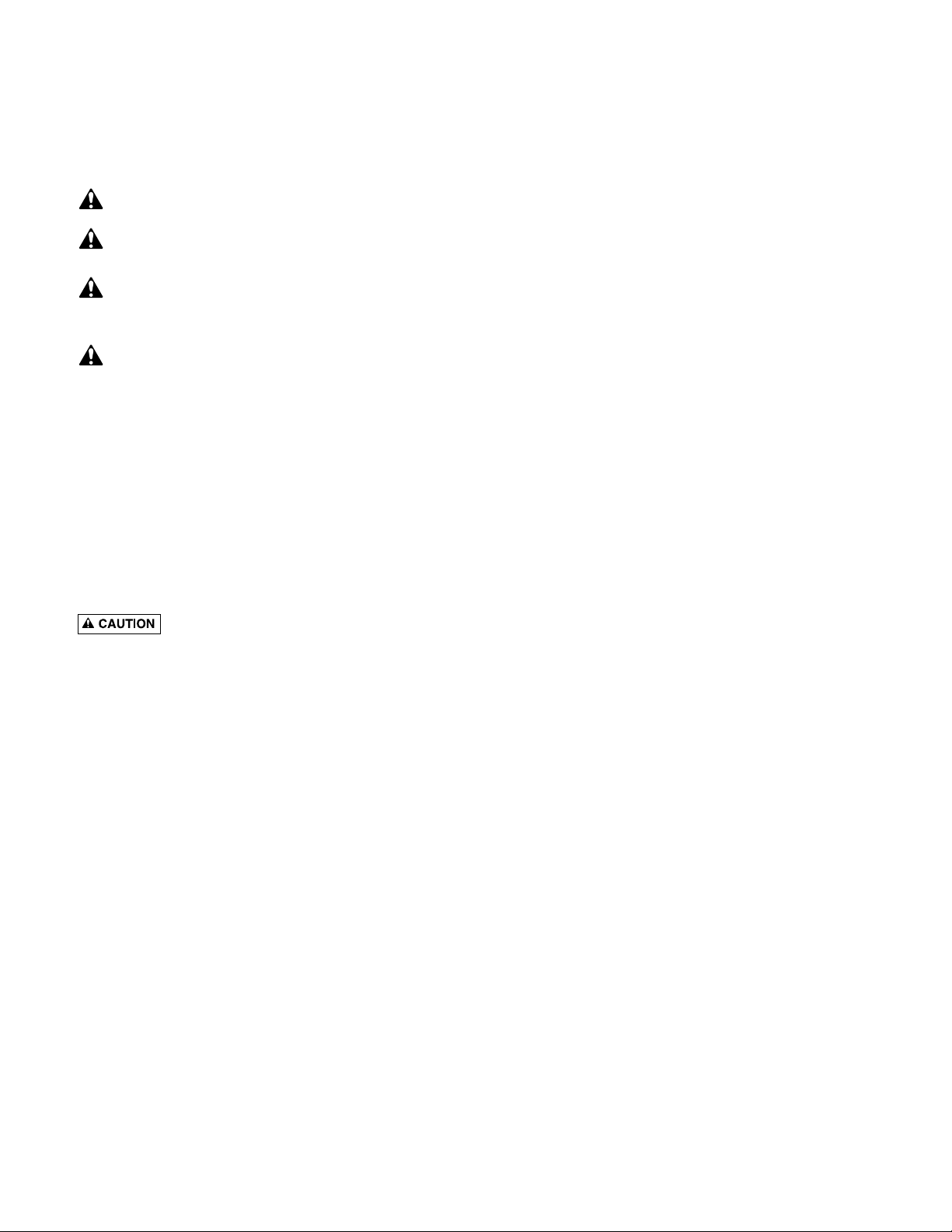

Valve Installation:

See Figures 6, 7, and 8

1. Install O-Ring on valve flange; make sure O-Ring is

clean, dry, and has no nicks, tears, or scrapes.

2. Make sure tank and valve flanges are clean and free

of sand; put valve on top of tank. Vertical pipe of collector assembly inserts into base of valve.

3. Install clamp; make sure knob is positioned for easy

access for filter maintenance. Valve port labeled

“PUMP” should point toward pump.

4. Tighten clamp knob until clamp ends (under bolt) are

1/4" (6mm) apart. Tap around outside of clamp with

a mallet to help seat clamp.

Hazardous pressure. Clamp will not

hold unless it is seated properly! DO NOT START

PUMP until clamp ends are 1/4" (6mm) apart or

less.

5. If clamp will not pull up to 1/4" (6mm) gap, wait

15-30 minutes and retighten. Tap clamp gently with

mallet to help seat clamp.

6. Connect pipe from pump discharge to valve port labeled “PUMP”; use union half provided. Assemble

union as follows for leakfree operation:

A. O-Ring and sealing surfaces must be clean.

B. Assemble hand tight only (no wrenches).

C. NO pipe compound or teflon tape on unions.

7. Complete all plumbing connections (see Page 5 for

piping requirements).

A. Pipe from valve RETURN port to pool return.

B. Pipe from valve WASTE port to waste.

C. Suction piping from pool to trap inlet on pump.

8. System is ready for startup.

NOTICE: If there are leaks from beneath valve/clamp

area, STOP PUMP, release all pressure, remove

clamp and valve and clean sealing surfaces.

B. Insert assembly

into top of

filter tank.

A. Insert first lateral into socket;

twist clockwise 1/4 turn

to lock lateral into hub.

Lateral is correctly installed

when slots face down.

731 0294

C. Hold assembly up

near top of tank and

add remaining

laterals.

732 0294

S

A

N

D

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

Fill tank

about

half full

of water

before

adding

sand.

Sand Shield

keeps collector

hub assembly

clean when

loading filter.

734 0294

Figure 2

Figure 3

Figure 4

Figure 5

6

Page 7

7

Follow directions under “Valve In stallation”, Page 6,

when reinstalling valve. See Figures 6 and 7.

ELECTRICAL

Risk of electrical shock.

Plug pump into a

grounded, GFCI-protected 115

Volt circuit only. Incorrect voltage can cause fire or seriously

damage motor and voids warranty. Protect cord from water

and physical damage.

GFCI tripping indicates

an electrical problem. If

GFCI trips and will not reset,

have a qualified electrician inspect and repair electrical

system.

Risk of electrical

shock. Unplug

motor before servicing or repairing pump or motor.

Wiring:

Install a Ground Fault Circuit Interrupter (GFCI) in circuit; it will sense a short-circuit to ground and disconnect power before it becomes dangerous to pool users.

For size of GFCI required and test procedures for

GFCI, see manufacturer’s instruction.

In case of power outage, check GFCI for tripping (which

will prevent normal water circulation). Reset if necessary.

Match circuit breaker size to Table III, Page 8.

• Do not modify cord, plug, or receptacle. If an existing

circuit must be used and the receptacle and plug do

not match exactly, consult a licensed electrician.

• Do not use an extension or drop cord with this system; it could cause a fire hazard or low voltage problems. Wet cords cause shock hazards. Extension

cords can easily become cut or frayed and dangerous when placed across yard areas or walkways.

Voltage:

Voltage at motor must be not more than 10% above or

below motor nameplate rated voltage or motor may

overheat, causing overload tripping and reduced component life. If voltage is less than 90% or more than

110% of rated voltage when motor is running at full

load, consult power company.

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

E

W

A

S

T

E

F

I

L

T

E

R

1. Install O-Ring

on valve flange.

2. Install valve on tank.

Tank flange must

be clean; insert

collector pipe

into bottom

of valve.

Delavan, WI.

53115

USA

1/4" Max.

Port labeled

"PUMP" should

point toward

pump.

Install clamp

and tighten

until clamp

ends (under

bolt) are 1/4"

apart.

If unable to

close gap

to 1/4" or less,

wait 15-30

minutes and

retighten.

Tap around

clamp while

tightening to

help seat

clamp.

.WATERFORD,WI.

53185

USA

736 0294

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

E

W

A

S

T

E

F

I

L

T

E

R

Figure 6

Figure 7

Hazardous voltage.

Can shock, burn,

or cause death.

Disconnect power

before working

on pump or motor.

