Page 1

x

User's Manual

FLOW-i 4.2

Anesthesia System

Page 2

Page 3

Table of contents

| Table of contents |

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

5|Introduction

9|Important

17|System overview

47|Startup and system checkout

65|System functionality

119|Breathing system

149|AFGO (Additional Fresh Gas Outlet, Option)

155|Membrane buttons

183|Alarms and patient safety

209|Ventilation modes

233|System shutdown

235|Routine cleaning and maintenance

265|Technical specifications

291|EMC Declaration

299|Definitions

301|Certificates

303|Index

309|Log sheet

FLOW-i 4.2, User's Manual

Infologic 1.67

3

Page 4

| Table of contents |

4

FLOW-i 4.2, User's Manual

Infologic 1.67

Page 5

1 Introduction Table of contents

| Introduction |

6|Indications for use1.1

6|Intended use1.2

7|Using this manual1.3

1 |

FLOW-i 4.2, User's Manual

5

Page 6

| Introduction |

| 1

1.1 Indications for use

The indication for FLOW-i Anesthesia System is administering inhalation anesthesia while

controlling the entire ventilation of patients with no ability to breathe, as well as in supporting

patients with a limited ability to breathe. The system is intended for use on neonatal to adult

patient populations. The system is intended for use in hospital environments, except MRI

environment, by healthcare professionals trained in inhalation anesthesia administration.

1.2 Intended use

The system is intended for use in administrating anesthesia while controlling the entire ventilation

of patients with no ability to breathe, as well as in supporting patients with a limited ability to

breathe.

The system is intended for use by healthcare professionals, trained in the administration of

anesthesia.

The system is intended for use on neonate to adult patient populations.

The system is intended for use in hospital environments, except the MRI environment.

When not in operation, the system is designed for in-hospital transport.

6

FLOW-i 4.2, User's Manual

Page 7

| Introduction |

1 |

1.3 Using this manual

This manual is divided into the following

chapters:

• Chapters 1 and 2: Important information

before use, along with a basic introduction

to the system and User's Manual.

• Chapter 3: Overview of the functional parts

of the system.

• Chapters 4 through 11: Understanding and

working with the system.

• Chapter 12: Routine cleaning and

maintenance procedures.

• Chapter 13: The technical specification of

the system.

• Chapter 14: EMC Declaration

• Chapter 15: Terminology and definitions

• Chapter 16: Certificates

• Chapter 17: Index

Important information is highlighted with

Warning or Caution, where:

WARNING! Indicates critical information

about a potential serious outcome to the

patient or the user.

CAUTION: Indicates instructions that must

be followed in order to ensure the proper

operation of the equipment.

• Chapter 18: Log sheets

References made to optional accessories

within the FLOW-i User's Manual are

accompanied by the text 'option' in brackets.

FLOW-i 4.2, User's Manual

7

Page 8

| Introduction |

| 1

8

FLOW-i 4.2, User's Manual

Page 9

2 Important Table of contents

| Important |

10|General information2.1

11|Connection2.2

12|Operation2.3

13|Installation and service2.4

14|Accessories and auxiliary equipment2.5

2 |

FLOW-i 4.2, User's Manual

9

Page 10

| Important |

| 2

2.1 General information

• The following applies throughout this User's

Manual:

- 'FLOW-i', 'anesthesia system' and

'system' represent FLOW-i anesthesia

system version 4.2.

• This manual applies to the FLOW-i

anesthesia system models C20, C30 and

C40, and optional equipment that can be

fitted onto these.

• Only authorized personnel who are well

trained in its use should operate the

anesthesia system. It must be operated

according to the instructions in this User's

Manual.

• Gas volumes, flows and leakages

associated with the breathing system are

stated in the technical specifications and

adhere to BTPS reference conditions. (Body

temperature, ambient pressure, Saturated).

• All gas concentration readings are normally

referenced to dry gas conditions, ambient

room temperature and atmospheric

pressure (ATPD).

• The condition for measured inlet gas

pressures and flows is STPD (Standard

Temperature and Pressure Dry); 20° C,

standard pressure at 101.3 kPa and 0 %

relative humidity (dry).

• All data on pressures are given in either

cmH2O or bar, where

1 cmH2O = 1 hPa = 1 mbar

1 bar = 15 psi = 1 atm = 1 kgf/cm2 (kp/cm2)

• The anesthesia system is not made with

natural latex.

• Applied parts, i.e. equipment making

physical contact with the patient, comprise

gases (including agents) and the patient

mask.

• If the mains power supply is interrupted,

the internal battery will provide temporary

power to the system (approx. 90 minutes

when fully charged).

• The fresh gas/gas supply outlets are not

affected by switch to battery power.

• Malfunction of the central gas supply can

potentially cause one or several of the

devices connected to the system to stop

their operation simultaneously.

• When the system is in use, a backup gas

supply shall always be available.

• If the central gas supply is interrupted, the

backup gas cylinders O2/N2O or O2/Air

(option) will provide gas to the system.

• In case of automatic ventilation failure,

switch to manual ventilation. In case of

manual ventilation failure, switch to

emergency ventilation.

• In case of a total power (mains power and

battery) or other electronic failures, the

built-in emergency ventilation system can

be used.

• The system maintains its performance when

tilted up to two degrees.

• In case of a complete system failure,

immediate access to alternative means of

ventilation, e.g. a manually powered

resuscitator, must be ensured to avoid

possible patient injury.

• MAQUET takes full responsibility for

compliance of the CE mark requirements

for the MAQUET CO2 cartridge produced

by Molecular Products Ltd (MPL). MAQUET

takes full responsibility for the supply of the

instructions for use in accordance with the

legislation relevant for the intended use for

this product.

10

FLOW-i 4.2, User's Manual

Page 11

| Important |

2 |

WARNING! To avoid the risk of electric

shock, this equipment must only be

connected to a supply mains with protective

earth.

CAUTION: Federal law restricts this device

to sale by or on the order of a physician.

2.2 Connection

• A full System checkout procedure must be

performed at least once a day.

• The system must never be left unattended

while connected to a patient.

• Electronic accessories and auxiliary

equipment other than the vaporizers must

not be connected or disconnected during

operation or when the system is plugged

into a mains power outlet. Such connection

or disconnection may interfere with the

functioning of the system.

• Supplied gases shall meet the requirements

for medical grade gases according to

applicable standards.

• The backup gas supply should only be

turned ON (valves open) when the backup

gas supply is in use, or during System

checkout.

FLOW-i 4.2, User's Manual

11

Page 12

| Important |

| 2

2.3 Operation

• The system shall always be used in

combination with other vital signs

monitoring devices and/or professional

human judgements of patient condition.

• To protect the patient from high airway

pressure, an upper pressure limit must

always be set. See Chapter 10 for details.

• To protect the patient, an alarm limit must

always be set for low expired minute

volume. See Chapter 10 for details.

• Only anesthetic agents recommended by

MAQUET are suitable for use.

• Anesthetic agent bottles without keying may

not be used with the system, nor is it

allowed to tamper with the keying of

anesthetic agent bottles.

• Ensure that the operating room is properly

ventilated.

• The system is not intended for use during

interhospital transportation.

• The system is not intended for use in an MR

environment.

• Antistatic or electrically conductive

breathing tubes should not be used. If such

breathing tubes are used in combination

with high frequency electric surgery

equipment, burns may occur.

• To allow for mains power disconnection,

make sure that the power cable connected

to the mains power supply remains visible

and fully accessible during patient treatment

and not obstructed in any way by ME

(Medical Electrical) equipment.

• If the integrity of the protective earth

conductor or the protective earthing system

in the installation is in doubt, unplug the

mains power cable and use battery power.

12

• The equipotentiality terminal is designed for

the connection of a potential equalization

conductor according to DIN 42 801 and

IEC 60601-1. The function of the

equipotentiality terminal is to equalize

potentials between the system and other

medical electrical devices that can be

touched simultaneously. The

equipotentiality terminal must not be used

for a protective earth connection.

• The anesthesia system has been designed

and tested to comply with requirements

specified in electromagnetic compatibility

standard IEC 60601-1-2. It is the

responsibility of the user to take necessary

measures to ensure that the EMC

environment in which the workstation will

be used is compatible with the requirements

of IEC 60601-1-2 and that the installation

is carried out according to the EMC

information. See Chapter 16 for details on

EMC environments. If limits are exceeded,

the accuracy and safety of the system may

be impaired. Proactive measures include,

but are not limited to, avoiding the use of

portable and mobile radio-emitting devices,

such as cellular phones and high frequency

apparatus, in the proximity of the system.

• Full performance is reached after a 15

minute warm-up. In case of an emergency,

the system can be used immediately.

• FLOW-i shall be connected to a

centre-tapped single phase supply circuit

when connected to a 240 Vac

(L1-L2-N-GND) supply in the United States.

• The breathing system can handle negative

pressures down to -200 cmH2O, but is not

designed to withstand pressures below that.

• The operator must not touch the patient

and any of the following parts

simultaneously:

Accessible contacts of connectors-

FLOW-i 4.2, User's Manual

Page 13

| Important |

2 |

- Contacts of fuse holders that are

accessible during replacement of the

fuse.

- Contacts of lamp holders that are

accessible after removal of the lamp.

- Parts inside access covers that can be

opened without the use of a tool, e.g.

patient cassette lid connector.

WARNINGS!

• In case of system failure, the lack of

immediate access to appropriate

alternative means of ventilation can result

in patient injury.

• Gas inlets and outlets shall not be

covered or in any other way be

obstructed.

• FLOW-i is not designed to be resistant

to direct exposure to high ionizing

radiation. Such exposure may result in

memory erasure and/or interruption of

ventilation.

