Page 1

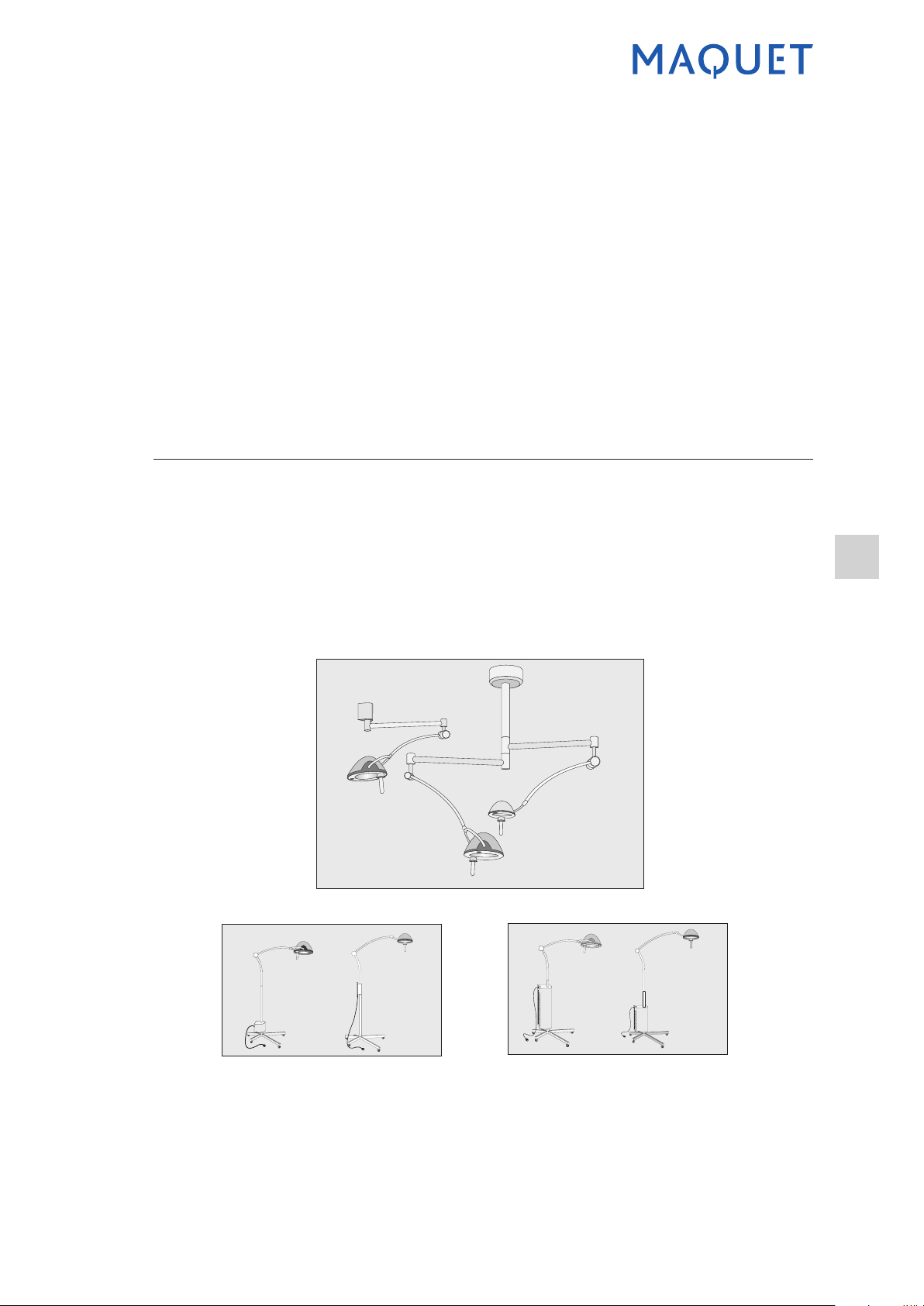

BLUELINE

Ceiling, wall-mounted or mobile surgical light

Technical manual

EN

BLUELINE NT 0136201 EN Ed1A 01/08

Page 2

Ceiling, wall-mounted or

mobile surgical light

0136201

2

Technical manual

BLUELINE

Ceiling, wall-mounted or

mobile surgical lighting

CONTENTS

QUALITY STANDARDS COMPLIANCE ......................................................................................................3

SYMBOLS USED IN THESE INSTRUCTIONS ............................................................................................4

1 GENERAL CHARACTERISTICS ........................................................................................................5

2 CLEANING / DISINFECTION / STERILISATION ................................................................................6

2.1 Cleaning and disinfecting the surgical light ....................................................................................6

2.2 Cleaning and sterilising the handles ...............................................................................................6

3 GENERAL MAINTENANCE ................................................................................................................8

3.1 Preventive maintenance .................................................................................................................8

3.2 First level maintenance ..................................................................................................................8

3.3 Changing the bulb ........................................................................................................................11

3.4 Adjusting the balance ...................................................................................................................15

3.5 Adjusting the top limit stop of the BLUE 80 lighthead

3.6 Adjusting the lighthead brake .......................................................................................................17

3.7 Removing and installing the BLUE 30 lighthead ..........................................................................19

3.8 Removing and installing the BLUE 80 lighthead ..........................................................................21

3.9 Checking the BLUE 30/80 HOSPITAL .........................................................................................22

4 MAINTENANCE PROCEDURES ......................................................................................................24

4.1 BLUE 30 .......................................................................................................................................24

4.2 BLUE 80 .......................................................................................................................................27

5 SPARE PARTS AND MAINTENANCE KITS ....................................................................................34

5.1 BLUE 30 .......................................................................................................................................34

5.2 BLUE 80 .......................................................................................................................................36

6 ELECTRICAL INSTALLATION .........................................................................................................38

6.1 Suggested electrical installation ...................................................................................................38

6.2 Ceiling-mounted BLUE 30 ...........................................................................................................40

6.3 Ceiling-mounted BLUE 80 ...........................................................................................................41

6.4 BLUE 30 MOBILE ........................................................................................................................42

6.5 BLUE 80 MOBILE ........................................................................................................................43

6.6 BLUE 30 HOSPITAL ....................................................................................................................44

6.7 BLUE 80 HOSPITAL ....................................................................................................................45

7 DIAGRAMS AND PARTS LISTS .......................................................................................................47

7.1 Ceiling-mounted BLUELINE .........................................................................................................47

7.2 Wall-mounted BLUELINE .............................................................................................................67

7.3 BLUELINE MOBILE .....................................................................................................................79

7.4 BLUELINE HOSPITAL .................................................................................................................87

7.5 Lightheads ....................................................................................................................................99

7.6 Power supply boxes ...................................................................................................................105

8 TROUBLESHOOTING .....................................................................................................................111

Page 3

Ceiling, wall-mounted or

mobile surgical light

0136201

3

Technical manual

BLUELINE

QUALITY STANDARDS COMPLIANCE

Certication of MAQUET SA’s quality system

LNE/G-MED certies that the quality system developed by MAQUET SA for design, implementation, sales,

installation and after-sales service of surgical lights complies with the requirements of the following interna-

tional standards:

• ISO 9001:2000

• NF EN ISO 13485:2004

Reference standards

The BLUE 30/80 surgical light was designed to comply with the following standards:

• EN ISO 14971:2000 Medical devices - Application of risk management to medical devices

(ISO 14971:2000)

• EN ISO 14971:2000/A1:2003

• EN 60601-1:1990 Medical electrical equipment - Part 1: General requirements for safety

Amendment A1:1993 to EN 60601-1:1990

Amendment A2:1995 to EN 60601-1:1990

Amendment A13:1996 to EN 60601-1:1990

• EN 60601-1-2:2001 Medical electrical equipment - Part 1-2: General requirements for safety Collateral standard: Electromagnetic compatibility - Requirements and tests

• EN 60601-1-4:1996 Medical electrical equipment - Part 1-4: General requirements for safety -

Collateral standard: Programmable electrical medical systems

Amendment A1:1999 to EN 60601-1-4:1996

• EN 60601-1-6:2004 Medical electrical equipment - Part 1-6: General requirements for safety -

Collateral standard: Usability

• EN 60601-2-41:2000 Medical electrical equipment - Part 2-41: Particular requirements for the safety of

surgical luminaires and luminaires for diagnosis

This product has been veried for compliance with the following additional standards: CAN/CSA-C22.2

No. 601.1-M90 (R2005) (includes national differences for Canada), EN 60601-1:1990 + A1:1993 + A2:1995

+ A13:1996, UL 60601-1, rst edition, 2006-04-26 (includes national differences for the USA).

This product only meets FCC/UL requirements when equipped with a MAQUET SA power supply.

CE labelling/intended use

Compliance with the requirements of Directive 93/42/EEC on medical devices has been assessed and

approved by LNE/G-MED. BLUE 30/80 surgical lights belong to Class I as described in Annex IX of Directive

93/42/EEC.

This range includes single or dual ceiling-mounted, single wall-mounted and mobile light units with or without

battery-backed power supply.

Page 4

Ceiling, wall-mounted or

mobile surgical light

0136201

4

Technical manual

BLUELINE

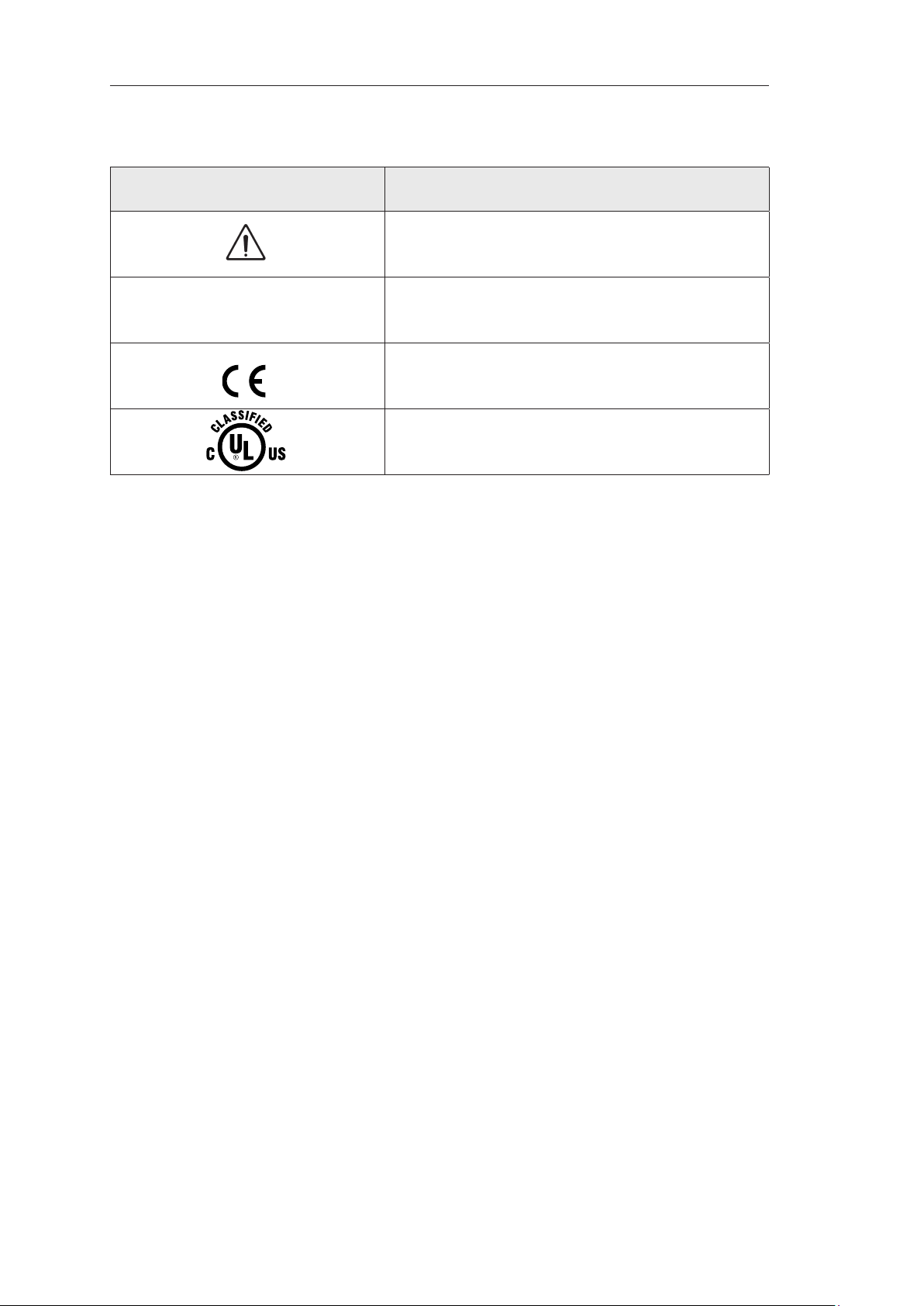

SYMBOLS USED IN THE MANUAL

Symbol Meaning

F

Mandatory:

may affect patient or user safety

Recommendation:

risk of damage to device or accessories

CE mark: The device complies with the requirements of

European Directive 93/42/EEC on Medical Devices.

This device complies with Canadian and US safety

requirements.

Page 5

Ceiling, wall-mounted or

mobile surgical light

0136201

5

Technical manual

BLUELINE

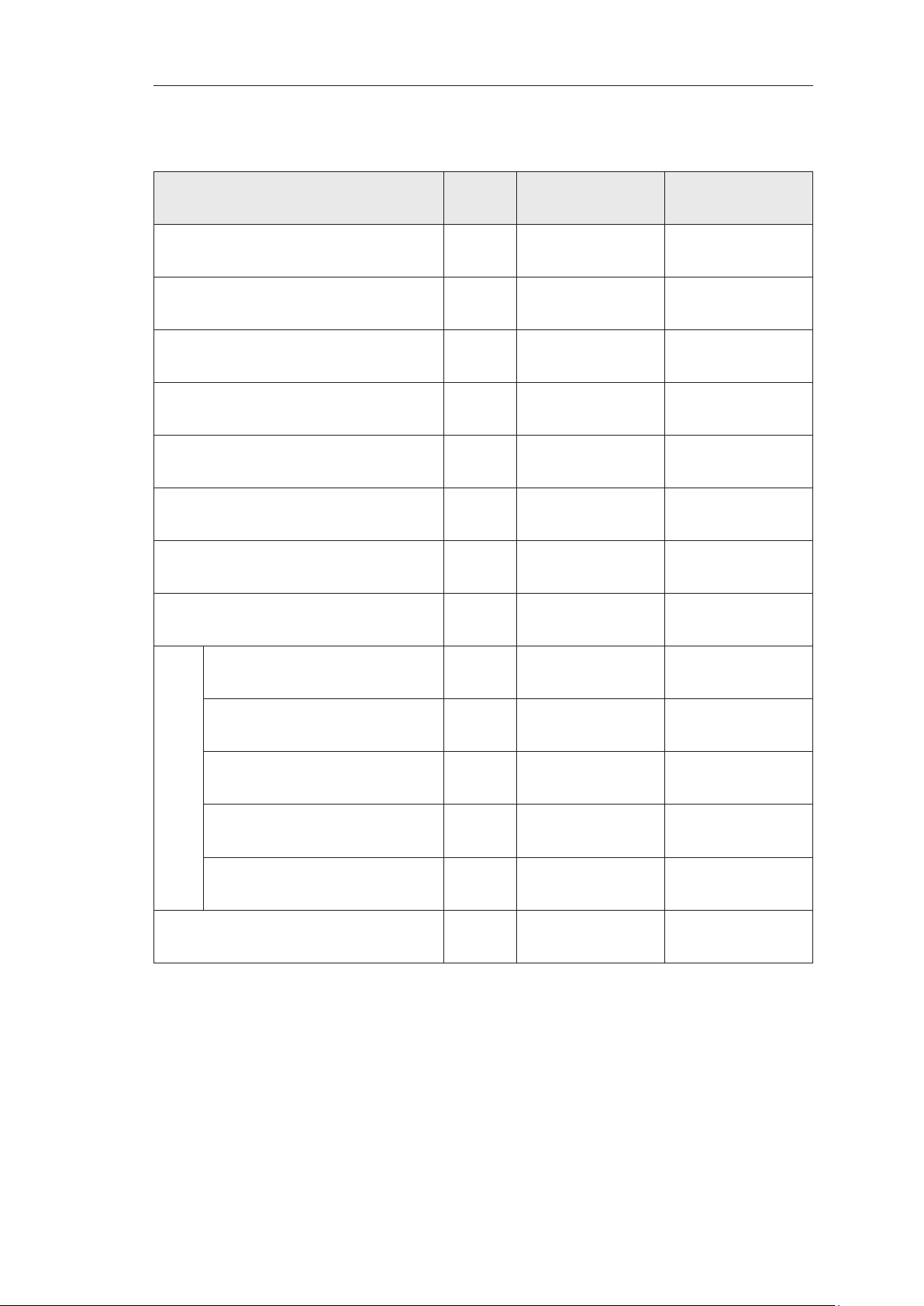

1 GENERAL CHARACTERISTICS

(IN ACCORDANCE WITH STANDARD IEC 60 601-2-41)

Specications Unit BLUE 30 BLUE 80

Nominal illumination*

Nominal voltage V DC 22.8 22.8

Maximum power W 40 80

Colour temperature

Colour rendering index >85 >85

Illumination depth cm (inch) 175 (69) 140 (67)

Diameter d10

Diameter d50

With one mask % 0 % 6 %

lx

+/- 10%

K

+/-6%

cm (inch)

+/- 10%

cm (inch)

+/- 10%

35,000 90,000

4600 4600

17 (6.7) 16 (6.3)

10 (3.9) 10 (3.9)

With two masks % 62% 49 %

At base of tube % 100 % 100 %

Shadow dilution

With one mask, at base of tube % 0 % 6 %

With two masks, at base of tube % 62 % 49 %

Irradiance (Ee)* W/m

* Values measured during certication:

BLUE 30: 38.400 lx / 139 W/m

BLUE 80: 85.500 lx / 305 W/m

2

2

2

140 360

Page 6

Ceiling, wall-mounted or

mobile surgical light

0136201

6

Technical manual

BLUELINE

2 CLEANING / DISINFECTION / STERILISATION

Users must contact their hospital's sanitary specialists. The recommended products and procedures must

be applied. Should there be any doubt concerning the compatibility of active agents to be used, contact the

local Maquet customer service department.

