Market Forge 2400HE Service Manual

SERVICE & PARTS MANUAL

Supplement to

17-0393,

for

SUPPLEMENT

Cook & Hold for Power Saver II

Convection Ovens

Models:

2400 HE

2492 HE

MARKET FORGE CANADA LTD.

Mississauga, Ontario, Canada

Form No. 17-0406 Printed in U.S.A.

Power Saver II Ovens equipped with

Cook & H old Controls.

35 Garvey St., Everett, MA. 02149

Tel. (617) 387-4100, Telex 94-9414, Cable MAFORCO

TABLE OF CONTENTS

SECTION

3

PRINCIPLES OF OPERATION

Paragraph

SECTION 1 INTRODUCTION

11 Description 1-1

12 Basic Functioning 1-1

13 Service 1-1

SECTION 2 OPERATION

21 Operating Controls and Indicators 2-1

22 Operating Procedures 2-1

221 Preheating 2-1

222 Cook Mode Operation 2-1

223 Cook & Hold Operation 2-1

SECTION 3 PRINCIPLES OF OPERATION

31 General 3-1

32 Theory of Operation 3-1

321 Power and Heating

Element Operation 3-1

322 Cook Mode Controls 3-1

323 Cook & Hold Mode Operations 3-2

33 Electrical Circuits 3-3

331 Power Circuit Components 3-3

332 Control Circuit Components 3-3

SECTION 4 TROUBLE-SHOOTING

41 General 4-1

42 Trouble-Shooting Guide 4-1

43 Electrical Fault Isolation 4-1

44 Electrical Trouble-Shooting

Procedures 4-5

Page

Paragraph

441 Trouble-Shooting Sequence 4-5

442 Incoming Power 4-5

443 General Oven Test 4-5

444 Transformer (440/480

volt service only) 4-5

445 Circuit Breaker 4-6

446 Power ON-OFF Switch 4-6

447 Door Switch 4-6

448 Operating Thermostat Control 4-6

449 Selector Switch 4-7

4410 60-Minute Timer and Buzzer 4-7

4411 Fan Motor and Mini-Relay

for 440/480 Volt 4-7

4412 Heater Contactors and

