Page 1

STACKED HIGH EFFICIENCY

G

MODELS: 2392 HEC, 2592 HEC, 2792 HEC *

SIZE: 2392 HEC, 2792 HEC, 39

wide (997mm front-to-back by 914mm wide) 2592 HEC,

33" front-to-back by 36" wide (838mm front-to-back by

914mm wide)

❍ Model 2392 HEC with COOK & HOLD:Will be two

Market Forge! High Efficiency Pilotless Ignition Gas Connection Ovens equipped with COOK & HOLD controls.

COOK & HOLD permits operator to preset oven to cook

food and hold it at 150°F (65°C) at the completion of the

cooking cycle.

❍ Model 2592 HEC:

PILOTLESS GAS CONVECTION OVEN

1

/4" front-to-back by 36"

JOB NAME

ITEM NO.

NO. REQUIRED

T op Oven Shown with Cook & Hold

❍ Model 2792 HEC:

Will be two Market Forge! High Efficiency Pilotless Ignition Gas Convection Ovens.

Stacking will be done at installation site using gas oven

stacking kit. Kit will include stand, 2" (51mm) spacer for

between ovens, flue extenders, flue diverter, and mounting hardware.

Exterior will be finished in grey hammertone baked

enamel with stainless steel front. Oven front, top, rear,

and sides will contain minimum of 1 “ (25mm) insulation.

French-type doors will open a fuIl 180° and will be:

❍ Stainless steel with minimum 1 “ (25mm) insulation

❍ Glass

Oven interior dimensions will be:

3

/4" wide by 203/4" high by 275/8" deep

26

(679mm wide by 527mm high by 702mm deep).

(Model 2592 HEC-213/8" (543mm deep.)

Oven shelves and shelf supports will provide nine shelf

positions centered 2" (51mm) apart. Shelf stop on oven

shelf will prevent tipping within the shelf supports. Five

shelves will be furnished as standard. Oven interior will

be stainless steel with coved corners for ease of cleaning, with steam release vent exhaust out the back.

Controls will be independent for each oven. Controls will

be located on recessed panel on right front of ovens.

Controls will include main power switch, thermostat with

indicator light and temperature range of 200°-475°F (93°246oC), mechanical 60-minute and 5 hour (12-hour elec-

trical on Model 2392 HEC) timers with audible alarms

that sound at end of preset interval, and Cook/Cook &

Hold selector switch with hold indicator light (Model 2392

HEC only). Unit will be equipped with a high limit control.

Convector fan will turn on automatically when power is

on and right door is closed, and turn off automatically

when right door is opened. For rapid cooling purposes, it

will be possible to operate convector fan with left door

open in order to quickly evacuate heated air from the

oven. Convector fan motor will be rated at 1/4 HP at 3

amps.

OPERA TION WILL BE BY :

Oven will be equipped for operation with:

❍ Natural Gas (60,000 BTU/hour) per oven

❍ Propane Gas (63,000 BTU/hour) per oven

Manifold gas pressure will be 4" (102mm) for natural gas

and 10" (254mm) for propane gas. Incoming gas pressure must not exceed 14" (357mm) W.C.

NOTE:

If the equipment is to be installed where the elevation

exceeds 2,000' (609.6 meters) above sea level, specify

installation altitude so that proper orifices can be provided.

Oven controls and convection fan will operate on nominal 120 volts AC.

Oven will be serviceable from the front. Back of oven will

be completely enclosed by louvered panel.

OPTIONAL A T EXTRA COST:

❍ Extra shelves ______quantity

❍ Stainless steel left side

❍ Stainless steel right side

❍ Stainless steel top

❍ Stainless steel back panel

SPEC NO.

02/03

S-2202I

Stacked High Efficiency Oven

FOOD SERVICE EQUIPMENT

The manufacturer reserves the right to modify materials and specifications without notice.

An Employee Owned Company

35 Garvey Street * Everett * MA * 02149

Tel: (617) 387-4100 * Fax: 1-800-227-2659 (Ex. MA) * (617) 387-4456 (MA and Overseas)