2.1 Cleaning and disinfecting the surgical light

F

2.1.1 General instructions concerning cleaning, disinfection and safety

• Remove the sterilisable handles.

• Clean the system using a cloth soaked in surface detergent, in line with the manufacturer's recom-

• Use a cloth to rinse the unit with clean water and wipe dry.

• Disinfect uniformly using a cloth soaked in a disinfectant, in line with the manufacturer’s recommenda-

• Use a cloth to rinse with clean water in order to remove residues (in particular products containing al-

• Wipe with a dry cloth.

2.1.2 Examples of recommended products

Getinge USA product: TEC-QUAT 256

Anios products: SURFA’SAFE, 0.5% HEXANIOS G + R (ammonium IV, polyhexanide); ANIOSYME P.L.A

(quaternary ammonium, enzymes); SALVANIOS pH10 (quaternary ammonium, guanidinium); ANIOS DDSH

(quaternary ammonium, guanidinium).

Schülke & Mayr products: Antifect Plus (Glyoxal), Terralin (Benzyl-C12-18-alkyldimethyl ammonium, phe-

noxypropan and phenoxypropanol).

2.1.3 Examples of prohibited products

F

Check that the power is switched off and the light is cool before cleaning.

mended dilution, application time and temperature.

tions.

dehydes, quaternary ammonium or surfactants).

Solutions containing glutaraldehyde, phenol, iodine, bleach, alcohol or chloride ions must not be

used.

Fumigation methods are unsuitable for disinfecting the unit and must not be used.

2.2 Cleaning and sterilising the handles

2.2.1 Before cleaning

• Use a soft cloth immediately after use to wipe away soiling from the handle surface.

• Store handles in a place that keeps them moist to make further cleaning easier.

• Take care to store them in such a way that the inside does not get soiled.

2.2.2 Cleaning

• Soak the handles in a detergent solution.

• Soak for 15 minutes to allow the solution to act, then clean by hand with a soft brush and a lint-free

cloth.

• During cleaning, check regularly that the handles are fully clean and that no soiling remains on the

inside or outside.

• If any soiling remains, repeat cleaning or use an ultrasonic cleaning process.

• Rinsing: Rinse thoroughly in clean water to completely eliminate the detergent solution.

• Drying: Wipe with a clean lint-free cloth.

1

Never soak the handles in enzyme-based detergents as they may damage the material used; rinse thoroughly if

these detergents are used.

1

Page 7

Ceiling, wall-mounted or

mobile surgical light

0136201

7

Technical manual

BLUELINE

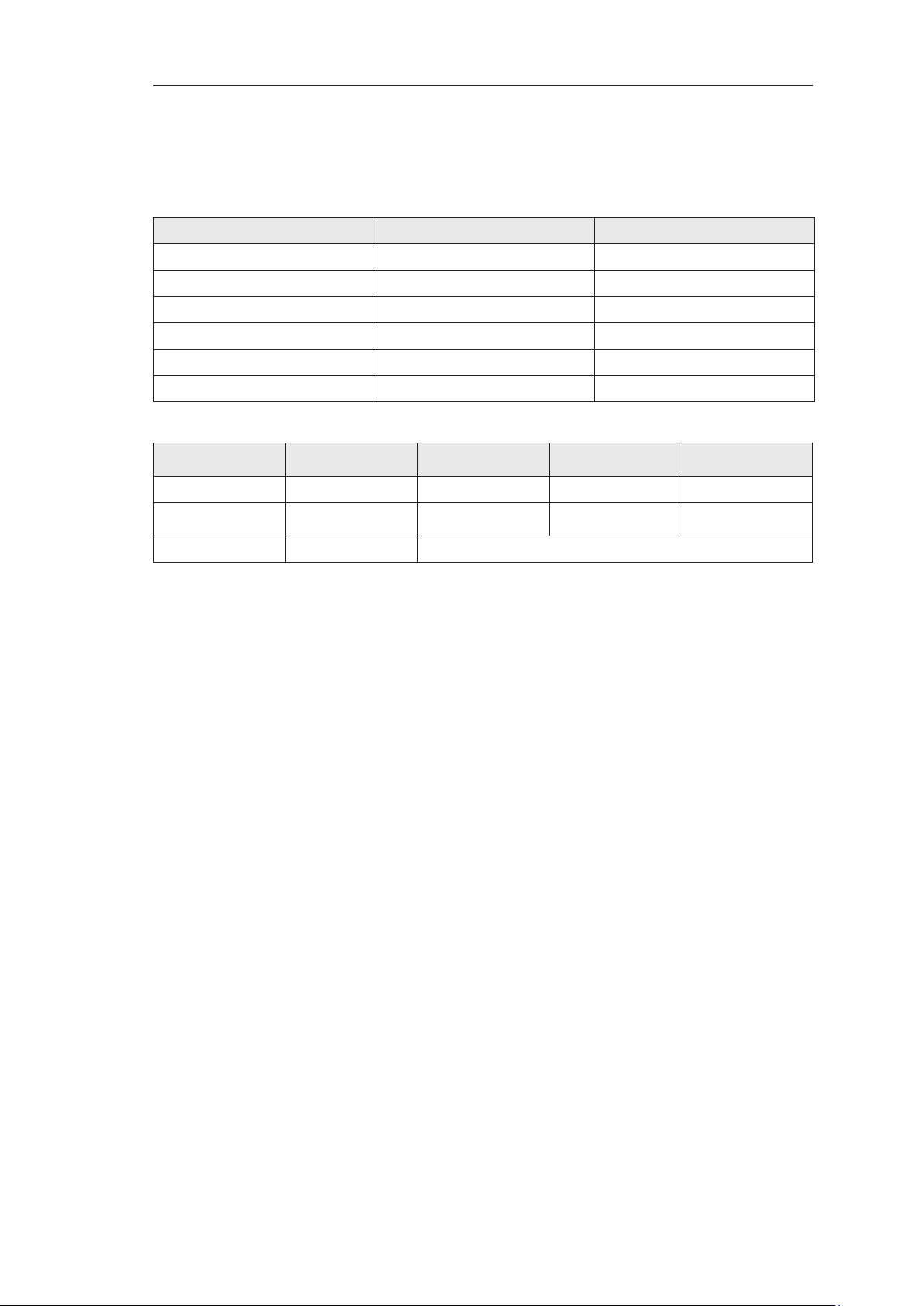

2.2.3 Washing and disinfection

Handles may be disinfected by machine (Clean Maquet) and rinsed at a maximum temperature of 93°C.

Typical recommended cycles:

2.2.4 Sterilisation

Step Temperature Time

Pre-wash 18 - 35°C 60 sec

Wash 46 - 50°C 300 sec

Neutralisation 41 - 43°C 30 sec

Wash 2 24 - 28°C 30 sec

Rinse 92 - 93°C 600 sec

Dry 20 min

After cleaning, the handles must be steam sterilised as set out below:

Countries

USA & Canada Prevacuum

France

Other countries Prevacuum Comply with national regulations

Sterilisation cycle

2

ATNC (Prion)

(Prevacuum)

Temperature [°C] Time [min] Drying [min]

132 - 135 10 16

134 18

• Check that each handle is clean before continuing the process.

• Wrap the handles with sterilisation wrapper material (double wrapper or equivalent).

Handles may also be placed in paper or plastic sterilisation bags3, for easier identication and reuse.

• Place the handles on steriliser trays with the opening downwards.

• Package with biological and/or chemical indicators for monitoring the sterilisation process, in accord-

ance with applicable regulations.

• Run the sterilisation cycle according to the steriliser manufacturer's instructions.

F

F

• Dispose of sterilisable handles in the same way as other hazardous products in a hospital environ-

To ensure correct sterilisation do not allow any soiling to penetrate inside the handle.

Handles are not guaranteed beyond 350 sterilisation cycles with the above sterilisation param-

eters.

ment.

4

2

This handle is made of a porous material.

3

Possible sterilisation bag suppliers:

Medical Action Industries

SBW Medical

Baxter International

4

For air removal and faster drying.

Page 8

Ceiling, wall-mounted or

mobile surgical light

0136201

8

Technical manual

BLUELINE

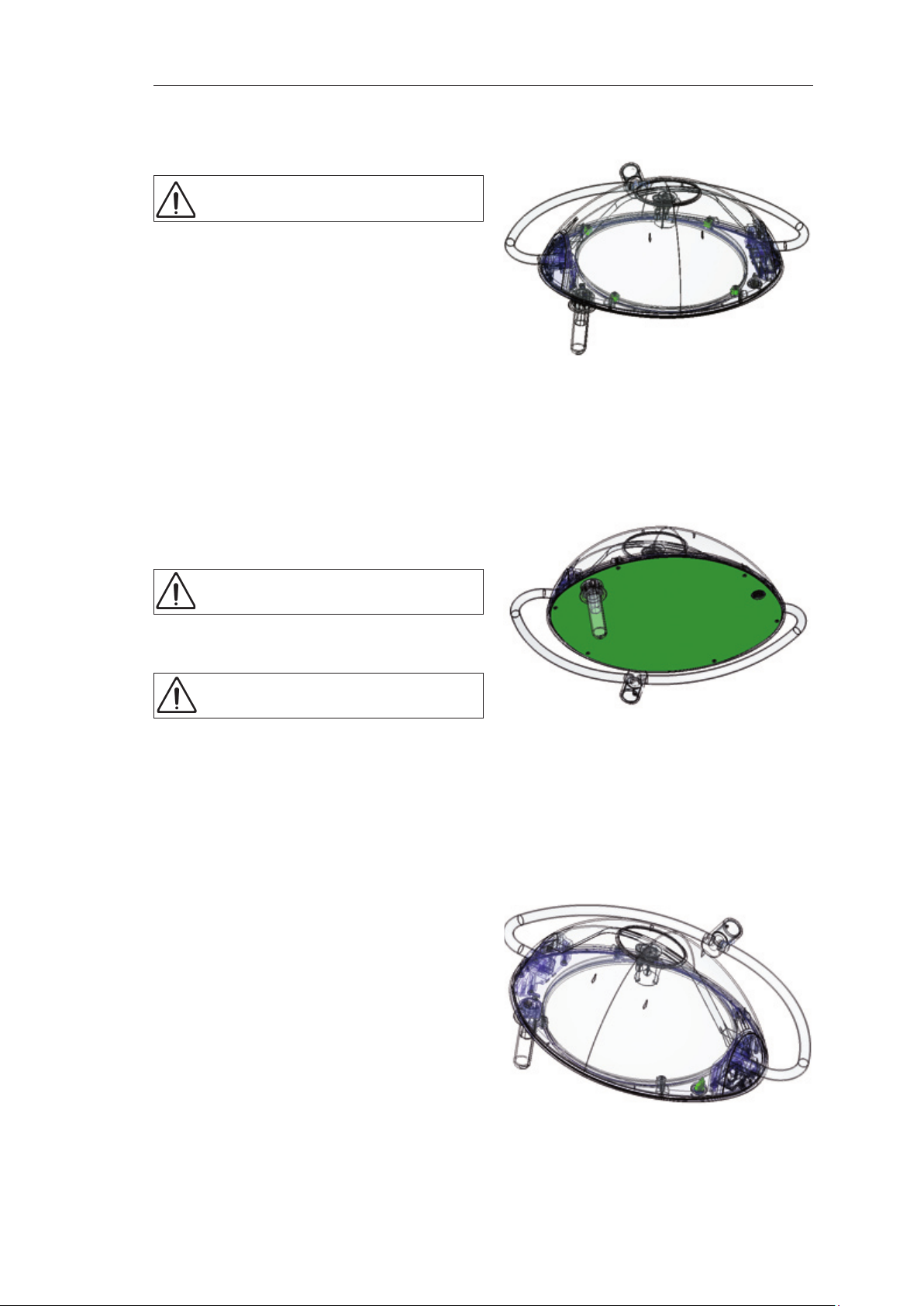

3 GENERAL MAINTENANCE

Isolate the surgical light from all electrical power sources and/or check that it is connected to an

isolating transformer at very low voltage.

If the spring arm is not disabled when dismantling the lighthead, the arm may spring up abruptly

and present a hazard. The rst step is therefore to disable the spring arm.

The light unit becomes hot during operation. Allow it to cool down before any maintenance or

repair work.

3.1 Preventive maintenance

To preserve your surgical light’s original performance and reliability, annual maintenance and inspections

should be performed as follows:

• By a Maquet technician or Maquet-approved distributor during the guarantee period.

• By a Maquet technician or Maquet-approved distributor or by the hospital's technical maintenance de-

partment outside the guarantee period (contact your dealer to arrange the required technical training).

3.2 First level maintenance

3.2.1 Daily inspection (user)

• Check that the bulbs operate correctly.

• Check that the sterilisable handle locks correctly in place, and replace it if not.

• Check the arm position.

• If a backup power supply is installed, check that the light would operate correctly if a power cut were to

occur.

• Check the overall condition of the unit: paintwork in good condition, screws fastened tightly, bezels and

covers in position.

3.2.2 Annual inspection (must be performed by an authorised technician)

• Check that the limit stops are in place and in good condition.

• Check and tighten the brakes.

• Check the bulb holder and replace if necessary.

• Check that the lighthead limit stops are in place and in good condition.

• For the BLUE HOSPITAL, check the battery autonomy and the backup supply changeover system (see

section 5.4).

• Check that the underside is in good condition and replace it if necessary.

Safety items

Check the following points:

• Attachment screws on suspension tube correctly tightened, seals in position.

• Arm(s) correctly mounted.

• All covers and caps installed.

Other checks

• Nominal illumination: see technical data.

• Earth continuity: 0.1 Ohm maximum.

• Suspension tube vertical.

• Balancing system adjusted correctly.

• Sterilisable handle locking mechanism.

• Voltage.

Page 9

Ceiling, wall-mounted or

mobile surgical light

0136201

9

Technical manual

BLUELINE

Dismantling certain elements may affect operation and safety. For example:

• Servicing the electrical power supply.

• Servicing the suspension arm and balance system.

• Servicing the optical system of lightheads equipped with lters designed to eliminate radiation not

visible to the patient. Surgical lights must never be used without these lters.

Contact the authorised Maquet after-sales service department for this type of inspection.

