Marathon tiga 800 SL, tiga 1100 SL Instructions Manual

Installation and Operating Instructions 1 - 33

46621V001-342004-0-OCE-Rev.A

marathon tiga 800 SL, marathon tiga 1100 SL

Table of Contents

1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Symbols 2

Safety Instructions 2

Intended Use 2

Te r ms 3

Functional description 3

Maximum door dimensions* 4

Technical Data 4

EU Manufacturer’s Declaration 4

Preparations for Installation . . . . . . . . . . . . . . . . . . . . . 5

Safety Instructions 5

Scope of Supply 5

Safety Instructions 6

Door Types and Special Accessories* 6

Installation Tips 6

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Accessories 7

Operator Pre-installation 8

Installing the Operator 8

Mounting the control unit 10

Signal light: Installation + connection 10

Inside button: Installation + connection 11

Install the socket outlet 11

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety Instructions 12

Setting Door OPEN + CLOSED End Positions 12

“Teaching” the Operator 12

Checking End Positions OPEN + CLOSED 13

Checking the emergency release 13

Checking the Force Setting 13

Setting the Maximum Force 13

“Teaching” the remote control transmitter 13

Operation and Handling . . . . . . . . . . . . . . . . . . . . . . . . 15

Safety Instructions 15

Open and close the door 15

Emergency Release 15

Resetting the control unit 15

Adjusting warning time OPEN 15

Setting the CLOSE warning time 15

Setting the clearance time 15

Setting the hold open time 15

Priority switching with time relay 16

Radio Receiver 16

Description of Display and Push-buttons 16

“Teaching” the remote control transmitter 16

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Obstruction in the door travel path: Recognition and behaviour (DIP

1) 17

Safety connectionfunction 1 (DIP 2) 17

Priority switching (DIP 3) 17

Premature closing (DIP 4) 17

Extending the hold open time (DIP 5) 17

BackJump (DIP 6) 17

Display type red signal light (DIP 7) 17

Test mode (DIP 8) 17

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Terminal bar, 24-pole 18

Trolley board 18

Connect button 1 (inside) 18

Connect button 2 (outside) 18

Connecting photoelectric cell 1 18

Connect 8.2 k Ohm strip 18

Connecting photoelectric cell 2 19

24 Volt Connection 19

12 Volt Connection 19

Connecting an External Aerial 19

Connecting Fraba System 19

Connections for Signal Light Controller 1 20

Connections for Signal Light Control Unit 2 20

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Maintenance and Care . . . . . . . . . . . . . . . . . . . . . . . . . 26

Important Information 26

Regular Checks 27

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Disassembly 28

Correct Disposal 28

Warranty and After-Sales Service 28

Help in case of malfunction . . . . . . . . . . . . . . . . . . . . . 29

Troubleshooting Tips 29

Replacement part list marathon tiga 800 SL . . . . . . . 31

Replacement part list marathon tiga 1100 SL . . . . . . 32

Schematic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2

Symbols

Exclamation mark:

Indicates a potential risk! Failure to follow instructions may

result in serious injuries!

Note symbol:

Information, useful advice!

Refers to the relevant illustration in the introduction or main text.

This illustration of a button represents all types of buttons:

such as key-activated buttons, pull-cord switches, etc.

Safety Instructions

General

• These installation and operating instructions must be read, understood,

and complied with, by the person who installs, operates, or maintains the

operator.

• Only specialised personnel should assemble, connect, and commission

the operator.

• Only install the operator to correctly aligned and weight-balanced doors.

An incorrectly aligned door can cause serious injury or damage to the

operator.

• The manufacturer cannot be made liable for any damage or disruptions

to operation occurring due to non-compliance with the Installation and

Operating Instructions.

• Ensure that these Installation and Operating Instructions remain in the

garage in an easily accessible location.

• Observe and comply with accident prevention directives and applicable

standards in the respective countries.

• Observe and comply with the directive on “Power-driven Windows, Doors

and Gates - ZH 1/494” issued by the Employers’ Liability Insurance Association. (Applicable in Germany for the operator)

• Always disconnect (unplug) the operator from the mains supply before

performing any work on the operator.

• Use only manufacturer’s original replacement parts, accessories, and

mounting material.

Storage

• The operator may only be stored indoors, in a dry, enclosed environment

at an ambient temperature between -20°C and +50°C.

• The operator should be stored horizontally.

Operation

• The operator may only be activated if a hazard-free force tolerance has

been set, or if safety is ensured at all times through other safety fixtures.

The force tolerance must be set as low as possible in order to ensure

that the door’s closing force does not constitute a danger, see section

“Force Setting”.

• Keep your hands clear of a moving door or any moving parts.

• Keep children, disabled persons and animals away from the door.

• Only drive into the garage when the door is completely open and the signal light is green.

• There is a risk of persons getting trapped or cutting themselves in/on the

door system’s moving parts or the edges where it closes.

• If the door is not equipped with a slip door, or if there is no separate

access to the garage, then install an emergency release system (emergency release lock or Bowden cable) that can be activated from outside

of the garage.

(1)1

Radio Remote Control

• The radio remote control may only be used for equipment and systems

where defective remote operation of the transmitter or receiver does not

constitute a risk to people, animals or objects, or in cases where this risk

is eliminated by means of additional safety fixtures.

• The user must be made aware of the fact that the remote control of

equipment with accident risk potential may only occur, if at all, when the

equipment concerned is clearly visible.

• Radio remote control may only be used if door travel can be supervised,

and if there are no persons or objects in the travel range.

• Store the remote control transmitter so that there is no risk of it being

accidentally activated; e.g. by children or animals.

• The operator of this radio-controlled equipment is in no way protected

from interference from other telecommunications systems and facilities

(e.g. other radio-controlled equipment that is licensed to operate at the

same frequency range). Should serious interference be encountered,

then please contact your nearest telecommunications office with interference measuring facilities (radio signal localisation)!

• Do not use the remote control transmitter near locations or installations

that are susceptible to radio interference (such as airports or hospitals).

Rating Plate

The rating plate is located on the cover of the control unit housing.

Exact type designation and date of manufacture (month/year) of the opera-

tor are indicated on the rating plate.

Intended Use

Attention! There is a risk of injury or property damage!

Always connect the slip-door safety mechanism to safety input 2

(terminals 8 + 9). If the slip-door safety mechanism is connected

to the trolley, then the operator will not recognise the door position.

Attention! Risk of serious damage to operator!

Do not open or close the door using the operator without first

adjusting the balance weight (springs tensioned). Otherwise, the

motor (gear system) might be seriously damaged.

• The operator is designed for the exclusive purpose of opening and closing doors. Any other use does not constitute intended use. Manufacturer

is not liable for damages that arise due to non-intended use. The risk is

borne solely by the operator. Non-intended use renders the warranty null

and void.

• Doors operating automatically with an operator must comply with the

standards and directives valid at the given time: e.g. EN 12604, EN

12605.

