Page 1

PURR-FECT HEIGHT SERIES ELECTRIC

CONVECTION OVEN

OWNER’S MANUAL

MODELS:

2600PHE

2692PHE

Printed in U.S.A. 35 Garvey Street l Everett l MA l 02149

Tel: (617) 387-4100 l Fax: (617) 387-4456 l Outside MA Fax: (800) 227-2659

E-Mail: CUSTSERV@mi.com l Website: www.mi.com

Form Number: S-6032 01/06

An Employee Owned Company

COVERING:

INSTALLATION

OPERATION

SERVICE & PARTS

Page 2

i

TABLE OF CONTENTS

Your Energy Efficient Convection Oven ...........................................................................................

How the Oven Operates ....................................................................................................................

Operating Controls and Indicators ....................................................................................................

Operating Instructions .......................................................................................................................

Cleaning/Preventive Maintenance .....................................................................................................

Trouble-Shooting Guide ....................................................................................................................

Illustrated Parts List ...........................................................................................................................

Appendix ..........................................................................................................................................

i

i

i

1

2

2-3

4-8

9-11

YOUR ENERGY EFFICIENT CONVECTION OVEN

HOW THE OVEN OPERATES

The Purr-fect Height Convection Oven is electrically

powered, high capacity ovens featuring high energy

efficiency. These ovens are designed to radically cut

power consumption, delivering the cooking power

of a 16 KW oven from only 11 KW’s of energy input. Improvement of energy use is made possible by

a carefully designed insulating system which keeps

heat inside the oven longer.

A convector fan distributes heat uniformly through-

out the oven interior, for fast even roasting and

baking.

Like all Market Forge products, our ovens are built

to the highest standards of workmanship, employing only the finest materials and components Of

course, Power Saver II ovens are fully approved by

UL, UL Sanitation, and other official testing authorities.

The Purr-fect Height Convection Oven operates by

use of two simple controls-a power switch for turning on the fan motor and control circuit, and a thermostat for setting the oven temperature. The oven

is otherwise automatic. A thermostat maintains oven

temperature by cycling heating elements on and

off, with temperature fluctuating no more than 20°F

from the setting. Uniform distribution of heat within

the oven is assured by continuous operation of a convector fan.

A 60-minute and Constant Heat timer serves as an

aid in using the oven, when the timer expires the

heating elements shut off. To prevent unnecessary

loss of heat when the doors are opened, a interlock

switch stops fan operation whenever the rightside door is opened. Should the operator wish to

cool the oven, opening just the left- side door will

quickly ventilate the oven interior.

