Page 1

PLAY IT SAFE!

OPERATION, MAINTENANCE

AND INSTALLATION MANUAL

FOR

VERTICAL RECYCLER BALER

INCLUDING THESE MODELS:

V-4830 V-4830HD V-6030LP

V-6030 V-6030HD V-6042LP

V-7230HD

A

DOVER

INDUSTRIES COMPANY

Marathon Equipment Co. OMI Manual No. 0003, Rev. 01/01

VERNON, AL - YERINGTON, NV - CLEARFIELD, PA

LEEDS, AL - FAYETTE, AL

Page 2

SECTION 1 - Operation

Introduction ................................................................. 1-1

Pre-Operating Instructions ....................................... 1-2

Controls

For HD and V-6030LP Units ................................1-3

For V-6030 and V-4830 Units ..............................1-4

For V6042LP Units .............................................. 1-5

Control Description ...................................................... 1-6

Operating Instructions

Making A Bale - HD and LP Units ....................... 1-7

Making a Bale - V-6030 and V-4830 ................... 1-8

Bale Tie Off - V-6030HD, V-4830HD, V-7230HD 1-9

Diagram .......................................................... 1-10

Bale Tie Off - V-6030LP ...................................... 1-11

Diagram .......................................................... 1-12

Bale Tie Off - V-6042LP ...................................... 1-13

Diagram .......................................................... 1-14

Bale Tie Off - V-4830 and V-6030 ...................... 1-15

Diagram .......................................................... 1-16

Tie Slot Cleaning-Diagram ........................................ 1-17

Decals ......................................................................... 1-18

Decal Placement For Vertical Balers ...........................1-20

SECTION 2 - Maintenance

Lock-Out & Tag-Out Instructions ............................ 2-1

Supporting of Platen ................................................... 2-2

Periodic Maintenance ................................................. 2-3

Procedures

Pressure Setting .................................................. 2-4

Interlock Testing .................................................. 2-4

Cylinder Removal ................................................ 2-5

Cylinder Rebuilding ............................................ 2-6

Limit Switch Adjustment ...................................... 2-6

Warranty and Service on Motors ......................... 2-6

Feed Gate Latch Adjustment ...............................2-7

Principles of Operation ............................................... 2-8

Baler Specifications..................................................... 2-10

Timer Adjustment ....................................................... 2-11

Charts ......................................................................... 2-12

Parts List .....................................................................2-13

Panel Box

For HD and LP Units ........................................... 2-14

For V-6030 and V-4830 Units ............................. 2-15

CONTENTS

Page 3

CONTENTS

SECTION 2 - Maintenance (continued)

Power Unit

For 4830, 6030, 4830HD, 6030HD, & 7230HD ... 2-16

For 6030LP ......................................................... 2-17

For 6042LP ......................................................... 2-18

Hydraulic Schematic

For Vertical Balers - Typical ................................ 2-19

For V6042LP ....................................................... 2-20

Trouble-Shooting Chart ...............................................2-21

SECTION 3 - Installation

Off-Loading and Up-Ending Of Baler ......................... 3-1

General Installation .................................................... 3-2

Electrical Installation .................................................. 3-3

Start-Up Instructions .................................................. 3-4

Copyright Marathon Equipment Company, January 2001.

Page 4

1 OPERATION

INTRODUCTION

THANK YOU FOR PURCHASING A MARATHON VERTICAL BALER.

This product is designed to give you reliable service and superior performance for years

to come. To guarantee top performance and the safest operation of the baler, each person involved in the operation, maintenance and installation of the baler should read and

thoroughly understand the instructions in this manual and follow all warnings.

The employer(s) involved in the operation, maintenance and installation of the baler

should read and understand the most current version of the following applicable standards:

ANSI Standard No. Z245.5, “Safety Requirements For Baling Equipment”

(A copy of this standard may be obtained from Marathon Equipment

Company, Field Service Department, at 1-800-633-8974).

OSHA 29 CFR, Part 1910.147, “The control of hazardous energy (lockout/tagout)”

IF YOU SHOULD NEED FURTHER ASSISTANCE, PLEASE CONTACT YOUR

DISTRIBUTOR. YOU WILL NEED TO PROVIDE THE BALER SERIAL

NUMBER, INSTALLATION DATE, AND ELECTRICAL SCHEMATIC NUMBER

TO YOUR DISTRIBUTOR.

IF YOU HAVE ANY SAFETY CONCERNS WITH THE EQUIPMENT, OR

NEED FURTHER INFORMATION, PLEASE CONTACT US AT:

Marathon Equipment Company

P.O. Box 1798

Vernon, Al 35592-1798

Attn: Field Service Department

1-800-633-8974

1-1

ALL SERVICE OR REPAIR PROCEDURES DESCRIBED IN THIS

MANUAL SHOULD BE PERFORMED BY AUTHORIZED, FULLY

TRAINED PERSONNEL.

Any service or repairs that go beyond the scope of this manual

should be performed by factory authorized personnel only.

Page 5

1 OPERATION

PRE-OPERATING INSTRUCTIONS

NEVER ENTER ANY PART OF THE BALER UNLESS THE DISCONNECT

SWITCH HAS BEEN TURNED OFF AND PADLOCKED. Before starting the

baler, be sure no one is inside. Be certain that everyone is clear of all points of

operation and pinch point areas before starting. See Lock-Out & Tag-Out

instructions in the Maintenance section.

THE EMPLOYER SHOULD ALLOW ONLY AUTHORIZED AND TRAINED PERSONNEL TO OPERATE

THIS BALER. This baler is equipped with a key oper-

ated locking system. The key(s) should be in the possession of only authorized personnel. Turn off and

remove key after use.

Pay close attention to the RED WARNING LIGHT on the control panel. If the light

is illuminated when the feed gate is raised, there is a malfunction of the magnetic interlock system. IN THIS EVENT, DISCONTINUE USE OF THE BALER AND

LOCK-OUT & TAG-OUT THE BALER PER THE INSTRUCTIONS IN THE

MAINTENANCE SECTION, PAGE 2-1. Perform necessary repairs before continuing operation of the baler.

ONLY AUTHORIZED PERSONNEL

SHOULD BE ALLOWED INSIDE THE

PANEL BOX. The panel box contains

high voltage components. See Lock-Out

& Tag-Out instructions in the

Maintenance section.

BE CERTAIN TURNBUCKLE AND LATCH IS FULLY LOCKED IN PLACE ON BALE

CHAMBER DOOR BEFORE STARTING BALER.

STAND CLEAR WHILE

BALER IS IN OPERATION.

WARNING: DO NOT OPERATE BALER UNTIL OPERATING INSTRUCTIONS ARE

THOROUGHLY UNDERSTOOD.

1-2

Federal regulation prohibits operation by persons under 18 years of age.