Page 10

Ceiling, wall-mounted or

mobile surgical light

0136201

10

Technical manual

BLUELINE

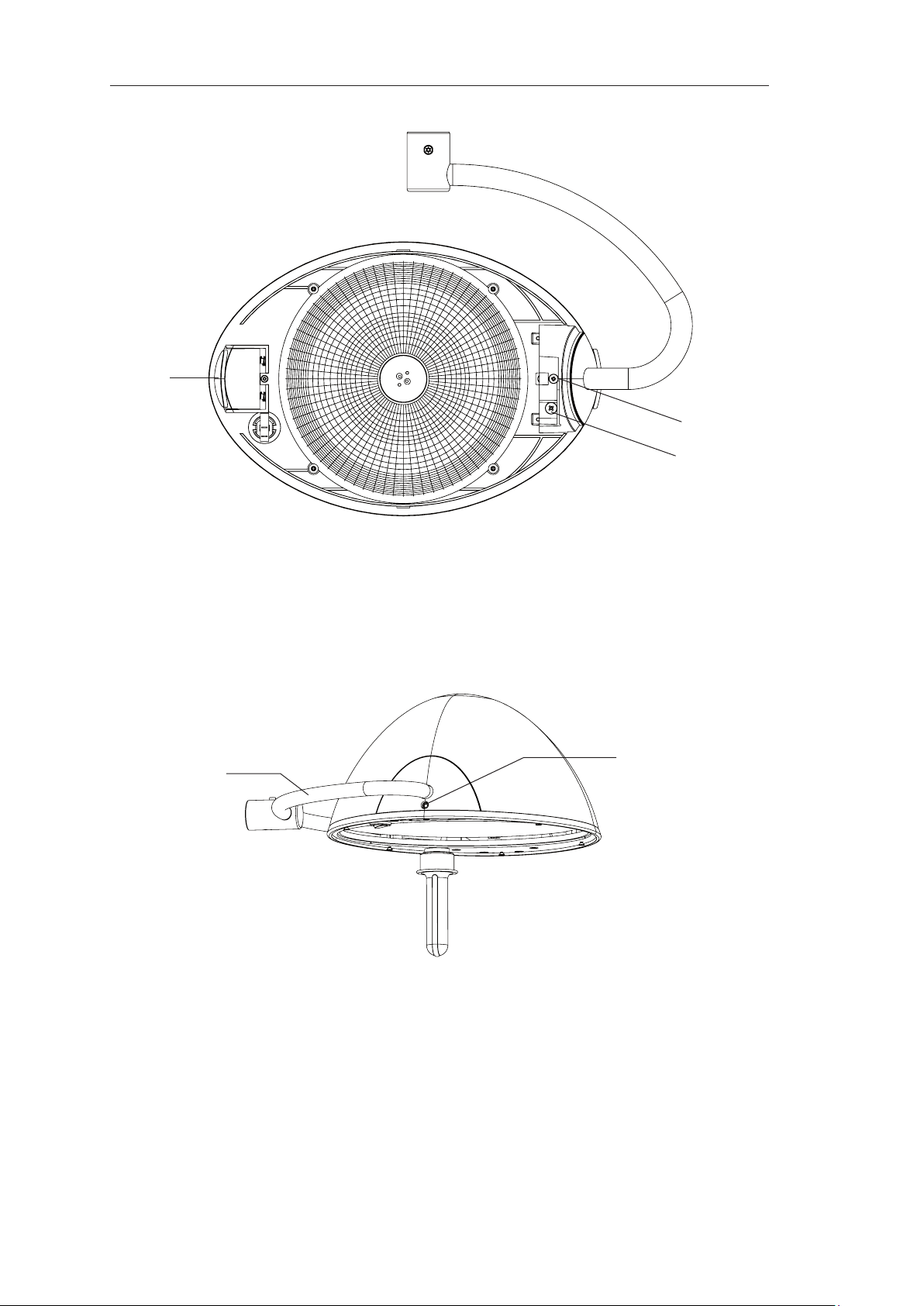

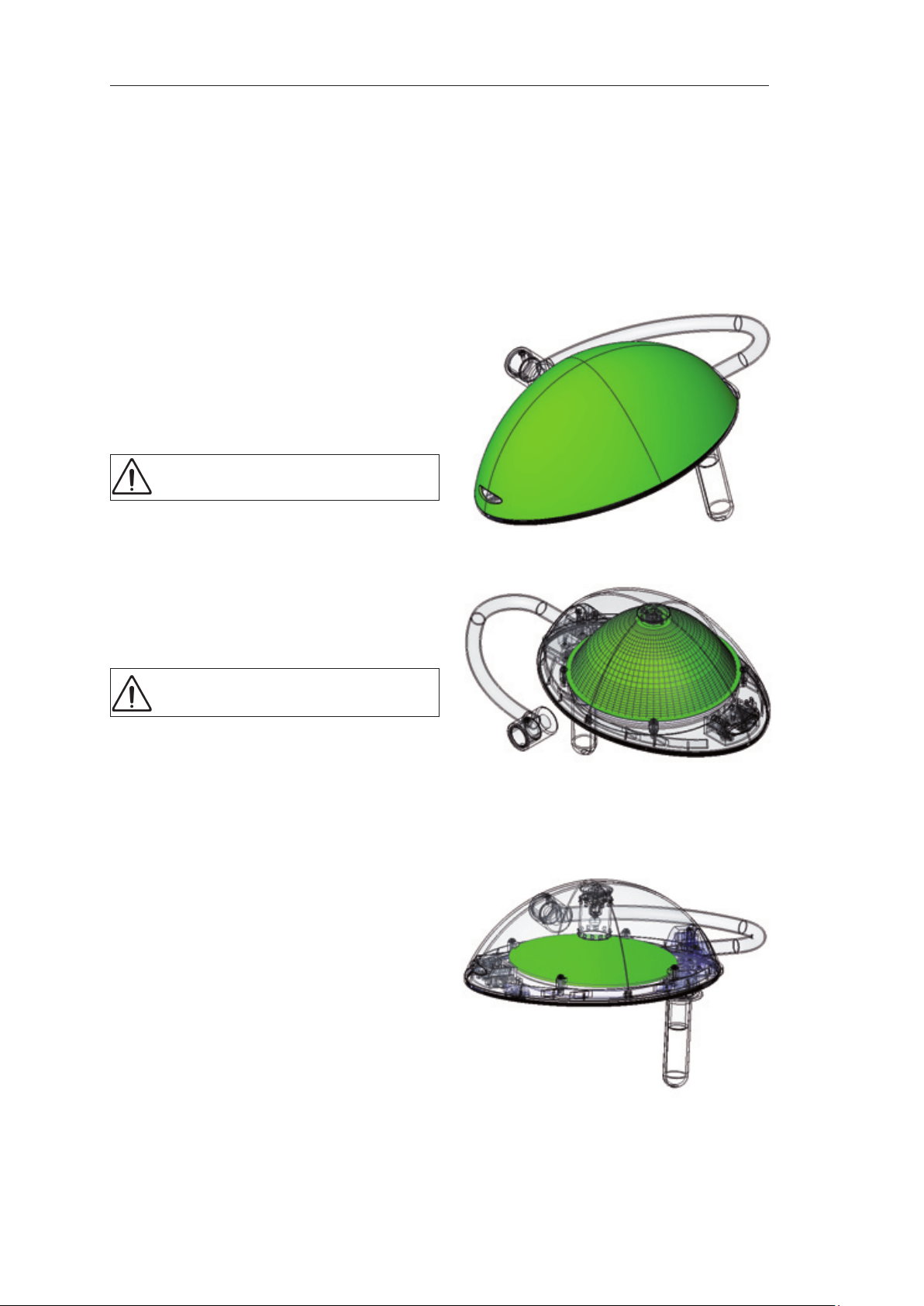

BLUE 30

2

1

Figure 1

3

Figure 3

4

Figure 2

Figure 4

Figure 5

Figure 7

Figure 6

Page 11

Ceiling, wall-mounted or

mobile surgical light

0136201

11

Technical manual

BLUELINE

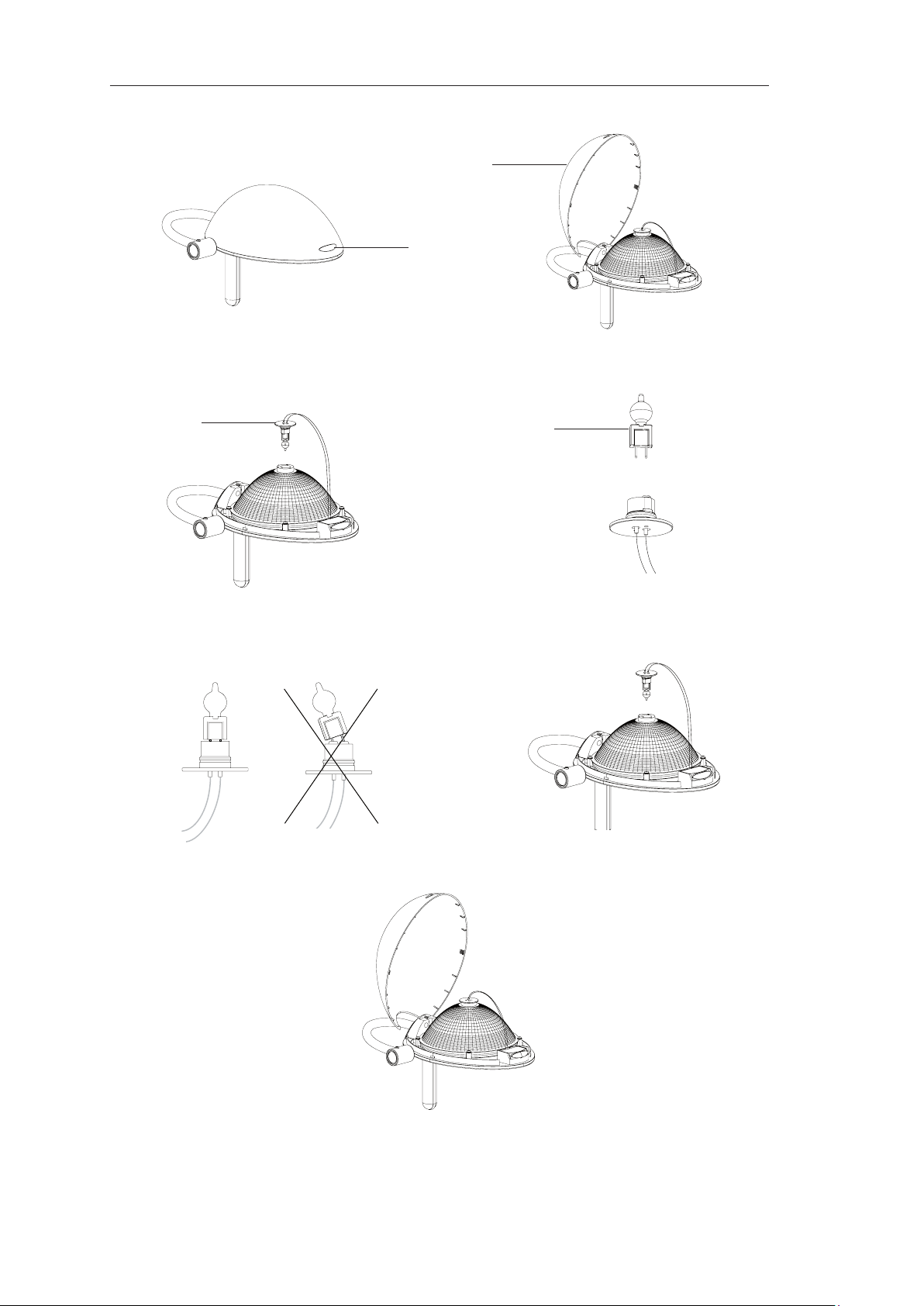

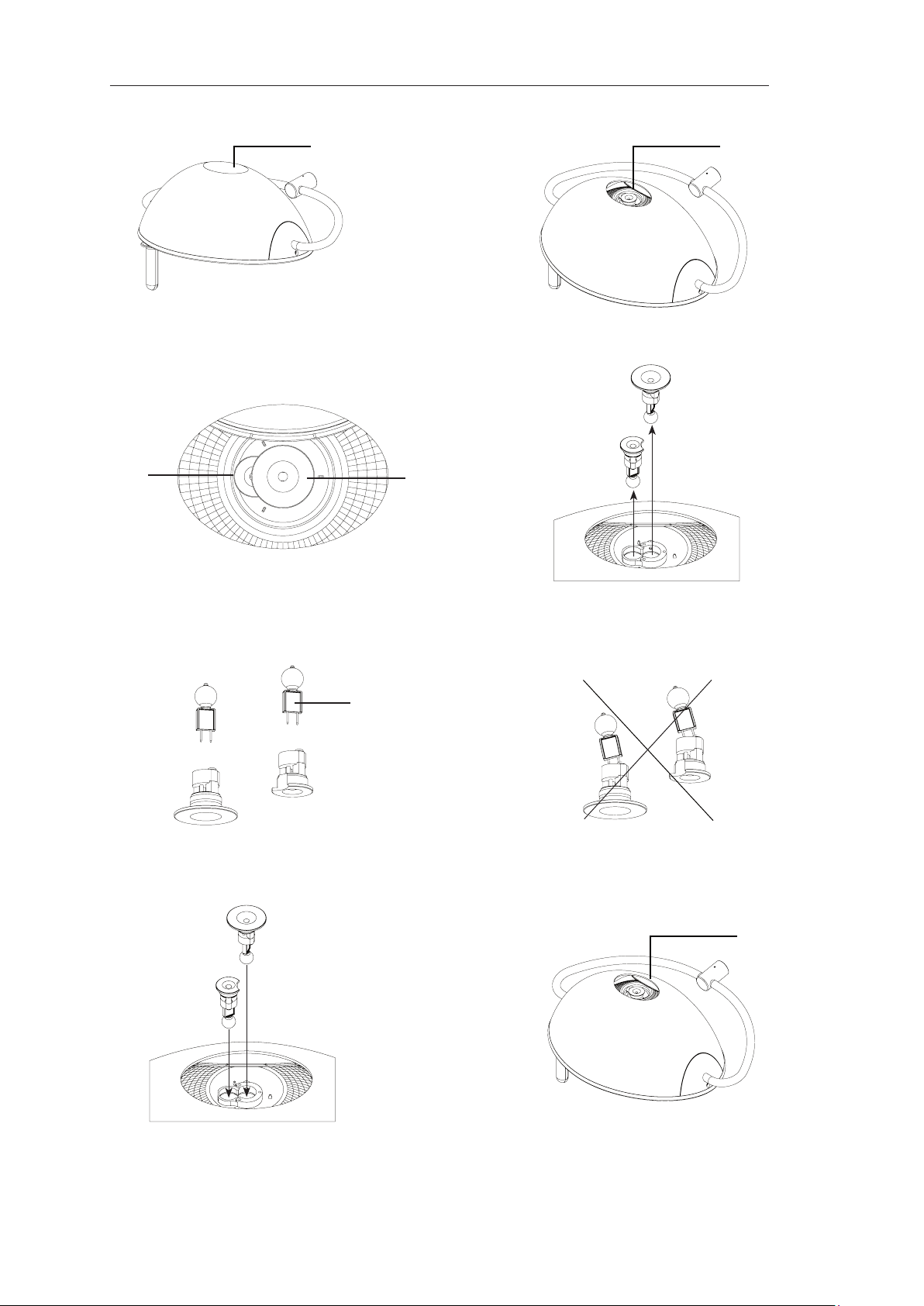

3.3 Changing the bulb

BLUE 30 lighthead

F

Figures 1 and 2

• Press the locking tab (1) and raise the casing of the failed bulb (2).

Figure 3

• Remove the bulb holder (3), taking care not to knock the hot bulb against any surfaces.

Figure 4

• Take the failed bulb (4) and remove it from the holder.

• Take the new bulb and remove it from its packaging.

Figure 5

• Insert the bulb pins into the bulb holder as far as they can go.

• Check that the bulb is correctly seated.

F

Figure 6

• Replace the bulb holder (3) and check that the locking tab clicks audibly into place.

Figure 7

• Close the cover and check that the locking tab clicks audibly into place.

F

When changing a blown bulb:

• Switch off the power supply and leave the lighthead to cool for 25 minutes.

• Only use MAQUET bulbs.

• Handle bulbs carefully through a cloth or wearing gloves.

• Never touch bulbs with bare hands. Grease on bulbs can shorten their life.

Do not change bulbs during an operation.

The unit is designed to operate with the cover closed. When conducting maintenance, take precautions to avoid touching surfaces marked as hot with the following symbol:

To avoid failures during operations, we recommend changing the bulbs on a preventive basis

every 600 hours.

If the bulb cannot be inserted fully, do not force it beyond the limit stop.

Check that the cover is correctly in place.

Page 12

Ceiling, wall-mounted or

mobile surgical light

0136201

12

Technical manual

BLUELINE

BLUE 80

4

Spare bulb

Figure 1

1

Figure 2

1

1

3

Main bulb

2

Figure 3

Figure 5

2

1

Figure 4

5

Figure 6

1

Figure 7

Figure 8

Page 13

Ceiling, wall-mounted or

mobile surgical light

0136201

13

Technical manual

BLUELINE

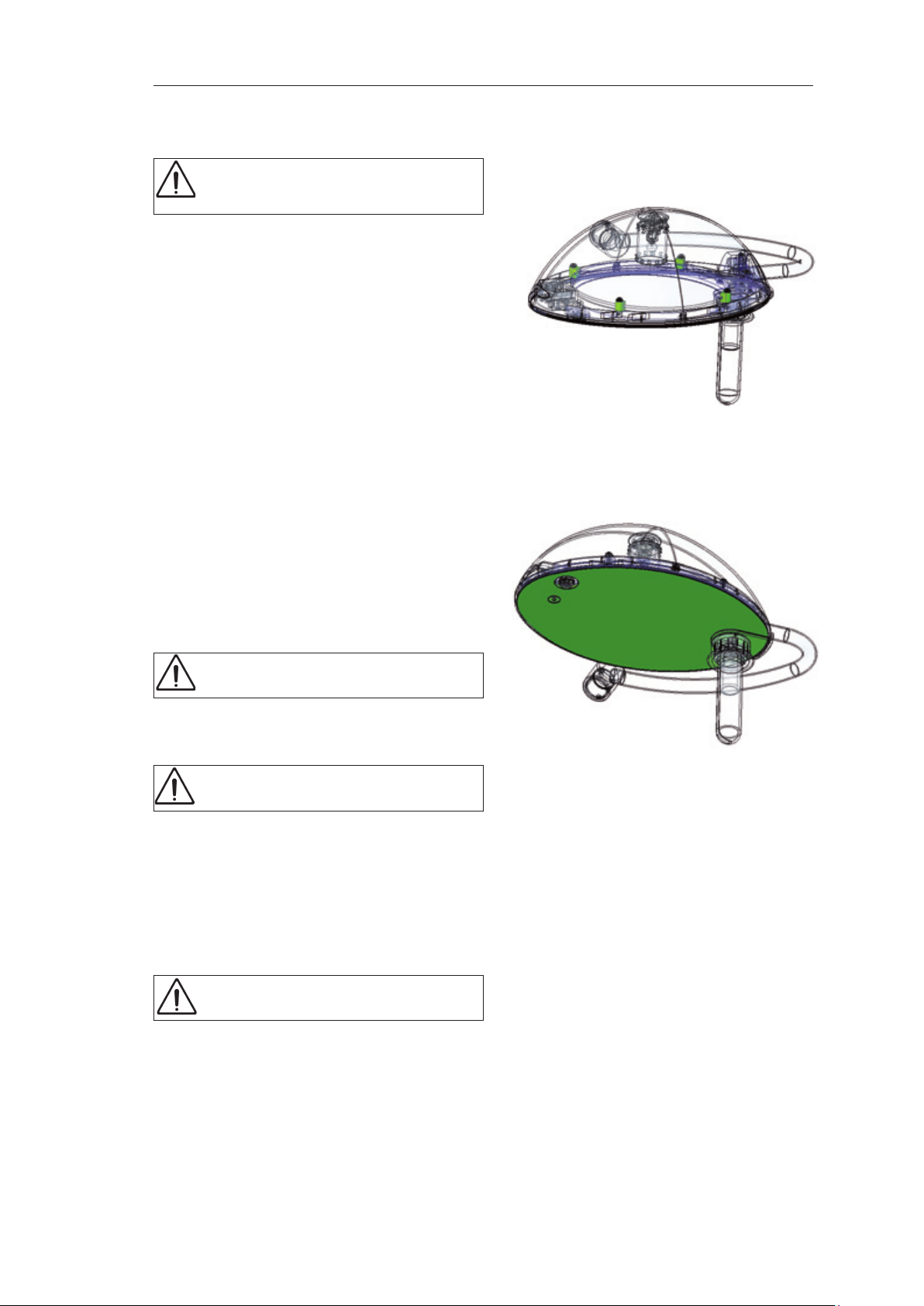

BLUE 80 lighthead

F

Figures 1 and 2

• Push the cover in slightly (1) and slide it sideways.

Figures 3 and 4

• First remove the main bulb holder (3), then the spare bulb holder (4), taking care not to knock the hot

Figure 5

• Take the failed bulb (5) and remove it from the holder.

• Take the new bulb and remove it from its packaging.

• Insert the bulb pins into the bulb holder as far as they can go.

F

Figure 6

• Check that the bulb is correctly seated.

Figure 7

• Replace the spare bulb holder rst, then the main bulb holder, checking that the locking tab clicks audi-

Figure 8

• Close the cover (1) and check that it is correctly in place.

When changing a blown bulb:

• Switch off the power supply and leave the lighthead to cool for 20 minutes.

• Only use MAQUET bulbs.

• Handle bulbs carefully through a cloth or wearing gloves.

• Never touch bulbs with bare hands. Grease on bulbs can shorten their life.

Do not change bulbs during an operation.

