Page 1

Marathon Sensors Inc.

Oxymit™ Transmitter

Operators Manual

Page 2

F200060

Revision: 00 04/18/2001

01 04/23/2001

02 05/08/2001

03 09/19/2001

04 11/01/2001

05 11/21/2001

06 04/19/2002

07 10/30/2002

08 11/13/2002

09 11/06/2003

10 12/03/2003

11 09/30/2004

12 04/04/2005

13 04/11/2005

14 11/14/2006

COPYRIGHT © 2004

MARATHON SENSORS INC.

3100 East Kemper Road, Cincinnati, Ohio 45241

1-800-547-1055 (513) 772-1000 FAX: (513) 326-7090

All trademarks used in this publication are duly marked and the sole property of their

respective owners. No attempt at trademark or copyright infringement is intended or

implied.

Marathon Sensors makes no warranties express or implied beyond the written warranty

presented at initial purchase. Marathon Sensors Inc. is not responsible for any product,

process, damage or injury incurred while using this equipment. Marathon Sensors makes

no representations or warranties with respect to the contents hereof and specifically

disclaims any warranties of merchantability or fitness for any particular application or

purpose.

Page 3

Table of Contents

GENERAL DESCRIPTION............................................................................................................................ 2

SAFETY SUMMARY......................................................................................................................................3

CONNECTIONS..............................................................................................................................................3

GROUNDING AND SHIELDING .........................................................................................................................4

PARAMETER SELECTIONS........................................................................................................................4

PROCESSPARAMETERS...................................................................................................................................4

Process Type.............................................................................................................................................5

Carbon Process Factor.............................................................................................................................5

Dew Point Process Factor........................................................................................................................ 5

Oxygen Exponent......................................................................................................................................6

TC Type.....................................................................................................................................................6

ANALOG OUTPUT CHANNELS .........................................................................................................................6

CALIBRATION...............................................................................................................................................7

PROCESS VARIABLE CALCULATIONS...................................................................................................8

PERCENTOXYGEN.......................................................................................................................................... 8

PERCENTCARBON..........................................................................................................................................8

DEWPOINT...................................................................................................................................................... 8

COMMUNICATIONS.....................................................................................................................................9

MODBUS.........................................................................................................................................................9

RTU Framing............................................................................................................................................ 9

Address Field.......................................................................................................................................... 10

Function Field......................................................................................................................................... 10

Data Field...............................................................................................................................................10

Error Check Field (CRC)........................................................................................................................10

MEMORY MAP.............................................................................................................................................12

OPERATIONAL SPECIFICATIONS..........................................................................................................18

Page 4

NOTE:

Please specify the following parameters when ordering a transmitter; process type, process

range (%, ppm), thermocouple type, temperature scale F/C, analog output 1 process and

scale, analog output 2 process and scale.

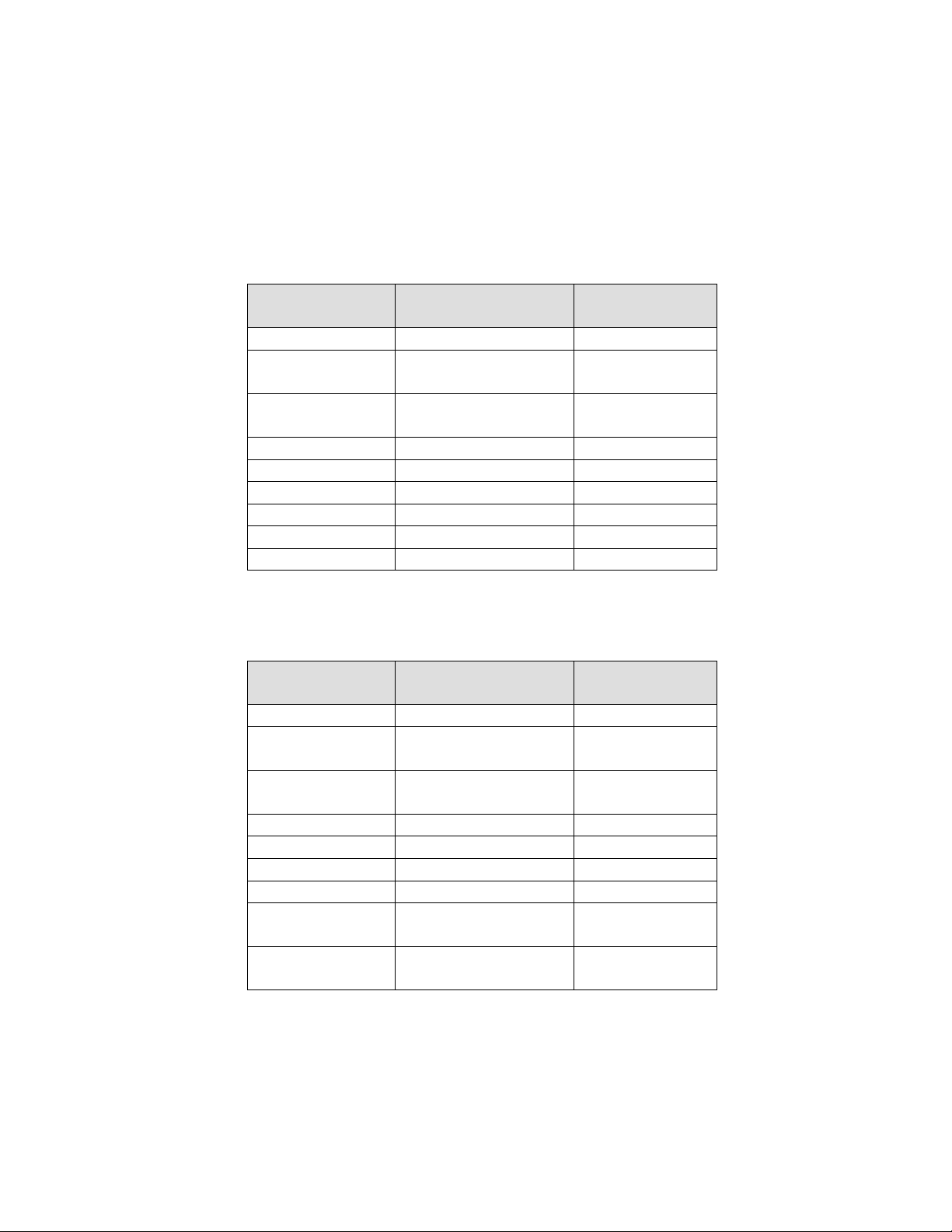

Typical Oxygen Transmitter Calibration

(F840030)