Page 6

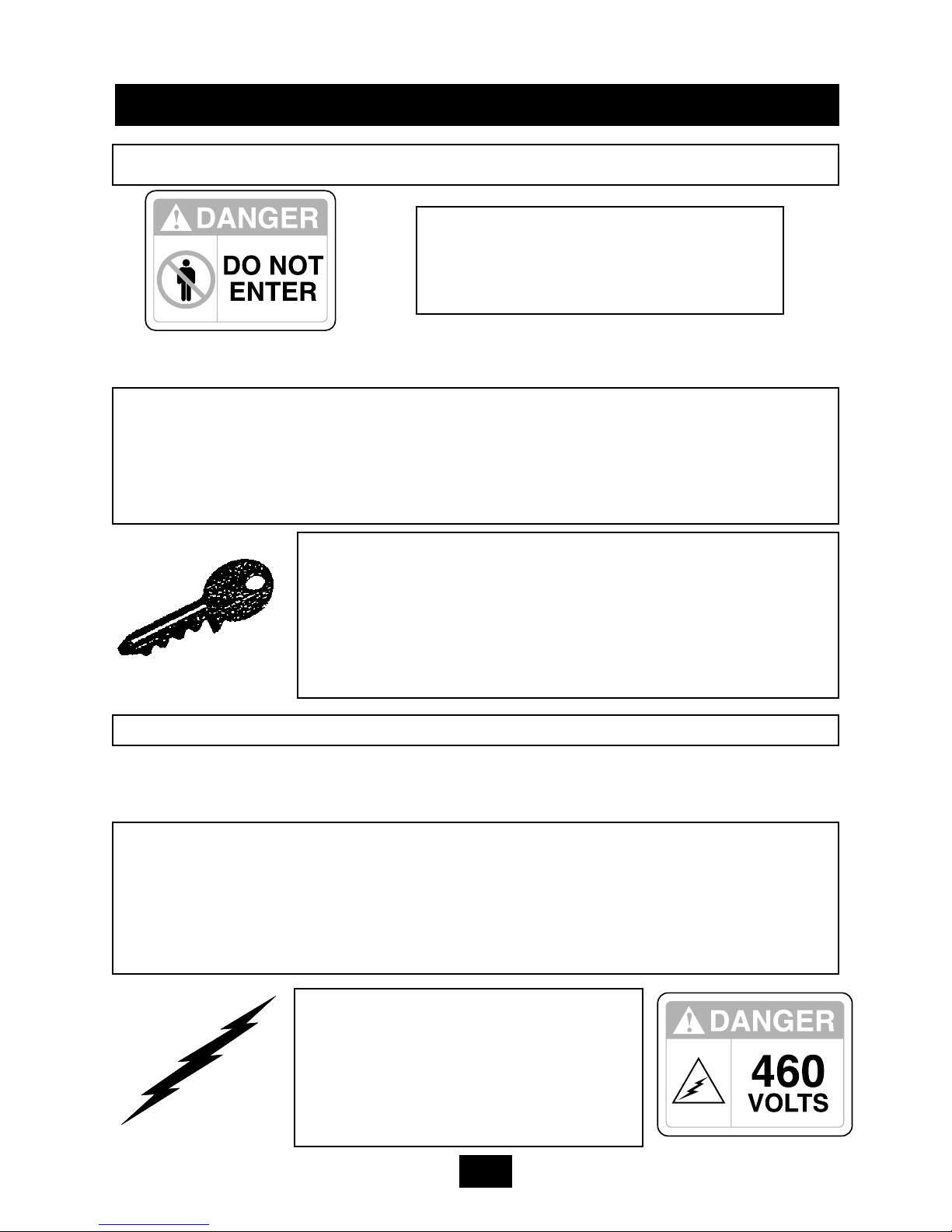

1 OPERATION

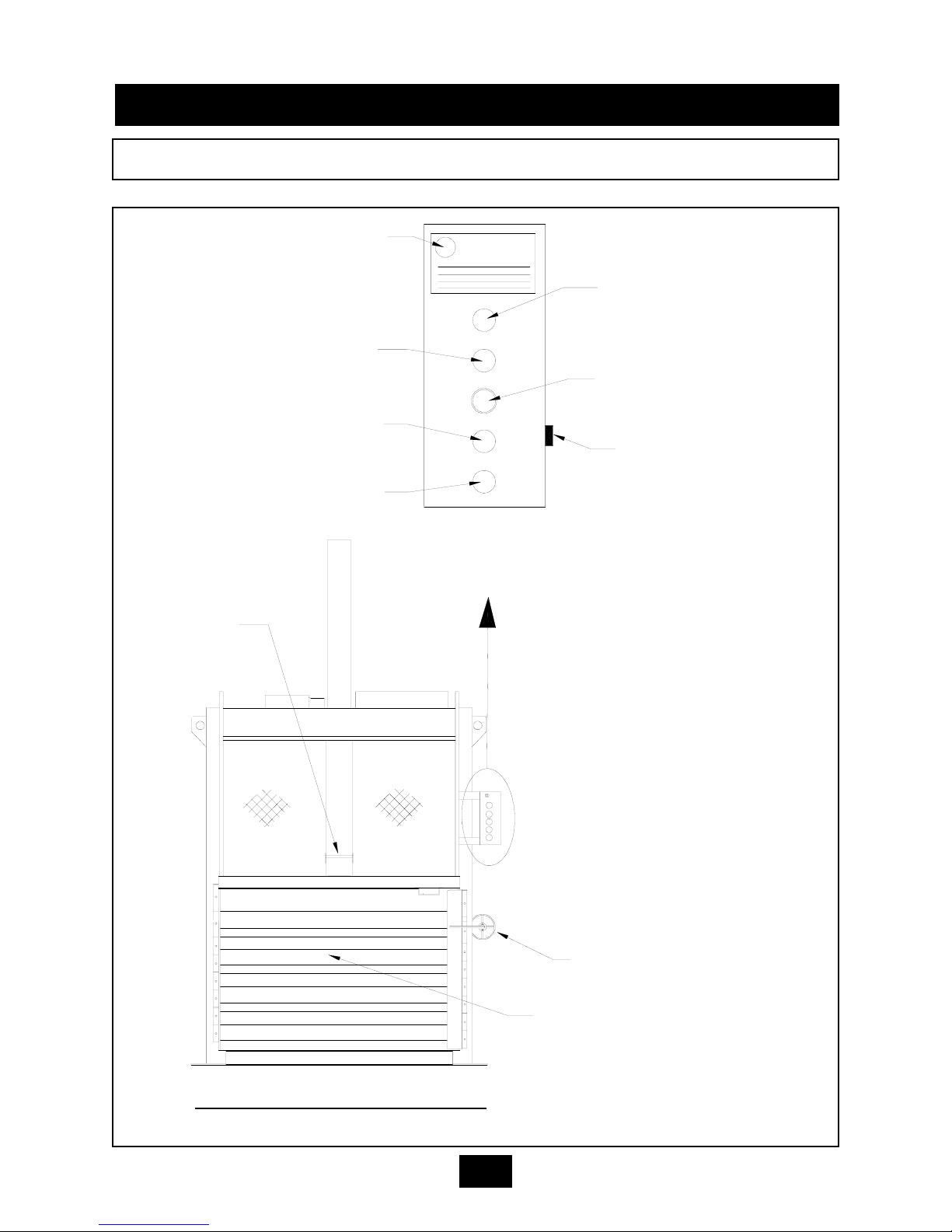

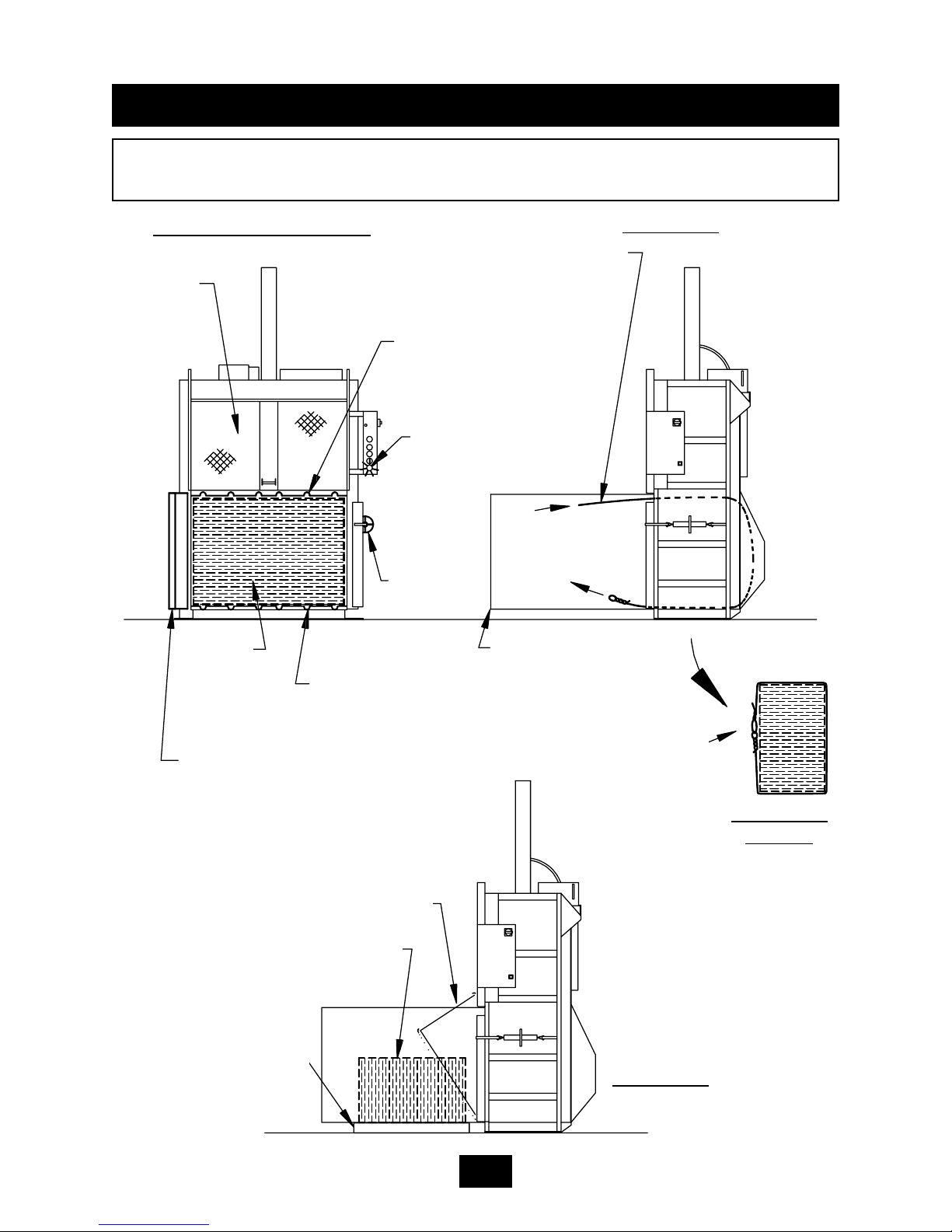

CONTROLS FOR V-4830HD, V-6030HD, V-6030LP, & V-7230HD

FRONT VIEW - VERTICAL BALER

MANUAL DOWN PUSHBUTTON

BALE MADE LIGHT

RED WARNING LIGHT

AUTOCYCLE BUTTON

KEYED ON-OFF SWITCH

EMERGENCY STOP BUTTON

MANUAL UP PUSHBUTTON

MOTOR OVERLOAD

RESET BUTTON

(ON DOOR)

DISCONNECT SWITCH

FEED GATE

CONTROL PANEL

PANEL BOX

TURNBUCKLE TO BALE

CHAMBER DOOR LATCH

BALE CHAMBER DOOR

WARNING

NOTICE

1-3

Page 7

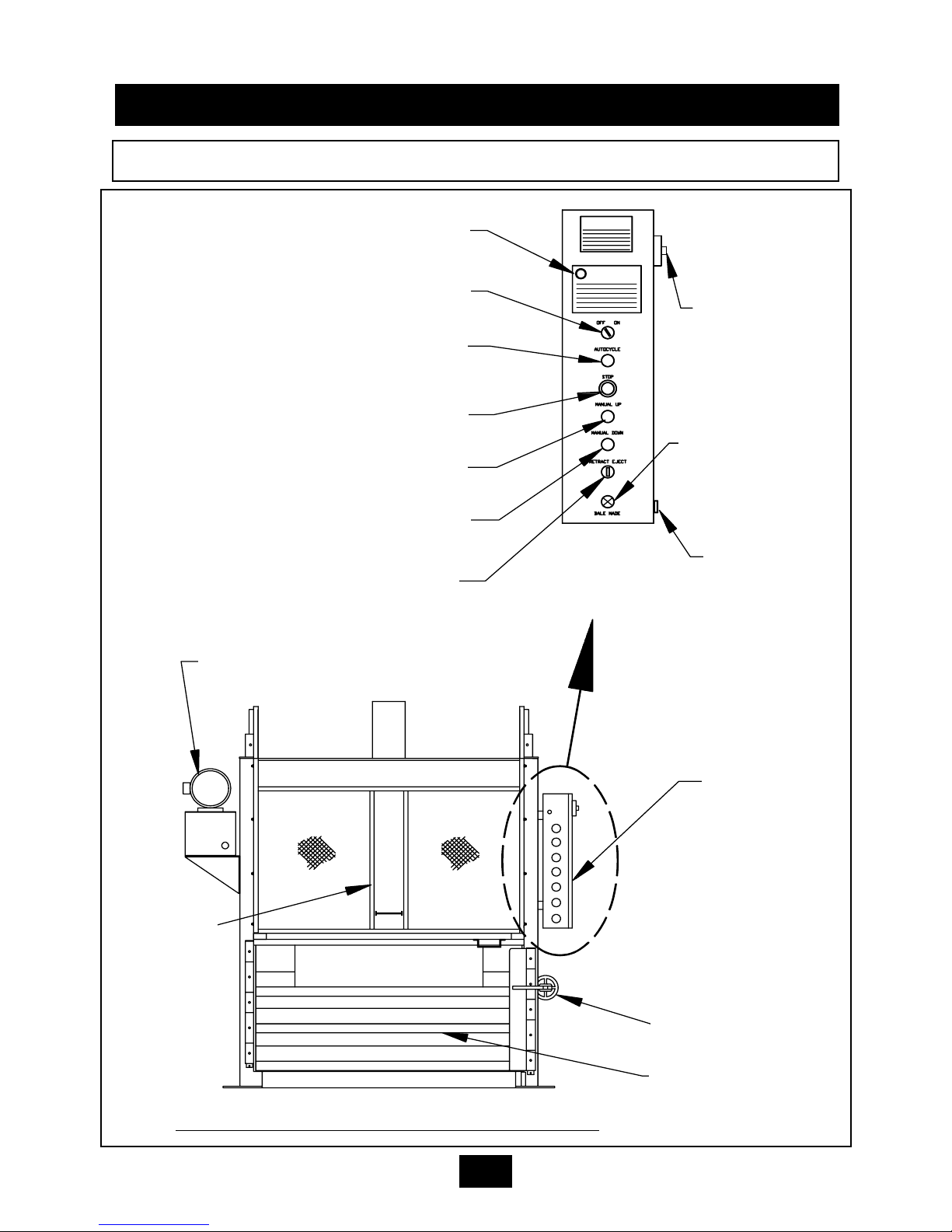

1 OPERATION

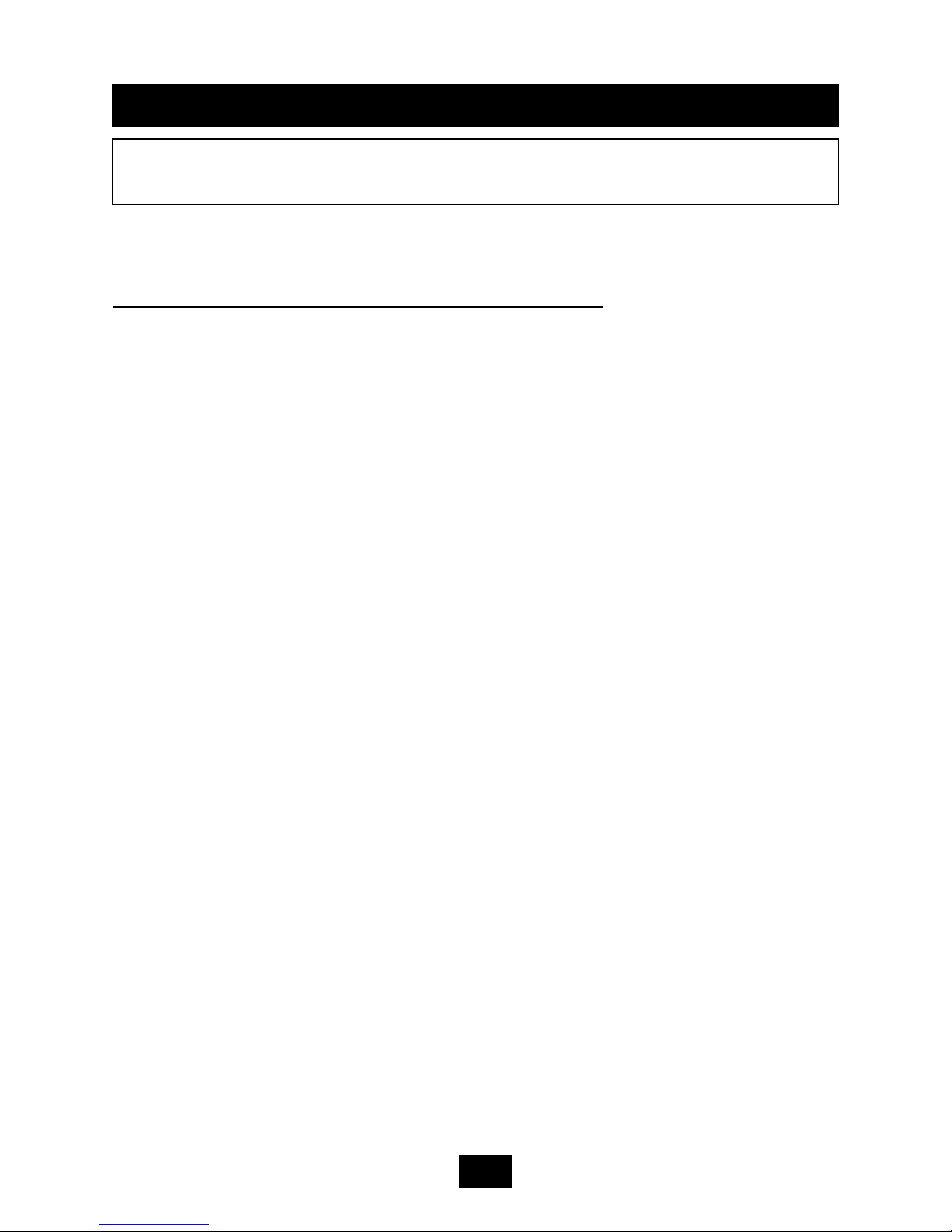

CONTROLS FOR V-6030 & V-4830

WARNING

STOP

MANUAL DOWN

MANUAL UP

AUTO CYCLE

OFF ON

RED WARNING LIGHT

KEYED ON-OFF SWITCH

AUTOCYCLE BUTTON

EMERGENCY STOP

BUTTON

MOTOR OVERLOAD

RESET BUTTON

(ON DOOR)

MANUAL UP BUTTON

MANUAL DOWN BUTTON

FEED GATE

TURNBUCKLE TO BALE

CHAMBER DOOR LATCH

BALE CHAMBER DOOR

CONTROL PANEL

PANEL BOX

NOTE: A fused disconnect is not provided on these models. The disconnect

must be provided, by the installer, per

the installation instructions in the

Installation section of this manual.

