Page 1

®

DVR

Installation, Operation,

and Maintenance Manual

2000E

Main Index

3

Page 2

Page 3

INTRODUCTION

This manual provides information concerning the operation and installation of the DVR2000E, Digital Voltage

Regulator. To accomplish this, the following is provided:

• General Information and Specications

• Human-Machine Interface

• Functional Description

• Installation

• Software for Windows Operating System

• Software for the Palm Operating System Platform

• Maintenance and Troubleshooting

WARNING!

DVR2000E presents an electric shock risk. Terminals and heat sinks are live at potentially lethal

voltages. This high voltage may cause electrical shock that could result in injury or death.

To avoid personal injury or equipment damage, only qualied personnel should perform the

procedures presented in this manual.

CAUTION

Meggers and high potential test equipment should be used with extreme care. Incorrect use of

such equipment could damage components contained in the device.

It is not the intention of this manual to cover all details and variations in equipment, nor does

this manual provide data for every possible contingency regarding installation or operation. The

availability and design of all features and options are subject to modication without notice.

Main Index

3

1

Page 4

S

ection

1

CONTENTS

3

3

Main Index

A table of contents in the front of each section provides detailed information for that section. The sections in this

manual are as follows.

Section 1 General Information ...............................................................................................................3

Section 2 Human-Machine Interface......................................................................................................7

Section 3 Functional Description ......................................................................................................... 17

Section 4 Installation............................................................................................................................ 25

Section 5 Marathon-DVR2000E-32 Software for Windows® OS ..........................................................38

Section 6 Marathon-DVR2000E Software for the Palm OS® Platform .................................................68

Section 7 Maintenance and Troubleshooting .......................................................................................85

2

Page 5

SECTION 1 • GENERAL INFORMATION

TABLE OF CONTENTS

SECTION 1 • GENERAL INFORMATION ....................................................................................................4

GENERAL..............................................................................................................................................4

FEATURES ............................................................................................................................................4

SPECIFICATIONS .................................................................................................................................4

Operating Power..............................................................................................................................5

Generator Voltage Sensing..............................................................................................................5

Generator Current Sensing .............................................................................................................5

Contact Input Circuits ......................................................................................................................5

Common Alarm Output....................................................................................................................5

Field Output .....................................................................................................................................5

AVR Operating Mode.......................................................................................................................5

FCR (Manual) Operating Mode .......................................................................................................5

Var Operating Mode (Optional)........................................................................................................5

PF Operating Mode (Optional) ........................................................................................................5

Parallel Compensation.....................................................................................................................5

Communication Port ........................................................................................................................5

Field Overvoltage Protection ...........................................................................................................5

Field Overcurrent Protection............................................................................................................5

Generator Overvoltage Protection...................................................................................................5

Soft-Start Function ..........................................................................................................................6

Analog (Auxiliary) Input ...................................................................................................................6

Metering...........................................................................................................................................6

Environment ....................................................................................................................................6

Type Tests........................................................................................................................................6

Physical ...........................................................................................................................................6

ection

S

1

Main Index

3

3

Page 6

S

S

ection

1

5

3

Main Index

5

Section 1 Index

ection

1

SECTION 1 • GENERAL INFORMATION

GENERAL

The DVR2000E is an electronic, solid-state, microprocessor-based control device. The DVR2000E regulates the

output voltage of a brushless, ac generator by controlling the current into the generator exciter eld. Input power

to the DVR2000E is from a multi-pole, high-frequency, permanent magnet generator (PMG).

The DVR2000E is supplied in an encapsulated package designed for behind-the-panel mounting. The DVR2000E

is held in place by thread-forming screws that thread into its plastic shell. Front panel indicators (LEDs) annunciate

regulator status and system conditions. DVR2000E connections are made through quarter-inch, quick-connect

terminals on the rear panel. A 9-pin DB-9 type connector on the rear panel provides communication between the

DVR2000E and an IBM compatible PC.

FEATURES

DVR2000E units have the following features and capabilities.

• Four control modes: automatic voltage regulation (AVR), manual or eld current regulation (FCR), power

factor (PF) regulation, and reactive power (Var) regulation.

• Programmable stability settings.

• Soft start control with an adjustable time setting in AVR control mode.

• Overexcitation (OEL) limiting in AVR, Var, and PF control modes.

• Underfrequency (volts/hertz) regulation.

• Crowbar circuitry protects the eld.

• Overtemperature protection.

• Three-phase or single-phase generator voltage (RMS) sensing/regulation in AVR mode.

• Single-phase generator current sensing for metering and regulation purposes.

• Field current and eld voltage sensing.

• Four contact sensing inputs for system interface.

• One common output relay for alarm indication and trip functions.

• Six protection functions (overexcitation shutdown, generator overvoltage shutdown, DVR overtemperature

shutdown, loss of generator sensing shutdown, overexcitation limiting and crowbar shutdown).

• Generator paralleling with reactive droop compensation and reactive differential compensation.

• Front-panel human-machine interface (HMI) indicates system and DVR2000E status and gives the ability to

make setting changes at the front panel.

• Rear RS-232 communication port for personal computer communication using MARATHON-DVR2000E-32

Windows® based software for fast, user-friendly, setup and control.

SPECIFICATIONS

DVR2000E electrical and physical specications are listed in the following paragraphs. The adjustment

increments shown apply to the PC software. Adjustment increments for the Front Panel Controls are listed in

Section 2.

4

Main Index

3

Section 1 Index

5

Page 7

Operating Power

Single-Phase: 180 to 240 Vac

Frequency Range: 200 to 360 Hz

Burden: 350 VA

Terminals: 3, 4

Underfrequency (V/Hz)

Characteristic: Slope from 1 to 3PU is adjustable in

0.01 increments.

Range: 40 to 65 Hz

Increment: 0.01 Hz

Generator Voltage Sensing

Type: 1-phase/3-phase, 4 ranges,

50/60 Hz

Terminals: E1, E2, E3

Burden: <1 VA per phase

Range 1: 120 Vac (100 to 140 Vac)

Range 2: 240 Vac (200 to 280 Vac)

Range 3: 480 Vac (400 to 560 Vac)

Range 4: 600 Vac

Generator Current Sensing

Type: 1-phase (BØ), 50/60 Hz

Rating: 5 Aac maximum continuous

Burden: <0.1 VA

Terminals: CT1, CT2

Contact Input Circuits

Type: Dry Contact

Interrogation Voltage: 13 Vdc

Terminals

Unit/Parallel Control: 52L, 52M

Raise: 6U, 7

Lower: 6D, 7

Var/PF Enable 52J, 52K

Common Alarm Output

Type: Form A

Rated Load: 7 Aac/7 Adc continuous

Make: 30 Aac/30 Adc, carry for 0.2

sec

Break: 7 Aac/0.1 Adc

Operating Voltage: 240 Vac/250 Vdc maximum

Terminals: AL1, AL2

Field Output

Continuous Rating: 75 Vdc, 3.0 Adc

10 Second Forcing Rating

200 Vac Power Input: 150 Vdc, 7.5 Adc

Field Resistance: 18 minimum

Terminals: F+, F-

FCR (Manual) Operating Mode

Adjustment Range: 0 to 3 Adc

Increment: 0.01 A

Var Operating Mode (Optional)

Adjustment Range: 100% to –100%

Increment: 0.1%

PF Operating Mode (Optional)

Adjustment Range: 0.6 lead to 0.6 lag

Increment: 0.001

Parallel Compensation

Modes: Reactive Droop and

Reactive Differential (cross-current)*

Droop

Adjustment Range: 0 to 10%

Increment: 0.01%

*Burden can exceed 1 VA if external resistors are added to

the CT circuit.

Communication Port

Interface: Full Duplex RS-232

Connection: DB-9 connector on rear panel

Baud: 4800

Data Bits: 8

Parity: None

Stop Bit: 1

Field Overvoltage Protection

Pickup: 0 -250 Vdc

Time Delay: 15 seconds (xed)

Field Overcurrent Protection

Pickup

Adjustment Range: 0 to 7.5 Adc

Increment: 0.001 Adc

Time Delay

Adjustment Range: 0 to 10 seconds

Increment: 1 second

ection

S

1

AVR Operating Mode

Adjustment Range: See generator voltage sensing

Voltage Regulation: ±0.25% over load range at rated

power factor and constant generator

frequency.

Temperature Drift: ±0.5% for a 40°C change

Response Time: ≤1 cycle

Main Index

3

Section 1 Index

5

Generator Overvoltage Protection

Pickup

Range: 105 to 120% of setpoint

Increment: 1.0%

Time Delay

Fixed Setting: 0.75 seconds

5

Page 8

S

7

3

Main Index

ection

1

Soft-Start Function

Time Adjust Range: 1 to 120 seconds

Increment: 1 second

Analog (Auxiliary) Input

Voltage Range: -3 Vdc to +3 Vdc

Setpoint Range: -30% to +30% shift

Burden: 1 k

Terminals: A, B

Metering

Accuracy of all metering values assumes 25°C, 50/60 Hz

and less than 20% THD.

Generator Voltage

Range: 10 V to 79 kV

Accuracy: 0.5%

Generator Current

Range: 0.1 to 5,000 A (5 A CTs)

Accuracy: 0.5%

Frequency

Range: 40 to 65 Hz

Accuracy: 0.2 Hz

Field Voltage

Range: 0 to 200 Vdc

Accuracy: 5.0%

Field Current

Range: 0 to 8.0 Adc

Accuracy: 0.5%

Power (Apparent, Real and Reactive)

Range: 0 to 99 MVA, MW and MVar

Accuracy: 3.0%

Power Factor

Range: -1.0 to –0.6, +0.6 to +1.0

Accuracy: 0.02

Environment

Operating Temp.: -40°C to +70°C (-40°F to

+158°F)

Storage Temp.: -40°C to +85°C (-40°F to

+185°F)

Type Tests

Shock: 20 Gs in 3 perpendicular planes

Vibration: 1 G at 5 to 26 Hz

0.036” double amplitude (27 to 52 Hz)

5 Gs at 53 to 500 Hz

Salt Fog: Tested per MIL-STD-810E

Physical

Weight: 1.52 lb. (690 g)

Phase Angle

Range: 0 to 360°

Accuracy: 2.0°

Main Index

3

Section 1 Index

5

6

Page 9

SECTION 2 • HUMAN-MACHINE INTERFACE

TABLE OF CONTENTS

SECTION 2 • HUMAN-MACHINE INTERFACE .................................................................................... 8

GENERAL....................................................................................................................................... 8

FRONT PANEL CONTROLS AND INDICATORS ........................................................................... 8

INITIAL ADJUSTMENTS ................................................................................................................ 9

MAKING SETTINGS CHANGES .................................................................................................. 10

Front Panel Operation............................................................................................................. 10

Setting Level Indication........................................................................................................... 11

COMMUNICATION PORT ............................................................................................................ 16

