Page 1

SERVO VENTILATOR 900 C

OPERATING MANUAL

CRITICAL CARE

Page 2

Important

!

▲

General information

• Servo Ventilator 900 C must be operated only by authorized

personnel who are well trained in its use.

It must be operated according to the instructions in this

Operating Manual.

• After unpacking, the ventilator must be checked and, if

necessary, calibrated.

• All data on pressures for Servo Ventilator 900 C are given in

cm H2O.

1 kPa (kilopascal) ≈ 10 cm H

100 kPa = 1 bar ≈ 1 atm ≈ 1 kgf/cm

100 kPa ≈ 15 psi

• Responsibility for the safe functioning of the equipment

reverts to the owner or user in all cases in which service or

repair has been done by a non-professional or by persons

who are not employed or authorized by MAQUET, and when

the equipment is used for other than its intended purpose.

•A full technical description – including circuit diagrams, parts

list and service data – is contained in the service

documentation, copies of which are held by your supplier.

O

2

2

(kp/cm2)

Connection

• When connected to a patient, the ventilator must never be

left unattended.

•A check on functions must be done before a patient is

connected to the ventilator.

• When anaesthetic gas is metered via a flow meter on the low

pressure inlet, compressed air must not be connected at the

same time.

• To avoid explosion hazards, flammable agents such as ether

and cyclopropane must not be used in this machine. Only

agents which comply with the requirements on nonflammable agents in the IEC standard “Particular

requirements for electrical safety of anaesthetic machines”

are suitable in this machine.

• As this machine is not suitable for use with flammable agents

such as ether and cyclopropane, the use of antistatic

breathing tubes and face masks is not necessary.

The use of antistatic or electrically conductive breathing

tubes when using high frequency electric surgery equipment,

may cause burns and is therefore not recommended in any

application of this machine.

• Never connect or disconnect auxiliary equipment to the outlet

on the rear of the ventilator when the ventilator is connected

to mains.

• All gases must fulfill the specifications for medical grade gas.

The gases supplied must be dry and free from oil and dust.

Air H2O< 5 g/m

Oxygen H2O< 20 mg/m

Nitrous oxide/gaseous phase) H2O< 58 ppm

Oil < 0.5 mg/m

3

3

3

Operation

• The APNEA ALARM is not intended to and will not monitor

for disconnections.

• The APNEA ALARM is not functional in VOL. CONTR., VOL.

CONTR. + SIGH, PRESS. CONTR. or MAN.

• In the case of a power failure, manual ventilation using a

Servo Ventilator 900 C is possible only with the help of

power supply from external battery. A resuscitator should

always be available, however, as an extra safety measure.

• The SV 900 C is certified, with regard to safety, to be

compatible with electromagnetic environments complying

with IEC 601-1-2. It is the responsibility of the user to take

necessary measures in order to ascertain that the specified

limits are not exceeded as this may impair the safety of the

ventilator.

Such measures should include, but are not limited to:

– normal precautions with regard to relative humidity and

conductive characteristics of clothing in order to minimize the

build-up of electrostatic charges.

– avoiding the use of radio emitting devices in close

proximity of the ventilator, such as high-frequency surgery

apparatus or cordless (mobile) telephones, resulting in a field

level exceeding 3 V/m (IEC 601-1-2).

Magnetic fields of MR equipment having flux densities above

20 mT may cause deactivation of the ventilator functions and

may result in permanent damage to the Servo Ventilator.

• To protect the patient against high pressures, the WORKING

PRESSURE and UPPER PRESS. LIMIT must always be set

at suitable values.

• Do not forget to set the manual ventilation valve to position

AUT after completed manual ventilation. Otherwise the

patient may be hypoventilated without any alarm from the

ventilator. (Not applicable to manual ventilation accessory

with motor).

• When mains supply is switched off or in the case of a mains

power failure, the inspiratory and expiratory valves will

automatically open. This may also occur in the case of an

internal electronic failure. Thus, if the WORKING

PRESSURE is set too high and the gas supply through the

gas supply unit continues, this may result in increased airway

pressure.

• When excess gas is being scavenged, the scavenging

system must meet the following requirements:

– At the point at which the scavenging system is

connected to the ventilator, the sub-atmospheric pressure

must not exceed 0.5 cm H

the breathing system greater than 0.5 l/min.

– With continuous air flows of 30 l/min and 90 l/min for

not less than 5 seconds at the inlet of the anaesthetic

gas scavenging system, the resistance in the system

shall not exceed 0.25 cm H

The Servo Evac 180 basic evacuation unit meets these

requirements.

• If the ventilator is equipped with electronic gas supply unit,

the following applies:

When mains supply is switched off or in the case of power

failure, the gas supply is automatically blocked.

O or cause an induced flow from

2

O and 2.5 cm H2O, respectively.

2

Cleaning

• The ventilator must not be gas sterilized.

• The flow transducers must not be cleaned in a dish washing

machine, by ultrasonic methods or by using agents that

contain aldehydes.

• Agents used for cleaning must have a pH value between

4–8.5.

• Complete cleaning should be done after every 1000 hours

of operation or, at the latest, after every six months.

Service

• The Servo Ventilator 900 C must be serviced at regular

intervals by specially trained personnel. Any maintenance

must be noted in the log book provided for that purpose,

in accordance with national regulations. We recommend that

service is done as a part of a service contract with MAQUET.

• The 1000 hours overhaul shall be done after every 1000

operating hours or, at the latest, every six months. In

addition, the ventilator shall undergo a technical safety check

twice a year, at six months intervals, according to national

regulations.

• Service and repairs on the ventilator may be done only

by MAQUET authorized personnel.

• Only original parts from MAQUET must be used in the

ventilator.

Equipment combinations

• Only MAQUET-approved accessories and auxiliary

equipment may be connected to the ventilator.

• In order to maintain system safety and integrity only

accessories complying with IEC 601-1, or the safety of which

has been verified in another way must be

connected to the signal outputs on the rear of the ventilator.

For details on connections and allowed

voltages, please see Circuit Diagram.

Page 3

Product information program

This Operating Manual is a part of a comprehensive

information program for Servo Ventilator 900 C.

The program is planned to contain the following:

Promotional and Scientific Publications

Brochure Servo Application Product Leaflet Reprints

Ventilator Brochures:

Concept

Operating and Service Instructions

Operating Brief Wall Diagram Service Manual Circuit Diagram

Manual Operating with Cleaning

Instructions Instructions

Intensive Care

Anesthesia

Transportation

Product Training Material

Training Advisory Slide Series “I am breathing The Patient’s

Instructions Booklet including through a ABSee

for Instructors Textbook ventilator” Cards

Film and and Poster

Booklet

Front Panel Panel Block Trainee’s set Video programs

Flip-chart Video guide

Video news

®

Page 4

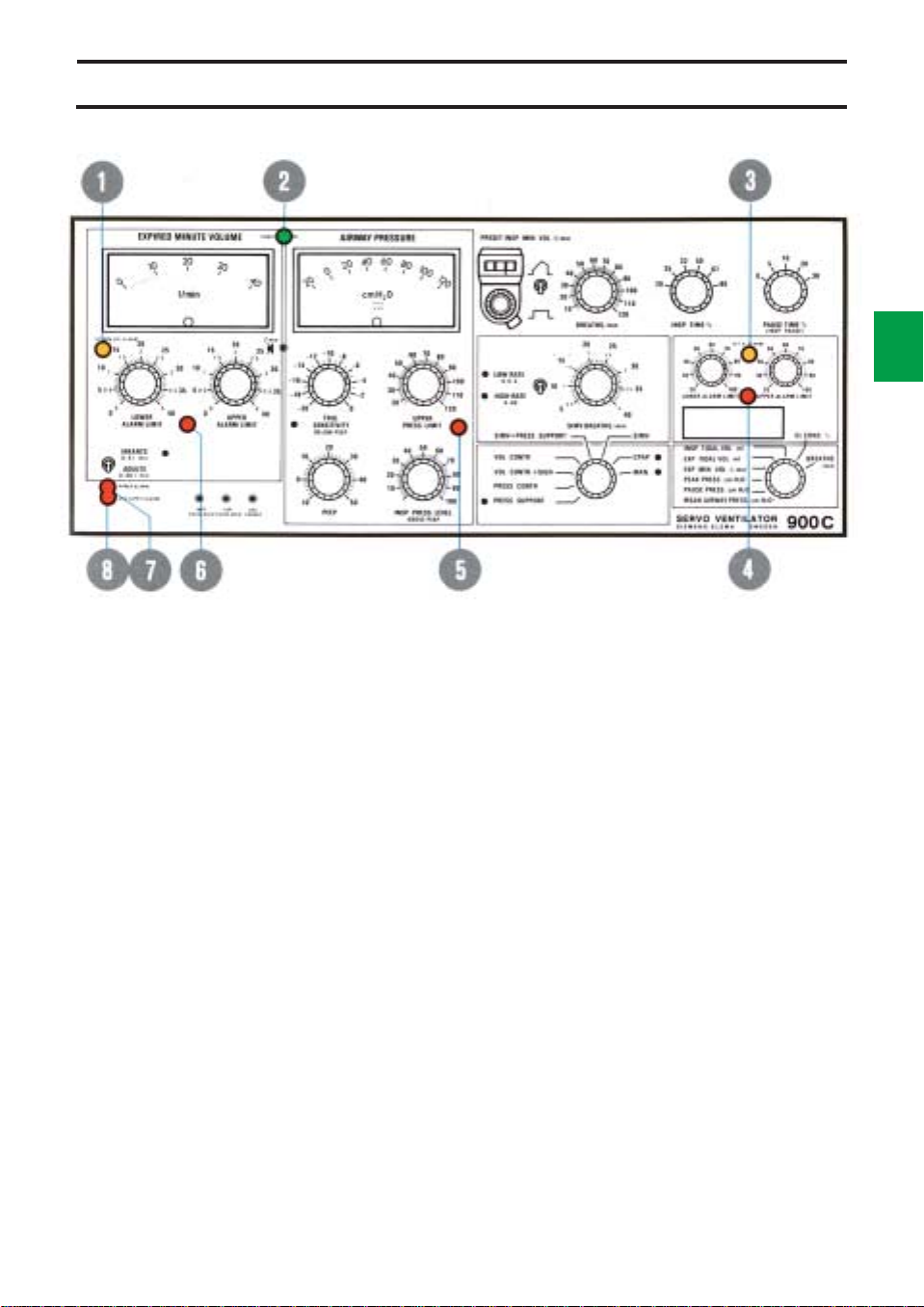

Servo Ventilator 900 C-Front

Page 5

Page 6

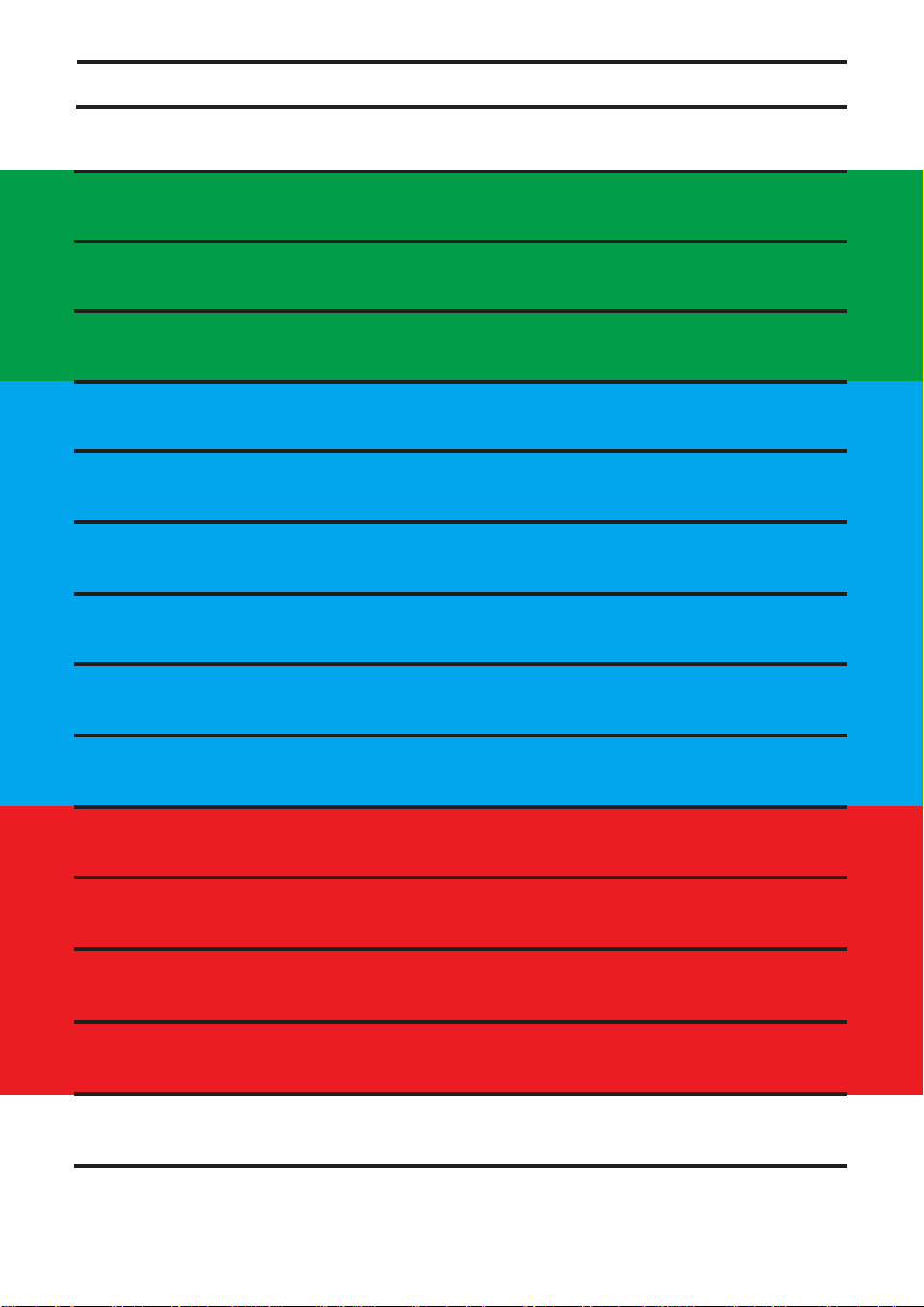

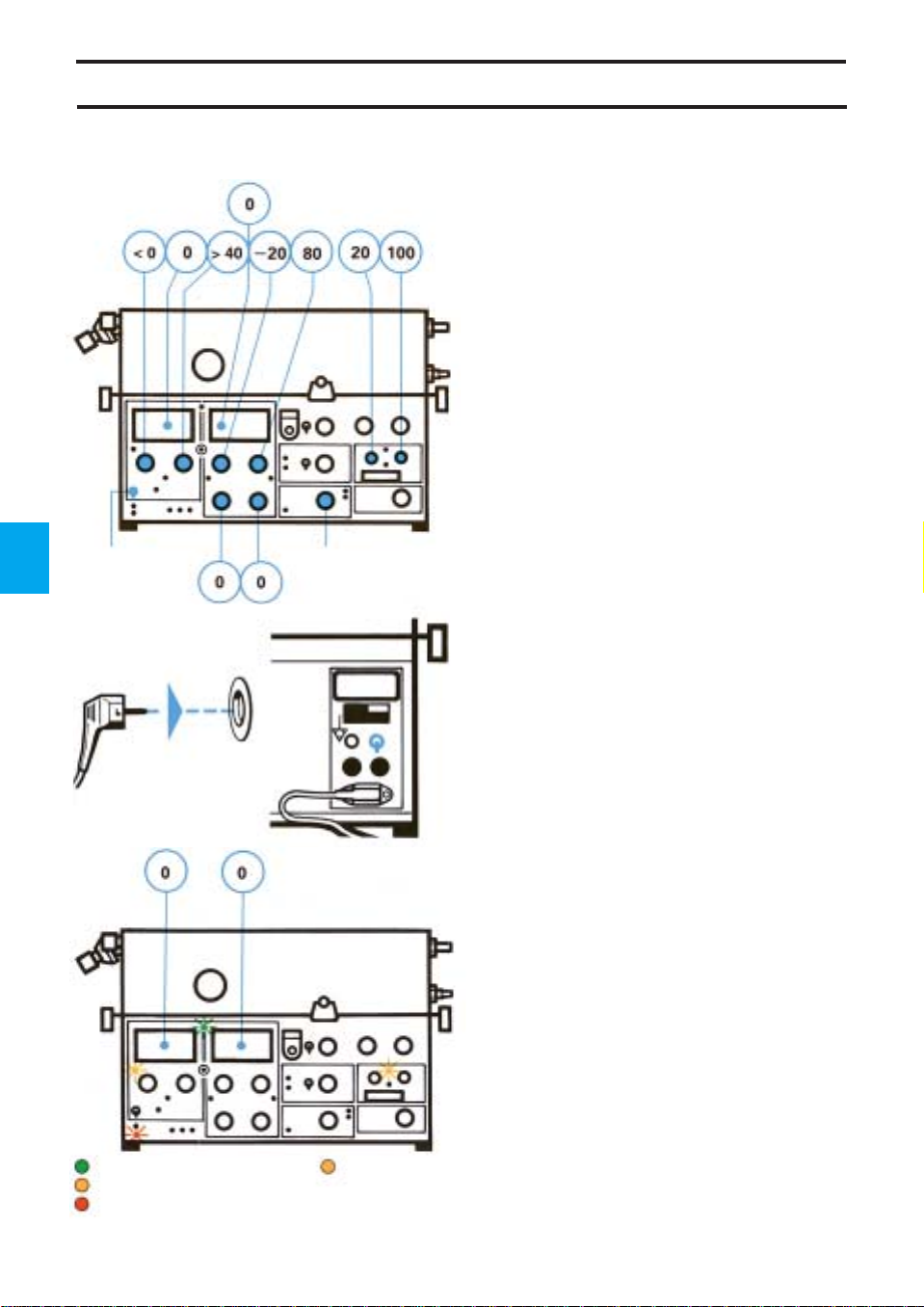

Operating instructions

Servo Ventilator 900 C is simple to operate.

Operating instructions are found:

!

On the ventilator in the form of a panel and

cleaning instructions on the lid of the

pneumatic unit.

“Normal” settings are indicated in green on

the front panel. Settings indicated in red

should be used with caution, since these

settings may involve a certain risk for the

patient.

@

In the Brief Operating Instructions in the drawer

under the ventilator.

A log sheet is available with the Brief

Operating Instructions. After certain routines,

e. g. cleaning etc., the person responsible for

the work should complete and sign the log

sheet. The log sheet can then be filed.

#

On a separate wall poster with cleaning

instructions.

$

In this Operating Manual.

The inside of the cover shows a picture of

the ventilator. This picture can be used as a

foldout when reading the manual.