The unit is designed to operate with the cover closed. When conducting maintenance, take precautions to avoid touching surfaces marked as hot with the following symbol:

To avoid failures during operations, we recommend changing the main and spare bulbs on a preventive basis every 750 hours.

The yellow indicator on the underside of the BLUE 80 lighthead is lit if the spare bulb is activated.

To avoid a total failure of the surgical light, change the main bulb as soon as possible. We recommended changing the spare bulb at the same time.

bulb against any surfaces.

If the bulb cannot be inserted fully, do not force it beyond the limit stop.

bly into place in each case.

Page 14

Ceiling, wall-mounted or

mobile surgical light

0136201

14

Technical manual

BLUELINE

2

1

1 Bezel on mobile arm of spring arm

2 Bezel on xed arm of spring arm

3 Adjustment nut

3

Figure 33

1

1 Bezel on mobile arm of spring arm

2 Set screw

Figure 34

2

Page 15

Ceiling, wall-mounted or

mobile surgical light

0136201

15

Technical manual

BLUELINE

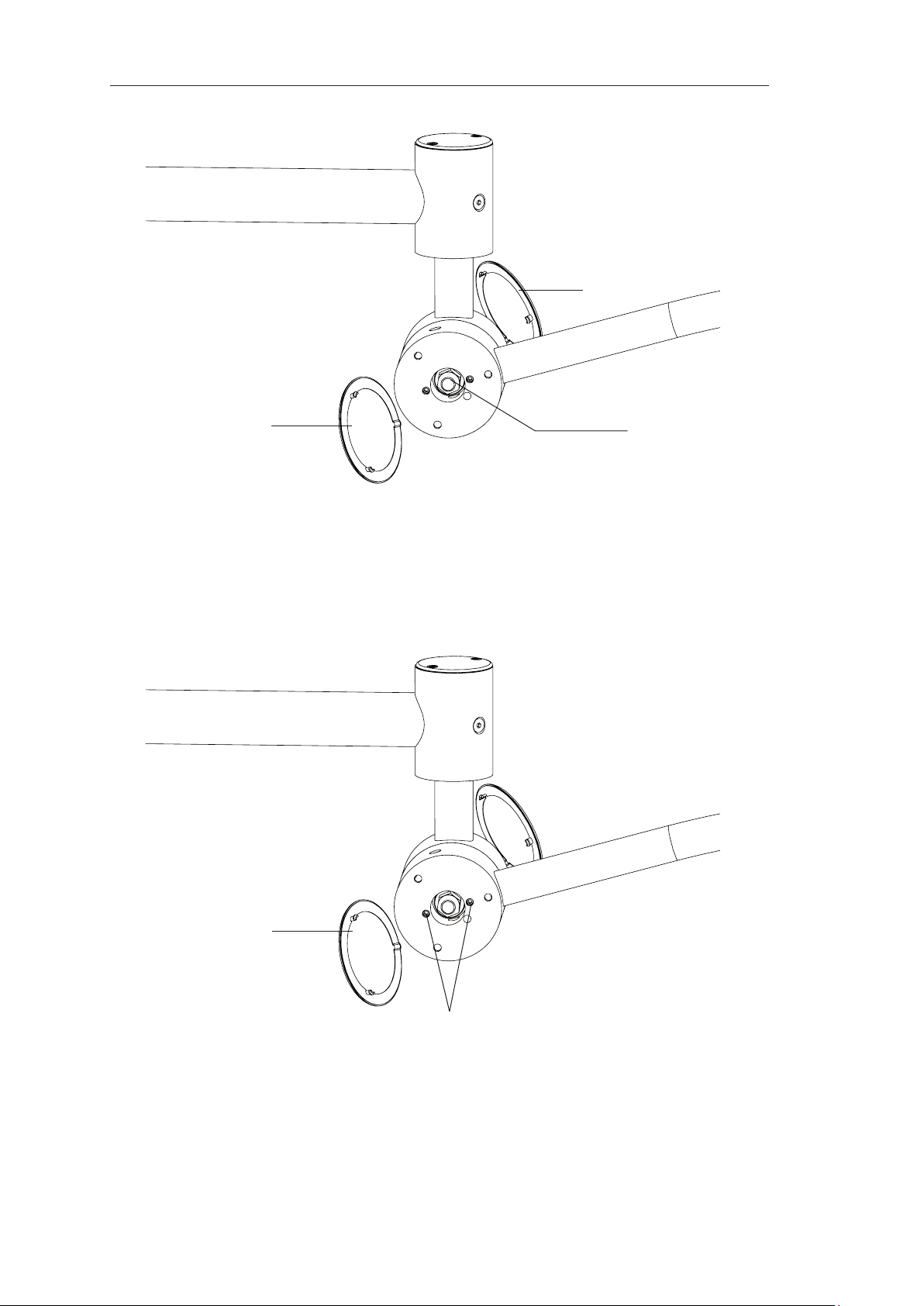

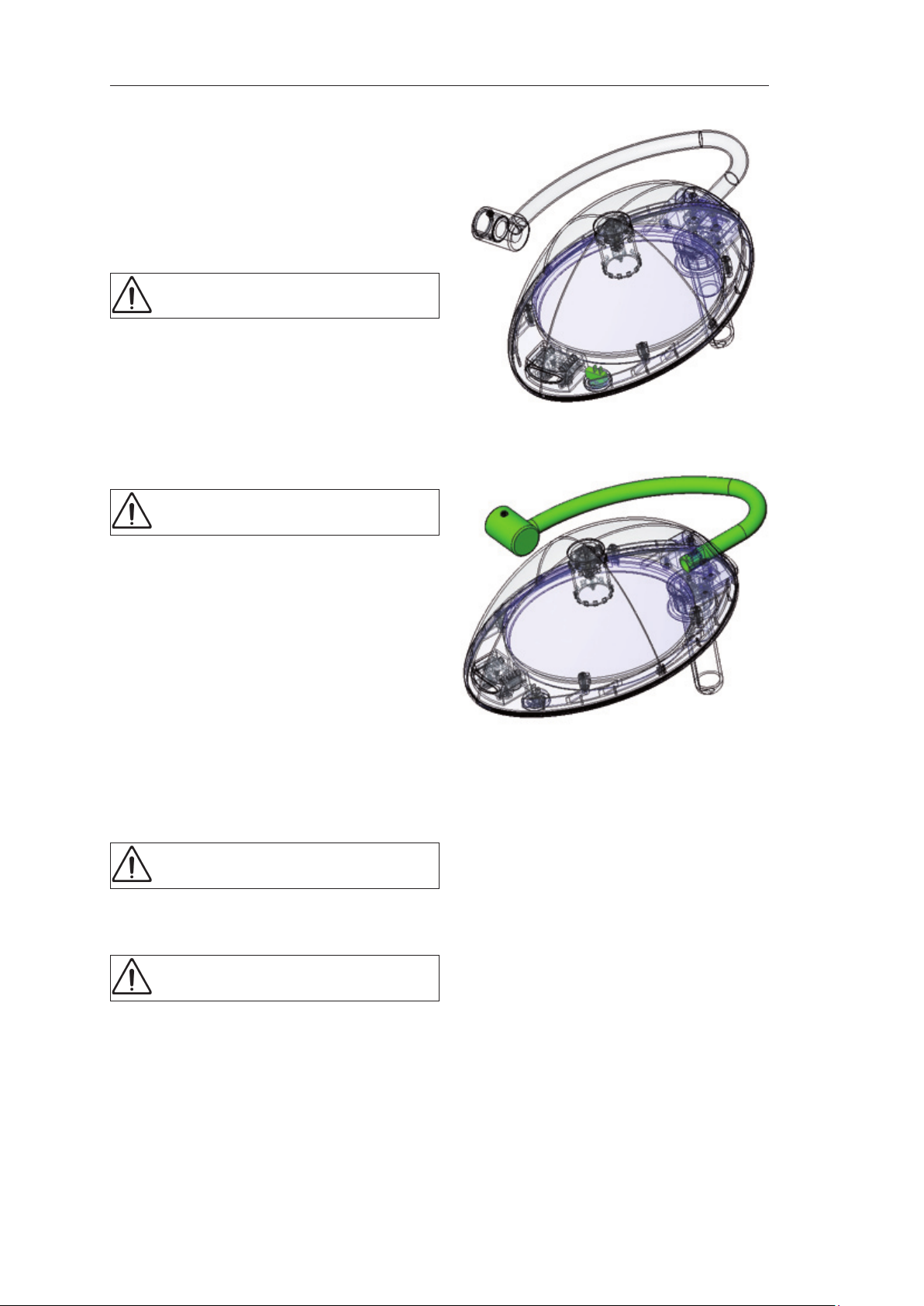

3.4 Adjusting the balance

Figure 33

F

• Remove the bezel from the mobile arm of the spring arm (1) and, for the BLUE 80, the bezel from the

• Turn the adjustment nut (3) by no more than half a turn, holding the hexagon socket screw on the op-

• If the lighthead goes down, turn to the right.

• If the lighthead goes up, turn to the left.

• Check that the spring arm remains steady in each position.

• Replace the bezel(s).

3.5 Adjusting the lighthead top limit stop

Figure 34

F

• Carefully remove the bezel from the mobile arm of the spring arm (1).

• Position the lighthead at the maximum desired height.

• Tighten the two socket screws (2) until resistance is felt.

If the spring arm does not remain steady in all positions, the force of the spring in the arm can be

increased or decreased.

xed arm (2).

posite side in position for the BLUE 80.

BLUE 80

BLUE 80 lightheads can be adjusted so that the travel cannot exceed the ceiling height.

The spring arm may be damaged if the socket screws are not tightened evenly.

Tighten the socket screws uniformly.

Page 16

Ceiling, wall-mounted or

mobile surgical light

0136201

16

Technical manual

BLUELINE

BLUE 30

1

2

3

1 Locking tab

2 Brake screw

3 Retaining screw (do not loosen)

BLUE 80

2

Figure 35

1

Figure 36

1 Brake screw

2 Lighthead fork

Page 17

Ceiling, wall-mounted or

mobile surgical light

0136201

17

Technical manual

BLUELINE

3.6 Adjusting the lighthead brake

The lighthead brakes are adjusted during installation. Brakes, like all mechanical parts, are subject

to wear. If the lighthead no longer remains steady in all positions the brake must be readjusted.

The light unit becomes hot during operation. Allow it to cool down before adjusting the brake.

BLUE 30 lighthead

Figure 35

• Turn off the BLUE 30 lighthead and allow it to cool down.

• Press the locking tab (1) to remove the bezel.

• Adjust the lighthead braking by tightening or loosening the brake screw (2). The retaining screw (3)

holds the lighthead in place and must not be loosened.

• Close the cover and check that the locking tab clicks audibly into place.

• Check that the cover is correctly in place.

BLUE 80 lighthead

Figure 36

• Turn off the BLUE 80 lighthead and allow it to cool down.

• Adjust the lighthead braking by tightening or loosening the brake screw (1) above the lighthead fork

(2).

Page 18

Ceiling, wall-mounted or

mobile surgical light

0136201

18

Technical manual

BLUELINE

2

3

1

Figure 4

4 65

2

7

Figure 5

Page 19

Ceiling, wall-mounted or

mobile surgical light

0136201

19

Technical manual

BLUELINE

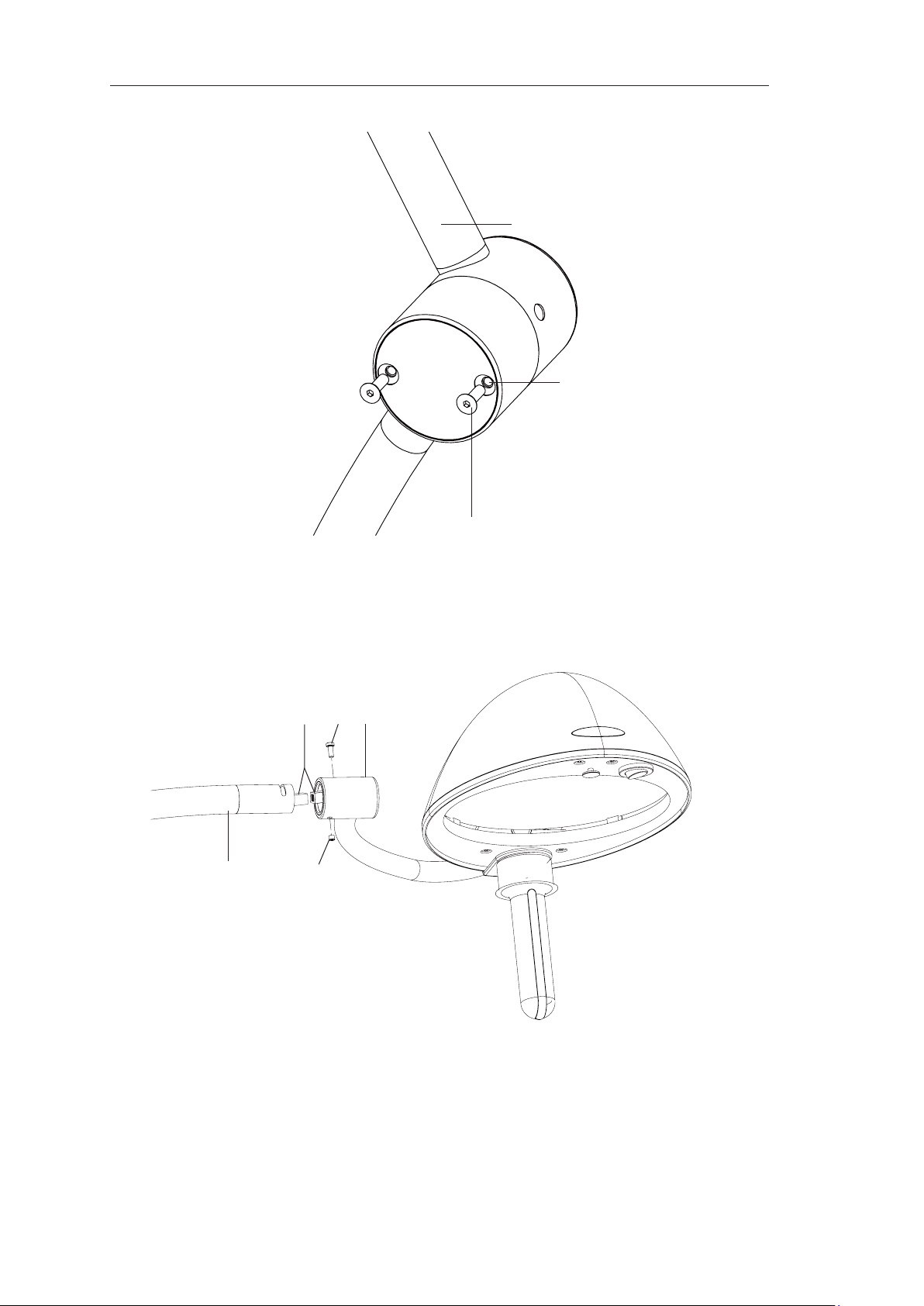

3.7 Removing and installing the BLUE 80 lighthead

If the spring arm is not disabled when removing the lighthead, the arm may spring up abruptly and

present a hazard.

• Lower the spring arm and lock it in a safe position when installing the lighthead.

• Assemble in the correct order: rst install the lighthead then enable the arm.

• Place the arm in the topmost position when removing the lighthead.

• Keep clear of the spring arm when enabling it.

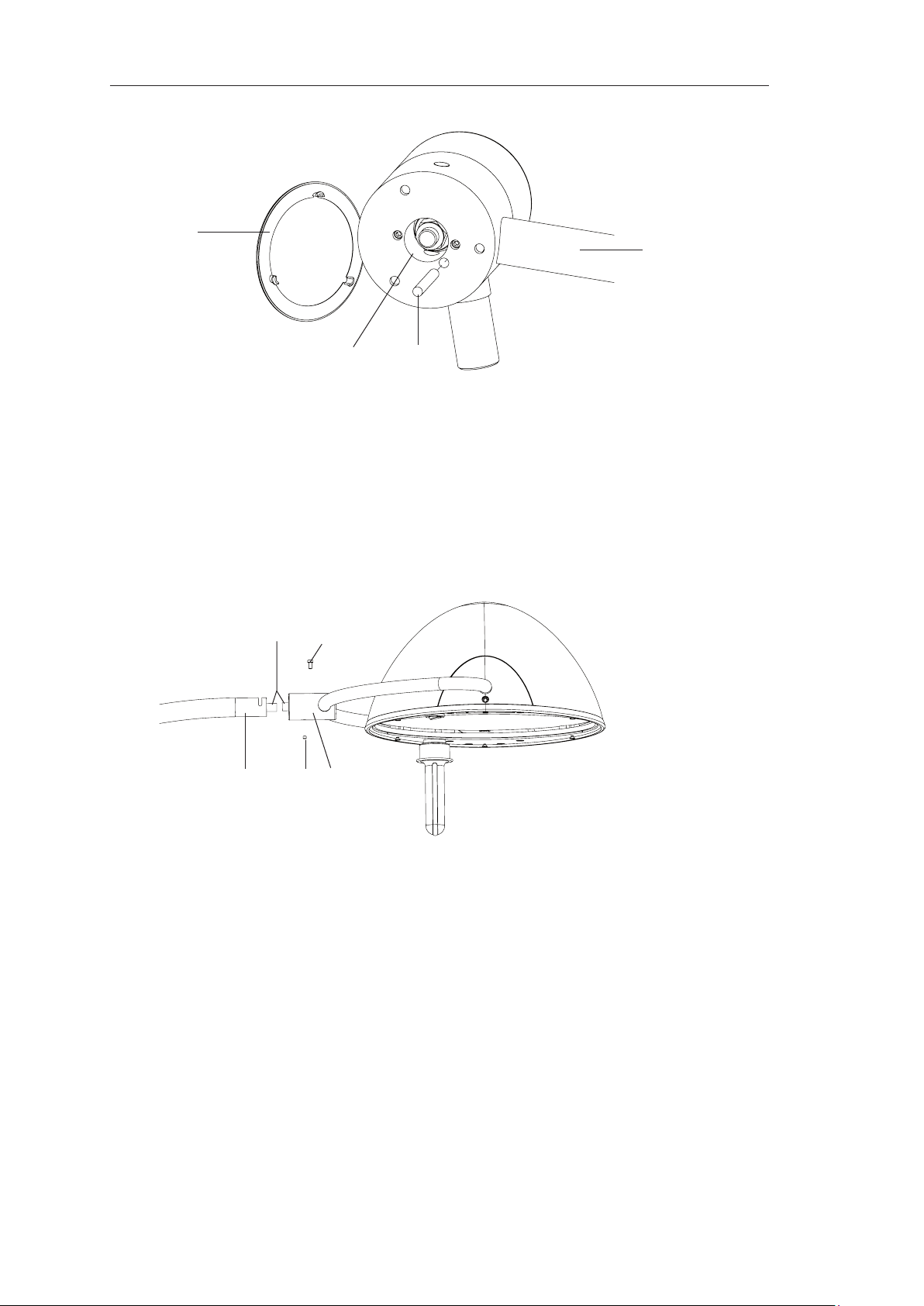

Removing the BLUE 30 lighthead

Figure 4

• Place the spring arm (2) in the top position.

