Page 1

Service

VP-15S1/VP-15S1L

VP15S1 /F B/N1B/U1B

VP15S1L /N1B/U1B

Manual

DLP Projector

TABLE OF CONTENTS

SECTION PAG E

1. TECHNICAL SPECIFICATIONS.................................................................................................... 1

2. SERVICE TOOLS .......................................................................................................................... 1

3. ABOUT THE REPAIR METHOD ...................................................................................................2

4. DISASSEMBLE PROCEDURE .....................................................................................................3

5. COLOR WHEEL REPLACEMENT PROCEDURE / (Japan Ver.) .........................................9 / (11)

6. ADJUSTMENT PROCEDURE .................................................................................................... 13

7. TROUBLESHOOTING AND HINT / (Japan Ver.) ................................................................35/ (43)

8. WIRING DIAGRAM ..................................................................................................................... 63

9. BLOCK DIAGRAM ...................................................................................................................... 65

10. SCHEMATIC DIAGRAM .............................................................................................................. 67

11. PARTS LOCATION ...................................................................................................................... 91

12. MICROPROCESSOR AND IC DATA ........................................................................................... 99

13. EXPLODED VIEW AND PARTS LIST ....................................................................................... 107

14. ELECTRICAL PARTS LIST ....................................................................................................... 114

15. ABOUT REPLACE THE MICROPROCESSOR WITH A NEW ONE ......................................... 132

Please use this service manual with referring to the user guide ( D.F.U. ) without fail.

VP-15S1 / VP-15S1L

Part no. 90M29AV855010

First Issue 2007.08

MZ

Page 2

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components,

Only original

MARANTZ

parts can insure that your

MARANTZ

MARANTZ

product will continue to perform to the specifi cations for which

company has created the ultimate in stereo sound.

it is famous.

Parts for your

MARANTZ

ORDERING PARTS :

equipment are generally available to our National Marantz Subsidiary or Agent.

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specifi ed.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

100 CORPORATE DRIVE

MAHWAH, NEW JERSEY 07430

USA

JAPAN

D&M Holdings Inc.

D&M BUILDING, 2-1 NISSHIN-CHO,

KAWASAKI-KU, KAWASAKI-SHI,

KANAGAWA, 210-8569 JAPAN

EUROPE / TRADING

MARANTZ EUROPE B.V.

P. O. BOX 8744, BUILDING SILVERPOINT

BEEMDSTRAAT 11, 5653 MA EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2507844

FAX : +31 - 40 - 2507860

CANADA

D&M CANADA INC.

5-505 APPLE CREEK BLVD.

MARKHAM, ONTARIO L3R 5B1

CANADA

KOREA

D&M SALES AND MARKETING KOREA LTD.

CHUNG JIN B/D., #1001,

53-5, WONHYORO 3 GA, YONGSAN-GU,

SEOUL, 140-719, KOREA

PHONE : +82 - 2 - 323 - 2155

FAX : +82 - 2 - 323 - 2154

CHINA

MARANTZ SHANGHAI TRADING LTD.

ROOM.506 SHANGHAI LIGHT INDUSTRY MANSION

1578 NANJING (WEST) ROAD SHANGHAI

CHINA

TEL : 021 - 6248 - 1064

FAX : 021 - 6248 - 3565

NOTE ON SAFETY :

Symbol Fire or electrical shock hazard. Only original parts should be used to replaced any part marked with symbol .

Any other component substitution (other than original type), may increase risk of fi re or electrical shock hazard.

安全上の注意:

がついている部品は、安全上重要な部品です。必ず指定されている部品番号のものを使用して下さい。

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product

and controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied,

and verifi ed before it is return to the user/customer.

Ref. UL Standard No. 60065.

In case of diffi culties, do not hesitate to contact the Technical

Department at above mentioned address.

070719MZ

Page 3

1. TECHNICAL SPECIFICATIONS

❖ Optical characteristics

Panel 0.95 inch 16:9

1920 x 1080 pixels

1080p DLP® chip

Lamp Super High Pressure 200W DC

Lens [VP-15S1] f: 30.7 to 44.5mm

[VP-15S1L] f: 44.5 to 66.75mm

Projection size 70 to 250 inches

❖ Input/Output

VIDEO IN RCA x 1

NTSC-3.58/PAL-4.43/SECAM

Composite video 1.0Vp-p/75 Ohm

S-VIDEO IN S-Connector x 1

NTSC-3.58/PAL-4.43/SECAM

S-Video

COMPONENT IN 3RCA x 2

Y, C

RGB/HD IN D-sub M 15 pin x 1

Analog RGB

HD:1080i/p, 720p, 480p

HDMI IN HDMI x 2

HDMI 1.3 compliant (single link only)

REMOTE CONTROLLER IN

Mini jack x 1

REMOTE CONTROLLER OUT

Mini jack x 1

AC IN 3 Prong Grounding Type

TRIG.1 OUT, TRIG.2 OUT

Mini Jack x 2

Output: DC12V or 0V, 100mA

RS232C RS232C receptacle plug x 1

B/PB

, CR/P

R

❖ General

Power requirement

[/F] AC 100V, 50/60 Hz

[/N] AC 230V, 50 Hz

[/U] AC 120V 60 Hz

Power consumption < 350 W

Standby consumption < 0.3 W (AC 100V, 120V)

< 0.5 W (AC 230V)

Chassis isolation Class-1

Safety UL60950-1

CSAC22.2 E60950

EN60950-1

J60950

EMC FCC Part-15 Class-B

EN55022 Class-B

Net weight 13 kg

Operating Temperature 5 to 35 °C

Operating humidity 30 to 85%

Storage Temperature – 20 to 60 °C

Storage humidity 30 to 85%

❖ Accessories

• Lens cap x 1

• Remote controller x 1

• Batteries x 2

• Mains code x 1

• User Guide

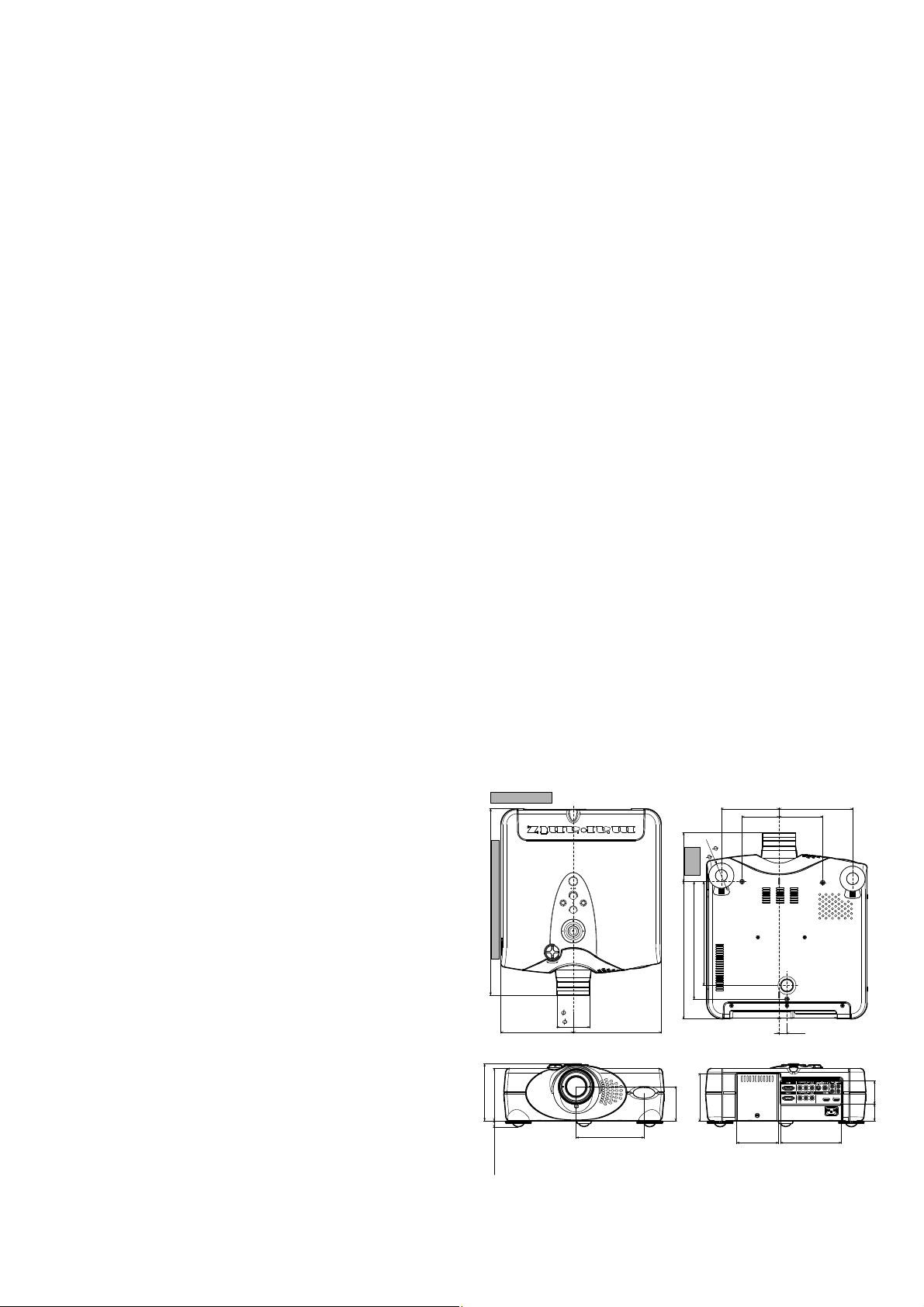

❖ Dimensions

[VP-15S1] 15 15/16(W) x 18 5/16(D) x 6 1/8(H) inch

404.5(W) x 489.5(D) x 158(H) mm

[VP-15S1L] 15 15/16(W) x 19 19/32(D) x 6 1/8(H) inch

404.5(W) x 497.5(D) x 158(H) mm

Top

VP-15S1L only

(142-143)

5 9/16 -55/8

Bottom

8/16

9/16

5

(141.0)

5 3/4

(145.75)

3 11/16

(93.5)

(64)

2

(185.25)

4 11/16

(110.0)

7 5/16

2. SERVICE TOOLS

• Windows PC.

• RS-232C cable straight type. (9 pin female - 9 pin female)

• Color temperature sensor ....................00MZK09AV0070

(Color Temperature Adj.)

18 1/4 -185/16 (488.5 - 489.5)

Front

5 5/8 (143.0)

5 3/16 (132.0)

9/16 - 2 7/16

(15.0 - 61.8)

1

19 9/16 - 19 19/32 (496.5 - 497.5)

7 3/16

(182.5)

3 1/4

( 82.6)

8 12/16

(222.0)

6 12/16 (171.0)

11 11/16 (296.5)

14 6/16 (346.5)

4 11/16 (119.0)

3-39/16 (76.0 - 91.0)

10 5/16 (262.0)

Rear

12/16

(19.75)

4 1/8 6 1/16

(105.0)

(153.5)

Unit : inch (mm)

2 5/16

1 10/16

(58.0)

(42.0)

Page 4

3. ABOUT THE REPAIR METHOD

基板及び光学エンジンのサービス部品供給について

修理方法

About service spare part supply of the PWB and OPTICAL ENGINE

When the PWB and the UNIT are repaired, confi rm contents of the following.

POS.NO DESCRIPTION How to repair

P101 FORMATTER PWB PWB ASSY is replaced

P201 FAN PWB Can be repaired on component level

P202 LEAF SWITCH PWB Can be repaired on component level

P301 DMD PWB Repair isn’t allowed : UN04 is replaced (DMD PWB and OPTICAL

ENGINE:UN04 are harmonized)

P501 IO PWB Can be repaired on component level

P601 HDMI PWB PWB ASSY is replaced

P701* / P801 SSB1 PWB / SSB2 PWB PWB ASSY is replaced (Replace P701and P801 in pairs)

P801 can be repaired on component level

PK00* P701* / P801 PWB ASSY KIT PWB ASSY is replaced (Replace P701and P801 in pairs)

P901 IR-F PWB Can be repaired on component level

P902 IR-R PWB Can be repaired on component level

P903 KEY PWB Can be repaired on component level

P904 INLET PWB Can be repaired on component level

UN01 LAMP POWER SUPPLY PWB PWB ASSY is replaced

UN02 POWER SUPPLY PWB ASSY is replaced

LU-12VPS3 (UN03) LAMP UNIT LAMP UNIT(LU-12VPS3) is replaced

UN04* UNIT KIT OPTICAL ENGINE UNIT KIT is replaced

(DMD PWB:P301 and OPTICAL ENGINE are harmonized)

* : When P701, PK00 or UN04 are replaced, 13-page adjustment is required.