The following information is found in the

corresponding chapters:

Description ............................................ 1-3

Operating............................................... 4-9

Maintenance......................................10-13

Technical specifications ......................... 14

Page 7

Contents

1. Arbetsprincip

1. Arbetsprincip

1. Basic principles

2. Kontrollpanel och ventilationssätt

2. Kontrollpanel och ventilationssätt

2. Control panel and ventilation modes

3. Patientsäkerhet

3. Patientsäkerhet

3. Patient safety

4. Uppställningar

4. Uppställningar

4. Set-ups

5. Förberedelser

5. Förberedelser

5. Preparations

6. Funktionskontroll

6. Funktionskontroll

6. Check on functions

7. Anslutning till patient

7. Anslutning till patient

7. Connection to patient

8. Klinisk bedömning och felsökning

8. Klinisk bedömning och felsökning

8. Clinical judgement and troubleshooting

9. Registrering

9. Registrering

9. Recording

10. Rutinrengöring

10. Rutinrengöring

10. Routine cleaning

11. 1000-tim.-översyn med fullständig rengöring

11. 1000-tim.-översyn med fullständig rengöring

11. 1000 hours overhaul with complete cleaning

12. Utbyte av O2-cell

12. Utbyte av O2-cell

12. Replacement of O

13. Kalibrering

13. Kalibrering

13. Calibration

14. Tekniska specifikationer

14. Tekniska specifikationer

14. T echnical specifications

cell

2

1

Page 8

2

Page 9

Chapter 1

Basic principles

In this chapter:

General design .................1:2

Pneumatic unit..................1:3

Rear ...................................1:4

1

1

Page 10

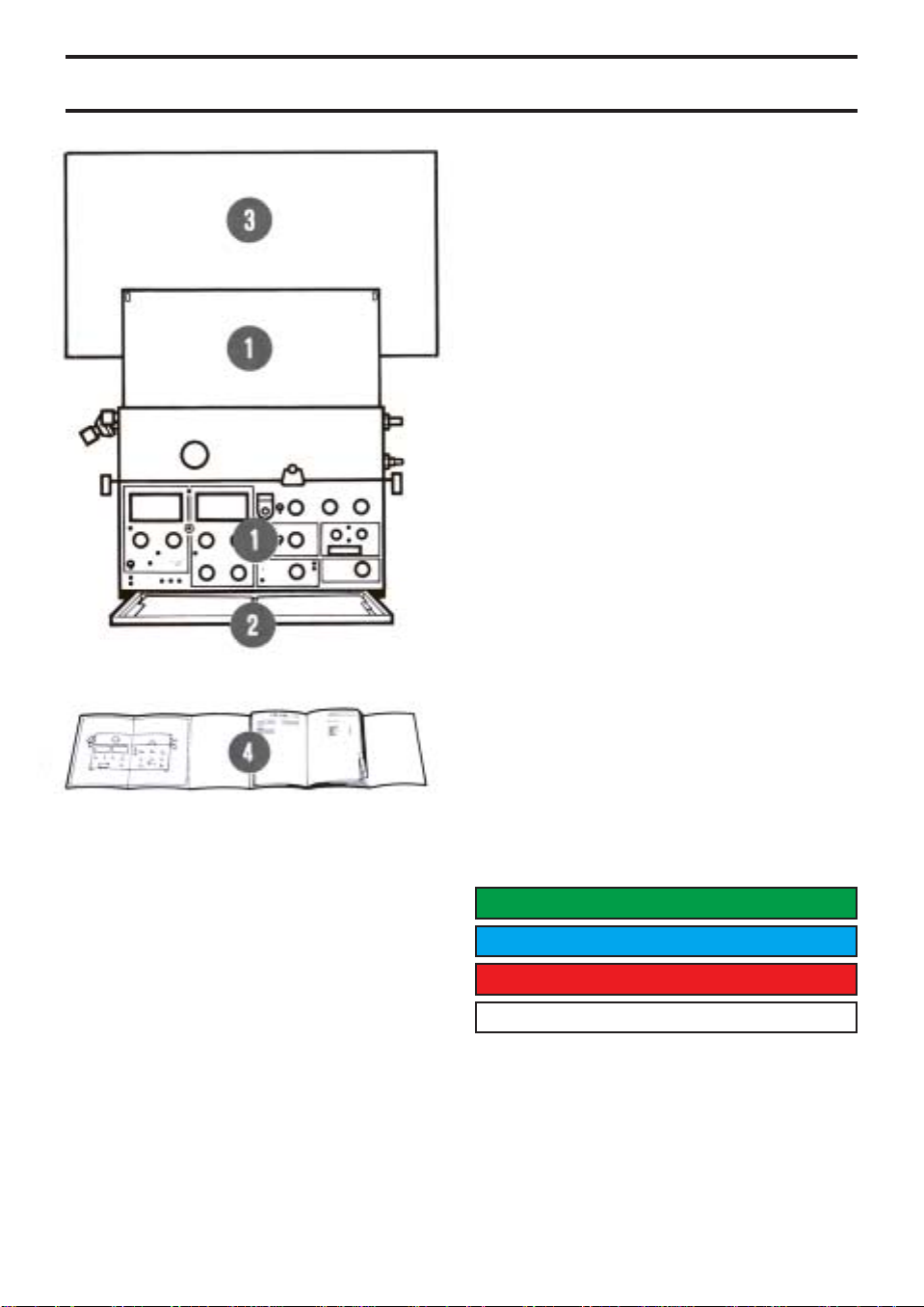

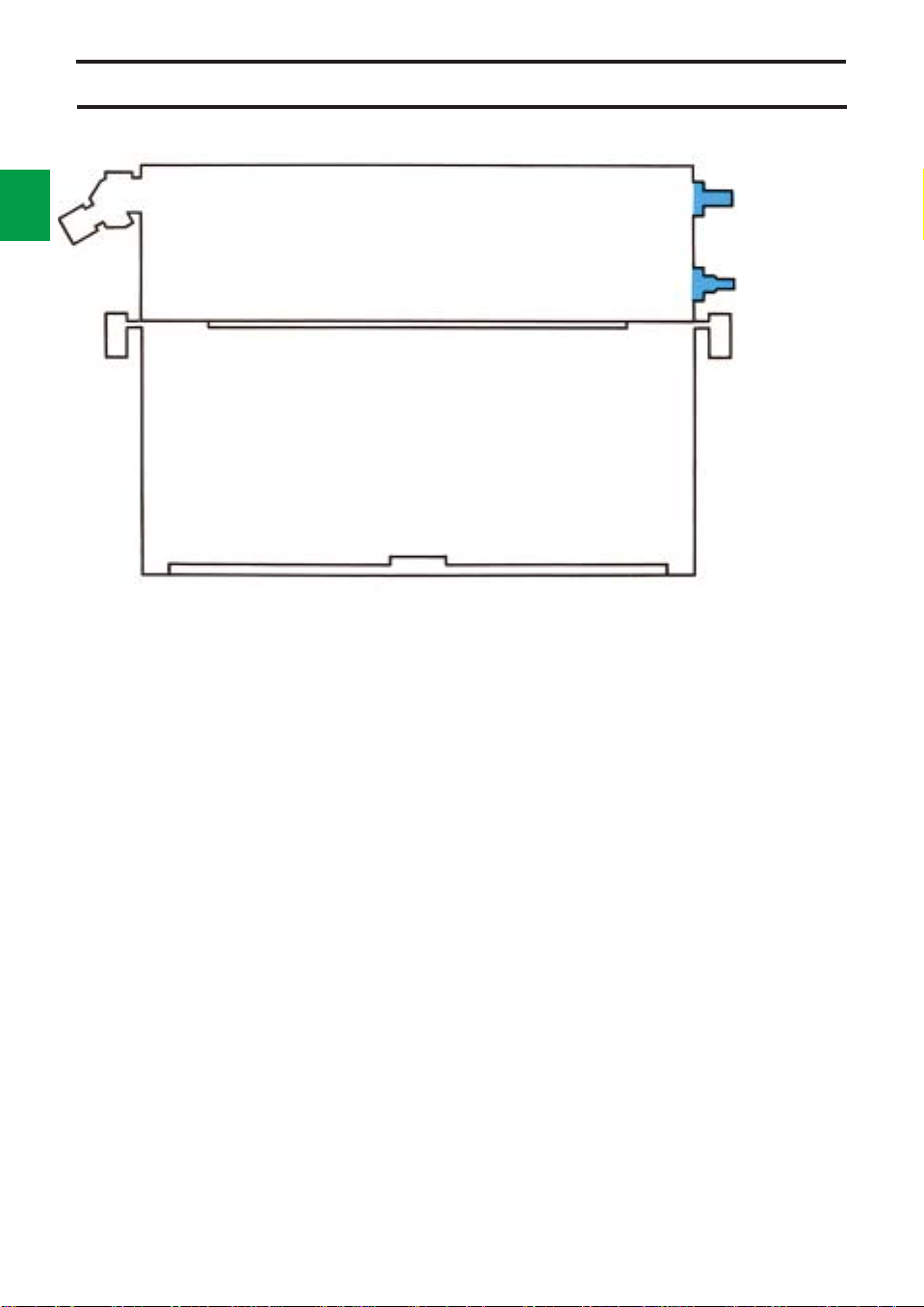

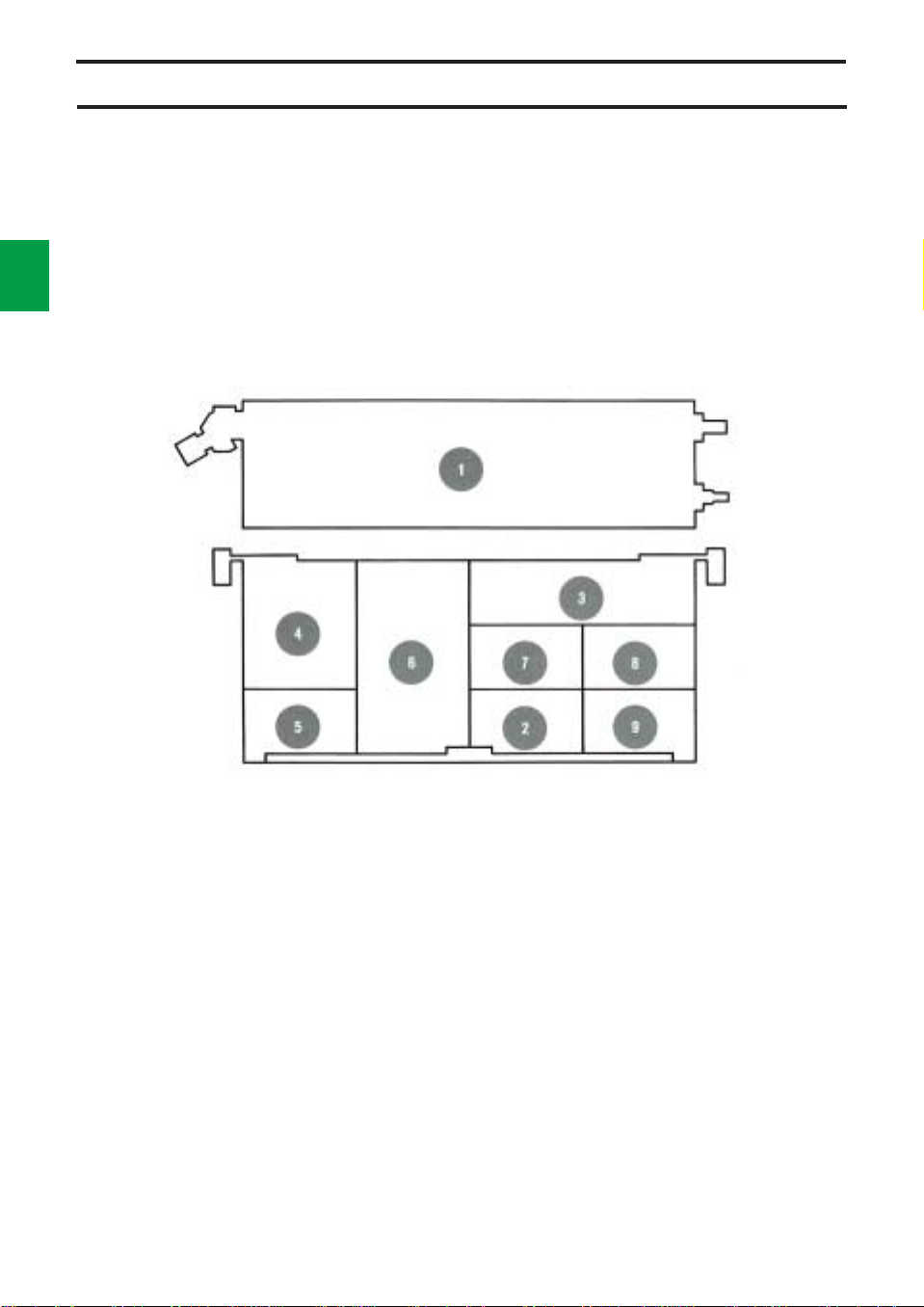

General design

1

2

Pneumatic unit

The pneumatic unit comprises the gas

conduction system, pressure and flow

transducers and control valves.

The control of flow and pressure is done by a

feed-back system. The transducers continually

measure the flow and pressures. The

information is compared with the panel settings

and a difference between the actual and the

preset values results in correction signals to

the control valves.

For detailed description, see chapter “Basic

principles” in the Training Instructions.

Low pressure

High pressure

Electronic unit

The electronic unit contains a number of plugin PC-boards with the circuits for regulation,

alarms and monitoring.

The unit effects the electronic control of the

pneumatic unit.

Servicing of the ventilator is facilitated by the

spare parts exchange system. The faulty parts

are replaced by factory trimmed exchange

parts.

Service on the electronic unit must be done

by MAQUET, or by MAQUET authorized

personnel only.

Page 11

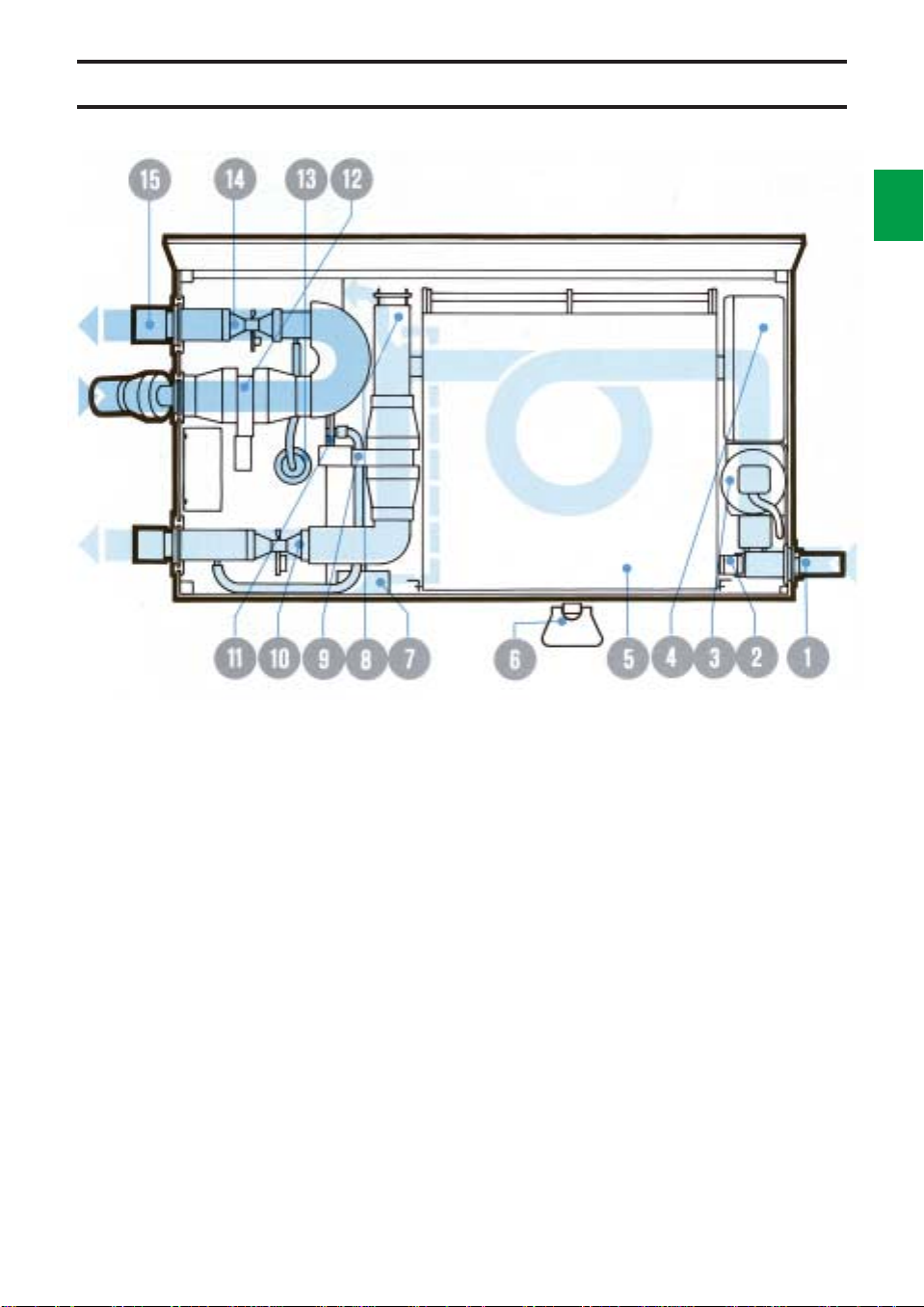

Pneumatic unit

1

3

!

Gas connection. The upper inlet, not visible in

the picture, is used for low pressure gas and

the lower inlet is used for high pressure gas.

For anaesthesia, a gas supply unit with three

inlets is available.

@

The gas supply is regulated by a valve so that a

constant pressure is maintained in the bellows.

#

The O2 cell measures the O2 concentration in

the gas.

$

The gas flows through a bacteria filter.

%

The respiratory gases are mixed and stored at

a constant pressure in the bellows.

^

The working pressure is set with an adjustment

screw.

&

A manometer shows the working pressure.

*

A safety valve opens if the bellows is overfilled,

or if the pressure exceeds approx. 120 cm H

O.

2

(

The flow transducer on the inspiration side

measures the gas flow to the patient.

BL

The inspiration valve regulates the inspiratory

gas flow. It is closed during the pause and

expiratory parts of the respiratory cycle.

BM

The pressure transducer on the inspiration side

measures the airway pressure.

BN

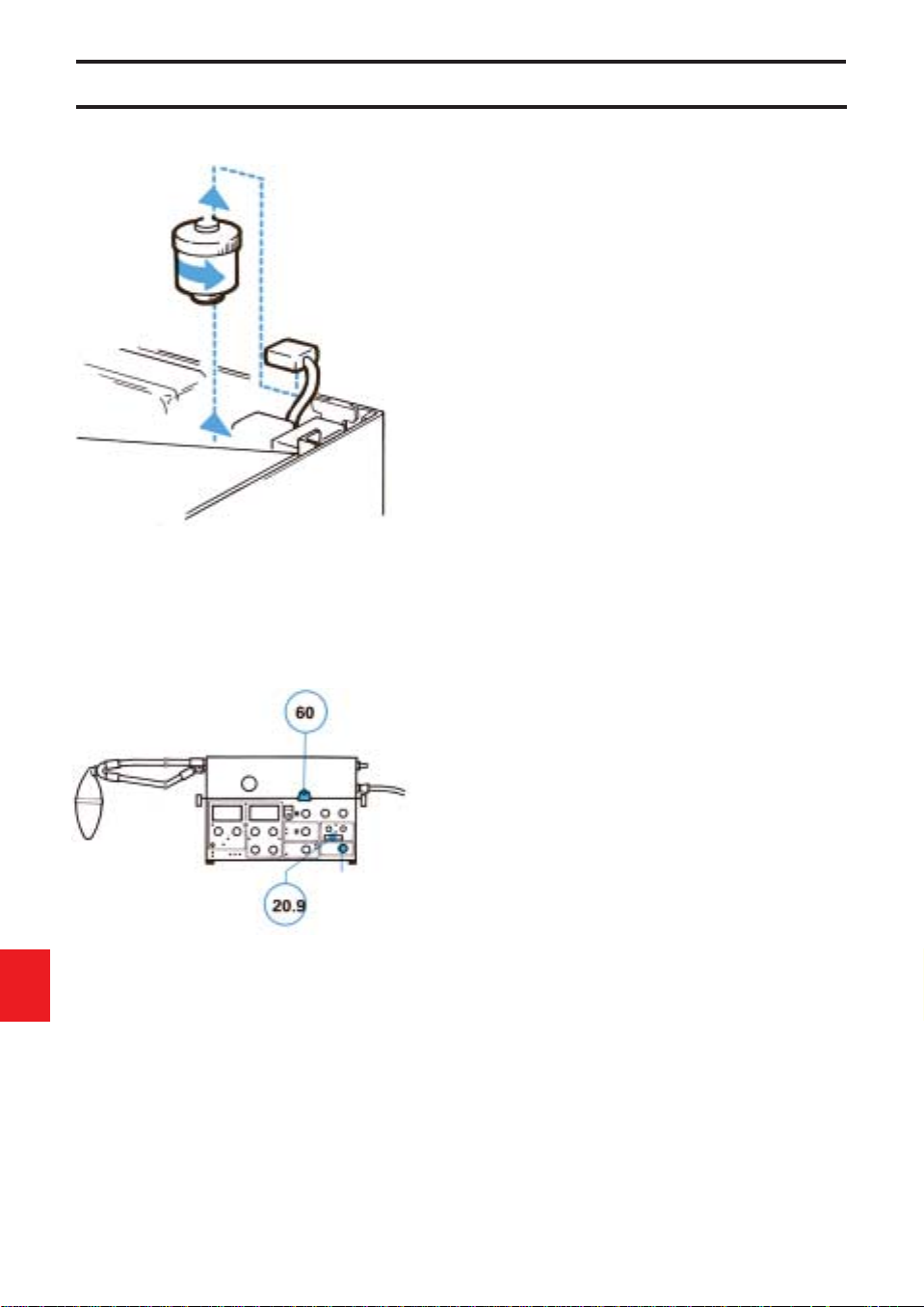

The flow transducer on the expiration side

measures the gas flow from the patient.