2.4 Installation and service

• Installation, service and maintenance of the

system must be performed by personnel

trained and authorized by MAQUET.

• Instructions for installation, service and

maintenance, i.e. a service manual, is

available for personnel trained and

authorized by MAQUET.

• Only original spare parts from MAQUET

must be used in the system.

FLOW-i 4.2, User's Manual

13

Page 14

| Important |

| 2

2.5 Accessories and auxiliary equipment

• External equipment intended for connection

to signal input, signal output or other

connectors shall comply with relevant IEC

standards (e.g. IEC 60950 for IT equipment

and the IEC 60601 series for medical

electrical equipment). In addition, all such

combinations – systems – shall comply with

the standard IEC 60601-1 'Safety

requirements for medical electrical

systems'. Equipment not complying with

IEC 60601-1 shall be kept outside the

patient environment, as defined in the

standard.

• Any person who connects external

equipment to signal input, signal output or

other connectors has formed a system and

is therefore responsible for ensuring that

the whole system complies with the

requirements of IEC 60601-1. If in doubt,

contact a qualified medical technician or

your local representative.

• For optional equipment and accessories,

refer to the user documentation supplied

by the manufacturer.

• Use of an anesthesia gas scavenging

system is compulsory and must comply

with ISO 7396-2 (wall connection) and ISO

80601-2-13 (tubings).

• Values measured at the signal outputs of

the anesthesia system, which have been

processed in auxiliary equipment, must not

be used as a substitute for therapeutic or

diagnostic decisions. Such decisions can

be made only by staff with medical

expertise, and according to established and

accepted practice.

• If there should be any deviation between

information shown on the system and that

shown by auxiliary equipment, the

parameters shown on the system shall be

considered the primary source of

information.

• When electrical equipment is connected to

the auxiliary power outlet or

communications interface, a medical

electrical system (ME system) is effectively

created, potentially reducing the level of

safety. This could result in previously

unidentified risks to patient, users or third

parties. It is the responsibility of the user to

ensure that the connected equipment is

compatible with the requirements of IEC

60601-1.

• Connecting auxiliary equipment to the

auxiliary power outlet can potentially

increase leakage currents to values above

the allowable limits.

• External monitors or similar devices

connected to the VGA port of the system,

must be powered via a medical grade

isolation transformer. No other use is

allowed.

• The responsible organization should

identify, analyze, evaluate and control these

risks.

• Subsequent changes to the medical

electrical system could introduce new risks

and require additional analysis.

• Changes to the medical electrical system

include configuration changes, connection

of additional items, disconnection of items,

update or upgrade of connected equipment.

14

FLOW-i 4.2, User's Manual

Page 15

| Important |

2 |

• The use of O2 and Air gas outlets may,

depending on central gas supply pressure

and ventilation settings, affect ventilation

performance.

• Reprocessing parts labelled 'Single-use'

will degrade biocompatibility and

cleanliness.

WARNINGS!

• The use of other accessories,

transducers and cables other than those

specified by MAQUET may result in

increased emissions or decreased

immunity (EMC) of the system.

• No other electrical equipment other than

those described in this user's manual

may be placed on, or in the immediate

vicinity of the system.

• The patient monitor power connector

must only be used for patient monitors

or equipment mounted on the top shelf.

CAUTIONS:

• Only MAQUET recommended

accessories, supplies and auxiliary

equipment must be connected to or used

in conjunction with the system. Use of

other unvalidated accessories, supplies

and auxiliary equipment may impair the

performance and safety of the system.

• To prevent the system from tilting, follow

the restrictions for patient monitors and

auxiliary equipment specified in Chapter

15, page 268. Maximum torque on the

side rails by the table is 20 Nm.

• Equipment placed on shafts or rails must

not restrict opening of the Emergency

Ventilation cover.

FLOW-i 4.2, User's Manual

15

Page 16

| Important |

| 2

16

FLOW-i 4.2, User's Manual

Page 17

3 System overview Table of contents

| System overview |

18|System parts3.1

19|Control panel3.2

25|Patient monitor (option)3.3

25|Breathing system3.4

26|Vaporizer unit3.5

26|Emergency ventilation system3.6

27|External connections3.7

32|Explanation of symbols3.8

36|Ergonomical positioning3.9

38|Storage and transportation3.10

40|System models3.11

41|Optional equipment3.12

3 |

FLOW-i 4.2, User's Manual

17

Page 18

| System overview |

| 3

The anesthesia system is designed to enable the operator to work with the basic parts of the

system in the most suitable way for each procedure. As the system is mounted on wheels,

and the control panel is mounted on a rotatable arm, it can be easily moved into an

ergonomically-suitable position.

There are a number of different system models available. For more information on the different

models, see page 40.

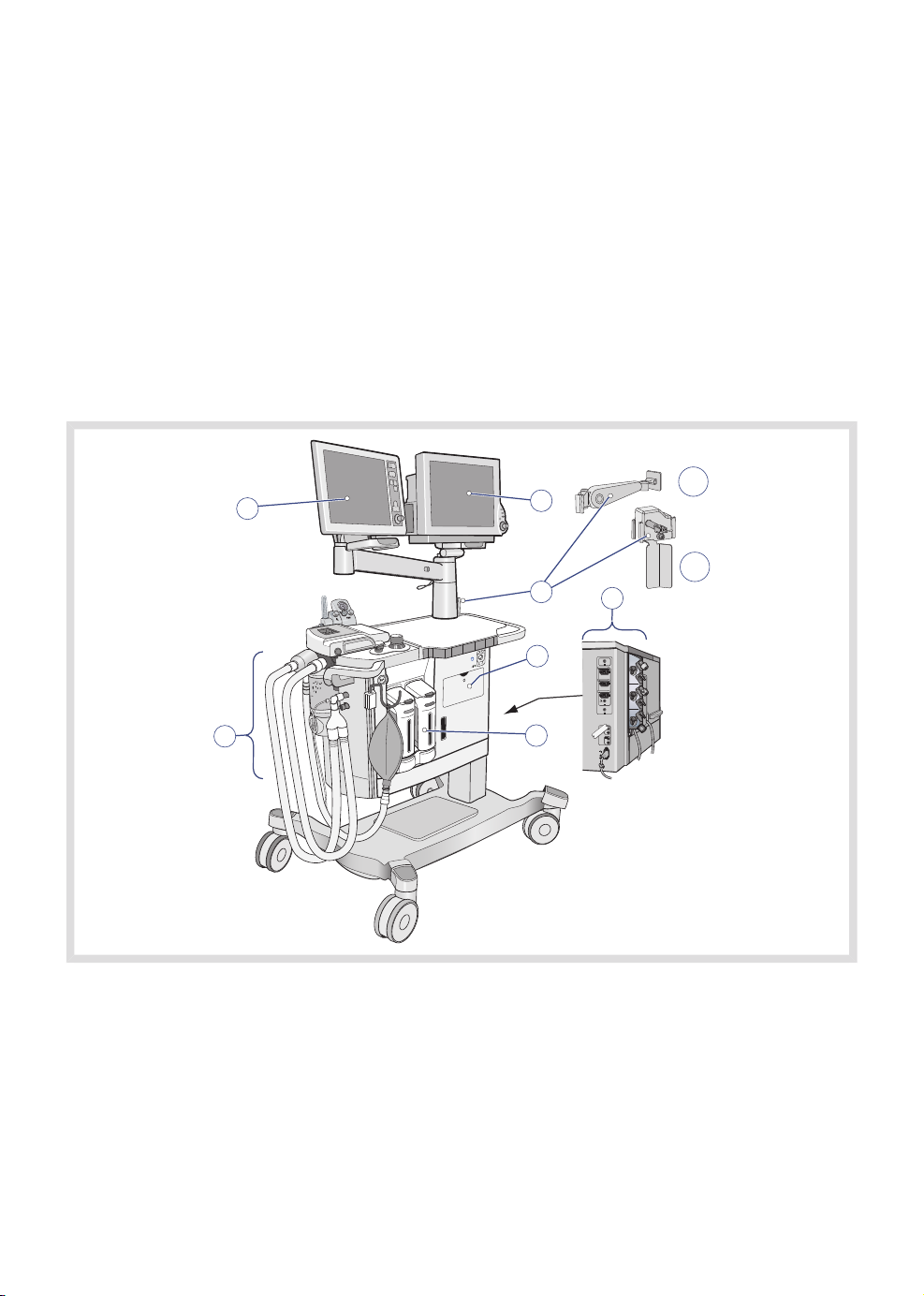

3.1 System parts

The system comprises the following basic parts:

1

7

2

3

5

220-240V~

400 VA

T 1.6 A

6

250 V

T 4 A

250 V

5. Emergency ventilation system1. Control panel

2. Patient monitor (option) 6. Vaporizer unit

7.3. Additional arm 'A' (option) and/or

Breathing system

Gas backup holder 'B' (option)

