Page 1

SERVICE & PARTS MANUAL

Models:

Power Saver II Electric Convection Oven

2600HE

MARKET FORGE CANADA LTD.

Mississauga, Ontario, Canada

Form Number 17-0393 3/81

2692HE

2800HE

2892HE

Page 2

TABLE OF CONTENTS

Paragraph Page

SECTION 1 INTRODUCTION

1.1 Description 1-1

1.2 Oven Components 1-1

1.3 Basic Functioning 1-1

1.4 Service 1-1

SECTION 2 INSTALLATION

2.1 Receiving 2-1

2.2 Assembly 2-1

2.2. 1 Single Oven On Modular Base 2-1

2.2.2 Oven On 7"{178mm) Stand 2-1

2.2 3. Stacked Ovens On 7" (178mm)

Stand 2-1

2.2.4 Oven on 28"( 711 mm) Open

Stand 2-1

2.3 Electrical Connection 2-3

2.4 Installation Check-Out 2-3

2.4.1 Oven Check Out & Adjustments 2-3

2.4.2 Shut -Down Procedure 2-4

SECTION 3 OPERATION

3.1 Operating Controls and Indicators 3-1

3.2 Operating Procedures 3-1

3.2.1 Preheating 3-1

3.2.2 Cooking 3-1

SECTION 4 PRINCIPLES OF OPERATION

4.1 General 4-1

4.2 Heating Circuits 4-1

4.3 Electrical Circuits and Controls 4-1

4.3.1 Circuit Breaker 4-1

4.3.2 On-Off Switch 4-1

4.3.3 Door Interlock Switch 4-1

4.3.4 Thermostat Control 4-1

4.3.5 Indicator Light 4-1

SECTION 5 TROUBLE-SHOOTING

5.1 General 5-1

Paragraph Page

5.2 Trouble-Shooting Guide 5-1

5.3 Electrical Fault Isolation 5-2

5.4 Electrical Trouble-Shooting

Procedures 5-2

5.4.1 Incoming Power 5-2

5.4.2 Electrical Inspection 5-2

5.4.3 Thermostatic Control 5-2

5.4.3.1 Thermostat Contacts 5-2

5.4.3.2 Thermostat Capillary 5-2

5.4.4 Wiring 5-3

SECTION 6 MAINTENANCE

6.1 General 6-1

6.2 Preventive Maintenance 6-1

6.3 Adjustment Procedures 6-1

6.3.1 Oven Door Adjustments 6-1

6.3.1.1 Door Catch Adjustment 6-1

6.3.1.2 Door Switch Adjustment 6-1

6.3.1.3 Oven Door Horizont al Adjustment 6-2

6.3.1.4 Oven Door Vertical Adjustment 6-2

6.4.1 Control Panel and Contactor

Removal 6-2

6.4.2 Right Side Panel Removal 6-2

6.4.3 Fan Disassembly and Repair 6-2

6.4.3.1 Fan Blade Removal 6-2

6.4.3.2 Fan Motor Removal 6-3

6.4.4 Heating Element Removal 6-3

6.4.4.1 Rear Heating Element Removal 6-3

6.4.4.2 Bottom Heating Element Removal 6-3

6.4.5 Thermostat Removal 6-3

SECTION 7 ILLUSTRATED PARTS LIST

7.1 General 7-1

7.2 Ordering Information 7-1

7.3 Index Of Illustrated Parts List 7-1

iii 17-0393

Page 3

LIST OF ILLUSTRATIONS

17 0393

IV

Figure

SECTION 2 INSTALLATION

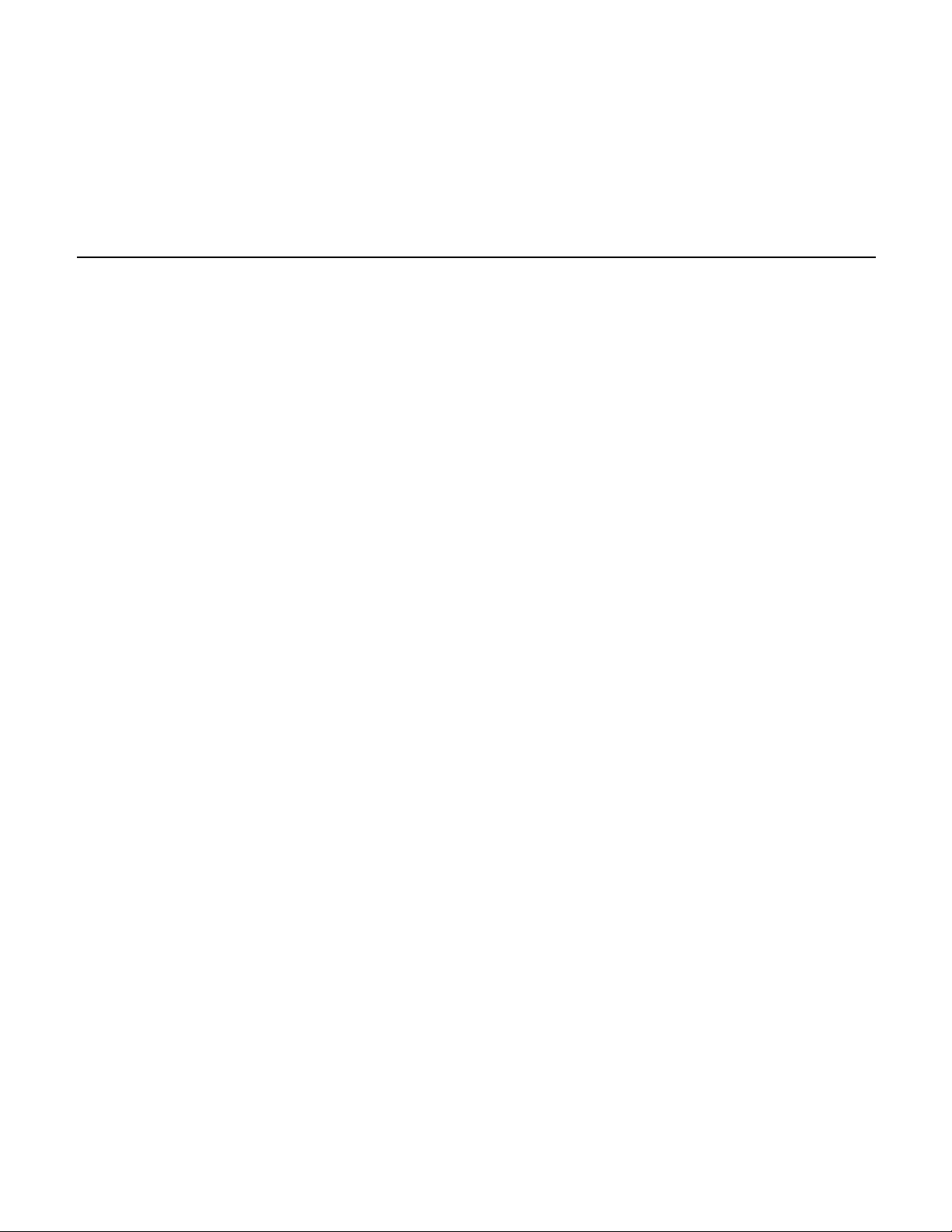

2-1 Counter Stand Assembly 2-2

2-2 Stacked Oven Assembly 2-2

2-3 Open Stand Assembly (Inverted) 2-2

2-4 Electrical Connection 2-3

SECTION 3 OPERATION

3-1 Operating Controls & Indicators 3-2

SECTION 5 TROUBLE SHOOTING

5-1 Wiring Diagram, 208/240 V 5-4

5-1 Wiring Diagram, 440/480 V 5-5

5-3 Wiring Diagram, 220/240/380/415V. 5-6

LIST OF TABLES

Table Page

SECTION 3 OPERATION

3-1 Operating Controls & Indicators 3-2

Figure Page

5-4 Schematic Diagram, 208/240/380 V. 5-7

5-5 Schematic Diagram, 440/460/480 V. 5-8

SECTION 6 MAINTENANCE

6-1 Blower Guard/Deflector Assembly 6-1

6-2 Wheel Puller Kit Components 6-2

SECTION 7 ILLUSTRATED PARTS LIST

7-1 Cabinet & Frame Assembly 7-2

7-2 Door Assembly 7-4

Heating Element Assembly 7-6 7-3

Control Panel Assembly 7-8

Table Page

SECTION 5 TROUBLE-SHOOTING

5-1 Trouble-Shooting Guide 5-1

5-2 Electrical Fault Isolation Guide 5-3

Page 4

SECTION 1 INTRODUCTION

1-1

17-0393

This service and parts manual contains general information, installation, operation, principles of operation, trouble-

shooting and maintenance information for the Market Forge Power Saver II High Efficiency Electric Convection

Oven. Also included are parts lists, in which each replaceable part is identified and shown in an accompanying

exploded view.

1.1 DESCRIPTION

The Market Forge Power Saver II High Effi ciency

Electric Convection Oven is an electrically powered

convection ove n designed to achieve high-volume

