Page 1

UNIPRO v3.5

Users Manual

COPYRIGHT © 1998

MARATHON MONITORS INC

Page 2

Marathon Monitors Inc.

Description and Applications

The Marathon Monitors Inc. UNIPRO Controller/Programmer

represents the latest technology in microprocessor-based process

control instrumentation. Through flexible PID (Proportional,

Integral, Digital) control along with programmable features, even

the most complex, system can be handled. For a thorough

explanation of PID please refer to Zeigler and Nichols; “Optimum

Settings for Automatic Controllers”, Transactions of ASME, Nov.

1942. Or St. Clair, David W.; Controller Tuning and Control Loop

Performance, a Primer; Straight-Line Control Company, Newark

,Delaware 1989.

The UNIPRO's control actions are based upon input from a

Thermocouple, RTD, Voltage or Current source. The

UNIPRO allows Manual, Automatic, or Programmed control

of a single loop. Its built-in RS-422 computer interface

allows it to be completely supervised by a computer, either

on-site or in some remote location within the plant. The

Programmer can be used, and is strongly recommended, to

allow complete control of temperature or other process

cycles.

The following features have been included to allow use of the

instrument in a wide variety of applications:

Fully site-configurable for single point control from one of three

(3) fully isolated analog input sources, each separately configurable

for thermocouple, RTD, voltage, or current.

Powerful process/logic programmer that can store up to

two-hundred (200) programs, each consisting of nineteen (19)

steps, subroutine calls, test and branch capability, and full access to

all instrument parameters.

Unipro 3.5 Process Control 1 Aug. 1997

Page 3

Marathon Monitors Inc.

Two (2) control output triacs for use in single or dual control

mode.

Two (2) fully isolated analog outputs, each separately configurable

for voltage or current output.

Two (2) configurable alarm triacs, assignable as process Alarms,

deviation alarms, program alarms, or fault alarms.

Four (4) programmer events, assignable in any combination as

either inputs or outputs (expandable to 16 I/O with external event

boards).

Three (3) communication ports for talking with host computers,

controllers, and discrete digital and / or analog event expansion

racks.

This manual provides all of the information required to install,

operate and maintain the MMI UNIPRO.

The manual is divided into parts: Installation, Setup and

Configuration, Operation, Programming, and Maintenance and

Troubleshooting. Installation and Setup and Configuration will be

used initially to get the instrument into use. Operation and

Programming will be used daily. Maintenance and

Troubleshooting will be used for servicing the instrument

periodically or if trouble occurs.

Unipro 3.5 Process Control 1 Aug. 1997

Page 4

Marathon Monitors Inc.

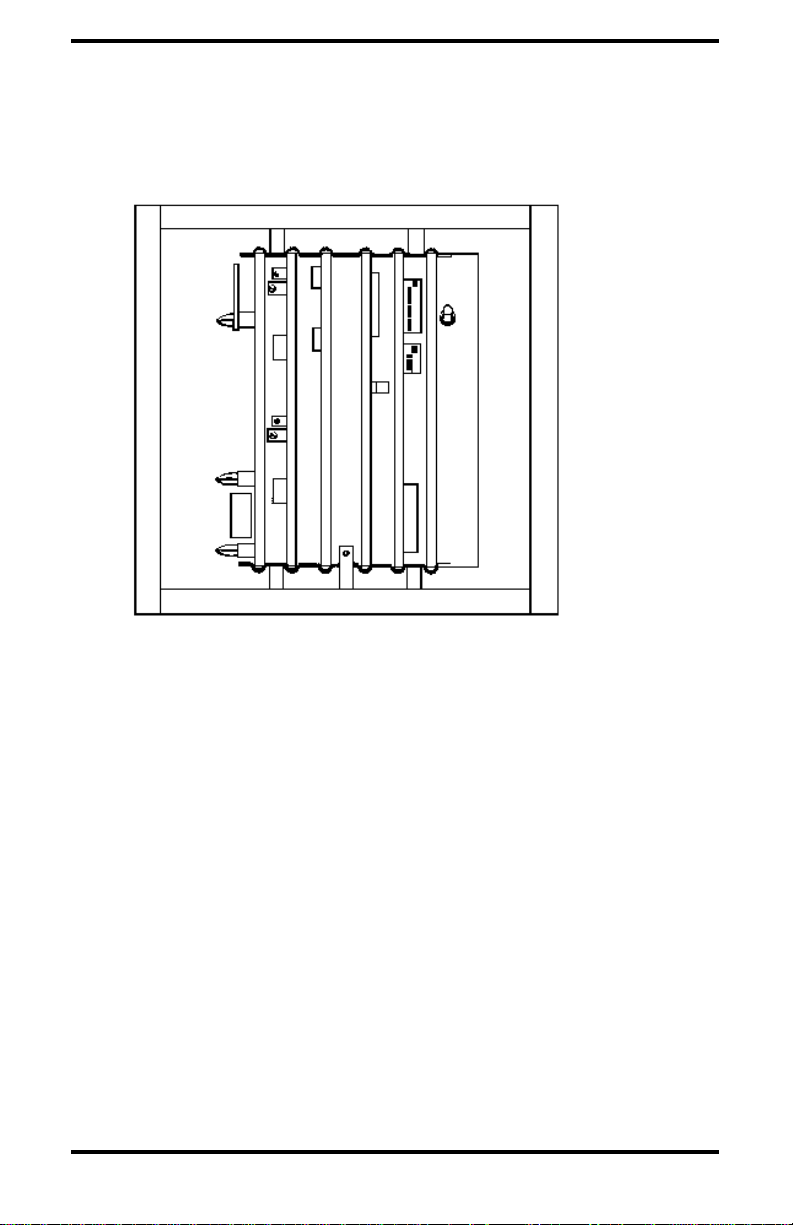

Installation

Installation Location

The UNIPRO instrument is designed for 1/8 inch panel mounting in

a DIN standard opening of 5.43 inches square (adapter panels

available by special order). Required rear clearance is 10.5 inches

to allow for wiring. As with all solid state equipment, the

controller should be away from excessive heat, humidity, and

vibration (refer to specifications). Since the unit uses red LED

display devices, avoid placing it in direct sunlight to reduce

interference with the display's visibility. The instrument requires

100/120/200/240 VAC (jumper selectable on power interconnect

board inside the rear panel) 50/60 Hz. It should not be on the

same circuit with other noise-producing equipment such as

induction machines, large electrical motors, etc. All instrument

wiring must be run separate from all control wiring.

Panel Mounting/Removal

Because the instrument uses a ventilated enclosure, it is not

dust-tight and should therefore always be mounted in a sealed

control panel. To mount the UNIPRO in a control panel, a hole

must be cut 5.43 inches square in the necessary location on the

panel. The following procedure should be followed to mount the

UNIPRO in the panel.

1. Insert the unit into previously cut out 5.43 inches square

hole in the panel.

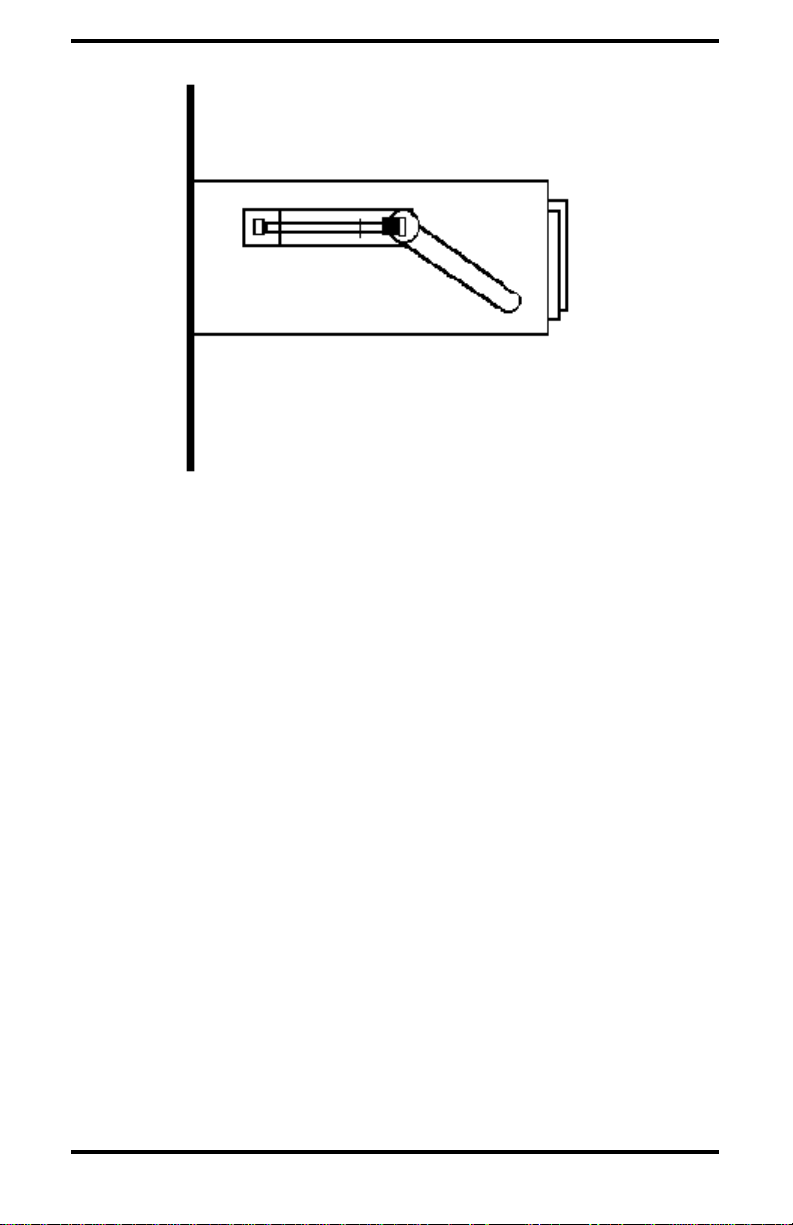

2. While supporting the unit, insert one slotted clamping

bracket, with head of the bolt facing to the rear of the unit, into the

0.62 inch by 0.82 inch cutout on the side of the unit.