To prevent condensation, the transducer is

heated to approx. 60°C.

BO

The pressure transducer on the expiration side

measures the airway pressure.

BP

The expiration valve is closed during

inspiration. During the expiratory phase it is

either fully open or regulating the PEEP level.

BQ

The flap valve prevents a back flow of exhaled

gases. It is also necessary for the trigg function.

Page 12

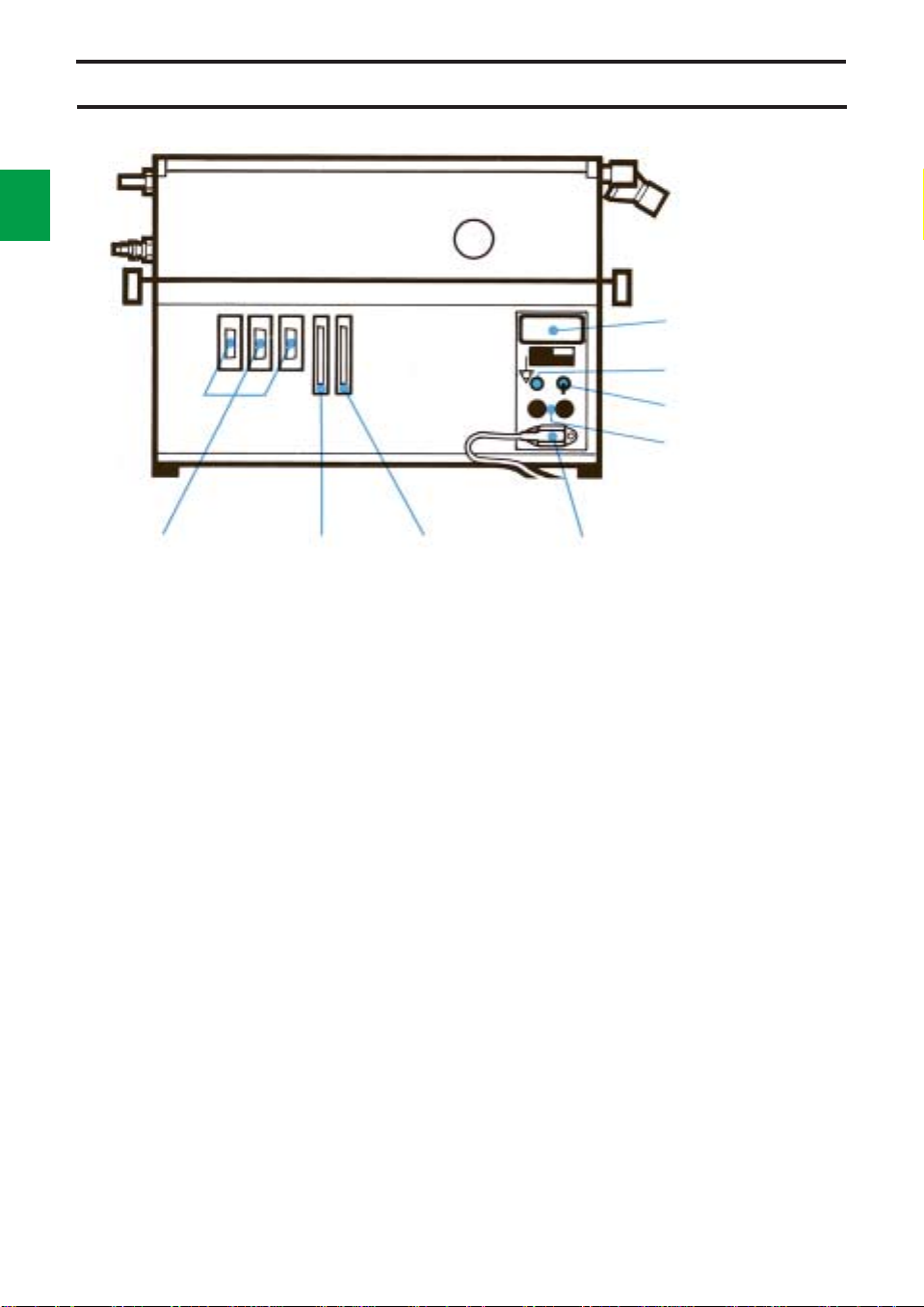

1

Rear

4

Operating time meter

Equipotential socket

On/Off switch

Fuse holders

Outputs for

auxiliary

equipment

Control

terminal

Recorder

output

Rear of

Servo Ventilator 900 C

To the right on the electronic unit are the mains

inlet socket, fuse holders, On/Off switch,

voltage rating, equipotential socket and

operating time meter.

To the left on the electronic unit are three

15-pole sockets for auxiliary equipment.

The 37-pole socket is used for recording of

pressure and flow curves.

There are labels with the serial number of the

apparatus on both the pneumatic unit and the

electronic unit.

Mains inlet socket

Control terminal

Under the secured lid, there is a connector for

external control of ventilation.

For details see separate Operating Manual.

Page 13

Chapter 2

Control panel and

ventilation modes

In this chapter:

Panel design

and symbols ................... 2:2

Panel functions............... 2:3

Working pressure........... 2:3

Mode selection ............... 2:3

Respiratory pattern ........ 2:4

I:E ratio............................ 2:5

Expired minute volume.. 2:6

Special functions............ 2:7

Airway pressure ............. 2:8

SIMV ................................ 2:10

O

alarm........................... 2:11

2

Parameter selection ....... 2:11

2

121

Controlled ventilation .... 2:12

Supported ventilation .... 2:13

Spontaneous ventilation. 2:15

Manual ventilation .......... 2:16

Page 14

Panel design and symbols

2

For easy operation, the panel is divided into

fields. Each field is described in this chapter.

“Normal” settings are indicated in green on

the front panel. Settings indicated in red should

be used with caution since these settings may

involve a certain risk for the patient.

2

A number of knobs and the EXPIRED

MINUTE VOLUME meter have dual scales.

The blue scale is always to be used when the

low range is selected.

Power on is indicated by a green lamp.

A yellow lamp is either an indication of a

certain setting or a reminder to set an alarm

limit.

A red lamp always indicates an alarm.

! Working Pressure

@ Mode Selection

# Respiratory Pattern

$ Expired Minute Volume

% Special Functions

^ Airway Pressure

& SIMV

* O

Concentration Alarm

2

( Monitoring

Page 15

Panel functions

Working pressure

The working pressure is set with an adjustment

screw and is read on the manometer

WORKING PRESSURE.

The working pressure must always be set at

a value somewhat higher than the highest

airway pressure.

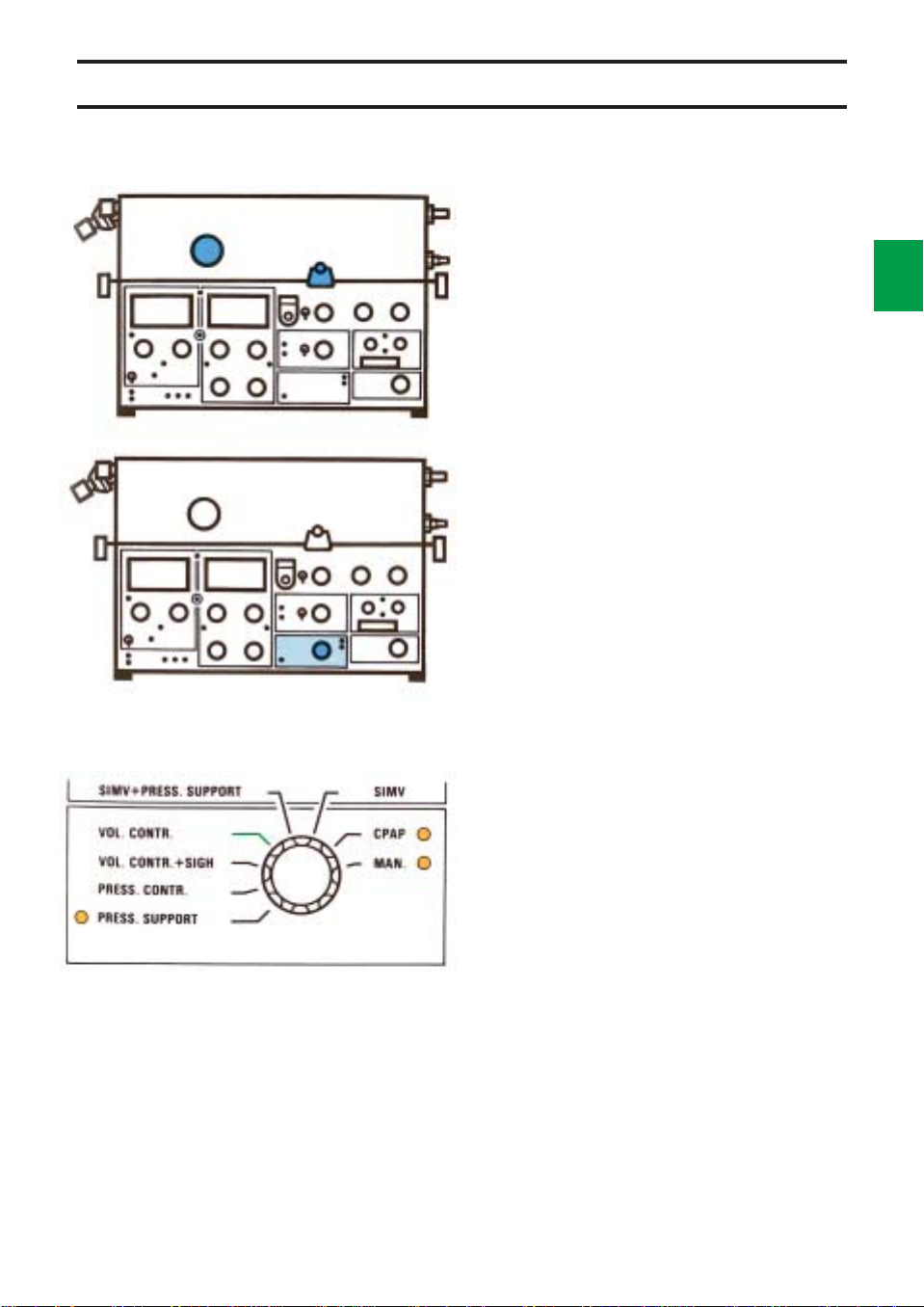

Mode selection

The Servo Ventilator 900 C can be operated in

8 different modes, which are selected by means

of the mode selector.

The modes are described in special sections

in this chapter.

Controlled ventilation

Volume controlled ventilation (VOL. CONTR.)

Volume controlled ventilation + sigh (VOL.

CONTR. + SIGH)

Pressure controlled ventilation (PRESS.

CONTR)

2

3

Supported ventilation

Pressure supported ventilation (PRESS.

SUPPORT)

SIMV (Synchronized Intermittent Mandatory

Ventilation)

SIMV + Pressure support (SIMV + PRESS.

SUPPORT)

Spontaneous ventilation

CPAP (Continuous Positive Airway Pressure)

Manual ventilation

MAN

Page 16

2

4

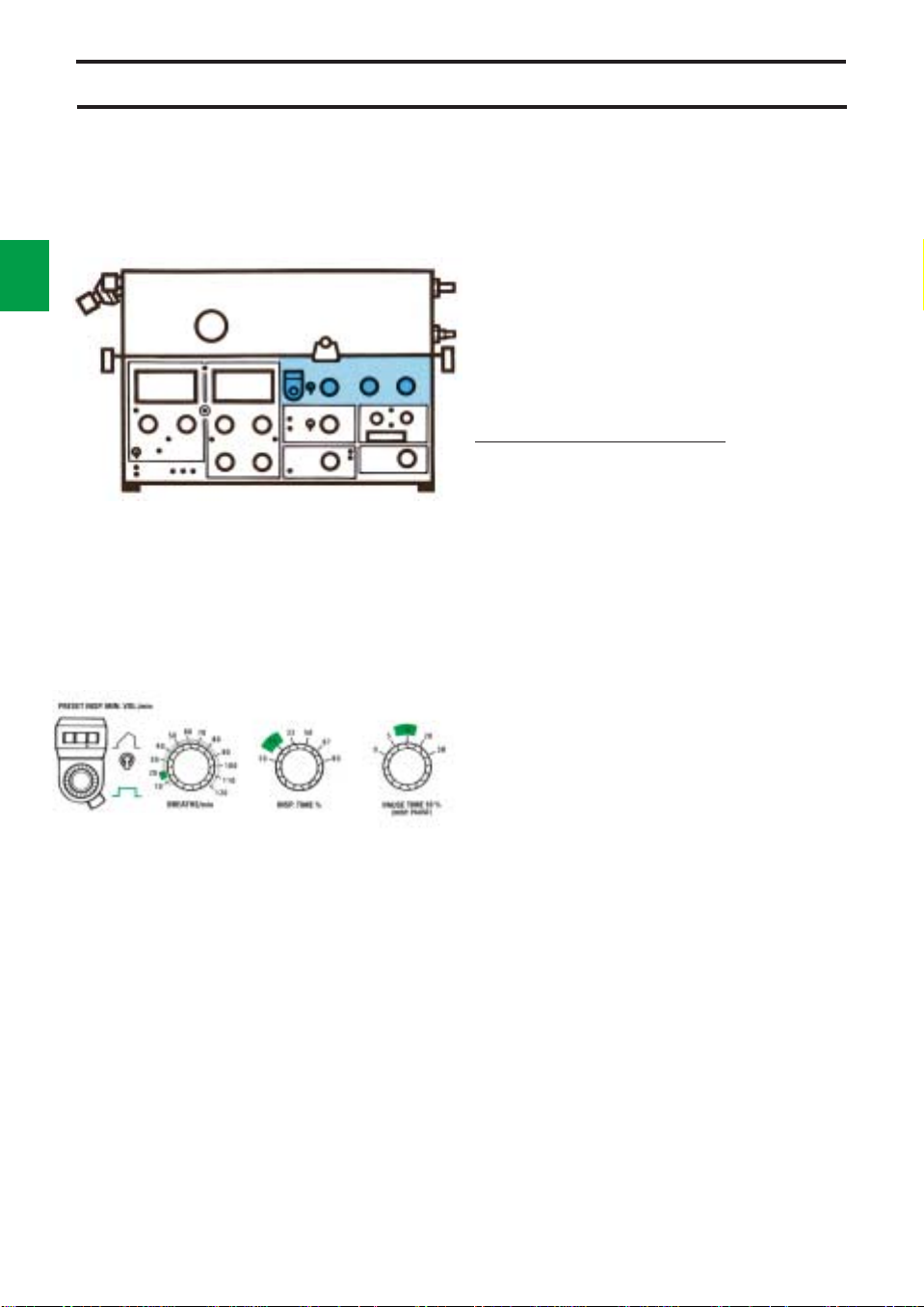

Panel functions

PRESET INSP. MIN. VOL./min

60

70

50

80

40

30

20

90

100

110

120

33

25 50

INSP. TIME %BREATHS/min

PAUSE TIME 10 %

(INSP. PAUSE)

Respiratory pattern

Preset inspiratory minute volume

The inspiratory minute volume is set with the

knob PRESET INSP. MIN.VOL. l/min. The

knob has a locking button on the underside.

A suitable initial value can be calculated by,

for instance, using a Radford nomogram. The

minute volume can be readjusted after

indication from a CO

auxiliary equipment for the Servo Ventilator.

The setting range is 0.4-40 l/min.

The tidal volume =

PRESET INSP. MIN. VOL. l/min

BREATHS/min

The tidal volume can be read on the digital

display.

At extremely high flows it may be necessary

to increase the working pressure in order to

obtain the desired minute volume.

Flow pattern switch

During VOL. CONTR. and VOL. CONTR. +

SIGH, a constant or an accelerating inspiratory

flow can be selected. Constant flow gives a

lower peak pressure and is the pattern

normally used.

A decelerating flow will be obtained in

PRESS. CONTR.

Breaths per minute

The respiratory rate is steplessly adjustable

within the range of 5 to 120 BREATHS/min.

Analyzer 930, which is

2

Inspiration time %

There are 6 fixed inspiration times, 20, 25, 33,

50, 67 and 80% of the breathing cycle.

Pause time %

There are 5 fixed pause times, 0, 5, 10, 20 and

30% of the breathing cycle.

Page 17

Panel functions

I:E ratio

Insp. Pause I:E ratio

time time

%%

20 0 1:4

20 5 1:3

25 0 1:3

20 10 1:2.3

25 5 1:2.3

33 0 1:2

25 10 1:1.9

33 5 1:1.6

20 20 1:1.5

33 10 1:1.3

25 20 1:1.2

20 30 1:1

50 0 1:1

33 20 1.1:1

25 30 1.2:1

50 5 1.2:1

50 10 1.5:1

33 30 1.7:1

67 0 2:1

50 20 2.3:1

67 5 2.6:1

67 10 3.4:1

67 20* 4:1

80 0 4:1

* Reduced to 13%

To the left is a conversion table for INSP. TIME

% and PAUSE TIME % to I:E ratio for those

who are more used to working with the latter.

On the basis of an I:E ratio, i.e. the relation of

inspiration time to expiration time, the pause is

allocated to inspiration time.

For example, insp. time 25% and pause time

10% = I:E ratio 35/65 = approx. 1:1.9.

If the ventilator has been set so that insp. time

+ pause time exceeds 80%, then expiration

automatically begins when 20% of the

respiratory cycle remains (safety function).

The pause time is then reduced.

Example 1:

Preset insp. time = 67% ➞ 67% inspiration

Preset pause time = 20% ➞ 13% pause

20% expiration

Example 2:

Preset insp. time = 80% ➞ 80% inspiration

Preset pause time = 30% ➞ 0% pause

20% expiration

The settings are independent of changes in the

patient’s compliance and resistance.

