Page 1

1425.01A/BORTHOSTAR II

Operating instructions

Mobile operating

and extension table

for:

traumatology

orthopaedics

spinal surgery

Englisch

GA142501GB03

Page 2

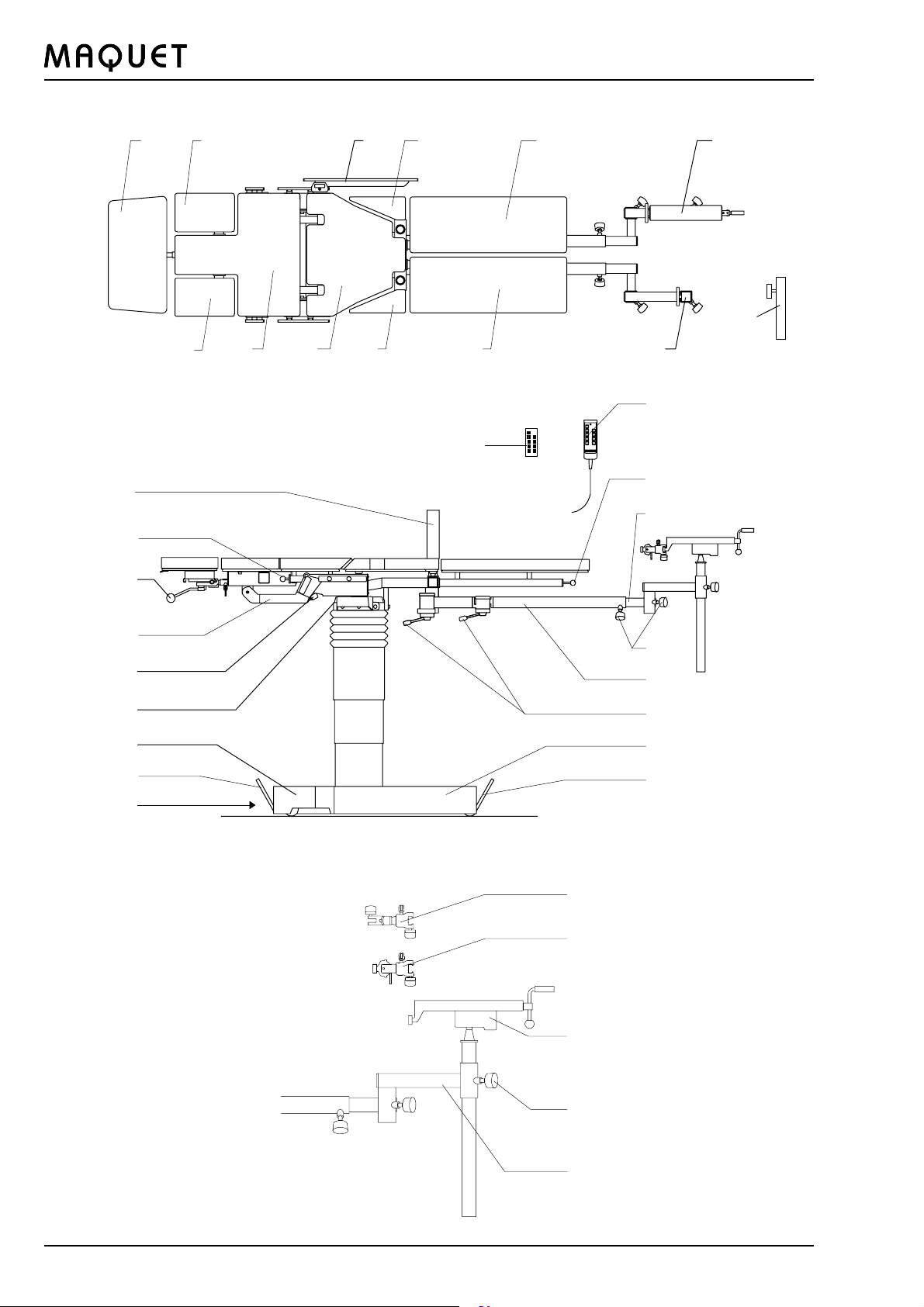

1425.01A/B ORTHOSTAR II

32

27

2

GA142501GB03

Page 3

1425.01A/B ORTHOSTAR II

Pictorial guide

1 Head rest

2 Shoulder segment, left

3 Shoulder segment, right

4 Back plate

5 Seat plate

6 Side rail elongation

7 Triangular buttock support, left

8 Triangular buttock support, right

9 Leg plate, left

10 Leg plate, right

11 Countertraction post for neck of femur

12 Quick-release catch

13 Clamping lever

14 Supporting arm

15 Rocking lever

16 Pin for potential equalization (beneath the table top)

17 Rear base cover

18 Pedal

19 Supply cord on cable reel in the base

20 Pedal

21 Front base cover

22 Eccentric clamping lever

23 Traction bar

24 Handle screw

25 Telescopic bars

26 Quick-release catch for leg plates

27 Cable-connected hand control or IR hand control with charging station

28 Rotation and traction stirrup clamp

29 Rotation-tilt clamp

30 Screw tension device

31 Bar elongation

32 Foot plate support

GA142501GB03

3

Page 4

1425.01A/B ORTHOSTAR II

Contents:

Pictorial guide

I. Safety

II. Summary of safety precautions

III. General description

1. General description

2. Displacing / locking the operating table

3. Control of electrically controlled,

hydraulically powered motions

IV. Use of the operating table

1. Potential equalization

2. Mains operation

3. Battery-powered operation

4. Explosion protection

V. Table top components

1. Removing the back plate

2. Mounting sockets at the supporting frame

3. Leg plates

4. Triangular buttock supports

5. Traction bars

6. Padding

VI. Accessories

VII. Special accessory units

VIII. Removing the back plate

IX. Hazard of accident and injury

Accessories for Morbus Bechterew operations

Page

2 - 3

5

6

7 - 10

7

7

8

11

11

11

11

11

12

12

12

12

13

13

13

14 - 19

20

21

22

23

X. Care and maintenance

XI. Patient positioning using accessories

XII. List of accessories

XIII. Technical data

XIV. Spare part supply see spare parts list 9 491 320

4

24 - 25

26 - 34

35 - 36

37

38

GA142501GB03

Page 5

1425.01A/B ORTHOSTAR II

I. Safety

Important notes on these operating instructions:

Please read these operating instructions completely and carefully before using the unit. They were provided to

familiarize you with the features and correct use of the ORTHOSTAR II. Be sure to always follow the instructions

contained herein.

Store these instructions in a location near the equipment so that they will be available for ready reference.

We have used the following symbols to identify important notes in these instructions:

This symbol identifies information which is critical to safety as described in the international standard

applicable to the field of medicine.

è An arrow is placed in front of all information which is important to trouble-free operation of the system.

Intended use of an operating table

The operating tables sold by the MAQUET company are solely intended for medical treatment of humans. The

operator must be instructed in the correct use of the equipment. The equipment should be located in an area that

adheres to the current valid standards and guidelines. An absolute prerequisite for the use of the equipment is its

correct assembly and maintenance.

è For use the operating-room table has to be covered with clothes according to the established hygienic standards.

Fundamental safety aspects

l Any other use of the operating table, e.g. as a lifting platform, for material transport, as a rest rest platform, etc.

is considered not in accordance with the intended purpose.

Intended use

The operating table is intended for

l Positioning the patient during the operation incl. the preparatory and postoperative phases

l For transport of the patient inside the surgical department, e.g. from the patient transfer unit to the operating room

and vice versa.

This mobile operating table satisfies the requirements of the standard which is applicable internationally, IEC

601-1 (EN60601-1), corresponding to DIN VDE Standard 0750, Part 1. The operating table may be used only in

rooms where the installation technology satisfies the requirements of DIN 0107 or an equivalent national standard.

The ORTHOSTAR II operating table may be operated only by persons who have been instructed in the correct use

of the equipment. This familiarization by MAQUET was confirmed in an acceptance log.

CLASSIFIED BY UNDERWRITERS LABORATORIES INC: WITH RESPECT TO ELECTRIC SHOCK;

FIRE AND MECHANICAL HAZARDS ONLY IN ACCORDANCE WITH UL 2601-1

Whenever maintenance work is required, remember that the MAQUET Service Department is always the right

address in terms of quality and maintaining guarantee protection. You will certainly understand that MAQUET can

assume responsibility for the safe operation of your operating table only if maintenance, repairs, modifications, etc.

are carried out either by our service department or by a firm expressly authorized to do this work and only if the

unit has been utilized in full compliance with the operating instructions.