cooking with a minimum of power consumption. The

unit consists of a heavily insulated cooking

compartment fitted with a convector fan and heated by

electric elements. All oven controls are located on a

recessed panel on the right front of the oven as seen

from the front.

1.2 OVEN COMPONENTS

The major assemblies of the Power Saver II are

the stainless steel or baked enamel-finish cabinet

enclosure, solid doors, stainless steel cooking

compartment with nine-position shelf supports,

heating element and contactor assembly, and control

panel assembly. Controls and indicators include the

thermostat, main power switch, ELEMENTS on

indicator light, 60-minute and 5-hour timers, and twopole circuit breaker. The oven is available in a variety

of mounting configurations: 7" 178mm high counter

stand, on legs with shelf and optional storage rack, or

stacked on top of another Power Saver II with the

bottom unit on 6" 152mm stainless steel legs.

1.3 BASIC FUNCTIONING

The Power Saver II becomes operational when the

power switch is placed in the ON position, doors are

closed, and thermostat set. Contactors located in the

control section close the

circuit to heating elements located underneath and at

the rear of the cooking chamber. When the chamber

reaches the preset temperature, the thermostat

contacts open, causing the contactors to interrupt the

circuit to the heating elements. When the temperature

in the chamber drops enough to close the thermostat

contacts, the circuit closes again. Any number of such

cycles might occur during the cooking time, indicated

by the ELEMENT indicator light coming on and off.

1.4 SERVICE

Required service, both preventive and corrective, is

explained in section 6. Should repairs be required, a

network of authorized agencies is available to assist

with prompt service. A current directory of Authorized

Service Agencies may be obtained by contacting:

Product Service Department

Market Forge

35 Garvey Street

Everett, Massachusetts 02149

(617) 387-4100

Product Service Department Market Forge

Canada, Ltd. 1375 Aimco Blvd., Unit 5

Mississauga, Ontario, Canada L4W 1B5

(416)621-9252

The model and serial number must be referenced

when corresponding with Market Forge. The data

plate with serial number is located on the center of the

bottom front trim ledge.

Page 5

SECTION 2 INSTALLATION

2.1 RECEIVING

The unit is shipped strapped and bolted to a skid,

and covered by a corrugated container. Packing

materials must be removed prior to installation

Examine shipment for external or internal damage

and completeness. A complete shipment normally

includes the oven unit, two shelf supports and five

interior shelves, a carton containing stand

components (if a stand has been specified), and a

packet of documents pertaining to the unit.

GENERAL CAUTION: Tilt oven onto back or left

side (seen from front) to access bottom when

necessary DO NOT AT ANY TIME LAY THE OVEN

DOWN ON ITS TOP , RIGHT SIDE, OR FRONT TO

DO SO MAY DAMAGE THE EQUIP MENT AND

INVALIDATE THE WARRANTY.

2.2 ASSEMBLY

Set-up assembly procedures for the various oven

configurations are described in the following

paragraphs. Assembly requires that the stand be

completely assembled first, then set in place and the

oven mounted upon it before service connections

are completed.

2.2.3 Stacked Ovens on 7" (178mm) Stand

1. Mount bottom oven on stand (Figure 2-2) using

hex head screws and washers provided.

NOTE

Stand is 32" 813mm front to back. When used

with deep oven, overhang may be either front or

back, as desired. (Recommended overhang is in

back)

2. Remove upper trim strip screws on front of lower

oven. This is necessary to permit door

adjustment, if required, at a later date.

