Page 1

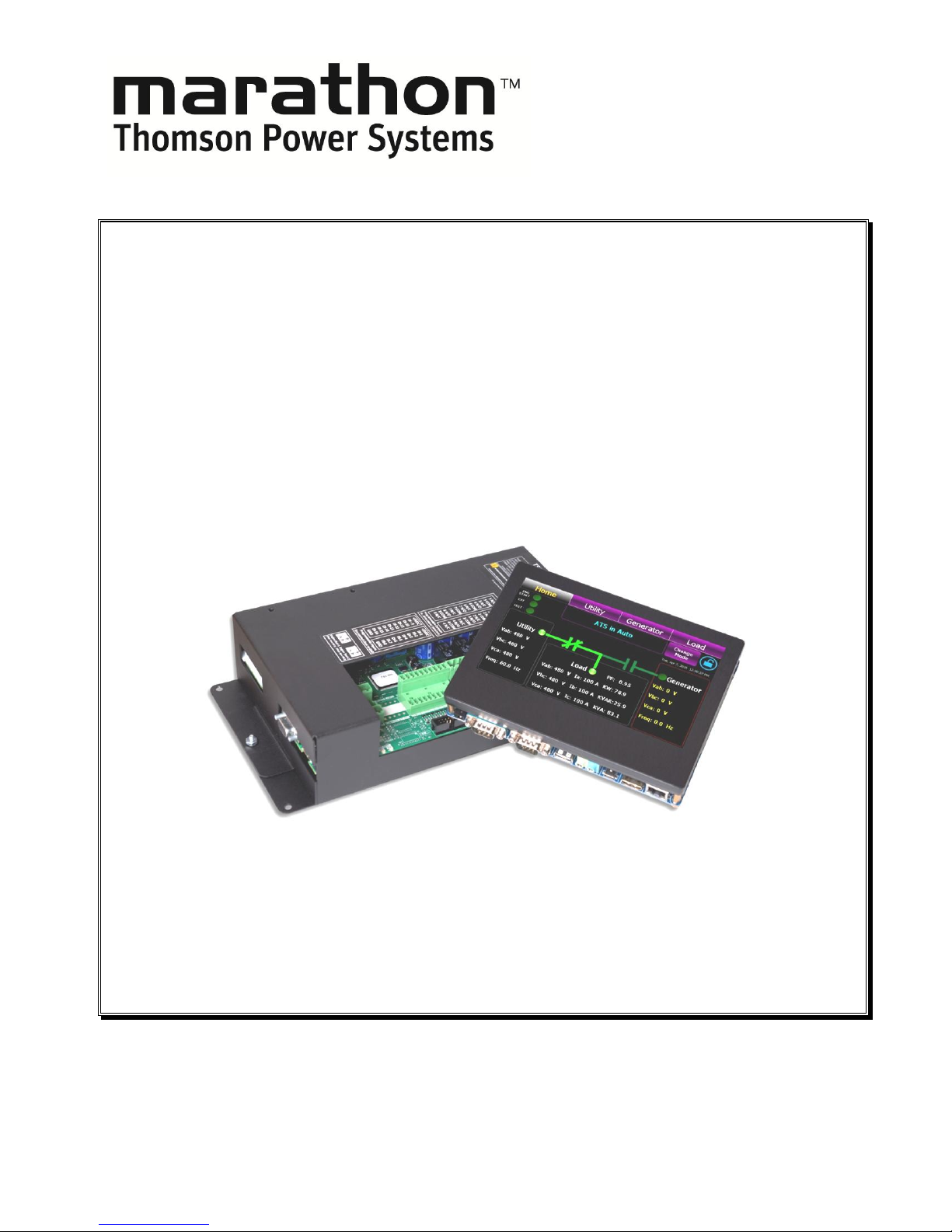

TSC 900

TRANSFER SWITCH CONTROLLER

INSTALLATION, OPERATING &

Part ID 013190 PM0151 REV 1 15/10/08

9087A – 198th Street, Langley, BC Canada V1M 3B1 Telephone (604) 888-0110

Telefax (604) 888-3381 E-Mail: info@thomsonps.com www.thomsonps.com

SERVICE MANUAL

Page 2

9087A – 198th Street, Langley, BC Canada V1M 3B1 Telephone (604) 888-0110

Telefax (604) 888-3381 E-Mail: info@thomsonps.com www.thomsonps.com

Page 3

TSC 900 TRANSFER SWITCH CONTROLLER

TABLE OF CONTENTS

1. INTRODUCTION 1

1.1. PRODUCT REVISION HISTORY 1

1.2. GENERAL DESCRIPTION 1

2. INSTALLATION 2

2.1. GENERAL INFORMATION 2

2.2. NOTES TO INSTALLER 3

2.3. AC VOLTAGE SENSING INPUT 4

2.4. AC CURRENT SENSING INPUT 4

2.5. AC CONTROL POWER INPUT 5

2.6. AUXILIARY DC CONTROL POWER INPUT 5

2.7. PROGRAMMABLE INPUTS 5

2.8. OUTPUTS 5

2.9. EXTERNAL ATS CONTROL WIRING 5

2.10. REMOTE START CONTACT FIELD WIRING 6

2.11. COMMUNICATION CABLE INSTALLATION 6

2.12. DIELECTRIC TESTING 7

3. DESCRIPTION 8

3.1. GRAPHICAL HMI CONTROLLER (GHC) DISPLAY HARDWARE 9

3.2. SWITCH CONTROL UNIT (SCU) HARDWARE 10

3.3. ATS OPERATION MODE DESCRIPTIONS 12

3.4. AUTOMATIC SEQUENCE OF OPERATION 14

3.4.1. OPEN TRANSITION TRANSFER 14

3.4.2. CLOSED TRANSITION TRANSFER 15

3.4.3. AUTOMATIC LOAD SHED OPERATION 17

3.4.4. TEST MODE 18

3.4.5. ABNORMAL SEQUENCE OF OPERATION 19

3.5. GHC DISPLAY MAIN MENU PAGE DESCRIPTIONS 20

3.5.1. HOME PAGE 21

3.5.2. UTILITY METERING PAGE 22

3.5.3. GENERATOR METERING PAGE 22

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 4

TSC 900 TRANSFER SWITCH CONTROLLER

3.5.4. LOAD METERING PAGE 23

3.5.5. ALARMS PAGE 24

3.5.6. ALARMS LOG PAGE 25

3.5.7. EVENTS LOG PAGE 25

3.5.8. SYNC PAGE 26

3.5.9. SCHEDULER PAGE 27

3.5.10. SETTINGS PAGE 27

3.5.11. SYSTEM PAGE 28

3.6. GHC DISPLAY SYSTEM SUBMENU PAGE DESCRIPTIONS 29

3.6.1. IMPORT/EXPORT DATABASE 29

3.6.2. TIME/DATE SETUP 29

3.6.3. MANAGE USERS 30

3.6.4. SYSTEM INFORMATION 30

3.6.5. INPUT MAPPING 31

3.6.6. OUTPUT MAPPING 31

3.6.7. LOGS 32

3.6.8. COM STATUS 32

4. OPERATING INSTRUCTIONS 33

4.1. GHC SCREEN PAGE NAVIGATION 33

4.2. ON LOAD TEST INSTRUCTIONS (UTILITY POWER FAIL SIMULATION) 34

4.3. OFF LOAD TEST INSTRUCTIONS (GENERATOR NO LOAD TEST) 35

4.4. TIMED TEST INSTRUCTION 36

4.5. OPEN/CLOSED TRANSITION TRANSFER OPERATION 37

4.5.1. OPEN TRANSITION IN-SYNC TRANSFER OPERATION (MODEL X) 38

4.5.2. CLOSED TRANSITION OPERATION (MODEL 3 & 4) 38

4.6. TRANSFER FAIL ALARM RESET 39

4.7. TIMER BYPASS 40

4.8. MANUAL UTILITY RETRANSFER CONTROL 41

4.9. SERVICE DISCONNECT MODE 41

4.10. PHASE UNBALANCE PROTECTION ALARM RESET 42

4.11. TRANSFER HALTED ALARM RESET 43

5. PROGRAMMING INSTRUCTIONS 44

5.1. PASSWORD SECURITY DESCRIPTION (USERS ADMIN) 44

5.2. USER LOGIN PROCEDURE 45

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 5

TSC 900 TRANSFER SWITCH CONTROLLER

5.3. ADMINISTRATOR PASSWORD MANAGEMENT PROCEDURE 46

5.4. SYSTEM TIME/DATE ADJUSTMENT 47

5.5. VOLTAGE CHANGE PROCEDURE 48

5.6. EXERCISE TIMER SETUP 49

5.6.1. ADDING NEW EXERCISE SCHEDULE EVENT 50

5.6.2. EDITING EXISTING EXERCISE SCHEDULE EVENT 50

5.7. PROGRAMMABLE INPUT MAPPING 51

5.8. PROGRAMMABLE OUTPUT MAPPING 54

5.9. SYSTEM SETTINGS 58

5.9.1. SYSTEM PHASES 58

5.9.2. SYSTEM VOLTAGE 58

5.9.3. SYSTEM FREQUENCY 58

5.9.4. PHASE ROTATION REVERSED 58

5.9.5. RATED GENERATOR POWER 59

5.9.6. CT RATIO (CURRENT TRANSFORMER) 59

5.9.7. PT RATIO (POTENTIAL TRANSFORMER) 59

5.9.8. LOAD NAME 59

5.9.9. SOURCE 1 (UTILITY) NAME 59

5.9.10. SOURCE 2 (GEN) NAME 59

5.9.11. APPLICATION MODEL 59

5.9.12. SWITCH OPERATION 59

5.9.13. SWITCH MODEL 60

5.9.14. TRANSFER SWITCH MECHANISM OPERATION TIME 60

5.10. OPTION SETTINGS 60

5.10.1. CURRENT METERING 60

5.10.2. GEN (SOURCE 2) COMMIT TO TRANSFER 60

5.10.3. ENABLE LOAD SHED ON UNDER FREQUENCY 60

5.10.4. ENABLE LOAD SHED ON OVER POWER 61

5.10.5. HALT OPERATION ON REVERSED SOURCE 61

5.10.6. ENABLE FAIL TO UNLOAD ALARM (CTTS MODEL 4) 61

5.10.7. TRIP UTILITY (SRC 1) WHEN CLOSED TRANSITION INHIBIT ACTIVATED 61

5.10.8. HALT TRANSFER ON FAIL TO EXTERNAL SYNC CHECK 61

5.10.9. MANUAL UTILITY RETRANSFER CONTROL 62

5.10.10. FORCE TRANSFER 62

5.10.11. GHC SLEEP MODE TIMEOUT 63

5.10.12. LOAD POWER METERING 63

5.10.13. MODBUS RTU 63

5.10.14. MODBUS TCP/IP 63

5.10.15. ENABLE SECURITY BYPASS 63

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 6

TSC 900 TRANSFER SWITCH CONTROLLER

5.10.16. FAIL TO AUTO SYNC ALARM 63

5.10.17. OPEN TRANSITION IN-SYNC TRANSFER (ATS MODEL X) 64

5.10.18. CLOSED TRANSITION TRANSFER (CTTS MODEL 3 & 4) 64

5.10.19. NEUTRAL DELAY BYPASS 64

5.10.20. REVERT TO OPEN TRANSITION 65

5.10.21. ENABLE TRANSFERS TO UTILITY 65

5.10.22. ENABLE TRANSFERS TO GENERATOR 65

5.10.23. EXTENDED PARALLEL TRANSFER (CTTS MODEL 4) 66

5.11. DELAY SETTINGS 67

5.11.1. UTILITY RETURN DELAY 67

5.11.2. GEN COOL DOWN DELAY 67

5.11.3. GEN START DELAY 67

5.11.4. GEN WARM UP DELAY 67

5.11.5. GEN COMMIT TO TRANSFER DELAY 67

5.11.6. DEPART DELAY 67

5.11.7. TRANSFER FAIL DELAY 68

5.11.8. TRANSFER MAX ERROR CONDITION DELAY 68

5.11.9. TIMER GUARD DELAY 68

5.11.10. TRANSFER FIND NEUTRAL DELAY 68

5.11.11. TRANSFER NEUTRAL DELAY 68

5.11.12. TRANSFER PRE DELAY (LDC) 68

5.11.13. TRANSFER POST DELAY (LDC) 69

5.11.14. DISCONNECTION RESUME TIME 69

5.11.15. LOAD SHED INITIATE DELAY 69

5.11.16. LOAD SHED UNSHED DELAY 69

5.11.17. TRIP RETRY ON/OFF PULSE TIME (SRC1&2) 69

5.11.18. TRIP RETRY DURATION TIMER (SRC1&2) 70

5.11.19. CLOSE RETRY ON/OFF PULSE TIME (SRC1&2) 70

5.11.20. CLOSE RETRY DURATION TIMER (SRC1&2) 70

5.12. UTILITY/GEN SET POINTS (VOLTAGE/FREQUENCY) 71

5.12.1. UNDER VOLTAGE DELAY (DROPOUT) 71

5.12.2. UNDER VOLTAGE DROPOUT 71

5.12.3. UNDER VOLTAGE PICKUP 71

5.12.4. OVER VOLTAGE DELAY (PICKUP) 71

5.12.5. OVER VOLTAGE DROPOUT 71

5.12.6. OVER VOLTAGE PICKUP 72

5.12.7. UNBALANCED VOLTAGE LATCH 72

5.12.8. PHASE UNBALANCE DELAY (PICKUP) 72

5.12.9. PHASE UNBALANCE DROP OUT 72

5.12.10. PHASE UNBALANCE PICK UP 72

5.12.11. UNDER FREQUENCY DELAY (DROPOUT) 72

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 7

TSC 900 TRANSFER SWITCH CONTROLLER

5.12.12. UNDER FREQUENCY DROPOUT 73

5.12.13. UNDER FREQUENCY PICKUP 73

5.12.14. OVER FREQUENCY DELAY (PICKUP) 73

5.12.15. OVER FREQUENCY DROPOUT 73

5.12.16. OVER FREQUENCY PICKUP 73

5.12.17. SOURCE VOLTAGE BLACKOUT DELAY (DROPOUT) 73

5.12.18. SOURCE VOLTAGE BLACKOUT DROPOUT 73

5.12.19. SOURCE VOLTAGE BLACKOUT PICKUP 74

5.12.20. PHASE REVERSAL DELAY (PICKUP) 74

5.12.21. PHASE REVERSAL DROP OUT 74

5.12.22. PHASE REVERSAL PICK UP 74

5.12.23. GEN MUST START DELAY 74

5.13. LOAD VOLTAGE SET POINTS 74

5.13.1. LOAD VOLTAGE BLACKOUT DELAY (DROPOUT) 75

5.13.2. LOAD VOLTAGE BLACKOUT DROPOUT 75

5.13.3. LOAD VOLTAGE BLACKOUT PICKUP 75

5.14. LOAD SHED SET FREQUENCY & POWER POINTS 75

5.14.1. LOAD SHED POWER (kW) DELAY (PICKUP) 76

5.14.2. LOAD SHED POWER (kW) DROP OUT 76

5.14.3. LOAD SHED POWER (kW) PICK UP 76

5.14.4. LOAD SHED FREQUENCY PICK UP 76

5.14.5. LOAD SHED FREQUENCY DROP OUT 76

5.15. IN-SYNC TRANSFER SET POINTS 76

5.15.1. CLOSED TRANSITION MAX OVERLAP TIMER 76

5.15.2. IN-SYNC WAIT DELAY 77

5.15.3. EXTERNAL SYNC CHECK WAIT DELAY 77

5.15.4. SOURCE FREQUENCY DIFFERENTIAL HIGHER THRESHOLD 77

5.15.5. SOURCE FREQUENCY DIFFERENTIAL LOWER THRESHOLD 77

5.15.6. SOURCE VOLTAGE DIFFERENTIAL HIGHER THRESHOLD 77

5.15.7. SOURCE VOLTAGE DIFFERENTIAL LOWER THRESHOLD 77

5.15.8. FAIL TO UNLOAD TIMER (CTTS MODEL 4) 78

6. FACTORY DEFAULT PROGRAMMING 79

7. TSC 900 TYPICAL CONNECTION DIAGRAM 80

8. TSC 900 WIRING PIN CONNECTIONS 81

9. TROUBLESHOOTING 82

10. REPLACEMENT PARTS 85

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 8

TSC 900 TRANSFER SWITCH CONTROLLER

11. PRODUCT RETURN POLICY 86

12. NOTES 87

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 9

1

1. INTRODUCTION

621, 15/04/07

Original Release

867, 15/10/03

Add Closed Transition Transfer Capability, Misc

Feature Enhancements & Bug Fixes

1.0.0.0 15/04/07

Original Release

1.1.0.xxxxx 15/10/03

Add Closed Transition Transfer Capability, Misc

Feature Enhancements & Bug Fixes

Rev 0 15/04/07

Original release

Rev 1 15/10/08

Add Closed Transition Transfer Capability, Misc

Feature Enhancements & Bug Fixes

1.1. PRODUCT REVISION HISTORY

The following information provides an historical summary of changes made to this product

since the original release.

SCU Firmware Version

GHC Firmware Version

Operating & Service Manual Version

TSC 900 TRANSFER SWITCH CONTROLLER

Related Product Instruction Manuals

TSC 900 ModbusTM Communication, PM152

TS 870 Instruction Manual, PM062

TS 870 Quick Start Manual, PM150

TS 880 Instruction Manual, PM064