GA142501GB03

5

Page 6

1425.01A/B ORTHOSTAR II

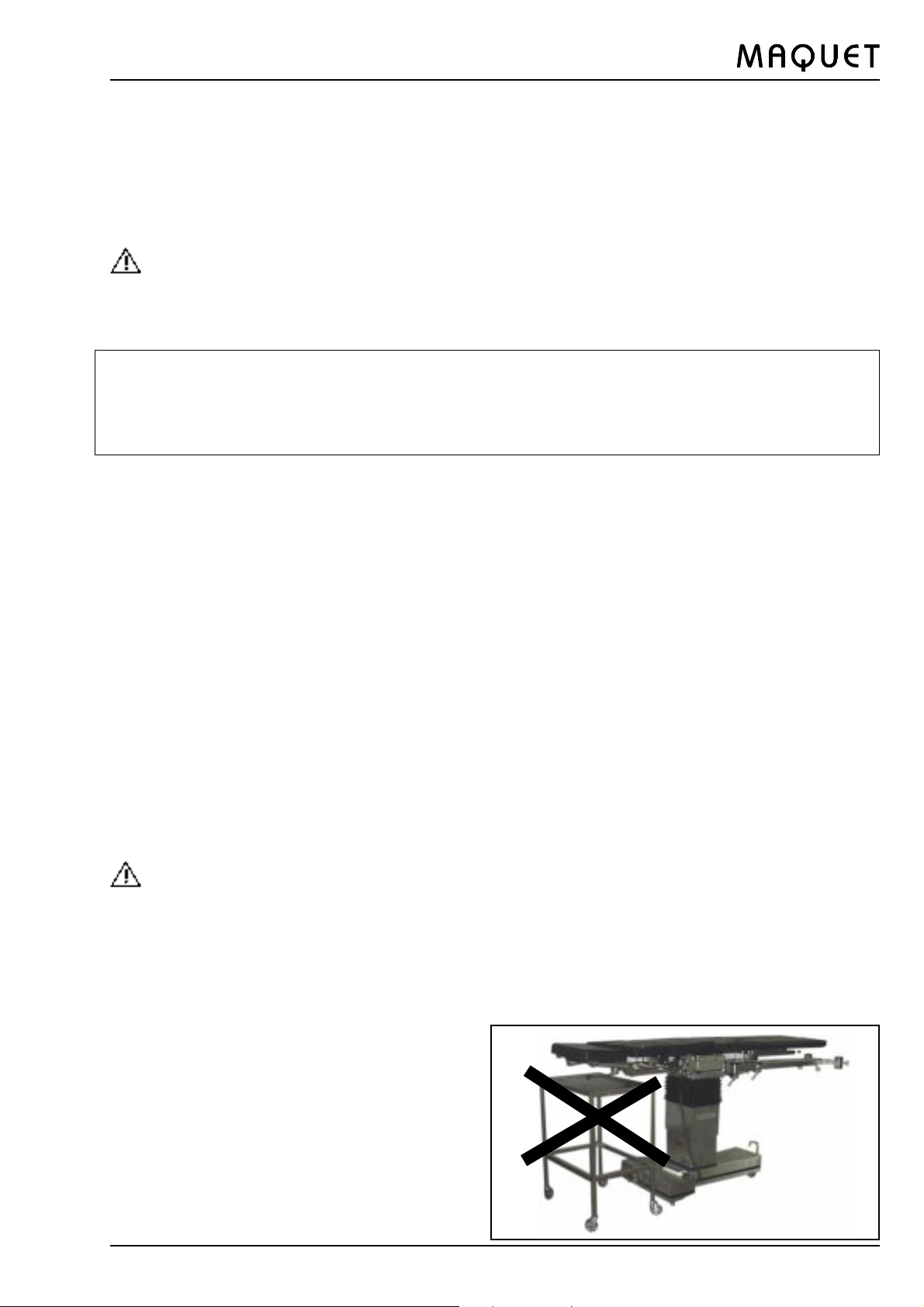

II. Summary of safety precautions

Pinch points are created during certain table top adjustments. Do not reach under the back plate or

attached accessory components and the joints.

The operator has to ensure that the location of the operating table is horizontal and safe.

The nursing staff must ensure that the patients are positioned and monitored so as to prevent compromising

respiration, nerve pathways or circulation.

Displacement of the operating table with patients weighing up to 135 kg (300 lb.) is allowed only up to a

table top height of 0.9 m (35.4 inches).

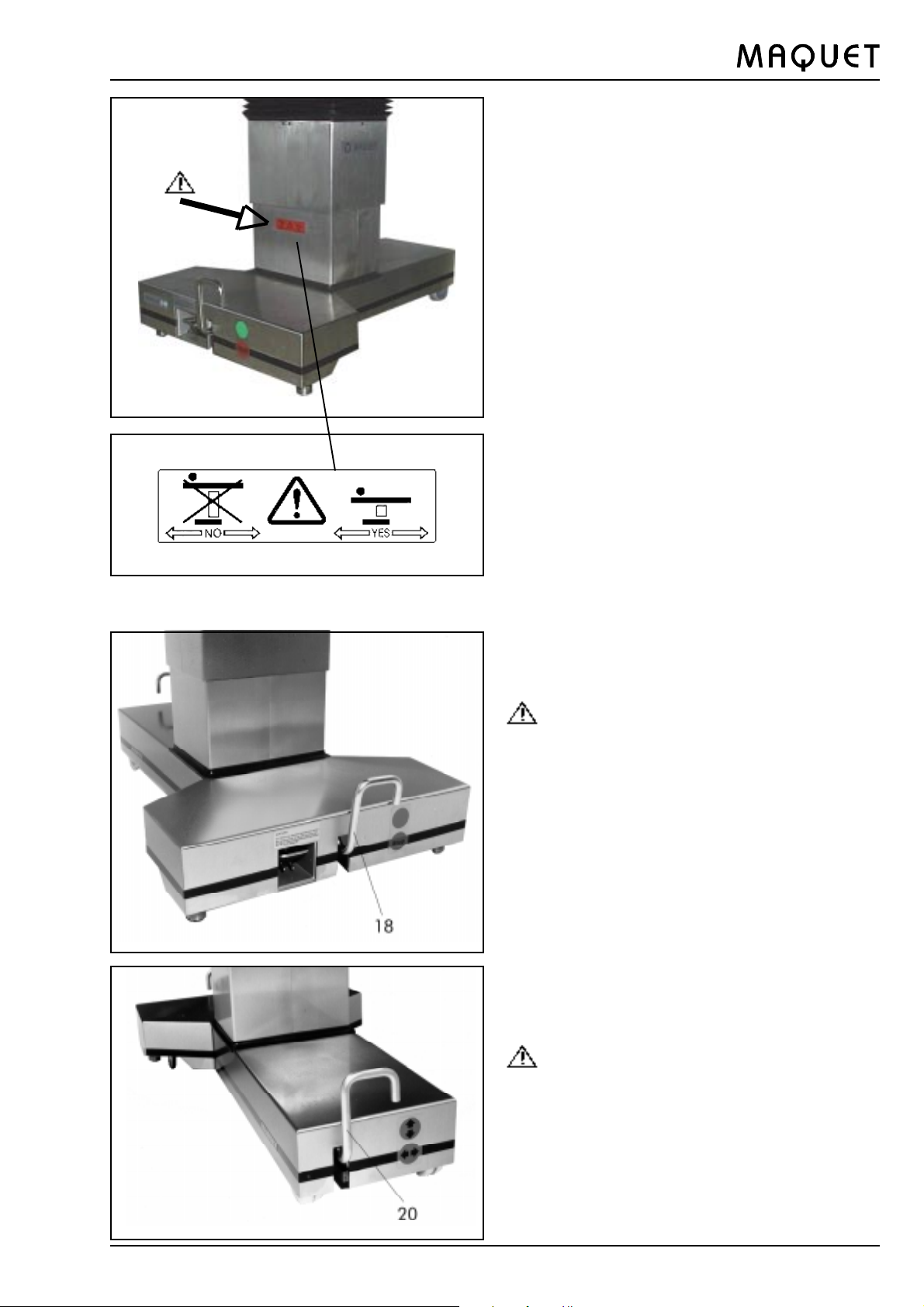

Note: The warning plate at the column must not be visible (Fig. A, page 7).

If the table top components contact an obstacle during an adjustment procedure, the table may tip. Remove

possible obstacles before lowering the operating table or individual table top components.

Lock the operating table when transferring the patient.

The operating table must not be operated from the mains in the presence of flammable anaesthetics.

Electrically conductive properties must be monitored by trained service personnel. Trained service personnel

must perform subsequent routine testing at least once a year.

When installing operating table accessories, check for correct attachment and tighten securely. Do not use

worn or damaged accessories. Check installation before using any accessory.

Unexpected table movement with a patient who is not secured could cause patient injury. The patient must

be secured to the operating table in accordance with the specific requirements, using the appropriate

accessories such as body strap, lateral supports, etc.

6

GA142501GB03

Page 7

1425.01A/B ORTHOSTAR II

Bild A

III. General description

1. General description

The ORTHOSTAR II 1425.01 is a mobile operating

table for traumatology, orthopaedics, spinal surgery

and shoulder operations.

The table top is divided into 8 sections (9 sections

including head rest to choice) and provided with

electrically controlled and hydraulically powered

adjustment functions for height, lateral tilt,

Trendelenburg / reverse Trendelenburg, and at the

back section.

Guide rails beneath the seat plate allow for X-ray film

cassette insertion from the sides. The side rails are

provided for fitting accessories.

The operating table is powered by batteries or mains

operated.

The batteries are recharged with a built-in battery

charger. The charge level of the batteries is indicated

by a luminous diode. Using an 0-position key, the

Trendelenburg and lateral tilt adjustments may be

reset and the table top returned to the horizontal

position. A pedal is used to lock and release the

operating table for travel.

According to IEC 601-1, the table is built for safe

è

handling of patients weighing up to 135 kg. If heavier

loading is to be expected, consult the manufacturer.

The operating table shall be equipped only with

MAQUET accessories (observe the operating

instructions!). Accessories made by other

manufacturers shall not be used without express

approval by MAQUET and must be particularly carefully

examined to ensure that they do not represent a

hazard to the patient, the personnel, or the operating

table.

When a patient is lying on the operating table, the

pedals for unlocking the base may be actuated

only when the warning plates are no longer visible

(Fig. A).

è Note:

All surgical procedures are permissible on the

locked operating table up to a patient weight of

135 kg (300 lb.).

2. Displacing / locking the operating table

è Always lock the operating table in position using

the pedals (18) and (20) before setting up the

patient position and during the operation.

For longitudinal displacement of the operating table,

l push the two pedals (18) and (20) upward

Displacement of the operating table with patients

weighing up to 135 kg (300 lb.) is allowed only up

to a table top height of 0.9 m (35.4 inches).

Note: The warning plate at the column must not

be visible (Fig. A).

For transverse displacement,

l push pedal (20) downward and

l pedal (18) upwar

For locking the operating table

l push pedal (20) upward and pedal (18) downward.