Calibration

Function

Measured Value or

Input

Output / Units

Cold Junction Room Temp °F

Thermocouple

min

Thermocouple

max

800°F (B type)

standard t/c type

3000°F (B type)

standard t/c type

°F

°F

Millivolt 0.0 mV Millivolts

Millivolt 2000 mV Millivolts

Analog 1 Zero 0% O2 4.0 mA +/- 0.1

Analog 1 Span 20.9% O2 20.0 mA +/- 0.1

Analog 2 Zero 800°F +/- 5° 4.0 mA +/- 0.1

Analog 2 Span 3000°F +/- 5° 20.0 mA +/- 0.1

Typical Carbon Transmitter Calibration

(F840031)

Calibration

Function

Measured Value or

Input

Output / Units

Cold Junction Room Temp °F

Thermocouple

Min

Thermocouple

Max

MUST BE

SPECIFIED

MUST BE

SPECIFIED

°F

°F

Millivolt 0.0 mV Millivolts

Millivolt 2000 mV Millivolts

Analog 1 Zero 0% Carbon 4.0 mA +/- 0.1

Analog 1 Span 2.55% Carbon 20.0 mA +/- 0.1

Analog 2 Zero MUST BE

4.0 mA +/- 0.1

SPECIFIED

Analog 2 Span MUST BE

20.0 mA +/- 0.1

SPECIFIED

Page 1 of 23

11/14/2006 Rev. 14

Page 5

General Description

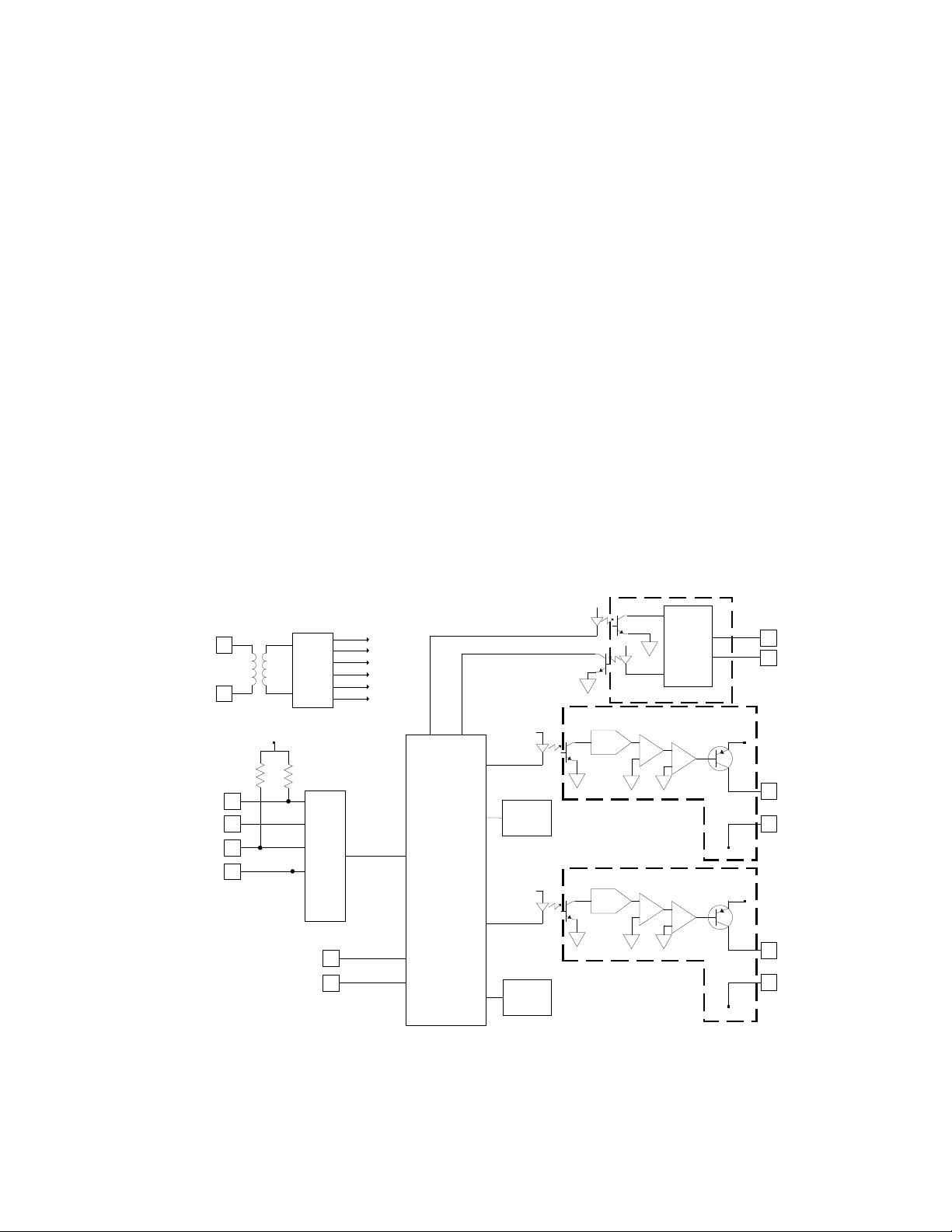

The Oxymit™ Transmitter has been designed to work as an analog or digital interface for

any zirconia based oxygen probe used to track dew point, carbon potential, or oxygen. The

transmitter connects to the temperature and millivolts outputs of an oxygen probe and can

produce analog outputs proportional to the selected process value.

The features available are:

Isolated inputs for thermocouple and probe millivolt

24 bit Sigma-Delta ADC for inputs.

SerialEEPROM to store setup and calibration values.

Two isolated self-powered 4-20mA outputs for process value and temperature.