基板及び光学エンジンのサービス部品供給について

のサービス部品の供給内容を「単品部品で修理」、「完成品で交換」、「修理不可」に区別し下記に記載します。

本体

POS.NO DESCRIPTION

P101 FORMATTER PWB

P201 FAN PWB

P202 LEAF SWITCH PWB

P301 DMD PWB

P501 IO PWB

P601 HDMI PWB

P701* / P801 SSB1 PWB / SSB2 PWB

PK00* P701* / P801 PWB ASSY KIT PWB

P901 IR-F PWB

P902 IR-R PWB

P903 KEY PWB

P904 INLET PWB

UN01 LAMP POWER SUPPLY PWB

UN02 POWER SUPPLY

LU-12VPS3 (UN03) LAMP UNIT LAMP UNIT(LU-12VPS3)

UN04* UNIT KIT OPTICAL ENGINE

: P701, PK00

*

または

UN

From J310(P701)

LENS SHIFT SW

を交換したときは、13頁の調整が必要です。

04

修理方法

PWB

完成品で交換

単品部品で修理できます(

単品部品で修理できます(

修理を許可しません(

単品部品で修理できます(

PWB

完成品で交換

PWB

完成品で交換(

P801

は単品部品での修理も可能です。

完成品で交換。(

単品部品で修理できます(PWB 完成品の供給はありません)

単品部品で修理できます(PWB 完成品の供給はありません)

単品部品で修理できます(PWB 完成品の供給はありません)

単品部品で修理できます(

PWB

完成品で交換

PWB

完成品で交換

修理を許可しません

PWB

完成品の供給はありません)

PWB

完成品の供給はありません)

OPTICAL ENGINE:UN04

PWB

完成品の供給はありません)

P701とP801

P

701

PWB

で交換

(UNIT KIT

のペアで交換)

と

のペア)

P

801

完成品の供給はありません)

UN03(LAMP)

で交換、含む

P301

DMD PWB

と一体です)

のみの交換も可能

DMD PWB)

From J205(P201)

LENS IRIS

From J211(P201)

ILLUMINATION IRIS

UN04 UNIT KIT

OPTICAL ENGINE

2

035G

Color wheel

From J224(P201)

CW SENSOR

From J221(P201)

CW DRIVE

Page 5

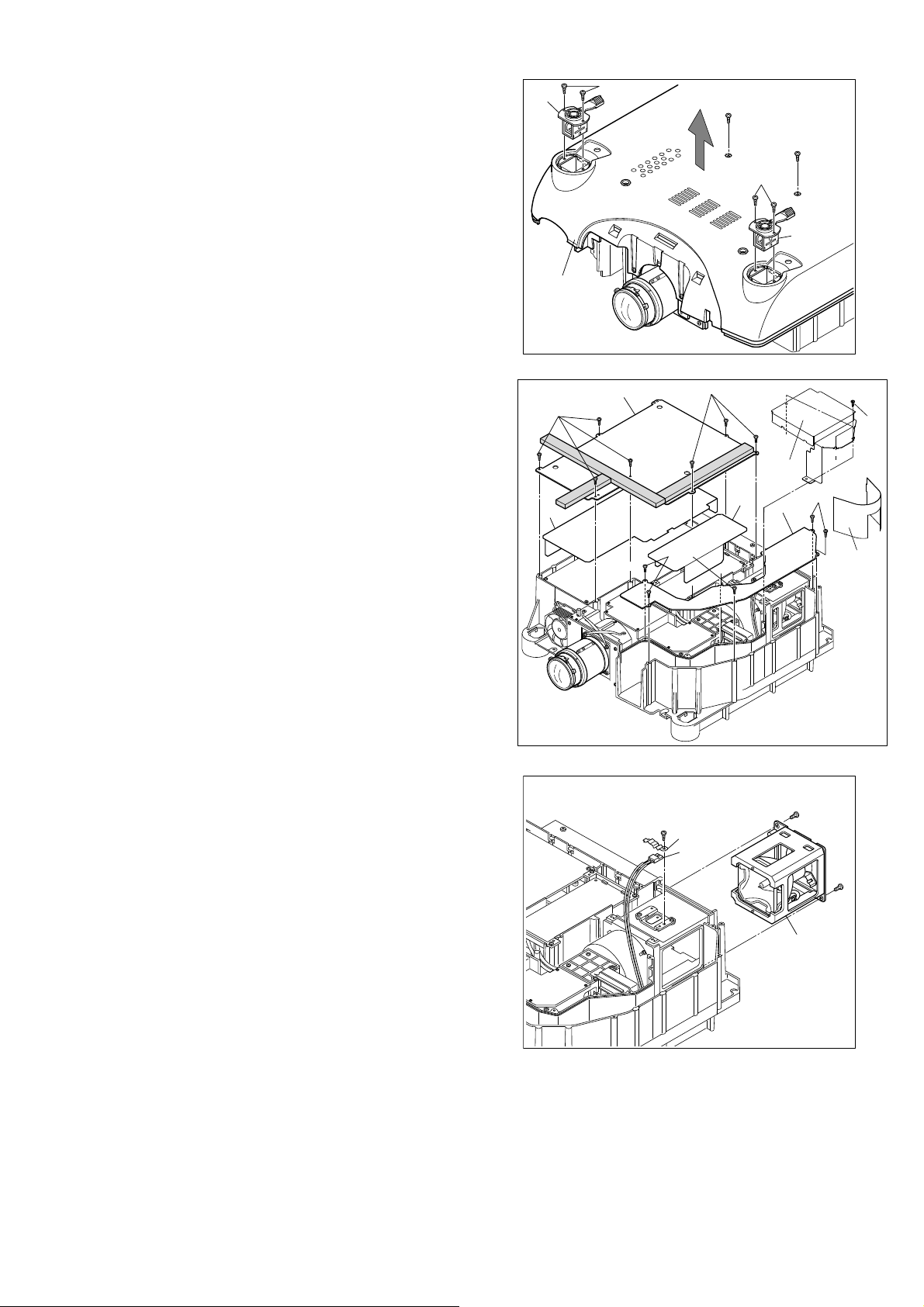

4. DISASSEMBLE PROCEDURE

フォーカスレンズ及びズームリングの取り外し

フロントカバーの取り外し

リアパネルの取り外し

注)

注)

1. Disassemble of the lens ring.

1) Turn the ring (170B) counter clockwise and remove the ring.

2) Remove 3 screws (167B) and remove the focus ring (165B).

3) Remove 3 screws (162B) and remove the zoom ring (160B).

Fig.1

フォーカスレンズ及びズームリングの取り外し

1.

1

)リング

2

)ネジ

3

)ネジ

2. Disassemble of the front cover.

1) Remove the cap (154B) with a minus driver, as shown in a

2) Remove 2 screws (152B) and 1 screw (153B) from the front

3) The front cover is locked by 4 hooks (A to D). The part of

Fig.2

フロントカバーの取り外し

2.

1

)キヤップ

2

)ネジ

3

)フロントカバーにはフックA~Dが有ります。フロントカバ

(170B)

を矢印方向に回し取り外します。

(167B) 3

本を外しフォーカスリング

(165B)

を取り外しま

す。

(162B) 3

本を外しズームリング

(160B)

を取り外します。

fi gure.

cover.

the C, D are strongly pulled to the direction shown and

remove it.

(154B)

を図の様にドライバーで取り外します。

(152B) 2本, (153B) 1

本を外しフロントカバーを取り外

します。

ーを両手でフック

C, D

部に指を掛け手前に強く引き矢印方向

に取り出します。

FRONT COVER

150B

C

152B

154B

170B

A

167B

160B

162B

165B

167B

A

B

162B

162B

Fig.1

Caution

Never touch these screws.

注) このネジに触れてはいけません。

B

D

153B

Fig.2

A

B

3. Disassemble of the rear panel.

1) Remove 3 screws (120B) from the rear panel.

2) Disconnect the connector (J331) from the IR-R PWB (P902).

Cautions in disassembling

When removing the rear panel, take care not to damage the

cable for the IR sensor and lights.

Since the IR window (110B) fends to get damaged, the IR

window should not put the IR window downward.

Fig.3

リアパネルの取り外し

3.

1

2

(120B) 3

)ネジ

本を外します。

)両手でリアパネルの下側に指を掛け手前に回転する様に少し引

き出します。

3)IR-R

基板

(P902)

に接続されているコネクター

(J331)

を取り外

します。

4

)リアパネルを矢印方向に取り出します。

注)IRセンサーのリード線が接続されているのでリアパネルは少

しだけ引き出しコネクターを取り外します。

IR

ウィンドウ

(110B)

がキズ付きやすいので、

IR

ウィンドウ

を下向きに置かないで下さい。

3

120B

Fig.3

J331

P902

120B

110B

REAR PANEL

100B

120B

Page 6

4. Disassemble of the top case.

トップケースの取り外し

ボトムケースの取り外し

1) Remove 4 screws (200B), 3 screws (045B) and the screw

(202B) from the top and bottom case.

2) Disconnect the 2 connectors (J334 and J329) from the top

case.

3) Remove the top case (001B) vertically.

Cautions in disassembling

When removing the top case, take care not to damage the

cable for the IR sensor, inside of set the product and key

control.

Fig.4

トップケースの取り外し

4.

1

2

3

(200B) 4本, (045B) 3本, (202B) 1

)ネジ

)コネクター

(J329, J334) 2

個所を取り外します。

)トップケースを矢印方向に取り外します。

本を外します。

注)IRセンサー及び本体内部とトップケース基板にリード線が接

続されているのでトップケースを少し持ち上げてコネクター

を取り外します。

200B

202B

200B

TOP CASE

001B

IR SENSOR

J334

J329

Fig.4

045B

045B

045B

200B

200B

5. Disassemble of the bottom case.

1) Remove 2 E-rings (040C) and 2 washers (041C).

2) The set is turned over, then turn the lever(arrow A) and

remove the leg (arrow B) vertically.

Cautions

When turning the set over, take care not to damage the

lens shift shaft.

Fig.5-1

ボトムケースの取り外し

5.

1)E

2

)本体を裏返してレバーを矢印Aの方向に回し,脚を矢印

リング

(040C) 2

個、ワッシャ

(041C) 2

個を取り外します。

B

の方向へ引き抜いて下さい。

注)レンズシフトシャフトが本体より出張っています。本体を

反転する時はレンズシフトシャフトが直接テーブル等に当

たらないように置いて下さい。

3) Remove 4 screws. (321G)

Fig.5-2

3

)ネジ

(321G) 4

本を取り外します。

LENS SHIFT SHAFT

040C

041C

LEG

B

A

LEVER

Fig.5-1

321G

321G

321G

321G

Fig.5-2

4

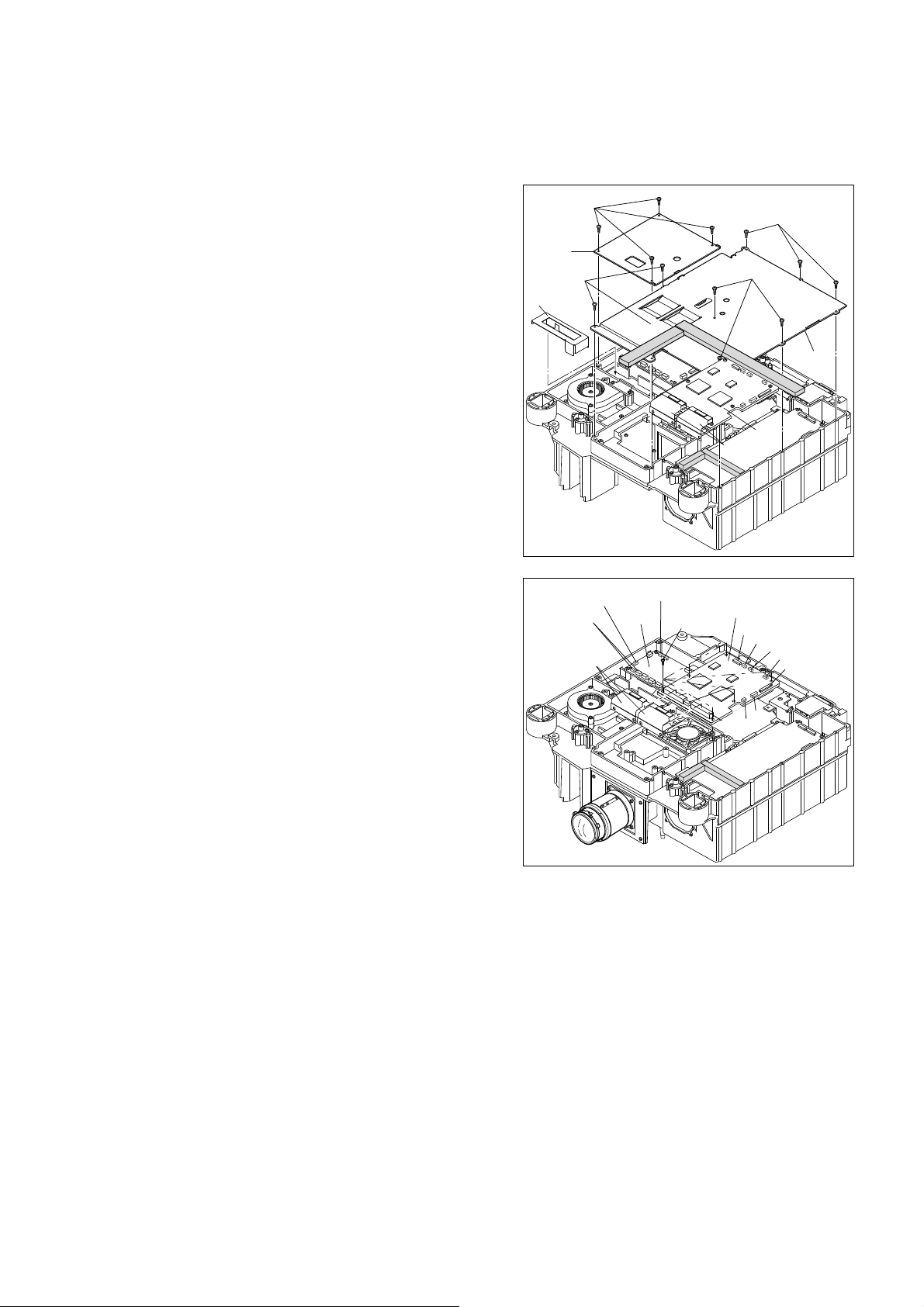

Page 7

4) Remove 2 screws. (059B)