• Remove the two taper-head hex socket screws (1) to disable the spring arm.

Figure 5

F

• Unscrew the hexagon socket screw (5).

• Unscrew the brake screw (7).

• Remove the fork (6) from the spring arm and separate the connectors (4).

The hex socket screw (5) is a safety screw* that must be replaced each time the unit is

reassembled.

Reinstalling the BLUE 30 lighthead

Figure 4

F

• To disable the spring arm, unscrew the two taper-head hex socket screws (1).

Figure 5

• Secure the connectors (4).

F

• Insert the fork (6) in the spring arm (2) such that the hole in the spring arm lines up with the hole in the

• Lock the fork in place with the hex socket safety screw (5).

• Use a at screwdriver to tighten the brake screw (7).

Figure 4

• To enable the spring arm, tilt the lighthead and spring arm (2) upwards until the holes (3) line up with

• Install the two taper-head hex socket screws (1).

* Safety screws are available in packs of 5 (3 690 51 555).

The spring arm must be disabled before installing the BLUE 30 lighthead.

The hex socket screw (5) is a safety screw that must be replaced each time the unit is

reassembled.

fork.

the tappings (3).

Page 20

Ceiling, wall-mounted or

mobile surgical light

0136201

20

Technical manual

BLUELINE

1

2

4

8

2

5

76

3

Figure 9

Figure 10

Page 21

Ceiling, wall-mounted or

mobile surgical light

0136201

21

Technical manual

BLUELINE

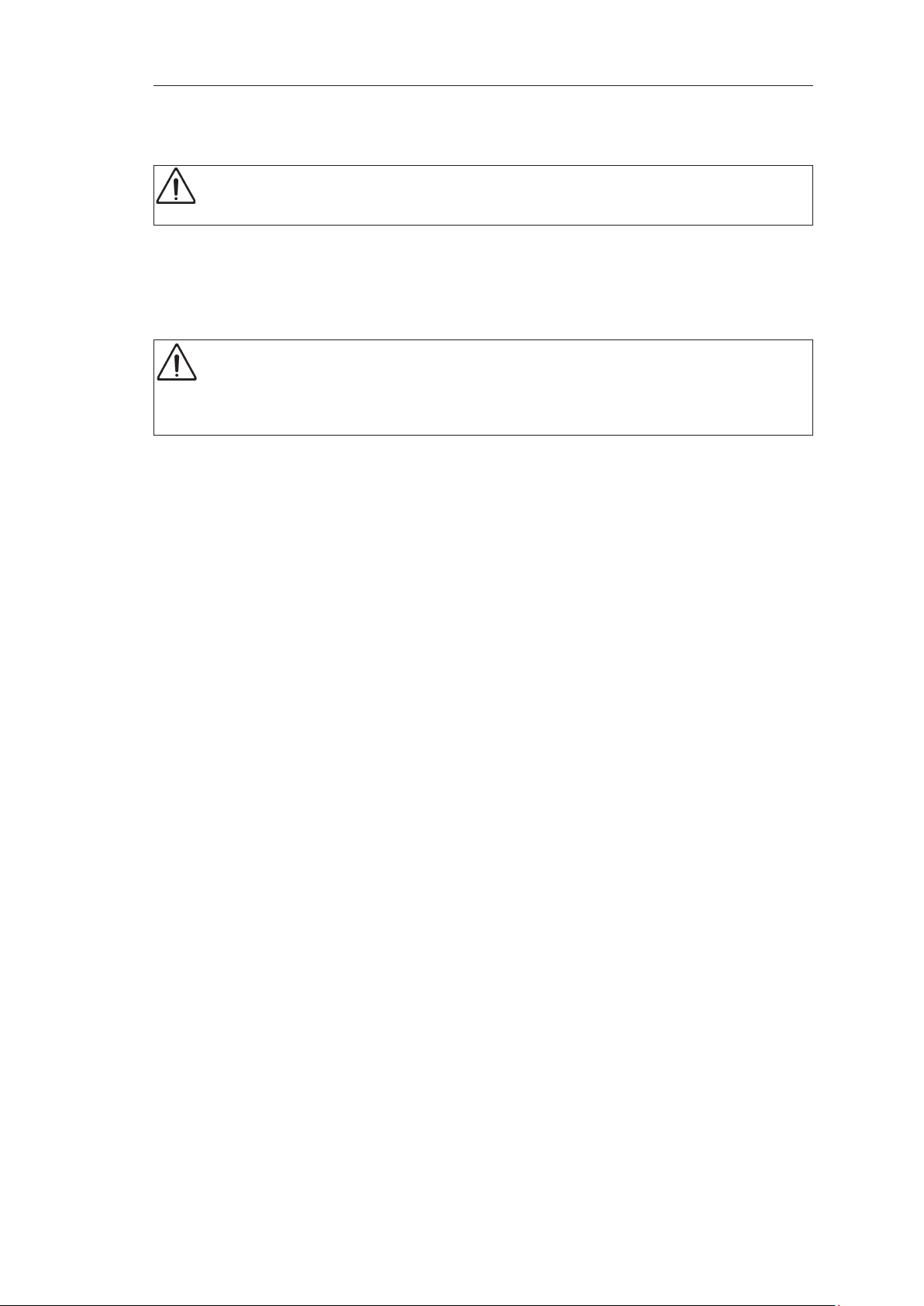

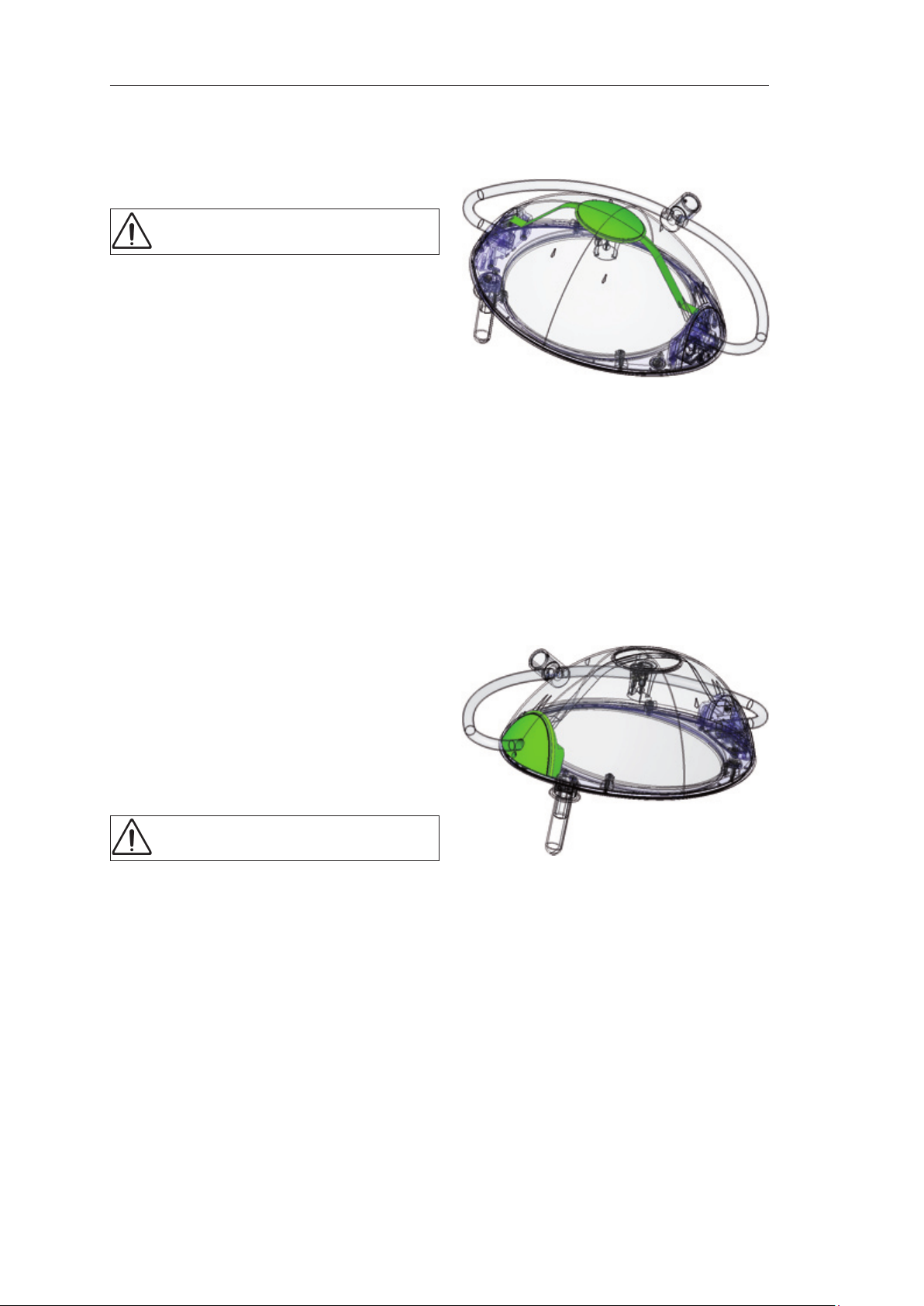

3.8 Removing and installing the BLUE 80 lighthead

The order of disassembly is important:

If the spring arm is not disabled when disassembling the BLUE 80 lighthead, the arm may spring

up abruptly and present a hazard. The rst step is therefore to disable the spring arm.

Disabling the BLUE 80 spring arm

Figure 9

• Remove the bezel (1) from the mobile side of the spring arm (2).

• Pivot the spring arm down to the oor and insert the locking pin (3) in hole (4).

If the locking pin is not inserted deeply enough in the hole the spring arm may spring up abruptly

and present a hazard.

Check that the spring arm correctly locked in place before releasing it.

Only use the supplied locking pin.

Removing the BLUE 80 lighthead

Figure 10

F

• Unscrew the hexagon socket screw (5).

• Unscrew the brake screw (6).

• Remove the fork (7) from the spring arm and separate the connectors (8).

Reinstalling the BLUE 80 lighthead

Figure 10

• Secure the connectors (8).

F

• Insert the fork in the spring arm such that the hole in the fork lines up with the hole in the ring.

• Lock the fork in place using the shakeproof hex socket screw (5) and the brake screw (6).

Enabling the BLUE 80 spring arm

Figure 9

• Lower the spring arm (2) and lighthead slightly by pressing on it.

• Remove the locking pin (3).

• Install the bezel (1) and check that it is correctly in place.

The hex socket screw (5) is a safety screw that must be replaced each time the unit is reassembled.

The hex socket screw (5) is a safety screw* that must be replaced each time the unit is

reassembled.

* Safety screws are available in packs of 5 (3 690 52 555).

Page 22

Ceiling, wall-mounted or

mobile surgical light

0136201

22

Technical manual

BLUELINE

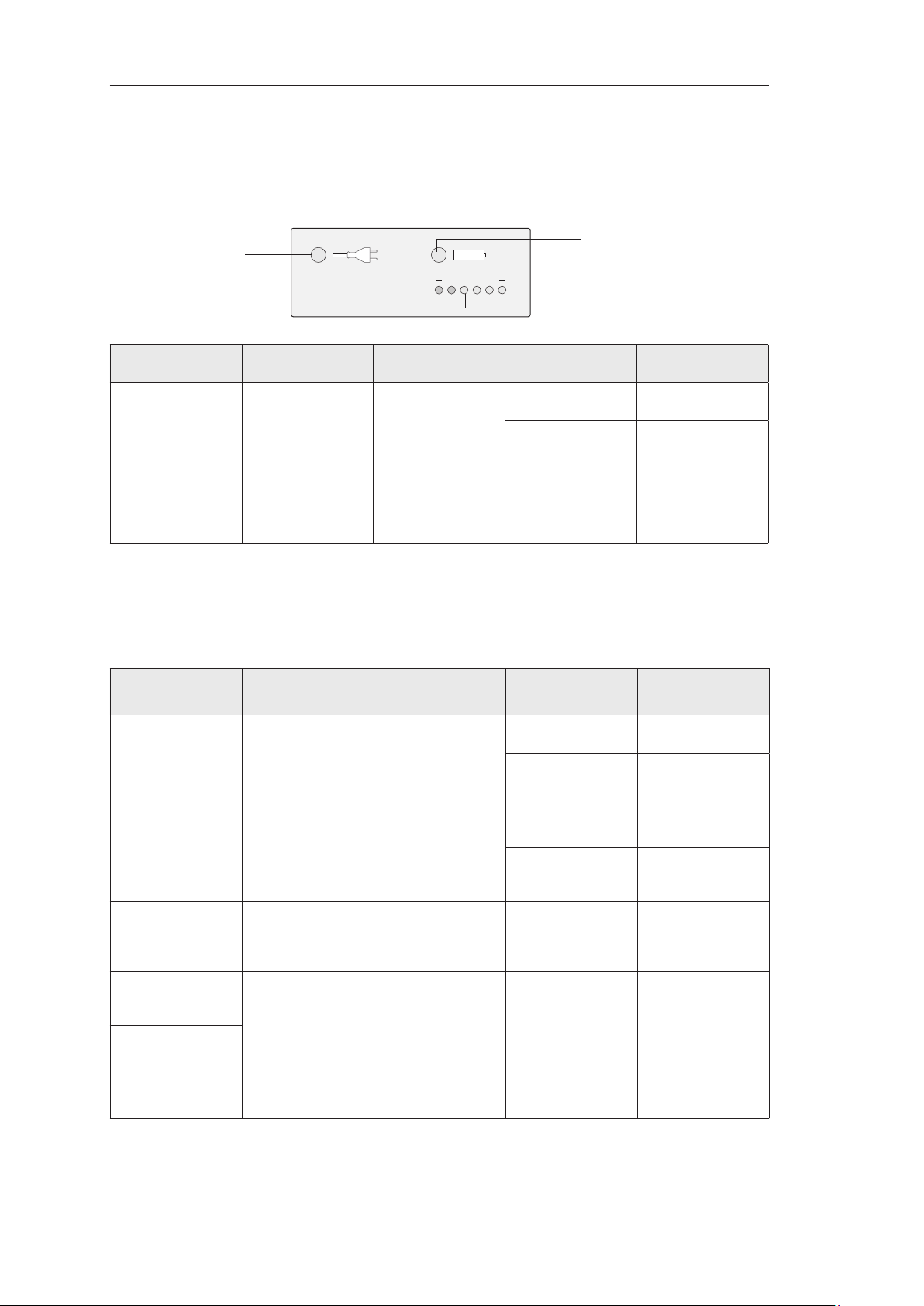

3.9 Checking the BLUE 30/80 HOSPITAL

F

To ensure that the surgical light will operate correctly in the event of a power failure it must be

checked before each use.

LED 1

Check Mains

LED 1

Plug the light into

the power outlet

and turn it on

Disconnect the

power outlet (the

light should remain

on)

Testing the autonomy of the batteries in the BLUE 30/80 HOSPITAL light

F

To guarantee that the light will operate correctly in the event of a power cut, the battery autonomy

must be checked at least once a year, as part of preventive maintenance work.