Page 3

1

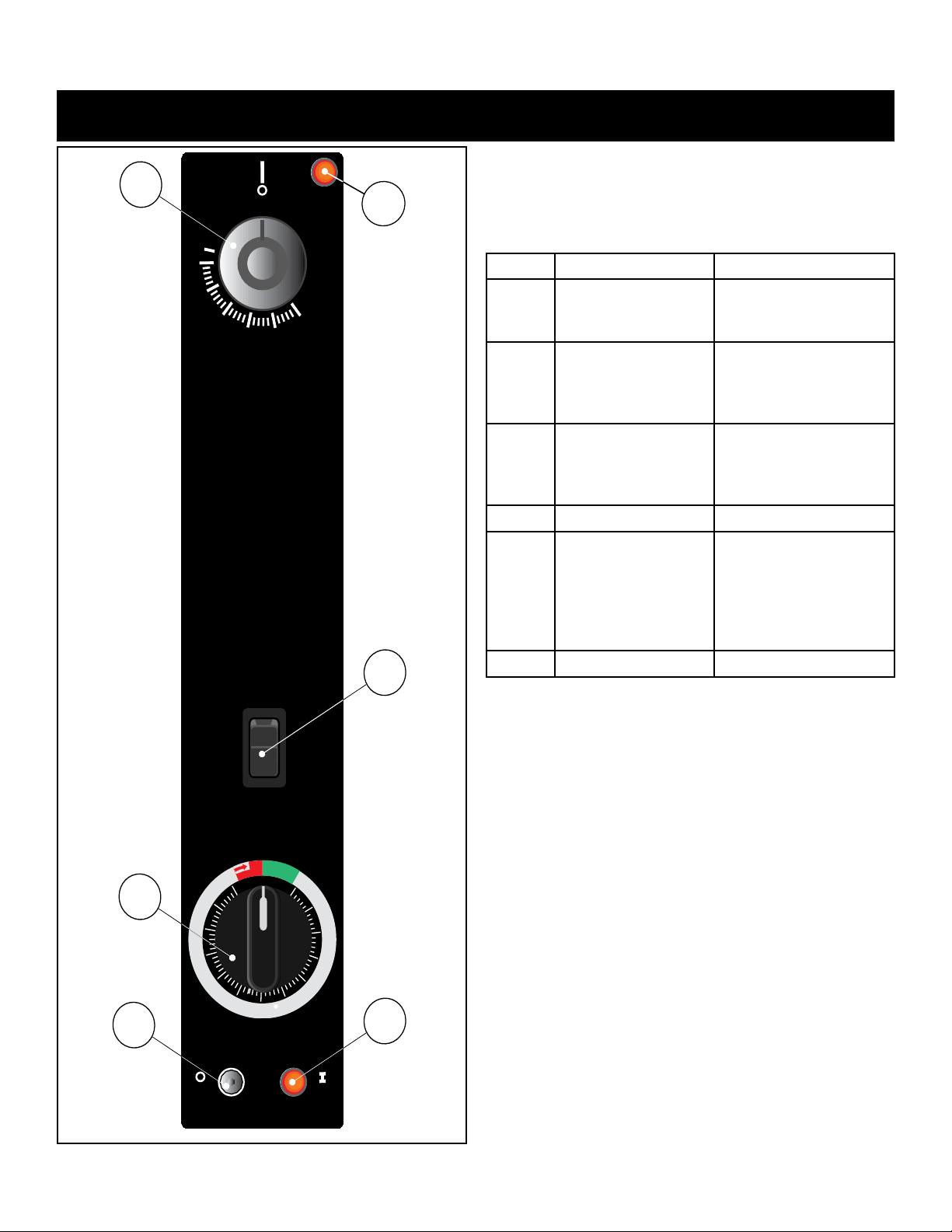

OPERATING CONTROLS & INDICATORS

The controls required to operate the oven are listed in the

following table. together with a short functional description

of each. The physical location of each control is shown in

FIG.1.

Check that power is available to the oven

Arrange shelf positions according to the item to be

cooked.

Close doors. Move fan switch to HIGH or LOW. Fan

should come on.

Set thermostat dial to desired cooking temperature. Element indicator light should come on

Allow oven to preheat for about 5-10 minutes. Preheating is complete when indicator light goes out and the

buzzer sounds. Do not waste energy by turning the oven

on too early.

Load oven. The load should be adjacent to the oven, so

the doors will be open as short a time as possible.

Close doors. Set timer for desired cooking time.

Buzzer will sound at end of preset interval. Oven is

ready to unload.

If oven temperature is to be lowered, set the thermostat

to the desired temperature to cool interior. Fan will continue to run with left door open and right door closed.

Where indicator light comes on, oven is at lower temperature. Close left door. When light goes off, oven is

ready for use.

For daily shutdown, place oven thermostat and power

switch in OFF position. For extended shut- down, leave

doors ajar as well.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

FIG. 1 Operating Controls & Indicators

ITEM DESCRIPTION FUCTION

1 Thermostat Control Regulates oven temper-

ature. controls heating

element operation.

2 Thermostat Light Indicates when the

thermostat is calling for

heat and the elements

are ON.

3 Timer/Constant Heat Electrical timer to aid

in time ccoking cycles.

Controls oven and constant heat mode.

4 Power Light Indicates power is ON.

5 Fan Switch Three position fan

switch. Controls fan

speed either HIGH/

LOW or in the middle

position the oven is

OFF.

6 Light

Momentary Switch

0

C

O

O

K

5

10

15

20

25

30

35

40

45

50

55

60

C

O

N

S

T

A

N

T

O

F

F

246˚C

475˚F

246

450

204

400

177

350

149

300

121

250

93˚C

200˚F

OFF

OFF

HIGH FAN

LOW FAN

POWER

ON

ON

LIGHT

6

4

5

3

1

2

Page 4

2

CLEANING/PREVENTIVE MAINTENANCE

TROUBLE-SHOOTING GUIDE

A good preventive maintenance program in the form of

daily cleaning procedures is outlined in the following

steps:

Remove oven shelves and wash in mild detergent

and water. Rinse and dry.

Remove left and right hand shelf supports by lifting up and out toward center of oven. Wash, rinse

and dry.

Remove fan baffle by lifting up and out. Wash,

1.

2.

3.

rinse and dry.

Wash interior sides, bottom, and top with mild

detergent and water. A stainless steel cleaner (not

polish) should be used for the interior. Rinse and

dry.

Replace fan baffle, shelf supports and shelves.