The transmitter makes a carbon or oxygen probe an intelligent stand alone sensor. The

transmitter is located near the probe, preferably mounted in an enclosure. The transmitter

mounts onto a DIN rail and requires a 24VDC power supply. It measures the probe

temperature and millivolts. At the time of order the transmitter can be configured to

calculate percent carbon, dewpoint, or percent oxygen from these inputs. The results of

any of these calculations are made available via two4-20mA loop outputs. Typically one

first loop is set up for the process value the second loop transmits probe temperature.

T/C INPUT

mV INPUT

+24V

24V

COM

12

11

6

5

8

7

5V_A

44M

EVENT INPUT

Power

Supplies

22M

A/D

CONV.

5V_A

5V_B

+15V

-15V

+15V

-15V

EEPROM

Process

Controller

3

4

Figure 1 BLOCK DIAGRAM

5V_A

5V_A

DISPLAY

CONN.

5V_A

10

5V_B

A

RS485

B

ISOLATED

RTX+

9

RTX-

ISOLATED

-15V

+15V

1

ANALOG

OUT 1

4-20mA

2

D/A

C

C C

ISOLATED

-15V

+15V

14

ANALOG

OUT 2

4-20mA

13

D/A

D

D D

Page 2 of 23

11/14/2006 Rev. 14

Page 6

Safety Summary

All cautions and instructions that appear in this manual must be complied with to prevent

personnel injury or damage to the Probe Transmitter or connected equipment. The

specified limits of this equipment must not be exceeded. If these limits are exceeded or if

this instrument is used in a manner not intended by Marathon Sensors Inc., damage to this

instrument or connected devices could occur.

Do not connect this device directly to AC motors, valves, or other actuators. All AC alarm

functions must be connected through an interposing DC coil relay with a maximum coil

load of 0.5 amps DC. The Probe Transmitter is not rated to act as a safety device. It

should not be used to provide interlocking safety functions for any temperature or process

functions. Alarm capabilities are provided for probe test and input faults only and are not

to be considered or used as safety contacts in any application.

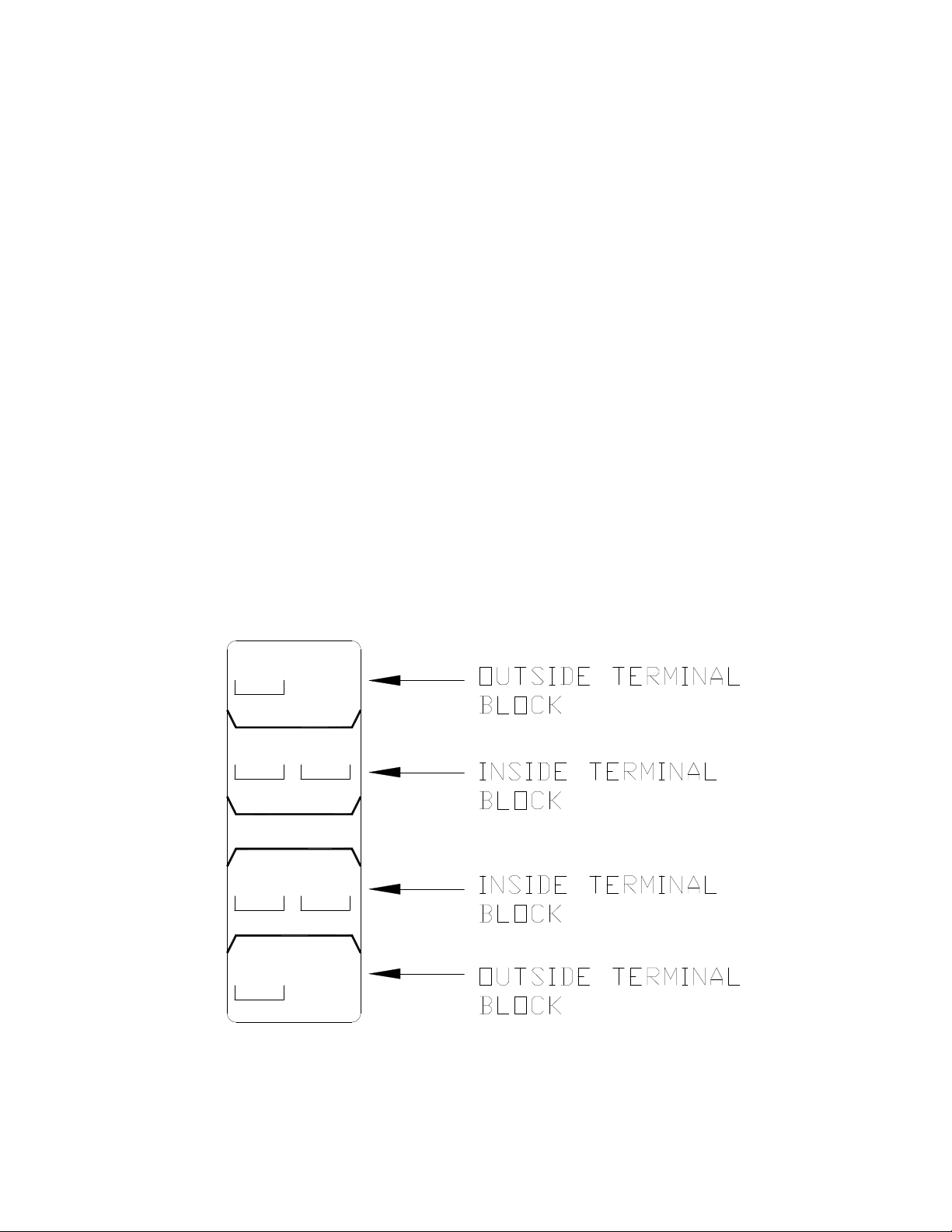

Connections

The Probe Transmitter has four removable terminal blocks grouped with four terminals

each. Each terminal is a wire clamp type with a standard slot screw. Each clamp can

accommodate AWG 24 to 12 flexible stranded wire. Maximum torque on the terminal

screws should not exceed 0.8 Nm.

The figure below shows the arrangement of the terminals.