GA142501GB03

7

Page 8

1425.01A/B ORTHOSTAR II

3. Control of electrically controlled, hydraulically

powered motions

Depending on the customers requirements, the

operating table motions may be controlled by the

following three elements:

l Cable-connected hand control

l IR hand control

l Foot switch (only for the table top up/down and

Trendelenburg/reverse Trendelenburg functions.

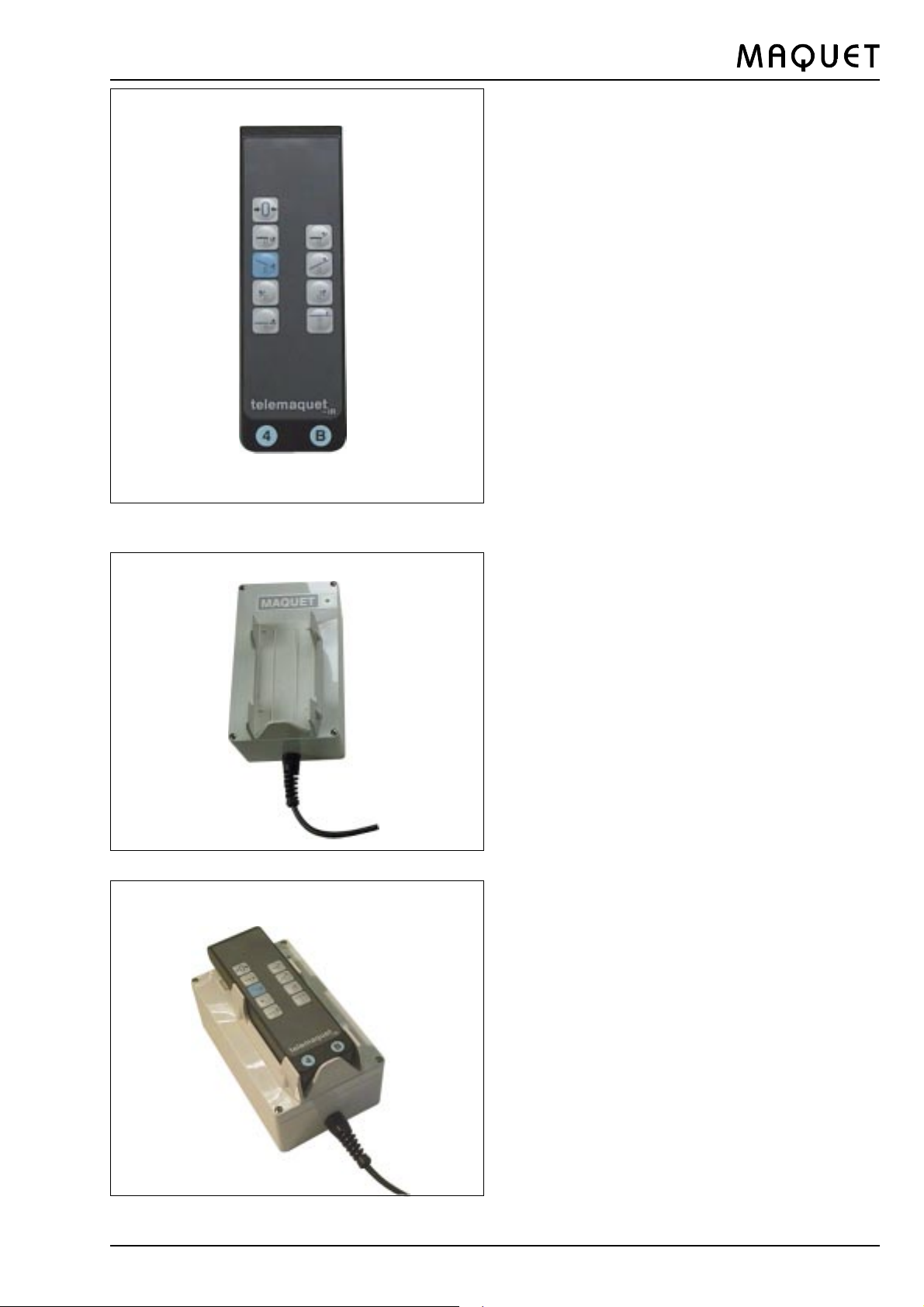

3.1 Cable-connected hand control

Once it has been removed from its packaging, the

plug for the cable-connected hand control is

connected at one of the two sockets (33) at the

column head. The operating table can then be

adjusted on battery power.

n

a

b

d

f

h

c

e

g

i

The column is equipped with two sockets for

simultaneous connection of the cable-connected

hand control and the foot switch.

3.2 Functions

Press the appropriate function key to invoke the desired

adjustment function.

a Automatic 0-position feature

b Back plate downward

c Back plate upward

d Trendelenburg position

e Reverse Trendelenburg position

f Lateral tilt to left

g Lateral tilt to right

h Table top downward

j Table top upward

n Capacity indicator

3.3 Foot switch control

The foot switch (separate ref. no. 1009.79-B) is also

connected to one of the two sockets at the column

head. Now the electrically controlled, hydraulically

driven functions up/down and Trendelenburg/reverse

Trendelenburg can be operated by either the foot

switch, the cable-connected hand control or the IR

hand control.

èNote:

If functions are initiated simultaneously via foot

switch and hand control, each function of the

system will be stopped instantly and will be

resumed only when one of the control elements has

been released.

3.3a Infrared remote control

If desired, the table may be equipped with an IR

remote control. The arrangement of the function keys

for the adjustments of the operating table is the same

as on the cable-connected hand control.

If the operating table is equipped with an infrared

remote control, it differs from the version with the

cable-connected hand control in the following

characteristics:

l Cordless hand control

l Additional charging station with supply cable for IR

hand control

l Capacity indicator for battery capacity of the

operating table at the column head

l Additional acoustic signals of the operating table

and the IR hand control in particular use situations.

8

GA142501GB03

Page 9

1425.01A/B ORTHOSTAR II

è Note

The transmission power of the IR hand control is

sufficient to be able to adjust the operating table

even from a greater distance and with the

operating table draped. If the operating table does

not respond to the command even though the

function key is completely depressed, either reaim

the hand control or move to a slightly different

transmission position. In such cases the sensor

at the column is being blocked by a person.

3.4 IR system code

Each operating table and its IR hand control are

identified with the same codes. The encoding is

undertaken by authorized personnel.

The operating table and its hand control are

marked

with blue labels. The label is located

l at the lower end of the hand control

l at the base of the operating table near the supply

cable.

The IR system code is identified by a numeral from

0 to 9 or a letter from A to F.

Examples of possible IR system codes:

4B

C2

DA

è Note

The order of the numerals and letters is significant

here; IR system code 4 B is not equivalent with B

4, for instance.

The operating table can, of course, be used at any

time by connecting a cable-connected hand

control; here the IR system code is of no

significance.

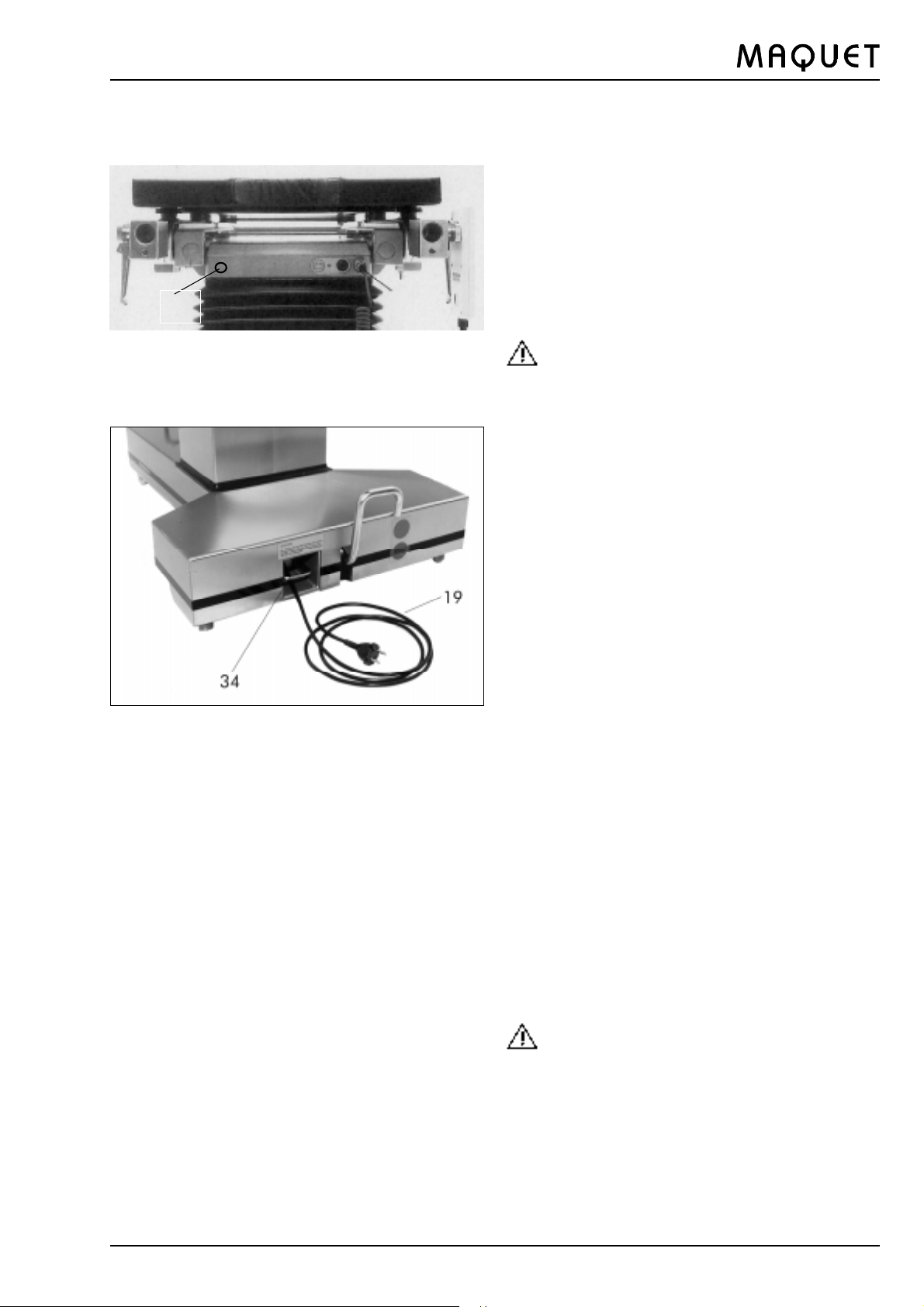

3.5 Charging station

The charging station of the IR hand control is used for

recharging the battery in the hand control. The charging

station can be mounted on the wall near a power

socket; however, it does not necessarily have to be

mounted at all.

