Page 1

Service

CD5000/N1B, /T1B, /U1B, /F1B, /K1B

/N2B, /T2B, /U2B, /F2B, /K2B

CD5000

Manual

Technical Specification................................................................................................. 2-1

Safety Instructions ....................................................................................................... 3-1

Mechanical Instructions ............................................................................................... 4-1

Service Tools................................................................................................................ 5-1

Service Test Program................................................................................................... 5-2

Blockdiagram ............................................................................................................... 5-3

Wiring Diagram ............................................................................................................ 6-1

Circuit Diagram AF Board/Supply Part......................................................................... 7-1

Component Layout AF Board....................................................................................... 7-2

Circuit Diagram AF Board/DAC Part ............................................................................ 7-3

Component Layout AF Board....................................................................................... 7-4

Circuit Diagram Front Board ........................................................................................ 7-5

Component Layout Front Board................................................................................... 7-6

Circuit Diagram Headphone Board .............................................................................. 7-6

Component Layout Headphone Board ........................................................................ 7-6

Circuit Diagram CD Board ........................................................................................... 7-7

Component Layout CD Board ...................................................................................... 7-8

Fault Finding Tree CD.................................................................................................. 7-9

Exploded View of Set ................................................................................................. 10-1

Exploded View CD Short Loader ............................................................................... 10-2

Electrical Partslist....................................................................................................... 10-3

CD Player

TABLE OF CONTENTS

Please use this service manual with referring to the user guide (D.F.U) without fail.

Printed in Japan

- CD5000 -

273W855010 AO

3120 785 00050

First Issue:1999.06

Page 2

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original

it is famous.

Parts for your

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

USA

MARANTZ AMERICA, INCMARANTZ AMERICA, INC.

440 MEDINAH ROAD

ROSELLE, ILLINOIS 60172

USA

PHONE : 630 - 307 - 3100

FAX : 630 - 307 - 2687

SUPERSCOPE TECHNOLOGIES, INC.SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AMERICAS

AUSTRALIA

SCAN AUDIO PTY. LTD.SCAN AUDIO PTY. LTD.

52 CROWN STREET, RICHMOND 3121

VICTORIA

AUSTRALIA

PHONE : +61 - 3 - 9429 - 2199

FAX : +61 - 3 - 9429 - 9309

NEW ZEALAND

SCAN AUDIO PTY. LTD.SCAN AUDIO PTY. LTD.

8C PIERMARK DRIVE, ALBANY.

NORTH SHORE, AUCKLAND.

NEW ZEALAND

PHONE : +64 - 9444 - 4710

FAX : +64 - 9444 - 1346

EUROPE / TRADING EUROPE / TRADING

MARANTZ EUROPE B.V.MARANTZ EUROPE B.V.

P.O.BOX 80002, BUILDING SFF2

5600 JB EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2732241

FAX : +31 - 40 - 2735578

CANADA

LENBROOK INDUSTRIES LIMITEDLENBROOK INDUSTRIES LIMITED

633 GRANITE COURT,

PICKERING, ONTARIO L1W 3K1

CANADA

PHONE : 905 - 831 - 6333

FAX : 905 - 831 - 6936

THAILAND

MRZ STANDARD CO.,LTDMRZ STANDARD CO.,LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

BRAZIL

MARANTZ BRAZILMARANTZ BRAZIL

CAIXA POSTAL 21462

CEP 04698-970

SAO PAULO, SP, BRAZIL

PHONE : 0800 - 123123

FAX : +55 11 534. 8988

(Discagem Direta Gratuita)

SINGAPORE

WO KEE HONG (S) PTE LTDWO KEE HONG (S) PTE LTD

WO KEE HONG CENTRE

NO.23, LORONG 8, TOA PAYOH

SINGAPORE 319257

PHONE : +65 2544555

FAX : +65 2502213

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.WO KEE HONG ELECTRONICS SDN. BHD.

NO. 102 JALAN SS 21/35, DAMANSARA

UTAMA, 47400 PETALING JAYA

SELANGOR DARUL EHSAN, MALAYSIA

PHONE : +60 3 - 7184666

FAX : +60 3 - 7173828

JAPAN

Technical

MARANTZ JAPAN, INC.MARANTZ JAPAN, INC.

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 748 9190

KOREA

MK ENTERPRISES LTD.MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

990521A.O

Page 3

2-1

General

Dimensions (WxHxD) : 435 x 86 x 265mm

Weight : 2,9kg

Accessories

Instruction for use : 3139 116 19120 for /F

: 3139 116 19130 for /K

: 3139 116 18900 for /N, /T

: 3139 116 19110 for /U

Remote control : 3139 228 82600

Mains voltage

/N, /T : 220-230V( 10%) 50Hz

/K :110-120/220230V( 10%) 50/60Hz

/U :120V( 10%) 60Hz

/F :100V( 10%) 50/60Hz

Power consumption

stand by : 5W

operating : approx. 8W

Audio performance

Number of channels : 2

Output voltage (Line out) : 2V

RMS

3dB

Unbalance left-right : 1dB

Frequency response : 20Hz-20kHz 0,4dB

Signal to noise ratio : 108 dB typ.

Dynamic range : 105dB typ. at 1kHz

THD : 0,0063% at 1kHz

Channel separation : 98dB typ. at 1kHz

Headphone output

Output level (1kHz, 0dB) : 5V

RMS

Unbalance left-right : 1,2dB

Output impedance : 120

Load impedance : 32 - 600

Output power : 25mW at 32

: 52mW at 120

: 29mW at 600

Laser

Output power : <5mW (3mW typ.)

Wavelength : 780nm

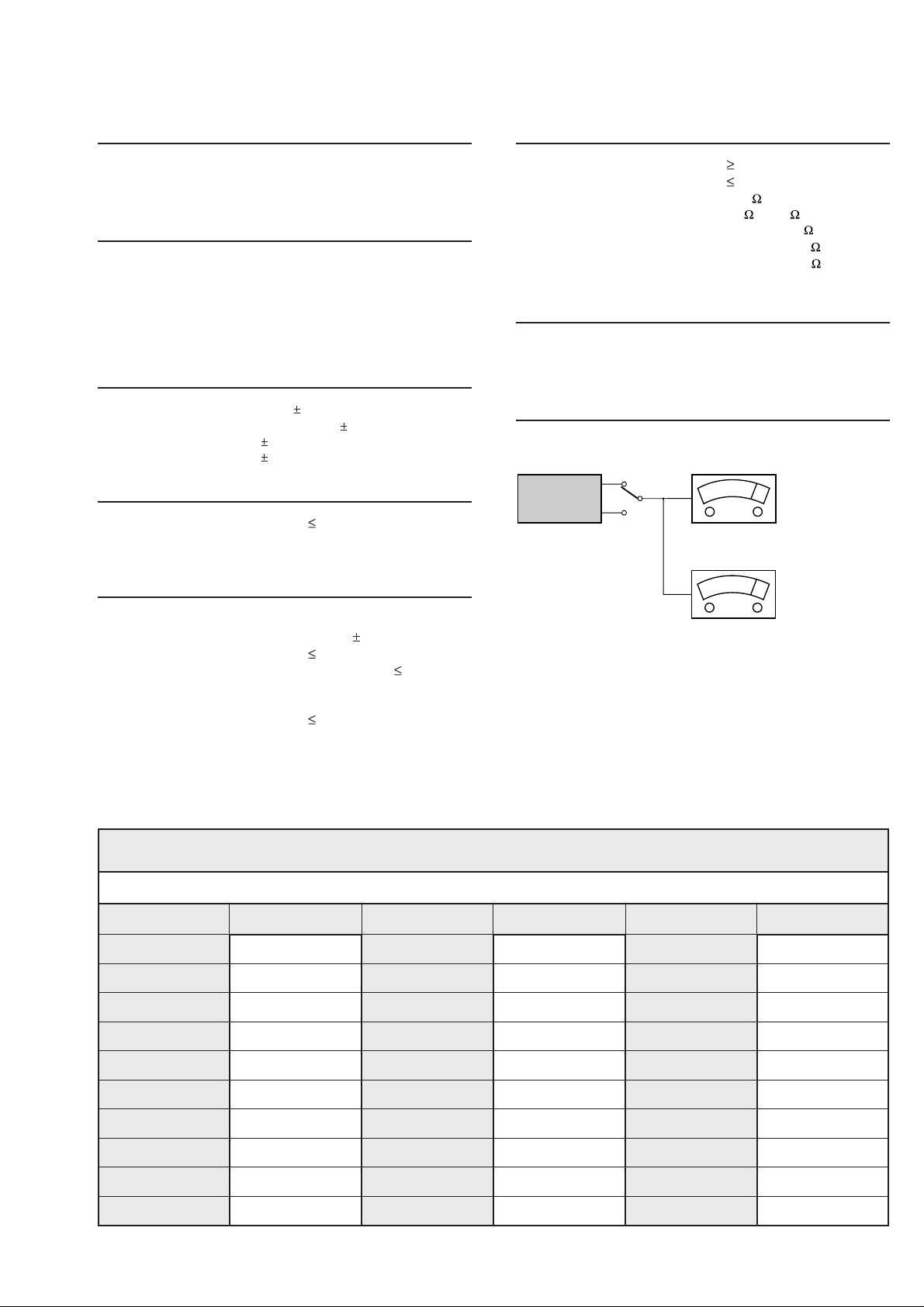

Measurement setup

Use Audio Signal disc SBC429 4822 397 30184

L

R

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

S/N and distortion meter

e.g. Sound Technology ST1700B

TECHNICAL SPECIFICATION

sdnammoC5CR

02=edocmetsyS

dnammoC edoC dnammoC edoC dnammoC edoC

"0"YEK LLORCSYALPSID15ELFFUHS28

"1"YEK YALP53THGILHGIH43

"2"YEK POTS54TAEPER29

"3"YEK ESUAP48EDAF201

"4"YEK EMIT11PUEMULOV16

"5"YEK SUOIVERP33NWODEMULOV17

"6"YEK WEIVER50YBDNATS12

"7"YEK EUC52TXETDC88

"8"YEK MARGORP36TXEN32

"9"YEK B/ATAEPER59

0

1

2

3

4

5

6

7

8

9

Page 4

3-1

WARNING

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD). Careless handling during

repair can reduce life drastically.

When repairing, make sure that you are connected with the

same potential as the mass of the set via a wristband with

resistance. Keep components and tools at this potential.

ATTENTION

Tous les IC et beaucoup d´autres semi-conducteurs sont

sensibles aux décharges statiques (ESD). Leur longévite

pourrait être considérablement écourtée par le fait qu´aucune

précaution nést prise à leur manipulation.

Lors de réparations, s´assurer de bien être relié au même

potentiel que la masse de l´appareil et enfileer le bracelet

serti d´une résistance de sécurité.

Veiller à ce que les composants ainsi que les outils que l´on

utilise soient également à ce potentiel.

WARNUNG

Alle ICs und viele andere Halbleiter sind empfindlich

gegenüber elektrostatischen Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kann die

Lebensdauer drastisch reduzieren.

Sorgen Sie dafür, daß sie im Reparaturfall über ein Pulsarmband mit Widerstand mit dem Massepotential des

Gerätes verbunden sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls auf diesem

Potential.