2

5

Inspiration time settings of 33%, 67% or

80% should be avoided in volumecontrolled respiration with accelerating flow

patterns. With these settings patient

triggering may cause the temporary partial

blocking of the inspiration valve which,

however, would be indicated by a minute

volume alarm. Should the valve be blocked,

the situation can be remedied immediately

by switching over to a constant flow.

Inspiratory flow

In mode VOL. CONTR. (constant flow) or SIMV the

inspiratory flow is calculated by:

PRESET INSP. MIN. VOL. l/min

INSP./TIME %

Example:

PRESET INSP. MIN. VOL. l/min = 8 l/min

INSP. TIME % = 25%

Results in an inspiratory flow: = 8 × 100/25

Or

Adjustment of INSP. TIME% (use reverse value)

20% = 1/5= 5

25% = 1/4= 4

33% = 1/3= 3

50% = 1/2= 2

67% = 2/

80% = 4/

× PRESET INSP. MIN. VOL = inspiratory flow (l/min)

1.5

1.25

= 1.5

= 1.25

= 32 l/min

Page 18

2

Panel functions

6

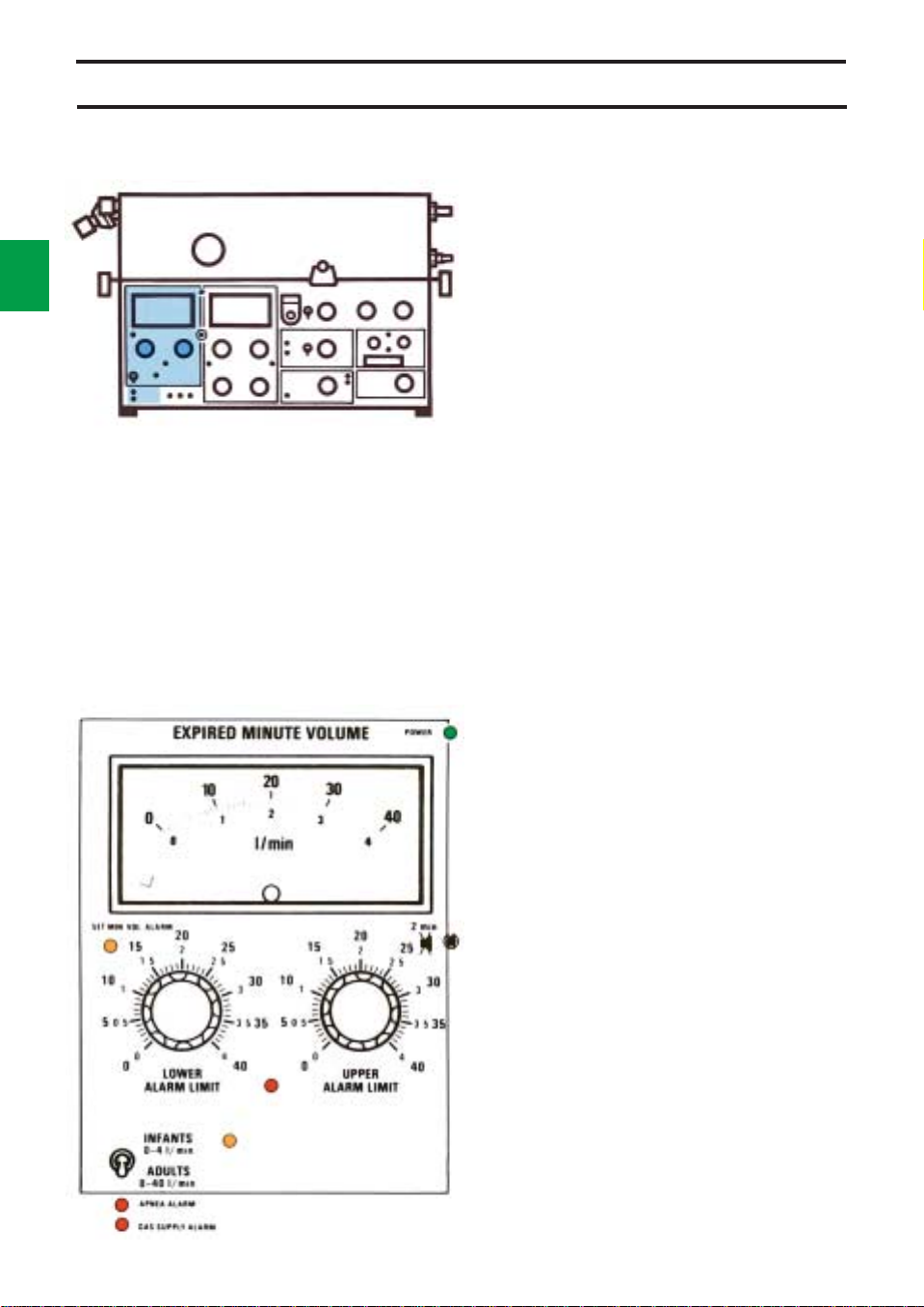

Expired minute volume

EXPIRED MINUTE VOLUME is indicated on a

meter which has dual scales: 0-40 l/min and

0-4 l/min.

The scale 0-4 l/min is intended for use when

greater accuracy, e. g. for infants, is needed.

The knobs for LOWER ALARM LIMIT and

UPPER ALARM LIMIT also have the same

dual scales.

The end stop positions for the knobs do not

coincide with the end positions on the scale.

This is correct and no attempt should be made

to alter the range.

The desired scale is selected with the switch

INFANTS/ADULTS.

The alarm limits for expired minute volume

must always be set. If either of the knobs has

been set in end position (out of scale), the

yellow lamp SET MIN. VOL. ALARM flashes.

The alarm limits are normally set at approx.

20% below and above the selected minute

volume. The upper limit may be set at approx.

30% above the selected minute volume in the

mode VOL. CONTR. + SIGH.

The APNEA ALARM is activated with audible

signals and flashing light if the time between

any two consecutive breaths, spontaneous or

mandatory or a combination of the two, is

greater than approximately 15 seconds

(4 breaths per minute or less). The APNEA

ALARM is not intended to and will not monitor

for disconnections. The APNEA ALARM is

operative in CPAP, PRESS. SUPPORT, SIMV

and SIMV + PRESS. SUPPORT.

Failure of gas supply to the ventilator will

result in visual and audible GAS SUPPLY

ALARM signals. The GAS SUPPLY ALARM is

not operative at respiratory rates over 80

breaths/min., and INSP. TIME % 20 or 25.

Page 19

Panel functions

INSP. EXP. GAS

PAUSE PAUSE CHANGE

HOLD HOLD

Special functions

Under the small hood below the UPPER

ALARM LIMIT knob are three pushbuttons for

special functions.

Inspiratory pause hold

When the pushbutton INSP. PAUSE HOLD is

depressed, the valves close after inspiration

and the pause is prolonged as long as the

pushbutton is depressed.

This provides an exact measurement of the

end inspiratory lung pressure. It may also give

time for an equilibration of the blood gas and

alveolar pressures.

Expiratory pause hold

The valves are closed, after the expiration, as

long as the pushbutton EXP. PAUSE HOLD is

depressed, i.e. a prolonged expiratory pause.

This provides an exact measurement of the

end expiratory lung pressure.

2

7

EXP. PAUSE HOLD must not be used in

SIMV or SIMV + PRESS. SUPPORT mode.

Two inspirations may occur at the same

time. However, the UPPER PRESS. LIMIT

is still functional.

Gas Change

The pushbutton GAS CHANGE is used, for

instance, when it is desirable to rapidly alter the

gas mixture to the patient. The concentration

setting on the vaporizer/gas mixer/flowmeters

must be altered first.

The inspiration and expiration valves open so

that the pressure in the patient circuit is max.

20 cm H2O.

During the gas changing time, the EXPIRED

MINUTE VOLUME meter is zeroed

automatically.

Page 20

2

Panel functions

8

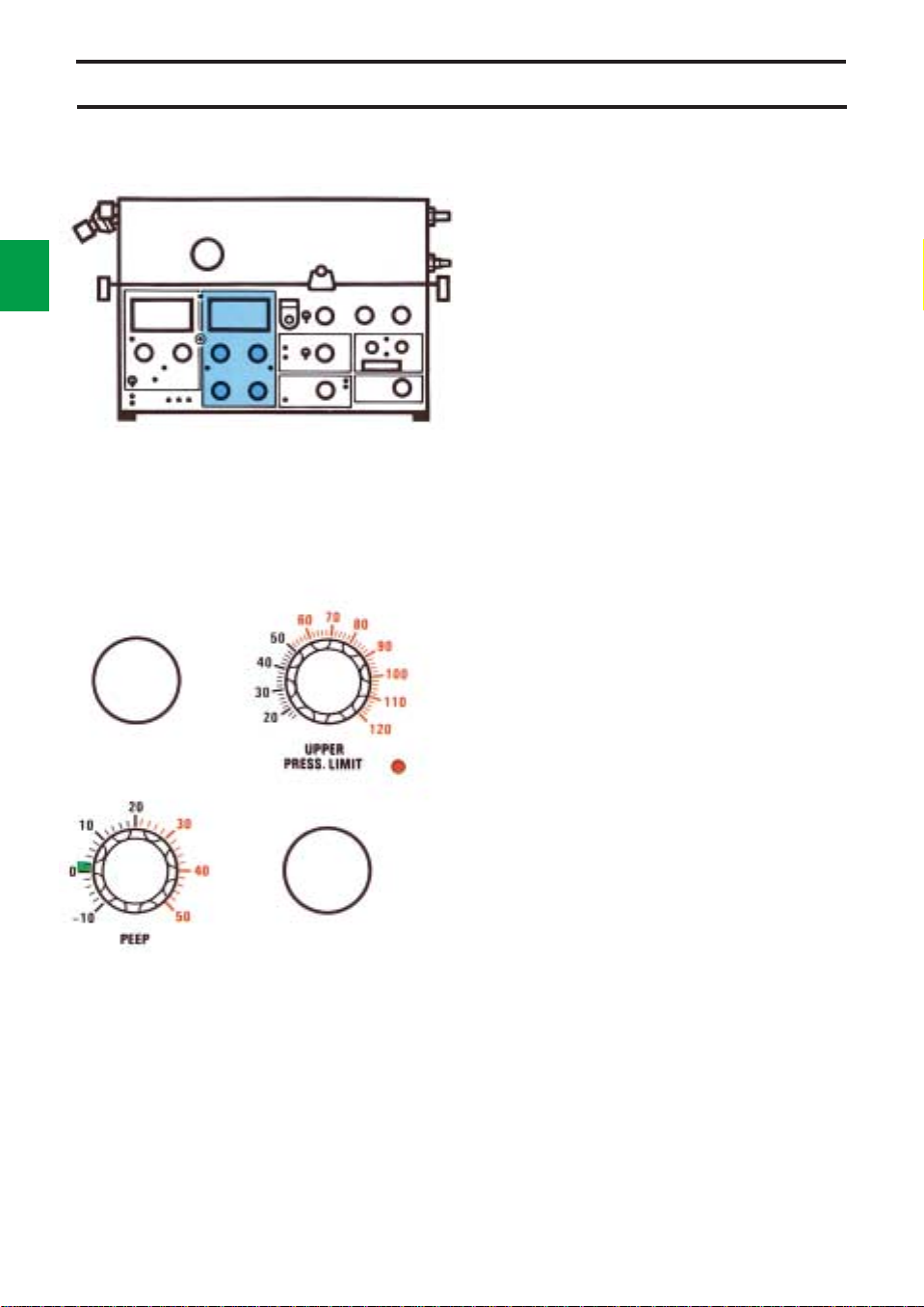

Airway Pressure

Airway pressure meter

The meter continually indicates the airway

pressure reading.

Upper pressure limit

The knob UPPER PRESS. LIMIT is used to set

the upper limit for airway pressure. When this

pressure limit has been reached, inspiration is

immediately discontinued and there is a

change over to the expiratory phase. Visual

and audible alarms are activated.

Since the inspiration is discontinued, the

complete tidal volume will not be delivered and,

consequently, the LOWER ALARM LIMIT for

EXPIRED MINUTE VOLUME may be

activated.

Upper pressure limit is connected in all

modes.

There are safety catches on the knob at 80

and 100 cm H

PEEP

PEEP is the setting of a Positive End

Expiratory Pressure, e.g. used to counteract

the formation of atelectasis.

The PEEP range is from 0 to 50 cm H2O.

There are safety catches on the PEEP knob at

0 and at 20 cm H

In case of a leakage, e.g. if a tracheal tube

without cuff is being used, the PEEP-setting

may cause self-triggering. To avoid this, the

TRIG. SENSITIVITY should be set at a

somewhat lower value.

The PEEP knob is prepared for NEEP

(Negative End Expiratory Pressure). In order

to use NEEP, it is necessary to connect

auxiliary equipment to the expiration outlet.

The NEEP range is from 0 to -10 cm H

O.

2

O.

2

O.

2

Page 21

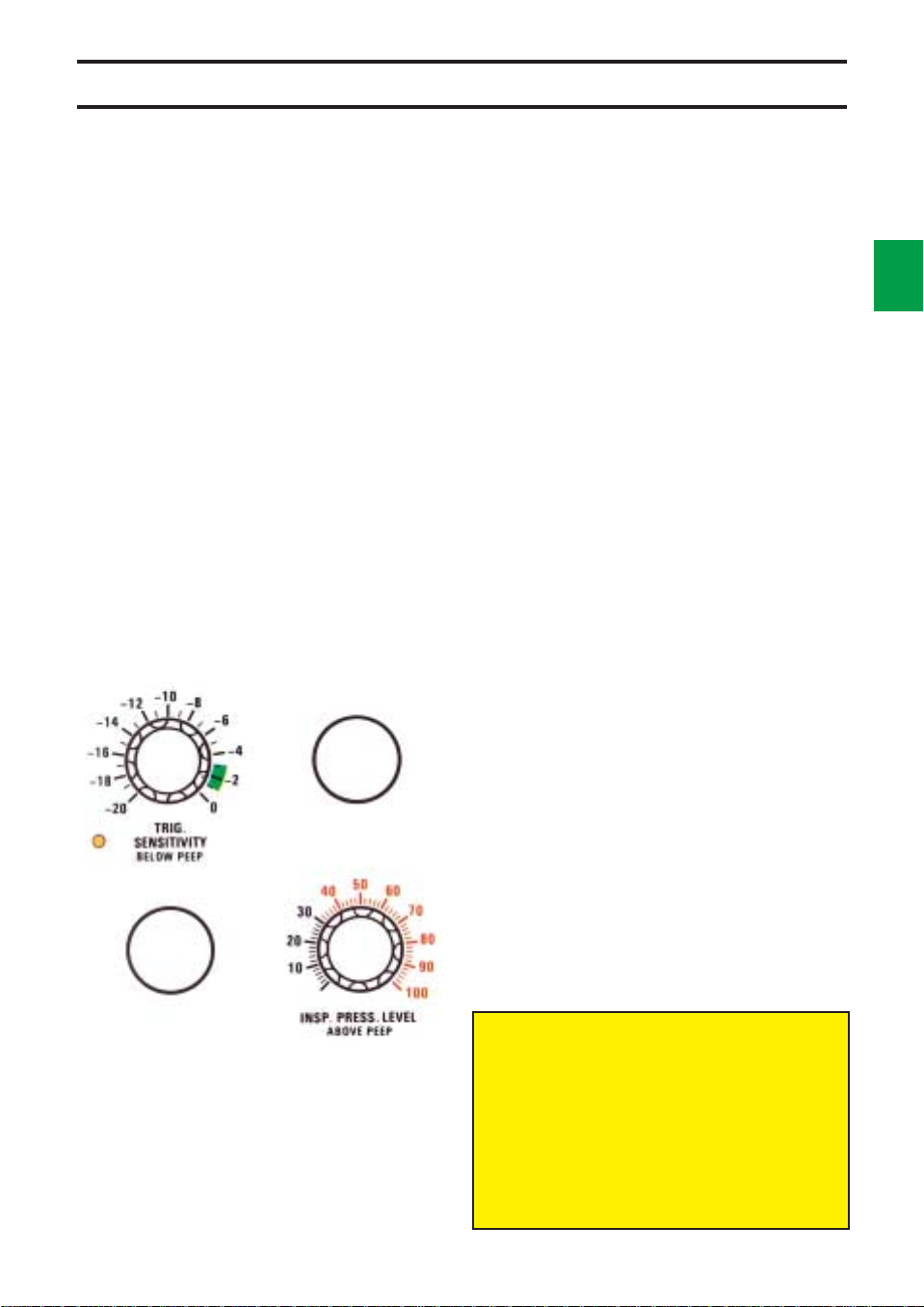

Panel functions

Trig. sensitivity

The knob TRIG. SENSITIVITY is used to set

the value of negative pressure that the patient

must produce in order to trigger a breath.

The TRIG. SENSITIVITY is relative to PEEP.

For instance, PEEP +10 and TRIG.

SENSITIVITY -2 cm H2O mean that the patient

must produce a pressure of -2 cm H

to the setting to trigger a breath.

This corresponds to a pressure of +8 cm H

relative to atmospheric pressure in the patient’s

airways.

The airway pressure, measured on the

expiration side, is compared with the preset

TRIG. SENSITIVITY + PEEP. If the airway

pressure drops below TRIG. SENSITIVITY +

PEEP, a breath is triggered.

If it is desirable for the patient to be able to

easily trigger the ventilator, the knob is set at

green value.

If it is undesirable for the patient to be able to

trigger the ventilator, the knob is set at

-20 cm H

Trig. sensitivity is connected in all modes

except MAN. For further details, see

description on different modes.

O.

2

O relative

2

2

2

9

O

Inspiratory pressure level

The knob INSP. PRESS. LEVEL is used to set

the constant inspiratory pressure, relative to

PEEP, when any of the following modes of

ventilation are used: PRESS. CONTR.,

PRESS. SUPPORT, SIMV + PRESS.

SUPPORT.

A safety catch is located at 30 cm H2O.

The total inspiratory pressure level also

includes PEEP. This is why there is a

marking under the PEEP knob leading to

the INSP. PRESS. LEVEL knob. At a PEEP

of +5 cm H

LEVEL of +15 cm H

pressure level would be +20 cm H

relative to atmospheric pressure.

O and an INSP. PRESS.

