Page 1

OPERATING INSTRUCTIONS

1433.01XX

MOBILE OPERATING TABLE

YUNO OTN

GA 1433.01 EN 08

Page 2

Copyright notice

All rights reserved.

Any duplication, adaption or translation without prior written consent is prohibited unless otherwise

provided for in the relevant copyright laws.

© Copyright MAQUET GmbH

Subject to technical modification!

Illustrations and technical specifications may vary slightly from those in these Operating Instructions

as a result of ongoing product development.

V08.05 22-11-2013

1433.01XX

GA 1433.01 EN 08

Page 3

Table of contents

1 Introduction

1.1 Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 How to use these operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2.2 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2.3 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.3.1 Order number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.3.2 Cross-references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.3.3 Actions and responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.3.4 Buttons and menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.4 Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.4.1 Design of safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.4.2 Design for other notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

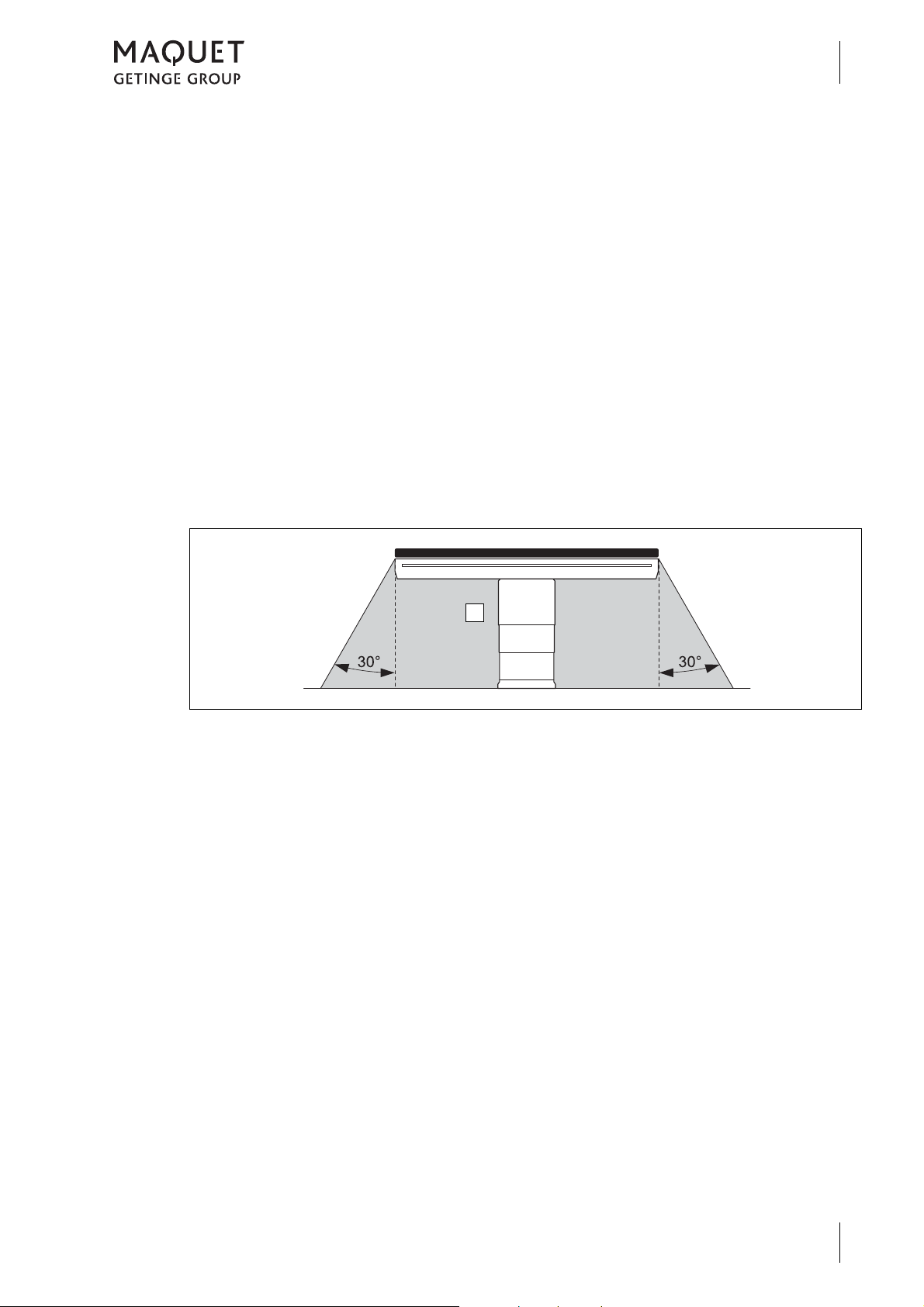

1.2.4.3 Definition for 3-dimensional coordinate system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.4.4 Definition of slope and tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.4.5 Definition of permissible overall load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.4.6 Definition of protrusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.4.7 Definition of area prone to explosion, Zone AP-M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.4.8 Definition Positioning- / Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.4.9 Definition of travelling forwards / backwards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.4.10 Definition of patient orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.5 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3.2 Packing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3.3 Padding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3.4 Rechargeable batteries/ Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3.5 MAQUET products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3.6 Used electrical equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3.6.1 Within the European Economic Community . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3.6.2 Outside the European Economic Community. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

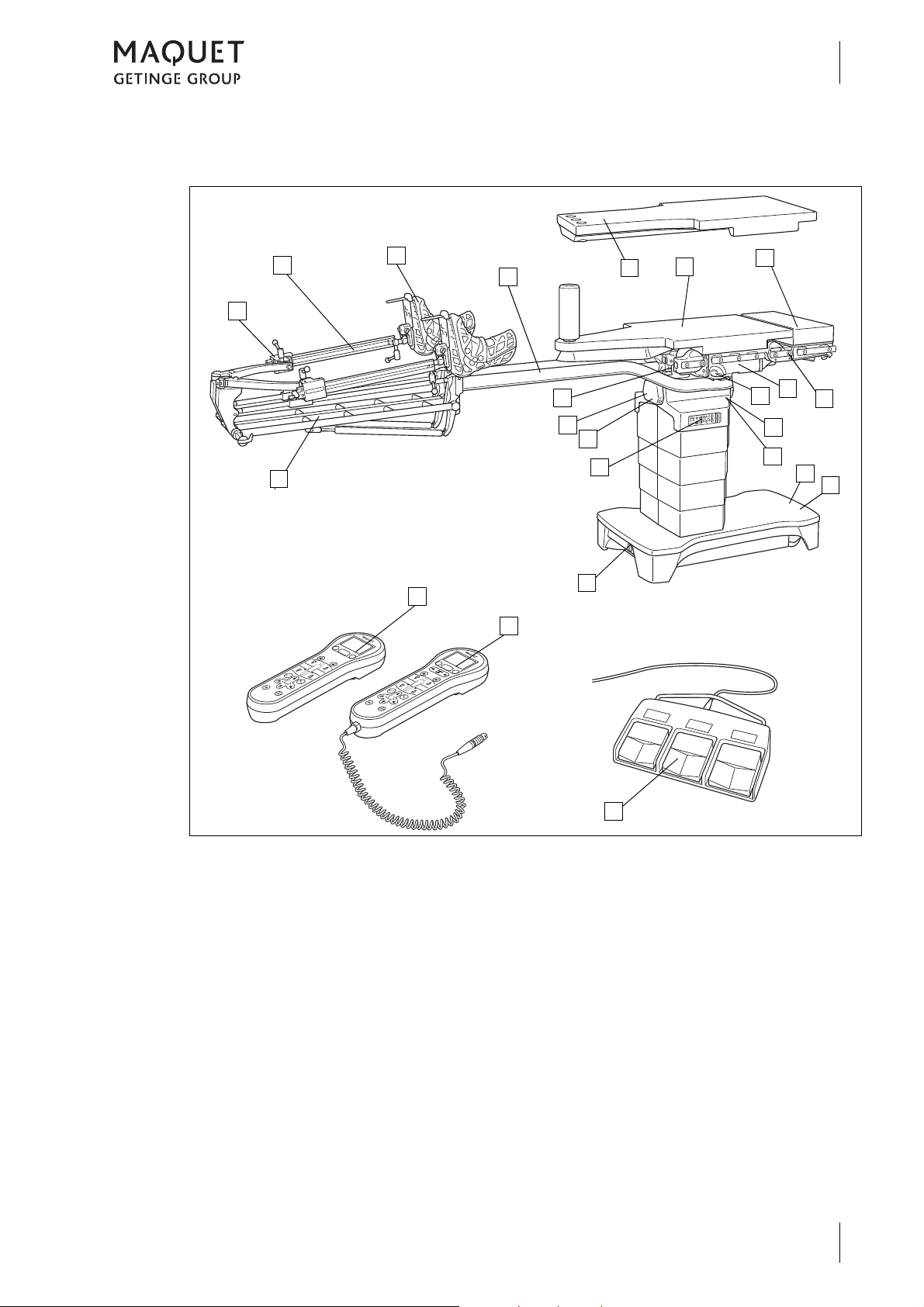

1.4 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.5 Basic requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5.1 Use in accordance with the intended purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5.2 Applicable standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5.3 Intended purposes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5.3.1 Mobile operating table YUNO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5.3.2 Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5.3.3 Product features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5.3.4 Hand controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.5.3.5 Side rails. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 Basic safety instructions