3. Stack top oven on bottom oven.

NOTE

If stacked ovens are adjacent to moisture

producing equipment (such as kettles or steam

cookers) it is necessary to prevent

condensation from entering the control section

of the bottom oven. The seam between the two

ovens, and between the ovens and the moisture

producing equipment, must be sealed with

silicone synthetic rubber or equal high grade

sealant.

4. Proceed to subsection 2.3.

2.2.1 Single Oven on Modular Base

1. Screw adjustable feet into cabinet base.

2. Mount oven to base using four 3/ 8 - 1 6 x 3/4 Ig.

hex head cap screws and four 3/ 8 plain

washers provided.

3. Proceed to subsection 23.

2.2.2. Oven on 7" (178mm) Stand

1. Screw legs ( Figure 2-1, #4) into top frame assembly

(1).

2. Place into position front and rear channel assembly

(2) and side angles (3). These items are loose parts

and are secured with mounting of oven to stand.

3. Mount oven to stand using four % - 1 6 x % Ig. hex

head cap screws and four % plain washers

provided.

4. If oven is to be stacked, proceed to paragraph 2.2.4.

2.2.4 Oven on 28" (711mm) Open Stand

1. Plac e top frame (Figure 2-3, #2) upside down on a

clean, smooth surface.

2. Place front and rear angle assemblies (8)

(Stainless stands only) and legs (1) into position.

3. Align holes in legs, frame and angles. Secure

using carriage bolts, lockwashers and hex nuts

provided.

4. Align holes in shelf (3) with leg holes and secure

using hardware (5,6,7).

5. Screw adjustable feet (4) into stand legs.

6. Install four clips for oven rack supports inside top

frame using hardware (5,6,7) (included with rack

support opt ion).

7. Place stand in upright position. Install rack.

2-1

17 0393

Page 6

2-2 POWER SAVER II ELECTRIC CONVECTION OVEN

Figure

2-1

Counter Stand Assembly

. 17-0393

Figure 2-2 Stacked Oven Assembly .

Figure 2-3 Open Stand Assembly (Inverted)

Page 7

INSTALLATION 23

supports (if supplied), inserting ends through

holes in clips and shelf.

8. Mount oven to stand using four 3/8 - 1 6 x 3/4 Ig.

hex head cap screws and four 3/8 plain washers

provided.

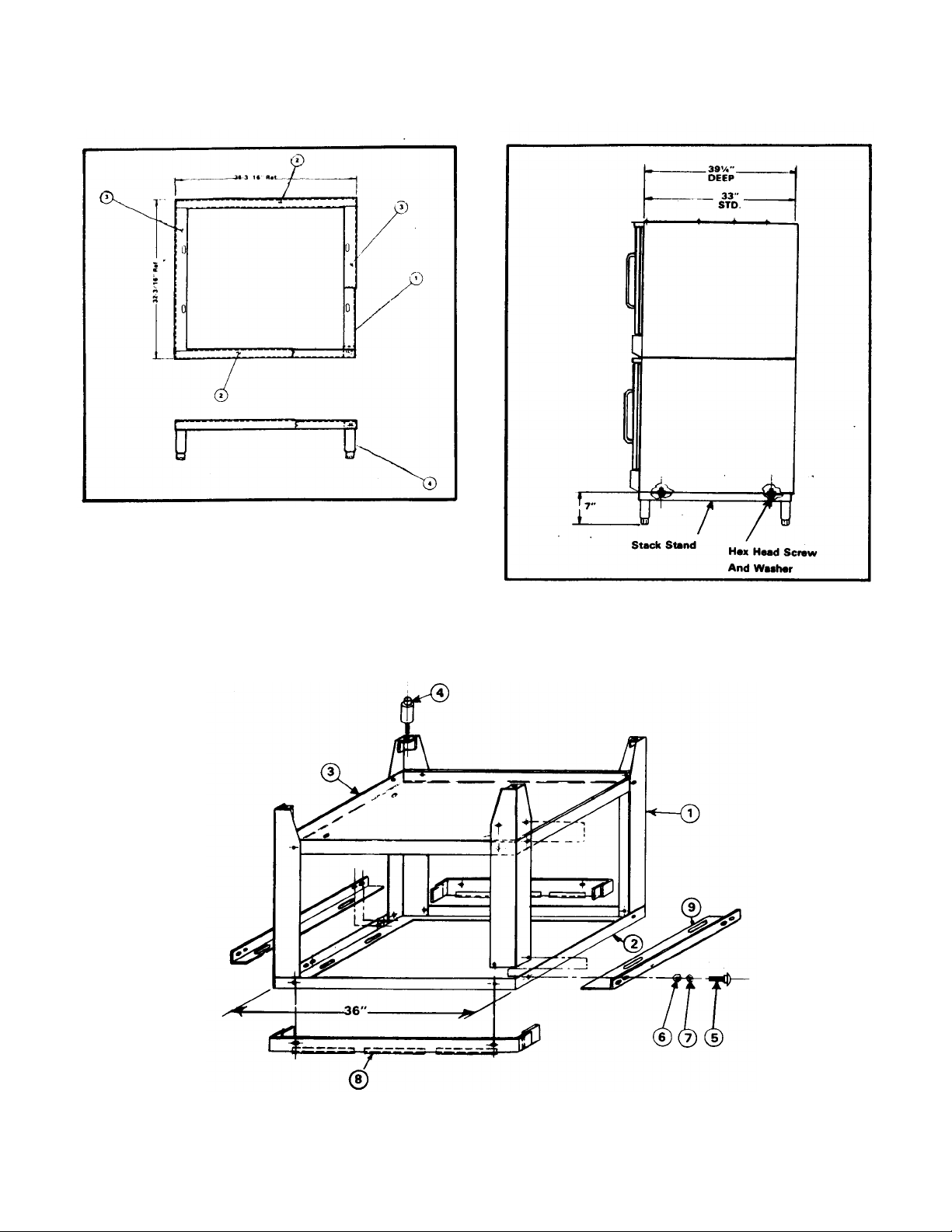

2.3 ELECTRICAL CONNECTION

Where applicable, all wiring shall be done in

accordance with the Canadian Electrical Code ANSI

C1 - 1975. Figures 5-1, 5-2 and 5-3 show the

various internal wiring configurations for the different

models and voltages.

1. Pull bottom trim panel forward to release

from spring catches and lower to full open

position as shown. See Figure 2-4.

2. Remove screws and terminal block cover

(3,2).

