Market Forge 2800 Service Manual

MODULAR ELECTRIC CONVECTION OVEN

AREA CODE

617 387

-

4100

MODEL NUMBERS 2600, 2800

STYLE A & B

PARTS & SERVICE MANUAL

TABLE OF CONTENTS

Subject Code No. Page

OPERATING INSTRUCTIONS 5194 2

EXPLODED VIEW & PARTS LIST 5195 3

HEATING ELEMENTS ASSEMBLY & PARTS LIST 5196 4

SERVICING THE CONTROL PANEL 5197 5

SERVICING INNER OVEN COMPONENTS 5197 5

SERVICING CONVECTION FAN & THERMOSTAT 5185 6

CONTROL PANEL VIEW 5199 7

CONTROL PANEL COMPONENTS 81 BLOWER GUARD

STACKED ELECTRIC OVENS 5201 9

OVEN DOOR VIEW - STYLE A 5190 10

OVEN DOOR VIEW - STYLE B 5191 11

OVEN DOOR INSTRUCTIONS 5192 12

WIRING DIAGRAM (C-99-1694) 5202 13

WIRING DIAGRAM (C-99-3050) 5203 14

WIRING DIAGRAM (C-99-1693) 5204 15

WIRING DIAGRAM (B -99-3036) 5205 16

WIRING DIAGRAM (C-99-3036) 5206 17

5200 8

Printed in U.S.A.

Rev 12/79

5198

OPERATING INSTRUCTIONS

Do not attempt to operate ovens without first reading the following instructions thoroughly:

1. Be sure that power is available to the unit.

2. Be sure that both the blower quard and deflector are properly mounted.

3. Snap on "Power On" switch with doors open.

4. Arranqe shelf positions dependent upon item to be baked or roasted. Refer to cooking chart on right panel of

oven and to Recipe Cards for correct positioning.

5. Close doors. Blower should come on and rotate clockwise, otherwise unit is not operating correctly. If blower

does not start or starts and immediately stops, this may indicate an electrical overload. Reset circuit breaker

on control panel. If blower still does not operate, this is an indication of incorrect wiring or other electrical

problems. Have your electrician check the wiring if this is an initial operation, otherwise call your dealer from

whom this equipment was purchased.

6. Preheat to temperature and allow to cycle once to obtain even temperature throughout oven. Total time,

approximately 15 minutes.

7. Oven is ready to cook and may be loaded when indicator light goes off. The load should be adjacent to the

oven to facilitate rapid loading so that doors will be open as short a time as possible.

8. If using the convection oven for long term roasting of meats, fish or poultry, place about a quart of water in a

suitable container in the oven or under a trivet in the same pan as the meat.

9. Close doors and set timer for desired cooking time.

10. Interior lights may be turned on or off as desired. If lights fail to operate reset circuit breaker on control panel.

If lights still fail to operate this indicates faulty bulbs. If lights still fail to operate this indicates an internal

electrical fault and an electrician should be notified.

11. Bell will ring when cooking is completed. Oven is ready to unload.

12. If oven temperature is to be lowered, set thermostat to the desired temperature. Keep the blower operating

by leaving right door closed and left door open.

When indicator light comes ON, oven is at lower temperature. Close both doors. When indicat or light goes off

— oven is ready to use.

13. When oven is to be turned off, turn oven thermostat to off — turn power switch to off. Leave doors ajar.

NOTE: Fan should always operate in a clockwise rotation.