Page 8

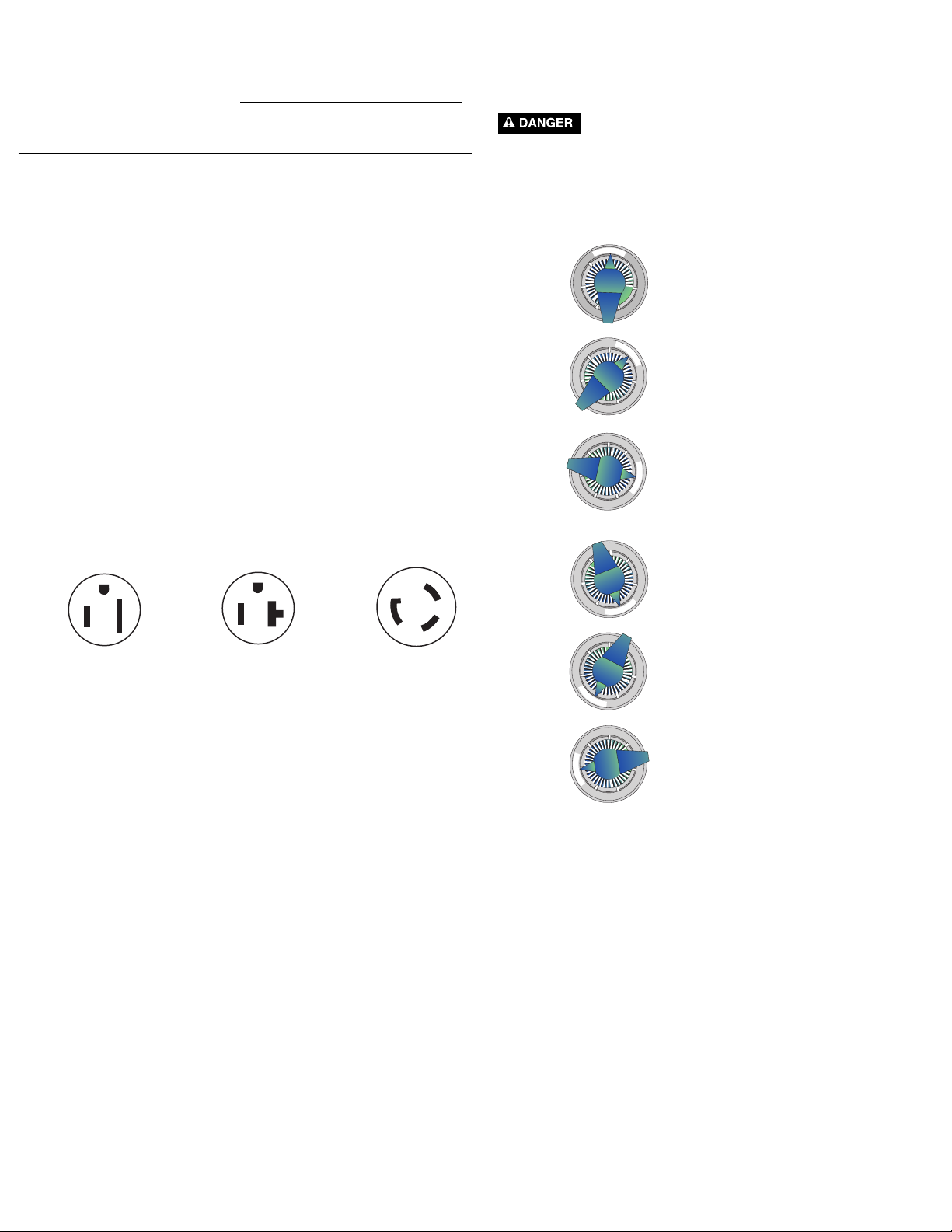

Startup/Operation (See Figure 9)

Hazardous suction. Can trap and tear

hair or body parts and can cause drowning. Do not

block pump suction. Small children using pool

must ALWAYS have close adult supervision.

Dist. In Ft. (m) (Serv. To Motor)

Motor Nameplate

Full Load Amps

Branch

Circuit

Volts/Hz/

Phase

0-100'

(0-30)

101-200'

(31-60)

201-300'

(61-90)

Temp

Rating- ◦C

12.0 or Less 15A 115/60/1 14 (2) 12 (3) 10 (5.5) 75

12.1 - 16.0 20A 115/60/1 10 (5.5) 8 (8.4) 6 (14) 75

16.1 - 20.0 25A 115/60/1 10 (5.5) 8 (8.4) 6 (14) 75

12.0 or Less 15A 230/60/1 14 (2) 12 (3) 10 (5.5) 75

8

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

Valve Setting

Purpose/Flow

FILTER

Normal filtration and

vacuuming; water goes

through filter to pool.

RINSE

For initial startup cleaning

and sand bed leveling

after backwash; water goes

through filter to waste.

RECIRCULATE

Circulates pool water;

bypasses filter.

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

737 0294

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

BACKWASH

Reverses flow for

cleaning; water

goes through filter

to waste.

CLOSED

Shuts off all flow to

filter and pool.

WINTERIZE

Leaves all valve ports

partially open for

winter storage.