2.1 Personal safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2 Safety notes for the OR table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3 Safety notes regarding the use of accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4 Safety notes regarding padding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1433.01XX

GA 1433.01 EN 08

I

Page 4

Table of contents

3 Operation and use

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2 Acoustic signals issued by the OR table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.3 Set up the equipotential bonding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4 Mains operation / battery operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4.1 Charge batteries (mains operation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4.2 Battery operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.5 Connecting the service mounting point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.6 Attaching the hand control to the side rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.7 Mechanical adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.7.1 Accessory recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.7.2 Mounting and removing table width extensions (1001.75A0/76A0). . . . . . . . . . . . . . . . . . . . . . . . . 32

3.7.3 Mounting/removing the head rest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.7.3.1 Mounting and removing the head rest using the head rest adapter (1130.81A0) . . . . . . . . . . . . . . 33

3.7.4 Mounting and removing the extension plate (1131.31XX). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.7.5 Seat plate extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.7.5.1 Mounting and removing the seat plate extension (1131.55XX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.7.6 Leg plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.7.6.1 Mounting and removing the pair of leg plates (1133.53BC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.7.6.2 Mounting and removing the leg plate (1133.58BC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.7.7 Basic table top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.7.7.1 Mounting/removing the standard plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.7.7.2 Mounting / removing the extension plate (1433.66XC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.7.8 Mounting and removing the filler pieces for the pair of leg plates (1433.50AC) . . . . . . . . . . . . . . . 41

3.8 Padding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1433.01XX

II

GA 1433.01 EN 08

Page 5

Table of contents

4 Hand controls

4.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.2 Override control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.2.1 Overview of override control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.2.2 Overview of displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.2.2.1 Overview of status display mains operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.2.2.2 Overview of the status display for battery operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.2.2.3 Overview of change display LOCK / UNLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.3 Corded hand controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.3.1 Foot switch (1009.81G0/G1/G2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.3.2 Corded hand control (1433.90A0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.3.3 Connecting corded hand controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.4 IR remote control (1433.91A0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.4.1 Control buttons and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.4.1.1 Switching on the illumination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.4.1.2 [Leg side] selector key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.4.2 Special features of the IR remote control (1433.91A0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.4.2.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.4.2.2 Acoustic signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.4.2.3 IR code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.4.2.4 Transmission power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.4.2.5 Charging unit (1009.70A0) / Charging station (1009.71A0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.4.2.6 Mobile charger (1009.70A0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.4.2.7 Stationary charging station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.4.2.8 Inserting the IR remote control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.4.2.9 Removing the IR remote control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.5 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.5.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.5.2 Display design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.5.3 Symbols for status bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.5.4 Symbols for the navigation bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.5.5 Standard patient positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.5.5.1 FLEX / REFLEX position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.5.5.2 BEACH CHAIR / BACK HORIZONTAL position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.5.5.3 NORMAL/REVERSE patient orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.5.6 Menu item [System information] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.5.7 [Patient positions] menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.5.7.1 Select the patient position function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.5.7.2 Moving into patient position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.5.7.3 Saving the patient position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.5.7.4 Editing names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.5.8 [Settings] menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.5.8.1 Selecting the [Settings] menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.5.8.2 Activating and deactivating the operating table lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.5.8.3 Activating and deactivating the table top lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.5.8.4 Switching illumination ON / OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.5.8.5 Switching the signal tone at the column ON / OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.5.9 [Fast memory] menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.5.9.1 Selecting the function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.9.2 Move into patient position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.5.9.3 Saving patient position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.6 Adjustment functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.6.1 Moving/immobilising the OR table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.6.1.1 Moving the OR table using(UNLOCK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4.6.1.2 Standing the OR table on the floor (LOCK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.6.2 Lowering / raising the patient (table top) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

. . . . . . . . . . 69

1433.01XX

GA 1433.01 EN 08

III

Page 6

Table of contents

4.6.3 Motorised adjustment of the table top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.6.4 Aligning the patient horizontally . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.6.5 Inclining the patient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4.6.6 Tilting the patient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.6.7 Deactivating the lock function temporarily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.6.8 Aligning the leg plate horizontally . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.7 Explanation of instructions for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.7.1 Height for operating table lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.7.2 Risk of collision with traction bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5 Display notes

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.1.1 Structure of display notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.2 Notes on operation / special notes on operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

5.3 Warning notes / Status messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

6 Extension positioning

6.1 Assembling the extension device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.1.1 Mounting the extension plate (1433.66XC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.1.2 Mounting the traction bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.1.3 Mounting the pair of leg plates (1433.50AC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.1.4 Mounting the height adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.1.5 Mounting the screw tension device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.1.6 Mounting the countertraction post . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.1.7 Fixing patient's leg in the extension shoe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.1.8 Mounting the extension shoe (1003.67X0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.1.9 Removing the pair of leg plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6.2 Setting the extension device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6.2.2 Adjusting the height of the extension device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6.2.3 Abducting the extension device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6.3 Setting the screw tension device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

6.3.1 Setting the internal / external rotation of the extension shoe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.4 Detaching the extension device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.4.1 Releasing the traction of the screw tension device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

6.4.2 Aligning the traction bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.4.3 Mounting the pair of leg plates (1433.50AC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.4.4 Removing the extension shoe (1003.67X0). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

6.4.5 Removing the countertraction post . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.4.6 Removing the screw tension device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.4.7 Removing the gas strut assisted height adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.4.8 Removing the traction bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.4.9 Removing the leg plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.4.10 Removing the extension plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

7 Patient positioning

7.1 Table top configuration for an overall load of up to 155 kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

7.1.1 NORMAL patient orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

7.1.2 REVERSE patient orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7.2 Table top configuration for an overall load of 155 kg to 250 kg . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.2.1 NORMAL patient orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

7.2.2 REVERSE patient orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

7.3 Table top configuration for an overall load of 250 kg to 454 kg . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

7.4 Special accessories YUNO OTN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

1433.01XX

IV

GA 1433.01 EN 08

Page 7

Table of contents

8 Cleaning and disinfection

8.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

8.2.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

8.2.2 Cleaning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

8.3 Disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

8.3.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

8.3.2 Suitable disinfectants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

8.3.3 Disinfection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.4 Stainless steel surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.5 Padding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.6 Cleaning and manual disinfection of the swivel castors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

9 Maintenance

9.1 Visual and functional inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

9.2 Malfunctions and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

9.2.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

9.2.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

9.3 Inspection and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

9.4 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

10 Technical specifications

10.1 General specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

10.2 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

10.3 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

10.4 Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

10.5 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

10.6 Inclination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

10.7 Tilt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

10.8 Motorised joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

10.8.1 REVERSE mounting point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

10.8.2 NORMAL mounting point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

10.9 Radiolucent area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

10.10 Extension device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

11 Approved accessories

11.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

11.2 Accessories for head-end mounting point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

11.2.1 Maximum overall load of 155 kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

11.2.2 Maximum overall load of 250 kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

11.2.3 Maximum overall load of 454 kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

11.3 Accessories for NORMAL mounting point (back plate mounting point) . . . . . . . . . . . . . . . . . . . . 129

11.3.1 Maximum overall load of 155 kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

11.3.2 Maximum overall load of 250 kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

11.3.3 Maximum overall load of 454 kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

11.4 Accessories for REVERSE mounting plate (leg plate mounting point). . . . . . . . . . . . . . . . . . . . . 141

11.4.1 Maximum overall load of 155 kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

11.4.2 Maximum overall load of 250 kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

11.5 YUNO accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

11.5.1 YUNO accessories, overall load 250 kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

11.5.2 Side rail accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

11.5.3 Hand controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

1433.01XX

GA 1433.01 EN 08

V

Page 8

Table of contents

1433.01XX

VI

GA 1433.01 EN 08

Page 9

1Introduction

1.1 Foreword

Introduction

Foreword

1

Your facility has selected the leading-edge

medical technology made by MAQUET.

We sincerely appreciate the trust you have

placed in us.

MAQUET is a member of the GETINGE group

which is consistently directing its attention to

pioneering medico-technical solutions.

1.2 How to use these operating instructions

1.2.1 General

These operating instructions are provided to

familiarise you with the features of this

MAQUET product. They are subdivided into

several chapters.

MAQUET is one of the world’s leading suppliers

for emergency rooms, operating rooms and

intensive care units. MAQUET has been

standing for innovation and advance in medical

technology ever since it was founded in 1838.

Solutions relevant to the needs of practice and

customer-oriented services optimise working

cycles and boost economy in hospitals – all to

the benefit of the patient.

