Page 1

HANAULUX® 2000

Operating instructions

for all HANAULUX 2000 ceiling- and wall modells

56351039/C

Page 2

Operating Instructions 56351039/C HANAULUX

TABLE OF CONTENTS PAGE

®

2000

1.0 Important safety information

2.0 Description of the HANAULUX 2000 system

2.1 The HANAULUX concept 5

2.2 Standard components 5

2.3 Special components 6

2.4 Expandability 7

3.0 The HANAULUX benefits

3.1 Briliant cool light 8

3.2 In-depth illumination 9

3.3 Optimal hygiene 9

3.4 Easy manoeuvrability, true positioning 9

4.0 Operating your HANAULUX 2000 system

4.1 Mounting the sterilisable handle 10

4.2 Positioning the lights 11

4.3 Focussing the lights and changing the fieldsize 12

4.4 Dimming the light 13

4.5 Operating the HANAULUX 2007 iXL AF/2007 iXL

D

1

5

8

10

14

5.0 Important information about halogen bulbs

5.1 Changing the bulb 16

6.0 Adjustments

6.1 Adjusting the brakes 17

6.2 Adjusting the spring-arms 18

7.0 Cleaning/desinfecting and sterilising

7.1 Cleaning/ desinfecting the light 19

7.2 Cleaning the lenses 19

7.3 Sterilising the handles 19

7.4 Cleaning HANAUVISION 19

8.0 Maintenance and Repair

9.0 Troubleshooting your HANAULUX 2000 system

10.0 Technical Data

15

17

19

20

21

23

Page 3

1.0 Important safety information

Dear User!

• These instructions are intended for medical and technical staff in hospitals and

general practice.

• The work in the section entitled ”Maintenance” can be carried out by the operator’s

service man with due consideration for the safety notes.

• The unit can be cleaned by trained cleaning staff.

• Please read these instructions carefully before using the unit. This will allow you to

obtain the full benefit from the unit and will protect you and others from any injury.

Dear Operator!

These instructions apply to all HANAULUX 2000 ceiling and wall models.

• Your HANAULUX 2000 operating theatre lighting system was developed with

consideration for the high demands made on the surgeon’s eyes during surgery. Modern

technology and the HANAUCHROME optical system optimise the illumination and detail

recognition in the operating field.With the HANAULUX 2000 operating theatre lighting

system you have a unit which together with the HANAUCHROME optical system brings

brilliant light into the operating field. More light with greater colour reproduction and a

lower heat load penetrates deep into the wound.This unit has been designed using the

latest technology and is fail-safe. Nevertheless there are risks in using this unit,

especially when it is operated by staff who are not adequately trained or when it is used

incorrectly or not as intended.

• Using these instructions show cleaning staff how to clean and care for the unit.

• Where there are translations in foreign languages the German version of these

instructions is binding.

• Unauthorised modifications or alterations to the unit are not permitted for safety reasons.

• In the event of particular problems which are not covered in sufficient detail in these

instructions please contact your supplier for your own safety.

Keep these instructions in a safe place close to the unit so that they can be

consulted for safety notes and important information.

HANAULUX, HANAUPORT and HANAUVISION are registered trade marks of

MAQUET SA.

1

Page 4

Operating Instructions 56351039/C HANAULUX® 2000

The Operating Instructions are designed to be as clear as possible. The illustrations are all numbered

to correspond to the relevant text. This helps you follow the instructions in the text more easily.

These operating instructions refer to the following HANAULUX 2000 luminaire systems, as a single

light or in combination with other HANAULUX 2000 lights or accessories:

HANAULUX 2007 iXL/2007 iXL D/2007 iXL AF

HANAULUX 2005 i und 2005 iXL

HANAULUX 2004 i und 2004 iXL

HANAULUX 2003 i und 2003 iXL

HANAULUX 2002 i.

Explanation of the symbols used in these operating instructions:

1. COMMENT! is used where the correct functioning of the appliance could be affected.

2. ATTENTION! is used where the appliance could be damaged.

3. DANGER! is used where someone could be injured or killed.

1.1

General Safety Notes

To aid the surgeon where vision is difficult the light units offer a high degree of

illumination. The laws of physics mean that even visible light produces heat in the

operating field. If light fields from several light units are superimposed on each other,

illumination over 1000 W/m2 can be obtained. This involves an increased risk of the

tissue drying out and, especially in the case of longer use and reduced blood flow, there

is also the possibility of tissue damage.

A red band is located under the retaining ring on

the light unit side of the spring arm. This band

should not be visible during normal operation.If

the band is visible inform an authorised service

man immediately as there is a risk that the light

unit could fall.

2

Page 5

1.1.1 Use as intended

• The HANAULUX

®

2000 is for illuminating an

examination or operation area of a patient in

the clinic or doctor’s surgery.

• A single HANAULUX

®

2000 lamp is only

suitable for operations in which the light going

out does not endanger the patient.

®

• The HANAULUX

2000 light system must be

assembled as in the assembly instructions

accompanying the components.

• For service, repairs and alterations and as

accessories, only original Heraeus MED parts

may be used.

• A HANAULUX 2000 operation luminaire

system with several lamps is suitable without

limitation.

• The optimum working distance is 70 to 140

cm.

• The HANAULUX

®

2000 operation luminaire

system is suitable for continuous operation.

• Additional load on the light suspension is not

permitted.

• The light system is not for operation in areas

where there is danger of explosion

• The light system is not suitable for use in

combustible mixtures of anaesthetics with air

or oxygen or nitrous oxide.

• Keep the ambient temperature from 10°C to

40°C during operation.

• The relative humidity must not exceed 75%.

1.2.2 Requirements for safe operation

1.2.3 Transport and Storage

The following storage conditions apply for up to

15 weeks:

• Temperature- 25....+70°C

• Relative humidity 10%....75%

• Air pressure 500hPa....1060hPa

after which the values for the operating

conditions apply

• Do not subject the apparatus to severe

shaking

1.2.4 Disposal

Old units contain materials which are still

valuable. Do not take old units to the nearest

tip but find out about possible local

recycling from the town/ local authority.