Figures

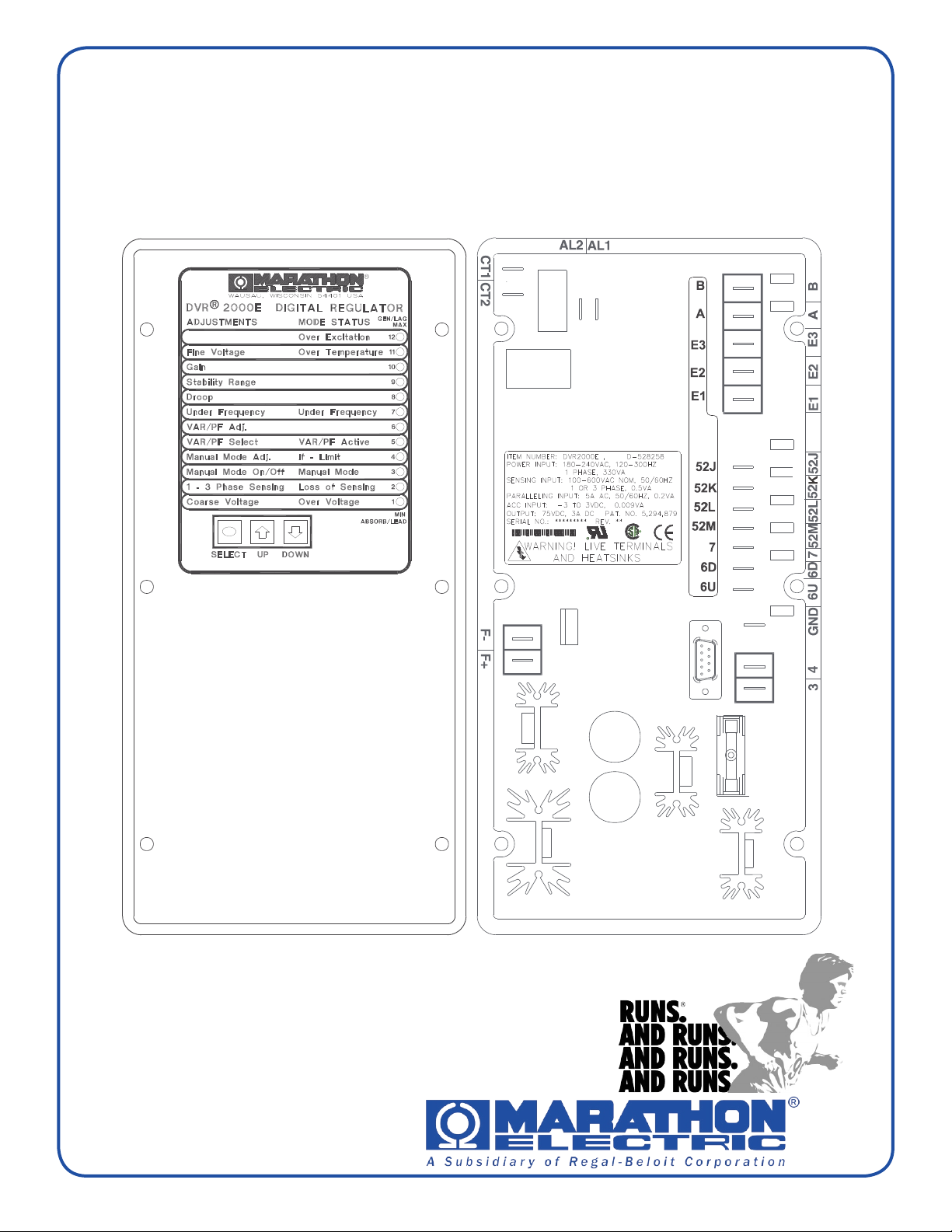

Figure 2-1. DVR2000E Front Panel Indicators....................................................................................... 8

Figure 2-2. DVR2000E Communication Port Location ........................................................................ 16

Tables

Table 2-1. DVR2000E Front Panel Control Descriptions........................................................................ 8

Table 2-2. DVR2000E Front Panel Mode Status Indicator Descriptions ................................................ 9

Table 2-3. DVR2000E Front Panel Adjustment Indicator Descriptions ................................................ 10

Table 2-4. Coarse Voltage Adjust Setting Ranges ............................................................................... 11

Table 2-5. Sensing Mode (Single-phase/Three-phase) Select ............................................................ 11

Table 2-6. Manual Mode (On/Off) Select ............................................................................................. 12

Table 2-7. Manual Mode (If – Limit) Adjustment Ranges..................................................................... 12

Table 2-8. On-Line Operating Mode (AVR (OFF) / VAR / PF) Select ................................................... 12

Table 2-9. VAR Control Adjustment Ranges ........................................................................................ 13

Table 2-10. Power Factor Control Adjustment Ranges ........................................................................ 13

Table 2-11. Underfrequency Adjustment Ranges................................................................................ 14

Table 2-12. Droop Adjustment Ranges................................................................................................ 14

Table 2-13. Stability Range Selection Settings.................................................................................... 15

Table 2-14. Gain Adjustment Ranges.................................................................................................. 15

Table 2-15. Fine Voltage Adjust Setting Ranges.................................................................................. 15

ection

S

2

Main Index

3

7

Page 10

S

ection

2

SECTION 2 • HUMAN-MACHINE INTERFACE

9

3

Main Index

5

Section 2 Index

GENERAL

The DVR2000E human-machine interface (HMI) consists of front panel controls and indicators and a rear panel

communication port.

FRONT PANEL CONTROLS AND INDICATORS

S

ection

2

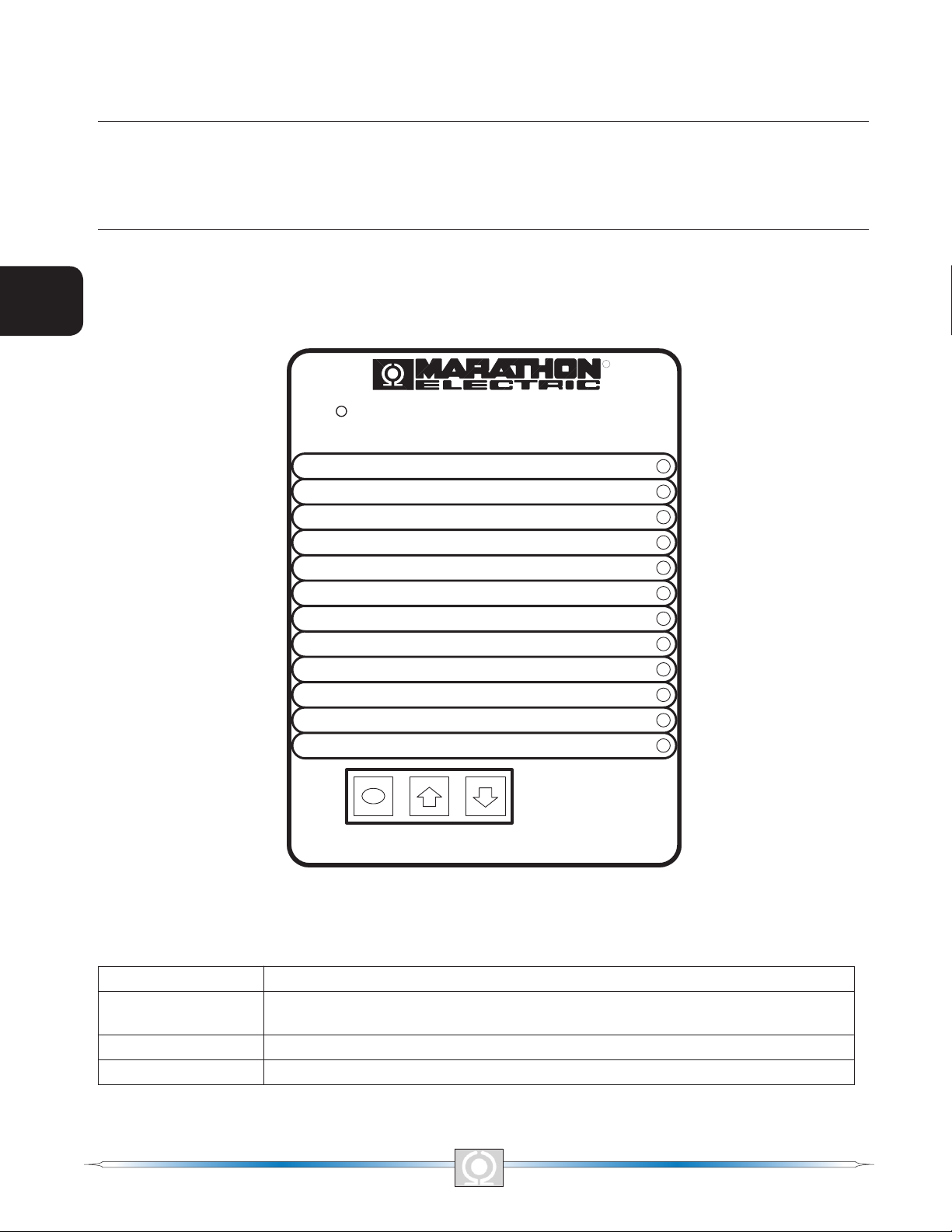

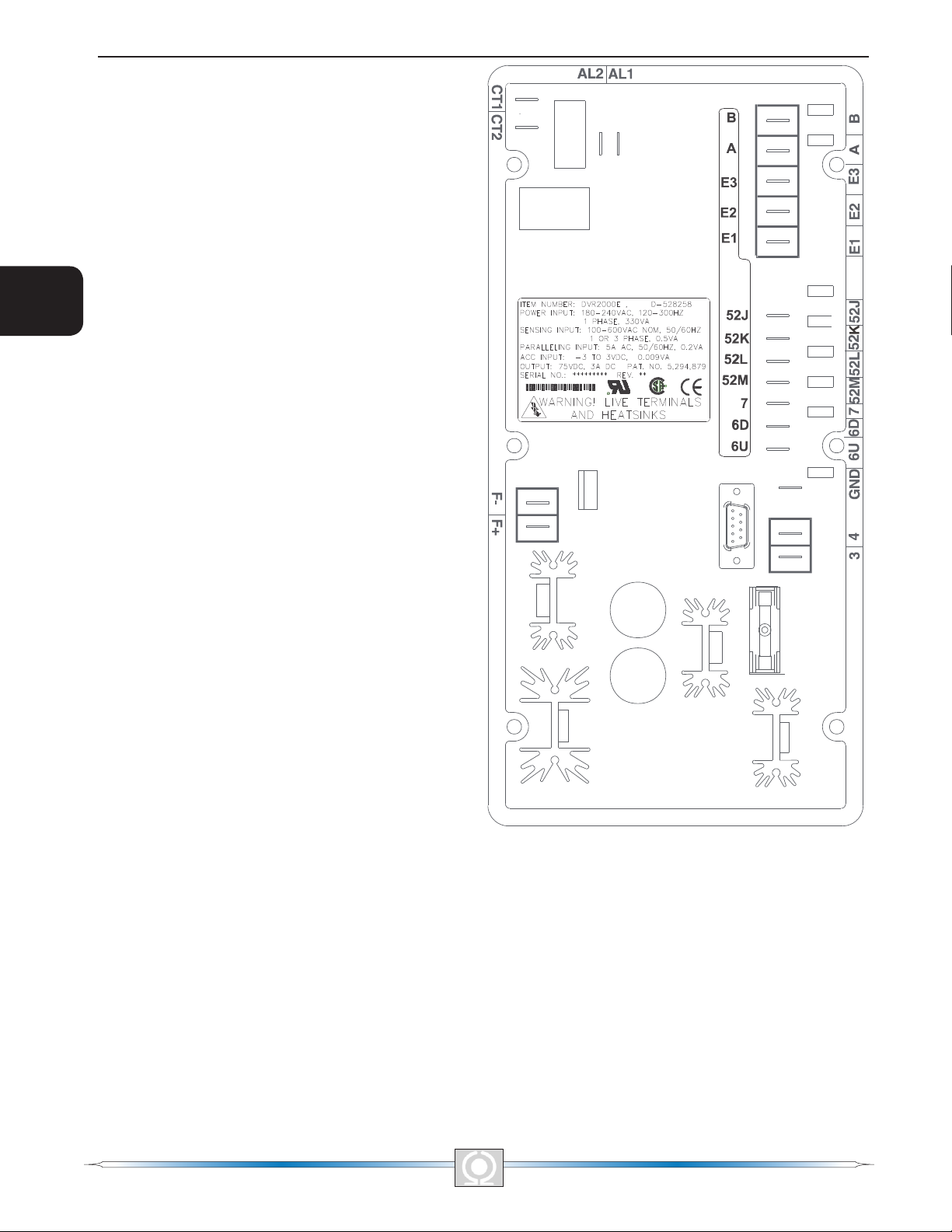

DVR2000E front panel controls and indicators consist of 12 red LEDs and three pushbuttons. Figure 2-1 illustrates

the front panel controls and indicators of the DVR2000E. The LEDs indicate control mode and status conditions

and are also used when adjusting settings at the front panel.

Figure 2-1. DRV2000E Front Panel Indicators

Main Index

3

Control Description

SELECT

DOWN This pushbutton decreases the setting level of the function being adjusted.

UP This pushbutton increases the setting level of the function being adjusted.

5

Table 2-1. DVR2000E Front Panel Control Descriptions

This pushbutton selects a function for adjustment. Successive presses of the

SELECT pushbutton scrolls through the list of DVR2000E functions to be adjusted.