Element Light 4-7

4413 12-Hour Timer and Cook Light 4-8

4414 Mini-Relay-Thermostat Interrupt 4-8

4415 Hold Light Thermostat and

Hold Light 4-8

4416 150°F Hold Temperature Control 4-9

4417 Contactor-Hold Heat and

Fan Control 4-9

SECTION 5 ILLUSTRATED PARTS LIST

51 General 5-1

52 Ordering Information 5-1

53 Index of Illustrated Parts List 5-1

Page

LIST OF ILLUSTRATIONS

Figure

SECTION 2 OPERATION

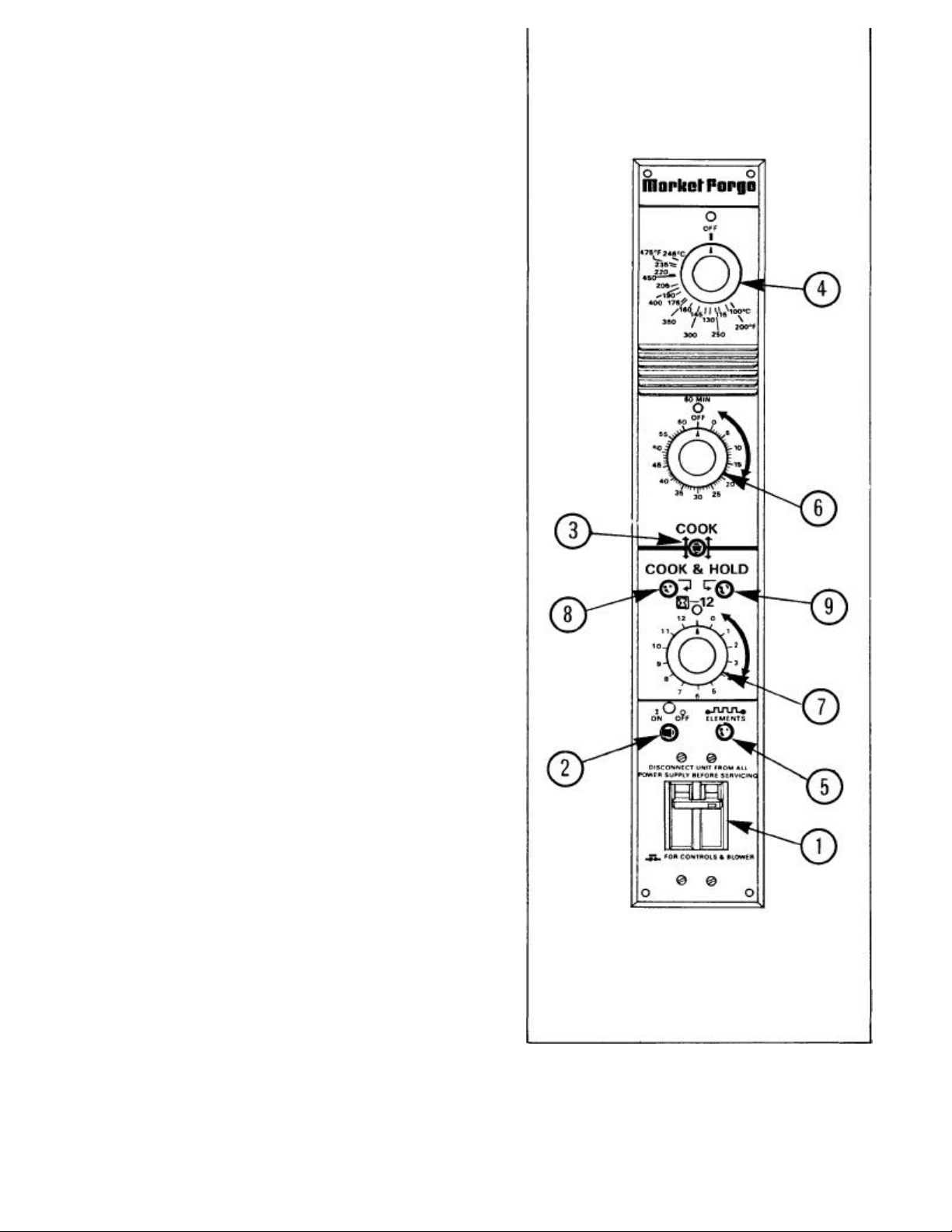

2-1 Controls & Indicators

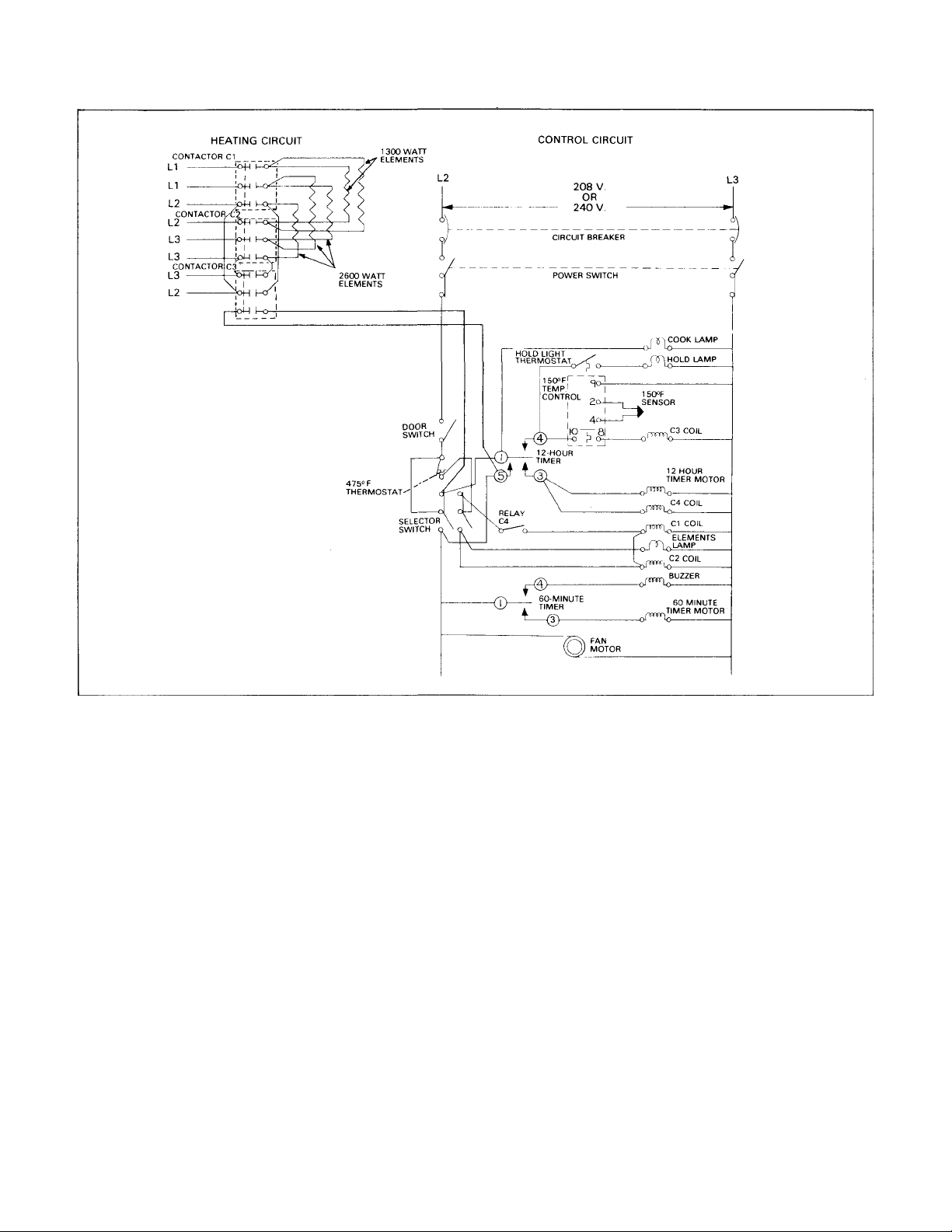

3-1 Pictorial Schematic- Typical Configuration 3-2

SECTION 4 TROUBLE-SHOOTING

4-1 Wiring Diagram-208/240 Volt, Single & 3 Phase,

60 Hz

4-2 Wiring Diagram - 440/480 Volt, 3 Phase, 60 HZ

4-3 Wiring Diagram - 220/380, 240/415 Volt 3-Phase

50 HZ, 4-Wire

Page

2-2

4-10

4-11

4-12

LIST OF TABLES

SECTION 2 OPERATION

2-1 Controls & Indicators 2-3

Figure

4-4 Schematic Diagram - 208/240 Volt, 3-Phase,

60 HZ

4-5 Schematic Diagram - 220/240 Volt, Single

Phase, 60 HZ

4-6 Schematic Diagram - 440/480 Volt, 3-Phase,

60 HZ

4-7 Schematic Diagram - 220/380, 240/415 Volt, 3

Phase, 50 HZ

SECTION 5 ILLUSTRATED PARTS LIST

5-1 Control Panel Assembly 5-2

5-2 Electrical Control Assembly 5-4

SECTION 4 TROUBLE-SHOOTING

4-1 Trouble-Shooting Guide

4-2 Major Electrical Fault Isolation Guide

Page

4-13

4-14

4-15

4-16

4-1

4-4

SECTION 1 INTRODUCTION

1-1

17-0406

This service and parts supplement to Power Saver II Electric Convection Oven Service & Parts Manual

contains descriptive information, trouble-shooting and maintenance information, and parts identification for