3. Bring power supply line in through 1 3/4"

44mm access hole in rear panel and feed

through conduit.

NOTE

If desired, right side panel(s) may be removed

from oven(s) to facilitate connec tion.

5. If required, ground unit to ground lug located at

lower right (seen from front) of terminal block.

Consult appropriate electrical codes.

2.4 INSTALLATION CHECK-OUT

After the oven is completely assembled and

properly located with electrical supply connected, the

unit should be given a thorough check-out before

being put into operation. Check-out procedures for

the oven are given in subsection 2.4.1. If the unit fails

to operate as described, consult the trouble-shooting

guide in Section 5 for corrective action.

Before making this check-out, the operator must

be thoroughly familiar with the operating procedures

in Section 3, and with the function of each control

described in Table 3-1. Reference Figure 3-1 for

identification of controls.

2.4.1 Oven Check-Out & Adjustments

Begin check-out procedure with power switch and

thermostat dial in OFF positions. A final check of the

controls and connections should be made as follows:

1. Make sure that the fan guard and deflector

are properly installed. See Figure 6-1.

4. Connect line to terminal block. This is a 1/2" 1

3mm conduit connection. Use wire suitable for at

least 90°C.

17-0393

Figure 2-4 Electrical Connection.

Page 8

24

2. Seat wire shelf supports in mounting locations

inside oven, and slide shelves into position with

raised 'stop' edge at rear.

NOTE

Make sure wire shelf supports are in, not on,

brackets

3. With a level on the oven shelves, make sure the

oven is level both front and back, left and right To

adjust, turn feet in stand legs.

4. Make sure power supply is available to the oven

5. Set thermostat dial at 350°F.

6. Place power switch in the ON position with doors

open

7. Close doors. Indicator light should come on;

fan should come on and rotate clockwise

POWER SAVER II ELECTRIC CONVECTION OVEN

(seen from front). If not, see Table 5-1.

8. Indicator light will remain on while oven is heating,

and go out when preset temperature is reached.

During the heat -up period, some slight smoke or

fumes may be produced by oil or grease on metal

surfaces. This should cease after five minutes.

9. After this check is completed, turn thermostat dial

and power switch to the OFF position.

2.4.2 Shut-Down Procedure

1. For daily shut -down, place thermostat dial and

power switch in OFF position.

2. For extended shut -down, place thermostat dial and

power switch in OFF position. Leave doors ajar.

170393

Page 9

SECTION 3 OPERATION

3.1 OPERATING CONTROLS AND

INDICATORS

All the controls required to operate the oven are

listed in Table 3-1, with a short functional description

of each. Figure 3-1 shows the physical location of

each control and indicator.

3.2 OPERATING PROCEDURES

Before attempting to use the oven for cook ing, be

sure that proper electrical connections have been

made, and fan guard and deflector are properly

mounted. (See Figure 6-1).

3.2.1 Preheating

1. Arrange shelf positions according to the item to be

cooked. Refer to Test Kitchen Bulletin #41 for

correct positioning.

2. Place ON-OFF switch in the ON position and

close doors. Fan will begin rotating. If not, reset

circuit breaker.

3. Set thermostat dial to desired cooking temperature. Element indicator light should come on.

4. Allow oven to preheat for about 15 minutes.

Preheating is complete when indicator light

goes out. Do not waste energy by turning the

oven on too early,

3.2.2 Cooking

The oven is ready for cooking use when the

element indicator light goes off. The load should be

adjacent to the oven so that the doors will be open for

as short a time as possible.

1. Load oven.

2. Close doors and set timer for desired cooking time.

Buzzer will sound at end of preset interval.

3. Unload oven and proceed as follows:

a) If oven is to be turned off, place thermostat dial

and ON-OFF switch in the OFF position.

b) If oven temperature is to be lowered, reset the

thermostat to the desired temperature and close

the right door. Fan will continue to operate with

left door open. When light comes on, oven is at

lower temperature. Right door is then closed until

light comes on to show that temperature is

stabilized.

4. Place thermostat dial and ON-OFF switch in OFF

position for daily shut -down. For extended shutdown, place dial and switch in OFF position and

leave doors ajar.

3-1 17-0393

Page 10

POWER SAVER II ELECTRIC CONVECTION OVEN

1

REF.

3-2 POWER SAVER

II

TABLE 3-

OPERATING CONTROLS AND INDICATORS

FIG.

3-1

DESCRIPTION FUNCTION

Regulates oven temper-

1 Thermostat Control

ature. Controls heating

element operation.

Electric timer to aid

2 60-Minute Timer

operator in timing cook ing

cycle. Does not control

oven operation.

3 5-Hour Timer Same as 60-Minute Timer.

Controls electrical power to

4 ON-OFF Switch

thermostat and fan motor.

Must be in ON position for

oven to operate.

Indicates when lit that

5 Indicator Light

heating elements are

operating. Cycles on and

off with thermostat control.

Protects fan motor and

6 Circuit Breaker

control circuits. Must be in

ON position for oven to

operate.

Figure 3-1 Operating Controls & Indicators

17-0393

Page 11

SECTION 4 PRINCIPLES OF OPERATION

4.1 GENERAL

The Power Saver II electric convection oven uses a

carefully designed insulation system, which achieves

optimal cooking heat from power consumed. A

convector fan distributes heated air uniformly

throughout the oven interior. Heat is supplied by

electric elements, controlled by a thermostat mounted

on the control panel.

4.2 HEATING CIRCUITS

With electrical power available, power switch on,

doors closed and thermostat set, a circuit is closed to

a contactor mounted behind the oven controls. This

contactor in turn closes, supplying power to the oven

heating elements, located beneath and at the rear of

the cooking chamber.

4.3 ELECTRICAL CIRCUITS AND CONTROLS

Input power is connected at the terminal block

mounted at the right front of the oven, behind the

hinged lower trim. The control circuit is shown in the

schematic drawings. Figures 5-4 & 5-5. They show the

relationship of each control and the sequence of

operation. A brief description of major electrical circuit

components is included in the following paragraphs.

4.3.1 Circuit Breaker

A 15 Amp circuit breaker located at the bottom of

the control panel provides overload protection for the

208/240 volt branch circuit to controls. Input

connection is made from L1 and L3 for 3-phase

connection, L1 and L2 for single-phase, and N and L3

for four-wire, 3-phase. It feeds power to the poles of

the power switch.