Section 2 Index

8

Page 11

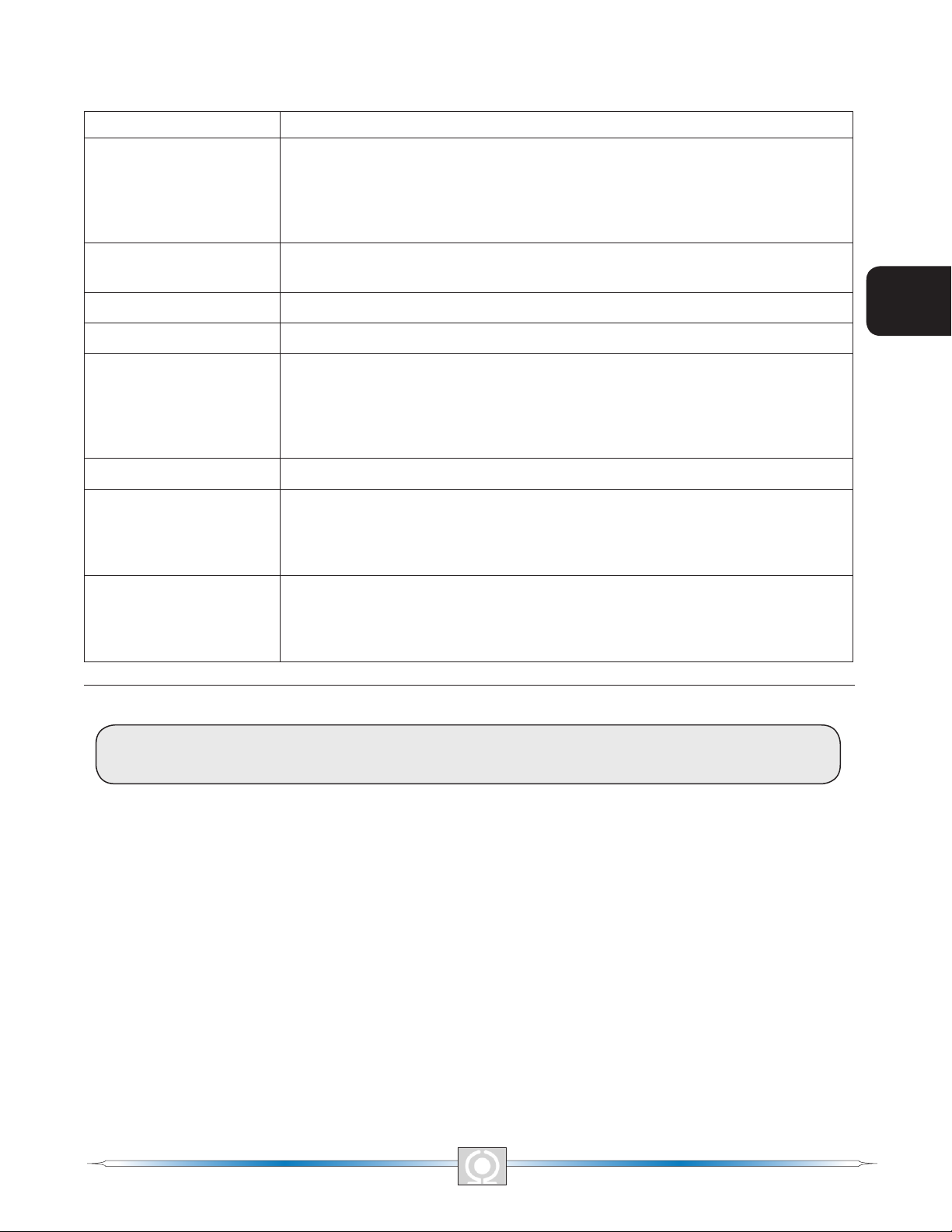

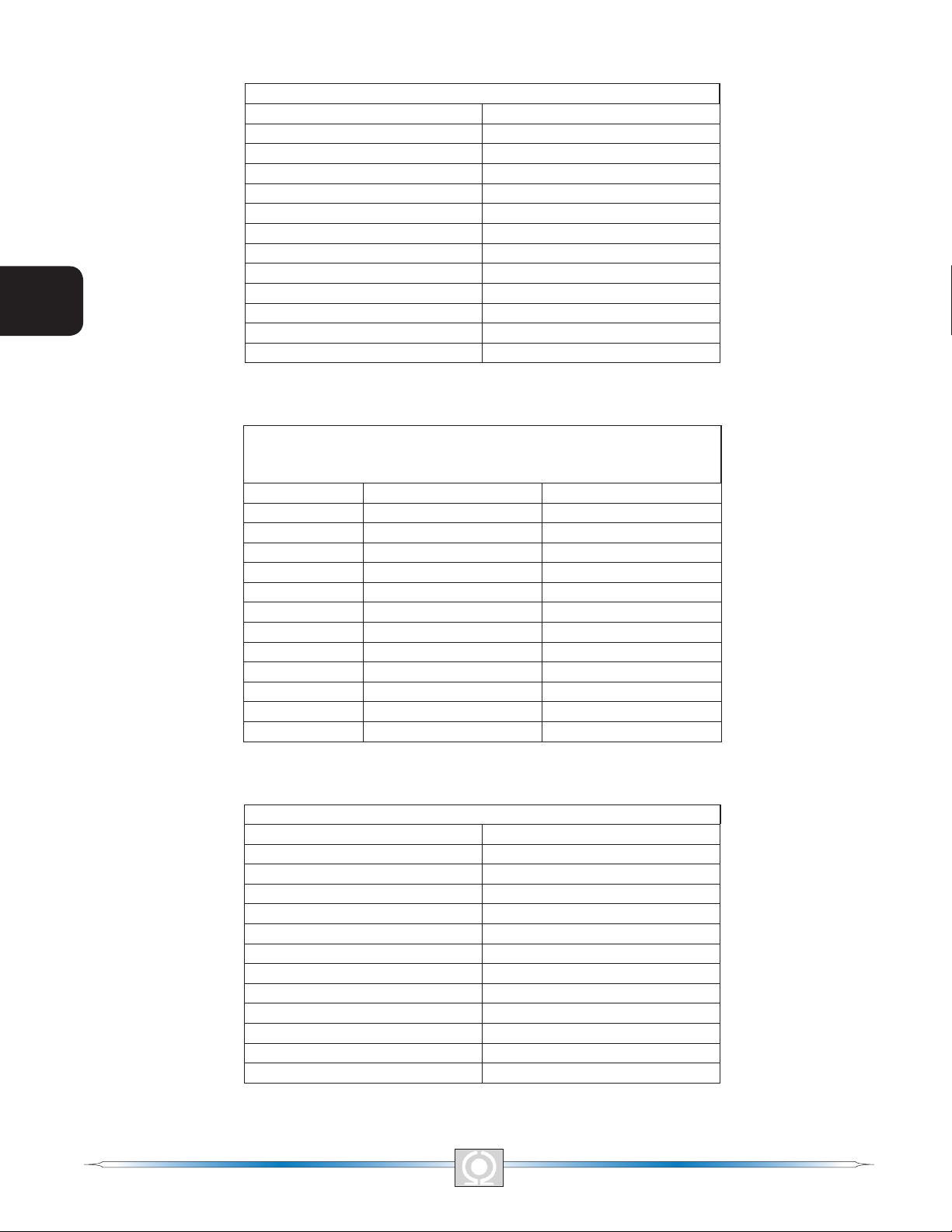

Table 2-2. DVR2000E Front Panel Mode Status Indicator Descriptions

Indicator Description

Over Excitation LED #12

This LED blinks rapidly when the Overexcitation Protection feature is enabled

and the eld voltage exceeds the setpoint (80 V default) for 15 seconds. The

DVR2000E will shut down when an overexcitation condition is detected. The Over

Excitation LED blinks for 5 seconds when the DVR2000E is powered up following

an overexcitation condition.

Over Temperature LED

#11

Under Frequency LED #7 This LED blinks rapidly during an under frequency condition.

Var/PF Active LED #5 This LED blinks rapidly when operating in Var or Power Factor mode.

If – Limit LED #4

Manual Mode LED #3 This LED blinks rapidly when operating in Manual mode.

Loss of Sensing LED #2

Over Voltage LED #1

This LED blinks rapidly when the internal temperature of the DVR2000E has

exceeded its limit and causes the unit to shut down.

This LED blinks rapidly when the eld current exceeds the programmed

overexcitation limit. It will continue to ash until the overexcitation condition

ceases or the overexcitation time delay expires and the DVR2000E shuts down.

The Overexcitation Limiting LED ashes for 5 seconds when the DVR2000E is

powered up following an overexcitation limiting condition.

This LED blinks rapidly when a loss of generator sensing voltage is detected.

The DVR2000E will shut down. The Loss of (Generator) Sensing LED ashes

for 5 seconds when the DVR2000E is powered up following shutdown for loss of

generator sensing condition.

This LED blinks rapidly when the generator output voltage exceeds the setpoint

for 0.75 seconds. The DVR2000E will shut down when a generator overvoltage

condition is detected. The (Generator) Overvoltage LED ashes for 5 seconds

when the DVR2000E is powered up following a generator overvoltage condition.

INITIAL ADJUSTMENTS

ection

S

2

CAUTION

Read and understand the operation of the individual adjustments before attempting any initial adjustments.

Before starting the generator, the procedures in the following paragraphs should be performed.

Remove the 5 ampere fuse before starting the generator for the rst time. Perform all preliminary engine governor

adjustments without the regulator energized.

After initial governor adjustments are complete, reinstall the 5 ampere fuse and connect only the power input

leads or PMG leads to the regulator. Remove all other regulator connections that may be present and temporarily

insulate them.

Start and run the generator at rated speed. The regulator will perform the self-test and enter a shutdown mode. At

this time, initial adjustments can be made. To do this, step through each adjustment using the “SELECT” button.

For each adjustment, press the “UP” or “DOWN” button to obtain the desired level on the LED bar graph.

After the initial adjustments are made, shut down the generator and connect the remaining regulator leads. The

generator may be started and nal adjustments may be performed on the regulator.

9

Main Index

3

Section 2 Index

5

Page 12

S

S

ection

2

11

3

Main Index

5

Section 2 Index

ection

2

MAKING SETTINGS CHANGES

The following paragraphs describe how the HMI is used to make setting changes.

Front Panel Operation

The LEDs indicate control mode and status conditions and are also used when adjusting settings at the front

panel. Repeatedly pressing the “SELECT” button steps through the various adjustments, starting with the “Course

Voltage” adjustment and progressing through to the “Fine Voltage” adjustment. The next press of the “SELECT”

button exits the adjustment mode.

When in the adjustment mode, only the adjustment LEDs will be lit. All mode status LEDs will be turned off.

Adjustment LEDs are of two types. The rst type is the LED that indicates the function being adjusted. This LED

blinks slowly (approximately once per second). The second type is the LED that indicates the level of adjustment.

This LED is on steady. The level of adjustment is changed by pressing the “UP” or “DOWN” button. When an

adjustment level LED (on steady) overlaps the function LED (slow blinking), the LED will remain in the slow

blinking mode. If no button is pressed for a period of one minute, the regulator saves the settings and exits the

adjustment mode. If regulator power is interrupted before the automatic save feature is commanded, that level of

adjustment will be lost.

When the regulator is not in the adjustment mode and either the “UP” or “DOWN” button is pressed, the regulator

enters the “Fine Voltage” adjustment mode and changes the generator ne voltage set point by 0.1V. Successive

presses of the “UP” or “DOWN” button shall continue to adjust the ne voltage setting. Pressing the “SELECT”

button causes the regulator to exit the adjustment mode. Mode status LEDs blink approximately twice per

second.

Table 2-3. DVR2000E Front Panel Adjustment Indicator Descriptions

Indicator Description

Fine Voltage

LED #11

Gain

LED #10

Stability Range

LED #9

Droop

LED #8

Under Frequency

LED #7

VAR/PF Adjust

LED #6

VAR/PF Select

LED #5

Manual Mode Adj.

LED #4

Manual Mode On/

Off LED #3

This LED blinks slowly when the “Fine Voltage” level is selected for adjustment via the

front panel push buttons.

This LED blinks slowly when the “Gain” adjustment is selected for ne tuning of loop gain

via the front panel push buttons.

This LED blinks slowly when selecting the desired “Stability Range” via the front panel

push buttons.

This LED blinks slowly when the “Droop” percentage level is selected for adjustment via

the front panel push buttons.

This LED blinks slowly when the “Under Frequency” knee point is selected for adjustment

via the front panel push buttons.

This LED blinks slowly when the level of the programmed mode (VAR or Power Factor) is

selected for adjustment via the front panel push buttons (DVR2000EC only).

This LED blinks slowly when selecting the programmed mode (VAR, Power Factor, or

none(AVR)) via the front panel push buttons. When in this adjustment mode, LED #1 is

on solid for none(AVR), LED #2 is on solid for Power Factor mode, and LED #3 is on solid

for VAR mode (DVR2000EC only).

This LED blinks slowly when the “Manual Mode” (eld current) regulation set point is

selected for adjustment via the front panel push buttons.

This LED blinks slowly when selecting or deselecting “Manual Mode” (eld current

regulation) as the active operating mode via the front panel pushbuttons. When in this

adjustment mode, LED #1 is on if Manual Mode is off, LED #2 is on if Manual Mode is

on.