ovens equipped with Cook & Hold controls. Only information pertinent to these controls is contained in the

supplement. For details of standard oven controls and all other assemblies, see

Service & Parts Manual

1.1 DESCRIPTION

The Model 2400HE Power Saver II Electric

Convection Oven has Cook & Hold controls in addition

to the standard controls of the Model 2800HE Power

Saver II Oven. A selector switch allows the operator to

use either standard (COOK) oven operation or COOK

& HOLD operation. Controls and circuits spec ific to

COOK & HOLD ovens are included in this supplement.

1.2 BASIC FUNCTIONING

Operation of the oven in the Cook & Hold mode is

preceeded by preheating. Preheating is done by

placing the selector switch in the COOK (up) position,

power switch ON and thermostat set at 350°F. for 15

minutes operation.

Initial Roasting - The oven is then loaded, the

selector switch placed in the COOK & HOLD (down)

position, the thermostat set to the required roasting

temperature and the 12-hour timer set for the

approximate roasting time. (Times vary from normal

roasting and are supplied by Market Forge in

Operator's Manual 17-0405). The convector fan will

operate and the COOK light will come on indicating

contactors have closed to heating element circuits and

roasting cycle has begun under control of the

thermostat.

Residual Heat Roasting - When the 12-hour timer

setting has elapsed and the dial has returned to the "0minute" position, the thermostat and fan circuits are

interrupted to stop fan and heating element operation.