Purpose/Flow

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

738 0294

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

Valve Setting

Figure 8

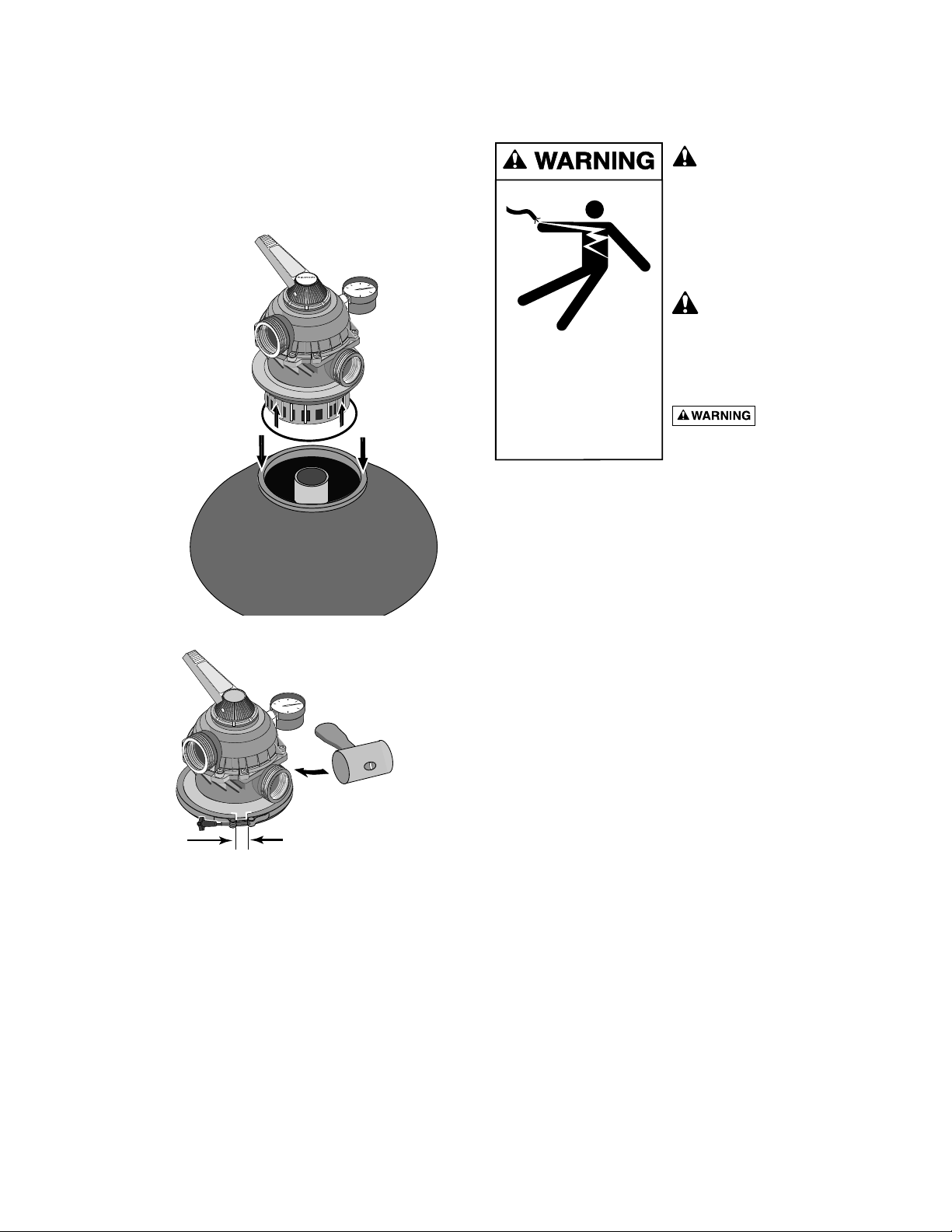

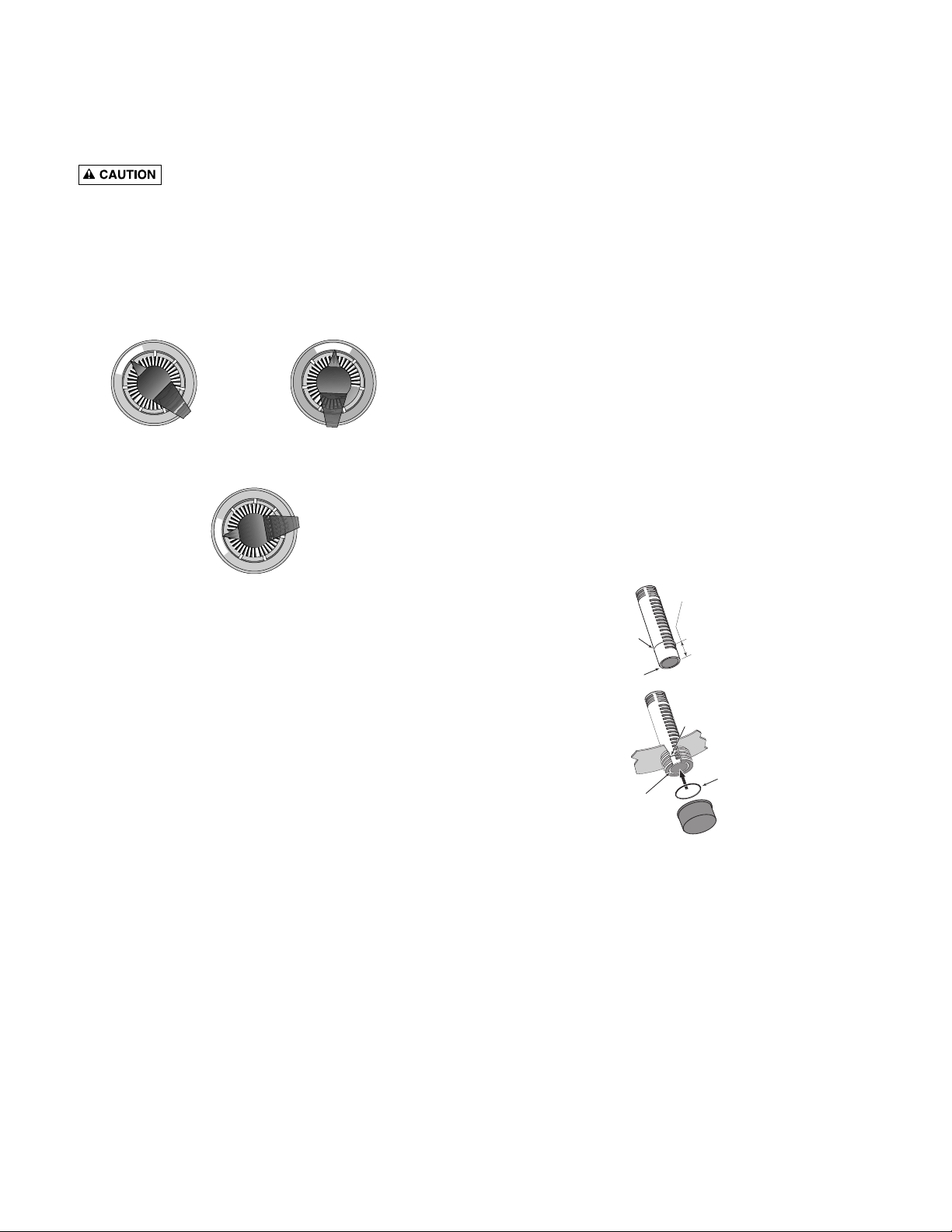

NOTICE: Determine circuit breaker rating from the table above.

Determine correct outlet required from illustration below.

JWP 1/2, 3/4 and 1 HP Models

with suffixes -2A2, -A2U and

-6A2, as well as JWP 1-1/2 HP

models with suffixes -2A4U and

-6A2 use 15-amp straight

outlet, above.

JWP 1-1/2 HP Models with

suffixes -2A2 and -A2U use

20-amp straight outlet, above.

JWP Models with

suffixes -2A1 and -6A1 use 20-

amp twist-lock outlet, above.

Notice: Values given are for Pump motor only. Do not put any other accessories on this circuit.

Page 9

9

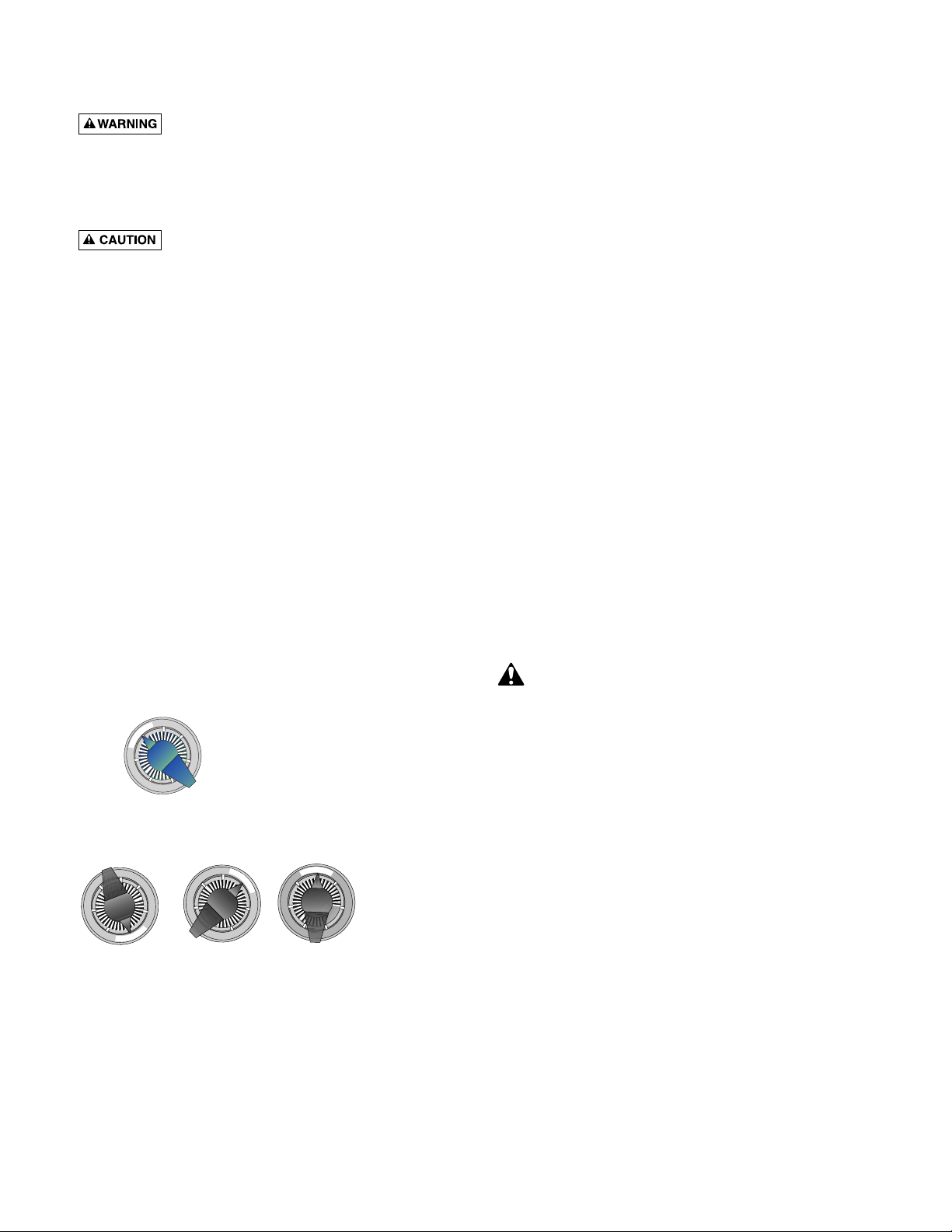

Hazardous pressure. To avoid explosion and possible severe or fatal injury, filter system pressure must not exceed 50 PSI (345 kPa)

under any circumstances. NEVER test this filter

system with compressed air; never operate system

with water temperature above 95° F (35° C).

To prevent equipment damage and possible injury, turn pump OFF before changing valve

position.

NOTICE: Do not add chemicals directly into the pool

skimmer. Adding undiluted chemicals may damage

equipment and void warranty.

1. Open system valves and make sure pump is filled

with water.

Make sure pool water level is above skimmer or the

suction outlet.

2. With pump OFF, set valve to ‘BACKWASH’ position.

3. Start pump, circulating water backwards through filter to waste.

4. Backwash until water runs clear (3-5 minutes).

5. Stop pump; set valve to ‘RINSE’ position.

6. Start pump; run pump for one minute.

7. Stop pump; set valve to ‘FILTER’ position.

8. Filter is now ready for service.

9. Record clean starting filter pressure gage reading

as a reference.

10. When pool is first filled, backwash once a day until

pool water is sparkling clear. After that, backwash

when pressure gage shows 5 to 7 PSI (34.5 to 48

kPa) higher than starting pressure.

MAINTENANCE

General:

• Wash outside of filter with a mild detergent and water.

Rinse off with hose.

NOTICE: DO NOT use solvents to clean filter; solvents may damage plastic components in system.

• Inspect sand bed at least once a year to remove foreign material which has not been backwashed out of

system.

NOTICE: When the sand bed gets hard and crusty

on top, remove all the old sand and replace it with

new sand.

Weekly Pool Equipment Inspection:

1. Check pressure during operation. When pressure is

5 to 7 PSI (34.5 to 48 kPa) higher than initial operating pressure, backwash filter (see instructions under

“Startup/Operation”).

2. Except during hot weather with heavy swimmer loads,

operating filter 6 to 12 hours per day should be sufficient. Carefully monitor water chemical balance and follow recommendations of your local pool professional.

Water Maintenance

• Keep water level at least two inches above bottom of

skimmer opening when system is not in operation.

Failure to do so can allow air to enter system, causing pump to lose prime and filter to entrap air.

• Maintain pH at 7.2 to 7.6 in pool.

To prevent damage to system components,

keep water temperature below 95° F (35° C) at

all times.

Vacuum Pool:

1. Fill vacuum hose by submerging in water from one

end to the other.

2. To vacuum, insert hose into skimmer suction mani-

fold or into vacuum line in pool wall. See instructions

provided by pool builder or pool manufacturer. Start

pump, making sure it is primed and pumping.