Please note:

• Please read these operating instructions

carefully and completely before using the

product for the first time.

• Always proceed in accordance with the

information contained herein.

• Store these operating instructions in a

location near the product.

1.2.2 Abbreviations

EMC Electromagnetic compatibility

EN European standard

EU European Economic Community

IR Infrared

INT Intermittent

IPS Internal Power Source

LED Light Emitting Diode

OR table Operating table

PUR Polyurethane integral foam

SELV Safety Extra Low Voltage

SFC Soft Foam Core (special foam core)

1433.01XX

GA 1433.01 EN 08

1

Page 10

Introduction

1

How to use these operating instructions

1.2.3 Symbols

1.2.3.1 Order number

An "X" in the order number (e.g. 1122.33X4) is

a placeholder for a number of variants.

1.2.3.2 Cross-references

References to other pages in these operating

instructions are identified with a double arrow

symbol "

1.2.3.3 Actions and responses

The "

the user while the "

reaction that this will induce in the system.

".

" symbol identifies an action taken by

" symbol identifies the

Example:

Turn on the light switch.

Lamp lights up.

1.2.3.4 Buttons and menus

Buttons and menus are enclosed in square

brackets.

Example:

Press the [DOWN] button in the [Operation]

menu.

1433.01XX

2

GA 1433.01 EN 08

Page 11

1.2.4 Definitions

1.2.4.1 Design of safety notes

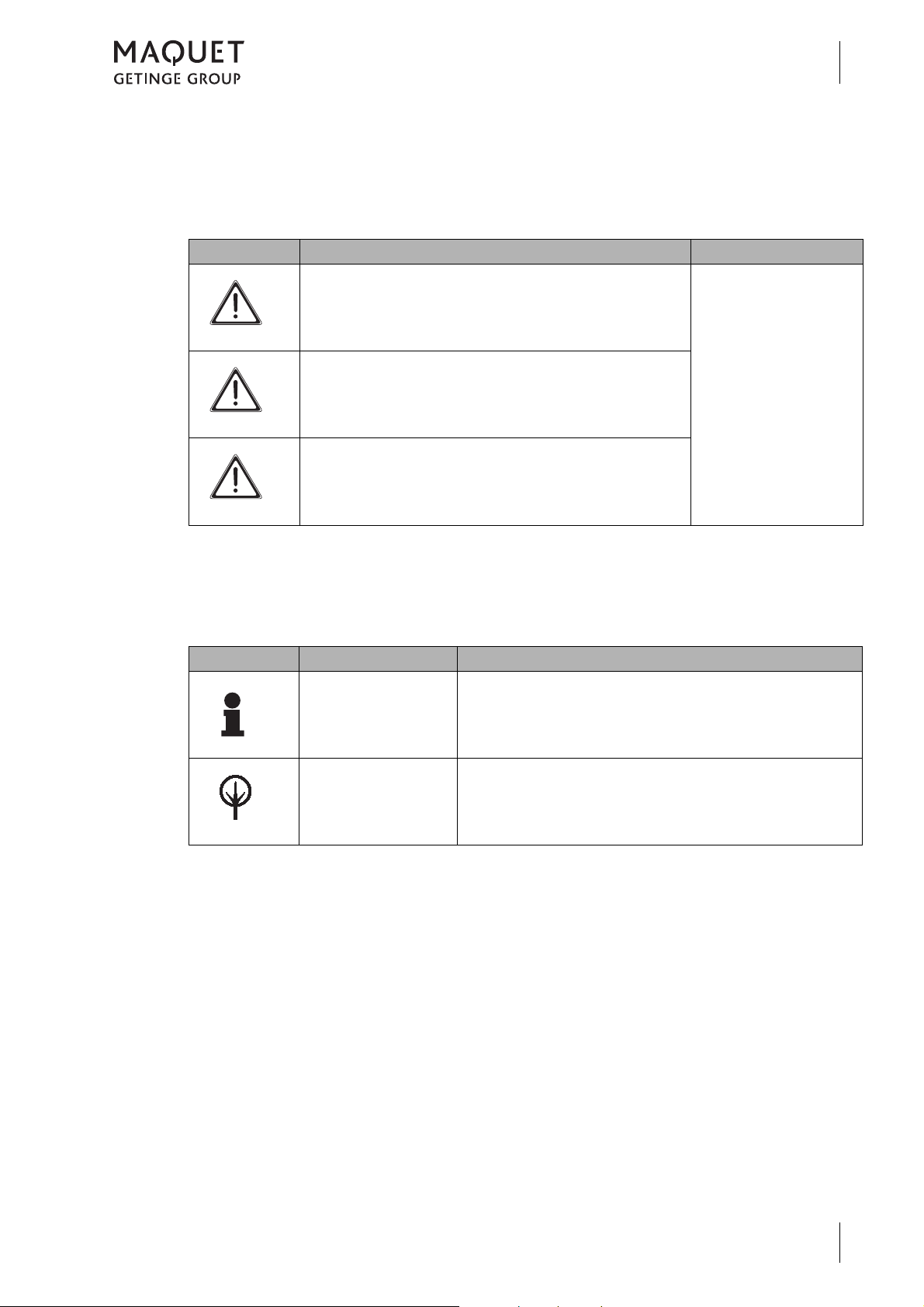

Pictogram Descriptor Text

D ANGER!

How to use these operating instructions

Indicates a direct and immediate risk

to persons, which may be fatal or

result in most serious injury.

Introduction

1

The text for the safety

note describes the type

of risk and how to avert

it.

W ARNING!

C AUTION!

Fig. 1: Design of safety notes

1.2.4.2 Design for other notes

Notes not referring to personal injury or

property damage are used as follows:

Pictogram Descriptor Reference to

N OTE

E NVIRONMENT

Indicates a potential risk to persons

or property which may result in health

hazard or grave property damage.

Indicates a potential risk to property

which may result in property damage.

Supplementary assistance or further useful information.

Proper disposal.