1

4. External connections

A

B

4

1. C30 can only be equipped with the additional arm or the extra backup gas holder.

18

FLOW-i 4.2, User's Manual

Page 19

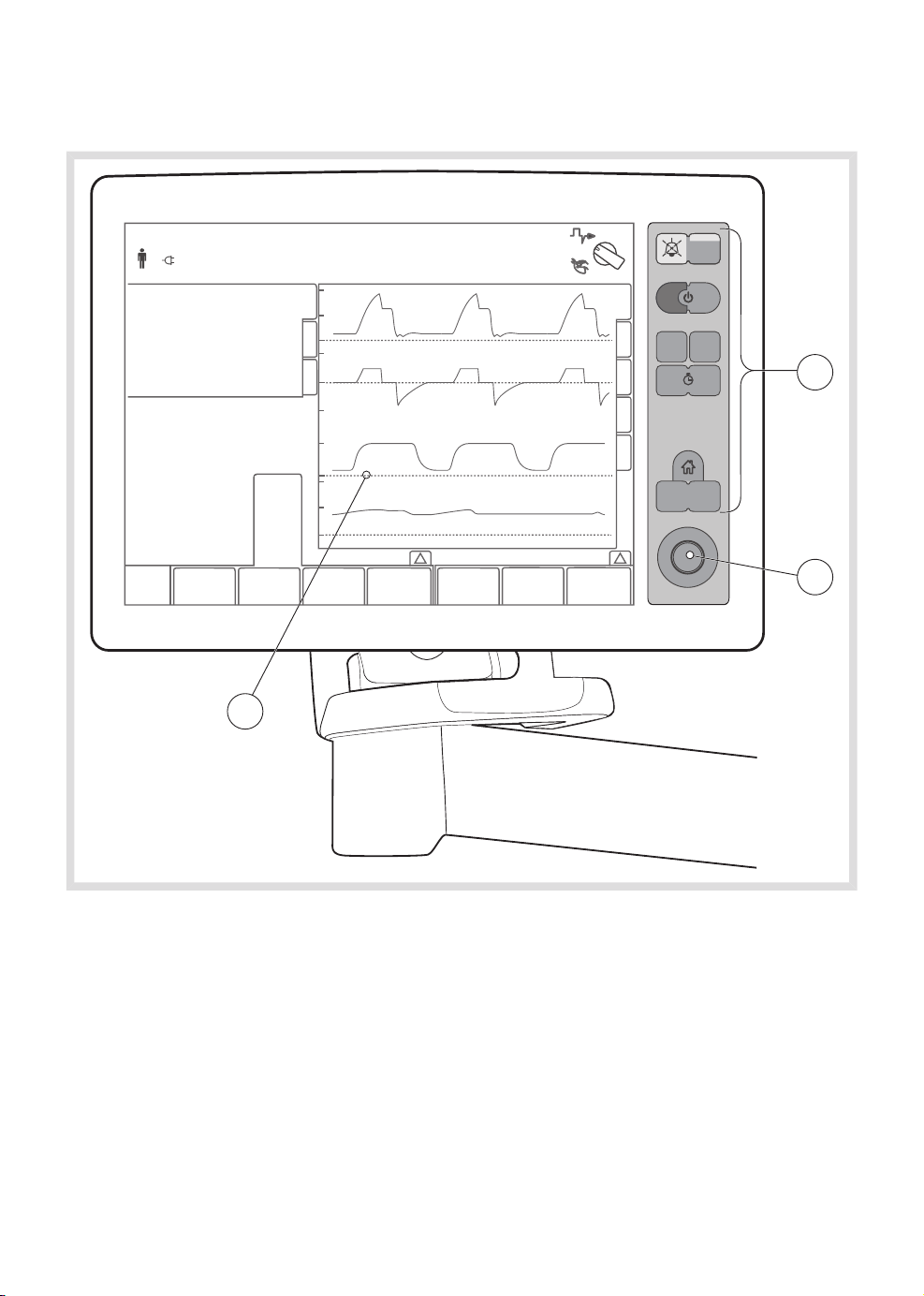

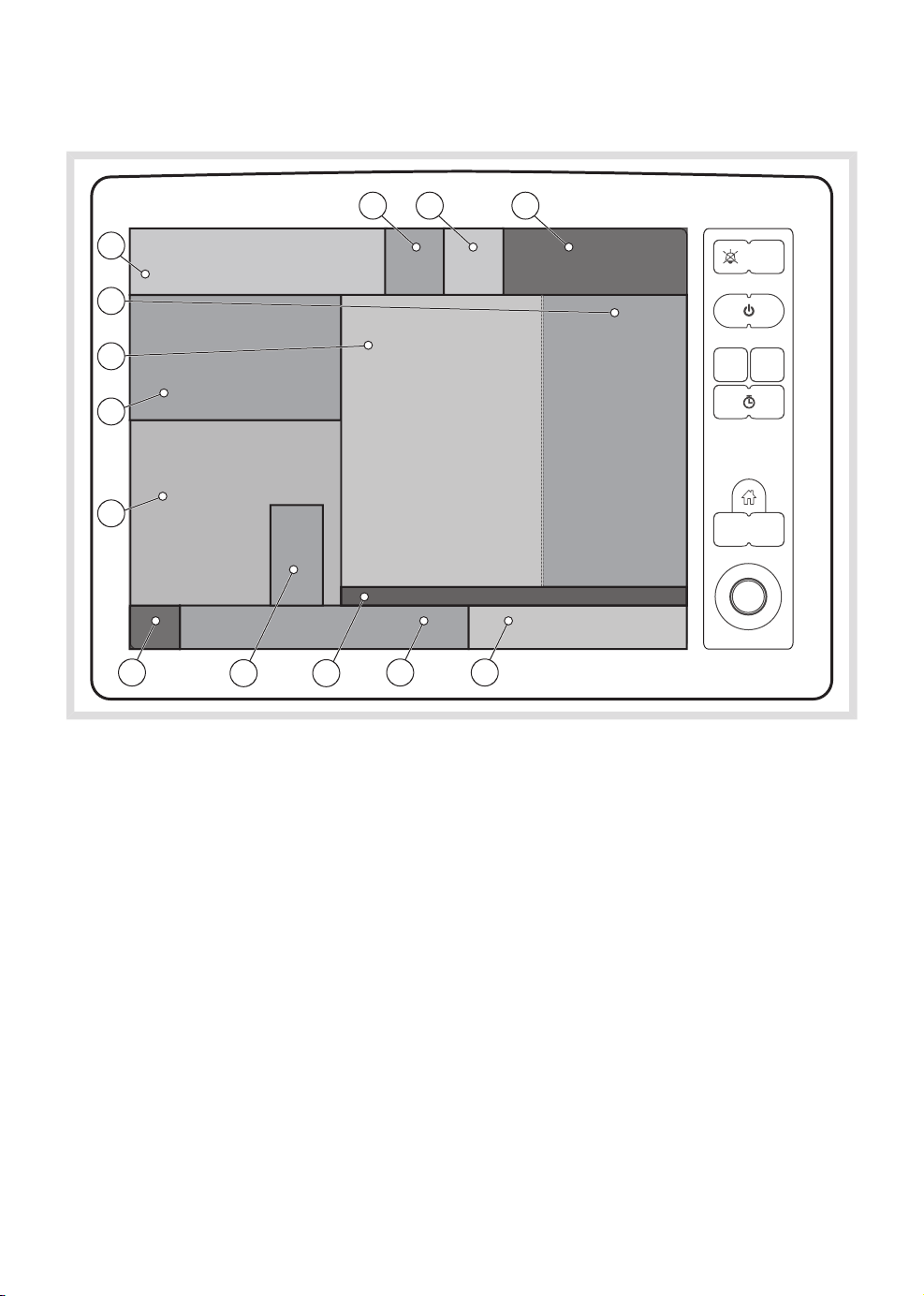

3.2 Control panel

01-01 13 00

| System overview |

3 |

312

3

2

1

The control panel includes:

1. Screen with active touch pads

2. Rotary knob

3. Membrane buttons

FLOW-i 4.2, User's Manual

19

Page 20

| System overview |

| 3

3.2.1 Areas of the screen

10

9

8

7

6

11 12 13

5 2 1

4 3

The screen is divided up into a number of different areas:

1. Ventilation direct access settings

2. Gas direct access settings

3. Activate additional settings/gas settings

window

4. Fresh gas mix rotameter

9. Tab area:

- Short trends

- Loops

- Volume Reflector Indicator

- Gas supply pressure

5. APL valve value

6. Gas measurement area

7. Ventilation measurement area

8. Waveform area

10. Current alarm and status area

11. Alarm functions

12. Timer

13. Mode indicator

20

FLOW-i 4.2, User's Manual

Page 21

| System overview |

3 |

The touch screen and rotary knob allow the

operator to control the primary functions of

the anesthesia system, where the patient's

condition is monitored through measured

values and waveform displays.

Measured values and waveforms are displayed

on the screen in the following color groups:

Color for measured values and waveforms

YellowPressure

GreenFlow

BlueVolume

2

2

Light grayCO

WhiteO

BlueN2O

GrayMAC

PurpleIsoflurane

BlueDesflurane

YellowSevoflurane

Messages are displayed in the Alarm message

area or System message area. The following

color scheme is adopted:

Color for alarms and system messages

High priority alarms

Medium priority alarms

Low priority alarms

Technical alarms, i.e.

alarms with the prefix

TEXXX, where XXX is an

integer.

System messages

Black text on red

background

Black text on yellow

background

Black text on blue

background

Black text on red,

yellow or blue

background, dependent

on priority

(high/medium/low)

White text on black

background

A detailed description of alarms and patient

safety is found in Chapter 10.

The colors for O2 and N2O in the above table

may vary due to country-specific standards.

FLOW-i 4.2, User's Manual

21

Page 22

| System overview |

| 3

3.2.2 Navigating the screen

There are several ways of navigating the

screen and setting values.

Using the touch screen

1. Press the required touch pad. The touch

pad becomes active, which is indicated

by a blue highlight.

2. Turn the rotary knob to the required value.

3. Press the touch pad to confirm setting.

An activated touch pad is only active for 20

seconds. The system will prompt the user to

enter a value when 10 seconds have passed.

If no value is entered and confirmed within the

following 10 seconds, the touch pad setting

returns to its previous setting and is

deactivated.

Using the rotary knob

1. Turn the Rotary knob to move between

the touch pads on the screen. The

selected touch pad is indicated by a blue

frame.

2. On required touch pad, press the rotary

knob to activate the touch pad. This will

highlight the touch pad in blue.