FRONT VIEW - VERTICAL BALER

1-4

Page 8

1 OPERATION

CONTROLS FOR V-6042LP

1-5

FRONT VIEW - LOW PROFILE VER

TICAL BALER

RETRACT/EJECT SWITCH

SIDE-MOUNTED

POWER UNIT

MANUAL DOWN PUSHBUTTON

BALE MADE LIGHT

RED WARNING LIGHT

AUTOCYCLE BUTTON

KEYED ON-OFF SWITCH

EMERGENCY STOP BUTTON

MANUAL UP PUSHBUTTON

RESET BUTTON

(ON DOOR)

DISCONNECT

SWITCH

FEED GATE

CONTROL PANEL

PANEL BOX

TURNBUCKLE TO BALE

CHAMBER DOOR LATCH

BALE CHAMBER DOOR

Page 9

ON-OFF (Keyed Selector Switch)

Turning this switch to the ON position activates the other controls on the control station.

The baler can not be operated unless the key is in the switch and the switch is in the ON

position. The purpose of this switch is to allow only authorized and trained personnel to

operate the baler. The key should be removed from the baler when not in use and should

stay in the possession of only responsible and trained personnel.

EMERGENCY STOP (Red Mushroom Head Pushbutton)

Depressing this button will stop the machine at any point in the cycle.

AUTOCYCLE (Green Pushbutton)

The AUTOCYCLE button can be used only when the feed gate and bale door are closed

and the keyswitch is in the ON position. Once depressed, the AUTOCYCLE button will

cause the platen to move to the fully down position and back to the fully raised position

(one complete cycle).

MANUAL UP (Black Pushbutton)

This button will only start the baler with the keyswitch in the ON position. Depressing the

button will raise the platen with the feed gate and bale door opened or closed. It is normally

used during bale ejection. It can also be used to interrupt the automatic cycle and raise the

platen should it become necessary. The MANUAL UP button is a “Hold To Run” control,

causing the baler to stop when it is released. WARNING: STAY CLEAR OF MOVING

PARTS WHEN USING THE MANUAL UP BUTTON WITH THE FEED GATE OPEN.

MANUAL DOWN (Black Pushbutton)

This button will only start the baler with the keyswitch in the ON position. Depressing the

button will lower the platen only if the feed gate and bale door are closed. It can be used to

interrupt the automatic cycle and lower the platen should it become necessary. The MANUAL DOWN button is a “Hold To Run” control, causing the baler to stop when it is released.

RED WARNING LIGHT

This light will warn the operator of a magnetic interlock switch malfunction. If the light is on

and the feed gate is in the up position, there is a problem. Discontinue use of the baler.

Turn off the baler and Lock-out and Tag-out per the instructions on page 2-1. Then call a

qualified service person. The light SHOULD BE ON when the feed gate is in the down position.

BALE MADE LIGHT (Not included on V-6030 and V-4830 models)

This light will come on if enough material has been compacted to make a complete bale.

RETRACT/EJECT (Spring-centered Switch) (USED ON THE V-6042LP ONL

Y)

This spring-centered switch will eject the bale by means of a hydraulic ejector when the

switch is held to the EJECT position. When the button is held to the RETRACT position, the

ejector will retract. The MANUAL UP button must be depressed and held at the same time

the RETRACT/EJECT switch is used.

1 OPERATION

CONTROL DESCRIPTION

1.

2.

3.

4.

5.

6.

7.

8.

1-6

Page 10

1 OPERATION

T

O MAKE A BALE : HD & LP Units

1. Feed material into baler. If starting a new bale, place a large flat piece of mater-

ial flat on the baler floor. NOTE: Do not attempt to overfill the feed chamber by

forcing material into the chamber with the feed gate. This can cause gate release

malfunction and may damage baler.

2. Pull gate handle down to close feed gate. NOTE: Check red warning light

before closing feed gate. If gate is open and light is on, discontinue use of the

baler and call for service.

3. To start the baler, insert the key into the keyswitch and turn to the ON

position.

4. Press the AUTOCYCLE button. The platen will make a complete cycle down

and back up. When the platen is in the full up position, the feed gate will automatically open and the motor will automatically shutdown.

5. Repeat steps 1 through 4 until platen stops in down position and “BALE MADE”

light comes on.

NOTE: In normal operation, the feed gate will be open when you walk up to

place material into the baler. For added security, the feed gate can be manually

closed after the AUTOCYCLE(S). To open the gate, you will have to insert the

key into the keyswitch and run the baler through a complete AUTOCYCLE.

IN CASE OF EMERGENCY:

Push the large red button to

STOP

OPERATING INSTRUCTIONS - MAKING A BALE

WARNING: DO NOT OPERATE BALER UNTIL OPERATING INSTRUCTIONS ARE

UNDERSTOOD.

See pages 1-3 through 1-5 for control panel layout and location.

1-7

WARNING: Interlocks and safety devices were installed on this unit for

your protection. Never disable or bypass any interlock or safety

device. Failure to comply with this warning could result in serious injury or

death.

Page 11

TO MAKE A BALE : V-6030 & V-4830

1. Feed material into baler. If starting a new bale, place a large flat piece of mater-

ial flat on the baler floor. NOTE: Do not attempt to overfill the feed chamber by

forcing material into the chamber with the feed gate. This can cause gate release

malfunction and may damage baler.

2. Pull gate handle down to close feed gate. NOTE: Check red warning light

before closing feed gate. If gate is open and light is on, discontinue use of the

baler and call for service.

3. To start the baler, insert the key into the keyswitch and turn to the ON

position.

4. Press the AUTOCYCLE button. The platen will make a complete cycle down

and back up. When the platen is in the full up position, the feed gate will automatically open and the motor will automatically shutdown.

5. Repeat steps 1 through 4 until the arrow on the platen dwells in direct line with

the arrow on the NOTICE decal on the feed gate, before returning to the up

position.

NOTE: In normal operation, the feed gate will be open when you walk up to

place material into the baler. For added security, the feed gate can be manually

closed after the AUTOCYCLE(S). To open the gate, you will have to insert the

key into the keyswitch and run the baler through a complete AUTOCYCLE.

WARNING: Interlocks and safety devices were installed on this unit for

your protection. Never disable or bypass any interlock or safety

device. Failure to comply with this warning could result in serious injury or

death.

IN CASE OF EMERGENCY:

Push the large red button to

STOP

OPERATING INSTRUCTIONS - MAKING A BALE

1 OPERATION

1-8

WARNING: DO NOT OPERATE BALER UNTIL OPERATING INSTRUCTIONS ARE

UNDERSTOOD.

See pages 1-3 through 1-5 for control panel layout and location.

Page 12

When the BALE MADE light comes on, it is time to tie off the bale and eject the bale

from the baler. See page 1-3 for control panel layout and location. See the following

page for a diagram of the following steps.

FOR BALE TIE OFF & BALE EJECT (HD MODELS):

1. Depress the MANUAL UP button until the feed gate opens.

2. Insert a large, flat piece of material across the top of the bale.

3. Close feed gate and depress the AUTOCYCLE button. The platen

will stop in the down position and the BALE MADE light will be illuminated.

CAUTION: CLEAR ALL PERSONNEL FROM FRONT OF BALER

BEFORE PROCEEDING WITH STEPS 4 THROUGH 8.

4. Release the bale chamber door latch on the side of baler and open

the bale chamber door all the way. Feed gate is closed but will raise

when the chamber door is opened.

5. CAUTION: Wear safety glasses and leather gloves during the following operation:

Tie off bale by inserting bale ties through the platen, “loop end” first.

Always insert bale ties through the tie slots in the platen, first.

Feed wire through until it comes out of the slot in the baler floor.

Tie off each tie. Bale ties should be tightened only hand tight, allowing for bale expansion when released.

6. Standing at the side, make sure all personnel are clear of the front of

the baler. Depress the MANUAL UP button.

7. Hold the MANUAL UP button until bale ejects, then release the

button.

8. Remove bale.

9. Close and latch the bale chamber door. Close feed gate. Depress

AUTOCYCLE to cycle and reset ejector. Bale sequence is ready to

be repeated.

1 OPERATION

OPERATING INSTRUCTIONS BALE TIE OFF/BALE EJECT FOR V-6030HD, V-4830HD, V-7230HD

1-9

Page 13

1 OPERATION

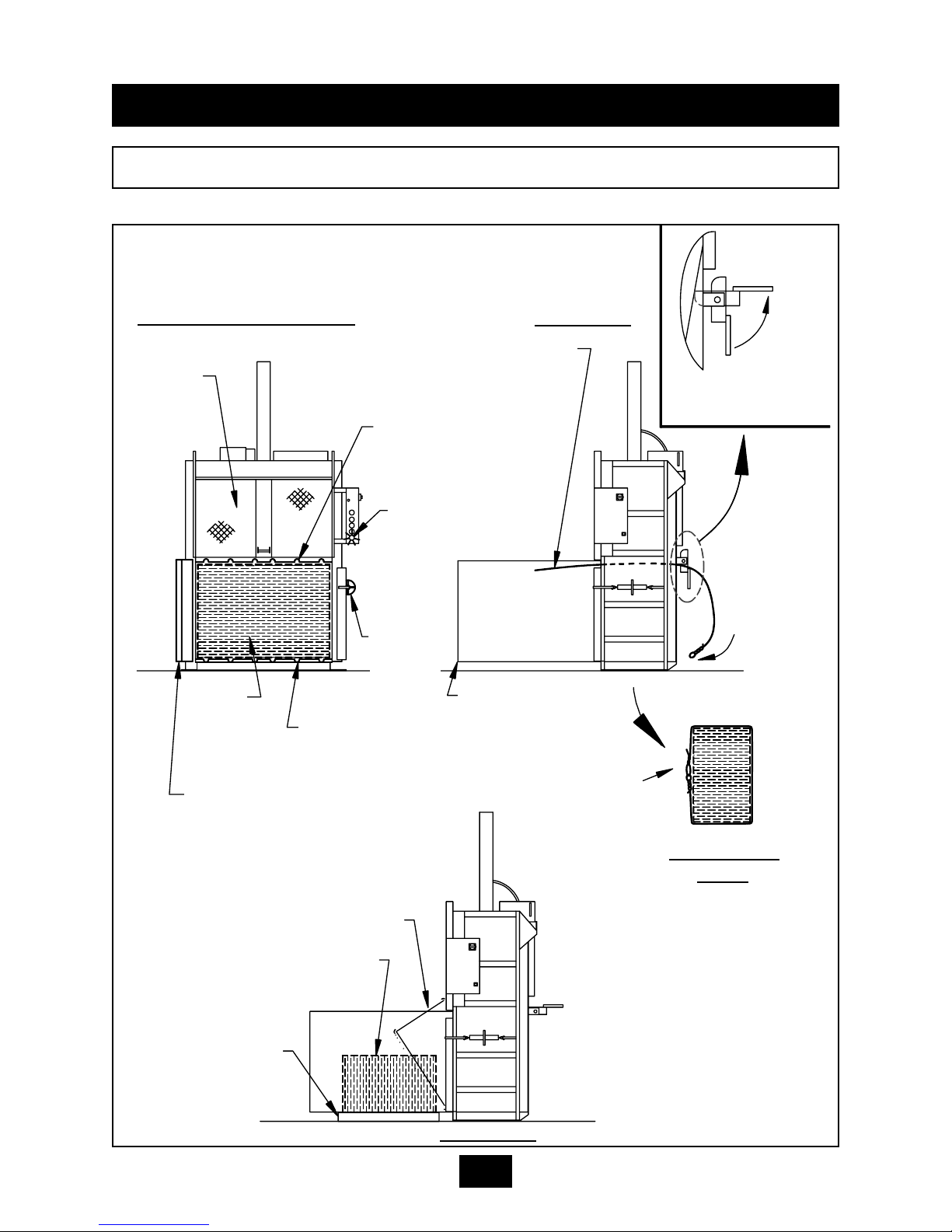

DIAGRAM BALE TIE OFF/BALE EJECT FOR V-6030HD, V-4830HD, V-7230HD

GATE CLOSED.

STEP 3.

PLATEN - BALE TIE

GUIDE, 6 PLACES.

SEE STEP 5.

BALE

MADE

LIGHT

DOOR

LATCH OPEN

BALE CHAMBER DOOR - OPEN.

SEE STEP 4.

FLOOR - BALE TIE

GUIDE, 6 PLACES.

SEE STEP 5.

FEED

FRONT VIEW OF BALER

SIDE VIEW

BALE TIE - TIGHTENED

HAND TIGHT

BALE DURING EJECTION

BALE

PALLET RECOMMENDED

FOR SUPPORTING BALE

SIDE VIEW

BALE CHAMBER

DOOR

SIDE VIEW

- BALE

BALE TIE - INSERT AND PUSH THROUGH

PLATEN GUIDES. TIES WILL CIRCLE THE

BALE AND COME OUT OF THE FLOOR

GUIDES. SEE STEP 5.

BALE

1-10

Page 14

When the BALE MADE light comes on, it is time to tie off the bale and eject the bale

from the baler. See page 1-3 for control panel layout and location. See the following

page for a diagram of the following steps.