The safe and correct function of the luminaire

system HANAULU 2000 within the given

technical data is only guaranteed if the following

conditions are fullfilled:

• The ceiling anchorage must be statically

safesecure and there must be a statics

certificate.

• The electrical installations of the rooms

concerned must conform to the nationally

valid specifications. VDE 0107 applies for

Germany.

• Extensions, alterations or repairs must be

carried out by Heraeus Med or an authorized

specialist.

HANAULUX halogen lamps can be disposed of

as domestic waste.

3

Page 6

Operating Instructions 56351039/C HANAULUX® 2000

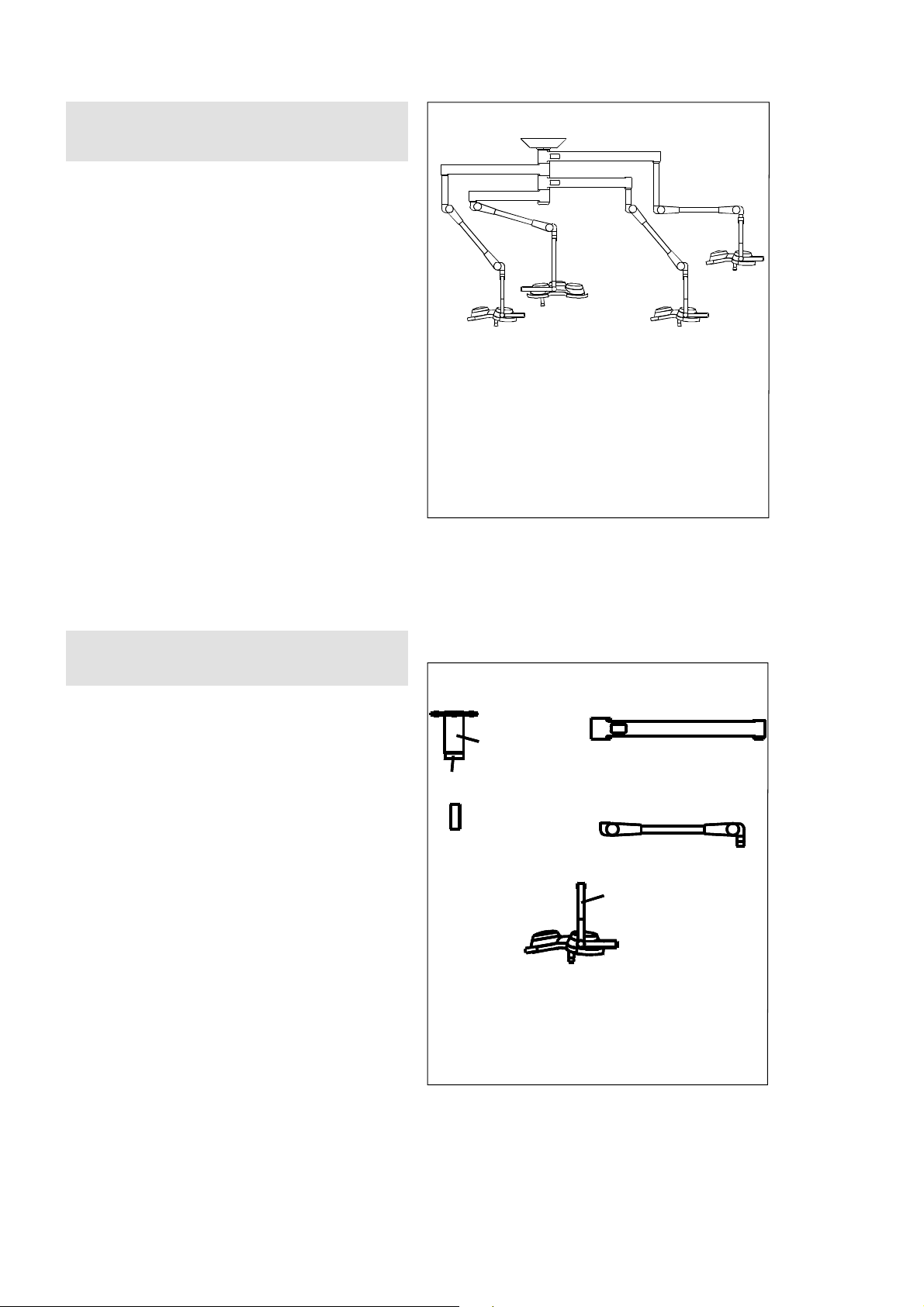

2.1 The HANAULUX 2000 concept

The HANAULUX 2000 system is a modern

operating theatre lighting concept which fulfils the

highest requirements for light quality, hygiene

and flexibility. The basic principle of the

HANAULUX 2000 lighting systems is the

compatibility and interchangeability of the

individual components. The modular construction

concept allows configuration of the systems to

suit any surgical discipline.

The version "main light with SATELLIT" refers to

a combination with two or more different

lightheads.The lighthead with the highest

light-intensity is called the main light and is

always mounted on the lowest position, or

"position 1", of the central axle.