Main Index

3

Section 2 Index

5

10

Page 13

1 - 3 Phase

Sensing

LED #2

This LED blinks slowly when selecting single or three phase sensing via the front panel

push buttons. When in this adjustment mode, LED #1 is on if single phase sensing is

selected, LED #3 is on if three phase sensing is selected.

Coarse Voltage

LED #1

Setting Level Indication

Indication of a setting level is provided by the 12 front panel LED indicators. The upper limit of a setting range is

represented by the top LED which is labeled GEN/LAG and MAX. The lower limit of a setting range is represented

by the bottom LED which is labeled MIN and ABSORB/LEAD. The setting range for each LED is summarized in

Tables 2-4 through 2-15. LEDs in the tables are numbered from 1 to 12 with 1 being the lowermost LED (labeled

MIN/ABSORB/LEAD) and 12 being the uppermost LED (labeled GEN /LAG/MAX.

This LED blinks slowly when the “Coarse Voltage” level is selected for adjustment via the

front panel push buttons.

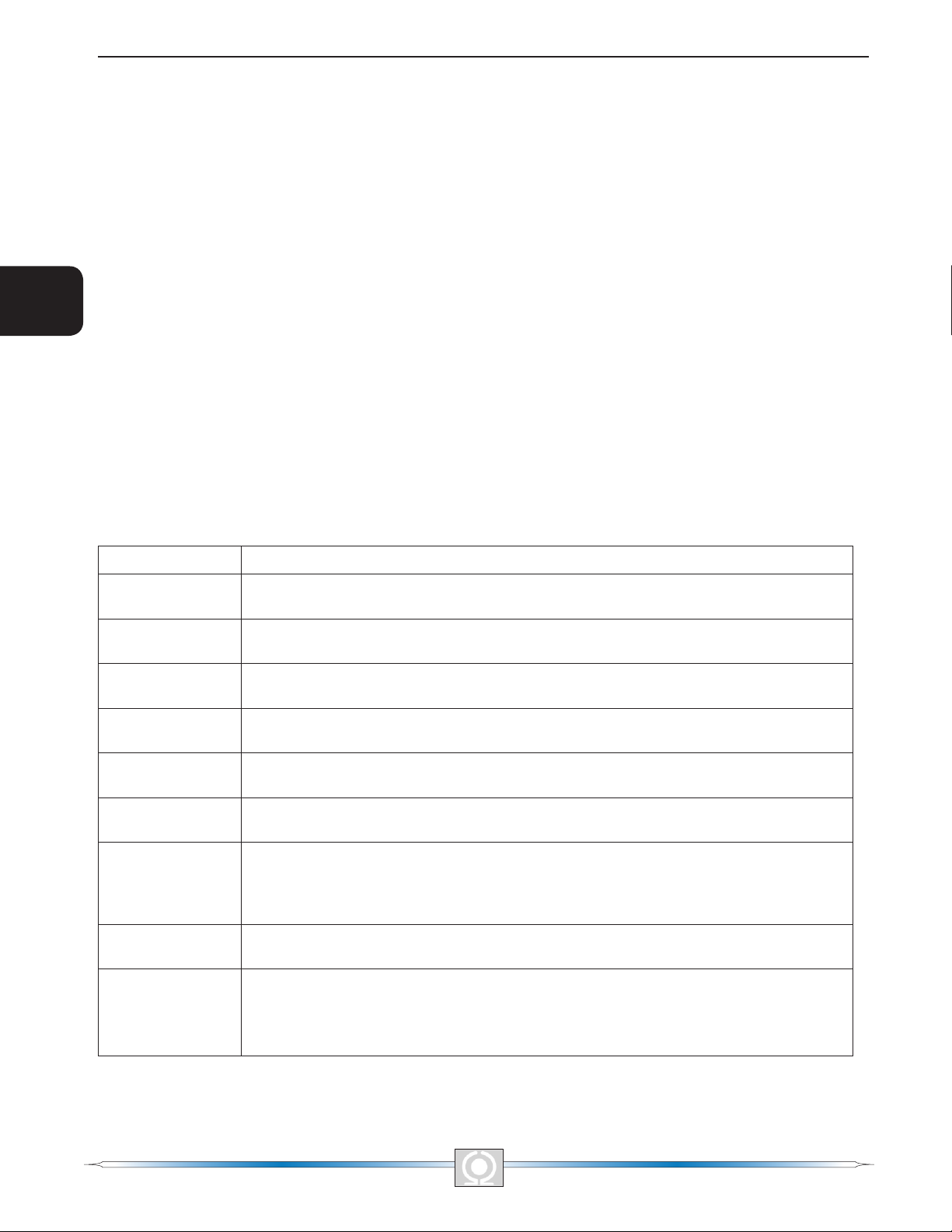

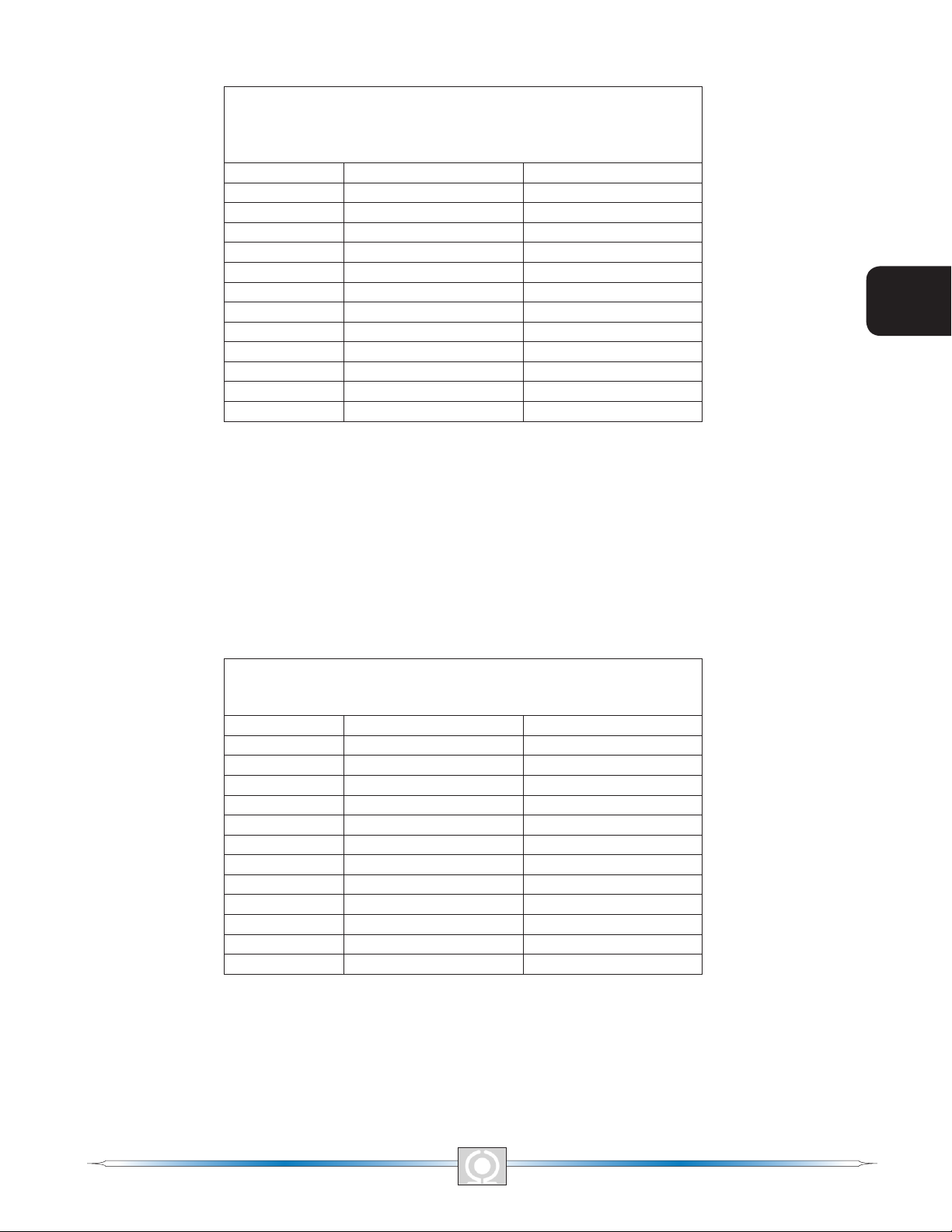

Table 2-4. Coarse Voltage Adjust Setting Ranges

Coarse Voltage – LED 1 Blinking Slowly

Maximum Adjustment Range

Increment: 6 Vac

Increase Decrease

Minimum

LED

12 563 600 558 600

11 521 557 516 552

10 479 515 474 510

9 437 473 432 468

8 395 431 390 426

7 353 389 348 384

6 311 347 306 342

5 269 305 264 300

4 227 263 222 258

3 185 221 180 216

2 143 179 138 174

1 95 137 95 132

Value

Maximum

Value

Minimum

Value

Maximum

Value

ection

S

2

Main Index

3

Table 2-5. Sensing Mode (Single-phase/Three-phase) Select

Single-phase/Three-phase select – LED #2 Blinking Slowly

LED MODE

12 N/A

11 N/A

10 N/A

9 N/A

8 N/A

7 N/A

6 N/A

5 N/A

4 N/A

3 Three-phase

2 N/A

1 Single-phase

11

Section 2 Index

5

Page 14

S

S

ection

2

13

3

Main Index

5

Section 2 Index

ection

2

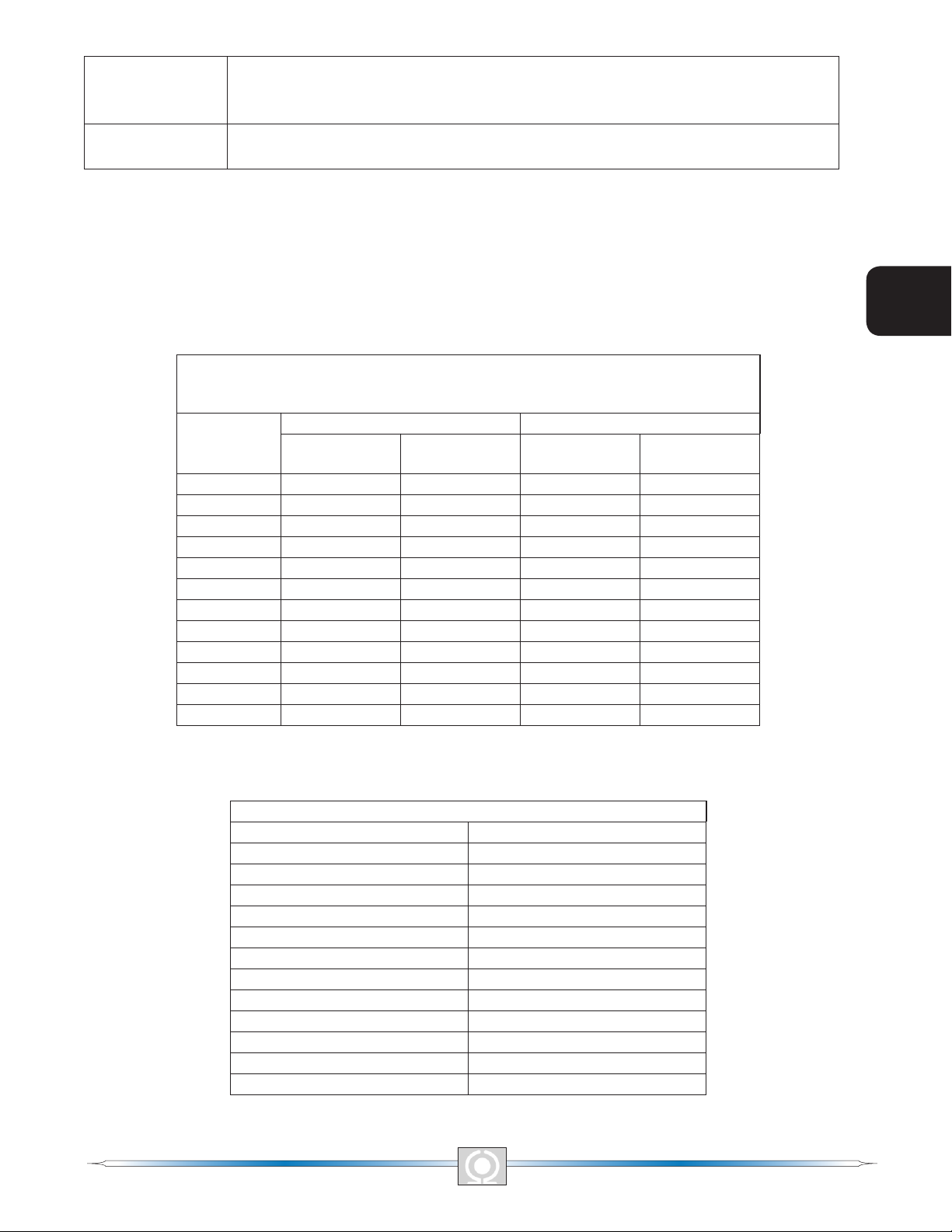

Table 2-6. Manual Mode (On/Off) Select

Manual Mode On/Off – LED 3 Blinking Slowly

LED MODE

12 N/A

11 N/A

10 N/A

9 N/A

8 N/A

7 N/A

6 N/A

5 N/A

4 N/A

3 N/A

2 ON

1 OFF

Table 2-7. Manual Mode (If – Limit) Adjustment Ranges

Manual Mode Adjust – LED 4 Blinking Slowly

Adjustment Range: 0 to 3 Adc

Increment: 0.01 Adc

LED Minimum Value Maximum Value

12 2.75 3

11 2.50 2.74

10 2.25 2.49

9 2.00 2.24

8 1.75 1.99

7 1.50 1.74

6 1.25 1.49

5 1.00 1.24

4 0.75 0.99

3 0.50 0.74

2 0.25 0.49

1 0 0.24

Main Index

3

Table 2-8. On-Line Operating Mode (AVR (OFF)/VAR/PF) Select *

AVR (OFF) / VAR / PF Select – LED #5 Blinking Slowly

LED MODE

12 N/A

11 N/A

10 N/A

9 N/A

8 N/A

7 N/A

6 N/A

5 N/A

4 N/A

3 Var

2 PF

1 AVR

* Var/PF control is available only on DVR2000EC.

