Market Forge 2500HE Service Manual

SERVICE & PARTS MANUAL

Models:

2500 HE

2700 HE

2592 HE

High Efficiency Gas Convection Oven

2792 HE

MARKET FORGE industries Inc

Employee Owned Company

World Headquarters: 35 Garvey Street, Everett, MA 02149

Tel. (617) 387-4100, Fax 800-227-2659 (U.S. Except MA) or (617) 387-4456 (In MA)

Form No. S-2207 6/94 Printed in U.S.A.

TABLE OF CONTENTS

Paragraph Page Paragraph Page

SECTION 1 INTRODUCTION

11 Description 1-1 51 General 5-1

12 Basic Functioning 1-1 52 Trouble-Shooting Guide 5-1

13 Service 1-1 53 Electrical Fault Isolation 5-3

SECTION 2 INSTALLATION

21 Receiving 2-1 541 Incoming Power 5-3

22 Assembly 2-1 542 Electrical Inspection 5-3

221 Oven on 7" (178mm} Stand 2-1 543 Direct Spark Ignition System 5-3

222 Oven on Modular Base 2-1 544 Thermostatic Control 5-5

223 Oven on 28" (711mm} Open Stand 2-1 545 Solenoid Gas Valve 5-5

224 Stack Oven on 7" (178mm} Stand 2-1 546 Wiring 5-5