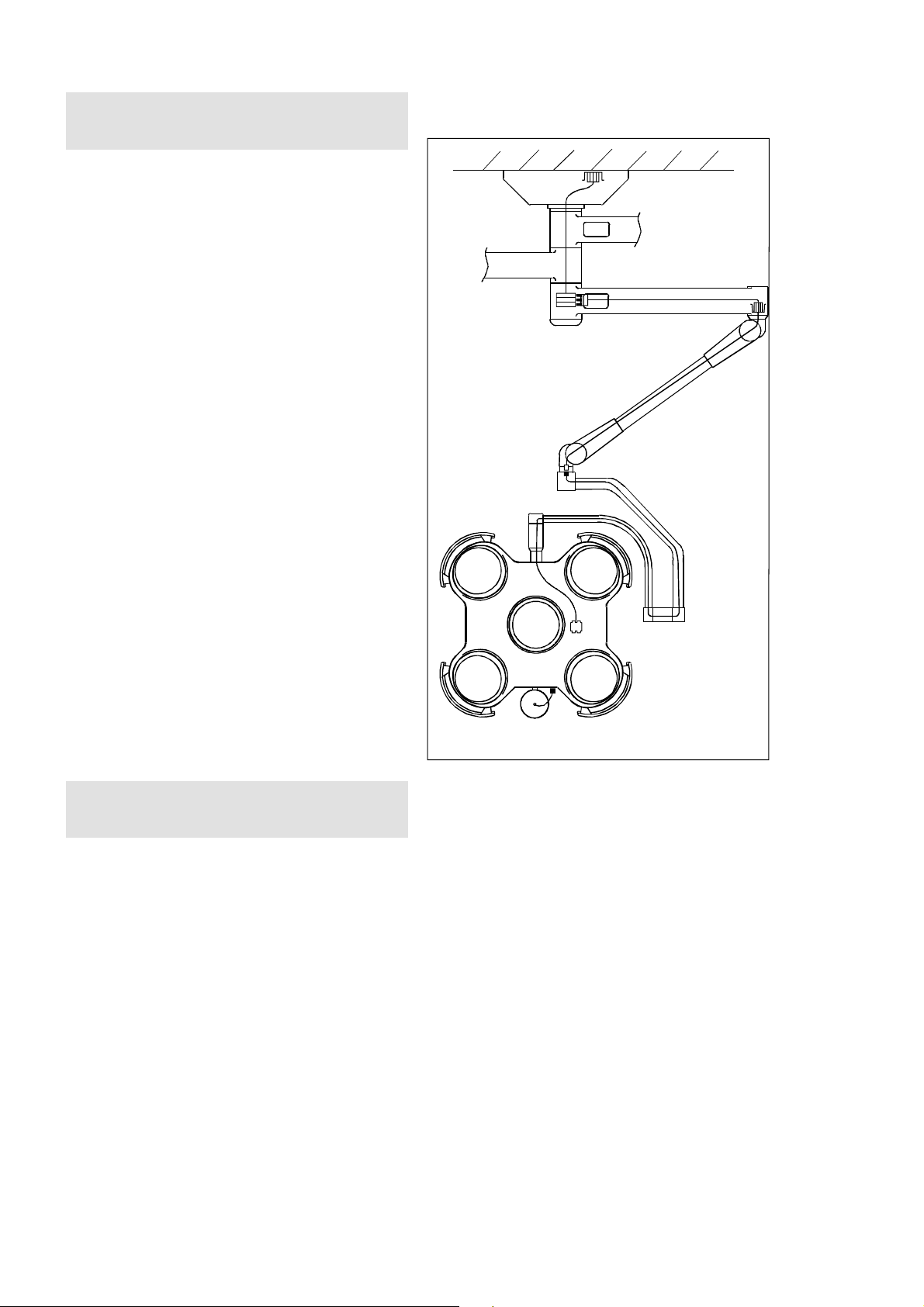

Fig. 2-1 shows a HANAULUX 2000 luminaire

system with the following components:

- 2005 main light, position 1

- 2003 SATELLIT light, position 2/3/4

2.2 Standard components

The standard HANAULUX 2000 components are

as follows:.