FOR BALE TIE OFF & BALE EJECT (V-6030LP):

1. Depress the MANUAL UP button until the feed gate opens.

2. Insert a large, flat piece of material across the top of the bale.

3. Close feed gate and depress the AUTOCYCLE button. The platen

will stop in the down position and the BALE MADE light will be illuminated.

CAUTION: CLEAR ALL PERSONNEL FROM FRONT OF BALER

BEFORE PROCEEDING WITH STEPS 4 THROUGH 8.

4. Release the bale chamber door latch on the side of baler and open

the bale chamber door all the way. Feed gate is closed but will raise

when the chamber door is opened.

5. CAUTION: Wear safety glasses and leather gloves during the following operation:

Facing the front of the bale, tie off bale by inserting bale ties (loop

end first) through the platen. Always insert bale ties through the

tie slots in the platen, first. Go to the rear of the baler and feed

the loop end of the bale ties down and through the aligned tie slots in

the floor. Finally, go to the front of the baler and tie each of the

ties. Bale ties should be tightened only hand tight, allowing for bale

expansion when released.

6. Before ejecting the bale, go to the rear of the baler and manually

engage the bale eject latch (WARNING: Never engage eject latch if

bale door is closed). To engage the latch, pull (rotate) the latch handle up all the way. Standing at the side, make sure all personnel are

clear of the front of the baler. Depress the MANUAL UP button.

7. Hold the MANUAL UP button until bale ejects, then release button.

8. Remove bale.

9. Close and latch bale chamber door. Close feed gate. Depress AUTOCYCLE to cycle and reset ejector. Bale sequence is ready to be

repeated.

1 OPERATION

OPERATING INSTRUCTIONS BALE TIE OFF/BALE EJECT FOR V-6030LP

1-11

Page 15

1 OPERATION

DIAGRAM - BALE TIE OFF/BALE EJECT FOR V-6030LP

FEED

GATE

PLATEN - BALE TIE

GUIDE, 6 PLACES.

SEE STEP 5.

BALE

MADE

LIGHT

DOOR

LATCH OPEN

BALE CHAMBER DOOR OPEN.

SEE STEP 4.

FLOOR - BALE TIE

GUIDE, 6 PLACES.

SEE STEP 5.

FRONT VIEW OF BALER

SIDE VIEW

BALE TIE - TIGHTENED

BALE DURING EJECTION

- STEP 7.

BALE

PALLET RECOMMENDED FOR

SUPPORTING

BALE

SIDE VIEW

BALE CHAMBER

DOOR

SIDE VIEW -

BALE

BALE TIE - INSERT AND PUSH

THROUGH PLATEN GUIDE.

SEE STEP 5.

BALE

- CLOSED.

STEP 3.

HAND TIGHT

BALE EJECT LATCHENGAGED. STEP 6.

FEED TIES

THROUGH

FLOOR

GUIDES STEP 5.

1-12

Page 16

1 OPERATION

OPERATING INSTRUCTIONS BALE TIE OFF/BALE EJECT FOR V-6042LP

1-13

When the BALE MADE light comes on, it is time to tie off the bale and eject the bale

from the baler. See page 1-5 for control panel layout and location. See the following

page for a diagram of the following steps.

FOR BALE TIE OFF & BALE EJECT (V-6042LP):

1. Depress the MANUAL UP button until the feed gate opens.

2. Insert a large, flat piece of material across the top of the bale.

3. Close feed gate and depress the AUTOCYCLE button. The platen

will stop in the down position and the BALE MADE light will be illuminated.

CAUTION: CLEAR ALL PERSONNEL FROM FRONT OF BALER

BEFORE PROCEEDING WITH STEPS 4 THROUGH 8.

4. Release the bale chamber door latch on the side of baler and open

the bale chamber door all the way. Feed gate is closed but will raise

when chamber door is opened.

5.

CAUTION:

Wear safety glasses and leather gloves during the follow-

ing operation: Tie off bale by inserting bale ties through the platen,

“loop end” first. Always insert bale ties through the tie slots in the

platen, first. Feed wire through until it comes out of the slot in the

baler floor. Tie off each tie. Bale ties should be tightened only hand

tight, allowing for bale expansion when platen is released.

6. Depress the MANUAL UP button until the platen reaches its up position.

7. Standing at the side, make sure all personnel are clear of the front of

the baler. Depress and hold the MANUAL UP button and hold the

RETRACT/EJECT switch to the right (EJECT) until the bale ejects.

Depress and hold the MANUAL UP button and hold the RETRACT/

EJECT switch to the left (RETRACT) until the ejector retracts all the

way. Baler will not function if ejector is not fully retracted.

8. Remove bale from in front of baler.

9. Close and latch the bale chamber door. Bale sequence is ready to be

repeated.

NOTE: You can close the feed gate at this time if added security is required. To

open the gate you will have to run the baler through a complete AUTOCYCLE.

Page 17

1 OPERATION

DIAGRAM - BALE TIE OFF/BALE EJECT FOR V-6042LP

1-14

FEED GATE CLOSED.

STEP 3.

PLATEN - BALE TIE

SLOT, 6 PLACES.

SEE STEP 5.

BALE

MADE

LIGHT

DOOR

LATCH OPEN

BALE CHAMBER DOOR - OPEN.

SEE STEP 4.

FLOOR - BALE TIE

SLOT, 6 PLACES.

SEE STEP 5.

FRONT VIEW OF BALER

SIDE VIEW

BALE TIE - TIGHTENED

HAND TIGHT

BALE DURING EJECTION

SEE STEP 7

RECOMMEND

SUPPORTING

BALE WITH

PALLET JACK

OR FORK LIFT

SIDE VIEW

BALE

CHAMBER

DOOR

SIDE VIEW

- BALE

BALE TIE - INSERT AND PUSH

THROUGH PLATEN TIE SLOTS.

TIES WILL COME OUT OF THE

FLOOR TIE SLOTS. SEE STEP 5.

BALE

Page 18

1 OPERATION

OPERATING INSTRUCTIONS BALE TIE OFF/BALE EJECT FOR V-4830 & V-6030

When the arrow decal on the platen dwells in direct line with the notice decal arrow on

the feed gate, it is time to tie off the bale and eject the bale from the baler. See page

1-4 for control panel layout and location. See the following page for a diagram of the following steps.

FOR BALE TIE OFF & BALE EJECT (V-4830 & V-6030):

1. Insert a large, flat piece of material across the top of the bale.

2. Close feed gate and depress the MANUAL DOWN button. The platen

will dwell in the down position and the arrows on the platen and feed

gate will be in direct line. Release the MANUAL DOWN button.

3. Place the ejector hook on the platen (located on the rear of machine).

CAUTION: CLEAR ALL PERSONNEL FROM FRONT OF BALER

BEFORE PROCEEDING WITH STEPS 4 THROUGH 7.

4. Release the bale chamber door latch on the side of baler and open the

bale chamber door all the way. Feed gate is closed but will raise when

chamber door is opened.

5. CAUTION: Wear safety glasses and leather gloves during the follow-

ing operation: Tie off bale by inserting bale ties through the platen,

“loop end” first. Always insert bale ties through the tie slots in the

platen, first. Feed wire through until it comes out of the slot in the

back of baler. Go to the rear of the baler and feed the looped end of

the bale ties down and through the aligned tie slots in the floor.

Finally, go to the front of the baler and tie each of the ties. Bale ties

should be tightened only hand tight, allowing for bale expansion

when platen is released.

6. Standing at the side, make sure all personnel are clear of the front of

the baler. Depress and hold the MANUAL UP button until the bale

ejects.

7. Remove bale from in front of baler. Close and latch the bale door.

8. Close the feed gate, and press the MANUAL DOWN button until the

ejector hook releases from the platen

10. Press and hold the MANUAL UP button until the platen is in the up

position, and the feed gate raises. Bale sequence is ready to be

repeated.

NOTE: You can close the feed gate at this time if added security is required. To

open the gate you will have to run the baler through a complete AUTOCYCLE.

1-15

Page 19

DIAGRAM - BALE TIE OFF/BALE EJECT FOR V-4830 & V-6030

1 OPERATION

FRONT VIEW

SIDE VIEW

WIRE GUIDES

ARROWS ALIGNED

TO SHOW BALE

MADE POSITION

EJECTOR HOOK ON

PLATEN

INSERT WIRE TIES

THROUGH FLOOR

GUIDES

PALLET RECOMMENDED

HOOK POSITION WHILE

BALING

BALE DOOR

BALE DOOR LATCH

FEED GATE

BALE TIE- INSERT AND PUSH

THROUGH PLATEN AND FLOOR

GUIDES. TIE BALE TIES HAND

TIGHT TO ALLOW FOR EXPANSION.

BALE- AFTER

EJECTION

BALE- DURING

EJECTION

EJECTOR

HOOK WHEN

BALE IS

EJECTED

1-16

Page 20

1 OPERATION

DIAGRAM - TIE SLOT CLEANING

1-17

AT TIMES THE TIE SLOTS MAY BECOME OBSTRUCTED WITH MATERIAL AND PREVENT THE

WIRE TIES FROM PROPER INSERTION THROUGH THE SLOTS AND AROUND THE BALE. THE

BALER IS SUPPLIED WITH A SLOT CLEANING TOOL FOR RODDING OUT THE TIE SLOTS.

TO USE, INSERT THE TOOL INTO THE PROBLEM SLOT AND PUNCH OR DRAG THE MATERIAL

OUT.

IF THE WIRE GUIDES BECOME OBSTRUCTED WITH MATERIAL , THE BALER SHOULD BE

EMPTIED, LOCKED OUT AND TAGGED OUT, AND THE PLATEN SHOULD BE CHOCKED AS

SHOWN IN THE MAINTENANCE SECTION OF THIS MANUAL BEFORE CLEANING THE WIRE

GUIDES.

FRONT VIEW

SIDE VIEW

BALE

WARNING LIGHT

FEED GATE

WIRE GUIDES

TIE SLOTS

SLOT CLEANING T

OOL

HANDLE

Page 21

WARNING DECAL REQUIREMENTS

When your baler leaves the factory, several WARNING DECALS are installed for protection. These labels are subject to wear and abuse due to the nature of the operation.

THESE DECALS MUST BE MAINTAINED. Additional decals may be purchased

through your distributor.

1 OPERATION

DECALS

DANGER: DO NOT ENTER.

DANGER: 208 VOLTS. or

DANGER: 230 VOLTS. or

DANGER: 460 VOLTS.

DANGER: 208 VOLTS. or

DANGER: 230 VOLTS. or

DANGER: 460 VOLTS.

CAUTION: GATE MUST BE CLOSED BEFORE OPERATING

BALER.

DANGER: KEEP HANDS OUT.

CAUTION: STAND CLEAR WHEN BALE IS EJECTED.

CAUTION: STAND CLEAR WHILE OPERATING DOOR

LOCK.

NOTICE: PERIODIC MAINTENANCE IS REQUIRED AND IS

YOUR RESPONSIBILITY.

DANGER. DISCONNECT AND LOCK OUT POWER

BEFORE OPENING THIS PANEL.

WARNING: FEDERAL REGULATION PROHIBITS OPERA-

TION OF THIS EQUIPMENT BY PERSONS UNDER 18

YEARS OF AGE.

MARATHON EQUIPMENT COMPANY.

Decal Number 06-0039 Decal Number 06-0043 Decal Number 06-0044 Decal Number 06-0045 Decal Number 06-0101 Decal Number 06-0102 Decal Number 06-0103 Decal Number 06-0115 -

Decal Number 06-0116 Decal Number 06-0117 Decal Number 06-0118 -

Decal Number 06-0119 -

Decal Number 06-0120 -

Decal Number 06-0121 -

Decal Number 06-0126 -

1-18

Page 22

WARNING DECAL REQUIREMENTS

When your baler leaves the factory, several WARNING DECALS are installed for protection. These labels are subject to wear and abuse due to the nature of the operation.

THESE DECALS MUST BE MAINTAINED. Additional decals may be purchased

through your distributor.

1 OPERATION

DECALS

CAUTION: DO NOT OPERATE BALER UNTIL OPERATING

INSTRUCTIONS ARE UNDERSTOOD. NEVER PLACE ANY

PART OF BODY INSIDE BALE CHAMBER. STAND CLEAR

WHILE BALER IS IN OPERATION. FEDERAL LAW PROHIBITS OPERATION OF THIS EQUIPMENT BY PERSONS

UNDER 18 YEARS OF AGE. TURN OFF AND REMOVE KEY

AFTER USE. STAND CLEAR WHILE EJECTING BALE.

(Also, includes Operating Instructions).

WARNING: STAY CLEAR OF BALE CHAMBER WHEN

LIGHT IS ILLUMINATED. IF LIGHT IS ILLUMINATED WHEN

BALE DOOR OR FEED GATE IS OPEN, DISCONTINUE

USE OF THIS EQUIPMENT AND CALL QUALIFIED SERVICE PERSONNEL.

DANGER: STAY OFF TOP BALER. DO NOT CLIMB ON

SIDES. USE WORK PLATFORM FOR SERVICING.

NOTICE BALE MADE IF ARROW DOES NOT PASS.

(V-4830 & V-6030 ONLY)

ORANGE ARROW.