AVAILABLE ESD PROTECTION EQUIPMENT :

anti-static table mat large 1200x650x1.25mm 4822 466 10953

anti-static wristband 4822 395 10223

connection box (3 press stud connections, 1M ) 4822 320 11307

extendible cable (2m, 2M , to connect wristband to connection box) 4822 320 11305

connecting cable (3m, 2M , to connect table mat to connection box) 4822 320 11306

earth cable (1M , to connect any product to mat or to connection box) 4822 320 11308

KIT ESD3 (combining all 6 prior products - small table mat) 4822 310 10671

wristband tester 4822 344 13999

AVAILABLE JIG for FR980

Extension PCB and wire kit 4822 395 10815

ESD

WAARSCHUWING

Alle IC´s en vele andere halfgeleiders zijn gevoelig voor

electrostatische ontladingen (ESD).

Onzorgvuldig behandelen tijdens reparatie kan de levensduur

drastisch doen vermindern. Zorg ervoor dat u tijdens reparatie

via een polsband met weerstand verbonden bent met hetzelfde

potentiaal als de massa van het apparaat.

Houd componenten en hulpmiddelen ook op ditzelfde potentiaal.

AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono sensibili alle scariche

statiche (ESD).

La loro longevità potrebbe essere fortemente ridatta in caso di

non osservazione della più grande cauzione alla loro

manipolazione. Durante le riparationi occorre quindi essere

collegato allo stesso potenziale che quello della massa

delápparecchio tramite un braccialetto a resistenza.

Assicurarsi che i componenti e anche gli utensili con quali si

lavora siano anche a questo potenziale.

small 600x650x1.25mm 4822 466 10958

Safety regulations require that the set be restored to its

original condition and that parts which are identical with

those specified be used.

Safety components are marked by the symbol

Les normes de sécurité exigent que l`appareil soit remis

à l`état d`origine et que soient utilisées les pièces de

rechange identiques à celles spécifiées.

Les composants de sécurité sont marqués

DANGER: Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

Varning !

Advarsel !

Osynlig laserstrålning när apparaten är öppnad och

spärren är urkopplad. Betrakta ej strålen.

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten. Der Originalzustand des Gerätes

darf nicht verändert werden. Für Reparaturen sind Originalersatzteile zu verwenden.

Sicherheitsbauteile sind durch das Symbol markiert.

LASER PRODUCT

Usynlig laserstråling ved åbning når sikkerhedsafbrydere

er ude af funktion. Undgå udsaettelse for stråling.

SAFETY

Veiligheidsbepalingen vereisen, dat het apparaat in zijn

oorspronkeliijke toestand wordt teruggebracht en dat

onderdelen, identiek aan de gespecificeerde, worden toegepast.

De Veiligheidsonderdelen zijn aangeduid met het symbool

Le norme di sicurezza estigono che l´apparecchio venga

rimesso nelle condizioni originali e che siano utilizzati i

pezzi di ricambiago identici a quelli specificati.

Componenty di sicurezza sono marcati con

CLASS 1

Varoitus !

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen !

After servicing and before returning the set to customer

perform a leakage current measurement test from all

exposed metal parts to earth ground, to assure no

shock hazard exists.

The leakage current must not exceed 0.5mA.

CS 53 135

"Pour votre sécurite, ces documents doivent être utilisés par

des spécialistes agréés, seuls habilités à réparer votre

appareil en panne".

Page 5

4-1

CS 53 140

MECHANICAL INSTRUCTIONS

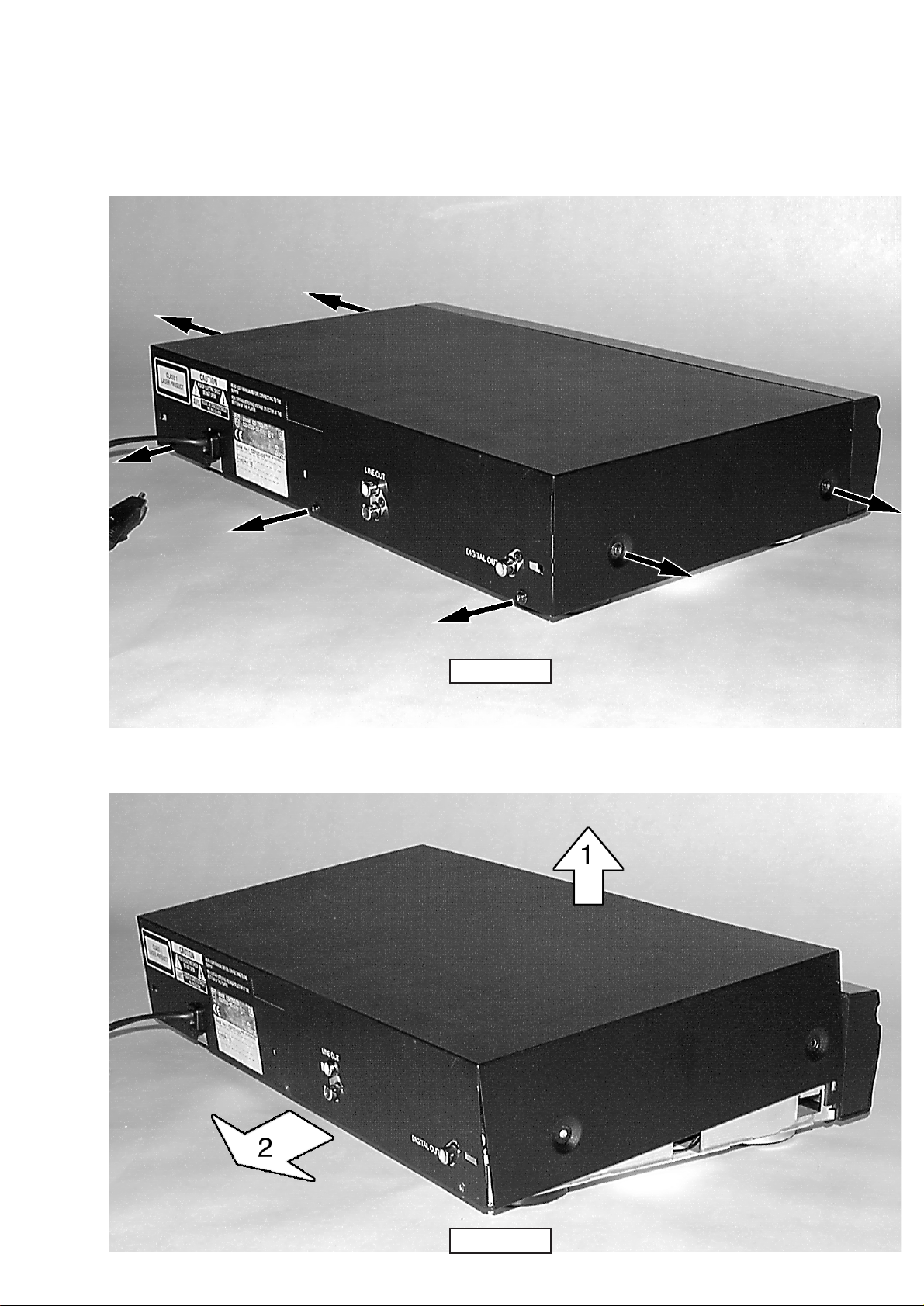

1) Loosen 7x screw as shown in picture 1.

picture 1

picture 2

2) Lift top cover as shown in picture 2.

3) Remove top cover.

Dismantling Top Cover

Page 6

MECHANICAL INSTRUCTION

Dismantling Front

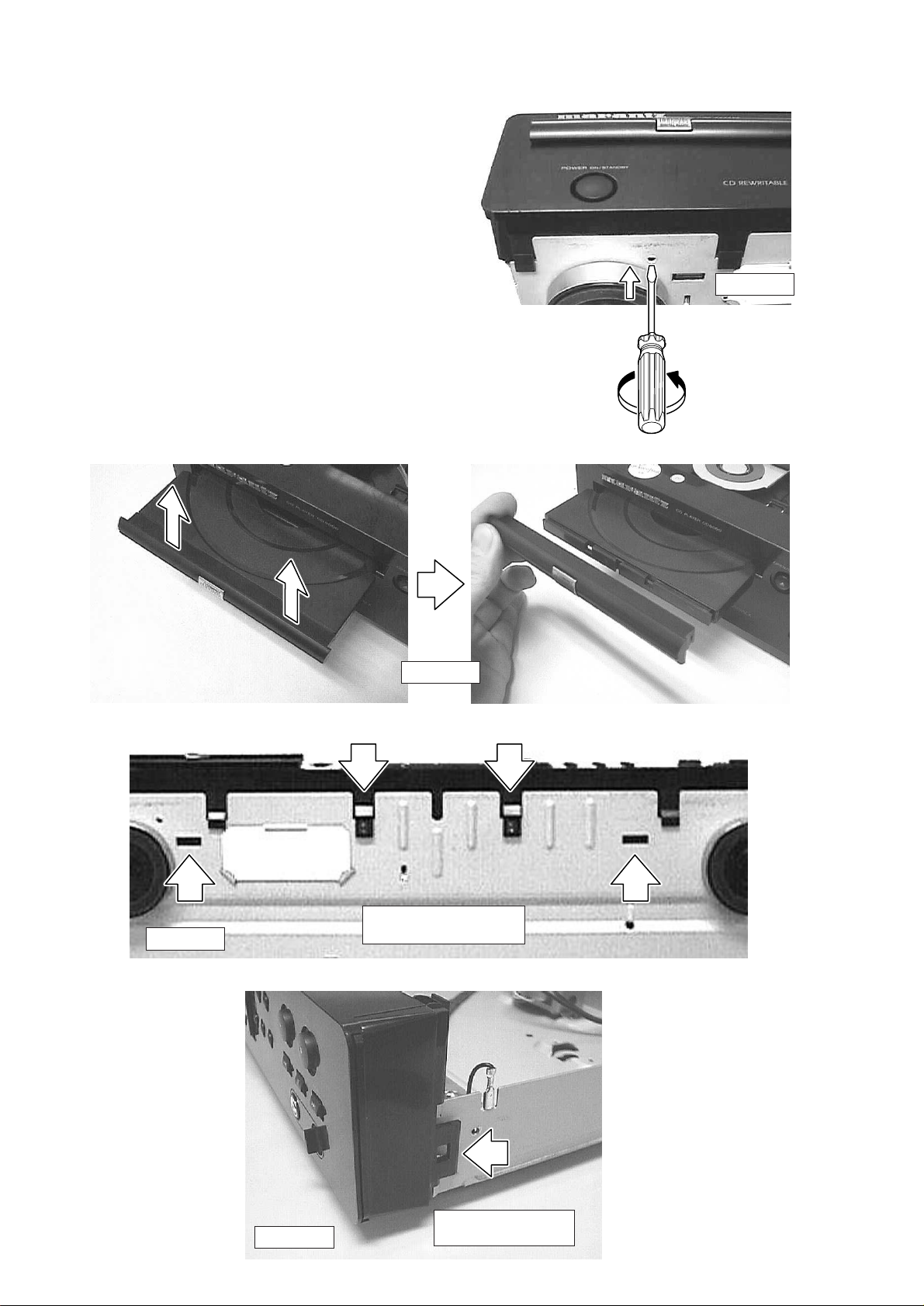

1) Press open/close button to open the tray. If the tray doesnít

work, turn counterclockwise a small screwdriver into the

hole as shown in picture 3. Then the tray comes out. After

the first centimeter it is possible to pull the tray out by

hand.