Wash both sides of doors, top & bottom trim using

a stainless steel cleaner. Rinse and dry.

4.

5.

6.

PROBLEM Probable Cause REMEDY

CONVECTOR FAN FAILS TO OPERATE.

a. Power to oven is off. Locates external circuit breaker for power and place in

ON position.

b. Power switch off. Place in ON position.

c. Right oven door open. Close Door.

d. Control circuit breaker off. Place in ON position.

e. Faulty circuit breaker, door interlock switch, fan

motor, or wiring.

Refer to wiring diagram or obtain outside service.

INDICATOR LIGHT FAILS TO LIGHT WITH FAN OPERATING, THERMOSTAT SET.

a. Indicator light burned out. Replace light. See service and parts manual for proce-

dure.

b. Electrical failure. Refer to wiring diagram or obtain outside service.

FAN OPERATION - NO HEAT.

a. Thermostat not set. Set thermostat.

b. Faulty contactor, wiring, electrical failure. Refer to wiring diagram or obtain outside service.

LIGHT INSIDE COOKING COMPARTMENT

a. Light fails to turn on. Replace bulb.

Page 5

3

FIG. 2 Wiring Diagram

TROUBLE-SHOOTING GUIDE

Page 6

4

RECOMMENDED SPARE PARTS LIST (P/N 98-3623)

PART NO. DESCRIPTION QTY.