23 Gas Connection 2-3 547 Buzzer Relay 5-5

231 Placement 2-3

232 Materials 2-3 SECTION 6 MAINTENANCE

233 Connection 2-3 61 General 6-1

234 Gas Leak Test 2-3 62 Preventive Maintenance 6-1

24 Electrical Connection 2-3 63 Adjustment Procedures 6-1

25 Ventilation 2-5 631 Oven Door Adjustments 6-1

251 Flue Deflector Installation 2-5 632 Thermostat Calibration 6-2

26 Installation Check-Out 2-5 64 Repair and Replacement 6-2

261 Initial Control Settings 2-5 641 Control Panel Removal 6-2

262 Oven Check-Out 2-5 642 Right Side Panel Removal 6-3

263 Shut -Down Procedure 2-6 643 Fan Blade Removal 6-3

SECTION 3 OPERATION

31 Operating Controls and Indicators 3-1 646 Gas Valve Removal 6-4

32 Operating Procedures 3-1 647 Thermostat Removal 6-4

321 Preheating 3-1 648 Ignition Control Board Removal 6-4

322 Cooking 3-1 65 Adjustments and Operational

SECTION 4 PRINCIPLES OF OPERATION

41 General 4-1 652 Regulator Adjustment 6-4

42 Combustion/Vent Circuits 4-1

43 Electrical Circuits 4-2 SECTION 7 ILLUSTRATED PARTS LISTS

431 Control Circuit Components 4-2 71 General 7-1

SECTION 5 TROUBLE -SHOOTING

54 Electrical Trouble-Shooting

Procedures 5-3

644 Burner Pan Removal 6-3

645 Electrode Removal 6-4

Checks of Burner Components 6-4

651 Gas Burners 6-4

72 Ordering Information 7-1

73 Index of Illustrated Parts Lists 7-1

LIST OF ILLUSTRATIONS

Figure

Page

SECTION 1 INTRODUCTION

1-1 High Efficiency Gas Convection Oven

SECTION 2 INSTALLATION

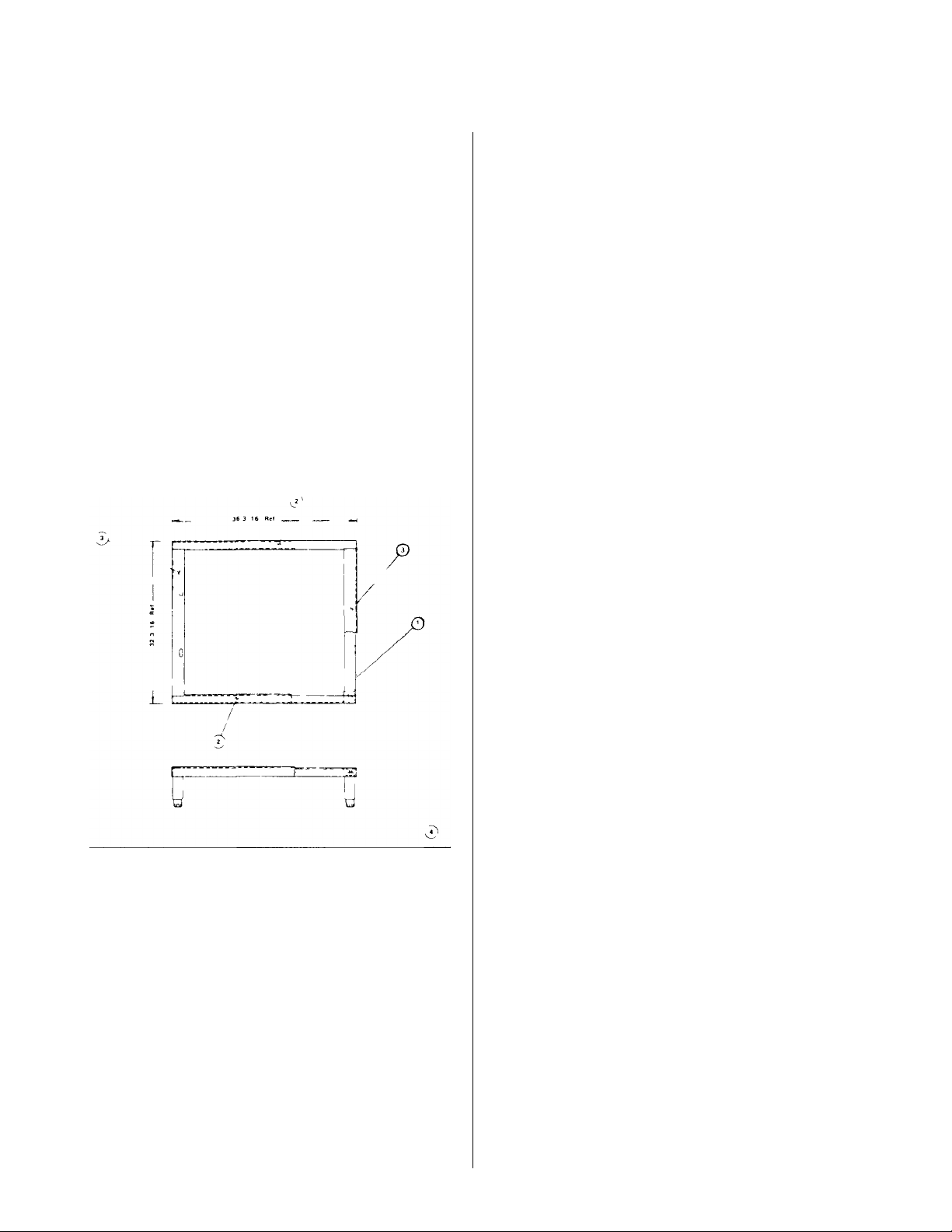

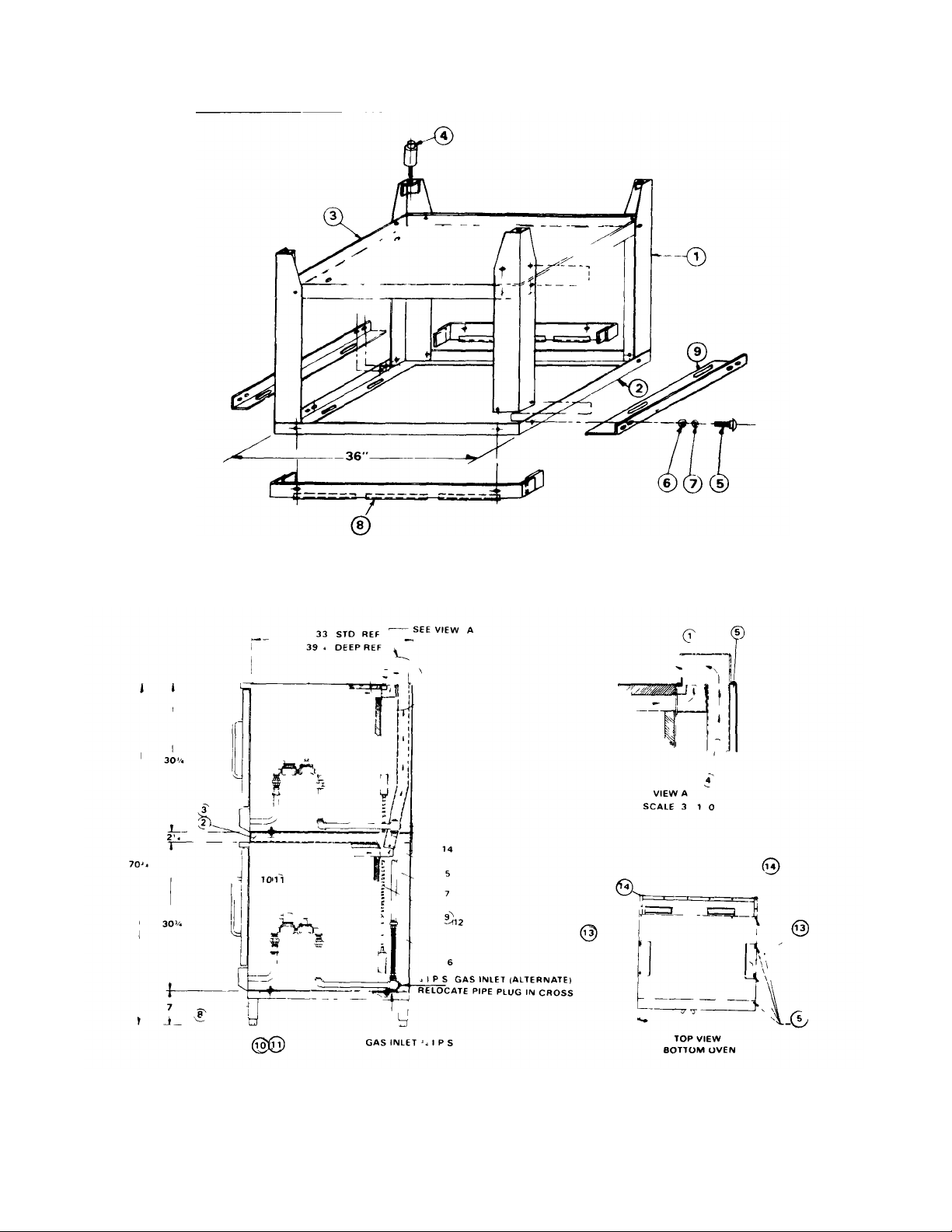

2-1 7" Stand 2-1

2-2 28" Stand 2-2

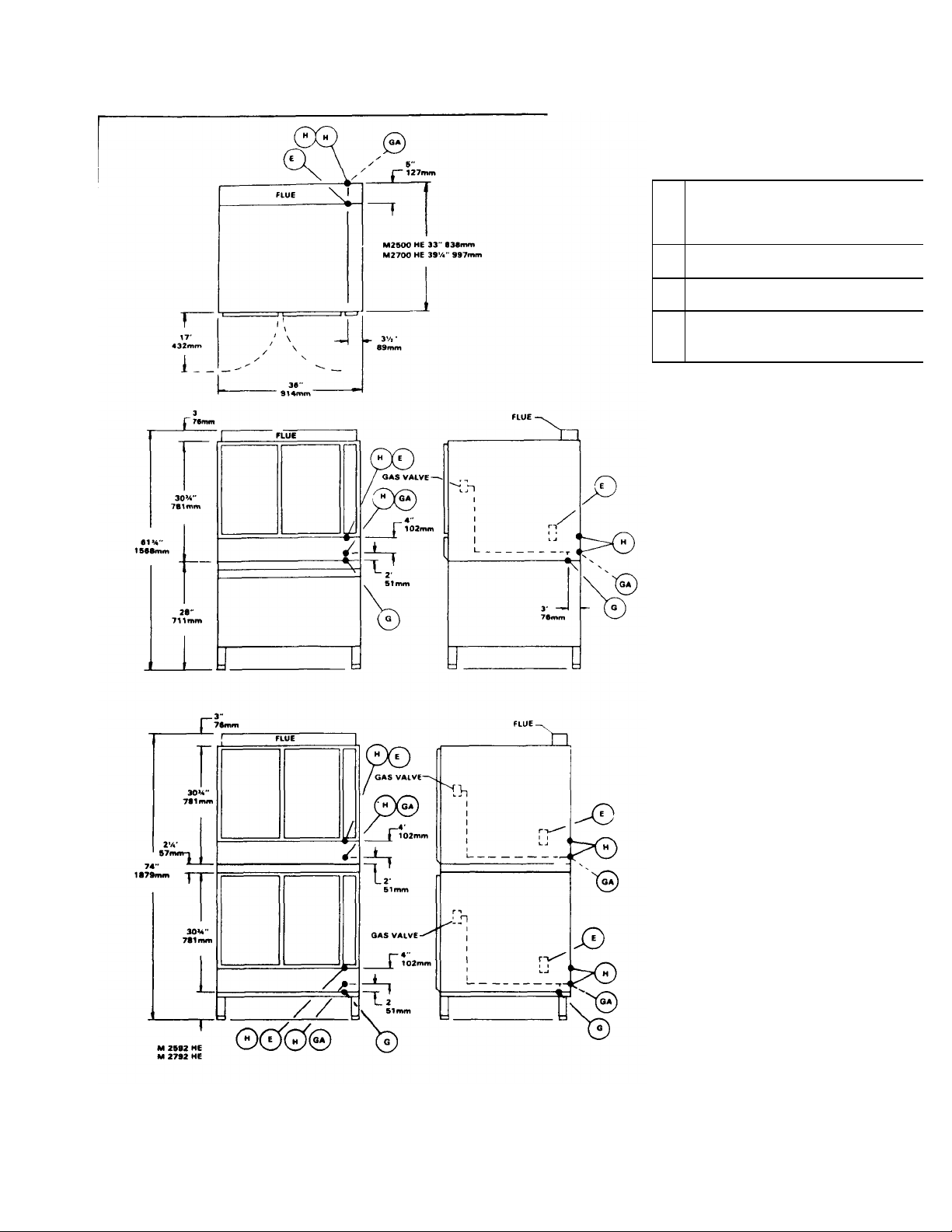

2-3 Stacked Ovens 2-2

2-4 Service Connections 2-4

SECTION 3 OPERATION

3-1 Control Panel 3-2

SECTION 4 PRINCIPLES OF OPERATION

4-1 Cutaway Oven 4-1

4-2 Schematic Control Circuits 4-2

1-2

LIST OF TABLES

Figure

SECTION 5 TROUBLE -SHOOTING

5-1 Wiring Diagram 5-3

5-2 Flame Current Meter Placement 5-4

SECTION 6 MAINTENANCE

6 1 Blower Guard 6-1

6-2 Wheel Puller Kit 6-3

6-3 Air Shutter Adjustment 6-5

SECTION 7 ILLUSTRATED PARTS LISTS

7-1 Frame & Cabinet Assembly 7-2

7-2 Manifold & Burner Pan Assembly 7-4

7-3 Door Assembly 7-6

7-4 Control Panel Assembly 7-8

7-5 Ignition Control Board Assembly 7-10

Page

Table Page Table

SECTION 3 OPERATION SECTION 5 TROUBLE-SHOOTING

3-1 Control Panel Components 3-3 5-1 General Trouble-Shooting Guide 5-1

5-2 Electrical Fault Isolation Guide 5-2

Page

SECTION 1 INTRODUCTION

This service and parts manual contains general information, installation, operation, principles of operation, trouble-

shooting, and maintenance information for the Market Forge High Efficiency Gas Convection Oven Also included

are parts lists, in which each replaceable part is identified and shown in an accompanying exploded view