Unipro 3.5 Process Control 1 Aug. 1997

Page 5

Marathon Monitors Inc.

Unipro 3.5 Process Control 1 Aug. 1997

Page 6

Marathon Monitors Inc.

3. Repeat step 2 for the opposite side of the unit.

4. With 1/8 inch HEX KEY wrench, alternately tighten bolts

on either side of the instrument to a torque of 4 in-lbs. (See warning

below). Insure rigidity of mounting.

Warning

To prevent warping of the unit's case, do not over tighten the

clamp bolts.

5. To remove the unit, loosen the side clamping brackets and

reverse steps 1 through 3 above.

Note

Unipro 3.5 Process Control 1 Aug. 1997

Page 7

Marathon Monitors Inc.

On subsequent removals and installations the rear

panel can be removed (4 screws) and the wiring

does not have to be disturbed.

Warning

All connections, rear panel installations and removals; plus

triac board installations and removals must be done with

power removed from TBA and TBB. All PC boards should

only be removed or installed with power off via the switch

mounted on the triac board. Otherwise, serious personal

and/or equipment damage can occur.

Thermocouples and Other Signal Wires

The wiring used to connect the signal wires to the instrument

should be run in a conduit, separate from any AC lines in the area.

This provides noise immunity and physical protection.

Thermocouples should be wired with the appropriate alloy

extension wire with no termination other than at the instrument. As

with all cold-junction compensating instruments, extreme care

should be used when an existing thermocouple is to be used for

both the Controller and another instrument at the same time.

Control Devices

The UNIPRO provides simple ON/OFF as well as Proportional

control through its two contact closure Control Outputs (TBA-7,

TBB-7, TBA-8, and TBB-8) and two Analog Outputs (TBD-13

through TBD-16). Refer to the Section on Control Modes for

more details on the outputs. This allows control through simple

ON/OFF devices or through Proportional control methods.

SIMPLE ON/OFF CONTROL: Set Control Mode for

ON/OFF Control. This provides contact closure at Control Output

#1 to control absolute heat application/removal for such devices as

heating elements, etc.

Unipro 3.5 Process Control 1 Aug. 1997

Page 8

Marathon Monitors Inc.

Three types of Proportional control are:

1. Time-Proportioning: Referring to the

modulation of the duty cycle. That is,

changing the ratio of On Time versus Off

Time in systems that use such devices as

heating elements, electronically

operated/assisted valves, or servo drives that

use analog command signals for control.

2. Position-Proportioning: Referring to the

adjustment of a variable positioning device

such as a positioning motor with slidewire

feedback.

3. Voltage or Current Output Proportioning:

An Analog output's (voltage or current)

amplitude is varied based on input from

rheostats, thermocouples, ammeters, etc. to

control heat applications.

The UNIPRO provides many ways to use the above control

methods. Setup has details for setting the Control Modes to

determine the method to be used. Some typical applications for the

Proportioning method are:

1. HIGH/LOW or HEAT COOL heat application system: Set

Control Modes for Time-Proportioning. This provides that

CONTROL OUTPUT #1 (TBA-7, TBB-7) and CONTROL

OUTPUT #2 (TBA-8, TBB-8) are in opposite conditions at either

extreme of the control range and are both OFF at the midpoint of

the control range.

2. ANALOG OUTPUT control: Set Control Modes for

Time-Proportioning. This provides a 0 to 5 VDC or 4 to 20 mA

output which is selectable on the ANALOG OUTPUT BOARD

(TBD-13 through TBD-16, see Section 2.14 and Section 8.0 for

Unipro 3.5 Process Control 1 Aug. 1997

Page 9

Marathon Monitors Inc.

more details). The output control is based on 0 to 99% of the

output device's control range. For example, 50% control would

equal 2.5 VDC out where 5 VDC equals maximum heat output of

the drive. This can be used with servo drives that require a voltage

or current command signal for controlling heat output or servo

positioning.

3. POSITIONING MOTOR with SLIDEWIRE FEEDBACK:

Set Control Modes for Single Position-Proportioning with slidewire

feedback. CONTROL OUTPUT #1 will drive the motor in the

open direction, CONTROL OUTPUT #2 in the close direction.

Remember, the above methods are just examples of the typical

applications of the UNIPRO. Please call your MMI representative

or application engineer for questions concerning your particular

system.

Chart Recorders

If a chart recorder is to be used, it must have input specifications

within the following ranges:

0 to 4 VDC

0 to 45 mA

corresponding to a FRONT PANEL display of 0-2000. The ideal

location of the recorder is adjacent to the instrument but it may be

located remotely if the connecting wires are properly shielded.

Long wiring runs from the chart recorder outputs may require

resistive termination

(2 K ohms or so) at the chart recorder input(s) should be isolated

from ground.

Computer Interface

If you wish to take advantage of the UNIPRO's RS-422 digital

communications capabilities, refer to "Communications" for more

details.

Unipro 3.5 Process Control 1 Aug. 1997

Page 10

Marathon Monitors Inc.

Alarms

Two user-programmable triac alarm contacts are available for

connection in appropriately-engineered systems.

Programmer

The Programmer can run an entire process, depending on how

thoroughly the capabilities are set up and used. Refer to

"Operation" and "Programming" for further information.

Unipro 3.5 Process Control 1 Aug. 1997

Page 11

Marathon Monitors Inc.