• The operator may only be used in a technically perfect condition, as

intended, in a safety-conscious and hazard-conscious manner, in compliance with the installation and operating instructions.

• Malfunctions that can impair safety must be resolved immediately.

• The door must be stable and warp-proof, i.e. it should not bend or warp

during opening or closing operations.

• The operator is unable to compensate for any defects in the door or for

its incorrect installation.

• Only use the operator in a dry, indoor environment where there is no risk

of explosion.

• Do not use the operator in rooms where a hostile

environment prevails (e.g. salty air).

General Information

General Information

3

Ter ms

Abbreviations

GI Signal light green inside

RI Signal light red inside

GO Signal light green outside

RO Signal light red outside

TorMinal

Programming device The door operator can be adjusted, or special functions can be set, with this unit. See “Accessories”.

“Teaching”

The operator “learns” the required time and the force that it requires to

open and close the door. The operator stores these values, which remain

intact even if there is a power failure.

Door OPEN

The door opens or it is already opened.

Door CLOSE

The door closes or it is already closed.

Warning time

Time prior to opening or closing; during this time the red signal lights flash

and thus indicate that the operator is in motion:

Door OPEN:

Warning time can be adjusted with the TorMinal in a range from 0...63.75

seconds, in intervals of .025 seconds, memory slot (mem) 027.

Factory setting is door OPEN: 4 seconds

Door CLOSE:

The warning time can be adjusted with the TorMinal in a range from

0...63.75 seconds, in intervals of .025 seconds, memory slot (mem) 027.

Factory setting is door CLOSE: 5 seconds

Hold open time

Time that the door remains open. The side (inside / outside) that initiated

the command to open the door gets the green signal. The door can only be

opened by a command issued via a push-button or remote control transmitter; it cannot be closed. When the door is opening, no command issued can

stop it from doing so.

If the door is closing automatically and a command is reissued, then the

door opens fully. Any command issued during the hold open time restarts

the hold open time.

The hold open time can be adjusted with the TorMinal in a range from

2...255 seconds, in 1 second increments, memory slot (mem) 031. Factory

setting: 30 seconds

Clearance time

Time in which the red signal lights are illuminated after expiration of the

hold open time; thus providing time for the persons or vehicles who had the

green light to clear the entries.

Clearance time can be adjusted with the TorMinal in a range from 0 ..63.75

seconds, in 0.25 second increments, memory slot (mem) 032.

Factory setting: 10 seconds

Inside

The side which is inside the garage or the parking area.

Outside

The side which is outside the garage or the parking area.

Command inside

Radio channel 1 or button connection 1 on terminal 2 + 3

(button line connected to the control unit)

Button or radio signal for opening the door from inside and thus drive authorisation for inside, signal light (GI) is green.

Command outside

Radio channel 2 or button connection 2 on terminal 4 + 5

Button or radio signal for opening the door from outside and thus drive

authorization for outside, signal light (GO) is green.

Command side

The side (inside or outside) that issues a command.

Functional description

The command inside/outside, which was first transmitted to the control unit,

has priority, regardless of whether it was transmitted via radio or button

connection.

Priority for “Command Outside” is set with DIP switch 3. As soon

as “Command Outside” is received the hold open time for inside

will be aborted and switched to drive authorization for outside

after the clearance time.

Operator behaviour at factory setting

Behaviour after power connection

Door closed and operator “taught”. All signal lights are switched off. Operator waits for a command from inside/outside. The first travel direction is

always door OPEN; if the door is already open, then the operator recognises this and switches the signal light to green on the side that gave the

command. Then the operator closes the door after the following individual

times expire: Warning, clearance and hold open time.

Behaviour after inside/outside command, door CLOSE

Sequence and display behaviour:

1. Command from inside/outside.

2. Door OPEN warning time starts. Red signal lights flash. Green signal

lights are switched off.

3. The operator opens the door. Red signal lights light up. Green signal

lights are switched off.

4. Door OPEN. Command side green signal light on. Red signal light is on

for the other side.

5. The set hold open time expires.

6. Warning time starts for door CLOSE. Red signal light flashes on the

command side. Red signal light lights up on the other side. Green

signal lights are switched off.

7. Clearance time starts. Red signal lights switch on. Green signal lights

are switched off.

8. The operator closes the door Red signal lights switch on. Green signal

lights are switched off.

9. Door CLOSED All signal lights are switched off.

Behaviour after command inside and then command

outside, door CLOSE

Sequence and display behaviour:

1. Command from inside.

2. Door OPEN warning time starts. Red signal lights flash. Green signal

lights are switched off.

3. The operator opens the door. Red signal lights light up. Green signal

lights are switched off.

4. Door OPEN. Command side green signal light on. Red signal light is on

for the other side.

5. Command from outside. The hold open time which was set for the pre-

vious command expires.

6. Clearance time starts. Red signal lights switch on. Green signal lights

are switched off.

7. Outside gets drive authorization. Command side green signal light

lights up. Red signal light is on for the other side.

8. The set hold open time expires.

9. Warning time starts for door CLOSE. Outside red signal light blinks.

Inside red signal light lights up. Green signal lights are switched off.

10. Clearance time starts. Red signal lights switch on. Green signal lights

are switched off.

11. The operator closes the door Red signal lights switch on. Green signal

lights are switched off.

12. Door CLOSED All signal lights off.

General Information

4

Maximum door dimensions*

marathon tiga 800 SL 1100 SL

max. width:

- Up-and-over door 6000 8000 mm

- Sectional door: 6000 8000 mm

- Wing door **: 2800 2800 mm

- Side sectional door

Rail 2600 2350 2350 mm

- Up-and-over door: 5500 7500 mm

Height (app.)

- Swing door:

Rail 2600 2600 2600 mm

- Sectional door:

Rail 2600 2350 2350 mm

- Wing door **: 3000 3500 mm

- Side sectional door

3000 3500 mm

- Up-and-over door:

Rail 2600 1900 1900 mm

Duration of operation: 40 40 %

* door conforming to EN 12604, EN 12605

** with standard wing-door hinges prod. no. 1501.

Larger doors are only available on request. For higher doors, appropriate

rail lengths must be ordered, or the necessary height can be achieved by

installing rail extensions (see accessories).

Technical Data

General

Rated voltage: 220 ...240 V/AC

Rated frequency: 50/60 Hz

Operating temp. range: -20 ...+50 °C

Safety class IP 20

Workplace-specific emission value < 75 dBA - operator only

marathon tiga 800 SL 1100 SL

maximum traction and pressure force: 800 1100 N

Rated traction: 240 330 N

Rated current consumption: 0,8 0,9 A

Rated power consumption: 160 190 W

Maximum speed: 130 130 mm/s

Power consumption, stand-by: ~ 5 ~ 5 W

Weight with: rail 2600: 18,5 19,0 kg

Packaging (L x W x H):

- Rail 2600 1980 x 240 x 180 mm

EU Manufacturer’s Declaration

The company

SOMMER Antriebs- und Funktechnik GmbH

Hans-Böckler-Straße 21-27

D-73230 Kirchheim/Teck

herewith declares that its operators:

- marathon tiga 800 SL

- marathon tiga 1100 SL

comply with the following directives:

- Machine Directive 98/37/EC

- Low Voltage Directive 73/23/EEC

- EU Directive for Electromagnetic Compatibility 89/336/EEC.

