Marathon Computer V-4224 User Manual

PLAY IT SAFE!

OPERATION, MAINTENANCE

AND INSTALLATION MANUAL

FOR

VERTICAL RECYCLER BALER

V-4224

Marathon Equipment Co. OMI Manual No. 0011CE, Rev. 02/02

VERNON, AL - FAYETTE, AL

YERINGTON, NV - CLEARFIELD, PA

CE RATED MODEL

Introduction .................................................................. 1-1

EC Declaration of Conformity....................................... 1-2

Pre-Operating Instructions ....................................... 1-3

Controls ....................................................................... 1-4

Control Description ...................................................... 1-5

Operating Instructions

Making A Bale ................................................... 1-6

Bale Tie Off/Bale Eject ...................................... 1-7

Diagram ................................................. 1-8

Tie Slot Cleaning ......................................................... 1-9

Decals ......................................................................... 1-10

Decal Placement ......................................................... 1-11

Lock-Out & Tag-Out Instructions ............................. 2-1

Supporting Of Platen ................................................... 2-2

Periodic Maintenance .................................................. 2-3

Pressure Setting .......................................................... 2-4

Interlock Testing .......................................................... 2-5

Cylinder Removal And Rebuilding .............................. 2-6

Feed Gate Latch Adjustment ...................................... 2-7

Principles Of Operation ............................................... 2-8

Charts ......................................................................... 2-9

Panel Box .................................................................... 2-10

Power Unit ................................................................... 2-11

Electrical Schematic .................................................... 2-12

Hydraulic Schematic ................................................... 2-13

Parts List ..................................................................... 2-14

Recommended Oil ...................................................... 2-14

Motor Warranty ........................................................... 2-14

General Installation ..................................................... 3-1

Anchoring To Concrete Pad ........................................ 3-2

Electrical Installation ................................................... 3-3

Start-Up Instructions .................................................... 3-4

CONTENTS

Copyright © 2002 Marathon Equipment Company

SECTION 1 - Operation

SECTION 2 - Maintenance

SECTION 3 - Installation

1 OPERATION

INTRODUCTION

THANK YOU FOR PURCHASING A MARATHON VERTICAL BALER.

This product is designed to give you reliable service and superior performance for years

to come. To guarantee top performance and the safest operation of the baler, each

person involved in the operation, maintenance and installation of the baler should read

and thoroughly understand the instructions in this manual and follow all warnings.

The employer(s) involved in the operation, maintenance and installation of the baler

should read and understand the most current version of the following applicable

standards:

ANSI Standard No. Z245.5, “Safety Requirements For Baling Equipment”

A copy of this standard may be obtained from:

Environmental Industries Association

4301 Connecticut Avenue, N.W.

Suite 300

Washington, D.C. 20008

Telephone: 1-202-244-4700

OSHA 29 CFR, Part 1910.147, “The control of hazardous energy (lockout/tagout)”

IF YOU SHOULD NEED FURTHER ASSISTANCE, PLEASE CONTACT YOUR

DISTRIBUTOR. YOU WILL NEED TO PROVIDE THE BALER SERIAL

NUMBER, INSTALLATION DATE, AND ELECTRICAL SCHEMATIC NUMBER

TO YOUR DISTRIBUTOR.

IF YOU HAVE ANY SAFETY CONCERNS WITH THE EQUIPMENT, OR

NEED FURTHER INFORMATION, PLEASE CONTACT US AT:

Marathon Equipment Company

P.O. Box 1798

Vernon, Al 35592-1798

Attn: Field Service Department

1-800-633-8974

1-1

ALL SERVICE OR REPAIR PROCEDURES DESCRIBED IN THIS

MANUAL SHOULD BE PERFORMED BY AUTHORIZED, FULLY

TRAINED PERSONNEL.

Any service or repairs that go beyond the scope of this manual

should be performed by factory authorized personnel only.

EC DECLARATION OF CONFORMITY

The Supply of Machinery (Safety) Regulations 1992

Pursuant to The Council of The European Communities Directive 89/392/EEC, as amended by

91/36P/EEC

The Machine/Installation:

PRODUCT: V-4224 Vertical Recycler Baler

SERIAL NUMBER: As specified for EC export

YEAR OF MANUFACTURE: 2006

The above has been developed, designed and manufactured in accordance with the above relevant

statutory provisions by:

Marathon Equipment Company

950 County Road

Vernon AL, USA 35592

THIS DECLARATION WILL BECOME INVALID IF, FOLLOWING HAND OVER, THE

MACHINE/INSTALLATION IS ALTERED IN ANY WAY.