3. Turn the Rotary knob to the required

value.

4. Press the Rotary knob to confirm setting.

22

FLOW-i 4.2, User's Manual

Page 23

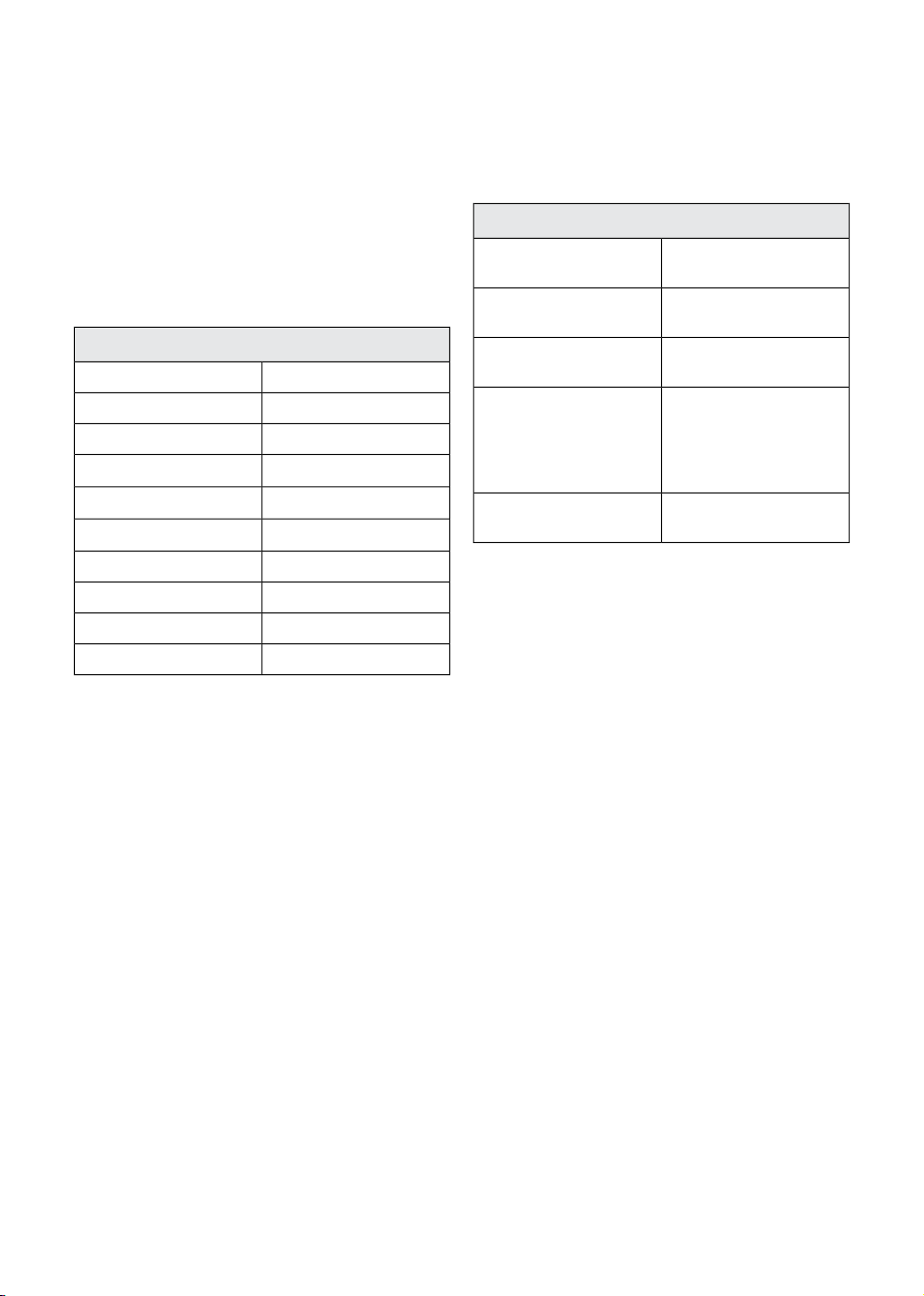

Active screen

| System overview |

3 |

5

6

4

8

3

2

Pressing any of the areas labelled with a

number in the illustration, displays a window

according to the table below.

7. Mode indicator area

9. Tab area (displayed window depends on

selected tab)

7

9

1

Dialog/window producedScreen area

Multiple windows, see Chapter 51. Gas settings/ Ventilation settings

Patient category, see Chapter 5, page 75.2. MAC value

Alarm profile window, see Chapter 10, page 187.3. Gas measurement area

Alarm profile window, see Chapter 10, page 187.4. Ventilation measurement area

Patient category, see Chapter 5, page 75.5. Patient category symbol

Alarm profile window, see Chapter 10, page 187.6. Alarm functions

Ventilation mode selection, see Chapter 5, page

87.

Waveforms and scales, see Chapter 9, page 163.8. Waveform area

- Waveforms and scales, see Chapter 9, page 163.

- Screen layout, see Chapter 9, page 163.

FLOW-i 4.2, User's Manual

23

Page 24

| System overview |

| 3

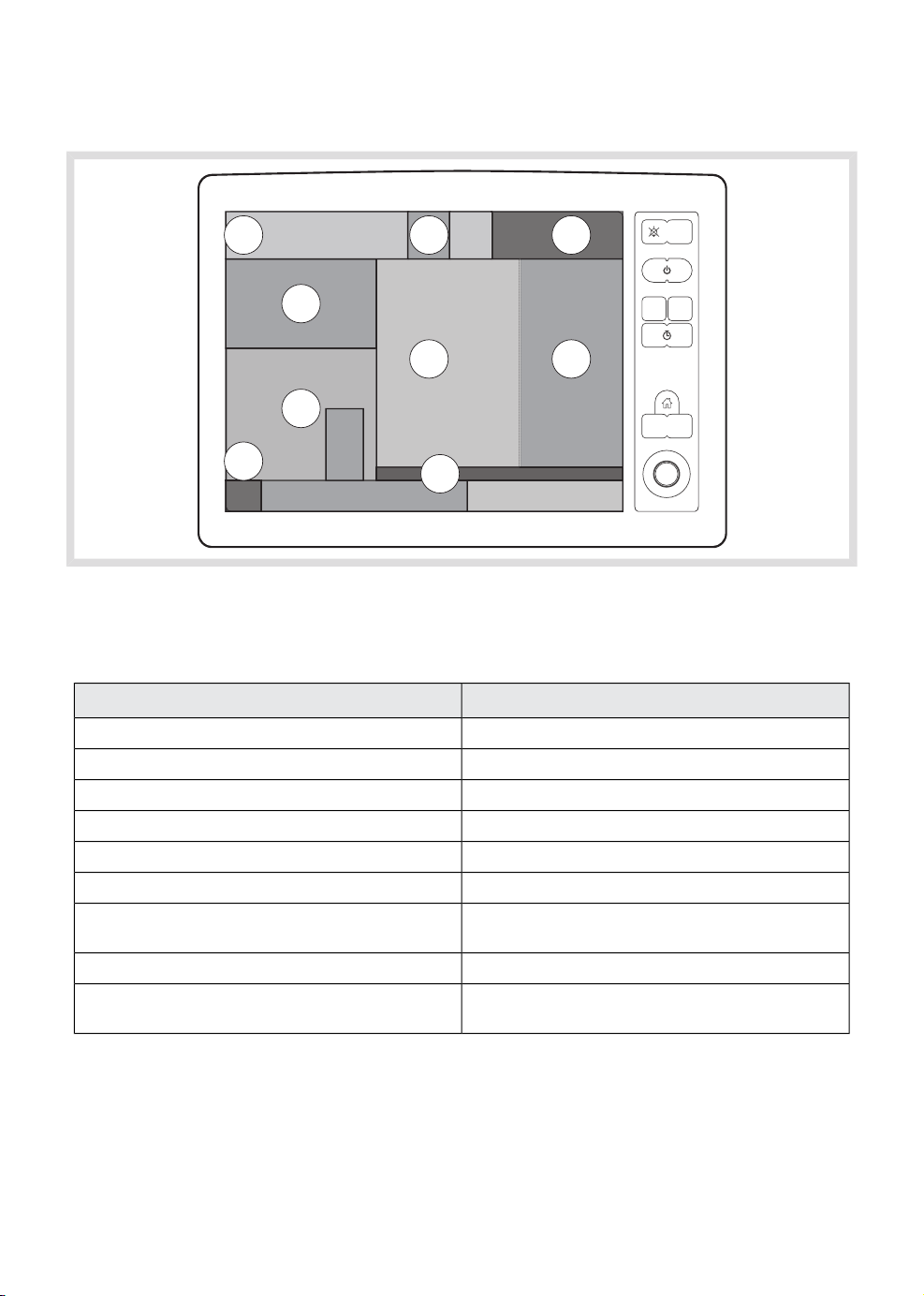

3.2.3 Touch pad settings

A range bar is located at the bottom of all

ventilation and gas touch pads, where a

numeric value can be specified by the user. If

the entered value deviates too far from the

norm given the current ventilation mode and

other parameter settings, the bar will change

color according to the table below.

DescriptionTouch pad setting

A black range bar

indicates normal

20

0 120

cmH20

50

0 120

cmH20

75

0 120

cmH20

parameter setting.

A yellow range bar

indicates that the

parameter setting is

high (or low, depending

on the parameter).

A red range bar

indicates that the

parameter setting is

very high (or very low,

depending on the

parameter).