The following standards/draft standards were particularly applied:

- EN 12 453:2000, EN 12 445:2000, EN 60204-1:1997, EN 954-1:1996

- DIN V VDE 0801, EN 60335-1:1994

Note:

The door system may not be commissioned until such time as it has been

established that the system in which the given operator is to be installed,

satisfies the specifications of all relevant EU directives.

Kirchheim, 16.03.04 Frank Sommer

Managing Director

EU Conformity Declaration

Messrs

SOMMER Antriebs- und Funktechnik GmbH

Hans-Böckler-Straße 21-27

D-73230 Kirchheim/Teck

declares herewith that the product designated below complies with the relevant fundamental requirements as per Article 3 of the R&TTE Directive

1999/5/EG, insofar as the product is used correctly, and that the following

standards apply:

Product: RF Remote Control for Doors & Gates

Type:

- RM04-868-2, RM03-868-4, RX01-868-2/4, RFSDT-868-1, RFSW-868-1

- RM02-868-2, RM06-868-2, RM04-868-1, RM02-868-2-TIGA

- RM08-868-2, RM01-868, RM02-434-2, RM03-434-4, RM04-434-2

The relevant guidelines and standards are:

- ETSI EN 300220-1:09-2000, -3:09-2000

- ETSI EN 301489-1:07-2004, -3:08-2002

- DIN EN 60950-1:03-2003

Kirchheim/Teck, 04.08.2004 Frank Sommer

Managing Director

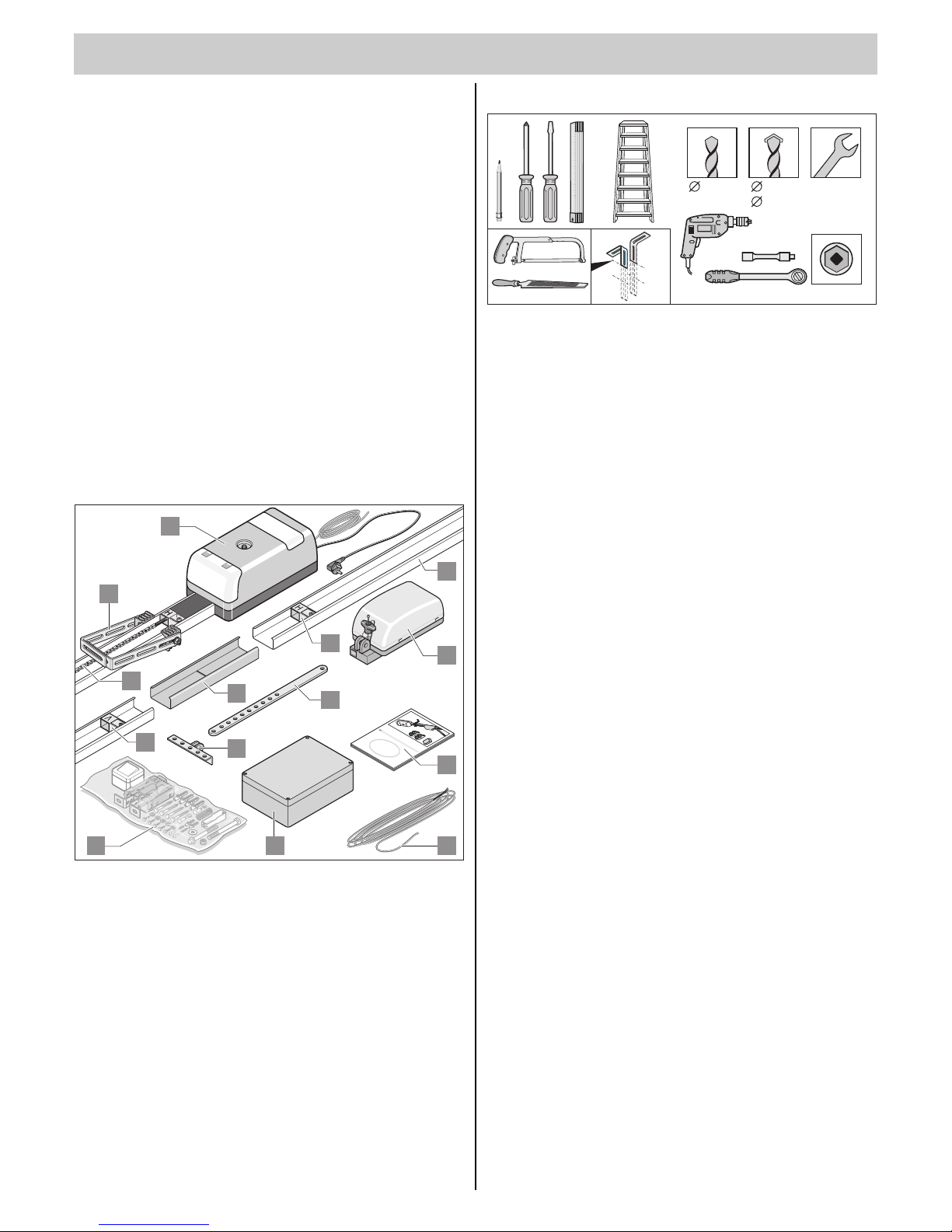

Required Tools

5mm 6mm

10mm

10mm

13mm

10mm

17mm2x

Safety Instructions

• The power cable supplied as standard may neither be shortened nor

lengthened.

• The power supply voltage must correspond to that indicated on the

operator’s rating plate.

• All devices requiring external connection must be equipped with safe

contact separation as per IEC 364-4-41, in order to isolate them from the

mains voltage supply.

• Live parts of the operator (voltage-carrying parts e.g. C-rails) may not be

connected to earth or to the live parts, or to protective conductors of

other circuits.

• IEC 364-4-41 must be observed when laying the external device conduc-

tors.

Installing the Slip-door Safety

Mechanism or Release Lock

• If your garage door is fitted with a slip door but not with a slip-door safety

mechanism, then you need to have one installed (see “Accessories”).

• If your door does not have a slip-door and your garage does not have a

separate entrance, then install a release lock or Bowden cable for operator release from the outside (see “Accessories” instructions).

