Page 1

Service

DV9600

DV9600 /

F N/K1G/L1G/S1G

/F B/U1B

/N1S

Manual

SECTION PAGE

1. TECHNICAL SPEC I FI CA TIONS ........................................................................................... 1

2. SERVICE HINTS AND TOOLS ............................................................................................. 6

3. WARNING AND LASER SAFETY IN STRUC TIONS ............................................................. 7

4. TAKING THE DISC OUT OF EMERGENCY......................................................................... 8

5. UPDATE BACK END SOFTWARE (FIRM WARE) PRO CE DURE ......................................... 9

6. UPDATE PANEL MICROPROCESSOR PRO CE DURE ...................................................... 10

7. SER VICE MODE................................................................................................................. 36

8. WRITE-IN ID DATA FOR DVD AUDIO PROCEDURE......................................................... 37

9. TROUBLESHOOTING/(Japan) .................................................................................... 42/(65)

10. WIRING DIAGRAM ............................................................................................................. 87

11. BLOCK DIAGRAM .............................................................................................................. 89

12. SCHEMATIC DIAGRAM...................................................................................................... 91

13. PARTS LOCATION............................................................................................................ 133

14. MI CRO PRO CES SOR AND IC DATA................................................................................. 153

15. EXPLODED VIEW AND PARTS LIST............................................................................... 186

16. ELECTRICAL PARTS LIST .............................................................................................. 194

Super Audio CD / DVD Player

TABLE OF CONTENTS

Please use this service manual with referring to the user guide ( D.F.U. ) without fail.

DV9600

Part no. 90M25AK855010

First Issue 2005.09

MZ

Page 2

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components,

Only original

MARANTZ

parts can insure that your

MARANTZ

MARANTZ

product will continue to perform to the specifi cations for which

company has created the ultimate in stereo sound.

it is famous.

Parts for your

MARANTZ

ORDERING PARTS :

equipment are generally available to our National Marantz Subsidiary or Agent.

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specifi ed.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

1100 MAPLEWOOD DRIVE

ITASCA, IL. 60143

USA

PHONE : 630 - 741 - 0300

FAX : 630 - 741 - 0301

AUSTRALIA

QualiFi Pty Ltd,

24 LIONEL ROAD,

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - (0)3 - 9543 - 1522

FAX : +61 - (0)3 - 9543 - 3677

EUROPE / TRADING

MARANTZ EUROPE B.V.

P. O. BOX 8744, BUILDING SILVERPOINT

BEEMDSTRAAT 11, 5653 MA EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2507844

FAX : +31 - 40 - 2507860

THAILAND

MRZ STANDARD CO., LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

CANADA

MARANTZ CANADA INC.

5-505 APPLE CREEK BLVD.

MARKHAM, ONTARIO L3R 5B1

CANADA

PHONE : 905 - 415 - 9292

FAX : 905 - 475 - 4159

SINGAPORE

WO KEE HONG DISTRIBUTION PTE LTD

No.1 JALAN KILANG TIMOR

#08-03 PACIFIC TECH CENTRE

SINGAPORE 159303

PHONE : +65 6376 0338

FAX : +65 6376 0166

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64 - 9 - 8451958

FAX : +64 - 9 - 8463554

JAPAN

D&M Holdings Inc.

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 741 9190

Technical

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

SHOCK, FIRE HAZARD SERVICE TEST :

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

2ND FLOOR BANGUNAN INFINITE CENTRE

LOT 1, JALAN 13/6, 46200 PETALING JAYA

SELANGOR DARUL EHSAN, MALAYSIA

PHONE : +60 - 3 - 7954 8088

FAX : +60 - 3 - 7954 7088

KOREA

MARANTZ KOREA CO., LTD.

ROOM 604, ELECTRO OFFICE, 16-58,

HANGGANG-RO 3GA, YONGSAN-KU,

SEOUL, 140-013, KOREA

PHONE : +82 - 2 - 323 - 2155

FAX : +82 - 2 - 323 - 2154

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied,

and verifi ed before it is return to the user/customer.

Ref. UL Standard No. 6500.

In case of diffi culties, do not hesitate to contact the Technical

Department at above mentioned address.

050224MJI

Page 3

1. TECHNICAL SPECIFICATIONS

440

115

100

15

4

384

370 1

General

System.......................... DVD-Video, DVD-Audio, DVD-R/RW,

Video-CD, Super Audio CD, CD, MP3 files and JPEG files

Power requirements

F Version............................................AC 100 V, 50 / 60 Hz

K Version ..................................................AC 220 V, 50 Hz

L Version...................................................AC 110 V, 60 Hz

N Version ..................................................AC 230 V, 50 Hz

S Version ...........................................AC 230 V, 50 / 60 Hz

U Version ..................................................AC 120 V, 60 Hz

Power consumption ........................................................35 W

Power consumption in standby mode............................0.6 W

Weight .....................................................8.6 kg (18 lb 15 oz)

Dimensions......................... 440 (W) x 384 (D) x 115 (H) mm

(17.3 (W) x 15.1 (D) x 4.5 (H) in.)

(Not including protruding cables, etc.)

Operating temperature ... + 5 °C to + 35 °C (+ 41 °F to + 96 °F)

Operating humidity ................5 % to 85 % (no condensation)

S-Video output

Y (luminance) - Output level............................. 1 Vp-p (75 Ω)

C (color) - Output level : NTSC.................. 286 mVp-p (75 Ω)

: PAL ..................... 300 mVp-p (75 Ω)

Jacks ...............................................................S-VIDEO jack

Video output (2 individual outputs)

Output level....................................................... 1 Vp-p (75 Ω)

Jacks .......................................................................RCA jack

Component video output (Y, C

B/PB

, CR/PB)

Output level...............................................Y : 1.0 Vp-p (75 Ω)

C

B/PB

, CR/PR : 0.7 Vp-p (75 Ω)

Jacks .......................................................................RCA jack

HDMI output

Output Terminal ............................................................19-pin

21-pin connector assignment

AV connector output.................................... 21-pin connector

This connector provides the video and audio signals for

connection to a compatible color TV or monitor.

Audio output

Output level (During audio output).........2 Vrms (1 kHz, 0 dB)

Number of channels .............................................................2

Jacks .......................................................................RCA jack

Audio output (multi-channel / L, R, C, SW, LS, RS)

Output level (During audio output).........2 Vrms (1 kHz, 0 dB)

Number of channels .............................................................2

Jacks .......................................................................RCA jack

Digital audio characteristics

Frequency response............4 Hz to 44 kHz (DVD fs: 96 kHz)

4 Hz to 88 kHz (DVD-Audio fs: 192 kHz)

S/N ratio...................................................................... 130 dB

Dynamic range ........................................................... 110 dB

Total harmonic distortion .........................................0.0008 %

Wow and flutter.................................... Limit of measurement

(± 0.001 % W. PEAK) or lower

Digital output

Optical digital output..................................Optical digital jack

Coaxial digital output ...............................................RCA jack

i.LINK in/output

Output Terminal ..................................................4-pin (S400)

Other terminals

Control in/out ...........................................................RCA jack

Flasher input..................................................Mini jack (3.5Ø)

RS232C................................................................................1

Accessories

Audio/Video cable (yellow / red / white)................................1

System control cable ............................................................1

Power cable ..........................................................................1

Remote controller .................................................................1

AA (R6P) dry cell batteries ...................................................2

User guide ............................................................................1

2018161412108642

PIN no.

1 Audio 2/R out 11 G out

3 Audio 1/L out 15 R or C out

4 GND 17 GND

7 B out 19 Video out or Y out

8 Status 21 GND

21191715131197531

D1/D2 video output [except for N, U Version]

Output level...............................................Y : 1.0 Vp-p (75 Ω)

C

Jacks ..................................................................... D terminal

B/PB

, CR/PR : 0.7 Vp-p (75 Ω)

1

Page 4

Features

Equipped with an i.LINK port for

digital transfers of high-quality media

By simply connecting a single i.LINK cable

between components with i.LINK ports, you

can get direct digital transfers of not only

DVD-Video audio but also multi-channel

audio such as Super Audio CD or DVDAudio, which previously could only be

connected in analog with five audio cords, as

well as 2-channel audio like conventional

CDs (see page 55).

.

When transferring DVD-Audio or Super

Audio CD audio digitally by i.LINK, this unit

employs the Jitter Free Transfer System

(JFTS), a technology that removes jitter from

transfers. By combining this unit with JFTScompatible components, you can play jitterfree audio.

An HDCP-compatible HDMI*1 terminal

is provided to ensure the very highest

picture and digital sound quality by

fully digital transmission.

This unit comes with a High-Definition

Multimedia Interface (HDMI) jack, an

extended DVI interface for next-generation

televisions. This interface allows transfers of

uncompressed digital video and digital audio

(audio streams like Dolby Digital and DTS as

well as linear PCM) with a single connector.

HDMI standard Ver. 1.1 compatibility means

the unit can also transfer DVD-Audio multichannel audio over HDMI.

End-to-end full-digital transfers with alldigital processing make it possible to enjoy

realistic video without any of the image

degradation from AD/DA conversions. And

with the inclusion of our newly developed,

high-precision 10-bit scaler IC, the unit can

up-convert 480p video signals to 720p,

1080i, and 1080p video output signals by

way of the scaling function and the HDMI

jack (see page 52).

.

to let you enjoy beautiful video possible

with DVD. Furthermore, NSV technology

suppresses noise during DA conversion.

Support for 10-bit advanced

progressive NTSC/PAL with newly

developed chroma-error

compensation.

Our newly developed chroma-error compensation completely eliminates the chroma

error that occurs near perpendicular edges

in color-difference signals.

dts 96kHz/24 bit compatibility

It is equipped with a dts 96/24 decoder

that lets you enjoy dts audio with sound

quality as high as 96kHz/24bit. This product does not support dts 88.2kHz/24bit.

Dolby Headphone compatibility

The Head Phone can reproduce the world of

Dolby Surround with realistic ambience like

that you would experience using a 5.1 ch

system (Excluding Super Audio CD) (see

page 13).

.

Lip Sync capability

When it is connected to a plasma display or

projector, it corrects the time lag between

the video and audio created by the video

circuit processing time in units of 10msec up

to a maximum of 200msec. It precisely

synchronizes the actors’ voices and the

movements of their mouths (see page 31).

.

Equipped with a Super Audio CD

Distance compensation function

It can perform Distance adjustment of Super

Audio CD that was formerly impossible by

converting it to PCM (see page 44).

.

Superlative audio performance with

Super Audio CD, DVD-Audio, Dolby*

3

Digital and DTS*4 software

Logos:

High quality 14-bit/216MHz Video D/

A converter*

The unit uses a Video D/A converter that

performs D/A conversion of all video signals

in 14-bits and can perform 8X over-sampling

2

The DV9600 delivers breathtaking sound

quality with Super Audio CD, DVD-Audio,

Dolby Digital and DTS discs.

2

Page 5

Discs compatible with this player

Any disc that displays one of the following

logos should play in this player. Other

formats, including DVD-RAM, DVD-ROM,

DVD+RW, DVD+R, CD-ROM (except those

that contain MP3/JPEG files) and Photo CD

will not play.

DVD-Video compatibility:

• Logos:

• Single sided or double sided discs

• Single layer or dual layer discs

• Dolby Digital, DTS, MPEG or Linear PCM digital

audio

• MPEG-2 digital video

Discs are generally divided into one or more titles.

Titles may be further subdivided into chapters.

DVD-Audio compatibility:

• Logos:

• Single sided discs

• Single layer or dual layer discs

• Linear or packed PCM digital audio

• Some discs may contain MPEG-2 video, and

Dolby Digital, DTS or MPEG digital audio

Discs are generally divided into one or more

groups. Groups may be further subdivided into

tracks.

DVD-R compatibility:

This unit can play DVD-R discs. Please note the

following points when using these discs:

• Logo:

• This unit can play DVD-R discs recorded as

DVD-Video format.

• DVD-R discs that were recorded with copy-once

only permission cannot be played.

Capture

You can store a photograph of your children

as background (see page

.

29).

SRS TruSurround

*5

Logo:

When used with stereo sources, SRS

TruSurround creates a realistic surroundsound effect using just two speakers (see

page 44).

MP3 compatibility

This player is compatible with CD-R, CD-RW

and CD-ROM discs that contain MP3 audio

tracks (see pages 9, 28).

.

JPEG compatibility

This player is compatible with CD-R, CD-RW

and CD-ROM discs that contain JPEG data

(see pages 9, 29).

*1HDMI, the HDMI logo and High-Definition

Multimedia Interface are trademarks or registered trademarks of HDMI Licensing LLC.

*2“NSV” is a registered trademark of Analog

Device Co. Ltd.

*3Manufactured under license from Dolby

Laboratories. “Dolby” and the double-D symbol

are trademarks of Dolby Laboratories. Confidential unpublished works. © 1992-1997 Dolby

Laboratories. All rights reserved.

4

“DTS” and “DTS 96/24” are trademarks of

*

Digital Theater Systems, Inc.

5

*

TruSurround, SRS and the

trademarks of SRS Labs, Inc. TruSurround

technology is incorporated under license from

SRS Labs, Inc.

.

®

symbol are

.

3

Page 6

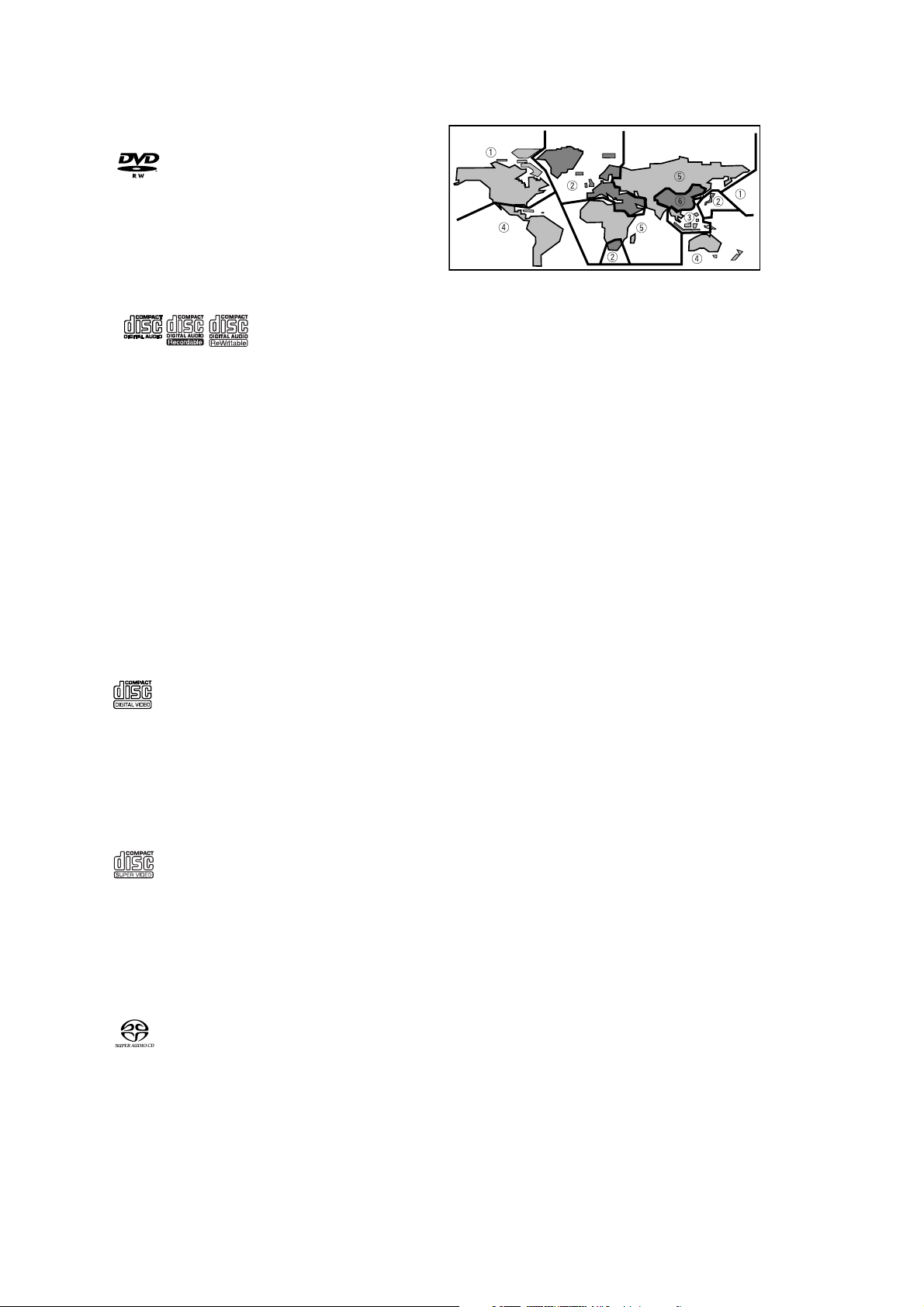

DVD-RW compatibility:

DVD-Video regions

All DVD-Video discs carry a region mark on

the case somewhere that indicates which

region(s) of the world the disc is compatible

with. Your DVD player also has a region

mark, which you can find on the rear panel.

Discs from incompatible regions will not play

in this player. Discs marked ALL will play in

any player.

MP3 compatibility information

• The CD-ROM must be ISO 9660 compatible.

• Files should be MPEG1 Audio Layer 3 format,

44.1kHz or 48kHz. Incompatible files will not

play.

• This player is not compatible with MP3 PRO,

ID3-Tag and packet write.

• When using a variable bit rate, files may be

played back at speeds between 32Kbps and

320Kbps.

• This player cannot play DVD-R/RW discs with

recorded MP3 music data.

• VBR files may not show play times correctly.

• This player only plays tracks that are named

with the file extension “.mp3” or “.MP3”.

• This player is not compatible with multi-session

discs. If you try and play a multi-session disc,

only the first session will be played.

• Use CD-R or CD-RW media for recording your

MP3 files. The disc must be finalized in order to

play.

• Audio encoded at 128Kbps should sound close

to regular audio CD quality. Although this

player will play lower bit-rate MP3 tracks, the

sound quality becomes noticeably worse at

lower bit-rates.

• Only the first 8 characters of folder and track

names (excluding the “.mp3” extension) are

displayed.

• This player can recognize about total 600 files/

folder.

This unit can play DVD-RW discs. Please note the

following points when using these discs:

• Logo:

• This unit can play DVD-RW discs recorded as

DVD-Video format.

• DVD-RW discs that were recorded with copyonce only permission cannot be played.

Audio CD compatibility:

• Logos:

• 12cm (5in.) or 8cm (3in.) discs

• Linear PCM digital audio

• Audio CD, CD-R* and CD-RW* formats

CDs are divided into tracks.

*This unit can play CD-R and CD-RW discs

recorded in Audio CD or Video CD format, or with

MP3 audio files.

*Some copy-controlled CDs may not conform to

official CD standards. They are special discs and

may not play on the DV9600.

*The audio side of dual discs does not conform to

CD standards and may not play on the DV9600.

Video CD compatibility:

• Logo:

• 12cm (5in.) or 8cm (3in.) discs

• MPEG-1 digital audio

• MPEG-1 digital video

Video CDs are divided into tracks.

Super VCD compatibility:

• Logo:

• 12cm (5in.) or 8cm (3in.) discs

• MPEG-1 digital audio

• MPEG-2 digital video

Super VCDs are divided into tracks.