温度センサー及びランプブラケットの取り外し

トップケース側基板シールド及びダクトシールドの取り外し

5) Remove the adjusters (001C) and 4 screws. (045C)

6) Remove the bottom case (050B) vertically.

Fig.5-3

4

5

6

(059B) 2

)ネジ

(045C) 4

)ネジ

)ボトムケース

本を外します。

本を外しアジャスタ

(050B)

を矢印方向に引き上げて取り外します。

(001C)

を取り外します。

6. Disassemble of the PWB shield and the duct shield.

(Top case side).

1) Remove 7 screws (217G), 3 screws (202G) and remove the

PWB shield (215G), color wheel cover (191G).

2) Remove 3 insulators (338G, 340G and 486G).

3) Remove 6 screws (202G) and remove the duct shield

(200G).

Fig.6

トップケース側基板シールド及びダクトシールドの取り外し

6.

1

2

3

(217G) 7

)ネジ

本とネジ

とカラーホイールカバー

)インシュレータ

(202G) 6

)ネ ジ

(338G), (340G)と(486G)

本を外しダクトシールド

(202G) 3

(191G)

本を外し基板シールド

を取り外します。

を取り外します。

(200G)

を取り外します。

(215G)

001C

340G

050B

217G

045C

215G

202G

Fig.5-3

202G

217G

059B

338G

045C

191G

200G

059B

001C

202G

202G

486G

7. Disassemble of the thermal sensor and lamp bracket.

1) Remove the screw. (308G)

2) Remove the clamp (306G) and remove thermal sensor

(TH02).

3) Remove the 2 screws (180G) and remove lamp bracket

(160G)

Fig.7

温度センサー及びランプブラケットの取り外し

7.

1

2

3

(308G) 1

)ネジ

)クランパー

(180G) 2

)ネジ

本を外します。

(306G)

を取り外し温度センサーを取り外します。

本を外しランプブラケットを引き出します。

Fig.6

308G

Fig.7

306G

SENSOR

TH02

180G

BRACKET LAMP

160G

180G

5

Page 8

g

8. Disassemble of the OPTICAL ENGINE unit.

光学エンジンユニットの取り外し

電源ユニット及び

ユニットの取り外し

1) To remove a OPTICAL ENGINE unit (UN04), a procedure

(Fig.10 - Fig.13) is required. Because the screw (157G) is

hidden by the duct of the fan for lamp cooling (M703).

2) Disconnect 4 connectors from (J205, J211, J221, J224) on

P201. (See fi g. 11)

3) Remove the 6 screws (155G) and 2 screws (157G), after

the process 1).

4) Remove the 2 screws (153G) for the lamp connector, and

remove the lens base (UN04) and the lamp case (150G)

vertically.

Cautions

When removing the lens base, please be sure to lift the lens

base main part.

Do NOT touch the lens part.

Fig.8

光学エンジンユニットの取り外し

8.

1

)光学エンジンユニット

(UN04)

を取り外すには、図10~図

13

の手順を参照して下さい。

注)ランプ冷却用ファン

1

本が有りますので取り外します。

2

)

P201

のコネクター

ます。(図11参照

3)図10

4

)ランプコネクター取り付けネジ

~図13の分解を全て修了後にネジ

(157G) 2

ス

本を取り外します。

(UN04)

とランプケース

(M703)

(J205, J211, J221, J224) 4

)

のダクト部の下にもネジ

(155G) 6

(153G) 2

(150G)

本を外しレンズベー

を取り外します。

(157G)

個所を取り外し

本及びネジ

注)レンズベースを取り外す時はレンズ部分には触れずに必ずレ

ンズベース本体を持って取り外して下さい。

LENS BASE

J021

UN04

155G

Fi

LAMP CASE

150G

157G

.8

153G

157G

155G

9. Disassemble of the POWER SUPPLY UNIT and the

BALLAST UNIT.

1) Remove 6 screws (022G).

2) Disconnect 7 connectors (CN1, CN2, A:CN3-CN7) and

remove the POWER SUPPLY UNIT (UN02).

3) Remove 4 screws (207G) and remove the BALLAST UNIT

(UN01).

Cautions

· When removing the POWER SUPPLY UNIT (UN02),

remove 3 PWBs and loose the cables that is fi xing the

cables in opposite side main chassis. (See fi g. 12)

Because cables of POWER SUPPLY UNIT (UN02) is fi xed

on opposite side main chassis under the 3 PWBs.

· When removing the BALLAST UNIT (UN01), remove the

lens base before. (See fi g. 8) The lamp connector was fi xed

between the main chassis and the lens base.

Fig.9

電源ユニット及び

9.

注)電源ユニット

BALLAST

(UN02)

ユニットの取り外し

を取り外すには、ボトム側に電源ユニッ

トのリード線が固定されている為、ネジを外してもユニットは

取り出せません。ボトム側の基板3枚を取り出し(図12参照

リード線をゆるめて外します。

1

2

(022G) 6

)ネジ

)コネクター

本を外します。

(CN1, CN2, A:CN3~CN7) 7

個を取り外し電源ユ

ニットを取り外します。

POWER SUPPLY UNIT(UN02)

022G

)

022G

CN1

C

207G

207G

BALLAST UNIT(UN01)

LAMP CONNETOR

D

CN2

A

B

Fig.9

6

Page 9

ボトム側基板シールドの取り外し

基板

及び

基板

の取り

外し

3

注)

)ネジ

BALLAST

(207G) 4

本を外し

BALLAST

ユニットを取り外します。

ユニットを取り外すには、ランプコネクターがレン

ズベースの下側に有りますのでレンズベースを取り外して下

さい。( 図8参照

)

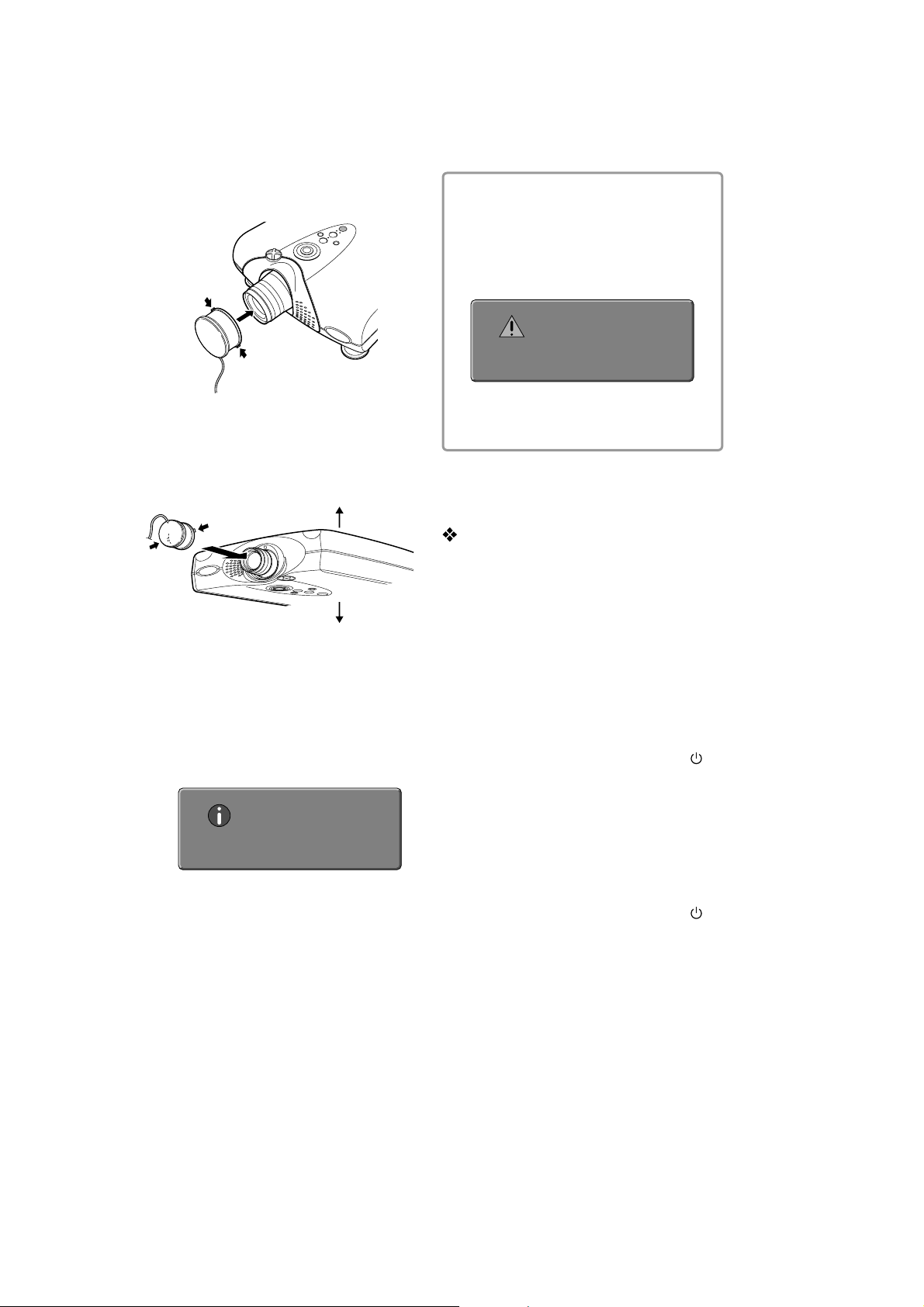

10. Disassemble of the shield for PWB of bottom side.

1) Remove 4 screws (311G) and remove the shield (310G) for

PWB.

2) Remove 9 screws (302G) and the shield (300G) for PWB.

3) Remove the cover (484G).

Fig.10

ボトム側基板シールドの取り外し

10.

1

2

3

)ネジ

)ネジ

)カバー

(311G) 4

(302G) 9

(484G)

本を外し基板シールド

本を外し基板シールド

を取り外します。

(310G)

を取り外します。

(300G)

を取り外します。

11. Disassemble of the FORMATTER PWB and the EXTEND

PWB.

1) Remove 4 screws (135G).

2) Disconnect 8 connectors (J001, J004, J005, J007 - J009,

J011 and J012).

3) FORMATTER PWB (P101) is connected with EXTEND

PWB (P400) by the connector (J002, J003). Pll out the

connector.

4). Remove the EXTEND PWB (P400) from PWB support

(132G).

Fig.11

11. FORMATTER

外し

1

2

3

(135G) 4

)ネジ

)コネクター

8

個所を取り外します。

)基板

(

J001, J004, J005, J007 - J009, J011and J012

(P101)

は基板

れています、基板

(

P101

)

及び

基板

本を取り外します。

(P400)

とコネクター

(P400)

を上側に持ち上げて基板

EXTEND

(

基板

P400

(

J002, J003

)

)

接続さ

(P101)

の取り

)

を

取り外します。

4

)

PWB

サポート

(132G)

から基板

(P400)

を取り外します。

310G

302G

484G

J224, J221

EXTEND PWB

311G

J211

P400 x 2

FAN PWB

P201

Fig.10

J205

135G

J003

Fig.11

302G

302G

P101

P400 x 2

FORMATER PWB

P101

J005

J008

J011

J004

J007

J009

J002

J012

J001

300G

7

Page 10

12. Disassemble of the SSB2 PWB, the SSB1 PWB and the

SSB2 基板

(P801)

及び SSB1 基板

(P701),

HDMI 基板

(P601)

の取り外し

基板取り付けブラケット及びランプ冷却ファンブロックの取り

外し

HDMI PWB.