4-1 17 0393

4.3.2. ON-OFF Switch

Control of power to the oven control circuits is

provided by the ON-OFF Switch. It is a double-pole,

double-throw toggle switch connected between the

circuit breaker and the door switch.

4.3.3 Door Interlock Switch

The door interlock switch is a single pole, two

position microswitch with normally open contacts. The

switch lever is operated by an actuat ing bar built into

the door jamb of the right side door. When the door is

open, the bar remains retracted with the switch

contacts in the normally open position. When the door

is closed, the door pushes the actuating bar against

the switch lever to close the contacts. Connected into

the circuit for the fan and thermostat, the door switch

interrupts fan operation and deactivates the heating

circuits when the door is opened.

4.3.4 The rmostat Control

The thermostat is a bulb and capillary type system,

manually adjustable from 200-475°F 94-246°C. The

oven is put into an automatic heating cycle with the

setting of the thermostat to any of its calibrated

temperature settings. Expansion and contraction of

gas within the capillary/bellows system in response to

temperature change opens and closes the thermostat

contacts, energizing and deenergizing the heat ing

element circuit.

4.3.5 Indicator Light

The Indicator Light is wired to operate only when

the circuit is completed through the thermostat control

to the coil of the heater contactor. It is on only when

the heating elements are under power.

Page 12

SECTION 5 TROUBLE-SHOOTING

a) Indicator light burned out.

5.1 GENERAL

The information in this section is intended to assist

both the operator and service personnel in locating

the general source of problems which may occur with

the Power Saver II. Before following any of the

procedures given in this section, the operator should

be thoroughly familiar with the operating instructions

and the function

TABLE 5-1 TROUBLE -SHOOTING

of all controls described in Section 3. If the problem

cannot be readily corrected, the operator should

contact the nearest authorized Market Forge service

agency for assistance.

5.2 TROUBLE-SHOOTING GUIDE

A general trouble-shooting guide for use by service

personnel is given in Table 5-1.

GUIDE

PROBLEM

Probable Cause

1. CONVECTOR FAN FAILS TO OPERATE.

a) Power to oven is off.

b) Control circuit breaker open.

c) ON-OFF switch off.

d) Right oven door open.

e) Faulty circuit breaker, ON-OFF switch,

door switch, fan motor, wiring.

2. OVEN WILL NOT HEAT WITH THERMOSTAT AT MAXIMUM SETTING, (FAN OPERATING).

a) Faulty thermostat or wiring.

b) Thermostat contacts or coil faulty.

3. INDICATOR LIGHT FAILS TO LIGHT WITH THERMOSTAT SET, FAN OPERATING, OVEN HOT.

b) Faulty wiring.

4. ERRATIC OVEN TEMPERATURE.

a) Faulty thermostat operation.

Remedy

Locate external circuit breaker for power and place in ON

position. Reset to ON position. Place in ON position. Close

door. Test each component and connecting wiring.

Replace as required.

Test thermostat and connecting wiring. Replace as

required. Replace Thermostat.

Replace light. Check wiring and repair as needed.

Recalibrate or replace as required. See subsections 6.3.2

and 6.4.5.

5. UNEVEN HEATING.

a) One or more heating elements

inoperative.

Check wiring to elements; check for burned-out elements.

Replace as required.

5-1 17-0393

Page 13

52 POWER SAVER II ELECTRIC CONVECTION OVFN

5.3 ELECTRICAL FAULT ISOLATION

Correction of an electrical fault first requires

isolation of the fault to a single circuit or component

In most cases, the nature of the failure and its effect

upon the operation of the oven will he sufficient to

isolate it to one or more circuit elements Table 52 is

provided as a guide for isolating electrical faults

5.4 ELECTRICAL TROUBLE SHOOTING

PROCEDURES

Before performing the trouble-shooting procedures in this section, the servicer must be familiar

with the function of all controls as described in

Section 3 and the Principles of Operation described

in Section 4.

Electrical trouble-shooting procedures which

follow require access to components and terminals

of the operating controls. Electrical controls are

reached by removing the control panel as described

in paragraph 6.4.1. Wiring and terminal locations are

shown in figures 5-1, 52, and 5-3 Figures 54 and 5-5

show the circuits in schematic form.

5.4.1 Incoming Power

Before trouble-shooting any of the electrical

parts or assemblies, make sure power is being

supplied to the terminal block (figure 7-3, 8A).

With power connected to the oven an a-c voltmeter

is used to measure 208 or 240 volts (depending on

the oven model) across terminals. Make sure the

unit is properly grounded to the ground lug beside

the terminal block. If the proper voltage (as noted on

the unit rating plate) is pres ent, the fault lies in the

electrical circuits of the oven

5.4.2 Electrical Inspection

The first step in any electrical trouble-shooting

procedure is a thorough inspection of all wiring

connections. To access the electrical components,

remove panel as des cribed in subsection 6 4.1

Before removing the control panel or checking

connections or wiring, make sure incoming

power is shut off. When power is supplied, all

exposed terminals carry at least 208 volts.

Check all connections by hand to ensure that all

connection points are tightly secured. Use a

screwdriver to tighten if necessary Inspect all quickdisconnect terminals for evidence of corrosion.

Terminals in this condition should be replaced.

5.4.3 Thermostatic Control

5.4.3.1 Thermostat Contacts

Defective contacts will result in failure of the oven

to operate properly. If the oven fails to heat when the

thermostat knob is set to the desired temperature, the

fault may be the thermostat switch contacts or

thermostat wiring. When this occurs, remove the

control panel (subsection 6.4.1) and proceed as

follows:

1. Turn off power to the oven at circuit breaker

2. Disconnect all wires from thermostat terminals.

(See Figures 5-1, 5-2, and 5-3).

3. Rotate the thermostat knob to the maximum

setting. With the oven cool, a zero ohm reading

should be obtained on the ohmmeter. If zero

reading cannot be obtained, contacts are defective

and the thermostat must be replaced.

4. Remove ohmmeter and replace all leads on

terminals as shown on appropriate wiring diagram.

5.4.3.2 Thermostat Capillary

A defective or punctured capillary/bellows system

may cause continuous operation of the elements. If

continuous operation occurs and recalibration of the

thermostat as explained in subsection 6.3.2 fails to

correct the problem, the entire thermostat control

must be replaced.