Fig. 2: Design for other notes

1433.01XX

GA 1433.01 EN 08

3

Page 12

Introduction

1

How to use these operating instructions

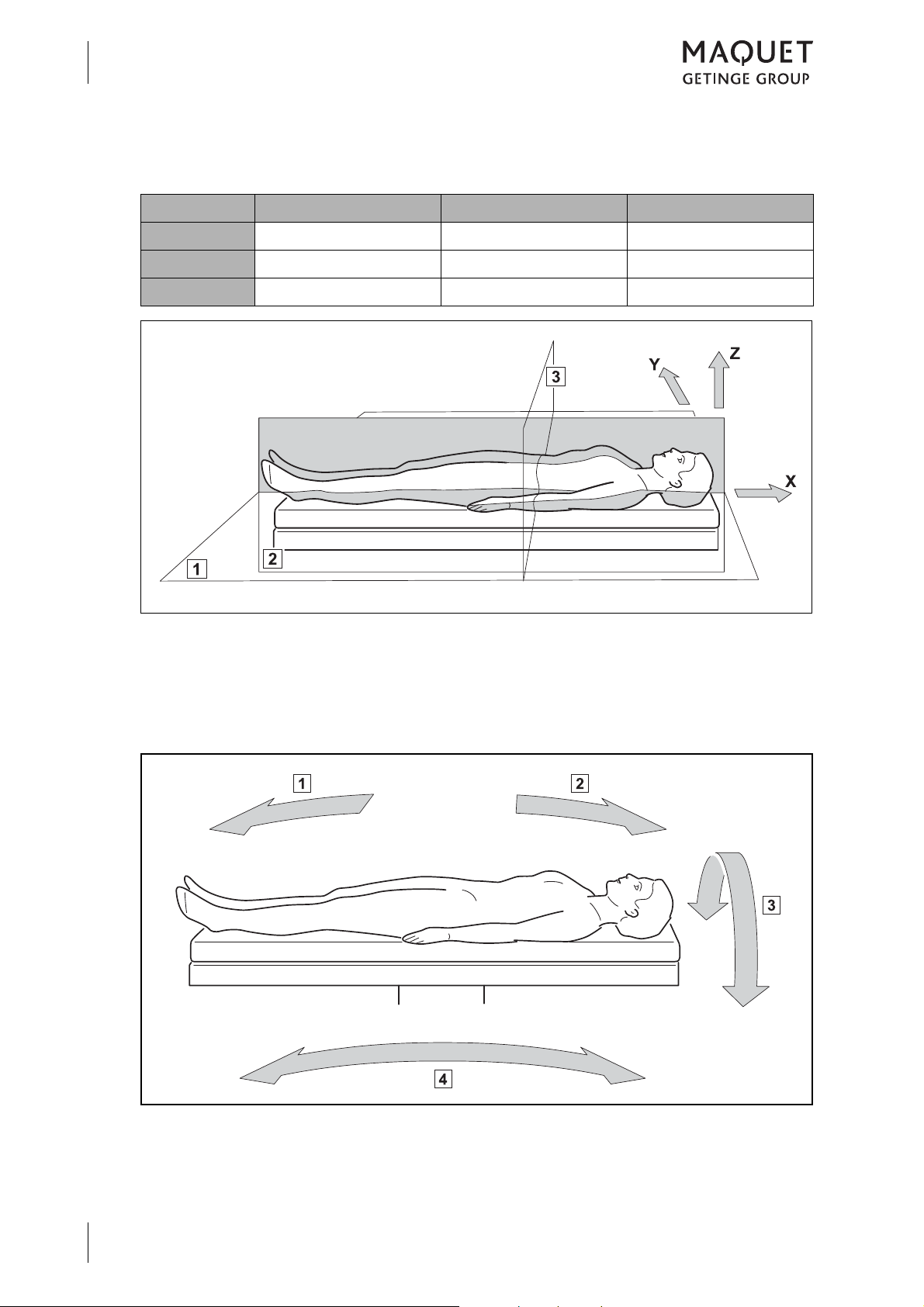

1.2.4.3 Definition for 3-dimensional coordinate system

Reference X axis Y axis Z axis

Product Longitudinal direction Lateral direction Height

Patient Longitudinal Transverse Sagittal

Neutral Horizontal Horizontal Vertical

Fig. 3: Definition of terms for the 3-dimensional coordinate system

1 Frontal plane (horizontal plane)

2 Sagittal plane

1.2.4.4 Definition of slope and tilt

3 Transverse plane

1433.01XX

4

GA 1433.01 EN 08

Fig. 4: Definition of slope and tilt

1 Reverse Trendelenburg (foot down)

2 Trendelenburg (head down)

3 Tilt

4 Slope

Page 13

1.2.4.5 Definition of permissible overall load

1

Introduction

How to use these operating instructions

1

The "permissible overall load" results from adding up patient weight, side rail accessory weight

and positioning aids. The "permissible overall

load" is the load which may be put on the table

top.

1.2.4.6 Definition of protrusion

Protrusion is the gap between the mounting

point(s) of a table top to the relevant outer edge

of the table top components (e.g. head rest, leg

plates) applied to the front.

1.2.4.7 Definition of area prone to explosion, Zone AP-M

The medical environment is designated as

"Zone AP-M" (1).

Restrictions might result from the components

table top and transporter for which other overall

loads may be valid, or from special patient positions.

The maximum protrusion of a table top may not

be exceeded.

Fig. 5: Area prone to explosion, Zone AP-M

1.2.4.8 Definition Positioning- / Transporting

When moving, a distinction is made between

moving the mobile operating table with a patient

and without a patient.

Positioning

Positioning refers to the process of moving the

mobile operating table with a patient within the

operating room.

Transporting

Transporting refers to the process of moving

the mobile operating table without a patient in

the operating room.

1433.01XX

GA 1433.01 EN 08

5

Page 14

Introduction

12

1

How to use these operating instructions

1.2.4.9 Definition of travelling forwards / backwards

Fig. 6: Travelling forwards / backwards

The following definition applies to motor-powered motion:

• forwards (1)

• backwards (2)

1433.01XX

6

GA 1433.01 EN 08

Page 15

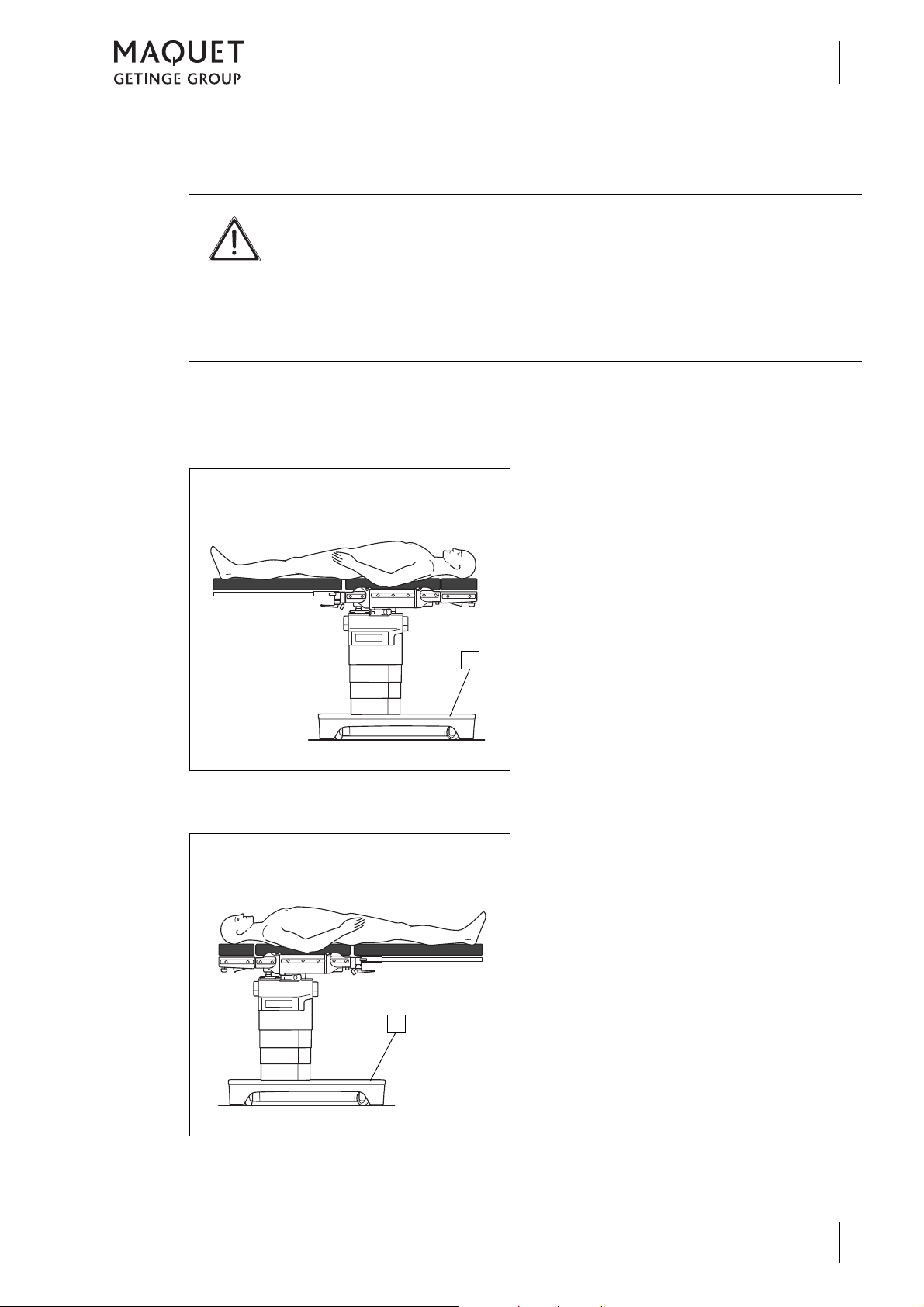

1.2.4.10 Definition of patient orientation

1

1

W ARNING!

Risk of injury!

Incorrectly adjusted patient orientation may cause adjustment of the

operating table in a direction that was not intended.

Check the correct patient orientation prior to making any adjustments.

The patient orientation is indicated in the status bar on the display on the hand

control.

The patient orientation depends on the position

of the patient on the table top with regard to the

operating table base (1).

NORMAL patient orientation

Introduction

How to use these operating instructions

The upper part of the patient's body is located

above the longer section of the operating table

base (1).

1

Fig. 7: NORMAL patient orientation

REVERSE patient orientation

Fig. 8: REVERSE patient orientation

The legs are located above the longer section

of the operating table base (1).