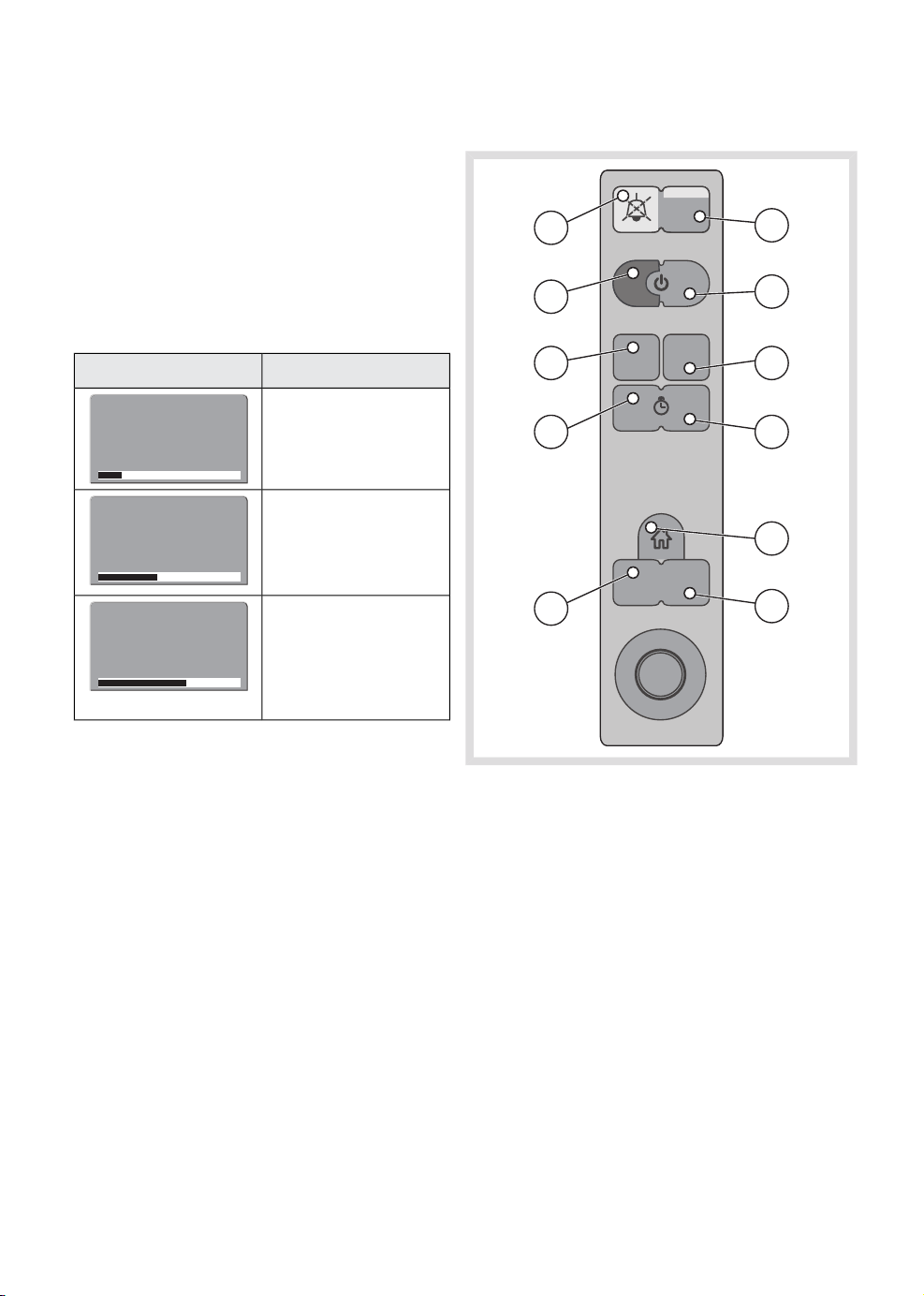

3.2.4 Membrane buttons

1

3

5

7

10

2

4

6

8

9

11

The change in color of the range bar is

accompanied by a system message that

remains displayed on the screen until the

trigger condition is relieved.

24

1. Audio pause

2. Alarm profile

3. Start case

4. End case

5. Save screen

6. Trends

7. Start/Stop timer

8. Reset timer

9. Home

10. Screen layout

11. Menu

See Chapter 9 for more information.

FLOW-i 4.2, User's Manual

Page 25

| System overview |

3 |

3.3 Patient monitor (option)

The system can be connected to a selection

of different patient monitors. For full details,

contact your local MAQUET representative.

The patient monitor must comply with

IEC 60601-1 ed. 3.

During mains power failure, the backup battery

in the anesthesia system will not power the

patient monitor.

3.3.1 Panel interchangeability

If desired, the placement of the control panel

and the patient monitor can be switched so

that the patient monitor is placed on the

display arm. This procedure shall only be

performed by a service technician trained and

authorized by MAQUET. Contact your local

MAQUET supplier for more information.

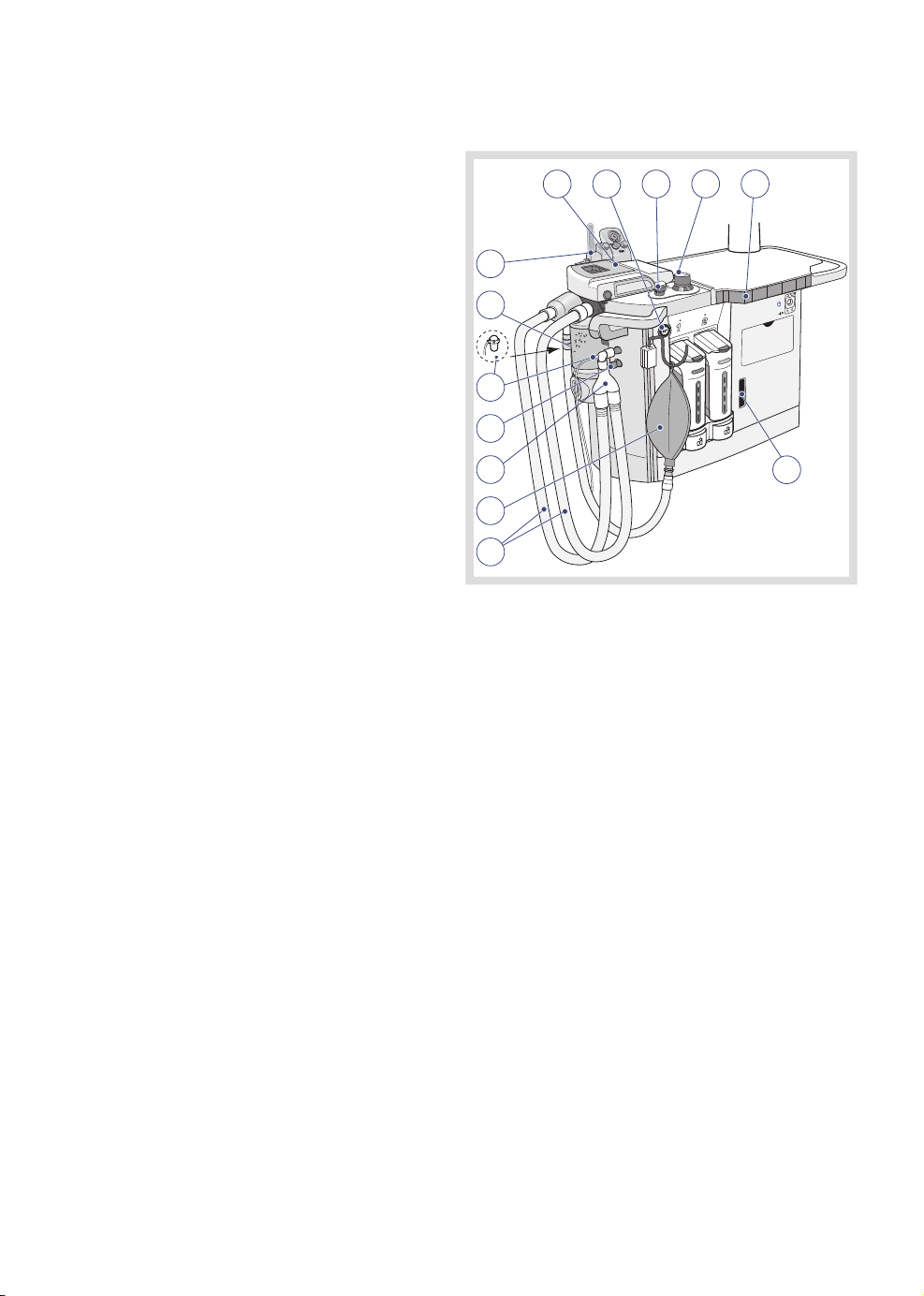

3.4 Breathing system

4

1

2

13

12

11

10

9

8

7

The breathing system comprises the following:

1. Patient cassette

2. O2 flush

3. MAN/AUTO ventilation switch

4. APL valve

5. Volume reflector

6. AGS (Anesthetic Gas Scavenging) flow

indicator

7. Patient tubing

8. Manual breathing bag with tubing

9. Y-piece

10. AFGO - Additional Fresh Gas Outlet

(option)

11. Water trap and sampling line

12. CO2absorber

13. Auxiliary O2 and suction module (option)

53

6

FLOW-i 4.2, User's Manual

MAQUET recommends that a bacterial/viral

filter is always connected to the expiratory

connection on the patient cassette. This will

minimize the risk of cross-contamination.