1 Flange tube

2. Central axle (in flange tube)

3. Extension-arm

4. Spacer

5. Spring-arm

1

2

4

6

3

5

6. Comfort arm

7. Lighthead with half semi-circular

bracket

7

4

Page 7

Operating Instructions 56351039/C HANAULUX® 2000

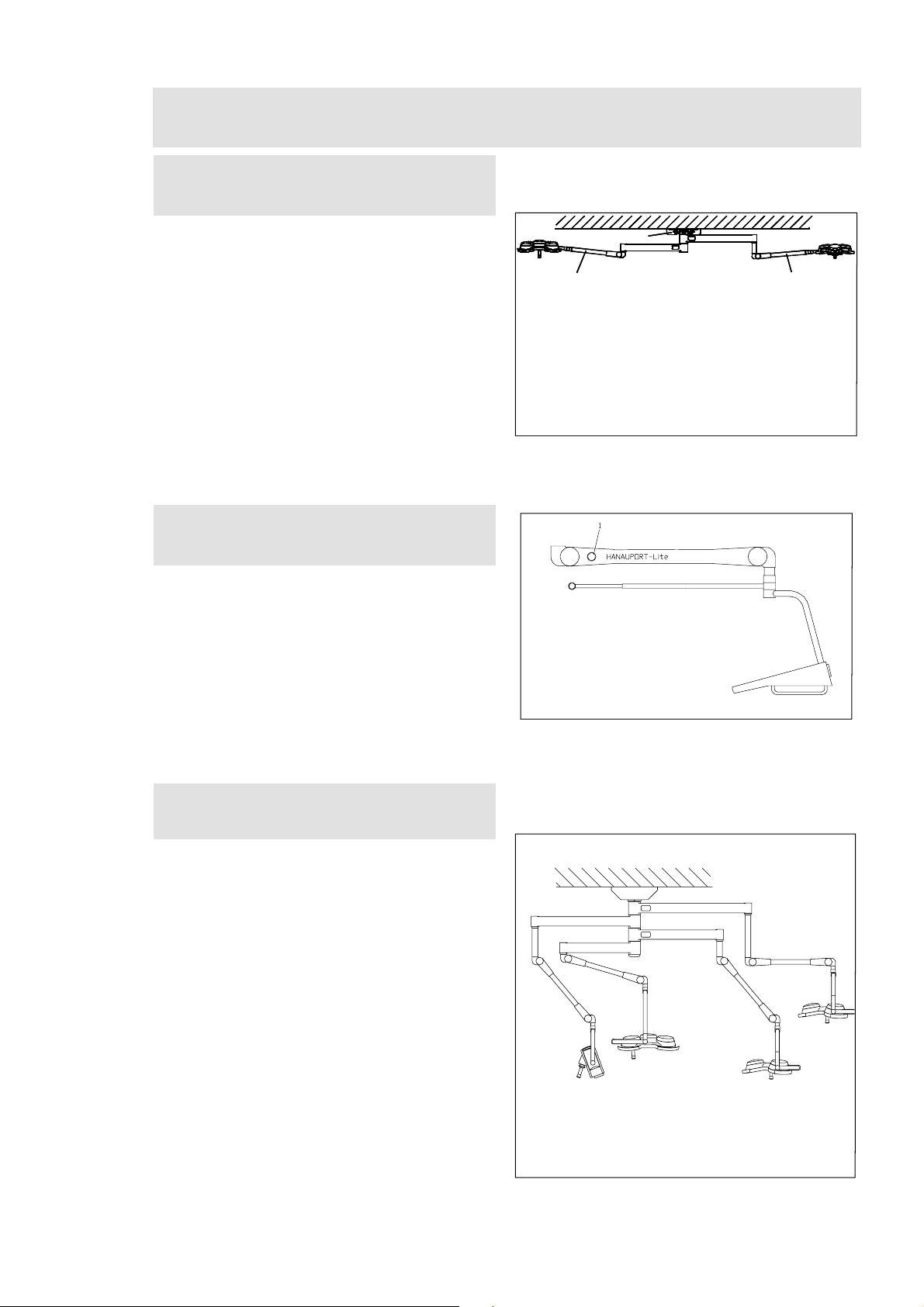

2.3 Special components

2.3.1. Special suspension system for low

ceilings

1

1

The full benefits of the HANAULUX 2000 system

can still be enjoyed even if the ceiling in your

operating theatre is very low. Two special

products are offered for low ceilings:

(i) A Flange-axle 1 which allows the central axle

to be mounted directly to the ceiling without

the need for a flange tube.

(ii) Straight spring-arms 2 with a restricted

upward movement offer optimal manoeuvrability

even in very low rooms.

2

Fig. 2.3.1

2

2.3.2. HANAUPORT-Lite equipment carrier

An appliance console which can support medical

appliances can be combined with HANAULUX

2000 light system. This console is suspended

from a HANAUPORT-Lite Arm and can bear

weights of 7-14 kg

2.3.4 HANAUVISION camera system

The HANAUVISION camera system combines all

the advantages of the latest in camera

technology with the ease of manouevrability of

the HANAULUX 2000 suspension system.

Fig. 2.3.2

A separate Installation and Operating Instruction

is available for the HANAUVISION system.

Fig. 2.3.3

5

Page 8

Operating Instructions 56351039/C HANAULUX® 2000

2.3.5 Versions with limited rotation

The versions with camera (without WDV

models), have additional cables inside the arms

and central axle. The rotation in these joints is

however limited in order to protect the additional

cables. The rotation in the central axle is limited

o

to 330

exact details please see the data sheet for the

product.

It is always possible to limit the rotation in the

axle or the arms in a HANAULUX 2000 system

should this be required. Please contact your

Heraeus Med service agent for further

information.

, the arms are limited to 360o or 225o. For

2.4 Expandability

The HANAULUX 2000 luminaire system can also

be prepared for the later installation of a

SATELLIT light, or a HANAUVISION camera

system. In this case, one axle position is left

"free" and is covered with a sleeve until the

SATELLIT light or camera is to be installed.

Fig. 2.3.4

6

Page 9

Operating Instructions 56351039/C HANAULUX® 2000

3.0 The HANAULUX Benefits

3.1 Brilliant cool light

The heart of the HANAULUX 2000 lighting

system is the HANAUCHROME optical system.

Each HANAULUX 2000 lightheads has a different

number of HANAUCHROME optical systems,

from one in the HANAULUX 2001 up to five units

in the HANAULUX 2005.

Each individual HANAUCHROME system

consists of a number of specially designed

components, all optimised to ensure maximum

illumination of the operating field.

A special halogen bulb 3, with a unique filament

geometry generates the high light-intensity.

A revolutionary glass reflector 2, coated with a

colour correcting conversion film, and an infrared

reflection disc 4 remove the heat from the light,

producing the famous HANAULUX cool light.

A specially developed double Fresnel lens 1,

creates a homogenous lightfield and completes

the HANAUCHROME optical system which

guarantees a cool "white" light for every surgical

discipline.

The HANAUCHROME socket 5, completes the

system. This socket is constructed to be extra

safe and ensure that changing an

HANAUCHROME bulb is never dangerous.

reflection disc 4 remove the heat from the light,

producing the famous HANAULUX cool light.

Abb. 3.1

7

Page 10

Operating Instructions 56351039/C HANAULUX® 2000

3.2 In-Depth illumination

The double Fresnel lens produces a cascade of

focal points underneath the HANAUCHROME

system. The result is a well illuminated field with

homogeneous light distribution and great

operating depth (50 cm), almost cylindrical in

shape.

3.3 Optimal hygiene

Every light unit in the HANAULUX 2000

luminaire system has a sealed housing with

smooth surfaces. Chrome plated outer handles 1

and a removable,sterilisable central handle 2 are

mounted on this housing for moving the light. All

handles are robust and chemically resistant and

are designed to withstand aggressive disinfecting

agents.

The high glance powder coat paint system has a

low surface energy. This means that it does not

easily attract dirt or germs and is easy to clean.

This tough paint system is also particularly

resistant to scratches and scuffs.

3.4 Easy manoeuvrability, true positioning

Even if the HANAULUX 2000 system is equipped

with several SATELLIT lights and a

HANAUPORT Lite arm, all can be easily moved

without damage or interference. Three special

features make this possible: graduated extension

arm lengths, graduated spacers and

limitless rotation of the main joints.

The weight of the lightheads is exactly

compensated by spring balances in the

spring-arms which also hold every position. The

finely adjustable brakes in the joints of the

supporting arms ensure light, easy movement

and true positioning.

Abb. 3.2

Abb. 3.3

1

1

2

3

4

1. 1200 mm extension-arm with spacer 4

2. 1050 mm extension-arm with spacer 3

3. 900 mm extension-arm with spacer 2

4. 750 mm extension-arm

5. 900 mm extension-arm for 2006 iXL TV /

2007iXL lights

Abb. 3.4

5

8

Page 11

Operating Instructions 56351039/C HANAULUX® 2000

4.0 Operating your HANAULUX 2000 luminaire system

4.1 Mounting and removing the

sterilisable handle

All HANAULUX 2000 models have a sterilisable

handle which can be removed and sterilised.

To mount the handle 1, push it up onto the

handle pillar until the ball bearing 2 snaps into

place, as shown. The ball bearing must make an

audible click.