2

O, the total inspiratory

2

O,

2

Page 22

2

10

Panel functions

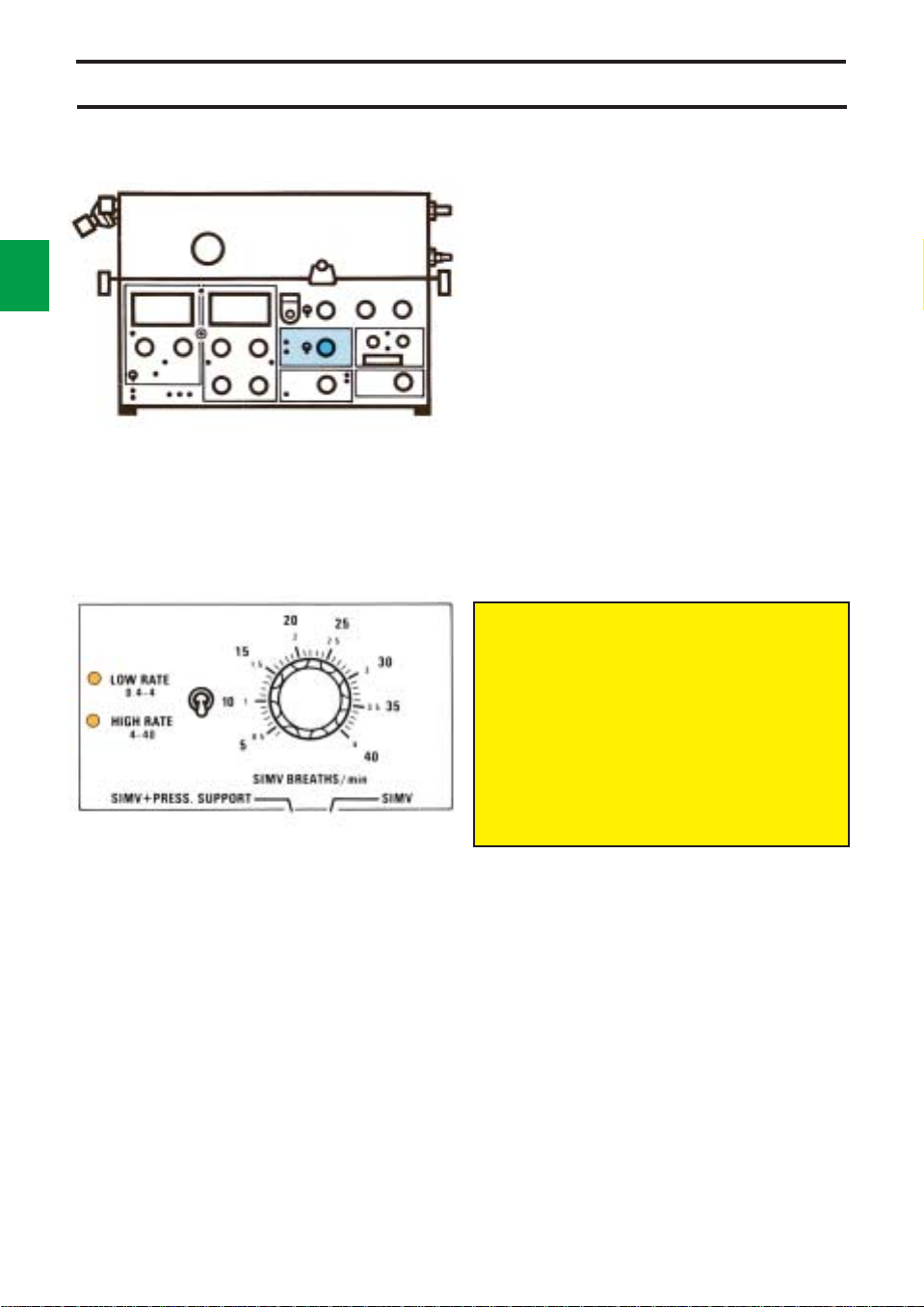

SIMV

SIMV (Synchronized Intermittent Mandatory

Ventilation) means that the patient gets

mandatory breaths controlled by the ventilator,

and that he also has the possibility of breathing

spontaneously.

The mandatory breaths are synchronized

with the breaths of the patient so that he need

not breathe against the ventilator.

SIMV-rate (SIMV BREATHS/min) is the rate

of the mandatory breaths per minute. The rate

is set between 0.4 and 4 breaths per minute on

the LOW RATE scale, and between 4 and 40

breaths/min on the HIGH RATE scale. The

desired rate is selected by means of a switch.

There are two indicating lamps, one for each

rate.

The tidal volume and the frequency can be

read on the digital display.

Minute volume, respiratory rate, inspiration

time and pause time must be set for the

SIMV mode. These functions determine the

respiratory pattern of the mandatory

breaths. The BREATHS/min must always

be set higher than the SIMV BREATHS/min

to allow time for the spontaneous period.

The SIMV cycle is divided into SIMV period and

spontaneous period. See page 2:14.

Page 23

Panel functions

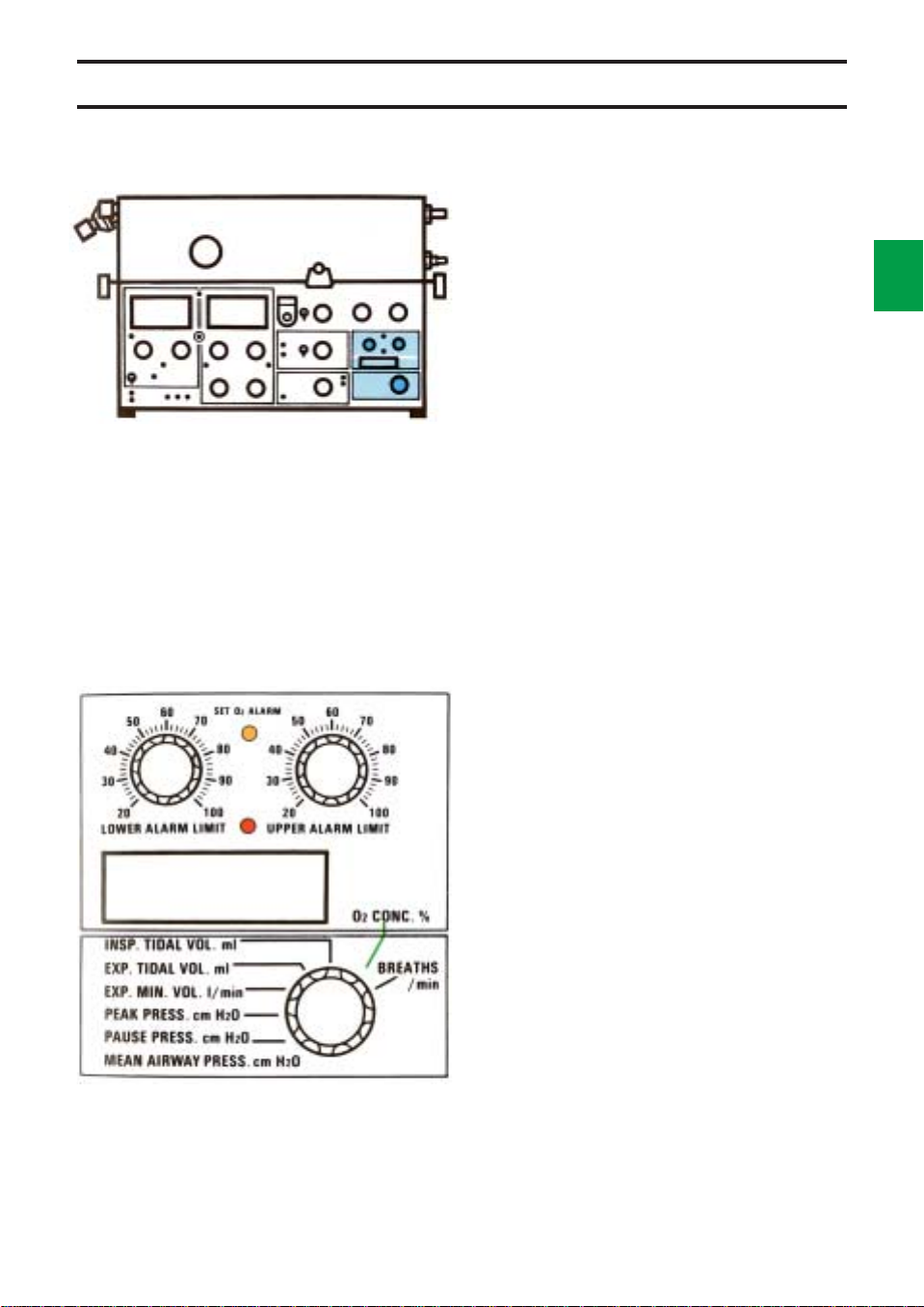

O2 alarm

Alarm limits for O2 concentration are set with the

knobs UPPER ALARM LIMIT and LOWER

ALARM LIMIT. The SET O

alarm limits have not been set.

The end stop positions for the knobs do not

coincide with the end positions on the scale.

This is correct and no attempt should be made to

alter the range.

The alarm limits are set as follows:

• Set O2 concentration on the gas mixer/

flowmeters.

• Set the parameter selector at O

and read the value.

• Set the alarm limits at approx. 6% by volume

(3 scale divisions) below and above the O

concentration reading on the digital display.

Visual and audible alarms are activated when

any of the alarm limits is exceeded.

If the O

the ventilator, the O

If not, the LOWER ALARM LIMIT will activate

alarm.

If no O2 cell is mounted, neither digital displays

nor alarm is activated when the parameter

selector is set at O2 CONC. %.

cell is expended but still mounted in

2

2

ALARM flashes if the

2

CONC. %

2

2

cell has to be disconnected.

2

11

Parameter selection

A digital display of the O2 concentration is given

when the selector is set in position O

Other displayable parameters are:

INSPIRED TIDAL VOLUME ml—the volume

provided by the ventilator at each breath.

EXPIRED TIDAL VOLUME ml—the volume

produced by the patient at each breath (with no

leakage in the patient circuit).

EXPIRED MINUTE VOLUME l/min—(also

indicated on the EXPIRED MINUTE VOLUME

meter).

PEAK PRESSURE cm H2O—the pressure at

the end of the inspiration phase.

PAUSE PRESSURE cm H

the end of the pause. This pressure normally

corresponds to the maximal alveolar pressure in

the lungs.

MEAN AIRWAY PRESSURE cm H2O—the

mean value in the patient circuit, continually

measured.

BREATHS/min—the respiratory rate of the

patient. In controlled ventilation, this value

equals the set respiratory rate plus eventual

patient triggered breaths. In the SIMV mode, it is

the sum of the spontaneous and the mandatory

breaths. In the CPAP and PRESSURE

SUPPORT modes, the value represents the

spontaneous breaths/min of the patient.

O—the pressure at

2

CONC. %.

2

Page 24

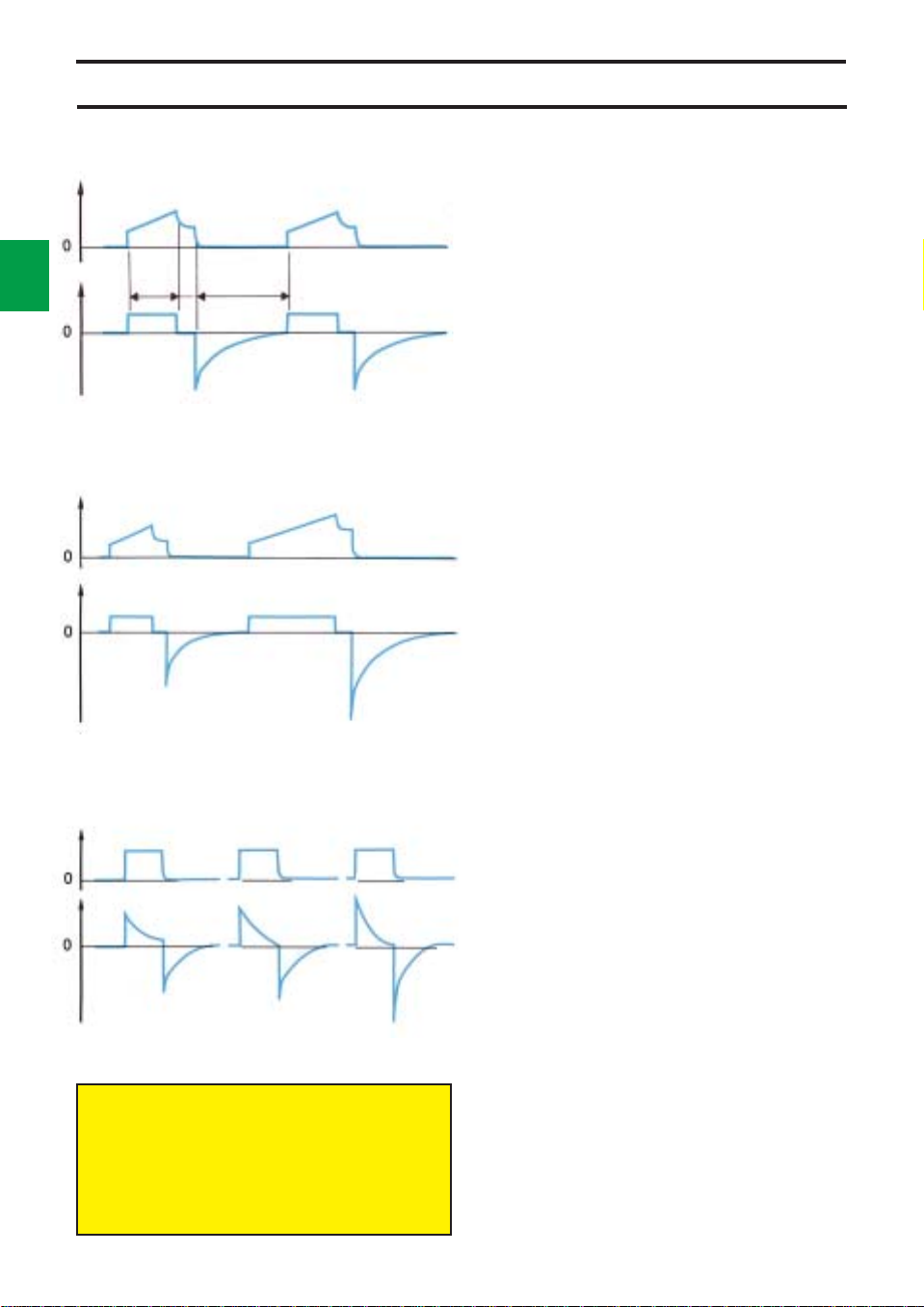

Controlled ventilation

2

12

O

2

Insp. Exp.

l/s cm H

Flow Pressure

Flow Pressure

Flow Pressure

WORKING PRESSURE and UPPER

PRESS. LIMIT must always be set at

adequate values. This is extremely

important when treating infants.

Pause

Sigh

Volume controlled ventilation

Volume controlled ventilation (VOL. CONTR.)

ensures that the patient receives a certain preset

tidal volume.

Servo Ventilator 900 C delivers a specific tidal

volume at a specific rate during a specific time

(preset values).

If the patient makes inspiratory efforts so that

the airway pressure falls below the triggering

level, a preset tidal volume will be delivered

earlier and the expired minute volume will

increase.

A constant or an accelerating flow can be

selected.

A patient trigg initiates a breath with the preset

values.

Volume controlled ventilation

+ sigh

In this mode of operation, the Servo Ventilator

900 C delivers a sigh every hundredth breath.

At sigh, double tidal volume is delivered since

the flow is constant and the inspiration time is

doubled.

The first sigh will occur at the second

inspiration after setting the mode selector to

VOL. CONTR. + SIGH.

The UPPER ALARM LIMIT for EXPIRED

MINUTE VOLUME may have to be set

somewhat higher in this mode.

Pressure controlled

ventilation

In the mode PRESS. CONTR., gas is delivered

at a constant pressure during the set inspiration

time.

The pressure is set with the knob INSP.

PRESS. LEVEL.

The flow is decelerating in this mode.

The set inspiratory pressure, respiratory rate,

and inspiration time determine the volume the

patient will receive.

Servo Ventilator 900 C works with a constant

pressure during the entire inspiration.

The minute volume can be read on the

EXPIRED MINUTE VOLUME meter.

Tidal volume can be read on the digital display

with the parameter selector in position INSP.

TIDAL VOLUME or EXP. TIDAL VOLUME.

In case of leakage in the system, e.g. due to

the use of a tracheal tube without cuff, a pause

time of 0% is recommended to ensure that the

measurement of the expired minute volume will

be as correct as possible.

A patient trigg initiates a breath with the preset

values.

Page 25

Supported ventilation

Trig.

Flow Pressure

Pressure supported

ventilation

PRESS. SUPPORT is a spontaneous breathing

mode in which the patient must trigger breaths.

Some applications for PRESS. SUPPORT

are: weaning, patients suffering from asthma

or, in post-operative use, when the patient’s

own breathing efforts are insufficient.

When the patient triggers the ventilator, an

inspiration pressure support is given at a preset

constant pressure.

The ventilator regulates the pressure during

inspiration so that it corresponds to preset

INSP. PRESS. LEVEL + PEEP.

The pressure during expiration drops to

0 cm H

occurs when the flow decreases to 25% of the

peak inspiratory flow.

change from inspiration to expiration, for

instance in the case of a leakage.

has closed the inspiratory valve and the airway

pressure has increased to +3 cm H

the preset INSP. PRESS. LEVEL + PEEP or

after 80% of the preset respiratory cycle.

Because of this safety function the respiratory

rate should always be set with the knob

BREATHS/min.

O, or alternatively to PEEP-level.