10-7371 Power Switch 1

10-5052 Light, Fan Power 1

10-5052 Light, Heating Element 1

08-6308 Reed Switch 1

08-6472 Relay, 120V

1

08-6475 Relay, Socket

1

10-4714 Thermostat, 475oF

1

09-5259 Thermostat, Knob

1

08-6464 Timer

1

08-3826 Timer, Knob

1

10-5944 Contactor

1

09-7248 Motor, 2 Speed

1

08-6351 Hi-Limit, Thermostat

1

08-6468 Fuse, 5Amp

2

09-6475 Transformer, 500VA

1

10-7395 Buzzer, 120 Volt

1

08-7978 Fan, Cooling

1

98-1717 Element, Heating

1

08-6469 Fuse, Holder

1

ILLUSTRATED PARTS LIST

Page 7

5

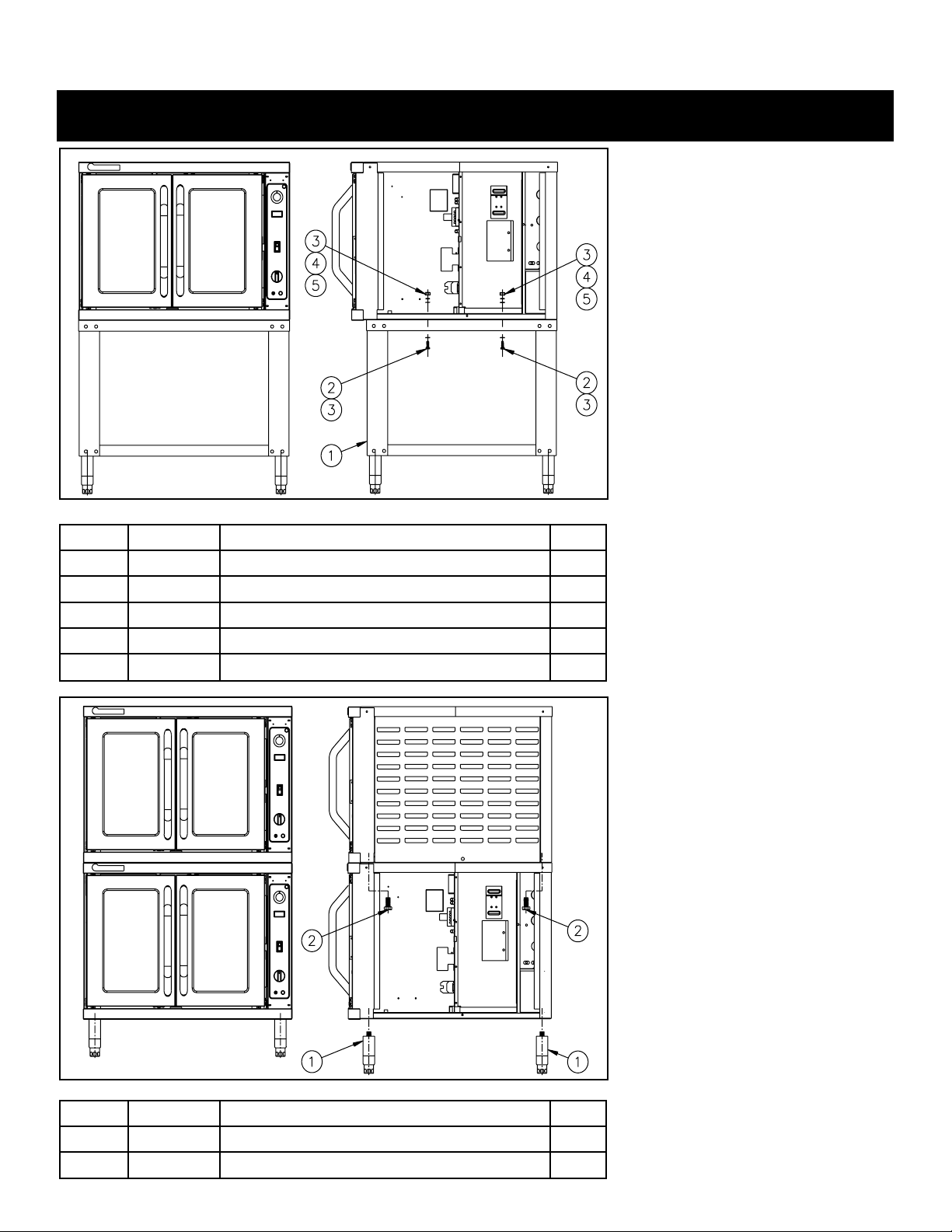

ILLUSTRATED PARTS LIST

ITEM NO. PART NO. DESCRIPTION

1 08-7978 Fan, Cooling

2 08-6472 Relay, 120 Volts

3 08-6469 Fuse, Holder

4 08-6552 Terminal Strip

5 09-6575 Plug, Hole

6 10-5944 Contactor

7 98-1720 Terminal Block

8 08-6475 Base, Relay

9 98-3562 Panel, Electric Controls

10 08-6468 Fuse, 5 Amps

11 10-1720 Screw, #6-32 Thread x 1/2” Long, Stainless Steel

12 08-7993 Screw, #6-32 Thread x 1 1/2” Long, Stainless Steel

13 10-1761 Screw, #8-32 Thread x 3/8” Long, Stainless Steel

FIG. 3 Electric Control Panel with Probe Option

Page 8

6

ILLUSTRATED PARTS LIST

FIG. 4 Glass Door Assembly

FIG. 5 Solid Door Assembly

Page 9

7

ILLUSTRATED PARTS LIST

FIG. 6 Control Panel

ITEM

NO.

PART

NO. FIG. 5 DESCRIPTION

1 98-1717 Control Panel, Embossed

2 10-7395 Buzzer

3 10-5052 Light, Power & Fan

4 09-5259 Knob, Thermostat

5 10-4717 Thermostat

7 08-6597 Switch, Mode

8 08-3826 Knob, Timer

9 08-6464 Timer

10 10-7371 Switch, Power

Page 10

8

ILLUSTRATED PARTS LIST

ITEM PART NO. DESCRIPTION QTY.

1 10-0631 6” Adjustable Leg 4

2 10-2564 Hex Hd. Cap Screw 3/4-10 x 1-1/2 Lg. 4

FIG. 8 2692PHE Mounting Assembly

NOTE:

Oven is shown with

side panel removed.

NOTE: Bottom oven

is shown with side panel

removed.

FIG. 7 2600PHE Mounting Assembly

ITEM PART NO. DESCRIPTION QTY.

1 99-4480 Open Stand with Shelf REF.

2 10-2002 Hex Hd. Cap Screw 3/8-16 x 1-1/4 Lg. 4

3 10-2401 Plain Washer 3/8” 8

4 10-2503 Lock Washer 3/8” 4

5 10-2302 Hex Nut 3/8-16

4

2600PHE Mounting Instructions:

1. Assemble stand (#1) per instructions

provided with stand.

2. Remove the side panels from oven.

3. Set the oven in place on top of the stand.

Align the holes in the bottom of the oven

with the sloted holes in the stand.

4. Fasten the oven to the stand with four

(#2) screws, eight (#3) washers, four

(#4) lock washers and four (#5) nuts, as

shown in figure 7.

5. Replace the side panels to the oven.

2692PHE Mounting Instructions:

1. Attach four (#1) feet to bottom of the

oven. Remove both side panels and

remove knock-outs in the top panels from

the bottom oven.

2. Set top oven in place on the bottom oven.

Align the holes in the top of the bottom

oven with the weld nhuts in the bottom of

the top oven.

3. Fasten the two ovens together with the

four (#2) screwa as shown.