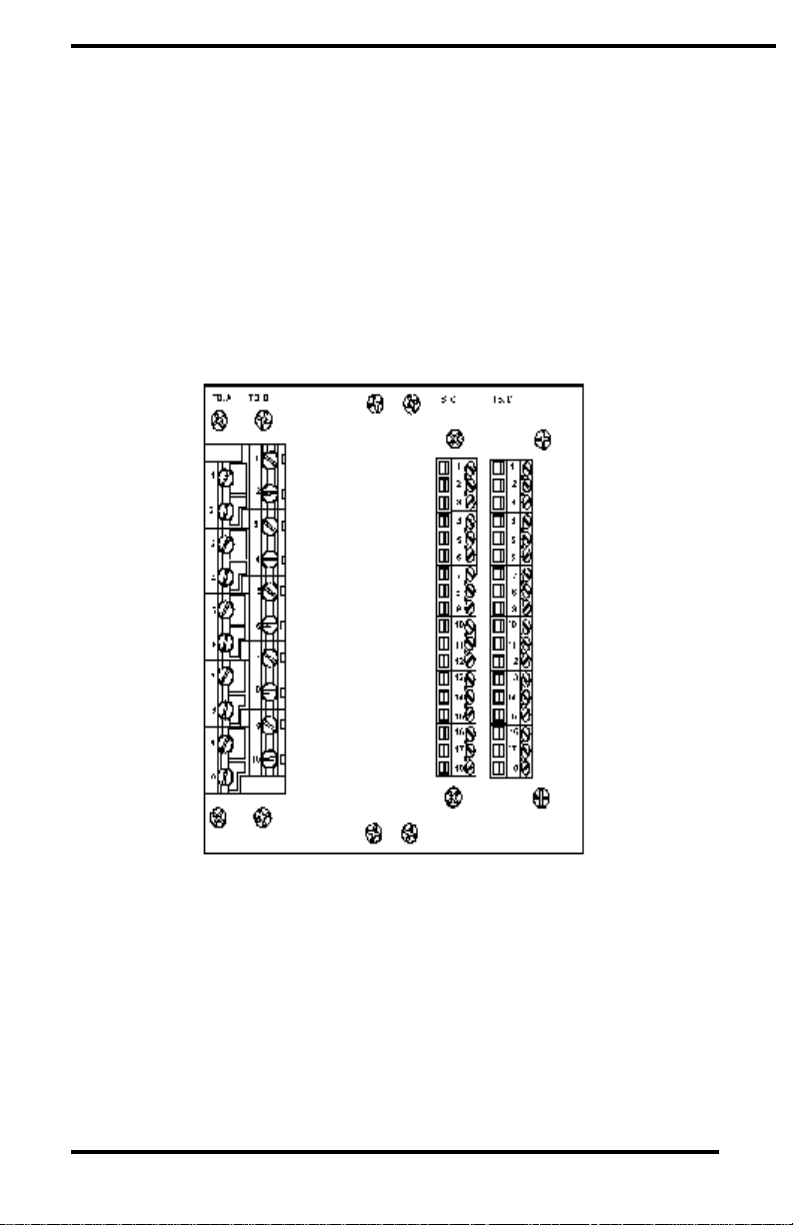

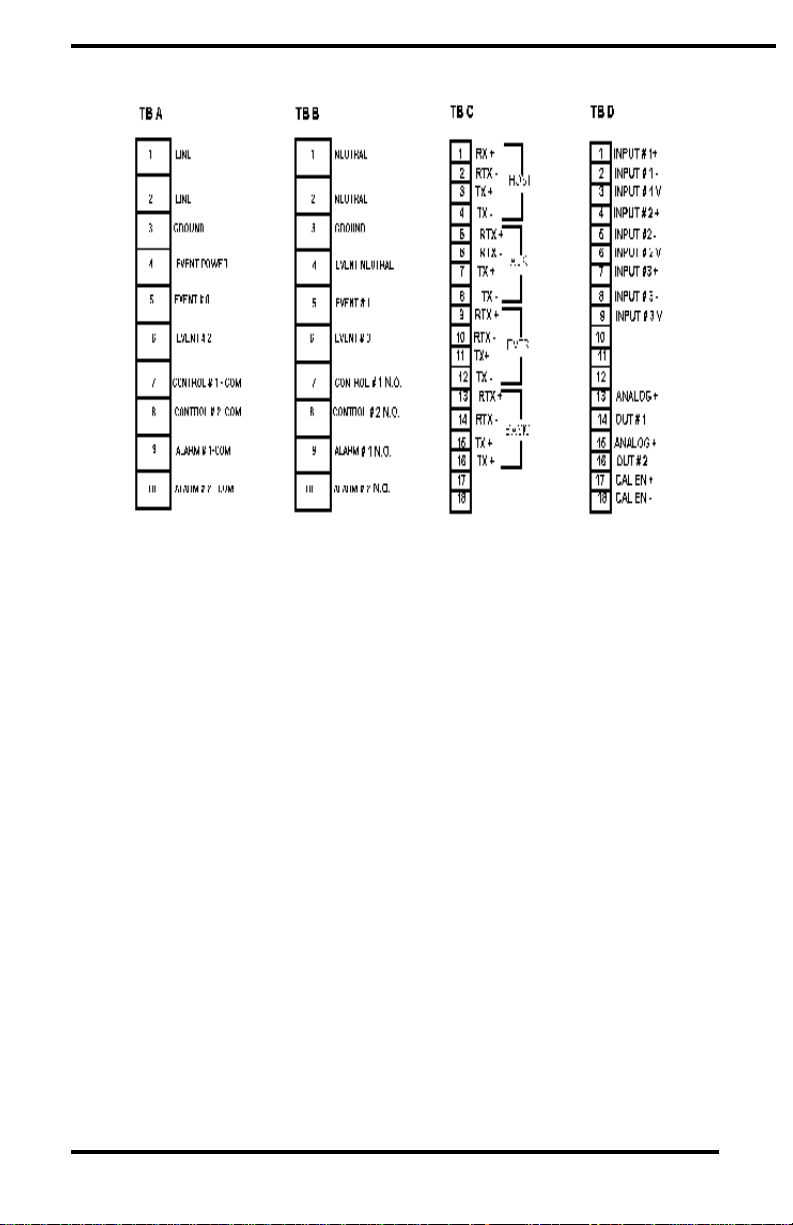

Electrical Connections

Connections to the unit are made via four terminal blocks, on the

rear panel, labeled TBA, TBB, TBC, and TBD. (Position 1 is at

the top the position 10 (TBA and TBB) or 18 (TBC and TBD) is at

the bottom of the terminal strip.) AC power, event, control, and

alarm connections are made on TBA and TBB. All

communications are on TBC and all analog I/O signals are on TBD.

Refer to the Figure below for a complete layout of the UNIPRO

rear panel connections.

Unipro 3.5 Process Control 1 Aug. 1997

Page 12

Marathon Monitors Inc.

Unipro 3.5 Process Control 1 Aug. 1997

Page 13

Marathon Monitors Inc.

UNIPRO Rear Panel

UNIPRO Electrical connections

AC Power

The UNIPRO requires 100/120/200/240 VAC at 1 AMP,

Communications

Three communications busses are at TBC and use RS-422 full or

half duplex protocol for all ports. (Refer to "Communications" in

Maintenance and Troubleshooting.) Typically, the HOST port will

connect to a host computer, the AUXILIARY BUSS to other

instruments, and the OPTOMUX PORT to OPTOMUX

I/O devices.

Unipro 3.5 Process Control 1 Aug. 1997

Page 14

Marathon Monitors Inc.

Analog Inputs

The UNIPRO allows for three analog inputs with their individual

functions determined by "daughter board" located on the analog

input board inside the unit. The standard connection, at TBD, will

have the first input as a thermocouple, the second for the oxygen

probe, and the third optionally used to input voltage or milliamp

signals.

Analog Outputs

Two, separate, isolated analog outputs are provided on TBD and

can be selected as 4-20 mV (for maximum accuracy, see

Specifications for further details) or 0-10 V output through DIP

switch settings on the analog output board. Additionally, outputs

can be calibrated by placing a jumper on the two terminals supplied.

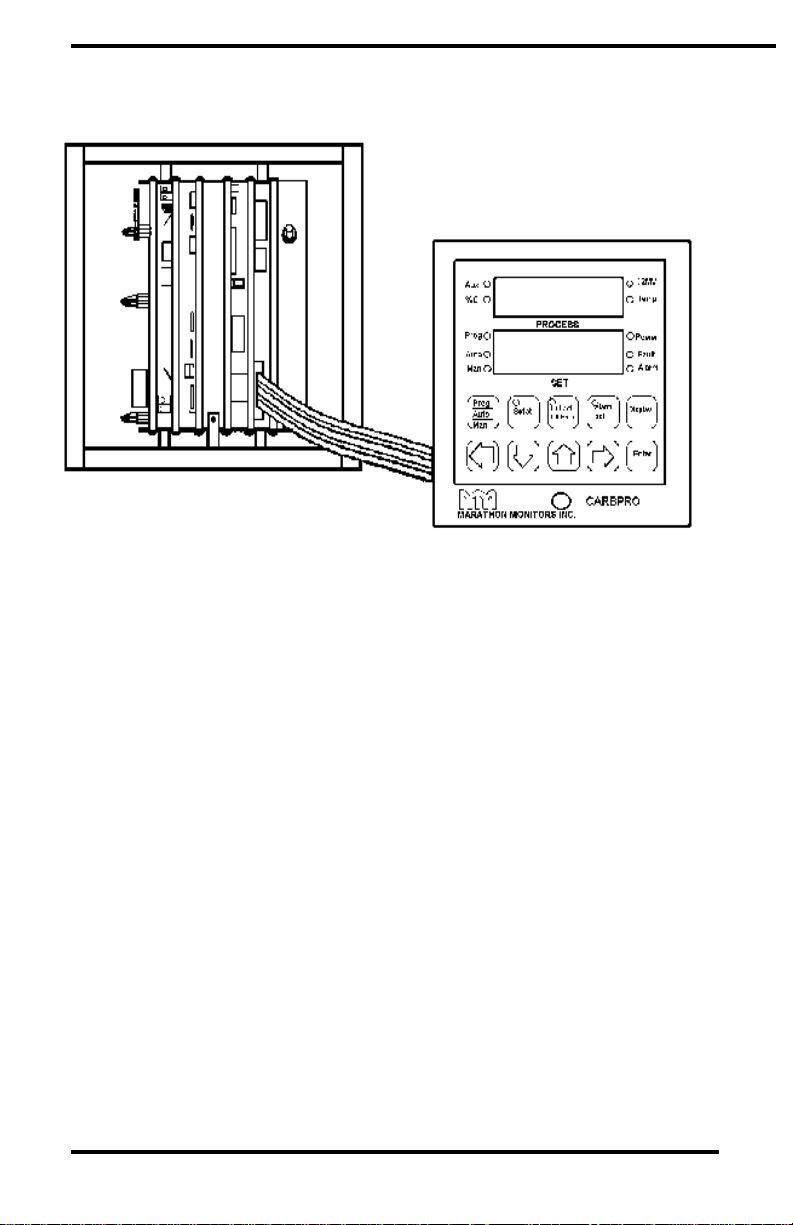

DIP Switch Setup

The user may use the UNIPRO in a multi-instrument system by

giving the instrument a unique HOST address, specified by using

the DIP switches on the Interface Board inside the UNIPRO

To get to the DIP switches, loosen the black knurled knob on the

front panel by turning in a counterclockwise direction. Carefully

remove the front panel but DO NOT remove the ribbon cable

connecting the front panel to the Interface Board. Safely support

the front panel near the instrument. Adjust the DIP switches per

Section 2.16 for the desired operating mode. When switch

adjustment is complete, replace the front panel to prevent

contamination.

Unipro 3.5 Process Control 1 Aug. 1997

Page 15

Marathon Monitors Inc.

UNIPRO Front Panel Removal

Find the appropriate switches by referring to the figure below.

Unipro 3.5 Process Control 1 Aug. 1997

Page 16

Marathon Monitors Inc.

UNIPRO Internal Layout

DIP Switch Assignments

Bank 0

Switch # Description

1 Unassigned

2 Unassigned

3 Slide wire Deadband (see the following table)

4 Slide wire Deadband (see the following table)

5 Slide wire Deadband (see the following table)

6 Unassigned

7 Unassigned

8 Service (Must be OFF)

Selectable deadband for slidewire feedback control.

Unipro 3.5 Process Control 1 Aug. 1997

Page 17

Marathon Monitors Inc.

Slidewire Dead Band Offset

offset Switch 3 Switch 4 Switch 5

0.4% OFF OFF OFF

0.8% ON OFF OFF

1.2% OFF ON OFF

1.6% ON ON OFF

2.0% OFF OFF ON

2.4% ON OFF ON

2.8% OFF ON ON

3.2% ON ON ON

Unipro 3.5 Process Control 1 Aug. 1997

Page 18

Marathon Monitors Inc.