WARNING

170393

Page 14

TROUBLE SHOOTING 53

a. Incoming power

c. Thermostat control

OFF switch

f. Contactor

b. Contactor coil

OFF switch

c. Door switch

a. Indicator light

TABLE 5-2 ELECTRICAL FAULT ISOLATION

FAILURE FAULT LOCATION

1 Oven will not operate when thermostat is set.

b. Door switch

d. ONe. Circuit breaker

g. Wiring

2 Intermittent operation of heaters. a. Thermostat control

c. Wiring

3. Convector fan fails to operate. a. Circuit breaker

b. ON-

d. Fan motor

e. Wiring

4. Indicator light off, (heater under power).

b. Wiring

5 Uneven heating. a. Heating elements

b. Wiring

5.4.4 Wiring

All the electrical components of the Power Saver II

(ON-OFF switch, door switch, thermostat control,

contactors, circuit breaker, fan motor, and indicator

light) are connected to each other by wiring shown in

figures 5-1, 5-2, or 5-3. If all the electrical components

are operating correctly and the incoming power has

been checked, but the unit fails to operate, the fault

lies in the wiring.

Using an ohmmeter, wiring continuity between the

connections, shown on the wiring diagrams, is readily

verified. This is best done in stages, removing only

those wires required for each continuity check. As

each lead is replaced, it should be checked for

evidence of corrosion and cleaned if necessary. All

leads must be tightly attached to provide a good

electrical connection.

17-0393

Page 15

FIG. 5-1 WIRING DIAGRAM-208/240V 60HZ 1 OR 3 PHASE

Page 16

55

Troubleshooting 5-5

Figure 5-2. Wiring Diagram — 440/480 Volt, 60 Hz, 3 Phase

Page 17

5-6

Power Saver II Electric Convection Oven

Figure 5-3. Wiring Diagram — 220/240/380/415 Volt, 50/60 Hz.. 3 Phase.

Page 18

TROUBLE SHOOTING

5-7

Figure 5-4 Schematic Diagram — 208/240/380/415 Volt, 50/60 Hz.. 1 or 3 Phase

Page 19

POWER SAVER II ELECTRIC CONVECTION OVEN

5-8

Figure 5-5. Schematic Diagram — 440/460/480 Volt, 60 Hz., 3 Phase.

17-0393

Page 20

SECTION 6 MAINTENANCE

6-1

17

-

0393

6.1 GENERAL

This section contains both preventive and

corrective maintenance information. Preventive

maintenance may be performed by maintenance

personnel at the establishment where the oven is

installed. It is recommended that us er personnel

never attempt to make repairs without the assistance

of an authorized service agency. Assistance in

service methods or a current directory of authorized

Service Agencies may be obtained from Market

Forge. (See subsection 1.3).

6.2 PREVENTIVE MAINTENANCE

A good preventive maintenance program in the

form of daily cleaning procedures is outlined in the

following steps. Use mild detergent and water for

washing unless otherwise directed.

1. Remove oven shelves. Wash, rinse and dry.

2. Remove left and right hand shelf supports by lifting

up and out toward center of oven. Wash, rinse and

dry.

3. Remove deflector and fan guard (Figure 6-1) by

lifting up and out. Wash, rinse and dry.

4. Clean interior sides, bottom and top using stainless

steel cleaner (not polish). Rinse as required and

dry.

5. Replace deflector, fan guard, shelf supports and

shelves.

6. Clean both sides of doors, using a stainless steel

cleaner. Rinse as required and dry.

6.3 ADJUSTMENT PROCEDURES 6.3.1

Oven Door Adjustments

Access to adjustable parts is obtained by first

removing upper oven trim (Figure 7-2 #17), held in

place by screws (1 and 2), and lower trim (34), which

can be pulled forward without removing hardware.

Figure 6-1 Blower Guard/Deflector Assembly.

6.3.1.1 Door Catch Adjustment

1. Loosen door catch assembly mounting screws

(Figure 7-2, 4) at top and bottom of door frame.

2. Move door catch assembly (7) in or out as required

to hold door firmly against oven front. Do not leave

any gaps or space between roller on door catch

assembly and dimple on door trim.

3. Tighten the screws (4) and replace trim.

6.3.1.2 Door Switch Adjustment

If convector fan fails to turn on when the right -side

oven door is closed and power is on (circuit breaker

and ON-OFF switch in ON positions) the door switch

may require adjustment. With upper trim removed

switch (Figure 7-2, 20) is fully exposed. Adjustment is

made by bending the actuator arm until correct

operation is obtained.

1. Bend lever to left (away from switch) to shorten

switch action throw. Bend right to lengthen throw.

2. Open and close door several times to check switch

adjustment. Repeat step 1 as required to obtain

proper ON-OFF operation of con-vector fan.

3. Replace upper trim (17).

Page 21

6-2

6.3.1.3 Oven Door Horizontal Adjustment

To adjust the doors horizontally (either left to right

or front to back, remove upper and lower trim and

proceed as follows:

1. Loosen the four hex nuts (Figure 7-2, 10)

[two at top and two (not shown) at bottom] on both

doors.

2. Close both doors, and reposition so that doors are

square with top angle and control panel. The gap

between the raised embossments of abutting door

edges should be approximately 1/32" 1mm. It is

important that this gap be maintained the full

height of the doors. Tighten nuts (10).

3. Open each door. Check that inside surface of door

trim contacts raised edge of oven liner at top and

bottom. Readjust if necessary.

4. Replace trim.

6.3.1.4 Oven Door Vertical Adjustment

To adjust the doors vertically:

1. Loosen the two hex nuts (Figure 7-2, 9).

2. Back off top door pivot pin (8).

3. Reposition door by turning bottom door pivot pin

(8). Turn pin clockwise (up) or counter-clockwise

(down) as required. Top of doors should be level

with each other and equally spaced between top

and bottom trim.

4. Retighten the two hex nuts.

5. Replace trim.

POWER SAVER II ELECTRIC CONVECTION OVEN

6.4.2 Right Side Panel Removal

1. Remove six screws from top panel (Figure 7-1, 11)

on right side.

2. Remove four screws from rear of right side panel.

(2).

3. Remove four screws (22) from control panel. (14).

WARNING

Controls carry 208 volts. Make sure external circuit

breaker is shut off before removing panel, to avoid

accidental shock or short circuit.