Contact Thomson Power Systems, to obtain these instruction manuals. A soft-copy of the

most current versions of these manuals are available at www.thomsonps.com.

1.2. GENERAL DESCRIPTION

The TSC 900 controller utilizes multiple 32 bit microprocessor-based design technology, which

provides high accuracy for all voltage sensing and timing functions. Digital Signal Processing

(DSP) technology is utilized for all voltage, frequency and current sensing. The TSC 900 is

factory configured to control all the operational functions and display features of the automatic

transfer switch. All features of the TSC 900 are fully programmable from the front panel color

graphical touchscreen display and are security password protected. The graphical

touchscreen display screen provides a user-friendly operator interface with many display

options available. The microprocessor design provides many integrated standard features,

which were previously only available as add-on optional features.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 10

2

2. INSTALLATION

This equipment contains static-sensitive parts. Please observe the following

anti-static precautions at all times when handling this equipment. Failure to

observe these precautions may cause equipment failure and/or damage.

TSC 900 TRANSFER SWITCH CONTROLLER

CAUTION!!!

The following precautions must be observed:

Discharge body static charge before handling the equipment (maintain exposed body contact

with a properly grounded surface while handling the equipment, a grounding wrist strap

can/should also be utilized).

Do not touch any components on the printed circuit board with your hands or any other

conductive equipment.

Do not place the equipment on or near materials such as Styrofoam, plastic and vinyl. Place

the equipment on properly grounded surfaces and only use an anti-static bag for transporting

the equipment.

2.1. GENERAL INFORMATION

NOTE:

Installations should be done in accordance

The following installation guidelines are provided for general information only pertaining to

typical site installations. For specific site installation information, consult Thomson Power

Systems as required. NOTE: Factory installations of THOMSON POWER SYSTEMS

PM 151 REV 1 15/10/08 Thomson Power Systems

with all applicable electrical regulation

codes as required.

Page 11

TSC 900 TRANSFER SWITCH CONTROLLER

3

supplied transfer switches that have been tested and proven may deviate from these

recommendations.

2.2. NOTES TO INSTALLER

If the transfer switch has programmable/multi-tap system voltage capability (refer to electrical

schematic), confirm the transfer switch has been configured for the system voltage.

WARNING

Failure to confirm and match transfer

switch voltage with the system voltage

could cause serious equipment damage.

If the transfer switch requires reconfiguring, the TSC 900 controller will also require

reprogramming.

CAUTION!!!

Qualified personnel must complete all installation and/or service work performed

only. Failure to do so may cause personal injury or death.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 12

TSC 900 TRANSFER SWITCH CONTROLLER

4

2.3. AC VOLTAGE SENSING INPUT

The TSC 900 can accept direct AC voltage sensing inputs on the generator, utility and load

from 120-600VAC (nominal). Sources up to 600VAC (phase to phase) and can connected wye

or delta with grounded or ungrounded neutral without the need for additional sensing

transformers. The TSC 900 voltage sensing can support the following types of electrical

systems:

2.4. AC CURRENT SENSING INPUT

The TSC 900 can accept 4 x 0-5Aac current inputs from the secondary windings of current

transformers (CT’s). CT’s are to be connected on the load side of the ATS (Phase A,B,C & N).

Wiring of CT primary and secondary windings must be done in strict accordance with

schematic diagram to ensure the correct phasing on 3 phase systems.

Do not unplug any current transformer inputs while

energized as severe high voltages can develop which may

PM 151 REV 1 15/10/08 Thomson Power Systems

WARNING

cause personal injury or death.

Page 13

TSC 900 TRANSFER SWITCH CONTROLLER

5

Engine Start Contacts

Qty 2

Isolated Form B contacts (10A, 250VAC Resistive)

Programmable Output Contacts

Qty 8

Isolated Form C contacts (2A, 250VAC Resistive)

Close to Utility Supply

Qty 1

120VAC1, 10A (Resistive) powered output contact

Close to Generator Supply

Qty 1

120VAC1, 10A (Resistive) powered output contact

Trip Utility Supply

Qty 1

120VAC1, 10A (Resistive) powered output contact

Trip Generator Supply

Qty 1

120VAC1, 10A (Resistive) powered output contact

2.5. AC CONTROL POWER INPUT

The TSC 900 requires 120VAC (nominal) control power input voltage. Independent AC control

power is required from both utility and generator supplies via potential transformers. AC

control power is utilized for internal TSC 900 control circuits and external control device loads.

The TSC 900 requires approximately 12VA AC power for internal control circuits. The

maximum external load is limited by output contact ratings (i.e. 10A resistive, 120/250VAC).

Total AC control power requirements for each supply must be determined by adding both

internal and external load requirements.

2.6. AUXILIARY DC CONTROL POWER INPUT

The TSC 900 can be optionally supplied with 24Vdc auxiliary control power input voltage for

applications requiring continuously energized control and display features. The maximum input

power draw is 20Watts. The 24Vdc power must be from a regulated/filtered DC supply with

maximum +-10% voltage range.

2.7. PROGRAMMABLE INPUTS

The TSC 900 provides Qty 16 Programmable Inputs. Each input is activated by external

contact closure to common (i.e. DC Negative ground). Each programmable input can be

independently programmed to different functions. Refer to Programming section for available

features.

2.8. OUTPUTS

The TSC 900 provides the following types of output circuits:

1

NOTE: Output voltage is dependent upon AC control power input voltage.

Interposing relays are required between the TSC 900 outputs and the end device if loads

exceed the output current rating.

2.9. EXTERNAL ATS CONTROL WIRING

As a minimum, all external control wiring to/from the ATS must conform to the local regulatory

authority having jurisdiction on electrical installations. Specific wire sizes listed below are for

typical circuits of distances up to 500ft (150m)1, are as follows:

Utility or Generator Voltage Sensing #14 AWG (2.5mm2)

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 14

TSC 900 TRANSFER SWITCH CONTROLLER

6

Transfer output signals #14 AWG (2.5mm2)

Remote Start Contact for Engine Controls #14 AWG (2.5mm2)

NOTE: For long control wire runs or noisy electrical environments the control wires

should be twisted & shielded with a suitable drain wire. The shielded cable drain wire

must be grounded at one end only. The drain wire grounding location may vary as

micro-processor controllers generally exist at both ends (engine generator set &

transfer switch) and one may be more susceptible depending on the level of induced

noise. The most susceptible controller will require the shield ground point as close as

possible to the controller. Wire runs from 500ft to 1000ft should be twisted and

shielded and increased to #12 AWG where total loop resistance is greater than 5

ohms.

1

For distances exceeding 1000ft. (300m) consult Thomson Power Systems

2.10. REMOTE START CONTACT FIELD WIRING

Field wiring of a remote start contact from a transfer switch to a control panel should conform

to the following guidelines to avoid possible controller malfunction and/or damage.

2.8.1. Remote start contact wires (2 #14 AWG (2.5mm2)) should be run in a separate

conduit (ferromagnetic type) and in all cases separated from any AC wiring.

2.8.2. Avoid wiring near AC power cables to prevent pick-up of induced voltages.

2.8.3. An interposing relay may be required if field-wiring distance is excessively long

(i.e. greater than 1000 feet (300m)) and/or if a remote contact has a resistance

of greater than 5.0 ohms. In extremely noisy environments, the wire run

lengths indicated may not provide reliable operation and can only be corrected

by the use of an interposing relay. The interposing relay is generally installed at

the engine controls and utilizes DC power. It is strongly suggested that the

ground return wire of the interposing relay be used for the interface to the TSC

900 remote start contact, this will ensure integrity of the DC power supply to the

engine generator set controls in the event of a shorted or grounded wire remote

start interface wire.