4. Replace the side panels to bottom oven.

Page 11

9

APPENDIX

SERVICE CONNECTIONS - Electrically Operated

EC Electrical Connection - Connection for incoming

power supply wire on terminal block.

EP Power supply - 1 3/8 (44mm) E access holes for

power supply wires. Use wire suitable for at least

90°C. Nominal amp per line wire per oven: 11 kW

VOLTS 1pH 3pH

208V 53 31

240V 46 27

480V --- 15

D Interior Drain Connection - 3/4” E (

19mm) NPT to

open floor drain.

CW Cold Water Connection for optional spray hose 1/2”

NPT.

NOTE: Details of other electrical systems available upon request.

MODEL 2600PHE MODEL 2692PHE

Page 12

10

A. OVEN PERFORMANCE

A.1 Verification Check List

1. Verify that the doors are properly aligned and that there is no interference occuring at room temperature and 400oF.

2. Verify that all screws and bolts are tight.

3. Verify that the blower fan can operate at high and low speeds.

4. Clean oven with a rag and run oven for 2 hours to burn off oil, clean interior prior to use.

5. Verify that the racks do not bind at 400oF.

Verify the accuracy of the oven’s thermostat at 350oF by comparing the temperature control setting to the temperature

at the center of the over (one thermocouple). The maximum difference is to be no more than +/- 5oF.

APPENDIX

PART

NO.

SPARE PARTS LIST

DESCRIPTION QTY.

10-7371 Power Switch 1

10-5052 Light, Fan Power 1

10-5052 Light Heating Element 1

08-6308 Reed, Switch 1

08-6472 Relay, 120 Volt 1

10-4714 Thermostat, 475oF 1

09-5259 Thermostat, Knob 1

08-6464 Timer 1

08-3826 Timer, knob 1

10-5944 Contactor 1

09-7248 Motor, 2 Speed 1

08-6351 Hi-Limit, Thermostat 1

08-6468 Fuse, 5 Amp 2

09-6475 Transformer, 500 VA 1

10-7395 Buzzer, 120 Volt 1

08-7978 Fan, Cooling 1

98-4066 Element, Heating, 208 Volt (Nest of three) 1

98-4067 Element, Heating, 240 Volt (Nest of three) 1

98-4065 Element, Heating, 480 Volt (Nest of three) 1

08-8004 Loctite 268 1

08-8003 RTV 106 Silicone Sealant 1

08-7999 * Hardware Kit (Fasteners) 1

98-3623 Complete Spare Parts Kit 1

08-8032 Replacement Bulb 1

08-8033 Replacement Lens 1

08-8034 Replacement Lens Gasket 1

* NOTE: For individual fasteners refer below for specific part numbers.

Page 13

11

APPENDIX

PART

NO.

PARTS LIST OF FASTENERS

DESCRIPTION

LENGTH

(inches)

THREAD

SIZE QTY.

10-1864

SCREW CAP HEX HEAD

0.5 1/4”-20 77

10-1814

SCREW CAP HEX HEAD

0.75 1/4”-20 7

08-7840

NUT, SERRATED FLANGE

1/4”-20 73

08-7995

BOLT, HEX HEAD

3 5/16”-18 4

08-7956

NUT, SERRATED FLANGE

5/16”-18 8

10-2045

SCREW CAP HEX HEAD

0.5 #10-32 2

08-7996

TEK SCREW PHILLIPS PAN HEAD #2

0.5 #10-16 10

10-2146

SCREW, SLOTTED PAN HEAD

0.25 #6-32 26

10-1728

SCREW, PHILLIPS FLAT HEAD C-SUNK

#8-32 8

08-7994

SCREW, PHILLIPS FLAT HEAD C-SUNK

1 #10-32 8

10-1749

SCREW, MACHINE ROUND HEAD

0.25 #8-32 6

10-1761

SCREW, MACHINE TRUSS HEAD

#8-32 41

10-2571

NUT, KEPS

#8-32 20

08-8005

NUT, SERRATED FLANGE

#10-32 8

08-7992

SOCKET SET SCREW

1 #8-32 4

10-1790

SCREW, CAP HEX HEAD

1/4”-20 8

10-1939

BOLT, SHOULDER

0.5 1/4”-20 4

08-7991

SCREW, SLOTTED FLAT HEAD C-SUNK

0.5 #8-32 2

08-7990

SCRW, SLOTTED TRUSS HEAD

0.5 1/4”-20 3

08-3822

WASHER, STAINLESS STEEL TYPE B

1/4” 4

Loading...

Loading...