2) Release the door cover of the tray as shown in picture 4.

3) Loosen 2x screw as shown in picture 5.

4) Release 2x snap on button (see picture 5).

5) Release 2x snap on side (see picture 6).

6) Remove front.

4-2

Picture 3

Picture 4

3

3

44

Picture 5

Bottom view

Picture 6

5

Side view

Page 7

4-3

CS 53 142

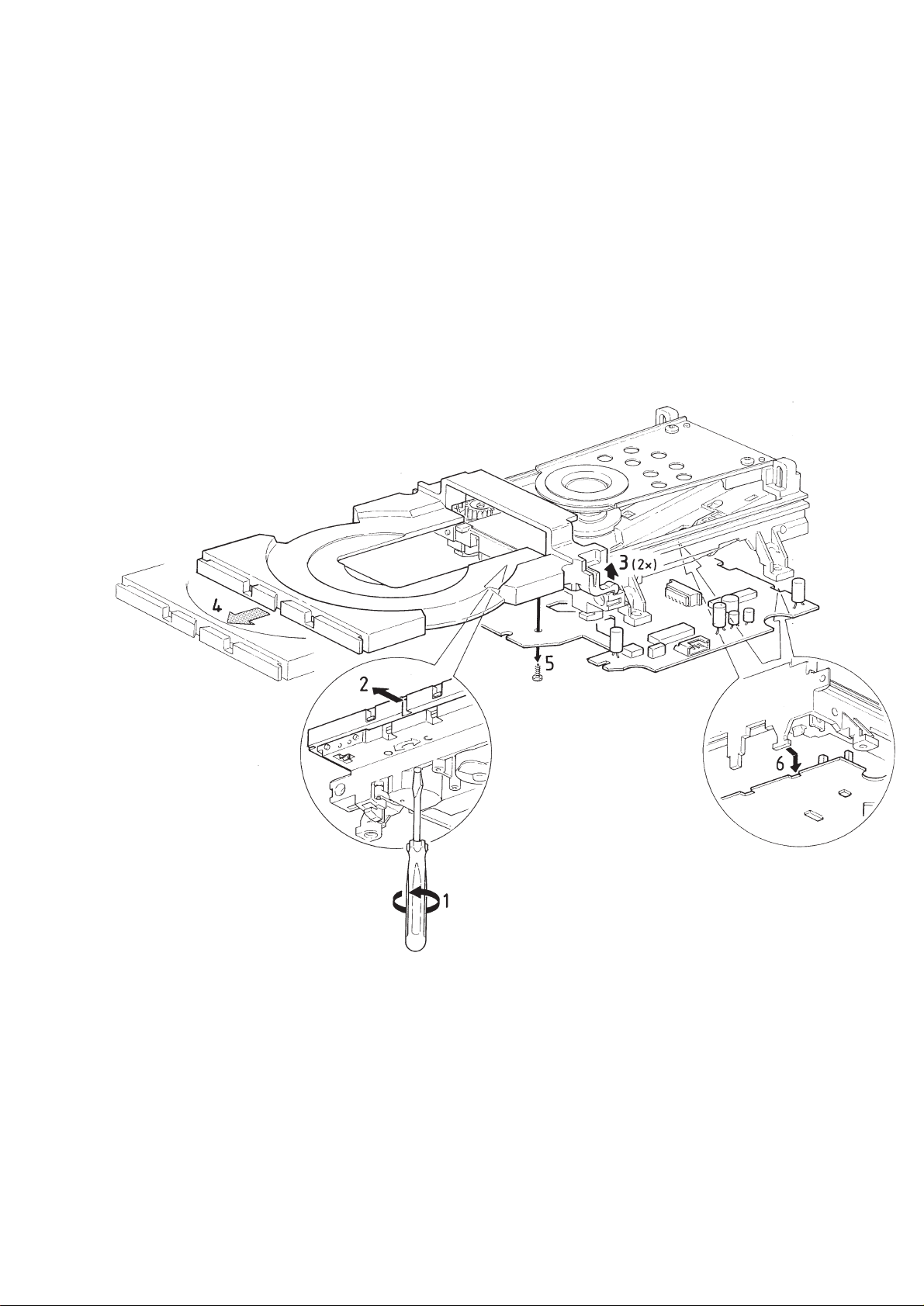

Dismantling hints CD Short Loader

Dismantling the tray

a) Press open/close button to open the tray. If the tray

doesn´t work, use a small screwdriver as shown in Fig.1

step 1 to move the tray outside. After the first centimetre

it is possible to pull the tray out by hand.

b) Release two snaps and remove tray.

Fig. 1

Page 8

4-4

CS 53 143

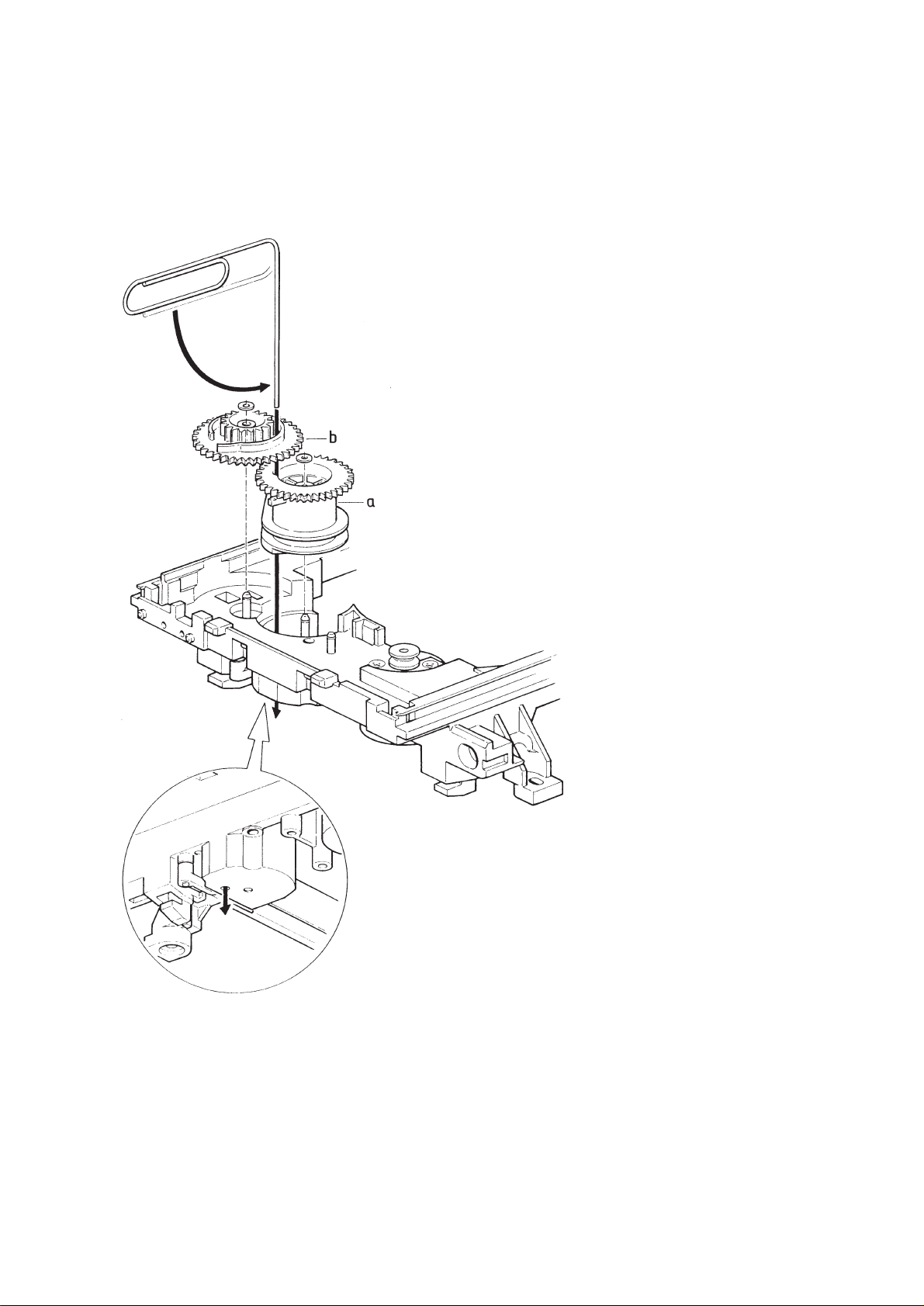

Assembly of gear

a) Use a pin (e.g. a paperclip) to align the cam wheel (a)

with the gear wheel (b). See Fig. 2.

b) Fix the wheels with the small plastic washers.

Fig. 2

Page 9

4-5

CS 53 144

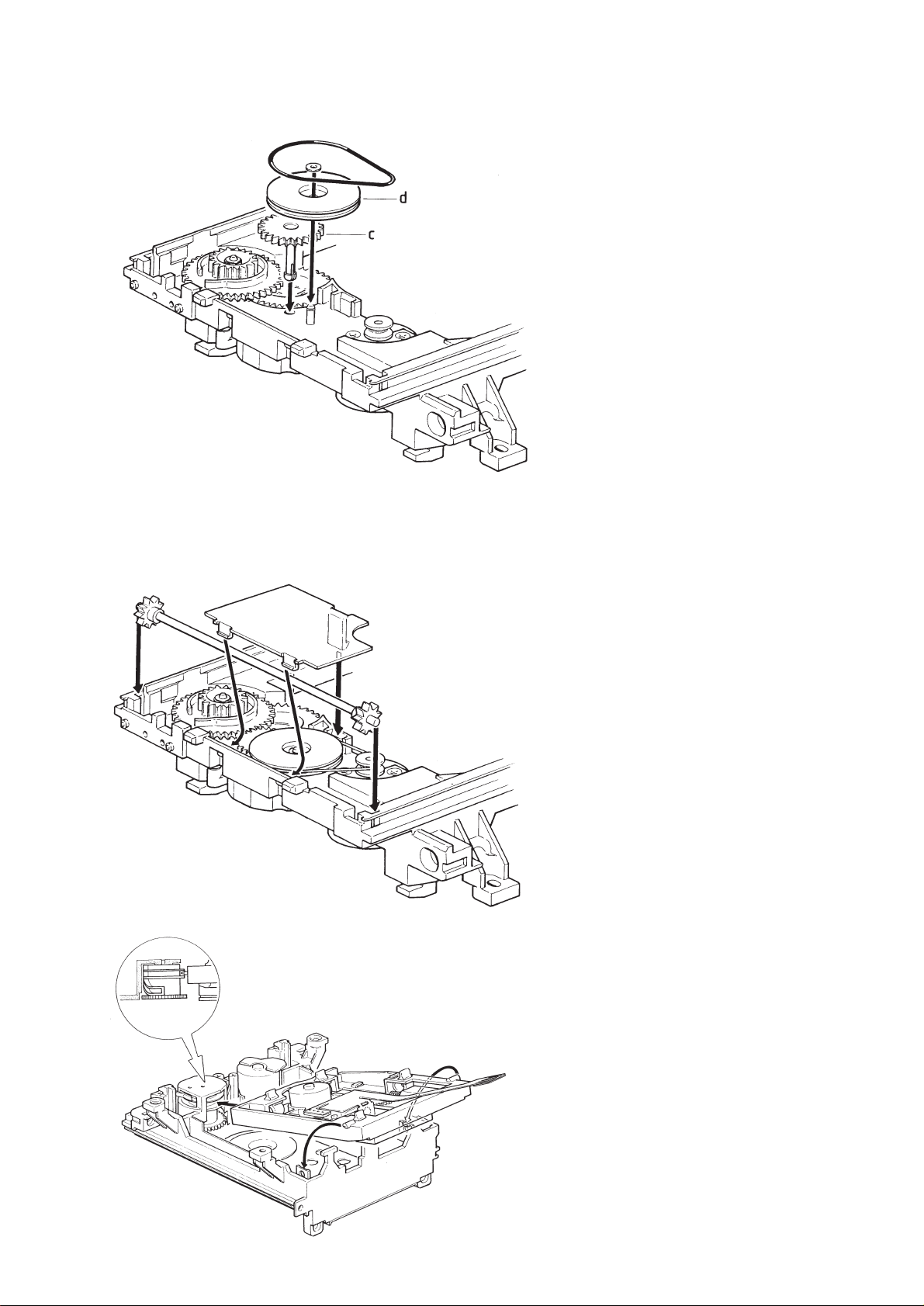

c) Mount idle wheel 2 (c) and idle wheel 1 (d) in any

position. See Fig. 3.