1.1 DESCRIPTION

The Market Forge Model HE Gas Convection

Oven is a gas fired, pilotless, direct-spark-igni-tion

system convection oven The unit is designed to

operate from a natural, propane, or butane gas

supply when equipped with appropriate gas orifices

It consists of a heavily insulated cooking

compartment fitted with a convector fan and heated

by a gas burner system designed to achieve optimal

efficiency from the fuel burned All oven controls are

located on a recessed panel on the right front of the

oven as seen from the front

The major assemblies of the HE oven are the

stainless steel or baked enamel finish cabinet

enclosure, solid doors, stainless steel cooking

compartment with nine shelf supports, convector

fan, pressure regulator and gas valve manifold

assembly, burner box assembly consisting of gas

burners, orifices, and direct spark ignition elec trode

The control panel assembly includes the thermostat,

electronic ignition control board, 60-minute and 5hour mechanical timers, red indicator light, ON-OFF

power switch, warning buzzer, and ignition and

motor reset switches

The unit is available in a variety of mounting

configurations 7" (178mm) counter stand, 28"

(711mm) modular base, open stand on legs with

shelf and optional storage rack, or stacked on top of

another HE oven with the bottom unit on 6" (152mm)

stainless steel legs

1.2 BASIC FUNCTIONING

The HE oven becomes operational when the

power switch is placed in the ON position, doors are

closed, and thermostat set Electronic ignition

activates, energizing the burner electrodes and

opening the gas valve (The fan operates continuously

with power on and doors closed, regardless of

thermostat setting ) Gas passes through the regulator

and valve to the burners, where it is ignited by the

sparking of the elec trodes The resulting flame heats a

flame baffle plate mounted under the cooking

chamber, which in turn heats the chamber The fan

circulates air uniformly through the chamber When the

chamber reaches the preset temperature, the

thermostat contacts open and the gas valve closes

When the temperature drops enough to close the

contacts, the ignition system reactivates Any number

of such cycles might occur during the cooking time If

for any reason the burners fail to ignite, the system

automatically closes the gas valve Should the burners

go out prematurely, the system will automatically activate the ignition electrodes, and if flame is not

established the system will shut down and close the

gas valve

1.3 SERVICE

Required service, both preventive and corrective,

is explained in Section 6 Should repairs be required, a

network of authorized agencies is

available to assist with prompt service. A current directory

of Authorized Service Agencies may be obtained by

contacting:

Product Service Department

Market Forge

35 Garvey Street

Everett, Massachusetts 02149

Telephone (617) 387-4100

Product Service Department

Market Forge Canada Ltd.

1375 Aimco Blvd., Unit 5

Mississauga, Ontario, Canada L4W 1B5

Telephone (416) 621-9252

The model and serial numbers must be referenced when

corresponding with Market Forge. The data plate with serial

number is located on the center of the bottom front trim

ledge.