To recharge the battery in the IR hand control,

connect the charging station to the mains via supply

cable. The green indicator lights up.

Insert the hand control in the charging station as

follows:

GA142501GB03

l Hold the hand control so that the keypad is

visible, in the position for normal use

l the 0-position key is at the top

l the lower, narrow end of the hand control is in

contact with the lower edge of the holder.

9

Page 10

27

1425.01A/B ORTHOSTAR II

The battery in the IR hand control has sufficient

capacity to control adjustments of the operating table

for several days. We nonetheless recommend that the

hand control be stored in the charging station in the

evening so that the battery will be recharged overnight.

3.6 Battery charge level

The capacity of the batteries in the operating table and

the IR hand control is indicated by optical and acoustic

signals.

a) IR hand control

l A continuous tone will be sounded when one of the

function keys is pressed (the adjustment motion is

being executed). The capacity of the battery in the

hand control has dropped to approx. 10 %. Insert the

hand control in the charging station once the

adjustment motion has been completed.

b) Operating table

The battery charge level is indicated optically by the

luminous diode n.

When using a cable-connected hand control, the

luminous diode is integrated in the hand control.

n

When using an operating table with an IR hand

control, the luminous diode is located at the column

head.

Charging capacity

green continuous light at n:

Charging condition 100 30 % = good

Red continuous light at n:

Charging condition 30 10 % = still sufficient

Red intermittent light at n:

Charging condition less than 10 % = very low;

The batteries should urgently be recharged on

completion of the surgical intervention.

èNote

In addition to the luminous diode blinking red, this

charging condition is also indicated by an

intermittent acoustic signal for operating tables with

IR hand control.

Green intermittent light at n:

The operating table has been connected to the mains

supply. The batteries are being recharged; adjustments

can be made.

The operating table has been connected to the mains

supply. The batteries are being recharged; adjustments

can be made.

No signal at n:

The maximum discharge limit has been reached.

The electronics have shut down the unit to avoid

deep discharge which would damage the batteries.

The batteries must be charged.

10

Charging the batteries:

To recharge the batteries, connect the operating table

via the supply cable to the mains supply. The full

charging capacity is attained after a charging time of

approx. 15 hours. Overcharging is avoided by an

electronic power control. We recommend recharging

the batteries overnight or during the weekends.

GA142501GB03

Page 11

1425.01A/B ORTHOSTAR II

IV. Use of the operating table

1. Potential equalization

Connect the potential equalization pin (16) with cable to

a potential equalization point in the operating room (as

per VDE Electrical Standard 0107 or the corresponding

national codes).

2. Mains operation

Use the cable (19) to connect the operating table to

the mains supply. To do so, pull the supply cable out of

the opening in the base (cable length approx. 4.5 m).

The separation of the OR-table from the mains is

made by the power plug.

èNote

Damaged mains cables must be replaced!

When pressing the lever (34) upward, the supply cable

is automatically wound on the cable reel inside.

3. Battery-powered operation

Unplug the operating table. At full charge,

the batteries will power the operating table

for several weeks, depending on the frequency

with which the adjustments are made.

èNote

Operating the table under battery power is always

to be given preference to operation from the mains

supply.

4. Explosion protection

When running on the integral batteries only with

no connection to the mains supply, the operating

table satisfies the requirements of Class M for the

anaesthetic test. It may be used in areas subject

to explosion hazard, Zone M.

When the operating table is connected to the

mains supply, it is not suitable for use in areas

subject to explosion hazard (AP-M).

Please refer to your national safety regulations.

GA142501GB03

Attention

To prevent oil leakage after the bleed screw has

been installed, do not tilt the operating table through

more than 25°.

11

Page 12

1425.01A/B ORTHOSTAR II

V. Table top components

1. Back plate (4)

The Orthostar II is equipped with a back plate (4) which

can be raised from the horizontal position under motor

power, using the hand control modules (see Section 3,

from page 8).

For shoulder operations, the shoulder segment (2) or

(3) may be removed by pulling off.

To attach the shoulder sections (2/3), insert them in the

square tube of the back plate and apply gentle pressure

to snap them in position. They will engage

automatically.

The entire back plate may be removed from the

operating table in order to attach other accessory units

for operations on the spinal column.

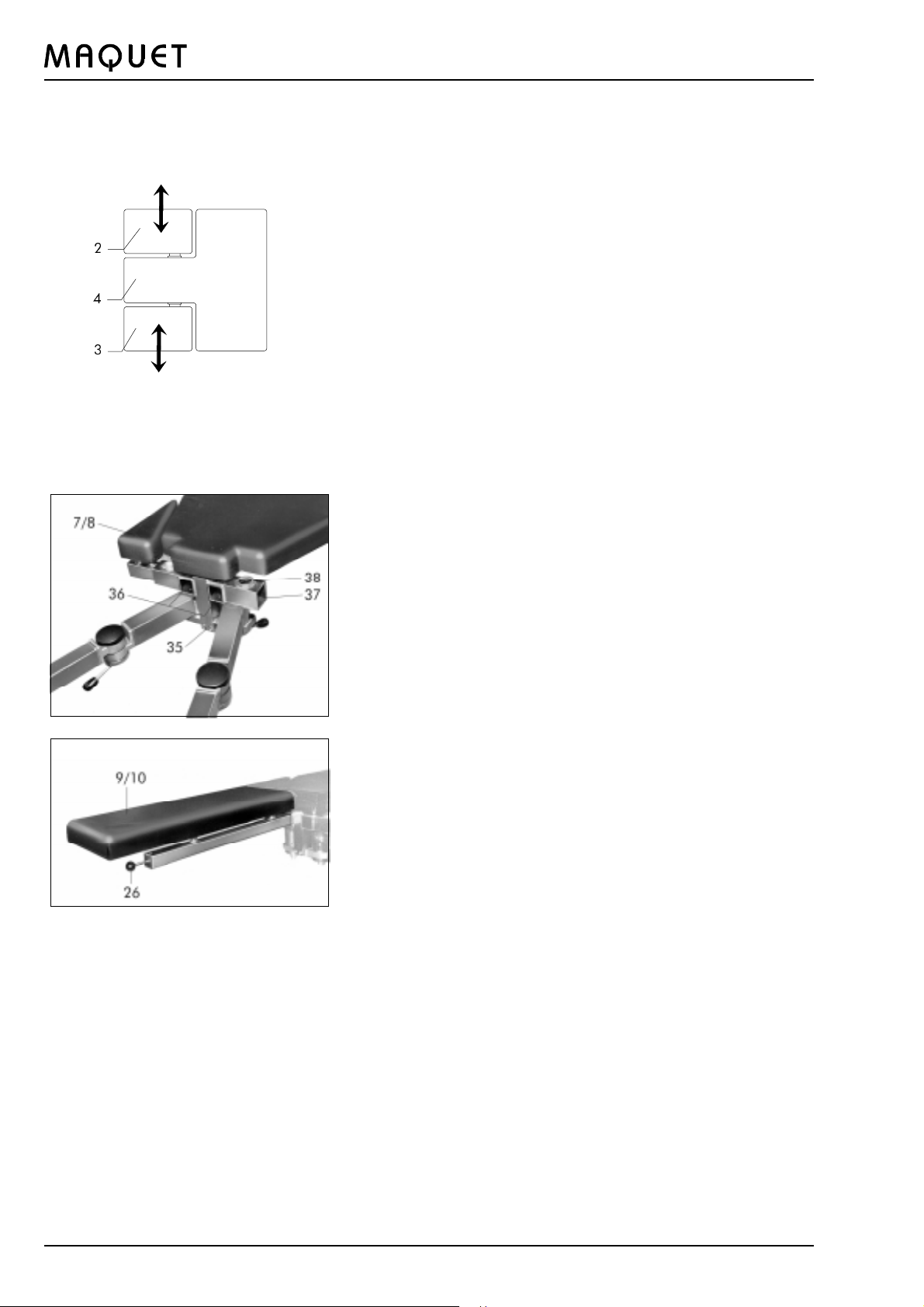

2. Mounting sockets at the supporting frame

The following mounting sockets are located at the

supporting frame (35) in the foot side area of the seat

plate:

l The square sockets (36) pointing towards the foot

end are used to attach the leg plates (9/10).

l The square sockets at the sides (37) are used to

attach the triangular buttock supports (7/8) and

various accessories.

l The vertical round sockets (38) are used to attach

the countertraction posts (see Chapter Basic

accessories)

3. Leg plates

To attach the leg plates (9/10), pull on the quickrelease catch (26) and insert the leg plate in the

square socket (36) up to the stop with the quickrelease catch (26) still being pulled on. The leg

plates will automatically be fixed in position as soon

as the catch (26) is released. To pull out the leg

plate, first pull on the quick-release catch (26) and

remove the leg plate with the catch (26) still being

pulled on.

12

GA142501GB03

Page 13

1425.01A/B ORTHOSTAR II

4. Triangular buttock supports

The triangular buttock supports (7/8) are

complementary parts of the table top. Like the leg

plates, they are used in the preparatory phase and

will be removed during the operation. To remove

them, pull them out of the sockets (37) to the side.