25

Page 26

| System overview |

| 3

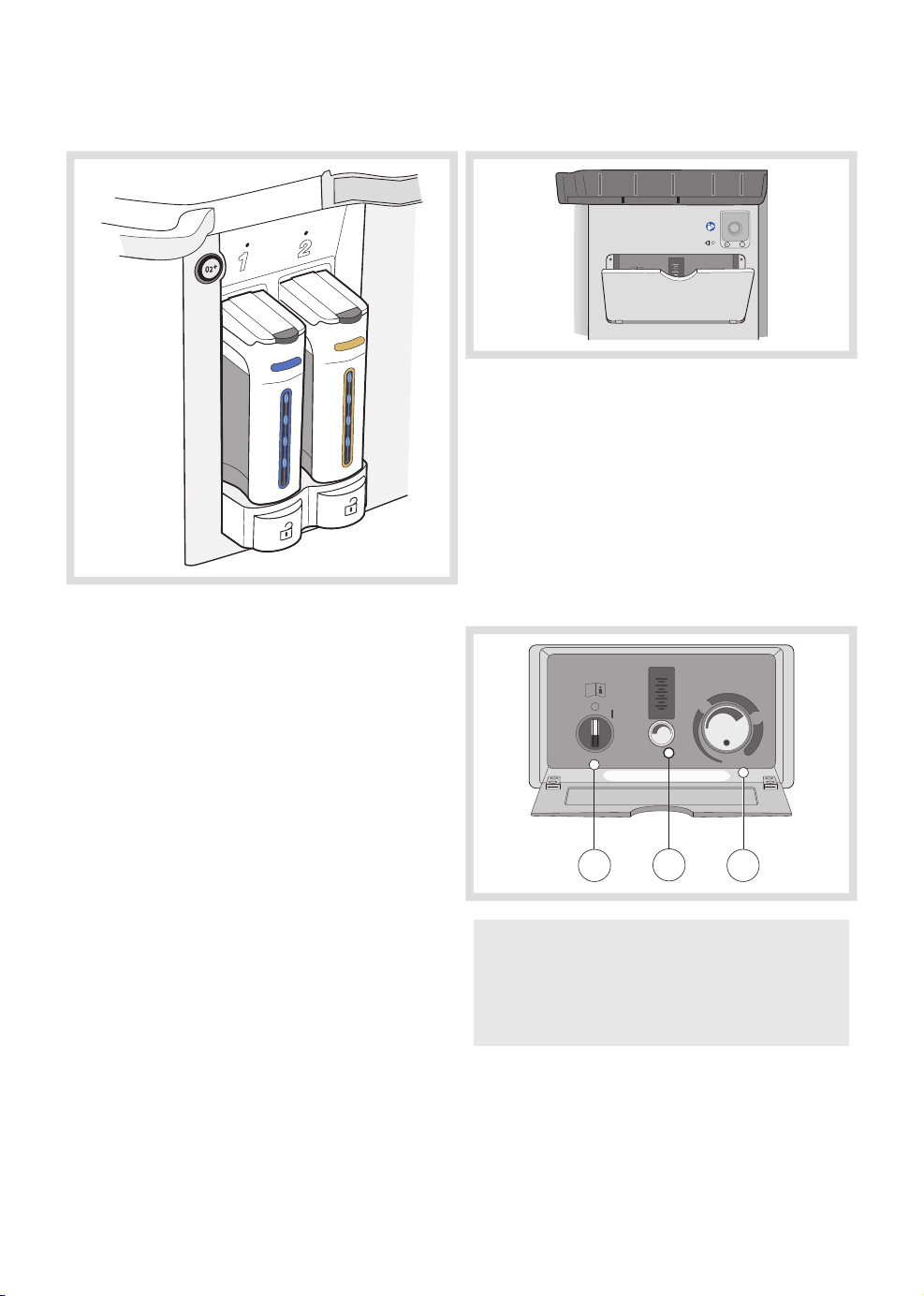

3.5 Vaporizer unit

The vaporizer unit holds one to two vaporizers,

where vaporizers can be selected for the

following agents:

• Isoflurane

• Sevoflurane

• Desflurane

3.6 Emergency ventilation system

O

2

10

8

mbar / cmH2O

6

4

2

30

I/min

Emergency ventilation

O

I/min

2

In case of a total power (i.e. mains power and

battery) or system failure, this system will allow

the patient to be manually ventilated. The

emergency ventilation system comprises:

1. Activation switch

2. O2 gas supply and flowmeter, graded up

to 10 l/min.

3. Mechanical APL

O

2

10

8

6

4

2

I/min

I/min

O

2

Not for use with AFGO

APL

80

SP

mbar / cmH2O

APL

60

26

1 3

2

WARNING! If the emergency ventilation

system is activated while the anesthesia

system is in operation, the anesthesia

system will be shutdown.

FLOW-i 4.2, User's Manual

Page 27

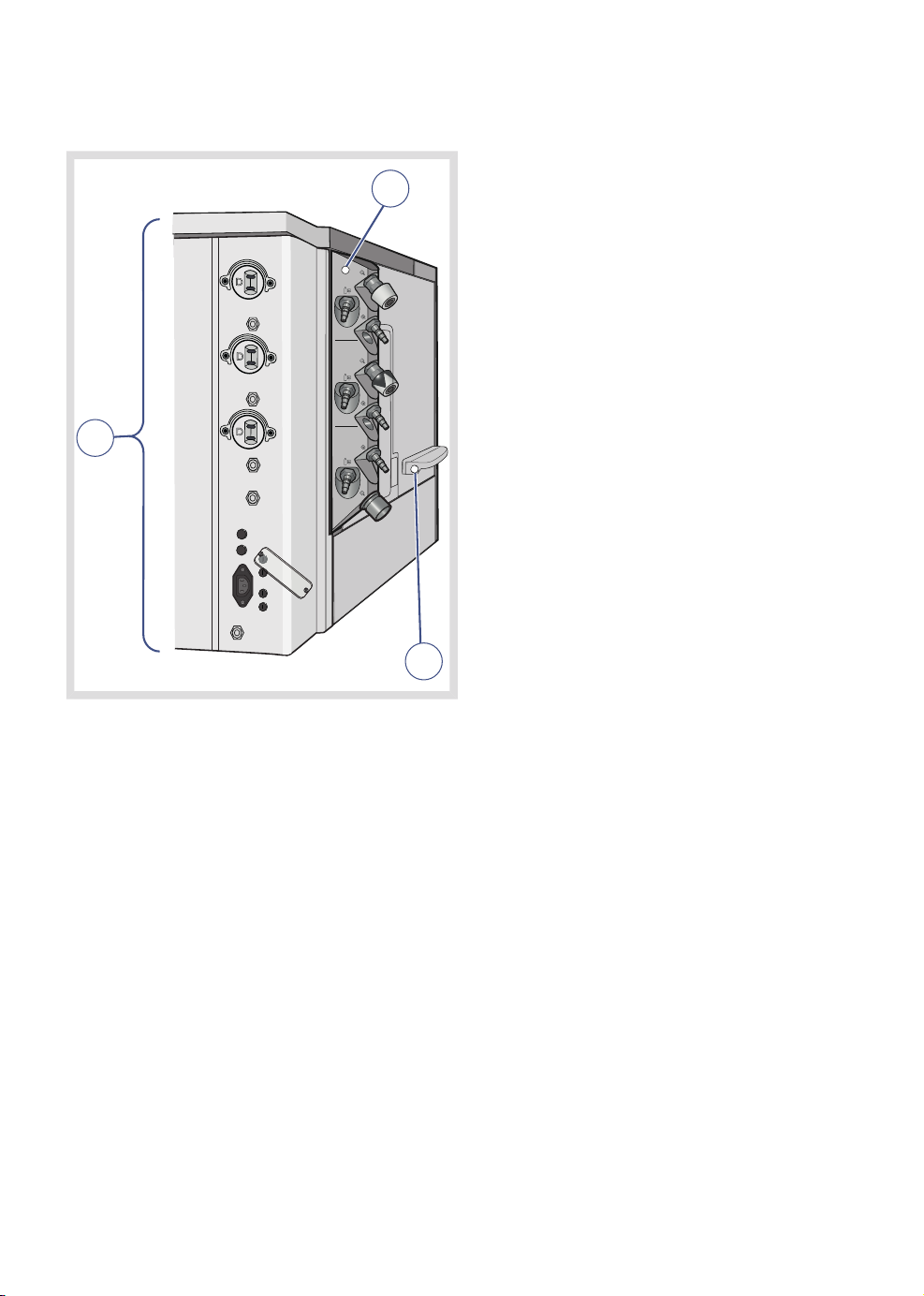

3.7 External connections

| System overview |

3 |

2

O

2

Air

1

N2O

3

The following external connections exist on

the system:

1. Power supply and fuses

2. Gas connections

3. Input/Output ports

FLOW-i 4.2, User's Manual

27

Page 28

| System overview |

| 3

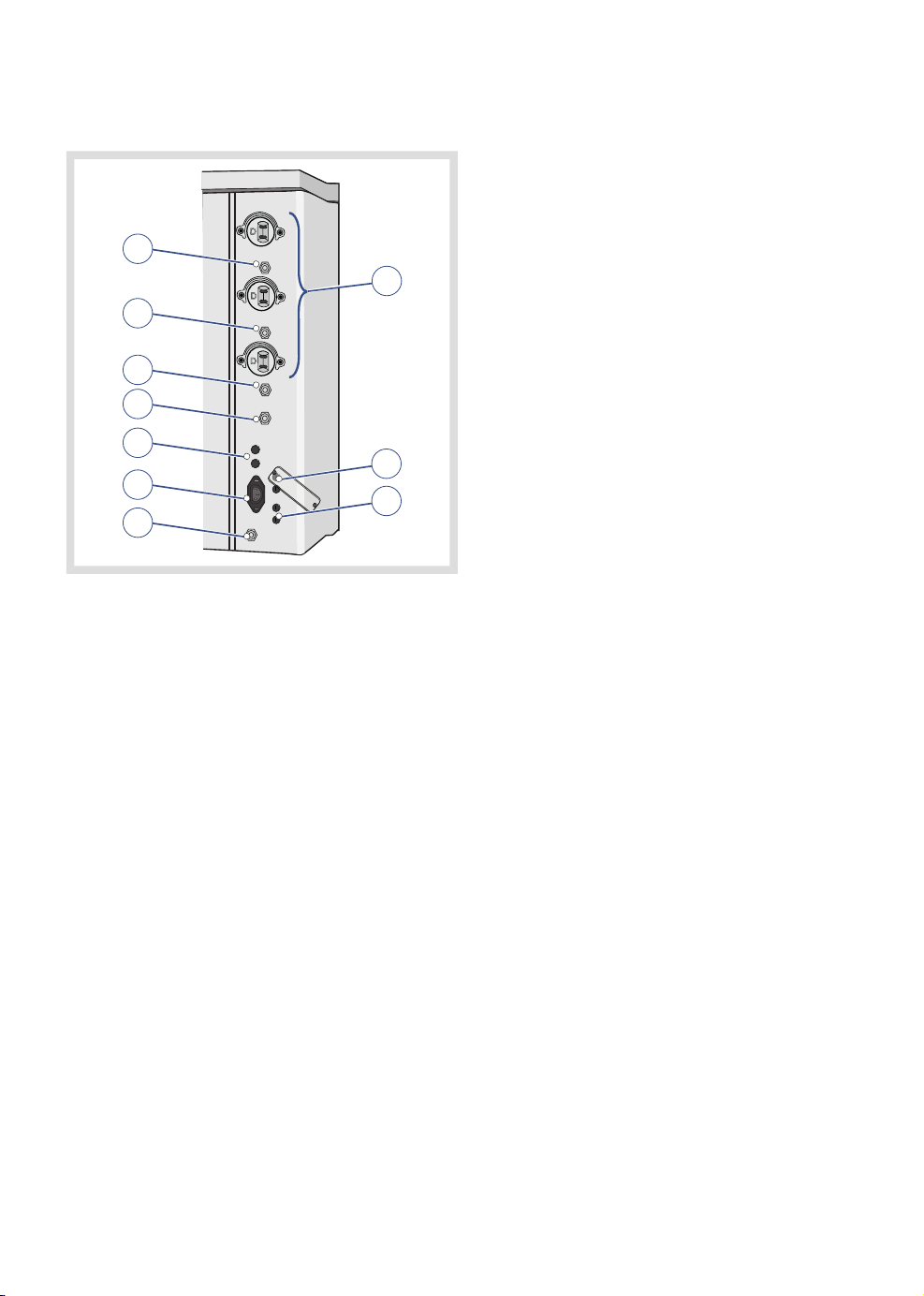

3.7.1 Power supply and fuses

1

2

3

4

5

6

7

9

8

10

1. Auxiliary power outlets fuse 2A (option)

2. Auxiliary power outlets (option)

3. Auxiliary power outlets fuse 1A (option)

4. Auxiliary power outlets fuse 1A (option)

5. Patient monitor fuse (option)

6. Isolation transformer fuse (option)

7. Mains power inlet fuses

8. Lift fuses (C30 model only)

9. Mains power inlet

10. Equipotential terminal (earth)

The patient monitor outlet and the auxiliary

power outlets do not have a battery backup.

Auxiliary power supply outlet connections vary

depending on country specific standards.

In addition to the individual fuses, the

maximum current delivered through the

system is regulated by a shared fuse.

In case of mains power failure, a battery

backup will power the system for a limited

time.

28

FLOW-i 4.2, User's Manual

Page 29

| System overview |

3 |

WARNING!

Restrictions apply to the use of auxiliary

power outlets:

• Outlets must not be used to power life

support equipment unless the life support

equipment itself is equipped with battery

backup.

• A multiple socket extension cord must

not be connected to any of the outlets.

CAUTION: The auxiliary power outlets shall

only be used for supplying power to

equipment intended to form part of the

medical electric system.

For more details on the power supply and

status, see Chapter 10, page 203.

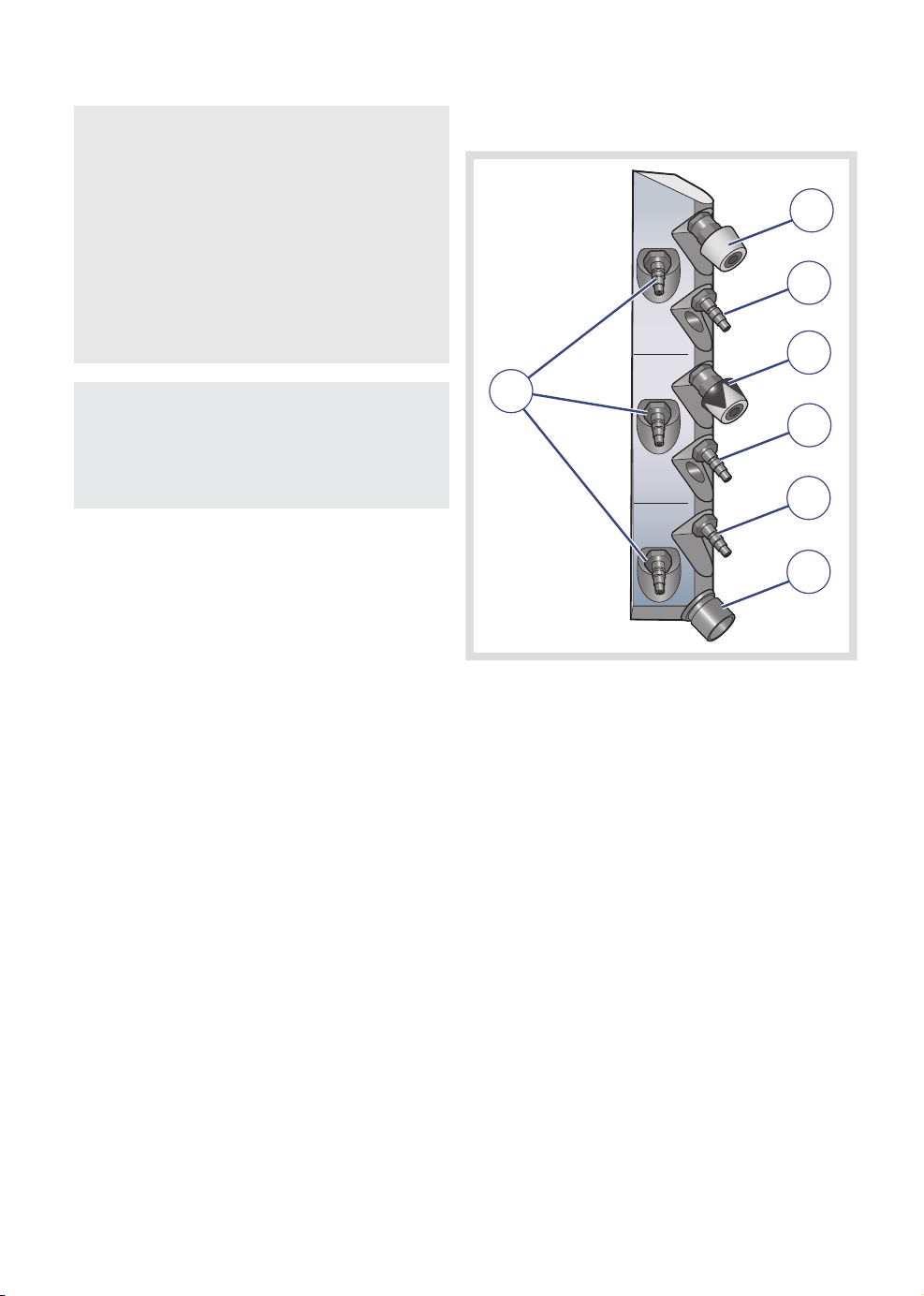

3.7.2 Gas connections

1

2

3

7

4

5

6

FLOW-i 4.2, User's Manual

1. O2 outlet (option)

2. O2 inlet

3. Air outlet (option)

4. Air inlet

5. N2O inlet

6. AGS outlet (country-specific connections)

7. Gas cylinder inlets for O2, Air and N2O

(option)

If equipment with high gas consumption are

connected to the gas outlets, the central gas

supply pressure should be above 3 bar (300

kPa, 44 PSI). Make sure that the central gas

supply is sufficient for the extra equipment.

29

Page 30

| System overview |

| 3

The intended use for the Auxiliary O2 outlet is

to provide oxygen for patient therapy.

The intended use for the Auxiliary AIR outlet

is to provide drive gas for small ejector driven

suction devices.

Maximum allowed air flow from each of the

O

and Air outlets is 60 l/min.

2

The central N2O gas supply (wall supply) is

connected to the system via a pressure

regulator attached to the N2O gas inlet.