Figure 1-1. High Efficiency Gas Convection Oven on Optional Stand

SECTION 2 INSTALLATION

2.1 RECEIVING

The oven is shipped bolted to a skid and cov ered by

a carton which is nailed to the skid, these must be

carefully removed prior to installation DO NOT AT ANY

TIME LAY THE OVEN ON ITS TOP, SIDE, OR FRONT

TO DO SO MAY DAMAGE THE EQUIPMENT AND

INVALIDATE THE WARRANTY

2.2 ASSEMBLY

Set-up and assembly procedures for the various oven

configurations are described in the following paragraphs

2.2.1 Oven on 7" (178mm) Stand

1. Screw legs (Figure 2-1, #4) into top frame assembly

(1)

2. Place into position front and rearchannel assembly

(2) and side angles (3) These items are loose parts

and are tied together with mounting of oven to stand

3. For single oven, mount oven to stand using four

3/8-16 x 3/4 Ig hex head cap screws and four 3/8

plain washers provided

4. For stacked oven, proceed to paragraph 2 2 4

5. For single oven, proceed to subsection 2 3

2.2.2 Oven on Modular Base

1. Screw adjustable feet into cabinet base

2. Mount oven to base using four 3/8- 16 x 3/4 Ig

hex head cap screws and four % plain washers

provided

3. Proceed to subsection 2 3

2.2.3 Oven on 28" (711mm) Open Stand

1. Place top frame (Figure 2-2, #2) upside down on

a clean smooth surface

2. Place into position front and rear angle as semblies (8) (stainless only) and legs (1)

3. Align holes in legs, frame, and angle assemblies

Secure using carriage bolts, lockwash-ers, and

nuts provided (5,6,7)

4. Align holes in shelf (3) with leg holes and secure

using hardware (5,6,7)

5. Screw adjustable feet (4) into stand legs

6. Install four clips for oven rack support inside top

frame using hardware (5,6,7) optional

7. Place stand in upright position Install rack

support, if supplied, inserting ends through holes

in clips and shelf

8. Mount oven to stand using four ¾-16 x 3/4 Ig

hex head cap screws and four 3/8 plain washers

provided

9. Proceed to subsection 2. 3

Figure 2-1. 7" (178mm) Stand

2.2.4 Stack ovens on 7" (178mm) stand

See 2.2.1 for stand assembly and proceed as

Follows:

1. Remove rear panels from both ovens by

removing 14 Phillips head screws from each

rear panel.

Figure 2-2 28" (711mmi Open Stand (Inverted for Assembly)

Figure 2-3 Stacked Ovens

2. Tilt ovens onto left sides as seen from front to

access bottoms DO NOT AT ANY TIME LAY THE

OVENS DOWN ON TOPS, RIGHT SIDES, OR

FRONTS. TO DO SO MAY DAMAGE THE

EQUIPMENT AND INVALIDATE THE WARRANTY

3. Install 7" (178mm} stand to bottom oven using

hardware (Figure 2-3, #10, 11). Either oven may

serve as bottom oven. Stand is 32" (813} front to

back. When used with deep ovens, overhang may

be either front or back, as desired. (Recommended

overhang is in back )

4. Stand bottom oven upright, onto stand.

5. Install top retaining brackets (13) on top of bottom

oven by removing two screws from top panel, left

and right, as shown, and replacing through holes in

brackets.

6. Install spacer assembly (2 or 3) on bottom of top

oven using hardware (10, 11).

7. Stack top oven on bottom oven.

8. Attach long flue assemblies (4) to top and bottom

ovens. See Figure 2-3, view "A".

NOTE

If stacked ovens are adjacent to moisture producing

equipment (such as kettles or steam cookers) it is

necessary to seal the seam between the stacked ovens

and the moisture producing equipment to prevent

condensation from entering the control section of the

bottom oven Silicone synthetic rubber is recommended

for a sealant

rear wall if adjoining wall is combustible Allow 6" (152mm}

clearance on right from another gas fired heat generating

piece of equipment, unless the equipment is another Market

Forge High Efficiency Oven, in which case no spacinq is

needed.

2.3.2 Materials

Use new pipe 3/4" (19mm} IP S properly reamed, free from

chips, and threaded to the proper length. If pipe dope is

used, apply a moderate amount, leaving two end threads

bare If Teflon tape is used, apply one and one-half turns,

leave ing the two end threads bare

2.3.3 Connection

Connect the gas line into the oven bottom at the right rear as

seen from the front, or alternate connection right rear back.