2.8.4. The remote start contact provided is voltage free (i.e. dry contact). Exposing

the remote start contact to voltage or current levels in excess of its rating will

damage the transfer controller.

2.11. COMMUNICATION CABLE INSTALLATION

Communication cable wiring from the controller’s communication port must be suitably routed

to protect it from sources of electrical interference. Guidelines for protection against possible

electrical interference are as follows:

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 15

TSC 900 TRANSFER SWITCH CONTROLLER

7

Use high quality, shielded cable only with drain wire grounded at the controller end

only.

Route the communication cable at least 3 M (10’) away from sources of electrical

noise such as variable speed motor drives, high voltage power conductors, UPS

systems, transformers, rectifiers etc.

Use separate, dedicated conduit runs for all communication cables. Do not tightly

bundle communication cables together in the conduit. Conduit should be

ferromagnetic type near sources of possible electrical interference. The entire

length of conduit should be grounded to building earth ground.

When communication cables must cross over low or high voltage AC power

conductors, the communication cables must cross at right angles and not in parallel

with the conductors.

For additional information on protection against electrical interference, contact

THOMSON POWER SYSTEMS factory.

2.12. DIELECTRIC TESTING

Do not perform any high voltage dielectric testing on the transfer switch with the TSC 900

controller connected into the circuit, as serious damage will occur to the controller. All AC

control fuses or control/sensing circuit isolation plugs connected to the TSC 900 must be

removed/disconnected if high voltage dielectric testing is performed on the transfer switch.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 16

TSC 900 TRANSFER SWITCH CONTROLLER

8

USB 2.0 Cable

GHC

SCU

3. DESCRIPTION

The TSC 900 controller consists of two parts; a front door mounted graphical touch screen display

(GHC), and a switch control unit (SCU) which is mounted inside the transfer switch door. The two

parts are interconnected via a USB 2.0 high speed communication cable which includes DC power.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 17

TSC 900 TRANSFER SWITCH CONTROLLER

9

1 2 3 4 5 6 7

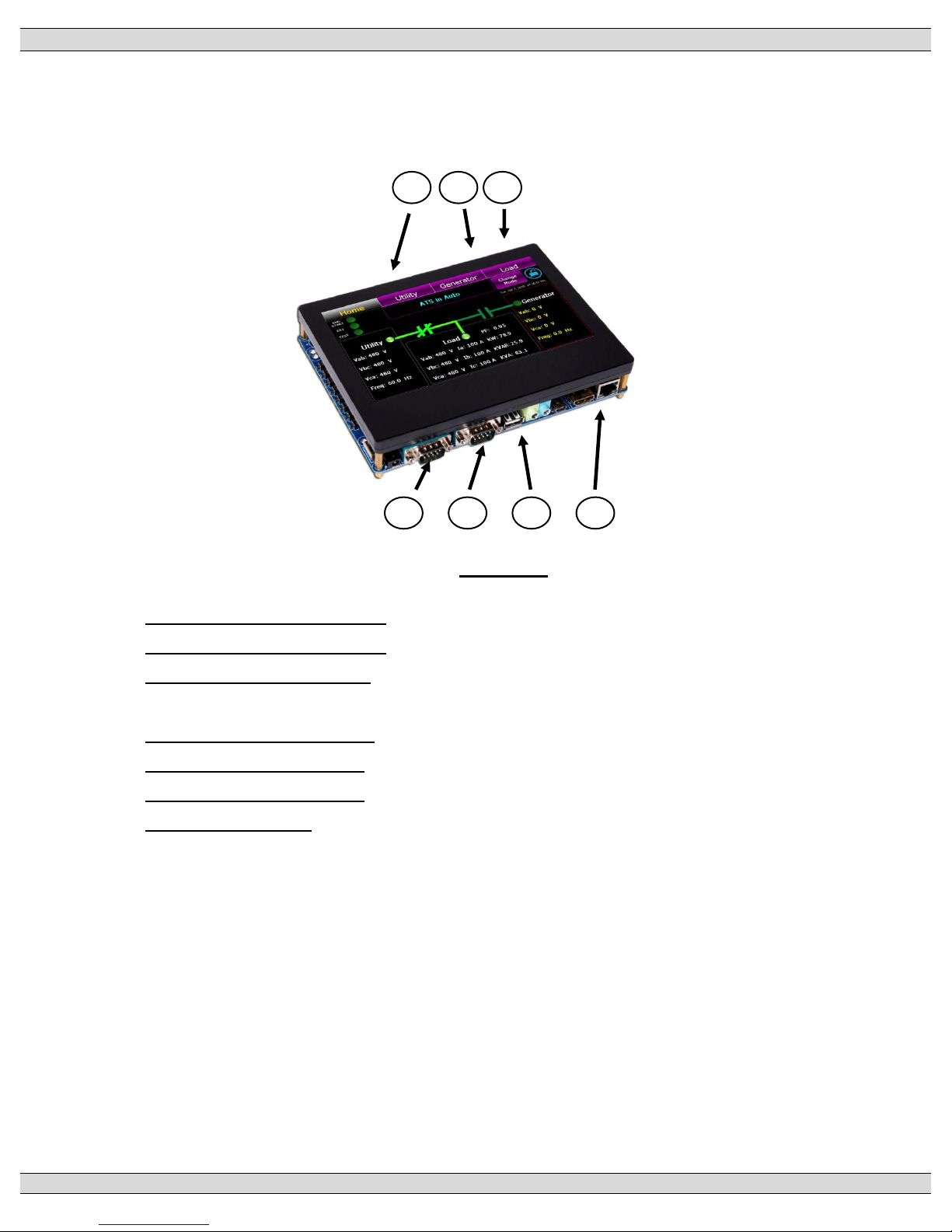

3.1. GRAPHICAL HMI CONTROLLER (GHC) DISPLAY HARDWARE

The GHC Display is shown as in FIGURE 7. The GHC is interconnected to the SCU via plug-in

USB cable. The main features of the GHC Display are described as follows with reference to

FIGURE 7.

FIGURE# 7

1. RS232 Communication Port #1: This port is utilized for Modbus RTU Serial communication

2. RS232 Communication Port #2: This port is utilized RS232 Serial communication

3. USB Communication Port #1: This port is utilized for communication from GHC to TSC 900

SCU module.

4. Ethernet Communication Port: This port is utilized for Modbus TCP Ethernet communication

5. USB Communication Port #2: This port is utilized for customer use.

6. USB Communication Port #3: This port is utilized for customer use.

7. SD Memory Card Slot: This is used for program operation and memory storage

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 18

TSC 900 TRANSFER SWITCH CONTROLLER

10

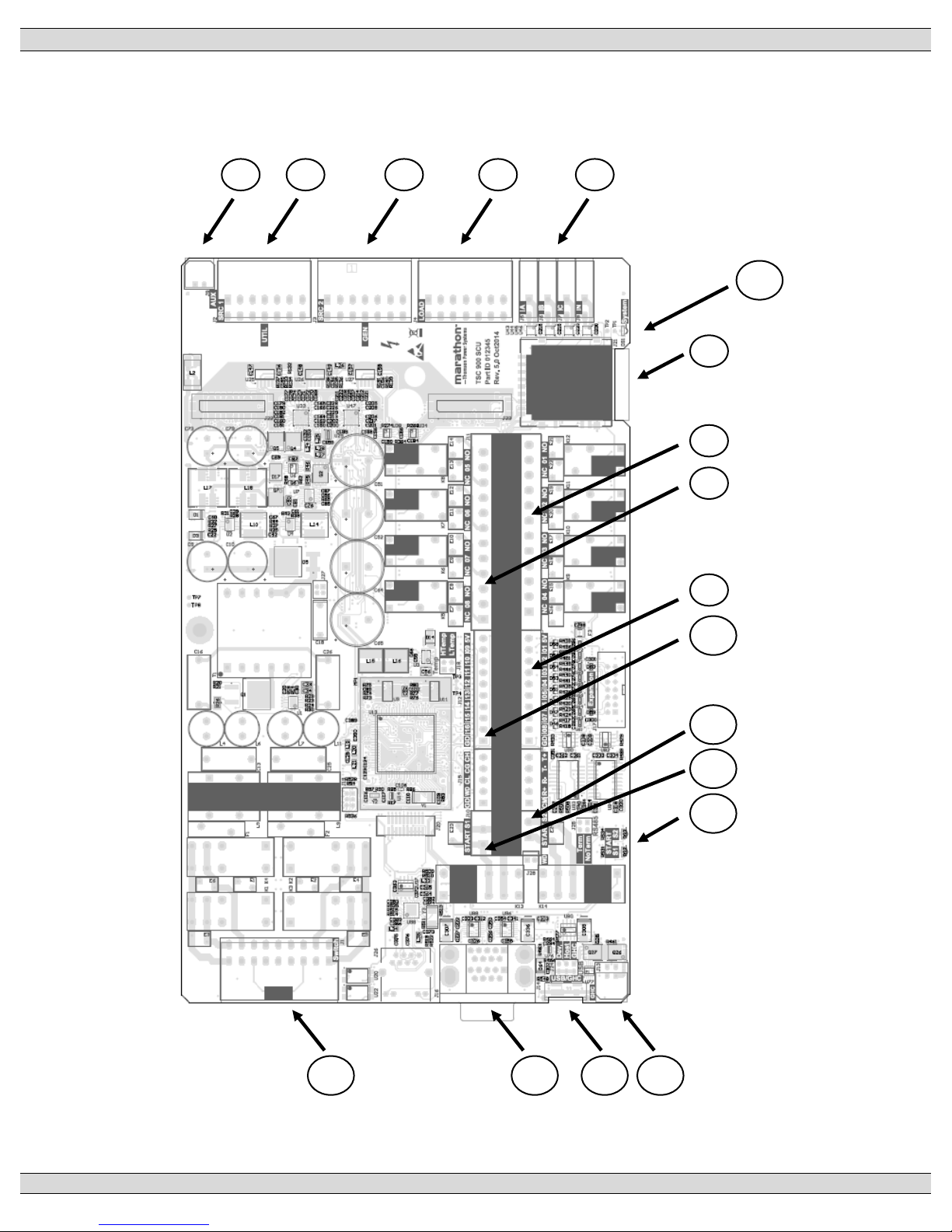

2 1 4 3 5 8 7

9

11

12

13

14

15

16 6 10

17

18

3.2. SWITCH CONTROL UNIT (SCU) HARDWARE

The Switch Control Unit internal PCB is shown in the following diagram:

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 19

TSC 900 TRANSFER SWITCH CONTROLLER

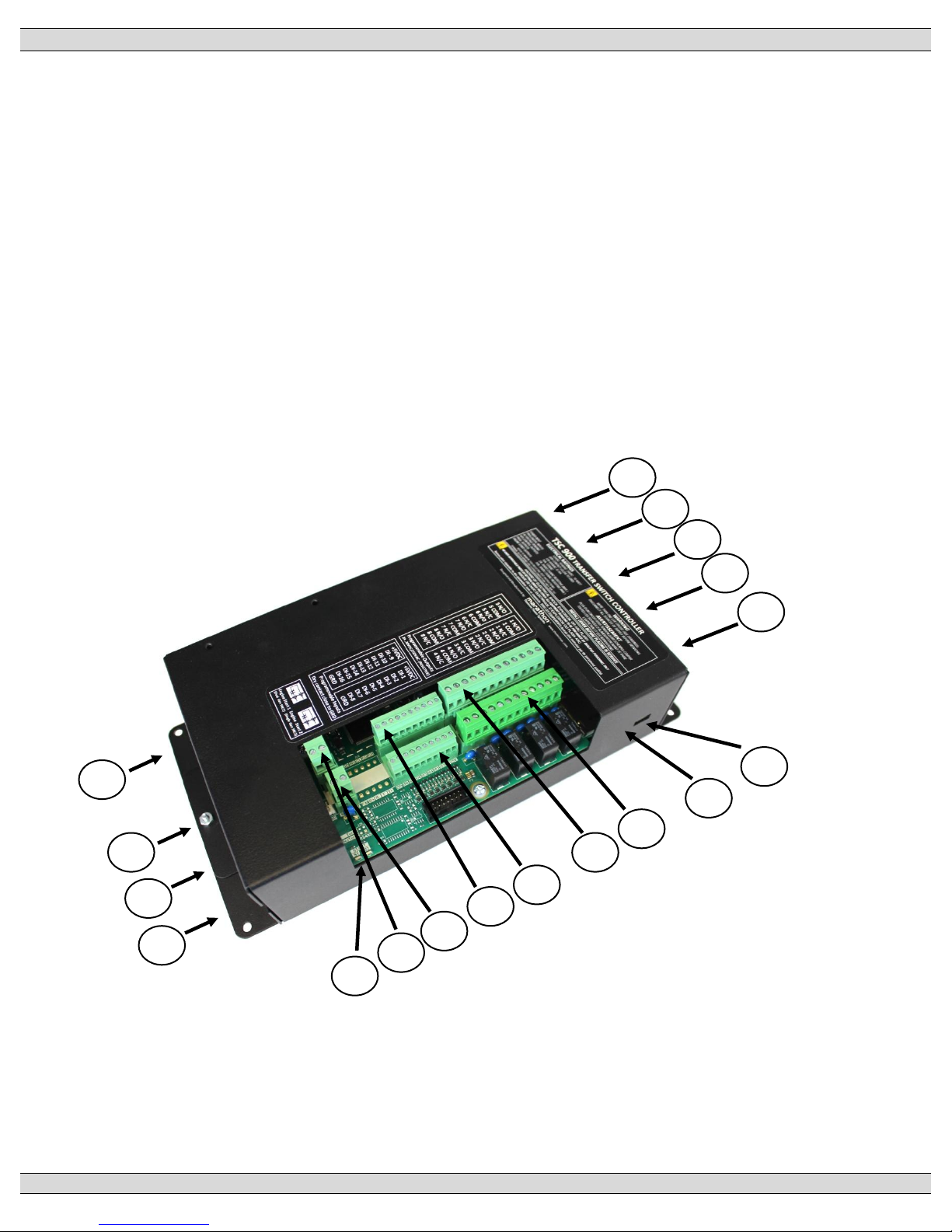

11

12

10

9

7

11

8

6

18

1 2 3

4 5 16

15

14

13

17

The Switch Control Unit (SCU) with case and main I/O connections are detailed in the

following diagram:

1. J9 – 24Vdc Auxiliary Control Power

2. J2 – Utility Voltage Sensing (PH A,B,C,N)

3. J3 – Generator Voltage Sensing (PH A,B,C,N)

4. J4 – Load Voltage Sensing (PH A,B,C,N)

5. J5,6,7,8 – Load Current Sensing (PH A,B,C,N)

6. J21 –SCU SD Memory Card (Card Located inside case-not shown)

7. J11a Programmable Output Contacts #1-4

8. J11b Programmable Output Contacts #5-8

9. J12a Programmable Inputs #1-8

10. J12b Programmable Inputs #9-16

11. J10a Engine Start 2 Contact (Single Gen SRC 2)

12. J10b Engine Start 1 Contact (Dual Gen SRC 1)

13. J13 – GHC Aux 5Vdc Power

14. J14- GHC USB Port

15. J15 – RS232 Programming Port

16. J1 – ATS Control

17. SCU Healthy Diagnostic LED

18. Engine Start Outputs On Diagnostic LED

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 20

TSC 900 TRANSFER SWITCH CONTROLLER

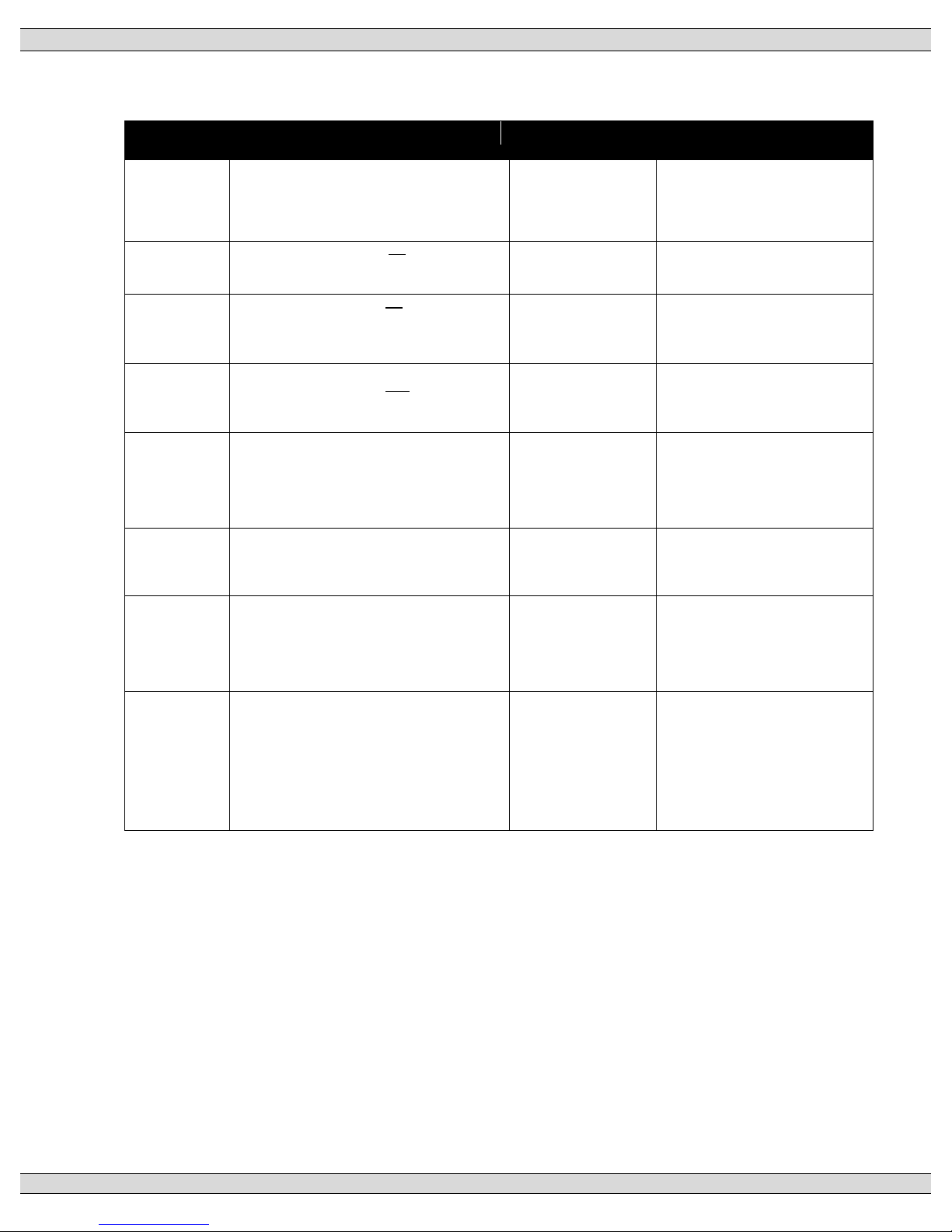

12

Mode

Description

ATS Mechanism

Control Outputs

Engine Start Output

AUTO

ATS automatically transfers to generator

(source 2) during a utility (source 1) failure and

automatically returns power to utility once

restored

Outputs automatically

operate ATS

mechanism per

automatic sequence of

operation

Output contact closes to start

engine during a utility (source 1)

failure and opens to stop engine

once utility power has transferred

back on load.

OFF

ATS is Out of Service - will not automatically

operate during a utility power failure

Outputs remain in their

last state to keep ATS

in its current position

Output is disabled - engine will not

start during a utility power failure1

MANUAL

ATS is Out of Service -will not automatically

operate during a utility power failure. ATS can

be operated manually for testing or emergency

operation

Outputs de-energize to

allow ATS to be

operated manually

Output is disabled - engine will not

start during a utility power failure1

.Engine will stop if was previously

running

SERVICE

DISCONNECT

ATS transfers to neutral position to disconnect

power to the load. ATS will not automatically

operate during a utility power failure.

Outputs momentarily

energize to move ATS

mechanism to the

neutral position

Output is disabled - engine will not

start during a utility power

failure1.Engine will stop if was

previously running

ON LOAD

TEST

When ONLOAD TEST mode is initiated, a utility

power failure condition will be simulated which

will cause engine to start and ATS will transfer

to generator supply. When TEST mode is

terminated, ATS will transfer back to utility

supply and engine will stop

Outputs automatically

operate ATS

mechanism per

automatic sequence of

operation

Output contact closes to start

engine during the ONLOAD TEST

mode. Output automatically opens

when test mode is terminated and

ATS is back on utility power

OFF LOAD

TEST

When OFF LOAD TEST mode is initiated,

engine will start and run off load. When OFF

LOAD TEST mode is terminated, engine will

stop

Outputs do not change

state unless utility or

generator supply fails

in Off Load test mode

Output automatically closes to start

engine during the OFF LOAD test

mode. Output automatically opens

when test mode is terminated

TIMED TEST

When a TIMED TEST is initiated, the ATS will

perform test per the selected type (i.e. on load

or off load) and time period. The Generator, will

continue to run for the TIMED TEST duration,

then will automatically stop.

Outputs operate ATS

mechanism per

automatic sequence of

operation if

programmed for ON

LOAD TEST operation.

Output contact closes to start

engine during the TIMED TEST

mode. Output automatically opens

when exercise mode is terminated

EXERCISE

SCHEDULE

When an EXERCISE SCHEDULE occurs, the

ATS will perform exercise test on the preselected calendar date and time. The

Generator will operate on load or off load as

selected, and will continue to run for the

Exercise duration period as selected. If a reoccurring Exercise mode is selected, ATS will

repeat an exercise test based on the calendar

dates and times as selected.

Outputs operate ATS

mechanism per

automatic sequence of

operation if

programmed for ON

LOAD TEST operation.

Output contact closes to start

engine during the EXERCISE test

mode. Output automatically opens

when exercise mode is terminated

3.3. ATS OPERATION MODE DESCRIPTIONS

The TSC 900 has the following main operating modes as described per the table below:

1

The TSC 900 requires continuous control power (i.e. utility/gen power on, or 24Vdc aux power on) to keep the automatic engine

start output disabled. If control power is de-energized, the engine start output will energize in approximately 3 minutes, once its

internal control power reservoir de-energizes. This in turn will cause a repeating engine start/stop event every 3-4 minutes. To

prevent engine start/stop cycling condition upon loss of control power, the local engine control panel should be selected for the OFF

operating mode.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 21

TSC 900 TRANSFER SWITCH CONTROLLER

13

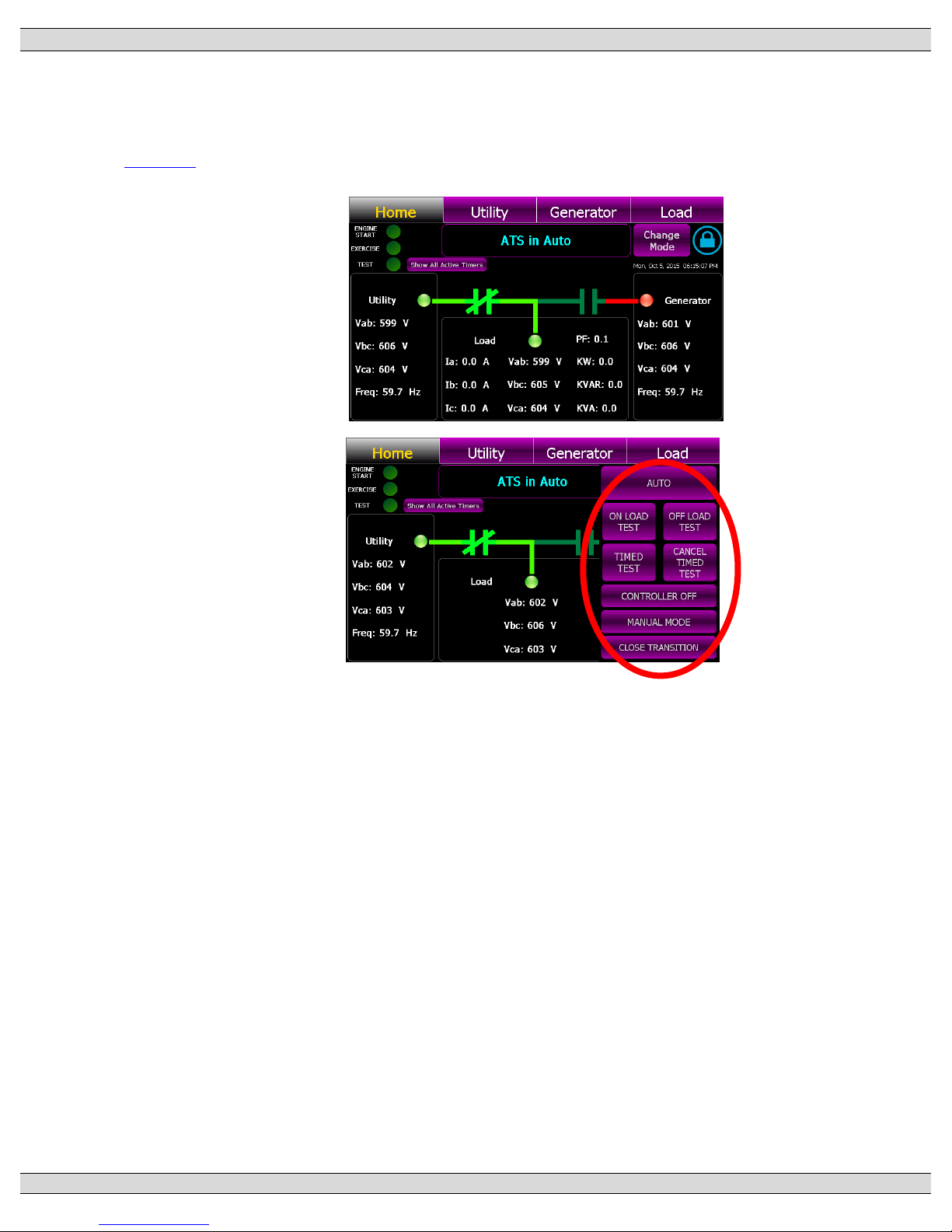

Operating modes for the ATS are selected either via the TSC 900 GHC Home page screen

(using the “Change Mode” button) as shown on the screen images below or can be selected via

external control switches as optionally connected to the TSC 900 Programmable inputs. Refer to

Section 4 - Operating Instructions for further information.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 22

TSC 900 TRANSFER SWITCH CONTROLLER

14

3.4. AUTOMATIC SEQUENCE OF OPERATION

3.4.1. OPEN TRANSITION TRANSFER

Note: For specific device settings and ranges, refer to Section 6 - Factory Default

Programming.