(V-4830 & V-6030 ONLY)

Decal Number 06-0130 -

Decal Number 06-0132 -

Decal Number 06-0133 -

Decal Number 06-0651-

Decal Number 06-0652 -

1-19

Page 23

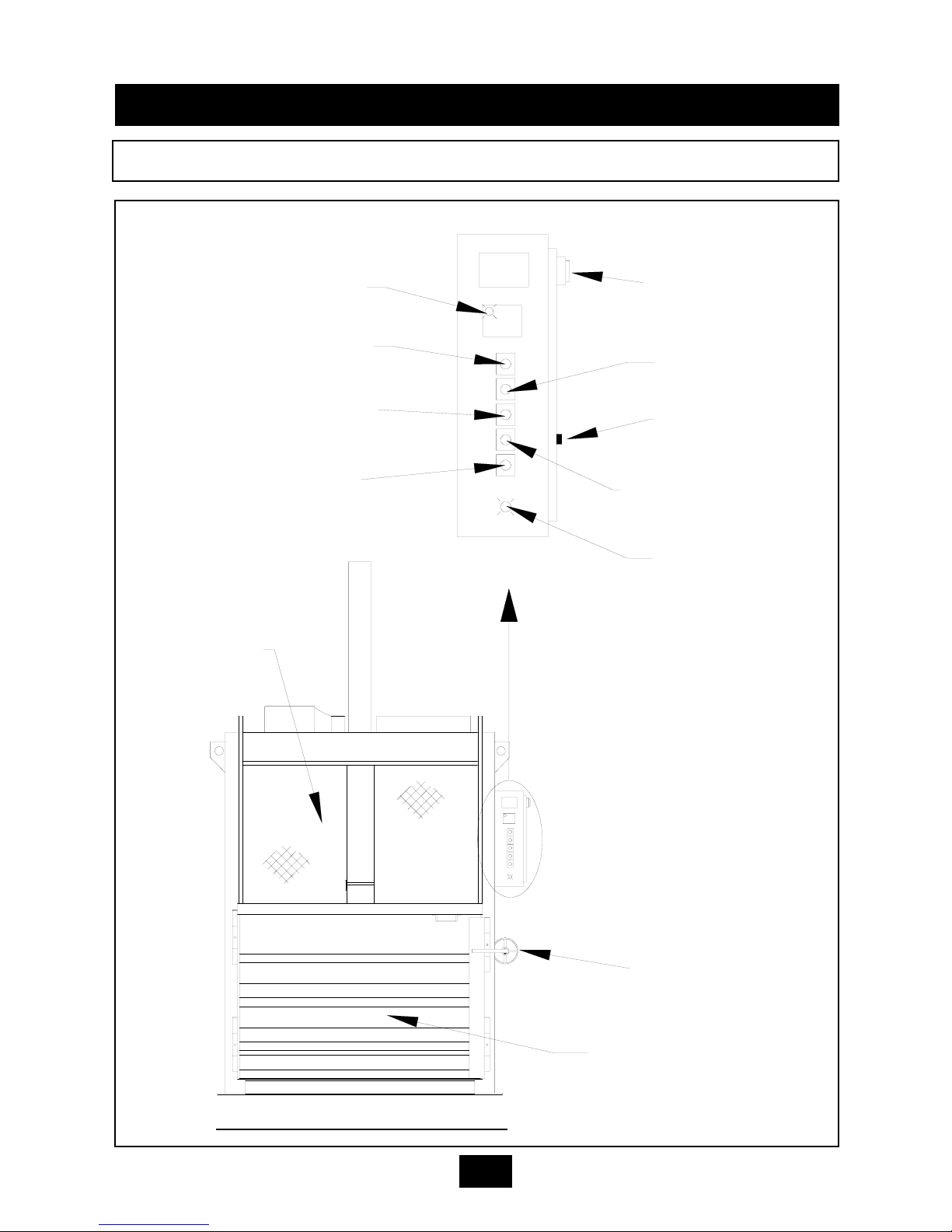

1 OPERATION

DECAL PLACEMENT FOR HD & LP MODELS

06-0116

06-0103

06-0039

DISCONNECT

06-0132

06-0117

06-0130

06-0119

06-0120

06-0043

06-0133

06-0118

06-0121

06-0126

06-0115

06-0102 or

06-0101 or

06-0044

06-0045

FRONT

VIEW

SIDE VIEW

1-20

FRONT VIEW OF V-6042LP

06-0101, 06-0102, OR 06-0103 (ON SIDE-MOUNTED POWER UNIT)

ALL OTHER DECALS ON THE

V-6042LP ARE LOCATED AS

SHOWN ABOVE.

NOTE: Installation is not

complete until all decals are

in place.

Page 24

1 OPERATION

DECAL PLACEMENT FOR V-4830 & V-6030

U

L

R

U

L

LISTED

16BF

C

DOVER

VERNON, AL − YERINGTON, NV − CLEARFIELD, PA

1−800−633−8974

VERTICAL BALER

PATENT # 5,044,271

MODEL

SERIAL #

THIS PRODUCT COMPLIES WITH

ANSI Z245.5−1990.

R

R

FRONT VIEW

OF PLATEN

06-0101,

OR 06-0102,

OR 06-0103

06-0652

06-0132

06-0119

PLACE ON

PANEL BOX

BRACKET

06-0121

06-0118

06-0275

FRONT VIEW

SIDE VIEW

06-0120

06-0101,

OR 06-0102,

OR 06-0103

06-0130

06-0133

BOTH SIDES

06-0117

06-0097

06-0039

06-0651

06-0116

06-0115

06-0126

06-0147

NOTE: Installation is not

complete until all decals are

in place.

1-21

Page 25

2 MAINTENANCE

LOCK-OUT & TAG-OUT INSTRUCTIONS

ELECTRICAL: The panel box contains high voltage

components. Only authorized service personnel

should be allowed inside the box. Authorized service

personnel should be allowed inside the box only

after the baler has been locked-out and tagged-out.

FOREWORD: Before entering any part of the baler, be

sure that all sources of energy have been shut off, all

potential hazards have been eliminated, and the baler

is locked-out and tagged-out in accordance with

OSHA and ANSI requirements. Before servicing the

hydraulic system or the inside of the bale chamber,

THE PLATEN MUST BE PROPERLY SUPPORTED AS

SHOWN ON THE NEXT PAGE.

The specific lock-out and

tag-out instructions may vary from company to company (i.e.

multiple locks may be required, or other machinery may need to

be locked-out and tagged-out). The following instructions are

provided as minimum guidelines.

INSTRUCTIONS

1. Move the main disconnect lever to the OFF position. The disconnect switch on

models V-4830 & V-6030 is located in the disconnect panel on the wall. The disconnect

switch on all other models is located in the panel box of the machine.

2. Padlock the disconnect lever with a keyed padlock and take the key with

you.

(To insert the lock through the lock tab on the disconnect handle, pull the lock tab out of

the disconnect handle when the handle is in the OFF position.)

3. Along with the padlock, place an appropriate, highly visible, warning tag on

the disconnect lever. The tag should provide a warning such as: “ Danger: Do not oper-

ate equipment. Person working on equipment.” or “ Warning: Do not energize without the permission of ________________________.”

4. After locking and tagging the baler, try to start and operate the baler (as outlined in the Operating Instructions) to make sure the lock-out and tag-out is

effective. If the lock-out and tag-out is effective, remove the key from the

keyswitch and take it with you.

HYDRAULIC: Stored hydraulic energy must be removed from the baler hydraulic cir-

cuit for complete lock-out and tag-out. Make sure that this energy has been relieved

by manually depressing the solenoid valve pin located in the center of the coil end of

each valve.

2-1

(Typical disconnect shown, other types may lock-out differently.)

Page 26

2 MAINTENANCE

SUPPORTING OF PLATEN

BALE CHAMBER DOOR,

OPEN

FEED GATE OPEN PLATEN IN UP

POSITION

DISCONNECT

IN OFF POSITION AND

LOCKED-OUT

4” X 4” WOOD

BEAM IN EACH

REAR CORNER

FRONT VIEW OF BALER

WARNING: BEFORE ENTERING BALE CHAMBER FOR SERVICE, BE SURE THAT

THE PLATEN IS SECURELY SUPPORTED. AT A MINIMUM, USE TWO WOODEN

4” X 4” BEAMS (GOOD CONDITION), CUT TO FIT SNUG IN EACH REAR CORNER

OF THE CHAMBER WHILE SUPPORTING THE PLATEN IN THE UP POSITION. THE

TOP END OF EACH BEAM SHOULD BE IN THE EXTREME CORNER, WHILE THE

BOTTOM END SHOULD BE POSITIONED OVER THE OUTER TIE SLOT IN THE

FLOOR. SEE DIAGRAM BELOW.

DANGER: DO NOT CLIMB ON SIDES OF BALER. USE A LADDER OR WORK

PLATFORM WHEN WORKING ON TOP OF THE BALER OR OTHER AREAS OF THE

BALER THAT CAN NOT BE REACHED FROM GROUND LEVEL.

WARNING: PARTS OF THE PLATEN WILL EXTEND ABOVE THE TOP OF THE

BALER WHEN THE PLATEN IS FULLY RAISED.

BEAM OVER

OUTER TIE

SLOT IN FLOOR

2-2

Page 27

Check external hoses for chafing, rubbing, leakage, or other deterioration and damage. Tighten all fittings as necessary. Check hydraulic cylinder, cylinder pin and

bolts for signs of wear and fatigue.

Check for any obvious unsafe conditions, such as operator obstructions, in baler

area.

Check oil level in hydraulic reservoir.

Lubricate the door hinge, and mechanical door lock with oil.

Check magnetic interlock on feed gate for proper operation.

Clean out wire guides on machines equipped with them. Follow platen chocking

procedures and lock out and tag out procedures.

Check guide shoes for wear, and lubricate as needed with an all purpose grease.

Apply a light coating of all purpose grease in the feed gate tracks.

Apply a light application of all purpose oil to the feed gate latch moving parts.

Check functional operation of controls and options (stop button, timers, lights, etc.).

Check hydraulic cylinder, and hoses, for leakage, chafing and wear.

The hydraulic filter should be cleaned at regular annual intervals.

The filter may be removed from the power unit through the cleanout cover in the top

of the reservoir.

Care should be exercised in cleaning the fiIter to insure that the element is not torn.

Clean the element with a soft brush and standard industrial solvent.

Replace the filter after cleaning and check fittings for tightness. Pump noise and a

"crackle" sound is most often caused by air entering the pump suction line.

Tightening the suction fittings will usually eliminate the problem.

2 MAINTENANCE

PERIODIC MAINTENANCE

1.

2.

3.

4.

5.

6.

7.

8.

9.

1.

2.

1.

2.

3.

4.

MONTHLY

THREE MONTHS

ANNUAL FILTER MAINTENANCE

ANNUALLY

1.

2.

3.

Replace the hydraulic fluid. See Recommended Oil.

Electric motor bearings should be lubricated once a year.

Clean the top of the power unit to remove the dirt build up.

2-3

WARNING: BEFORE PERFORMING ANY MAINTENANCE OR SERVICE PROCEDURES ON THE

BALER, MAKE SURE THE BALER IS LOCKED-OUT AND TAGGED OUT PER THE INSTRUCTIONS

ON PAGE 2-1. FOR MAINTENANCE INSIDE THE BALE CHAMBER, SEE THE PLATEN CHOCKING

PROCEDURE ON PAGE 2-2.

Page 28

With the key switch in the ON position, use the MANUAL DOWN button to move the

platen to the full down position.

Turn off the power and perform the LOCK-OUT and TAG-OUT procedures

described on page 2-1.

Manually shift the solenoid valve in each direction to relieve pressure.

Remove the 1/4” plug from the 3/4” 90 degree elbow in the valve subplate.

Install a pressure gauge in the 1/4” hole.

Remove the Lock-out and Tag-out provisions and turn on power to the baler.

Have an operator hold the MANUAL DOWN button. This will start the baler and the

hydraulic system will build relief pressure. Turn the adjustment screw on the relief

valve clockwise to increase the pressure, or counter clockwise to decrease the

pressure. See CHARTS for proper setting for your model.

Tighten locknut on adjustment screw.

Have the operator release the MANUAL DOWN button and press the STOP button.

Turn off the power and perform the LOCK-OUT and TAG-OUT procedures

described on page 2-1.

Remove the pressure gauge and reinstall the 1/4” plug.

This procedure is complete.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

2 MAINTENANCE

PROCEDURES - PRESSURE SETTING, INTERLOCK TESTING

HYDRAULIC SYSTEM PRESSURE SETTING

MAGNETIC INTERLOCK TESTING

1.

2.

3.

4.

This baler is equipped with a solid state output magnetic interlock switch. Because

it is a semiconductor device, it can not be checked with a continuity light or OHM

tester. The switch must be checked with the power ON. The RED WARNING

LIGHT on the control panel has been provided to indicate if the switch is working

properly.

To check the switch, turn the keyswitch to the ON position. When the feed gate or

bale door is open, the light should be off. When the bale door and feed gate are

closed, the light should be on.

If further verification is required, a volt meter (120V) may be connected to terminal

#2A and terminal #7 in the panel box. The meter should read “0” volts with the gate

open and 120 volts with the gate closed.

In no instance should the baler operate in either MANUAL DOWN or AUTOCYCLE

with the feed gate up or bale door open.