1 2 3 4

- + EVT EVT

AO1 COM NO

LOWER

5 6 7 8

- + - +

TC MV

UPPER

UPPER

9 10 11 12

- + - +

RS485 24VDC

LOWER

13 14 15 16

- + N/C N/C

AO2

Figure 2 Terminal Layout

Page 3 of 23

11/14/2006 Rev. 14

Page 7

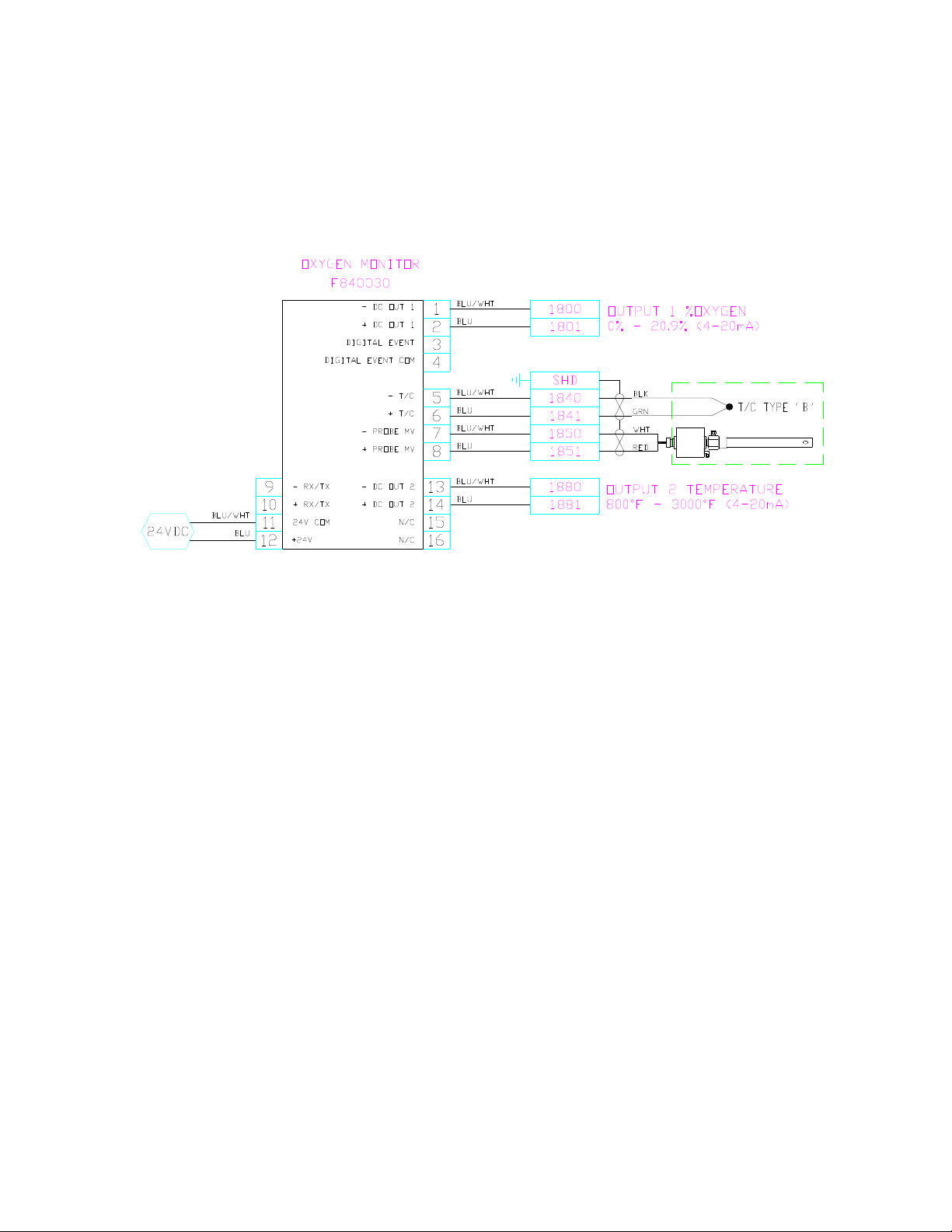

The next figure shows a schematic representation of the Probe Transmitter and typical

connections required in the field.

Figure 3 Schematic Connections

Grounding and Shielding

To minimize the pick-up of electrical noise, the low voltage DC connections and the sensor

input wiring should be routed away from high-current power cables. Where it is

impractical to do this, use shielded cables with the shield grounded at the Probe Transmitter

enclosure ground as show above.

Parameter Selections

The following tables list the parameters available in the Probe Transmitter. Default values

are also listed. The default values are loaded if a reset is force in the device. Changes to

these parameters must be specified at the time of order.

Process Parameters

The following table shows the process selections and other parameters that effect the

process value.

Page 4 of 23

11/14/2006 Rev. 14

Page 8

Table 1 Process Parameters

Parameter Name Selection

Units or Options Range

Default

PROCESS TYPE %O2 CARBON, DPT,

%O2, MV

CARB PROC FACT 150 0 to 1000

DEWPT PROC FACT 150 0 to 1000

OXYGEN EXPON 0002 POWER OF TEN 0 to 31

TC TYPE B B, C, E, J, K, N,

NNM, R, S, T

Process Type

Selecting the process type determines what type of calculation the Smart Transmitter is

going to do based on the probe millivolt and probe temperature inputs. The default process

value for the Smart Transmitter is %O2 with an exponent selection of 2. This is the

selection most often used in Boiler control and Combustion applications.

Percent Carbon and dew point are typically processes that are used in steel treating

applications. Percent Carbon is the process value most often used for the control of case

depth or the percent of carbon in asteel hardening furnace. Dew Point is used in the control

for endothermic generators.

Carbon Process Factor

The carbon process factor can be used to adjust the % carbon value. This number takes

into account a number of assumptions that the carbon value is based on. Primary among

these is the assumed level of CO in the atmosphere. See the Theory of Process Calculation

section for a complete explanation of this value.