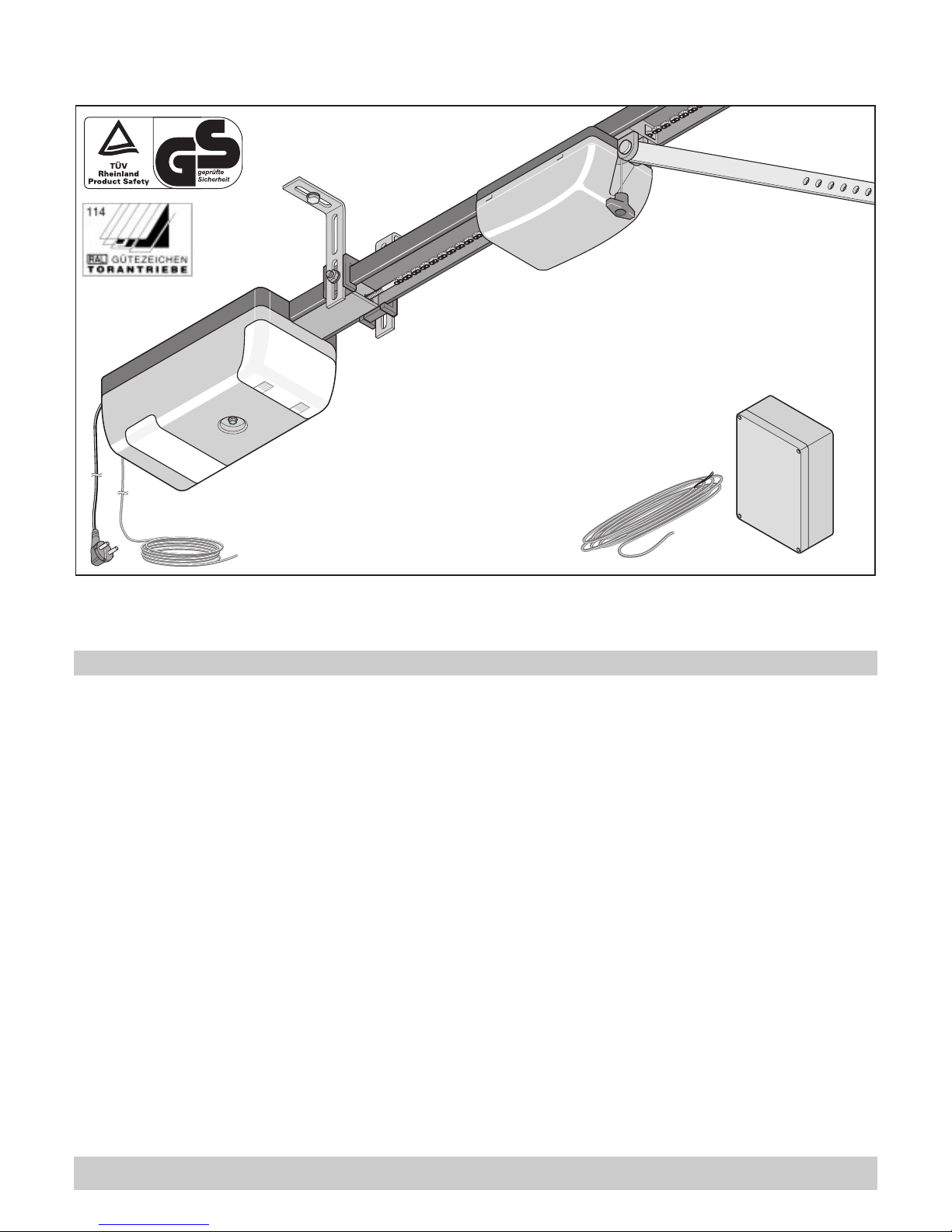

Scope of Supply

• The scope of supply can vary according to the type of operator supplied.

1. 1 x control unit housing (with button line and power cord)

2. 1 x trolley

3. 2x C-rails

4. 1 x connecting piece

5. 1x switch trigger “H”

6. 1x switch trigger “V”

7. 1x chain

8. 1x connecting rod

9. 1x door hinge

10. 1x ceiling suspension bracket (for marathon tiga 1100 SL 2 units)

11. 1x Installation and Operating Instructions

12. 1x assembly kit

13. 1x signal light control unit

14. 1x signal line (7m)

M

o

n

t

a

g

e

u

n

d

B

e

t

r

i

e

b

s

s

a

n

l

e

i

t

u

n

g

1

3

0

D

D

EBS-II550SL, 800 SL, 1100 SL

1

10

7

3

2

11

1412 13

4

5

6

8

9

Preparations for Installation

5

6

Assembly

Safety Instructions

• Installation, connection and initial operation of the operator may only be

carried out by qualified specialists.

• Do not operate the door if people, animals or objects are in its range of

travel.

• Keep children, disabled persons, and animals away from the door.

• Safety goggles should be worn when drilling the mounting holes.

• Cover the operator when drilling to ensure that no grime penetrates the

unit.

The walls and ceiling must be firm and stable. Only fit the operator to a correctly aligned door. A door that has not been aligned

correctly can cause serious injuries.

• Doors must be stable because they are subjected to high traction and

pressure forces. Light doors made of plastic or aluminium must be reinforced before installation if necessary. Ask your dealer for advice.

• Remove door locking system or disable same.

• Only use approved fixing material (e.g. plugs, screws). The fixing materials must be suitable to the wall and ceiling material.

• Check that the door runs easily.

• The door must be balanced.

Test: Manually open the door half-way. The door must remain in this

position. If the door moves downward or upward, then mechanically readjust it. Ask your dealer for advice.

• Check the clearance between the door’s highest up-position (DHP, see

fig. 7) and the ceiling. The minimum clearance is 35 mm and the maximum clearance is 100 mm; the push arm can be at a max angle of 30°. If

clearance is less than that specified, then the operator must be shifted

towards the rear and an extended operator rail must be fitted. Ask your

local dealer for advice.