2

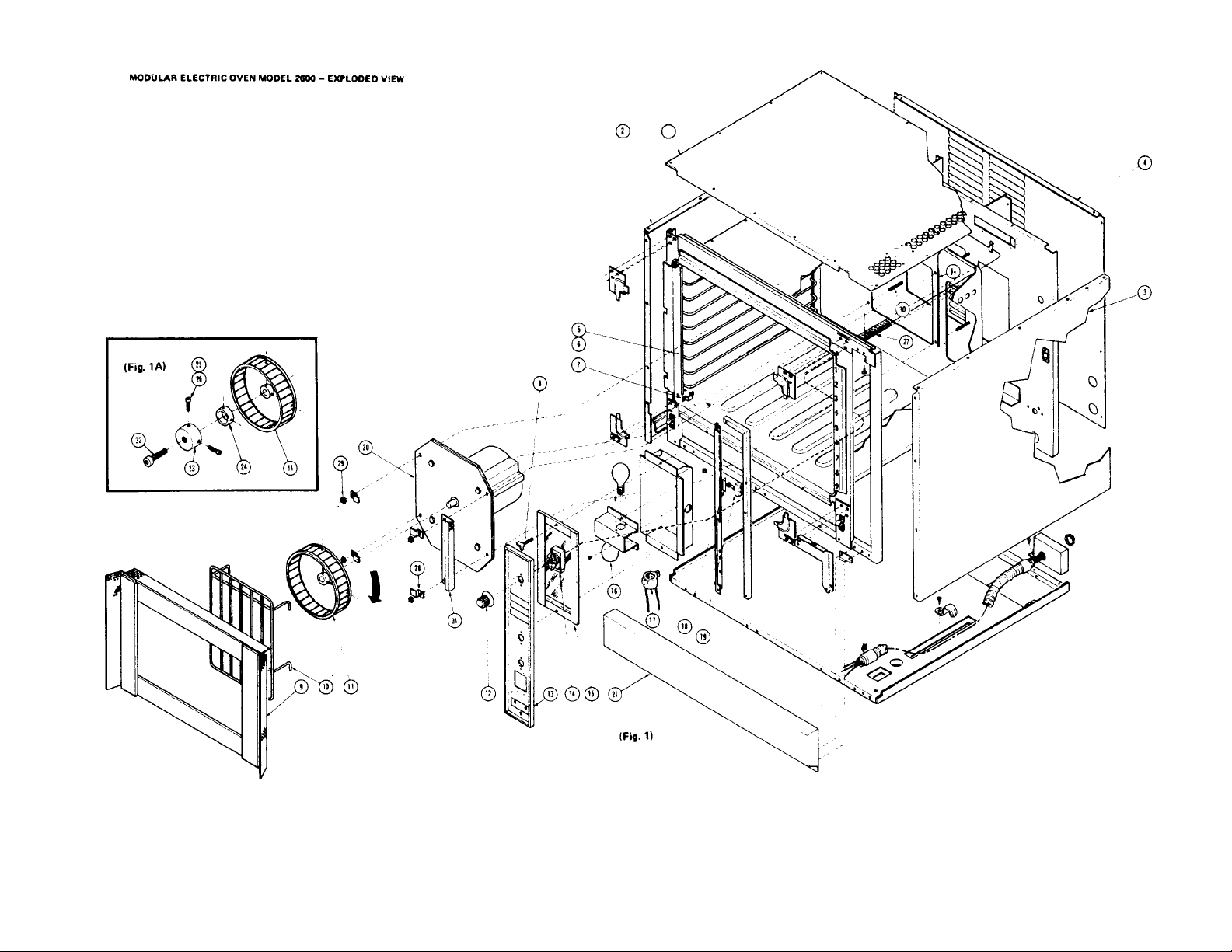

ELECTRIC OVENS

1 Top Panel

………………………………………

99-

1570

99-

1569

Socket Ass'y……………………………………

31 Thermostat Guard

……………………………

99-

3039

99-

3039

MASTER ILLUSTRATION - Parts List

Item No Description Standard Deep

2 L H Panel Ass'y……………………………… 99-1574 99 1578

3 R H Panel Ass'y……………………………… 99-1576 99-1580

4 Rear Panel …………………………………… 99-1572 99-1572

5 LH Rack Support …………………………… 10 1295 10-1296

6 RH Rack Support …………………………… 10-1295 10-1296

7 Clip ……………………………………………… 99-1925 99-1925

8 Wing Screw …………………………………… 10-1988 10-1988

9 Deflector Ass'y ……………………………… 99-0959 99-0959

10 Fan Guard ……………………………………… 10-5957 10-5957

11 Blower Wheel ………………………………… 10-5453 10-5453

12 Knob …………………………………………… 10-4472 10-4472

13 Control Panel Ass'y…………………………… 99-3049 99-3049

14 Thermostat …………………………………… 10-4714 10-4714

15 Glass Ass'y …………………………………… 99-3026 99-3026

16 Light Bulb ……………………………………… 10-5148 10-5148

17

18 Insulation ……………………………………… 99-3052 99-3052

19 Door Switch …………………………………… 10-6209 106209

20 Motor Ass'y 60Hz 115/230V ……………… 99-0665 99-0665

Motor Assy - 50 Hz 110/220V……………… 99-0675 99-0675

Motor Assy - 60 Hz 460 V…………………… 99-0676 99-0676

21 Bottom Panel Ass'y…………………………… 99-3035 99-3035

22 1/2"-13 Allen Soc Hd Cap Screw ………… 10-1984 10-1984