Handles which are cracked or

damaged must be replaced

immediately. Otherwise they could

fall down into the operating area

during an operation.

Fig. 4.1

To remove the handle, push in the ball bearing 2

and gently pull handle off pillar.

4.2

The weight of the appliance is balanced by

weights in the shelf. These are installed during

assembly of the appliance pendant. When

changing the appliance for another one which

weighs more or less than the previous appliance,

the weights in the shelf must be changed. For

further details please refer to the assembly

instructions. The spring arm can be locked in the

uppermost, lowermost and mid position by

pressing the lock button 1, if the appliance has to

be removed from the pendant. Press button 1

and move the arm in the desired direction until it

clicks fully into position

HANAUPORT Lite with Equipment

Carrier

Fig. 4.2

Fig. 4.3

9

Page 12

Operating Instructions 56351039/C HANAULUX® 2000

4.2.2. Positioning the lights

The extension arm at position 1 is specially

shaped to allow the light to be positioned directly

under the central axle, as is required for some

disciplines.

In order to achieve best possible mobility please

position this arm in relation to the second light in

a M position, as shown in fig. 4.2-2. In the M

position the spring-arm is always on the inside of

the extension arm, never on the outside, so that

the light can be easily moved.

Failure to position the arms in the

M position shown could result in

the spring-arms hitting the

extension-arms and damage

could occur.

To move the lighthead up or down:

Make sure that the sterilisable handle 2 is in

position (For details on mounting the handle

please see chapter 4.1).

Grip the handle tightly with your hand and gently

push or pull the lighthead upwards or downwards

into position.

To move the lighthead from side to side

Firmly grip the outer handles 1 with both hands

and gently pull or push the lighthead towards you

or away from you.

The lighthead must never be turned

upside down while switched on, as

the heat generated in the optical

system will not be able to radiate

downwards and the optical system

could be damaged as a result.

:

Fig. 4.2.2

10

Fig. 4.2.3

Page 13

Operating Instructions 56351039/C HANAULUX® 2000

4.3 Focussing the lights

4.3.1 Avoiding light spill

When focusing or adjusting the fieldsize of your

lights please keep the fieldsize to the minimum.

The fieldsize should be just sufficiently large to

illuminate the incision and surrounding tissues.

If the field is too big, light spill around

the operating area could dazzle and

tire the eyes.

4.3.2 Focussing the light

To focus the 2002-2005 models with

ERGO-FOCUS, proceed as follows::

1. Make sure the sterilisable handle is correctly

mounted.

2. Make sure the light is positioned within 70 to

140 cm of the operating field.

3.Turn the handle 1 until it locks into place. The

field remains in this position focused on the

operating area.

4.To focus the

handle until the field is round and is of the

required field size.

This also applies to the special model 2007

Autofokus. Please consult Section 4.5 for

information on how to set the field size of this

light at the controls.

2007

model turn the central

Fig. 4.3.1

To change the fieldsize turn the sterilisable

handle 1:

to the right to increase

to the left to decrease the fieldsize.

or

Fig. 4.3.2

11

Page 14

Operating Instructions 56351039/C HANAULUX® 2000

4.3.3 Working area and focus range

Your HANAULUX 2000 lights have a special

optical system (see chapter 3.1) which has the

unique feature of providing a column of light

which approximately 50 cm long. In practise this

means that once the light is focussed the lighting

conditions within an area of 50 cm are more or

less uniform. Within this area minimal

refocussing is required.

The focus range or operating distance of the

lights is 700-1400 mm. This distance is

measured from the bottom of the light unit.

If the light is closer than 70 cm to

or further than 140 cm from the

operating field the light cannot be

properly focussed.

Fig. 4.3.3

4.4 Dimming the light

We recommend the installation of a dimmer for

varying the light-intensity. The Heraeus

recommended dimmer allows the light-intensity

to be varied between 50% and 100% and is

mounted in a control panel on the wall. For

further details of the recommended dimmer

please see our "Preparatory Measures for

Installing HANAULUX 2000."

Before starting any operation please adjust the

illuminance in accordance with the requirements

of the intended operation and the surgeon’s

personal preference.

If the operation is to last more than 2 hours our

tip is to begin the operation with a lower

light-intensity, e.g. 50 %. This allows you to

increase the light-intensity gradually during the

operation and to thus compensate the eye

fatigue which often occurs during longer

operations.

12

9

6

50%

Fig. 4.4

3

h

lux

9

100%

12

3

6

12

Page 15

Operating Instructions 56351039/C HANAULUX® 2000

4.5 Operating the 2007 iXl D and 2007 iXL AF

4.5.1 Operating the 2007 iXL AF light

The HANAULUX 2007 iXL AF is equipped with

an autofocus system which automatically

regulates the fieldsize. In order to optimise the

use of your 2007iXL AF light the following must

be observed.

The autofocus system has a working range

of 70 to 140 cm, measured from the bottom edge of the lighthead to the operating

area.

The light tests itself when it is turned on.

This test lasts about 30 seconds. In order

to activate the light after this test a handle

must be lightly touched.

The autofocus system is now ready for operation.

The fieldsize can be adjusted at the touchpanel

and the middle handle. To change the fieldsize at

the touchpanel, the switches "+" or " -" must be

pressed. To increase the fieldsize press the

switch 1, to decrease it press the switch 2. The

corresponding light diode lights up.

The autofocus system is now set. The fieldsize

will remain the same during the entire operation.

The autofocus only reacts when the distance

between the light and the operating field

increases. The system will not react if hands or

tools are in the operating field. If the light is to be

refocussed to a higher point before or after the

operation a handle must be lightly touched. The

autofocus system will now focus on the first

object it finds within its working range.

The autofocus system can be turned off by

pressing switch 3. Press switch 4 to turn the

system on again.

4.5.2 Operating the dimmer on the

2007 iXL AF and 2007 iXL D

The 2007 iXL AF and 2007 iXL D lights are

equipped with a light-intensity regulator on the

touch panel. For important information about the

proper use of a dimmer please see chapter 4.4

Press switch 5 to reduce the light-intensity,

switch 6 to increase.