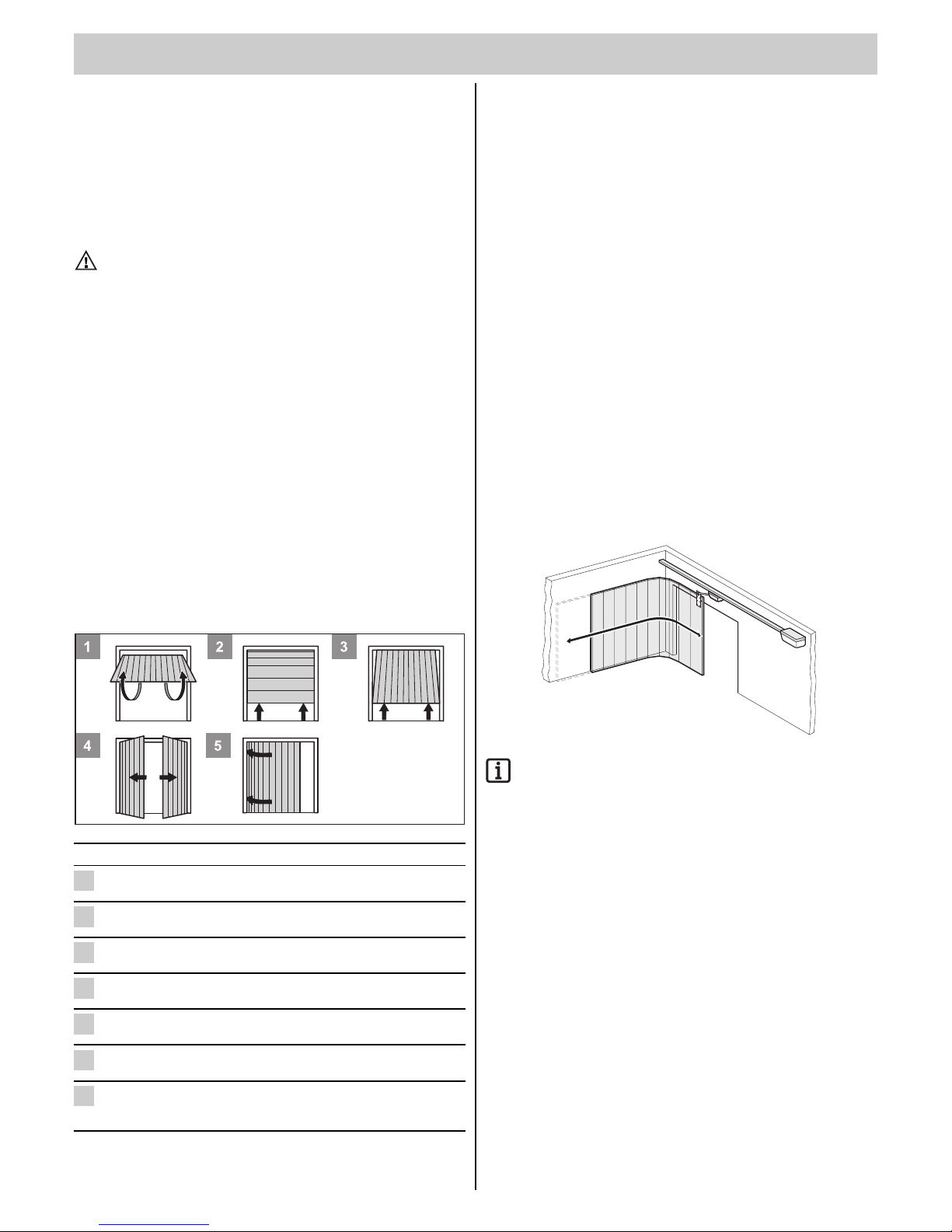

Door Types and Special Accessories*

* Accessories are not included in the delivery specification.

Door type Accessories

Swing door No special accessories required

Sectional door with single Sectional door fitting with

guide rail boomerang *

Vertical sectional door with Sectional door fitting without

double guide rail boomerang *

Rolling shutter door No special accessories required

Up-and-over door Tilting arm *

Wing door Wing-door fitting *

Side-opening sectional door Side opening sectional

door fittings*

Please consult your dealer

5

4

3

2

2

2

1

Installation Tips

• Check that all the parts have been supplied before you start installation

work in order to save time and unnecessary work if a part is missing.

• Installation work can be carried out quickly and reliably by two people.

• The operator can be installed to one side of the door if it cannot be

installed at the centre. In this regard, you must ensure that the door does

not bend and thus jam in the guide rails.

Test: Open and close the door several times by hand, holding it at the

point where you intend fitting the operator. If the door can be

moved at this point without difficulty (in compliance with the

prescribed forces), then the operator can be fitted.

• Emergency Release:

If the garage has no separate entrance (e.g. slip-door), the user must be

able to operate the emergency release mechanism from the outside.

Consequently route the emergency release to the outside. This can be

done with a Bowden cable or an emergency release lock. The backjump

(DIP switch 6 ON) should always be activated in this process.

• Swing doors

As the mechanical lock of a door with an operator must be dismantled or

deactivated, it is possible to open the door manually up to app. 50mm

depending on the door design.

To counter this situation, spring latches can be installed that lock the

door, in addition to the operator. These spring latches are connected to

the operator via a locking set in order to first unlock the spring latches

before the operator opens the door. Ask your dealer for advice.

• Wing door / side-opening sectional door:

For operators that push open a door of the above-mentioned type (see

Fig.):

- the polarity of wires 12 +13 must be swapped in the terminal bar.

Other pulse generators include: Remote control transmitters,

funkcody, radio-operated interior switches and key-operated

buttons. No connection line to the operator needs to be installed

for radio transmission, ask your dealer.