It maybe necessary to change the apparent furnace carbon as measured by the oxygen

probe if this value is different than actual load samples, shim stocks, or gas analysis. The

basic rule of thumb is that an increase is the carbon process factor will decrease the

apparent carbon level in the furnace. The default value is 150. Typical values can very

from 50 to 400. Increase or decrease the process factor until the desired carbon level is

achieved. A process factor that is drastically different than normal may be an indication of

a failing probe, water or air leak in the furnace, or excess methane present. Refer to probe

troubleshooting guides to determine what other factors maybe effecting the carbon value.

Dew Point Process Factor

The dew point process factor is similar to the carbon process factor but is used to adjust the

dew point value if dew point is selected as the process value. This number takes into

account a number of assumptions that the dew point value is based on. Primary among

these is the assumed level of hydrogen in the atmosphere. See the Theory of Process

Calculation section for a complete explanation of this value.

Page 5 of 23

11/14/2006 Rev. 14

Page 9

Oxygen Exponent

The range of oxygen is factory configured using the oxygen exponent number. Percent

oxygen is the standard setting where the oxygen exponent is set to 2 and the output range is

0.00% to 20.9%. For a part per million (ppm) range the exponent would be set to 6 and the

output range of 0.00 X 10-6to 99.99 X 10-6.

TC Type

The following table shows the available thermocouple types and the ranges. BOLD

indicates the typical oxygen default.

Thermocouple

Zero ºF Zero °C Span ºF Span °C

type

B 800 425 3000 1650

C 32 0 3000 1650

E 32 0 1300 700

J 32 0 1300 700

K 32 0 2300 1260

N 32 0 2300 1260

NNM 32 0 2000 1090

R 300 150 3000 1650

S 300 150 3000 1650

T 32 0 700 370

The Cold Junction correction is applied to all thermocouple types.

Analog Output Channels

The analog outputs are factory configured to provide 4 to 20mA signals proportional to

selectable process values.

NOTE

The Analog Output Channels are isolated self-powered

current sources and do not require an external supply.

If a chart recorder is to be used, it should have input specifications within 4 to 20mA. If

the recorder only responds toVDC inputs it will be necessary to add a 250 ohm dropping

resistor across its input terminals.

The ideal location of the recorder is adjacent to the instrument but it may be located

remotely if the connecting wires are properly shielded. For best results, the chart recorder

input(s) should be isolated from ground.

Page 6 of 23

11/14/2006 Rev. 14

Page 10

Table 2 Analog Outputs

Parameter

Name

OUTPUT 1

MODE

Oxygen

Default

O2

0–20.9%

4-20mA

Possible

Options

O2, CARBON,

DEWPT, TEMP, LIN,

PROG

Possible

Ranges

O2 = 0 – 9999

%C = 0.00 – 2.55

DP = -99.9 – 212.0

Temp = -999 – 3000

LIN = -999 – 9999

PROG = 0 – 4095

OUTPUT 2

MODE

TEMP

800-3000°F

4-20mA

O2, CARBON,

DEWPT, TEMP, LIN,

PROG

O2 = 0 – 9999

%C = 0.00 – 2.55

DP = -99.9 – 212.0

Temp = -999 – 3000

LIN = -999 – 9999

PROG = 0 – 4095

NOTE: SEE PAGE 4 FOR TYPICAL CALIBRATION VALUES.

Calibration

The Smart Transmitter is factory calibrated. The calibration can be verified once a year or

according to customer calibration schedules. The instrument should be returned to the

factory if calibration is required.

Page 7 of 23

11/14/2006 Rev. 14

Page 11

Process Variable Calculations

The transmitter has a selectable process calculation for percent carbon, percent oxygen, or

dewpoint. The following equations are used to derive these values;

Percent Oxygen

20.95

%O2 = -----------------------

(E/0.0215*Tk)

e

Where: E = probe millivolts, Tk = probe temperature in degrees Kelvin.

The 20.95 is the %O2 in air.

Percent Carbon

((E-786)/(0.043102*Tk))

e

%C = 5.102 ---------------------------------------------------

(29*PF + 400)+e((E-786)/(0.043102*Tk))

Where: E = probe millivolts, Tk = probe temperature in Kelvin, and PF is the process

factor.

Dewpoint

4238.7

DP = -------------------------------------------------------------------- - 459.69

6.281216 + log((29*PF+400)+(E-1267.8)/(0.05512*Tr)

Where: E = probe millivolts, Tr = probe temperature in Rankin, PF is the process factor,

and DP is the dewpoint in Fahrenheit.

Page 8 of 23

11/14/2006 Rev. 14

Page 12

Communications

The Transmitter is capable of digital communications using the Modbus protocol. This is

possible by connecting to the half duplex RS-485 terminals using a shielded twisted pair.

Modbus

The MODBUS protocol describes an industrial communications and distributed control

system (DCS) that integrates PLCs computers, terminals, and other monitoring, sensing,

and control devices. MODBUS is a Master/Slave communications protocol, whereby one

device, (the Master), controls all serial activity by selectively polling one or more slave

devices. The protocol provides for one master device and up to 247 slave devices on a RS485 half duplex twisted pair line. Each device is assigned an address to distinguish it from

all other connected devices. All instruments are connected in a daisy-chain configuration.

The instrument communicates with baud rate settings 1200, 2400, 4800, 9600, or 19.2K.

The default baud rate is 19.2Kbuad. The default address is 1. Changes to these values can

be made by writing to the appropriate memory register.

The Transmitter communicates in Modbus RTU (Remote Terminal Unit) protocol using 8bit binary data characters. Message characters are transmitted in a continuous stream. The

message stream is setup based on the following structure:

Number of bits per character:

Start bits 1

Data bits (least significant first) 8

Parity None only (no bits for no parity)

Stop bits 1

Error Checking CRC (Cyclical Redundancy Check)

The Transmitter recognizes threeRTU commands. These are: read single I registers

(command 4), read a single H register (command 3), and preset a single H register

(command 6)

In Modbus mode, the Transmitter can be only be configured for the ‘none’ parity option.

The instrument never initiates communications and is always in receive mode unless

responding to a query.