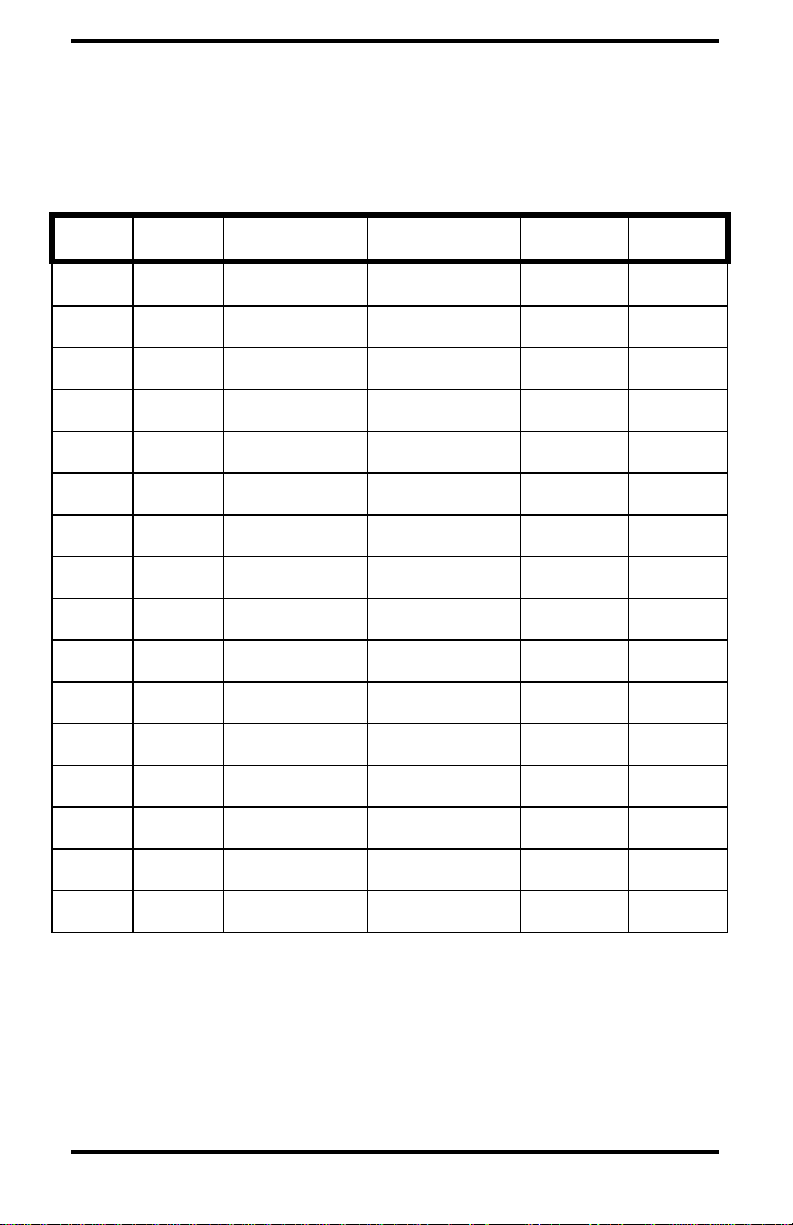

Each UNIPRO in a multiple instrument system must have a unique

address for proper communications.

HOST address selection switches: Bank 1Address

DEC HEX SW1 SW2 SW3 SW4

0 0 OFF OFF OFF OFF

1 1 ON OFF OFF OFF

2 2 OFF ON OFF OFF

3 3 ON ON OFF OFF

4 4 OFF OFF ON OFF

5 5 ON OFF ON OFF

6 6 OFF ON ON OFF

7 7 ON ON ON OFF

8 8 OFF OFF OFF ON

9 9 ON OFF OFF ON

10 A OFF ON OFF ON

11 B ON ON OFF ON

12 C OFF OFF ON ON

13 D ON OFF ON ON

14 E OFF ON ON ON

15 F ON ON ON ON

Unipro 3.5 Process Control 1 Aug. 1997

Page 19

Marathon Monitors Inc.

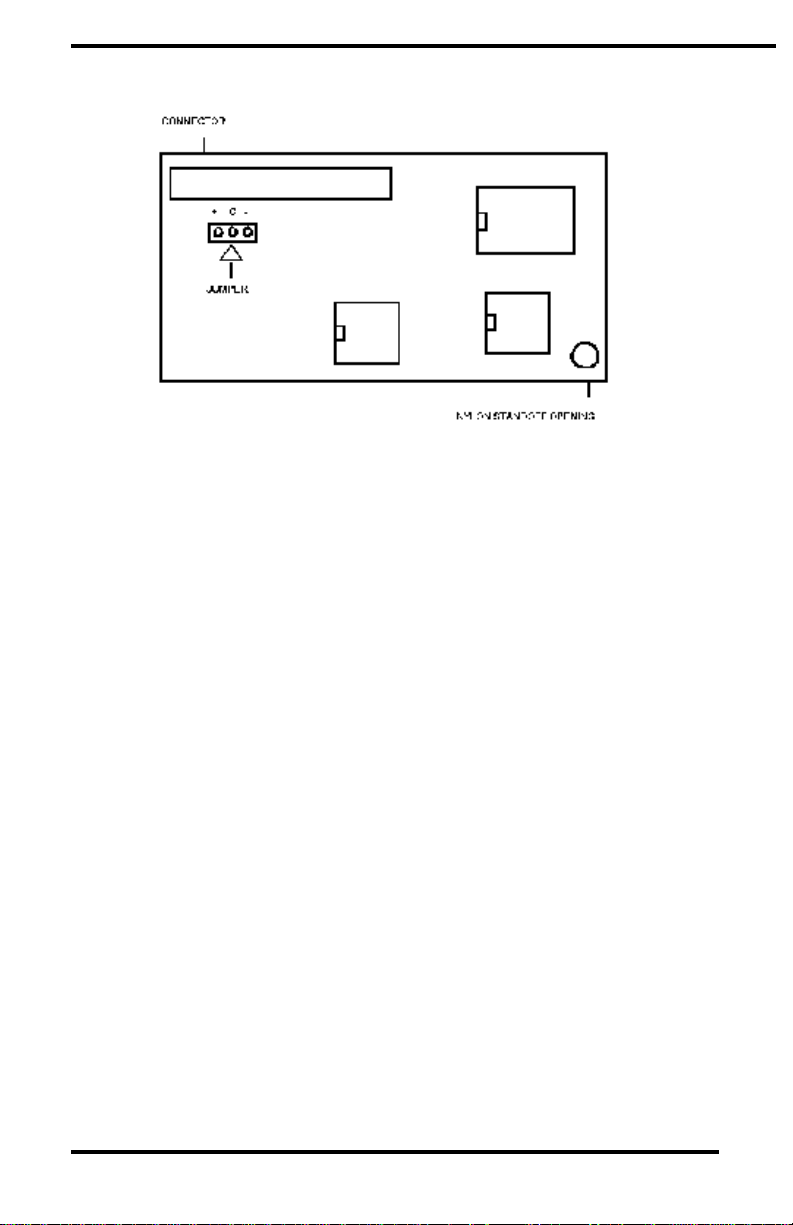

Thermocouple Burnout Jumper Selection

The thermocouple jumper selects either a full upscale or a full down

scale reaction to take place when a thermocouple fails or becomes

open. The jumper can be found on the thermocouple board, and

has two possible settings (see Figure). For full scale upwards, place

the jumper from the + to the C, and for full scale downwards, place

the jumper from the - to the C.

Unipro 3.5 Process Control 1 Aug. 1997

Page 20

Marathon Monitors Inc.