12

Section 2 Index

5

Page 15

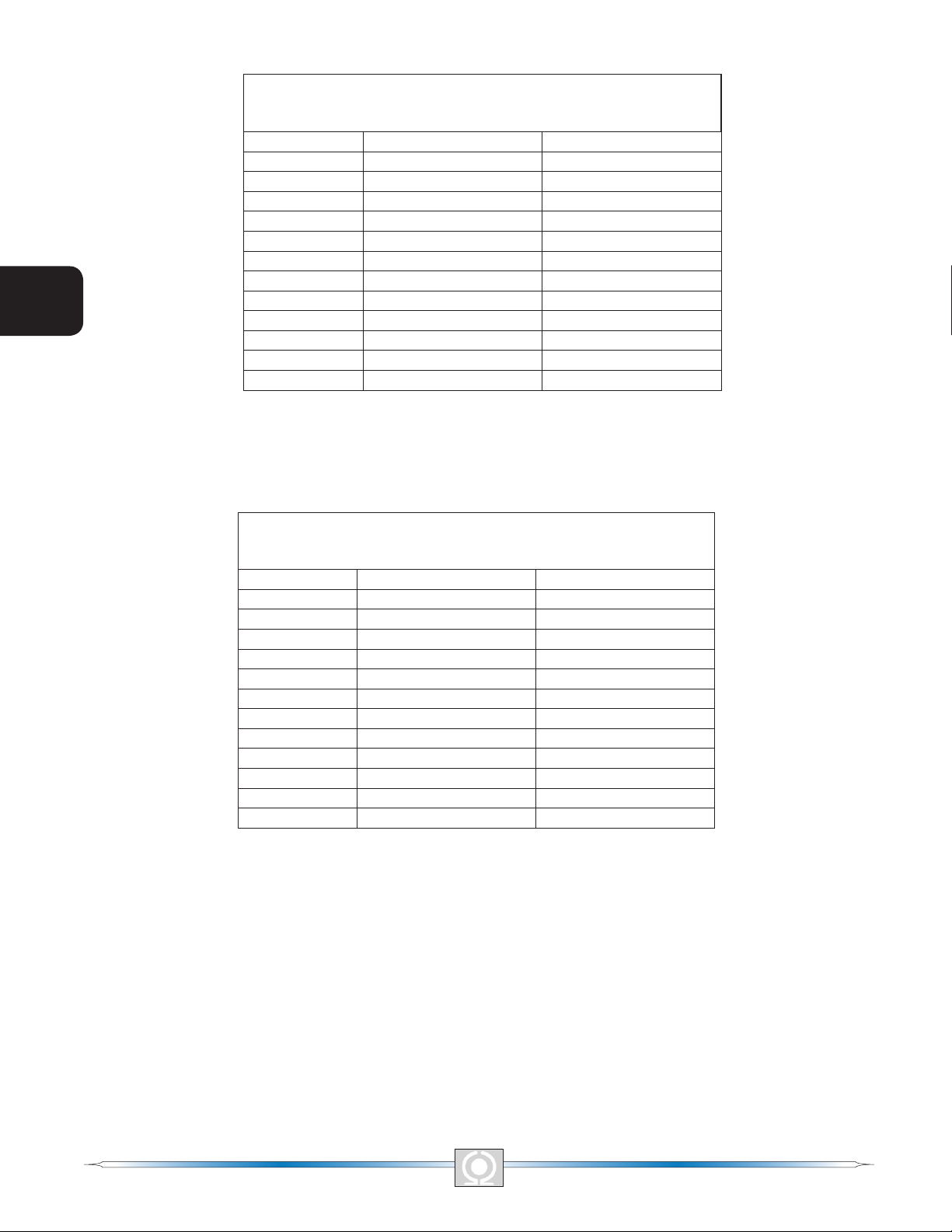

Table 2-9. VAR Control Adjustment Ranges *

VAR Control Adjust – LED 6 Blinking Slowly

Maximum Adjustment Range: −100% (absorb) to +100%

(generate)

Increment: 1.0%

LED Minimum Value † Maximum Value †

12 84 100

11 67 83

10 51 66

9 34 50

8 17 33

7 1 16

6 -16 0

5 -33 -17

4 -49 -34

3 -66 -50

2 -83 -67

1 -100 -84

* Var/PF control is available only on DVR2000EC.

† Minimum and maximum values may differ from the Table 2-9 values if

the value has been changed in MARATHON-DVR2000E-32 software.

MARATHON-DVR2000E-32 software has 0.5 percent resolution compared

to the 1.0 percent resolution of the HMI.

ection

S

2

Table 2-10. Power Factor Control Adjustment Ranges *

Power Factor Control Adjust – LED 6 Blinking Slowly

Maximum Adjustment Range: +0.6 (lag) to –0.6 (lead)

Increment: 0.01

LED Minimum Value † Maximum Value †

12 0.66 0.60

11 0.73 0.67

10 0.80 0.74

9 0.86 0.81

8 0.93 0.87

7 1.0 0.94

6 -0.94 -0.99

5 -0.87 -0.93

4 -0.80 -0.86

3 -0.74 -0.79

2 -0.67 -0.73

1 -0.60 -0.66

* Var/PF control is available only on DVR2000EC.

† Minimum and maximum values may differ from the Table 2-10 values if

the value has been changed in MARATHON-DVR2000E-32 software.

MARATHON-DVR2000E-32 software has 0.001 resolution compared to

the 0.01 resolution of the HMI.

Main Index

3

Section 2 Index

5

13

Page 16

S

S

ection

2

15

3

Main Index

5

Section 2 Index

ection

2

Table 2-11. Underfrequency Adjustment Ranges

Underfrequency Adjust – LED 7 Blinking Slowly

Maximum Adjustment Range: 40 to 65 Hz

Increment: 0.1 Hz

LED Minimum Value Maximum Value

12 63.0 65.0

11 60.9 62.9

10 58.8 60.8

9 56.7 58.7

8 54.6 56.6

7 52.5 54.5

6 50.5 52.4

5 48.4 50.4

4 46.3 48.3

3 44.2 46.2

2 42.1 44.1

1 40.0 42.0

Table 2-12. Droop Adjustment Ranges

Droop Adjust – LED 8 Blinking Slowly

Adjustment Range: 0 to 10%

Increment: 0.25%

LED Minimum Value * Maximum Value *

12 9.25 10.00

11 8.5 9.00

10 7.75 8.25

9 6.75 7.50

8 6.00 6.50

7 5.25 5.75

6 4.25 5.00

5 3.5 4.00

4 2.75 3.25

3 1.75 2.5

2 1 1.5

1 0 0.75

* Minimum and maximum values may differ from the Table 2-12 values if

the value has been changed in MARATHON-DVR2000E-32 software.

MARATHON-DVR2000E-32 software has 0.01% resolution compared to

the 0.25 percent resolution of the HMI.

Main Index

3

Section 2 Index

5

14

Page 17

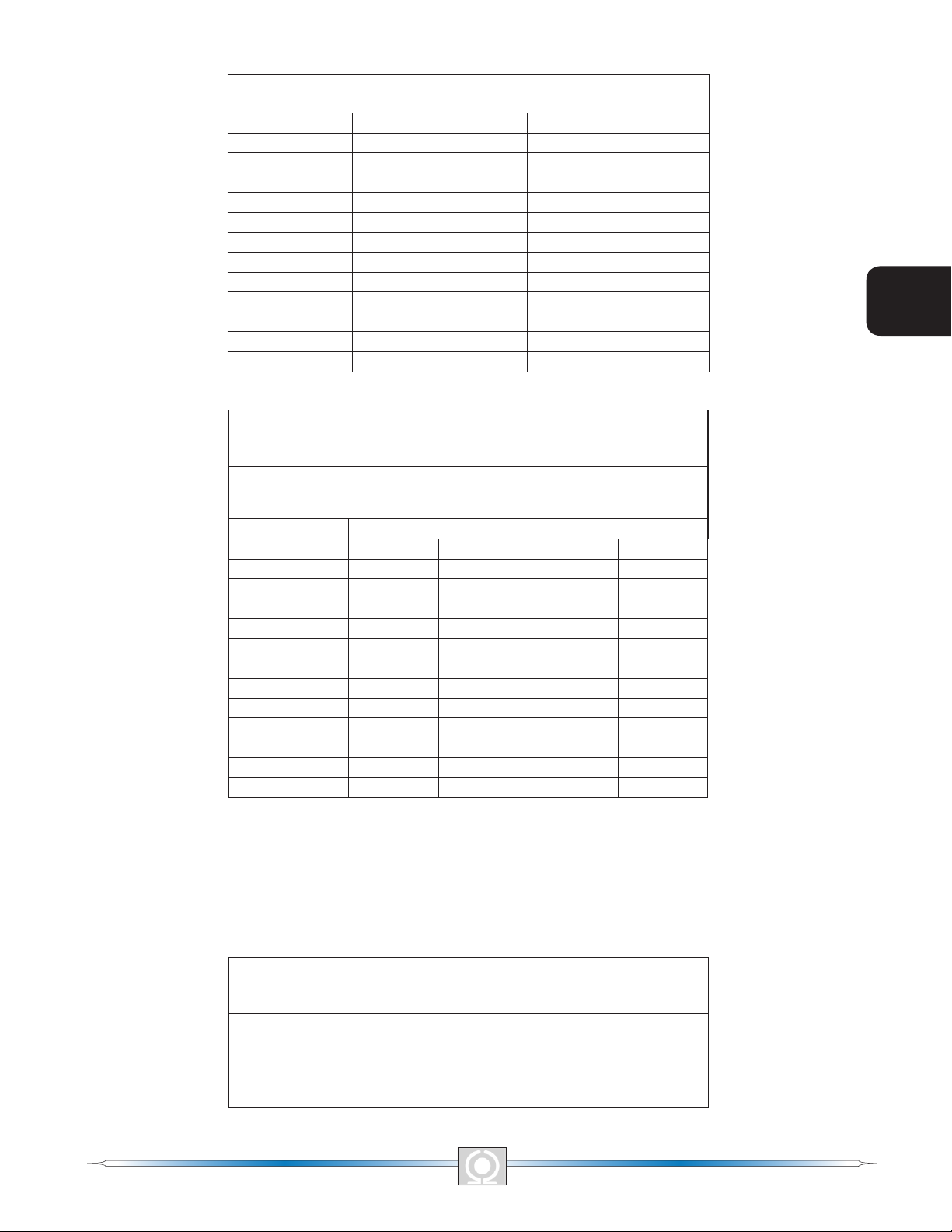

Table 2-13. Stability Range Selection Settings

Stability Range Select – LED 9 Blinking Slowly

Adjustment Range per LED: 1

Frame/Poles LED Range Selected

12 N/A

11 N/A

10 N/A

9 N/A

Programmable 8 21

1,000/6 7 7

740/6 6 6

1,000/4 5 5

740/4 4 4

570/4 3 3

430/4 2 2

360/4 1 1

Table 2-14. Gain Adjustment Ranges

Gain Adjust – LED 10 Blinking Slowly

Maximum Adjustment Range:

0.5 to 4.5 kg for AVR and 0 to 100 kg for FCR

When the unit is operating in AVR, PF, and var modes, gain adjustments are

made to AVR kg. When in FCR mode, gain adjustments are made to FCR

kg. Front Panel increments: AVR kg = 0.01 FCR kg = 0.1

Minimum Value * Maximum Value *

LED

12 4.17 11.1 4.50 12

11 3.84 10.1 4.16 11

10 3.50 9.1 3.83 10

9 3.17 8.1 3.49 9

8 2.84 7.1 3.16 8

7 2.50 6.1 2.83 7

6 2.17 5.1 2.49 6

5 1.84 4.1 2.16 5

4 1.50 3.1 1.83 4

3 1.17 2.1 1.49 3

2 0.85 1.1 1.16 2

1 0.5 0 0.84 1

* Minimum and maximum values may differ from the Table 2-14 values if the gain value has been changed in

MARATHON-DVR2000E-32 software.