Installation

7

1

4

7

P

2

5

8

0

M

3

6

9

E

sc

0

1

2

1

4

7

P

2

5

8

0

M

3

6

9

Esc

8

2.1

4

6

4 x 0,75 mm

2

3 x 0,75 mm

2

3 x 1,5 mm

2

3 x 1,5 mm

2

3 x 1,5 mm

2

3 x 1,5 mm

2

3

5

2 x 0,75 mm

2

1.2

0

1

2

7

8

1.1

9

10

3

2 (4) x 0,75 mm

2

2 x 0,75 mm

2

2.2

9

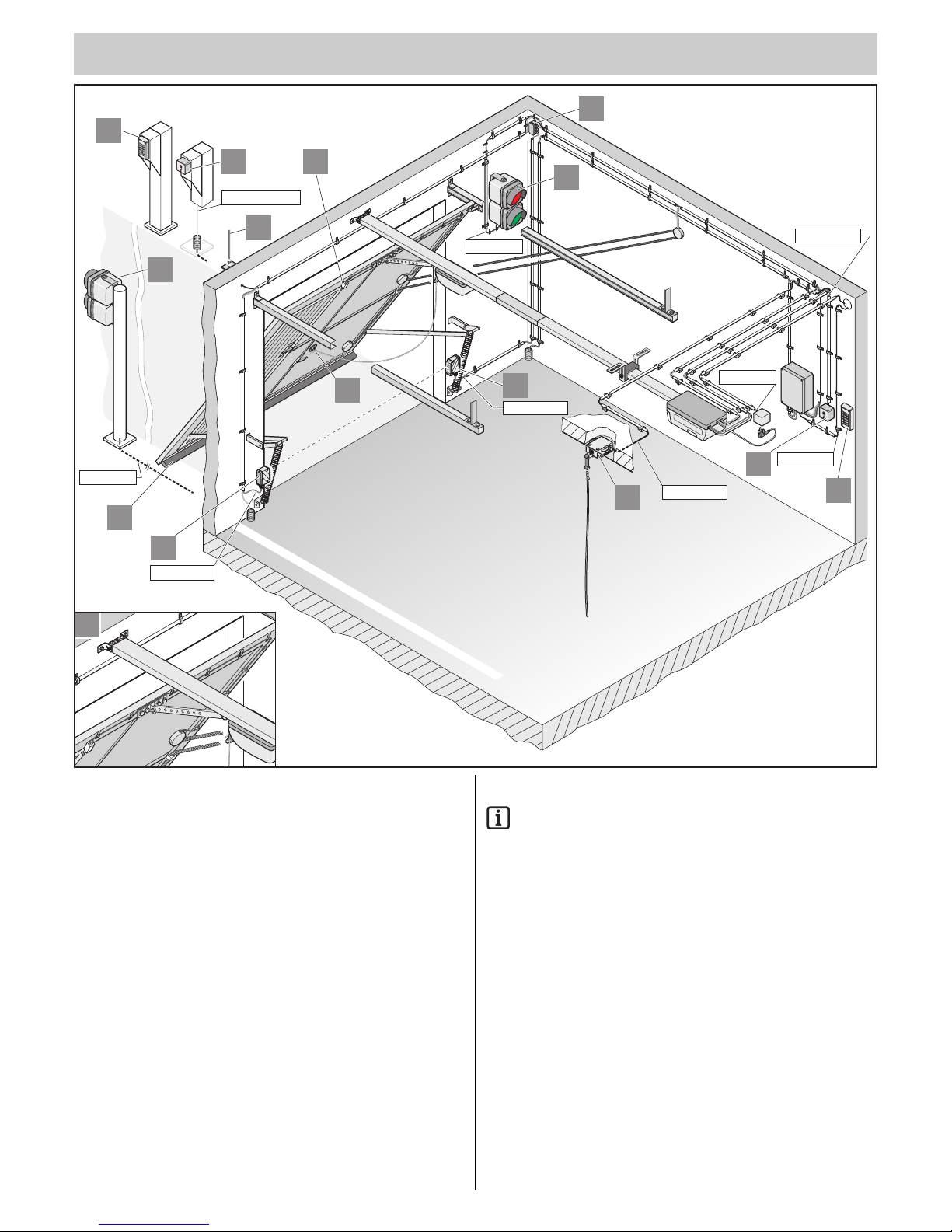

Installation Tips

• Determine the mounting points for the operator and the signal light

control unit together with the operator.

• Determine the mounting point of the signal lights and additional

accessories together with the operator.

• Do not install the housing where it can be seen from the street, otherwise

passersby could damage the control unit.

Accessories

Other pulse generators include: Remote control transmitters,

funkcody, radio-operated interior switches and key-operated

buttons. No connection line to the operator needs to be installed

for radio transmission, ask your dealer if you have questions.

1.1 Red / green signal light: Outside

1.2 Red / green signal light: Inside

2.1 Key-operated button, outside

2.2 Key-operated button, inside

3. Photoelectric cell

4. Junction box

5. Flagpole aerial (incl. 6 m, 10 m or 16 m cable)

6. Release lock

7. Pull-cord switch

8. Funkcody

9. Slip-door safety mechanism

10. Safety contact strip: 8.2 k Ohm or Fraba

Additional accessories on request.

8

• Unscrew two steel angle irons with length adjustment holes (1) and

screw them onto ceiling bracket (2) as shown.

• Dismantle connecting rod (1):

Pull out retainer and remove bolt (3).

Installing the Operator

If the distance between the ceiling and the lower edge of the

C-rail is greater than 245 mm, then extend the suspension

bracket (with perforated steel strip).

• Determine door’s highest up-position (DHP): Open door and

measure smallest clearance (min. 35 mm) between top edge of door

and ceiling. The clearance between the highest up-position and the

bottom edge of the C-rails must be a min. of 5 mm and it may be a

max. of 65 mm; the push arm must be at a max. angle of 30°(for

swing doors) (see Fig. 17)!

• The operator can be mounted on the lintel (S) or ceiling (D).

• Measure front centre point (VM) of door and mark on door and on

lintel or ceiling.

9

8

8

VM

S

30

30

15

15

D

9

7

7

min. 35mm

THP

5 - 65mm

THP

6

5

65

2

1

2

3

1

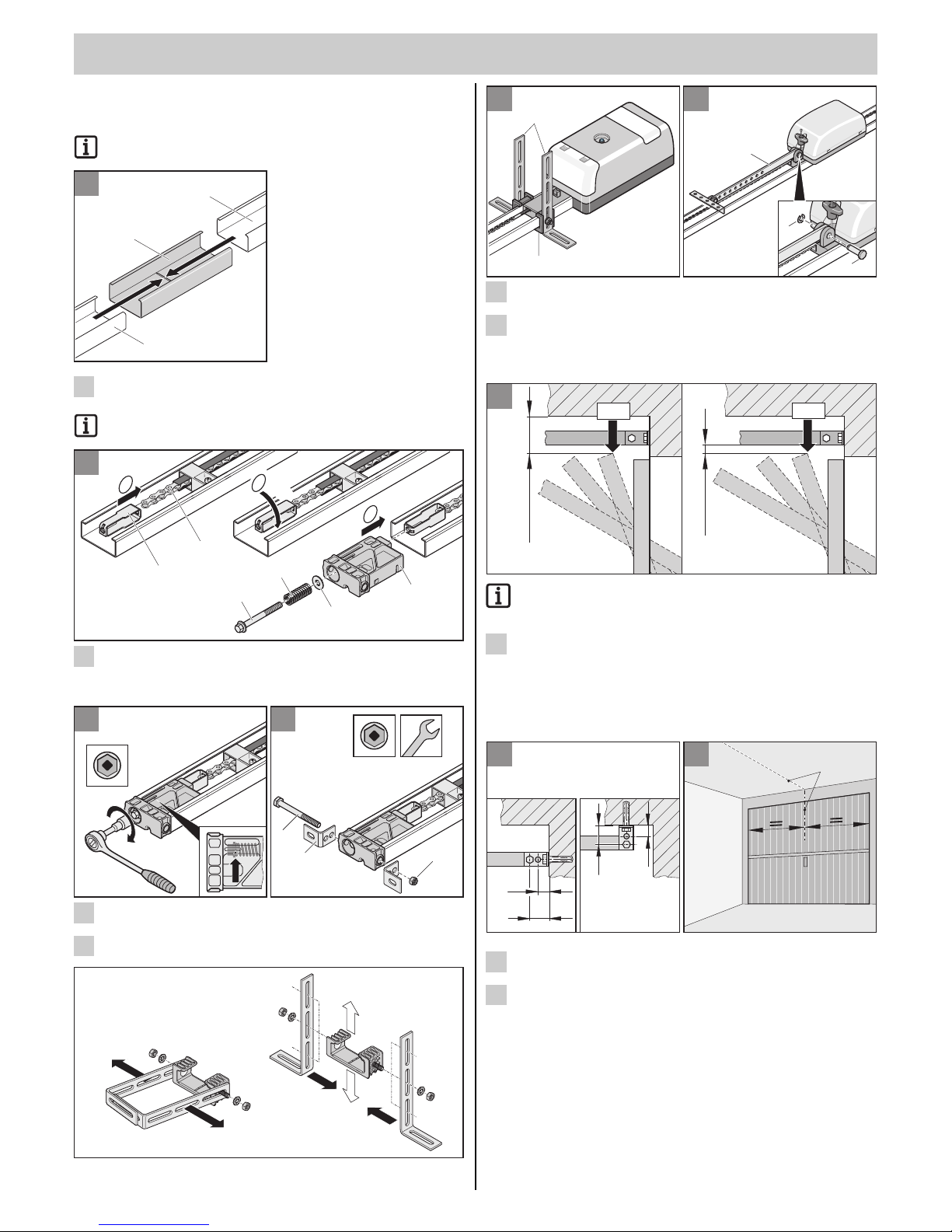

Operator Pre-installation

• Remove the operator from its packaging.