Super Audio CD compatibility:

• Logo:

• Single layer, dual layer or Hyblid layer

• 12cm (5in.) or 8cm (3in.) discs

• Digital audio (DSD)

Super Audio CDs are divided into tracks.

4

Page 7

JPEG compatibility information

• While this player is designed to be able to

handle image data recorded in JPEG format, no

assurances are given that the player will be able

to display image data recorded in all JPEG

formats.

• Display is limited to the display of files up to

30MB in size.

• This player cannot display progressive JPEG

images.

• When writing JPEG files to CD-R/RW discs,

always be sure to set the writing format to ISO

9660 Level 1.

• Always be sure to specify a file extension of

“.JPG” or “.JPE” for JPEG files. The file will not be

able to be displayed if a file extension other

than “.JPG” or “.JPE” is specified or if no file

extension is assigned to the file. (Note that this

means that JPEG files created on a Macintosh

will not be able to be displayed as is.)

Caution!

• DVD-R/RW and CD-R/RW discs recorded using

a personal computer or a DVD or CD recorder

may not play if the disc is damaged or dirty, or

if there is dirt or condensation on the player’s

lens.

• If you record a disc using a personal computer,

even if it is recorded in a compatible format,

there are cases in which it may not play because

of the settings of the application software used

to create the disc. (Check with the software

publisher for more detailed information.)

• Unfinalized DVD-R/RW discs cannot be played.

• Unfinalized CD-R/RW discs cannot be played.

• For more information on using DVD-R/RW and

CD-R/RW discs, see “Handling discs” on page

60.

• Never try to replay anything other than a music

CD (CDA format) or a CD-R/RW on which MP3

and/or JPEG files have been stored. Depending

on the type of file, there may be times when

doing so will result in problems or erroneous

operation.

• There may be times when it is impossible to

replay a CD-R/RW disc because of the characteristics of the disc being used or because of

dirt or scratches on the disc.

.

5

Page 8

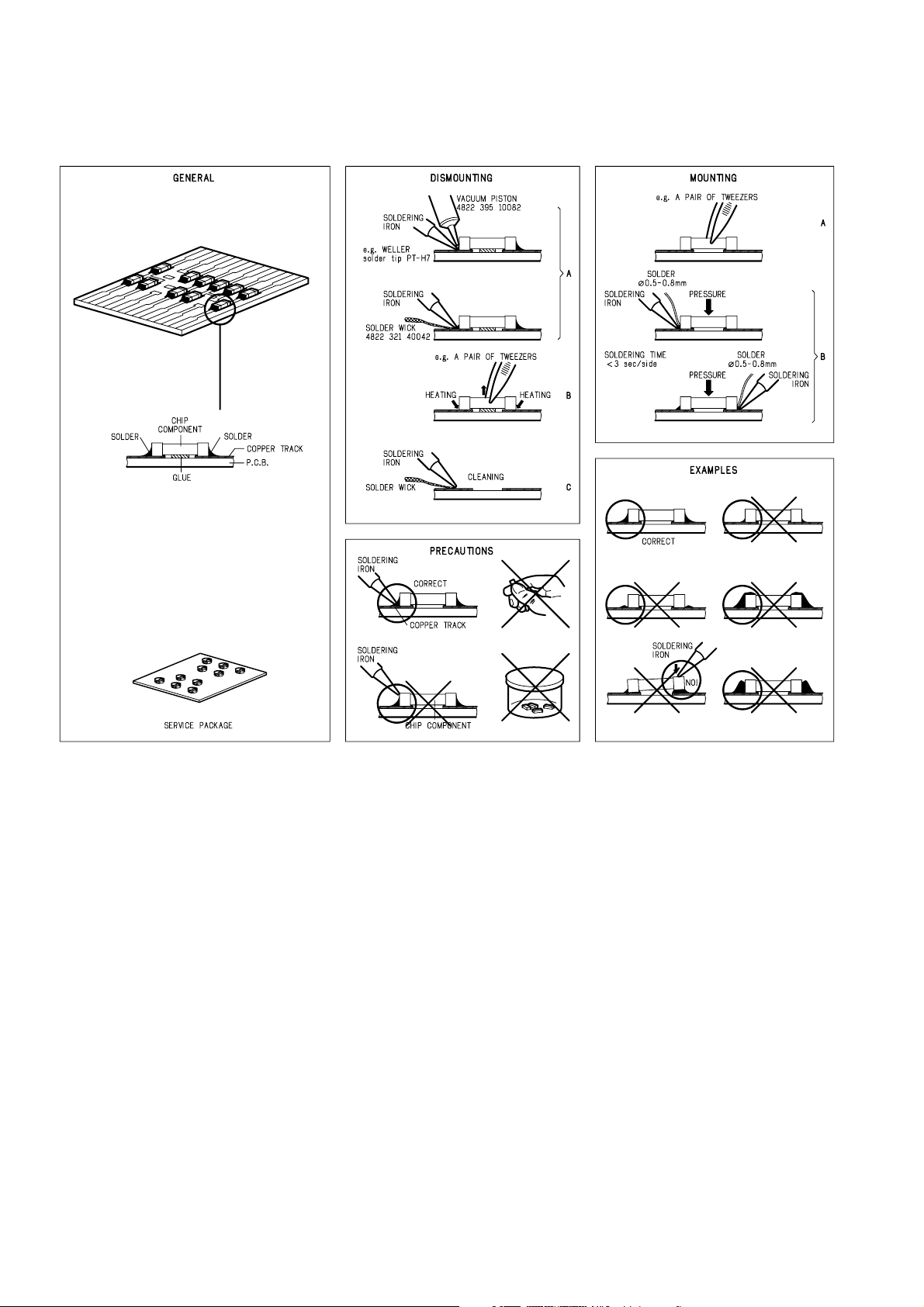

2. SERVICE HINTS AND TOOLS

SERVICE HINTS

SERVICE TOOLS

Audio signals disc 4822 397 30184

Disc without errors (SBC444)+

Disc with DO errors, black spots and fingerprints (SBC444A) 4822 397 30245

Disc (65 min 1kHz) without no pause 4822 397 30155

Max. diameter disc (58.0 mm) 4822 397 60141

Torx screwdrivers

Set (straight) 4822 395 50145

Set (square) 4822 395 50132

13th order filter 4822 395 30204

DVD test disc (PAL) 4822 397 10131

DVD test disc (NTSC) ALMEDIO TDV-540

6

Page 9

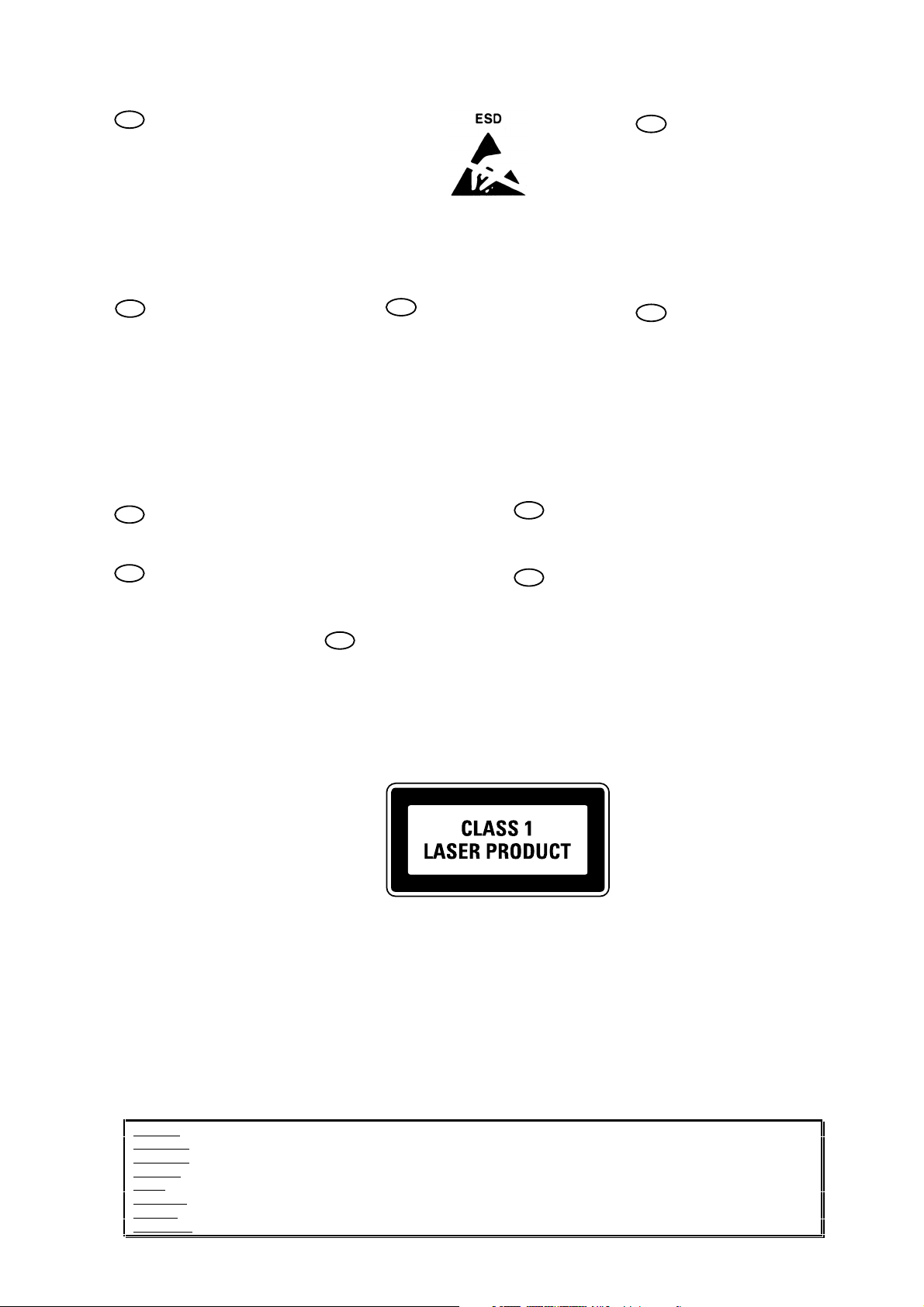

3. WARNING AND LASER SAFETY INSTRUCTIONS

GB

WARNING

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce

life drastically.

When repairing, make sure that you are

connected with the same potential as the

mass of the set via a wrist wrap with

resistance.

Keep components and tools also at this

potential.

F

ATTENTION

D

WARNUNG

I

WAARSCHUWING

AVVERTIMENTO

NL

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor elektrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie

kan de levensduur drastisch doen

verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

Tous les IC et beaucoup d’autres semiconducteurs sont sensibles aux décharges

statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution

n’est prise a leur manipulation.

Lors de réparations, s’assurer de bien être

relié au même potentiel que la masse de

l’appareil et enfiler le bracelet serti d’une

résistance de sécurité.

Veiller a ce que les composants ainsi que les

outils que l’on utilise soient également a ce

potentiel.

GB

Safety regulations require that the set be restored to its original condition

and that parts which are identical with those specified be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat in zijn oorspronkelijke

toestand wordt terug gebracht en dat onderdelen, identiek aan de

gespecifieerde worden toegepast.

Alle IC und viele andere Halbleiter sind

empfindlich gegen elektrostatische

Entladungen (ESD).

Unsorgfältige Behandlung bei der Reparatur

kann die Lebensdauer drastisch vermindern.

Sorgen sie dafür, das Sie im Reparaturfall

über ein Pulsarmband mit Widerstand mit

dem Massepotential des Gerätes verbunden

sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls

auf diesem Potential.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten.

Der Originalzustand des Gerats darf nicht verandert werden.

Fur Reparaturen sind Original-Ersatzteile zu verwenden.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso nelle

condizioni originali e che siano utilizzati pezzi di ricambiago idetici a quelli

specificati.

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevita potrebbe essere fortemente

ridatta in caso di non osservazione della piu

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello

della massa dell’apparecchio tramite un

braccialetto a resistenza.

Assicurarsi che i componenti e anche gli

utensili con quali si lavora siano anche a

questo potenziale.

F

“Pour votre sécurité, ces documents

doivent être utilisés par des

spécialistes agrées, seuls habilités à

réparer votre appareil en panne.”

Les normes de sécurité exigent que l’appareil soit remis a l’état d’origine et

que soient utilisées les pièces de rechange identiques à celles spécifiées.

LASER SAFETY

This unit employs a laser. Only a qualified service person should remove the cover or attempt to service this

device, due to possible eye injury.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURE OTHER THAN THOSE

SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

AVOID DIRECT EXPOSURE TO BEAM

WARNING

The use of optical instruments with this product will increase eye hazard.

Repair handling should take place as much as possible with a disc loaded inside the player

WARNING LOCATION: INSIDE ON LASER COVERSHIELD

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDS

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL Å PNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATT AESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

Æ

TTELSE FOR STRÅLING

030804ecm

7

Page 10

4. TAKING THE DISC OUT OF EMERGENCY

1. Remove the top cover of the player.

2. Remove 2 screws shown in the picture follows.

3. Remove the disc clamper.

4. Now you can remove the disc.

Remove those screws

8

Page 11

5. UPDATE BACK END SOFTWARE

(FIRMWARE) PROCEDURE

5. Back End Software(Firmware)の

書き換え方法

Necessary Equipment

• Update Disc (for Back End Software).

1. Press POWER button, and turn on the DVD Play er.

2. Press Open/Close button, and open the tray.

3. The update disc is placed on the tray.

4. Press Open/Close button, and close the tray.

5. After Loading the Disc, the front display shows "VCD"

for a moment. Next, the front dis play shows "WRITNG",

And Back End Software is updated au to mat i cal ly.

6. At this time, "Updating Flash Memory" shows on the

mon i tor.

7. The tray will be opened, when finished updating

software.

8. At this time, after the front dis play shows "VCD" for a

mo ment, it shows "COMPLETE".

9. Take out the update disc from the tray.

10. Press the Open/Close button, and close the tray.

11. Press the POWER button, and turn off the DVD Player.

必要機器

• Back End Software のアップデート用 CD-ROM

1. POWER

2. Open/Close ボタンを押し、トレーを出します。

3. Back End Software のアップデートディスクをトレーに乗

せます。

4. Open/Close ボタンを押し、トレーを戻します。

5. Disc の Loading を行った後フロントディスプレイに

"VCD" と一瞬表示し、"WRITING" と表示され Soft ware

のアップデートは自動で行われます。

6. TV またはモニターの OSD には "Updating Flash

Memory"

7. アップデートが終わるとトレーが自動で開きます。

8. フロントディスプレイに一瞬 "VCD" と表示された後、

"COMPLETE" と表示されます。

9. アップデートディスクを取り出します。

10. Open/Close を押し、トレーを閉じます。

11. POWER ボタンを押し、電源を切ります。

ボタンを押し、DVD Player の電源を入れます。

と表示されます。

9

Page 12

6. UPDATE PANEL MICROPROCESSOR

PROCEDURE

Necessary Equipment

• Windows PC (OS: Windows2000 or WindowsXP) with

Serial Port

• RS-232C Cable straight type (9 Pin female - 9 Pin

female)

• Update Tool: FDTsetup.EXE(FDT3.0) or

fdtv30300.exe(FDT3.3)

• Update data (CSIDE_vxxx.mot)

NOTE: File name will change according to release date.

Update of PANEL Microprocessor can be updated by

FDT3.0 or FDT3.3.

Supposing you already installed FDT3.0 or FDT3.3, move

on to the Writing software setup procedure.

If you do not have FDT, move on to the Download and

install updating software for Microprocessor.

6. PANEL MICROPROCESSOR の書き換え方法

必要機器

• Windows PC Serial Port 付き (OS: Windows2000 または

WindowsXP)

• RS-232C

書き込み用アプリケーションツール (FDTsetup.EXE

•

(FDT3.0)

書き込み用データ (CSIDE_vxxx.mot)

•

NOTE: xx

パネルマイコンのアップデートは

アップデートすることが出来ます。

既に

FDT3.0 または FDT3.3 をインストールしてある場合は書

き込みソフトウェアの設定に進んでください。

もし、

ダウンロードとインストール手順に進んでください。

ストレートケーブル (9Pin メス− 9Pin メス )

または fdtv30300.exe(FDT3.3))