During this cycle only stored heat is used for cooking,

which continues until the oven temperature drops to 1

50°F.

17-0393.

Hold - When the temperature sensor located at the

rear of the oven interior registers a temperature drop

to 150°F., it activates a temperat ure control device to

maintain the 150°F. temperature for an indefinite

period. The control functions through a separate

contactor to control a single heating element and the

convector fan simultaneously. The control cycles the

heater and fan on and off in response to demand of

the sensor. A separate Hold light thermostat closes at

150°F. to verify the Hold cycle by lighting the HOLD

indicator light. The oven remains in the Hold condition

until the 12-hour timer is turned to the OFF position.

All other oven operation, including the Cook mode

is described in the service and parts manual for the

Power Saver II Convection Oven.

1.3 SERVICE

Should repairs be required, a network of authorized

service agencies is available to assist with prompt

service. A current Director of Authorized Service

Agencies and service assistance may be obtained by

contacting:

Product Service Department

Market Forge

35 Garvey Street

Everett, Massachusetts 02149

Tel.: (617)387-4100

Product Service Department

Market Forge Canada Ltd.

1375 Aimco Boulevard, Unit 5

Mississauga, Ontario,

Canada L4W 1 B5

Tel.: (416) 621-9252

The model and serial numbers must be referenced

when corresponding with Market Forge.

SECTION 2 OPERATION

2.1. OPERATING CONTROLS AND

INDICATORS

All controls required to operate the Power

Saver II with Cook & Hold are listed in Table 2-1

with a short functional description of each. Figure

2-1 shows the physical location of each control

and indicator.

2.2 OPERATING PROCEDURES

The Cook & Hold oven may be used as either a

standard oven or an oven which roasts and then

automatically holds at 150°F. for an indefinite

period. Instructions for operation in either cooking

mode are included in this section.

2.2.1 Preheating

1. Arrange shelf positions according to the food

product to be cooked. Refer to Test Kitchen

Bulletin #41 for correct positioning.

2. Place selector switch in the COOK (up) position

and close doors.

3. Place power switch in the ON position. Fan will

begin rotating.

4. Set thermostat dial to desired cooking

temperature. ELEMENTS indicator light will

come on.

5. Allow oven to preheat for about 15 minutes.

Preheating is complete when ELEMENTS

indicator light goes out.

2.2.2 Cook Mode Operation

The oven is ready for cooking use when the

ELEMENTS indicator light goes out following

preheating, (See subsection 2.2.1). For standard

cooking proceed as follows:

1. Load food into oven and close doors.

2. Set 60 MINUTE timer for desired cooking time.

Buzzer will sound at end of preset interval. For

cooking times longer than 60 minutes, reset

timer for additional time. (Timer is a

convenience feature only and has no oven

controlling function).

3. Unload oven and proceed as follows:

a. If oven is to be turned off, place thermostat dial

and power switch in OFF position.

b. If oven temperature is to be reduced, reset

thermostat to the desired temperature and

close the right door. Fan will continue to

operate with left door open. When ELEMENTS

indicator light comes on, oven is at lower

temperature. Left door is then closed until light

comes on to show that temperature has

stabilized.

4. Leave doors ajar if shut -down is to be longer than

one day.

2.2.3 Cook & Hold Operation

The oven is ready for cooking use when the

ELEMENTS indicator light goes out following

preheating, (See subsection 2.2.1). For Cook &

Hold operation proceed as follows:

1. Load food into oven and close doors.

2. Place selector switch in COOK & HOLD (down)

position.

3. Reset thermostat dial to initial roasting

temperature. (See Operators Manual, #17-0405 for

recommended temperature settings).

4. Set 12-HOUR timer (5-Hour Timer on some early

units) to approximate roasting time. (See

Operator's Manual #17-0405 for recommended

time settings). COOK indicator light will come on

and stay on throughout Cook & Hold operation.

NOTE

Once controls are set, all operation is automatic

and continuous. At end of primary cooking cycle,

when 12-HOUR timer dial has returned to '0minute' position, fan and heaters will shut off.

Product continues to cook with stored heat. 12HOUR timer must be left at '0-minute' position for

automatic operation to continue.

2-1 17-0406

2-2 COOK & HOLD POWER SAVER

CAUTION

Do not open doors or return timer dial to OFF

position until ready for oven unloading. If doors

are accidentally opened product must be finished

in Cook mode with meat thermometer used to

test doneness.