Under normal operating conditions, the transfer switch operates automatically during a

failure and restoration of utility power and does not require operator intervention.

When utility supply voltage drops below a preset nominal value on any phase, an

engine start delay circuit will be initiated. Following expiry of the engine start delay

period an engine start signal (contact closure) will be given.

Once the engine starts, the transfer switch controller will monitor the generators

voltage and frequency levels. Once the generator voltage and frequency rises above

preset values, a warm up time delay will be initiated. Once the warm up timer expires,

the transfer to utility supply signal will be removed (i.e. contact opening) and the

transfer to generator supply signal (contact closure) will be given to the transfer switch

mechanism. The load will then transfer from the utility supply (i.e. opening the utility

power switching device) to the generator supply (closing the generator power switching

device) to complete a break-before-make open transition transfer sequence.

The generator will continue to supply the load until the utility supply has returned and

the retransfer sequence is completed as follows: When the utility supply voltage is

restored to above the preset values on all phases, a utility return delay circuit will be

initiated. Following expiry of the utility return timer, the transfer to generator supply

signal will be removed (contact opening), the transfer to utility supply signal (contact

closure) will be given to the transfer switch mechanism. The load will then be

transferred from the generator supply back to the utility supply. During the utility retransfer sequence a neutral position delay circuit can be employed which will cause the

transfer mechanism to pause in the “neutral position (i.e. with both transfer power

switching devices open) for the duration of the neutral delay timer setting, once the

time delay expires, the re-transfer sequence will be completed.

An engine cooldown timer circuit will be initiated once the load has successfully retransferred back onto the utility supply. Following expiry of the cooldown delay period

the engine start signal will be removed (remote start contact opened) to initiate

stopping of the generator set.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 23

TSC 900 TRANSFER SWITCH CONTROLLER

15

3.4.2. CLOSED TRANSITION TRANSFER

For transfer switches equipped with the closed transition transfer option (i.e. ATS

Model Code Digit #13 “Operation Type” 3 or 4), the TSC 900 is configured to provide

additional logic for this application. When the TSC 900 controller receives an input

signal for Closed Transition Transfer Mode, the TSC 900 is configured to operate as

follows:

Under normal closed transition operating conditions, the transfer switch operates

automatically during a failure and restoration of utility power and does not require

operator intervention.

When utility supply voltage drops below a preset nominal value on any phase, an

engine start delay circuit will be initiated. Following expiry of the engine start delay

period an engine start signal (contact closure) will be given.

Once the engine starts, the transfer switch controller will monitor the generator voltage

and frequency levels. When the generator voltage and frequency rises above preset

values, a warm up time delay will be initiated. When the warm up timer expires the

transfer to utility supply signal will be removed (logic contact(s) opening) and the

transfer to generator supply signal (logic contact(s) closure) will be given to the transfer

switch Power Switching Devices. The load will then transfer from the utility supply (i.e.

opening the utility power switching device) to the generator supply (closing the

generator power switching device) to complete a break-before-make open transition

transfer sequence.

The generator will continue to supply the load until the utility supply has returned and

the retransfer sequence is completed as follows: When the utility supply voltage is

restored to above the preset values on all phases, a utility return delay circuit will be

initiated. Following expiry of the utility return timer, the utility power-switching device

will close when it is in synchronism with the generator supply. If the transfer switch is

supplied with a Fast (Momentary) Closed Transition transfer control option, the

generator power switching device will immediately trip within ~100 milliseconds after

the utility power switching device closes to complete the “make-before-break” retransfer sequence. If the transfer switch is supplied with a “Soft-Load” Closed

Transition transfer control option, the generator power switching device will remain

closed for a longer time period to allow a soft-load power transfer sequence to be

completed via external loading controller. The generator power switching device will

then trip open to complete the “make-before-break” re-transfer sequence.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 24

16

An engine cooldown timer circuit will be initiated once the load has successfully retransferred back onto the utility supply. Following expiry of the cooldown delay period,

the engine start signal will be removed (remote start contact opened) to initiate

stopping of the generator set.

TSC 900 TRANSFER SWITCH CONTROLLER

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 25

TSC 900 TRANSFER SWITCH CONTROLLER

17

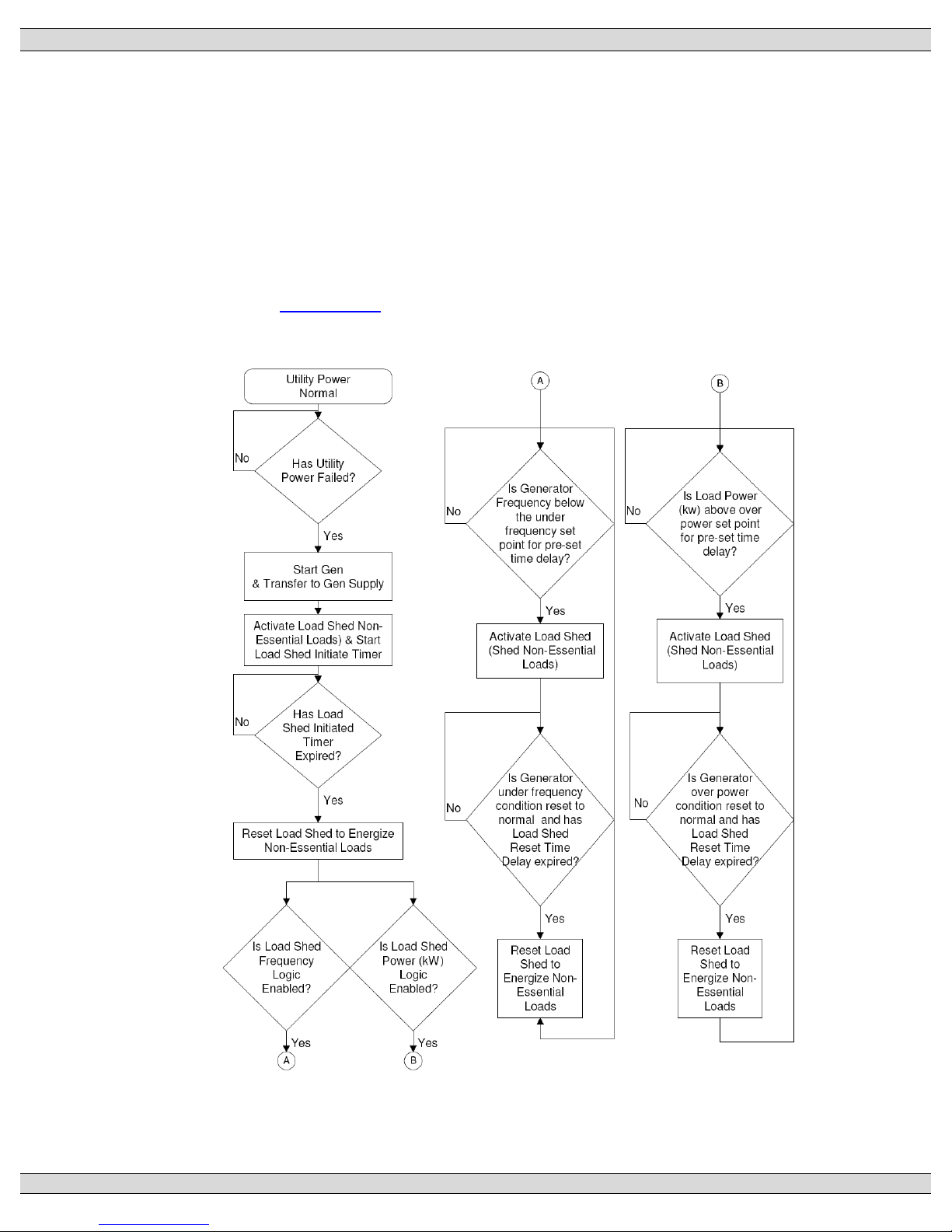

3.4.3. AUTOMATIC LOAD SHED OPERATION

The TSC 900 can be configured for automatic load shedding operation by use of a

programmable output contact. Under normal utility power conditions, the load shed

control is not activated. When an utility power failure occurs and the ATS transfer’s to

the generator supply, the load shed circuit is automatically initiated for a preprogrammed time delay setting. Once the Load shed initiate timer expires, the Load

shed circuit is reset. Automatic Load shed can also be configured for automatic load

shed based on generator under frequency and/or ATS load kW (over power) set points.

Refer to Section 5.14 for programming instructions. The automatic sequence of

operation is further described as per the following flow chart.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 26

TSC 900 TRANSFER SWITCH CONTROLLER

18

3.4.4. TEST MODE

3.4.4.1. ON LOAD TEST (OPEN TRANSITION TRANSFER)

When an operator selects an ON LOAD TEST mode, the ATS controller will

initiate a simulated utility power failure condition. The transfer switch will

operate as per a normal utility power fail condition with all normal time delays

enabled. The neutral delay circuit logic will be active during transfer to and

from the generator supply (i.e. when both sources of power are available). The

transfer switch will remain on generator supply while in the Test mode. When

the Test mode is manually canceled, the ATS will re-transfer back to the utility

supply following the utility return delay, then the generator will cooldown before

stopping.

3.4.4.2. ON LOAD TEST (CLOSED TRANSITION TRANSFER)

When a load test is initiated in the closed transition transfer mode, the

generator will start and following its warm up delay, the generator will close its

power-switching device when it is in synchronism with the utility supply. If the

transfer switch is supplied with a “Momentary” Closed Transition transfer control

option, the utility power switching device will immediately trip open within ~100

milliseconds after the generator power switching device closes to complete the

“make-before-break” transfer sequence. If the transfer switch is supplied with a

“Soft-Load” Closed Transition transfer control option, the utility power switching

device will remain closed long enough to allow a soft-load power transfer

sequence to be completed as controlled by an external device. The utility power

switching device will then trip open to complete the “make-before-break”

transfer sequence. The generator will continue to supply the load until the test

mode has been removed and the re-transfer sequence is completed as follows:

The utility power-switching device will close when it is in synchronism with the

generator supply via external logic device. If the transfer switch is supplied with

a “Momentary” Closed Transition transfer control option, the generator power

switching device will immediately trip open within ~100 milliseconds after the

utility power switching device closes to complete the “make-before-break” retransfer sequence. If the transfer switch is supplied with a “Soft-Load” Closed

Transition transfer control option, the generator power switching device will

remain closed long enough to allow a soft-load power transfer sequence to be

completed as controlled by an external device. The generator power switching

device will then trip open to complete the “make-before-break” re-transfer

sequence.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 27

TSC 900 TRANSFER SWITCH CONTROLLER

19

3.4.5. ABNORMAL SEQUENCE OF OPERATION

3.4.5.1. GENERATOR FAILURE ON LOAD

Should the generator set fail while on load, the transfer switch will automatically

re-transfer the load back to the utility supply if within nominal limits. The utility

return timer will be bypassed in this condition.

NOTE:

This operating condition applies to a normal utility failure as well

as any test condition.