1

2

4

3

Fig. 4.5

6

5

13

Page 16

Operating Instructions 56351039/C HANAULUX® 2000

5.0 Important information about halogen bulbs

5.1 Changing a bulb

The shape and structure of the filament of the

halogen bulbs used for the HANAULUX 2000

DUO lighting systems are specially designed for

the HANAUCHROME optical system (see

chapter 3.1).

Only original Hereaus bulbs should be used as

any of the following could otherwise occur:

A lower light-intensity

A higher temperature increase in the operating

field

Colour falsifications

Inhomogenous lightfield

Reduced bulb life

Damage to the optical system.

The halogen bulbs significantly

determine the technical data for the

HANAULUX operating theatre lights.

They are, therefore, accessories

under the terms of the law on

medical products (§ 3 MPG) and

must therefore only be brought into

circulation with the CE symbol as

this type of accessory.

Important information about voltage,

light-intensity and life of bulb and

optical system

The HANAUCHROME bulbs and optical system

are rated for a voltage of 22,8 V (AC or DC) at

the bulb socket. Higher voltages should be

avoided as they cause a decreased bulb life. In

extreme cases the life of the optical system could

be also be reduced.

Fig. 5.0

In order to optimise the life and

performance of the optical system

the voltage to the bulb should not

exceed more than 10 % above

the rated value of 22,8 V.

Excessive voltages could result in

damage to the optical system.

Voltage

at flange

(V)

Voltage

at bulb

(V)

Rel. light

intensity

(%)

23.0 21.8 90 120

23.5 22.3 96 105

24.0 22.8 100 100

24.5 23.3 105 95

25.0 23.8 109 85

25.5 24.3 70 50

Rel. life

of bulb

(%)

A lower voltage results in a lower light-intensity.

Significantly lower voltages can also reduce the

life of the halogen bulb.

Table showing the relationship between voltage,

light-intensity and the life of the bulb.

14

Page 17

Operating Instructions 56351039/C HANAULUX® 2000

The bulb generates considerable

heat which is emitted through the

top of the lighthead. The covers

will therefore be quite warm to the

touch.

Never change a bulb as long as

the cover is still warm as you could

burn yourself.

Switch off the light system.

1. With one hand push the button 2 in as far as

possible. At the same time turn the cover 1

towards the right or the left until it opens.

2. Remove the cover 1 and place carefully to one

side. The cover will not fall out as it is attached

to the lighthead by a grounding cable.

3. Open the two clips 3 on the socket 4.

4. Gently pull the socket 4 as far as possible out

of the socket holder.

5. Remove bulb 5 from socket 4.

Never touch a bulb with bare

hands as the life of the bulb could

be considerably shortened.

7. Still holding the bulb 5 in the plastic

packaging, gently push the bulb as deeply as

possible into the socket 4. Make sure the bulb is

sitting straight. Gently remove the plastic

packaging from the bulb.

6. Carefully unpack the new bulb by tearing the

bottom of the plastic bubble packaging and

pushing the bulb down until the pins protrude

about 1.5 cm out of the packaging.

Fig. 5.1.a

Fig. 5.1.b

8. Replace the socket 4 in the socket holder,

taking care not to knock the bulb in the

process.The holes on the socket 4 must be

matched up to the corresponding fittings on

the socket holder. Close the two spring clips 3.

9. Closing the lighthead cover: Place the cover 1

on the light, making sure that the spring latch 2

is lined up to one of the arrows. Gently press

down on the cover 1 and at the same time

slowly turn the cover in the direction indicated

by the arrow until the cover snaps audibly into

place.

15

Page 18

Operating Instructions 56351039/C HANAULUX® 2000

6.0 Adjustments

The brakes are always adjusted during the

commissioning phase and before official

handover. The brakes should always be

adjusted so that the manoeuvrability of the light

is as light as possible but the light still maintain

it’s position.

As with all mechanical parts it is to be expected

the brakes and the spring balance will fatigue or

wear and need readjusting.

6.1 Adjusting the brakes

Tools:

A flatheaded screwdriver, ca. 6mm is required.

The brake adjustment points are shown in fig.

6.1.

Should the brakes be worn they will be too soft

and the light could drift from side to side.

Should the brakes be too hard the light will be

difficult to move. In either case the brakes can be

easily readjusted.

Single Lights: Single lights, ceiling and wall

version, do not have a brake screw at position 1.

The 2003 i and 2004 i/iXL single lights have

brake screws at Points 2, 3 and 4, the 2002 i

single light only has them at Points 3 and 4.

All brake screws are slotted screws.

To set the brake force, gently tighten or loosen

the brake screw.

All other screws are fixing screws

and should not be adjusted as a

part could loosen and fall down.

Fig. 6.1

16

Page 19

Operating Instructions 56351039/C HANAULUX® 2000

6.2 Adjusting the spring-arms

Should the lighthead drift downwards or jump

upwards then the spring balance in the

spring-arm is fatigued and must be readjusted.

The adjustment method varies with the

spring-arm version.

6.2 .1 Adjusting the spring-arms 2002 i

-2005 i/iXL

1. Open the spring-arm covers 1 by removing

the screw 2.

2. Use a small screwdriver to gently force the

covers apart.

3. Push the spring-arm upwards until the adjustment nut is visible in the opening 1 of the

spring-arm. (Fig. 6.2.b)

4. Insert the metal pin which is supplied with the

arm into the nut and turn nut to adjust spring

force.

5. Place the spring-arm covers on the pring-arm.

The holes for the screw 3 and the hole in the

cover nose must line up. Make sure that the

metal strips 2 are not bent or twisted.

6. Tighten screw 3 to fix covers into place. Check

that covers are sitting properly.

The covers must always be screwed

into place. Otherwise they could open

and fall off during operation.

Fig. 6.2.c

Fig. 6.2.a

Adjust the spring force, so that:

(i) The strength required to pull the spring-arm

up or down is the same in both directions,

(ii) The lightheads remain stable and firm in

both directions.

Turning the nut decrease the spring force

Turning the nut increases the spring force

6.2.2

Remove the fixing screw 1 and the cover 2. Push

the spring-arm upwards until the adjustment nut

is visible in the opening 3 of the spring-arm.

Adjust spring-arm as described in steps 3 and 4.