d) Fix the idle wheel 1 (d) with the small plastic washer.

e) Mount the driving belt.

f) Mount the pinion guiding assy and the cover as shown in

Fig. 4.

g) Turn the gear wheel (b) counter clockwise to

endposition.

Check if tray mechanism works correctly!

1) Turn the gear wheel (b) clockwise to its endposition

(Use a small screwdriver as shown in Fig. 1 step 1).

The tray has to move to inner position first and then the

CD mechanism has to move to its upper position.

2) Turn the gear wheel (b) counter clockwise to its

endposition.

The CD Mechanism has to move to its lower position first

and then the tray has to move outside.

h) Mount the CD Mechanism as shown in Fig. 5.

i) Mount the tray (Align the tray to the chassis and push it

inside).

Fig. 3

Fig. 4

Fig. 5

Page 10

5-1

CS 53 145

HANDLING CHIP COMPONENTS

SERVICE TOOLS

TORX T10 screwdriver with shaftlength 150mm ......................................4822 395 50423

TORX screwdriver set T6 - T20 SBC 163...............................................4822 395 50145

Audio signal disc SBC 429......................................................................4822 397 30184

Playability test disc SBC444/444A..........................................................4822 397 30245

Test disc 444 (disc without errors) +

Test disc 444A (disc with dropout errors, black spots and fingerprints)

Burn in test disc SBC442........................................................................4822 397 30155

(65 min. 1kHz signal at -30dB level without "pause")

Page 11

5-25-2

CS 53 146

N

Y

Y

N

TIME

Button pressed?

YN

TIME

Button pressed?

TIME

Button pressed?

DISPLAY

TEST

DISPLAY TEST

Fig. 1

Fig. 2

Display shows Fig. 1

Display shows Fig. 2

PROGRAM

CD TEXT

PEAK

REPEAT REMTO T AL TRACK TIMESCAN TRACKSHUFFLE 1A-B

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 +

CD TEXT

PEAK

34 7 10131619+

NEXT

Button pressed?

Y

N

FOR CD TEST

see next page

Display becomes dark

Set is in stand by

PLAY

Button pressed?

Y

N

Set works as in normal Mode.

In case of failures error codes

according table 2 will be

displayed.

The CD PLAY Test is intended

to be used for continuously playing

a disc in order to detect intermittend

or not reproducible failures.

The error code indicates where the

failure can be found.

CD

TEST

CD PLAY

TEST

Table 2

CD PLAY TEST

SERVICE TEST PROGRAM

W = Warning

Error number remains on display till next warning/error

F = Fatal error

Set stops playing → Error number remains on display

PROGRAM

Button pressed?

Y

Y

N

N

STOP

Button pressed?

Display shows

8M

Output at

pin80 of 7800=1953,125Hz

QUARTZ

TEST

SHUFFLE

Button pressed?

Y

N

STOP

Button pressed?

Y

N

KEY

TEST

Y

N

any key pressed?

Display shows "--"

Display shows

corresponding key number

(see table 1)

Table 1

KEY TEST

To start service test

program hold

PLAY & STOP depressed

while plugging in

the mains cord

Display shows number of

ROM version

"S Vzz"

S stands for Service Testprogram

V stands for Software Version

zz version number counted from 01 upwards

Service Test Program CD713/CD723 (980429)

yalP3margorP9txeT-DC51

potSTIXEhcraeskaeP01llorcS61

tidE6esuaP21nottubCRynaCR

yeK rebmuN yeK rebmuN yeK rebmuN

txeN1elffuhS7edaF31

suoiverP2nacS8emiT41

esolC/nepO5taepeR11ybdnatS71

rebmunrorrE epyT noitpircseD

0001W

1001W

2001W

3001W

5001W

6001W

7001W

8001W

0201F

rorresucoF

roDCehtpugnitratsnehwemitniatrecanihtiwdnuofebtondluocsucofehtnehwdereggirT

.DCehtgniyalpgnirudemitniatrecaroftsolsisucofehtnehw

rorrelaidaR

.DCehtgniyalpgnirudemitniatrecarofkcartnotonsiovreslaidarehtnehwdereggirT

rorreniedilS

sdnoces6erofeb)desolcsihctiwsrenni(noitisoprennistihcaertondidedilsehtnehwdetareneG

.melborprotomedilsrohctiwsrennI.ybdessapevah

rorretuoedilS

sm052erofeb)neposihctiwsrenni(noitisoprennistifotuoemoctondidedilsehtnehwdetareneG

.melborprotomedilsrohctiwsrennI.ybdessapevah

rorrepmuJ

.emitniatrecanihtiwdnuofebtondluocnoitanitsedpmujehtnehwdetareneG

rorreedocbuS

.emitniatrecarofedocbusdilavoN

rorreLLP

.emitniatrecanihtiwkcoltondluocpooL-kcoL-esahPehT

rorrerotomelbatnruT

.emitniatrecanihtiwpugnitratsgniruddeepsfo%57hcaertondluocDCehtnehwdetareneG

melborprotomcsiD

rorrehcraessucoF

.emitniatrecanihtiwdnuofneebtonsahtniopsucoF

Page 12

5-3 5-3

CS 53 147

NEXT

Button pressed?

Y

N

SHUFFLE

Button pressed?

Y

PROGRAM

Button pressed?

Y

N N

PLAY

Button pressed?

Y

N

NEXT

Button pressed?

Y

PLAY

Button pressed?

N

STOP

Button pressed?

Y

Y

N

PREV

Button pressed?

Y

Display shows

CD

Disc Motor turns CCW

Display shows

CCW

Disc Motor turns CW

Display shows

CW

Slide moves outside

Slide moves inside

Display shows

FOC OK

Display shows

FOC ERR

FOCUS found?

Y

Y

N

STOP

Button pressed?

Y

N

Display shows

FOC XXX

Disc Motor Slide Motor

Focus Servo Test

Motor Test

PLAY

Button pressed?

STOP

Button pressed?

NN

Disc speeds up

Display shows

DISC

Disc Servo Test

PLAY

Button pressed?

Y

Y

STOP

Button pressed?

Y

NN

Display shows

RDL

Radial Servo Test

FOC ERR = Focus not found

FOC OK = Focus found

To start service test

program hold

PLAY & PAUSE depressed

while plugging in

the mains cord

Display shows number of

ROM version

"S Vzz"

In case of focus lost FOC ERR

will be displayed and

Focus Servo Test is entered again

It is possible to control the

slide motor with the

NEXT & PREV button

SERVICE TEST PROGRAM CD-Part

STP-CD Part CD713/CD723 (980429)

Since the CD-RW reflects much less light than an ordinary

CD-A, the gain of the HF-amplifier stage and the sensitivity

of the ADC inside the signal processor must be increased.

The gain is switched via the HG line (pin41 of CD7), the

ADC-sensitivity is switched via software (µP → CD7).

During start-up the correct mode is choosen automatically;

in the service test program it can be switched manually in

order to allow individual measurements in both conditions.

Sensitivity can be toggled

via EDIT Button.

CD RW resp. CD NORM is displayed

for two seconds.

STOP

button pressed in any step returns

to begin of Service Testprogram.

NOTE: If sensitivity is switched to high

the set will not work with normal Audio CDs!

SAA7372 – DECODER AND DIGITAL SERVO IC CD7

Pin Name Direction Description

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

1 VSSA1 GND supply (analog) of CD7

2 VDDA1 +4V supply (analog) of CD7

3 D1 HF-preamp → CD7 unipolar current input (central diode signal input)

4 D2 HF-preamp → CD7 unipolar current input (central diode signal input)

5 D3 HF-preamp → CD7 unipolar current input (central diode signal input)

6 VRL GND reference input for ADC

7 D4 HF-preamp → CD7 unipolar current input (central diode signal input)

8 R1 HF-preamp → CD7 unipolar current input (satellite diode signal input)

9 R2 HF-preamp → CD7 unipolar current input (satellite diode signal input)

10 IREFT → CD7 current reference for calibration ADC

11 VRH not connected reference output from ADC

12 VSSA2 GND supply (analog) of CD7

13 SELPLL +4V selects whether internal clock multiplier PLL is used

14 ISLICE CD7 → current feedback from data slicer

15 HFIN → CD7 comparator signal input

16 VSSA3 GND supply (analog) of CD7

17 HFREF → CD7 comparator common mode input

18 IREF → CD7 reference current pin (nom. VDD/2)

19 VDDA2 +4V supply (analog) of CD7

20 TEST1 GND test control input

21 CRIN X-Tal → CD7 crystal/resonator input

22 CDOUT X-Tal → CD7 crystal/resonator output

23 TEST2 GND test control input

24 CL16 not connected 16.9344MHz system clock output

25 CL11 not connected 11.2896MHz or 5.6448MHz clock output (3-state)

26 RA CD7 → servo driver radial actuator output

27 FO CD7 → servo driver focus actuator output

28 SL CD7 → servo driver slide actuator output

29 TEST3 GND test control input

30 VDD1P +4V supply (digital) of CD7

31 DOBM CD7 → digital output bi-phase mark output (3-state)

32 VSS1 GND supply (digital) of CD7

33 MOTO1 CD7 → servo driver motor output1 of CD7; versatile (3-state)

34 MOTO2 CD7 → servo driver motor output2 of CD7; versatile (3-state)

35 SBSY not connected subcode block sync (3-state)

36 SFSY not connected subcode frame sync (3-state)

37 RCK GND subcode clock input

38 SUB not connected P to W subcode bits (3-state)

39 VSS2 GND supply (digital) of CD7

40 V5 not connected versatile output pin of CD7

41 V4 not connected versatile output pin of CD7

42 V3 not connected versatile output pin of CD7 (open drain)

43 KILL CD7 → kill output; programmable (open drain)

44 MISC not connected C2 error flag; output only defined in CD-ROM modes (3-state)

45 DATA CD7 → DAC serial data output (3-state)

46 WCLK CD7 → DAC word clock output (3-state)

47 VDD2P +4V supply (digital) of CD7

48 BCLK CD7 → DAC serial bit clock output (3-state)

49 VSS3 GND supply (digital) of CD7

50 CL4 not connected 4.2336MHz µP clock output

51 SDA µP → CD7 µP interface data I/O line (open drain output)

52 SCL µP → CD7 µP interface clock line

53 RAB µP → CD7 µP interface R/W and load control line

54 SILD µP → CD7 µP interface R/W and load control line

55 NC no connection

56 VSS4 GND supply (digital) of CD7

57 RESET µP → CD7 power-on reset input (active low)

58 STATUS not connected servo interrupt request line/CD7 status register output (open drain)

59 VDD3C +4V supply core (digital)

60 C2FAIL not connected indication of correction failure (open drain)

61 CFLG not connected correction flag output (open drain)

62 V1 → CD7 versatile input pin

63 V2 → CD7 versatile input pin

64 LDON CD7 → 7820 laser drive on output (open drain)

Abbreviations CD Part

Page 13

5-45-4

CS 53 148

BCLK

WCLK

SDA

BCLK

WCLK

SDA

SERIAL DATA

INTERFACE

D/A

D/A

DAC BUFFER

Left out

MUTE

VOLUME

MUTE

Right out

7505

KILL

KILL

STBY

(COMMAND FROM µP)