3.4.5.2. TRANSFER SWITCH FAIL ALARM LOGIC

The TSC 900 controller contains logic to detect a transfer mechanism failure.

Should a failure be detected, a forced transfer to the alternate supply will be

initiated if the TSC 900 is programmed for force transfer. Refer to the

programming Section 5 for further information in Force Transfer operation.

3.4.5.3. SERVICE ENTRANCE ATS

For Service Entrance Rated transfer switch applications, the transfer switch

control logic will include signal the transfer switch mechanism to move to the

“Service Disconnected” position when Service Disconnect Operation is

required. In this mode the TSC 900’s transfer control outputs and Transfer Fail

feature is disabled. On return to normal operation, the Utility Power-Switching

Device will be closed to the utility supply if available. Should the utility supply

be out of limits the generator will be issued a start command and the load

transfer to the generator supply once its warm-up time has expired. The ATS

returns to Auto control and will return to the utility supply as previously describe

for the appropriate ATS design type.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 28

20

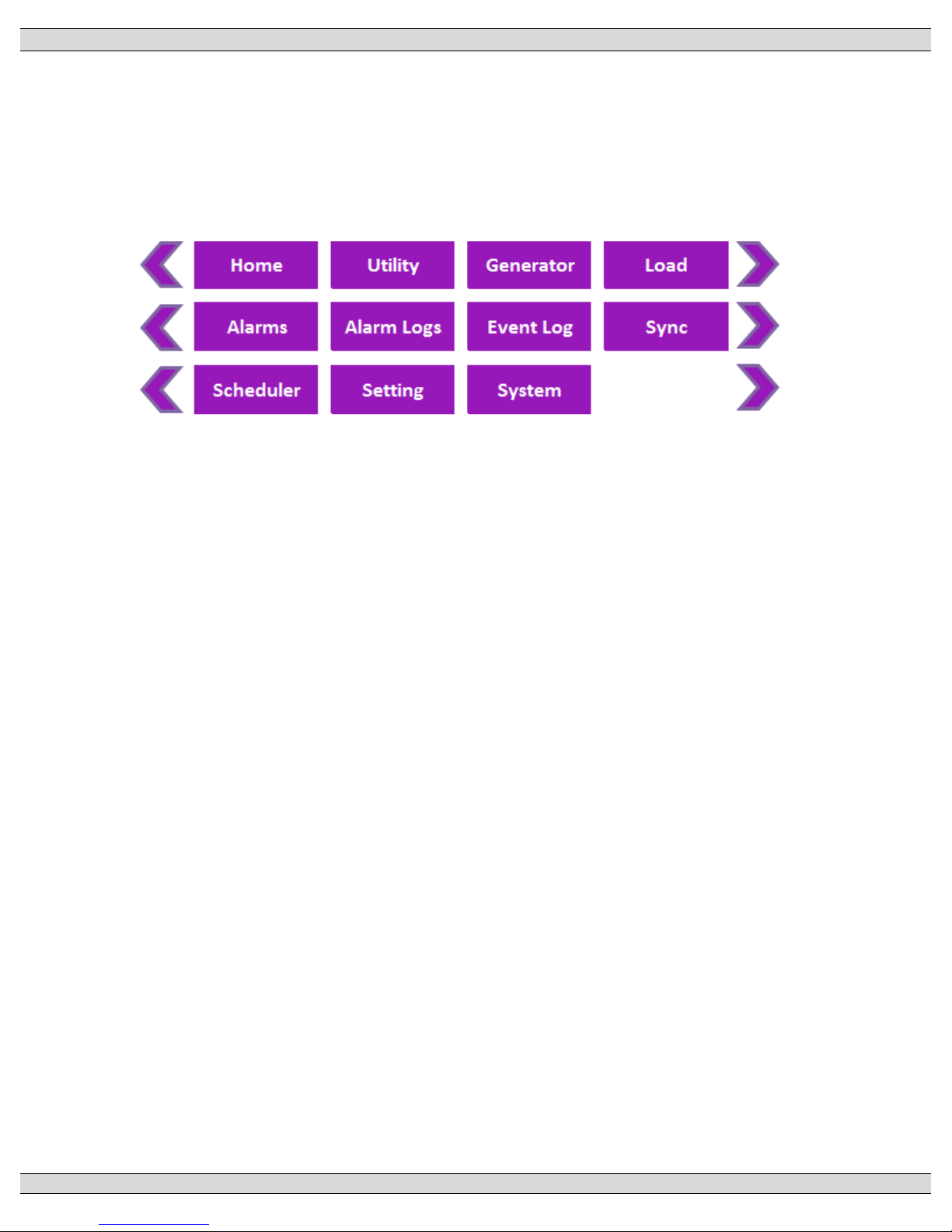

3.5. GHC DISPLAY MAIN MENU PAGE DESCRIPTIONS

The GHC software provides the TSC 900 control and monitoring information which is visible

on the GHC Display or remote PC. All screen page navigation is controlled by a touchscreen

display using a “finger swipe” motion and/or button press actions. The GHC has preprogrammed display pages which are selected manually using the touchscreen display. The

display pages are organized into the following main menu pages in software:

TSC 900 TRANSFER SWITCH CONTROLLER

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 29

TSC 900 TRANSFER SWITCH CONTROLLER

21

LED

Label

Light Off

Light On

Light Flashing

Engine

Start (RED)

Engine is not commanded to

start/run

Engine is commanded to

start/run

n/a

Exercise

(Yellow)

Exercise Schedule is not

enabled or active

Exercise Schedule is enabled

but not currently active

Exercise is

currently active

Test

(Yellow)

Test is not active

Local Test is active (On Load

or Off Load)

Remote Test is

active

Load Shed

(Yellow)

Load Shed is not active

Load Shed is activated

n/a

Alarm Icon –flashes when a new Alarm has been activated

Press to view active alarms

Security Icon - Settings Locked (Read only mode)

Press to access security login

Security Icon - Settings Un-Locked (Read/write mode)

Press to access security login

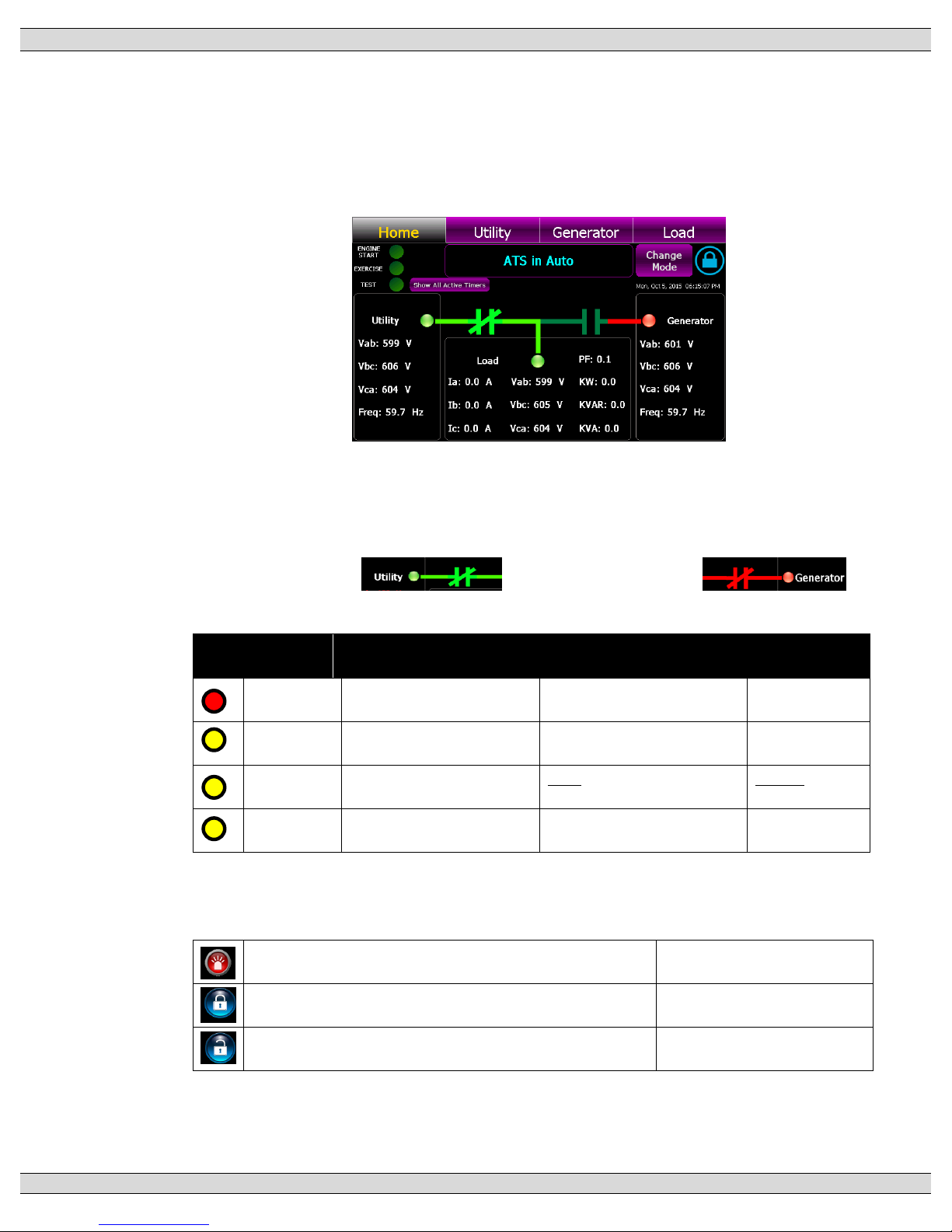

3.5.1. HOME PAGE

The Home Page is utilized as a summary control and monitoring screen for the ATS.

This screen provides a mimic bus showing current ATS position, identifies which

sources are energized, voltage levels and overall ATS operating mode. On three

phase systems, all phase to phase voltages will be displayed for each source and load.

The mimic bus will automatically change color as follows:

Utility –dark green = de-energized, light green = energized

Generator - dark green = de-energized, red = energized

Power Switching Device status is depicted as follows:

Utility Closed: Generator Closed:

The following Status LEDs are shown on the Home page:

Test or Timed test modes can be activated from the Home page by press of the

“Change Mode” button which activates a pull down menu. Refer to OPERATING

INSTRUCTION section of this manual for operating procedures.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 30

TSC 900 TRANSFER SWITCH CONTROLLER

22

3.5.2. UTILITY METERING PAGE

The utility metering page provides detailed voltage and frequency metering data for the

utility supply. Metering data is displayed in both text and graphical representation. On

3 phase systems, all phase to phase and phase to neutral voltages are displayed as

well as a Phasor diagram showing relative phase angles and magnitudes between

phases. A shortcut button is provided to access the Utility Symmetrical components

information screen as follows:

3.5.3. GENERATOR METERING PAGE

The generator metering page provides detailed voltage and frequency metering data

for the generator supply. Metering data is displayed in both text and graphical

representation. On 3 phase systems, all phase to phase and phase to neutral voltages

are displayed as well as a Phasor diagram showing relative phase angles and

magnitudes between phases. A shortcut button is provided to access the Generator

Symmetrical components information as shown for Utility Metering.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 31

TSC 900 TRANSFER SWITCH CONTROLLER

23

3.5.4. LOAD METERING PAGE

The load metering page provides detailed voltage, current and power metering data for

the ATS load bus. Metering data is displayed in both text and graphical representation.

On 3 phase systems, all phase to phase voltages are displayed. A shortcut button is

provided to access the Load bus Symmetrical components information.

Note: Load CT and/or Load Power Metering options must be supplied with the ATS to

provide load current and power data.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 32

TSC 900 TRANSFER SWITCH CONTROLLER

24

ALARM NAME

ALARM DESCRIPTION

Fail to Transfer to Utility (SRC 1)

Alarm is activated if a transfer from generator (SRC 2) to utility (SRC 1) fails to

connect to the utility (SRC 1) supply within the pre-defined time period. Time delay is

programmable –see Section 5.11.16.

Fail to Transfer to Gen (SRC 2)

Alarm is activated if a transfer from utility (SRC 1) to generator (SRC 2) fails to

connect to the generator (SRC 2) supply within the pre-defined time period. Time

delay is programmable –see Section 5.11.16.

Fail on Utility (SRC 1)

Alarm is activated if the “Load On Utility” (SRC 1) ATS signal to the TSC 900 is lost

during normal operation, while the Utility is supplying the load.

Fail on Gen (SRC 2)

Alarm is activated if the “Load On Generator” (SRC 2) ATS signal to the TSC 900 is

lost while the Generator is running and is supplying the load.