23 Wheel Puller …………………………………… 99-3333 99-3333

24 Collar (Use with Small Hub) ………………… 99-3332 99-3332

25 5/16"-18 Allen Soc Hd Cap Screw ………… 10-1985 10-1985

26 5/16"-24 Allen Soc Hd Cap Screw ………… 10-1986 10-1986

27 Capillary Tube Guard ………………………… 99-3040 99-3040

28 Clip ……………………………………………… 99-0951 99-0951

29 Hex Nut - 5/16-18 ……………………………… 10-2335 10-2335

30 5/16-18 Hex Head Cap Screw 2-1/4" Lg…… 10-2117 102117

10-5149 10-5149

3a 5195

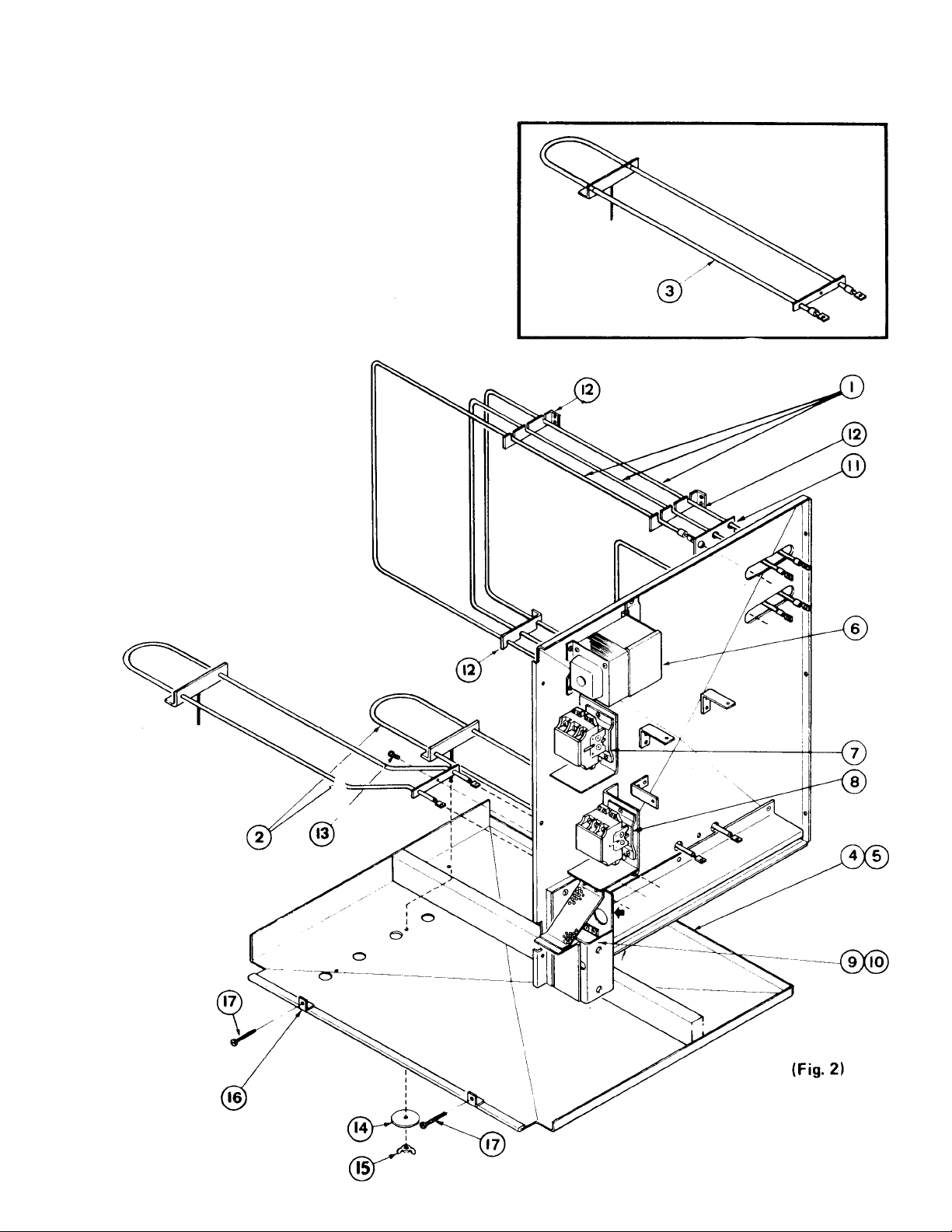

MODULAR ELECTRIC OVEN MODEL 2600 - HEATING ELEMENTS

4

ELECTRIC OVEN HEATING ELEMENTS - Parts List

INSIDE OVEN LINER STYLE B

Item No. Description Part No.

1 Heating Elements, Standard Oven, 3100 Watts, 208 V 10-6084

Heating Elements, Standard Oven, 3100 Watts, 230 V 10-6085

2 Heating Elements, Standard Oven, 1400 Watts, 208 V 10-6650

Heating Elements, Standard Oven, 3100 Watts, 440/479 V 10-6086

Heating Elements, Standard Oven, 3100 Watts, 480 V 10-6087

Heating Elements, Deep Oven, 4000 Watts, 208 V 10-6678

Heating Elements, Deep Oven, 4000 Watts, 230 V 10-6843

Heating Elements, Deep Oven, 4000 Watts, 440/479 V 10-6844

Heating Elements, Deep Oven, 4000 Watts, 480 V 10-6845

BELOW OVEN LINER STYLE B

Heating Elements, Standard Oven, 1400 Watts, 230 V 10-6651

Heating Elements, Standard Oven, 1400 Watts, 440/479 V 10-6652