2

The change from inspiration to expiration

There are also safety functions to control the

Expiration will then start when the step motor

O above

2

2

13

Page 26

2

14

Supported ventilation

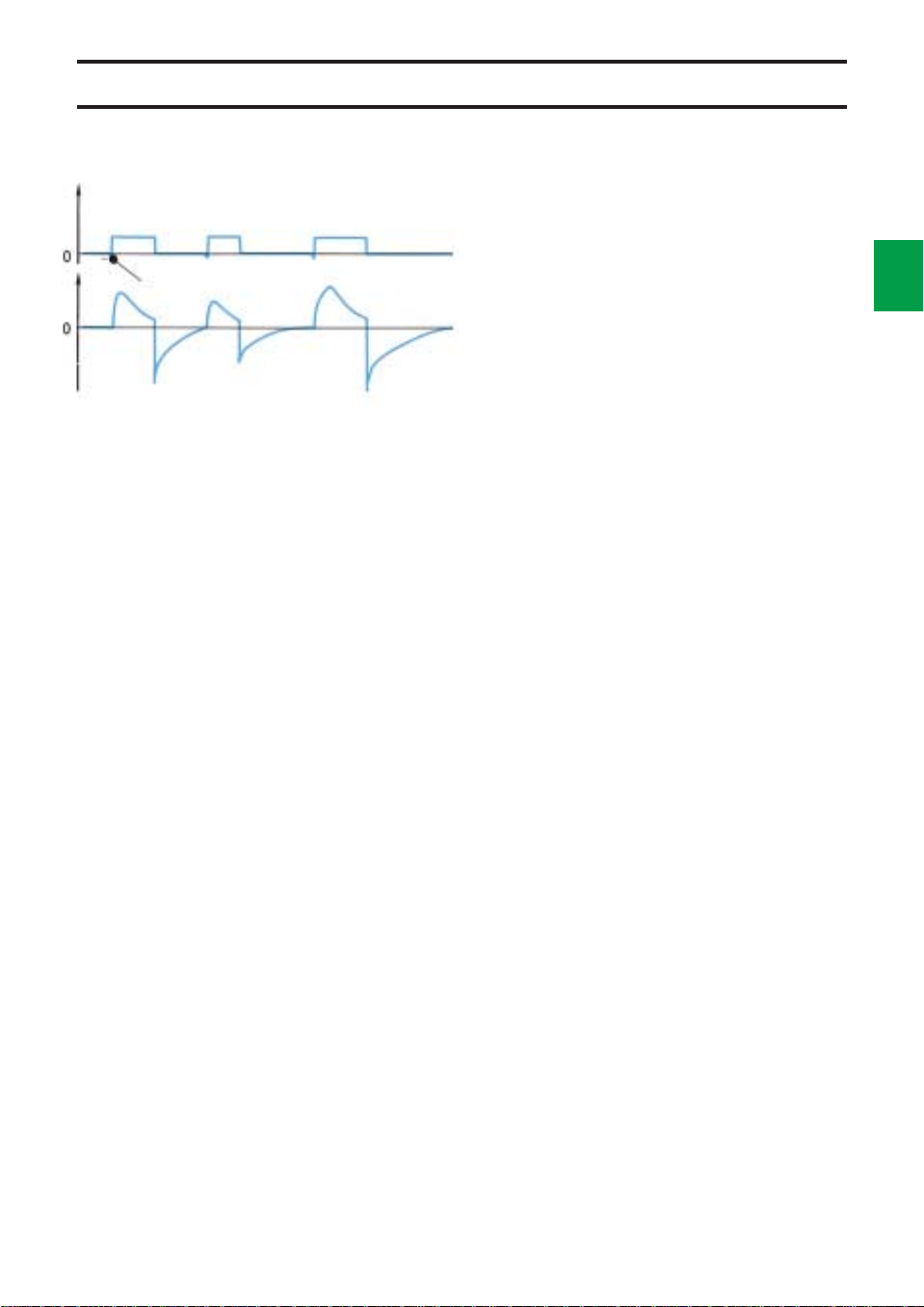

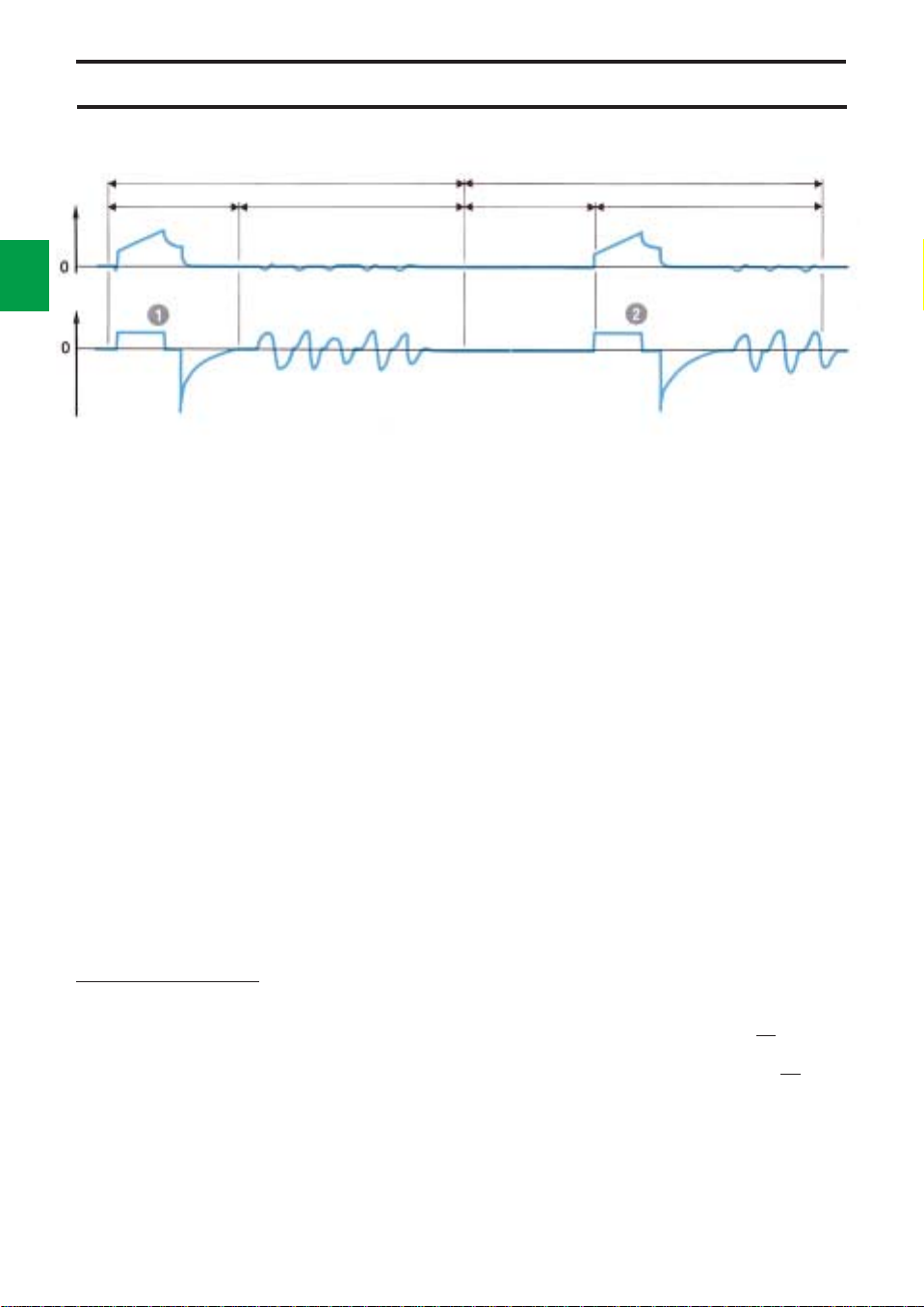

SIMV cycle 10 s SIMV cycle 10 s

SIMV period 4 s Spontaneous period 6 sSpontaneous period 6 sSIMV period 4 s

Flow Pressure

!

A patient trig. during the SIMV period initiates a

mandatory breath. After that, spontaneous

breathing.

SIMV

SIMV (Synchronized Intermittent Mandatory

Ventilation) means that a preset number of

breaths are ventilator controlled, mandatory

breaths (SlMV BREATHS/min). The patient

may breathe spontaneously between those

breaths.

Breathing pattern and tidal volume for the

mandatory breaths are selected with the knobs

PRESET INSP. MIN. VOL., BREATHS/min,

INSP. TIME % and PAUSE TIME %.

The time in seconds for one SIMV cycle is

calculated from the formula

60

preset SIMV freq.

The SIMV cycle is divided into SIMV period

and spontaneous period.

The spontaneous period consists of

spontaneous breathing time if the patient has

triggered a mandatory breath during the

previous SIMV period.

If the patient has insufficient spontaneous

breathing, the maximum time between two

mandatory breaths is just over one SIMV cycle,

(cp 1 to 2 in the picture above).

@

During the SIMV period no breath has been

triggered. The next period begins with a

mandatory breath. After that, spontaneous

breathing.

To ensure adequate ventilation, apnea alarm is

activated if the time between two breaths

exceeds approx. 15 sec., and the minute volume

alarm is activated if any of the preset alarm limits

is exceeded.

Either of these alarms is a command to take

the necessary action (e.g. clinical judgement of

the patient, increased SIMV frequency, altered

trig. sensitivity).

The SIMV period is approx. equal to one

respiratory cycle.

The spontaneous period is calculated as SIMV

cycle-SIMV period.

Example:

BREATHS/min 15 ➞ SIMV period =

SIMV BREATHS/min 6 ➞SIMV cycle =

Spontaneous period ➞10-4 = 6 s

A patient trig during the SIMV period initiates a

breath with the preset values. A patient trig

during the spontaneous period opens the

inspiratory valve, and the patient can breathe

through the ventilator.

60 = 4 s

15

60 = 10 s

6

Page 27

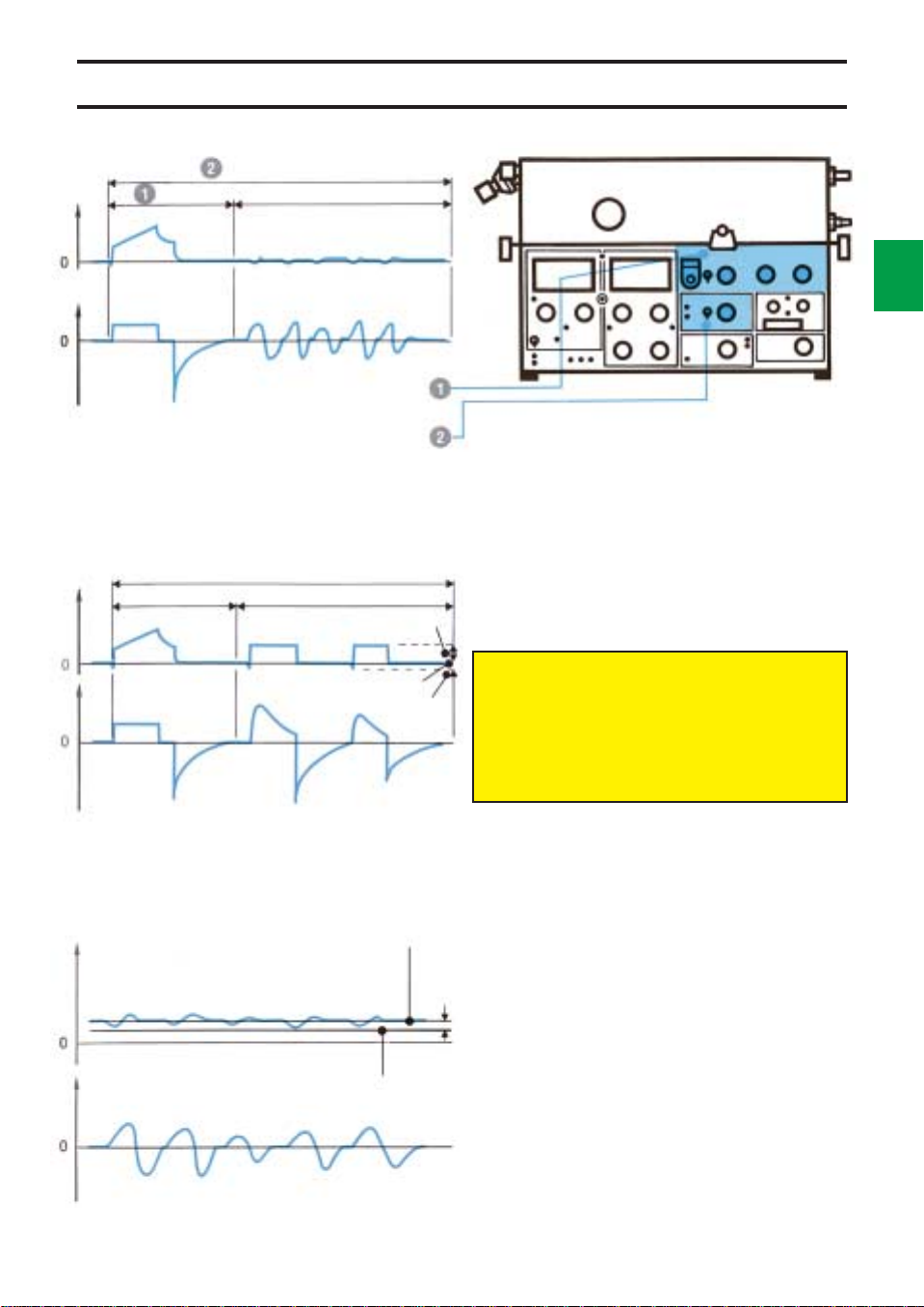

Supported and spontaneous ventilation

SIMV cycle 10 s

SIMV

period 4 s

Flow Pressure

These settings determine

the SIMV period.

This setting determines the

SIMV cycle.

SIMV cycle

SIMV period Spontaneous period

Spontaneous

period 6 s

SIMV + pressure support

The main difference between this mode and the

SIMV mode is that the spontaneous, triggered

breaths are pressure supported.

The level of support is set with the control

INSP. PRESS. LEVEL. The level also includes

PEEP.

See also description of pressure support on

page 2:13.

INSP. PRESS. LEVEL

2

15

0 or PEEP-level

TRIG. SENSITIVITY

Flow Pressure

Mandatory breath Pressure supported

spontaneous breaths

TRIG. SENSITIVITY

Flow Pressure

PEEP

Care should be taken in setting the preset

BREATHS/min, so that the spontaneous

pressure-supported breaths are not

prematurely time-cycled rather than flow-

cycled to expiration.

Spontaneous ventilation

CPAP

In this mode, CPAP (Continuous Positive Airway

Pressure), the patient breathes spontaneously

through the ventilator at an elevated pressure

level. The positive pressure is set with the

PEEP control.

The TRIG. SENSITIVITY control must be set

at a position which allows the patient to trigger

the ventilator. Upon triggering, the inspiration

valve opens, and the patient can inspire through

the ventilator and control the tidal volume and

respiratory rate.

To avoid self-triggering due to leakage, the

trig. level should be set at a low value.

If CPAP (PEEP) = 0, it will be possible to

check the patient’s ability to breathe

spontaneously without help from the ventilator.

The minute volume, tidal volume and

respiratory rate can be monitored.

Page 28

2

16

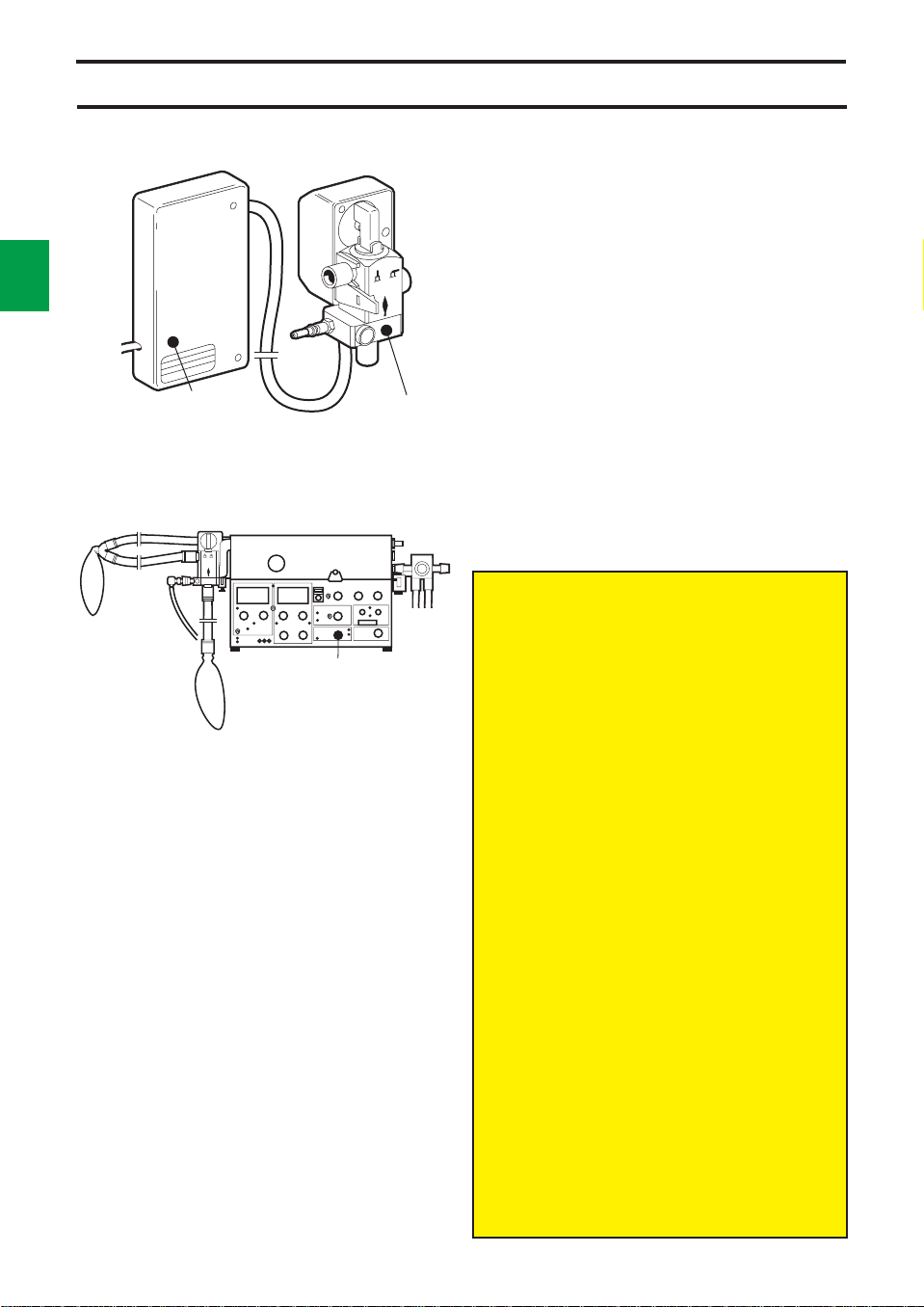

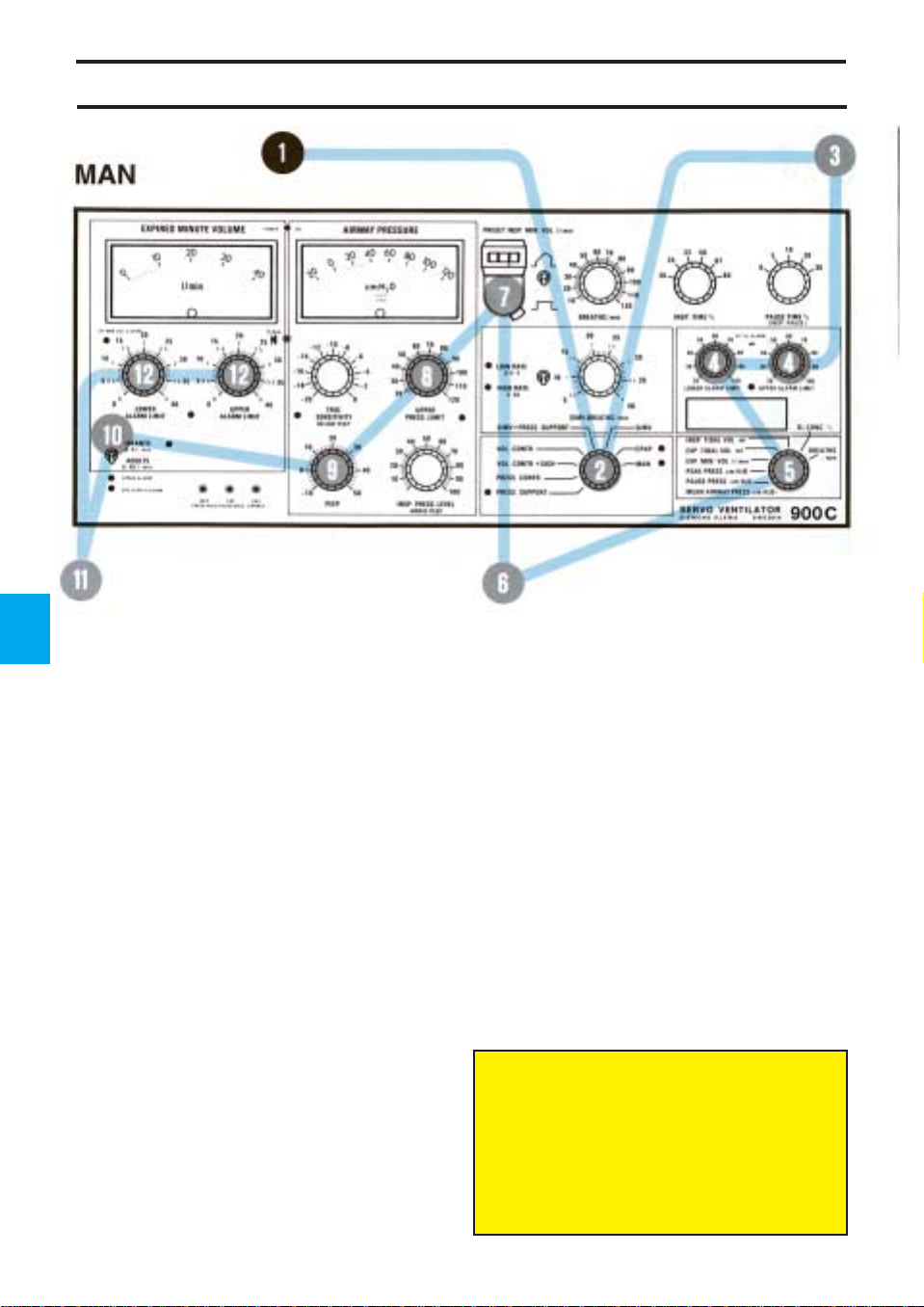

Manual ventilation

T

U

A

N

A

M

Electronic unit

MAN

AUT

Mode selector

If the breathing bag becomes overfilled, the

expiratory valve in the ventilator may go to a

locked position.

To unlock the valve:

• Set UPPER PRESS. LIMIT below 20 cm

H

O.

2

• Squeeze the breathing bag and check that

the pressure in the bag is lowered.