+5V

Standby circuit

1251

1

2

3

4

5

6

7

1506

1504

1

2

3

4

5

+10V

+5V (switched)

+10V

-10V

+5V

AMPLIFIER

HEADPHONE BOARDAF BOARD

7670

1600

HEADPHONE SOCKET

162

1

2

3

4

5

+10V

-10V

MUTE

LINE OUT

MUTE

1252

1

2

3

4

5

6

7

8

POWERED

KILLI

STBY

STBY

-VKK

F2

F1

+5V

KILLI

(COMMAND FROM µP)

POWERED

KILLP

Mute control

1802

1

2

3

4

5

6

7

BCLK

WCLK

SDA

KILL

+10V

+5V

1250

1

2

3

4

5

6

F1

-VKK

+10V

+5V

-10V

F2

VOLTAGE

SELECTOR

(/01 only)

MAINS PLUG

110V

220V

F1,F2 Filament for FTD (

FRONT BOARD

)

-VKK Supply for FTD (

FRONT BOARD

)

+10V +Supply for buffer and headphone amplifier

-10V -Supply for buffer and headphone amplifier

+5V Stabilized 5V supply for DAC and µP

PROGRAM

CD TEXT

PEAK

REPEA T REMTOT AL TRACK TIMESCAN TRACKSHUFFLE 1A-B

1 2 3 4 5 6 7 8 9 10111213141516171819+

181

1

2

3

4

5

6

7

8

ROM

RAM

VDD

VKK

Converter

A/D

P7

P8

P9

TEST

RESET

DISPLAY-DRIVERS

VSS

CLOCK

P2 P1

P4

P5

P3

P0

P6

8BIT CPU

KEY MATRIX

4

4

IR EYE

7810

+5V

RC5

TRAYTRAY+

TRAY_SW

CD_PORE

CD_DATA

GND

CD_SILD

CD_SICL

µP CLK

GND

SRDT

DOSY

1804

1

2

3

4

5

6

7

8

TRAYTRAY+

TRAY_SW

CD_PORE

CD_DATA

GND

CD_SILD

CD_SICL

182

1

2

3

4

5

6

7

8

POWERED

KILLI

STBY

-VKK

F2

GND

F1

+5V

1810

1

2

3

4

µP CLK

GND

SRDT

DOSY

1720

4

3

2

1

ECO SHORT LOADER

for details see next page

CD753 Blockdiagram 19980604

FRONT BOARD

BLOCKDIAGRAM

Page 14

5-5 5-5

CS 53 149

SAA7372

CD7

TDA1302T

DALAS

R2

D1

D2

D3

D4

R1

BCLK

WCLK

SDA

BCLK

WCLK

SDA

BCLK

WCLK

SDA

HFIN

GAIN SELECTION H=CD-R/W, L=normal CD

R2

D1

D2

D3

D4

R1

LDON

DISC

PHOTO DIODE

ARRAY

TURNTABLE

MOTOR

TRACK

SERVO

FOCUS

SERVO

SLIDE

SERVO

D1 D2

R2R1

D3

FLEX PCB

A/D-CONVERTER

SERIAL

INTERFACE

P

INTERFACE

CONTROL PART

EBU

INTERFACE

RAM

ADDRESS.

SUBCODE

PROCESS.

MOTOR

CONTROL

OUTPUT

STAGES

ERROR

CORRECT.

FRONT END TIMING

DIGITAL PLL

SRAM

EFM

DEMOD.

Vref

KILL

PRE-PROC.

FUNCTION

CONTROL

VERSATILE

INTERFACE

AUDIO

PROCESS.

PEAK

DET.

RA (PWM signal)

RA FO SL

FO

(PWM signal)

SL (PWM signal)

TRACK

FOCUS

DISC Motor-

DISC Motor+

SLIDE Motor+

SLIDE Motor-

FOCUS Servo+

FOCUS Servo-

TRACK Servo+

TRACK Servo-

SLIDE

DISC MOTOR

MOTO1

(from CD7)

MOTO2

(from CD7)

L.P.F.

L.P.F.

L.P.F.

MOTO2MOTO1 16.93MHzDOBM

RESET

1

CD - Drive

VAM1201

pick up

unit

slide motor

t

u

r

n

t

a

b

l

e

Inner switch

TDA7073A

SERVO DRIVER

TDA7073A

MOTOR DRIVER

7851

7802 7819 7860

7852

Laser

on/off

Laser

+5V

ALPC

Automatic Laser Power Control

DATA

RESET

TRAY_SW

TRAY +

TRAY -

SILD

SICL

1802

1804

1803

STABILIZER

+5ESDV

+5V

+4V

+A

+A

+5

7877

TRAY

SUPPLY & AUDIO

INTERFACE

CONTROL INTERFACE

MOTOR

TRAY

7855

TDA7072A

+

-

M

HF-PREAMPLIFIER

CD TEXT (optional)

VDD

SCLK

XMODE

MCK

WFCK

SCOR

SBSQ

EXCK

CD-TEXT INTERFACE

DQSY

SRDT

DQSY

SRDT

uP_CLK

7821

1720

LC89170M

+4V

Timing & Sync

Protection

CRC

Check

CPU

Interface

RAM

32kx8

L.P.F.

L.P.F.

L.P.F.

L.P.F.

L.P.F.

L.P.F.

6

2,5V

0

-2,5V

eye-pattern signal

> 800 mVpp

TB=0.5 s

during focus search

TB=0.1s

2

4

3

5

SDA

WCLK

left channel

MSB

LSB

MSB

right channel

BCLK

TRANSFER OF AUDIO SAMPLES VIA SERIAL INTERFACE OF CD7

CD7 → DAC

1

LSB

ECO SL Mk3 Blockdiagram (IIs) 19980601

BLOCKDIAGRAM ECO SHORTLOADER Mk3

Page 15

6-16-1

blue

red

red

white

green

white

1

1252

1

188

connect cover

1

162

1

184

1

1

182

181

1880

1

1804

1502

1

161

1

1250

1

1251

1

1506

1802

1

1

1

8007

8

8007

8

8006

8

8006

8

8004

8001

connect cover

8010

2

8005

3

8005

3

8001

7

8001

7

8003

5

6

CD MODULE

ECO SL Mk3

FRONT - BOARD

HEADPHONE

STAND BY

AF - BOARD

Digital out

1503

Line out

1504

TRANSFORMER /

TRANSFORMER /K

blue

red

red

white

green

white

Th

ermal fuse

130°C

Thermal fuse

125°C

Mains plug

Mains plug

Voltage selector

black

red 220 - 230V

blue 110 - 127V

WIRING DIAGRAM

1600

GND

DOBM

SHIELD

+10V

-10V

LEFT

AGND

RIGHT

+10V

-10V

LEFT

AGND

RIGHT

KILL

DATA

BCKWS+5V

GND

+10V

POWERED

KILLI

STDBY

-VKKF2F1

GND

+5V

POWERED

KILLI

STDBY

-VKKF2F1

GND

+5V

+A(+10V)