The following harmonized standards have been applied:

1991 EN 292/1 and EN 292/2, Safety of machines, devices and installations

1992 EN 418, Safety of Machinery, Emergency Stop Equipment, Functional Aspects.

Principals for Design

1992 EN 294, Safety distance to prevent access to danger zones

1993 EN 60 204-1, Safety of Machinery, Electrical Equipment of Machines

1993 EN 349, Safety of Machinery, Minimum Gaps to Avoid Crushing Parts of the

Human Body

1996 BS EN 982, Safety Requirements of fluid systems and components

1997 BS EN 1050, Safety of Machinery, Principles for Risk Assessment

1998 BS EN 953, Safety of machinery, Guards.

Technical documentation is available upon request.

The operating manual for the machine/installation is provided.

(* ) in the language of the country of manufacture

(*) in the national language of the user

P.O. Box 1798

Vernon, AL 35592-1798

800-633-8974

205-695-9105

http//www.marathonequipment.com

1-2

1 OPERATION

PRE-OPERATING INSTRUCTIONS

06-0045

460

VOLTS

DANGER

NEVER ENTER ANY PART OF THE BALER UNLESS THE DISCONNECT

SWITCH HAS BEEN TURNED OFF AND PADLOCKED. Before starting the

baler, be sure no one is inside. Be certain that everyone is clear of all points of

operation and pinch point areas before starting. See Lock-Out & Ta g - O u t

instructions in the Maintenance section.

THE EMP LOY ER SH OUL D ALLOW ON LY

AUTHORIZED AND TRAINED PERSONNEL TO

OPERATE THIS BALER. This baler is equipped with

a key operated locking system. The key(s) should be

in the possession of only authorized personnel. Turn

off and remove key after use.

Pay close attention to the RED WARNING LIGHT on the control panel. If the light

is illuminated w hen the feed gate is raised, there is a malfunction of the

magnetic interlock system. IN THIS EVENT, DISCONTINUE USE OF THE BALER

AND LOCK-OUT & TAG-OUT THE BALER PER THE INSTRUCTIONS IN THE

MAINTENANCE S ECTION, PAGE 2-1. Perform necessary repairs before

continuing operation of the baler.

O N LY AUT H ORIZE D P ERSONN E L

SHOULD BE ALLOWED INSIDE THE

PA N E L B O X . The panel box contains

high voltage components. See Lock-Out

& Ta g -Out i n struc ti ons i n the

Maintenance section.

BE CERTAIN TURNBUCKLE AND LATCH IS FULLY LOCKED IN PLACE ON BALE

CHAMBER DOOR BEFORE STARTING BALER.

STAND CLEAR WHILE

BALER IS IN OPERATION.

WARNING: DO NOT OPERATE BALER UNTIL OPERATING INSTRUCTIONS ARE

THOROUGHLY UNDERSTOOD.

1-3

Federal regulation prohibits operation by persons under 18 years of age.