3. After vacuuming, clean pump trap to remove accu-

mulated debris, then check filter pressure gage. If

reading is 5 to 7 PSI (34.5 to 48 kPa) higher than initial operating pressure, backwash filter

Lower or Drain Pool

(See Figure 10, Page 10)

1. Turn pump ‘OFF’; set valve handle to ‘WASTE’.

2. Use vacuum cleaner hose and head.

3. Start pump; run until pool is lowered to desired level.

4. Turn pump ‘OFF’; set valve handle to ‘FILTER’.

5. Start pump.

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

Figure 9: Valve settings for startup. Stop

pump before changing valve position.

WASTE

Lowers pool level or

drains pool; water

bypasses filter,

goes to waste.

Valve Setting

Purpose/Flow

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

743 0294

Page 10

10

STORAGE/

WINTERIZING

Pool chemicals may give off corrosive

fumes. Store chemicals away from system in a well

ventilated area.

NOTICE: Allowing water to freeze will damage filter and

void warranty. If antifreeze is needed, use propylene glycol; it’s plastic compatible and non-toxic. Follow manufacturers instructions. Do not use ethylene glycol based

anti -freeze – it’s toxic and it may damage plastic components.

1. Open all system valves. Set multiport valve at ‘WIN-

TERIZE’ to allow air passage to all ports (Figure 11).

2. Remove drain plug from filter.

3. Drain filter tank completely and replace drain cap

(Figure 12).

4. Cover with plastic or tarpaulin to protect from

weather.

5. Remove drain plugs from pump.

6. Protect from freezing.

Startup for Winterized Equipment:

1. Remove any temporary weather protection placed

around system for shutdown.

2. See “Startup”, Page 8, for reactivation of the filter.

3. Inspect all electrical wiring to pump for damage or

deterioration over the shutdown period. Have a qualified serviceman repair/replace wiring as needed.

Inspect and tighten all watertight connections.

4. Open all valves in suction and return piping.

5. Remove any winterizing plugs in system.

6. Drain all winterizing chemicals (if used) from system;

flush system.

7. Close all drain valves and replace all drain plugs in

system.

8. Fill pool with water to proper level (see pool maufac-

turer’s instructions).

Drain Fitting Installation/Removal

NOTICE: If pool is above height of filter, first close

valves in pump suction and return lines to prevent

draining pool. If there are no shutoff valves installed,

disconnect suction and return lines and raise ends

above pool water level.

1. Installation: See Figure 12.

2. To Drain Filter:

A. Remove drain cap. Lateral tube should remain in

place inside drain opening to prevent sand from

draining out.

B. Open union coupling on backwash port of Multi-

Port valve. This will allow air into filter and allow

water to drain from filter tank.

C. Replace cap when tank is empty.

3. Removing Sand From Filter:

A. Remove both drain cap and slotted lateral tube

(see Figure 12). Sand and water will drain from

tank.

B. To completely flush filter tank of sand,

remove top clamp and multiport valve and flush

the inside of the tank with a hose.

C. Thoroughly clean sand from all parts and from

tank drain opening before reassembling drain fitting.

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

Figure 10: Valve settings to lower pool water level.

Stop pump before changing valve position.

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

Figure 11: Valve setting for winter storage.

Stop pump before changing valve position.

About 1"

Small

O-Ring

Open end

of lateral

Seat small

O-Ring

Large

O-Ring

End of lateral is

flush with end of

drain fitting

746 0294

Figure 12: Drain Fitting Assembly. This assembly allows water to drain without losing the

sand out of the filter tank.

Make sure all surfaces are clean and free of

sand. Don’t cross thread cap; don’t overtighten

cap.

Page 11

11

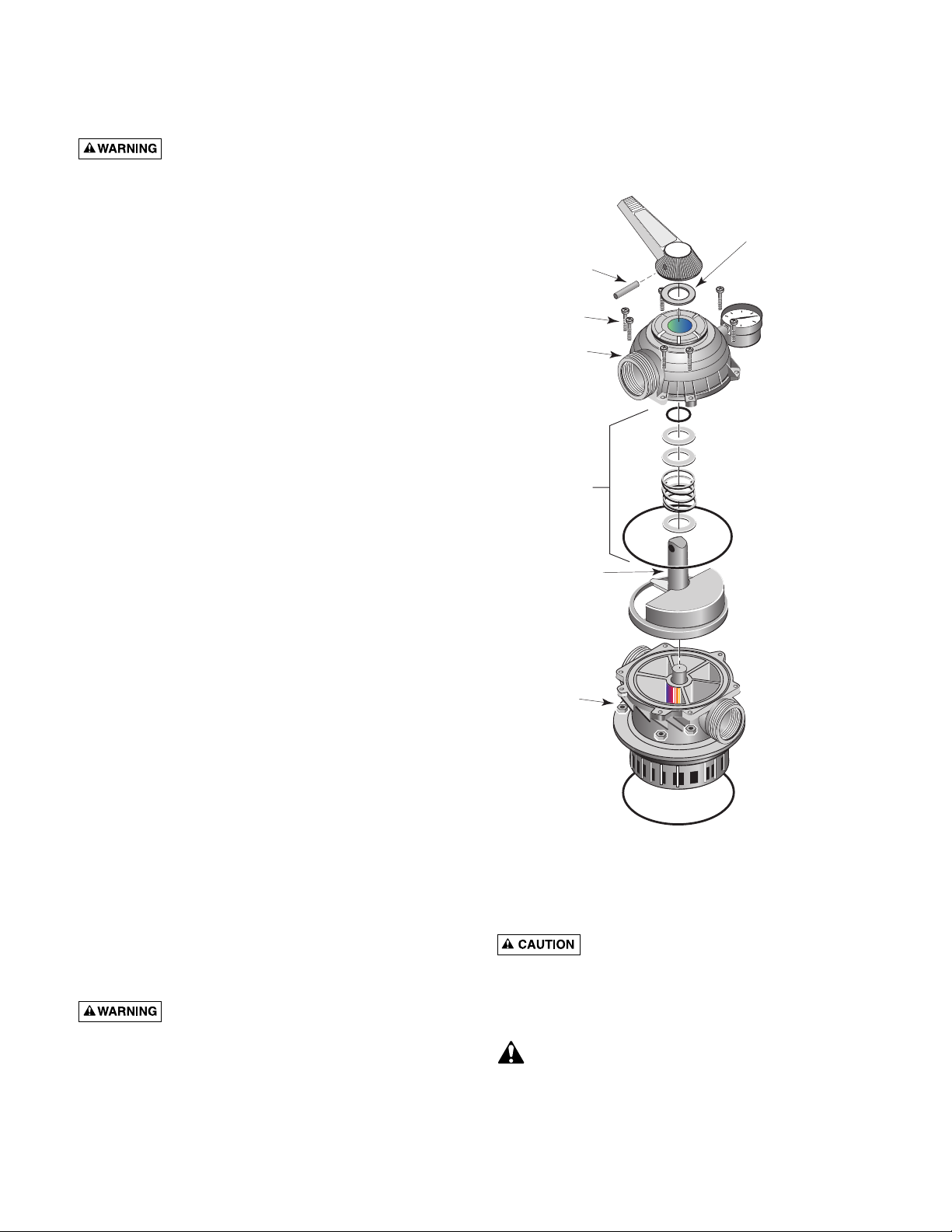

MULTI-PORT VALVE SERVICE

Hazardous pressure. Stop pump and

release all pressure from system before working on

filter, valve, or clamp.

NOTICE: If Multi-Port valve is below pool water level,

close suction and discharge valves before disassembly

to prevent draining pool.

Handle Replacement:

1. Stop pump.

2. Place handle in ‘FILTER’ position.

3. Remove pin (Key 1, Figure 13) to disconnect handle.

If it cannot be removed by hand, use a hammer and

center punch and lightly tap it out.

4. Remove handle; replace with a new one. Be sure

new handle is in ‘FILTER’ position.

5. Replace pin.

Lid and Plug replacement:

A. Remove Handle (see ‘Handle Replacement’,

above).

B. Remove plug:

1. Remove all screws and nuts (Key Nos. 2 and 6,

Figure 13).

2. Remove lid (Key No. 3) by pulling straight up

while holding plug shaft (Key No. 5) down with

thumb.

C. Inspect Internal Parts:

Inspect plug and gasket spring, O-Rings, and internal

washers (Key No. 4). Replace if necessary.

D. Reassemble Valve:

1. Replace plug gasket and shaft, mounting spring,

washers, and O-Ring on plug shaft. Lubricate ORing with Amojel.

2. Replace lid; match screw holes in lid and body.

3. Press down on lid to allow screws to engage nuts;

tighten each nut securely.

4. Replace top washer (Key No. 1A) and handle,

making sure indexing pin on plug shaft points in

same direction as pointer on handle. Replace

handle pin.

5. Tighten all lid screws to 55 inch-lbs. (63.4 kg-cm)

torque.

Valve Removal

Hazardous pressure. Stop pump and

release all pressure from system before working on

filter, valve, or clamp.

NOTICE: If multi-Port Valve is below pool water level,

close suction and discharge valves before disassembly

to prevent draining pool.