GND

+5V

WS

BCK

DATA

KILL

GND

DOBM

SHIELD

SICL

GND

SILD

DATA

RESET

TRAY_SW

TRAY+

TRAY-

TRAYTRAY+

TRAY_SW

RESET

DATA

SILD

GND

SICL

phones

not for CD713

1810

1

P CLK

GND

SRDT

DOSY

8002

4

1

1720

P CLK

SRDT

DOSY

GND

connect cover

N, /T, /U, /F

/N, /T : 220-230V

/U : 120V

/F : 100V

Page 16

7-1 7-1

6

N, /T, /U, /F

K

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

A

B

C

D

E

A

B

C

D

E

1250 B4

1255 C5

1256 D5

2250 B6

2251 B5

2252 C6

2253 C6

2254 D7

2255 D8

2256 D6

2257 D6

2258 D7

2259 E5

3251 A5

3252 A5

3253 A5

3254 B6

3255 B6

3256 E6

3257 E7

3258 E7

3260 C7

3557 B4

6250 C6

6251 A6

6252 B5

6253 C6

6254 C6

6255 D6

6256 D6

6257 D5

6258 D5

6259 E6

6260 D8

7250 A6

7251 C8

7252 E6

F560 C4

F561 C4

F562 C4

F563 C4

F564 C4

F565 C4

F566 B5

F567 E6

F568 E6

F567

F568

F566

F564

F565

F563

F561

F562

T630mA

1256

F560

T630mA

1255

6R8

3557

1N4003

6260

D2

3260

5R6

2259

220u

22n

2257

4K7

3254

A

POWERED

2K2

3255

470R

3251

470R

3252

F1

+5V

6251

BZX55-C4V7

2

VIN

1

VOUT

3

-VKK

F2

7250

BC327-40

7251

L7805CV

KILLI

KILLP

A

D

A

-10V

A

DD

D2

A

+10V

D2

4K7

3258

3257

4K7

7252

BC558C

1K

3256

BZX79-C3V9

6259

6258

1N4003

2258

1N4003

6257

100n

2255

3m3

2256

22n

2254

4m7

22n

2252

6255

1N4003GP

2253

22n

1N4003GP

6254

1N4003GP

6253

6256

1N4003GP

470n

2250

2251

TO/FROM AF BOARD / DAC PART

220u

BZX79-C27

6250

1N4003

6252

EH-B

1250

/N, /T : 220-230V

/U : 120V

/F : 100V

1

2

3

4

5

6

22K

3253

AF Board / Supply part

5V~

5V~

-28,5V

-31,4V -27,8V -27,8V

10,7V

5,6V

0,6V

-11,7V

3,9V

-8,3V

3,4V

10,2V

9,5V~

9,5V~

V

EVM

...DC voltages measured

in Play mode

Page 17

7-27-2

CS 53 152

AF Board stage .4 19980513

AF Board Componentside view

1250 A1

1251 A4

1252 A1

1255 A1

1256 A1

1502 A4

1503 B4

1504 B1

1505 B4

1506 B1

2250 A1

2251 A2

2252 A1

2253 A1

2254 A2

2255 A3

2256 A1

2257 A1

2258 A2

2259 A2

2501 A3

2502 A3

2503 A4

2504 A3

2505 A4

2506 A4

2507 A3

2508 B3

2511 B2

2512 B2

2513 B2

2514 B1

2515 A3

2516 A4

2521 B2

2522 B3

2523 A3

2524 A4

2527 B4

2540 B4

2541 A4

2543 B4

2544 A4

2545 B4

3251 A1

3252 A1

3253 A1

3254 A2

3255 A1

3256 A2

3257 A2

3258 A2

3260 A3

3500 A3

3501 A2

3502 A4

3503 A4

3504 A4

3505 A3

3506 A3

3507 B2

3508 B2

3509 B3

3510 B3

3511 B2

3512 B2

3513 B2

3514 B2

3515 A3

3527 A2

3532 A2

3533 B4

3534 A3

3535 A3

3537 B2

3538 B3

3539 B2

3540 B1

3541 B2

3542 B2

3543 B1

3544 B2

3545 B1

3547 B1

3548 A2

3550 A4

3552 A4

3553 A4

3556 B4

3557 A1

5801 B4

5803 B4

6250 A1

6251 A1

6252 A1

6253 A1

6254 A2

6255 A1

6256 A1

6257 A2

6258 A1

6259 A2

6260 A3

6500 A2

7250 A1

7251 A3

7252 A2

7500 A3

7501 A2

7504 A2

7505 B2

7507 B1

7508 B1

7509 B1

7510 B1

7511 B4

9253 A1

9254 A2

9256 A2

9257 A2

9258 A2

9262 A3

9263 A3

9264 A3

9265 A3

9266 B3

9267 B1

9269 A2

9270 A3

9272 A4

9274 B4

This assembly drawing shows a summary of all possible versions.

For components used in a specific version

see schematic diagram respectively partslist.

Page 18

7-3 7-3

DRIVER

SOURCES

CURRENT SINKS/

OUTPUT SWITCHES

DATA ENCODERS

NOISE SHAPERS

OVERSAMPLING

TIMING

AND

CONTROL

FILTER

FIR

to headphone

to/from ECO_SL

to/from FRONT

STANDBY

LINE OUT

DIGITAL / OPTICAL OUT

DAC

from ECO_SL

1 2 3 4 5 6 7 8 9 10 11 12 13 14

1 2 3 4 5 6 7 8 9 10 11 12 13 14

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

1251 B1

1252 F14

1502 G2

1503 G4

1504 D14

1505 F7

1506 B14

2501 C4

2502 D4

2503 C4

2504 D4

2505 D7

2506 D5

2507 B8

2508 E7

2511 B10

2512 E10

2513 D13

2514 E13

2515 E4

2516 E4

2521 A9

2522 F9

2523 C2

2524 D7

2527 F6

2540 F2

2541 G3

2543 H4

2544 B2

2545 H3

3500 D2

3501 D2

3502 B3

3503 B3

3504 C3

3505 C4

3506 D4

3507 B8

3508 E8

3509 B8

3510 E8

3511 C9

3512 D9

3513 B10

3514 E10

3515 D4

3527 C10

3532 D10

3533 F5

3534 C10

3535 D2

3537 A8

3538 F8

3539 B12

3540 C12

3541 D12

3542 E12

3543 B12

3544 D12

3545 C12

3547 E12

3548 E3

3550 F4

3552 F4

3553 G4

3556 G4

5801 G3

5803 F6

6500 F11

7500 C2

7501 E2

7502 C7

7504 C10

7505-A E9

7505-B B9

7507 B13

7508 C13

7509 D13

7510 E13

7511-F F4

F510 B1

F511 B1

F512 B1

F513 B1

F514 C1

F515 C1

F516 C1

F517 D2

F518 C4

F519 C5

F520 D5

F521 B8

F522 E7

F523 B8

F524 E7

F525 B14

F526 B14

F527 C14

F528 C14

F529 C14

F530 D14

F531 D14

F532 D14

F540 G2

F541 G2

F542 G2

F543 G4

F544 G4

F545 F7

F546 F7

F550 F14

F551 G14

F552 G14

F553 G14

F554 G14

F555 G14

F556 G14

F557 G14

BC337-40

7510

A

4U7

5803

2545

10n

F523

A

F522

F520

22n

2544

2K2

3527

220R

3537

+10V

220u

2521

A

10n

2523

3538

220R

3514

47K

3532

220K

A

2516

10n

2515

47u

A

+5V

3515

100R

+5V

F546

F545

3552

2K2

22K

3553

F544

F543

F542

F540

F541

13

7

14

12

3556

68R

7511-F

74HCU04N

100n

2543

2540

22u

1

2

34

6

78

GND

2541

5801

PH-B

1502

1

2

3

1u

YKC21-3564

DIGITAL OUT

OPTICAL OUT

preliminary

1503

3

2

1

F531

F532

F530

F556

F557

F555

F553

F554

F551

F552

F550

F528

F529

F526

F527

F525

F524

F521

F519

F517

F518

F516

F514

F515

F512

F513

F511

-10V

+10V

F510

3535

5K6

3533

33R

10K

3548

2K2

NJM4560D

7505-A

3

2

1

4

3534

NJM4560D

7505-B

5

6

7

8

7509

BC337-40

7507

BC337-40

7508

BC337-40

3542

1K

3547

1K

3544

1K

3545

1K

3541

1K

3540

1K

3539

1K

3543

1K

47u

2527

GND

GP1F32T

1505

3

1

2

GND

3503

100R

100R

3504

A

100R

3502

470p

2513

A

A

2K7

3512

3508

4K7

3511

2K7

4K7

3507

+5V

470p

2505

2506

470p

A

47K

3513

A

AA

POWERED

KILLI

STDBY

D

F1

F2

-VKK

+5V

EH-B

1252

1

2

3

4

5

6

7

8

KILL

+5V

-10V

BC557B

7504

KILL

D

3510

4K7

47u

2508

A

4

5

A

2507

47u

EH-B

1506

1

2

3

A

47u

2524

2503

10n

D

4K7

3509

10n

2504

12

2502

47u

DD

D

3506

100R

47u

2501

7501

BC558C

100R

3505

3501

10K

3500

5K6

7500

BC327-40

D

14

VSSD

9

VSSO

1

WS

+10V

STDBY

TDA1549T

2

BCK

16

DATA

5

FILTCL

6

FILTCR

13

NC

3

TEST

11

VDDA

15

VDDD

10

VDDO

4

VOL

7

VOR

8

VREF

12

VSSA

7502

A

+5V

-10V

A

A

A

A

A

A

A

A

A

A

4

3

KILLP

A

A

1N4148

6500

1504

YKC21-3418

1

2

2514

470p

2511

47u

47u

2512

7

220u

2522

EH-B

1251

1

2

3

4

5

6

3550

2K2

WS

SHIELD

DOBM

EBU/GND

KILL

+5

BCK

DATA

AF Board / DAC part

5,4V

-8,3V

-8,3V

-8,3V

-8,3V

5,4V

0V

0V

4,5V

5,1V

5,0V

5,6V

PLAY=5,3V

Stand by=0V

PLAY=1,4V

Stand by=5,5V

PLAY=4,9V

Stand by=5,6V

2,5V

2,5V

0V

0V

0V

0V

-8,3V

-11,2V

0V

0V

0V

0V

11,2V

5V

5V

5V

left channel

MSB

LSB

MSB

LSB

right channel

TRANSFER OF AUDIO SAMPLES VIA SERIAL INTERFACE

TB 0.5 s/Div

4.23MHz

176.4kHz

DATA

WORD SELECT

CLOCK

CLOCK

WORD SELECT

DATA

V

EVM

...DC voltages measured

in Play mode

Page 19

7-47-4

CS 53 154

AF Board stage .4 19980513

AF Board Componentside view

1250 A1

1251 A4

1252 A1

1255 A1

1256 A1

1502 A4

1503 B4

1504 B1

1505 B4

1506 B1

2250 A1

2251 A2

2252 A1

2253 A1

2254 A2

2255 A3

2256 A1

2257 A1

2258 A2

2259 A2

2501 A3

2502 A3

2503 A4

2504 A3

2505 A4

2506 A4

2507 A3

2508 B3

2511 B2

2512 B2

2513 B2

2514 B1

2515 A3

2516 A4

2521 B2

2522 B3

2523 A3

2524 A4

2527 B4

2540 B4

2541 A4

2543 B4

2544 A4

2545 B4

3251 A1

3252 A1

3253 A1

3254 A2

3255 A1

3256 A2

3257 A2

3258 A2

3260 A3

3500 A3

3501 A2

3502 A4

3503 A4

3504 A4

3505 A3

3506 A3

3507 B2

3508 B2

3509 B3

3510 B3

3511 B2

3512 B2

3513 B2

3514 B2

3515 A3

3527 A2

3532 A2

3533 B4

3534 A3

3535 A3

3537 B2

3538 B3

3539 B2

3540 B1

3541 B2

3542 B2

3543 B1

3544 B2

3545 B1

3547 B1

3548 A2

3550 A4

3552 A4

3553 A4

3556 B4

3557 A1

5801 B4

5803 B4

6250 A1

6251 A1

6252 A1

6253 A1

6254 A2

6255 A1

6256 A1

6257 A2

6258 A1

6259 A2

6260 A3

6500 A2

7250 A1

7251 A3

7252 A2

7500 A3

7501 A2

7504 A2

7505 B2

7507 B1

7508 B1

7509 B1

7510 B1

7511 B4

9253 A1

9254 A2

9256 A2

9257 A2

9258 A2

9262 A3

9263 A3

9264 A3

9265 A3

9266 B3

9267 B1

9269 A2

9270 A3

9272 A4

9274 B4

This assembly drawing shows a summary of all possible versions.

For components used in a specific version

see schematic diagram respectively partslist.