は改版番号です。

FDT3.0 でも FDT3.3 でも

FDT を持っていない時は、アップデートソフトウェアの

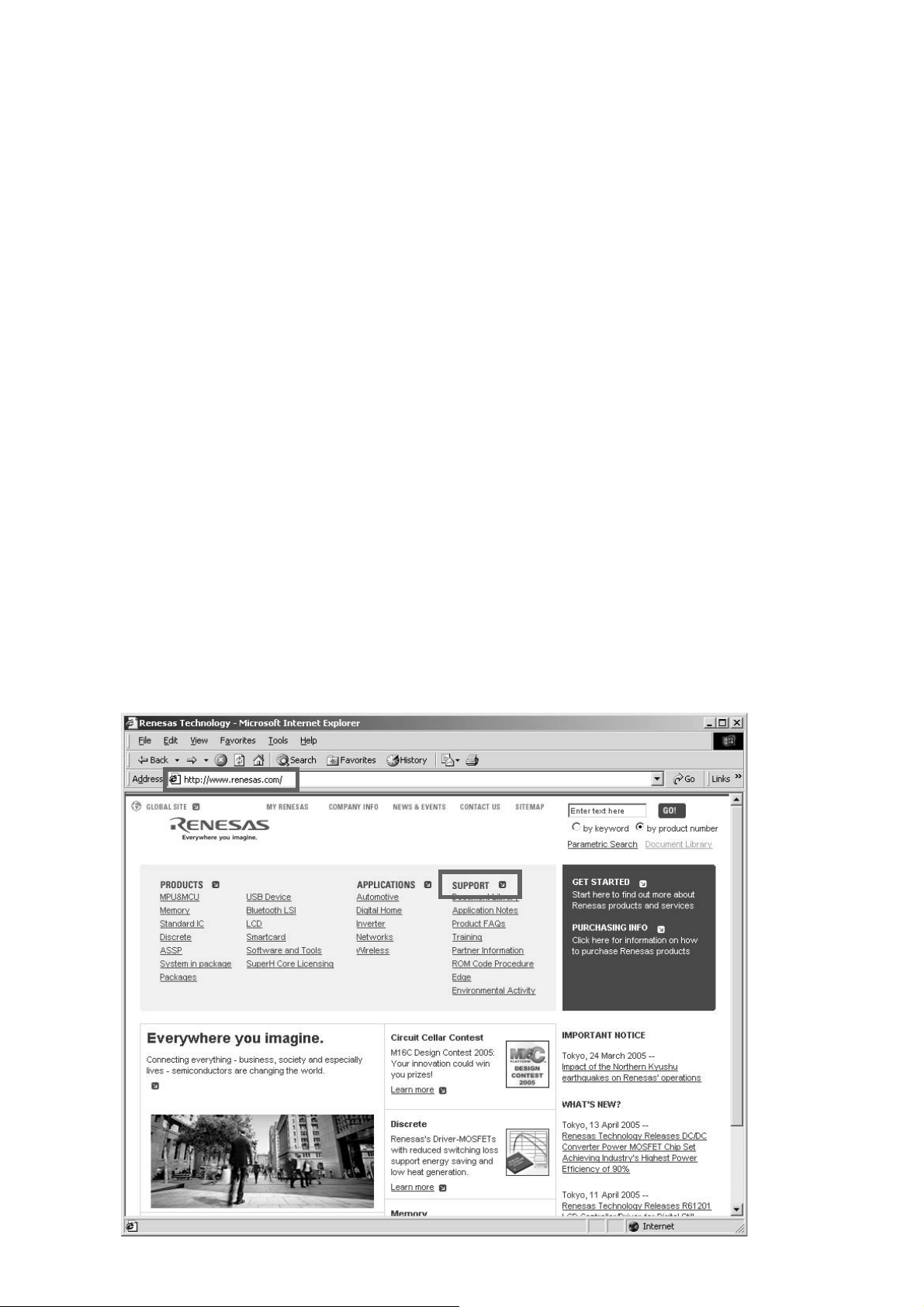

Panel Microprocessor Update Procedure

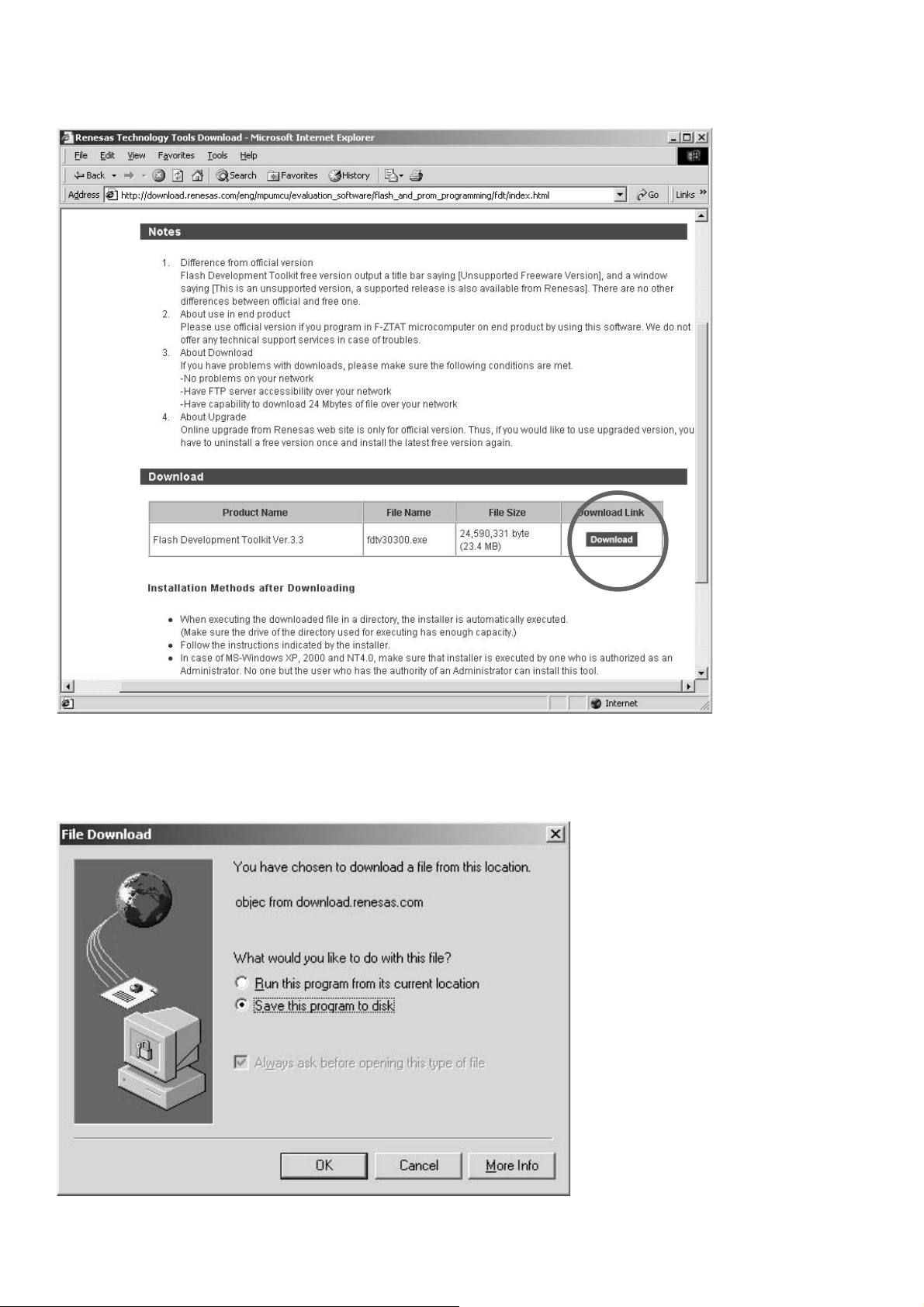

1. DOWNLOADS OF THE SOFTWARE

Download the software for update of the PANEL

microprocessor.

Launch up the browser. Type http://www.renesas.com/ into

an address. And press Enter.

(When site of Renesas is modified, please search "Flash

Development Toolkit", or type http://download.renesas.com/e

ng/mpumcu/index.html into an address.)

Click the SUPORT on the site of Renesas.

書き込み手順

1. DOWNLOADS OF THE SOFTWARE

PA NE L

ドします。

Browser を起動し、Address へ http://www.renesas.com/ と入

力し、

(Renasas

Toolkit

com/eng/mpumcu/index.html

Renesas

SUPPORT

マイコンのアップデート用ソフトウェアをダウンロー

Enter を押します。

のサイトが変更になった場合は、

を検索するか、

のホームページが開きますので、ここから

をクリックします。

Addressへhttp://download.renesas.

を入力してください。

Flash Development

)

10

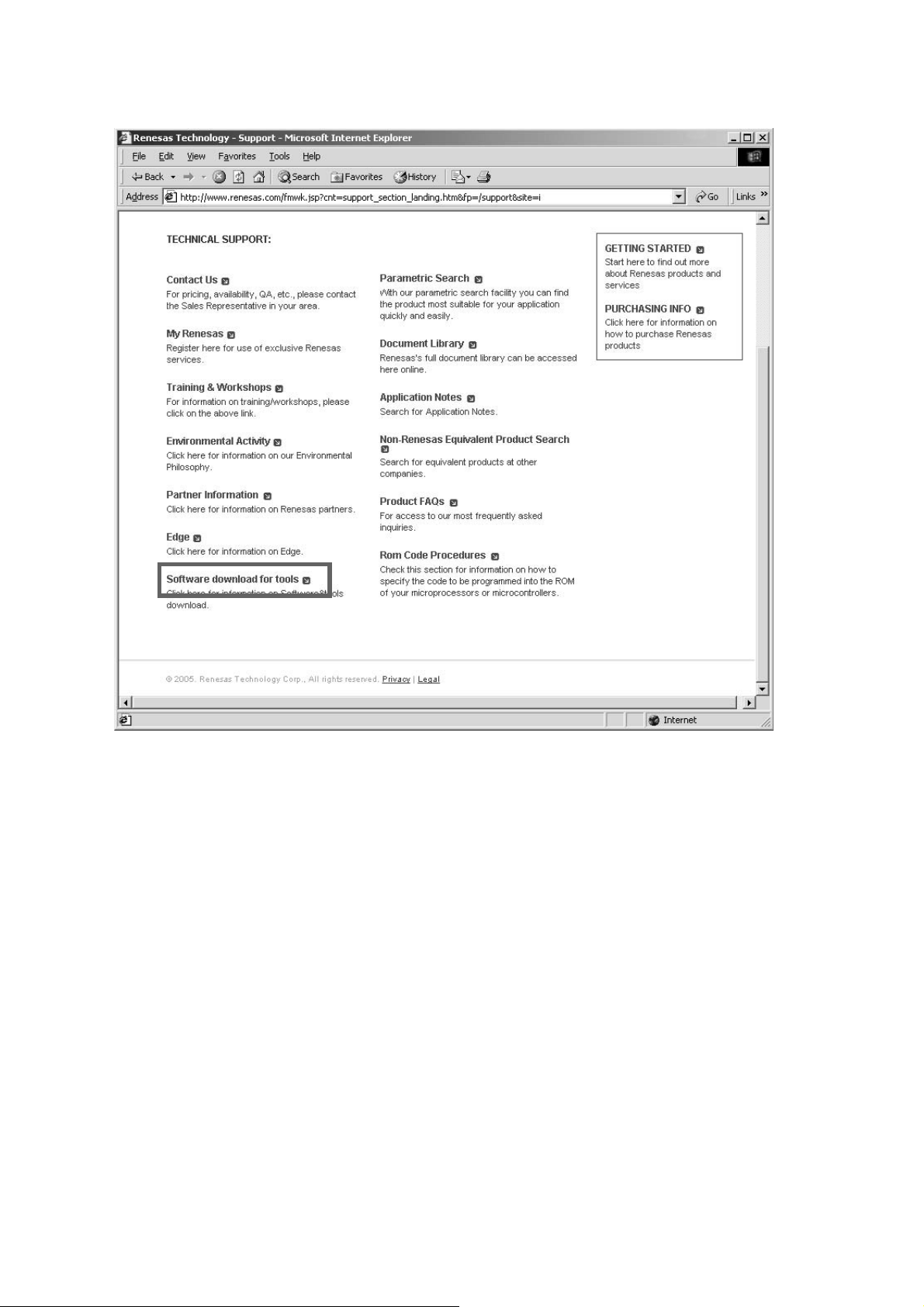

Page 13

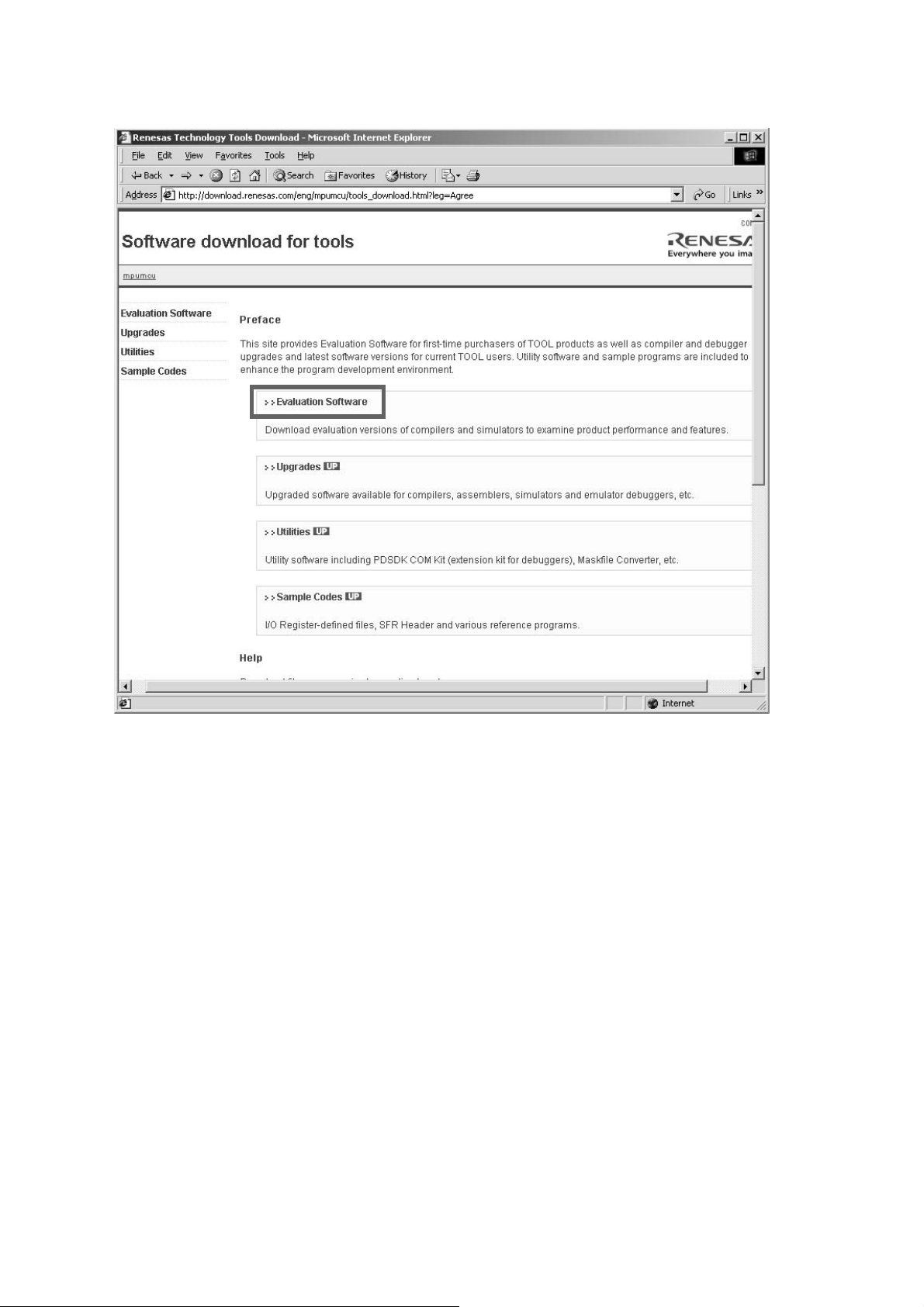

Click the Software download for tools on Support.

Support のページから Software download for tools をクリ

ックします。

11

Page 14

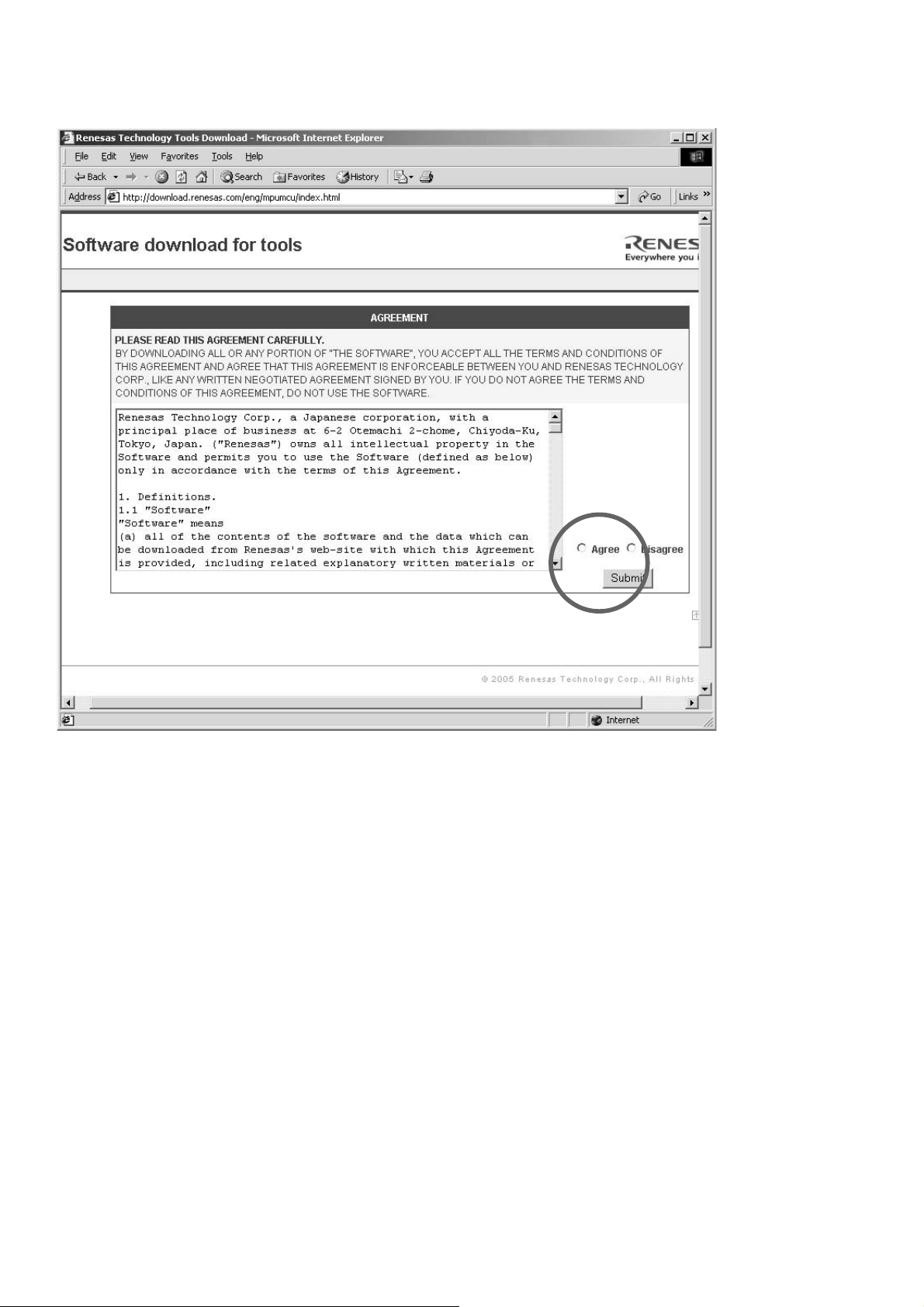

Check the Agree on AGREEMENT. And click Submit.

AGREEMENT から Agree にチェックを入れ Submit をクリ

ックします。

12

Page 15

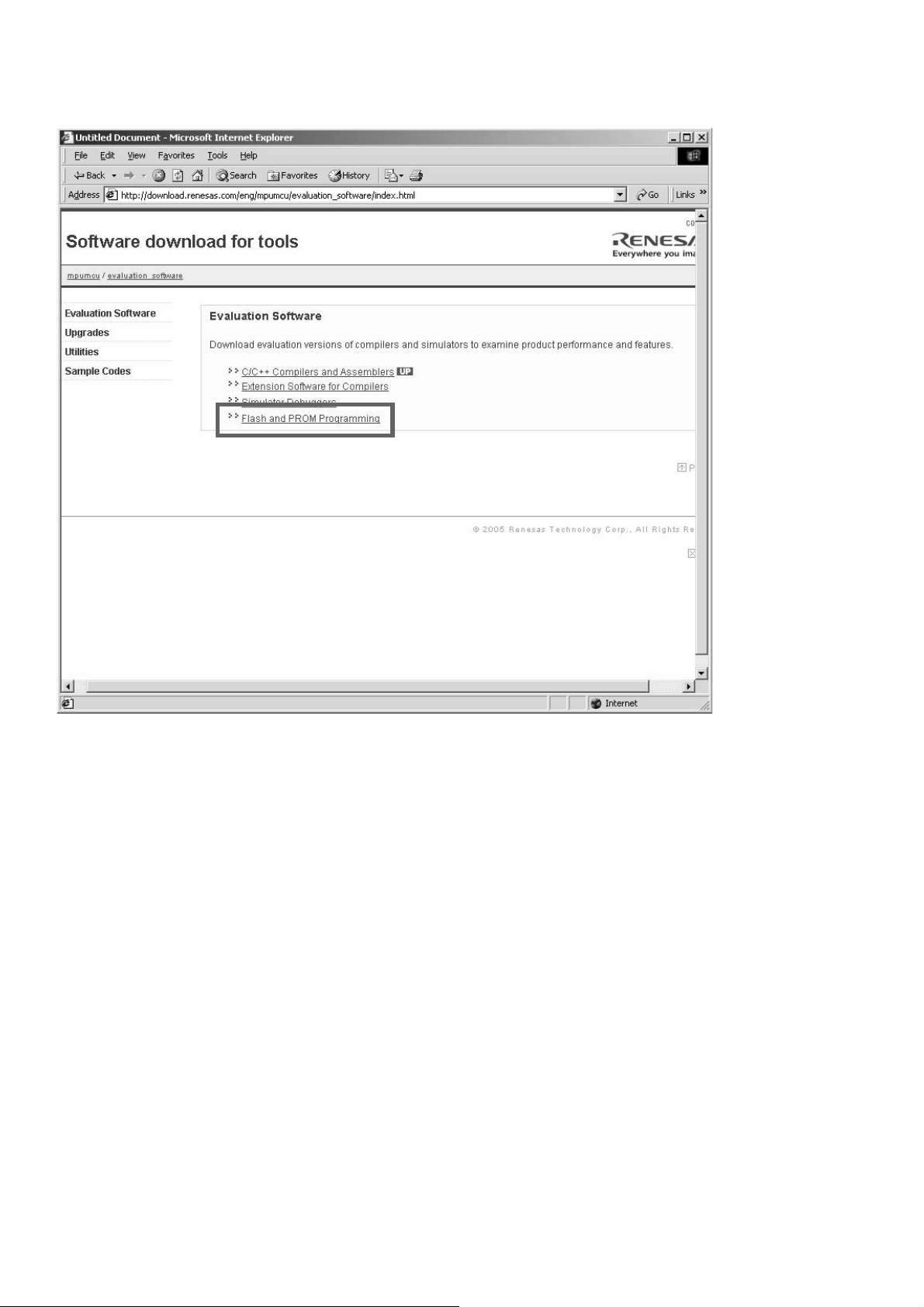

Click Evaluation Software.