1. Disconnect piping from pump and pool.

2. Remove clamp.

3. Remove valve from filter top.

4. To reinstall valve, follow “Valve installation” instructions, Page 6. BE SURE to follow clamp tightening

instructions.

PUMP SERVICE

To protect against possible electric

shock, use only identical replacement parts when

servicing.

System should only be serviced by qualified personnel.

Before removing trap cover:

1. STOP PUMP before proceeding.

2. CLOSE GATE VALVES in suction and discharge

pipes.

3. RELEASE ALL PRESSURE from pump and pip-

ing system.

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

1

1A

2

3

4

5

6

Aquatools

.WATERFORD, WI.

53185

USA

744 0294

Figure 13: Valve Disassembly

Page 12

12

To avoid dangerous or fatal electrical shock

hazard, turn OFF power to motor before work-

ing on pump or motor.

Trap needs no lubrication or regular maintenance beyond reasonable care and periodic cleaning of strainer

basket.

If shaft seal is worn or damaged, repair as follows:

Pump Disassembly:

1.Unplug motor before servicing or repairing pump or

motor.

2.Close all valves in suction and discharge piping.

3.Remove drain plugs from the bottom of pump and

trap; drain pump completely.

4.Disconnect pipe unions (or clamps) on suction and

discharge piping. Remove hold down bolts and

withdraw complete pump/motor/trap assembly.

5.Remove cap screws (Key No. 16, Pages 15 and 16)

from front plate (Key No. 13). Remove front plate

with trap (Key No. 20) attached. Remove and inspect O-Ring (Key No. 12).

6.Remove end cap (Key No. 2) from motor cover

(Key No. 7). NOTICE: JWP Series pump motors do

not have a motor cover or switch.

7.Hold motor shaft with 7/16” wrench on flats on

motor shaft; unscrew impeller (Key No. 11).

8.Carefully remove rotating half of seal (Key No. 10)

from impeller sleeve. Twist as you pull; make sure

you do not damage surface of sleeve where seal

both seats and seals. See Figure 14.

9.Remove motor throughbolts (see Figure 15).

Remove seal plate (Key No. 9). Tap stationary half

of seal out of seal plate (see Figure 16).

10. If necessary, disconnect electrical wiring from motor

terminal board and remove motor (Key No. 6) from

motor cover (Key No. 7).

Pump Assembly:

1. Examine seal cup and O-Rings. Replace anything

that shows signs of wear or damage.

2. Check the shaft seal (Key No. 10, Pages 15 and

16) for scoring, scratches, chips, etc., and for any

signs of damage to spring or retainer. Replace if

any wear or damage is visible.

3. Press stationary half of seal into seal plate (Key

No. 9) using finger pressure only (see Figure 17).

Make sure seal is firmly and evenly seated.

4.Install rotating half of seal on impeller sleeve. Push

it onto sleeve until it butts against back of impeller.

5.Insert impeller sleeve through center hole in seal

plate (Key No. 9). Thread slinger (Key No. 8) over

the end of the impeller sleeve.

6.If motor has been removed from motor cover, reinstall it now. Set up seal plate (Key No. 9) in front of

motor cover; hold motor shaft with 7/16” wrench on

shaft flats (under cap) and thread impeller through

center hole in seal plate onto shaft). Make sure that

slinger is in place on impeller sleeve – not loose on

shaft.

7.Install motor throughbolts; make sure seal plate

butts firmly against motor endbell. If necessary, install motor cover and switch.

8.Install wear ring on back of front plate.

NOTICE: Teeth on wear ring interlock with ribs in

front plate.

9.Install front plate (Key No. 13). Tighten cap screws

in sequence as shown in Figure 18; tighten to 30

inch-lbs. (34.5 cm-kg.) torque.

10.Reinstall drain plugs; reinstall pump and motor on

base and tighten hold-down bolts.

11. Reconnect unions; tighten hand tight only.

Figure 14 Figure 15 Figure 16 Figure 17

#1

#6

#2

#5 #3

#4

Start

Here

Figure 18: Pump front Plate Torque Sequence.

Page 13

13

TROUBLESHOOTING GUIDE –

PUMP

Read and understand safety and operating instructions in this manual before doing any

work on pump.

A. Pump does not operate:

1. Check GFCI (Ground Fault Circuit Interrupter) for

proper operation according to GFCI manufacturer’s instructions.

2. Check for blown fuses, circuit breakers, or disconnected electrical wiring.

3. Check for sand locked impeller. Disconnect

power to motor; follow “Pump Disassembly” instructions, Page 12. Clean out sand from impeller and from wear ring in front plate.

Reassemble according to instructions, Page 12.

4. Consult dealer/installer or service representative.

B. Motor runs, but does not pump water or pressur-

ize system:

1. Check to make sure all valves are open.

2. Check skimmer, trap basket, and piping for debris or obstructions.

3. Check pump impeller for obstructions such as

hair, leaves, grass, or stones. Follow “Pump

Disassembly” instructions, under “Pump Service”

on Page 12.

4. Consult with dealer/installer or service

representative.

C. Excessive air in system – pump loses prime:

1. Make sure water level in skimmer is at least 2”

above bottom of skimmer throat with system not

operating.

2. Make sure that there are no leaves in suction

piping.

3. Make sure there is no vortex (whirlpool) at the

suction; add water to pool if necessary.

4. Consult dealer/installer or service representative.

D. Circuit breaker in home panel trips repeatedly:

1. Breaker must be of adequate capacity.

2. If breaker is a GFCI breaker, test according to

GFCI manufacturer’s instructions.

3. Be sure no other lights and appliances are on circuit.

4. Check wiring size leading to pump. Inadequate

size wiring will cause overheating of pump and

excessive amp draw leading to circuit breaker

tripping.

5. Consult dealer/installer or service representative

TROUBLESHOOTING GUIDE –

FILTER

A. Short Cycle between backwashes:

NOTICE: Time between backwashes will vary with

each installation and between different areas of the

country. Ask installer about normal backwash interval in

your area. The following causes and remedies are for

cycle times shorter than normal for your area.

1. Flow rate too high or filter too small; consult

dealer for system sizing recommendations.

2. Water is chemically out of balance; consult pool

serviceman.

3. Excess dirt/dust in pool; vacuum pool directly to

waste.

4. Body oil/lotion build-up in filter; consult dealer for

chemical filter cleaners and follow cleaner manufacturer’s instructions.

5. Filter inadequately backwashed. See instructions

under “Startup/Operation”, Page 8.

6. Algae in pool. Consult pool professional about

proper chemical maintenance.

7. Residual chlorine level too low. Consult pool professional about proper chemical maintenance.

8. Inspect filter sand for solidification caused by

dust, calcium, skin oils, of suntan lotions.

B. Low Flow:

1. Pipe blocked downstream from filter; remove obstruction.

2. Piping too small; use larger pipe (consult dealer

for sizing).

3. Plugged pump; plugged hair and lint trap or skimmer basket. Clean thoroughly.

C. Pool Water Not Clear:

1. Water is chemically out of balance; consult pool

professional.

2. Filter is too small; consult dealer about equipment

sizing.

3. Sand in pool means broken lateral. Drain both

water and sand out of tank. Remove valve; follow

procedure under “Filter Setup”, Page 6, and instructions with new lateral to replace broken part.

To avoid severe injury or major property damage, follow instructions under 'Valve

Installation', Figures 6, 7 and 8, Pages 6, 7 and 8).

1. Follow “Valve Removal” procedure, Page 11.

2. Replace lateral according to instructions supplied

with new lateral.

3. Reassemble filter according to instructions under

“Filter Setup”, Page 6

Page 14

14

MODELS

Key No. JSAL15 Series JSAL18 Series JSAL21 Series

No. Part Description Used 15” Filter

18” Filter 21” Filter

1 Pump* (Models with -06, -09 suffix) 1 JWP Series JWP Series JWP Series

1 Pump** (All other suffixes) 1 JWP Series JWP Series JWP Series

2 O-Ring 2 U9-226 U9-226 U9-226

3 Hose Assembly (Includes Key No. 2) 1 24203-0036 24203-0033 24203-0034

4A Hose Adapter 2 11201-0002 11201-0002 11201-0002

4B Sight Glass 1 14962-0012 14962-0012 14962-0012

5 Multiport Valve** (Includes Key Nos. 6, 7 and 16) 1 WC112-148A WC112-148A WC112-148A

6 O-Ring, Tank Flange 1 U9-369 U9-369 U9-369

7 V-Clamp with Knob 1 WC119-87A WC119-87A WC119-87A

8 Pedestal Platform 1 24201-0055P 24201-0055P 24201-0055P

9 Drain Cap 1 14965-0025 14965-0025 14965-0025

10 O-Ring, Drain Cap 1 U9-371 U9-371 U9-371

11 Drain Lateral Tube 1 24201-0058 24201-0058 24201-0058

12 O-Ring, Lateral Tube 1 U9-370 U9-370 U9-370

13 Lateral Tube 8 24600-0003 24600-0003 24600-0003

14 Collector Hub Assembly 1 24200-0110 WC137-516P WC137-517P

15 Tank Assembly 1 24200-0100 24201-0100 24203-0100

16 Clamp Knob 1 WC36-22 WC36-22 WC36-22

17 Filter Tank Ass’y (Includes Key Nos. 8 thru 15) 1 24200-9100S 24201-9100S 24203-9100S

18 Washer 1/4" 2 U43-60SS U43-60SS U43-60SS

19 Screw 1/4-20x3/4" Lg. 2 U30-52SS U30-52SS U30-52SS

• Hose, 1-1/2" x 6’ Lg.*** 2 34055-7038 34055-7038 34055-7038

• Sand Shield 1 24201-0043 24201-0043 24201-0043

• Nameplate Decal 1 32155-4115A 32155-4115B 32155-4115C

• Clamp Decal, Warning 1 32165-4030 32165-4030 32165-4030

• Information Decal 1 32155-4112 32155-4112 32155-4112

• Not illustrated. *See Page 15. **See Page 16.