Check Mains

Turn off the light

and charge the

batteries for at

least 14 hours

Turning on the light LED green LED off LEDs 3 to 8

Disconnect the

power outlet (the

light should remain

on)

BLUE 30:

After 1 hour's battery operation

BLUE 80:

After 4 hours' battery operation

Connect the power

outlet

LED green LED off LEDs 3 to 8

LED off LED yellow One of LEDs 3 to

LED 1

LED green LED off LEDs 3 to 8

LED off LED yellow One of LEDs 3 to

LED off LED yellow One of LEDs 3 to

LED green LED off LEDs 3 to 8

Batteries

LED 2

Batteries

LED 2

Charging

LEDs 3 to 8

scrolling

LED 8 ashes Batteries

8 lit

(battery charge

level)

Charging

LEDs 3 to 8

scrolling

LED 8 ashes Batteries

scrolling

LED 8 ashes Batteries

8 lit

(battery charge

level)

8 lit

(battery charge

level)

scrolling

LED 2

LEDs 3 to 8

Comment

Batteries charging

completely

charged

Operation on

batteries

Comment

Batteries charging

completely

charged

Batteries charging

completely

charged

Operation on

batteries

Operation on

batteries

Batteries charging

Page 23

Ceiling, wall-mounted or

mobile surgical light

0136201

23

Technical manual

BLUELINE

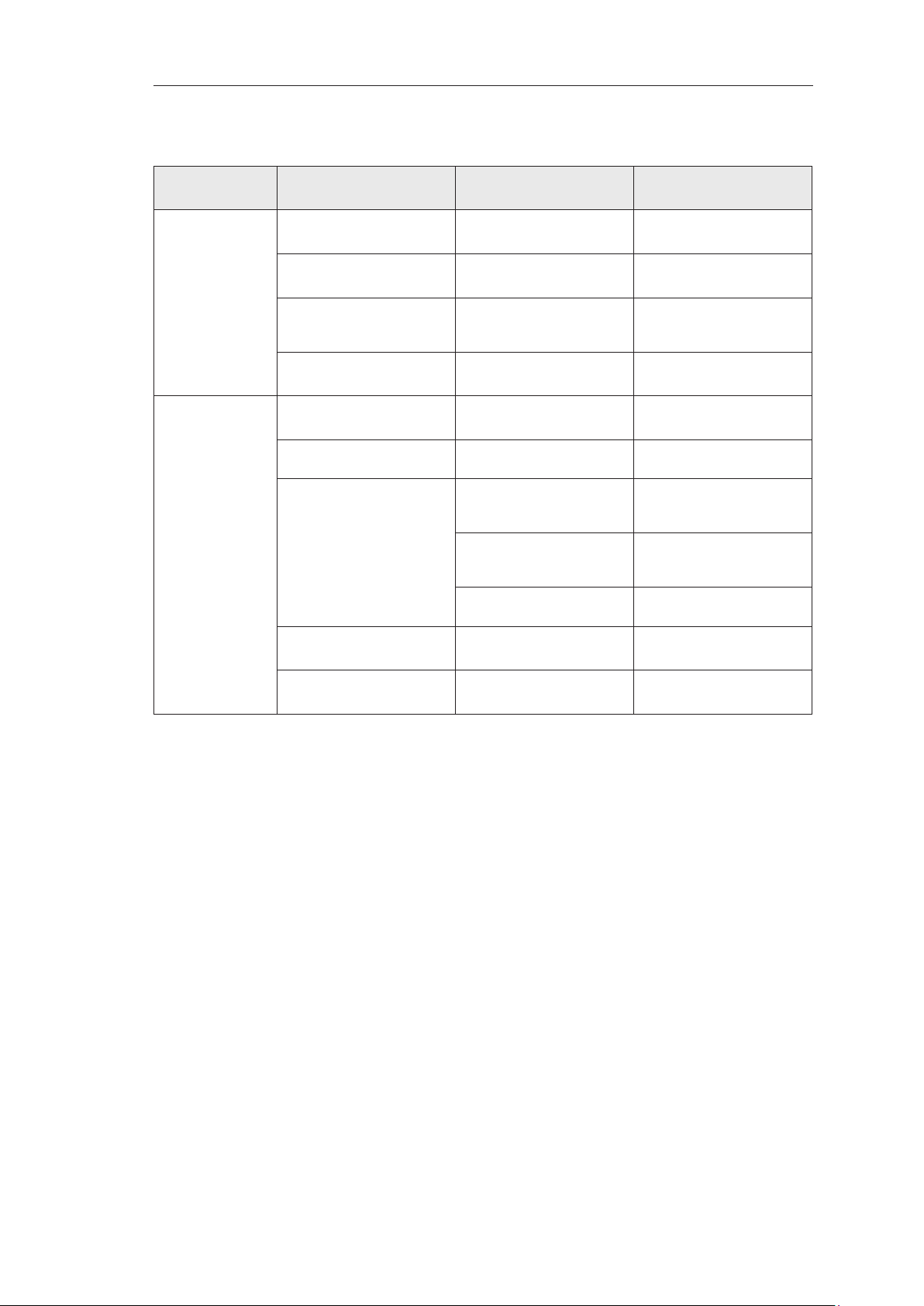

Anomalies

Operation Anomaly Likely cause Corrective action

On power outlet

(light on)

On batteries (light

on)

LED 1 not lit green Electronic fault Call Maquet technical

department

LED 2 lit yellow Mains fuse missing or

blown

LED 1 ashes red Charging circuit safety

fuse fault

LEDs 3 to 8 not scrolling;

LED 8 not lit

LED 2 not lit yellow Electronic fault Call Maquet technical

None of LEDs 3 to 8 lit Electronic fault Call Maquet technical

The light goes out when

the power outlet is

disconnected

LED 4 ashes Batteries discharged Recharge batteries

Electronic fault Call Maquet technical

Batteries faulty or

incorrectly connected

Charging circuit safety

fuse fault

Electronic fault (charger

board)

Change the fuse

Change the fuse

(quick-blow automotive

type, 7.5 A/32 V)

department

department

department

Check the connections

and change the batteries if

necessary

Change the fuse

(quick-blow automotive

type, 7.5 A/32 V)

Call Maquet technical

department

F

LED 3 lit red

LED 1 lit red

No warning is provided if the batteries are completely discharged or out of order. The fault may be

checked by disconnecting the power outlet. No indicators are lit in this case.

Batteries close to deep

discharge

Recharge batteries

urgently

Page 24

Ceiling, wall-mounted or

mobile surgical light

0136201

24

Technical manual

BLUELINE

4 MAINTENANCE PROCEDURES

Required tools

• Cross-head screwdriver

• Torx screwdriver

• Allen wrench

4.1 BLUE 30

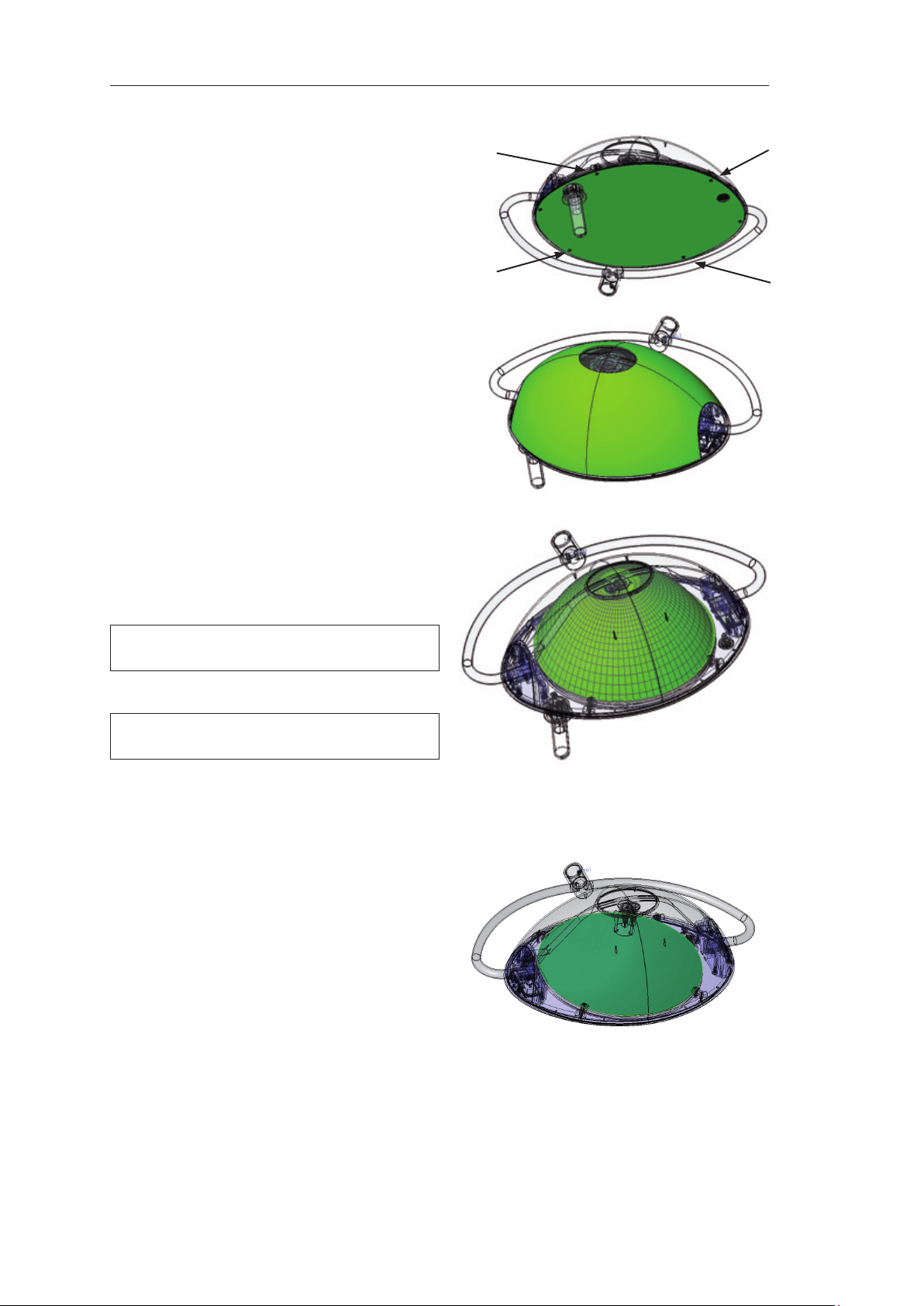

4.1.1 Removing the BLUE 30 lighthead cover

• Press the tab.

• Lift the cover.

4.1.2 Reinstalling the BLUE 30 lighthead cover

• Proceed in reverse order.

Check that the tab is correctly located.

4.1.3 Replacing the reector subassembly

• Remove the BLUE 30 lighthead cover.

• Disconnect and remove the lamp bracket.

• Unscrew and remove the four screws and wash-

ers.

• Remove the reector subassembly.

The spacers (and lens) may adhere to the

reector slightly.

• Install the new reector subassembly on the

spacers.

• Put the screws in place.

• Tighten the screws.

• Connect and position the lamp bracket.

• Reinstall the BLUE 30 lighthead cover.

4.1.4 Replacing the lens

• Remove the BLUE 30 lighthead cover.

• Remove the reector subassembly.

• Remove the lens.

• Remove the four spacers from the lens.

• Take the new lens and place the four spacers 90°

apart.

• Place this assembly on the base of the BLUE 30

lighthead.

• Reinstall the reector subassembly.

• Reinstall the lamp bracket.

• Reinstall the BLUE 30 lighthead cover.

Page 25

Ceiling, wall-mounted or

mobile surgical light

0136201

25

Technical manual

BLUELINE

4.1.5 Replacing the spacers

Always change the four spacers at the

same time.

• Remove the BLUE 30 lighthead cover.

• Remove the reector subassembly.

• Remove the lens.

• Remove the four spacers.

• Place the four new spacers 90° apart on the lens.

• Place this assembly on the base of the BLUE 30

lighthead.

• Reinstall the reector subassembly.

• Reinstall the lamp bracket.

• Reinstall the BLUE 30 lighthead cover.

4.1.6 Replacing the underside

• Remove the BLUE 30 lighthead cover.

• Loosen the brake screw.

• Loosen the screw to allow the fork to slide.

• Unscrew the screw.

• Remove the sterilisable handle bracket.

The handle bracket may fall.

• Remove the screw.

• Remove the underside (with plastic washer and clip).

The underside may fall.

• Put the new underside in place.

• Re-attach the side with the clip.

• Install the sterilisable handle bracket.

• Tighten the screw holding the sterilisable handle bracket.

• Reposition the fork in the base of the BLUE 30 lighthead.

• Tighten the limit stop screw.

Check that it is correctly in place.

• Tighten the brake screw.

• Reinstall the BLUE 30 lighthead cover.

Page 26

Ceiling, wall-mounted or

mobile surgical light

0136201

26

Technical manual

BLUELINE

4.1.7 Replacing the switch

• Remove the BLUE 30 lighthead cover.

• Remove the switch, separating the pivoting head

from the rest of the switch.

• Disconnect the switch from the connectors.

• Connect the new switch.

The wires are colour-coded.

• Separate the pivoting head to put the switch in

place.

• Reinstall the BLUE 30 lighthead cover.

4.1.8 Replacing the fork

• Remove the lighthead from the spring arm.

• Remove the lighthead from the spring arm.

• Remove the BLUE 30 lighthead cover.

• Disconnect the connector connected to the lamp

• Disconnect the connectors from the switch.

• Unscrew the brake screw to release the fork.

• Unscrew the limit stop screw.

• Remove the fork from the base of the BLUE 30

• Slide the wiring through rst.

• Position the fork in the base of the BLUE 30

• Tighten the limit stop screw.

• Tighten and adjust the brake screw.

• Connect the connectors to the switch.

The spring arm may spring up sharply.

bracket.

lighthead along with the wiring.

body.

Check that it is correctly in place.

The wires are colour-coded.

• Connect the connector to the lamp bracket.

• Reinstall the BLUE 30 lighthead cover.

Page 27

Ceiling, wall-mounted or

mobile surgical light

0136201

27

Technical manual

BLUELINE

4.1.9 Replacing the lamp bracket

• Remove the BLUE 30 lighthead cover.

• Disconnect the lamp bracket.

• Remove the lamp bracket from the reector

subassembly.

• Connect the new lamp bracket.

• Place the lamp bracket on the reector.

• Reinstall the BLUE 30 lighthead cover.

Page 28

Ceiling, wall-mounted or

mobile surgical light

0136201

28

Technical manual

BLUELINE

4.2 BLUE 80

4.2.1 Removing the BLUE 80 lighthead cover

• Remove the four central screws from the underside.

• Remove the BLUE 80 cover.

4.2.2 Reinstalling the BLUE 80 lighthead cover

• Put the BLUE 80 cover in place.

• Tighten the four screws.

4.2.3 Replacing the reector subassembly

• Remove the BLUE 80 cover.

• Remove the lamp brackets from the reector.

• Unscrew and remove the four screws and washers.

• Remove the reector subassembly.

Avoid touching the inside of the reector.

• Install the new reector subassembly on the spacers.

Ensure that it is correctly oriented relative

to the fork.

• Put the screws in place and tighten them.

• Put the lamp brackets back in position.

• Reinstall the BLUE 80 cover.

4.2.4 Replacing the lens

• Remove the BLUE 80 cover.

• Remove the reector subassembly.

• Remove the lens.

• Remove the four spacers from the lens.

• Take the new lens and put the four spacers in place.

• Place the assembly on the base of the BLUE 80.

• Reinstall the reector subassembly.

• Reinstall the lamp brackets.

• Reinstall the BLUE 80 cover.

Page 29

Ceiling, wall-mounted or

mobile surgical light

0136201

29

Technical manual

BLUELINE

4.2.5 Replacing the spacers

Always change the four spacers at the

same time.

• Remove the BLUE 80 cover.

• Remove the reector subassembly.

• Remove the lens.

• Remove the four spacers from the lens.

• Put the four new spacers in place.

• Place the assembly on the base of the BLUE 80.

• Reinstall the reector subassembly.

• Reinstall the lamp brackets.

• Reinstall the BLUE 80 cover.

4.2.6 Replacing the underside

• Remove the six visible screws from the underside.

Four of these six screws hold the cover in

place. It may fall after they are removed.

• Remove the two screws from the sterilisable handle bracket.

The underside may fall.

• Put the new underside in place.

• Install the sterilisable handle bracket.

• Tighten the screws holding the sterilisable han-

dle.

• Tighten the six visible screws on the underside.

• Ensure that the two short screws are placed at

the join with the ends of the fork.

• Reinstall the BLUE 80 cover.

4.2.7 Replacing the switch

• Remove the BLUE 80 cover.

• Remove the switch, separating the pivoting head

from the rest of the switch.

• Disconnect the connectors from the switch.

• Connect the new switch.

• Separate the pivoting head to put the switch in

place.

• Reinstall the BLUE 80 cover.

Page 30

Ceiling, wall-mounted or

mobile surgical light

0136201

30

Technical manual

BLUELINE

4.2.8 Replacing the ap

• Remove the BLUE 80 cover.

• Remove the reector subassembly.

Take care not to let the lens fall.

• Unscrew the two screws holding the ap.

• Check the ap.

• Put the new ap in place.

• Tighten the two screws holding the ap.

• Reinstall the reector subassembly.

• Reinstall the BLUE 80 cover.

4.2.9 Replacing the fork bracket

• Remove the BLUE 80 cover.

• Remove the reector subassembly.

• Remove the ap.

Remove the lens to avoid it falling by accident.

• Remove the underside.

• If both fork brackets are to be replaced, remove

and reinstall one fork at a time.

Left side:

• Unscrew (but do not remove) the screw from the

limit stop.

• Remove the four screws.

• Remove the fork bracket from the base and from

the fork.

• Install the new fork bracket.

Check that the limit stop screw, brake

screw and nut are in place on the new fork

bracket.

• Tighten the four screws holding the fork bracket

to the base.

• Position the fork bracket correctly in the fork.

• Tighten the limit stop screw.

Page 31

Ceiling, wall-mounted or

mobile surgical light

0136201

31

Technical manual

BLUELINE

Right side:

• Remove the switcher board from its slot.

• Disconnect the wires from the board.

• Remove the four screws.

• Remove the fork bracket from the base of the

fork.

• Install the new fork bracket.

Check that the brake screw and nut are in

place on the new fork bracket.

• Tighten the four screws holding the fork bracket

to the base.

Ensure that all cables are in place before

tightening.

• Connect the wires to the switcher board.

• Place the switcher board in its slot.

• Reinstall the underside.

• Reinstall the ap.

• Reinstall the lens.

• Reinstall the reector subassembly.

• Reinstall the BLUE 80 cover.

4.2.10 Replacing the switcher board

• Remove the BLUE 80 cover.

• Remove the underside.

• Remove the switcher board from its slot.

• Disconnect the wires.

• Connect the wires to the new switcher board.

• Place the switcher board in its slot.

• Reinstall the underside.

• Reinstall the BLUE 80 cover.

Page 32

Ceiling, wall-mounted or

mobile surgical light

0136201

32

Technical manual

BLUELINE

4.2.11 Replacing the lamp brackets

• Remove the BLUE 80 cover.

• Remove the underside.

• Disconnect the connectors from the lamp brack-

ets.

• Unscrew (but do not remove) the screws holding

the fork bracket, to release the cables to the new

lamp brackets on the switcher board.

• Connect the new lamp bracket connectors to the

switcher board.

• Place the switcher board in its slot.

• Reinstall the underside.

• Reinstall the BLUE 80 cover.

4.2.12 Replacing the fork

• Remove the lighthead from the spring arm.

Take care as the spring arm may spring

up.

• Remove the BLUE 80 cover.

• Remove the underside.

• Remove the reector subassembly.

• Remove the lens (and spacers).

• Remove the ap.

• Remove the fork brackets.

• Remove the fork.

• Take the new fork.

• Reinstall the fork brackets and fork on the base

of the lighthead.

• Reinstall the underside.

• Reinstall the lens.

• Reinstall the ap.

• Reinstall the reector subassembly.

• Reinstall the BLUE 80 cover.

Ensure that the limit stop screw ts properly

into the slit. Do not overtighten.

• Reinstall the lighthead on the spring arm.