1) Remove 3 screws (247G) and the screw (250G).

2) Disconnect 3 connectors (A : J501, J502 and J503) and the

FPC(J505).

Caution

When remove FPC (J505, JF02), a stopper is moved as

shown fi gure, and pull out FPC.

3) Remove the SSB2 PWB (P801) vertically.

4) Remove the 6 screws (250G).

5) Disconnect the 10 connectors. (B-G : J310, J301, J302,

J305, J702, J303, J311, J314, J304, J309)

6) Remove the SSB1 PWB (P701) vertically.

7) Remove 4 screws (237G) and 2 screws (241G), then remove

the HDMI PWB (P601).

Caution

When removing P601, Don’t strike against the chassis.

There is fear of part destruction.

Fig.12

12.

SSB2 基板

の取り外し

1

)ネジ

2)A部

(P801)

及び SSB1 基板

(247G) 3

本とネジ

コネクター 3個所

(250G) 1

(J501, J502, J503)とFPC(J505)1

(P701),

HDMI 基板

本を取り外します。

(P601)

個所

を取り外します。

注)コネクタ (

図のように動かしてから

3

)基板

側に持ち上げて基板

4

)ネジ

5)B~G部

J303, J311, J314, J304, J309)

6

)基板

7

)ネジ

J505, JF02)のFPC

FPC

を抜きます。

(P801)

(250G)6

コネクター

(P701)

は基板

(P801)

本を外します。

10

とコネクター接続されています、上

を取り外します。

(J310, J301, J302, J305, J702,

個所

を取り外します。

(P701)

は上側に持ち上げて取り外します。

(237G) 4

本とネジ

(241G) 2

取り外しは、ストッパー部を

本を外し、基板

(P601)

を取

り外します。

注)基板

(P601)

を取り外すさい、シャーシにぶっつけないよう注

意します。部品を破壊する恐れがあります。

250G

044Gx2

042G

247G

SSB2 PWB

B

250G

P601

HDMI PWB

Fig.12

P801

C

236Gx4

250G

D

E

250G

A

237Gx4

235G

x2

A

A

247G

F

G

M703

046Gx3

250G

P701

SSB1 PWB

241Gx2

239G

Stopper

13. Disassemble of the bracket and the fan Block for lamp

cooling.

1) Remove 2 screws (232G) and remove the bracket (230G).

2) Remove 3 screws (048G) and the fan Block for lamp cooling

(M703, M705).

Fig.13

基板取り付けブラケット及びランプ冷却ファンブロックの取り

13.

外し

1

2

)ネジ

)ネジ

M705)

(232G) 2

(048G) 3

本を外しブラケット

本を外しランプ冷却ファンブロック

を取り外します。

(230G)

を取り外します。

(M703,

8

FAN PWB

P201

038G

034G

030G

036G

048G

Fig.13

048G

040Gx2

M705

048G

232G

032G

x2

A

230G

A

Page 11

5. COLOR WHEEL REPLACEMENT PROCEDURE

1. Remove the 4 screws shown in the picture below and

remove the top cover of the optical engine.

Remove screw

Top cover

2. Remove the 2 screws shown in the picture below and

remove the bottom cover of the optical engine.

Bottom cover

4. Remove the screws at the front and back sides of the

color wheel and remove the color wheel cover.

Remove screw

3. Remove the condenser lens part.

Remove screw

Remove screws

Condenser

Remove color wheel cover

9

Page 12

5. Remove the 3 hex-screws then remove the color wheel.

Remove hex-screws

(Caution)

The rubber dumper are glued to the color wheel, Be

careful and remove.

The color wheel of VP-15S1 is not the same as VP-11S1,

VP12S1 to VP12S4 and VP13S1.

Be careful when exchange the color wheel.

Please check the part number under Rubber dumper.

Rubber dumper

(Caution)

Rubber dumper is in between the color wheel and the

optical engine, so it can be hard to remove the color

wheel. If it is diffi cult to remove the rubber dumper and the

color wheel, use a minus screw driver to remove those.

Be careful not to make a scratch on the color wheel fi lter.

6. Before assembling the color wheel, remove the rubber

dumpers form the optical engine then put them on to the

color wheel as shown in the picture below.

VP15S1 Color wheel model no.: 102299690

7. Adopt the color wheel to the optical engine and put on

the color wheel cover.

(Caution)

Do not push the motor part hard when putting on the

color wheel. It may break the motor. (Rotating noise may

become bigger)

8. Adjust the color wheel by following the Color Wheel

Adjustment Procedure.

Rubber dumper 1

Rubber dumper 2

10

Page 13

カラーホイール交換手順

5. COLOR WHEEL REPLACEMENT PROCEDURE

カラーホイール交換手順

1

. 下図の 4 箇所のネジを外し、光学エンジンの表側カバーを

外す。

表側カバー

2. 下図の 2 ヶ所のネジを外し、光学エンジンの裏側カバーを

外す。

4. カラーホイール前後のネジを外し、カラーホイールカバ

ーを外す。

ネジ

3. コンデンサレンズ部を外す。

ネジ

ネジ

コンデンサレンズ部

カラーホイールカバー

11

Page 14

. 3 ヶ所の六角ネジを外し、カラーホイールを外す。

5

ネジ

(注意)

振動防止ゴム

外し時注意してください。

VP-15S1 に使用しているカラーホイールは VP-11S1,

VP-12S1 〜 VP12-S4

間違いのないよう交換時注意してください。

振動防止ゴムの下の型番号を確認してください。

1、2 は、同じものを再び使用します。取り

, VP13S1 と共通ではありません。

振動防止ゴム

(注意)

カラーホイールと光学エンジンの間に振動防止ゴムが挟ま

っている為、外しにくい時があります。もし外れない時は、

カラーホイールのフィルターが傷つかないように、マイナ

スドライバー等でゴムとカラーホイールを外して下さい。

6. カラーホイールを取り付ける前に、振動防止ゴムを光学エ

ンジンから取り外し、下図のようにカラーホイールに取り

付けて下さい。

7.

(注意)

取り付ける時に、モーター部を強く押して取り付けないよ

モーターが破損する恐れがあります。(回転音が大きくな

VP-15S1 カラーホイール型番:102299690

カラーホイールを光学エンジンに取り付け、カラーホイー

ルカバーを取り付ける。

うにして下さい。

る原因となります。)

8. カラーホイールの調整方法に従い、再調整を行って下さい。

振動防止ゴム

振動防止ゴム 2

1

12

Page 15

6. ADJUSTMENT PROCEDURE

各調整が必要な場合

[A]

カラーホイールの調整手順

準備するもの

接続

プログラムの起動と設定

Cases Adjustment is needed

P701 PWB Board PK00 SSB PWB Kit 035G Color wheel UN04 Optical Engine

Color Wheel Adjustment

カラーホ イール調 整

Color Temperature Adjustment

色温度補正

Serial Number Inastall

シリアルナンバー書込み

Comfi rm of Software Version

ソフトウェアーヴァージョンの確認

AD9888 adjustment

ADC 調整

○○○ ○

○○○ ○

○○

○○

△

△: If the black image from the component or the RGB terminal is visible of some color, then please adjust.

△: コンポーネントもしくは RGB 端子からの黒画面で何らかの色が見える場合、調整を行ってください。

[A] Color Wheel Adjustment Procedure

1. Necessary Equipments

A service remote controller that can output the RC5

code "16 63 63". (The unit can adjust without a service

remote controller)

2. Connections

Confi rm that power cord is not connected to the UNIT.

3. Adjustment

1) Pressing the 3 buttons LEFT, ENTER, INPUT on the

unit within 10 seconds after turning on power or RC5

code "16 63 63" is sent using service remote, and turn

into the service mode.

2) With the direction buttons, up, down, left and right, select

"Optics Check" under "Optics Check".

各調整が必要な場合

Replaced item 交換したアイテム

[A]

カラーホイールの調整手順

1.

準備するもの

RC5 コード "16 63 63" が出せるサービスリモコン

( サービスリモコンを使用せず、本体のみで調整できます )

2.

接続

本体に電源ケーブルが接続されていないことを確認します。

3.

プログラムの起動と設定

1) 電源投入後 10 秒以内に本体の LEFT、ENTER、INPUT

の 3 つのボタンを同時に押してサービスモードに入ります。

または、サービスリモコンを使い

を送りサービスモードに入ります。

2) 上下左右の矢印ボタンを使い、"Optics Check" の "Optics

Check" を選択します。

RC5 コード "16 63 63"

3) Press the THROUGH button and the all-tone

monochrome image is displayed.

4) Confi rm that no OSD is displayed then press ENTER

button. Turn into the "Index Delay" adjustment mode.

5) "Index Delay" adjustment bar is displayed at the bottom

of the screen. Figure out the best number with the LEFT

and RIGHT buttons. (For adjustment detail, see the topic

'Detailed Adjustment Procedure' below.)

Figure: Adjustment Bar

3) リモコンの THROUGH ボタンを押し、" モノクロの全階調

画面

" を表示します。

4) OSD が表示されていないことを確認し、ENTER ボタンを

押します。

5) 画面下部に "Index Delay" 調整バーが表示されますので

LEFT、RIGHT ボタンを使い最適値を見つけ出します。

( 調整方法詳細を参照 )

13

Index Delay 調整モードに入ります。

Page 16

6) When the adjustment is made, press ENTER button.

調整方法詳細

7) Press MENU button to display the service menu.

8) With the direction buttons, select "Service Exit" and

press ENTER button.

9) When the unit has exited from the service mode, press

Standby button to turn the unit into the stand-by mode.

10) Disconnect Mains power cord from the unit.

All the procedure is complete.

Detailed Adjustment Procedure

This is to adjust location of color of the color wheel and

location of the mirror on/off of DMD. If the phases are

not coherent, vertical color stripes appear in the all-tone

monochrome image as shown in the pictures below.

調整が終了したら、ENTER ボタンを押します。

6)

7) MENU ボタンを押し、サービスメニューを表示します。

8) 矢印ボタンを使い "Service Exit" を選択し、ENTER ボタ

ンを押します。

9) サービスモードから抜け出たら、Standby ボタンを押し

セットをスタンバイ状態にします。

10) セットから電源ケーブルを抜きます。

以上で調整終了です。

調整方法詳細

これはカラーホイールの色位置と

DMD のミラー ON/OFF

位置を合わせるための操作で、この位相がズレると下の写真

のようにモノクロの全階調画面の中に色の付いた縦縞が現れ

ます。

Not color stripes appear

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

Color stripes appear

* To adjust the phases, set the value at middle of A and B

with seeing the PROJECTED IMAGE.

Color stripes appear Color stripes appear

Cyan magenta

Middle

Minimum value : A B : Maximum value

「色ズレのない画面」

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

+++++++

「色ズレの発生した画面」

※ 調整は 投影画面を見ながら 下図の中央「設定値」に設

定します。

色ズレが発生 色ズレが発生

シアン マゼンタ

下限値

A 中央 上限値 B

1. Seek the maximum value B when color stripes appear.

2. Likewise seek the minimum value A when color stripes

appear.

3. Set the value at the middle of A and B.

1. 色ズレの発生する「上限値 B」を探す。

2. 色ズレの発生する「下限値 A」を探す。

3. 「上限値 B」と「下限値 A」の中央の値に合わせる。

14

Page 17

[B] Color Temperature Adjustment Procedure

Color Temperature Adjustment

After replacing the lamp or in other cases where

the lighting changes, color temperature can be

adjusted using the color temperature sensor. In the

adjustment procedure, you must first initialize the

sensor itself before adjusting color temperature. It

takes about 10 minutes from when the power to

the projector is activated for the lamp’s brightness

to stabilize. Wait for lamp brightness to stabilize

before adjusting color temperature.

1. Connect the cable of the color temperature

sensor to the RS-232C port.

2.

Pressing the 3 buttons LEFT, ENTER,

INPUT on the unit within 10 seconds after

turning on power or RC5 code "16 63 63"

is sent using service remote, and turn into

the service mode.

With the direction buttons, up, down, left and

3.

right, select "Color Temp Calibration" under

"Color Temp."

Press the ENTER button. The below message

appears on the screen.

Initialize

Press "Enter" to start

Before pressing the ENTER button, turn the

color temperature sensor over on its dark side

as shown in the below figure, to prevent

outside light from penetrating to the sensor’s

condenser.