*** Models JSAL15D-59, JSAL180F-05, and JSAL210F-05 do not include 6’ hose.

7

8

17

16

15

14

13

12

11

10

9

1

3

2

18

19

4A

4B

5

6

1277 0994

Repair Parts List - Filter

Page 15

15

• Not illustrated.

* Not available separately.

Model Motor No. Impeller No.

No. HP (Key No. 6) (Key No. 11)

Single Speed

JWPA5DC-2A3 3/4 AS901DL C105-228PWBS

JWPA5EC-2A3 1 AS901EL C105-228PWS

JWPS5FC-2A3 1-1/2SPL AS901SFL C105-228PWS

Dual Speed

17290-J1002 1 – 1/6 17182-0090 C105-228PWS

Model Cord & Cap Assembly

No. HP (Key No. 2)

JWPA5DC-2A3 3/4 17190-0026-S

JWPA5EC-2A3 1 17190-0026-S

JWPS5FC-2A3 1-1/2SPL 17190-0026-S

Dual Speed

17290-J1002 1 – 1/6 17190-0028-S

Parts are common to all models listed except as noted;

Key Nos. 2, Cord & Cap Assembly; 6, Motor; and 11,

Impeller, are listed below.

Order PKG. 115 for 5" Trap complete (includes

Key Nos. 17 through 25).

1

2

3

4

5

6

7

8

9

10

13

13B

13A

12

11

14

20

21

22

23

19

24

25

26

9A

15

16

17

18

19

NOTICE:

AT23 series models use the

same front plate and

seal plate as other models;

however, they are rotated

90° counter-clockwise

when installed.

782 0294

Key Part

No. Description Qty. Number

1 End Cap Screw 3 37337-0085

2 End Cap and Cord Assembly 1 Chart at Right

3 Toggle Switch 1 16920-0511

4 Toggle Switch Boot 1 32800-0107

5 Baffle Ring 1 17290-0004

6 Motor 1 Chart at Right

7 Motor Cover 1 17190-0021

8 Slinger 1 17351-0009

9 Seal Plate 1 C1-260P

10 Shaft Seal 1 37400-0027S

11 Impeller 1 Chart at Right

12 O-Ring 1 U9-357

13 Front Plate (Includes

Key Nos. 13A, 13B, 19) 1 C101-272PS

13A Wear Ring* 1

13B Pipe Plug 2 WC78-40T

14 Cap Screw 4 30387-0005

15 Trap Lid 1 C3-139P1

16 Trap Lid Gasket 1 U9-229

17 Trap Basket 1 C108-33P

18 Trap Body 1 C153-53P

19 Drain Plug w/O-Ring 2 U178-920P

20 Cap Screw 4 U30-64SS

21 Lock Washer 4 U43-11SS

22 Plain Washer 4 U43-41SS

23 Trap Outlet Gasket 1 C20-123

24 Mounting Foot 1 17190-0023

25 Plain Washer 4 U43-117SS

26 Cap Screw 4 U30-52SS

• Nameplate 1 32155-4073

• Decal – GFCI Required 1 U27-558

• Decal – Insulated Wet End 1 U27-584

• Tag – Do Not Use Pipe Dope 1 61002-0002

• Tag – Caution 1 61002-0004

REPAIR PARTS LIST

POOL PUMPS

3/4 thru 1-1/2 HP Single Speed

1 Hp Dual Speed

Page 16

16

6

8

9

10

11

12

13A

13

14

19

21

22

23

13B

15

17

16

18

19

20

381 1293

Model Number

Key

No. Description Qty.

JWP5CL

1/2 HP

JWPA5DL

JWP5DL

3/4 HP

JWPA5EL

JWPA5E

JWPA5YEL

JWP5EL

JWPS5GL

1 HP

JWPA5FL

JWPAS5F

JWPA5YFL

JWP5FL

1-1/2 HP

6 Motor, Energy Efficient, 115/60H/1Ph 1 62003-2095 62003-2096 62003-2097 62003-2098

6 Motor 115/60H/1Ph (Without Cord) 1 – AS920DLL AS920ELL AS920FLL

6 Motor 230/60H/1Ph (Without Cord) 1 – – AS923EL –

6 Motor 115/60H/1Ph 1-Speed (Without Cord) 1 – – – 62003-2031

6 Motor 115/60H/1Ph 2-Speed (Without Cord) 1 – – 62003-2021 62003-2032

8 Slinger 1 – 17351-0009 17351-0009 17351-0009

9 Seal Plate 1 – 17301-0150 17301-0150 17301-0150

10 Shaft Seal 1 37400-0027S 37400-0027S 37400-0027S

11 Impeller (1/2 HP) 1 C105-228PJ1 C105-228PH C105-228PG 17301-0101

11 Impeller 1 – C105-228PH C105-228PG C105-228PG

12 O-Ring 1 – U9-357 U9-357 U9-357

13 Front Plate (Includes Key Nos. 13A, 13B, 19) 1 – C101-272PS C101-272PS C101-272PS

13A Wear Ring* 1 – – – –

13B Pipe Plug 2 – WC78-40T WC78-40T WC78-40T

14 Screw, 1/4-20 x 1-3/4 6 – 30787-0005 30787-0005 30787-0005

15 Trap Cover 1 – C3-139P1 C3-139P1 C3-139P1

16 Strainer Basket 1 – C108-33P C108-33P C108-33P

17 O-Ring Cover 1 – U9-229 U9-229 U9-229

18 Trap Body 1 – C153-53P1 C153-53P1 C153-53P1

19 Drain Body, 1/4” NPT (w/o O-Ring) 2 – U178-920P U178-920P U178-920P

20 Capscrew, 5/16-18 x 1-1/4” 4 – U30-64SS U30-64SS U30-64SS

21 Washer, Lock 5/16” 4 – U43-11SS U43-11SS U43-11SS

22 Washer, Flat 5/16” 4 – U43-41SS U43-41SS U43-41SS

23 Gasket 1 – C20-123 C20-123 C20-123

• Cord Assembly 1 – See Chart Above See Chart Above See Chart Above

• Nameplate 1 – U33-155 U33-155 U33-155

• Decal “Tested for Pools & Spas” 1 – U27-635 U37-635 U27-635

• Decal - GFCI 1 – U27-558 U27-558 U27-558

• Tag - Bonding Instructions 1 – C63-12 C63-12 C63-12

• Tag - CAUTION Securely Tighten...Warning... 1 – C63-13 C63-13 C63-13

JWPA PUMPS

HP

-2A1 Models

Cord Ass’y with

Twist-lock Plug

-2A2 Models

-A2U Models

Cord Ass’y with

Straight Plug

-2A4U Models

Cord Ass’y with

Straight Plug 2A1, 6A1 Models 2A, 2A2, 6A2 Models 2A4 Models

1/2 – – – 31953-0101 U117-1117 –

3/4 31953-0101 U117-1117 – 31953-0101 U117-1117 –

1 31953-0101 U117-1117 – 31953-0101 U117-1117 –

1-1/2 31953-0101 U117-1118 31953-0116 31953-0101 U117-1117 (2A2, 6A2) –

1-1/2 – – – 31953-0101 U117-1118 (A2) 31953-0116

•

Not illustrated

*

Not available separately

CORD AND PLUG PART NUMBERS

REPAIR PARTS LIST

Page 17

17

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

1

2

3

4

5

6

7

8

9A

10

11

9B

12

13

14

15

16

Aquatools

.WATERFORD, WI.

53185

USA

762 0294

Key Part

No. Description Qty. Number

1 Decal, Valve Handle 1 32145-4016

2 Handle 1 14962-0032

3 Dowel Pin 1 35857-0021

4 Washer 1 14965-0007

5 Decal, Operating Instructions 1 14965-0020

6 Screw 7 37067-0714

7 Valve Cover 1 14965-0011

8 O-Ring 1 35505-1228

9A Washer 2 14965-0007

9B Washer 1 14965-0007

10 Spring 1 14965-0006

11 Pressure Gage 1 15060-0000T

12 O-Ring, Cover 1 35505-1275

13 Plug & Gasket Assembly 1 14965-0028

14 Valve Body Assembly 1 14965-0013

15 Nut 7 35407-0071

16 O-Ring, Tank Flange 1 U9-369

REPAIR PARTS LIST

WC112-148A MULTIPORT VALVE

Page 18

18

For technical information about this product, contact the installer or call PENTAIR at (800) 831-7133.