1433.01XX

GA 1433.01 EN 08

7

Page 16

Introduction

1

How to use these operating instructions

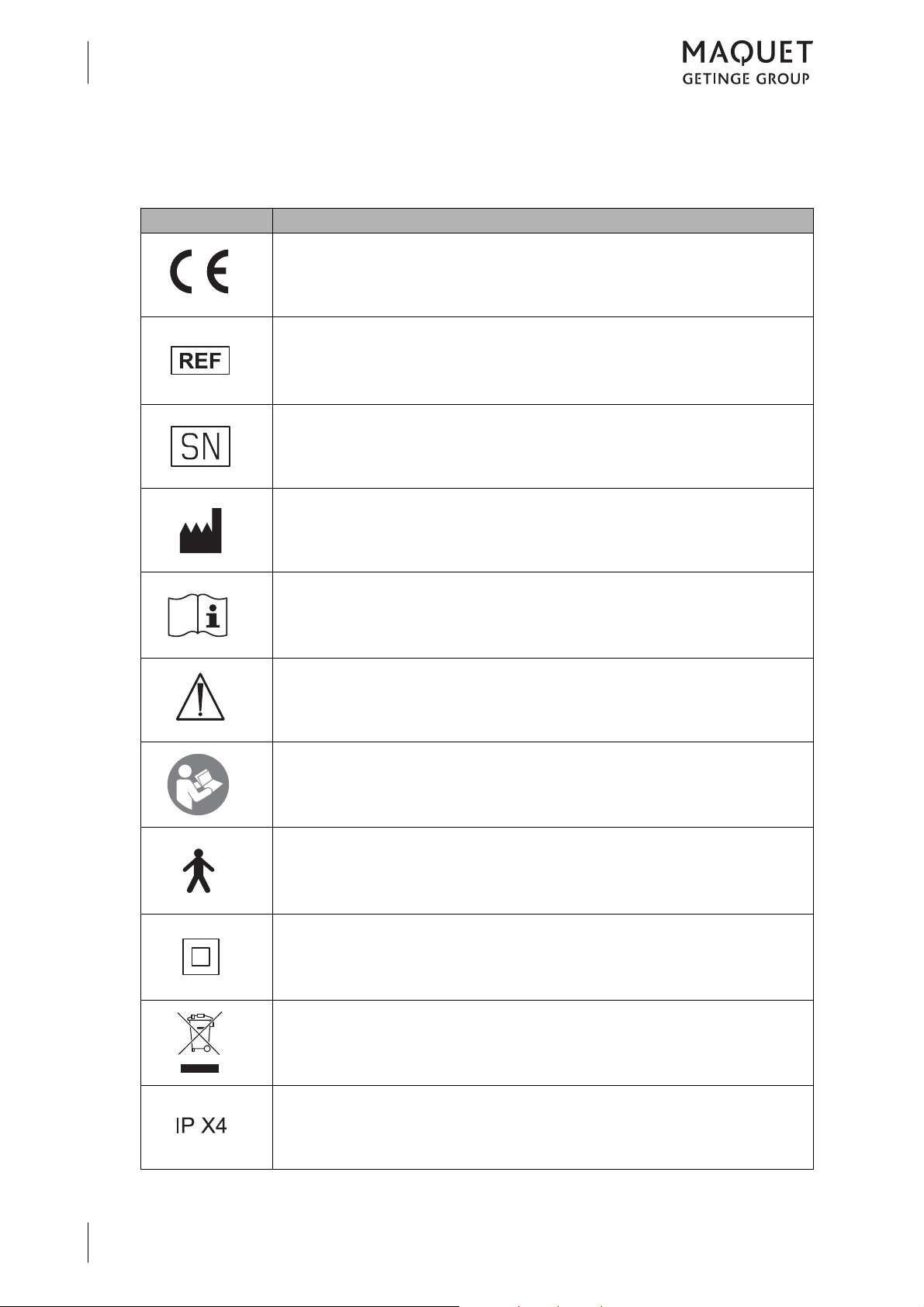

1.2.5 Symbols used

Symbols are attached to products, type plates and packaging.

Symbols Identification

Labelling for Class I products, developed and marketed in compliance with

Medical Device Directive 93/42/EU.

Labelling in compliance with the ISO 15223-1 standard.

Symbol for "Product number"

Labelling in compliance with the ISO 15223 -1 standard.

Symbol for "Serial number".

Designation in compliance with the ISO 15223-1 standard.

Symbol for "Name and address of the manufacturer as well as date of

manufacture".

Labelling in compliance with the IEC 60601-1 standard.

Symbol for "Follow Operating Instructions".

Labelling in compliance with the IEC 60601-1 standard.

Symbol for "Observe the accompanying documents".

Symbol for "Observe operating instructions".

Labelling for devices incorporating a Type B applied part as defined in the

IEC 60601-1 standard.

Degree of protection against electric shock.

Labelling in compliance with the IEC 60601-1 standard.

Symbol for "Class II".

Labelling as per 2002/96/EU Directive

(Directive on Waste Electrical and Electronic Equipment).

Symbol for "Do not dispose of at the municipal collection points for used

electrical equipment".

1433.01XX

8

GA 1433.01 EN 08

Labelling as per IEC 60529 standard.

Symbol for "splash protection".

Fig. 9: Symbols (Part 1 of 2)

Page 17

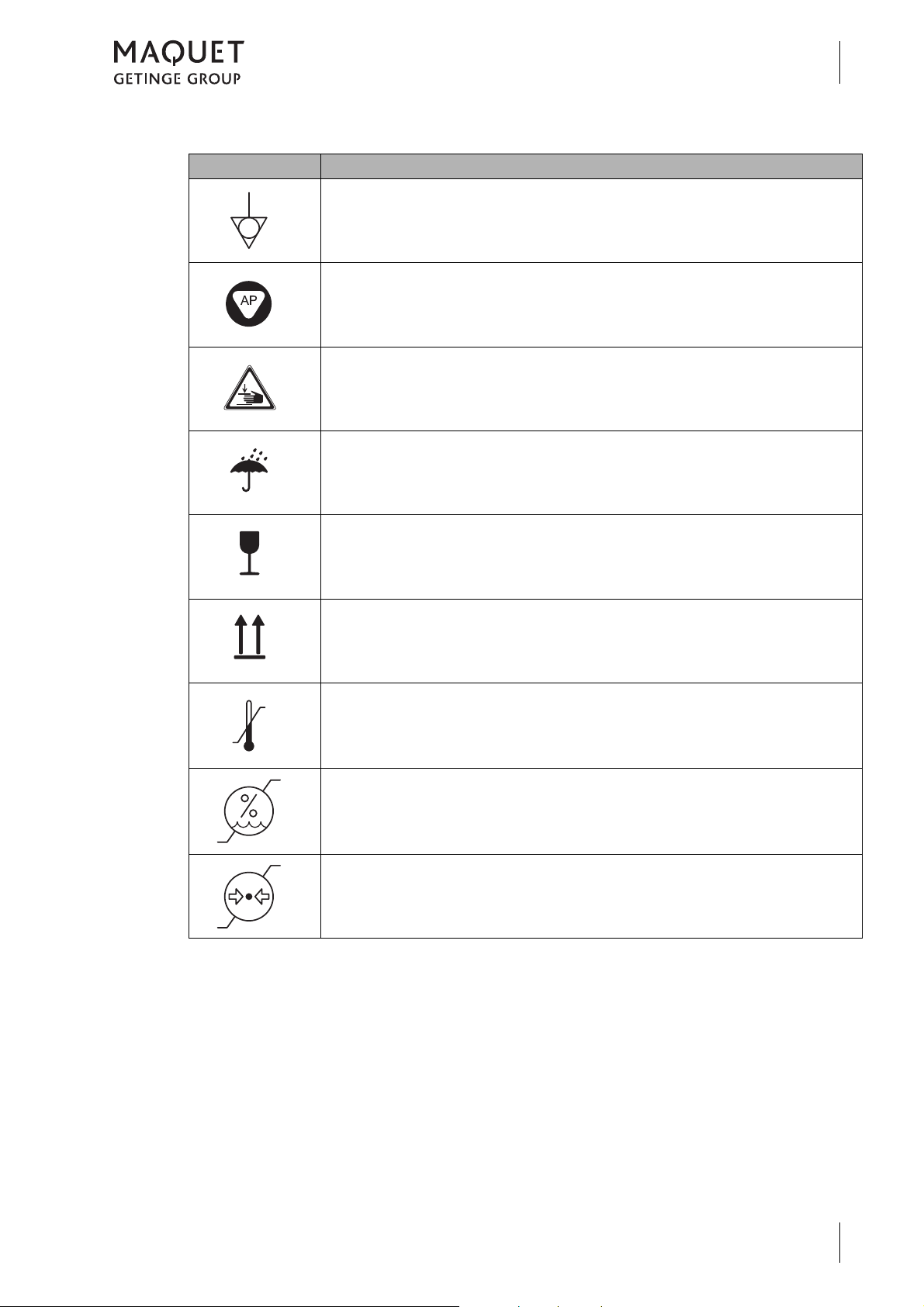

Symbols Identification

Labelling in compliance with the IEC 60601-1 standard.

Symbol for "Potential equalisation".

Labelling of Category AP equipment as per the IEC 60601-1 standard.

Explosion protection by avoiding sources of ignition when using flammable

blends of anaesthetics which are mixed with air, oxygen or nitrous oxide.

Labelling in compliance with the BGV A 8 Accident Prevention Regulations

(previously VBG 125).

Symbol for "Risk of pinching and crushing".

Packaging label.

Symbol for "Keep dry".

Introduction

How to use these operating instructions

1

Packaging label.

Symbol for "Fragile! Handle with care".

Packaging label.

Symbol for "Top".

Labelling in compliance with the ISO 15223 -1 standard.

Symbol for "Temperature range".

Labelling in compliance with the ISO 15223-1.

Symbol for "Relative humidity".

Labelling in compliance with the ISO 15223-1.

Symbol for "Air pressure".

Fig. 9: Symbols (Part 2 of 2)

1433.01XX

GA 1433.01 EN 08

9

Page 18

Introduction

1

Disposal

1.3 Disposal

1.3.1 General

Used products or parts thereof may be contaminated. To prevent potential infection, please

clean and disinfect the product prior to return/disposal.

1.3.2 Packing

The packing is made of materials compatible

with the environment. MAQUET will dispose of

the packing materials upon request.