Setup And Configuration

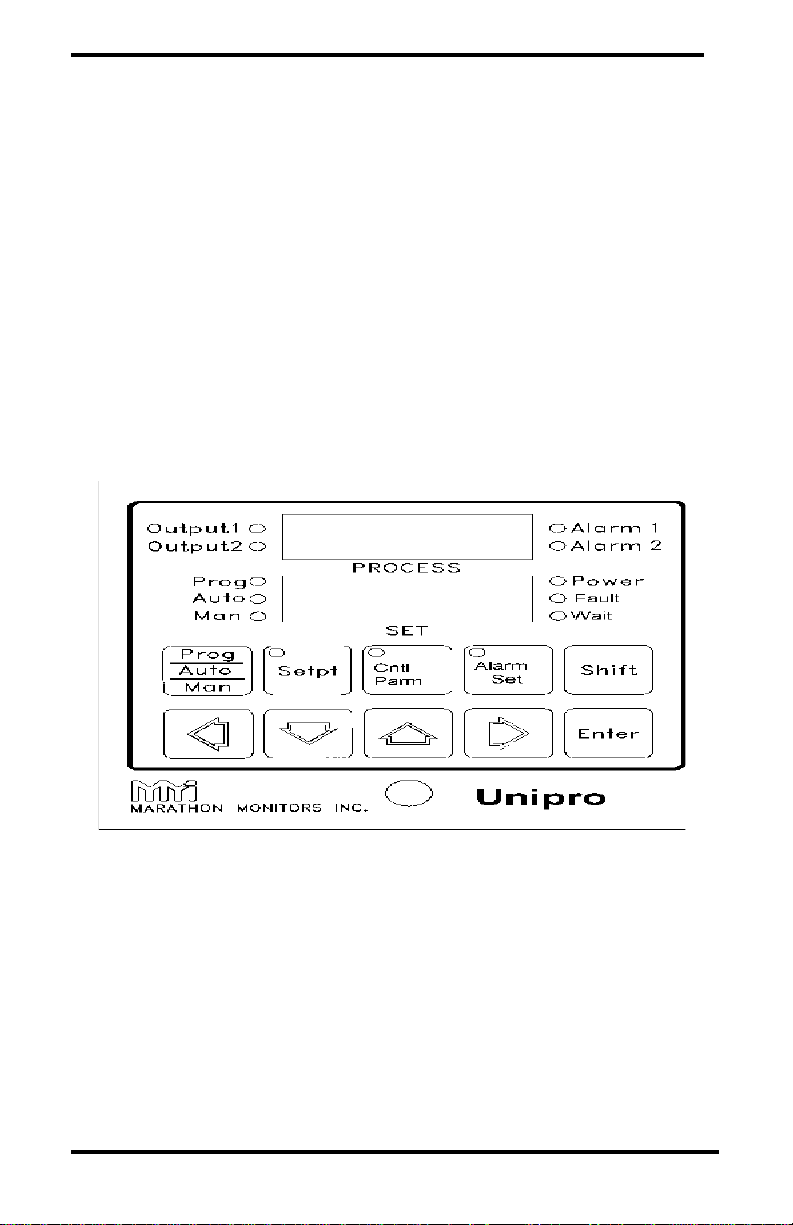

Front Panel

The front panel of the UNIPRO consists of three main parts, two

display windows and a keyboard. Refer to the figure shown below

for a layout of the front panel. The display windows each contain

four 14-segment digits that are used to display helpful messages

and numerical parameter values.

PROCESS Display

This 4 digit 14-segment display provides the value of the current

process value, along with messages for ease of operator use when

setting up parameters. The PROCESS window displays the step

number and OPCODE when in the Program Editor.

SET Display

Unipro 3.5 Process Control 1 Aug. 1997

Page 21

Marathon Monitors Inc.

This 4 digit 14-segment display provides the value of the process

setpoint value during Auto and Program operation. In Manual

mode the Time-Proportioning % Output value is displayed. During

operator input procedures this display shows the data being

entered. The SET window displays the corresponding data for the

OPCODES displayed in the PROCESS window when in the

Program Editor.

LEDs

Several small LEDs indicate operations and functions of the

UNIPRO. Ten are on the face and three are in the keys.

Output 1 indicates when the Output 1 Control relay is closed.

Output 2 indicates when the Output 2 Control relay is closed.

Alarm 1 indicates when the process value has closed the relay

based upon trip point and type of alarm.

Alarm 2 indicates when the process value has closed

the relay based upon the trip point and type of alarm. Also, if

Switch 6, Bank 1 is ON the LED indicates the closed control

output relay.

Prog indicates that a program is running and Automatic control is

activated. If flashing, the program is in HOLD. Refer to the

section "The Programmer".

Auto indicates that the UNIPRO is in Automatic control mode. If

flashing, a program is in HOLD.

Manual indicates that no control action is being executed by the

UNIPRO. If flashing, a program is in HOLD.

Power indicates that the UNIPRO's 5 volt power supply is

functioning.

Unipro 3.5 Process Control 1 Aug. 1997

Page 22

Marathon Monitors Inc.

Fault indicates that an open circuit is detected at the signal input.

Wait indicates that the Programmer is waiting for some condition

to be satisfied before continuing.

Setpt indicates that the Setpt Enter mode has been selected.

Cntrl Parm indicates that the Control Parameter Enter mode has

been selected.

Alarm Set indicates that the Alarm Setup mode has been selected

or one or both alarm values are non-zero.

Unipro 3.5 Process Control 1 Aug. 1997

Page 23

Marathon Monitors Inc.

Keyboard

The UNIPRO keyboard consists of ten keys for operating and

programming the instrument. There are no "hidden" keys on the

UNIPRO keyboard.

Various operations with the UNIPRO involve dual-key operations

using the [Shift] key in the same way a shift key on a typewriter is

used. When activating a dual-key assignment do not try to press

both keys simultaneously; rather, follow the sequence below:

1. Press and hold the[ Shift] key,

2. Press and release the second key,

3. Release the [Shift] key.

KEY DESCRIPTION

This key selects the operating mode of the

UNIPRO. The mode selected is indicated by

the illuminated LED.

This key selects the Setpoint Enter mode

where the Setpoint, Setpoint Offset and

Reference Number can be accessed and

altered. When used in the dual-key

operation Shift/Setpt it allows the operator

to pull any program into the edit space or

decrease the remaining time of a program step

if a program is currently running.

Unipro 3.5 Process Control 1 Aug. 1997

Page 24

Marathon Monitors Inc.

This key selects the Control Parameter Enter

mode where the Proportional Band, Reset,

Rate, Cycle Time and Percent Output values

(if in solenoid mode) can be accessed and

altered. When used in the dual-key

operation Shift/Cntrl Parm it selects the

keyboard Lock Level change mode.

This key selects the Alarm Setup mode where

the Alarm 1 and Alarm 2 conditions can be

accessed and altered or Alarm 2 can be used

to determine setpoint for auxiliary control

loop. When used in the dual-key operation

Shift/Alarm Set it selects the Thermocouple

Type, Custom Features, and Events Partition.

After Shift/Alarm Set the Thermocouple Type

is initially displayed, if Enter is pressed the

Custom Feature option is available while the

second press of Enter allows the Events

Partition to be observed and altered if

necessary.

This key has no function by itself. The

function of the Shift key is for all dual-key

operations, Security Sequence and the

start-up sequences.

Unipro 3.5 Process Control 1 Aug. 1997

Page 25

Marathon Monitors Inc.

usually used to select which digit is to be

modified in a data entry mode. In Manual

mode this key will cause the control output

to go to the full reverse control direction

while the value is displayed in the SET

window. In Automatic mode pressing "left

arrow" causes the % on-time valve position

to be displayed in the SET window.

(positive-Output 1, negative-Output 2). In

the Programmer Status Display it causes the

display to move to a new page.**

usually used to decrease the value of a digit in

the data entry mode or scroll through various

parameter sequences. In Manual mode this

key will cause the control action

to move toward the Output 2 direction.

When used in the dual-key operation

Shift/"down arrow" it accesses the

Programmer Status Display.

usually used to increase the value of a digit in

the data entry mode or scroll through various

parameter sequences. In Manual mode this key will

cause the control action to move in the Output 1

direction. When used in the dual-key operation

Shift/"up arrow" an LED test is activated, where every segment and

decimal point should light in both displays. If any segment or

decimal point does not light a keyboard problem may exist, contact

a qualified MMI representative.

Unipro 3.5 Process Control 1 Aug. 1997

Page 26

Marathon Monitors Inc.

usually used to select

which digit is to be

modified in a data entry

mode. In Manual mode

this key will cause the

control output to go to the full Output

1 direction. In the Programmer Status

Display mode it causes the display to

move to a new page.

this key is used to enter

data, clear alarms, or

cancel programs.

Unipro 3.5 Process Control 1 Aug. 1997

Page 27

[

C

o

n

t

r

o

l

P

a

r

a

m

Setup and Configuration

Unipro 3.5

e

t

e

r

]

S

e

t

u

p

M

e

Unipro 3.5 Process Control 1 Aug. 1997

Page 28

n

MENU

PROG

auto

xxx

xxx

asev

xxx

lock

pswd

lock

X

u

Setup and Configuration

Unipro 3.5

MENU

CON

pb

xxxx

res

xxxx

rate

xxxx

cyc

xxxx

hipo

xxxx

lopo

xxxx

ldln

xxxx

conv

xxxx

Cm

x xx

setp

xxxx

MENU

INP

in a

xxxx

cjca

xxxx

iaof

xxxx

iasp

xxxx

iadp

xxxx

in b

*

in C

*

Tc

ºX

MENU

AOUT

ao 1

xxxx

ao1o

xxxx

ao1r

xxxx

ao2

xxxx

ao2o

xxxx

ao2r

xxxx

MENU

COM

host

xxxx

auxm

xxxx

aux

xxxx

ssoa

xxx

sso1

xxxx

:

:

sso8

xxxx

n

o

t

e

s

:

*

f

u

l

l

s

e

Unipro 3.5 Process Control 1 Aug. 1997

Page 29

MMI Product Documentation

q

u

e

n

c

e

o

f

“

I

N

A

”

r

e

p

e

a

t

s

f

o

r

i

n

p

u

t

s

B

Unipro 3.5 Process Control 1 Aug. 1997

Page 30

Setup and Configuration

Unipro 3.5

a

n

d

C

.

:

t

h

e

s

c

r

e

e

n

r

e

p

e

a

t

s

f

o

r

n

u

Unipro 3.5 Process Control 1 Aug. 1997

Page 31

MMI Product Documentation

m

b

e

r

s

0

-

8

d

e

c

i

m

a

l

a

n

d

h

e

x

a

n

d

h

e

x

n

Unipro 3.5 Process Control 1 Aug. 1997

Page 32

u

m

b

e

r

s

9

-

f

.