Page 20

7-5 7-5

ROM

RAM

VDD

VKK

Converter

A/D

P7

P8

P9

TEST

RESET

DISPLAY-DRIVERS

P4

P5

P1

VSS

CLOCK

P2P3

P0

P6

8BIT CPU

GND

OUT

SUP

V

to/from ECO_SLto/from AF

HLIGHT

SHUFFLE FADE

PRGM

EDIT PEAK

STOP

PLAY

PREV PAUSE NEXT

CD TEXT

OPEN/CLOSE

CD_SICL

CD_SILD

DGND

CD_PORE

TRAY_SW

TRAY+

TRAY-

CD_DATA

TIMESCROLL

preliminary

1 2 3 4 5 6 7 8 9 10 11 12 13

1 2 3 4 5 6 7 8 9 10 11 12 13

A

B

C

D

E

F

G

H

I

A

B

C

D

E

F

G

H

I

181 F1

182 H1

184 E1

1800 C10

1810 I6

1820 F1

1821 F11

1822 F11

1823 F12

1824 F12

1825 F12

1826 F12

1827 F13

1828 G11

1829 G12

1830 F13

1831 G12

1832 G13

1833 H11

1834 H12

1844 G7

2800 B5

2801 B11

2803 I7

2807 I8

2808 G2

2810 I8

2811 G8

2812 E3

2813 H8

2814 E3

2815 D10

3804 H7

3805 H7

3806 H6

3807 H8

3808 H8

3809 I7

3810 E10

3811 E11

3812 E10

3813 F11

3814 F10

3815 F10

3816 F10

3817 F11

3818 G11

3819 G11

3820 H11

3821 G10

3822 E5

3823 F6

3829 E2

3830 E2

3832 F3

3833 F3

3834 F3

3835 F3

3836 E2

3837 G9

3838 H2

3841 H2

3842 H2

3844 G3

3845 G3

3846 G3

3847 D10

3848 B4

3849 B11

5802 E3

6801 D5

6802 D6

6820 I2

7800 D6

7810 H9

7811 H8

9800 G10

1

2

3

4

5

6

7

8

9

182

1N4148

6802

1N4003

6820

3849

4R7

1N4148

6801

3848

10R

F842

F843

F841

D

F840

D

1833 1834

22K

3820

1K

3806

1K

3821

1K

3804

13

P1312P1411P1510P16

9

P223P322P421P520P619P718P817P9

16

1K

3805

30G531G632G733G834G935

NC1

5

NC2

6

NC3

7

NC4

8

NC5

41

P1

24

P1015P1114P12

1800

F111F12

2

F2144F22

45

G1

27

G10

36

G1137G12

38

G13

39

G14

40

G228G329G4

D

14-BT-54GK

FFC

12

34

2803

22n

72

73

74

75

76

77

78

79

8

80

9

1810

58 59660 61 62 63 64

65

66

67

68

69

7

70

71

43 44 45 46 47 48 49550 51 52 53 54 55 56 57

29

3

30

31

32

33

34

35

36

37

38

39

4

40

41 42

14151617181922021222324

25

26

27

28

7800

TMP87CP71F

1

10111213

3847

100R

2815

220n

F823

F826

F825

F824

F821

F800

F814

F815

F812

F813

F811

F809

F810

F808

F801

F816

F803

F802

F804

F806

F805

F807

F818F817

F820

F819

F822

D

D

D

D

1844

CST

D

D

9800

47K

3837

10n

2811

D

D

100n

2813

10n

2810

D

7811

BC547B

5802

2u2

3846

1K

3836

22K

38441K1K

3845

100n

2812

1K

3842

3841

1K

D

1K

3838

3829

22K

2814

47u

1

2

1K

3822

22n

2808

D

184

1K

3816

1K

3814

3815

1K

3818

22K 22K

3817

3823

1K

22K

3819

22K

3830

1820

D

3813

1K

1832

3811

1K

1K

3812

1K

3810

1827

1830

1825

18261824

18311829

1823

10u

2801

2800

10u

D

D

1K

3807

D

DD

3833

1K

1K

3832

38341K1K

3835

DIPMATE

DIPMATE

181

1

2

3

4

5

6

7

8

D

2807

100u

47R

3808

100K

3809

1822

1828

1821

+5V

+5V

7810

1

2

34

+5V

+5V

+5V

+5V

VC

POWERED

KILLI

STDBY

POWERED

KILLI

STDBY

+5V

+5V

+5V

-VKK

VC

G04

G03

+5V

F2

F1

-VKK

F2

F1

VC

VC

P05

P04

P03

P02

P01

G10

G11

G12

G13

G14

P16

P15

P14

P13

P12

P11

P10

P09

P08

P07

P06

G02

G01

G01

G02

G03

G04

G05

G06

G07

G08

G09

G12

G11

G10

G09

G08

G07

G06

G05

G04

G03

P13

P12

P11

P10

P09

P08

P07

P06

P01

G14

G13

P02

P03

P05

P04

P16

P15

P14

FRONT BOARD

CD753 Front Board 19980512

4,9V

-18V

4,8V

4,8V

4,8V

0V

STAND BY

1840

188

GND

Page 21

7-6 7-6 7-6

CD753 Front Board stage .4 19980520

Front Board Componentside view

Front Board Copperside view

181 B1

182 B2

184 B3

1800 A3

1810 B1

1820 A1

1821 A5

1822 B5

1823 A5

1824 B5

1825 A6

1826 B6

1827 A7

1828 B7

1829 B7

1830 A8

1831 B8

1832 A4

1833 A4

1834 B4

1844 B4

2800 A1

2801 A4

2803 B1

2807 B2

2808 B1

2810 B5

2811 B4

2812 B3

2813 B4

2814 B3

2815 A3

3804 B4

3805 B4

3806 B3

3807 B4

3808 B2

3809 B5

3810 A5

3811 A5

3812 A5

3813 B5

3814 B5

3815 B5

3816 B5

3817 B5

3818 B5

3819 B5

3820 B4

3821 A4

3822 B3

3823 B2

3829 B4

3830 B2

3832 B1

3833 B1

3834 B1

3835 B1

3836 B2

3837 B4

3838 B1

3841 B1

3842 B2

3844 B1

3845 B1

3846 B1

3847 B2

3848 A1

3849 A3

5802 B3

6801 A2

6802 A2

6820 B2

7810 B3

7811 B5

9800 B4

9801 A3

9802 A3

9803 A5

9804 A4

9805 A5

9806 A6

9807 A6

9808 A7

9809 A7

9810 B2

9811 B2

9812 B2

9813 B2

9814 B4

9815 B3

9816 B4

9817 B4

9818 B5

9819 B1

9820 A1

7800 B3

7800

7800

Left

Right

AGND

-10V

+10V

6.3mm

*

*

*

*

1 2 3 4

1 2 3 4

A

B

C

A

B

C

F607

220u

2602

F608

F606

F604

F605

F602

F603

F601

3609

10R

3608

3604

120R

15K

3607

120R

3605

3603

15K

3602

10K

10K

161

1

2

10K

3601

DIPMATE

162

1

2

3

4

5

2601

220u

10R

3611

HLJ1540

1600

1

2

3

2610

100n

2603

22n

2604

1n

2605

1n

7670-A

NJM4560D

3

2

1

8

4

3606

10K

7670-B

NJM4560D

5

6

7

8

4

VCC

VSS

VCC

VSS

VCC

VSS

+10V

-10V

+10V

-10V

Headphone Board

10,8V

10,8V

-11,7V

0V

0V

0V

0V

0V

0V

-11,7V

* preliminary

3600-B

10K

10K

3600-A

3600-A B1

3600-B B1

161 C4

162 B1

1600 B4

2601 A3

2602 C3

2603 A2

2604 B3

2605 B3

2610 C4

3601 C2

3602 B2

3603 B3

3604 B3

3605 B2

3606 B2

3607 B3

3608 B3

3609 C3

3611 A4

7670-A C3

7670-B A3

CD753 Headphone Board 1998 05 11

Headphone Board Copperside view

161 B4

162 B2

1600 D2

2601 B2

2602 C3

2603 B3

2604 D3

2605 D1

2610 B4

3600 D4

3601 B4

3602 B4

3603 C2

3604 B2

3605 D2

3606 D3

3607 B3

3608 C1

3609 B3

3611 B1

7670 B3

9600 C4

9601 C4

9602 C4

9603 C4

9604 D4

This assembly drawing shows a summary of all possible versions.

For components used in a specific version

see schematic diagram respectively partslist.

Page 22

7-7 7-7 7-7

LS

Vdd

O4

O6

O3

O1

O5

O2I2

I5

I1

I3

I6

I4

DALAS

Vg

Vdd

LDon

MI

Lo

Adj

C

GNDL

Vrfe

Vrf

HG

CD TEXT

PDM

for coax out: 3875 = 22R

22p

for COAXIAL OUT version only

not for flap

comm.cath

D1

D5

D3

D2

D4

INNERSWITCH

-

+

-

+

-

-

+

+

CD DRIVE

VAM 1201

Track

Focus

MM

SLEDGE

DISC

Do not split cables!

length 30cm

for OPTICAL OUT version only

during speed up play brake

Timing & Sync

Protection

CRC

Check

CPU

Inter-

face

32kx8

RAM

M

TRAY

MOTOR

Loader

for TRAY Version only

for FLAP version only

##

(H = CD-R/W)

(H = Laser On)

CD R/W Front End

WS

SDA

BCLK

TRAY_SW

SICL

SICL

SILD

SILD

RESET

RESET

DATA

DATA

SWITCH

INNERSWITCH

INNERSWITCH

#

NFR: +A = 8 ... 13.5V

PTC: +A = 6 ... 13.5V(only for battery powered versions)

JST EH

TRAY

Break-Away PB OPT OUT

VDD

DQSY

SRDT

SCLK

SW2

SW1

TEST

GND

XMODE

MCK

WFCK

SCOR

SBSQ

EXCK

CD-TEXT INTERFACE

only if not CD-TEXT

TURNTABLE

TRAY_SW

TRAY-

TRAY+

KILL

SUPPLY & AUDIO INTERFACE

CONTROL INTERFACE

WS

SDA

HF

SLIDE

BCLK

+5V

GND

+A

FOCUS

TRACK

SERVO-DRIVER

MOTOR-DRIVER

RESET

DATA

SILD

KILL

SICL

GND

JST PH

for BLER measurement

CFLG output (open drain)

"L"=dig out, "H"= no dig out

EBU_GND

SHIELD

DOBM

+5V

DOBM (TTL)

GROUND

for Coaxial: for Optical:

JST PH

resistor for flap version only

SHARP TOSLINK

JST EH

1

2

3

4

5

6

JST EH

DQSY

SRDT

uP_CLK

JST FE hor

JST PH

(to versatile pin 63 of decoder IC)

#

#

[7]

1

2

3

4

5

6

7

8

for R/W: 270k

for coax. out: 33R

#

##

#

#

#

[1]

[2]

[3]

[4]

[5]

[6]

[6]

[5]

[4]

[3]

[2]

[1]

# ... for provision only

CD-BOARD

(

ECO-SL Mk3)