WARNING: IF THE INTERLOCK IS NOT WORKING PROPERLY, DISCONNECT

THE POWER AND LOCK-OUT AND TAG-OUT THE BALER UNTIL REPAIRS CAN

BE MADE.

DANGER: DO NOT CLIMB ON SIDES OF BALER. USE A LADDER OR WORK PLATFORM

WHEN WORKING ON TOP OF THE BALER OR OTHER AREAS OF THE BALER THAT CAN

NOT BE REACHED FROM GROUND LEVEL.

WARNING: PARTS OF THE PLATEN WILL EXTEND ABOVE THE TOP OF THE BALER

WHEN THE PLATEN IS FULLY RAISED.

2-4

Page 29

2 MAINTENANCE

PROCEDURES - CYLINDER REMOVAL

CYLINDER REMOVAL (ALL UNITS EXCEPT LOW PROFILE, LP)

Raise platen up to the top position with the MANUAL UP button.

Disconnect and Lock-out and Tag-out power per instructions on page 2-1.

Remove guide shoes.

Turn on power and lower platen using the MANUAL DOWN button. Turn off power.

Support platen with fork lift to take pressure off of cylinder pin and to prevent platen from falling

when pin is removed.

Remove bolts and cotter pins in cylinder pin.

Remove platen from front of baler.

Turn on power and retract cylinder rod.

Disconnect and Lock-out and Tag-out power.

Relieve hydraulic pressure by manually depressing solenoid valve (both sides).

Disconnect one hydraulic hose at a time. Plug the hose port before disconnecting the other hose.

NOTE: Remove hose fittings slowly.

WARNING: BE SURE HYDRAULIC CYLINDER IS SECURELY SUPPORTED BEFORE PROCEEDING.

With the hydraulic cylinder supported, loosen the 3/4” grade 5 cylinder bolts and grade 5 locknuts.

Remove cylinder.

Before reinstalling cylinder, check cylinder pin, bolts, and cylinder rod for signs of fatigue. Do not

reuse parts if wear or cracks are present.

To reinstall the cylinder, reverse the above steps.

Be sure to use new bolts, nuts, and cotter pins in the cylinder pin.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

DANGER: DO NOT CLIMB ON SIDES OF BALER. USE A LADDER OR WORK PLATFORM WHEN

WORKING ON TOP OF THE BALER OR OTHER AREAS OF THE BALER THAT CAN NOT BE

REACHED FROM GROUND LEVEL.

WARNING: PARTS OF THE PLATEN WILL EXTEND ABOVE THE TOP OF THE BALER WHEN THE

PLATEN IS FULLY RAISED.

2-5

MAIN CYLINDER REMOVAL - LOW PROFILE

Raise platen up to the top position with MANUAL UP button. Lock-out and Tag-out power per

instructions on page 2-1. Remove guide shoes.

Turn on power and lower platen using MANUAL DOWN button. Turn off power.

Support platen with fork lift to take pressure off of cylinder pin and to prevent platen from falling

when pin is removed. NOTE: Because of the long pin length, make sure the fork lift is no closer

than 24” to the platen.

Remove the two bolts attaching the cylinder pin assembly to the front of the platen. The cylinder pin

assembly consists of a 21 3/4” long pin (1 1/2” dia) with a ”U” bracket welded to the end. This bracket fastens to the front of the platen with the two bolts. Slide the pin assembly out of the cylinder and

platen.

Remove platen from front of baler. Turn on power and retract cylinder rod.

Disconnect and Lock-out and Tag-out power. Relieve hydraulic pressure per Lock-out and Tag-out.

Disconnect one hydraulic hose at a time. Plug the hose port before disconnecting the other hose.

NOTE: Remove hose fittings slowly.

WARNING: SUPPORT HYDRAULIC CYLINDER BEFORE PROCEEDING.

With the hydraulic cylinder supported, remove the 1” grade 5 cylinder bolts and grade 5 locknuts.

Remove cylinder.

Before reinstalling cylinder, check cylinder pin, bolts, and cylinder rod for signs of fatigue. Do not

reuse parts if wear or cracks are present.

To reinstall the cylinder, reverse the above steps. Be sure to use new bolts, and cotter pins in the

cylinder pin.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Page 30

2 MAINTENANCE

PROCEDURES - CYLINDER REBUILDING, LIMIT SWITCH ADJUSTMENT

CYLINDER REBUILDING

Remove hydraulic cylinder from baler.

Remove bolts and retainer plate from gland.

Remove internal retaining ring.

Remove rod from cylinder barrel.

Remove piston locknut and piston from cylinder rod.

Replace all seals. Discard old seals and old piston locknut.

Replace gland on rod.

Install piston on cylinder rod using new locknut (included in seal kit).

NOTE: Do not reuse old locknut. Torque new locknut to 1000-1200 ft-lbs.

Install piston and rod assembly in cylinder barrel. Be careful not to damage seals.

Install gland in barrel. Install internal retaining ring.

Bolt retainer plate to gland. Reinstall cylinder in baler.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

WARRANTY AND SERVICE ON MOTORS

If the baler motor fails under warranty, have it checked by a qualified electrician or service person. If

there is no problem with fuses or wiring, the motor should be taken to the nearest authorized motor warranty shop. If you do not have a list of qualified shops, contact Marathon Equipment Co. The motor warranty shop will be able to inspect the motor and determine if it is factory defective. If the motor failed due

to defects in material or workmanship, contact the factory to determine if the motor will be replaced or

repaired. If motor failure was not due to defective material or workmanship, it will be repaired only if customer agrees to pay for expenses. Marathon Equipment Co. will not absorb cost for pickup and delivery

to service centers. Removal and reinstallation are covered in the standard warranty policy.

2-6

LIMIT SWITCH ADJUSTMENT (ALL HD UNITS)

The baler has only one limit switch. This switch controls the size of the bale and activates the BALE MADE light.

Make a mark on the inside of the bale chamber 39 3/4” from the baler floor (top of

corrugations).

Close the bale chamber door and feed gate and lower the platen until the line just

touches the top of the platen side panel.

Turn off and lock-out and tag-out the power. Adjust the BALE MADE limit switch arm

to the highest point on the actuator.

Remove the Lock-out and Tag-out provisions and turn on power.

1.

2.

3.

4.

LIMIT SWITCH ADJUSTMENT (ALL LP UNITS)

The baler has only one limit switch. This switch controls the size of the bale and activates the BALE MADE light.

Make a mark on the inside of the bale chamber 29 3/4” from the baler floor (top of

corrugations).

Close the bale chamber door and feed gate and lower the platen until the line just

touches the top of the platen side panel.

Turn off and lock-out and tag-out the power. Adjust the BALE MADE limit switch arm

to the highest point on the actuator.

Remove the Lock-out and Tag-out provisions and turn on power.

1.

2.

3.

4.

Page 31

2 MAINTENANCE

PROCEDURES - FEED GA TE LATCH ADJUSTMENT

BALE DOOR

FEED GATE

LATCH

SPRING

FEED GATE

STRIKER

TENSION

ADJUSTMENT

NUT

BOLTS

FOR

STRIKER

NOTE: Adjustment is made by tightening or loosning the TENSION ADJUSTMENT NUT with the

feed gate in the up position. Spring tension

should not exceed 5 lbs to prevent excessive

wear on the feed gate latch and striker.

NOTE: In the event of excessive wear, the feed gate latch

STRIKER is removable and replaceable. Striker may be

replaced by removing the two (2) striker bolts. Access to the

striker bolts can be achieved by removing the front cover

from the bale door

2-7

Page 32

2 MAINTENANCE

PRINCIPLES OF OPERATION

OPERATING CHARACTERISTICS FOR:

V-6030HD, V-4830HD, V-6030LP, AND V-7230HD

When the AUTOCYCLE button is depressed, a contact is made that energizes the motor starter

coil, starting the electric motor and at the same time energizing T1 timer coil, T2 timer coil, and

R1 relay coil. When R1 is energized, the hydraulic oil is directed by the directional control valve

from a signal to the solenoid that shifts the valve. The oil is directed to extend the cylinder and

lower the platen. When T2 times out, the contacts reverse. This de-energizes R1 which causes

the down solenoid to de-energize, and the up solenoid to energize. Oil is directed to the rod end

of the cylinder and the platen is raised. As the platen reaches the full up position, the baler feed

gate opens. Opening the feed gate causes the magnetic interlock contact to open which stops

power to the motor starter coil and shuts the baler down. If the feed gate fails to open, the T1

timer will time out and break power to the motor starter coil, shutting the baler down.

NOTE: The BALE MADE LIGHT will be illuminated if the T2 timer times out while the BALE

MADE limit switch is activated. When this happens, the motor will stop with the platen in the

down position.

2-8

OPERA

TING CHARACTERISTICS FOR:

V-6030, AND V-4830HD

When the AUTOCYCLE button is depressed, a contact is made that energizes the motor starter

coil, starting the electric motor and at the same time energizing T1 timer coil, T2 timer coil, and

R1 relay coil. When R1 is energized, the hydraulic oil is directed by the directional control valve

from a signal to the solenoid that shifts the valve. The oil is directed to extend the cylinder and

lower the platen. When T2 times out, the contacts reverse. This de-energizes R1 which causes

the down solenoid to de-energize, and the up solenoid to energize. Oil is directed to the rod end

of the cylinder and the platen is raised. As the platen reaches the full up position, the baler feed

gate opens. Opening the feed gate causes the magnetic interlock contact to open which stops

power to the motor starter coil and shuts the baler down. If the feed gate fails to open, the T1

timer will time out and break power to the motor starter coil, shutting the baler down.

NOTE: When the platen dwells in the down position with the arrow on the platen in line with the

arrow on the NOTICE decal on the feed gate, it is time to tie the bale. See Bale Tie Off instructions on page 1-15.

Page 33

2 MAINTENANCE

PRINCIPLES OF OPERATION

V-6042 XLP OPERATING CHARACTERISTICS

Feed Gate and Platen Operation

When the AUTOCYCLE button is depressed, a contact is made that energizes the motor starter

coil, starting the electric motor and at the same time energizing T1 timer coil, T2 timer coil, and

R1 relay coil. When R1 is energized, the hydraulic oil is directed by the directional control valve

from a signal to the SV1A solenoid that shifts the valve. The oil is directed to the base end of

the cylinder to extend the cylinder and lower the platen. When T2 times out, the contacts

reverse. This de-energizes R1 which causes the down solenoid to de-energize, and the up

solenoid (SV1B) to energize. Oil is directed to the rod end of the cylinder and the platen is

raised. As the platen reaches the full up position, the baler feed gate opens. Opening the feed

gate causes the magnetic interlock contact to open which stops power to the motor starter coil

and shuts the baler down. If the feed gate fails to open, the T1 timer will time out and break

power to the motor starter coil, shutting the baler down. NOTE: The BALE MADE LIGHT will be

illuminated if the T2 timer times out while the BALE MADE limit switch is activated. When this

happens, the motor will stop with the platen in the down position.

Ejector Operation

When the bale is ejected, the MANUAL UP button must be depressed and held which energizes the motor starter coil, starting the electric motor. At the same time, the RETRACT/EJECT

switch must be turned and held to the right (EJECT). This energizes the coil on the SV2A solenoid valve causing it to shift and direct fluid to the base end of the cylinder which cause the

ejector to eject the bale.

When the ejector is retracted, the MANUAL UP button must be depressed and held which energizes the motor starter coil, starting the electric motor. At the same time, the RETRACT/EJECT

switch must be turned and held to the left (RETRACT). This energizes the coil on the SV2B

solenoid valve causing it to shift and direct fluid to the rod end of the cylinder which cause the

ejector to retract.

2-9

Page 34

2 MAINTENANCE

BALER SPECIFICATIONS

V-4830 V-6030 V-4830HD V-6030HD V-7230HD V-6030LP V-6042LP

Performance:

Cy c le Time:( empty) 69 sec. 69 sec. 69 sec. 69 sec. 48 sec. 48 sec. 48 sec.

Tot al Force: 62,200 lbs. 62,200 lbs. 62,200 lbs. 62,200 lbs. 70,700 lbs. 80,800 lbs. 80,800 lbs.

Platen Face PSI: 47 PSI 37 PSI 47 PSI 37 PSI 35.3 P S I 48 PSI 34 PSI

Electrical:

Control Voltage 120 VAC 120 VAC 120 V AC 120 VAC 120 VAC 120 VAC 120 VAC

M otor: 10 HP 10 HP 10 HP 10 HP 15 HP 10 HP 10 HP

RPM: 1760 RPM 1760 RP M 1760 RPM 1760 RPM 1725 RPM 1760 RPM 1760 RPM

Timer Settings T1 75 75 75 75 51 55 55

T2 38 38 38 38 26 28 28

Hydraulic:

Pump: 9 GPM 9 GPM 9 GPM 9 GPM 13 GPM 9 GPM 9 GPM

Pressure:(3 Phase) 2200 PSI 2200 PSI 2200 PSI 2200 PSI 2500 PSI 2100 PSI 2100 PSI

Pressure:(1 Phase) 1700 PSI 1700 PSI 1700 PSI 1700 PSI N/A 1700 PS I 1700 PSI

Cy linder B or e: 6" 6" 6" 6" 6" 7" 7"

Cy linder Rod: 3" 3" 3" 3" 3" 4" 4"

Cy linder S troke: 48" 48" 48" 48" 48" 26" 26"

Reservoir Capac ity: 14 GAL. 14 GAL. 14 GA L. 14 GAL. 14 G AL. 17 GAL. 17 GAL.