Loss of Load Voltage -SRC 1

Contacts Open

Alarm is activated if the ATS is in the Utility (SRC 1) position and its power switching

device contacts open causing a loss of ATS load voltage.

Loss of Load Voltage -SRC 2

Contacts Open

Alarm is activated if the ATS is in the Generator (SRC 2) position and its power

switching device contacts open causing a loss of ATS load voltage.

Generator Failed to Start

Alarm is activated if the genset fails to start and reach nominal voltage and frequency

within 60 seconds from the time an engine start signal was initiated.

Fail to Sync Timeout

Alarm is activated if a transfer to alternate source is initiated and the two sources fail

to reach acceptable synchronization limits within the pre-defined time period. Time

delay is programmable –see Section 5.15.2. Alarm is only active on Transfer switches

configured for Open Transition-in Sync (Model X) or Closed Transition (Fast or Softload Models 3 / 4)

Fail to External Sync Timeout

Alarm is activated if a transfer to alternate source is initiated and the two sources fail

to reach acceptable synchronization limits within the pre-defined time period. Time

delay is programmable –see Section 5.15.3. Alarm is only active on Transfer switches

configured with an external automatic synchronizer used in Closed Transition (Fast or

Soft-load (Models 3 / 4) applications.

Fail to Unload Utility (SRC 1)

Alarm is activated if during a Closed Transition Transfer sequence, the utility supply

(SRC 1) fails to unload within the pre-defined time period. Time delay is

programmable –see Section 5.15.8. Alarm is only active on Transfer switches

configured with an external load sharing controller used in Closed Transition Soft-load

(Model 4) applications.

Fail to Unload Gen (SRC 2)

Alarm is activated if during a Closed Transition Transfer sequence, the generator

supply (SRC 2) fails to unload within the pre-defined time period. Time delay is

programmable –see Section 5.15.8. Alarm is only active on Transfer switches

configured with an external load sharing controller used in Closed Transition Soft-load

(Model 4) applications.

3.5.5. ALARMS PAGE

The alarms page displays any active alarms during operation of the ATS. A button is

provided on this page to reset all activated alarms.

The following Alarms are provided on the TSC 900

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 33

TSC 900 TRANSFER SWITCH CONTROLLER

25

3.5.6. ALARMS LOG PAGE

The alarms log page shows time/date stamped information as to when alarms have

occurred. A drop down menu is provided to select a desired filter to view the logs.

3.5.7. EVENTS LOG PAGE

The events log page shows time/date stamped information as to when events have

occurred. A drop down menu is provided to select a desired filter to view the logs.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 34

TSC 900 TRANSFER SWITCH CONTROLLER

26

3.5.8. SYNC PAGE

The virtual synchroscope page is utilized for applications when the ATS is provided

with closed transition or fast in-sync transfer capability. This page will display the

phase angle difference, voltage difference and slip frequency difference between two

available sources.

Note: The Sync page is only visible if the ATS model is capable of closed transition

transfer operation or open transition in-sync transfer operation

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 35

TSC 900 TRANSFER SWITCH CONTROLLER

27

3.5.9. SCHEDULER PAGE

The scheduler page is utilized to set on load or off-load Exercise events using a

calendar based scheduler. Multiple exercise events, dates and times can be selected.

By pressing the “New” or “Edit” buttons a pop-up menu will appear as shown below.

Refer to Operating Instruction section of this manual for further details on how to

configure the Exercise Scheduler.

3.5.10. SETTINGS PAGE

The settings page is utilized for programming or configuring any timer, voltage set

point, frequency set point, I/O mapping or optional features in the controller. The

settings can be viewed via different filter settings based on function. Refer to the

Programming section of this manual for further details on function programming.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 36

28

3.5.11. SYSTEM PAGE

The System Page is utilized for viewing or programming specific settings based on the

application. Each System sub-menu page can be viewed by selecting the specific

button. Refer to Section 3.6 for description of each submenu.

TSC 900 TRANSFER SWITCH CONTROLLER

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 37

TSC 900 TRANSFER SWITCH CONTROLLER

29

3.6. GHC DISPLAY SYSTEM SUBMENU PAGE DESCRIPTIONS

The system page is utilized for viewing and/or programming site specific settings based on the

application. Different sub-menu pages are available as shown below. Each System sub-menu

pages can be viewed by selecting the specific button. Refer to Section 5 for programming

description of each submenu. Note: To exit any submenu, press the red x icon.

3.6.1. IMPORT/EXPORT DATABASE

The import/back-up database page is utilized for importing either new program settings

or updated firmware. Current controller settings can also be backed-up or restored

from the GHC SD memory card. Refer to the Programming section of this manual for

further details on import/back-up operating procedures.

3.6.2. TIME/DATE SETUP

The time/date setup page is utilized for changing the TSC 900 real time clock settings

to match the installed location. Refer to the Section 5.4 for further details on time/date

change procedures.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 38

TSC 900 TRANSFER SWITCH CONTROLLER

30

3.6.3. MANAGE USERS

The manage users page shows what users currently exist in the controller and allows

new users to be added as required. Refer to the Programming section of this manual

for further details on editing or adding new users.

3.6.4. SYSTEM INFORMATION

The System page shows what current firmware versions are installed on the TSC 900

controller.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 39

TSC 900 TRANSFER SWITCH CONTROLLER

31

3.6.5. INPUT MAPPING

The input mapping page shows what functions the TSC 900 programmable digital

inputs are configured for and which inputs are currently activated. Refer to the

Programming section of this manual for further details on configuring the digital input

mappings.

3.6.6. OUTPUT MAPPING

The output mapping page shows what functions the TSC 900 programmable relay

output are configured for and which outputs are currently activated. Refer to the

Programming section of this manual for further details on configuring the relay output

mappings.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 40

TSC 900 TRANSFER SWITCH CONTROLLER

32

3.6.7. LOGS

The logs page shows the available data logs the TSC 900 controller is logging on a

real-time basis.

3.6.8. COM STATUS

The com status page shows status of the TSC 900 controller Serial (RS232)

communication port or the TCP (Ethernet) communication port. Specific com port

settings can be accessed via this screen. Refer to the Programming section of this

manual for further details on configuring the com port settings.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 41

TSC 900 TRANSFER SWITCH CONTROLLER

33

4. OPERATING INSTRUCTIONS

The GHC software provides the TSC 900 control and monitoring information which is visible on the

GHC Display or remote PC. All screen page navigation is controlled by a touchscreen display using a

“finger swipe” motion and/or button press actions. The GHC has pre-programmed display pages

which are selected manually using the touchscreen display. The following screen naming conventions

will be used throughout the document when describing the GHC software screens:

4.1. GHC SCREEN PAGE NAVIGATION

Two methods are available to manually select a desired screen page as follows:

1) Navigation Menu Bar –a finger swipe motion can be used (swipe left or right) on

the menu bar itself.

2) Home Short-Cut Button - To directly access the Home Page from any screen

press the following ICON:

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 42

TSC 900 TRANSFER SWITCH CONTROLLER

34

4.2. ON LOAD TEST INSTRUCTIONS (UTILITY POWER FAIL SIMULATION)

To perform a load Test and simulate a utility power fail condition, press the “Change Mode”

control button on the GHC Home Page and select “ON LOAD TEST” mode from the available

list of modes as shown below. The Yellow “Test” light on the upper left-hand corner of the

screen will come on. The generator will start and transfer on load per Automatic Sequence.

To cancel Load Test, press the “Change Mode” control button on the GHC Home Page and

select “Return to Auto” mode from the available list of modes as shown below. The “Test” light

on the upper left-hand corner of the screen will go off and the load will re-transfer back to the

utility power per Automatic Sequence.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 43

TSC 900 TRANSFER SWITCH CONTROLLER

35

4.3. OFF LOAD TEST INSTRUCTIONS (GENERATOR NO LOAD TEST)

To perform an “Off Load” Test mode to run the generator set without transferring on load,

press the “Change Mode” control button on the GHC Home Page and select “OFF LOAD

TEST” mode from the available list of modes as shown below. The Red “Engine Start” light

and the Yellow “Test” lights on the upper left-hand corner of the screen will come on. The

generator will start and will run continuously.

To cancel the “Off load” Test, press the “Change Mode” control button on the GHC Home

Page and select “Return to Auto” mode from the available list of modes as shown below. The

“Engine Start light on the upper left-hand corner of the screen will go off and the generator set

will stop.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 44

TSC 900 TRANSFER SWITCH CONTROLLER

36

4.4. TIMED TEST INSTRUCTION

To perform a TIMED TEST, follow procedure as detailed below:

From the GHC Home page, press the “Change Mode” control button on the GHC Home Page

and select “TIMED TEST” mode from the available list of modes as shown below. . A Pop-up

screen will appear as shown below. Enter in desired type of test (i.e. ONLOAD or OFFLOAD)

and the duration time in minutes. Once the “Confirmed” button is pressed, the Yellow “Test”

light on the upper left-hand corner of the screen will come on. The generator will start and if

selected for On Load test, the generator will transfer on load per automatic sequence and

remain operating on load until the Timed Test duration period as selected expires.

To cancel TIMED TEST mode, press the “Change Mode” control button on the GHC Home

Page and select “CANCEL TIMED TEST” mode from the available list of modes as shown

below.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 45

TSC 900 TRANSFER SWITCH CONTROLLER

37

4.5. OPEN/CLOSED TRANSITION TRANSFER OPERATION

The ATS may be supplied with a number of different Open or Closed Transition Transfer

operational features. The ATS model code depicts the options available as shown below:

Operational behavior of an ATS equipped with these different features is depicted in the

following diagram:

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 46

TSC 900 TRANSFER SWITCH CONTROLLER

38

4.5.1. OPEN TRANSITION IN-SYNC TRANSFER OPERATION (MODEL X)

If the ATS is supplied with ATS Model X feature (i.e. Open Transition – In-sync

Transfer), the ATS will operate as per automatic sequence of operation (open

transition) however all transfers will occur using in-sync transfer control sensing instead

of neutral delay control logic. All In-sync transfer operations will occur only when both

sources of power are available and within normal operating limits. Note: Open

Transition In-sync Transfer operation is only possible if the ATS mechanism is

equipped for in-sync operation and optional feature is enabled in Settings. Refer to

Section 5.10.10 for further details.

4.5.2. CLOSED TRANSITION OPERATION (MODEL 3 & 4)

If the ATS is supplied with any of the Closed Transition Transfer features, the CLOSE

TRANSITION control selection will be provided on the GHC display via the Change

Mode button selection.

When the CLOSE TRANSITION button is selected, a pop-up screen will appear

showing operation mode selections as shown below;

The current operating transfer mode” is displayed in the Transfer Mode Window as

shown. To change to a different operating mode, select the following;

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 47

TSC 900 TRANSFER SWITCH CONTROLLER

39

Enable = Fast (Momentary) Closed Transition. The ATS will operate in a

Closed Transition transfer sequence if both sources are available. The ATS will

automatically revert to open transition transfer mode should only 1 source of

power be available at time of transfer. Note: Closed Transfer operation is only

possible if the optional feature is enabled in Settings. Refer to Section 5.10.11

for further details.

Disable = Open Transition. All Closed Transition Transfers are disabled in this

mode.

Three different Closed Transition Control Modes are selectable as follows:

Fast (Momentary) Transfer: The ATS will operate in a Fast Closed Transition

transfer sequence if both sources are available. The two sources will be

permitted to stay in parallel for a maximum of 100 milliseconds only.

Soft-load Transfer: The ATS will operate in a Soft-Load Closed Transition

transfer sequence if both sources are available. The two sources will be

permitted to stay in parallel for a maximum of 10 seconds only to allow loads to

be ramped between the sources by an external controller. Note: Soft-Load

Closed Transition operation is only possible if the optional feature is enabled in

Settings. Refer to Section 5.10.11 for further details.

Extended Parallel: The ATS will operate both sources closed to the ATS load

bus for an extended period of time as controlled by an external device. Note:

Extended Parallel Closed Transition operation is only possible if the optional

feature is enabled in Settings. Refer to Section 5.10.11 for further details.

4.6. TRANSFER FAIL ALARM RESET

Should a Transfer fail alarm occur, the flashing ALARM ICON will appear on the GHC Home

page as shown below. If the transfer switch is pre-programmed as Force Transfer, the ATS will

automatically transfer to the alternate source (if available) and will still stay locked onto the

alternate source unit the Transfer Fail alarm is manually reset by the ATS operator.