Dispose of the packaging correctly in accordance with local

requirements.

• Slot two C-rails (1) into the connecting element (2) and push together

as far as they will go.

Note the uncoated inner side of the C-rails, this side must always

be facing the chain.

• Hook tensioner (1) in chain (2) and turn it 90°.

Insert connecting element (6) and push tensioner (1) through it.

Place plain washer (5) and spring (4) onto the tensioning bolt (3) and

screw it into the tensioner (1).

• Tighten chain until the mark (arrow) is reached.

• Mount bracket (2) with screw (1) and nut (3) on the connecting element (4).

4

3

3 4

17mm 17mm

10mm

V

1

2

3

V

2

2

a

c

90°

b

1

2

3

4

5

6

V

V

1

1

1

1

2

Installation

Assembly

9

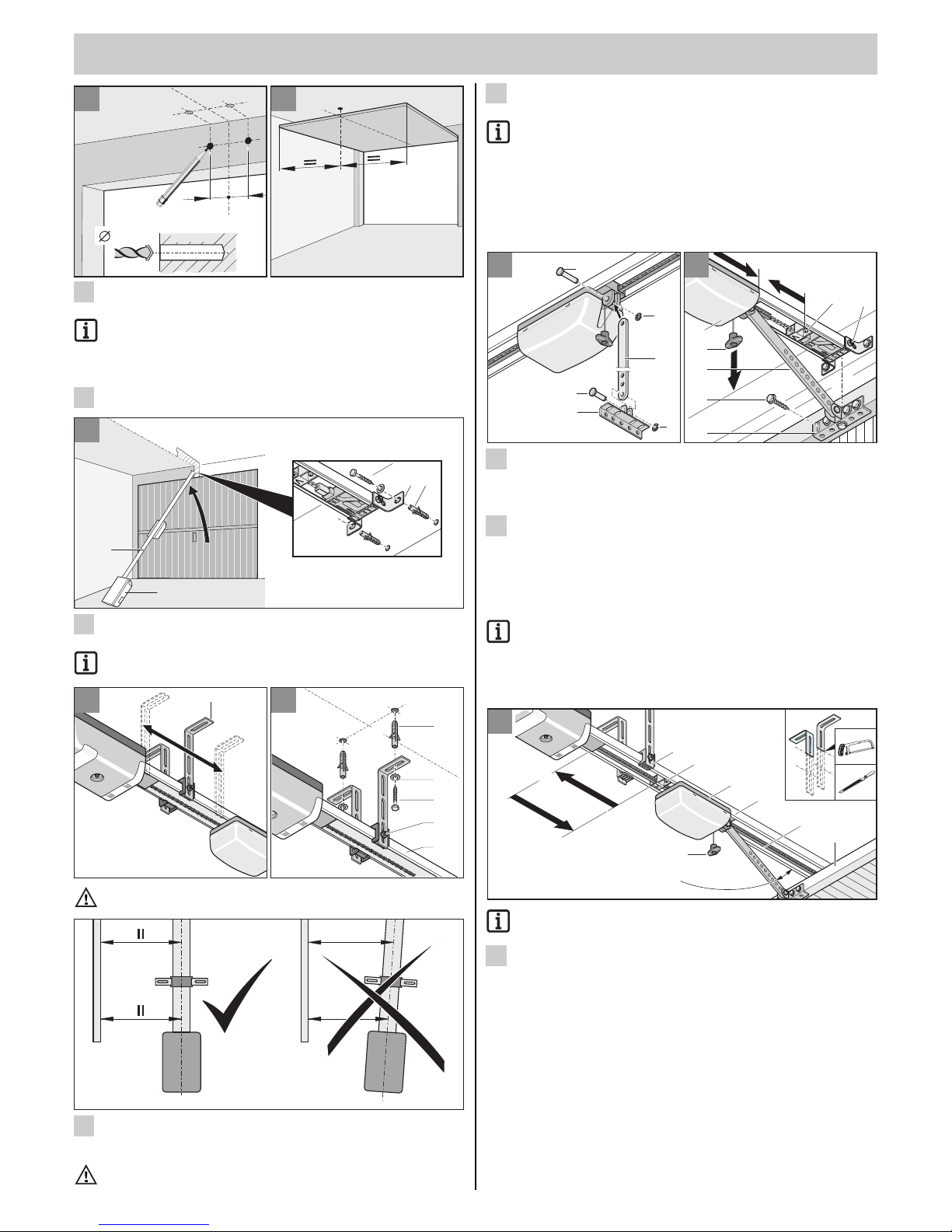

• Mark points 74 mm to right and left of the centre of door (VM), and at

same height on lintel or ceiling (see Fig. 8).

Wear safety goggles when drilling!

Check thickness of ceiling, particularly in the case of prefabricated garages!

• Drill two holes (Ø 10 x 65 mm).

• Open door. Transfer door centre mark (HM) to ceiling.

Close door.

• Insert plug (1). Lift up operator (2) at front. Secure lintel fitting (3) at

the front with two screws (4) and plain washers (5).

Protect control unit housing (6) from damage!

Attention !!

Always install operator parallel to the guide rails of the door.

• Lift up operator.

• Align ceiling bracket (1). It should be located within a range of

(R = 0 ...600 mm).

Use a non-slip, stable stepladder!

13

HM

14

B

600

0

1

1

HM

3

2

5

4

13

12

2

6

S10

4

5

31

12

11

10

VM

74mm 74mm

10mm

65mm

HM

10 11

• Align operator mechanism horizontally to rear centre of door (HM).

Mark position of holes.

Wear safety goggles when drilling!

Check thickness of ceiling, particularly in the case of prefabricated garages!

• Drill two holes (Ø 10 x 65 mm).

• Insert plug (1). Fit two screws (2) with plain washers (3). Tighten

screws (2) securely.

• Align C-rail (4) at correct height. If necessary, move screws (5).

Tighten screws (5).

• Mount connecting rod (1):

Introduce bolt (2) and attach the retainer (3).

• Mount door fitting (4)

insert bolt (5) and attach retainer (3).