Heating Elements, Standard Oven, 1400 Watts, 480 V 10-6653

Heating Elements, Deep Oven, 1800 Watts, 208 V 10-6677

Heating Elements, Deep Oven, 1800 Watts, 230 V 10-6684

Heating Elements, Deep Oven, 1800 Watts, 440/479 V 10-6685

Heating Elements, Deep Oven, 1800 Watts, 480 V 10-6686

BOTTOM ELEMENTS STYLE A

3 Heating Elements, St'd. and Deep Ovens, 1400 Watts, 208 V 10-6527

4 Retaining Shield Ass'y. - Standard 99-3055

5 Retaining Shield Ass'y. - Deep 99-3043

6 Transformer, 440-480 V 10-5396

7 Contactor, 208 V 10-5466

8 Contactor, 230 V, 440-480 V 10-5467

9 Terminal Block, 440-480 V. Units Only 10-5503

10 Circuit Breaker, 208/230 V. 70 Amps 10-6520

11 Insulation 99-1882

12 Bracket - 208/230 V 99-1653

13 # 8 Sheet Metal Screw 10-1735

14 Washer 99-1789

15 Wing Nut, #8-32 10-2382

16 Weld Bracket, # 8-32 10-2356

17 Pan Head Slotted Machine Screw # 8-32 x 1-5/8" Lg. 10-1954

Heating Elements, St'd. and Deep Ovens, 1400 Watts, 230 V 10-6528

Heating Elements, St'd. and Deep Ovens, 1400 Watts, 440/479 V

Heating Elements, St'd. and Deep Ovens, 1400 Watts, 480 V 10-6530

Bracket - 440/480 V 99-1820

4a 5196

10-6529

SERVICING THE CONTROL PANEL

5 5197

1. Remove 6 screws from control panel (Fig.

1) (13). All controls on the control panel are

serviceable from the front.