T

h

i

s

Setup and Configuration

Unipro 3.5

i

n

d

i

c

a

t

e

s

t

h

a

t

t

h

e

Unipro 3.5 Process Control 1 Aug. 1997

Page 33

MMI Product Documentation

r

e

p

e

a

t

i

n

g

s

c

r

e

e

n

s

h

a

v

e

b

e

e

n

l

e

f

t

o

u

t

Unipro 3.5 Process Control 1 Aug. 1997

Page 34

b

e

t

w

e

e

n

t

h

e

f

i

r

s

t

Setup and Configuration

Unipro 3.5

a

n

d

l

a

s

t

n

u

m

b

e

r

s

.

Unipro 3.5 Process Control 1 Aug. 1997

Page 35

MMI Product Documentation

Control Parameter Key

Menu Selections

The following shows the

order of configuration options

set from the [Cntl Parm] key

and their range of values.

Press [ENTER] to go

forward to the next option, or

[Shift] to back up to a

previous option. The arrow

keys are used to change the

option within its limits see the

keys portion of this section

for a complete description of

how they are used. Pressing

[Cntl Parm] at any time will

exit from this option setup

sequence.

Note

Options are saved as they are

changed.

CON menu

Proces

Unipro 3.5 Process Control 1 Aug. 1997

s

d

i

s

p

l

a

y

S

Page 36

Setup and Configuration

Unipro 3.5

e

t

d

i

s

p

l

a

y

o

p

t

i

o

n

s

D

e

s

c

r

i

p

t

i

o

n

0 to 9999

Propor

Unipro 3.5 Process Control 1 Aug. 1997

Page 37

MMI Product Documentation

tional

band

0 to 99.99

Reset

0 to

9.99

Rate

1 to

250

Cycle

time in

second

0 to

100

High

limit

s

Unipro 3.5 Process Control 1 Aug. 1997

Page 38

Setup and Configuration

Unipro 3.5

percent

output

-100 to

100

percent

output

-100 to 100

on

Low

limit

on

Load

Unipro 3.5 Process Control 1 Aug. 1997

Line

Page 39

MMI Product Documentation

CON menu Continued...

Process

display

Set

display

Descri

ption

xxx

Contro

l mode

XXX=

X__ =

D or R

direct

reverse

Unipro 3.5 Process Control 1 Aug. 1997

for

or

.

Page 40

Setup and Configuration

Unipro 3.5

_XX =

tp for

propor

tioning

time

.

tc for

time

propor

tioning

with

compli

ment

td for

time

propor

tioning

dual

Unipro 3.5 Process Control 1 Aug. 1997

Page 41

MMI Product Documentation

ms for

motor

with

slide

wire

feedba

ck

of for

OFF /

control

oc for

OFF /

compli

Unipro 3.5 Process Control 1 Aug. 1997

ON

ON

with

ment

Page 42

Setup and Configuration

Unipro 3.5

od for

OFF /

pp for

positio

propor

tioning

ON

dual

n

LOC

C

Setpoi

source;

local or

input C

Unipro 3.5 Process Control 1 Aug. 1997

, IN

nt

Page 43

Page 44

INP menu

Input A, B, or C values and

actions are programmed from

this menu. Display choices

shown are for input A. The

other input choices follow

through the same cycle.

Exceptions are noted in the

table. Thermocouple degree

choices for temperature

display come at the end of the

full menu cycle.

Setup and Configuration

Unipro 3.5

Proces

s

d

i

s

p

l

a

y

S

e

t

Unipro 3.5 Process Control 1 Aug. 1997

d

i

s

p

l

a

y

c

Page 45

MMI Product Documentation

h

o

i

c

e

s

D

e

s

c

r

i

p

t

i

o

n

Unipro 3.5 Process Control 1 Aug. 1997

L

I

N

,

T

c

,

O

f

f

,

Page 46

Setup and Configuration

Unipro 3.5

P

r

o

g

L

i

n

e

a

r

i

z

a

t

i

o

n

Unipro 3.5 Process Control 1 Aug. 1997

f

o

r

i

n

p

u

t

A

:

Page 47

MMI Product Documentation

L

I

N

f

o

r

l

i

n

e

a

r

Unipro 3.5 Process Control 1 Aug. 1997

T

c

?

F

o

r

t

h

e

Page 48

Setup and Configuration

Unipro 3.5

r

m

o

c

o

u

p

l

e

t

y

p

e

*

Unipro 3.5 Process Control 1 Aug. 1997

O

f

f

P

Page 49

MMI Product Documentation

r

o

g

f

o

r

P

r

o

g

r

a

m

m

e

d

.

Unipro 3.5 Process Control 1 Aug. 1997

I

n

p

u

t

C

h

a

s

t

h

r

e

e

Page 50

Setup and Configuration

Unipro 3.5

m

o

r

e

c

h

o

i

c

e

s

L

3

0

,

Unipro 3.5 Process Control 1 Aug. 1997

L

5

0

,

a

n

d

L

1

0

0

.

Page 51

MMI Product Documentation

Y

E

S, NO

Cold

junctio

n

compe

nsation

active

for

input A

-999

to

9999

Input

offset

progra

mode

-999 to 999

Input

A span

value

progra

Unipro 3.5 Process Control 1 Aug. 1997

A

for

m

for

Page 52

Setup and Configuration

Unipro 3.5

mode

0 to 3

display

decima

l point

locatio

progra

mode.

m

Input

A

ed

n for

m

deg C

Tempe

rature

display

Notes:

* thermocouple types are found in

the specifications. Values and types are also

found in Maintenance and Troubleshooting.

Unipro 3.5 Process Control 1 Aug. 1997

de

g

F,

units

Page 53

MMI Product Documentation

AOUT menu

P

Unipro 3.5 Process Control 1 Aug. 1997

Page 54

Setup and Configuration

Unipro 3.5

O

,

I

N

B

,

P

2

0

,

P

2

P

Unipro 3.5 Process Control 1 Aug. 1997

Page 55

MMI Product Documentation

1

,

A

n

a

l

o

g

o

u

t

p

u

t

REFN, PROG, TEMP,

AUX

1

s

o

u

r

c

e

*

-

9

Unipro 3.5 Process Control 1 Aug. 1997

Page 56

Setup and Configuration

Unipro 3.5

9

9

t

o

9

9

9

9

A

n

a

l

o

g

Unipro 3.5 Process Control 1 Aug. 1997

o

u

t

p

u

t

1

o

f

f

s

e

t

Page 57

MMI Product Documentation

0

t

o

9

9

9

9

A

n

a

l

o

g

Unipro 3.5 Process Control 1 Aug. 1997

o

u

t

p

u

t

1

r

a

n

g

e

Page 58

Analog out put 2

choices are the same

menu items repeated.

*Analog output

source 1 menu items:

PO = percent

output

P 20 & P 21 are specialized parameter

settings. Check with your programmer

Setup and Configuration

Unipro 3.5

IN B = input B

before entering data.

REFN = the reference number

PROG = the program

TEMP = temperature

AUX =Auxiliary output

Unipro 3.5 Process Control 1 Aug. 1997

Page 59

MMI Product Documentation

COM menu

P

r

o

c

e

s

s

d

i

s

p

l

a

y

S

e

t

d

i

s

p

l

a

y

D

e

s

c

r

i

p

Unipro 3.5 Process Control 1 Aug. 1997

Page 60

Setup and Configuration

Unipro 3.5

t

i

o

n

commu

nicatio

and 0 to 3

H or

F, E

or N

Host

ns

setup

TE

M

or

UDC

Aux

commu

nicatio

ns port

mode;

MMI

10Pro

or

Honey

well

UDC3

000

Unipro 3.5 Process Control 1 Aug. 1997

Page 61

MMI Product Documentation

H or

F, E or

N

Aux

commu

nicatio

ns

setup

and

0

t

o

3

Slave

setpoin

t offset

active

to 500

Slave

temper

ature

Unipro 3.5 Process Control 1 Aug. 1997

NO,

YES

-500

Page 62

Setup and Configuration

Unipro 3.5

control

setpoin

t offset

UNIPR

O can

transfe

temper

atures

offset

Addres

original

UNIPR

ler

The

r 7

slave

and

have

an

for

each.

s 1 is

the

O.

Notes:

communications choices for the

UNIPRO are:

H = Half

F = full duplex

E = even

N = no parity

BAUD rate code

0 = 1200

1 = 4800

Unipro 3.5 Process Control 1 Aug. 1997

or

or

Page 63

MMI Product Documentation

2 = 9600

3 = 19.2k

Unipro 3.5 Process Control 1 Aug. 1997

Page 64

PROG menu

Setup and Configuration

Unipro 3.5

P

r

o

c

e

s

s

d

i

s

p

l

a

y

S

e

t

d

i

s

p

l

a

y

D

e

s

c

r

i

Unipro 3.5 Process Control 1 Aug. 1997

Page 65

MMI Product Documentation

p

t

i

o

n

NO,

YES

Auto

start-

up

NO,

YES

Auto

progra

m start

NO, YES

Asynch

ronous

event

3

Unipro 3.5 Process Control 1 Aug. 1997

0 to

Page 66

Setup and Configuration

Unipro 3.5

accessi

level is

3, the

least is

0. To

passwo

rd see

below.

Lock

level

The

most

ble

set a

Password Entry

The password can be entered by

pressing the Dual-key sequence

[Shift] + [Cntl. Parm] keys. Any

order of keys, except for the

[Shift] or [ENTER] key, can be

entered as a password, up to nine

keys maximum. Press [ENTER]

to save the password. The

number in the set display will

count the number of keys

entered. Pressing [ENTER]

without pressing any other key

(i.e. set display=0) will clear the

password. So to have no

password the sequence [Shift] +

Unipro 3.5 Process Control 1 Aug. 1997

Page 67

MMI Product Documentation

[Cntl Parm], [Enter], [Enter]

,[Enter] must be pressed.