• Pull once on the emergency release cord (N). This unlocks the trolley

(1). Tighten screw (8) on lintel fitting.

• Use connecting rod (2) to push trolley (1) as far forward as possible

(3). If necessary, release switch-trigger (4).

• Align angle of door fitting with centre of door (VM) and mark 5 drill

holes. Drill 5 holes (Ø 5 mm).

Wear safety goggles when drilling!

Use screws that are suitable for the door material.

• Insert 5 hexagon-head screws (6) and tighten securely.

• Release switch-trigger (4) and push right up to trolley (7).

• Tighten switch-trigger buffer screw (4) securely.

Trim (e.g. saw off and debur) projecting part of ceiling bracket (4).

• Release rear switch-trigger buffer (1) and push right back to stop (2).

Open door (3) by hand.

• Push switch-trigger (1) right up to trolley (5). Securely tighten screw

on switch-trigger (1).

17

4

7

N

1

8

2

6

max. 30°

4

5

3

17

16

15

15

2

3

5

4

3

1

2

48

7

3

6

5

1

N

VM

16

14

Assembly

10

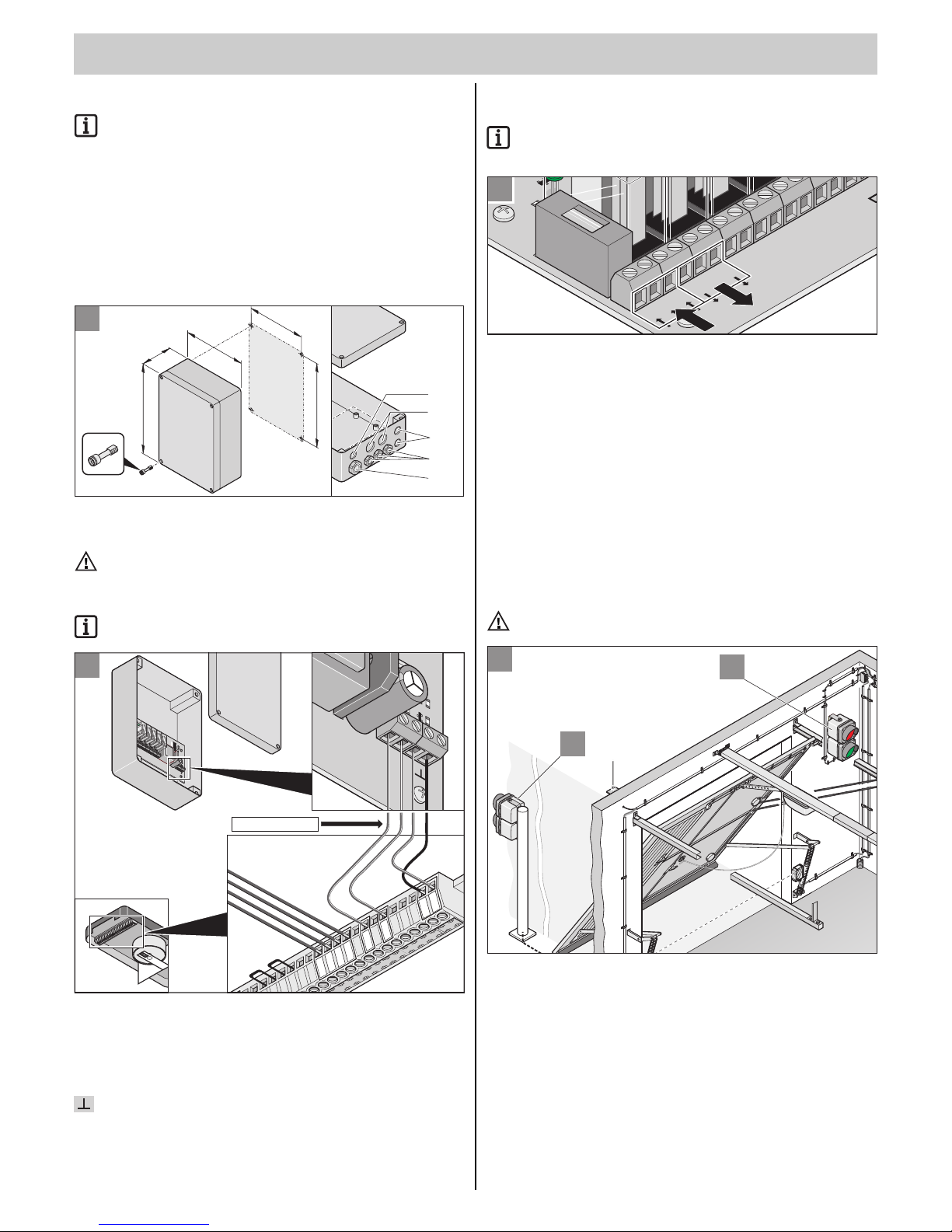

Mounting the control unit

Connect to mains voltage according to EN 12453 (all-pole

separating fixture)

• Work on the control unit may only be executed if it is de-energised.

• Dry any moisture that has penetrated with a blower.

• Only qualified electricians may connect the control unit to the mains

supply.

• Always install the control unit housing vertically, with the cable channels

downward, without deformation of the housing, so that water cannot penetrate and so that the lid forms a watertight seal.

• Only attach the housing using the intended fixing points, do not drill

through the rear wall of the housing. The housing will leak.

Connect the signal light control unit to the operator

Attention!

Always lay the cable separately from the house installation. Otherwise it is possible that the house installation can influence the

function of the signal light control unit.

Permissible cable cross-sections for all terminals:

0.5 mm

2

...1.5 mm2.

Signal light control unit Control unit Operator Cable colour

Terminal Terminal

SIG 0 -> 17 grey

SIG 1 -> 19 red

SIG 2 -> 24 blue

-> 23 black

19

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

L

L

N

N N

N

NGARI

RA

Licht

S

IG

0

S

IG

1

S

IG

2

N

GI

PE

PE

FUSE

5x20

5x20

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

12

14

17

13

15

19

24

23

SIG 0

SIG 1

SIG 2

4 x 0,5 ...1,5 mm

2

18

190

165

4x

254

90

M16

M20

M16

M16

M20

180

Connecting the signal light control unit to the mains

supply

Permissible cable cross-sections for all terminals:

1 mm

2

...2.5 mm2.

Description from left to right

Signal light control unit Mains supply: Input

Terminal

L -> AC 220 ...240 V

N -> Neutral conductor

PE -> Protective earth

Signal light control unit Mains supply: Voltage tap mains power

Terminal

PE -> Protective earth

N -> Neutral conductor

L -> AC 220 ...240 V

Signal light: Installation + connection

Please note!

Connect all signal lights to the signal light controller.

21

B

A

L

L

N

N

NN N

GA

RI

RA Lic

ht

NGI

PE PE

FUSE

5x20

20

Loading...

Loading...