1.3.3 Padding

Padding can be disposed of as normal household waste.

1.3.4 Rechargeable batteries/ Batteries

Rechargeable batteries/batteries can be turned

in to your local disposal system.

1.3.5 MAQUET products

MAQUET will take back used products or those

which are no longer in service.

1.3.6 Used electrical equipment

1.3.6.1 Within the European Economic Community

This product is governed by the 2002/96/EU Directive (Directive on Waste Electrical and Electronic Equipment).

This product has not been registered for use in

private households; disposal using municipal

1.3.6.2 Outside the European Economic Community

When disposing of this product, ensure compliance with the applicable national regulations on

the handling and disposal of used equipment.

Please contact your MAQUET representative

for more detailed information.

collection points for used electrical equipment

is not permitted.

Please contact your MAQUET representative

for more detailed information on correct and legal disposal.

10

1433.01XX

GA 1433.01 EN 08

Page 19

1.4 Overview

7

6

8

1

12

10

3

11

15

9

14

13

19

18

17

15

16

14

5

1a

1b

2

4

Introduction

Overview

1

Fig. 10: Overview of OR table (1433.01XX)

1 Extension device (1433.62A1), optional:

Screw tension device (1a)

Gas strut assisted height adjustment (1b)

2 Extension shoe (1003.67C0), optional

3 Traction bar (1433.61AC), optional

4 Extension plate (1433.66AC), optional

5 Extension plate (1433.66BC), optional

6 Extension plate (1131.31BC), optional

7 NORMAL mounting point

8 Basic table top

9 Release button for traction bar

10 Connection for equipotential bonding

11 Connection for mains cable

12 Service mounting point

13 Override control panel

14 Connections for corded hand control / foot

switch

15 Infrared receiver

16 REVERSE mounting point

17 IR remote control (1433.91A0), optional

18 Corded hand control (1433.90A0), optional

19 Foot switch (1009.81GX), optional

1433.01XX

GA 1433.01 EN 08

11

Page 20

Introduction

1

Basic requirements

1.5 Basic requirements

1.5.1 Use in accordance with the intended purpose

This product is an active Class I medical device

according to the Medical Device Directive

93/42/EU, which will have to be entered in the

medical device log.

In accordance with the above-mentioned

Directive, the only persons who may operate

this product are those who have been instructed, by authorised personnel, in the use of the

product.

This product is to be used exclusively in human

medicine.

Patients may be placed on the device and

brought into position only under the supervision

of medical personnel.

1.5.2 Applicable standards

The product satisfies the basic requirements

set forth in Annex I to the 93/42/EU Directive

drafted by the Medical Products Council

(Medical Device Directive) as well as the

applicable national codes and the Medical

Rooms used for medical purposes and in which

the product is used shall comply with

VDE Regulation 0100 Part 710 and/or the corresponding local codes.

Accessories

Accessories or combinations of accessories

may be utilised only when and as indicated in

these operating instructions.

Use other accessories, combinations and parts

subject to wear only if these are intended

expressly for the application and will not

adversely affect performance features or safety

requirements.

Products Act in Germany. This is certified by

compliance with harmonised standards such as

IEC 60601-1 and related standards and the

respective special sections.

12

1433.01XX

GA 1433.01 EN 08

Page 21

1.5.3 Intended purposes

1.5.3.1 Mobile operating table YUNO

Introduction

Basic requirements

1

The YUNO mobile operating table (1433.01XX)

is designed for the support and positioning the

patient for surgical treatment immediately before, during and after surgical interventions as

well as for examination and treatment.

The table top is radiolucent and enables intraoperative use of X-ray equipment. The design

of the table top makes the OR table suitable for

all surgical disciplines.

The product may only be operated by medically

trained staff within the OR environment. Any

use other than described above is deemed not

to be in accordance with the intended purpose.

The OR table can be used for an overall load of

up to 155 kg without restrictions on positions

and adjustment functions. The OR table can be

1.5.3.2 Variants

The product is available in the following versions:

• 1433.01B0

with SFC padding, side rails in EUROPE format (10 x 25 mm) and autodrive

• 1433.01F0

with SFC padding, side rails in USA format

(9.54 x 28.6 mm) and autodrive

used with restrictions with an overall table top

load between 155 kg and 454 kg.

In conjunction with the extension device

(1433.62A1), the OR table can be used without

restrictions up to 250 kg.

The OR table (1433.01XX) may not be used

under the following conditions:

• if the overall load exceeds 454 kg,

• if the overall load exceeds 155 kg, without

taking restrictions into account,

• to transport the patient within the hospital,

• with accessories which are not approved by

MAQUET,

• in rooms where MR tomographs are employed.

1.5.3.3 Product features

All materials used by MAQUET (e.g. materials

used for SFC and PUR padding, gel pads,

belts, transport belts, etc.) are latex-free.

1433.01XX

GA 1433.01 EN 08

13

Page 22

Introduction

1

Basic requirements

1.5.3.4 Hand controls

The hand controls are used to adjust the OR table.

1.5.3.5 Side rails

Side rails are used to mount approved

accessories, in accordance with the

manufacturer's instructions.

The following distinctions are made:

• Corded hand control (1433.90A0)

• IR remote control (1433.91A0)

• Foot switch (1009.81G0/G1/G2)

• Override control panel on the column (integrated into the column)

14

1433.01XX

GA 1433.01 EN 08

Page 23

2 Basic safety instructions

2.1 Personal safety notes

D ANGER!

Potentially fatal!

Hazard resulting from improper handling.

Be absolutely sure to follow the operating instructions for the operating table.

D ANGER!

Potentially fatal!

Risk caused by incorrect handling.

Please always observe the technical description for the mobile operating table.

W ARNING!

Risk of injury!

Patient may be endangered as a result of incorrect use.

Follow the operating instructions for all accessories.

Basic safety instructions

Personal safety notes

2

D ANGER!

Potentially fatal!

Danger due to unauthorised modifications.

The product may not be modified.

D ANGER!

Potentially fatal!

Vital functions can be impaired through incorrect positioning.

Position the patient correctly and maintain continuous observation.

W ARNING!

Risk of injury!

Improper positioning can be detrimental to patient health (causing bedsores, for

instance).

Always position the patient correctly and maintain continuous observation.

W ARNING!

Injury hazard!

MAQUET products may be used only when fully functional.

Check to ensure that this MAQUET product is fully functional and in good working

order prior to use.

W ARNING!

Risk of injury!

MAQUET products may be used only when properly lubricated.

Lubricate MAQUET products at regular intervals.

GA 1433.01 EN 08

1433.01XX

15

Page 24

Basic safety instructions

2

Personal safety notes

D ANGER!

Risk of explosion!

The operating table may not be used in hazardous locations (AP-M) during mains

operation.

An explosion could occur when using disinfectants or cleaning agents containing

alcohol, or flammable anaesthetics which are blended with air, oxygen or nitrous

oxide.

When operating on the mains supply, never use disinfectants or cleaning agents

containing alcohol, or flammable anaesthetics which are blended with air, oxygen

or nitrous oxide!

W ARNING!

Risk of injury!

Park the mobile operating table on level ground and secure with the [LOCK] func-

tion before each application and after each movement.

W ARNING!

Risk of injury!

Park the mobile operating table on level ground and secure with the [LOCK] func-

tion before each application and after each movement.

W ARNING!

Risk of injury due to material breakage or tipping of the OR table!

The accessories attached to the OR table may not exceed the maximum protru-

sion (protrusion = maximum distance to leg plate/back plate mounting point of the

OR table, see section on patient positioning).

The accessory can be deployed without restriction within the permitted overhang

of the OR table and up to a proportionate patient weight of 135 kg.

If the overall load is between 155 kg to maximum 454 kg, the protrusion of the OR

table and all accessories used must be authorised for such use respectively.

Please observe these specifications for positioning the patient.

W ARNING!

Risk of injury due to the OR table tipping!

With an overall load of in excess of 250 kg, do not extend the swivel castors of the

mobile operating table.

Function [UNLOCK] is not permitted.

16

W ARNING!

Injury hazard resulting from the operating table tipping!

Observe the prescribed orientation for the patient.

Do not lay the patient's upper part of the body on the leg plates.

1433.01XX

GA 1433.01 EN 08

Page 25

Basic safety instructions

Personal safety notes

W ARNING!

Risk of injury due to the operating table tipping!

If the patient is transferred to the operating table over the head end of the

operating table, the operating table may tip.

The patient may be transferred only from the side of the operating table.

W ARNING!

Risk of injury due to the operating table tipping!

If the operating table is not locked during patient transfer, the operating table may

tip.

The operating table must be locked on the floor before transferring the patient.

W ARNING!

Risk of injury!

If the patient is not secured during positioning of the OR table, when adjusting the

table top or when positioning the patient (particularly when the inclination and tilt

features are used), the patient could slip, uncontrolled, off the table top.

Always secure the patient and maintain continuous observation.

2

W ARNING!

Injury hazard!