See Figure 2-4 For stacked ovens, connect gas pipe lines

between ovens using 3/4" (19mm} I.P.S. flexible connector

(Figure 2-3, #6) and 3/4" (19mm} I.P.S. x 20 1/4 tg nipple

(7). Install 3/4" (19mm} external gas supply shut -off valve

(furnished with unit) in an easily accessible location.

NOTE:

MANIFOLD PRESSURE MUST BE 4.0" (102mm} WATER

COLUMN FOR NATURAL GAS OVENS AND 10.0"

(254mm} FOR LP GAS OVENS SUPPLY PRESSURE

MUST BE AT LEAST 6.0" (152mm} FOR NATURAL GAS

AND 100" (254mm} FOR LP GAS. INSTALL PIPE PLUG IN

SIDE OF PIPE NOT BEING USED TO FEED GAS TO UNIT

2.3 GAS CONNECTION

This oven is factory adjusted for a gas consumption

rate of 60,000 BTU/hour. Read the nameplate on the

lower front access panel If this plate is marked for a

different gas than that being supplied, notify your dealer

immediately. DO NOT CONNECT GAS LINES Only a

qualified service technician should make the installation.

Installation must conform with the National Fuel Gas

Code ANSI Z223 1-1974, or CSAB1491 installation

codes, where applicable.

2.3.1 Placement

Allow 2" (51mm} clearance from side wall and

2.3.4 Gas Leak Test

Perform a gas leak test of all newly made joints, as well as

those leading to the main gas control valve. Check for leaks

using soap solution. DO NOT USE FLAME.

2.4 ELECTRICAL CONNECTION

Where applicable, installation must conform with

National Electrical Code ANSI C1-1975 or Canadian

Electrical Code C22 1, and/or local codes.

SERVICE CONNECTIONS

Hz.

1/2" 13mm conduit connection or equivalent

amps per oven Use wire suitable for at

Alternate

2.

Access to electrical junction box

GAS OPERATED

E

Electrical connection — 120 volt AC. 60

10

least 90°C

G 3/4" 19mm I.P.S Gas Connection Inlet,

Standard

GA 3/4" 19mm I.P.S Gas Connection Inlet,

H 1 3/4" 44mm dia. access holes for

1. Alternate gas supply connection GA

1. Connect the power supply wires to the junction

box at the right back of the oven Use wire

suitable for at least 90°C Ensure that hot wire

connects to terminal L1 and neutral wire to L2

2. For stacked ovens, connect power supply to

bottom oven junction box Install flexible conduit

assembly (Figure 2-3, #9 or 12) between top

and bottom junction boxes

3. Ground unit using ground lug in supply box

4. Replace rear panel(s)

5. For stacked ovens, add back retainer clips

(Figure 2-3, #14) to back of both units using

existing screws

2.5 VENTILATION

Proper ventilation is highly important for good

oven operation The use of a mechanical exhaust

system is ideal A properly designed unit will extend

approximately 4" to 6" (102-152mm) beyond all

sides of the oven unit In such instances the oven will

be equipped with a flue deflector, which is shipped

separate from the oven in the stand carton If the flue

outlet is to be connected directly to a chimney, then

a down draft diverter should be employed AT NO

TIME SHOULD A DAMPER BE INSTALLED IN THE

EXHAUST SYSTEM OF THIS OVEN

2.5.1 Flue Deflector Installation

To install deflector, remove back row of screws from

oven top panel Add flue deflector with open side

facing front, and replace screws For stacked ovens,

see Figure 2-3, view "A"