To determine which transfer alarm condition has been triggered, press the ALARM ICON to

navigate to the ALARMS Page as shown below. Once the specific alarm condition has been

be determined and necessary corrective action has been implemented the alarm can be reset

by pressing the “RESET ALARMS button.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 48

TSC 900 TRANSFER SWITCH CONTROLLER

40

4.7. TIMER BYPASS

The following automatic sequencing time delays can be temporarily bypassed when the time

function is active as shown on the TSC 900 GHC display:

Utility Return Timer

Cooldown Timer

Warm up Timer

This feature is typically used when testing to avoid waiting for the complete duration of the

time period. To activate the bypass function, press the BYPASS button when the timer is in

operation as displayed on the screen.

NOTE: The Time delay functions will return to the normal time settings on the subsequent

automatic operating sequence.

Neutral Delay Timer

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 49

TSC 900 TRANSFER SWITCH CONTROLLER

41

4.8. MANUAL UTILITY RETRANSFER CONTROL

If the TSC 900 is pre-programmed to provide a Manual return to the utility supply following a

utility power failure, an operator can decide when to initiate the re-transfer sequence by

pressing the “”MANUAL RETURN” button when displayed on the GHC Home page as shown

below.

NOTE:

The manual re-transfer sequence will only be initiated if the

button is pressed and the utility supply (source 1) is at nominal

voltage and frequency levels.

4.9. SERVICE DISCONNECT MODE

For transfer switches equipped with the Service Entrance Mode option, the TSC 900 is

configured to provide additional logic for the application. When the TSC 900 controller

receives an input signal from the door mounted Service Disconnect switch to transfer to the

neutral position, the TSC 900 control outputs will change state to cause the ATS mechanism

to move to the neutral position. The ATS operator must wait ~2 seconds to allow the ATS to

move to the neutral position before selecting the “Disconnected” position. When the Service

Disconnect switch is moved to the “Disconnected” position, all transfer logic control outputs

from the TSC 900 are disconnected and the engine start signal is disabled. When the Service

Disconnect switch is returned to the “Energized position, the TSC 900 control outputs are reconnected and will change state to cause the ATS mechanism to transfer back to the Utility

position.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 50

TSC 900 TRANSFER SWITCH CONTROLLER

42

4.10. PHASE UNBALANCE PROTECTION ALARM RESET

When the TSC 900 is programmed with Phase Unbalance protection enabled, should a

transfer occur due to an out of limit phase unbalance condition, an alarm message will be

shown on the TSC 900 GHC display “UTILITY (or GEN) UNBALANCED”. The Phase

unbalance feature may be user programmed to provide two different re-transfer operating

sequences (i.e. AUTO or MANUAL RETRANSFER). When the “AUTO” re-transfer mode is

selected, the load will be automatically re-transferred back to the original source and does not

require operator intervention. When the “MANUAL” retransfer mode is selected, a re-transfer

back to the original source will not occur until the ALARM RESET button is pressed by ATS

operator. For further details on phase unbalance programming refer to Section 5.

NOTE: When in the MANUAL RETRANSFER mode, if the alternate source fails, the alarm

lockout will not be bypassed inhibiting the load to re-transfer back to the original source even if

within limits. The reason the re-transfer is inhibited is phase unbalance is generally only

detected when load is applied to the source and the condition will appear to clear when the

load is removed, as such allowing a re-transfer to the failed source previously determined to

have a phase balance fault will only result in multiple unnecessary transfers of the load

between sources. Retransfer is set to lockout and requires operator intervention.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 51

TSC 900 TRANSFER SWITCH CONTROLLER

43

4.11. TRANSFER HALTED ALARM RESET

Should a transfer switch failure occur during a transfer to a new intended source, a

“TRANSFER HALTED” alarm will be posted to the GHC home screen as shown below. The

transfer switch will remain in this current position until the Transfer Halted condition is

manually reset by ATS operator utilizing the RELEASE TRANSFER reset button on the GHC

home page.

NOTE:

The TRANSFER HALTED condition will be initiated by one of

the following operating conditions:

- Power Switching Device fail to close or open

- Reverse Phase Rotation between connected sources

- Phase unbalance alarm

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 52

TSC 900 TRANSFER SWITCH CONTROLLER

44

Group Name

Rights

Default

User Login

Default

Password

Administrators

Allowed to manage users

Admin

pass

Power Users

Allowed to change ATS mode, send

commands in the system and modify

settings

Power

pass

Users

Acknowledge and reset alarms,

Manual Return and Un-halt the switch after

a failure

User

pass

5. PROGRAMMING INSTRUCTIONS

5.1. PASSWORD SECURITY DESCRIPTION (USERS ADMIN)

To prevent un-authorized access, users are required to “Login” in order to:

- Acknowledge and reset alarms

- Change operating modes

- Change Configuration settings

- Manage Users

- Map Inputs/Outputs

The device security is organized in groups. Using the Users Management screen a device

Administrator can create new users, enable and disable access for existing users. There is

one default user created for every group: admin, power and user. Is the responsibility of the

installer to make sure the default passwords are changed during ATS commissioning.

Once a user logs in they are not automatically logged out. Action attempts to functions that

require elevated rights will trigger a pop-up message box

Note on Privacy: The GHC is not storing user passwords. Using an encryption mechanism a

hash of the UserID + Password+ encryption key is created and stored. During the login process

the UserID + the provided password + key is used to rebuild the hash and compare with the

stored one.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 53

TSC 900 TRANSFER SWITCH CONTROLLER

45

5.2. USER LOGIN PROCEDURE

With the transfer switch energized, follow the procedure below to Login to the TSC 900

controller:

Navigate to the “Home” Page below and select the Locked Icon as shown below

The Login entry screen automatically pops-up as shown below. Select User Name drop

down box and choose desired group, then type in password, then select “Apply” button.

Note: Initial Factory Default Password is “pass”

A Login confirmation screen will pop-up if attempt was successful. Select Return to go

back to the Home page.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 54

TSC 900 TRANSFER SWITCH CONTROLLER

46

5.3. ADMINISTRATOR PASSWORD MANAGEMENT PROCEDURE

With the transfer switch energized, follow the procedure below to add or edit a list of ATS

users.

Navigate to the “System” Page and select “Manage Users” as shown below

When the “Manager Users” button is pressed, the following pop-up screen will appear.

This page will indicate which existing users have been entered already and new users

to be added or existing users to be edited. Select desired action button (i.e. Add User or

Edit User)

To Add a user, press “Add User” button and the following pop-up screen will appear. Complete

the information as listed, then press Apply to accept the change.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 55

TSC 900 TRANSFER SWITCH CONTROLLER

47

5.4. SYSTEM TIME/DATE ADJUSTMENT

To adjust the TSC 900 controller’s internal time clock, follow the detailed procedure below.

Navigate to SYSTEM screen and press TIME/DATE SETUP button as shown below.

Select Date field and a calendar will automatically pop-up to allow selection of day, month

and year as shown below.

Select Time field and a numeric keypad will automatically pop-up to allow entry of specific

time as shown below. Use back-space key to erase current time, then use keypad to enter

time in HR:SEC format. Note: time to be entered using a 24 hr Clock (e.g. 3:15PM =

15:15). Note: By default, daylight savings is enabled for applicable time zones.

Select applicable Time zone per dropdown list.

Once correct time/date & time zone is entered, then use the Apply button to accept the

change.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 56

TSC 900 TRANSFER SWITCH CONTROLLER

48

5.5. VOLTAGE CHANGE PROCEDURE

To change system voltage on the TSC 900 controller, the transfer switch must be energized

to provide control power to the controller to allow software programming. If safe to do so,

energize Transfer Switch on either Utilty or Generator sources and follow the programming

procedure shown below.

NOTES:

1. The following instructions detail re-programming the TSC 900

controller only. Additional procedures are required to change the

voltage sensing transformer taps inside the ATS. Refer to

separate ATS model instructions.

2. The TSC 900 controller does not contain any voltage jumpers

on the printed circuit board. All voltage changes are done via

software programming only.

Login to the TSC 900 with a level of “POWER” or “ADMIN” as described in Section 5.2.

Note: Initial Factory Default Password is “pass”

Once successfully logged in, From the TSC 900 DISPLAY Home Page, Navigate to the

“Settings” Page shown below and select “System Voltage” parameter as shown below.

2.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 57

TSC 900 TRANSFER SWITCH CONTROLLER

49

On the System Voltage Row, select the type of system configuration (i.e. wye or delta) per

voltage diagrams provided, then select the applicable voltage from the drop down list as

shown below. If the desired voltage is not listed, selcect “Custom” and enter the Line to

Line System voltage.

If utilizing external voltage sensing potential transformers, un-check the identified PT box,

then enter the applicable PT primary and secondary winding voltages as shown below.

The controller will calculate the required PT ratio for the application.

To confirm the change, press the “Apply” button.

5.6. EXERCISE TIMER SETUP

The TSC 900 controller has a built-in calendar based programmable exercise timer. The

exercise timer is fully programmable for, day of week, time of day, duration of the test and type

of test mode (i.e. On Load or Off Load). The exercise timer utilizes the TSC 900 GHC internal

real-time clock for referencing all timing functions. The GHC real-time clock utilizes a battery

back-up power source to retain correct time/date settings during short duration utility power

failures.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 58

TSC 900 TRANSFER SWITCH CONTROLLER

50

5.6.1. ADDING NEW EXERCISE SCHEDULE EVENT

From the GHC Home Page, Navigate to the GHC “Scheduler” Page and select

NEW as shown below;

Once in the Scheduler Editor page, select desired Exercise type (on load or off

load), then select desired Exercise schedule (i.e. period, reoccurrence, start time,

stop time, end date, end time and exercise duration).

5.6.2. EDITING EXISTING EXERCISE SCHEDULE EVENT

From the GHC Home Page, Navigate to the GHC “Scheduler” Page, select desired

schedule (row) to be edited, then select EDIT button on the selected item as shown

below;

Once in the Scheduler Editor page, select desired Exercise type (on load or off

load), then select desired Exercise schedule (i.e. period, reoccurrence, start time,

stop time, end date, end time and exercise duration).

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 59

TSC 900 TRANSFER SWITCH CONTROLLER

51

5.7. PROGRAMMABLE INPUT MAPPING

All 16 Programmable inputs can be mapped to a number of different parameters to suit the

application. The TSC 900 is factory programmed with the following programmable input

mapping defaults:

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 60

TSC 900 TRANSFER SWITCH CONTROLLER

52

The following input functions can be mapped to any programmable input. Note: inputs

can be programmed only once (i.e. same input type cannot be utilized on multiple

programmable inputs).

To edit programmable inputs follow the procedure listed below:

a) From the GHC Home Page, Navigate to the “SYSTEM” Page and select Input

Mapping as shown below

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 61

TSC 900 TRANSFER SWITCH CONTROLLER

53

b) With the Input Mapping page displayed, press the EDIT button as shown below:

c) With the Input Mapping page displayed, select the desired programmable input #

(row) to be edited, then select the desired function for mapping (scroll up or down to

navigate to desired function):

d) Once desired function is selected, press Map button to accept the change.

e) To return to the input mapping page once the change is accepted, press red X icon

on the screen.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 62

54

5.8. PROGRAMMABLE OUTPUT MAPPING

All 8 Programmable outputs can be mapped to a number of different parameters to suit the

application. The TSC 900 is factory programmed with the following programmable output

mapping defaults:

TSC 900 TRANSFER SWITCH CONTROLLER

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 63

TSC 900 TRANSFER SWITCH CONTROLLER

55

The following output functions can be mapped to any programmable output. Note:

outputs can be programmed multiple times to provide additional output contacts of

same type.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 64

TSC 900 TRANSFER SWITCH CONTROLLER

56

The edit the programmable outputs, follow the procedure listed below:

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 65

TSC 900 TRANSFER SWITCH CONTROLLER

57

a) From the GHC Home Page, Navigate to the “SYSTEM” Page and select Output

Mapping as shown below

b) With the Output Mapping page displayed, press the EDIT button as shown below:

c) With the Output Mapping page displayed, select the desired programmable output #

(row) to be edited, then select the desired function for mapping (scroll up or down to

navigate to desired function):

d) Once desired function is selected, press Map button to accept the change.

e) To return to the output mapping page once the change is accepted, press red X icon

on the screen.

PM 151 REV 1 15/10/08 Thomson Power Systems

Page 66

TSC 900 TRANSFER SWITCH CONTROLLER

58

5.9. SYSTEM SETTINGS

Note: For specific device settings and ranges, refer to Section 6 - Factory Default

Programming.

The TSC 900 controller provides a flexible control system to allow specific operation for a wide

range of applications. To program settings, navigate to the “Settings” page as shown below.

Once on the Settings Page, select the group of Settings by adjusting the filter and scroll

through available list of functions as available.

5.9.1. SYSTEM PHASES