Page 33

Ceiling, wall-mounted or

mobile surgical light

0136201

33

Technical manual

BLUELINE

Page 34

Ceiling, wall-mounted or

mobile surgical light

0136201

34

Technical manual

BLUELINE

5 SPARE PARTS AND MAINTENANCE KITS

5.1 BLUE 30 spare parts and maintenance kits

The quantities listed are those included in the kit.

Part number Description Quantity

5 690 03 039 BLUE 80/30 single 850 cable 1

5 690 03 040 BLUE 80/30 duo 1000 cable 1

5 690 10 106 BLUE 30-80 wall-mounting cover 1

5 690 03 038 BLUE 80/30 850 cable 1

5 690 10 102 BLUE 30 spring arm cap 1

5 605 17 82 50-ZIO x 35.5 caster with brake (set of 2) 2

5 605 17 84 Assembly kit for 3/5 legs

M8 x 35 CHc screw DIN 912 5

8.4 mm star washer DIN 6797 5

M8 x 22 CHc screw DIN 912 1

M8 nut DIN 934 5

5 690 14 026 BLUE 30 stand star section 1

3 690 57 555 Set of 10 5x20 3.15 A quick-blow fuses 10

5 607 52 05 Mains cable (Europe) 1

5 607 52 05 Mains cable (US) 1

5 690 05 624 BLUE 30 body 1

3 690 03 997 BLUE 30 reector S/A

5 690 05 004 BLUE 30 Reector 1

5 690 05 021 Spring blanking plate - machined 1

6 000 80 306 Pan-head cross-head screw - 6 lobes - zinc-plated steel - M3 x 6 4

5 690 05 024 BLUE 30 glass tube 1

5 690 05 020 Spring blanking plate 1

6 566 00 011 Spring bush - hex socket - stainless steel - M4 x 9 4

6 014 10 402 H 0.8 M4 nut - stainless steel 1

5 690 05 070 Bracket 1

3 690 40 555 BLUE 30 spacer kit

5 690 05 060 BLUE 30 spacer 4

6 009 90 040 Plastic raised countersunk head screw - Pozidriv - L 20 - Ø 4 4

6 023 70 043 Flat washer - Ø8 - Ø4.3 - thickness 0.5 mm - zinc-plated steel 4

3 690 50 555 BLUE 30 underside replacement kit

5 690 05 002 Underside 1

5 665 31 87 Plastic washer 1

5 607 72 72 Clip 1

6 000 80 306 Pan-head cross-head screw - 6 lobes - zinc-plated steel - M3 x 6 1

6 024 20 306 Flat washer - Ø6 - Ø3.2 - thickness 0.5 mm - zinc-plated steel 1

Page 35

Ceiling, wall-mounted or

mobile surgical light

0136201

35

Technical manual

BLUELINE

3 690 51 555 Set of BLUE 30 safety screws (pack of 5)

6 007 70 410 Low-prole pan head Torx screw - M4 x 10 - stainless steel 5

5 690 05 034 BLUE 30 - lens 1

5 605 17 83 Caster 50 210 - 35.5 (pack of 2) 2

5 605 31 53 3-track brushes 1

5 690 10 104 Bumper 1

3 693 01 555 Pack of 10 miniature 7.5 A 32 V quick-blow fuses 10

3 643 02 555 BLUE plastic ring with bearings 1

3 690 08 998 Diode bridge kit

3 693 06 555 BLUE 30 wall/ceiling-mounted adjustable power supply

3 693 07 555 BLUE 30 MOBILE adjustable power supply (Europe)

3 693 08 555 BLUE 30 MOBILE adjustable power supply (US)

3 693 03 555 BLUE 30/80 HOSPITAL power supply

3 690 09 997 New B30 fork S/A

Page 36

Ceiling, wall-mounted or

mobile surgical light

0136201

36

Technical manual

BLUELINE

5.2 BLUE 80 spare parts and maintenance kits

Part number Description Quantity

5 690 03 039 BLUE 80/30 single 850 cable 1

5 690 03 040 BLUE 80/30 duo 1000 cable 2

5 690 10 106 BLUE 30-80 wall-mounting cover 1

5 690 42 999 BLUE 80 wall/ceiling-mounted spring arm 1

5 690 03 038 BLUE 80/30 850 cable 1

3 690 10 997 BLUE 80 MOBILE mains cable loom S/A

5 690 03 031 Wiring 1

6 914 00 095 KEC mains connector (BLUE 30/80) 1

6 890 04 520 2-pole fuse drawer without mains cut-out 1

5 601 89 21 Sleeve 1

6 936 00 020 5x20 3.15 A quick-blow fuse 2

3 690 57 555 Set of 10 5x20 3.15 A quick-blow fuses

3 690 11 997 BLUE 80 MOBILE power supply cable outlet loom

6 887 00 02 Ferrite 1

5 690 03 029 BLUE 80 power supply cable outlet 1

5 607 52 05 Mains cable (Europe) 1

5 607 52 05 Mains cable (US) 1

5 690 10 100 BLUE 80 spring arm cap 1

5 690 05 035 BLUE 80 - lens 1

5 601 97 05 Switch assembly 1

5 690 03 016 Circuit board 1

3 690 04 997 BLUE 80 reector S/A

5 690 05 042 Painted bezel 1

5 690 05 041 Bezel bracket 3

6 000 80 306 Pan-head cross-head screw - 6 lobes - zinc-plated steel - M3 x 6 3

5 690 05 005 BLUE 80 - reector 1

5 690 05 080 Bracket 1

6 566 00 011 Spring bush - hex socket - stainless steel - M4 x 9 1

6 014 10 402 H 0.8 M4 nut - stainless steel 1

3 690 42 555 BLUE 80 spacer kit

5 690 05 061 BLUE 80 spacer 4

6 009 90 041 Plastic raised countersunk head screw - Pozidriv - L 20 - Ø 5 4

6 021 81 652 Flat washer - Ø16 - Ø5.3 - thickness 1 mm - stainless steel 4

3 690 54 555 BLUE 80 ap kit

5 601 95 21 Plastic raised countersunk head screw - Pozidriv - L 8 - Ø 5 2

5 690 05 630 BLUE 80 ap assembly 1

Page 37

Ceiling, wall-mounted or

mobile surgical light

0136201

37

Technical manual

BLUELINE

3 690 53 555 Fork bracket kit

5 690 05 616 BLUE 80 fork bracket 1

5 665 20 68 Square nut 10x10 - M6 - thickness 5 mm 1

5 607 73 04 Modied screw 1

5 665 04 70 Raised countersunk head screw - Pozidriv - M4 x 8 1

3 690 52 555 Set of BLUE 80 safety screws (pack of 5)

6 012 40 510 Low-prole pan head Torx screw - M5 x 10 - stainless steel (x5) 1

3 690 55 555 BLUE 80 handle bracket kit

5 690 05 621 BLUE 80 sterilisable handle bracket - assembled 1

6 009 50 430 Pan head screw - 6 lobes - stainless steel - M4 x 30 2

3 690 08 999 Fork S/A

5 690 03 015 BLUE 80 fork cable kit

5 607 78 57 BLUE 80 fork ring 1

6 005 80 504 Hex socket set screw - M5 x 4 - stainless steel 1

6 012 40 510 Low-prole pan head Torx screw - M5 x 10 - stainless steel (x5) 1

5 690 05 515 Fork 1

3 690 05 999 Spare bulb holder

5 690 03 012 B80 halogen socket, wired 1

5 690 05 082 Socket bracket 80 - 2 1

6 012 50 312 Pan head screw - 6 lobes - M3x12 - stainless steel 2

3 690 06 997 Main bulb holder

5 690 03 012 B80 halogen socket, wired 1

5 690 05 081 Socket bracket 80 - 1 1

6 012 50 312 Pan head screw - 6 lobes - M3x12 - stainless steel 2

5 605 31 53 3-track brushes 1

5 690 10 104 Bumper 1

3 693 01 555 Pack of 10 miniature 7.5 A 32 V quick-blow fuses 10

3 643 02 555 BLUE plastic ring with bearings 1

3 690 08 998 Diode bridge kit

3 693 05 555 BLUE 80 wall/ceiling-mounted power supply

3 693 04 555 BLUE 80 MOBILE power supply

3 693 03 555 BLUE 30/80 HOSPITAL power supply

3 693 07 555 Pack of 5 x 6.3 A fuses for B80 circuit board

Page 38

Ceiling, wall-mounted or

mobile surgical light

0136201

38

Technical manual

BLUELINE

6 ELECTRICAL INSTALLATION

6.1 Suggested electrical installation

Installation components

E1M BLUE 30 or BLUE 80 lighthead

F1F Fuse for indicators

K1N +

K2N

Q1M Main switch

T1M power supply

H1H Red LED, backup supply operating

H2H Green LED, main power supply operating

Technical characteristics of components

Component Technical characteristics Part number

K1N + K2N

Measurement relays

T1M

Voltage control relay

24 V DC ARD 6 886 00 220

BLUE 30 100-230 V 50/60 Hz 70 VA ARD 5 690 03 018

BLUE 80 100-230 V 50/60 Hz 120 VA ARD 5 690 39 999

Page 39

Ceiling, wall-mounted or

mobile surgical light

0136201

39

Technical manual

BLUELINE

(13)

A1

(14)

A2

(9)

11

(1)

12

(5)

14

(12)

41

(4)

42

(8)

44

(13)

A1

(14)

A2

(9)

11

(1)

12

(5)

14

(12)

41

(4)

42

(8)