(Part no. : 00MZK09AV0070)

Condenser

5. Press the ENTER button. The below message

appears on the screen for a few seconds as

the sensor is being calibrated.

Initializing...

6. Position the lamp so that its light passes

through the center of the lens. This is

necessary in order to calibrate color

temperature correctly. First, turn the lens shift

knob all the way to the left so that the lens

lowers to the lowest position. Then, turn it five

and a half turns to the right to raise the lens.

In this position, the light of the lamp passes

almost through the center of the lens.

Press the cursor button B (RIGHT).

4.

The below message appears on the screen.

Color Temp. Calibration?

Press "Enter" to start

Yes No

Note:

Color temperature cannot be correctly

calibrated unless the lens is properly

positioned.

15

Page 18

7. Fit the color temperature sensor onto the lens

and press the ENTER button. Color

temperature adjustment starts and the

projector’s WARNING and STANDBY

indicators begin flashing simultaneously.

When installed on a tabletop

Attach the color temperature

sensor so that the cable is to the

bottom side of the projector.

9. Press the ENTER button to return to the menu

and disconnect the cable of the color

temperature sensor from the projector.

Note:

If color temperature adjustment is not

correctly processed or if adjustment

processing is interrupted in course by

pressing the MENU button or for some other

reason, the below message appears on the

screen.

Quit

Press "Enter" to exit

Also, adjustment processing can be

interrupted by pressing the MENU button.

When installed on a ceiling

Bottom

To p

Attach the color temperature sensor so that the

cable is to the bottom side of the projector.

8. When the WARNING and STANDBY

indicators go out, color temperature

adjustment is complete. Adjustment takes

about 2 to 3 minutes. When the color

temperature sensor is detached from the lens,

the below message appears on the screen.

Complete

Press "Enter" to exit

10. Turn the lens shift knob until returning the lens

to the screen position you want to use.

Color Temperature Sensor

Protection

If no operations are performed for approximately 10

minutes from the moment color temperature

adjustment processing ends, power to the projector

shuts OFF automatically in order to protect the color

temperature sensor. If power is shut OFF to protect

the color temperature sensor, do the following.

If the WARNING indicator does not light

•

When color temperature adjustment ends

successfully and the sensor protection feature

trips, the projector goes on standby. As usual,

activate power by pressing either the ON

button on the remote control or the /I

button on the projector.

If the WARNING indicator lights

•

If color temperature adjustment does not end

successfully and the sensor protection feature

trips, the projector's WARNING and STANDBY

indicators light simultaneously to indicate the

error mode. Unplug the power cable and then

plug it back in. Then, press either the ON

button on the remote control or the /I

button on the projector to reactivate power.

16

Page 19

[B] 色温度補正

色温度の補正

ランプを交換したときなどに、色温度センサー

を使い色温度を補正することができます。

この補正手順の流れは、先ずセンサー自体を

初期化し、その後に本機の色温度を補正する

手順となっています。

本機の電源をONにしてから、ランプの明る

さが完全に安定するまで約10分かかります。

色温度の補正はランプの明るさが安定した後

に行ってください。

1. 色温度センサーのケーブル端子を本機の

RS-232C端子に接続します。

2.

電源投入後10秒以内に本体のLEFT、

ENTER、INPUTの3つのボタンを同時

に押してサービスモードに入ります。

または、サービスリモコンを使いRC5

コード"166363"を送りサービスモー

ドに入ります。

ENTERを押します。下記のメッセージ

画面が表示されます。

%NTER

ここで必ず ENTERボタンを押す前に、

下図のように色温度センサーを暗部にふ

せて、センサーの集光部に外からの光が

入らないようにしてください。

0ARTNO-:+!6

集光部

5. ENTERボタンを押すと、下記のメッセ

ージ画面が数秒間表示されます。色温度

センサー自体が初期化されます。

上下左右の矢印ボタンを使い、"色温度

3.

"の"色温度補正"を選択します。

方向ボタン

4.

のメッセージ画面が表示されます。

#(右)を押します。下記

%NTER

6. 次に、ランプからの光がレンズの中央を

通るように位置合わせを行います。これ

は正確な色温度補正を行うためです。ま

ず、レンズシフトノブを止まるまで左い

っぱいに回し、レンズを一番下側に下げ

ます。次に約5回転半だけ右に回し、レ

ンズを上げます。この状態でランプから

の光はレンズのほぼ中央を通るようにな

ります。

:この位置調整を行わないと、正確

な色温度補正が行われません。

17

Page 20

7. 色温度センサーを本機レンズ部分に取り

付け、 ENTERボタンを押します。色温

度の補正が開始され、本機のWARNING

ランプとSTANDBYランプが同時に点滅

します。

卓上設置の場合

本体に対して、センサーケー

ブルを必ず下側にして取り付

けてください。

天吊り設置の場合

:

色温度補正が正常に処理できなかっ

たり、色温度補正中に MENU ボタン

を押したり、何らかの理由で補正処

理が中断された場合は、下記のメッ

セージ画面が表示されます。

%NTER

またMENUボタンを押すことで、強

制的に補正処理を中断させることが

できます。

10.

レンズシフトノブを回して、ご使用のス

クリーン位置にレンズ位置を戻します。

色温度センサーの保護

本機は色温度センサーを保護するために、補

正処理が完了してから 無操作状態で約10分

経過すると、自動的に本機の電源が切れるよ

うになっています。

センサー保護のため電源が切れたときは、以

下の処置を行ってください。

本体に対して、センサーケーブルを必ず下側

にして取り付けてください。

8. WARNINGランプとSTANDBYランプの

点滅が消えると補正完了です。補正時間

は約2分かかります。色温度センサーを

取り外すと、下記のメッセージ画面が表

示されます。

%NTER

9. ENTERボタンを押してメニューに戻り、

色温度センサーのケーブル端子を外しま

す。

●

WARNINGインジケーターが点灯していな

い場合

色温度補正が正常に処理され、センサー保

護が働いた場合は、本機はスタンバイ状態

になります。

通常通り、リモコンの ONボタンまたは本

体の / I ボタンを押して電源を入れてく

ださい。

●

WARNINGインジケーターが点灯している

場合

色温度補正が正常に処理されず、センサー

保護が働いた場合は、本機のWARNINGラ

ンプとSTANDBYランプが同時に点灯しエ

ラーモードを表示します。

一度AC電源コードを抜き、再度差し込ん

でからリモコンの ONボタンまたは本体

の/I ボタンを押して電源を入れてくだ

さい。

18

Page 21

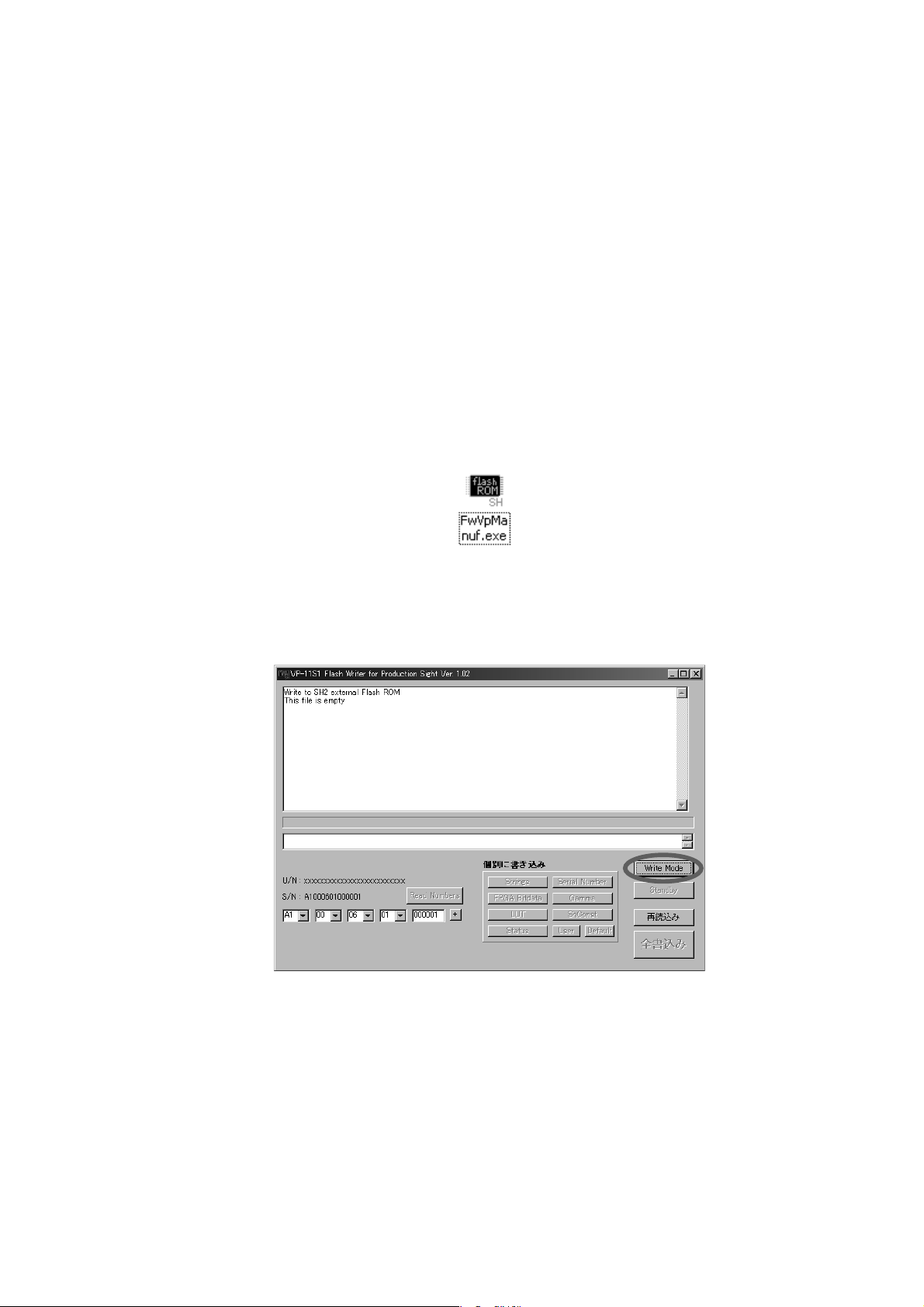

[C] Serial Number Installing Procedure

1. Necessary Equipments

• RS232C cable (Straight type: Female to Female)

• PC (Windows 200 or XP)

• Serial Number installing software "FwVpManf.exe" on the

PC

• A HyperTerminal Applet "VP_232C.hp" on the PC

2. Connections

Connect the RS232C cable to the RS232C ports of the

PC and the Projector.

3. Installing

1) Press the POWER button. And wait until the lamp lights

up completely.

2) Open the "FwVpManf.exe" on the PC.

1. 準備するもの

• RS232Cケーブル (ストレート タイプ:メス⇔メス)

• PC (Windows200 もしくは XP)

• PCにインストールされたシリアルナンバー書込みツール

"FwVpManf.exe"

• PCにインストールされたハイパーターミナルアプレット

"VP_232C.hp"

2.

接続

RS232CケーブルをプロジェクターとPCのRS232Cポートに

接続します。

3. プログラムの起動と書込み、確認

1) POWERボタンをおして、ランプが点灯することを確認してくだ

さい。

2) "FwVpManf.exe"を開いてください。

3) Click the "Write Mode" button. And confirm the 3

indicators (ON, STANDBY and WARNING) on the

projector are flashing in sequence.

4) Click the "Standby" button. Make sure that the lamp is

turned off.

5) Input the serial number of the back panel of the target

projector.

3) "Write Mode"ボタンをクリックして 、プロジェクターの 3つのイ

ンジケーター

確認してください。

(ON, STANDBY, WARNING)が点滅することを

4) "Standby"ボタンをクリックし てください 、ランプが 消 灯します。

5) プロジェクターのバックパネルのシリアルナンバーを入力してく

ださい。

19

Page 22

6) Click "Serial Number" button to install.

6) "Serial Number"ボタンをクリックすると書き込まれます 。

7) Remove the main AC cable. Don’t power off by any other

means.

8) Connect the main AC cable and Press the POWER

button for confirmation.

9) Open the "VP_232C.hp" on the PC.

10) Input "@VER_SERIAL?" and press Enter key on the PC.

7) 電源ケーブルを抜いてください。

8) 確認のため、電源ケーブルを差し、プロジェクターをオンしてく

ださい。

9) "VP_232C.hp"を開いてください。

10) "@VER_SERIAL?"と入力し、PCのEnterキーを押してくださ

い。

20

Page 23

11) Confirm the serial number on the window and the

projector.

12) Turn off the projector.