Fig. 6.2.d

Straight spring-arm:

Fig. 6.2.b

17

Page 20

Raise the arm above the horizontal to facilitate ad-

justment (Fig. 2).

6.3 Adjustment of Acrobat

2000 spring arm

Unscrew to

raise stop

Screw to lower

stop (to horizontal)

Abb. / Fig. 1

Abb. / Fig. 2

6.3.2 Adjustment of spring arm:

balancing

Unscrew to

increase the

strength of the

spring arm (cupola goes up)

Screw to

reduce the

strength of

the spring arm

(cupola goes

down)

Use the 5 mm Allen key provided

(Fig. 1).

Reinstall the arm to check the new position

obtained. Adjust if required.

Make sure that the cupola appears

to weigh the same during raising and

lowering and that it remains stable in any

position in which it is left.

+

-

Abb. / Fig. 3

6.4.1 Adjustment of spring arm:

upper stop

6.4 Adjustment of Acrobat

2000 straight spring arm

Locate the setting. Use the rod provided (Fig. 3)

Turn downwards to

lower stop (to

horizontal)

Turn upwards

to raise stop

Reinstall the side covers, engaging the end first

(Fig. 4).

Then engage the other end taking care to leave

the spring blades on the outside.

Fasten the covers using a 2.5 mm Allen key

(Fig. 5).

Lower the arm to reinstall the top spring blade.

Then raise the arm to reinstall the bottom blade.

Abb. / Fig. 4

Abb. / Fig. 5

6.3.1 Adjustment of spring arm:

upper stop

Operating Instructions 56351039/C HANAULUX® 2000

6.4.2 Adjustment of spring arm:

balancing

See 6.3.2 Adjustment of spring arm: balancing

18

COMMENT!

COMMENT!

Page 21

Operating Instructions 56351039/C HANAULUX® 2000

7.0 Cleaning/desinfecting and sterilising

7.1 Cleaning/ desinfecting the

light

Sterilising or cleaning agents which

The HANAULUX 2000 system has a special

powder coat paint coating which is easy to clean

and resistant to chemicals. The outer handles are

chrome plated to make them chemically

resistant.

Note

The user has to pay attention to th

demands of the national committee for

hygiene and disinfection.

e

7.3 Sterilising the handles

contain alcohol should never be

used on the HANAULUX 2000

lenses.

Alcohol attacts the lenses causing

them to become cloudy or milky

and the light-intensity will therefore

decrease.

To avoid damage to plastic and glass

parts, do not use any scouring agent, or

any cleaning agent which is alkaline

acidic or contains alcohol (e.

propanal, ...) or aldehyde.

• Only disinfect the apparatus when it i

cold.

•We recommend our teste

cleaning/desinfection agent HANAU

-clean.

•Because there are a

cleaning/desinfecting agents on the

market, and we do not know their

interactions with plastic used, damage

cannot be ruled out if other agents are

used.

•For cleaning, use a soft, lint-free cloth.

7.2 Cleaning the lenses

g. ethanol

great number of

The central handles, both metal and plastic, can

withstand up to 350 sterilisation cycles without

damage, provided they are correctly sterilised.

The handles should be sterilised as follows:

The handle should be placed upright in the

sterilisation unit with the opening facing

s

downwards to prevent any condensation occuring

in the cavity. Otherwise the handles could crack.

d

The sterilisation temperature should not exceed

o

134

C. The handles should not come into contact

with any other appliances during the sterilisation

process.

Handles which show signs of wear

(discolouration, cracking, etc.)

should be replaced immediately. A

damaged handle could fall off into

the sterile area during an

operation.

7.4 Cleaning HANAUVISION

The HANAULUX 2000 lenses are made of tough,

high quality acrylic. As all plastics are subject to

aging processes the lenses should be visually

inspected from time to time. Alcohol based

cleaning agents should not be used. We

recommend the cleaning agent HANAUCLEAN.

Lenses which are damaged,

cracked or cloudy shoudl be

immediately replaced as they

could otherwise break during an

operation.

For details regarding the special care and cleanig

of your HANAUVISION camera system please

refer to the separate HANAUVISION operating

Instructions.

19

Page 22

Operating Instructions 56351039/C HANAULUX® 2000

8.0 Maintenance and repair

HANAULUX operating theatre lights have been

designed and built to last for a very long time.

However, to guarantee perfect and safe

operation over long periods, it is necessary to

check the lights regularly. Regional regulations

must also be observed when doing this.

8.1 Inspection by the operator

All HANAULUX 2000 products are to be

inspected by the operator every six months with

attention to the following points:

- defects in paint work

- cracks in plastic parts

- deformation in the supporting system

In the case of any problems or damage,

please inform our customer services.

8.2

Inspection by the Service

When ordering spare parts please observe the

following:

Identifying the correct parts:

Please check the model type on the type label

which is to be found on lighthead axle.

Model Reflector

(Part. no.)

2006/7 iXL

2007 iXL AF

2004/2005 iXL

2002 i to 2005 i

Visible markings:

In order to facilitate identification of the correct

parts the reflectors and lenses are marked as

follows:

56052959

56052969

56052961 56052962

56052961 56052609

Lenses

(Part. no.)

56050730

56050732

All HANAULUX 2000 products are

serviced once a year by

HERAEUS Med or an authorised

customer services office. This

service covers the following

points:

- performance check test

- electrical safety test

- inspection of the supporting system

The service man is trained in how to conduct

the tests.

8.3 Important information about

Description Part. No.

HANAUCHROME bulb

HANAUCHROME bulbs, 8 off 56 051 757

Sterilisable handle, plastic 3 off 560 50 756

Sterilisable handle, metal 3 off 56 050 755

HANAUCLEAN 56 051778

The HANAULUX 2000 offers two different light

systems:

- HANAULUX Improved (i)

- HANAULUX Improved Extra Large (iXL)

, 1off

56 115 282

Fig.1: Reflectors

Marking: Label with part number

Fig. 2: Lenses

2 strips for 2002-5 i, 3 strips for 2004/5 iXL

Reflectors and lenses may only be

used in the combinations shwon

above. Other combinations could

result in poor light quality.