Evaluation Software をクリックします。

13

Page 16

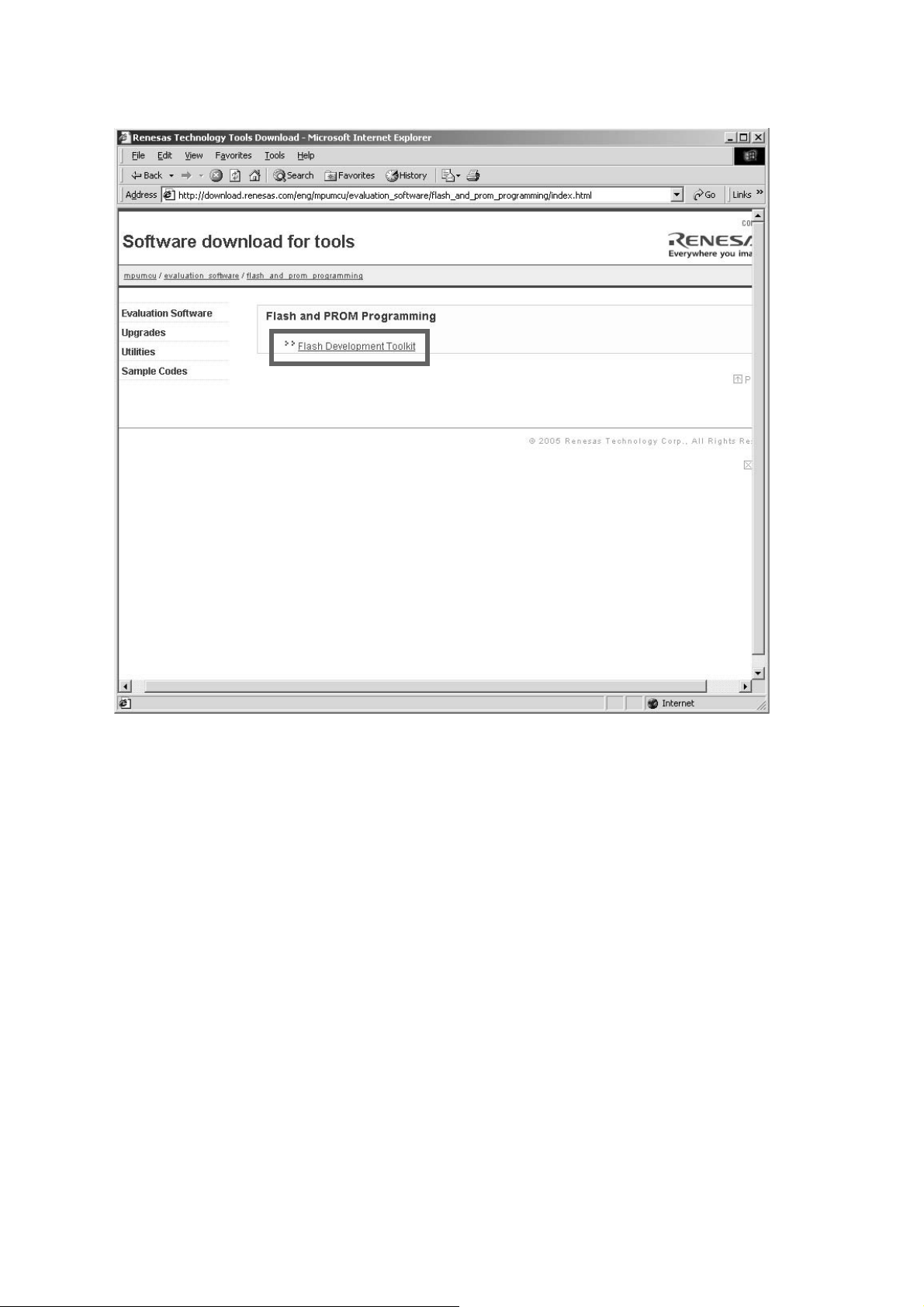

Click Flash and PROM Programming.

Flash and PROM Programming をクリックします。

14

Page 17

Click Flash Development Toolkit.

Flash Development Toolkit をクリックします。

15

Page 18

Click Download.

Page Down をし、Download をクリックします。

Save the fdtv30300.exe on your PC’s hard disc.

(A file name is changed by improvement.)

fdtv30300.exe を任意のフォルダに保存します。

( ファイル名はヴァージョンアップにより変更になる場合があ

ります。

)

16

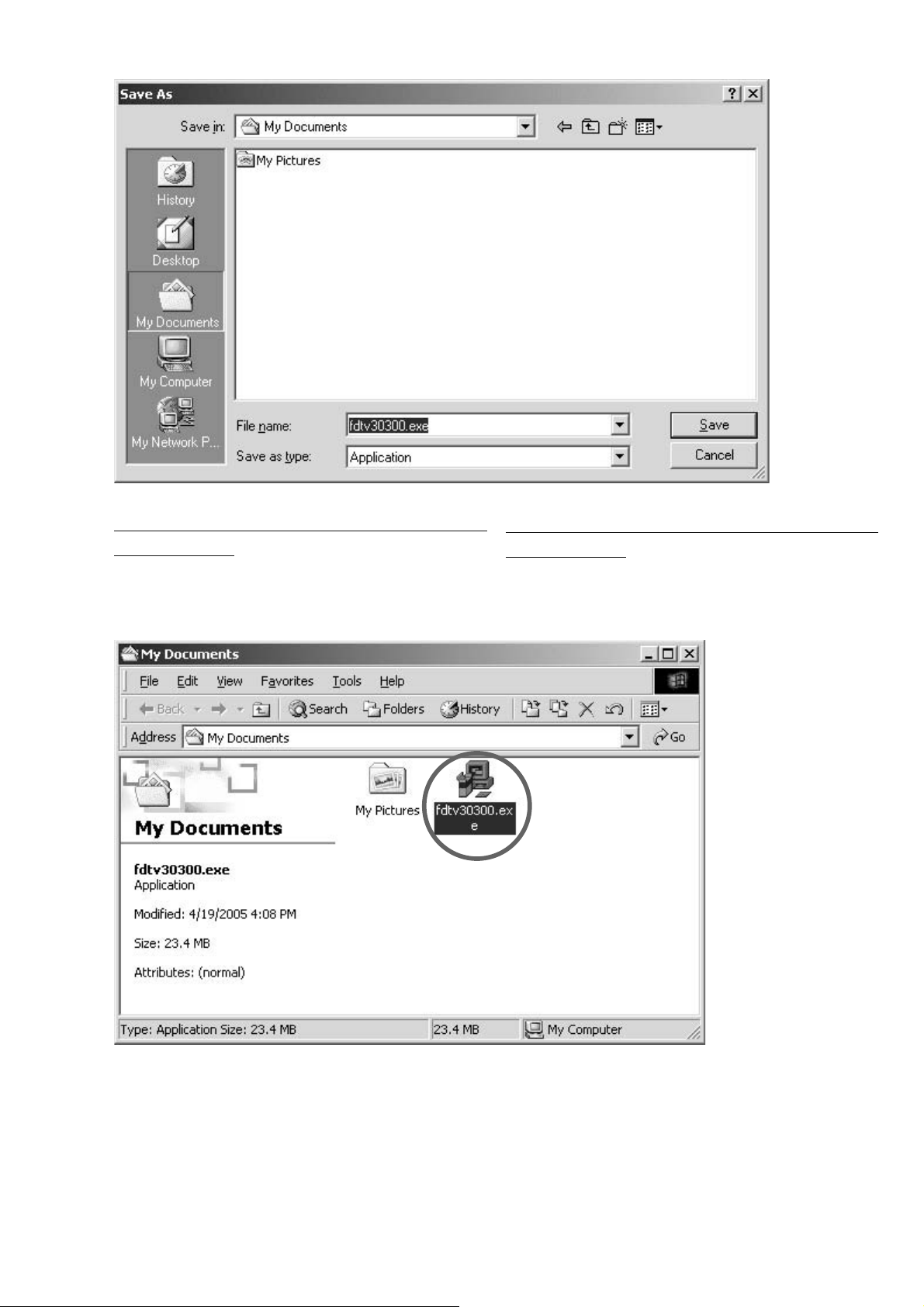

Page 19

INSTALLS OF THE SOFTWARE (FLASH DEVELOPMENT

TOOLKIT VER.3.3)

Open the folder with the downloaded file. And double click

the fdtv30300.exe.

INSTALLS OF THE SOFTWARE (FLASH DEVELOPMENT

TOOLKIT VER.3.3)

ダウンロードしたファイルを保存しているフォルダを開きま

す。

fdtv30300.exe ファイルをダブルクリックします。

17

Page 20

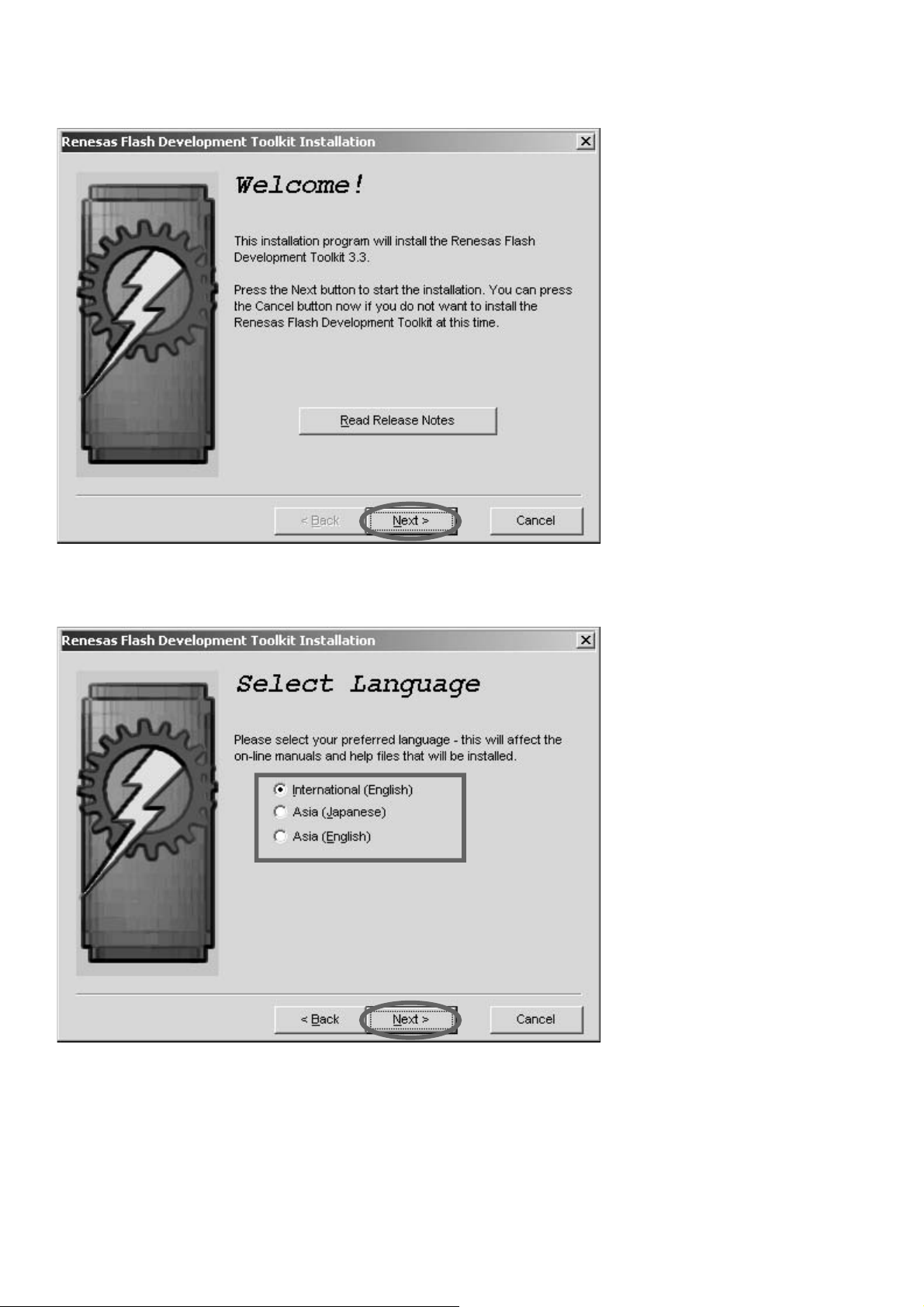

Click Next >.

Next > をクリックします。

Choose the language. And click Next >.

言語を選んで

Next > をクリックします。

18

Page 21

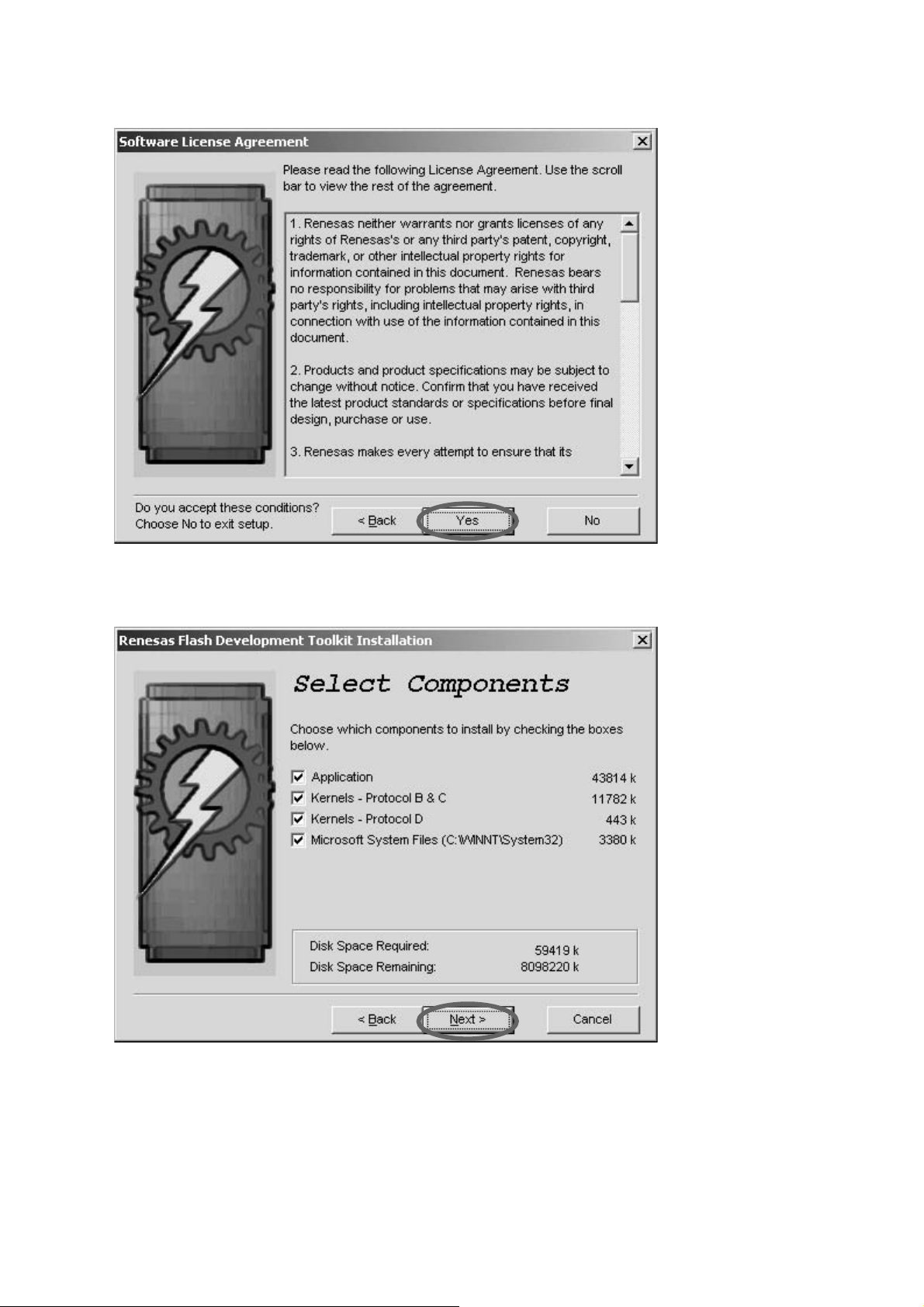

Click Yes .

Yes をクリックします。

Click Next >.