11) プロジェクターとPCのウインドウのシリアルナンバーと確認し

てください。

12) プロジェクターの電源をオフします。

21

Page 24

[D] Confirmation procedure of software version

1. Necessary Equipments

A service remote controller that can output the RC5 code

"00 63 63". (The unit can adjust without a service remote

controller.)

2. Confirmation

1) Pressing the 3 buttons LEFT, ENTER, INPUT on the unit

within 10 seconds after turning on power or RC5 code

"00 63 63" is sent using service remote, and turn into

the service mode.

The Service Mode window is displayed.

2) With the direction buttons, up and down, select

"Contrast".

3) Press the "ENTER" button and the software version

information window is displayed.

1. 準備するもの

RC5コード"00 63 63"が出せるサービスリモコン

(サービスリモコンを使用せず、本体のみでも調整できます)

2.

確認

1) 電源投入後10秒以内に本体のLEFT, ENTER, INPUTの3つ

のボタンを同時に押してサービスモードに入ります。

Service Modeのウインドウが表示されます。

2) 上下の矢印ボタンを使い、"コントラ スト"を選 択します。

3) "ENTER"ボタンを押すとソフトウェア ー・ヴァージョン確 認 ウイ

ンドウが表示されます。

4) Confirm the software version.

The item(s) might be highlighted in red color at the

software version information window, when the software

combination didn’t true. In that case, please confirm

combination of software in Service Britain.

5) Press "ENTER" button to exit the software version

window.

6) Select "Service Exit" and press the "ENTER" button to

go the normal operation.

4) ソフトウェア ー ・ ヴァージョン を 確 認 します 。

赤色の文字で表示されている場合、ソフトウェアーの組合せが

正しく有りません。

ェアーの組み合わせを確認してください。

その場合は、サービスブリテンにてソフトウ

5) "ENTER"ボタンを押すとソフトウェアー ・ヴァー ジョン 確 認 ウ イ

ンドウ が 閉 じ ます 。

6) "Service Exit"を選択して"ENTER"ボタンを押すと通常動作

になります。

22

Page 25

[E] AD9888 Adjustment Method

[1] Necessaries

• Desktop Windows PC (for signal generator)

• Video card (It has to be filled the following features. ex.

NVIDA GeForce6600)

1. VGA/60Hz RGB signal can be generated.

2. 480P/60Hz, 720P/60Hz Component signal can be

generated.

**By way of example, this adjustment method mentions

about the example of use for the video card "NVIDA

GeForce6600".

• Windows PC(XP/2000) built in RS232C terminal (for

adjustment)

***Application software for AD adjustment (AtAdAdjEng.

exe) has to be installed to this PC already.

(Please note that you have to arrange 2 PC’s at least if

you perform this adjustment without the signal generator.

Application software for AD adjustment (AtAdAdjEng.exe)

can not run through the USB-RS232C converter. )

• RS232C cable (straight type : Female <-> Female)

• Test pattern data (White 80%, Black 0%, Yellow 100%,

Cyan 100%)

[E] A/DコンバータAD9888の調整方法

PCを信号発生器として用います。

[1] 調整に必要なもの

• 信号発生器として用いるPC

• Windows搭載PC(バージョンは使用するグラフィックカー

ドの要求による)

• グラフィックカード

RGB信号:VGA/60Hz RGB信号が出力可能な事

コンポーネント信号:480p・720p/60Hz信号が出力可能な

事

※一例としてNVIDIA GeForce6600搭載のグラフィックカ

ード使用例を示します。

• 調整用PC

RS-232C

調整用アプリケーション"AtAdAdj_1_08"がインストールさ

れている事

• RS-232Cケーブル(ストレート)

• テストパターン

White(80%)

Black(0%)

Yellow(100%)

Cyan(100%)

※テストパターン作成例を添付いたします。

端子が実装されたWindows 搭載PC

[2] Make out a test pattern

A test pattern is created using Windows standard

software (paint).

Start → programs → Accessories → Paint.

Fig 1 Screen of Paint

[2] テストパターンの作成

テストパターンはWindows標準ソフト(ペイント)を使い作

成します。

Windowsスタート → プログラム → アクセサリ → ペイン

トを起動します。

Fig 1. ペイント起動画面

The edit display of the color which clicks a color and is

shown in Fig2 in the upper part of a screen is started.

画面上部にある、色をクリックしてFig 2に示す色の編集画

面を立ち上げます。

23

Page 26

Fig 2. The edit screen of color

Fig 2. 色の編集画面

White(80%) : R=204 G=204 B=204

Black(0%) : R=0 G=0 B=0

Yellow(100%) : R=255 G=255 B=0

Cyan(100%) : R=0 G=255 B=255

After inputting a numerical value, OK is clicked and it

returns to the original screen.

It smears away by the color made after returning to the

screen of Fig1, and a test pattern is completed.

Please give a suitable name and save to a suitable

directory, respectively.

[3] Connections

VGA cable

VGAケーブル

Fig 2に示す色の編集画面にて赤緑青(RGB)に数値を入れて

色を作ります。各テストパターンに必要な数値は以下の通

りです。

White(80%) :R=204 G=204 B=204

Black(0%)

Yellow(100%)

Cyan(100%)

数値を入力後、OKをクリックして元の画面に戻ります。

:R=0 G=0 B=0

:R=255 G=255 B=0

:R=0 G=255 B=255

Fig 1の画面に戻った後に作った色で塗りつぶしテストパタ

ーンを完成させます。適当な名前をつけて適当なディレク

トリにそれぞれ保存してください。

[3] VP-15S1とPCの接続

Fig 3に調整時のVP-15S1とPCの接続を示します。

Desktop windows PC

with video card

for Signal generator

信号発生用PC

VP-15S1

RS232C straight cable

RS-232C

ケーブル

Fig 3. Connections / 接続図

Component cable

Connect to COMP1

コンポーネントケーブル

COMP1へ

上図に示す様にVP-15S1と接続します。コンポーネントケ

ーブルは

24

Windows PC

for adjustment

調整用PC

Comp1に接続します。

Page 27

[4] How to setup the desktop PC for signal generator

[4] 信号発生用PCの初期設定

1) After connecting all cables, press the power button on

the VP-15S1, and PC for signal generator and PC for

adjustment.

2) Change the input setting of VP-15S1 to the RGB input,

confirm that the screen of PC for signal generator

shows.

3) Change the RGB output resolution to VGA (640 x 480).

4) On the desktop of PC for signal generator, click the right

button of mouse and open the property for screen.

1) 接続後にVP-15S1、信号発生用PC、調整用PCをそれぞれ立

ち上げる。

VP-15S1をRGB入力に切り替 える。

2) 信号発生用PCの画面表示が出ることを確認します。

3) RGB出力解像度を(640 x 480)に変更する

4) デスクトップ 上 で 右 クリックをし 、画面のプロパティを開く。

Fig 4. Property for screen

5) Open the tab of setting, click the button of detailed

setting.

Fig 4.画面のプロパティ1

5)

設定タブを開き、詳細設定をクリックします 。

Fig 5. Property for screen 2

Fig 5. 画面のプロパティ2

25

Page 28

6) Open the tab of GeForce 6600.

6) GeForce 6600タブを開きます。タブを展 開 するとFig 5の詳

細設定画面になります。

Fig 6. Property of screen 3

7) Select "Screen resolution & refresh rates", Change the

Screen resolution as Fig 6 to 640 x 480, and change

the Screen refresh rate to 60Hz. After setting, click the

button of application.

Fig 7.Screen of confirmation 1

Fig 6. 画面のプロパティ3

7) Screen resolution & refresh rates

resolution

refresh rate

をFig 6の様に640 x 480に設定し、Screen

を60Hzにします 。設定後、適用をクリックしま す 。

Fig 7.確認画面1

を選択し、Screen

Fig 8.Screen of confirmation 2

8) After applying, the screen for confirmation shows as Fig

7 and Fig 8. Click the button of OK with both screens.

Then the signal of resolution 640 x 480 will output from

RGB output of PC.

[5] How to display the test pattern on screen

1) Run the Microsoft PAINT on the PC for signal generator.

2) Open the file of a test pattern. (By way of example, this

adjustment method mentions about the example of use

for the MS PAINT.)

確認画面2

Fig 8.

8)

適用後、Fig 7, Fig 8の様に確認画面が現れます。共にOKをク

リックし て 下さい 。

この状態でRGB出力端子から調整に必要な640 x480の解像

度が出力されます。

[5] テストパターンの表示

1) テストパターン作成に使用したペイントを立 ち 上げます 。

2) 先に作ったテストパターンのファイルを読み込みます。(本手順

書ではペイントを用いた例を示します)

26

Page 29

Fig 9.Screen of MS PAINT

Fig 9.ペイント画 面

3) To display the full screen of test pattern, click the "View"

of menu bar on the top of MS PAINT and select the

bitmap view. Then the test pattern shows on the full

screen.

[6] How to adjust

1) Adjustment of RGB

Double click the application file "AtAdAdjEng.exe" of the

folder AtAdAdjEnglish on the desktop.

3) 全画面テストパターン表示を行う為に上部にある表示をクリッ

クし 、ビットマップ表示を選択します。全画面にテストパター ン が

表示されます。

[6] 調整

1) RGBの調整

調整用PCにインストールした調整用アプリケーション

"AtAdAdj_1_08"

立ち上がります。

を立ち上げます。起動するとFig 10の画面が

Fig 10.Screen of AtAdAdjEng

2) Press the "SPACE" key on the keyboard of PC for

adjustment.

3) Confirms that the following message.

4) Input 80% White RGB signal with the PC for signal

generator.

Fig 10. AtAdAdj_1_08起動画面

調整用PCの"SPACE"キーを押し、調整を開始します (RGB入

力は自動的に切り替わります

)。

Fig 11のメッセ−ジを確認後、手順[5] テストパター ン の 表

示に従い、信号発生用

ます。全画面表示した信号を

PCでWhite(80%)のファイルを開き

RGB端子に入力し、調整用

PCの"SPACE"キーを押します。

27

Page 30

Fig 11.Screen of AtAdAdjEng

Fig 11. AtAdAdj_1_08起動画面

5) Press the "SPACE" key on the keyboard of PC for

adjustment.

6) Confirms that the following message.

7) Input 0% Black RGB signal with the PC for signal

generator.

Fig 12のメッセ−ジを確認後、手順[5] テストパター ン の 表

示に従い、信号発生用

ます。全画面表示した信号を

PCでBlack(0%)のファイルを開き

RGB端子に入力し、調整用

PCの"SPACE"キーを押します。

Fig 12.Screen of AtAdAdjEng

8) Press the "SPACE" key on the keyboard of PC for

adjustment.

9) Confirms that the following message.

10) Then the input of VP-15S1 changes RGB input to

COMP1 input automatically.

However, return the RGB input manually.

Fig 12.AtAdAdj_1_08起動画面

RGB調整終了後のFig 13に示す画面になります。

480p-RGB調整完了後、自動で480p-YUV調整に移行します。

セット本体の入力は自動でCOMP1に切り替 わりますが、一旦

RGB入力に戻してください。

28

Page 31

Fig 13.Screen of AtAdAdjEng

Fig 13. AtAdAdj_1_08起動画面

1 1) Adjustment of copmponent (480p)

Open the property of GeForce 6600 on the PC for signal

generator.

Fig 14.Screen of property for GeForce 6600

12) Select "nView Display Setting", and change the setting

of "Current display" to HDTV. Select 480p on the Device

Settings and click the application.

Then the output of PC for signal generator will change

the RGB output to the component output.

Change the input of COMP1 on the VP-15S1.

13) Input 100% saturation Yellow 480P/60Hz Component

signal with the PC for signal generator.

2) コンポーネント(480p)の調整

RGB出力を変更した時と同様に画面のプロパティから

GeForce6600のプロパティ画面にします。

Fig 14. 画面のプロパティ4

Fig 14

に示すnView Disply Settingを選択しCurrent

の設定をHDTVにします。同時にDevice Settings から

disply

出力解像度

す。

(480p)を選択します。選択後、適用をクリックしま

RGBから出力が停止し、コンポーネント端子からのみ信号が出

力されます。

ください 。

VP-15S1の入力をコンポーネント1に切り替えて

テストパターンの出力は、手順[5] テストパターンの表示に従い

行ってください。

RGB調整後の調整用アプリケーション"AtAdAdj_1_08"が

Fig 15を示していることを確認後、コンポーネント1に480p

Yellow(100%)

す。テストパターンの出力は、手順

従い行ってください。

を入力し、調整用PCの"SPACE"キーを押しま

[5] テストパターンの表示に

29

Page 32

Fig 15.Screen of AtAdAdjEng

Fig 15. AtAdAdj_1_08起動画面

14) Press the "SPACE" key on the keyboard of PC for

adjustment.