When adjusting or moving the operating table or table top, the staff, the patient

and the accessories are exposed to pinching and shearing hazards, particularly

in the area around the joints at the head, back and leg plates.

Always ensure that no one can be subjected to pinching or shearing action or

injured in any other way and the accessories do not collide with any nearby

objects.

W ARNING!

Risk of injury!

Whenever the product is mounted and adjusted, there is a danger of pinching and

shearing to the staff, patient and accessories.

Always ensure that no one can be subjected to pinching or shearing action or

injured in any other way and that the accessories do not collide with any nearby

objects.

W ARNING!

Risk of injury!

If the individual adjustment function for a divided leg plate is activated at the joint

mounting point, although a single-piece accessory is attached to the mounting

point, the accessory may be damaged during individual adjustment in the event

of a malfunction.

Before adjusting single-piece accessories ensure that the individual adjustment

function is deactivated using the selector switch [leg side] (status LEDs for the left

and right leg side are on).

1433.01XX

GA 1433.01 EN 08

17

Page 26

Basic safety instructions

2

Personal safety notes

W ARNING!

Risk of injury!

When setting down the OR table, feet or objects lying on the floor may get pinched

or crushed.

Before setting the OR table down, make sure that there are neither feet nor any

objects underneath the column.

W ARNING!

Injury hazard!

Electrical devices (e. g. cellphones, radios, magnetic resonance tomographs) can

interfere with the functioning of the product when used near the product.

Electrical devices which can interfere with the functioning of the product may not

be used near the product.

Please observe the information concerning electromagnetic compatibility (EMC)

(radiation and resistance to interference) contained in the Technical Description.

Adhere to those specifications when using electrical devices and respond proper-

ly in the event of effects on the device or the product.

W ARNING!

Risk of burning!

Using high-frequency devices, defibrillators and defibrillator monitors exposes the

patient to burn hazard due to contact with metal components in the device or

accessories and/or if resting on wet drapes or electrically conductive padding.

Avoid any contact between the patient and metallic components; never use moist

of wet surgical drapes.

Be absolutely sure to comply with the manufacturers operating instructions!

W ARNING!

Risk of injury!

Magnetic fields of a magnitude of more than 0.5 mT may impair the function of the

product.

Never use the product within the 0.5 mT field.

W ARNING!

Risk of infection!

If the operating table is used in areas with varying hygienic requirements, there is

a risk of infection.

Treat the operating table in accordance with the hygiene guideline and the

instructions given in the chapter "Cleaning and disinfection".

18

1433.01XX

GA 1433.01 EN 08

Page 27

2.2 Safety notes for the OR table

W ARNING!

Risk of injury!

If locking elements (offset levers, handle screws, locking mechanisms etc.) are

opened, the clamps are released and the product can be moved.

Before opening the locking elements, hold the individual parts securely. Make

sure that all locking elements are closed after each adjustment procedure.

C AUTION!

Property damage!

Eliminate all potential hindrances and obstacles before moving the operating

table and avoid collisions.

C AUTION!

Property damage!

When tilting or sloping the table top or when articulating the leg plate ensure that

the table top does not collide with the column or the operating table base.

Basic safety instructions

Safety notes for the OR table

2

C AUTION!

Property damage!

Any objects left on the operating table base will damage the cladding as it moves.

Do not put any objects on the operating table base.

1433.01XX

GA 1433.01 EN 08

19

Page 28

Basic safety instructions

2

Safety notes regarding the use of accessories

2.3 Safety notes regarding the use of accessories

W ARNING!

Risk of injury due to material failure!

The side rail accessory weight may not exceed 25 kg.

The maximum permissible overall load is reduced in accordance with the weight

of the accessories attached. Never use accessories weighing more than this max-

imum.

W ARNING!

Risk of injury!

Patient may be endangered as a result of incorrect use.

Follow the operating instructions for all accessories.

W ARNING!

Risk of injury!

Accessories that are not approved by MAQUET for this product as well as acces-

sories from other manufacturers may cause injuries.

Only use MAQUET accessories that have been approved for the product.

Accessories made by other manufacturers may only be used after obtaining writ-

ten permission from MAQUET.

W ARNING!

Risk of injury!

When adjusting and moving the OR table, the table top or the accessories colli-

sions may occur with the patient, between the individual products or parts pointing

downwards.

During the adjustment procedures, always pay attention to the OR table and ac-

cessories and avoid collisions. Ensure that tubes, cables and drapes are not

trapped.

W ARNING!

Risk of injury!

Products / accessories not attached properly may loosen and cause injuries.

Always ensure that all locking elements (offset lever, setting clamps, catchs etc.)

of the product / accessory are closed and movable parts are fixed properly. Check

locking after every adjustment procedure.

C AUTION!

Property damage!

Side rail accessories with long lever arms may damage the product.

Never use accessories with long lever arms.

20

1433.01XX

GA 1433.01 EN 08

Page 29

Basic safety instructions

Safety notes regarding the use of accessories

C AUTION!

Property damage!

If accessories which are mounted to the side rail extend laterally beyond the side

rail near the table top articulations, the table top may collide with the accessories

when making table top adjustments.

When mounting accessories, be sure to observe that the accessory does not

extend laterally beyond the side rail near the table top articulations.

C AUTION!

Property damage!

Using accessories with release levers pointing downwards may cause a collision

with the traction bars during adjustment.

Observe the adjustment procedure carefully and avoid collisions.

2

1433.01XX

GA 1433.01 EN 08

21

Page 30

Basic safety instructions

2

Safety notes regarding padding

2.4 Safety notes regarding padding

D ANGER!

The patient may slip off the table if the padding is not secured properly.

Do not use padding if the Velcro straps on the padding do not line up with the

strips on the product.

Only apply padding to the product that has been authorised for use.

D ANGER!

The patient can slip off the table if the padding is not properly secured.

Worn, loose or wet loop strips will not secure the padding properly on the product.

When attaching the padding, check to ensure that it is properly affixed.

W ARNING!

Health hazard!

In the interests of hygiene the padding must be covered with sterile drapes.

C AUTION!

Property damage!

Padding may be deformed as a result of improper storage.

Padding should only stored flat.

C AUTION!

Improper use can cause property damage!

Use both hands to remove the padding.

22

1433.01XX

GA 1433.01 EN 08

Page 31

3 Operation and use

3.1 General

Operation and use

General

3

Motorised autodrive

The OR table may be moved within the OR environment by means of a motorised auto drive.

Motorised joint mounting points

The basic table top is equipped with two motoradjustable joint mounting points, the NORMAL

mounting point and the REVERSE mounting

point. The adjustment range of the joint mounting points is ±90°. Additional accessories for

patient positioning may be mounted to the joint

mounting points. These accessories may restrict the adjustment range of the joint mounting

points. For example, by mounting the back

plate (1433.33XX) the lowering function is restricted to -40°.

3.2 Acoustic signals issued by the OR table

In certain situations, the OR table outputs

acoustic signals.

Side rails

Additional side rail accessories may be mounted to the side rail of the basic table top

(

Page 125, Approved accessories). Acces-

sories and side rail accessories mounted to the

basic table top may be adjusted manually.

Operation

A corded hand control is used for the motorised

adjustments of the OR table; the OR table can

also be adjusted using an IR remote control and

a foot switch. The OR table can be controlled

using the override panel in the event of an

emergency.

Signals

Acoustic signals inform you about the status of

the OR table.

Intermittent tone

• Adjustment is at a critical stage.

• The battery of the OR table must be recharged.

Fig. 11: Acoustic signals issued by the OR table

Continuous tone

• Final position reached.

1433.01XX

GA 1433.01 EN 08

23

Page 32

Operation and use

1

3

Set up the equipotential bonding

3.3 Set up the equipotential bonding

W ARNING!

Risk of injury!

Without equipotential bonding, products with differing electrical potentials may

cause short circuits on the operating table.

Establish potential bonding prior to each use of the operating table.

N OTE

The electrical conductivity of the product has to be checked annually by an

authorized service technician.

Connect the supplied equipotential bonding

cable to the equipotential bonding pin (1) of

the mobile operating table before using.

Connect the other end of the equipotential

bonding cable to the operating room's equipotential bonding pin.

Fig. 12: Setting up equipotential bonding

24

1433.01XX

GA 1433.01 EN 08

Page 33

3.4 Mains operation / battery operation

1

2

3.4.1 Charge batteries (mains operation)

D ANGER!

Risk of explosion!

The operating table may not be used in hazardous locations (AP-M) during mains

operation.

An explosion could occur when using disinfectants or cleaning agents containing

alcohol, or flammable anaesthetics which are blended with air, oxygen or nitrous

oxide.

When operating on the mains supply, never use disinfectants or cleaning agents

containing alcohol, or flammable anaesthetics which are blended with air, oxygen

or nitrous oxide!

Operation and use

Mains operation / battery operation

3

N OTE

The operating table is disconnected from the mains by means of the plug.

Fig. 13: Establishing and separating the mains con-

nection

Connection to mains supply

Open the cover for the mains connection (1).