44

T1M

N

L

L1

N

PE

PA

+24Vdc

0V

Q1M

E1M

KN1

K2N

H2HH1H

F1F

E1M

+24V dc 0V

Page 40

Ceiling, wall-mounted or

mobile surgical light

0136201

40

Technical manual

BLUELINE

N

L

-

+

6.2 Ceiling-mounted BLUE 30

5 600 41 27

Suspension

5 600 41 29

anchorage

main arm

spring arm

mauve

5 690 03 39

5 600 44 83

black

switch

white

lighthead

grey

grey

bulb

Page 41

Ceiling, wall-mounted or

mobile surgical light

0136201

41

Technical manual

BLUELINE

6.3 Ceiling-mounted BLUE 80

anchorage

5 690 03 030

MPS 120 - 228 power supply

lighthead + fork

5 690 03 028

6.3 A fuse

spare bulb

grey

main bulb

grey

circuit board

black

switch

white

black

suspension

5 600 41 29

5 600 41 27

5 690 03 039

main arm

spring arm

5 600 44 84

Page 42

Ceiling, wall-mounted or

mobile surgical light

0136201

42

Technical manual

BLUELINE

6.4 BLUE 30 MOBILE

spring arm

lighthead

black

white

mauve

black

mauve

switch

white

grey

bulb

grey

brown

ferrite

blue

Page 43

Ceiling, wall-mounted or

mobile surgical light

0136201

43

Technical manual

BLUELINE

N

L

6.5 BLUE 80 MOBILE

transformer unit

spare bulb

grey

6.3 A fuse

lighthead + fork

main bulb

grey

circuit board

black

switch

white

black

white

MPS 120 - 228 power supply

white

24 V

black

blue

brown

green/yellow

3.15 A fuse

110 V/220 V

0 V

ferrite

straight tube

black

vertical tube

white

black

spring arm

Page 44

Ceiling, wall-mounted or

mobile surgical light

0136201

44

Technical manual

BLUELINE

- 0 V

N

L

+15 V

+

+

-

-

6.6 BLUE 30 HOSPITAL

transformer unit

black

mauve

bulb

white

switch

black

lighthead

batteries

black

mauve

red

black white

spring arm

brown

3.15 A fuse

110 V/220 V

blue

green/yellow

black

white

mauve

black

MPS 120 - 15 power supply

ferrite

charger board

mini. 7.5 A fuse

Page 45

Ceiling, wall-mounted or

mobile surgical light

0136201

45

Technical manual

BLUELINE

- 0 V

N

L

+15 V

+- +-

6.7 BLUE 80 HOSPITAL

transformer unit

spare bulb

grey

6.3 A fuse

lighthead + fork

main bulb

grey

black

white

black

circuit board

switch

batteries

white

red

black white

vertical tube

black

spring arm

MPS 120 - 15 power supply

blue

brown

green/yellow

3.15 A fuse

black

white

white

ferrite

black

charger board

110 V/220 V

mini. 7.5 A fuse

Page 46

Ceiling, wall-mounted or

mobile surgical light

0136201

46

Technical manual

BLUELINE

Page 47

Ceiling, wall-mounted or

mobile surgical light

0136201

47

Technical manual

BLUELINE

7 DIAGRAMS AND PARTS LISTS

7.1 CEILING-MOUNTED BLUELINE

Page 48

Ceiling, wall-mounted or

mobile surgical light

0136201

48

Technical manual

BLUELINE

34

33

32

31

30

35

39

28

1

2

3

4

5

6

7

8

29

22

23

24

36

25

26

9

10

11

12

13

14

15

16

17

18

27

19

2120

38

37

40

BLUE ANCHORAGE WITH POWER SUPPLY DIAGRAM 1

Page 49

Ceiling, wall-mounted or

mobile surgical light

0136201

49

Technical manual

BLUELINE

BLUE ANCHORAGE WITH POWER SUPPLY PARTS LIST 1

Ref. Part number Description Quantity

1 5 607 76 44 Anchor ring for DUO version 1

5 607 76 53 Anchor plate for single version 1

2 FHc M12 x 80 screw 6

3 5 665 20 38 M12 hex nut DIN 934-8 A4E 18

4 5 665 30 19 13 mm at washer DIN 125-ST-A4E 12

5 5 601 05 10 Sleeve 15/16x13x21 6

6 5 601 05 11 Plastic washer 30x15x7 12

7 5 608 00 05 BLUE 30/80 ange 1

8 5 608 01 33 Rail 1

3 693 05 555 BLUE 80 wall/ceiling-mounted power supply

9 6 005 30 320 CHc M3 x 20 stainless steel screw A2 NFE27161 4

10 6 023 70 032 M3 white zinc-plated washer DIN 433 8

11 5 690 03 044 Bracket for BLUE 80 MPS power supply 1

12 5 690 03 045 Plate for BLUE 80 MPS power supply 1

13 6 951 50 010 Round spacer Ø3.2 x 6 x 10 4

14 5 690 03 021 MPS 120 - 228 power supply for BLUE 80 1

15 6 951 00 555 Hexagonal spacer FF M3 x 55 4

16 5 690 03 046 Housing for BLUE 80 MPS power supply 1

17 6 005 30 310 CHc M3 x 10 stainless steel screw 5

18 5 690 11 000-10 200 mm to 1200 mm extension tube 1

19 5 690 05 609 Ceiling mounting cover, height 250 mm 2

20 5 690 10 105 BLUE 30/80 ceiling cover half-ring 2

21 CHc M3 x 25 white zinc-plated steel screw DIN 912 2

3 693 06 555 BLUE 30 wall/ceiling-mounted adjustable power supply

22 5 690 03 018 BLUE 30 wall/ceiling-mounted adjustable power supply 1

23 M5 Onduex washer 2

24 CHc M5 x 6 screw 2

25 13 mm at washer DIN 125 4

26 CHc M12 x 80 screw 2

27 M12 nylstop nut 2

28 5 665 31 02 4.3 mm star washer DIN 6797 FD-ST A4E 2

29 5 665 05 88 FHc M4 x 8 screw DIN 965-4.8 A4E 2

30 5 602 00 01 Earth terminal 1

31 6 890 10 013 Grey junction block 2

32 6 890 39 302 Blue junction block 2

33 6 89010 014 Yellow/green junction block 2

34 5 690 03 030 BLUE ange power cable 1

35 5 690 03 028 BLUE 30/80 power supply terminal strip outlet cable 1

36 5 665 30 31 12 mm Grower washer DIN 127 FD-ST A4E 6

37 5 665 07 30 M4x8 raised countersunk head screw DIN 7985 1

38 5 665 30 71 A-shape 4.3 mm star washer DIN 6797-A4E 2

39 5 600 41 29 Lighthead ange cable 1

40 5 600 44 16 Flange earth cable 1

Page 50

Ceiling, wall-mounted or

mobile surgical light

0136201

50

Technical manual

BLUELINE

30 29

27

26

25

24

28

1

22

2

3

4

5

6

7

19

20

23

21

14

15

11

12

13

16

10

8

9

1817

BLUE 30 ANCHORAGE WITHOUT POWER SUPPLY DIAGRAM 2

Page 51

Ceiling, wall-mounted or

mobile surgical light

0136201

51

Technical manual

BLUELINE

BLUE 30 ANCHORAGE WITHOUT POWER SUPPLY PARTS LIST 2

Ref. Part number Description Quantity

1 5 607 76 44 Anchor ring for DUO version 1

5 607 76 53 Anchor plate for single version 1

2 FHc M12 x 80 screw 6

3 5 665 20 38 M12 hex nut DIN 934-8 A4E 18

4 5 665 30 19 13 mm at washer DIN 125-ST-A4E 12

5 5 601 05 10 Sleeve 15/16x13x21 6

6 5 601 05 11 Plastic washer 30x15x7 12

7 5 608 00 05 BLUE 30/80 ange 1

8 5 608 01 33 Rail 1

9 5 665 31 02 4.3 mm star washer DIN 6797 FD-ST A4E 2

10 5 665 05 88 FHc M4 x 8 screw DIN 965-4.8 A4E 2

11 5 665 30 31 12 mm Grower washer DIN 127 FD-ST A4E 6

12

13 CHc M12 x 80 screw 2

14 13 mm at washer DIN 125 4

15 M12 nylstop nut 2

16 5 690 05 609 Ceiling mounting cover, height 250 mm 2

17 CHc M3 x 25 white zinc-plated steel screw DIN 912 2

18 5 690 10 105 BLUE 30/80 ceiling cover half-ring 2

19 5 665 30 71 A-shape 4.3 mm star washer DIN 6797-A4E 2

20 5 665 07 30 M4x8 DIN 7985 1

21 6 881 00 025 Diode bridge 1

22 6 590 00 014 Silicone thermal heatsink paste

23 6 005 10 516 CHc M5x16 screw 1

24 5 602 00 01 Earth terminal 1

25 6 890 10 013 Grey junction block 1

26 6 890 39 302 Blue junction block 1

27 6 89010 014 Yellow/green junction block 1

28 5 600 44 16 Earth cable 1

29 5 690 03 035 Diode bridge cable 1

30 5 600 41 29 Lighthead ange cable 1

5 690 11 000-10 200 mm to 1200 mm extension tube 1

Page 52

Ceiling, wall-mounted or

mobile surgical light

0136201

52

Technical manual

BLUELINE

1

2

3

4

5

6

22

7

19

20

23

21

10

8

9

11

12

13

16

1817

14

15

27

26

25

24

28

30 29

BLUE 80 DUO ANCHORAGE WITHOUT POWER SUPPLY DIAGRAM 3

Page 53

Ceiling, wall-mounted or

mobile surgical light

0136201

53

Technical manual

BLUELINE

BLUE 80 DUO ANCHORAGE WITHOUT POWER SUPPLY PARTS LIST 3

Ref. Part number Description Quantity

1 5 607 76 44 Anchor ring for DUO version 1

2 FHc M12 x 80 screw 6

3 5 665 20 38 M12 hex nut DIN 934-8 A4E 18

4 5 665 30 19 13 mm at washer DIN 125-ST-A4E 12

5 5 601 05 10 Sleeve 15/16x13x21 6

6 5 601 05 11 Plastic washer 30x15x7 12

7 5 608 00 05 BLUE 30/80 ange 1

8 5 608 01 33 Rail 1

9

5 665 31 02 4.3 mm star washer DIN 6797 FD-ST A4E 2

10 5 665 05 88 FHc M4 x 8 screw DIN 965-4.8 A4E 2

11 5 665 30 31 12 mm Grower washer DIN 127 FD-ST A4E 6

12 5 690 11 000-10 200 mm to 1200 mm extension tube 1

13 CHc M12 x 80 screw 2

14 13 mm at washer DIN 125 4

15 M12 nylstop nut 2

16 5 690 05 609 Ceiling mounting cover, height 250 mm 2

17 CHc M3 x 25 white zinc-plated steel screw DIN 912 2

18 5 690 10 105 BLUE 30/80 ceiling cover half-ring 2

19 5 665 30 71 A-shape 4.3 mm star washer DIN 6797-A4E 2

20 5 665 07 30 M4x8 DIN 7985 1

21 6 881 00 025 Diode bridge 1

22 6 590 00 014 Silicone thermal heatsink paste

23 6 005 10 516 CHc M5x16 screw 1

24 5 602 00 01 Earth terminal 1

25 6 890 10 013 Grey junction block 2

26 6 890 39 302 Blue junction block 2

27 6 89010 014 Yellow/green junction block 2

28 5 600 44 16 Earth cable 1

29 5 690 03 035 Diode bridge cable 2

30 5 600 41 29 Lighthead ange cable 2

Page 54

Ceiling, wall-mounted or

mobile surgical light

0136201

54

Technical manual

BLUELINE

23

29

27

26

25

24

28

1

13

2

3

4

5

6

8

10

22

12

9

19

20

11

7

15

14

21

16

18 17

BLUE LC ANCHORAGE WITHOUT POWER SUPPLY DIAGRAM 4

Page 55

Ceiling, wall-mounted or

mobile surgical light

0136201

55

Technical manual

BLUELINE

BLUE LC ANCHORAGE WITHOUT POWER SUPPLY PARTS LIST 4

Ref. Part number Description Quantity

1 5 607 76 44 Anchor ring for DUO version 1

5 607 76 53 Anchor plate for single version 1

2 FHc M12 x 80 screw 6

3 5 665 20 38 M12 hex nut DIN 934-8 A4E 18

4 5 665 30 19 13 mm at washer DIN 125-ST-A4E 12

5 5 601 05 10 Sleeve 15/16x13x21 6

6 5 601 05 11 Plastic washer 30x15x7 12

7 5 690 15 001 BLUE 30/80 LCH anchor tube 1

8 5 608 01 33 Rail 1

9 5 665 31 02 4.3 mm star washer DIN 6797 FD-ST A4E 2

10 5 665 05 88 FHc M4 x 8 screw DIN 965-4.8 A4E 2

11 5 665 30 31 12 mm Grower washer DIN 127 FD-ST A4E 6

12 5 665 30 71 A-shape 4.3 mm star washer DIN 6797-A4E 2

13 5 665 09 07 M4 nut DIN 934 A4E 2

14 6 881 00 025 Diode bridge

15 6 590 00 014 Silicone thermal heatsink paste

16 5 690 05 608 Ceiling mounting cover, height 115 mm 2

17 CHc M3 x 25 white zinc-plated steel screw DIN 912 2

18 5 690 10 105 BLUE 30/80 ceiling cover half-ring 2

19 5 665 30 71 A-shape 4.3 mm star washer DIN 6797-A4E 2

20 5 665 07 30 M4x8 DIN 7985 1

21 6 005 10 516 CHc M5x16 screw 1

22 5 665 04 70

23 5 600 41 29 Lighthead ange cable 2

24 5 602 00 01 Earth terminal 1

25 6 890 10 013 Grey junction block 2

26 6 890 39 302 Blue junction block 2

27 6 89010 014 Yellow/green junction block 2

28 5 600 44 16 Earth cable 1

29 5 690 03 035 Diode bridge cable 2

Page 56

Ceiling, wall-mounted or

mobile surgical light

0136201

56

Technical manual

BLUELINE

1

2

6

5

7

8

9

10

11

12

13

14

15

16

17

18

19

20 21 22 23 24 25 26 27 28

29

30

31

4

3

9

BLUE 30 SINGLE SUSPENSION ARM DIAGRAM 5

5 690 80 999

Page 57

Ceiling, wall-mounted or

mobile surgical light

0136201

57

Technical manual

BLUELINE

BLUE 30 SINGLE SUSPENSION ARM PARTS LIST 5

Ref. Part number Description Quantity

1 5 607 63 45 BLUE 30-80 single shaft 1

2 5 690 12 102 B30-80 850 mm single extension arm 1

3 Hm M4 nut 1

4 16/18 AWG M4 eyelet contact 1

5 M4 serrated washer 1

6 FHc M4 x 8 screw 1

7 FZ M4 x 25 screw 4

8 5 690 10 282 BLUE 30-80 single suspension arm cap 2

9 FHc M6 x 12 screw 4

10 5 601 64 00 ONDAL 3-way rotating contact 2

11 5 601 97 30 Circlips for 32 mm shaft 2

12 5 607 74 83 Ring 2

13 5 601 72 05 Set ring 2

14 HK 32x39x24 needle bush 2

15 5 690 10 011 Suspension shaft plastic ring 2

16 5 690 13 004 BLUE 30 spring arm interface 1

17 FHc M3 x 10 screw 1

18 FHc M5 x 16 screw 2

19 5 690 13 001 Spring arm shaft 1

20 5 665 31 78 22x30x0.5 mm washer DIN 988 A4E 2

21 5 601 97 04 40x20.4x2.25 mm spring washer DIN 2093-1.8159 14

22 5 690 13 210 BLUE 30 spring arm cam 1

23 5 690 13 004 BLUE 30 spring arm interface 1

24 5 668 00 50 NK 8/12 TN needle bearing 2

25 8M6x20 cylindrical pin 2

26 5 668 00 55 AS 1226 stop washer 1

27 5 668 0054 Axial needle bearing cage AXK 1226 1

28 5 668 00 56 LS 1226 stop washer 1

29 5 665 20 08 Nylstop nut DIN 985 A4E 1

30 5 690 10 102 BLUE 30 spring arm cap 1

31 5 690 03 039 BLUE 80/30 single 850 cable 1

Page 58

Ceiling, wall-mounted or

mobile surgical light

0136201

58

Technical manual

BLUELINE

1

15

14

13

12

11

10

9

2

3

4

5

6

7

7

8

9

10

11

12

13

14

15

16

17

BLUE 80 SINGLE SUSPENSION ARM DIAGRAM 6

5 690 81 999

Page 59

Ceiling, wall-mounted or

mobile surgical light

0136201

59

Technical manual

BLUELINE

BLUE 80 SINGLE SUSPENSION ARM PARTS LIST 6

Ref. Part number Description Quantity

1 5 607 63 45 BLUE 30-80 single shaft 1

2 5 690 12 102 B30-80 850 mm single extension arm 1

3 Hm M4 nut 1

4 16/18 AWG M4 eyelet contact 1

5 M4 serrated washer 1

6 FHc M4 x 8 screw 1

7 FZ M4 x 25 screw 4

8 5 690 10 282 BLUE 30-80 single suspension arm cap 2

9 FHc M6 x 12 screw DIN 7991 8.8 A4E 4

10 5 601 64 00 ONDAL 3-way rotating contact 2

11 5 601 97 30 Circlip for shaft Ø32 2

12 5 607 74 83 Ring 2

13 5 601 72 05 Set ring 2

14 HK 32x39x24 needle bush 2

15 5 690 10 011 Suspension shaft plastic ring 2

16 5 690 42 999 BLUE 80 spring arm 1

17 5 690 03 039 BLUE 80/30 single 850 cable 1

Page 60

Ceiling, wall-mounted or

mobile surgical light

0136201

60

Technical manual

BLUELINE

1

23

3

4

5

6

24

26

23

3

4

5

6

24

26

21

2

9

10

8

16

15

14

13

11

12

17

18

19

25

22

20

20

18

19

25

22

26

23

24

26

24

23

17

11

12

13

14

15

16

7

BLUE 30-30 DOUBLE SUSPENSION DIAGRAM 7

5 690 86 999

Page 61

Ceiling, wall-mounted or

mobile surgical light

0136201

61

Technical manual

BLUELINE

BLUE 30-30 DOUBLE SUSPENSION PARTS LIST 7

Ref. Part number Description Quantity

1 5 607 72 57 BLUE 30-80 double shaft 1

2 5 665 07 71 CHc M5x8 screw DIN 912-8.8 A4E 2

3 5 607 71 80 Needle bearing ring 4

4 5 607 73 13 BLUE 30-80 top shaft ring 2

5 5 607 73 15 Rotating contact 2

6 5 607 73 14 BLUE 30-80 bottom shaft ring 2

7 FHc M6x12 screw 4

8 5 690 10 104 Bumper 1

9 5 690 12 101 BLUE 30-80 1000 mm duo extension arm 1

10 5 690 12 100 BLUE 30-80 850 mm duo extension arm 1

11 FZ M4 x 25 screw 4

12 5 690 10 282 BLUE 30-80 single suspension arm cap 2

13 Hm M4 nut 2

14 16/18 AWG M4 eyelet contact 2

15 M4 serrated washer 2

16 FHc M4 x 8 screw 2

17 FHc M6 x 12 screw DIN 7991 8.8 A4E 4

18 5 690 03 040 BLUE 30/80 duo 1000 cable 2

19 5 601 64 00 ONDAL 3-way rotating contact 2

20 5 690 41 999 BLUE 30 wall/ceiling-mounted spring arm 2

21 5 605 31 53 3-track brushes 2

5 605 34 53 BLUE plastic ring with bearing

22 5 690 10 011 Suspension shaft plastic ring 2

23 5 668 00 39 Needle bearing bush HK 32x39x24 4

24 5 601 72 05 Set ring 4

25 5 607 74 83 Ring 2

26 5 601 97 30 Circlip for shaft Ø32 4

Page 62

Ceiling, wall-mounted or

mobile surgical light

0136201

62

Technical manual

BLUELINE

1

24

3

4

5

6

25

27

24

3

4

5

6

25

27

7

2

9

10

8

16

15

14

13

11

12

17

18

19

26

23

20

21

27

25

24

19

26

27

24

18

23

24

17

11

12

13

14

15

16

22

BLUE 30-80 DOUBLE SUSPENSION DIAGRAM 8

5 690 85 999

Page 63

Ceiling, wall-mounted or

mobile surgical light

0136201

63

Technical manual

BLUELINE

BLUE 30-80 DOUBLE SUSPENSION PARTS LIST 8

Ref. Part number Description Quantity

1 5 607 72 57 BLUE 30-80 double shaft 1

2 5 665 07 71 CHc M5x8 screw DIN 912-8.8 A4E 2

3 5 607 71 80 Needle bearing ring 4

4 5 607 73 13 BLUE 30-80 top shaft ring 2

5 5 607 73 15 Rotating contact 2

6 5 607 73 14 BLUE 30-80 bottom shaft ring 2

7 FHc M6x12 screw 4

8 5 690 10 104 Bumper 1

9 5 690 12 101 BLUE 30-80 1000 mm duo extension arm 1

10 5 690 12 100 BLUE 30-80 850 mm duo extension arm 1

11 FZ M4 x 25 screw 4

12 5 690 10 282 BLUE 30-80 single suspension arm cap 2

13 Hm M4 nut 2

14 16/18 AWG M4 eyelet contact 2

15 M4 serrated washer 2

16 FHc M4 x 8 screw 2

17 FHc M6 x 12 screw DIN 7991 8.8 A4E 4

18 5 690 03 040 BLUE 30/80 duo 1000 cable 2

19 5 601 64 00 ONDAL 3-way rotating contact 2

20 5 690 41 999 BLUE 30 wall/ceiling-mounted spring arm 1

21 5 690 42 999 BLUE 80 spring arm 1

22 5 605 31 53 3-track brushes 2

5 693 02 555 BLUE plastic ring with bearing

23 5 690 10 011 Suspension shaft plastic ring 2

24 5 668 00 39 Needle bearing bush HK 32x39x24 4

25 5 601 72 05 Set ring 4

26 5 607 74 83 Ring 2

27 5 601 97 30 Circlip for shaft Ø32 4

Page 64

Ceiling, wall-mounted or

mobile surgical light

0136201

64

Technical manual

BLUELINE

1

2

9

16

15

14

13

11

12

17

18

19

25

22

20

26

24

23

23

3

4

5

6

24

26

23

3

4

5

6

24

26

7

20

19

25

26

23

17

18

22

24

11

12

14

13

15

16

10

8

21

BLUE 80-80 DOUBLE SUSPENSION DIAGRAM 9

5 690 84 999

Page 65

Ceiling, wall-mounted or

mobile surgical light

0136201

65

Technical manual

BLUELINE

BLUE 80-80 DOUBLE SUSPENSION PARTS LIST 9

Ref. Part number Description Quantity

1 5 607 72 57 BLUE 30-80 double shaft 1

2 5 665 07 71 CHc M5x8 screw DIN 912-8.8 A4E 2

3 5 607 71 80 Needle bearing ring 4

4 5 607 73 13 BLUE 30-80 top shaft ring 2

5 5 607 73 15 Rotating contact 2

6 5 607 73 14 BLUE 30-80 bottom shaft ring 2

7 FHc M6x12 screw 4

8 5 690 10 104 Bumper 1

9 5 690 12 101 BLUE 30-80 1000 mm duo extension arm 1

10 5 690 12 100 BLUE 30-80 850 mm duo extension arm 1

11 FZ M4 x 25 screw 4

12 5 690 10 282 BLUE 30-80 single suspension arm cap 2

13 Hm M4 nut 2

14 16/18 AWG M4 eyelet contact 2

15 M4 serrated washer 2

16 FHc M4 x 8 screw 2

17 FHc M6 x 12 screw DIN 7991 8.8 A4E 4

18 5 690 03 040 BLUE 30-80 duo 1000 cable 2

19 5 601 64 00 ONDAL 3-way rotating contact 2

20 5 690 42 999 BLUE 80 spring arm 2

21 5 605 31 53 3-track brushes 2

5 693 02 555 BLUE plastic ring with bearing

22 5 690 10 011 Suspension shaft plastic ring 2

23 5 668 00 39 Needle bearing bush HK 32x39x24 4

24 5 601 72 05 Set ring 4

25 5 607 74 83 Ring 2

26 5 601 97 30 Circlip for shaft Ø32 4

Page 66

Ceiling, wall-mounted or

mobile surgical light

0136201

66

Technical manual

BLUELINE

Page 67

Ceiling, wall-mounted or

mobile surgical light

0136201

67

Technical manual

BLUELINE

7.2 WALL-MOUNTED BLUELINE

Page 68

Ceiling, wall-mounted or

mobile surgical light

0136201

68

Technical manual

BLUELINE

19

9

6

8

5

4

18

4

5

7

6

1

2

3

21

22

20

24 25 23

2726

14

15

13

12

11

16

17

10

11

12

13

7

8

15

WALL-MOUNTED BLUE 30 SUSPENSION ARM DIAGRAM 10

5 690 88 999

Page 69

Ceiling, wall-mounted or

mobile surgical light

0136201

69

Technical manual

BLUELINE

WALL-MOUNTED BLUE 30 SUSPENSION ARM PARTS LIST 10

Ref. Part number Description Quantity

1 5 608 00 16 Wall-mounted BLUE 30-80 mounting point 1

2 5 601 96 38 4-way connection strip 1

3 5 665 04 67 BZ M3 x 16 screw DIN 7985-4.8-A4E 2

5 693 02 555 BLUE plastic ring with bearing

4 5 690 10 011 Suspension shaft plastic ring 2

5 5 668 00 39 HK 32x39x24 needle bush 2

6 5 601 72 05 Set ring 2

7 5 607 74 83 Ring 2

8 5 601 97 30 Circlip for shaft Ø32 2

9 5 601 64 00 ONDAL 3-way rotating contact 1

10 5 690 12 103 B30-80 850 mm wall-mounted extension arm 1

11 FHc M6 x 12 screw DIN 7991 8.8 A4E 4

12 5 690 10 282 BLUE 30-80 single suspension arm cap 2

13 FZ M4 x 25 screw 2

14 Hm M4 nut 1

15 16/18 AWG M4 eyelet contact 2

16 M4 serrated washer 1

17 FHc M4 x 8 screw 1

18 5 690 41 999 BLUE 30 spring arm 1

19 5 690 03 038 Wiring 1

3 693 06 555 BLUE 30 wall/ceiling-mounted adjustable power supply

20 5 690 03 018 BLUE 30 wall/ceiling-mounted adjustable power supply 1

21 M5 Onduex washer 2

22 CHc M5 x 6 screw 2

23 5 690 10 106 BLUE 30-80 wall-mounting cover 1

24 M3x8 plastic screw T15 2