To attach the triangular buttock supports, place the

square tube to the socket (37) and press gently into

place with the ball of the thumb. It is locked

automatically.

5. Traction bars

Two traction bars are mounted on the supporting frame.

These bars (23) swivel in two swivel joints so that they

can be swung horizontally. The swivel joints nearer the

head are used to swing the entire traction bar, the ones

nearer the foot to adjust the angle of the bar. These

swivel joints make it possible to position the traction

bars during the operation so that they will not interfere

with using the image intensifier to examine the patients

extremities.

To adjust the traction bars, release completely the

clamping levers (22) for the appropriate swivel joint by

moving the lever horizontally. The directions of rotation

for releasing or tightening the clamping levers are shown

on the black covers on the swivel joints.

6. Padding

The table top consists of table top plates with pads

which are attached by means of Velcro straps.

èNote

l To clean the pads, remove them from the table top

plates.

l When re-placing them, take care that the soft bands

of the Velcro straps are completely dry.

GA142501GB03

13

Page 14

1002.86B0

13

1425.01A/B ORTHOSTAR II

VI. Accessories

1. Basic accessories

1

In addition to the leg plates, the extension table tops

are provided with the following basic equipment:

1.1 Head rest (to choice, 1002.81D0 or 1002.86 B0)

Mount the head rest (1) by inserting the square rod

in the mounting socket at the head end of the table

and tightening down the set screw.

To adjust the head rest, turn the clamping lever (13)

to the left and move the head rest to the desired

angle. Move the locking lever back to the right to

lock the head rest in position.

1.2 Telescopic bars

The telescopic bars (25) are supplied in two

different lengths.

Identification:

Long telescopic bar: with white end cap

Short telescopic bar: with black cap

The telescopic bars are inserted in the traction bars

(23) in preparation for mounting additional accessories;

the handle screws of the traction bars are used to fix

the telescopic bars at the required length.

è Note:

To ensure secure fixing of the telescopic bars they

must be inserted at least far enough into the

traction bars that the red mark is no longer visible.

14

GA142501GB03

Page 15

1425.01A/B ORTHOSTAR II

31

25

30

1.3 Bar elongations

The bar elongations (31) are inserted in the

telescopic bars (25) where additional length is

required; the bar elongations are fixed with the

handle screw. If turned through 180° and inserted,

they may be used where required to shorten the

telescopic bars.

1.4 Screw tension device 1003.37

The screw tension device (30) is used to adjust the

traction tension applied during the operation. The

supporting bar (30a) is inserted in the square

socket at the end of the telescopic bar and fixed at

the desired height by tightening the handle screw.

1003.37

1003.49

7/8

30b

30a

The screw tension device (30) is permanently joined

with the supporting bar (30a) by means of a balland-socket joint. Once the clamping lever (30b) has

been released, the screw tension device will swivel

freely on the ball. Swing the clamping lever (30b)

upward completely to release. To lock the screw

tension device in position, move the clamping lever

(30b) downward to the stop (the lever will then be

horizontal).

1.5 Foot plate support 1003.49

The foot plate support is also inserted in the socket

of the telescopic bar and used, in conjunction with

additional accessories (e.g. sole plate), to position

the sound leg of the patient.

1.6 Countertraction post for neck of femur

The countertraction post (11) is inserted in the

mounting socket (38) after removing the appropriate

buttock support (7/8). The countertraction post

serves to resist the traction applied during the

operation to the extremity affected. It will then be

located on the side corresponding to the fracture, in

the patients perineal area.

GA142501GB03

38

15

Page 16

1003.34

29

28

1425.01A/B ORTHOSTAR II

1.7 Rotation-tilt clamp 1003.34

The rotation-tilt clamp (28) serves to attach the foot

plates (to be ordered separately, ref. no. 1001.87)

to the screw tension device. The clamp is slid onto

the side rail at the screw tension device and is then

secured with the handle screw.

After loosening the upper locking handle, the side

rail may be rotated through 360°. Loosening the

lateral locking handle will make it possible to tip the

mounting rail section to accept the foot plate.

1.8 Rotation and traction stirrup clamp 1003.35

The rotation and traction stirrup clamp (29) serves

to attach to the screw tension device the traction

stirrups which are used for wire traction purposes.

The clamp is slid onto the mounting rail section at

the screw tension device and secured with the

handle screw. After loosening the locking handle,

the traction stirrup can be rotated through 360°.

After loosening the handle screw, the traction

stirrup may be inserted in the socket and secured

in position. The adjustment screws are provided for

fine positioning and exact fixing of the traction

stirrup.

1003.35

1004.91A0

1.9 Side rail elongation 1004.91A0

The side rail elongation (6) is mounted on the side

near the seat plate wherever accessory

6

components have to be attached at the lower end of

the seat plate (a Goepel knee crutch to support the

sound leg, for instance).

2. Optional accessories

The side rail elongation (6) is mounted on the side

near the seat plate wherever accessory

components have to be attached at the lower end of

the seat plate (a Goepel knee crutch to support the

sound leg, for instance).

2. Optional accessories

In addition to the basic accessories, there is

available a number of supplementary components

which may be utilized in accordance with the

requirements of the operation or the preferred

operating techniques.

2.1 Countertraction post for interlocking nailing

1004.90B0

This countertraction post is used instead of the

post for neck of femur (11) when treating femur

fractures with the patient in the supine position (and

also for interlocking nailing technique).

1004.90B0

16

The countertraction post for interlocking nailing is

inserted in the socket (38) at the supporting frame

after removing the buttock support (7/8) and the leg

plates (9/10) on the side corresponding to the

fracture.

GA142501GB03

Page 17

1425.01A/B ORTHOSTAR II

b

d

38

37

1004.85B0

c

40

37

2.2 Countertraction post for femur 1004.85B0

a

This countertraction post is used when treating

femur fractures with the patient in the lateral

position. The positioning plate (d) is supplied with

the 1004.85 countertraction post.

After removing the buttock support (7/8), the

countertraction post is inserted in the socket (37)

at the supporting frame and secured in the socket

(38) with the catch. The upper section of the

countertraction post (a) and the perineal bow (b)

may be removed by lifting it off. The perineal bow

(b) can be shifted through 180° and mounted for

use at the right or left of the table top. The vertical

spacing between the table top and the perineal bow

is adjusted with the hand crank (c).

The positioning plate (d) is inserted in the sockets

(37) after removing the leg plates (9/10).

2.3 Perineal support 1004.89

The perineal support is also used when treating femur

fractures with the patient in the lateral position. It

serves to absorb the traction tension applied to the

extremity being worked on.

The holder (a) is inserted in the socket (37) at the

supporting frame (40) after removing the buttock

support (7/8). Insert the perineal support and use the

handle screw to fix at the desired height.

1004.89

D

2.4 Countertraction post for tibia and fibula

a

E

F

1003.50A0

This countertraction post is used when operating on

lower leg fractures.

After removing the buttock support (7/8), insert the

countertraction post in the socket (37) at the

supporting frame, securing it with the catch in the

socket (38). The countertraction post (a) and the

telescopic bar (b) can be lifted off after loosening

the appropriate handle screw.

The countertraction post (a) can be shifted

through 180° and mounted for use at the right or left

of the table top. The vertical spacing between the

table top and the countertraction post (a) is

adjusted after loosening the handle screw (c).

After opening the eccentric safety lever (d) the

countertraction post (a) can be swivelled to the

front.

Attention:

Hold the countertraction post at the telescopic bar

(b) before opening the eccentric lever and until the

eccentric lever (d) is locked again!

[

1003.50A

GA142501GB03

G

17

Page 18

1425.01A/B ORTHOSTAR II

To set up the traction exerted at a downward

angle, the countertraction post for tibia and fibula

can be swivelled via the gear rim: Press the safety

button (x) and open the eccentric lever (d). Swivel

the countertraction post as desired and tighten the

eccentric lever (d).

Attention

D

E

F

[

G

With extension accessories fixed in the telescopic

bar, the countertraction post may drop

automatically! Therefore, always support the

countertraction post with the free hand when

making adjustments.

1003.50A0

1004.93B0

1003.51

2.5 Condyle fixation 1004.93-B0

The condyle fixation can be used to secure the

patients knee exactly on the tibia countertraction

post while operating on lower leg fractures and thus

will help to avoid rotary alignment errors. The swivel

holders are bolted at the right and left on the

countertraction ratchet disks. Height adjustments

to suit the patients anatomy are made possible by

the eccentric attachment of the pressure plates to

the horizontal holder bars.

2.6 Horizontal guiding bar 1003.51

The horizontal guiding bar may be used to correct

the direction of traction at right angles to the

longitudinal axis (e.g. tibia fractures). To use the

guiding bar, attach the telescopic bar shifted

through 90° and tighten the guiding bar in the

socket, using the handle screw. The square socket

of the horizontal guiding bar is used exclusively to

attach the screw tension device.

2.7 Pelvis support plate 1003.52

The pelvis support plate can be used for procedures

with the countertraction bar centred along the

longitudinal axis of the table top., e.g. bilateral hip

procedures (e.g. corrective osteotomy).

To attach the pelvis support plate, remove the leg plates

from the table top and insert the pelvis support plate in

the square sockets for the leg plates.

The patients legs are positioned over the traction bars

using the basic accessories.

1003.52

18

GA142501GB03

Page 19

1425.01A/B ORTHOSTAR II

1004.86

1004.87

30

a

x

c

b

23

2.8 Universal support 1004.86

The universal support is used to position the sound

extremity. It is mounted at the guide bushing (a) on

the supporting bar for the screw tension device (30)

and fixed with a handle screw. The horizontal

guiding bar (b) is pivoted and the extension length

variable. The upholstered support can be moved on

the ball joint at the vertical bar after loosening the

appropriate handle screw (x).