Unipro 3.5 Process Control 1 Aug. 1997

Page 68

Setup and Configuration

Unipro 3.5

EVTS menu

P

r

o

c

e

s

s

d

i

s

p

l

a

y

S

e

t

Unipro 3.5 Process Control 1 Aug. 1997

d

i

s

p

l

a

y

o

p

t

i

o

n

s

Page 69

MMI Product Documentation

D

e

s

c

r

i

p

t

i

o

n

NO,

YES

Extern

event

boards

active

1200

, 4800

Events

commu

nicatio

ns

baud

rate

al

Unipro 3.5 Process Control 1 Aug. 1997

Page 70

Setup and Configuration

Unipro 3.5

0 to 4

partitio

internal

16

Extern

analog

board

partitio

Eve

nts

n

0 to

al

n ?

Where

0,1, 2,

3, 4, 5,

6, 7, 8,

B, C,

D, E, F

Repres

enting

module

Unipro 3.5 Process Control 1 Aug. 1997

? is

9, A,

s 0

Page 71

MMI Product Documentation

throug

h 15

respect

ively.

XXX

Extern

al

analog

board

module

lineariz

ation.

Where

XXX =

lin,

prog,

n/a or

thermo

couple

type

and

value *

Unipro 3.5 Process Control 1 Aug. 1997

Page 72

Setup and Configuration

Unipro 3.5

All thermocouple displays have TC X format where X =

thermocouple type. See the list below

Thermocouple list:

Display T/c Type

B

C

K

N

E

J

Unipro 3.5 Process Control 1 Aug. 1997

NM

R

S

T

Page 73

MMI Product Documentation

[Alarm Set] key

The [Alarm Set] key also sets some

parameters. Its menu is limited to alarm

functions. Again [Enter] and [Shift] move

forward or back through the selections while

setting up, [arrow] keys change values and

[Alarm Set] exits. All values are saved as

they are changed.

Alarm Set key

P

r

o

c

e

s

s

Unipro 3.5 Process Control 1 Aug. 1997

d

i

s

p

l

a

y

S

e

t

d

i

s

p

l

Page 74

Setup and Configuration

Unipro 3.5

a

y

o

p

t

i

o

n

s

D

e

s

c

r

i

p

t

i

o

n

Rev. 8.00

November 30, 1995

See

not

es

Alarm

1

mode.

Selects

which

variabl

e, type

Page 75

MMI Product Documentation

of

alarm,

and

whethe

r direct

or

reverse

acting.

See

notes

below.

-999 to

9999

Alarm

1

value.

Decim

al point

is

automa

tically

set

based

on

control

variabl

e and

type of

alarm.

250

Unipro 3.5 Process Control 1 Aug. 1997

0 to

Page 76

Setup and Configuration

Unipro 3.5

Alarm

1 turn

time in

second

250

Alarm

1 turn

time in

second

on

delay

s.

0 to

off

delay

s.

At this point, if there is no need for ALARM 2 to be set, press

[Alarm Set] to exit alarm parameters.

If ALARM 2 does need to be set, press [Enter]. Use the

information starting at the top of the table for ALARM 1. The

process display will change only from a 1 to a 2. All other

information in the table remains accurate for ALARM 2.

Notes:

Variable Description

Rev. 8.00

November 30, 1995

Page 77

MMI Product Documentation

D This is

operation for

alarm actuation

(i.e. the contact is

normally open

until it reaches the

trigger limit

specified in the

ALARM VALUE

then the contact

R REVERSE operation (opposite of

NORMAL) for ALARM actuation (i.e. the

alarm contact is normally closed until it

reaches the trigger limit specified in the

ALARM VALUE then the contact opens).

DIRECT

closes).

Notes: continued

Variable Description

IN B Alarm actuation is based on the

analog signal at Input B inputs exceeding the

limit in the Alarm Value. Input B inputs is

physically located at TBD-4, TBD-5, and

TBD-6 on the unit's rear connectors.

AUX Alarm actuation is based on the analog signal

at Input C exceeding the limit in the

ALARM VALUE. Input C is physically

located at TBD-7, TBD-8, and TBD-9 on

the unit's rear conductors.

BND Alarm actuation uses BAND WIDTH

control above and below a programmed

setpoint limit. (i.e. If the band is set by the

ALARM VALUE to 0.10 and the

Unipro 3.5 Process Control 1 Aug. 1997

Page 78

Setup and Configuration

Unipro 3.5

programmed setpoint is at 0.80, the alarm

will trigger at 0.90 and 0.70.)

DEV Alarm actuation uses DEVIATION

control above or below the programmed

setpoint. The + and - symbols determine if

the deviation is allowed or if it is above (+)

the programmed setpoint or below (-) it.

(i.e. If deviation of 0.10 is placed in the

ALARM VALUE and 0.80 is the

programmed SETPOINT the alarm will

trigger at 0.90 or 0.70, for -0.10.)

FLT An input FAULT, or a program

alarm is to be used as basis for the actuation.

The ALARM VALUE is ignored.

PRG An Internal program will actuate the

alarm.

PERCENT OUTPUT exceeding the limit in

Rev. 8.00

November 30, 1995

PO Alarm actuation is based on the

the ALARM VALUE .

PV PROCESS control mode. Alarm

actuation is based on the PROCESS

VARIABLE exceeding the limit in the

ALARM VALUE.

Page 79

MMI Product Documentation

[SETPT] key

Parameter entry under the [Setpt] key is

the same procedure as under the other

two keys controlling parameters. [Enter]

moves forward [Shift] moves back and

[arrow] keys change the values in a

parameter. [Setpt] exits and values are

saved when changed.

Setpt key

P

r

o

c

e

s

s

Unipro 3.5 Process Control 1 Aug. 1997

d

i

s

p

l

a

y

S

e

t

d

i

s

p

l

Page 80

Setup and Configuration

Unipro 3.5

a

y

o

p

t

i

o

n

s

D

e

s

c

r

i

p

t

i

o

n

Rev. 8.00

November 30, 1995

-999 to

9999

Contr

ol loop

setpoi

nt.

The

locatio

n of

Page 81

MMI Product Documentation

the

setpoi

nt will

be

autom

aticall

y set

based

on the

contro

l loop

proces

s

variab

le.

0 to 9999

Refere

numbe

9999

Opera

input

which

can be

Unipro 3.5 Process Control 1 Aug. 1997

nce

r.

-999

to

tor

Page 82

Setup and Configuration

Unipro 3.5

access

ed by

compu

system

the

host

ter

.

Rev. 8.00

November 30, 1995

Page 83

MMI Product Documentation

Unipro 3.5 Process Control 1 Aug. 1997

Page 84

OPERATION

Once installation and setup

and configuration are complete,

the day to day operation needs of

the UNIPRO depend upon the

application. The basics are found

in the Quick Reference Guide.

TO RESPOND TO ALARM

MESSAGES:

Note the alarm and

determine what caused the alarm.

Press [ENTER] once to

deactivate (silence) alarm

relay contact and continue

program execution.

After acknowledging the alarm, one of the

following actions may be appropriate:

Abort the program by pressing the

In the case of a timed-out LIMIT

statement (message #93), it is normally

desirable to continue the program by

re-executing the offending LIMIT

statement to be sure it is satisfied. This is

done automatically when the [ENTER]

key is pressed to acknowledge the alarm.

If you do not want to re-execute the

LIMIT statement, pressing the [SETPT]

key will cause the LIMIT statement to be

skipped and the program to continue to

Operation

UNIPRO 3.5

[Prog/Auto/Man] key.

the next STEP.

Rev. 11.00

December 30,1995

Page 85

MMI Product Documentation

Correct the problem or do what

the programmed alarm indicates: see

“Maintenance and Troubleshooting”: the

alarm messages for complete information

on programmed alarms. Then press

[Enter] to continue the program.

If any alarm is only to be acknowledged and the operation is to

continue, press [ENTER] to silence the alarm and then press

[SETPT] to skip to the next operation.

CHANGING THE SETPOINT

AND THE REFERENCE NUMBER

[SETPT] is used to enter the setpoint, the Reference

Number, and the Operator Inputs. The first press of [SETPT]

will allow the arrow keys to adjust the value of the setpoint.

Use the [LEFT ARROW] or [RIGHT ARROW] keys to select

the character to be altered. Once the character to be changed

is flashing, use the [UP ARROW] or [DOWN ARROW] keys to

select the desired number or symbol. After all characters are

as desired, press [ENTER] to place the value in nonvolatile

memory and to continue paging through the parameters.

Pressing [ENTER] again allows the Reference Number to be

changed. Pressing [SHIFT] at any time allows the operator to

“back up”to the to the step before [ENTER] was pressed. An

additional press of [ENTER] allows the operator Input to be

changed. Anytime during the setting of values [SETPT] may

be pressed to save the value and exit.

All the parameters in this group have a lock level of 3.

Unipro 3.5 Process Control 1 Aug. 1997

Page 86

Operation

UNIPRO 3.5

SETPOINT PARAMETERS

Display Parameters Description

Stpt Setpoint

The SET

display window line

represents the basic

parameter for the

Control Loop that

the process needs.