1 OPERATION

400

1 OPERATION

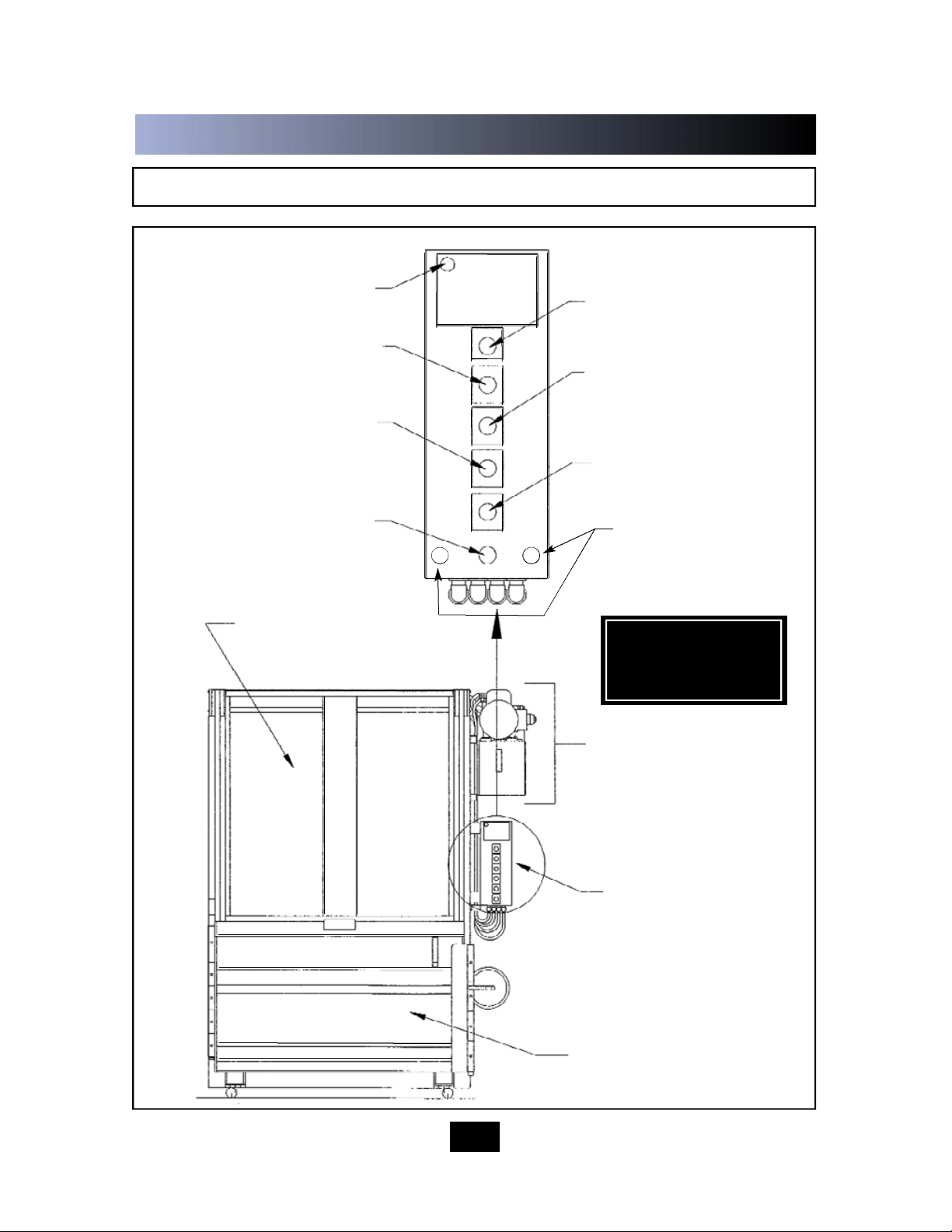

C O N T R O L S

1-4

MANUAL DOWN BUTTON

RED WARNING LIGHT

KEYED ON/OFF SWITCH

MANUAL UP BUTTON

BALE MADE LIGHT

EMERGENCY STOP BUTTON

CONTROL PANEL

FEED GATE

BALE DOOR

POWER UNIT

AUTOCYCLE BUTTON

*SEE CONTROL

DESCRIPTION ON

FOLLOWING PAGE

RESET INTERLOCK

OVERRIDE

1 OPERATION

CONTROL DESCRIPTION

1.

2.

3.

4.

5.

6.

7.

1-5

ON-OFF (Keyed Selector Switch)

Turning this switch to the ON position activates the other controls in the control panel. The

baler can not be operated unless the key is in the switch and the switch is in the ON

position. The purpose of this switch is to allow only authorized and trained personnel to

operate the baler. The key should be removed from the baler when not in use and should

stay in the possession of only responsible and trained personnel.

EMERGENCY STOP (Red Mushroom Head Pushbutton)

Depressing this button will stop the machine at any point in the cycle.

AUTOCYCLE (Green Pushbutton)

The AUTOCYCLE button can be used only when the feed gate and bale door are closed

and the keyswitch is in the ON position. Once depressed, the A U T OCYCLE button will

cause the platen to move to the fully down position and back to the fully raised position

(one complete cycle).

MANUAL UP (Black Pushbutton)

This button will only start the baler with the keyswitch in the ON position. Depressing this

button will raise the platen with the feed gate and bale door opened or closed. It is normally

used during bale ejection. It can also be used to interrupt the automatic cycle and raise the

platen should it become necessary. The MANUAL U P button is a “Hold To Run” control,

causing the baler to stop wh

en it is released. WA R N I N G : S T AY CLEAR OF MOVING

PARTS WHEN USING THE MANUAL UP BUTTON WITH THE FEED GATE OPEN.