Visit www.pentairpool.com and www.staritepool.com

S260 (Rev.A)01/31/2007

Page 19

Système Waterford

Système de Filtration à Sable à Grand Débit

Pour piscines hors-sol

NOTICE D’UTILISATION

POSE, FONCTIONNEMENT ET PIÈCES

839 0494

Pentair Water Pool and Spa, Inc.

© 2007 Pentair Water Pool and Spa, Inc. All rights reserved.

1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 553-5000

Pentair Water Pool and Spa logo are trademarks of Pentair Water Pool and Spa, Inc. Other trademarks and trade names may be used in

this document to refer to either the entities claiming the marks and names or their products. Pentair Water Pool and Spa Inc. disclaims proprietary interest in marks and names of others.

Printed in U.S.A.

04/18/2007

S260 (Rév. C)

Cette Notice doit être remise à l'utilisateur de ce système de filtration.

Page 20

2

SYSTÈME DE FILTRATION À

SABLE À GRAND DÉBIT

Pour éviter les appels inutiles d'un réparateur, éviter toutes blessures possibles et

obtenir le meilleur rendement de ce système de filtration, LIRE ATTENTIVEMENT

CETTE NOTICE!

Le système de filtration à sable à grand débit Aquatools :

• est conçu pour faire circuler et filtrer l'eau des piscines hors-sol.

• est un appareil à rendement efficace, à fonctionnement silencieux, durable et fiable.

• munies ou non d’un cordon électrique de 3 pieds doivent être utilisées SEULEMENT avec les piscines installées en permanence (se reporter à 7 ATTENTION,

ci-dessous).

• munies d’un cordon électrique de 25 pieds doivent être utilisées SEULEMENT

avec les piscines pouvant être remisées (voir 8 ATTENTION ci-dessous).

Table des matières

Consignes de sécurité..............................................................................................3

Spécifications/Données sur les dimensions..............................................................4

Renseignements généraux ......................................................................................5

Installation ............................................................................................................5-7

Assise du filtre/conduites.......................................................................................5

Montage du filtre ...................................................................................................6

Chargement du sable filtrant .................................................................................6

Installation de la vanne sélectrice ......................................................................6-7

Électricité .................................................................................................................7

Mise en service/fonctionnement/lavage à contre-courant......................................8-9

Entretien...................................................................................................................9

Entreposage et préparation pour l'hiver..................................................................10

Entretien des vannes à orifices multiples ...............................................................11

Dépose de la vanne sélectrice ...............................................................................11

Entretien de la pompe.......................................................................................11-12

Guide de diagnostic des pannes ............................................................................13

Liste des pièces de rechange............................................................................14-17

Garantie .................................................................................................................18

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES

Lorsque l'on installe et lorsque l'on utilise de l'équipement électrique, certaines consignes de sécurité de base

doivent toujours être observées, y compris les suivantes :

CONSERVER CES INSTRUCTIONS

1. IL FAUT TOUJOURS LIRE ET OBSERVER TOUTES

LES INSTRUCTIONS DE SÉCURITÉ.

2. Pour réduire les risques de blessures,

ne pas permettre aux enfants d'utiliser ce produit, à

moins qu'ils soient toujours attentivement surveillés.

3. Risque de secousses électriques. Ne

brancher cet appareil que sur une prise de courant mise

à la terre et protégée par un disjoncteur de fuite à la

terre. S'adresser à un électricien qualifié s'il est impossible de vérifier si la prise de courant est protégée par un

disjoncteur de fuite à la terre.

4. Ne pas enterrer le cordon d'alimentation. Le placer dans

un endroit où il ne pourra pas être endommagé par les

tondeuses à gazon, les tailles-haies ou tout autre

équipement.

5. Pour réduire les risques de secousses

électriques, tout cordon d'alimentation endommagé doit

être immédiatement remplacé.

6. Pour réduire les risques de secousses

électriques, ne pas utiliser de cordon prolongateur pour

brancher l'appareil à la source de courant; toujours

prévoir une prise de courant adéquatement positionnée.

7. Ces pompes doivent être utilisées avec

des piscines à installation permanente et elles peuvent

également être utilisées avec des cuves à remous et des

spas si elles sont désignées comme tel. Ne pas les

utiliser avec des piscines pouvant être remisées. Une

piscine installée en permanence est construite hors sol

ou creusée, ou bien elle est située dans un bâtiment, de

façon qu’elle ne puisse pas être facilement démontée

pour le remisage. Une piscine pouvant être remisée est

construite de façon qu’on puisse facilement la démonter

pour la remiser, puis la remonter dans son intégrité d’origine.

8. Ces pompes ne doivent être utilisées

qu’avec des piscines pouvant être remisées. Ne pas les

utiliser avec des pompes à installation permanente. Une

piscine pouvant être remisée est construite de façon

qu’on puisse facilement la démonter pour la remiser, puis

la remonter dans son intégrité d’origine. Une piscine installée en permanence est construite hors sol ou creusée,

ou bien elle est située dans un bâtiment, de façon qu’elle

ne puisse pas être facilement démontée pour le remisage.

Page 21

3

Ce symbole indique qu'il faut être prudent. Lorsque ce

symbole apparaît sur la vanne ou dans cette Notice,

rechercher un des DANGERS, AVERTISSEMENTS ou ATTENTIONS qui suivent, car ils indiquent la possibilité de

blessures corporelles.

avertit d'un danger qui causera des blessures

corporelles, la mort ou des dommages

matériels importants si on l'ignore.

avertit d'un danger qui risque de causer des

blessures corporelles, la mort ou des dom-

mages matériels importants si on l'ignore.

avertit d'un danger qui causera ou qui risquera

de causer des blessures corporelles, la mort

ou des dommages matériels si on l'ignore.

Le mot NOTA indique des instructions spéciales et impor-

tantes n'ayant aucun rapport avec les dangers.

Lire attentivement toutes les consignes de sécurité con-

tenues dans cette Notice et figurant sur le système de filtration et les respecter.

Toujours garder ces autocollants de sécurité en bon état.

Remplacer tous les collants de sécurité manquants ou

endommagés.

Si l'appareil est mal posé ou mal contrôlé, il

risque de tomber en panne, de causer de

graves blessures ou des dommage

matériels. Lire attentivement les instructions

contenues dans la Notice d'utilisation et les respecter pour in-

staller et faire fonctionner l'équipement. Demander à un professionnel qualifié en piscines de procéder à tous les contrôles de pression.

1. Ne pas brancher cet appareil sur un réseau d'eau de ville

ou haute pression.

2. N'utiliser cet équipement qu'avec une piscine ou une cuve

à remous.

3. L'air emprisonné dans le système peut causer une explosion. S'ASSURER que tout l'air est purgé du système

avant de faire fonctionner ou de contrôler l'équipement.

Avant d'effectuer un contrôle de pression, procéder aux vérifications de sécurité suivantes :

• Vérifier tous les colliers, couvercles, accessoires et toutes

les vis du système.

• S'ASSURER que tout l'air est purgé du système.

• Resserrer le couvercle de la crépine des pompes

Aquatools au couple de 4,1 kg-cm (30 lb-pi).

• La pression de l'eau doit être inférieure à 172 kPa (25

lb/po

2

).

• La température de l'eau doit être inférieure à 35 °C (95 °F).

• Limiter le contrôle à 24 heures. Après avoir procédé au

contrôle, examiner visuellement le système pour s'assurer

qu'il est prêt à être utilisé. Déposer le couvercle de la

crépine et ne le resserrer qu'à la main.

NOTA : Ces paramètres ne s'appliquent qu'à de

l'équipement Aquatools. Pour un équipement d'une autre

marque que de marque Aquatools, consulter le fabricant.

Pression dangereuse! Risque

d'explosion du réservoir.

LORSQUE L'ON

UTILISE LE FILTRE

Ne pas le contrôler à l'air

comprimé et ne pas le faire

fonctionner à une pression

supérieure à la pression

nominale

Tension dangereuse.

Risques de chocs

électriques, de brûlures,

voire de mort.

AVANT D'INTERVENIR SUR LA

POMPE OU SUR LE MO

TEUR

Débrancher le moteur de la

pompe de l'arrivée de

courant.

Aspiration dangereuse.

Les cheveux ou des parties du

corps risquent d'être aspirés

ou arrachés, ce qui peut entraîner de graves blessures,

voire la mort.

AVANT D'INTERVENIR

SUR LE SYSTÈME

Ne pas boucher l'aspiration

de la pompe ni la vidange

principale de la piscine.

LIRE ET OBSERVER CES CONSIGNES DE SÉCURITÉ!

AVERTISSEMENT

Page 22

1-1/2" NPT

Return to Pool

(Union Connection)

1-1/2" NPT

Suction

Connection

1-1/2" NPT

Waste Outlet

(Union Connection)

23

2-13/16

A

B

7

11

1278 0994

Drain

(To Tank

Flange)

D

2-5/16

9-1/16

11-1/4

Ta nk

Dia.