20

Page 23

Operating Instructions 56351039/C HANAULUX® 2000

9.0 Troubleshooting your HANAULUX 2000 system

Fault Possible cause Corrective measure Reference

Suspension System/Manoeuvrability

Light is heavy,

difficult to move

Light is too light,

drifts easily

Lighthead drifts

downwards

Lighthead jumps

upwards

Spring-arm

knocks against

ceiling

Spring arm

covers fall off

Metal strips

under spring-arm

covers broken

Extension-arms

move together,

scrape against

one another

Brakes are too tight Readjust brakes Chapter 6.1

Brakes are too loose

or worn

Spring-balance in

spring-arm is tired,

worn

Spring-balance is too

tight

Spring-arm upper

movement must be

restricted

Covers have been

knocked/damaged

- Arm has been

knocked/damaged

- Covers have been

incorrectly mounted

Arm has been

knocked too hard and

tilted

Readjust brakes or replace Chapter 6.1

Readjust spring-balance Chapter 6.2

Readjust spring-balance Chapter 6.2

Height restrictor must be adjusted.IContact service

agent

Replace covers. Check that arms

are correctly used

Replace arm

Check covers are correctly

mounted

Light must be checked

immediately

Chapter 4.2.2

Contact service

agent

Chapter 6.2

Contact service

agent

Optical system/Lighting parameters

Light flickers/

power fails when

light is moved

Light-intensity is

too low

Light not white/

colour wrong

Light too bright

Lightfield not

round

Life of bulb too

short

Bulbs explode

Electrical contact is

damaged

- Voltage is too low

- Wrong bulb(s) in

light

- Lenses damaged

from wrong cleaning

agent

- Wrong lens!

- Wrong bulb(s)

- Wrong lens

- Wrong bulb(s)

- Voltage too high

- Wrong bulbs

- optical system

damaged

- Wrong bulb(s)

- Voltage too high

- Voltage too high

- Short circuit in wiring

Contact must be replaced Contact service

agent

- Electrician must check

- Check bulb, replace

- Lenses must be replaced,

cleaning must be changed

- Check lens version

Replace bulb

Check lens version

- Check bulb, replace

- Electrician must check

- Check bulb, replace

- Optical system must be replaced

- Check bulb, replace

- Electrician must check

Electrician must check

- Chapter 11

- Chapter 5.0

- Chapter 8.0

- Chapter 9.0

- Chapter 5.0

- Chapter 9.0

- Chapter 5.0

- Chapter 11.0

Chapter 11.0

Chapter 5.0

21

Page 24

Operating Instructions 56351039/C HANAULUX® 2000

Fault Possible Cause Corrective Measure Reference

Lenses

Lenses cracked,

splitting

Lenses have

melted, bubbled

on inside

Wong cleaning agent

used

- Voltage too high

- Wrong bulbs used

- Replace lenses

- Check cleaning agent

- Replace lenses

- Check voltage

- check bulbs

Chapter 8.0

Chapter 5.0

Sterilisable Handles

Sterilisable

Handles do not

last long enough

(less than 150

cycles)

Handles are

cracked or

discoloured

Handles fall off

Handles incorrectly

sterilised

Handles have reached

end of working life

Handles are

damaged/worn

Check sterilisation process Chapter 8.0

Replace immediately Chapter 8.0

Replace immediately Chapter 8.0

Focussing/Field change

Light does not

focus when

middle handle

turned

Focus is

stiff/jerky

Light cannot be

focussed

properly,

although focus

mechanism

works

Focus mechanism

broken

Focus mechanism dry,

must be greased

Light is too close to /

too far from operating

field

Replace immediately Contact service

agent

Grease mechanism Contact service

agent

Check that light is within working

area

Chapter 4.3

If any of these faults reoccur or cannot be rectified, please contact your service

agent.

22

Page 25

Operating Instructions 56351039/C HANAULUX® 2000

10.0 Technical data: Lighting parameters

The lighting parameters are measured in accordance with EN 60601-2-41.

Model Light-intensity

(kLux)

2007 iXL

2007 iXLAF

2006 iXL TV

2005 i

2005 î TV

2005 i NRH

2005 iXL

2005 iXL TV 100 20-30 55 70-140

2005 iXL NRH

2004 i

2004 iXL

2004 i TV

2003 i

2002 i

130 20-35 60 70-140

130 20-35 60 70-140

115 20-35 60 70-140

130 17-25 55 70-140

130 17-25 55 70-140

130 17-25 55 70-140

100 20-30 55 70-140

100 20-30 55 70-140

100 17-25 50 70-140

80 20-26 50 70-140

100 17-25 50 70-140

80 17-23 50 70-140

60 17-23 40 70-140

Lightfield

(cm)

Working area

(cm)

Focussable

area (cm)

23

Page 26

10.1 Technical data: Mechanical data

Model max.

diameter of

rotation

(cm)

Vertical

action

(cm)

Mass of

lighthead

*

(kg)

Mass of

suspension

system

(main light)

(kg)

Mass of

Sat.

suspension

system

(kg)

2007 iXL

360 100 29 62 -----

2007 iXL AF 360 100 34 62 -----

2005 i 420 115 17 55 28

2005 i TV

420 115 20 55 28

2005 i NRH

420 115 15 55 28

2005 iXL

420 115 17 55 28

2005 iXL TV

420 115 20 55 28

2005 iXLNRH

420 115 15 55 28

2004 i

420 115 16,5 52 18

2004 iXL

420 115 16,5 52 18

2004 i TV

420 115 19 55 28

2003 i

420 115 13,5 52 18

2002 i

420 115 8,5 52 18

* All basis version except 2004/5 i/iXL TV which is always comfort version.

Mass of ceiling anchor ring with shortest flange tube: ca. 20 kg.

For longer flange tubes an extra 1,1 kg must be added for every 10 cm length.

Operating Instructions 56351039/B HANAULUX® 2000

MAQUET S.A.

Parc de la Limère

Avenue de la Pomme de Pin

ARDON 45074 ORLÉANS CEDEX 2

Tel: +33 (0) 2 38 25 88 88 Fax: +33 (0) 2 38 25 88 00

www.maquet-sa.fr

Loading...

Loading...