MANUAL DOWN (Black Pushbutton)

This button will only start the baler with the keyswitch in the ON position. Depressing this

button will lower the platen only if the feed gate and bale door are closed. It can be used to

interrupt the automatic cycle and lower the platen should it become necessary. T h e

M A N U A L DOWN button is a “Hold To Run” control, causing the baler to stop when it is

released.

RED WARNING LIGHT

This light will warn the operator of a magnetic interlock switch malfunction. If the light is on,

and the feed gate is in the up position, there is a problem. Discontinue use of the baler.

Turn off the baler and Lock-out and Tag-out per the instructions on page 2-1. Then call a

qualified service person. The light SHOULD BE ON when the feed gate is in the down

position.

BALE MADE LIGHT

This light will come on if enough material has been compacted to make a complete bale.

IN CASE OF EMERGENCY:

Push the large red button to

STOP

OPERATING INSTRUCTIONS - MAKING A BALE

WA R N I N G : DO NOT O P E R A TE BALER UNTIL O P E R A TING INSTRUCTIONS A R E

UNDERSTOOD.

See page 1-4 for control panel layout.

1-6

WARNING: Interloc ks and safety devices were installed on this u nit for your

p r o t e c t i o n . Never disable or bypass any interlock or safety device. Failure to

comply with this warning could result in serious injury or death.

TO MAKE A BALE :

1. Feed material into baler. If starting a new bale, place a large flat piece of

material flat on the baler floor. NOTE: Do not attempt to overfill the feed

chamber by forcing material into the chamber with the feed gate. This can cause

gate release malfunction and may damage baler.

2. Pull gate handle down to close feed gate. NOTE: Check red warning light

before closing feed gate. If gate is open and light is on, discontinue use of the

baler and call for service.

3. To start the baler, insert the key into the keyswitch and turn to the ON

position.

4. Press the AUTOCYCLE button. The platen will make a complete cycle down

and back up. When the platen is in the full up position, the feed gate will

automatically open and the motor will automatically shutdown.

5. Repeat steps 1 through 4 until the platen stops in the down position, and the

“BALE MADE” light comes on.

NOTE: In normal operation, the feed gate will be open when you walk up to

place material into the baler. For added security, the feed gate can be manually

closed after the AUTOCYCLE(S). To open the gate, you will have to insert the

key into the keyswitch and run the baler through a complete AUTOCYCLE.

1 OPERATION

OPERATING INSTRUCTIONS - BALE TIE OFF/BALE EJECT

1-7

When the “BALE MADE” light comes on it is time to tie off the bale and eject the bale

from the baler. See page 1-4 for control panel layout and location. See the following

page for a diagram of the following steps.

FOR BALE TIE OFF & BALE EJECT:

1. Press the MANUAL UP button until the platen is in the up position and the feed

gate raises.

2. Insert a large, flat piece of material across the top of the bale. With the platen in

the “up” position, make sure there is no cardboard, or other baled materials,

stuck between the back of the platen and the back wall of the baler. Remove any

materials found in this area.

3. Close feed gate and press the AUTOCYCLE button. The platen will move to the

down position and the BALE MADE light will come back on.

4. Release the bale chamber door latch on the side of baler and open the

bale chamber door all the way. Feed gate is closed but will raise when the bale

chamber door is opened.

5. CAUTION: Wear safety glasses and leather gloves during the following

operation: Facing the front of the bale, tie off bale by inserting bale ties (loop

end first) through the platen. Always insert bale ties through the tie slots in

the platen, first. Feed wire through until it comes out of the tie slot in the baler

floor. Tie off each tie. Bale ties should be tightened only hand tight, allowing for

bale expansion when released. See Diagram on Following Page.

6. Standing at the side, make sure all personnel are clear of the front of

the baler. Press and hold the MANUAL UP button until the bale ejects.

7. Remove bale from in front of baler. Close and latch the bale door completely.

Failure to close and latch the bale door completely may result in serious damage

to the bale ejector.

8. Close the feed gate, and press the AUTO CYCLE button and let the machine

run through a complete cycle to reset the bale ejector hook. When the feed gate

raises, the machine is ready to start the next bale.

NOTE: You can close the feed gate at this time if added security is required. To

open the gate you will have to run the baler through a complete AUTOCYCLE.