Demensional Data:

Feed O pening Height: 24" 24" 24" 24" 24" 19" 19"

Widt h: 48" 60" 48" 60" 72" 60" 60"

Feed Height : 50" 50" 50" 50" 52" 38" 38"

Bale Siz e-

Widt h: 48" 60" 48" 60" 72" 60" 60"

Depth: 30" 30" 30" 30" 30" 30" 42"

Height: 48" 48" 48" 48" 48" 30" 30"

Bale Door Clearanc e 49" 61" 49" 61" 73" 61" 61"

Overall Height: 139" 139" 139" 139" 141" 95" 95"

Overall Widt h: 68" 80" 68" 80" 92" 93" 93"

Overall Depth: 48 1/4" 48 1/4" 51 1/2" 51 1/2" 51 1/2" 48" 64"

Tot al Weight: 3,600 lbs. 4,050 lbs. 4, 150 lbs. 4, 600 lbs. 6, 000 lbs. 5, 000 lbs. 6, 200 lbs.

Bale Ties 14ga. X 14' 14ga. X 14' 14ga. X 14' 14ga. X 14' 14ga. X 14' 14ga. X 11' 14ga. X 11'

2-10

NOTE: The timer settings are determined by the cycle time of the machine which is

based upon the cylinder bore, rod size, stroke, and pump size. T2 is set at the amount

of time it takes the cylinder to fully extend, and T1 is set at the amount of time it takes to

fully extend and fully retract.

See chart for the correct timer settings for your machine.

Page 35

2 MAINTENANCE

PROCEDURES - TIMER ADJUSTMENT

Determine the cycle time of your machine from the CHARTS section in this manual

under TIMER SETTINGS. To set a timer, move the appropriate binary switches to the

ON position. The timer switch settings are cumulative (all switches in the ON position

add up to the total number of seconds for the timer setting).

Ex. : Switch 1 ( 1 sec) = OFF

Switch 2 ( 2 sec) = OFF

Switch 3 ( 4 sec) = ON 4 sec

Switch 4 ( 8 sec) = ON 8 sec

Switch 5 ( 16 sec) = ON 16 sec

Switch 6 ( 32 sec) = OFF

Switch 7 ( 64 sec) = OFF

Switch 8 (128 sec) = OFF

Switch 9 (256 sec) = OFF

Switch 10 (512 sec) = OFF

Timer Setting = 28 sec

T1

TIMER

T2

TIMER

BINARY SWITCHES FOR

SETTING TIMER

PRINTED CIRCUIT BOARD

(LOCATED IN PANEL BOX)

BINARY SWITCHES FOR

SETTING TIMER

TERMINAL

STRIP

TERMINAL

STRIP

R2

R3

R1

2-11

Page 36

2 MAINTENANCE

CHARTS

FUSES AND CIRCUIT BREAKERS

FULL DUAL ELEMENT INVERSE TIME SERVICE

MOTOR LOAD FUSE BREAKER DISCONNECT

SIZE VAC AMP MAX. SIZE MAX. SIZE AMP

10 HP, 208 30.8 50 80 60

3 PH 230 28.0 50 70 60

460 14.0 25 35 30

575 11.0 20 30 30

10 HP, 208 55.0 100 125 100

1 PH 230 50.0 90 125 100

15 HP, 208 46.2 60 90 60

3 PH 230 42.0 60 90 60

460 21.0 30 40 30

575 17.0 30 40 30

WIRE SIZES

THW Copper 75°C (165°F)

MOTOR SIZE VOLTAGE TO 100’ TO 200’ TO 300’

10 HP, 3 PH 208 6 4 2

230 8 4 3

460 12 10 8

575 12 12 10

10 HP, 1 PH 208 4 1 1/0

230 4 2 1/0

15 HP, 3 PH 208 4 2 1

230 6 3 2

460 10 8 6

575 12 10 8

2-12

1. Union - Unax-46, Unax-AW46

2. Gulf - Harmony 47, Harmony 48-AW

3. Exxon - Teresstic 46, Nuto 46

4. Texaco - Rando 46

5. Chevron - AW 46

6. Shell -Turbo 46, Tellus 46

7. Quaker State - Dextron ll (ATF)

8. Citgo - Pacemaker 46, Tellus - AW46

9. Amoco - (Rycon)

RECOMMENDED OILS

Adjust per FLA of motor.

MOTOR STARTER & HEATER ELEMENTS

MOTOR STARTER HEATER

SIZE VOLTAGE SIZE ELEMENTS

10HP, 3PH 208 2(AB) W-63

230 2(AB) W-63

460 2(AB) W-55

575 2(AB) W-53

15HP, 3PH 208 3(SIEMENS) ADJUST PER FLA OF MOTOR

230 2(AB) W-69

460 2(AB) W-61

575 2(AB) W-58

10HP, 1PH 208 3(SIEMENS) ADJUST PER FLA OF MOTOR

230 3(SIEMENS) ADJUST PER FLA OF MOTOR

Models V-4830 & V-6030 use an IEC contactor and has no NEMA size.

Page 37

2 MAINTENANCE

PARTS LIST

2-13

* After SERIAL NUMBER 127390

** After SERIAL NUMBER 97723

03-0010 LIMIT SW ITCH ARM XXXXXXX

03-0929 PUSHBUTTON, RED MUS HROOM HEAD XXXXXXXXX

03-0934 SWITCH, 2 POS. KEYED SELECTOR XXXXXXXXX

02-3839 PUMP, 9 GP M, VANE X X XXXX

02-1013 PUMP, 13 GP M, VANE X X X

05-0278 TURNBUCKLE, W/8" HA NDWHEEL XXXXXXX

22-4132 FEED GATE STRIKER (BOLT IN) XXXXXXXXX

7230HD

6030LP

6042LP

4830

PART # DESCRIP TION

03-0004 MOTOR, 10 HP, 3 PH

ELECTRICAL

03-0012 LIMIT SW ITCH, 5 DEG. FREE TRAVEL XXXXXXX

03-0288 TRANSFORMER

03-0335 LIGHT, RED OMNI GLOW XXXXXXXXX

03-0343 MOTOR, 15 HP, 3PH X

03-0398 LEGEND, BALE MADE XXXXXXX

03-0403 SOLENOID COIL FOR 02-0357 XXXXXXXXX

03-0148 MOTOR STARTER, SIZE 2 AB XXXXXXX

03-0486 MOTOR STARTER EXTERNAL RESET XXXXXXXXX

03-0488 FUSE, 1.5 AMP XXXXXXXXX

03-0498 SWITCH, MAGNE TIC INTERLOCK XXXXXXXXX

03-0509 LEGEND, AUTOCYCLE, 22mm XXXXXXXXX

03-0510 LEGEND, MANUAL DOWN, 22mm XXXXXXXXX

03-0511 LEGEND, MANUAL UP, 22mm XXXXXXXXX

03-0512 LEGEND, STOP, 22mm XXXXXXXXX

03-0513 LEGEND, OFF/ON, 22mm XXXXXXXXX

03-0600 PRINTED CIRCUIT BOARD XXXXXXXXX

03-0928 SWITCH, BLACK PUSHBUTTON, 22mm XXXXXXXXX

03-0935 KEY, FOR 03-0934 XXXXXXXXX

03-0936 CONTACT 1, N.O . FOR 22mm XXXXXXXXX

03-0937 CONTACT 1, N.C. FOR 22mm XXXXXXXXX

03-0987 SWITCH, GREEN PUHSBUTTON, 22mm XXXXXXXXX

03-1367 ENCLOSURE (PANEL BOX) XXXXXXX

03-1676 MOTOR STARTER, IEC CONTACTOR XX

03-1678 MOTOR STARTER, SOLID STATE XX

03-1679 ENCLOSURE (PANEL BOX) XX

03-1681 MOTOR STARTER, AUX. CONTACT XX

99-6875 DISCONNECT CON VERSION KIT XXXXXXX

HYDRAULIC

02-0050 SUCTION FILTER XXXXXXXXX

02-0197 BREATHER CAP XXXXXXXXX

02-0198 SIGHT GAUGE, 3 INCH XXXXXXXXX

02-0214 RELIEF CARTRIDGE XXXXXXXXX

02-0244 HUB COUPLING XXXXXXXXX

02-0264 SUBPLATE XXXXXXXXX

02-0357 VALVE, DIRECTIONAL CONTROL XXXXXXXXX

(208,230,460 VAC)

(208, 230, 460 VAC)

XXXX XXXX

XXXXXXXXX

6030

4830* 6030**4830HD 6030HD

04-0260 CYL. 6 BORE, 3 ROD, 48 STROKE XXXXX XX

04-0261 SEAL KIT, F/04-0260 XXXXX XX

04-0500 CYL. 2.5 BORE, 18.5 STROKE X

04-0520 CYL. 7 BORE, 26 STROKE X X

04-0521 SEAL KIT, F/04-0520 XX

05-0256 W IRE, BALE TIE XXXXXXXXX

05-0277 SPRIN G, 3/4 OD X 4 LONG X X X X X X

05-0283 CHAIN, 2040 RIVET XXXXXXXXX

05-0285 SPROCKET, F/2040 RIVET CHAIN XXXXXXXXX

05-0664 MASTER LINK, F/2040 RIVET CHAIN XXXXXXXXX

05-2382 CHAIN, F/EJECTOR XX

05-2383 LINK F/EJECTOR CHAIN XX

05-2384 TURNBUCKLE XX

MISC. HARDWARE

Page 38

2 MAINTENANCE

PANEL BOX FOR HD AND LP BALERS

2-14

Page 39

2 MAINTENANCE

PANEL BOX FOR V-6030 & V-4830

TRANSFORMER

PRINTED CIRCUIT BOARD

IEC

MOTOR STARTER

2-15

Page 40

2 MAINTENANCE

POWER UNIT FOR 4830, 6030, 4830HD, 6030HD, & 7230HD

TOP

VIEW

DIRECTIONAL CONTROL VALVE

TO BASE END

OF CYLINDER

TO ROD END OF

CYLINDER

RELIEF VALVE

RETURN LINE

SUCTION LINE

PUMP

ELECTRIC MOTOR

RESERVOIR

REAR SIDE

VIEW

HUB COUPLING

PUMP

DRAIN PLUG

CLEANOUT COVER

SUCTION FILTER

SUCTION LINE

SIGHT GAUGE

FILLER\BREATHER CAP

PRESSURE LINE

PRESSURE LINE

2-16

Page 41

2 MAINTENANCE

POWER UNIT FOR 6030LP

2-17

TOP VIEW

TO BASE END

-CYLINDER

TO ROD END

-CYLINDER

RELIEF VALVE

RETURN LINE

PUMP

ELECTRIC

MOTOR

RESERVOIR

BALER BODY

SIDE VIEW

HUB COUPLING

DRAIN PLUG

CLEANOUT COVER

SUCTION FILTER

SUCTION LINE

SIGHT GAUGE

FILLER\

BREATHER

CAP

PRESSURE

LINE

CONTROL

VALVE

ELECTRIC

MOTOR

RETURN LINE

DRAIN PLUG

PUMP

CONTROL

VALVE

SIGHT

GAUGE

PRESSURE

LINE

RETURN LINE

SUCTION LINE

PRESSURE LINE

TO BASE END

-CYLINDER

TO ROD END

-CYLINDER

Page 42

2 MAINTENANCE

POWER UNIT FOR 6042LP

2-18

TOP VIEW

DIRECTIONAL CONTROL

VALVE

TO BASE END

-CYLINDER

TO ROD END

-CYLINDER

RELIEF VALVE

RETURN LINE

PUMP

ELECTRIC

MOTOR

RESERVOIR

PRESSURE LINE

-EJECT CYL.

SIDE VIEW

HUB COUPLING

DRAIN PLUG

CLEANOUT COVER

SUCTION FILTER

SUCTION LINE

SIGHT GAUGE

FILLER\BREATHER

CAP

PRESSURE LINES

CYLINDER

CONTROL

VALVE

TO EJECT

CYLINDER

EJECTOR

CYLINDER

TO

EJECTOR

CYLINDER

RETURN LINE

BALER BODY

Page 43

2 MAINTENANCE

HYDRAULIC SCHEMATIC FOR VERTICAL BALERS - TYPICAL

2-19

Page 44

2 MAINTENANCE

HYDRAULIC SCHEMATIC FOR V-6042LP

2-20

Page 45

2 MAINTENANCE

TROUBLE-SHOOTING CHART

PROBLEM

UNIT WILL NOT START

UNIT WILL NOT CONTINUE RUNNING WHEN START BUTTON IS

RELEASED

MOTOR RUNS BUT PLATEN DOES

NOT MOVE NORMALLY

UNIT WILL NOT REVERSE

PUMP MAKES NOISE, SOUNDS

LIKE GRAVEL INSIDE

CAUSE

( 1) No electrical power to unit

( 2) No electrical power to control circuit

( 3) No electrical power to motor

( 1) Relay or contacts are inoperative

( 2) Motor Starter auxiliary contacts are

inoperative

( 3) Secondary contact on start button

is inoperative

( 1) Insufficient oil in reservoir

( 2) Low relief pressure

( 3) Oil leakage in cylinder

( 4) Defective pump

( 5) Oil leakage from hose fittings

( 6) Low voltage

( 7) Pump may be driven in the wrong

direction of rotation

( 8) Pump shaft broken, or shaft key

sheared

( 9) Intake pipe from reservoir blocked,

or oil viscosity too heavy to prime

(10) Intake air leaks (foam in oil or

sounds like gravel in pump)

(11) Units shift slowly

(12) Valve response sluggish

(13) Loose hub coupling

( 1) Solenoid valve is inoperative

( 2) Reverse button inoperative

( 3) Timer T2 inoperative

( 1) Partly clogged intake strainer or

restricted intake pipe

( 2) Defective bearing

( 3) Air leak at pump intake pipe joints

SOLUTION

( 1A) Turn on main disconnect

( 1B) Replace fuses or reset breakers

( 2A) Check primary and secondary sides of

transformer

( 2B) Check for correct voltage. Check control fuses.