2.9 Leg plate support 1004.87

The leg plate supports are used whenever the leg

plate (9/10) is to be attached to the traction bar

(23). Attach the leg plate support to the traction bar

and fix with the handle screw. Insert the leg plate in

the upper square socket. To do so, pull the quickrelease catches for the leg plate (26) towards to

foot end.

2.10 Clamp with side rail 1004.88

The clamp with side rail is used to mount

accessory components which are to be attached

to one of the traction bars. Use the handle screw

to fix the clamp with side rail to the traction bar.

1004.88

1001.87

2.11 Foot plate

The foot plate serves to secure the patients

extremity. It is most useful to attach it to the

rotation-tilt clamp (28) (see page 2) at the screw

tension device to make for exact adjustment in

regard to angle and rotation. The foot plate is

available in two sizes:

For adults

ref. no. 1001.87

For children

ref. no. 1001.90

2.12 Traction boots

For adults

ref. no. 1001.88

For children

ref. no. 1001.91

1004.41

GA142501GB03

2.13 Sole plate 1004.41

Use the 1001.41 sole plate as an alternative to the

combination of the foot plate and the traction boot.

The patients feet are fixed using gauze, tape or

the like.

19

Page 20

1425.01A/B ORTHOSTAR II

VII. Special accessory units

The ORTHOSTAR II can be equipped with special

accessory units (separate ref. nos.) for operations on

the spinal column.

For this purpose the entire back plate (4) can be

removed from the operating table, allowing to use the

electrically controlled, hydraulically driven interface for

these accessory units.

For interventions at the spinal column the shoulder

sections (2) and (3) can be removed by pulling them off

to the side.

Check to ensure that the bars are inserted up to

the stop and that the balls are fully engaged in the

mounts.

1. Positioning unit for operations on the spinal

column 1007.03A0 with the patient in the

genucubital position

Remove the entire back plate (4) from the

operating table to attach these accessory units;

mount and use 1007.03A0 as described in the

separate Operating Instructions 9 491 472 401

l Trolley 1007.07A0

l Bracket with lateral supports 1007.05A0

2. Pair of bars with skids 1007.08A0 for

Morbus Bechterew operations

Remove the entire back plate (4) from the

operating table to attach these accessory units;

mount and use 1007.08A0 as described in the

separate Operating Instructions 9 491 472 401.

l Sternum support 1007.10A0

l Thorax support 1007.11A0

l Guiding roller for head-side traction 1007.12A

20

GA142501GB03

Page 21

1425.01A/B ORTHOSTAR II

VIII. Removing the back plate

The back plate may be removed for cleaning or

attachment of other accessory components.

To remove the back plate, proceed as follows:

l Loosen the locking handle at the back plate (4) and

pull the head rest (1) out of the square rod.

l Remove the shoulder segments (2/3) by pulling them

off to the side.

l Pull the quick-release catches (12) at the back plate

(4) simultaneously towards the rear to release the

back plate.

Now the back plate is released and may be removed by

lifting it off in the direction of the arrow.

l To remove the supporting arm (14), pull the rocking

levers (15) towards the head end and pull out the

supporting arm.

l To attach the supporting arm (14), pull the rocking

levers (15) towards the head end and insert the rods

to the full depth of the mounting holes (45).

To attach the back plate, proceed as follows:

l Hang the clamps (43) of the back plate into the

openings (44).

l Pull the two quick-release catches (12)

simultaneously to allow the pins to engage in the

openings.

GA142501GB03

21

Page 22

1425.01A/B ORTHOSTAR II

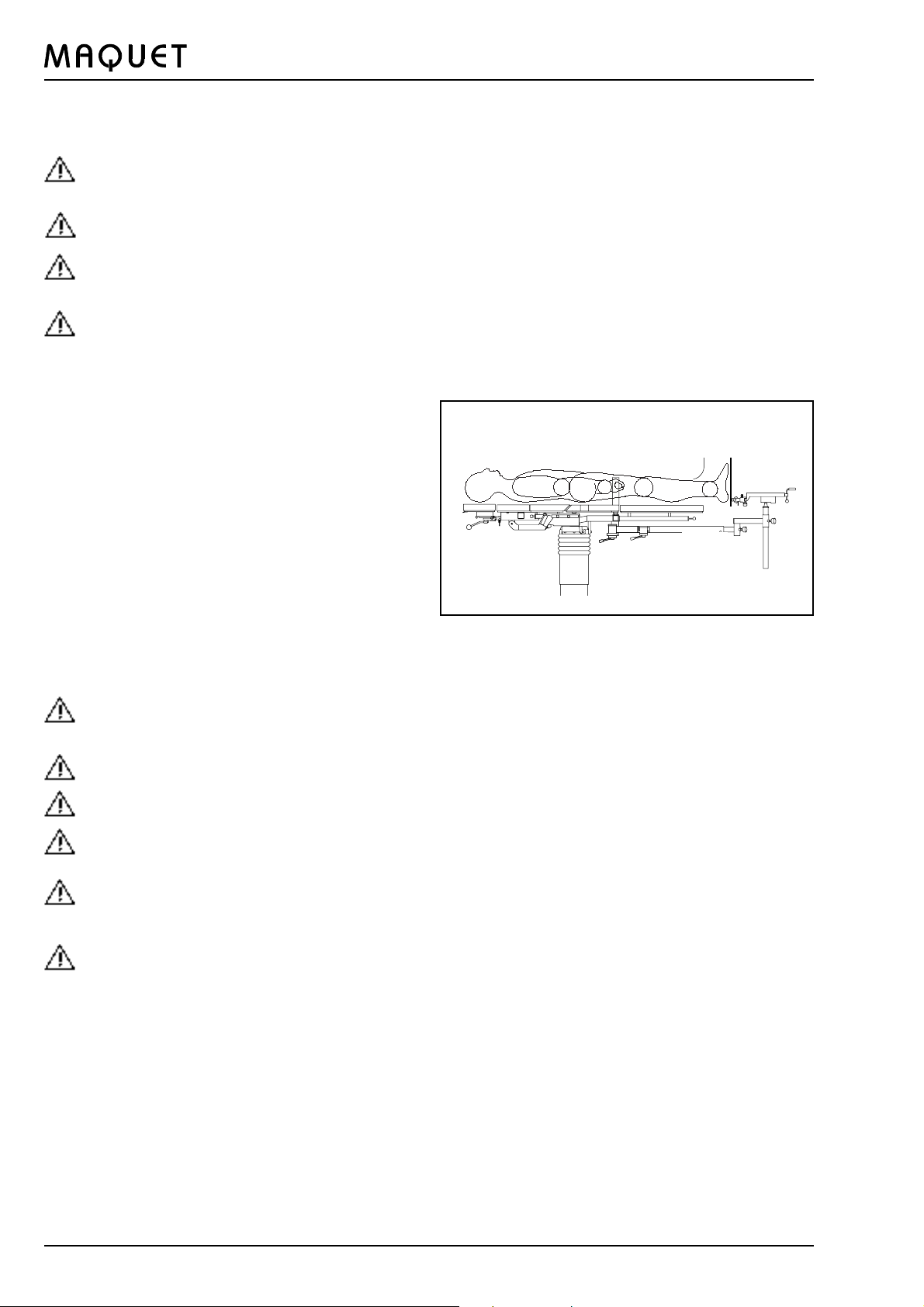

IX. Hazard of accident and injury

Caution hazard of accident and injury!

When the back plate is lowered, never reach into

this area and take care that there are no objects in

the area near the right and left hinged sockets (46)

and the right and left seat rails (47).

46

46

47

23

22

Caution hazard of accident and injury!

Danger of pinching between the traction bars (23)

and the hinged sockets (46) on either side

when swivelling the traction bars completely

towards the head end.

46

23

GA142501GB03

Page 23

1425.01A/B ORTHOSTAR II

1007.08A0

Accessories for Morbus Bechterew operations

2.1 Pair of bars with skids 1007.08A0

For interventions at the spinal column to treat, for

example, scoliosis of Morbus Bechterew. Suitable

for operating tables 1130 and 1425, for instance.

Pair of bars for mounting the skids which slide in

the longitudinal direction, for attachment of head

and arm positioning accessories and the sternum

support 1007.10-A0.

2.2 Sternum support 1007.10A0

Transverse, radiotranslucent unit for attachment to

the sliding skids of the 1007.08-A0; the patients

thorax is supported by an attached, pivoted

support plate with a foam pad measuring 300 x

175 mm, 100 mm diam. padded roll or 50 mm

diam. padded roll.

1007.10A0

1007.11A0

2.3 Thorax support 1007.11-A0

Suitable for 1007.08-A0; can be used instead of

the sternum support 1007.10A0 during

interventions in the lumbar vertebral area;

radiotranslucent with foam pad, electrically

conductive cover.

2.4 Guiding roller for head-side traction 1007.12-A0

In combination with 1002.7000; mounted on side rail

piece (e.g. on 1002.64A0) on 1007.08A0, with

longitudinal and height adjustment.

1007.12A0

GA142501GB03

23

Page 24

1425.01A/B ORTHOSTAR II

X. Care Maintenance

Electrically conductive properties must be monitored by trained service personnel. Trained service

personnel must perform subsequent routine testing at least once a year.

A mildly alkaline all-purpose cleaning agent (soap solution) is recommended for cleaning the operating table

and accessories. Further, the cleaning agent should

contain surfactants and phosphates as the active

cleaning agents. Use the cleaning agent in concentrated form if the surfaces are extremely soiled. This

will, however, make it necessary to rinse them afterwards with clear water. Then use a dry cloth to remove

any water which may have collected.

We recommend to cover the table top with sterile

sheets when not in use.

Surface disinfectants which contain neither chlorine

nor compounds which would liberate chlorine are

suitable for sanitizing. We suggest using a standard

surface disinfectant in an aqueous solution to disinfect

the operating table upholstery. Please observe the

manufacturers instructions for use and disinfect

manually.

Hand sanitizing compounds are not suitable for

disinfecting the operating table padding since they

usually contain alcohol or compounds of alcohol.