3245671 8 9 10 11 12 13 14 15 16 17 18 192 20 21 22 23 24 25 26 27 28 293 30 31

L

K

J

O

I

H

G

F

E

D

C

B

A

N

M

L

K

J

O

I

H

G

F

E

D

C

B

A

N

M

3245671 8 9 10 11 12 13 14 15 16 17 18 192 20 21 22 23 24 25 26 27 28 293 30 31

HF HF HF HF HF

HF

L

L

L

DA

L

L

L

L

L L

L

+5ESD

+5ESD

+4V

+5ESD

SVDDA1

T730

100n

2802

18p

2810

47n

2809

47n

2870

47n

2831

100n

2898

2848

10n

560p

2820

1n5

2823

2n2

2814

15k

3806

33k

3804

10k

3803

3883

100

3858

100

3818

120k

3817

4k7

560

3807

4k7

3882

10k

3827

10k

3828

10k

3829

10k

3830

10k

3825

3826

10k

PC74HCU04D

7819

F

13 12

1

PC74HCU04D

7819

E

11 10

1

PC74HCU04D

7819

D

98

1

PC74HCU04D

7819

C

56

1

PC74HCU04D

7819

B

34

1

PC74HCU04D

7819

A

12

1

2899

4u7

BC337/40

7822

7802TDA1302T

16

15

14

13 12

11

10

9

8

7

6

5

4

3

2

1

24

23

22

21

20

19

18

17

D

D

D D

D

L HF

DA

D

D

HF

HF

HF

DA

L

D

D

EBU

D EBU

D

D

D

D

DD

D

D

D

D

D

D

EBUEBUEBU

L

DA

to 3881

from 7860/Pin 41

TRAY_SW

TRAY+TRAY-

TRAY_SW

TRAY+

TRAY-

R2

R1

D4

D3

D2

D1

VDDA1

+A_TRAY +A_TRAY

+4V

+5ESD

+4V

+4V

+4V

+4V

+A

+5ESD

+4V

+5V+A+A

+4V +5V

+4V

+A_TRAY

+4V

+4V

+4V

+5V

DD4

DD5

DD3

DD2

DD1

LD-

HF

V4

LD_ON

47n

2722

1u/16V

2865

100n

2869

47p

2845

2861

22p

2862

22p

2856

47n

2857

22n

2858

47p

100n

2853

2851

10n

220p

2830

220p

2829

220p

2828

220p

2827

10n

2839

5n6

2836

2825

220p

2826

220p

2837

560p

2840

1n8

100n

2819

10n

2761

2890

10n

2842

2868

47p

100n

2838

1n

2720

47p

2721

10n

2891

100n

2818

100k

3857

33k

3895

1k8

3893

33k

3892

1k

3891

1k

3890

470

3721

22

3898

100

3875

3879

560

10k

3842

3763

3764

220R

220R

220R

3762

100

3860

100

3861

33

3832

1M

3862

22k

3856

1k

3844

3872

100

1k

3852

27k

3851

3853

6k8

1k

3820

1k2

3839

1k2

3836

39k

3843

22k

3838

27k

3835

1k

3815

3837

6k8

3840

6k8

3874

10k

3873

10k

3870

10k

3876

180

10

3871

100

3864

3896

330

470

3897

39k

3845

1k

3846

220

3751

3752

220

220

3865

10k

3867

10k

3866

10k

3868

10k

3869

220

3863

3848

1k

3850

1k

1k

3833

220

3859

10k

3819

3753

220

10k

3880

390k

3854

4k7

3881

47

3729

10k

3728

470

3727

470

3726

470

3725

470

3720

470

3723

470

3722

470

3724

10

3899

10

3894

4k7

3730

47u

2859

4u7/16V

2860

2847

47u/16V

2843

0.47u

2849

47u/16V

47u/16V

2863

4u7/16V

2844

2850

4u7

1u

2892

BC547C

7878

BC547B

7877

7821 LC89170M

10

11

12

13

141

2

3

4

5

6

7

8

9

1895

YKC21

1804

1890

1

2

3

1880

1

2

3

1881

1

2

3

9802

9800

9801

9803

9890

5890

920927-152B

1

2

34

6

MT

1807

1

2

1803

1

2

1850

1

2

1820

Leaf Switch

1810

2

17

1

100u AL04

5802

10u AL02

5810

1u AL02

5804

6888

BZX79F2V4

7855

TDA7072A

6

1

2

3

8

5

input-

input+

GND

+Vp

out-

out+

1720

1

2

3

4

9804

1802

7896

1

2

3

GP1F32T

IC

Driver

3R3

3849

3841

3R3

8.46MHz

5860

SAA7378

7860

10

11

12

13

14

15

16

17 18 19120 21 22 23 24 25 26 27 28 29230 31 32

33

34

35

36

37

38

39

3

40

41

42

43

44

45

46

47

48

4945051525354555657585956061626364

6

7

8

9

PINS

MICROPROCESSOR

V1...VV5

INTERFACE

DETECT

PEAK

KILL

MOTO2

MOTO1

WCLK

VDD2P

SCLK

SBSY

SFSY

VSS2

MISC

DATA

RCK

SUB

KILL

V5

V4

V3

VSSA1

VSSA3

SELPLL

HFIN

Vref

D3

D2

D1

VSSA2

VRH

IREFT

R2

R1

D4

VRL

VDDA1

ISLICE

DIGITAL

DEMOD.

CORRECTION

ERROR

PROC.

PRE-

EFM

PLL

CONTROL PART

CONTROL

FUNCTION

SRAM

FLAGS

TIMING

CONTROL

MOTOR

INT.

EBU

ADDR.

RAM

VERSATILE

OUTPUT

STAGES

FO

SILD

SL

RAB

TEST3

SCL

SERIAL DATAAUDIO

VDD1P

LDON

INTERFACEPROCESSOR

SDA

DOBM SUBCODE

CL4PROCESSOR

VSS1

VSS3

ADC

IREF

FRONT END

V2

VDDA2V1TEST1

CFLG

CRIN

C2FAIL

CROUT

VDD3C

TEST2

STATUS

CL16

RESET

CL11

HFREF

VSS4

RA

NC

1806

1

2

3

4

5

6

1801

10

11

12

1

2

3

4

5

6

7

8

9

PTC 4R6

3847

TDA7073A

7851

14

10

1

2

6

7

11

3

4

13

16

9

12

5

8

15

+

-

VDD

+

-

TDA7073A

7852

14

10

1

2

6

7

11

3

4

13

16

9

12

5

8

15

+

-

VDD

+

-

2767

2765

22p

22p

22p

2764

470p

2766

SUPPLY FOR 7819

470

3771

HF PRE-AMPLIFIER

TO 1804

FROM 1810

0V

4V

0V 0V

4V

0V 0V

0V

4V

1720J32

1801G2

1802F32

1803G26

1804D21

1806M2

1807H31

1810H30

1820H32

1850C16

1880M23

1881M27

1890M30

1895M29

2720L27

2721L27

2722I30

2761F28

2764E24

2765E24

2766C26

2767E25

2802C10

2809D8

2810D9

2814D11

2818J3

2819J4

2820I9

2823I9

2825I11

2826I11

2827I11

2828I12

2829I12

2830I12

2831G7

2836K10

2837K9

2838E20

2839L10

2840L9

2842E17

2843N9

2844F14

2845E19

2847J9

2848F5

2849M9

2850N14

2851N9

2853N10

2856K14

2857L15

2858K14

2859M31

2860L15

2861L17

2862L16

2863E17

2865H26

2868D19

2869K19

2870G4

2890N21

2891N29

2892M28

2898I4

2899G4

3720I27

3721J27

3722J27

3723K27

3724K27

3725J30

3726J30

3727K30

3728J31

3729I31

3730I29

3751E19

3752E19

3753E18

3762F22

3763F22

3764G22

3771C26

3803D9

3804C10

3806D9

3807C11

3815D12

3817G4

3818F5

3819D15

3820J3

3825H10

3826H10

3827G10

3828G10

3829G10

3830G10

3832E14

3833K16

3835K10

3836K10

3837K9

3838L10

3839L10

3840L9

3841J10

3842E15

3843N10

3844O9

3845O10

3846O9

3847J10

3848M14

3849M10

3850N14

3851M10

3852N10

3853M9

3854I14

3856J14

3857K15

3858E7

3859E16

3860K17

3861L16

3862K16

3863E17

3864F21

3865E18

3866A18

3867A18

3868A18

3869A18

3870D19

3871E16

3872C20

3873A19

3874A20

3875L19

3876F28

3879F27

3880B22

3881F11

3882E8

3883G3

3890H29

3891G29

3892G29

3893G29

3894M22

3895G28

3896M22

3897N22

3898M31

3899M29

5802G27

5804E26

5810E29

5860L16

5890M28

6888H30

7802E7

7819C3

7819C4

7819C5

7819C6

7819C7

7819D10

7821I28

7822I5

7851J8

7852M8

7855G28

7860F15

7877E28

7878C19

7896M32

9800C19

9801D15

9802G27

9803E28

9804J20

9890N22

2V

2V4V2V2V2V1.8V1.8V

0V

4V

0V

2V

4V

0V

4.2V 5.6V

4.9V

4.8V

4.8V

10V

2.4V

2.4V

5.6V

10V

V

EVM

...DC voltages measured

in Play mode

4V

2.7V

0V

1.3V

1 SEC

0.7V

4.6V

3.8V

4V

0V

LASER

ON/OFF

6

during focus search

5.4V

0.4V

1V

5.4V

10V

10V

2V

2V

10V

2V

2V

2V

2V

0.5V

0.3V

1.3V1.3V

eye-pattern

1

PDM

3

4 2

TB=0,5 us/DIV

3.8V

1.8V1.7V

11.29MHz

4.1V

0.8V

4.2V

2V

2V

5

4V 0V 4V 4V 3.3V0V0.2V 3.3V

4V2V2V

0V

4V

0V 0V

0V 0V

Page 23

7-8 7-8 7-8

3103 303 3397.2

ECO SL Mk3 (R/W&IIs) Layout stage .2 (19980330)

F

E

D

C

B

A

F

E

D

C

B

A

654321

654321

DISC MOTOR CONNECTION

(break away part)

ECO Short Loader Mk3

Copperside view

BC...

12

1

1850

9841

1

3876

7877

9800

3879

2761

9803

5810

7878

2847

FOIL

8820

FOCUS & TRACK

SERVO DRIVER

SCREENING

1804

3874

2868

9806

9816

9810

9820

5804

9801

3873

3871

3872

3870

3854

3859

3865

3866

3867

3868

3869

2856

2863

3752

3753

3819

38323842

3863

2825

28262827

2828

2829

2830

2842

2844

2818

2819

3815

3820

3856

9811

9825

1

9

1

9807

9809

9814

3853

7851

7852

3837

3839

3841

3847

3849

3852

2837

2840

2849

2851

3836

3840

1

1880

3880

3894

9817

9890

1

9804

9821

9840

3881

3896

3897

5860

3724

3751

3860

3864

3875

3763

3762

3764

2838

2845

2858

2869

2890

3721

3722

3723

3838

9823

3845

3848

3850

3851

3857

3862

3861

3720

3833

3835

3843

2862

2861

2860

2857

2721

1801

2836

2839

2853

6

9815

9819

9822

9824

98309839

9831

3728

3729

3844

3846

SLIDE & DISC

MOTOR DRIVER

3730

1806

2843

2850

3725

3726

3727

2722

2720

9

1802

9892

1

1810

9808

9842

9805

1

1

8

1

12

1807

TRAY MOTOR

DRIVER

7855

9802

3892

3893

3895

5802

1720

3890

3891

6888

2814

2802

2810

3803

3804

7822

3807

3882

9851

3806

3817

3818

3827

3828

3829

3830

3858

3883

2809

2831

2848

2870

2898

2820

2823

2899

3825

3826

9847 9850

3771

9703

9704

2764

2765

2766

2767

9705

9701

9702

5

2

3

4

1 6

SICL

GND

GND

DOBM

+5V/SHIELD

SILD

DATA

RESET

TRAY MOTOR+

-

TRAY_SW

+A

GND

+5V

WS

BCLK

SDA

KILL

P CLK

GND

SRDT

INNERSWITCH

GND

DISC+

DISCSLIDE+

SLIDE-

DQSY

HF-AMPLIFIER

HF PRE-AMPLIFIER

DALAS

SIGNAL PROCESSOR

CD-TEXT

7819

7802