• Set UPPER PRESS. LIMIT back to the

lowest possible value for normal operation.

If the breathing bag becomes overfilled with

the manual ventilation valve in posotition AUT:

• Remove the breathing bag.

• Exchange the manual ventilation valve.

Motor/

valve unit

Manual ventilation

The Manual Ventilation Accessory with Motor

consists of two units:

• Electronic unit

• Motor/valve unit

With this accessory switching between

manual ventilation and other modes is done with

the mode selector.

The valve is automatically set to the correct

position by a motor. The switch-over time is

about 5 seconds. An alarm with audible signals

and red light is activated if the positions of the

valve and mode selector are not the same.

In position

pressure of about 4 cm H

valve closes.

When the breathing bag is squeezed, the gas

flows to the patient via a non-return valve.

Always set UPPER PRESS. LIMIT at the

lowest possible value for normal operation.

The APNEA alarm is inoperative during

manual ventilation.

In the case of a power failure, manual

ventilation is not possible unless an

external power pack is connected.

PEEP cannot be used in manual

ventilation mode.

Set the mode selector to VOL. CONTR.

immediately before connecting the

ventilator to a patient. The reason is to zero

the gas flow reading.

At spontaneous breathing during manual

ventilation the following readings will be

incorrect.

– the displayed values for BREATHS/min.,

EXP. TIDAL VOLUME and EXP.

MINUTE VOLUME.

– the alarm monitoring instrument

EXPIRED MINUTE VOLUME.

The accuracy of the EXPIRED MINUTE

VOLUME meter reading decreases. After

about 5 minutes, the accuracy is about

±2 l/min. To get a correct meter reading,

the breathing bag should be squeezed at

least every 5 minutes.

For spontaneous breathing, the

PRESSURE SUPPORT mode is

recommeded. The INSP. PRESS. LEVEL

should be set at zero or at a low value. This

enables continuous monitoring of pressure

and volume.

MAN., the breathing bag is filled to a

O, then the inspiratory

2

Page 29

Chapter 3

Patient safety

In this chapter:

Protective devices......... 3:2

Alarm schedule.............. 3:4

3

131

Page 30

Protective devices

3

Alarms

There are a number of alarms on the ventilator

which protect the patient by alerting ward

personnel to any malfunctions. Alarms are

given with audible signals and flashing red

lights. An audible signal only is given as alarm

for power failure and certain technical

malfunctions.

2

Some audible alarms can be switched off for

a period of approximately 2 minutes. For details

see the alarm schedule on page 3:4.

In addition there are panel indicators with

fixed or flashing yellow lights.

Examples are given in chapter 8,

Troubleshooting, regarding actions for various

alarms.

The patient is protected against high

pressure by an electronic limiter, which is

controlled by the knob UPPER PRESS. LIMIT.

If the value set with this knob is too high or if

the limiting function should fail, the pressure is

limited to the set WORKING PRESSURE.

The WORKING PRESSURE is prevented

from exceeding the set value by a safety valve

and cannot be set at values exceeding

120 cm H

As an extra patient safety protection against

too high an airway pressure, there is a HIGH

PRESSURE PROTECTION circuit incorporated

when either of the modes CPAP, PRESS.

CONTR. or PRESS. SUPPORT is selected.

This protection circuit functions when the

airway pressure in the inspiration channel for

some reason, e.g. coughing, exceeds

30 cm H

level.

O.

2

O above INSP. PRESS. LEVEL/PEEP

2

Important!

The SV 900 is not designed to withstand

severe negative pressures, which, if applied

to the system may damage the internal

pressure transducers rendering the unit

inoperable.

Transducer pressure range

SV 900 up to and including SIN 188499 are

factory equipped with pressure transducers

that will tolerate pressures down to -100 cm

H20(mbar), whereas units from S/N 188500

are factory equipped with pressure

transducers that will tolerate pressures

ranging from -500 cm H20(mbar) to +500

cm H20(mbar).

Earlier units may have been retrofitted with

Transducer Upgrade EM12102/l featuring the

same pressure tolerance as units with S/N

≥188500. Uppgraded units are identified with

a label !Upgrade EMO12/02/l’ attached to

the inside of the pneumatic unit lid.

If closed system suctioning is applied, the

following must be considered:

A suctioning flow exceeding the flow

delivered by the ventilator will result in a

negative pressure affecting the patients

airways as well as the ventilators breathing

system.

Do not use the “Pause hold” function during

the procedure.

All audible alarms, with the exception of

upper pressure limit for airway pressure and

alarm for mains power failure, are switched

off for a period of 2 minutes when the button

2 min is depressed, while the red light

continues flashing. This means that no new

audible alarm will be possible during

approximately 2 minutes.

To switch off the power failure alarm, the

button must be depressed until the audible

alarm stops.

The APNEA ALARM is not intended to

and will not monitor for disconnections.

Page 31

Protective devices

3

3

!

Set minute volume alarm

Indicates that the alarm limits for expired

minute volume have not been set.

@

Mains power failure

The green lamp for POWER ON goes out.

Slow audible signals which stop after 5-10

minutes.

#

Set O2 alarm

Indicates that the alarm limits for O

concentration have not been set.

2

$

Alarm limit, O2 concentration

Upper or lower alarm limit has been exceeded.

If no O2 cell is mounted, neither digital

displays nor alarm is given.

A deterioration in the linearity and/or a rapid

fall in the values of O

adequate O

exhausted.

supply, indicates that the O2 cell is

2

concentration, despite

2

%

Upper pressure limit, airway pressure

The airway pressure exceeds the preset upper

pressure limit. When the alarm is activated,

inspiration and/or pause in progress is

immediately terminated and changed to

expiration. The alarm is given as a single

audible signal and a visual flashing signal.

^

Alarm limit, expired minute volume

Upper or lower alarm limit has been exceeded.

There are two alarm limit settings:

UPPER ALARM LIMIT 3-43 l/min (adults)

0-4.3 l/min (infants)

LOWER ALARM LIMIT 0-37 l/min (adults)

0-3.7 l/min (infants)

&

Apnea alarm

The APNEA ALARM is activated with audible

signals and flashing light if the time between

any two consecutive breaths, spontaneous or

mandatory or a combination of the two, is

greater than approximately 15 seconds

(4 breaths per minute or less). The APNEA

ALARM is not intended to and will not monitor

for disconnections. The APNEA ALARM is

operative in CPAP, PRESS. SUPPORT, SIMV

and SIMV + PRESS. SUPPORT.

*

Gas supply alarm

This alarm is inoperative if the respiratory rate

exceeds 80 breaths/min (with inspiration time

20 or 25%).

In the CPAP and PRESS. SUPPORT modes,

a patient trig is required to activate the alarm.

Page 32

Alarm schedule

Alarm Visible Audible

SET. MIN. VOL. ALARM

SET O2 ALARM

GAS SUPPLY ALARM

Mains power failure

Alarm limit, EXP. MIN. VOL.

2 min

UPPER PRESS. LIMIT

APNEA ALARM

Alarm limit, O

CONC. %

2

*The green lamp goes out

**The button must be depressed until the alarm stops

Page 33

Chapter 4

Set-ups

The Servo Ventilator 900 C is designed for

several different applications.

It can be positioned in many different ways,

e.g. on a cart, on an anesthesia table, on a wall

rail, or in an ambulance or a helicopter.

In this chapter:

Intensive care ................ 4:2

Anesthesia ..................... 4:4

Patient transportation ... 4:6

4

141

Page 34

Intensive care 1

4

Two proposals are given regarding the set-up

of Servo Ventilator 900 C in intensive care.

This is only an example of a possible set-up.

Some of the equipment shown is available in

2

different versions, e.g. for adults and children.

For details, please see “Products and

Accessories” catalogue and, for patient tubing,

“Assembling instructions with order form”.

Basic equipment

Servo Ventilator 900 C

! Mobile cart

@ Mixer

# Clamp

$ Support arm

% Bacteria filter

^ Nipple connector

& Patient tubes

* Y-piece

( Servo Humidifier

BL Nipple connector

BM Flex tube

BN Angled connector

Extra equipment

Analyzer 930

CO

2

Lung Mechanics Calculator 940

Mingograf Recorder

Recorder Cable for Servo Ventilator 900 C

Manual ventilation accessory

Page 35

Intensive care 2

This is only an example of a possible set-up.

Some of the equipment shown is available in

different versions, e.g. for adults and children.

For details, please see “Products and

Accessories” catalogue and, for patient tubing,

“Assembling instructions with order form.”

4

3

Basic equipment

Servo Ventilator 900 C

! Mobile cart

@ Mixer

# Bacteria filter

$ Humidifier

% Nipple connector

^ Patient tubes

& Muff, angled

* Nipple

( Nipple

BL Flex tube

BM Angled connector

BN Cup for water trap

BO Exp. water trap

BP Water trap

BQ Y-piece

Extra equipment

Analyzer 930

CO

2

Lung Mechanics Calculator 940

Mingograf Recorder

Recorder Cable for Servo Ventilator 900 C

Manual ventilation accessory

Page 36

Anesthesia 1

4

Two proposals are given regarding the set-up

of Servo Ventilator 900 C in anesthesia

applications.

This is only an example of a possible set-up.

Some of the equipment shown is available in

4

different versions, e.g. for adults and children.

For details, please see “Products and

Accessories” catalogue and, for patient tubing

“Assembling instructions with order form”.

Basic equipment

Servo Ventilator 900 C

! Mobile cart

@ Mixer

# Vaporizer

$ Bacteria filter

% Nipple connector

^ Manual ventilation accessory

& Tube

* Tube joint

( Breathing bag

BL Patient tubes

BM Y-piece

BN Servo Humidifier

BO Nipple connector

BP Flex tube

BQ Angled connector

BR Gas evacuation equipment

Extra equipment

Analyzer 930

CO

2

Lung Mechanics Calculator 940

Mingograf Recorder

Recorder Cable for Servo Ventilator 900 C

Page 37

Anesthesia 2

This is only an example of a possible set-up.

Some of the equipment shown is available in

different versions, e.g. for adults and children.

For details, please see “Products and

Accessories” catalogue and, for patient tubing,

“Assembling instructions with order form.”

4

5

Basic equipment

Servo Ventilator 900 C

Anesthesia table

Rotameter box

! Mixer

@ Bacteria filter

# Nipple connectors

$ Manual ventilation accessory

% Tube

^ Tube joint

& Breathing bag

* Patient tubes

( Y-piece

BL Servo Humidifier

BM Nipple connector

BN Flex tube

BO Angled connector

BP Gas evacuation equipment

Suction equipment

Extra equipment

Analyzer 930

CO

2

Lung Mechanics Calculator 940

Mingograf Recorder

Recorder Cable for Servo Ventilator 900 C

Page 38

Patient transportation

4

A proposal is given regarding the set-up of

Servo Ventilator 900 C during patient

transportation within the hospital, in an

ambulance or a helicopter.

This is only an example of a possible set-up.

6

Some of the equipment shown is available in

different versions, e.g. for adults and children.

For details, please see “Products and

accessories” catalogue and, for patient tubing

“Assembling instructions with order form”.

Basic equipment

Servo Ventilator 900 C

! Mobile cart

@ Mixer

# Vaporizer

$ Bacteria filter

% Manual ventilation accessory

^ Tube

& Tube joint

* Breathing bag

( Patient tubes

BL Y-piece

BM Servo Humidifer

BN Nipple connector

BO Flex tube

BP Angled connector

Power pack

Gas cylinders

Extra equipment

CO2 Analyzer 930

Lung Mechanics Calculator 940

Page 39

Chapter 5

Preparations

If any malfunction is detected during the

preparations, see chapter 8, Troubleshooting, or

chapter 13, Calibration.

In this chapter:

Prechecks and

presettings..................... 5:2

Connections................... 5:3

5

151

Page 40

5

Prechecks and presettings

2

VOL. CONTR.ADULTS

!

Make sure that the ventilator has been cleaned

(see the log sheet).

@

Set the following on the ventilator:

• Mode selector at VOL. CONTR.

• Alarm limits to end positions, according to the

picture.

• Scale range for ADULTS.

• TRIG. SENSITIVITY to –20 cm H

• UPPER PRESS. LIMIT to 80 cm H

• PEEP and INSP. LEVEL to 0 cm H

O.

2

O.

2

O.

2

#

Make sure that the meters for EXPIRED

MINUTE VOLUME and AIRWAY PRESSURE

give a zero reading. If not, see Calibration,

chapter 13.

Page 41

Connections

POWER ON

GAS SUPPLY ALARM

SET MIN. VOL. ALARM

SET O

ALARM

2

!

Connect patient tubes, holder arm, humidifier,

test lung and, if required, manual ventilation

accessory and gas evacuation accessory.

For details, see previous chapter.

The Manual Ventilation Accessory 963

must not be connected to Servo Ventilator

900 C. Always use the manual ventilation

accessory intended for Servo Ventilator

900 C only.

@

If required, connect CO2 Analyzer 930 and Lung

Mechanics Calculator 940.

#

• Connect the ventilator to mains.

• Set the mains switch on the rear of the

ventilator to on. The switch has to be pulled

out before switching.

• Make sure that the green lamp lights up when

you switch on.

• Make sure that the meters for EXPIRED

MINUTE VOLUME and AIRWAY PRESSURE

still give a zero reading. If not, see

Calibration, chapter 13.

• Make sure that the GAS SUPPLY ALARM

activates.

• Make sure that the SET MIN. VOL. ALARM

and SET O

ALARM flash.

2

5

3

$

Connect gases :

Alternative 1, via O

O

-air mixer

2

• Set the desired O2 concentration.

At extremely high flows it may be

necessary to increase the working

pressure, in order to obtain the desired

minute volume.

-air mixer or via O2-N2O/

2

Page 42

5

Connections

4

Alternative 2, via O2-N2O/O2-air mixer and

vaporizer

• Connect a Halothane, Enflurane or Isoflurane

vaporizer.

• Set the desired O

Alternative 3, via low-pressure flowmeters

• Connect O

flowmeters, necessary pressures at least

equal to WORKING PRESSURE.

• Set the desired flow proportions of O

N

O on the flowmeters, so that the total gas

2

flow exceeds PRESET INSP. MIN. VOL. of

the ventilator by 10-20%. The working

pressure will be constant and the flow pattern

unchanged in mode VOL. CONTR. In other

ventilation modes, only breaths with limited

tidal volumes can be maintained. The

limitation is shown by falling WORKING

PRESSURE.

Alternative 4, compressed air

• Connect compressed air.

2-N2

concentration.

2

O (air) via low-pressure

and

2

Check on functions

• Carry out a check on functions according to

chapter 6.

Page 43

Chapter 6

Check on

functions

A check on functions must always be carried out

after cleaning and before connecting a patient.

Accessories: Patient tubes, Y-piece, test lung

and manual ventilation accessory. If any

malfunction is detected during the check, see

chapter 8, Troubleshooting, or chapter 13,

Calibration.

In this chapter:

1. Checks prior to

connection of power

and gas....................... 6:2

2. Start-up.......................6:2

3. Check for leakages....6:3

6

161

4. Check, manual

ventilation................... 6:3

5. Upper pressure limit

alarm........................... 6:4

6. Minute volume ...........6:4

7. Minute volume alarm.6:4

8. O

alarm...................... 6:5

2

9. Apnea alarm............... 6:5

10. Digital display ............6:6

11. Check on pressure

levels ..........................6:6

12. Mains supply failure ..6:6

13. Log sheet....................6:6

Page 44

6

Prechecks

ADULTS

2

VOL. CONTR.

If preparation and prechecks, according to

chapter 5, have been done, start from para. 3.

1. Checks prior to

connection of power and gas

• Connect patient tubes, Y-piece, holder arm

and humidifier.

• Make sure that the meters for AIRWAY

PRESSURE and EXPIRED MINUTE

VOLUME give a zero reading.

• Set the mode selector at VOL. CONTR.

• Set alarm limits to end positions, according

to the picture.

• Set the scale range for ADULTS.

• Set the TRIG SENSITIVITY to -20 cm H

• Set the UPPER PRESS. LIMIT to 80 cm H

• Set PEEP and INSP. PRESS. LEVEL to

0 cm H2O.

O.

2

O.

2

2. Start-up

• Connect the ventilator to mains.

• Set the mains switch on the rear of the

ventilator to on.

• Make sure that the green lamp lights up

when you switch on.

• Make sure that the meters for AIRWAY

PRESSURE and EXPIRED MINUTE

VOLUME still give a zero reading.

• Make sure that GAS SUPPLY ALARM

activates.

• Make sure that SET MIN. VOL. ALARM and

SET O

ALARM flash.

2

POWER ON SET O

SET MIN. VOL. ALARM

GAS SUPPLY ALARM

ALARM

2

Page 45

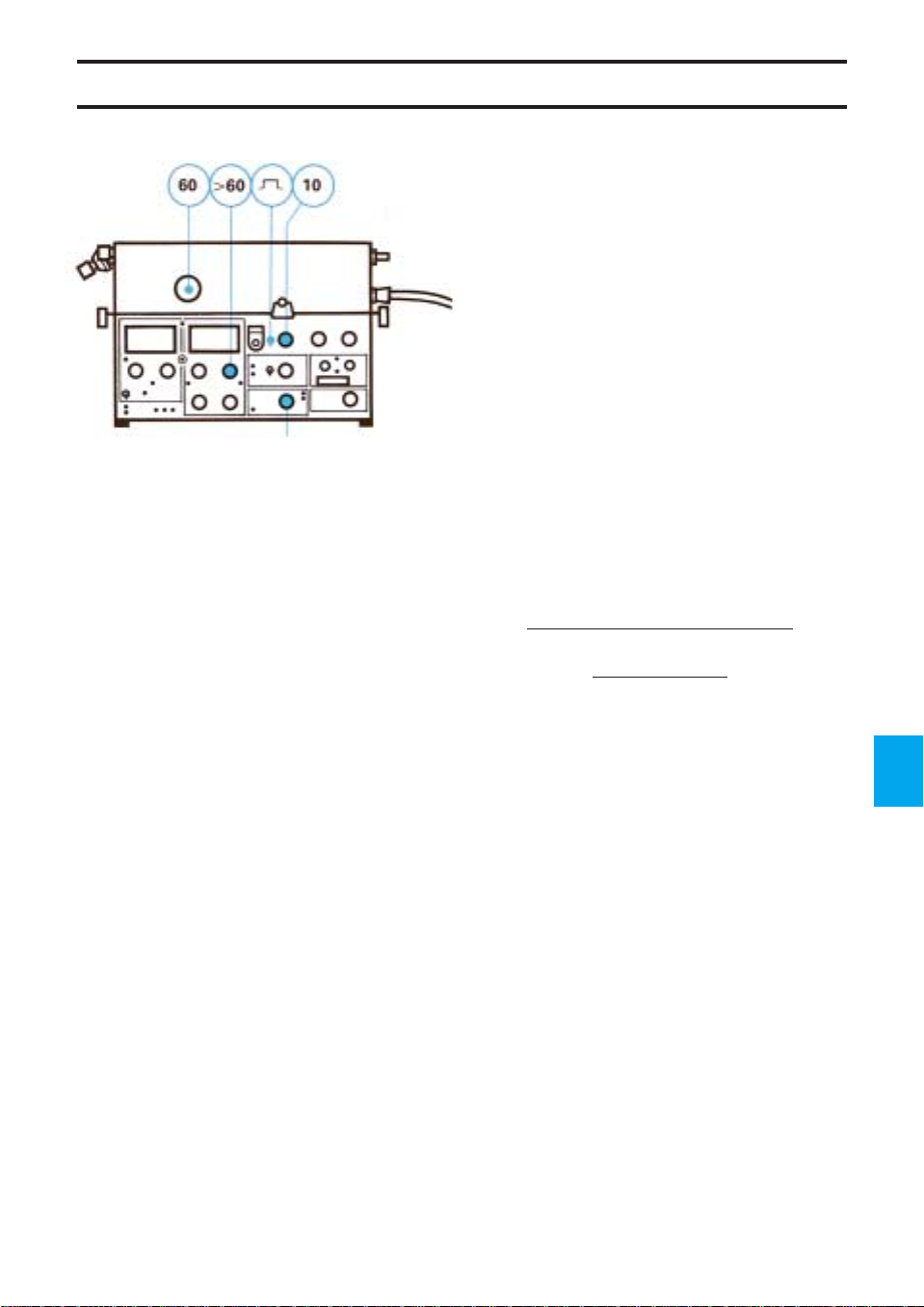

900C003S

1

60

7.5

INSP.=

10

60

25

30

EXP.=

3. Check for leakage

• Connect gases according to chapter 5.