5. Unload the oven at any time after the HOLD light

comes on.

NOTE

HOLD light comes on when oven temperature

drops to 150°F. to indicate cooking is completed

and product is on hold for unloading as needed.

Heat and fan will operate intermittently as needed

to maintain 150°F.

6. Return 12-HOUR timer to OFF position when all

product has been removed from the oven.

7. Place thermostat dial and power switch in OFF

positions and leave doors ajar for daily shut down.

17-0406

Figure 2-1. Controls and Indicators

OPERATION 2-3

OPERATING CONTROLS AND INDICATORS

Controls electrical power to control circuits and convector fan motor. Must

Hold mode.

f with

out all phases of

Hold mode and will

TABLE 2-1

FIGURE 2-1 REF. DESCRIPTION FUNCTION

1 Circuit Breaker

2 Power Switch

3

4

Cook/Cook & Hold Selector

Switch

Thermostat Control

5 Element Indicator Light

6 60-Minute Timer

7 12-Hour Timer

8 Cook Indicator Light

Protects control circuits and conv ector fan motor. Must be in ON position

for oven to operate.

be in ON position for oven to operate.

Selects standard (Cook mode) baking and roasting or Cook &

Regulates oven temperature. Controls heating element operation.

Indicates when lit that thermostat is calling for heat. Cycles on and of

thermostat control.

Electric timer to aid operator in timing Cook mode operation. Does not

control oven operation. Sounds buzzer at end of timed interval. Place in

OFF position to silence buzzer.

Controls duration of primary roast cycle in Cook & Hold mode. When

preset time has elapsed, timer is left at '0-hour' position until stored heat

cooking is completed. Product is cooked and can be held or used as

desired when HOLD light comes on. Timer setting is changed from '0minute' to OFF only when oven is unloaded.

Indicates when lit that 12-HOUR timer has been set, and that selector

switch is in COOK & HOLD position. Remains on throughCook & Hold operation.

9 Hold Indicator Light

Indicates when lit that oven is in Hold phase of Cook &

maintain 150°F. 65°C. until 12-Hour timer is manually shut off.

17-0406

SECTION 3 PRINCIPLES OF OPERATION

3.1 GENERAL

The model 2400 HE Electric Convection Ovens are

equipped with an optional factory installed control

system which povides operator selection of standard

(Cook) operation or Cook & Hold operation. The oven

is otherwise constructed like model 2800 HE Power

Saver II. Principles of operation for the oven as a

whole are included in section 4 of service and parts

manuals #17-0393. The following description of

functions and controls is for Cook & Hold models only.

3.2 THEORY OF OPERATION

Cook & Hold controls include power circuits and

control circuits for operation of the oven in two modes.

A brief description of the sequence of events and

interdependence of components in each mode follows.

Simplified Schematic figure 3-1 shows the

interrelationship of each component described below.

3.2.1 Power and Heating Element Operation

Incoming power is supplied to the oven from a

terminal block at the lower, front right side of the oven.

Power is connected from the terminal block to three

contactors which control operation of heating

elements. (A fourth contactor in 440/480 volt units is

used for the fan motor). A single phase branch circuit

from the terminal block connects to the control panel

circuit breaker. (In 440/480 volt ovens, a step-down

transformer is included before the circuit breaker to

supply 220 to 240 volts).

When the control circuit thermostat requires heat in

either the Cook mode or the 'Cook' cycle of the Cook

& Hold mode of operation, two contactors are

energized to power the five heating elements inside

the oven. When satisfied, the thermostat opens the

coil circuit to break power to the heaters. On-off

operation proceeds throughout oven operation.

A third identical contactor controls the power circuit

to a single 2600 watt heating element during the 'Hold'

cycle of Cook & Hold operation. It opens and closes

under the control of a 150°F. temperature control

device. Only two sets of contacts are required for

heater control. The third is used for simultaneous onoff control of the fan motor.

3.2.2 Cook Mode Controls

With the control panel circuit breaker in the ON

position 208 to 220 volt service is connected to the

power switch. The power switch is the routine on-off

control for the oven. A normally open switch actuated

by closing the right side oven door functions as a

circuit interrupter to prevent operation unless the door

is closed. Power is brought up to the control

components when the power switch is in the ON

position and the right side door is closed.