1 OPERATION

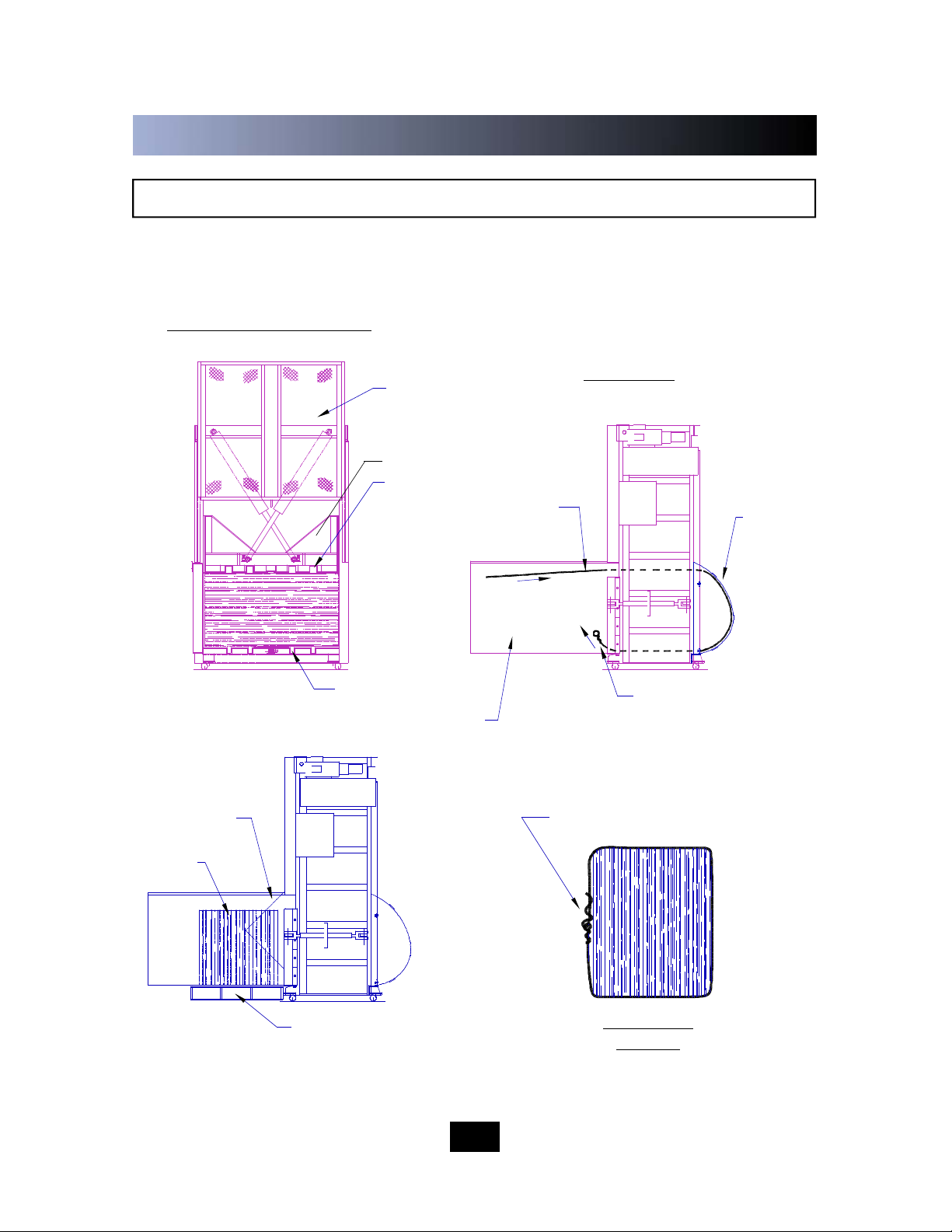

DIAGRAM - BALE TIE OFF/BALE EJECT

FRONT VIEW OF BALER

BALE TIE - TIGHTENED

HAND TIGHT

BALE DURING

EJECTION

PALLET OR BALE CART

RECOMMENDED FOR

SUPPORTING BALE

SIDE VIEW

BALE CHAMBER

DOOR OPENED

SIDE VIEW

- BALE

1-8

BALE TIES ENTER

THROUGH PLATEN

LOOPED END FIRST

BALE TIES EXIT

THROUGH FLOOR

EJECTED

BALE

BALE TIE SLOTS

PLATEN

BALE TIE SLOTS

FEED GATE OPENS

WHEN BALE DOOR

IS OPENED

BALE TIES

FOLLOW

WIRE

GUIDES

1 OPERATION

Loading...

Loading...