• Set the following: WORKING PRESSURE:

60 cm H

min., BREATHS/min.: 10, PAUSE TIME:

30%, constant flow and INSP. TIME: 25%.

• Cover the Y-piece/Servo Humidifier and

make sure that AIRWAY PRESSURE and

the manometer WORKING PRESSURE

0

show the same reading during inspiration

and pause.

• Press and hold the INSP. PAUSE HOLD

button and make sure that the AIRWAY

PRESSURE reading does not drop more

than 3 cm H

• Release INSP. PAUSE HOLD and make

sure that the AIRWAY PRESSURE reading

falls to 0 during expiration.

• If AIRWAY PRESSURE drops more than

allowed, block the outlet pipe on the insp.

side and repeat as described. If the pressure

drop is within the allowed limit, the leakage is

to be found in the breathing system or the

exp. channel.

O, PRESET INSP. MIN. VOL.: 7.5 l/

2

O during 5 seconds.

2

6

3

VOL. CONTR.

VOL.CONTR + SIGH

PRESS. CONTR.

PRESS. SUPPORT

900C004S

3

5

O2 FLUSH

9

7

CPAP

MAN.

4

6

8

2

VOL. CONTR.

VOL.CONTR + SIGH

PRESS. CONTR.

PRESS. SUPPORT

VOL. CONTR.

VOL.CONTR + SIGH

PRESS. CONTR.

PRESS. SUPPORT

VOL. CONTR.

VOL.CONTR + SIGH

PRESS. CONTR.

PRESS. SUPPORT

10

MAN

4. Check of manual

ventilation accessory

Applicable to manual ventilation accessory with

motor.

1. Attach a test lung.

CPAP

CPAP

MAN.

CPAP

MAN.

MAN.

0

2. Separate the valve and the motor units and

make sure that alarm is activated.

3. Set mode selector to MAN and make sure

that alarm is activated.

4. Set the valve arm to MAN and attach the

valve unit to the motor unit.

5. Push O

FLUSH and make sure that the

2

breathing bag fills.

6. Set VOL. CONTR.

7. Compress the breathing bag and make

sure that there is no leakage (the gas

remains in the breathing bag).

8. Set MAN.

9. Compress the breathing bag with one hand

to fill the test lung. With the other hand,

immediately compress the test lung and

make sure that the expiration valve opens.

10. Let the breathing bag hang loose and be

filled. Then make sure that the EXPIRED

MINUTE VOLUME meter drops to 0.

Page 46

6

4

Alarms

UPPER PRESS. LIMIT

MIN. VOL. ALARM

VOL. CONTR.

EXP. MIN.

VOL. l/min

5. Upper pressure limit alarm

• Set the mode selector at VOL. CONTR.

• Block the Y-piece/Servo Humidifier.

• Turn the knob UPPER PRESS. LIMIT to

55 cm H

• Make sure that inspiration is terminated and

the alarm is activated.

• Turn the knob back to 80 cm H

O.

2

O.

2

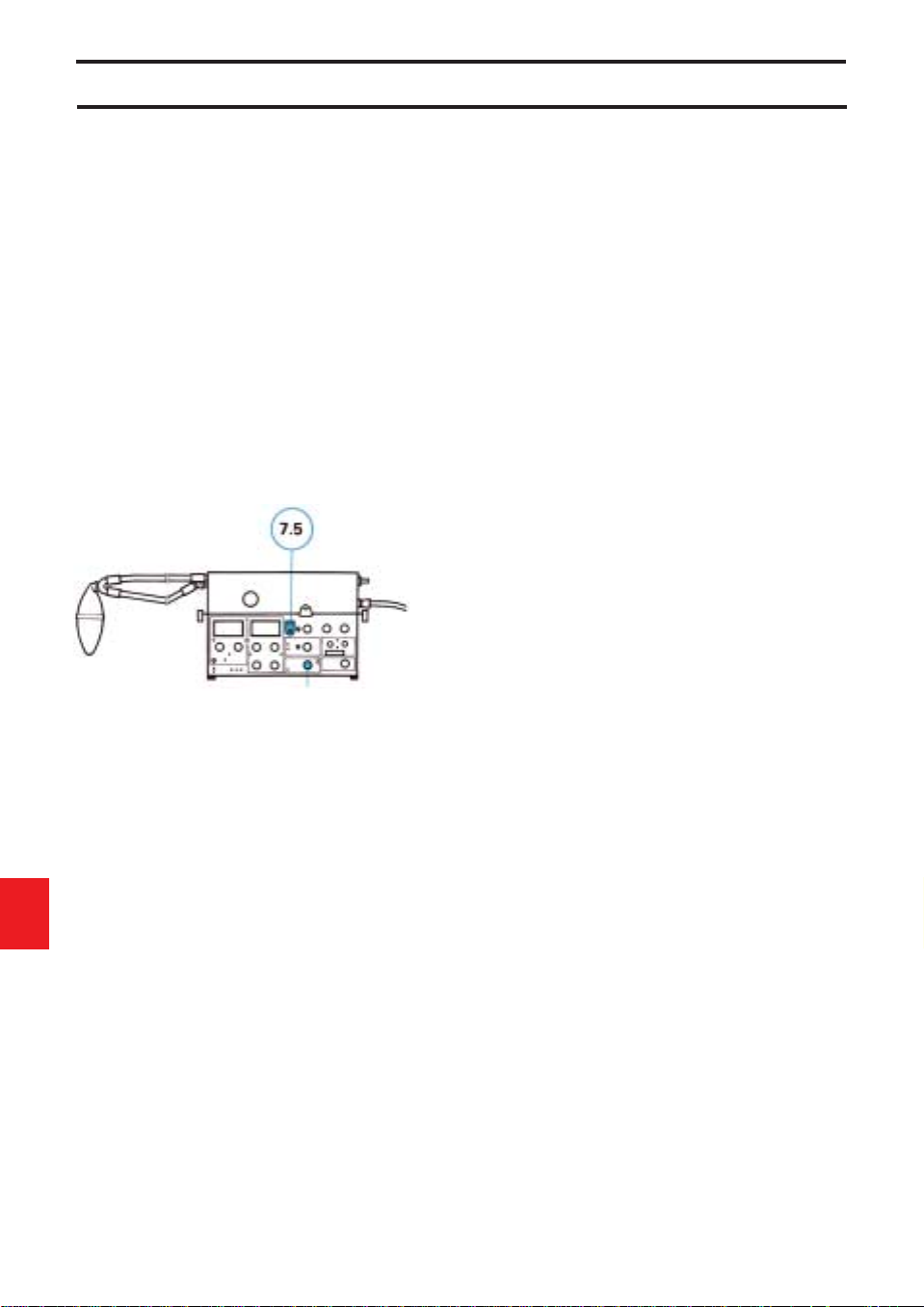

6. Minute volume

• Set the respiratory rate at 20 BREATHS/min.

• Connect a test lung.

• Set the parameter selector at EXP. MIN.

VOL. l/min.

• Make sure that the digital display and the

meter EXPIRED MINUTE VOLUME read

7.5 ± 0.5 l/min after a few minutes.

7. Minute volume alarm

Lower alarm limit

• Turn the knob LOWER ALARM LIMIT to

7.5 l/min and make sure that the alarm is

activated at 7.5 ± 0.5 l/min.

• Turn the knob LOWER ALARM LIMIT to

0 l/min.

If gas evacuation should be used:

• Connect the gas evacuation accessory.

• Set the LOWER ALARM LIMIT to the value

which is to be used during the treatment.

• Remove the test lung (“disconnect”).

• Make sure that the LOWER ALARM LIMIT is

activated.

• Make sure that the EXPIRED MINUTE

VOLUME meter reading is at least 25%

below the alarm limit setting.

• If the alarm is not activated:

—Set PEEP to 1 cm H

—Check the alarm and meter reading as

described above

or

—Decrease the evacuation flow until the

alarm is activated. Also check the meter

reading as described above.

Upper alarm limit

• Turn the knob UPPER ALARM LIMIT to

7.5 l/min and make sure that the alarm is

activated at 7.5 ± 0.5 l/min.

• Turn the knob UPPER ALARM LIMIT to

40 l/min.

O

2

Page 47

AlarmasAlarms

8. O2 alarm

900C000S

900C001S

60

O

KONC. %

2

O

CONC. %

2

O2 LARM

O

ALARM

2

20-

22%

When checking the O2 alarm, the working

pressure must be 60 cm H

O since the O

2

2

cell is calibrated at this pressure.

If there is no O

given when O

cell, no digital display is

2

CONC. % is set on the

2

parameter selector.

If the O

cell is expended but still

2

mounted, it has to be disconnected. If not,

the LOWER ALARM LIMIT will be

activated.

A deterioration in the linearity and/or a

rapid fall in the values of O

despite adequate O

cell is exhausted.

the O

2

2

• Set the parameter selector at O

• Set the gas mixer at the lowest O

concentration,

2

supply, indicates that

CONC. %.

2

2

concentration value (air) and make sure that

the digital display shows 20-22%.

• Set the gas mixer so that 40% is read on the

digital display.

Lower alarm limit

• Turn LOWER ALARM LIMIT clockwise and

make sure that alarm is activated when the

knob setting corresponds to the digital

display (±1 scale division).

• Turn LOWER ALARM LIMIT to 18%.

Upper alarm limit

• Turn UPPER ALARM LIMIT counterclockwise and make sure that alarm is

activated when the knob setting corresponds

to the digital display (±1 scale division).

• Turn UPPER ALARM LIMIT to 100%.

6

5

APNEA ALARM

PRESS. SUPPORT

9. Apnea alarm

• Set TRIG. SENSITIVITY at -10.

• Set the mode selector at PRESS.

SUPPORT.

• Make sure that the APNEA ALARM is

activated approx. 15 s after the mode

change.

Page 48

6

Pressures

6

BREATHS/min

PRESS. CONTR.

EXP.

10. Digital display

• Set the parameter selector at BREATHS/min.

• Make sure that the value set with the

BREATHS/min knob corresponds to the

BREATHS/min value read on the digital

display.

11. Check on pressure levels

• Set the mode selector at PRESS. CONTR.

• Set BREATHS/min. to lowest value.

• Set PEEP at +10 cm H

• Set INSP. PRESS. LEVEL at +10 cm H

• Make sure that the reading on the AIRWAY

PRESSURE meter remains at

+20 ± 2 cm H

• Make sure that a PEEP level of

10 ± 2 cm H2O is maintained on the AIRWAY

PRESSURE meter at the end of expiration.

• Set PEEP and INSP. PRESS. LEVEL at

0 cm H

• Set the mode selector at VOL. CONTR.

O during inspiration.

2

O.

2

O.

2

O.

2

VOL. CONTR.

12. Mains supply failure

alarm

• Switch off the ventilator with the mains switch

on the rear.

• Make sure that the green lamp POWER ON

goes out and the audible alarm sounds.

13. Log sheet

• Note on the log sheet that a check on

functions has been carried out.

If any malfunctions are detected during the

check, see chapter 8, Troubleshooting, or

chapter 13, Calibration.

Page 49

Chapter 7

Connection to

patient

Be careful when moving the ventilator from the

preparation room to the operating theatre. If you

bump into something, it may be necessary to

check the functions before connection to

patient.

For detailed description of the functions, see

chapter 2.

Always start with ventilator checked

according to chapter 6.

In this chapter:

7

171

Compressible volume and

dead space........................7:2

Controlled ventilation

VOL. CONTR. or

VOL. CONTR. + SIGH ..............

PRESS. CONTR. ......................7:5

7:4

Supported ventilation

PRESS. SUPPORT...................7:6

SIMV..........................................7:7

SIMV + PRESS. SUPPORT......7:8

Spontaneous ventilation

CPAP.........................................7:9

Manual ventilation

MAN ....................................... 7:10

Page 50

7

Compressible volume and dead space

Compensation for

compressible volume

Some of the preset minute volume does not

reach the patient because it is needed for

compression of gas in tubes and humidifier.

The compressible volume of the Servo

Ventilator itself is negligible.

When setting the preset insp. minute volume,

the compressible volume must be compensated

for by adding a corresponding minute volume to

the minute volume for the patient.

Compensation procedure

!

Connect the complete breathing system with

patient tubes and Servo Humidifier or heater

humidifier to the Servo Ventilator.

@

2

VOL. CONTR.

INSP. TIDAL VOL.

Set WORKING PRESSURE at 60 cm H2O.

#

Set the front panel values as shown. (Values

marked in green).

$

Set PRESET INSP. MIN. VOL. at 10 l/min.

%

Set UPPER PRESS. LIMIT for AIRWAY

PRESSURE at 80 cm H

^

Set the parameter selector at INSP. TIDAL

VOLUME.

&

Block the opening of the Y-piece/Servo

Humidifier.

*

Note the reading on the INSP. TIDAL VOLUME

(ml) display.

O.

2

Page 51

Compressible volume and dead space

(

Set the Servo Ventilator as desired for the

patient (including the desired minute volume for

the patient) and connect the patient. See pages

7:4 to 7:10.

PAUSE

PRESS.

PRESET INSP.

MIN. VOL. (l/min)

BL

Set the parameter selector at PAUSE

PRESSURE and read actual pause pressure

when the patient is connected.

BM

Calculate compensation (l/min) for compressible

volume =

read INSP. TIDAL. VOLUME (ml)

according to item 8 above

=

read PAUSE PRESSURE (cm H2O)

according to item 10 above

1000 (ml/l)

60 (cm H2O)

×

set BREATHS/

min according

×

to item 9 above

BN

Set PRESET INSP. MIN. VOL. = desired minute

volume for the patient + compensation (l/min)

Example 1 (Servo Humidifer):

Read INSP. TIDAL VOLUME (item 8) = 54 ml (at pause pressure 60 cm H2O).

Desired minute volume for the patient = 7.5 l/min.

Set BREATHS/min (item 9) = 15.

Read PAUSE PRESSURE (item 10) = 22 cm H

Compensation for compressible volume (item 11) = 54 ×22

PRESET INSP. MIN. VOL. (item 12) 7.5 + 0.3 = 7.8 l/min.

Example 2 (Heater humidifier):

Read INSP. TIDAL VOLUME (item 8) = 88 ml (at pause pressure 60 cm H2O).

Desired minute volume for the patient = 9.0 l/min.

Set BREATHS/min (item 9) = 17.

Read PAUSE PRESSURE (item 10) = 24 cm H

Compensation for compressible volume (item 11) = 88 ×24

PRESET INSP. MIN. VOL. (item 12) 9.0 + 0.6 = 9.6 l/min.

for compressible volume (calculated in item

11 above).

O.

2

1000 60

1000 60

× 15 = 0.3 l/min.

O.

2

× 17 = 0.6 l/min.

7

3

– Servo Humidifier 151 : 35 ml

– Servo Humidifier 152: 55 ml

– Servo Humidifier 153 (incl. flex tube): 70 ml

– CO

cuvette adult (for CA 930/CM 130) : 5 ml

2

cuvette infant (for CA 930/CM 130) : 2.5 ml

– CO

2

Compensation for dead space

When setting PRESET INSP. MINUTE VOLUME,

dead space in the breathing system between the

Y-piece and the patient should also be

compensated for.

Dead space for some accessories is shown in

the table to the left.

Page 52

Controlled ventilation

VOL. CONTR. or VOL. CONTR. + SIGH

7

4

Connect the patient

!

Set the WORKING PRESSURE.

@

Set the mode selector at VOL. CONTR. or VOL. CONTR. +

SIGH.

#

Set the desired minute volume (e.g. by means of a Radford

nomogram).

$

Select the curve shape for the inspiration flow.

%

Set the respiratory rate, BREATHS/min.

^

Set the INSP. TIME %.

&

Set the PAUSE TIME %.

*

Set the mixer.

(

Set the LOWER ALARM LIMIT and UPPER ALARM LIMIT

for O

CONC. %.

2

BL

Set the parameter selector.

BM

Set the PEEP-level.

To protect the patient against high pressures,

always start from a low value.

BN

Set the UPPER PRESS. LIMIT for AIRWAY PRESSURE to

approximately 10 cm H

O above the patient’s airway pressure.

2

BO

Set the TRIG. SENSITIVITY.

BP

Set the scale INFANTS/ADULTS.

BQ

Connect the ventilator to the patient and check:

– that the patient’s chest rises and falls in time with the preset

respiratory rate.

– the tidal volumes on the digital display and the reading on the

EXPIRED MINUTE VOLUME meter.

– that the AIRWAY PRESSURE meter gives a reading during

inspiration, and that the reading falls to 0 cm H

alternatively, to PEEP-level during expiration.

O or,

2

BR

Set the LOWER ALARM LIMIT and UPPER ALARM LIMIT for

EXPIRED MINUTE VOLUME. If the VOL. CONTR. + SIGH

mode is selected, it may be necessary to increase the UPPER

ALARM LIMIT for EXPIRED MINUTE VOLUME as well as the

UPPER PRESS. LIMIT for AIRWAY PRESSURE. This is done

in order to avoid activating the alarms when the sigh occurs.

In VOL. CONTR. or VOL. CONTR. + SIGH mode

with respiratory rate above 80 BREATHS/min,

INSP. TIME % should be set at 33 or 50%.

Otherwise the ventilator may give incorrect

minute volumes and incorrect EXPIRED

MINUTE VOLUME meter readings.

Page 53

Controlled ventilation

PRESS. CONTR.

Connect the patient.

!

Set the WORKING PRESSURE.

@

Set the mode selector at PRESS. CONTR.

#

Set the respiratory rate, BREATHS/min.

$

Set the INSP. TIME %.

%

Set the PAUSE TIME %.

^

Set the mixer.

&

Set the LOWER ALARM LIMIT and UPPER

ALARM LIMIT for O

CONC. %.

2

*

Set the parameter selector.

(

Set the INSP. PRESS. LEVEL.

BL

Set the PEEP-level.

To protect the patient against high pressures,

always start from a low value.

BM

Set the UPPER PRESS. LIMIT for AIRWAY

PRESSURE.

BN

Set the TRIG. SENSITIVITY.

BO

Set the scale INFANTS/ADULTS.

BP

Connect the patient and adjust the INSP.

PRESS. LEVEL so that the patient receives

decided tidal volumes and check:

– the reading on the EXPIRED MINUTE

VOLUME meter.

– that the AIRWAY PRESSURE meter gives a

reading during inspiration, and that the reading

falls to 0 cm H

level, during expiration.

O, or alternatively, to PEEP-

2

BQ

Set the LOWER ALARM LIMIT and UPPER

ALARM LIMIT for EXPIRED MINUTE VOLUME.

7

5

Page 54

Supported ventilation

PRESS. SUPPORT

7

6

Connect the patient

!

Set the WORKING PRESSURE.

@