( 2C) Check stop button

( 2D) Check start button to be sure contact

closes when depressed

( 2E) Check magnetic interlock.

( 3A) Check heater resets

( 1A) Check relay coil, contacts, & wiring

( 2A) Check motor starter contacts and wiring

( 3A) Check contact to be sure it is operating

properly. Check wiring.

( 1A) Fill reservoir with oil

( 2A) Check relief pressure

( 2B) Clean orifice in relief valve & reset pressure

( 2C) Check o-rings on relief valve for damage or leakage

( 3A) Check cylinder for bypassing

( 3B) Replace seal kit, inspect rod and cylinder tube for scoring or nicks.

( 3C) Replace cylinder

( 4A) Replace pump

( 5A) Tighten hose fittings

( 6A) Check voltage

( 7A) Stop immediately to prevent

seizure.Check direction of drive rotation (proper rotation direction is indicated by arrow on

motor)

( 8A) Visually inspect motor and pump shaft

and hub couplings for damage. Replace if

necessary.

( 9A) Drain system. Add clean fluid of proper

viscosity and specifications. Filter as recommended. Check system filter for cleanliness.

(10A) Check intake connections. Tighten

securely and flush system.

(11A) Flow control valve (restrictor) clogged ,

remove and clean orifice.

(12A) Contaminated oil needs replacing.

(12B) Inadequate voltage, check voltage,

check coil

(12C) Disassemble valve and clean

(13A) Tighten set screws on hub coupling

halves

( 1A) Check coil in solenoid valve

( 2A) Check reverse button contacts

( 3A) Check T2 contact to see if it is opening

( 1A) Pump must receive intake fluid freely or

cavitation results. Drain system, clean intake

pipe and clean or replace strainer

( 2A) Replace pump

( 3A) Tighten joints as required.

2-21

Page 46

2 MAINTENANCE

TROUBLE-SHOOTING CHART

PROBLEM

EXCESSIVE HEAT

RAPID WEAR

ERRATIC OPERATION

UNIT DOES NOT SHUT DOWN AT

END OF CYCLE

OVERLOADS TRIP FREQUENTLY

GUIDE SHOES WEARING EXCESSIVELY ONLY ON ONE SIDE

CAUSE

( 1) Continuous running

( 2) Excessive system leakage

( 1) Abrasive matter in the hydraulic oil

being circulated through pump

( 2) Viscosity of oil too low at working

conditions

( 3) Pressure too high

( 4) Air recirculation

( 1) Valve sticking or binding

( 2) Viscosity of oil too high

( 3) Air in system

( 4) Low oil

( 5) Low voltage

( 1) Magnetic interlock malfunction

( 1) Material being loaded unevenly to

one side

SOLUTION

( 1A) When over 140 degrees F or hot in

comparison with circuit lines, pump should

be shut down immediately. Before restarting,

insure that fluid cooling capacity is adequate

to remove system generated heat.

( 1B) Install oil cooler (air or water type)

( 1C) Install oil temperature shut down

switch

( 2A) Check system for bypassing or leaks

( 1A) Install adequate filter or clean.

( 1B) Replace oil more often and clean tank

( 2A) Replace oil with factory recommended

viscosity

( 3A) Reduce pump pressures to factory

specifications.

( 4A) Tighten all suction fittings.

( 1A) Disassemble & clean as necessary

( 2A) Replace oil with factory recommended

viscosity

( 3A) Check for leaks, tighten fittings

( 4A) Fill reservoir with oil

( 5A) Check primary & secondary sides of

transformer for correct voltage.

( 1A) Check interlock per PROCEDURES

( 1A) Check for correct voltage (incoming

power.)

( 1B) Check fuses or breakers at disconnect

( 1C) Check heater elements to be sure

they are tight

( 1D) Check wiring from starter to motor to

make sure all connections are tight

( 1E) Check motor leads to be sure all connections are tight

NOTE: Excessive overload tripping and/or

motor or coil failures may occur if voltage

surges or voltage drops are frequent in your

area. This circumstance can be remedied by

the installation of phase protectors which

drop power to the motor if surges are present.

( 1A) Distribute material evenly when loading the machine

( 1B) Shim the cylinder up on the opposite

side from the wear

2-22

Page 47

3 INSTALLATION

OFF-LOADING AND UP-ENDING OF BALER

1. INSERT THE FORK LIFT FORKS UNDER THE BALER IN THE

APPROXIMATE LOCATIONS SHOWN BELOW AND MARKED BY

“X”. KEEP THE FORKS AS WIDE APART AS POSSIBLE. SET THE

BALER ON LEVEL GROUND.

FORKS

“X” IS RECOMMENDED LOCATION FOR FORK LIFT FORKS

WHEN OFF-LOADING BALER FROM TRAILER

INTEGRAL STAND-OFF

ON BALER

BOTTOM

END

VIEW OF

BALER

8000# CAP.

FORK LIFT

THE FOLLOWING REQUIRES AN EXPERIENCED FORK LIFT DRIVER,

8000# CAPACITY FORK LIFT, AND 8000# CAPACITY CHAINS OR CABLES.

FRONT VIEW

OF BALER ON SIDE

8000# CAP.

FORK LIFT

LEVEL

SURFACE

WOODEN

BLOCK

SIDE VIEW OF

BALER UPPER CORNER

LIFTING LUG LOCATED IN

UPPER CORNERS ON

SIDES

8000# CHAIN OR

CABLE ATTACHED

TO FORK LIFT

GUARD AND UPPER

BALER LIFT LUGS

FORK

LIFT

GUARD

USE THICK CARDBOARD

TO PROTECT BALER

DURING UP-ENDING

2. I

NSERT FORKS UNDER BALER AS SHOWN. DO NOT

LIFT BALER BY HYDRAULIC COMPONENTS. ATTACH AN

8000 LB. CHAIN OR CABLE FROM THE FORK LIFT

GUARD TO EACH UPPER LIFT LUG ON THE UPPER

SIDE OF THE BALER. THE CHAIN/CABLE SHOULD BE OF

SUFFICIENT LENGTH TO ALLOW BALER TO BE PIVOTED FROM A HORIZONTAL TO VERTICAL POSITION.

3. BEFORE UP-ENDING BALER, ATTACH A SAFETY CHAIN FROM EACH

FORK TO THE UPPER LIFT LUGS ON THE BALER THAT ARE CLOSEST TO

THE FORKS (SEE BELOW). TO UP-END THE BALER, SLOWLY RAISE THE

FORKS AND DRIVE FORWARD IN A STRAIGHT LINE.

8000# CHAIN

8000# SAFETY CHAIN/CABLE BETWEEN

FORKS AND BALER LIFT LUGS

TIP: BEFORE UPENDING, PLACE A

1”-2” STACK OF CARDBOARD IN

THIS POSITION, FOR THE BALER

TO SETTLE ON. REMOVE CARDBOARD AFTER BALER IS VERTICAL.

8000# CAP.

FORK LIFT

3-1

Page 48

Review this manual before beginning the installation. Study the jobsite and installation requirements carefully to be certain all necessary

safeguards and/or safety devices are provided to protect all personnel and equipment during the installation and as a completed system.

These instructions are not intended as a substitute for training and experience in proper use, safety procedures, maintenance, or installation of this

equipment.

This baler is designed for INDOOR USE ONLY.

Marathon does not assume responsibility for the installation procedures of this equipment. Conformance to applicable local, state, and

federal laws concerning installation rests with the customer.

3 INSTALLATION

GENERAL INSTALLATION

CAUTION:

ANCHORING TO CONCRETE PAD

The concrete pad should be level, and a minimum of 3000 PSI concrete,

steel reinforced, 6” thick. Anchor baler to floor using anchor plates on sides

of baler base. Four 3/4” diameter anchor bolts required, Red Head type

recommended.

DECALS

Installation of the baler is not complete until an inspection of the warning

decals has been made. Decals should be clearly visible, legible, securely

applied, and in the proper location. For decal description and location, see

DECALS and DECAL PLACEMENT in Section 1.

3-2

DANGER: DO NOT CLIMB ON SIDES OF BALER. USE A LADDER OR

WORK PLATFORM WHEN WORKING ON TOP OF THE BALER OR

OTHER AREAS OF THE BALER THAT CAN NOT BE REACHED FROM

GROUND LEVEL.

WARNING: PARTS OF THE PLATEN WILL EXTEND ABOVE THE TOP

OF THE BALER WHEN THE PLATEN IS FULLY RAISED.

Page 49

3 INSTALLATION

The panel box contains high voltage

components. Only authorized service

personnel should be allowed inside.

See Lock-Out & Tag-Out instructions in

the Maintenance section.

ELECTRICAL INSTALLATION

WARNING: BEFORE MAKING ANY ELECTRICAL CONNECTION, BE SURE

THAT THE DISCONNECT SWITCH HAS BEEN LOCKED-OUT AND TAGGED-OUT

PER THE LOCK-OUT AND TAG-OUT INSTRUCTIONS ON PAGE 2-1.

1. BRANCH CIRCUIT PROTECTION IS NOT PROVIDED WITH THIS UNIT,

AND MUST BE PROVIDED BY THE INSTALLER. Use the FUSE AND

CIRCUIT BREAKER chart and the WIRE SIZE chart in the MAINTENANCE section of this manual for reference during the electrical installation.

2. Before connecting power to the baler, check the incoming line voltage

with a voltmeter. Also, check voltage wiring in the baler panel box. If the

baler is not wired to the proper voltage, make necessary corrections

before proceeding.

3. A lockable disconnect switch IS PROVIDED, in the panel box, on models

V-4830HD, V-6030HD, V-7230HD, V-6030LP, and, V-6042LP, and is sized

in accordance with the baler. Three phase power should be connected to

the top of this switch (a single phase option is also available). Be careful

not to let incoming wires touch each other. A properly sized equipment

ground wire should be connected to the enclosure ground lug.

4. A lockable disconnect switch IS NOT PROVIDED on models V-4830 &

V-6030, and must be provided by the installer at the time of installation.

This disconnect switch must be fussed, lockable, and within sight of, and

not to exceed 50 feet from the baler, per the National Electrical Code.

Additional local codes may apply.

3-3

CAUTION: All equipment should be grounded per the National Electric Code.

Page 50

WARNING: BEFORE START-UP, REPLACE THE 3/4” PLUG ON THE TOP OF THE

POWER UNIT RESERVOIR WITH THE FILLER BREATHER CAP. THIS CAP IS

SHIPPED INSIDE OF THE PANEL BOX.

DANGER: DO NOT CLIMB ON SIDES OF BALER. USE A LADDER WHILE PER-

FORMING THE FOLLOWING PROCEDURES.

WARNING: PARTS OF THE PLATEN WILL EXTEND ABOVE THE TOP OF THE

BALER WHEN THE PLATEN IS FULLY RAISED.

CAUTION: MAKE SURE PERSONS AND MATERIAL ARE CLEAR OF CHARGE

BOX AREA.

1. After the electrical connections are complete, check motor rotation by the

following:

a. Close bale chamber door and feed gate.

b. Turn disconnect switch to the ON position.

c. Have someone turn ON the keyswitch and depress the AUTO-

CYCLE button for one second and then immediately depress the

EMERGENCY STOP button. Check motor rotation by watching the

hub coupling through the slot in the pump-to-motor adapter. There

is a rotation decal on the power unit showing correct rotation. In the

event that this decal is missing, look at the hub coupling from the

motor end. Rotation should be clockwise.

CAUTION: If the pump rotates backward, stop immediately

!

The pump will be damaged if it is operated in reverse even for

short periods. Reversing any two incoming power lines will change

the motor/pump rotation.

2. With the platen fully raised, check to be sure the oil reservoir is filled to the 3/4

level on the sight gauge (Refer to the maintenance chart for hydraulic oil recommendations). The hydraulic system pressure has been factory set.

3. The baler is equipped with an electrical interlock which prevents the use of

the AUTOCYCLE and MANUAL DOWN functions when the feed gate is in the up

position. If either of these buttons start the baler when the feed gate is up, dis-

continue use of the baler until repairs have been made.

4.

MAKE SURE THAT THE OPERATORS ARE TRAINED IN THE

PROPER USE OF THIS EQUIPMENT.

3 INSTALLATION

START-UP INSTRUCTIONS