RTU Framing

Frame synchronization can be maintained inRTU transmission mode only by simulating a

synchronous message. The instrument monitors the elapsed time between receipt of

characters. If three and one-half character times elapse without a new character or

completion of the frame, then the instrument flushes the frame and assumes that the next

Page 9 of 23

11/14/2006 Rev. 14

Page 13

byte received will be an address. The follow command message structure is used, where T

is the required character delay. Response from the instrument is based on the command.

T1,T2,T3 ADDRESS FUNCTION DATA CHECKSUM T1,T2,T3

8-BITS 8-BITS N X 8-BITS 16-BITS

Address Field

The address field immediately follows the beginning of the frame and consists of 8-bits.

These bits indicate the user assigned address of the slave device that is to receive the

message sent by the attached master.

Each slave must be assigned a unique address and only the addressed slave will respond to

a query that contains its address. When the slave sends a response, the slave address

informs the master which slave is communicating.

Function Field

The Function Code field tells the addressed slave what function to perform. MODBUS

function codes are specifically designed for interacting with aPLC on the MODBUS

industrial communications system. Command codes were established to manipulate PLC

registers and coils. As far as the Transmitter is concerned, they are all just memory

locations, but the response to each command is consistent with Modbus specifications.

The high order bit in this field is set by the slave device to indicate an exception condition

in the response message. If no exceptions exist, the high-order bit is maintained as zero in

the response message.

Data Field

The data field contains information needed by the slave to perform the specific function or

it contains data collected by the slave in response to a query. This information may be

values, address references, or limits. For example, the function code tells the slave to read

a holding register, and the data field is needed to indicate which register to start at and how

many to read.

Error Check Field (CRC)

This field allows the master and slave devices to check a message for errors in

transmission. Sometimes, because of electrical noise or other interference, a message may

be changed slightly while it is on its way from one device to another. The error checking

assures that the slave or master does not react to messages that have changed during

transmission. This increases the safety and the efficiency of the MODBUS system.

The error check field uses a CRC-16 check in the RTU mode.

Page 10 of 23

11/14/2006 Rev. 14

Page 14

The following is an example of a function 03 call fordata at memory location 03. The

value returned by the instrument is the hex value 1E.

Transmit from Host or Master

Address Cmd RegHIReg

LO

CountHICountLOCRCHICRC

LO

01 03 00 03 00 01 74 0A

Response from Transmitter

Address Cmd Byte

Count

HI

Byte

Count

LO

DataHIData

LO

CRCHICRC

Lo

01 03 00 02 00 1E 38 4C

Note that all the values are interpreted as hexadecimal values. The CRC calculation is

based on the A001 polynomial for RTU Modbus. The function 04 command structure is

similar to the 03 structure.

The following is an example of a function 06 call to change data in register 01 to 200. The

response from the instrument confirms the new value as being set.

Transmit from Host or Master

Address Cmd RegHIRegLODataHIData

LO

CRCHICRC

LO

01 06 00 01 00 C8 D9 9C

Response from Transmitter

Address Cmd RegHIRegLODataHIDataLOCRCHICRC

LO

01 06 00 01 00 C8 D9 9C

The Transmitter will respond to several error conditions. The three exception codes that

will generate a response from the instrument are:

01 – Illegal Function

02 - Illegal Data Address

03 – Illegal Data Value

04 – Slave Device Failure

The response from the Transmitter with an exception code will have the most significant

bit of the requested function set followed by the exception code and the high and lowCRC

bytes.

Page 11 of 23

11/14/2006 Rev. 14

Page 15

Memory Map

NOTE: Modbus refers to the hexadecimal register location. These parameters are

formatted as unsigned 16 bit integers. Any real number such as temperature can be

evaluated as a signed number, other parameters are bit mapped words that must be

evaluated as single bits are bit groups.

BLOCK 0

HEX DEC PARAMETER DESCRIPTION READ/WRITE

00 0 Not used READ ONLY

01 1 TIME CONTROL

SIOSET

LOW BYTE - TIMER CONTROL

BIT 0 – Timer Disabled (0), Timer Enabled (1)

BIT 1 – 7 SPARE

HIGH BYTE – SIO SETUP

BITS 8 – 9 PARITY SETTING

00 = Even Parity, 7 bits, 1 Stop bit

01 = No Parity, 8 bits, 1 Stop bit

10 = Odd Parity, 7 bits, 1 Stop bit

BITS 10 – 11 RESPONSE DELAY

0 = No delay applied to response

1 = 10ms delay applied to response

2 = 20ms delay applied to response

3 = 30ms delay applied to response

READ/WRITE

BITS 12 – 14 BAUD SELECT

000 = 76.8K

001 = 38.4K

010 = 19.2K (DEFAULT)

011 = 9600

100 = 4800

101 = 2400

110 = 1200

111 = 600

BIT 15 HOST FORMAT

0 = MSI (PROP)

1 = MODBUS (DEFAULT)

02 2 TC_ZERO

TC_SPAN

03 3 MV_ZERO

MV_SPAN

04 4 PF PROCESS FACTOR FOR CARBON OR

LOW BYTE - TC ZERO CALIBRATION

NUMBER

HIGH BYTE – TC SPAN CALIBRATION

NUMBER

LOW BYTE – MV ZERO CALIBRATION

NUMBER

HIGH BYTE – MV SPAN CALIBRATION

NUMBER

DEWPOINT

RANGE = 0 to 4095

READ/WRITE

READ/WRITE

READ/WRITE

Page 12 of 23

11/14/2006 Rev. 14

Page 16

BLOCK 0

HEX DEC PARAMETER DESCRIPTION READ/WRITE

DEFAULT = 150

05 5 EVENT

LDLN

LOW BYTE – INPUT EVENT

CONFIGURATION

Bits 0 – 3

0000 = None

0001 = Auto Mode Selected

0010 = Remote Setpoint Selected

0011 = Acknowledge alarms

0100 = Timer Hold

0101 = Timer End

0110 = Timer Start

0111 = Start probe test

1000 = Process hold

Bits 4 – 7 not used.