Connect the supplied mains cable to the mo-

bile operating table (2).

Then plug the mains plug into the mains

socket.

Green LED on the override control panel

is lit.

The rechargeable batteries in the mobile

operating table will be charged.

The plug must always be accessible to en-

sure that the OR table can be unplugged

from the mains at any time.

Detach the mains cable

Pull the plug out of the mains socket.

Detach the mains cable from the mobile op-

erating table.

1433.01XX

GA 1433.01 EN 08

25

Page 34

Operation and use

3

Mains operation / battery operation

3.4.2 Battery operation

N OTE

When battery-powered, without being connected to the mains, Class AP

explosion protection is ensured. The product may be used in areas subject to

explosion hazard, zone AP-M.

N OTE

To avoid recharging the batteries while the OR is in use, we recommend to re-

charge the batteries daily after the surgical work.

E NVIRONMENT

Defective rechargeable batteries shall be recycled as per 91/157/EEC.

Defective rechargeable batteries may not be opened, disposed of in household

waste, burned or thrown in water.

Defective rechargeable batteries must be disposed of at local collection points.

Please note:

• Fully charged rechargeable batteries will

provide power for about 1 week of OR operation (5-days of operation).

• A complete charging cycle takes about 10

hours.

• When the charge drops to below approximately 10 %, the mobile operating table will

shut down automatically.

• Recharge the batteries overnight.

• When the OR table is switched on, too low a

battery charge state will be indicated by the

error message "Charge column battery" on

an orange background on the display of the

hand control. In addition, the orange status

display LED on the OR table base flashes

when the OR table is adjusted and a fast intermittent signal sounds. When this happens, do not start a new operation.

• The rechargeable batteries are automatically

recharged as soon as the OR table is connected to the mains using the mains cable.

• After 10 days without a battery charge, at the

latest, the deep discharge protection function

of the rechargeable battery is activated. If the

deep discharge protection is active, the orange LED on the status display is not lit.

26

1433.01XX

GA 1433.01 EN 08

Page 35

3.5 Connecting the service mounting point

2

3

4

1

C AUTION!

Property damage!

The cable can be pinched when adjusting the operating table.

Ensure that the cable is not pinched.

C AUTION!

Material damage!

Risk of stumbling as a result of loosely laid cables.

Fix cables when laying in order to prevent them from becoming a stumbling haz-

ard.

Operation and use

Connecting the service mounting point

Inserting the plug

Undo the blind cap (1).

Insert the plug (2) into the socket in accord-

ance with the coding (3).

Grasp the plug at the knurl (4) and turn it in

clockwise direction until the plug is screwed

in fully.

3

Fig. 14: Connecting the service mounting point

1433.01XX

GA 1433.01 EN 08

27

Page 36

Operation and use

1

2

3

Attaching the hand control to the side rail

3.6 Attaching the hand control to the side rail

C AUTION!

Property damage!

If a hand control is attached to the side rail, it may slide along the side rail or cause

a collision between the hand control and operating table / accessories when the

table top is adjusted.

Remove the hand control from the side rail before adjusting the table top.

Attach the bracket (1) to the side rail (2).

Fig. 15: Attaching the hand control to the side rail

28

1433.01XX

GA 1433.01 EN 08

Page 37

3.7 Mechanical adjustments

3.7.1 Accessory recognition

W ARNING!

Risk of injury!

Additional accessories attached to the side rails, accessories which are not

mounted directly on the leg plate mounting point and manual adjustments (non-

motorised adjustments) of accessories will not be recognised by the collision rec-

ognition feature.

Observe the movement during the adjustment procedure and be sure to avoid any

collisions.

W ARNING!

Risk of collision!

When using the seat plate extension 1133.55B0 there is a risk of collision with the

column. The mount for the TUR drainage set and the x-ray cassette is not recog-

nised by the collision recognition on the NORMAL and REVERSE mounting

points.

If the seat plate extension 1133.55B0 is mounted to either the NORMAL or

REVERSE mounting point, the seat plate extension may not be lowered.

Operation and use

Mechanical adjustments

3

W ARNING!

Risk of collision!

When using the following accessories there is a risk of collision if these accesso-

ries are mounted to the REVERSE mounting point.

The following accessories may not be mounted to the REVERSE mounting point:

• Connection bracket (1130.54XX)

• Connection bracket (1130.62XX)

• Motor-driven head rest adjustment mechanism (1002.74XX)

• Positioning device for spinal surgery (1007.03XX)

• Adapter clamp pair (T555.6000) in conjunction with countertraction post for tibia and fibula (1003.50XX / 1004.92XX)

• Positioning device for spinal surgery (T483.0001)

1433.01XX

GA 1433.01 EN 08

29

Page 38

Operation and use

1

2

3

Mechanical adjustments

Fig. 16: NORMAL/REVERSE mounting point

General:

Whenever adjusting an accessory or the table

top module downward, there is a collision risk:

with other products in the adjustment range of

the OR table, the OR table base or the floor.

If a risk of collision is recognised the adjustment

procedure is halted as soon as mounted accessories are adjusted into the critical area. The

operating table can then only be adjusted in a

restricted adjustment mode. In addition, a collision recognition feature is shown for hand controls with display.

Pressing the adjustment function key again

within 3 seconds allows the adjustment of the

operating table to be continued with decreased

speed. An cyclical acoustic signal sounds dur-

ing the adjustment phase. The user must monitor the adjustment constantly to avoid a

possible collision with the operating table foot

or the floor.

The collision recognition feature can only recognize accessories that are directly attached to

the leg plate mounting point, i.e. no side rail accessories and accessories that can only be

connected to the leg plate mounting point by

using a further accessory.

The user must pay special attention to the accessory that is not recognized by the collision

recognition feature when adjusting the OR table.

30

1433.01XX

GA 1433.01 EN 08

Page 39

Fig. 17: Accessory recognition

1

Operation and use

Mechanical adjustments

The leg plate mounting point is fitted with accessory recognition.

In the event of the use of coded accessories at

the leg plate mounting point, the dimensions of

the accessories are recognised and evaluated

by the OR table. The adjustment range of a

coded accessory is defined in accordance with

the dimensions of the accessories. Coded accessories are marked by a "Code Plug" (1) located on the end of the mounting pin.

In the event of the use of uncoded accessories

at the leg plate mounting point, the dimensions

of the accessories are not recognised and are

not evaluated by the OR table.

The restricted adjustment range may be very

large, since accessories with the most critical

dimensions are considered for the accessory

recognition.

3

1433.01XX

GA 1433.01 EN 08

31

Page 40

Operation and use

2

1

3

3

Mechanical adjustments

3.7.2 Mounting and removing table width extensions (1001.75A0/76A0)

W ARNING!

Risk of injury!

Material failure.

The following accessories may be mounted to the table width extensions

1001.75A0 and 1001.76A0:

• 1x infusion stand 1009.01C0

• 1x anaesthesia screen 1002.57A0

• 1x wristlet 1002.24C0

• 1 x arm protector 1002.25A0

The patient must lie above the centre of the column (lateral direction).

W ARNING!

Risk of injury!

Material failure.

Further OR table width extenders may not be mounted to the table width extend-

ers 1001.75A0 and 1001.76A0.

Fig. 18: Table width extenders

Attach / remove OR table width extenders

Attach the clamp (1) of the OR table width

extension to the side rail (2).

Tighten the locking lever (3).

Check firm seat of the OP table width exten-

sion.

32

1433.01XX

GA 1433.01 EN 08

Page 41

3.7.3 Mounting/removing the head rest

2

2

1

1

Operation and use

Mechanical adjustments

3

Head rests may be connected using the extension plate (1131.31XX) or the head rest adapter

(1130.81A0) to both NORMAL / REVERSE

mounting points of the table top.

N OTE

Use and handling are described in detail in the operating instructions for this

product.

N OTE

The head plate adapter 1130.81A0 is required to mount head plates at the

NORMAL and REVERSE mounting points.

3.7.3.1 Mounting and removing the head rest using the head rest adapter (1130.81A0)

N OTE

The head plate adapter consists of a left and a right part.

If the adapters are mixed up, the distance of the drilled holes will not match up.

Observe the markings L and R.

Mounting the head rest

Insert the two head rest adapters 1130.81A0

(1), using their pins, as far as they will go into

the mounting sockets (2) at the front of the

table top.

Fig. 19: Mount the head rest adapter

1433.01XX

GA 1433.01 EN 08

33

Page 42

Operation and use

3

4

5

5

5

3

3

Mechanical adjustments

Fig. 20: Mounting the head rest

Insert the head rest (3) pins as far as they will

go into the mounting sockets (4) at the front

of the table top.

Fig. 21: Mounting and securing the head rest

Tighten the locking screws (5).

Pull on either side of the component to en-

sure that it is properly secured.

Removing the head rest

Loosen the locking screws (5).

Remove the head rest (3).

Remove the two head rest adapters

1130.81A0 (1).

34

Fig. 22: Removing the head rest

1433.01XX

GA 1433.01 EN 08

Page 43