15) Confirms that the following message.

16) Input 100% saturation Cyan 480P/60Hz Component

signal with the PC for signal generator.

Fig 16のメッセ−ジを確認後、コンポーネントに480p

Cyan(100%)

す。テストパターンの出力は、手順

従い行ってください。

を入力し、調整用PCの"SPACE"キーを押しま

[5] テストパターンの表示に

17) Press the "SPACE" key on the keyboard of PC for

adjustment.

18) Confirms that the following message.

19) Input 0% Black 480P/60Hz Component signal with the

PC for signal generator.

Fig 16. AtAdAdj_1_08起動画面

Fig 17のメッセ−ジを確認後、コンポーネントに480p

Black(0%)

テストパターンの出力は、手順

行ってください。

を入力し、調整用PCの"SPACE"キーを押します。

[5] テストパターンの表示に従い

30

Page 33

20) Press the "SPACE" key on the keyboard of PC for

adjustment.

21) Confirms that the following message.

Fig 17. AtAdAdj_1_08起動画面

ここまでの作業で480pの調整が終了します。

22) Adjustment of copmponent (720p)

Open the property of GeForce 6600 on the PC for signal

generator.

( Fig 14.Screen of property for GeForce 6600 )

3) コンポーネント(720p)の調整

720pにてコンポーネント480pで行った調整と同様の調整

を行います。調整ソフトウェアは自動的に

480pの調整が終了

720pの調整に入ります。

( Fig 14. 画面のプロパティ4 )

31

Page 34

23) Select "nView Display Setting", and change the setting

of "Current display" to HDTV. Select 720p on the Device

Settings and click the application.

24) Input 100% saturation Yellow 720P/60Hz Component

signal with the PC for signal generator.

25) Press the SPACE key on the keyboard of PC for

adjustment.

26) Confirms that the following message.

27) Input 100% saturation Cyan 720P/60Hz Component

signal with the PC for signal generator.

28) Press the SPACE key on the keyboard of PC for

adjustment.

29) Confirms that the following message.

30) Input 0% Black 720P/60Hz Component signal with the

PC for signal generator.

画面のプロパティからGeForce6600のプロパティ画面Fig

に示すnView Disply Settingを選択しDevice Settings か

14

ら出力解像度

す。信号発生用

(720p)を選択します。選択後、適用をクリックしま

PCからコンポーネント720pが出力されます。

480p同様に調整用ソフトウェアの指示に従い、Yellow(100%)・

Cyan(100%)・Black(0%)と調整を進めてください。( 表示内容

は英文も参考にしてください。

)

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

32

Page 35

31) Press the SPACE key on the keyboard of PC for

adjustment.

32) Confirms that the following message.

.

.

.

.

.

.

.

.

.

.

.

.

.

全ての調整終了後にFig 18に示すメッセージが現れます。確認

をし て か ら セットの電源を落としてください。

33) Press Standby button on the projector.

34) Remove all connection cables.

<Trouble shooting against adjustment problem>

Adjustment problem mode:

An adjustment process will stop into an adjustment process.

Adjustment is not completed.

When the adjustment problem occurs into 480p-RGB

adjustment process

Press ESC key on the key board. Adjustment process

returns to an initial 480p-RGB adjustment process. Again,

please perform 480p-RGB adjustment process.

When the adjustment problem occurs into 480p-YUV

adjustment process

Press ESC key on the key board. Adjustment process

returns to an initial 480p-YUV adjustment process. Again,

Fig 18.終了メッセージ

以上で調整終了です。

33

Page 36

please perform 480p-YUV adjustment process.

When the adjustment problem occurs into 720p-YUV

adjustment process

Press ESC key on the key board. Adjustment process

returns to an initial 720-YUV adjustment process. Again,

please perform 720p-YUV adjustment process.

34

Page 37

7. TROUBLESHOOTING AND HINT

[1] Check list for Troubleshooting

Symptom 1 Symptom 2 Condition check Check Locations

1.

Is the voltage of 5V at P701-J302 (2 pin)? UN02, W013

↓

2.

No STANDBY

LED light up.

No Power

(Lamp does

not light)

The Power key

dose not work

Warnig LED

lights or Flashing

No Picture

Remote control does not work

Iris does not work

No change brightness of image.

No change Color of Focus

(Lens Shift sensor does not

work)

Is the voltage of 5V at P903-J329 (10 pin)? P701, W014

↓

3.

Is the voltage of 3.3V at P903-J329 (8 pin)? P701, W014

↓

Check 1-3 have no problem P903

1.

Is the voltage of 3.3V at P903-J329 (1 pin)? P701, W014

↓

Does voltage of P903-J329 (2 pin) change to 2.0V from 0V

2.

when push the power key?

↓

Check 1-2 have no problem P701, W014

Refer to The Error Status item and solution.

No image of MENU and PATTERN

No image of VIDEO input.

No image of S-VIDEO input.

No image of COMPONENT 1, 2 input.

No image of RGB input.

No image of HDMI 1, 2 input. P601, P801

1.

Is't Menu-Config.-Remote Control "Weird"? Set "Wireless"

↓

Is the voltage of 5V at P901-J330 (1 pin) and P902-J331

2.

(1 pin)?

↓

Is the pulse signal of 0V to 5V at P903-J329 (12 pin) when

3.

push the remote controller button?

↓

Is the pulse signal of 0V to 5V at P501-JL16 (10 pin) when

4.

push the remote controller button?

↓

5.

Is the voltage of 3.3V at P501-JL16 (7 pin)? P701, W012

↓

Is the pulse signal of 0V to 5V at P501-JL16 (9 pin) when

6.

push the remote controller button?

↓

Check 1-6 have no problem P701, W012

Refer to The Frow from Iris Control.

VP-15S1L is not this sensor.

P903

P701, W001, P101, P400,

UN04

P501, P801 "VIDEO" signal

line

P501, P801 "Y_S" and

"Y_C" signal line

P501, P801 "Y_COM#",

"CB#", CR#" signal input

P501, P801 "RGB_R(G, B,

H, V)"

P903, W015, W016

P903 "IR_SENSE", "IR_

FRONT" and "IR_REAR"

P701, W012, W014

P501

UN04, P701

(Don't remove the PCB of

UN04. Detection position

shifts.)

35

Page 38

Symptom 1 Symptom 2 Condition check Check Locations

Current 100mA or more

The voltage of 12V is not

outputted to TRIG1.

The voltage of 12V is not

outputted to TRIG2.

1. Is output current 100mA or less?

↓

When the lamp lights up, is the voltage of 3.3V at P501-

2.

JL16 (11 pin)

↓

Check 1-2 have no problem P501

1. Is output current 100mA or less?

↓

2. Are the Menu setup and selection Aspect setup correctly? Setup the menu.

↓

3. Is the voltage of 3.3V at P501-JL16 (12 pin) P701, W012

↓

Check 1-3 have no problem P501

is not accepted by

specification.

P701, W012

Current 100mA or more

is not accepted by

specification.

36

Page 39

[2] The flow from IRIS Control

1) Refer to the schematic diagram of P201-2/2.

2) Q262 and Q264 is 74VHC123AFT "Mono stable multi vibrator".

Q263 and Q265 is BA6951FS "DC motor driver".

3) Refer to the following timing chart.

4) IRIS1 or IRIS2 = "L" level (0V) ------- Iris is narrow.

IRIS1 or IRIS2 = "H" level (3.3V) ---- Iris is Wide.

5) The iris mode in menu vs. Iris pattern.

Iris Mode Contrast Brightness Lens Iris Illumination Iris

1 High Low Narrow Narrow

2 Middle Middle Narrow Wide

3 Low High Wide Wide

37

Page 40

[3] The flow from turn on the projector to the picture projection

1) Turn on the projector.

2) P701-J302 (3 pin) "PWR-CTR" become to "H" level (3.3V).

3) P701-J301, P101-J005, P201-J201 and P601-JE05 are raised to true voltage.

PCB - Connector Pin No. Voltage (V) PCB - Connector Pin No. Voltage (V)

P701 – J302

Connectors Location

1 0 (GND)

2 13.3 2 13.3

3 -6.1 3 0 (GND)

4 0 (GND) 4 13.3

5 0 (GND) 5 0 (GND)

6 6.1 6 13.3

7 0 (GND) 7 0 (GND)

8 3.5 8 13.3

9 0 (GND) 9 0 (GND)

10 3.5 10 13.3

11 0 (GND) 11 0 (GND)

12 2.5 12 13.3

13 0 (GND)

14 1.2 2 0 (GND)

15 1.2 3 6.1

16 0 (GND)

P101 – J005

P201 – J201

P601 – JE05

1 0 (GND)

1 13.3

1 6.1

2 0 (GND)

3 3.5

4 0 (GND)

J301

On

P601

J301

J005

J201

4) Configuration of the main u-P, CPLD, FPGA and GF9351 on P701 and P801.

5) P101-R073 "PWR_GOOD" becomes to "H" level (3.3V) and D001 (Yellow LED) lights up.

38

Page 41

R049

"LAMPLIT"

R048 and D002

"ASIC_REDAY"

R073 And D001

"PWR_GOOD"

6) The drive signal (3 phase motor drive) output from P101-J008

The color wheel starts.

7) P101-J011 (1 pin) "SCI" of the control signal for the lamp ignition become to "H" level (5V).

The lamp lights up.

8) P101-J011 (3 pin) "FLAG_OUT" become to "L" level (0V)

When "FLAG_OUT" don’t become to "L" level (0V), it returns to 5). After repeating 3 times, Warning LED lights up.

9) "FLAG_OUT" signal go to SSB PCB board from P101-J012 (3 pin).

10) P101-R049 "LAMPLIT" become to "L" level (0V).

11) P101-R048 "ASIC_READY" becomes to "H" level (3.3V) and D002 (Green LED) lights up.

12) A picture is projected.

39

Page 42

[4] DMD [1080p] Image Quality Specification

1 Error definitions

1.1 Dark Blemish

A blemish is an obstruction or reflection of light.

This is dark visibility on light screen in the active area.

This is any form and size.

1.2 Light Blemish

A blemish is an obstruction or reflection of light.

This is light visibility on dark screen in the active area.

This is any form and size.

1.3 Dark Pixel

A dark pixel is a mirror that is stuck in the OFF position.

This is visible that is dark square pixel on light screen in

the active area.

Major Dark Blemish

Major Dark Blemish

Blue 60

Blue 60

Minor Dark Blemish

Minor Dark Blemish

White

White

Major Light Blemish

Major Light Blemish

Gray 10

Gray 10

Minor Light Blemish

Minor Light Blemish

Black

Black

WhiteWhite

1.4 Light Pixel

A light pixel is a mirror that is stuck in the ON position.

This is visible that is light square pixel on dark screen in

the active area.

1.5 Unstable Pixel

An unstable pixel is a mirror that does not operate.

This appears to be flickering asynchronously with image.

Flickering pixelFlickering pixel

1.6 Border Defect

Border defect is pixel defect or Blemish in border area

(see Fig. 2.2).

Gray 10Gray 10

Any other ScreenAny other Screen

Any ScreenAny Screen

40

Page 43

2 Screen image

2.1 Active Area

The Active area is the active pixel area on image screen.

This is visible white area when input signal is all white.

2.2 Border Area

The border is described as the area outside of the active area.

This is visible black outside white image when input signal is all white.

(See Fig. 2.2)

60inch(152cm)

Border area

Border area

Around 4inch(10cm)

Around 4inch(10cm)

Active area

Fig. 2.2 Border areaFig. 2.2 Border area

3 Test conditions and Specifications

3.1 Image size

The diagonal size of the projection image on the screen shall be at minimum 60 inches (152cm).

3.2 Viewing distance

The projected image shall be inspected from 8 foot (2.4m) minimum viewing distance.

3.3 Focus

Projection must be properly focused on DMD array as shown on the screen.

3.4 Screen image

Menu setting of the VP-15S1 should be initial "Optics check" in "service mode".

3.5 Hints

All error that scratches on DMD and so on shall be checked the projected image on the screen.

3.6 Image quality specification test criteria

Test

1 Major Dark Blemish Blue 60

2 Major Light Blemish Gray 10

3 Border Defects Any Screen Acceptable

4 Dark Pixel White

5 Light Pixel Gray 10 No pixels brighter than Gray 10 in Active Area.

6 Minor Blemishes

7 Unstable Pixel Any Screen No unstable pixels

screen

(Note 4)

White

Black

Maximum 6 visible blemishes darker then Blue 60.

No Blemish longer then 1 inch at 60 inches.

Maximum 6 visible blemishes darker then Gray 10.

No Blemish longer then 1 inch at 60 inches.

Maximum 8 dark pixels allowed in Active Area.