UPPER BYTE – LOAD LINE

READ/WRITE

06 6 CJTRM

HADR

07 7 SPARE SPARE

08 8 CONFIG0 Input Configuration

09 9 CONFIG2 SETUP VALUES

LOW BYTE – COLD JUNCTION TRIM

COLD JUNCTION TRIM (unsigned integer)

RANGE = –128 TO +127 WHERE

1 COUNT = 1 DEG (C or F) and –128 = 65408

HIGH BYTE – HOST ADDRESS

BITS 0-7

RANGE = 0 – 255

BITS 0-3TC Input TYPE

0000 = B (DEFAULT)

0001 = E

0010 = J

0011 = K

0100 = N

0101 = R

0110 = S

0111 = T

1000 = SPARE

1001 = SPARE

1010 = SPARE

1011 = SPARE

1100 = SPARE

1101 = SPARE

1110 = SPARE

1111 = SPARE

BIT 4 = SPARE

BIT 5 0 = NO CJ APPLIED, 1 = CJ APPLIED

BIT 6 0 = °F, 1 = °C

BIT 7 0 = 60HZ FILTER

BIT 8 – 11 Millivolt Input TYPE

0000 = LINEAR (DEFAULT)

All other bit combinations are spare

BITS 12 – 15 are spare

READ/WRITE

Page 13 of 23

11/14/2006 Rev. 14

Page 17

BLOCK 0

HEX DEC PARAMETER DESCRIPTION READ/WRITE

BITS 0 - 4 OXYGEN EXPONENT

RANGE = 0 to 31, where 2 = % and 6 = ppm

DEFAULT = 2

BITS 5 - 6 DISPLAY DECIMAL PLACE

where:

0 = no decimal point in display

1 = DisplayXXX.X

2 = DisplayXX.XX

3 = DisplayX.XXX

DEFAULT = 0

BITS 8 – 12 REDOX METAL NUMBER

RANGE = 0 – 14

DEFAULT = 0

BITS 13 – 15 SPARE

0A 10 FAULT FAULT BIT MAP

BIT 0 = Temperature Input Open

BIT 1 = MV Input Open

BIT 2 = Range of input is low

BIT 3 = Range of input is high

BIT 4 = Timer End

BIT 5 = Probe Care Fault

BITS 6 – 7 = SPARE

BIT 8 = CPU Fault

BIT 9 = Min Idle counter = 0

BIT 10 = Keyboard failure, stuck key or a key

was pressed during power up.

BIT 11 = Flash Erase Failed

BIT 12 = Flash Checksum Failed

BIT 13 = EEPROM Checksum Failed

BIT 14 = Flash/EEPROM Size Fault

BIT 15 = ADC Fault

0B 11 ASRC ANALOG OUT SOURCES

LOW BYTE, ANALOG OUTPUT 1

BITS 0 – 3

0000 = N/A

0001 = Temperature

0010 = Linear Input A

0011 = Carbon value

0100 = Dewpoint value

0101 = Oxygen value

0110 =Redox value

0111 = Output Power

1000 = Control Output 1

1001 = Control Output 2

1010 = Linear Input B

1011 = Programmable*

READ ONLY

READ/WRITE

*For Programmable, write required output

value into DACV1, where DACV1 = 0 is

minimum output and

DACV1 = 4096 is maximum output.

BITS 4 – 7 SPARE

Page 14 of 23

11/14/2006 Rev. 14

Page 18

BLOCK 0

HEX DEC PARAMETER DESCRIPTION READ/WRITE

HIGH BYTE, ANALOG OUTPUT 2

BITS 8 – 12

0000 = N/A

0001 = Temperature

0010 = Linear Input A

0011 = Carbon value

0100 = Dewpoint value

0101 = Oxygen value

0110 =Redox value

0111 = Output Power

1000 = Control Output 1

1001 = Control Output 2

1010 = Linear Input B

1011 = Programmable*

*For Reference Number and Programmable ,

write required output value into DACV2, where

DACV2 = 0 is minimum output and

DACV2 = 4096 is maximum output.

BITS 13 – 15 SPARE

Special case: If Analog Output 1 = CONTROL

OUTPUT 1 and Analog Output 2 = CONTROL

OUTPUT 2 and the Control Mode is dual, then

Analog Output 1 is 4-20ma for 0 to +100% PO

and Analog Output 2 is 4-20ma for 0 to -100%

PO.

0C 12 DAC_OFFSET_1 DAC 1 OFFSET CALIBRATION READ/WRITE

0D 13 DAC_SPAN_1 DAC 1 SPAN CALIBRATION READ/WRITE

0E 14 DAC_OFFSET_2 DAC2 OFFSET CALIBRATION READ/WRITE

0F 15 DAC_SPAN_2 DAC2 SPAN CALIBRATION READ/WRITE

10 16 AOUTOF1 ANALOG OUTPUT 1 OFFSET

Minimum source value that correlates to

minimum Analog Output of 4 mA. The source

value is based on the selection in ASRC lower

byte

11 17 AOUTRN1 ANALOG OUTPUT 1 RANGE

Maximum source value that correlates to

maximum Analog Output of 20 mA. The

source value is based on the selection in

ASRC lower byte where

12 18 AOUTOF2 ANALOG OUTPUT 2 OFFSET

Minimum source value that correlates to

minimum Analog Output of 4 mA. The source

value is based on the selection in ASRC upper

byte

13 19 AOUTRN2 ANALOG OUTPUT 2 RANGE

Maximum source value that correlates to

maximum Analog Output of 20 mA. The

READ/WRITE

READ/WRITE

READ/WRITE

READ/WRITE

Page 15 of 23

11/14/2006 Rev. 14

Page 19

BLOCK 0

HEX DEC PARAMETER DESCRIPTION READ/WRITE

source value is based on the selection in

ASRC upper byte where

14 20 SPARE SPARE READ/WRITE

15 21 SPARE SPARE READ/WRITE

16 22 SPARE SPARE READ/WRITE

17 23 TEMPFIL Temperature Input Filter in seconds

Range = 0 to 3276. The higher the number

the faster the reading update.

DEFAULT = 1000

BLOCK 1

HEX DEC PARAMETER DESCRIPTION READ/WRITE

18 24 MVFIL Millivolt Input Filter in seconds

Range = 0 to 3276. The higher the number

the faster the reading update.