Next > をクリックします。

19

Page 22

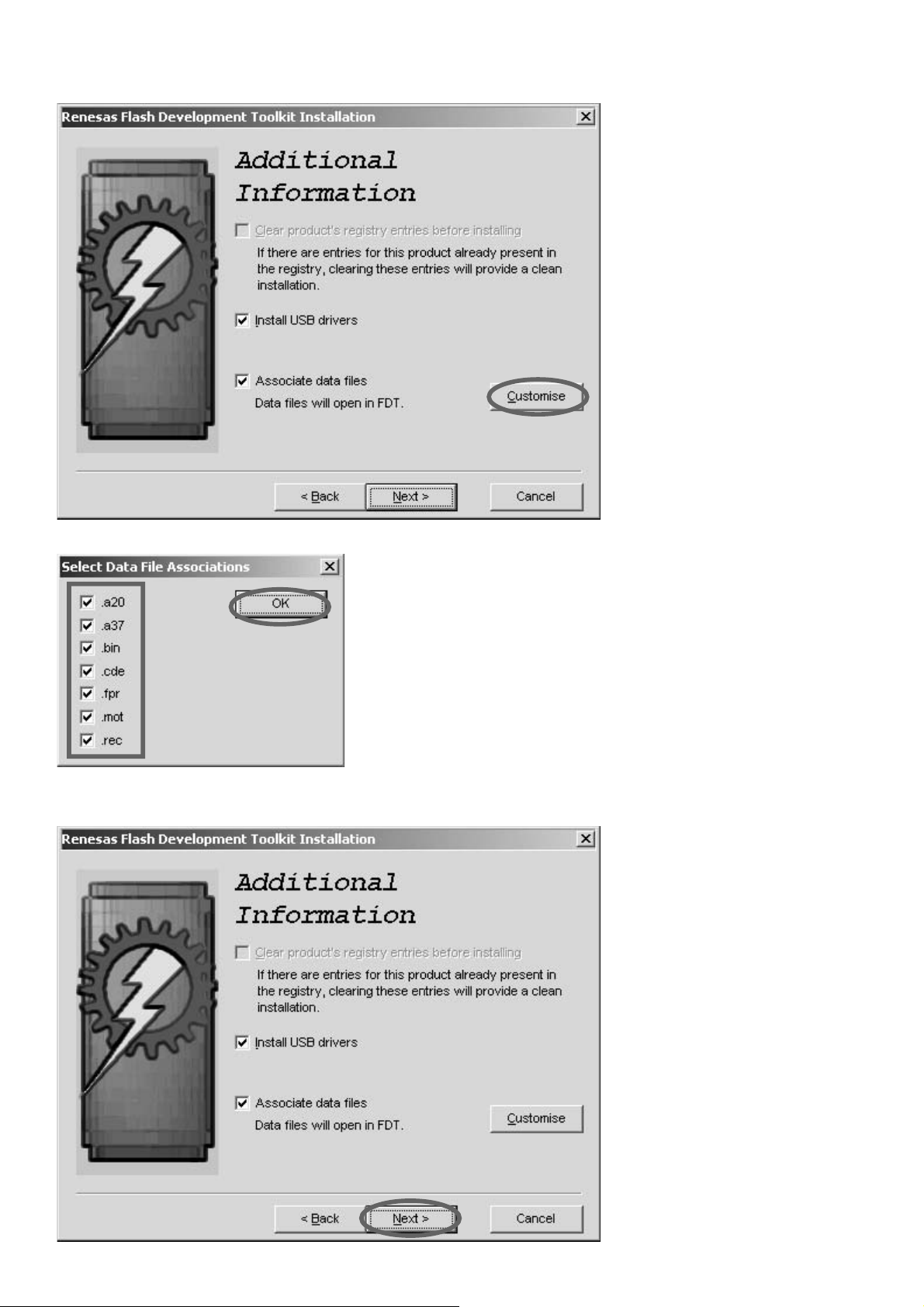

Click Customise.

Customise をクリックします。

Check to the all check box. And click OK.

Click Next >.

全てのチェックボックスにチェックが入っていることを確認

し、

OK をクリックします。

Next > をクリックします。

20

Page 23

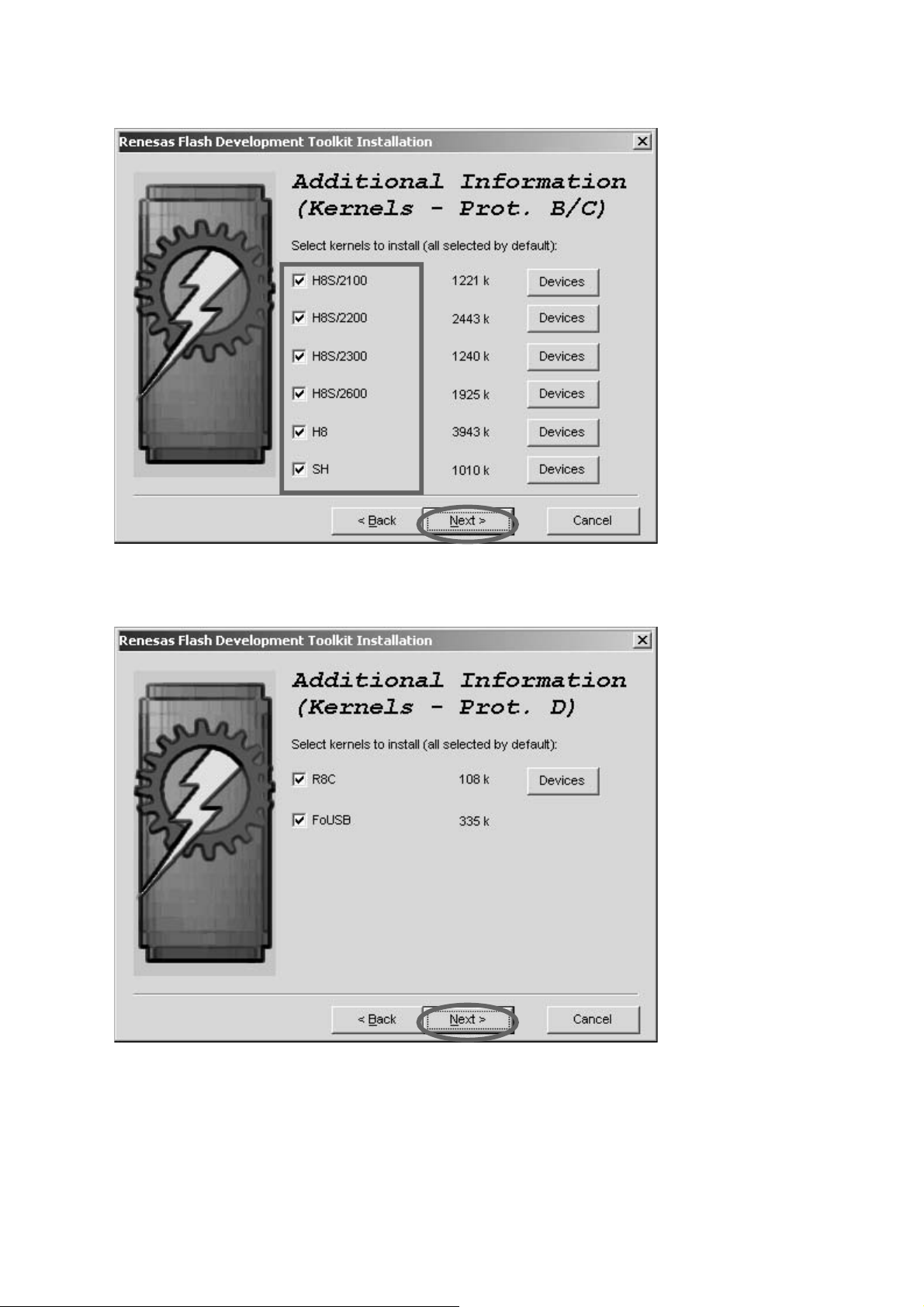

Check to the all check box. And click Next >.

全てのチェックボックスにチェックが入っていることを確認

し、

Next > をクリックします。

Click Next >.

をクリックします。

Next >

21

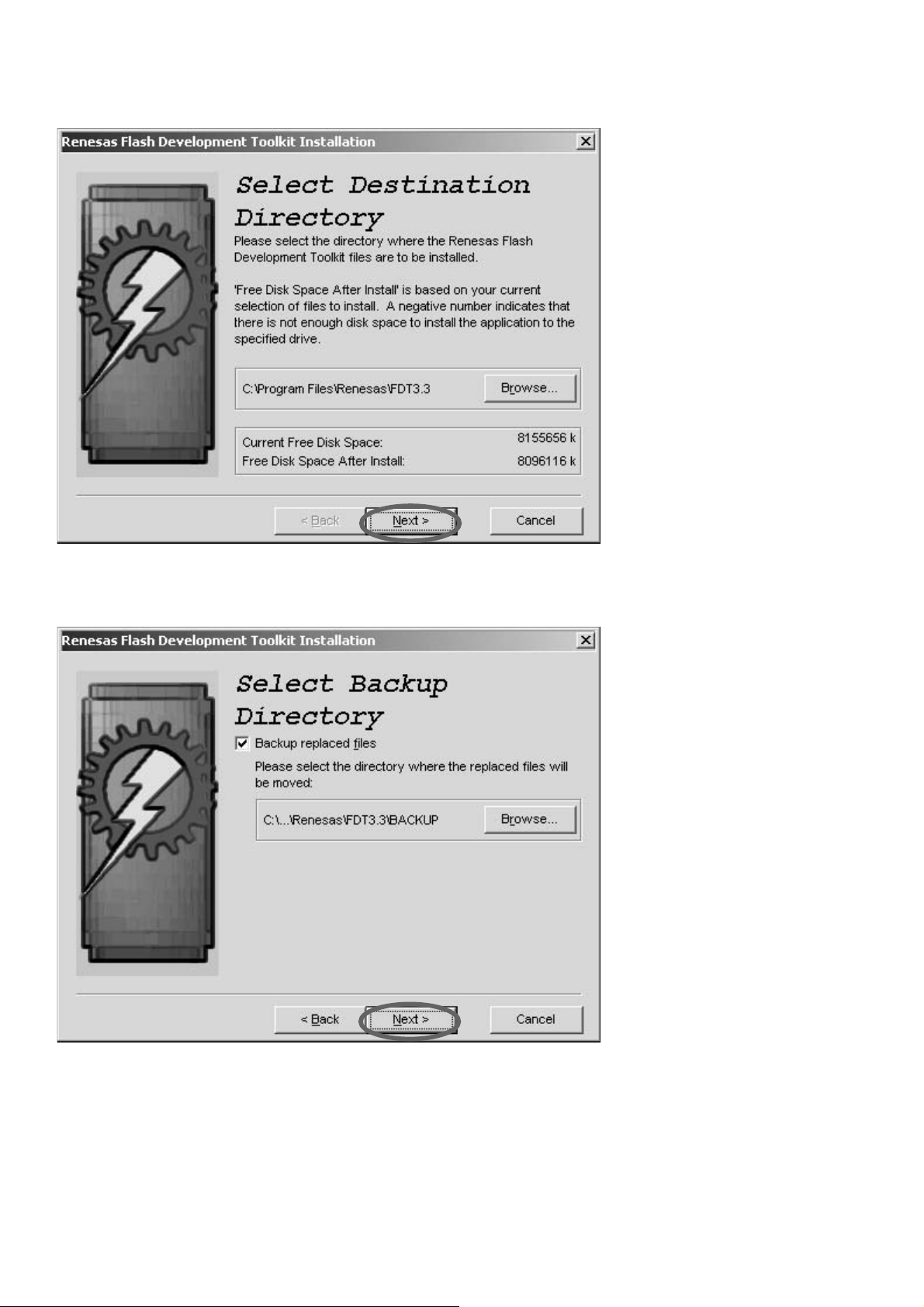

Page 24

Click Next >.

Next > をクリックします。

Click Next >.

Next > をクリックします。

22

Page 25

Click Next >.

Next > をクリックします。

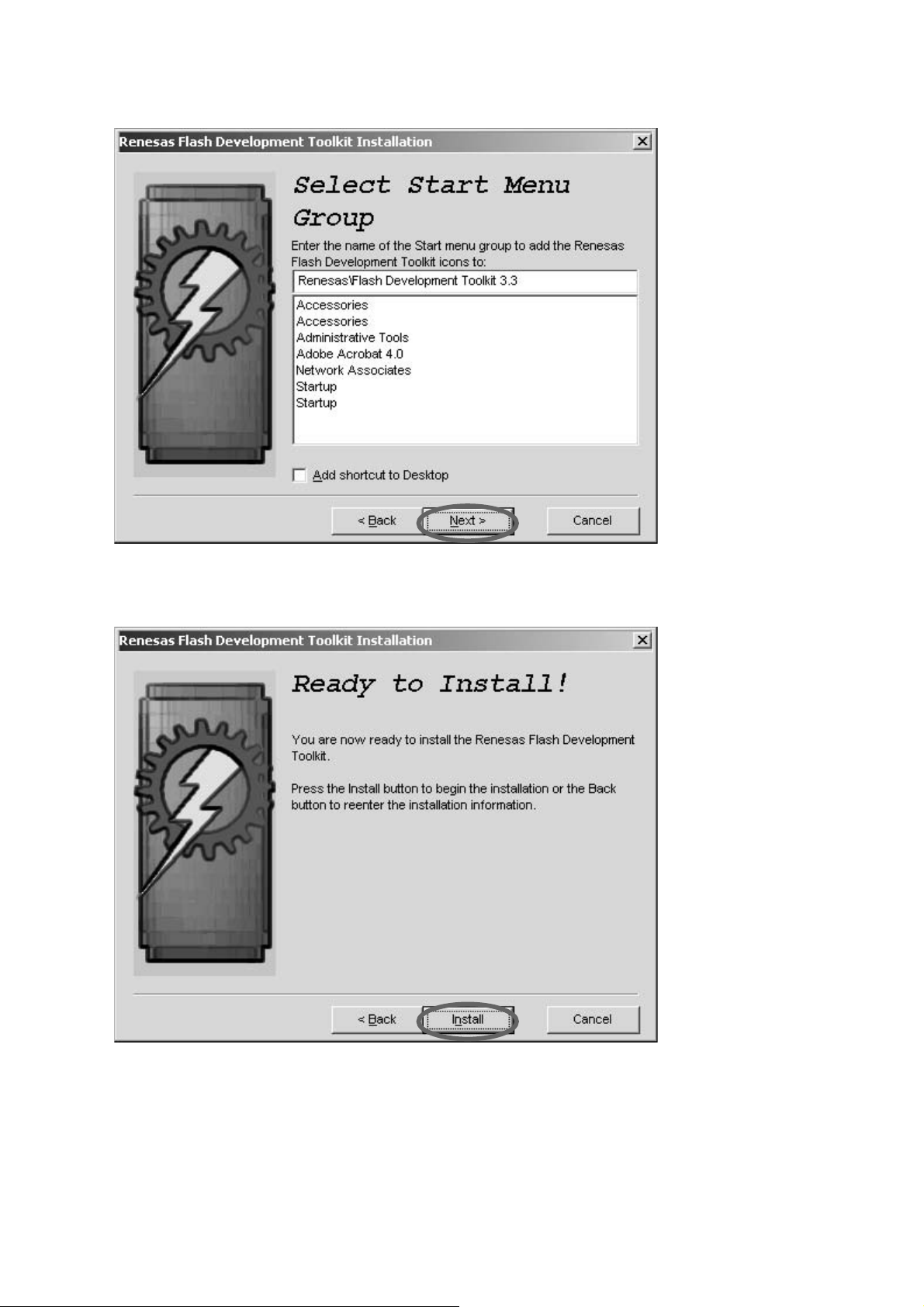

Click Install.

Install をクリックします。

23

Page 26

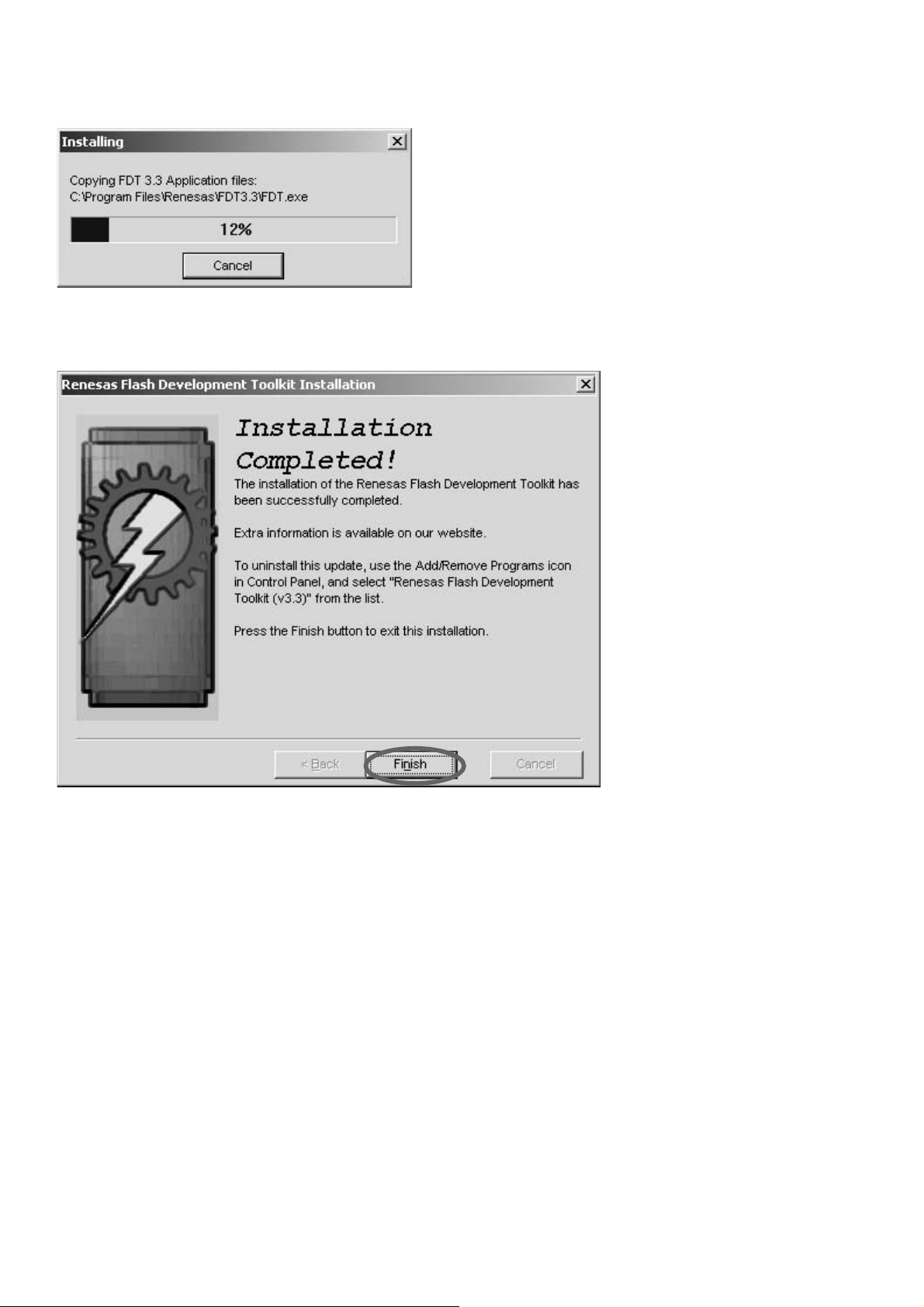

The status bar appears.

インストールを開始します。

Click Finish.

Finish をクリックしてインストールを完了します。

24

Page 27

2. The writing software setup pro ce dure.

Launch up the writing software.