4. Remove right side panel.

6.4.3 Fan Disassembly and Repair

6.4.3.1 Fan Blade Removal

Removal of the fan requires use of a wheel puller

kit (part #99-3334) supplied by Market Forge. Wheel

puller kit components are shown in Figure 6-2. To

remove fan blade, proceed as follows:

1. Remove deflector and fan guard (Figure 7-1, 18,

17).

2. Remove Allen head set screws which secure fan to

motor shaft.

3. Install wheel puller over hub of fan using Allen

head cap screws.

4. Gradually tighten hex bolt on wheel puller until fan

slides off motor shaft.

5. Remove wheel puller from fan blade and reinstall

replacement fan on motor shaft as required.

6.4.1 Control Panel and Contactor Removal

All controls of the oven are serviceable from the

front. By removing the control panel (Figure 7-1, 14)

all panel components and the contactor mounted

behind the panel are accessible for replacement.

1. Remove screws (Figure 7-1, 22) from control panel

(14).

2. Pull panel forward being careful to avoid damaging

controls and wiring.

WARNING

Controls carry a minimum of 208 volts. Make sure

external circuit breaker supplying power to the

oven is shut off before removing panel.

3. Remove contactor (Figure 7-3, 6) or panel

components identified in Figure 7-4 as required

and reassemble.

17-0393

Figure 6-2 Wheel Puller Kit Components .

Page 22

MAINTENANCE 6-3

6.4.3.2 Fan Motor Removal

Motor removal is completed from inside the oven

With external circuit breaker shut off, proceed as

follows 1 Remove deflector and fan guard (Figure 71, 18,17)

2. Remove four nuts (20) and clips (19, 21 and 23)

from motor assembly.

3. Pull motor forward. Carefully disconnect electrical

wiring.

4. Slide motor off screws. Identify and tag wires.

5. Install replacement motor assembly as required

6.4.4 Heating Element Removal

6.4.4.1 Rear Heating Element Removal

Removal of rear heating elements (Figure 7-3, 1)

is completed from inside the oven. With external

circuit breaker shut off, proceed as follows:

1. Remove oven shelves, shelf supports, (Figure 7-1,

12) deflector (18) and fan guard (1 7).

2. Remove screw from heating element bracket at

top right rear of oven liner.

3. Lift element up and off retaining brackets (Figure

7-3, 3).

4. Gently pull bracketed end of element away from

oven liner. Remove terminal screws from

elements and tag wires for identificat ion.

5. Replace with new element as required, proceeding

in reverse sequence of above.

6.4.4.2 Bottom Heating Element Removal

Removal of bottom heating elements is completed

from the front of the oven. With external circuit

breaker shut off, proceed as follows:

1. Lower hinged bottom front panel of oven, (Figure

7-2, 34).

2. Remove wing nut (Fig. 7-3, 12) and washer (10)

from underside of retaining panel (9).

3. Remove screws (11) from front of retaining panel,

and lower panel.

4. Remove screws (4) from heating element brackets.

5. Gently slide element (2) out. Remove terminal

screws from elements and tag wires for

identification.

6. Replace with new element as required, proceeding

in reverse sequence of above.

6.4.5 Thermostat Removal

1. Remove screws (Figure 7-1, 22) from control panel

(14).

2. Remove five screws that secure perforated

capillary tube guard (9) to oven liner.

3. Slide thermostat bulb out from clips (19 & 21) and

thread capillary tube through hole leading to the

control area.

4. Remove thermostat control (Fig. 7-4, 4) from

control panel.

5. Slide entire assembly out front of oven through the

control area.

6. Install replacement thermostat as required.

17-0393

Page 23

SECTION 7 ILLUSTRATED PARTS LIST

7.1 General

This section contains a complete listing of all

replaceable parts of the Power Saver II Electric

Convection Oven. For the purpose of parts

identification, the unit is broken down into functional

assemblies, and each assembly is shown in an

exploded view which is keyed to the accompanying

parts list. Each parts list contains the figure index

number, the Market Forge part number, and an

abbreviated description.

7.2 Ordering Information

Orders for repair parts should be directed to the

nearest authorized parts distributor. For a current

Market Forge Authorized Parts Distributor List

contact:

Customer Service Department

Market Forge

35 Garvey Street

Everett, Massachusetts 02149

Telephone: (617) 387-4100

Customer Service Department Market Forge

Canada Ltd. 1375 Aimco Boulevard, Unit 5

Mississauga, Ontario, Canada L4W 1B5

Telephone: (416) 621-9252

7.3 Index of Illustrated Parts Lists

Figure

7-1 Cabinet and Frame Assembly 7-3

7-2 Door Assembly

7-3 Heating Element Assembly

7-4 Control Panel

Page

7-5

7-7

7-8

7-1 17-0393

Page 24

7-2

Power Saver II Electric Convection Oven

Figure 7-1 Cabinet & Frame Assembly .

Page 25

ILLUSTRATED PARTS LISTS 7-3

Fig. 7-1

Item No.

1A 99-1681 Rear Panel, stainless steel

1B 99-1572 Rear Panel, enamel

2A 99-3327 Side Panel, right, 33" standard oven. s/s

2B 99-3244 Side Panel, right, 33" standard oven, enamel

2C 99-3328 Side Panel, right, 39" deep oven, s/s

2D 99-3222 Side Panel, right, 39" deep oven, enamel

3 99-4403 Inner Panel, rear

4 99-3018 Mounting Plate, conduit

5A 99-3981 Base Assembly, standard

5B 99-4368 Base Assembly, deep

6 — Conduit Assembly, see Figure 7-3, #7

7 99-3939 Spacer, motor mount

8 99-3558 Bracket, top panel, left side

9 99-3271 Guard, capillary tube

10A 99-3329 Side Panel, left, 33" standard oven, s/s

10B 99-3239 Side Panel, left, 33" standard oven, enamel

10C 99-3330 Side Panel, left, 39" deep oven, s/s

10D 99-3223 Side Panel, left, 39" deep oven, enamel

11A 99-4435 Top Panel, 33" standard oven, s/s

11B 99-4431 Top Panel, 33" standard oven, enamel

11C 99-4434 Top Panel, 39" deep oven, s/s

11D 99-4429 Top Panel, 39" deep oven , enamel

12A 10-1295 Rack Support, 33" standard oven

12B 10-1296 Rack Support, 39" deep oven

13 99-1925 Clip, rack support

14 — Control Panel Assembly, see Figure 7-4

15A 99-3932 Fan Motor Assembly, 1/2 HP, 115/230V, single ph, 60Hz

15B 99-3936 Fan Motor Assembly, 1/2 HP 208/240/480V, 3 ph, 60Hz

15C 99-3933 Fan Motor Assembly, 1/2 HP 110/220V, single ph, 50Hz

16 10-5453 Fan Wheel

17 10-5957 Fan Guard

18 99-3955 Deflector, electric oven

19 99-0950 Bracket, thermometer bulb, top

20 10-2335 Nut. 5/16-18

21 99-4560 Bracket, thermometer bulb, bottom

22 10-1836 Screw, #8-32 x 1/2" Ig.