AVR FCR AVR FCR †

† MARATHON-DVR2000E-32 software allows a maximum FCR kg setting of 1,000 kg. A kg setting of 12 or

more entered in MARATHON-DVR2000E-32 software will be reduced to 12 with the rst push of the HMI

“DOWN” pushbutton when adjusting FCR kg via the front panel.

ection

S

2

Main Index

3

Table 2-15. Fine Voltage Adjust Setting Ranges

Fine Voltage Adjust – LED #11 Blinking Slowly

Maximum Adjustment Range: -15% to +15%

Increment: 0.1V

The adjustment range for Fine Voltage Adjust is based on the ne

voltage adjustment band setting. The default adjustment range is

–10% to +10%. See Section 5, MARATHON-DVR2000E-32

Software for Windows® OS, Setting Denitions, Setting Adjustments

for information about the Fine Voltage Adjustment Band Setting.

15

Section 2 Index

5

Page 18

S

17

3

Main Index

ection

2

COMMUNICATION PORT

A communication port is located on the rear panel

and consists of a female RS-232 (DB-9) connector.

The communication port serves as an interface for

programming (setup) of the DVR2000E. Figure 2-2

illustrates the location of the communication port.

Programming requires a standard 9-pin serial

communication cable connected between the

DVR2000E and an IBM-compatible PC or handheld

computer operating with MARATHON-DVR2000E-32

software. MARATHON-DVR2000E-32 is a Windows®

98/NT based communication software package that is

supplied with the DVR2000E. A detailed description

of MARATHON-DVR2000E-32 software is provided in

Section 5, MARATHON-DVR2000E-32 Software.

Main Index

3

Section 2 Index

5

Figure 2-2. DVR2000E Communication Port Location

16

Page 19

SECTION 3 • FUNCTIONAL DESCRIPTION

TABLE OF CONTENTS

SECTION 3 • FUNCTIONAL DESCRIPTION ............................................................................................18

INTRODUCTION..................................................................................................................................18

DVR2000E FUNCTION BLOCKS ........................................................................................................18

Analog Inputs.................................................................................................................................18

Generator Voltage ...............................................................................................................................19

Phase B Line Current.......................................................................................................................... 19

Field Voltage (VFIELD)........................................................................................................................... 19

Field Current (IFIELD) ............................................................................................................................19

Analog (Auxiliary) Input .......................................................................................................................19

Contact Input Circuits ....................................................................................................................19

Raise ...................................................................................................................................................20

Lower...................................................................................................................................................20

Var/Power Factor Control (52J/K) Option ............................................................................................20

Parallel Generator Compensation (52L/M)..........................................................................................20

Communication Port ...................................................................................................................... 20

Microprocessor .............................................................................................................................. 20

Power Input Stage .........................................................................................................................20

Power Supply................................................................................................................................. 20

Power Amplier Stage ...................................................................................................................20

Front Panel Indicators.................................................................................................................... 20

Front Panel Switches..................................................................................................................... 21

Relay Output..................................................................................................................................21

DVR2000E OPERATING FEATURES..................................................................................................21

Operating Modes ........................................................................................................................... 21

Automatic Voltage Regulation Mode....................................................................................................21

Manual Mode.......................................................................................................................................21

Var Control Mode (Optional)................................................................................................................ 21

Power Factor Control Mode (Optional)................................................................................................ 21

Reactive Droop Compensation......................................................................................................22

Underfrequency ............................................................................................................................. 22

Generator Underfrequency..................................................................................................................22

Engine Unloading................................................................................................................................ 22

Protection ......................................................................................................................................22

Overexcitation Shutdown (Field Voltage).............................................................................................23

Generator Overvoltage Shutdown....................................................................................................... 23

DVR Overtemperature Shutdown........................................................................................................ 23

Loss of Generator Sensing Shutdown.................................................................................................23

Overexcitation Limiting (Field Current)................................................................................................23

Crowbar Shutdown.............................................................................................................................. 24

Generator Soft Start ......................................................................................................................24

ection

S

3

Figures

Figure 3-1. Simplied Block Diagram .........................................................................................................18

17

Main Index

3

Page 20

S

ection

3

SECTION 3 • FUNCTIONAL DESCRIPTION

19

3

Main Index

5

Section 3 Index

INTRODUCTION

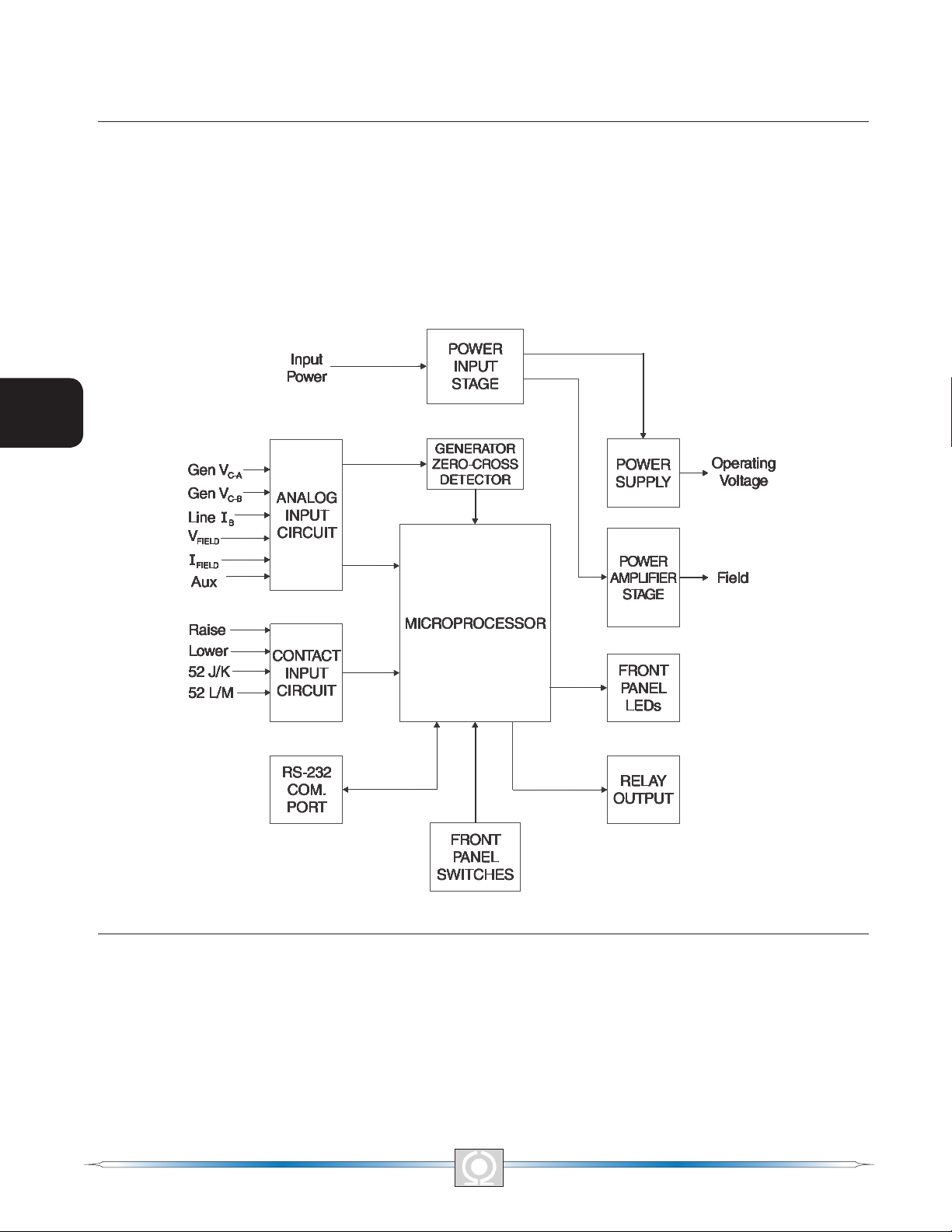

This section describes how the DVR2000E functions and explains its operating features. To ease understanding,

DVR2000E functions are illustrated in the block diagram of Figure 3-1. A detailed description of each function

block is provided in the paragraphs under the heading of DVR2000E Function Blocks.

DVR2000E operating features include four operating modes, four protective functions, startup provisions, reactive

droop compensation, underfrequency compensation, and an auxiliary analog input. A detailed description of each

operating feature is provided in the paragraphs under the heading of DVR2000E Operating Features.

S

ection

3

Figure 3-1. Simplied Block Diagram

DVR2000E FUNCTION BLOCKS

The following paragraphs describe each of the function blocks illustrated in Figure 3-1. The function of each block

is explained along with the operation of all function block inputs and outputs.

Analog Inputs

Six analog voltage and current inputs may be sensed and brought to the DVR2000E input.

18

Main Index

3

Section 3 Index

5

Page 21

Generator Voltage

Generator voltage is monitored at terminals E1 (A-phase), E2 (B-phase), and E3 (C-phase). Nominal voltages of

up to 600Vac may be sensed at these terminals. Voltage applied to these inputs is scaled and conditioned before

being applied to the input of the ADC. The voltage signal from phase C and A (V

the ADC to calculate the rms value of generator voltage across phases C and A. Likewise, the voltage signal from

phase C and B (V

phases C and B. The rms value of generator phase B to phase A voltage (V

from the phase C to phase A signal (V

Additionally, the generator phase C to phase A (V

signal is applied to the microprocessor and is used to calculate generator frequency.

Phase B Line Current

The phase B line current (IB) signal is developed through a customer supplied current transformer (CT) and

monitored through terminals CT1 and CT2. Current up to 5 amperes rms may be monitored at these terminals.

The current monitored at these terminals is scaled and conditioned by an internal current transformer and active

circuitry for use by the ADC. The signal applied to the ADC is used to calculate the rms value of phase B line

current.

Additionally, the phase angle between phase B line current and phase C to phase A generator voltage is calculated

for use during Droop and Var/Power Factor operation.

) of the generator is used by the ADC to calculate the rms value of generator voltage across

C-B

)and the phase C to phase B (V

C-A

) signal is applied to a ltered zero cross detector circuit. This

C-A

) is calculated by the microprocessor

B-A

) signal.

C-B

) of the generator is used by

C-A

ection

S

3

CAUTION

The DVR2000E CT connections are reversed from the DVR2000.

Field Voltage (VFIELD)

Voltage across the regulator eld output terminals, F+ and F-, is monitored, scaled, and conditioned before being

applied to the ADC. This signal is used to calculate the dc value of eld voltage for use in system protection.

Field Current (IFIELD)

Current through the main power output switch is converted to a proportional voltage level. This voltage signal is

scaled and conditioned before being applied to the input of the ADC. The result is used to calculate the dc value

of eld current for use in the Manual mode of operation as well as protection of the system.

Analog (Auxiliary) Input

CAUTION

If the DC voltage is removed from the Analog (Auxiliary) Input, the operating setpoint will

return to the original value.

This input allows adjustment of the DVR-2000E regulation setpoint by the application of a positive or negative

dc voltage across terminals A and B. Voltage up to +3 Vdc may be applied at this input. The circuit induces a

1,000-ohm burden on the dc source. The application of a +3 Vdc signal corresponds to a +30 percent change in

setpoint.

Contact Input Circuits

Four contact input circuits powered from an internal 13 Vdc supply provide input control from user-supplied

contacts.