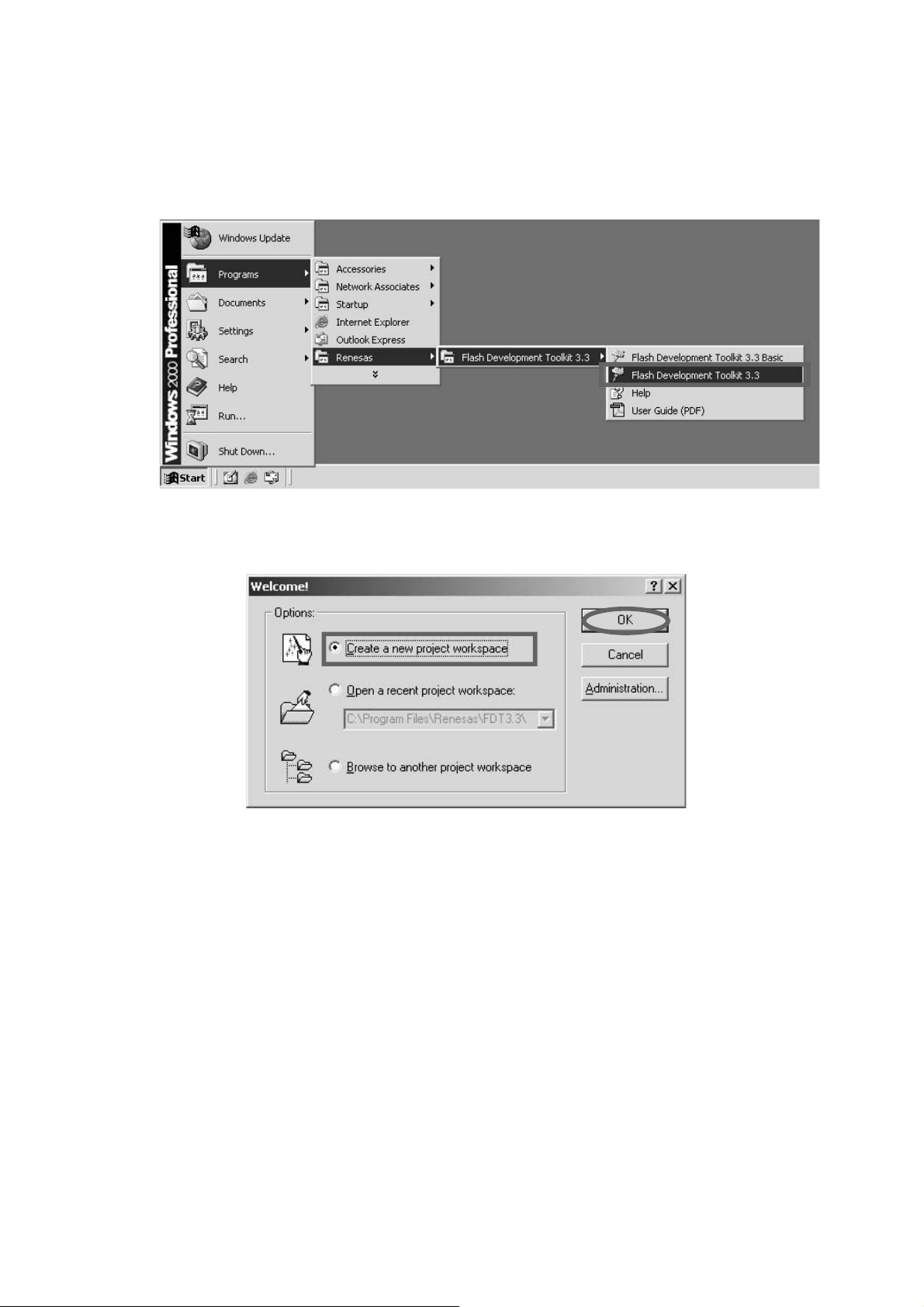

Click Start, Programs, Renesas, Flash Development

Toolkit 3.3 and Flash Development Toolkit 3.3.

(Although operation explanation by FDT3.3 is given

here, FDT3.0 is same operation too.)

2. 書き込みソフトウェアの設定

Start → Programs → Renesas → Flash Development

Toolkit 3.3

クします。

→ Flash Development Toolkit 3.3 をクリッ

( ここでは FDT3.3 での操作説明をしますが、

FDT3.0 も同じ操作になります。)

Check Create a new project workspace, and click OK.

Create a new project workspace にチェックを入れ、

OK をクリックします。

25

Page 28

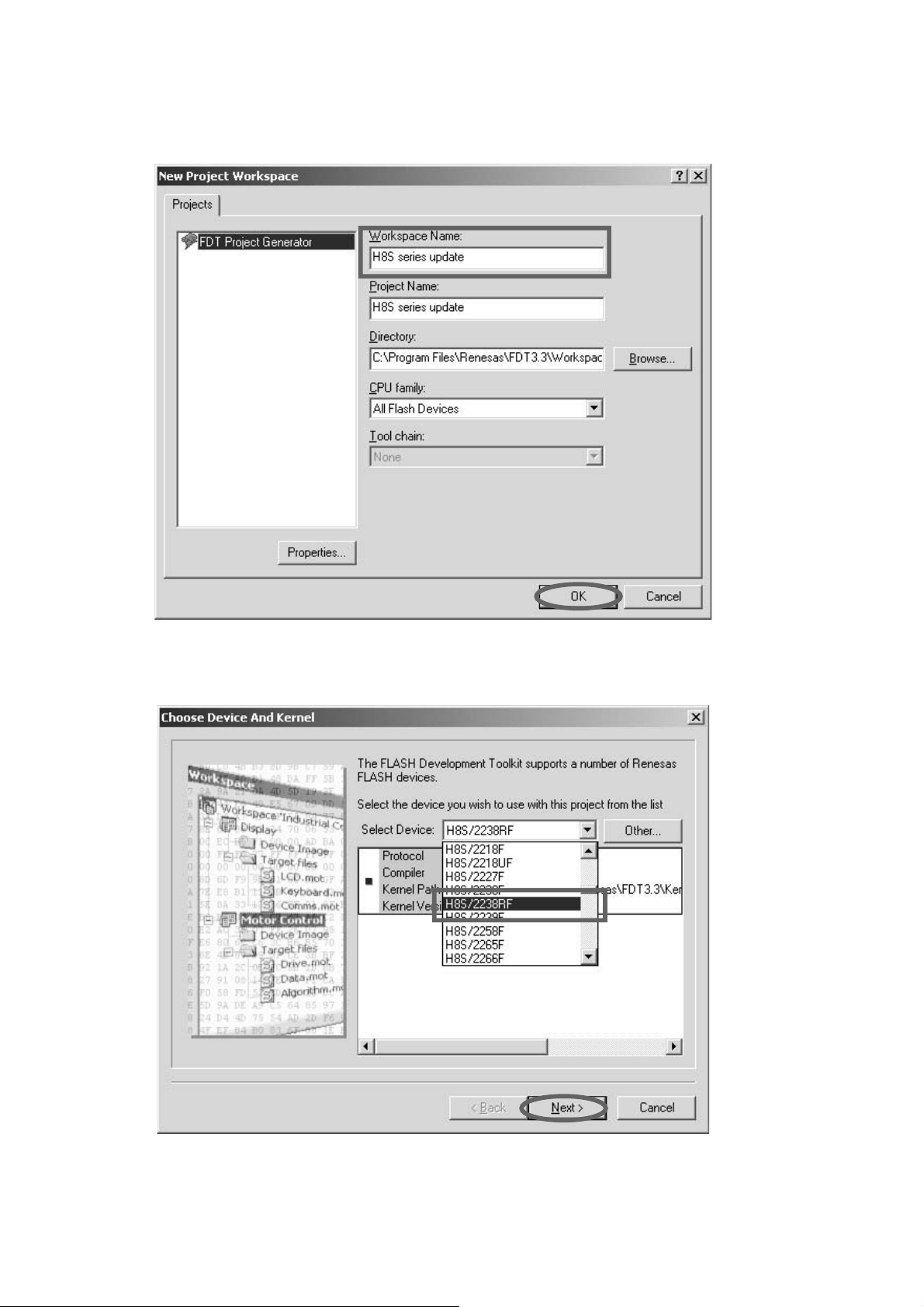

H8S series update is inputted into the Workspace

name. (It is si mul ta neous ly inputted into Project Name.)

Click OK.

Workspace Name に H8S series update と入力します。

( 同時に Project Name にも入力されます。)

をクリックします。

OK

Choose the H8S/2238RF in Se lect Device.

Click Next.

Select Device から H8S/2238RF を選びクリックします。

Next をクリックします。

26

Page 29

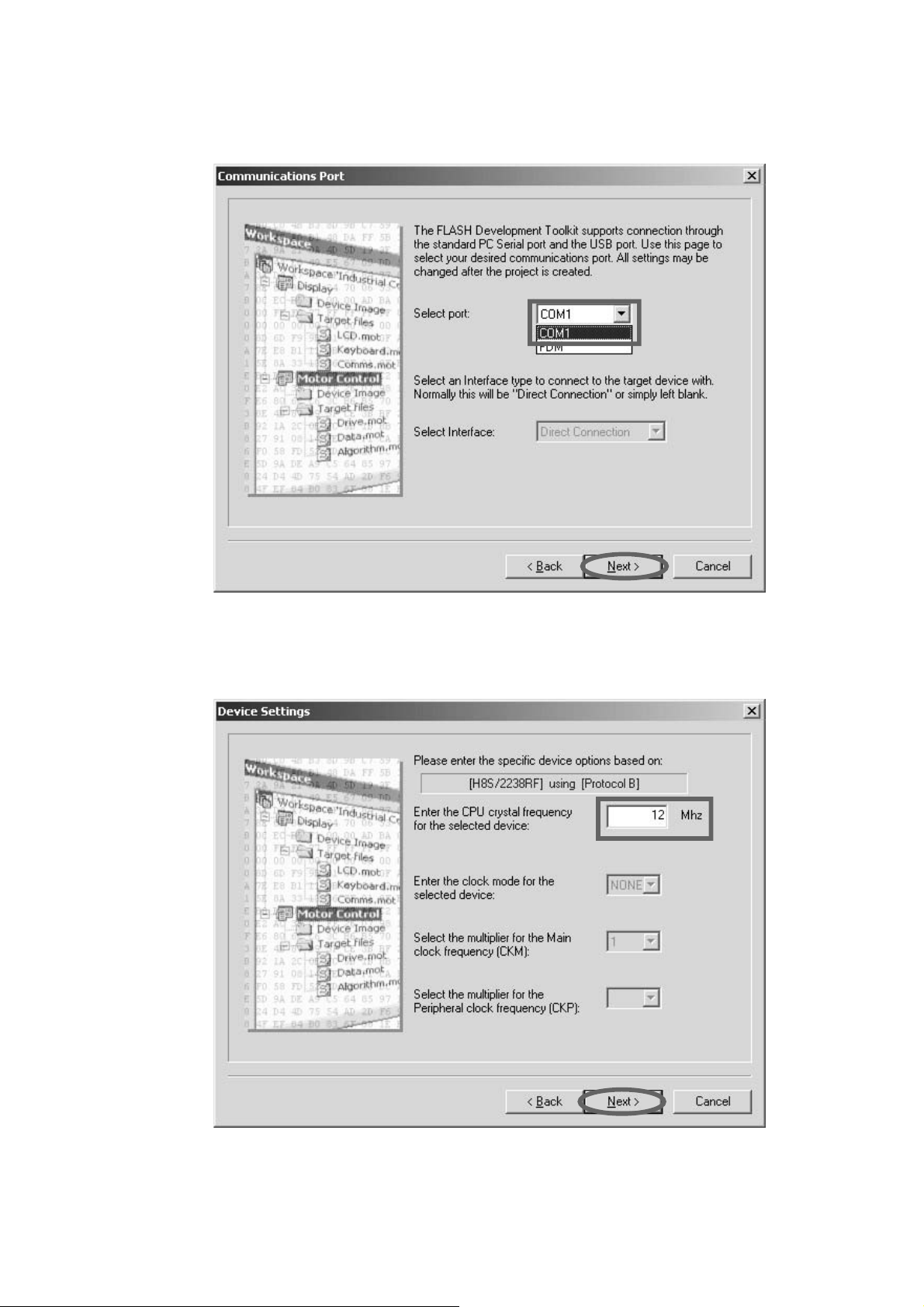

Choose the Serial port No. in the Se lect Port.

Click Next.

Select Port から接続する Serial Port 番号を選びクリック

します。

Next をクリックします。

12 is inputted into the Enter the CPU crystal frequency

for the selected device.

Click Next.

Enter the CPU crystal frequency for the selected

device:

に 12 と入力します。

Next をクリックします。

27

Page 30

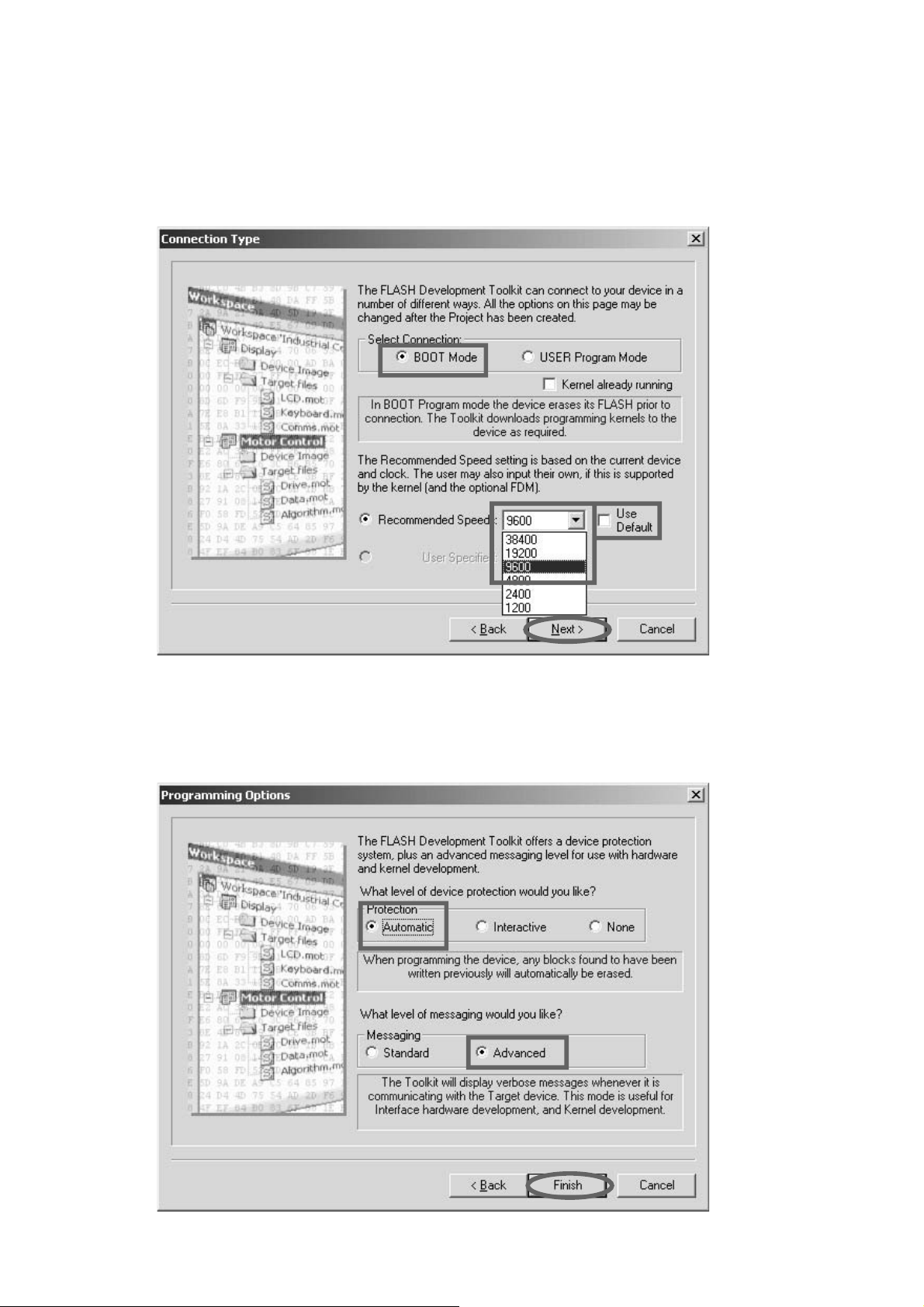

Check the BOOT Mode in Select Con nec tion.

Choose the 9600 in Select Baud rate.

Remark: Please remove check mark, if it is contained

in Use De fault.

Select Connection: から BOOT Mode にチェックを入れ

ます。

Select Baud rate: から 9600 を選びクリックします。

注意

) Use Default にチェックが入っていると Baud Rate

を変更できませんのでチェックを外してください。

Check the Automatic in Pro tec tion.

Check the Advanced in Mes sag ing.

Click Finish.

Protection から Automatic にチェックを入れます。

Messaging から Advanced にチェックを入れます。

Finish をクリックします。

以上で設定は完了です。

28

Page 31

3. Writing Procedure

When you carry out continuously from "2. The writing

software set up procedure", please move on to "Cable

connection" of next page.

Software is launched when the writ ing software is being

terminated.

Click Start, Programs, Renesas, Flash Development

Toolkit 3.3 and Flash Development Toolkit 3.3.

Check Browse to another project workspace, and

click OK.

3. 書き込み方法

インストールから引き続いて作業をしている場合は次頁の

「

PC と DVD Player の接続 」 に進んでください。

書き込みソフトウェアを終了させている場合は

Start →

Programs → Renesas → Flash Development Toolkit

→ Flash Development Toolkit 3.3 をクリックして起

3.3

動します。

Browse to another project workspace にチェックを入

れて

OK をクリックします。

Click the H8S series update.AWS, and click Open.

Remark: The file is stored in c:\Program Files\Renesas\

FDT3.3\Workspace\H8S series update.

H8S series update.AWS をクリックして、Open をク

リックします。

注意)

ファイルは c:

Workspace

ます。

\

rogram Files

P

\

S series update に格納されてい

H8

\

enesas

R

\

FD

T3.3

\

29

Page 32

Cable connection

PC (Windows 2000, XP )

with RS-232C port

PC と DVD Player の接続

RS232C Dsub-9 pin cable

(female to female/Straight cable)

Hole

ST81

Connect RS-232C on the rear pan el of the DVD Player

and Serial Port of windows PC with RS-232C cable.

Insert a thin rod to the hole near the RS-232C Port and

push the switch inside to turn on the switch.

Turn on by the POWER switch of DVD Player.

The DVD Player’s STANDBY (red) and DISPLAY OFF

(red) in di ca tors turn on lights simultaneously.

Windows PC の Serial Port と DVD Player の RS-232C

を RS-232C ケーブルで接続します。

Port

細い棒を使い

ある穴からスイッチ

ります。

DVD Player の RS-232C Port の右となりに

(ST81) を押して書き込みモードに入

DVD Player の Front Panel にある電源スイッチを押して電

源を入れます。

DVD Player の STANDBY( 赤 )、DISPLAY OFF( 赤 ) が点

灯します。

30

Page 33

Click Device in the menu bar and select Connect to

Device.

書き込みソフトウェアの Device から Connect to Device

を選びクリックします。

Error message will be displayed when an error occurs.

Check the connection cable and select Con nect to

Device again.

The following message is dis played that DVD Player

connects with PC.

接続に失敗すると下記のようなメッセージが出ます。ケー

ブル、接続を確認してもう一度

てください。

Connect to Device を行っ

PC と DVD Player の接続に成功すると下記のようなメッ

セージが出ます。

31

Page 34

Click File in the menu bar and se lect Open An

S-Record....

File から Open An S-Record... を選びクリックします。

xxxxx.mot is selected. And click Open.

update data の xxxxx.mot をクリックして Open をクリッ

クします。

32

Page 35

Click Device in the menu bar and select Download

Active File.

Device から Download Active File を選びクリックしま

す。

Software is written into the Panel microprocessor.

書き込みが開始され左下にステータスバーが出ます。

33

Page 36

The following message is dis played when the writing of

software was completed.

書き込みが完了すると下記のようにメッセージが表示され

ます。

Click Device in the menu bar and select Disconnect.

Device から Disconnect をクリックします。

The following message is dis played that DVD Player

disconnects with PC.

DVD Player との接続が切断されたメッセージが表示され

ます。

34

Page 37

Click File in the menu bar and se lect Exit.

RS232C Dsub-9 pin cable

(female to female/Straight cable)

Hole

ST81

PC (Windows 2000, XP )

with RS-232C port

File から Exit をクリックして書き込みソフトウェアを終了

します。

Turn off by the POWER switch in the front panel of DVD

Player.

After The DVD Player’s STANDBY (red) and DISPLAY

OFF (red) in di ca tors turn off lights, Insert a thin rod to

the hole near the RS-232C Port and push the switch

inside to turn off the switch.