Disinfection agents containing alcohol must not be

used on the padding since excess exposure to alcohol

(i.e. collections of liquids containing alcohol and

remaining in contact with the surface for longer than 5

minutes) could damage the finish of the padding. The

potential hazard of forming explosive mixtures also

precludes using agents containing alcohol for surface

disinfection.

It is for this reason that we recommend using an

aldehyde-based disinfectant to clean the surfaces.

Disinfection of the castors:

l Raise the operating table to the highest position,

function key (j).

l Grip the rear cover (17) with both hands from the

sides and pull it upwards.

l Slightly lift the front cover (21) at the front end and

pull it forward.

l Unscrew the castor covers (47/48); the castors are

now accessible for disinfection.

l Re-assemble the covers of the castors

l Slide the inclined front cover (21) from the front onto

the T-base and press firmly into place.

l Slide the rear base cover (17) from above onto the T-

base and take care that the edges of the front cover

are covered at the same time.

24

GA142501GB03

Page 25

1425.01A/B ORTHOSTAR II

Notes:

èIf the lateral tilt and Trendelenburg/reverse

Trendelenburg functions have not been used for a

longer time, play may be encountered in the

universal joint suspension.

Remedy:

Operate both movements until the final stop is

reached, e.g. lateral tilt right/left or Trendelenburg /

reverse Trendelenburg position.

The hydraulic system should be serviced by

MAQUET Customer Service staff only.

èRegular recharging of the batteries, e.g. at night or

over the weekend, even if the battery indicator

(luminous diode n) indicates sufficient charge, will

extend battery life.

The operating table has to be serviced annually. Please

contact the MAQUET Customer Service (Service

Hotline see last page) or a local representative.

To conclude a maintenance contract, please contact:

MAQUET Aktiengesellschaft

P.O. Box 2162

D-76411 Rastatt

Phone + 49 7222 932-0

Fax + 49 7222 931-631

For maintenance outside Germany, please contact your

local representative.

If your operating table malfunctions, please contact

your MAQUET representative or the company itself.

Describing the symptoms and quoting the serial

number will help us solve your problem faster.

In case of malfunctions do not try to repair the table nor

to use force.

Environmental protection

l Do not throw old, damaged batteries to the normal

waste.

l Do not throw batteries into water or fire

l Remove the hydraulic oil before disposing of the

table.

l Dispose of electronic waste from the control unit and

the hand control modules in accordance with the

rules.

GA142501GB03

25

Page 26

1425.01A/B ORTHOSTAR II

XI. Patient positioning

General:

All the patient positions described below may be set up

by just a single person (except for the position for

nailing the femur in lateral position).

The extension accessories are mounted after

anaesthesia has been initiated with the patient in the

supine position on the table top. Only after patients

extremities have been placed in the approximate

position are the leg plates removed and the final

position set up (by adjusting the accessory

components).

èOnce the patient position is completed, check

to ensure that all eccentric levers and clamping

screws at the operating table and the accessories

are tightened down completely.

On completion of the surgical treatment, first attach the

leg plates, then release the feet / legs and remove the

accessory components.

HF surgery

Use of defibrillators and defibrillation

monitors

When using electrocautery units,

defibrillators, and defibrillation monitors, it is

important to follow the manufacturers

instructions. Disregard of safety precautions

can lead to serious incidents. If the patient

should come into contact with the metal parts

of the operating table or with accessories,

there is a danger of burns. This also applies if

the patient is lying on moist underlays or

sheets on the conductive operating table

pads!

26

GA142501GB03

Page 27

1425.01A/B ORTHOSTAR II

Patient positioning for nailing neck of

femur

I. Recommendations for positioning

l Patient in supine position

l with his legs straddled

l feet attached in traction boots with a slight inward

rotation

l perineum close to the countertraction post

In order to permit image intensifier control in vertical

a.p. view, it is recommended to tilt the operating table

at the side of the affected leg 15° to the unaffected leg.

The C-arm can be inserted from between the legs or

laterally from the head end, depending on the medical

indication.

II. Patient positioning

Accessories:

11 Countertraction post for neck of femur

25 Telescopic bars

30 Screw tension device

28 Rotation-tilt clamp

Foot plates 1001.87

Foot plate support (for the unaffected leg)

1003.49

23

11

l Bars and accessories to be adjusted according to

the illustration, to be fitted to the patient and secured

l The countertraction post has always to be inserted

on the side of the affected leg

l Remove the leg plates

l Adjust the C-arm for control in a.p. and lateral view

l Drape the patient

èNote:

On completion of the surgical treatment, first attach the

leg plates (9/10) (see page 20), then release the feet /

legs.

Remove the countertraction post (11)! Swivel the bars

(23) towards the head end.

GA142501GB03

27

Page 28

1425.01A/B ORTHOSTAR II

Positioning for nailing femur in lateral

position

I. Recommendations for positioning

l Patient in lateral position on his sound side

l The affected femur is placed over the perineal bow of

the countertraction post with the hip bent at approx.

right angles. For transcondyle wire extension the

lower leg is supported at an angle of approx. 80°

l Clamp the sound leg and stretch backwards as far

as possible until the C-arm can be swivelled in both

planes without trouble.

l C-arm between the patients legs.

II. Patient positioning

Accessories:

Countertraction post for femur 1004.84

25 Telescopic bars, for transcondyle extension,

the short telescopic bar is used as traction bar.

29 Rotation and traction stirrup clamp

28 Rotation-tilt clamp

30 Screw tension device

Foot plate 1001.87

Universal support 1004.86

Foot plate support 1003.49

l Adjust bars (23) and accessories as shown on the

photo.

l Remove leg plates (9/10) and insert positioning plate

a

b

d

(d)

l Move patient towards the foot end, place fractured

femur over the perineal bow (b), adjust the height using

the crank (c)

l Adapt bars and accessories to the patient and secure

them

l Adjust C-arm for a.p. and lateral view

l Drape the patient

èNote:

c

On completion of the surgical treatment

l move the patient towards the head end

l remove the positioning plate (d)

l attach leg plates (9/10), then release feet/legs

l remove countertraction post, swivel the bars towards

the head end.

28

GA142501GB03

Page 29

1425.01A/B ORTHOSTAR II

Positioning for nailing femur in supine

position, as well as for interlocking nailing

I. Recommendations for positioning

Patient in supine position with

l transcondyle Steinmann nail extension on the distal

femur fragment or

l over the stretched leg with foot plate The sound leg is

placed

l in the Goepel knee crutch and adjusted laterally

towards the head end or

l downward in half-vertical position until the second

femur permits the unobstructed control of the affected

femur by means of the image intensifier.

Proximal fracture:

l Extreme flexion of the patients body to the sound

side

l Traction in the axis of the leg without adduction

Distal fracture:

l Flexion of the patients body to the sound side

l Traction with extreme adduction

l The C-arm is placed in a contra-lateral position at

right angles to the affected extremity.

II. Patient positioning

Only one traction bar is necessary for this positioning.

Accessories:

Countertraction post for interlocking nailing

1004.90

25 Telescopic bar short for transcondyle

traction

25 Telescopic bar long for traction over the

stretched leg

30 Screw tension device

29 Rotation and traction stirrup clamp

6 Side rail elongation

Radial setting clamp 1003.23

Goepel knee crutch 1001.65

alternatively for traction over the stretched leg

(see photo below):

28 Rotation-tilt clamp

Universal support

Foot plate

l Adjust bars and accessories as shown on the photo,

adapt them to the patient and secure them.

l Adjust bars and accessories as shown on the photo,

adapt them to the patient and secure them.

l Drape the patient.

GA142501GB03

èNote:

On completion of the surgical treatment

l remove the countertraction post

l attach leg plates (9/10)

l then release feet/legs

6

l swivel the bar (23) towards the head end

29

Page 30

1425.01A/B ORTHOSTAR II

Positioning for nailing femur in lateral

position

I. Recommendations for positioning

l Patient in lateral position

l Extension with foot plate

l The affected extremity is placed horizontally over the

perineal support which is used instead of the

countertraction post.

l The sound leg is placed on a leg plate and is

abducted or in nearly parallel position to the affected

extremity in order to permit unobstructed access of

the C-arm in both planes

l C-arm approached in contra-lateral position at right

angles to the affected leg.

II. Patient positioning

Accessories:

Perineal support 1004.89

25 Telescopic bar long

30 Screw tension device

28 Rotation-tilt clamp

Foot plate 1001.87

Leg plate support 1004.87

1004.89

l Adjust bars and accessories as shown on the photo

l Equip traction bar (23) with leg plate support.

Leg plate (9) must be swivelled laterally.

l Insert perineal support, adjust its height to the

patient

l Insert perineal support, adjust its height to the

patient

l Remove the second leg plate (10)

l Adjust C-arm for a.p. and lateral view

l Drape the patient

èNote:

On completion of the surgical treatment

l Attach leg plate (9)

l Align second leg plate (10) in parallel position

l release the foot

l remove the perineal support

l swivel the bars towards the head end.

30

GA142501GB03

Page 31

1425.01A/B ORTHOSTAR II

$

Positioning for nailing tibia and fibula

I. Recommendations for positioning

l Patient in supine position with trans-calcaneal

Steinmann nail extension

l The sound leg is placed in the Goepel knee crutch

and adjusted laterally towards the head end

l The countertraction post must lie close to the lower

third of the thigh - otherwise the proximal fragment

would take a ventral position

l The affected extremity is stretched over the

countertraction post downwards in half-vertical position

or in horizontal direction. The C-arm is placed in

contra-lateral position at right angles to the affected

extremity.

èNote:

With the knee secured by means of the condyle

fixation, the possibility of undesired rotation is

eliminated.

II. Patient positioning

Both traction bars are swivelled under the table top and

secured. Remove the triangular buttock support of the

seat plate on the side of the affected leg, insert the

countertraction post for tibia and fibula and secure with

the bracket (x). For traction at a downward angle, swivel

the countertraction post for tibia and fibula towards the

foot end and attach the extension accessories as shown

on the photo.