DEFAULT = 1000

19 25 AZERO LINEAR OFFSET, Y INTERCEPT LINEAR

SCALING FOR INPUT A

1A 26 ANUM LINEAR SPAN VALUE FOR INPUT A READ/WRITE

1B 27 BZERO LINEAR OFFSET, Y INTERCEPT LINEAR

SCALING FOR INPUT B

1C 14 BNUM LINEAR SPAN VALUE FOR INPUT B READ/WRITE

1D 15 PROC This value is the calculated process value

shown as an integer. The decimal point and

exponent values are required to determine the

actual scaled value.

Range = -999 to 9999.

For example: If the process = oxygen, display

decimal point = 2, and exponent = 6, and

PROC = 1234, then the actual value and

displayed as 12.34 ppm.

1E 16 COLDJCT COLD JUNCTION

Where 1 COUNT = 1°F (°C), RANGE = -99 TO

255°F (°C). Note this parameter is an

unsigned integer.

1F 17 TEMP MEASURED TEMPERATURE

Where temperature is presented in degrees C

or F, based on the C/F setting. Note this

parameter is an unsigned integer of

temperature -2721 = 62815

Range = max / min range of selected

thermocouple.

20 18 MV MEASURED MILLIVOLT

Where this value is scaled in 0.1 mV

increments, i.e. 10001 = 1000.1.

Range = 0 to 2000 mV.

21 19 DACV1 ANALOG OUTPUT 1

0 to 4095 is 4 to 20 mA In dual mode 4mA = -

100, 12mA = 0, 20mA = +100

READ/WRITE

READ/WRITE

READ/WRITE

READ/WRITE

READ ONLY

READ ONLY

READ ONLY

READ ONLY

READ/WRITE

Page 16 of 23

11/14/2006 Rev. 14

Page 20

BLOCK 1

HEX DEC PARAMETER DESCRIPTION READ/WRITE

22 20 DACV2 ANALOG OUTPUT 2

0 to 4095 is 4 to 20 ma In dual mode 4mA = -

100, 12mA = 0, 20mA = +100

23 35 SPARE SPARE

24 36 SPARE SPARE

25 37 SPARE SPARE

26 38 SPARE SPARE

27 39 SPARE SPARE

28 40 SPARE SPARE

29 41 SPARE SPARE

2A 42 SPARE SPARE

2B 43 SPARE SPARE

2C 44 SPARE SPARE

2D 45 SPARE SPARE

2E 46 SPARE SPARE

2F 47 SPARE SPARE

READ/WRITE

Page 17 of 23

11/14/2006 Rev. 14

Page 21

Operational Specifications

Power input 21.6 to 26.4 volts DC / 130mA

Thermocouple input

Thermocouple type Zero ºF Span ºF

B 800 3000

C 32 3000

E 32 1300

J 32 1300

K 32 2300

N 32 2300

NNM 32 2000

R 300 3000

S 300 3000

T 32 700

Bold shows default

Accuracy after linearization +/- 1 deg F

Millivolt input -200 to 2000 millivolts +/- 0.1 millivolt

Input Impedance 25 Megohm

Cold junction compensation +/- 1 deg F

DC outputs (Isolated) 0 to 20mA (650max).

Isolation 1000V DC/AC

Power input to signal inputs

Power input to communications

No Isolation Thermocouple input to Millivolt input, inputs must be differential.

Calculations Percent carbon 0 – 2.55%, no CO compensation

Dewpoint -99°F (-72.8°C) – 212 °F (100°C), no hydrogen

compensation

Percent oxygen. 0 – 20.9% (default)

CAUTION

DO NOT CONNECT ANY AC SOURCE OR LOAD TO

INSTRUMENT CONTACTS

Calibration Setups Millivolt Null

Millivolt Span

Page 18 of 23

11/14/2006 Rev. 14

Page 22

Thermocouple Null

Thermocouple Span

Cold Junction Trim

Communications port RS-485 Half Duplex Only

Protocol Modbus RTU

Baud rates 1200, 2400, 4800, 9600, 19.2K (19.2K default)

Parity None

Address 1 – 254 (Address 1 is default)

Housing

Material Polyamide PA non-reinforced

Inflammability Evaluation Class V0 (UL94)

Temperature Range -40 to 100°C

Dielectric Strength 600 kV/cm (IEC243-1)

Mounting Snaps on to EN 50022 top hat (T) style DIN rail.

Terminals

Wire clamp screw terminals on four position removable terminal blocks.

Wire Size AWG 24 – 12 flexible stranded, removable terminal blocks.

Max. Torque 0.8 Nm

CAUTION: DO NOT CONNECT OR DISCONNECT HOUSING PLUGS

WHILE MODULE IS POWERED OR UNDER LOAD.

Weight 10 oz

Environmental Conditions

Operating Temperature -20 °C to 55 °C (-4 to 130 F)

Storage Temperature -40 °C to 85 °C (-40 to 185 F)

Operating and Storage Humidity

85% max relative humidity,noncondensing, from –20

to 65°C

Certifications and Compliance (PENDING)

Safety EN 61010-1, IEC 1010-1

Safety requirement for electrical equipment for measurement, control, and

laboratory use, Part 1

Electromagnetic Compatibility

Immunity as specified by EN 50082-2

Electrostatic discharge EN 61000-4-2 Level 3: 8 kV air

Electromagnetic RF fields EN 61000-403 Level 3: 10 V/m

80 MHz – 1 GHz

Page 19 of 23

11/14/2006 Rev. 14

Page 23

Fast Transients EN 61000-4-4 Level 4: 2 kV I/O

Level 3: 2 kV power

RF conducted interference EN 61000-4-6 Level 3: 10 V/rms

150 KHz – 80 MHz

Emissions as specified by EN 50081-2

RF Interference EN 55011 Enclosure class A

Power main class A

Note: This instrument is designed for installation inside a grounded metal enclosure.

Always observe anti-static precautions when installing or servicing any electronic device.

Ground your body to discharge any static field before touching the body or terminals of any

electronic device.

This specification can change without notification.

Page 20 of 23

11/14/2006 Rev. 14

Loading...

Loading...