Disconnect RS-232C cable of the DVD Player and Serial

Port of win dows PC.

DVD Player の Front Panel にある電源スイッチを押して電

源を切ります。

STANDBY, DISPLAY OFF のランプが消灯したら

RS-232C の右横の穴からスイッチを押し書き込みモード

を解除します。

RS-232C のケーブルを外します。

35

Page 38

7. SERVICE MODE

7. SERVICE MODE

Press the POWER ON/OFF button while pressing STOP and

FL OFF buttons in front panel of DVD Player.

The front display indicates "S-MODE_NO.".

Press the 1, 4, 3 and PLAY buttons of the remote controller

in order, while indicating "S-MODE_NO.".

The front display indicates "SERVICE_2".

SERVICE_2

Press NEXT on front panel.

MODE 1 Bx.xx (B/E microprocessor Version No.: 5 digits)

Press PLAY on front panel.

Press NEXT/PREV. on front panel.

MODE 2 Px.xx (Panel microprocessor Version No.: 5 digits)

Press PLAY on front panel.

Press NEXT/PREV. on front panel.

MODE 3 Axxxx (CODE for audio DSP Version No.: 5 digits)

Press PLAY on front panel.

Press NEXT/PREV. on front panel.

MODE 4 REGION x (Region No.)

Press PLAY on front panel.

Press NEXT/PREV. on front panel.

MODE 5 BIDxxxxxxxxx (DVD AUDIO ID No.: B/E microprocessor)

Press PLAY on front panel.

Press NEXT/PREV. on front panel.

MODE 6 PIDxxxxxxxxx (DVD AUDIO ID No.: Panel microprocessor)

Press NEXT/PREV. on front panel.

MODE 7 (DON’T USED)

Press NEXT/PREV. on front panel.

MODE 8 (DON’T USED)

Press NEXT/PREV. on front panel.

DVD Player のフロントパネルにある STOP と FL OFF ボタン

を押しながら

フロントディスプレイに

この表示が出ている間に

PLAY を押します。

フロントディスプレイに

POWER ON/OFF ボタンを押します。

S-MODE_NO. と表示されます。

(10 秒間 ) リモコンから 1、4、3、

SERVICE_2 と表示されます。

36

Page 39

8. WRITE-IN ID DATA FOR DVD AUDIO

PROCEDURE

A case writing is needs

Writing is needed when Q103 (PM01) was replaced.

8. DVD AUDIO 用 ID データの書き込み方法

書き込みが必要なとき

Q103(PM01) を交換したときに書き込みが必要になります。

Necessary Equipment

Windows PC (With Serial Port)

RS-232C Cable straight type (9 Pin female - 9 Pin female)

Writing software (CPPMset.exe)

ID data and ID number

Remark: Only one ID data and ID number are assigned to

the serial number of DVD Player., Beforehand,

please ask cus tom er center "ID data" and" ID

number" corresponding to the serial number of

DVD Play er.

Writing time

The writing of ID data for DVD AUDIO takes about 2

sec onds.

Writing procedure

1. Put the "CPPM" folder into anywhere on your PC’s hard

disc.

2. Move ID data suitable for the serial number ordered in

ad vance to the "DeviceKey" folder in a "CPPM" folder.

Remark: Please set only to one ID data put on a

"DeviceKey" folder. If two or more ID data is

placed, writ ing may not be made correctly.

3. Open the "CPPM.ini" in a "CPPM\marantz" folder by text

editors, such as Note pad.

必要機器

Windows PC (Serial Port 付き)

RC-232C ケーブル (9pin メス− 9Pin メス ストレートタイプ )

書き込みソフト (CPPMset.exe)

データと ID ナンバー

ID

: ID データと ID ナンバーは DVD Player のシリアルナン

注意

バーに対して

う際は

データと ID ナンバーを事前にカスタマーセンターより取

り寄せてください。

書き込み時間

この

DVD AUDIO 用 ID データの書き込み時にかかる時間はお

よそ

2 秒です。

書き込み手順

1 つ割り当てられています。書き込みを行

DVD Player のシリアルナンバーに対応した ID

1. Windows PC の任意のフォルダに CPPM フォルダをコ

ピーします。

2. 事前に取り寄せたシリアルナンバーに合った ID データを

CPPM フォルダ内の DeviceKey フォルダに移動します。

注意: DeviceKey フォルダに置く ID データは 1 つだけ

にしてください。複数の

書き込みが出来ない場合があります。

ID データを置くと正しく

3. CPPM\marantz フォルダ内にある CPPM.ini を Note pad

などのテキストエディタで開きます。

37

Page 40

4. Type in the serial number of DVD Player to the first line.

And type in ID number to the second line.

4. 一行目に DVD Player のシリアルナンバーを入力します。

二行目に

ID ナンバーを入力します。

Input the 14 digits serial number.

Input the 9 digits ID number.

14桁のシリアルナンバーを入力

9桁のIDナンバーを入力

5. Click the "Save Ctrl+S" in the File.

5. File から Save Ctrl+S をクリックして保存します。

38

Page 41

6. Click the "Exit" in the File.

6. File から Exit をクリックして閉じます。

7. Connect RC-232C on the rear panel of DVD Player and

Serial Port of windows PC with RS-232C cable.

8. Turn on the power of DVD Player into the writing mode.

8.1 Press the POWER ON/OFF button while pressing

STOP and FL OFF buttons in front panel of DVD

Play er.

8.2 The front display indicates "S-MODE_NO.".

8.3 Press the 1, 2, 1 and PLAY buttons of the remote

con trol ler in order, while indicating "S-MODE_NO.".

8.4 The front display indicates "AUDIO_ID".

9. Double click the "CPPMset.exe" in the CPPM\marantz

fold er.

7. Windows PC の Serial Port と DVD Player のリアパネル

にある

RS-232C コネクタを RS-232C ケーブルで接続し

ます。

8. DVD Player を CPPM 書き込みモードにします。

8.1 DVD Player のフロントパネルにある STOP と FL

ボタンを押しながら POWER ON/OFF を押し

OFF

ます。

8.2 フロントディスプレイに S-MODE_NO. と表示され

ます。

8.3 この表示が出ている間に (10 秒間 ) リモコンから 1、2、

1、PLAY を押します。

8.4 フロントディスプレイに AUDIO_ID と表示されます。

9. CPPM\marantz フォルダ内の CPPMset.exe をダブルク

リックします。

39

Page 42

10. The picture shown below is displayed. Check the serial

number (S/N), ID number (ID), and ID data are right.

10. ID 書き込みソフトが立ち上がります。シリアルナンバー

(S/N)、ID ナンバー(ID)と ID データが正しいか確認し

てください。

11. Check the Serial Port number. When serial port

numbers dif fer, Press the C key of a keyboard, input the

right serial port number, and press the Enter key and

changed.

11. Serial Port の確認をします。接続した Serial Port

Num ber

と違う場合はキーボードの C を押し、接続した

Se ri al Port Number を入力してキーボードの Enter を押

して変更します。

40

Page 43

12. Press the space key of a keyboard and write ID data

into the DVD Player.

13. Display "Under transmission...". And terminates the

soft ware automatically, when writing was completed.

The writ ing of ID data for DVD AUDIO takes about 2

seconds.

12. キーボードのスペースキーを押して、ID データを DVD

書き込みます。

Player

13. Under transmission... と表示され、書き込みが完了する

とソフトウェアは自動的に閉じます。転送にかかる時間は

およそ

2 秒です。

14. Please check written-in ID data by MODE5 and MODE6

of SERVICE MODE.

14. 書き込まれた ID データの確認は SERVICE MODE の手順

に従い

MODE5、MODE6 にて確認してください。

41

Page 44

9. TROUBLESHOOTING

1. Power Supply PWB (P801)

1.1 The power cannot be turned on.

Is the E+6V voltage line (J808) normal?

OK

Is the control signal of J305 (10pin)

normal? STB_CTRL=H

OK

Is the each voltage line normal?

+12V, +8V, +5V_D2, D+4V, -27V,

DC+3.5V and HEATER

NG

NG

NG

• Check the fuse (F801) has not blown

out.

• Check the voltage inputted/outputted to

each pin of Q801, Q802 and Q803.

Note: When checking the primary circuit,

the GND of a measuring instrument

should be switched floating.

Refer to “3.1 Check the panel

microprocessor”.

Check the voltage inputted/outputted to

each pin of the connected components.

42

Page 45

2. DISPLAY CONTROL PWB (PF01) / PHONE PWB (PH01)

2.1 FL is not outputted.

Is the connector (JF02) voltage line

normal?

+5V_D1, -27V, DC+3.5V and HEATER

OK

Is the 61pin of the QF71 line H?

OK

NG

NG

Check the soldering of these componentson

the POWER SUPPLY PWB (P801) and

DISPLAY CONTROL PWB (PF01).

Check the 8pin of QF80 Signal.

Reset = H

NG OK

Check the soldering of RF72

and CF74.

Check the Signal of QF80 (9pin).

Reset = H

NG

OK

Replace QF80.

Check the soldering of RF11, RF80,

CF11, CF81, JF01 (12pin) and

QU01 (71pin).

Are the 62,63 and 64 pin of QF71 signal

normal? (H L)

OK

Are the 1 to 40pin and 42 to 54pin of

QF71 signal normal? (H L)

OK

Replace VF01.

NG

NG

Check the 2,5 and 12 pin of QF80 signal.

(H L)

NG

OK

Replace QF80 or / and QF71.

Check the soldering of RF08, RF09,

RF10, JF01 (8,10,11pin) and QU01

(9,70,73pin).

Replace QF71.

43

Page 46

2.2 No sound is output from Phones. (The headphones are connected to PHONES jack.)

Are the connector (J950, J951) voltage

line normal? 8pin and 10pin,+8VA,–8VA

OK

Is the 1pin of connector (J950, J951)

voltage line normal?

HP connection: L / HP un-connecting: H

(3.3V)

OK

Is the 6pin of Q950 MCLK signal normal?

OK

Is the waveform of Q950 (3 to 5pin)

normal?

OK

Is the waveform of Q950 (14,15,19pin)

normal?

NG

NG

NG

NG

NG

Check the +8VA and –8VA voltage line of

PM01 PWB, PA01 PWB and P801 PWB.

Replace J952.

Check the MCLK signal of PM01 PWB.

Check the Audio data output line of

PM01 PWB.

Replace Q950

OK

Is the 2pin of connector (J950, J951)

voltage line normal?

PLAY: L (–8V), STOP: H (3V)

OK

Are the MUTE signals normal?

NG

NG

Check the HP-MUTE output signal of

PA01 PWB.

Replace defect component.

44

Page 47

3. Main PWB (PM01)

3.1 Check the panel microprocessor

Are the E+6V and E+3.3V of QU91

voltage lines normal?

OK

Is the reset signal of QU01 (59pin) normal?

OK

Is the master clock waveform normal?

12.000MHz

OK

Is not QU01 write-in mode?

67pin=H, 66pin=L

OK

Is each output voltage normal?

(After the 15pin of QU01 changed to H)

OK

NG

NG

NG

NG

NG

• E+6V=0V: Check the E+6V voltage line

on POWER SUPPLAY PWB (P801).

• E+3.3V=0V: Check the soldering of

QU01, or replace QU91.

Check the soldering and the input/output

voltage of QU03.

Check the soldering XU01 and QU01

(63pin and 65pin).

Check the soldering of ST81, CT86 and

QU04.

OK

Replace QU04.

Refer to “1. POWER SUPPLAY PWB (P801)”.

Is communication to QT01 and QU01

(78pin and 79pin) normal?

OK

Is communication to Q301 and QU01

(75pin and 79pin) normal?

Is 88pin of QU01 H?

OK

Is communication to Q102 normal?

Is 28pin of QU01 H?

Is communication of 38pin, 83pin, 84pin

and 85pin on QU01 normal?

OK

Finish

NG

NG

NG

• Check the soldering of QT01,

circumference components and power

supply line.

• Check the soldering QT05, QW81,

QW01, QW02 and QW03.

• Check the output voltage of QT05 and

QW81.

• Check the soldering of Q301, Q302,

RU72, RU73 and RU74.

• Check the power supply line of Q301.

• Check the frequency of 126pin on Q301.

(12.288MHz)

Refer to “3.2 Check the B/E microprocessor”.

45

Page 48

3.2 Check the B/E microprocessor

Are the +3.3V_D1 and +2.5V_D2 of Q102

voltage lines normal?

OK

Is the clock waveform of 18pin on Q102

normal? (27MHz. 2Vp-p)

OK

Is the 15pin of Q102 H?

OK

NG

NG

NG

Check the soldering of Q117 and Q116,

and the input/output voltage.

NG

OK

Input voltage is OK: Check

the soldering of circumference

components of Q102.

Soldering is OK: Replace

Q117 or Q116.

Refer to “1. POWER SUPPLY PWB (P801)”.

Check the waveform of 4pin on Q105.

(27MHz 2Vp-p)

NG

OK

Check the soldering of R168

and R153.

Check the soldering of X101, circumference

components and Q105.

Check the soldering of QU01 (28pin),

R156 and C161.

Are the +3.3V_D1 and +1.8V_D1 of Q101

voltage lines normal?

OK

Is the clock waveform of 18pin on Q106

normal? (27MHz. 2Vp-p)

OK

Refer to B/E 2.

NG

NG

Check the soldering of Q118, and

the input/output voltage.

OK

Input voltage is OK: Check the soldering

of Q101.

Soldering is OK: Replace Q118.

Check the waveform of 3pin on Q105.

(27MHz 2Vp-p)

NG

OK

Check the soldering of R170

and R101.

Check the soldering of X101,

circumference components and Q105.

46

Page 49

B/E 2

Is the clock waveform of 172pin on Q101

normal? (24.576MHz. 2Vp-p)

OK

Is the 193pin of Q101 H?

OK

Is communication of the data bus on Q102

and Q103 normal?

OK

NG

NG

NG

Check the waveform of 9pin on Q105.

(24.576MHz 2Vp-p)

NG OK

Check the waveform of 6pin

on Q111. (24.576MHz)

OK

Check the soldering of R175

and R133.

Check the soldering of X101,

circumference components and Q105.

Check the soldering of Q102 (114pin),

R124, R143, C135 and Q101 (193pin).

Check the soldering of data bus lines.

(MCD0-MCD14 and MCA11-MCA30)

Finish

47

Page 50

3.3 Check the F/E microprocessor.

Are the +3.3V_D2, +1.8V_D2, +3.3V_A2

and +1.8V_A2, of Q502 voltage lines

normal?

OK

Is the clock waveform of 33pin on Q502

normal? (33.87MHz. 2Vp-p)

OK

NG

NG

• Check the soldering of Q114, Q115, and

the input/output voltage.

• Check the soldering of L404, L407 and

circumference components.

NG OK

Check the soldering of

the Q502 and circumference

components.

OK

Replace Q114 or Q115.

Refer to “1. POWER SUPPLY PWB (P801)”.

Check the waveform of 15pin on Q105.

(33.87MHz 2Vp-p)

NG OK

Check the waveform of 2pin

on Q111. (33.87MHz)

OK

Is the 51pin of Q502 H?

Finish

OK

NG

Check the waveform of 2pin

on Q405. (33.87MHz)

OK

Check the soldering of R491

and R574.

Check the soldering of X101,

circumference components and Q105.

Check the soldering of Q102 (108pin),

R129, R570, R648 and C638.

48

Page 51

3.4 Check the DIGITAL VEDEO OUTPUT.

Are digital output signals of Q101 normal?

PXD(0-7), VCLK(27MHz)

OK

Is the reset signal normal?

Q109 (9pin) = H

OK

NG

NG

Check the soldering of Q101 (183-192pin),

R201, R202 and R125.

OK

Refer to “3.1 Check the panel

microprocessor”.

Check the 11pin on Q109.

(Change to H from L, after turn on the unit.)

Check 8pin on Q109 H?

NG OK

Check the soldering of R189,

R190, R191 and Q108.

OK

Replace Q108.

Check the soldering R192 and Q109.

OK

Is communication to QK01 of digital

signals normal?

Check that 13pin, 16pin, 3-10pin and 137pin.

OK

Are the VD+3.3V and VD+1.8V voltage

lines of QK01 normal?

OK

NG

NG

Replace Q109.

Check the soldering of QK10, QK11 and

circumference components.

OK

Check theVD+3.3V line and soldering of

LK34.

OK

Replace QK10 or QK11.

Check the soldering of QK91, QK92 and

circumference components.

Check the soldering of LD01and LK02.

OK

Check the E+4V voltage line.

OK

Replace QK91 or QK92.

Refer to Video 2

49

Page 52

Video 2

Is the IIC waveform of 162pin and 165pin

on QK01 normal?

OK

Is communication of the data bus and

address line between QK03 and QK01

normal?

OK

NG

NG

Check the IIC waveform of 1pin on QK07

and QK08.

NG OK

Check the soldering of RK28,

RK29, QK07 and QK08.

OK

Replace QK07 or QK08.

Check the soldering of Q102 (57pin and

58pin), R160 and R161.

OK

Refer to Refer to “3.1 Check the panel

microprocessor”.

Check the VD+3.3V voltage line.

NG OK

Check the soldering of QK03,

RK14-26, RK31-33 and RK94.

OK

Are digital outputs of QK01 normal?

PY(0-9), SD(0-9), SDVSYNC,

SDHSYNC, SDCLK (27MHz) and

SDCLK2 (27MHz)

OK

Finish

Refer to “Check the Video encoder” or

“Check the HDMI PWB (PD01)”.

NG

Replace QK01 or QK03.

Check the soldering of LK03, CK30 and

CK31.

Check the soldering of QK01 (from 61 to

99 pin).

OK

Replace QK01 or QK03.

50

Page 53

3.5 Check the Video encoder. (Component, CVBS, Y/C)

Are the VD+3.3V and +2.5AD voltage lines

of QM01 normal?

OK

Is the reset signal of QM01 (33pin)

normal?

VRST_5=H

OK

Are the digital data of QM01 normal?

2-9pin, 12-18pin, 26-30pin, 51-55pin and

58-62pin

NG

NG

NG

Check the soldering of QM01, LM01, LM02,

LM03, QK91 and QM91.

OK

Check the input voltage of QK91 and QM91.

NG

OK

Replace QK91 or QM92.

Refer to “POWER SUPPLY PWB (P801)”.

Check the soldering of QK10 (18pin),

RM12 and CM09.

OK

Refer to “3.4 Check the DIGITAL VIDEO

OUTPUT”.

Check the soldering of RM01-05, RM26-29

and QM01.

OK

OK

Is the master clock waveform of 32pin on

QM01 normal? 27MHz 2Vp-p

OK

Is the IIC waveform of 21pin and 22pin on

QM01 normal?

OK

Are the video signals outputted to each pin

of JM01?

1pin=video, 3pin=S-C, 5pin=S-Y,

7pin=component-Y, 9pin=Cb, 11pin=Cr

OK

NG

NG

NG

Refer to “3.4 Check the DIGITAL VIDEO

OUTPUT”.

Check the soldering of RM11 and QM01.

OK

Refer to “3.4 Check the DIGITAL VIDEO

OUTPUT”.

Check the soldering of RM08, RM09 and

QM01.

OK

Check the soldering of QK07 and QK08.

OK

Refer to “3.4 Check the DIGITAL VIDEO

OUTPUT”.

Check the soldering of QM02-QM07 and

circumference resistors.