19

Main Index

3

Section 3 Index

5

Page 22

S

S

ection

3

21

3

Main Index

5

Section 3 Index

ection

3

Raise

Closing a contact across terminals 6U and 7 causes the active operating setpoint to increase. This function is

active as long as the contact is closed.

Lower

Closing a contact across terminals 6D and 7 causes the active operating setpoint to decrease. This function is

active as long as the contact is closed.

Var/Power Factor Control (52J/K) Option

Closing a contact across terminals 52J and 52K disables var/power factor control. An open contact enables the

DVR2000E(C) to control the generator reactive power in either the var or the power factor mode. The contact has

no effect when this option is not present. For more information, refer to the Parallel Generator Compensation

(52L/M) contact input.

Parallel Generator Compensation (52L/M)

Closing a contact across terminals 52L and 52M disables parallel operation. An open contact enables parallel

operation and the DVR2000E operates in reactive droop compensation mode.

If the Var/Power Factor Control option is present, the 52J/K input has priority. Therefore, if the 52J/K and the 52L/M

inputs are both open, the system operates in var/power factor mode.

Communication Port

The communication port provides the interface for user programming (setup) of the DVR2000E. Connection is

made to the female RS-232 (DB-9) connector with a user-supplied, standard 9-pin cable. The communication port

is optically isolated and is powered from a transformer-isolated supply.

Microprocessor

The microprocessor is the heart of the DVR2000E and performs measurement, computation, control, and

communication functions by the use of its embedded programming and the nonvolatile settings stored in its

memory.

Power Input Stage

Input power is applied to terminals 3 and 4 from the PMG. It is rectied and ltered before being applied to the

power amplier and the power supply. Input power is single-phase in the range of 180 to 240 Vac at a frequency

of 200 to 360 hertz.

Power Supply

The internal switch-mode power supply receives power from the power input stage and supplies power at the

required dc voltage levels to the internal circuitry of the DVR2000E.

Power Amplier Stage

The power amplier receives power from the power input stage and supplies a controlled amount of power to the

exciter eld via terminals F+ and F-. The amount of power supplied to the exciter eld is based on gating pulses

received from the microprocessor. The power amplier uses a solid state power switch to provide the required

power to the exciter eld. Power amplier output to the eld is rated up to 75 Vdc at 3 Adc continuous and 150

Vdc at 7.5 Adc for 10 seconds.

Front Panel Indicators

Twelve front panel LED indicators light to indicate various operating modes, protective functions, and adjustments.

Section 2, Human-Machine Interface provides more information about the front panel indicators.

Main Index

3

Section 3 Index

5

20

Page 23

Front Panel Switches

Changes to settings can be made at the front panel using the three pushbutton switches. These push-buttons are

labeled Select, Up, and Down. Section 2, Human-Machine Interface provides more in-formation about the front

panel switches.

Relay Output

A common alarm output contact is provided through terminals AL1 and AL2. This normally open, form A contact

annunciates alarm or generator trip conditions and closes in the event of a protective shutdown or transfer. The

relay output is non-latching.

DVR2000E OPERATING FEATURES

The following paragraphs describe the characteristics of each DVR2000E operating feature.

Operating Modes

The DVR2000E provides up to four modes of operation selectable through Windows® or Palm OS® communication

software. Automatic voltage regulation mode and Manual mode are standard features. Var and Power Factor

modes are an option.

Automatic Voltage Regulation Mode

In Automatic Voltage Regulation (AVR) mode, the DVR2000E regulates rms generator output voltage. This is

accomplished by sensing generator output voltage and adjusting dc output excitation current to maintain voltage

at the regulation setpoint. The regulation setpoint is adjusted by the Raise and Lower contact inputs, front panel

switches, or through Windows® or Palm OS® communication software. The regulation point may also be modied

by the Droop function or the Underfrequency function under certain conditions.

ection

S

3

Manual Mode

In Manual mode, also known as Field Current Regulation (FCR) mode, the DVR2000E maintains dc excitation

current at a set level. The current-level setpoint is adjustable from 0 to 3 Adc by the Raise and Lower contact

inputs, front panel switches, or through Windows® or Palm OS® communication software.

WARNING!

The Manual mode excitation level must be evaluated prior to enabling this feature. If the level of

excitation current is inappropriate for the generator, severe damage to the generator may occur.

For initial startup, if the regulator is in Manual mode and set at 0.25 amperes, the generator should come up to

approximately half-voltage. This allows wiring and sensing leads to be checked before the regulator is switched to

AVR mode. Increasing the eld current to 0.5 amperes will bring the generator up to approximately rated, no-load

voltage.

Var Control Mode (Optional)

In Var Control mode, the DVR2000E(C) maintains generator vars (volt-amperes, reactive) at a set level when

paralleling with an innite bus. The DVR2000E(C) calculates generator vars using the sensed generator output

voltage and current quantities and then adjusts the dc excitation current to maintain vars at the setpoint. Var control

is enabled and disabled through the front panel switches, Windows® or Palm OS® communication software.

When the software is turned on, var control is enabled or disabled through the Var/Power Factor Control (52J/K)

contact input circuit. The var setpoint is adjustable from 100 percent absorb to 100 percent generate through the

Raise and Lower contact inputs, front panel switches, or through Windows® or Palm OS® software.

Power Factor Control Mode (Optional)

In Power Factor Control mode, the DVR2000E(C) maintains generator power factor at a set level when paralleling

21

Main Index

3

Section 3 Index

5

Page 24

S

S

ection

3

23

3

Main Index

5

Section 3 Index

ection

3

with an innite bus. The DVR2000E(C) calculates generator power factor using the sensed generator output

voltage and current quantities and then adjusts the dc excitation current to maintain power factor at the setpoint.

Power factor control is enabled or disabled through the front panel switches, Windows® or Palm OS® software.

When the software is turned on, it is enabled or disabled through the Var/Power Factor Control (52J/K) contact

input circuit. The power factor setpoint is adjustable between 0.6 lag and 0.6 lead through the Raise and Lower

contact inputs, front panel switches, or through Windows® or Palm OS® communication software.

Reactive Droop Compensation

The DVR2000E provides a reactive droop compensation feature to assist in the sharing of reactive load during

parallel generator operation. When this feature is enabled, the DVR2000E calculates the reactive portion of the

generator load using the sensed generator output voltage and current quantities and then modies the voltage

regulation setpoint accordingly. A unity power factor generator load results in almost no change in generator

output voltage. A lagging power factor generator load (inductive) results in a reduction of generator output voltage.

A leading power factor generator load (capacitive) results in an increase of generator output voltage. Droop

is adjustable up to 10 percent with rated, nominal B-phase line current (5 amperes applied through terminals

CT1 and CT2) and 0.8 power factor. The droop feature is enabled and disabled through the Parallel Generator

Compensation contact input circuit (terminals 52L and 52M). If the Var/Power Factor option is present, the 52J/K

input must also be closed to disable droop.

Underfrequency

Generator Underfrequency

When generator frequency drops below the selected knee frequency setpoint, the voltage setpoint is automatically

adjusted by the DVR2000E so that generator voltage follows the selected PU (per unit) V/Hz curve. When

operating on the selected PU V/Hz curve, the Underfrequency Active indicator ashes on the front panel and in

MARATHON-DVR2000E-32. The knee frequency is adjustable from 40 to 65 hertz and the PU V/Hz curve may

be set to a slope from 1 to 3 in increments of 0.01 through the Windows® or Palm OS® communication software.

The default is 59 Hz and a slope of 1.

Engine Unloading

The Engine Unloading feature modies the underfrequency curve. This feature becomes active when the generator

frequency decreases a programmable amount (Unloading Activation – Frequency) below the knee frequency

setpoint, and when the speed change rate is greater than the Unloading Activation - Rate. The amount of droop

while Engine Unloading is active is adjusted by the Unloading Droop - Percentage (%) setting. The amount of time

Engine Unloading is active is set by Unloading Droop - Time (sec.).

Engine unloading adjustments are made through the Windows and Palm OS communication software.

Unloading Activation – Frequency (Hz) is entered as a value below the underfrequency corner where the engine

unloading feature may be activated. A frequency value of 0.9 to 9.0 hertz can be entered in 0.1 hertz increments.

The default value is 0.9 hertz.

Unloading Activation – Rate (Hz/25 msec) of 0 to 25.5 hertz per 25 milliseconds can be entered in 0.1 hertz per

25 millisecond increments. The engine unloading feature is activated when the frequency rate of change exceeds

the setting of this eld. The default value is 0.1.

Unloading Droop – Percentage (%) eld denes the percent drop in generator output voltage for each 1.5 percent

decrease in generator frequency when operating in the Engine Unloading mode. The Unloading Droop Percentage

is adjustable from 1 to 20 percent in 1 percent steps. The default value is 10 percent.

Unloading Droop – Time (sec) value denes the length of time that the Engine Unloading mode may be active

before control is passed to the normal Underfrequency mode of operation. Droop time is adjustable from 1 to 5

seconds in 1 second increments. The default value is 1 second.

Protection

The DVR2000E has the six protective functions listed below:

Main Index

3

Section 3 Index

5

22

Page 25

• Overexcitation shutdown

• Generator overvoltage shutdown

• DVR overtemperature shutdown

• Loss of generator sensing shutdown

• Overexcitation limiting

• Crowbar shutdown

Each function, except Crowbar Shutdown, has a corresponding front panel indicator that lights when the function

is active. An active function (except Crowbar Shutdown) is also annunciated through the Windows® or Palm OS®

communication software.

Overexcitation Shutdown (Field Voltage)

This function is enabled or disabled through MARATHON-DVR2000E-32 software. When enabled, if eld voltage

exceeds the setpoint (80 Vdc default), the Overexcitation Shutdown indicator ashes on the front panel and in the

Windows® or Palm OS® communication software, the relay output closes after 15 seconds and the DVR2000E

shuts down. When the DVR2000E is powered up following an over-excitation shutdown, the Overexcitation

Shutdown indicator will ash for 5 seconds.

Generator Overvoltage Shutdown

The DVR2000E monitors the sensed generator output voltage. If it exceeds the overvoltage setpoint (a percent

of nominal) for 0.75 seconds, the Generator Overvoltage indicator ashes on the front panel LED and in the

Windows® and Palm OS® communication software, the relay output closes and the DVR2000E shuts down.

When the DVR2000E is powered up following a generator overvoltage shutdown, the Generator Overvoltage

indicator will ash for 5 seconds. The default setpoint is 120 percent of nominal.

ection

S

3

DVR Overtemperature Shutdown

A temperature sensor within the DVR2000E continually monitors the temperature of the device. If the temperature

exceeds 70°C (158°F), the DVR Overtemperature indicator ashes on the front panel and in the Windows® and

Palm OS® communication software, the relay output closes and the DVR2000E shuts down.

Loss of Generator Sensing Shutdown

The DVR2000E monitors the sensed generator output voltage and takes protective action if a loss of sensing

voltage is detected. For single-phase sensing, a sensed voltage of less than 50 percent of nominal is interpreted

as a loss of sensing. For three-phase sensing, the total loss of a sensed phase or an imbalance between phases

of more than 20 percent nominal is interpreted as a loss of sensing. When sensing input continuity is not lost, an

adjustable time delay of 0 to 25 seconds is present when a loss of sensing condition is detected. If sensing input

continuity is lost, the time delay is disabled.

If a loss of sensing occurs, the Loss of Generator Sensing indicator ashes on the front panel and in the Windows®

and Palm OS® communication software, the relay output closes, and the DVR2000E shuts down. When the

DVR2000E is powered up following a loss of generator sensing shutdown, the Loss of Sensing indication will

ash for 5 seconds.

This function is disabled when a generator short circuit condition is detected or when sensed frequency drops

below 12Hz. A generator short-circuit is determined when the phase B CT current exceeds 3PU (>15 Aac sensing

current). Loss of sensing is not active during soft start time.

Overexcitation Limiting (Field Current)

The DVR2000E has a eld current limit that is factory preset at 6.5 amperes. The limit is adjustable from 0 to 7.5

amperes with an adjustable time delay that has a range of 0 to 10 seconds. Both settings are made through the

Windows® and Palm OS® communication software. When the overexcitation limit is exceeded, the Overexcitation

Limiting indicator ashes on the front panel and in the Windows® and Palm OS® communication software. When

the adjustable time delay expires, the relay output closes and the DVR2000E shuts down. When the DVR2000E is

powered up following overexcitation limiting, the Overexcitation Limiting indicator will ash for 5 seconds.