Accessories:

Countertraction post for tibia and fibula 1003.50A

25 Telescopic bar long and horizontal guiding

bar, if required

30 Screw tension device

6 Side rail elongation

29 Rotation-tilt clamp

Radial setting clamp 1003.23

Goepel knee crutch 1001.65

alternatively:

Universal support 1004.86

28 Rotation-tilt clamp

Foot plate 1001.87

Foot plate support 1003.49

l Remove triangular buttock support (7/8) on the side

of the affected leg

l Insert the countertraction post for tibia and fibula from

the side, secure it by pressing bracket (x) into the

socket (37).

l Swivel the bars and the accessories downward, adjust

them to the patient and secure them.

Attention:

Hold the bar after it has been released it may

drop with the accessories attached.

l Remove leg plates

l Adjust C-arm for a.p. and lateral view

l Drape the patient

èNote:

On completion of the surgical treatment

l Attach leg plates (9/10)

l Remove countertraction post

l Release feet / legs.

GA142501GB03

31

Page 32

1425.01A/B ORTHOSTAR II

Positioning for operations on the shoulder

I. Recommendations for positioning

l Patient in supine position

l Head rest adapted to the patients size

l Patient positioned with free access for use of the

image intensifier for the shoulder to be operated on

II. Patient positioning

Accessories:

Roll pad 1002.81D

Side rail elongation 1004.91C

l Use key (c) to raise the back plate (4) (function key c)

l Remove shoulder segment (2/3)

l Place roll pad beneath the patients knees

l Use key (d) to move the table top to a slight

Trendelenburg position (function key d)

32

GA142501GB03

Page 33

1425.01A/B ORTHOSTAR II

Positioning with special accessories

Positioning for hip endoprosthesis

The patient is turned to the side, he is supported at

the buttocks, back, breast bone and pubis.

Pelvis intervention and THR:

For pelvis interventions the traction bars (23) are

swivelled out of the area which will be controlled by

image intensifier and secured by means of the clamping

levers (22).

The traction bars, the countertraction post and the

screw tension device can help to reposition the patient.

They can be adjusted so that they do not obstruct the

radiation of the image intensifier.

For radiography an X-ray film cassette (max. dimensions

24 x 30 cm) may be inserted in the area of the seat

plate, from either left- or right-hand side.

Accessories:

1002.19 Universal lateral supports, 4 pcs.

1002.11A Back-buttocks support, 1 piece

1002.11-C Lateral support, 1 piece

1002.11-B Pubis-sacrum-sternum support, 1 piece

alternatively for 1002.11-A and 1002.11-C:

1002.21 Lateral support, 2 pcs.

Positioning for upper arm

The patient is in supine position, the upper arm to be

nailed is guided over the padded roll of the positioning

device, the lower arm is supported in the Weinberger

hand traction device at the screw tension device.

Extension is effected by the patients own weight. The

C-arm is conducted around the upper arm in both planes

horizontally.

Accessories:

1004.98 Humerus positioning device

1004.80 Humerus countertraction post

1001.48 Weinberger hand traction device

Procedures on the knee

The MAQUET knee positioning device 1004.94 offers

itself for interventions on the knee and arthroscopy of the

knee joint. It is equipped with a crank handle for

swivelling thigh / tibia and fibula from horizontal to

vertical position. The thigh holder is equipped with two

adjustable, axially swivelling thigh cheeks with

integrated foam padding.

The knee positioning device is mounted to the table top

by means of the side rail elongation, the crank handle is

inserted from the head end.

For taller patients the leg plates (9/10) with the leg plate

supports and fixed on the traction bars. .

GA142501GB03

33

Page 34

1425.01A/B ORTHOSTAR II

Patient positioning for operation on the spinal column,

e.g. Morbus Bechterew, using the 1007.08A0,

1007.10A0, 1005.5800, 1002.5800, 1002.7000.

It is absolutely necessary to observe the

Operating Instructions 9 491 472 401 before attaching the accessory components!

During the operation the patient is raised via the

powered interface and positioning the trunk, sliding in

the longitudinal direction (sternum support, arm boards

and head positioning accessory).

Operation on the cervical vertebral column; head-side

traction using the Mayfield accessories 1005.3600,

1005.3500 (refer to MAQUET Accessories Catalogue

1000).

Patient positioning for operation on the cervical vertebral

column with fluoroscopy using 1007.08A0, 1007.11A0,

1002.7000.

Patient positioning for operation on the spinal column,

e.g. on an intervertebral disk.

It is absolutely necessary to observe the

Operating Instructions 9 491 001 403 before attaching the accessory components!

Attach the accessory components according to the

Operating Instructions 9 491 001 403 and position the

patient in the genucubital position using the

1007.03A0, 1007.05A0.

34

GA142501GB03

Page 35

1425.01A/B ORTHOSTAR II

XII. List of accessories

1001.4600

1002.57B0

1000.6800

1001.65A0

1002.5800

1001.44D0

1001.8700

1002.64A0

1002.7000

1003.23C0

1003.5200 1004.8000

GA142501GB03

1002.81D0

1003.50A0

1004.4100

1002.86C0

1003.5100

35

Page 36

XII. List of accessories

1425.01A/B ORTHOSTAR II

1004.85B0

1004.8700

1004.93B0 1004.9800

1004.8800

1004.8900

1004.9700

1004.86B0

1004.90B0

1005.5800

1007.11A0

1009.68A0

36

1007.08A0

1007.12A0

1007.10A0

1009.67A0

GA142501GB03

Page 37

1425.01A/B ORTHOSTAR II

XIII: Table top dimensions / Technical data

Type: ORTHOSTAR II 1425.01 A0/B0

1HLJXQJ

Trendelenburg position

1HLJXQJ

Reverse Trendelenburg position

Length without head rest: 1680 mm

Length incl. head rest: 1965 mm

Width of table top: 530 mm

Width incl. side rails: 530 mm

Height (Europe): 810 1175 mm

Height (USA): 840 1205 mm

Trendelenburg position: 30°

Reverse Trendelenburg position: 25°

Lateral tilt left/right: 20°

Back plate up: 60°

Permissible load: 135 kg

at higher loads consult the manufacturer

Nominal voltage: 200 / 220 / 230-240 V

(100 / 110-115 / 127 V AC)

adjustable

Nominal frequency: 50 / 60 Hz

Power consumption: max.400 VA

Lateral tilt left/right

.DQWXQJ

Operating mode: int 10 min.on / 20 min.off

Fuse protection: T2 L (T4 L) 250 V AC

replacement as per Standard

IEC 127

Battery: Type dryfit A made by

Sonnenschein GmbH

12 V DC 9,5 Ah

Class: II

Degree of protection against electric shocks: Typ B

The enclosure leakage current meets the requirements of

the patient leakage current for CF conditions according to

EN 60601-1.

IPX 4* IPS** SELV*** Dc 24 V

(IPX = protection against splash water)

Explosion protection: AP for battery-powered

operation

If operated from the mains, the operating table is not

suitable for hazardous locations (AP-M).

GA142501GB03

The noise level is < 70 dB(a)

* IPX 4 = protection against ingress of liquids

** IPS = internal power source

*** SELV = safety extra low voltage

37

Page 38

1425.01A/B ORTHOSTAR II

XIV. Spare part supply

Individual components which are part of the operating table ORTHOSTAR II or which are intended to be combined

with this operating table. The spare parts can be ordered using the indicated reference numbers. For further spare

parts and information, please refer to the spare parts list for ORTHOSTAR II, No. 9 491 320 4. and the spare parts

lists for the accessory components.

Choice of control modules which may be used:

IR hand control:

Mobile charging station for IR hand control:

Stationary charging station for IR hand control:

Cable-connected hand control:

Foot switch:

Seat plate pad:

Back plate pad:

Shoulder plate pad:

Pad for triangular buttock support, left:

Pad for triangular buttock support, right:

Leg plate pad:

Roll pad:

Back plate:

Supporting arm:

Shoulder plate, left:

Shoulder plate, right:

Triangular buttock support, left:

Triangular buttock support, right:

Leg plate, left:

Leg plate, right:

Countertraction post:

Telescopic bar, short:

Telescopic bar, long:

Bar elongation:

Screw tension device:

Foot plate support:

Rotation-tilt clamp

Rotation and traction stirrup clamp:

Side rail elongation:

3 110 30 D9.

3 110 26 A9., 3 110 26 B9.

3 110 33 A9., 3 110 32 B9.

3 110 29 D9., 3 110 29 L9.

1009.79B0 (2 Funktions)

9 081 084 4.

9 081 085 4.

9 081 091 4.

9 081 019 4.

9 081 030 4.

9 081 020 4.

9 080 525 4.

3 140 304 2.

3 140 310 2.

3 140 307 2.

3 140 308 2.

3 111 846 9.

3 111 847 9.

3 111 849 9.

3 111 850 9.

3 112 313 4.

3 111 706 3.

3 111 710 3.

3 111 796 4.

1003.3700

1003.4900

1003.3400

1003.35A0

1004.91A0, 1004.91C0

Use only spare parts approved by MAQUET.

38

GA142501GB03

Page 39

1425.01A/B ORTHOSTAR II

GA142501GB03

39

Page 40

All notes and technical data contained in these operating instruction reflect the status at the publication

date. Since we constantly strive to improve all MAQUET products, however, we reserve the right to

adopt modifications at any time, without giving prior notice.

MAQUET Aktiengesellschaft

Kehler Straße 31 D-76437 Rastatt

Surgical Tables Division

Phone: + 49(0)7222 9 32-0

Facsimile: + 49(0)7222 9 32-838

Service-Hotline: + 49-172 923 03 83

e-mail: info.op-tische@maquet.de

Internet: http://www.maquet.com

GA142501GB03 12 / 99

Loading...

Loading...