A double-pole, double-throw selector switch which

functions as the mode selector switch is placed in the

COOK (up) position. The convector fan begins to

operate immediately, remaining on continuously

during Cook mode operation. The 475°F. (maximum

setting) thermostatic control is set to the required

preheat or baking temperature. Setting the dial when

the oven is cold automatically closes the thermostat

contacts to light the ELEMENTS indicator light and

energize the two contactor coils controlling the heating

elements. Thermostat contacts remain closed until the

capillary bulb inside the oven senses sufficient

temperature rise to open them. Elements are cycled

on and off by the thermostat as needed to maintain

temperature setting.

A 60-minute electric timer included as an operator

convenience has no controlling function. The dial is

set to the required oven operating time. At the end of

the timer setting a buzzer sounds until the dial is

returned to the OFF position.

3-1

3-2 COOK & HOLD POWER SAVER II

Figure 3-1. Pictorial Schematic — Typical Configuration

3.2.3 Cook & Hold Mode Operation

The same control circuit components are utilized

for Cook & Hold operation as for the Cook mode

except for the 60-minute timer. Setting the selector

switch in the COOK & HOLD (down) position supplies

power to control components for that mode. In normal

use the oven is first preheated in the Cook mode as

described in 3.2.2. The thermostat is then set to the

required initial roasting temperature prior to switching

to Cook & Hold.

Immediately on setting the selector switch to

COOK & HOLD, the COOK indicator light turns on.

The 12-hour timer, used for this mode, is set for the

initial roasting time. Timer contacts close to the fan

motor circuit to begin operation.

17-0406

Another circuit is closed to energize the coil of a

normally open single-pole relay (C4) which in turn

completes the circuit between the thermostatic control

and the heater contactor coils. Controls operate in

these positions, with timer motor running under the

continuous on-off control of the thermostat.

When the 12-hour timer setting elapses, the

common element transfers to complete a circuit to

'Hold' cycle components. Simultaneously the timer

motor and convector fan motor circuits are opened.

The relay contacts between the thermostat control and

heater element contactors are opened to interrupt

control by the thermostat. The oven is now in residual

heat roasting with only the COOK indicator light on.

The residual cycle continues until, by normal oven

heat loss, the interior temperature drops to 150°F.

PRINCIPLES OF OPERATION 3-3

The 'Hold' cycle of Cook & Hold operation is

controlled by a solid state 150°F. temperature

control. A thermistor probe mounted inside the oven

activates the control when the temperature drops to

150°F. Control contacts close to complete a circuit

to the contactor coil for single heater and fan

operation in the 'Hold' cycle. Each time the 150°F.

control contacts close the contactor pulls in to

power one 2600 watt heating element and the

convector fan. On-off operation proceeds

throughout the 'Hold' cycle, varying approximately +

1°F.from 150°F.

Simultaneous with 150°F. control operation, a

separate (normally closed at room temperature),

thermostat for the HOLD light senses interior oven

temperature. On temperature drop to 150°F. its

contacts close to turn on the HOLD light. Unlike the

150°F. control device, the light thermostat operates

in a wide temperature range from 150°F. to 170°F.

It keeps the HOLD light on throughout the 'Hold'

cycle, while the oven temperature fluctuates above

and below 150°F.

The 150°F. temperature control and HOLD light

thermostat operate throughout the 'Hold' cycle until

interrupted. Placing the 12-hour timer dial in the

OFF position terminates operation of both

thermostatic controls.

3.3 ELECTRICAL CIRCUITS

The electrical circuits for Cook & Hold controls

consist of the 208/220 or 440/480 volt power circuits

and the 208/220 volt control circuits. They contain

all contactors, relays, switches, timers, indicator

lights and wiring required for oven operat ion.

3.3.1 Power Circuit Components

The power circuits are shown in wiring diagrams

and schematic diagrams, figures 4-1 through 4-7.

Line voltage is connected to the line terminals of

two 30 Amp. contactors. Contactor load terminals

are connected to the leads of two 1300 watt and

three 2600 watt heating elements mounted inside

the oven. A third 30 Amp. contactor is connected to

two input poles with output to one 2600 watt

element for use in the 'Hold' cycle only. A fourth 10

Amp. contactor is used for fan motor control in

440/480 volt units only. All power circuit controls are

activated by the control circuits.

3.3.2 Control Circuit Components

Control circuits are shown in wiring diagrams and

schematic diagrams figures 4-1 through 4-7. Control

circuits are powered from a branch line off L3 and one

other terminal block terminal depending on voltage

characteristics for the oven. Input controls have

common use for both Cook and Cook & Hold modes

up to the selector switch. Beyond the mode selector

switch many controls are used for one mode only.