2.6 INSTALLATION CHECK-OUT

After the oven is completely assembled and

properly located with gas and electrical supplies

connected, the unit should be given a thorough

check-out before being put into operation Check-out

procedures for the oven are given in subsection 2 6

2 If the unit fails to perform as described, consult the

trouble shooting guides in section 5 for corrective

action

Before making this check-out, the operator must

be thoroughly familiar with the operating procedures

in Section 3, and with the function of

each control described in Table 3 1 Reference Figure

3-1 for identification of controls

2.6.1 Initial Control Settings

Power switch and thermostat dial are in OFF

position

2.6.2 Oven Check-Out

A final check of the controls and connections

should be made as follows

1. Make sure that the blower guard is properly

mounted See Figure 6-1

2. With a level on the oven shelves make sure that

the oven is level both front and back left and right

To adjust, turn feet in stand legs NOTE Be sure

wire shelf supports are in, not on, brackets

3. Make sure that gas and electrical supplies are

available to the unit

4. Set thermostat dial at 350°F

5. Place power switch in the ON position with doors

open

6. Close doors Indicator light should come on, fan

should come on and rotate clockwise (seen from

front) NOTE Buzzer may sound for an instant

a) If fan does not start, or starts and immediately

stops, press MOTOR RESET

b) If buzzer sounds, press IGNITION RESET

7. If fan still does not work or buzzer sounds again,

see Tables 5-1 and 5-2 for troubleshooting and

electrical fault isolation

8. Indicator light will remain on while oven is heating,

and go out when preset temperature is reached

During the heat -up period, some slight smoke or

fumes may result due to oil or grease on metal

surfaces This should cease after five minutes

9. During initial burner operation, observe flame

angle of each burner through the louvers on the

lower front panel If flames are not vertical, burners

may not be positioned properly, see subsection

6.4.4

10. After this check is completed, turn thermostat dial

and power switch to OFF position

2.6.3 Shut-Down Procedure

1. For daily shut -down, place thermostat dial

and power switch in OFF position.

2. For extended shut-down, place thermostat dial and

power switch in OFF position. Close external gas

supply shut -off valve. Leave doors ajar.

SECTION 3 OPERATION

3.1 OPERATING CONTROLS AND

INDICATORS

All the controls required to operate the oven are

listed in Table 3-1 with a short functional description

of each. Figure 3-1 shows the physical location of

each control and indicator.

3.2 OPERATING PROCEDURES

Before attempting to use the oven for cook ing,

be sure that proper gas and electrical connections

have been made, gas supply valve is open, and fan

guard properly mounted.

3.2.1 Preheating

1. Arrange shelf positions according to the item to

be cooked. Refer to Test Kitchen Bulletin #41

for correct positioning.

2. Place power switch in the ON position. Close

doors. Fan should come on and rotate clockwise. If not, depress the MOTOR RESET but ton. If fan still does not operate, consult Table 5-

1.

3. Set thermostat dial to desired temperature.

Indicator light should come on. Burners should

ignite. If not, buzzer will sound. Depress the

IGNITION RESET button. If burners still do not

ignite, consult Table 5-1.

4. Preheat to temperature and allow to cycle once

(indicator light on, off, on) to obtain

even temperature throughout oven Total time:

approximately 15 minutes

3.2.2 Cooking

The oven is ready for cooking use when the

indicator light goes off. The load should be adjacent to

the oven, so that doors will be open as short a time as

possible during loading.

1. Load oven. If using oven for long term roasting of

meats, fish, or poultry, place about a quart of

water in the oven in a suitable container or under

a trivet in the same pan as the food.

2. Close doors and set timer for desired cooking

time.

NOTE: Timer is for convenience only and does not

control oven operation. Bell will ring at end of

preset interval.

3. Unload oven and proceed as follows:

a) If oven is to be turned off, place thermostat

dial and power switch in the OFF position.

b) If oven temperature is to be lowered, set

thermostat to desired temperature. Close right

door and leave left door open. Fan will

continue to run. When light comes on, oven is

at lower temperature. Close left door. When

light goes off, oven is ready to use.

4. Place thermostat dial and power switch in OFF

position for daily shut -down. For extended shutdown, place dial and switch in OFF position,

close gas supply valve, and leave doors ajar.

3-1

Loading...

Loading...