WARNING

Be sure that the entire power supply is

disconnected before removing front control

panel to avoid accidental shorting.

REPLACEMENT OF CONTACTORS,

TRANSFORMERS OR CIRCUIT BREAKERS

1. Remove (4) screws from top panel (Fig. 1)

(1) on right hand side of oven and 4 screws

from rear panel (4).

2. Remove (6) screws from control panel (13).

3. Remove right side panel (3) to gain access

to controls.

2. Unscrew two screws and remove brackets

(12) on bottom of heating elements (1) on right

and left hand side of oven liner.

3. Slide heating element (1) out. Remove two

screws from heating element terminal end

holding wire to element.

4. Replace with new element (1) and install in

reverse sequence of above.

REPLACING BOTTOM HEATING ELEMENTS

1. Drop bottom front panel of oven (Fig. 1) (21).

2. Remove wing nut (Fig. 2) (15) and washer

(14) from retaining panel inside of oven liner.

Remove two screws (17) from front of oven liner.

3. Lower retaining panel (4) (5). Remove screw

(13) from insulated bracket of heating elements

(2).

4. Replace defective part and reassemble.

Note: Transformer only present on 440-480 V

units and foreign.

REPLACING REAR HEATING ELEMENTS

1. Unscrew three screws and remove

insulated bracket (Fig. 2) (11) on top rear right

hand corner of inside of oven liner.

4. Slide heating element (2) out. Remove

two screws from heating element terminal end

holding wire to element.

5. Replace new element (2) and install in

reverse sequence of above.

CHANGING FAN

1. To remove fan (Fig. 1A) (11), obtain wheel

puller (Part No. 99-3334) from Market Forge.

2. Remove baffle (9) and fan guard (10). Place

wheel puller over hub of fan (11). Tighten

set screws on wheel puller into hub.

3. Gradually tighten hex bolt on front of wheel

puller until fan slides out from shaft.

REMOVING FAN MOTOR

6. Slip thermostat bulb (14) out from clips

and through hole in side of oven.

7. Slide entire assembly out through front of

oven through the control area.

TO CALIBRATE THERMOSTAT

1. Be sure thermocouple is installed in clips

provided in the oven.

2. Attach your thermocouple lead to the

bulb of the thermostat (14).

1. Remove baffle (Fig. 1) (9) and fan guard (10).

2. Unscrew four hex nuts (29) from studs

(30). Disconnect wiring connected to fan

motor (20). Refer to wiring diagram B-99-

1 790. Motor is pulled forward off studs (30).

3. When remounting motor (20) be sure it is

mounted in the same position and that

deflector assembly is installed as outlined

below.

INSTALLING DEFLECTOR ASSEMBLY

Deflector assembly (Fig. 1) (9) should be installed

so it is equidistant in all directions (north, south,

east, west). If adjustment is required, use adjustment clips (28) located on fan motor assembly.

TO REPLACE THERMOSTAT

1. Remove six screws from top panel (Fig. 1) (1)

on right hand side of oven and four screws

from rear panel (4).

2. Remove six screws from control panel (13).

3. Remove right side panel (3).

4. Remove guard (31) that covers thermostat

bulb (14) secured to fan motor housing

inside oven liner.

5. Remove five screws that secure perforated

capillary tube guard (27) to oven liner.

3. With the line switch in the "on" position, set

the thermostat control switch to 400° F and

carefully remove the switch control knob.

4. Allow the unit to heat until the pilot light

goes out.

5. Adjust the thermostat setting (using a fine

blade screw driver in the stem of the

thermostat).

6. With the oven temperature set at 400°F

the cycling should retain a peak of 420°F

and a low of 380°F after two stabilizing

cycles. A good indication of proper calibration is the time when the heating

elements or burners cut off and cut in and

should be:

Example: Cut off 400°F to 405°F

Cut in 380°F to 385°F

7. After calibration has been complete, apply

Duco cement to the adjusting screw of the

thermostat switch and replace the knob.

IMPORTANT: If it is found that the

thermostat is our of calibration by 50°F or

more, the thermostat should be replaced

not calibrated.

6 5185

Loading...

Loading...