Components for each mode are described in the

following paragraphs.

3.3.2.1 Control Circuit Components For Both

Modes.

The components which control power to both Cook

and Cook & Hold controls include the following:

1. Tr ansformer - (440/480 volt ovens) -A 440/480 volt

to 220/240 volt step-down transformer supplies

input power for the control circuit. The primary field

windings are connected to L2 and L3 terminal

block locations.

2. Circuit Breaker - 15 Amp., 2-pole circuit breaker

provides overload protection for the control circuit.

Normally left in the ON position, it supplies 208 to

220 volts to the power switch.

3. Power ON-OFF Switch - A double-pole, doublethrow toggle switch provides routine on-off control

for the oven. In the ON position it connects

through one pole to the door switch, and through

the second pole to the L3 power feed for all

components.

4. Door Switch - A single-pole, normally open, microswitch actuated by closing the right side oven

door. It serve s as a circuit interrupter, stopping all

oven operation unless the door is closed. When

closed it completes the circuit from one selector

switch common element to the 475°F. operating

thermostat contacts.

5. Thermostat Control - A maximum setting 475°F.

control for oven operating temperature. A capillary

bulb mounted inside the oven is permanently

connected to the bellows in the control. When

thermostat contacts are closed a circuit is

completed to one common element of the selector

switch.

17-0406

3-4 COOK & HOLD POWER SAVER II

6. Mode Selector Switch - A double-pole, double-throw

toggle switch for selection of Cook or Cook & Hold

operation. Power is supplied to the two common

elements through controls described above. Output

terminals are connec ted with appropriate

components for each mode.

3.3.2.2 Cook Mode Components. The only

components used exclusively for Cook mode

operation are the 60-minute timer and buzzer. The

timer is a convenience item only and has no

controlling function. When the dial is set the common

element closes a circuit to the timer motor to maintain

timer operation. At the '0' minute setting the common

element switches to contacts for the buzzer circuit.

The buzzer sounds until the timer knob is placed in

the OFF position.

Other components used for the Cook mode are the

ELEMENTS indicator light and heater element

contactors which cycle on and off by control of the

475°F. thermostat control. The convector fan operates

continuously.

3.3.2.3 Cook & Hold Mode Components.

When the selector switch is placed in the COOK &

HOLD position the following components function to

control operation.

1 12-Hour Timer - The timer controls the duration of

initial roasting and switches to the 'Hold' cycle. The

common element is connected to one Cook & Hold

terminal of the mode selector switch. When set for

initial roasting, the timer completes a circuit to the

convector fan motor and timer motor, and closes a

relay in the thermostat circuit to the heater

contactors. At the end of the initial roasting period

the common element switches to the hold

component circuit. It remains in this position until

the dial is moved to the OFF position.

2. Relay C4-A single-pole, normally open relay.

Its coil is energized when the 12-hour timer is set

for initial roasting with closed contacts

ostat control to heater contactors. When the 12hour timer reaches '0' hours, the relay coil circuit is

opened, in turn causing relay contacts to open so

that the 475°F. thermostat circuit to heater

contactor is interrupted.

3. COOK Light - The light (red lens) is connected to

one selector switch terminal for Cook & Hold

operation. It comes on immediately upon setting

the switch.

4. 150°F. Temperature Control - A solid state

temperature actuated switch device, with switch

contacts normally open at room temperature. It is

actuated by a thermistor probe mounted inside the

oven and connected electrically to the control.

Operating potential is connected from L3 on one

side, and the 'Hold' cycle terminal of the 12-hour

timer on the other. The control/probe system

functions to maintain 150°F. temperature during

the 'Hold' cycle. When the oven temperature drops

to 150°F. at the end of residual heat roasting, the

control contacts close a circuit to the coil of the

contactor for 'Hold' cycle heater and fan control.

The contactor opens and closes under the control

of the 150°F. control until the 12-hour timer dial is

returned to the OFF position.

5. HOLD Light Thermostat And HOLD Light - A

separate button type thermostatic switch, normally

closed at room temperature is used to control

HOLD light operation. Its contacts close on

temperature drop to 150°F. and open on rise to

170°F. It functions to keep the HOLD light on

continuously during the 'hold' cycle.

completing the circuit from the 475°F. therm-

17-0406

Loading...

Loading...