E-Mail: CUSTSERV@mfii.com * Website: www.mfii.com

Page 2

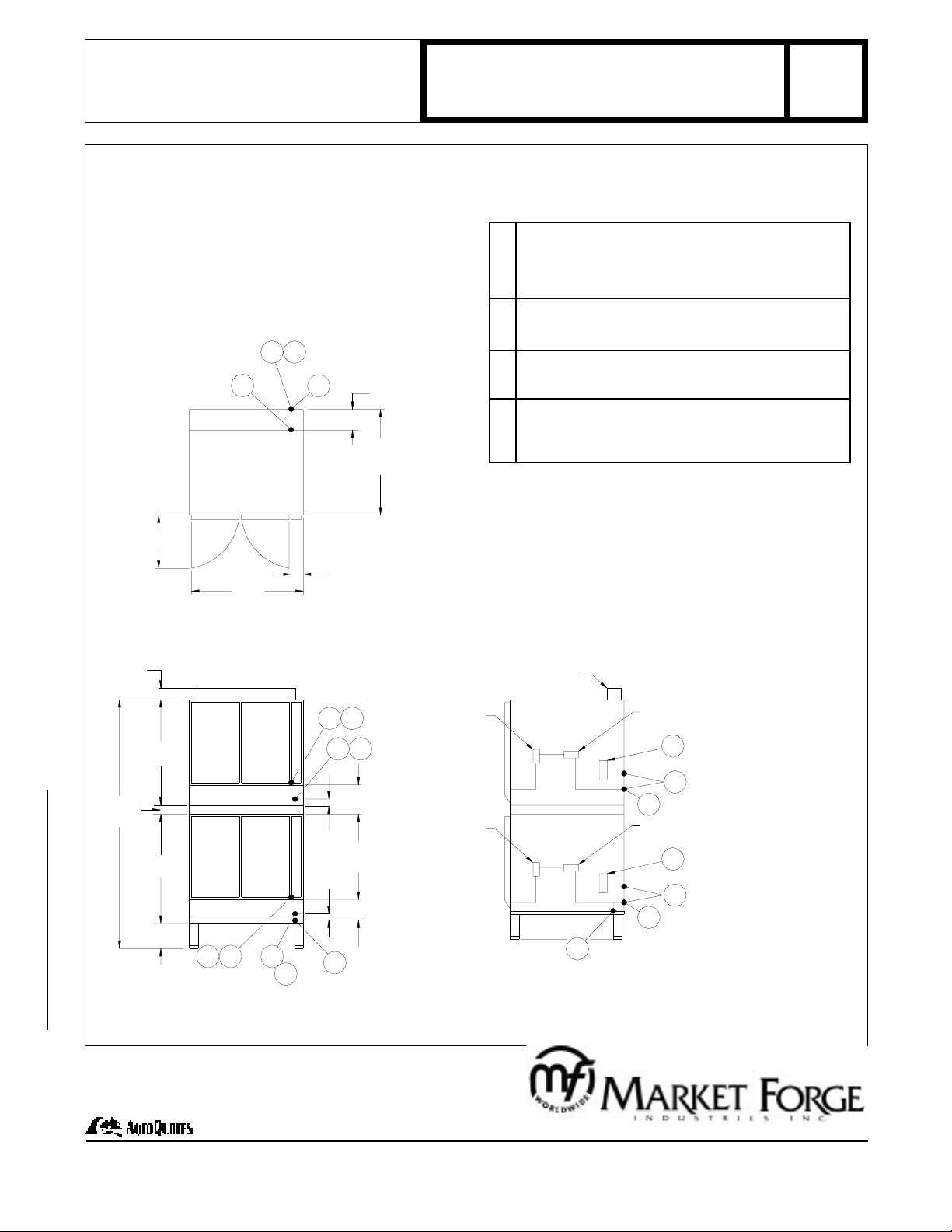

DETAILS & DIMENSIONS

STACKED HIGH EFFICIENCY

PILOTLESS GAS CONVECTION OVEN

SERVICE CONNECTIONS

Gas Operated

E Electrical Connection - Power Supply wire junction

box. 120V AC, 60Hz, 3 amps per oven. 1/2” (13mm)

conduit connection or equivalent. Use wire suitable

for at least 90

o

C.

G

S-2202I

02/03

SPEC NO.

1880mm

74"

3"

76mm

2 1/4"

57mm

17"

432mm

30 3/4"

781mm

30 3/4"

781mm

7"

178mm

G Gas Connection -

3

/4” (19mm) I.P.S. Gas Connection

Inlet, Standard.

H

H

GA Gas Connection - 3/4” (19mm) I.P.S. Gas Connection

E

FLUE

GA

5"

127mm

2592 HEC, 33" (838mm)

2792 HEC, 39 1/4" (997mm)

2392 HEC, 39 1/4" (997mm)

Inlet, Alternate.

H 1 3/4” (44mm) dia. access holes for:

1.) Alternate gas supply connection (GA).

2.) Access to electrical junction box.

NOTES:

Allow 6" (152mm) space from side wall and rear wall if

adjoining walls are combustible.

A 6" (152mm) space must be maintained between the

right side of the ovens and another heat generating piece

of equipment. All stands are 32" (813mm) front- to-back.

Modular base is 33" (838mm) front-to-back. When used

with deep oven, overhang may be either front or back as

36"

914mm

3 1/2"

89mm

desired. Allow 33/4" (95mm) beyond front edge for door

handles.

FLUE

FLUE

H

2"

51mm

H

E

GA

4"

102mm

Gas

Valve

Gas

Valve

Regulator

E

H

GA

Regulator

E

4"

102mm

2"

H

E

H

GA

51mm

G

G

H

GA

FOOD SERVICE EQUIPMENT

*It is our policy to build equipment which is design certified by U.L., A.S.M.E., N.S.F. and C.S.A. However, a continuing program of

product improvement makes it necessary to submit new models to the agencies as they are developed and consequently not all

models bear the appropriate agency labels at all times.

Stacked High Efficiency Oven

PRINTED IN U.S.A.

Tel: (617) 387-4100 * Fax: 1-800-227-2659 (Ex. MA) * (617) 387-4456 (MA and Overseas)

An Employee Owned Company

35 Garvey Street * Everett * MA * 02149

E-Mail: CUSTSERV@mfii.com * Website: www.mfii.com

Loading...

Loading...