C

E

1279 0994

4

TABLEAU I - DIMENSIONS EXTÉRIEURES EN POUCES (mm)

Modèle de filtres AB C DE

Filtres de 406 mm (15 pouces)

24 (610) 30-7/8 (784) 15-3/4 (400) 21-11/16 (551) 26-1/16 (662)

Filtres de 457 mm (18 pouces)

26-9/16 (675) 33-5/16 (846) 17-3/4 (451) 24-1/4 (616) 27-1/16 (692)

Filtres de 508 mm (21 pouces)

28-11/16 (729) 34-7/16 (875) 20-3/4 (527) 26-3/8 (670) 28-9/16 (725)

TABLEAU II - SPÉCIFICATIONS DU FILTRE ET RENSEIGNEMENTS SUR LE

FONCTIONNEMENT

MODÉLES DE 15" 18" 21"

FILTRE : (Sèrie JSAL15) (Sèrie JSAL180) (Sèrie JSAL210)

Surface utile de filtration 1.26 pi2(.117M2) 1.57 pi2(.223M2) 2.18 pi2(.203M2)

Débit maximum 25.2 GPM(95 L/m) 31.5 GPM(123 L/m) 43.6 GPM(165 L/m)

Pression de service maximum 50 PSI(345 kPa) 50 PSI(345 kPa) 50 PSI(345 kPa)

Température de service maximum 95° F(35°C) 95° F(35°C) 95° F(35°C)

Renouvellement en heures :

6 heures 9,070 Gal.(34 330 litres) 11,340 Gal.(42 922 litres) 15,700 Gal.(59 424 litres)

8 heures 12,100 Gal.(45 799 litres) 15,120 Gal.(57 229 litres) 20,930 Gal.(79 220 litres)

10 heures 15,120 Gal.(57 229 litres) 18,900 Gal.(71 536 litres) 26,160 Gal.(99 016 litres)

12 heures 18,144 Gal.(68 675 litres) 22,680 Gal.(85 844 litres) 31,390 Gal.(118 811 litres)

Qté de matériaux filtrants requis :

Pi

3

(cm3) 1(28 320cm3) 1.5(42 255cm3) 2(56 923cm3)

Poids en lb (kg) 100(45,4 kg) 150(68 kg) 200(90,7 kg)

NOTA : 1 pied cube (28 320 cm3) de sable pèse environ 45,4 kg (100 lb). NE PAS utiliser de sable de calibre plus fin que celui

recommandé.

SABLE RECOMMANDÉ :

N'utiliser que du sable de silice n° 20 de calibre 40 à 55 mm. Coefficient d'uniformité inférieur à 1,75.

NOTA : L'utilisation d'un autre sable réduira le rendement du filtre, risquera d'endommager la pompe et annulera la garantie.

Matériaux filtrants recommandés :

1. Wedron Silica/Best Sand Co., calibre du sable : Wedron - 45 à 55 mm; calibre utile : 0,46 mm; coefficient d'uniformité : 1,22.

2. U.S. Silica : Sable de filtration silurien, calibre du sable : 45 à 55 mm; calibre utile : 0,48 mm; coefficient d'uniformité : 1,18.

Figure 1 : Dimensions

C

Diamètr

e du

réservoir

D

(Vers la

bride du

réservoir)

Orifice de l'eau usée de

1-1/2 po NPT

(Raccord union)

Raccord

d'aspiration de

1-1/2 po NPT

Retour vers la

piscine de

1-1/2 po NPT

(Raccord union)

Page 23

5

RENSEIGNEMENTS

GÉNÉRAUX

• Si la piscine est neuve, la nettoyer le mieux possible avant

de la remplir et de faire fonctionner le filtre. Le filtre et la

pompe risquent d'être sérieusement endommagés si le

système contient trop de saletés ou de grosses particules

de corps étrangers.

NE JAMAIS contrôler ce filtre à l'air comprimé.

Ne pas faire fonctionner le filtre si la température

de l'eau est supérieure à 35 °C (95 °F).

NE JAMAIS faire fonctionner ce système de filtration par des pressions supérieures à 50 lb/po

2

(345

kPa)!

Ne brancher ce système que sur un circuit protégé

par un disjoncteur de circuit en cas de fuite à la

terre.

• Si la piscine est neuve, la nettoyer le mieux possible avant

de la remplir et de faire fonctionner le filtre. Le filtre et la

pompe risquent d'être sérieusement endommagés si le

système contient trop de saletés ou de grosses particules

de corps étrangers.

• Pour éviter l'irritation des yeux et de la peau, garder le pH

de l'eau de la piscine au niveau recommandé (entre 7,2 et

7,6).

• Ce système de filtration à sable à grand débit n'est conçu

que pour être utilisé avec des piscines hors-sol.

• N'utiliser que du sable de silice n° 20 d'un calibre de 0,45 à

0,55 mm. L'utilisation d'autres sables réduira le rendement

du filtre.

Pour minimiser le risque de secousses élec-

triques, poser la pompe à au moins 10 pieds

de la paroi intérieure de la piscine. Ne pas utiliser de cordon

prolongateur.

INSTALLATION

Pose de la cuve sur la pompe :

Utiliser les quatre vis de 5/16 de po, les quatre rondelles

plates et les quatre rondelles-freins pour monter la cuve sur

le corps de la pompe. Ne pas oublier de poser le joint entre la

cuve et le corps de la pompe. Serrer les vis au couple de 92

cm-kg (80 lb-po), mais ne pas les bloquer.

L'assise du filtre doit :

• assurer une protection contre le gel et les intempéries;

• offrir suffisamment d'espace et d'éclairage pour un accès

facile lors des entretiens périodiques. (Voir le Tableau 1 et

la Figure 1 à la page 4 pour les dégagements exigés.)

• reposer sur une surface raisonnablement de niveau et as-

surer un drainage adéquat;

• être aussi près que possible de la piscine pour réduire les

pertes par friction dans les conduites.

• être solide, de niveau, rigide et ne pas vibrer.

• être installée de façon que l'orifice d'aspiration de la cuve

de la pompe soit toujours sous le niveau de l'eau dans la

piscine, de façon que la pompe puisse s'amorcer.

• offrir une ventilation adéquate pour empêcher au moteur

de surchauffer.

Conduites :

• Utiliser du ruban Téflon ou du Plasto-Joint Stik1sur tous les

raccordements mâles des raccords et les tuyaux en plastique, sauf sur les raccords unions. NE PAS utiliser de pâte

pour raccords filetés sur les tuyaux en plastique, sinon les

tuyaux se fissureront. Ne pas utiliser de pâte d'étanchéité

pour raccords filetés ni de ruban sur les raccords unions les assembler à sec et ne les serrer qu'à la main.

• Ne pas endommager les surfaces d'étanchéité des raccords unions ni les joints toriques.

• Supporter chaque conduite de façon à empêcher toute

contrainte sur le filtre et sur la vanne sélectrice.

• Utiliser des tuyaux de 1-1/2 po ou de 2 po pour minimiser

autant que possible les pertes de pression. Si l'on utilise un

tuyau souple, utiliser un tuyau à paroi interne lisse.

• Les raccords diminuent le débit; pour une meilleure efficacité, utiliser le moins possible de raccords.

• Les tuyaux doivent être toujours bien serrés et ne pas fuir :

une fuite de la conduite d'aspiration de la pompe risque

d'emprisonner de l'air dans le réservoir de filtration ou de

désamorcer la pompe; on remarquera une fuite de la conduite de retour de la pompe par de l'humidité ou des jets

d'eau.

• Lorsque des raccords unions sont fournis, et pour obtenir

des raccordements qui ne fuient pas, les utiliser comme

suit :

1. Les surfaces d'étanchéité et les joints toriques doivent

être propres.

2. Les raccords ne doivent être serrés qu'à la main (pas

avec une clé).

3. Aucune pâte d'étanchéité pour raccords filetés ni ruban

Téflon ne doit être utilisés sur les raccords unions.

Robinets :

• De façon à pouvoir intervenir sur le système de filtration et

pour nettoyer la cuve de la pompe, poser des robinets à

boisseau sphérique ou des robinets-vannes :

A. Entre la cuve de la pompe et l'écumoire de la piscine,

et

B. la vanne sélectrice et la conduite de retour vers la

piscine.

• Un clapet antiretour posé entre le filtre et le chauffe-eau

empêchera l'eau de retourner dans le filtre et de causer la

déformation des éléments internes.

• Avant de procéder à l'assemblage, il faut être très prudent

et faire bien attention de ne pas endommager les surfaces

d'étanchéité des raccords unions ni les joints toriques.

Eau usée :

• S'assurer que toutes les dispositions prises pour l'élimination de l'eau usée se conforment aux codes fédéral, provinciaux ou municipaux. Pendant l'opération de lavage du

filtre à contre-courant, 379 litres (100 gallons) d'eau de la

piscine, voire plus, seront éliminés. Ne pas envoyer l'eau là

où elle risque de causer des inondations ou des dommages.

1

Lake Chemical Co., Chicago, IL

Page 24

Montage du filtre

B. Insert assem

into top o

filter tan

A. Insert first lateral int

twist clockwise 1/4 tur

to lock lateral into hu

Lateral is correctly in

when slots face down.

731 0294

C. Hold assembly up

near top of tank

add remainin

late

732 0294

D. After all

laterals

securely

sockets,

position

assembly

centering

boss in

bottom of

tank.

733 0294

S

A

N

D

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::