Main Index

3

Section 3 Index

5

23

Page 26

S

25

3

Main Index

Crowbar Shutdown

The Crowbar Shutdown Circuit protects the generator rotor from overcurrent damage resulting from a shorted

DVR2000E power switch. During operation, if the eld voltage exceeds the setpoint and the power stage receives

no gating pulses for 1.5 seconds, the Crowbar Circuit activates and places a short-circuit across the DVR2000E

input power terminals. This protects the generator by blowing the input power fuse and removing operating power

from the device.

Generator Soft Start

The DVR2000E incorporates an adjustable soft start feature that controls the time for generator voltage to ramp

to the regulation setpoint. The ramp rate is adjustable from 1 to 120 seconds in 1 second increments through the

Windows® and Palm OS® communication software. The underfrequency feature is also active during soft start

and takes priority in control of the generator voltage. The default setting is 7 seconds.

ection

3

Main Index

3

Section 3 Index

5

24

Page 27

SECTION 4 • INSTALLATION

TABLE OF CONTENTS

SECTION 4 • INSTALLATION.....................................................................................................................26

GENERAL............................................................................................................................................ 26

MOUNTING .........................................................................................................................................26

CONNECTIONS ..................................................................................................................................29

DVR2000E Terminations................................................................................................................ 29

Generator Voltage Sensing Inputs................................................................................................. 30

Phase B Line Current Sensing Input .............................................................................................30

Raise and Lower Contact Inputs ...................................................................................................30

Var/Power Factor Control Contact Input ........................................................................................30

Parallel Generator Compensation .................................................................................................30

Analog (Auxiliary) Adjust ...............................................................................................................30

Power Supply Inputs...................................................................................................................... 30

Chassis Ground.............................................................................................................................31

Power (Field) Output...................................................................................................................... 31

Relay Output..................................................................................................................................31

Communication Port ...................................................................................................................... 31

DVR2000E Connections for Typical Applications...........................................................................32

PRELIMINARY SETUP........................................................................................................................ 37

ADJUSTMENTS ..................................................................................................................................37

ection

S

4

Figures

Figure 4-1. DVR2000E Dimensions............................................................................................................ 27

Figure 4-2. Cutout and Drilling Dimensions................................................................................................ 28

Figure 4-3. DVR2000E Rear Panel Terminals ............................................................................................29

Figure 4-4. Communication Port Pin Assignments .....................................................................................31

Figure 4-5. Personal Computer to DVR2000E Connections....................................................................... 32

Figure 4-6. Typical Connections with ABC Rotation and Three-Phase Sensing......................................... 33

Figure 4-7. Typical Connections with ABC Rotation and Single-Phase Sensing ........................................34

Figure 4-8. Typical Connections to a Single-Phase Generator ...................................................................35

Figure 4-9. Cross-Current (Reactive Differential) Connections for Two Generators ...................................36

Figure 4-10. Cross-Current (Reactive Differential) Connections for Three or More Generators.................36

Tables

Table 4-1. Generator Voltage Sensing Terminals........................................................................................30

Table 4-2. Communication Port Pin Functions............................................................................................31

Main Index

3

25

Page 28

S

ection

4

SECTION 4 • INSTALLATION

27

3

Main Index

5

Section 4 Index

GENERAL

The DVR2000E is delivered in a sturdy carton to prevent shipping damage. Upon receipt, check the part number

against the requisition and packaging list for agreement. Inspect for damage, and if there is evidence of such,

immediately le a claim with the carrier and notify your sales representative or a sales representative at Marathon

Electric.

If the unit is not installed immediately, store it in the original shipping package in a moisture and dust free

environment.

MOUNTING

The DVR2000E is normally located in the generator conduit box. It is designed for behind the panel mounting

and requires a cutout for front panel viewing and access. Mounting hardware consists of six customer supplied,

#12 thread-forming screws that pass through mounting holes in the conduit box and thread into the plastic shell

of the DVR2000E. The unit must be mounted where the ambient temperature does not exceed the allowable

environmental conditions called out in Section 1, General Information, Specications. DVR2000E package

dimensions are shown in Figure 4-1. Cutout and drilling dimensions are shown in Figure 4-2.

S

ection

4

Main Index

3

Section 4 Index

5

26

Page 29

S

ection

4

Main Index

3

Section 4 Index

5

Figure 4-1. DVR2000E Dimensions

27

Page 30

S

S

ection

4

29

3

Main Index

5

Section 4 Index

ection

4

Main Index

3

Section 4 Index

5

Figure 4-2. Cutout and Drilling Dimensions

28

Page 31

CONNECTIONS

DVR2000E connections are dependent on the application. Incorrect wiring may damage the unit.

NOTE

Be sure that the DVR2000E is hard-wired to earth ground with no smaller than 12 AWG copper

wire attached to the ground terminal on the rear of the unit case. When the unit is congured in

a system with other devices, it is recommended to use a separate lead to the ground bus from

each device.

DVR2000E Terminations

DVR2000E units have two types of interface terminals (Figure 4-3). One type is quarter-inch, quick-connect

terminals and the other is a 9-pin DB9 connector. All terminals are located on the rear of the unit. The quarter-inch,

quick-connect terminal labels are located on the rear of the case. Wires performing common functions, such as

voltage sensing leads, should be grouped together. The 9-pin DB-9 type connector is used for temporary interface

with both IBM compatible PCs and hand-held computers.

Figure 4-3 shows the terminal connections located on the rear panel of the DVR2000E. Except as noted above,

connections should be made with minimum wire size of 14 AWG.

ection

S

4

Main Index

3

Section 4 Index

5

Figure 4-3. DVR2000E Rear Panel Terminals

29

Page 32

S

S

ection

4

31

3

Main Index

5

Section 4 Index

ection

4

Generator Voltage Sensing Inputs

The generator voltage sensing terminals are labeled E1, E2, and E3. A single-phase sensing connection is

obtained by connecting the C-phase sensing input to terminals E2 and E3. Table 4-2 lists the terminal assignments

for three-phase and single-phase generator voltage sensing.

Table 4-1. Generator Voltage Sensing Terminals

Sensing GeneratorPhase Terminal

A E1

3-Phase

1-Phase

Phase B Line Current Sensing Input

Generator line current is stepped down through a user-supplied current transformer (CT). Secondary current from

that transformer is applied to terminals labeled CT1 and CT2.

Raise and Lower Contact Inputs

Remote setpoint adjustment may be accomplished by connecting a single-pole, double-throw (SPDT), spring

return, center-off switch to the terminals labeled 6U, 7, and 6D. To connect this switch, the center pole, or

common terminal, must be connected to terminal 7. The other two terminals are connected to terminals 6U and

6D. This remote adjust switch may be mounted up to 150 feet away from the DVR2000E when using twisted,

shielded cable.

B E2

C E3

A E1

C E2, E3

Var/Power Factor Control Contact Input

A customer supplied enable/disable contact for this function connects to the terminals labeled 52J and 52K.

This function is disabled by a closed contact.

Parallel Generator Compensation

A customer supplied enable/disable contact for this function connects to the terminals labeled 52L and 52M.

This function is disabled by a closed contact.

Analog (Auxiliary) Adjust

CAUTION

If the DC voltage is removed from the Analog (Auxiliary) Input,

the operating setpoint will return to the original value.

This input allows adjustment of the DVR2000E regulation setpoint by the application of a positive or negative

DC voltage across terminals A and B. Voltage up to +3 Vdc may be applied at this input. The circuit induces a

1,000-ohm burden on the dc source. The application of a +3 Vdc signal corresponds to a +30 percent change in

setpoint.

Power Supply Inputs

Power input terminals are labeled 3, and 4.

Main Index

3

Section 4 Index

5

30

Page 33

Chassis Ground

The chassis ground terminal is labeled GND.

Power (Field) Output

The eld output terminals for connection to the generator exciter eld are labeled F+ and F-.

Relay Output

The common alarm relay output contact may be accessed at the terminals labeled AL1 and AL2. The relay output

is normally open.

Communication Port

The RS-232 port on the rear panel uses a DB-9 female connector. Figure 4-4 Illustrates the pin assignments of

the communication port and Table 4-3 identies the RS-232 connector pin functions. A standard communication

cable terminated with a DB-9 male connector is used for PC or hand-held computer interface with the DVR2000E

as shown in Figure 4-5.

Figure 4-4. Communication Port Pin Assignments

ection

S

4

Table 4-2. Communication Port Pin Functions

Pin Function Name Direction

1 N/C ---- N/A

2 Transmit Data TXD From DVR2000E

3 Receive Data RXD To DVR2000E

4 N/C ---- N/A

5 Signal Ground GND N/A

6 N/C ---- N/A

7 N/C ---- N/A

8 N/C ---- N/A

9 N/C ---- N/A

3

Main Index

Section 4 Index

5

31

Page 34

S

S

ection

4

33

3

Main Index

5

Section 4 Index

ection

4

Figure 4-5. Personal Computer to DVR2000E Connections

DVR2000E Connections for Typical Applications

Figures 4-6 through 4-9 illustrate typical applications using the DVR2000E. Figure 4-6 shows an application where

the DVR2000E is connected for three-phase voltage sensing. Figure 4-7 shows an application with single-phase

voltage sensing while Figure 4-8 illustrates an application with a single-phase generator.

Figure 4-9 illustrates the connection of two DVR2000E devices used in a Cross-Current (Reactive Differential)

application. Note that the .1 ohm resistor shown may have to vary. When operating in parallel reactive differential

mode (cross current), attention must be paid to the use of the burden resistor shown in Figure 4-9. The burden

resistor should have a value approximately 10 times the cross current loop resistance for proper differential

operation. The value of 0.1 ohm is a suggested value. The volt-ampere (VA) capacity of the paralleling current

transformers should be considered after sizing the burden resistor.

Main Index

3

Section 4 Index

5

32

Page 35

Caution

ection

S

4

Main Index

3

Figure 4-6. Typical Connections with ABC Rotation and Three-Phase Sensing

33

Section 4 Index

5

are reversed from the DVR2000

The DVR2000E CT connections

Page 36

S

S

ection

4

34

3

Main Index

5

Section 4 Index

35

3

Main Index

5

Section 4 Index

ection

4

Caution

Figure 4-7. Typical Connections with ABC Rotation and Single-Phase Sensing

are reversed from the DVR2000

The DVR2000E CT connections

Page 37

S

ection

4

Main Index

3

Figure 4-8. Typical Connections to a Single-Phase Generator

35

Section 4 Index

5

Page 38

S

ection

4

Figure 4-9. Cross-Current (Reactive Differential) Connections for Two Generators

37

3

Main Index

5

Section 4 Index

S

ection

4

Main Index

3

Figure 4-10. Cross-Current (Reactive Differential) Connections for Three or More Generators

Section 4 Index

5

36

Page 39

PRELIMINARY SETUP

WARNING!

Use caution when working around the rear of the DVR2000E.

Dangerous voltage levels are present at the exposed heatsinks when the unit is energized.

Before starting the generator and DVR2000E for the rst time, proceed as follows.

a. Tag and disconnect all wiring to the DVR2000E. Be sure to insulate the wire terminals to prevent a short.

b. Start the prime mover and perform all engine governor adjustments.

c. After all initial governor adjustments have been made, shut down the prime mover.

d. Connect only the power input terminals of the DVR2000E to an auxiliary power source in the specied power

input range.

e. Perform all initial DVR2000E settings by using the front panel HMI, connecting a handheld operating with

DVR2000E software, or connecting a PC operating with DVR2000E software to the rear commun-ications port

of the DVR2000E.

f. Connect the rest of the DVR2000E leads using the tagged identication.

g. Start the prime mover/generator and perform the nal adjustments at rated speed and load.

h. After the initial startup, the DVR2000E should not require any further adjustments unless there is a change in

the system.

ection

S

4

ADJUSTMENTS

All adjustments are made using external switching, the front panel HMI or with DVR2000E software via the rear

panel communication port. See Section 5, MARATHON-DVR2000E-32 Software for Windows® OS for more

information about making adjustments with DVR2000E software.

Main Index

3

Section 4 Index

5

37

Page 40

S

S

ection

5

39

3

Main Index

5

Section 5 Index

ection

5

SECTION 5 • MARATHON-DVR2000E-32 SOFTWARE

FOR WINDOWS® OS

TABLE OF CONTENTS

SECTION 5 • MARATHON-DVR2000E-32 SOFTWARE FOR WINDOWS® OS ........................................40

INTRODUCTION..................................................................................................................................40

INSTALLATION ....................................................................................................................................40

Installing MARATHON-DVR2000E-32 ...........................................................................................40

Connecting the DVR2000E and PC...............................................................................................40

STARTING THE MARATHON-DVR2000E-32 APPLICATION..............................................................40