OK

Check the output signals of QM01

(37-39 pin and 42-44pin).

OK

Finish

Replace QM02-QM07.

51

Page 54

3.6 Check the Video encoder. (RGB)

Are the VD+3.3V and +2.5AD voltage

lines of QN01 normal?

Is the reset signal of QN01 (33pin)

normal?

VRST_5=H

OK

Are the digital data of QN01 normal?

51-55pin and 58-62pin

OK

NG

NG

NG

Check the soldering of QN01, LN01, LN02,

LN03, QK91 and QM91.

OK OK

Check the input voltage of QK91 and QM91.

NG

OK

Replace QK91 or QM92.

Refer to “POWER SUPPLY PWB (P801)”.

Check the soldering of QK10 (18pin),

RN06 and CN09.

OK

Refer to “3.4 Check the DIGITAL VIDEO

OUTPUT”.

Check the soldering of RM23-26 and QN01.

OK

Is the master clock waveform of 32pin on

QN01 normal?

27MHz 2Vp-p

OK

Is the IIC waveform of 21pin and 22pin on

QN01 normal?

OK

Are the video signals outputted to each

pin of JN01?

4pin=G, 6pin=B, 8pin=R

NG

NG

NG

Refer to “3.4 Check the DIGITAL VIDEO

OUTPUT”.

Check the soldering of RN05 and QN01.

OK

Refer to “3.4 Check the DIGITAL VIDEO

OUTPUT”.

Check the soldering of RN02, RN03 and

QN01.

OK

Check the soldering of QK07 and QK08.

OK

Refer to “3.4 Check the DIGITAL VIDEO

OUTPUT”.

Check the soldering of QN02-QN04 and

circumference resistors.

OK

Finish

OK

Check the output signals of QN01

(37-39pin).

OK

Replace QN02-QN04.

52

Page 55

3.7 Check the Playback disc.

3.7.1 Loader is not rotate.

Is the laser beam light up?

Is the current of laser beam normal?

OK

Is Spindle drive signal normal? DM0=H

OK

Finish

3.7.2 CD playback

Is the RF signal normal?

RFAC test pint=approximately 1Vp-p

OK

Is communication of Q502 and Q503

normal?

OK

Finish

NG

NG

NG

NG

• Check the unsoldering of protection

solder pad on the pickup.

• Check the soldering of Q510 and

circumference components of Q511.

• Check the connection of F506 and

pickup connector.

• Check the soldering of Q501.

• Check the soldering of Q508.

• Check the soldering Q502 (111-113pin).

• Check the soldering R615, R699 and

R666-669.

• Check the soldering Q505.

• Check the soldering of Q501 and

circumference components.

• Check the soldering of Q502 (from 65 to

110 pin).

• Check the soldering Q502 and Q503.

• Check the soldering of data bus lines.

BD(0-15), BA(0-9)

• Check the soldering of XLCAS, XUCAS,

XMOE, XRAS and XMWR.

3.7.3 DVD playback

Is communication of VSTEM between

Q502 and Q404 normal? VDT(0-7)_COR,

XHAC_COR, VEFG_COR, XSHD_COR

and DCK_COR

OK

Is the Request signal normal?

HDRQ_COR=L, Q502 (45pin),

Q404 (21pin)

OK

Finish

NG

NG

• Check the soldering of Q502 (from 36 to

49pin).

• Check the soldering of R621-R633.

• Check the soldering of R401-R412.

Check the soldering of Q404.

53

Page 56

3.7.4 Super Audio CD playback

Is communication of VSTEM between

Q404 and Q401 normal?

SD(0-7), SDCK, XSRQ, SDEF and

XSHD2.

OK

Is the RF signal normal?

WM test pint (Q403: 1pin)=approximately

1Vp-p

OK

Is communication of the data bus line

between Q401 and Q402 normal?

OK

Finish

3.8 No sound or noisy

3.8.1 CD playback

Are the CD digital audio data output

signals of Q101 normal? CDLRCK,

CDBCLK, CDDIN and DOTX

OK

NG

NG

NG

NG

Check the soldering of Q404, and

R437-R449.

Check the soldering of Q403 and

circumference components.

Check the soldering of Q401, R141-R162

and Q402.

• Check the soldering of Q502 (from 58 to

62).

• Check the soldering of R641-R644.

Are digital audio data output signals of

Q101 normal?

DATA1, LRCK, BCK and DOUT0

OK

Are the output signals of PCM/DSD

selector normal? MCLK, DABCK, DAD0

and DSDR

OK

Refer to “6. AUDIO PWB (PA01)”.

NG

NG

• Check the soldering of Q101 (from 159

to 170 pin).

• Check the soldering of R134-R142.

• Check the soldering of Q204-Q207.

• Check the soldering of Q105 and Q111.

54

Page 57

3.8.2 DVD-Video/Audio playback

Are the DVD digital data output signalsof

Q101 normal?

0DATA(1-3), 0LRCK and 0BCK

OK

Are bass management output signals of

Q301 normal?

IBCK, ILRCK, IDT0, IDT1 and IDT2

OK

Are the output signals of PCM/DSD

selector normal?

MCLK, DABCK, DAD0, DSDR, DAD1,

DSDSW, DAD2 and DSDRS

OK

NG

NG

NG

• Check the soldering of Q101 (from 159

to 171 pin).

• Check the soldering of Q304.

• Check the +3.3V_D1 and +2.5VD1

voltage lines.

• Check the clock frequency on Q301.

12.288MHz

• Check the soldering of Q301 and Q302.

• Check the control signals of Q301.

DSPREQ1, FCS, DSPDIN,

DSPDCLOK, DSPREQ2, RSTDSP, SCS

and HINBSY

• Check the control signals (SPI) of Q304.

CDIN, CS3, CRST, CCLK and CDOUT

• Check the soldering of Q303 and Q305.

• Check the soldering of Q204-Q207.

• Check the soldering of Q203.

• Check the soldering of J271.

Refer to “6. AUDIO PWB (PA01)”.

3.8.3 Super Audio CD playback

Are the DSD data output signals of Q401

normal?

DSARS, DSALS, DSASW, DSAC, DSAR,

DSAL and BCKA0

OK

Are the output signals of PCM/DSD

selector normal?

MCLK, DABCK, DAD0, DSDR, DAD1,

DSDSW, DAD2 and DSDRS

OK

Refer to “6. AUDIO PWB (PA01)”.

NG

NG

• Check the soldering of Q401 (from 60

to76 pin).

• Check the soldering of R450-R456.

• Check the soldering of Q204-Q207.

• Check the soldering of Q203.

• Check the soldering of J271.

55

Page 58

4. HDMI PWB (PD01)

QW0

Q

4.1 Check the Scaler.

Are the SC+3.3V_1, SC+2.5V_1 and

SC+1.2V_1 voltage lines of QW01

normal?

OK

Is the reset signal of QW01 H?

RW12 VRST_3=H

OK

NG

NG

Check the soldering of LW01-LW03,

QW01 and QW81-QW83.

OK

Check the input voltage of QW81-QW83.

OK

Check the VD_PSW level. VD_PSW=L

OKNG

Replace QW81, QW82 or

QW83.

Check the soldering of JQ02, JK02 (8pin)

and QU01 (1pin).

Check the soldering of QW01, RW12.

OK

Check the soldering of JW02, JK02 (2pin)

and QU01 (24pin).

Are the digital data input signals normal?

PY_2䇼0-9䇽, SDCLK_2, SDHSYNC_2,

SDVSYNC_2, DE.

OK

Is the voltage lines of

QW05 normal?

19, 20pin 䋨SC+2.5V_1)

18pin (SC+3.3V_1)

NG

Check the soldering

of QW05, CW48-䌃

䌗50.

OK

Is the signal of QW05 H?

10pin (CONFIGDONE)=H

NG

#HECKTHESOLDERING

OF272䌗

/+

Check the soldering

of RW18-R䌗21 and

RW23.

NG

Check the soldering of JW01, JK01,

RW01-RW06, RW09, RW17, RW38 and

1.

OK

Check the soldering of QK05-QK06,

QK13 and circumference components of

K14.

OK

Check the input signals of

QK04-QK06.

NG

OK

Check the voltage

line QK04-QK06.

OK

NG

Replace

QK04-QK06.

Refer to “3.4 check the

DIGITAL VIDEO OUTPUT”

NG

Refer to Scaler 2

Replace QW05.

56

Page 59

Scaler 2

Is the PLLCLK of RW10 normal?

OK

Is the 30MHz CLK of XW0(2pin) and

XW0(3pin) normal?

OK

OK

NG

Check the soldering of

Is the waveform

of RW11

normal?

XW02 and

circumference

components.

Is the waveform of SD_RAM (RW59-61)

normal?

OK

Is the waveform of RW57-RW58 (each

pin) normal?

OK

Is the waveform of RW41-56 (each pin)

normal?

NG

NG

Check the soldering of RW10.

OK

Check the input voltage of QW04 and

LW05

OK

Check the input CLK of QW04(1pin).

NG

Check the soldering of RW26 and

circumference components of QW04.

Refer to Scaler 3

57

Page 60

Scaler 3

Is the IIC waveform of RW13 and RW14

(SDA1, SCL1) normal?

OK

Are digital output signals of QW01

normal?

HDB(0-9), HDG(0-9), HDR(0-9),

HDVSYNC, HDHSYNC, HDVCLK and

HDDE

OK

Finish

NG

NG

Check the soldering of RW13,

circumference components of RW14,

JW01 and JK01 (4,5pin).

OK

Check the waveform of QW02 (1pin) and

QW03 (1pin).

OKNG

Replace QW02 or QW03.

Check the soldering of QU01 (78, 79pin).

Replace HDMI PWB (PD01).

Notice

OUTPUT Format Frequency of HDVCLK Signal

720P 74.5MHz

1080i 74.5MHz

480P/480i 27MHz

576P/576i 27MHz

1080P 148.5MHz

58

Page 61

4.2 Check the HDMI driver.

Are the HDP+1.8V and HDP+3.3V

voltage lines of QT01 normal?

OK

Are input digital signals normal?

HDB(0-9), HDG(0-9), HDR(0-9), HDDE,

HDHSYNC, HDVSYNC and HDVCLK

OK

Is the reset signal (VRST_4) of QT01 H?

OK

NG

NG

NG

Check the soldering of QT01, QT07,

QT08 and LT01-LT04.

OK

Check the input voltage of QT07 and

QT08.

OKNG

Replace QT05 or QW81.

Check the soldering of JW02 and JK02.

OK

Refer to “1. POWER SUPPLY PWB (P801)”.

Check the soldering of QT01, RT01-RT03

and RT14-RT19.

Check the soldering RT27-RT29, QT02

and QT03 (25pin).

Is the IIC waveform of QT01 normal?

SDA1 and SCL1

OK

Is the picture of the television inputted by

HDMI normal?

OK

Finish

(Of course, there needs to be no problem

in video and audio output signal. And the

audio also checks HD_SPDIF.)

NG

NG

Check the soldering of QT01, RT30 and

RT31.

Check the soldering of JT01, LT06-LT09

and RT17-RT24.

OK

Check the soldering of QT04, QT05, LT05

and circumference components.

OK

Replace QT01.

59

Page 62

5. Check the analog video output signal : VIDEO PWB (PV01).

5.1 Picture is not outputted normally. (Com pos ite, Y/C)

Is the E+6V voltage line of JV05 normal?

OK

Is the +5VV voltage line of QV01 normal?

OK

Are the video signals inputted to each pin

of QV01?

4pin=video, 6pin=S-Y, 2pin=S-C

OK

Are the analog video signals outputted to

each pin of QV01?

13pin=video, 10pin=S-Y, 15pin=S-C

NG

NG

NG

NG

Refer to “1. POWER SUPPLY PWB (P801)”.

Check the output voltage of QV91.

+5VV

OK

Check the QV91 (1pin) level.

1pin=H

NG OK

Refer to “3.1 Check the panel

microprocessor”.

Replace QV91.

Refer to “3.4 Check the DIGITAL VEDEO

OUTPUT”.

Replace QV01.

60

Page 63

5.2 Picture is not outputted normally. (Com po nent)

Is the E+6V voltage line of JV05 normal?

OK

Is the +5VV voltage line of QY07 normal?

OK

Are the video signals inputted to QY01 (Y),

QY03 (Cb) and QY05 (Cr)?

OK

Are the video signals inputted to each pin

of QY07?

1pin=Y, 3pin=Cb, 5pin=Cr

NG

NG

NG

NG

Refer to “POWER SUPPLY PWB (P801)”.

Check the output voltage of QV91.

+5V

OK

Check the QV91 (1pin) level.

1pin=H

NG OK

Refer to “3.1 Check the panel

microprocessor”.

Replace QV91.

Refer to “3.4 DIGITAL VEDEO OUTPUT”.

Check the soldering of video filter block.

Y=QY01-QY02, Cb=QY03-QY04,

Cr=QY05-QY06

OK

Are the video signals outputted to each pin

of QY07?

9pin=Y, 11pin=Cb, 13pin=Cr

NG

Replace QY07.

61

Page 64

5.3 Picture is not outputted normally. (SCART)

Are the E+6V and SW+12 voltage lines of

JV05 normal?

OK

Is the +5VV line of QE01 normal?

OK

Are the video signals inputted to each pin

of QE01 and QE02?

QE01: 8pin=Y, 9pin=V, 11pin=C,

14pin=R,QE02: 10pin=B, 12pin=G

OK

NG

NG

NG

Refer to “1. POWER SUPPLY PWB (P801)”.

Check the output voltage of QV91.

+5V

OK

Check the QV91 (1pin) level.

1pin=H

NG OK

Refer to “3.1 Check the panel

microprocessor”.

Replace QV91.

Refer to “3.4 Check the DIGITAL VEDEO

OUTPUT”.

Are the video signals inputted to each pin

of QE02? 4pin=V/Y, 14pin=C/R

OK

Are the video signals outputted to each pin

of QE02?

16pin=C/R, 18pin=R, 20pin=B, 23pin=V/Y

NG

NG

Check the signal level of QE01 (12pin).

RGB/VIDEO output=H, S-VIDEO

output=L

NG

Refer to “3.2 Check the B/E

microprocessor”.

Replace QE01

Replace QE02.

OK

62

Page 65

6. AUDIO PWB (PV01)

6.1 Audio is not outputted normally.

Are the +3.3VDD and +5VDA voltage lines

of QD01, QD21 and QD41 normal?

OK

Are the +8VA and -8VA voltage lines of

JA01 normal?

OK

Is the MCLK signal of QD01, QD21 and

QD41 (6pin) normal?

OK

NG

NG

NG

Check the output voltage of J853 (3pin

and 6pin) on POWER SUPPLY PWB (P801),

afterthe wire between J853 and JA02

disconnected.

NG

OK

Check the soldering of QD01,

QD21 and QD41.

OK

Replace QD01, QD21 or

QD41.

Check the power supply circuit of +5VA and

+3.3VD on POWER SUPPLY PWB (P801).

Check the power supply circuit of +8VA

and -8VA on POWER SUPPLY PWB (P801).

Check the input signals of QD61

(1pin and 2pin).

NG

OK

Is the waveform of QD01, QD21 and

QD41 (3-5pin) normal?

OK

Are the AOUTA+/- and AOUTB+/- signals

of QD01, QD21 and QD41 normal?

OK

Are the MUTE signals of JD01 (4, 5pin)

normal?

OK

Are the MUTE signals inputted/outputted

to each pin of the connected components?

NG

NG

NG

NG

Check the soldering of QD61

and circumference components.

OK

Replace QD61.

Check the MCLK signal of MAIN PWB (PM01).

Check the audio data output signal of

MAIN PWB (PM01).

Check the soldering of QD01, QD21

and QD41.

Check the MUTE output signal of

MAIN PWB (PM01).

Replace defect component.

63

Page 66

7. IEEE1394 PWB (PI01)

7.1 Check the i.Link.

NG

Is the E+6V voltage line (JI61) normal? Refer to “1. POWER SUPPLY PWB (P801)”.

OK

NG

Is the 14pin of JI62 H?

OK

Check the soldering of JI62.

OK

Refer to “3.1 Check the panel

microprocessor”.

Is the 1 pin of JI62 H?

OK

Is the +3.3VU line (QJ01) normal?

OK

Is the +3.3VD line (QI01) normal?

OK

Is the +3.3VA line (QJ01) normal?

OK

Are the clock wave form of 89pin on

QJ01 normal? (16MHz, 3Vp-p)

OK

Are the clock wave form of 53pin on QI01

normal? (24.576MHz, 3Vp-p)

OK

NG

NG

NG

NG

NG

NG

Check the soldering of JI62.

OK

Refer to “3.1 Check the panel

microprocessor”.

Check the soldering of QI90 and the

input/output voltage.

OK

Check the soldering of FJ01.

Check the soldering of FI02.

Check the soldering of FI01.

Check the soldering of XJ01,

circumference components and QJ01.

Check the soldering of XI01,

circumference components and QI01.

Play DVD-Audio Disc.

Are the signal wave form of 9 to 18pin on

QI01 normal?

OK

Play SACD Disc. Are the signal wave

form of 158,159 and 163 to 167pin on

QI01 normal?

OK

Play CD Disc.

Are the signal wave form of 169 and

173pin on QI01 normal?

NG

NG

NG

Check the soldering of JI62,

circumference components and QI01.

Check the soldering of JI60,

circumference components and QI01.

Check the soldering of JI60 and JI62

circumference components and QI01.

64

Page 67

1. POWER SUPPLY PWB (P801)

電源入らず

1.1

Connector(J808)の電圧確認 E+6V

OK

Connector(J805)の10ピンSTB_CTL信号の

確認 STB_CTRL=H(3.3V)

OK

+12V、+8V、+5V_D1、+5V_D2、E+4V、

-27V、DC+3.5V、HAETERの各電源回路を

確認

2. DISPLAY CONTROL / PHONE PWB

2.1 FL

表示せず

コネクタ(JF03)の電圧確認

+5V_D1, -27V, DC+3.5V, Heater

OK

QF71 61pinのReset信号の確認

Reset=H?

OK

NG

NG

NG

NG

NG

F801切れ、1次側の発振回路(Q801、

Q802)及びQ803の確認

※1次側の回路を確認する場合は、

測定器のGNDはフローティングして下さい

3.1 Panel uPの動作確認へ

各電圧ラインの入出力電圧確認

Display PWB (PF01)と

Power Supply PWB (P801)の半田付け確認

QF80 8pinのReset信号の確認

Reset=H?

OK

QF71の62, 63, 64pinの信号変化(H L)の

確認

OK

NG

NG

RF72、CF74の半田付け確認

QF80 9pinのReset信号の確認

Reset=H?

OK

NG

QF80交換

RF11, RF80, CF11, CF81, JF01の12pin,

QU01(H8Sマイコン)の71pinの半田付け確認

QF80の2, 5, 12pinの信号変化(H L)の

確認

OK

NG

QF80 or/and QF71交換

RF08, RF09, RF10, JF01の8, 10, 11pin確認

QU01の9, 70, 73pinの半田付け確認

QF71の1-40, 42-54pinの信号変化(H L)の

確認

OK

VF01交換

NG

QF71交換

65

Page 68

2.2 ヘッドホン音出ず。(ヘッドホンを接続し確認します)

コネクタ(J950, J951)8, 10pinの電圧確認

+8VA, -8VA

OK

コネクタ(J950, J951)の1pin電圧確認

HP接続時:L HP未接続時:H(3.3V)

OK