REF Reference

Number

Assign

s a number to

a program for

reference.

numbers can

range from 0

to 9999.

future

These

Rev. 11.00

December 30,1995

NM Operator Input

SET display

window line = -999

to 9999. Allows the

operator to enter

information that

may be needed by a

program. This input

may be used

similarly to the

reference number.

Page 87

MMI Product Documentation

PROG/AUTO/MAN

The Operation Mode for control

of programs is selected by the

[Prog/Auto/Man] key. Pressing

this key allows access to the

operation mode selection controls.

The first selection, after pressing

[Prog/Auto/Man], allows for

control of the program to be

entered. The key presses that

follow it depend upon the state of

the program. If a program is not

running see “Running A Program”

below. Anytime during the

selection process [Prog/Auto/Man]

may be pressed to exit the selection

process. All of the parameters

under this key have a Lock Level

of 3.

MANUAL MODE.

In Manual mode the process

variable is displayed in the

PROCESS display, the SET

display shows the appropriate

control value, and no control

action is computed. The arrow

keys can also be used to activate

the control output.

Unipro 3.5 Process Control 1 Aug. 1997

Page 88

Either the percent ON time

(time-proportion) or valve position

(position proportion) is displayed

in the SET window. For single

control mode operation this

number is always positive

(0/50/100). The [UP ARROW] and

the [DOWN ARROW] keys

increase or decrease the percent

ON time or the valve position

toward its fully opened or closed

positions by approximately 1%.

This continues for as long as the

key is pressed. The [RIGHT

ARROW] and [LEFT ARROW]

keys force the CONTROL

OUTPUTs to increase or decrease

the percent output by

approximately 10%.

Operation

UNIPRO 3.5

AUTOMATIC MODE

In Automatic Mode the process

variable is displayed in the

PROCESS display, the

SETPOINT is displayed in the

SET display, and control action is

computed based upon the PID

parameters and the input(s).

Pressing and holding the [LEFT

ARROW] key will cause the SET

display to show the control action

as described previously in

"Manual Mode.”

Rev. 11.00

December 30,1995

Page 89

MMI Product Documentation

PROGRAM OPERATIONS

Running a Program

1. Press [PROG/AUTO/MAN]

until the instrument's Prog LED

lights.

2. The Program Number is

displayed in the SET

display, select the program

to be run using the arrow

keys.

3. OPTIONAL: If beginning at a step other than 1

Repeatedly press the [SHIFT] key to select the

step upon which the program should start. The

step number will appear in the PROCESS

display.

4. Press [ENTER] to run the program.

5. If the Program Number in the SET display

begins to flash, there is something wrong with

the program (i.e. memory disruption, wrong

command, etc.). Press the [PROG/AUTO/MAN]

key to escape, or select a new program using the

arrow keys. Troubleshoot the program and then

restart this procedure.

Stopping a Program

1. Press [PROG/AUTO/MAN] UNTIL either the

Auto or Man LEDs begin to flash, indicating a

program is in HOLD. Press [ENTER] to cancel

the program (flashing will stop).

OR

Unipro 3.5 Process Control 1 Aug. 1997

Page 90

Operation

UNIPRO 3.5

Press the [PROG/AUTO/ MAN] key until the

Auto or Man LED is flashing, indicating a

program is in HOLD. Return to the program

mode by pressing [PROG/AUTO/MAN] and the

PROCESS window will display the word HOLd.

The SET window indicates the program number

that is in hold. Press any of the arrow keys to

cancel the program. The hold symbol will be

replaced by the run symbol.

Placing a Program in HOLD

1. Press [PROG/AUTO/MAN] UNTIL the

instrument is in either Auto or Man mode as

indicated by the LEDs. The flashing LED

signifies the program is in HOLD.

OR

Press [SHIFT]+[LEFT ARROW].

Note

If the instrument is in Manual mode and a program is in

HOLD, no automatic control is taking place.

If the instrument is in Automatic mode and a program is in

HOLD, automatic control is continuing.

Rev. 11.00

December 30,1995

Page 91

MMI Product Documentation

Restarting a Program From HOLD

1. Press [PROG/AUTO/MAN] UNTIL the

instrument is in Programmer mode as indicated

by the Prog LED. The LED should be flashing

signifying a program is in HOLD.

OR

Press [SHIFT] +[LEFT ARROW].

2. Do not alter the program number, otherwise, the

program will start from the first step and not

where it had left off.

3. Press [ENTER] and the program will continue

executing with the step where the HOLD was

initiated.

To Enter Program Editor*

1. Press Shift/Setpt

2. Select the program to be edited using the "arrow

keys"(Edit / 0001)

3. Press Enter

* Note that the unit will allow editing of a program that

might be running. This editing will not affect the

currently-running copy of this program until the program is

actually restarted, either manually or by a program jump.

To Edit Program Steps

1. Use the [LEFT ARROW] and [RIGHT ARROW]

keys to select digits to be changed (either the

OPCODE or the data)

2. Use the [UP ARROW] and [DOWN ARROW]

keys to change the selected digit

3. Press [ENTER] to move forward to the next step, or

4. Press [Shift] to move backward to the previous step

5. If at any point the program does not advance or

back up, and the entire SET display starts flashing,

Unipro 3.5 Process Control 1 Aug. 1997

Page 92

Operation

UNIPRO 3.5

the data in the SET display is invalid for the

OPCODE shown. Use the [arrow keys] to enter the

correct data and then press [ENTER].

To Insert A Step

1. Go to the step of the desired insertion, using either

the [ENTER] or [Shift] keys

2. Press [Control Parm]

3. Enter the new step, OPCODE and data

4. Press [ENTER]

To Delete A Step

1. Go to the step to be deleted, using either[ Enter] or [Shift]

2. Press [Alarm Set]

Rev. 11.00

December 30,1995

Page 93

MMI Product Documentation

To Exit the Editor Without Saving the Program

1. Press [Setpt ]at any time, the edited program is lost (the

copy in non-volatile memory is unchanged)

To Exit the Editor Saving the Program

1. Edit through step 19 as required, inserting NOP's

wherever no operation is to be executed

2. Press [ENTER]

3. Select the program number in the SET display using the

[arrow keys] until the desired program number is being displayed

(SAVE / 0000)

4. Press [ENTER], the program stored in that location

previously is now lost (SAVE / Done)

CHANGING PARAMETERS

All of the UNIPRO parameters, program numbers,

OPCODES, and data values can be altered using the following

procedure:

Press [Pr. Fact. / Ctrl. Param.]. The word

MENU will appear in the PROCESS window.

The Parameter group will appear in the SET

window. Press [ENTER]. The symbol for the

parameter is displayed in the PROCESS window

while the current alterable data is shown in the

SET window. The flashing character is the one

that can be altered.

Use the [LEFT ARROW] or [RIGHT ARROW]

keys to select the character to be altered.

Once the character to be changed is flashing, use

the [UP ARROW] or [DOWN ARROW] keys to

select the desired number or symbol.

Unipro 3.5 Process Control 1 Aug. 1997

Page 94

Operation

UNIPRO 3.5

After all characters are as wanted, press the

[ALARM SET] key to place the value in

memory and exit,

press [ENTER] to save the value and continue

(forward) editing other parameters,

[SHIFT] to save the value and continue (back)

editing other parameters.

NOTE

If an entered number value is not within the acceptable data

range, the maximum/minimum value will flash in the SET

display. Repeat the above procedure until an acceptable value

has been entered.

See “Setup and Configuration” for the Menu table and

parameter definitions. The Alarms are also found there.

or

or

VIEWING A PROGRAM WHILE IT IS RUNNING

See “Status Display Page” in Maintenance and

Troubleshooting

Rev. 11.00

December 30,1995

Page 95

Page 96

Programming

Unipro3.5

Programmer

Operations

Introduction to

Programming

Techniques

The UNIPRO Programmer

uses a step/OPCODE

approach rather than a

segment approach.

The advantages of using

OPCODES (operation

code) are:

1) only what is to be

changed is entered,

2) features can be added to older instruments,

and

3) less information needs to be saved for each

step therefore more programs can be stored.

The step approach is very similar to what an operator would

do if he were manually controlling the process.

Some of the features in the OPCODEs may not be obvious as

to how they would be used until more experience is gained.

However, with a little practice and experimentation the

Programmer can soon be mastered.

Each program in the UNIPRO consists of nineteen steps (one

OPCODE per step). Some OPCODEs allow programs to be

linked together. The UNIPRO can store up to 200 programs in

non-volatile memory.

Rev. 11.00

December 30, 1995

Page 97

MMI Product Documentation

Description of OPCODEs

The following "alphabet" lists all of the

available OPCODEs for the UNIPRO

Programmer.

Programmer Alphabet

OPCO

Unipro 3.5 Process Control 1 Aug. 1997

Page 98

A

Programming

Unipro3.5

A

L

A

R

M

0

0

0

1

0

0

7

9

Rev. 11.00

December 30, 1995

8

0

8

3

*

M

E

S

S

A

G

E

Page 99

MMI Product Documentation

#

S

o

u

n

d

a

n

d

d

i

s

p

l

a

y

Unipro 3.5 Process Control 1 Aug. 1997

a

l

a

r

m

t

o

s

u

m

m

o

n

Page 100

Programming

Unipro3.5

o

p

e

r

a

t

o

r

a

n

d

c

o

n

v

e

y

a

m

e

s

s

a

g

e

.

b

BRAN

0000-0

019

Rev. 11.00

December 30, 1995

Loading...

Loading...