23 99-0951 Clip, fan guard

24 99-1925 Screw, sht. mtl.

Part No. Description

17-0393

Page 26

7-4 POWER SAVER II ELECTRIC CONVECTION OVEN

Figure 7-2 Door Assembly .

Page 27

ILLUSTRATED PARTS LISTS 7-5

Fig. 7-2

Item No.

1 10-1717 Screw, rnd. hd., #8-32 x 3/8" Ig.

2 10-1956 Screw, Phillips truss hd., #10-32 x 3/8" Ig,

3 10-2341 Washer, #10, thin

4 10-1759 Screw, rnd. hd., #10-32 x 3/8" Ig.

5 10-2509 Lock Washer, #10

6 10-2432 Washer, #10, medium

7 99-3362 Spring Catch Assembly

8 99-3279 Pivot Pin, door

9 10-2552 Nut, 3/8" - 24

10 10-2330 Nut, #8-32

11 10-2518 Lock Washer, #8

12 99-4466 Retention Clip, spring

13 99-3557 Support Bracket

14 10-1761 Screw, Truss hd., #8-32 x 3/8" Ig.

15 99-3562 Trip Lever

16 99-3559 Bushing

17 99-3236 Upper Trim

18 10-1883 Screw, rnd. hd., #6-32 x 1" Ig.

19 99-4308 Insulator

20 09-6431 Micro Switch

21 09-4401 Spring

22 99-3338 Support Link

23 99-4309 Bracket

24 10-2420 Lock Washer, #6

25 10-2337 Nut, #6-32

26 10-1996 Screw, flat hd., #8-32 x 5/8" Ig.

27 99-3237 Shield Assembly, right, front

28 99-3283 Front Frame Assembly

29 99-3279 Spacer, door pivot

30 10-2308 Nut, 1/4" -20

31 10-1990 Screw, button socket, # 10-24 x 1 3/4" Ig.

32 99-3534 Door Assembly, stainless steel

33 10-0657 Door Handle

34 99-3230 Lower Trim

35 10-1907 Screw, hex hd., 1/4-20 x 5/8" Ig.

36 10-2400 Washer, 1/4"

37 90-3795 Spacer

38 10-2500 Lock Washer, 1/4"

Part No. Description

17-0393

Page 28

7-6

POWER SAVER II ELECTRIC CONVECTION OVEN

Figure 7-3 Heating Element Assembly .

17-0393

Page 29

ILLUSTRATED PARTS LISTS 7-7

Item No.

Fig. 7-3

1A 09-6426 Heating Element, rear, 208V, 60Hz

1B 09-6436 Heating Element, rear, 240V, 60Hz

1C 09-6437 Heating Element, rear, 440V, 60Hz

1D 09-6438 Heating Element, rear, 480V, 60Hz

1E 09-6443 Heating Element, rear, 415V, 60Hz

1F 09-6482 Heating Element, rear, 380V, 50Hz

2A 09-6425 Heating Element, bottom, 208V, 60Hz

2B 09-6433 Heating Element, bottom, 240V, 60Hz

2C 09-6434 Heating Element, bottom, 440V, 60Hz

2D 09-6435 Heating Element, bottom, 480V, 60Hz

2E 09-6442 Heating Element, bottom, 415V, 60Hz

2F 09-6481 Heating Element, bottom, 380V, 50Hz

3A 99-1653 Bracket, rear elements, 208/240 volt

3B 99-1820 Bracket, rear elements, 440/480 volt

4 10-1735 Screw, #8, sheet metal

5A 99-3950 Retainer Assembly, electric comp., 33" standard oven

5B 99-3953 Retainer Assembly, electric comp., 39" deep oven

6A 10-5476 Contactor, 40 Amp, 208 volt

6B 10-5943 Contactor, 40 Amp, 240 volt

6C 10-5467 Contactor, 30 Amp, 240/440/480 volt

7A 99-4571 Conduit, 60Hz, standard & 50Hz deep ovens

7B 99-4570 Conduit, 60Hz, 39" deep oven

7C 99-4748 Conduit, 50Hz, 33" standard oven

8 99-3335 Cover, terminal block box

8A 10-6962 Terminal Block, (not shown)

9A 99-3575 Bottom Retainer Assembly, 33" standard oven

98 99-3576 Bottom Retainer Assembly, 39" deep oven

10 99-1789 Washer

11 10-1954 Screw, pan hd., #8-32 1 5/8"

12 10-2382 Wing Nut, #8-32

13 99-3290 Shield, terminal block

14 10-5396 Transformer, 480/240 volt, 50/60Hz, (for 440/480

volt service - not shown)

Part No. Description

1 7-0393

Page 30

7-8 POWER SAVER II ELECTRIC CONVECTION OVEN

1 10-6415

Bezel, panel

Fig. 7-4

Item No.

17-0393

Figure 7-4 Control Panel Assembly .

Part No. Description

2 10-6307 Knob, control

3 99-4561 Nameplate, 60Hz panel

4 10-4714 Thermostat

5 10-5520 Timer, 60-minute

6 10-5553 Timer, 5-hour

7 10-6669 Indicator Light, red

8 10-7903 Toggle Switch, OFF/ON

9 10-6280 Circuit Breaker, 15 Amp

10 10-6521 Mounting Plate, circuit breaker

11 10-1979 Screw, flat hd., #4-40

12 10-2541 Speed Nut, light

13 10-1836 Screw, rd. hd. , #8-32 x 1/2 Ig.

14 10-2332 Nut, #8-32

Loading...

Loading...