No adjacent dark pixels

Acceptable

Acceptance criteria

Note:

1. Projected blemish numbers count shadow of the artifact in addition to the artifact itself.

2. Border defects are bright blemishes or light pixel in the non-active area then may be visible.

41

Page 44

3. Screen select for remote controller

Component 1 Input video signal

Component 2 Lens Iris on/off

S-Video Illumination Iris on/off

Video Raster (Black)

RGB Raster (White)

Theater Red

Standard Green

Dynamic Blue

Info. Resolution

Full Horizontal Staircase

Normal Vertical Staircase

Cinema Color Bars

Through Horizontal Ramp

Zoom Blue 90

HDMI 1 Gray 5

Pattern Gray 10

V Mute Gray 30

Black level Blue 60

VCR Mode Gray 6

HDMI 2 Gray 1

42

Page 45

7. TROUBLESHOOTING AND HINT

[1] CHECK LIST FOR TROUBLESHOOTING 対処方法

症状 1症状 2 確認手順 対象箇所

1. P701-J302 (2 pin)に5Vの電圧が有りますか? UN02, W013

↓

STANDBY LED

しない

電源が入らない

(ランプが点灯し

ない

)

Power

キーを受付けない

STANDBY LEDが点灯し

たまま

Warnig LED

は点滅する

画面が表示されない

リモコンが効かない

アイリスが動作しない

画面の明るさが変わらない

Focusの色が変わらない

(

Lens Shiftセンサーが効かない)

が点灯

が点灯もしく

2. P903-J329 (10 pin)に5Vの電圧が有りますか? P701, W014

↓

3. P903-J329 (8 pin)に3.3Vの電圧が有りますか? P701, W014

↓

確認1〜3まで

OK P903

1. P903-J329 (1 pin)に3.3Vの電圧が有りますか? P701, W014

↓

Power

2.

キーを押した時、P903-J329 (2 pin)が0Vから

2.0Vに変化しますか?

↓

確認1〜2まで

OK P701, W014

P903

Error Status 参照

MENUや PATTERNが表示されない

入力が表示されない

VIDEO

S-VIDEO

入力が表示されない

P701, W001, P101,

P400, UN04

P501, P801 "VIDEO"

signal line

P501, P801 "Y_S" and

"Y_C" signal line

P501, P801 "Y_COM#",

COMPONENT 1, 2

入力が表示されない

"CB#", CR#" signal

input

入力が表示されない

RGB

HDMI 1, 2

メニュー-初期設定-リモートコントロールが"ワイヤー

1.

ド

"に設定されていませんか?

P901-J330 (1 pin)

2.

ますか

リモコンのボタンを押した時、 P903-J329 (12 pin)に

3.

0Vから5Vまでのパルスが有りますか?

リモコンのボタンを押した時、P501-JL16 (10 pin)に

4.

0Vから5Vまでのパルスが有りますか?

入力が表示されない P601, P801

↓

と P902-J331 (1 pin)に3.3Vが有り

?

↓

↓

↓

P501, P801 "RGB_R(G,

B, H, V)"

ワイヤレスにする

P903, W015, W016

P903 "IR_SENSE",

"IR_FRONT" and

"IR_REAR"

P701, W012, W014

5. P501-JL16 (7 pin)に3.3Vの電圧が有りますか? P701, W012

↓

リモコンのボタンを押した時、P501-JL16 (9 pin)に0Vか

6.

ら

5Vまでのパルスが有りますか?

↓

確認1〜6まで

OK P701, W012

P501

Frow from Iris Control 参照

UN04, P701

VP-15S1L

はセンサーが有りません

(UN04

ない事、検出位置がズレ

ます。

の基板ははずさ

)

43

Page 46

症状 1症状 2 確認手順 対象箇所

仕様で

せません

P701, W012

仕様で

せません

Setup the menu.

TRIG.1(トリガー1端子)に12Vの電圧が出

力されない

The voltage of 12V is not outputted to

TRIG2.

1. 出力電流は100mA以下ですか?

↓

ランプが点灯している時、P501-JL16 (11 pin)に3.3Vの

2.

電圧が有りますか

出力電流は100mA以下ですか?

1.

メニューの設定と選択しているアスペクトは正しく設定

2.

されていますか

?

確認1〜2まで

?

↓

OK P501

↓

↓

3. P501-JL16 (12 pin)に3.3Vの電圧が有りますか? P701, W012

↓

確認1〜3まで

OK P501

100mA以上は流

100mA以上は流

44

Page 47

[2] アイリス 制御の仕様

1) 回路図を確認ください。P201-2/2.

2) Q262

Q263とQ265はBA6951FS "DC motor driver"です。

3)

とQ264は74VHC123AFT "Mono stable multi vibrator" です。

下記のタイミングチャートを確認ください。

4) IRIS1とIRIS2は"L"レベル (0V)の時 ------- アイリス は 絞って います 。

IRIS1とIRIS2は"H"レベル (3.3V)の時 ---- アイリスは開いています。

5) メニューで の ア イリス設定値とアイリスの状態

アイリス設

定値

1

2

3

コントラスト 明るさ

高い 低い 狭い 狭い

中間 中間 狭い 開放

低い 高い 開放 開放

レンズ側

アイリス

照明側

アイリス

45

Page 48

[3] 電源ONから映像投影までのフロー

1) プロジェクターをONする。

2) P701-J302 (3 ピン) "PWR-CTRL"が"H"レベル(3.3V)になる。

3) P701-J301, P101-J005, P201-J201, P601-JE05に各電源が立上る。

PCB–コネクター ピン 電圧 (V) PCB-コネクター ピン 電圧 (V)

P701 – J302

1 0 (GND)

2 13.3 2 13.3

3 -6.1 3 0 (GND)

4 0 (GND) 4 13.3

5 0 (GND) 5 0 (GND)

6 6.1 6 13.3

7 0 (GND) 7 0 (GND)

8 3.5 8 13.3

9 0 (GND) 9 0 (GND)

10 3.5 10 13.3

11 0 (GND) 11 0 (GND)

12 2.5 12 13.3

13 0 (GND)

14 1.2 2 0 (GND)

15 1.2 3 6.1

16 0 (GND)

P101 – J005

P201 – J201

P601 – JE05

1 0 (GND)

1 13.3

1 6.1

2 0 (GND)

3 3.5

4 0 (GND)

J005

J301

On

P601

J301

J201

コネクターの位置

4) 各デバイスを初期化します。(メインマイコン、CPLD, FPGA, GF9351)

5) P101-R073 "PWR_GOOD"

が"H"レベル(3.3V)になり、D001(黄色のLED)点灯します。

46

Page 49

R049

"LAMPLIT"

R048 and D002

"ASIC_REDAY"

R073 And D001

"PWR_GOOD"

6) 3相モー タ のドライブが P101-J008から出力され、カラーホイールが 回 転します。

7) P101-J011(1 ピン) "SCI"が"H"レベル(5V)となり、ランプが 点灯します。

8) P101-J011 (3 ピン) "FLAG_OUT"が"L"レベル(0V)になります。

"FLAG_OUT"が"L"レベル(0V)にならない場合、5)にもどる、3回くり返し た 後 Warning LEDが点灯する。

9) "FLAG_OUT"信号はP101-J012 (3 ピン)からSSB基板へ送られる。

10) P101-R049 "LAMPLIT"が"L"レベル(0V)になる。

11) P101-R048 "ASIC_READY"が"H"レベル(3.3V)になり、D002(緑色のLED)が点灯する。

12) 映像が投影される。

47

Page 50

[4] DMD 検査基準

1 エラーの種類

1.1 Dark Blemish(ダーク・ブレミッシュ)

ホコリ、キズなどによる光りの障害・反射

明るい画面で暗くなって見える物

形、大きさは様々な物がある

1.2 Light Blemish(ライト・ブレミッシュ)

ホコリ、キズなどによる光りの障害・反射

暗い画面で明るくなって見える物

形、大きさは様々な物がある

1.3 Dark Pixel (黒点)

ミラーがオフ・ポジションに固定された物

明るい画面で黒い正方形(画素)として見える

Major Dark Blemish

Major Dark Blemish

Blue 60

Blue 60

Minor Dark Blemish

Minor Dark Blemish

White

White

Major Light Blemish

Major Light Blemish

Gray 10

Gray 10

Minor Light Blemish

Minor Light Blemish

Black

Black

WhiteWhite

1.4 Light Pixel (輝点)

ミラーがオン・ポジションに固定された物

暗い画面で白い正方形(画素)として見える。

1.5 Unstable Pixel (不安定画素)

ミラーが制御されず動いている物

ある静止画面を見た時、画素が固定されず明暗が動いて見

える物。

明るさが変わる明るさが変わる

1.6 Border Defect(ボーダー・ディフェクト)

ボーダー・エリア(2.2章)にあるブレミッシュ及び画素欠陥

Gray 10Gray 10

Any ScreenAny Screen

Any ScreenAny Screen

48

Page 51

2 画面

2.1 Active Area (アクティブ・エリア)

画素が動作する部分

白画面を投影した時、白くなる部分

2.2 Border Area(ボーダー・エリア)

アクティブ・エリアの外周部分、60 inchの画面で数cmの範囲

黒画面を投影した時、Active Areaの外枠で明るさが少し異なる部分

図2.2参照

60inch (152cm)

ボーダー・エリア

ボーダー・エリア

周囲 数cm

周囲 数cm

アクティブ・エリア

図2.2 ボーダー・エリア図2.2 ボーダー・エリア

3 テスト環境・基準

3.1 投影サイズ

スクリーン上の投影サイズは対角 60 inch (152 cm) 以上にしてください。

3.2 確認距離

スクリーンから2.4 m (8 feet) 以上離れてテストしてください。

3.3 フォーカス

フォーカスをDMDに合わせた状態でテストしてください。

3.4 表示画面は"Service Mode"内の"Optics check"で行う。

パターン変更は表3.1 表示パターン−リモコン対比 を参照ください。

3.5 確認方法

全てのエラーについて投影したスクリーンにてテストしてください。

DMDに付いたキズ等も投影したスクリーンにて判定してください。

3.6 試験項目

60 inch(152 cm)60 inch(152 cm)

検査項目 パターン 検査内容

1 Major Dark Blemish Blue 60

2 Major Light Blemish Gray 10

Active Area

60inch

Active Area

60inch

内に、Blue 60よりも暗いブレミッシュは6個までOK

の画面で1inch(2.5cm)より大きいブレミッシュが無い事

内に、Gray 10よりも明るいブレミッシュは6個までOK

の画面で1inch(2.5cm)より大きいブレミッシュが無い事

3 Border Defects Any Screen Active area外のピクセル欠陥、ブレミッシュ等はOKとする。

4 Dark Pixel White

Active Area

隣り合う画素が無いこと

内に、暗い画素欠陥は8個までOK

5 Light Pixel Gray 10 Active Area内にGray 10より明るい画素欠陥がない事

6 Minor Blemishes

White

Black

全てOKとします。

7 Unstable Pixel Any Screen 不安定なピクセルが無いこと

49

Page 52

表3.1 表示パターン−リモコン対比

Service Mode内Optics Checkのリモコンキー−表示パターン対応表

Component 1 Input video signal

Component 2 Lens Iris on/off

S-Video Illumination Iris on/off

Video Raster (Black)

RGB Raster (White)

Theater Red

Standard Green

Dynamic Blue

Info. Resolution

Full Horizontal Staircase

Normal Vertical Staircase

Cinema Color Bars

Through Horizontal Ramp

Zoom Blue 90

HDMI 1 Gray 5

Pattern Gray 10

V Mute Gray 30

Black level Blue 60

VCR Mode Gray 6

HDMI 2 Gray 1

50

Page 53

[5] The DC voltage value which was measured

PWB : P101

Input terminal : VIDEO

Input signal : SMPTE Color Bar

Equipment : Tester (DC Voltage mesure mode)

POS. NO. PIN NO. VOLTAGE DEVICE

1 5.0

J006

J009

J005

J011

J012

Q011

Q012

D001

Q013

Q014

Q016

D002

2 5.0

3 5.0

4 0.0

1 1.2

2 0.5

3 0.0

1 0.0

2 13.3

3 0.0

4 13.3

5 0.0

6 13.3

7 0.0

8 13.3

9 0.0

10 13.3

11 0.0

12 13.3

1 1.6

2 0.0

3 0.2

4 0.0

1 0.0

2 0.0

3 0.1

4 0.0

1 0.0

2 3.5

3 0.0

4 3.1

5 3.3

1 0.0

2 3.1

3 0.0

4 3.1

5 3.3

Anode 2.0

Cathode 0.0

1 0.0

2 3.3

3 0.0

4 3.2

5 3.3

1 3.3

2 3.3

3 5.0

4 3.3

5 3.3

6 5.0

1 0.0