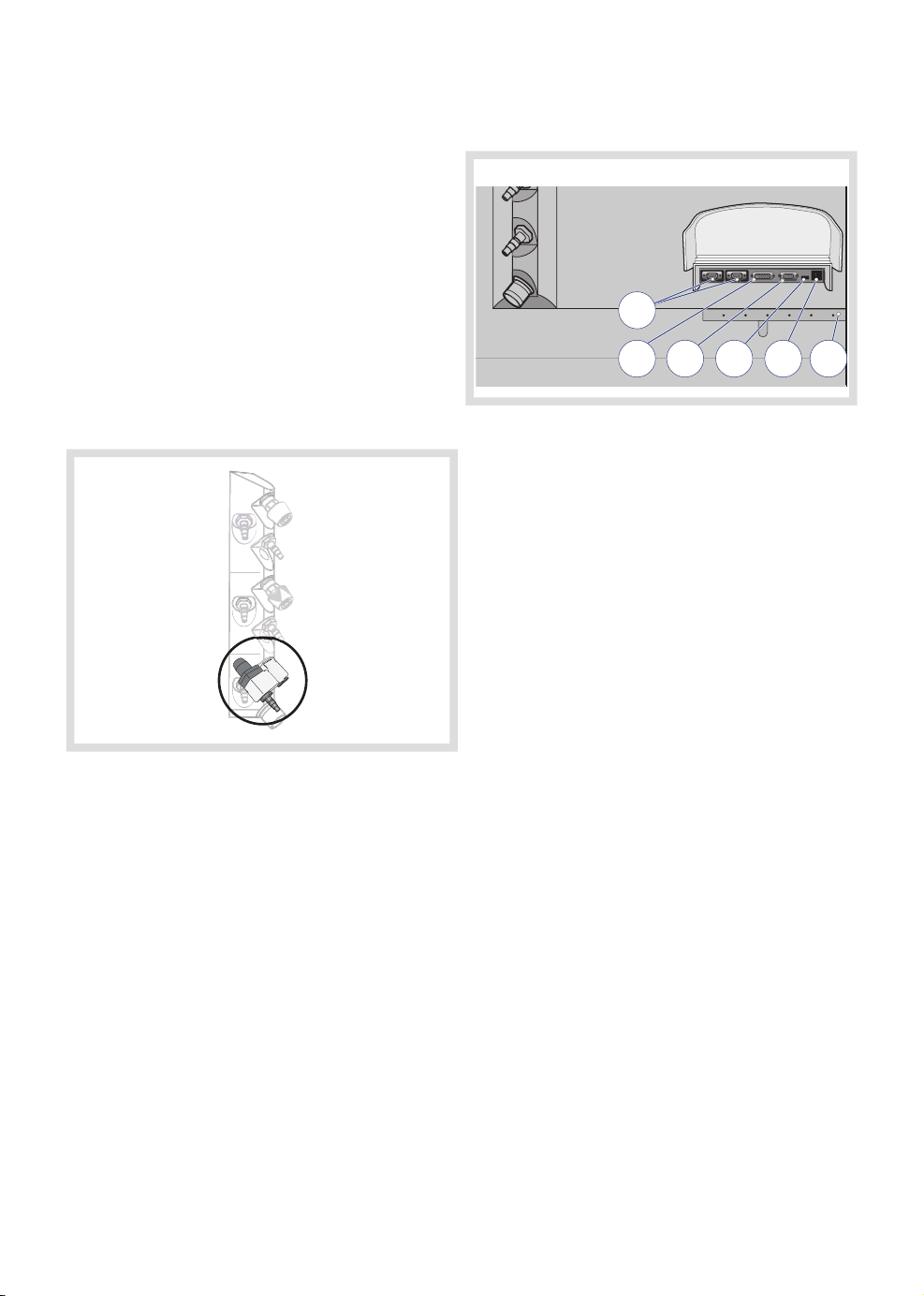

3.7.3 Input/Output ports

1

2 3 4

1. RS232 serial data communication ports

2. Control panel connection

3. VGA connector

4. USB port

5. Network connection

6. Cable restrainer

The intended use of the USB port is only for

USB memory flash drives. Restricted items

include, but are not limited to, external hard

drives, USB hubs and any equipment using

the USB port primarily as a power source.

6

5

Clinical situations that require high gas

consumption might affect the supply gas

pressure.

If the gas supply is low, i.e. close to 2.5 bar

(250 kPa, 36 PSI), the system's ability to

deliver gas according to all possible settings

might be compromised by additional gas

hoses and connections.

30

FLOW-i 4.2, User's Manual

Page 31

The network connection (LAN) port is for

service use, and should only be used by

personnel trained and authorized by MAQUET.

External cables connected to the I/O ports

must be secured using cable restrainers where

available.

CAUTION: The operator must not touch

any of the input/output ports, e.g. RS232,

VGA connector and USB port, and the

patient simultaneously.

| System overview |

3 |

FLOW-i 4.2, User's Manual

31

Page 32

Y

SN

| System overview |

| 3

3.8 Explanation of symbols

3.8.1 Labels

The following symbols are shown on the

system:

DescriptionSymbol

CE label. The device complies

with the requirements of the

0123

C US

European Council Directive

93/42/EEC (i.e. the Medical

Device Directive).

CSA label—Indicates compliance

with Canadian and US standards

Manufacturer

Manufacturing date

2012

UDI Label - Unique Device

Identification. See technical

specifications, page 290.

Class 1 equipment, Type B. The

device classification according

to IEC 60601-1.

Federal law restricts this device

Rx

to sale by or on the order of a

physician.

ONL

IP classification: IPX1, drip proof

IPX1

SN

LOT

DescriptionSymbol

Worn-out batteries must be

recycled or disposed of properly

in accordance with appropriate

industrial and environmental

standards.

White drawing on a blue

background. Consulting

accompanying documentation is

a mandatory action.

Indicates instructions that must

be followed in order to ensure

the proper operation of the

equipment.

Use by date

Black cross over an orange

background. Broken CO

absorber canisters may cause

skin irritation.

Use no oil. Applicable to parts

marked with this symbol.

Serial number

Batch code

Article number

Do not use if packaging is

damaged

2

32

Pb

Black border, black exclamation

mark over a yellow background.

Indicates critical information

about a potentially serious

outcome to the patient or the

user.

Special waste to be disposed of

in accordance with appropriate

industrial and environmental

standards.

Caution must be taken when

moving the system up or down

a slope. Refer to Transport

conditions, page 38.

FLOW-i 4.2, User's Manual

Page 33

| System overview |

3 |

<

2

365 kg

DescriptionSymbol

Medical device maximum weight

(C20 with three drawers). C30

and C40 are lighter, see

technical specifications, page

266.

Red circle with a single red line

over a black drawing. Pushing

prohibited

Red circle with a single red line

over a black drawing. Stepping

prohibited

Red circle with a single red line

over a black drawing. Sitting

prohibited

Lift button, 10% lift dutycycle,

for more information see Chapter

18

>

7, page 146.

Manual (MAN) ventilation

Autoclavable

DescriptionSymbol

CO2 absorber connected and

locked in position

CO2 absorber bypassed

CO2 absorber unlocked,

vaporizer unlocked,

patient cassette unlocked,

wheel brake unlocked

Wheel brake locked

Labelled part may be disinfected

using a steam autoclave

Use centre of floating ball as

reference when reading from the

Auxiliary O

flow scale

2

Inspiratory connection to the

patient cassette

FLOW-i 4.2, User's Manual

Automatic (AUTO) ventilation

Manual breathing bag

connection

Y-piece connection for System

checkout

Equipotentiality terminal.

Mains power On Off button

Insp.

Expiratory connection to the

patient cassette

Exp.

O2 flow meter/suction equipment

O2 flush

02 +

Anesthesia Gas Scavenging

AGS

Home touch pad symbol, see

Chapter 9, page 162

33

Page 34

| System overview |

| 3

Emergency

ventilation

Not for use with AFGO

N O

2

2 . 5 - 6.5 k Pa x 10 0

( 3 6 - 94 p s i )

DescriptionSymbol

Timer touch pad symbol, see

Chapter 9, page 162

Emergency ventilation

Not for use with AFGO.

Emergency O

flow is always

2

delivered through the patient

cassette.

N2O inlet pressure range:

250-650 kPa/2.5-6.5 bar/36-94

PSI

AFGO Max 120 mbar/cmH2O

Reading lamp

Cylinder gas inlet

DescriptionSymbol

Data communication

input/output ports

Fuse

Control panel connection

VGA connection

USB connection

RS232

34

Backup gas system pressure

increase/decrease

RS232 serial port

Gas supply inlet

Gas supply outlet

Network connection

FLOW-i 4.2, User's Manual

Page 35

2

| System overview |

3 |

3.8.2 Screen-displayed symbols

The following symbols are shown on the

screen:

DescriptionSymbol

Standby mode

Active alarm

Multiple active alarms

Audio pause, pre-mute alarm,

mute active alarm or remove

resolved alarms.

Audio off

Alarm off

Power indicator - indicates AC

power connected

Infant

+

60

58

2:00

88 min

DescriptionSymbol

Overlay loops

Numerical trends selected

Graphical trends selected

Activates a cursor in the trends

display window, and allows for

use of the rotary knob to scroll

through values.

Checkbox - can be selected to

mark an option or to choose a

feature for display on the screen

Gas analyzer has no information

to display

Audio pause—silence or confirm

an alarm

Power indicator - indicates

battery operation, along with

estimated time remaining

R

FLOW-i 4.2, User's Manual

Adult

Ventilation mode indicator

Manual ventilation selected

Automatic ventilation selected

Reference loop

Timer activated

02:35:10

Date and time

08-19 16 04

35

Page 36

| System overview |

| 3

3.9 Ergonomical positioning

• The C20 and C30 systems are on wheels

and can be rotated 360°.

• The C40 system is mounted onto a ceiling

pendant and can be moved and rotated as

allowed by the pendant solution.

• The control panel can be tilted up and down

15° and rotated 220° (without moving the

display arm).

• The display arm can be rotated 170°.

• The height of the C30 working surface can

be set anywhere between approx. 30 in.

and 40 in.

3.9.1 Using the brake

Once a suitable position has been found, the

wheels should be locked into position.

1 2

1. Push the brake down to lock the wheel.

2. Push the brake up to unlock the wheel.

CAUTION: Be careful when moving the

display arm to avoid damaging equipment

placed on the writing table or top shelf.

36

FLOW-i 4.2, User's Manual

Page 37

3.9.2 Working position

The flexibility of the system allows the operator

many alternative working positions:

Examples of working positions

| System overview |

3 |

FLOW-i 4.2, User's Manual

37

Page 38

| System overview |

| 3

3.10 Storage and transportation

3.10.1 Before transport

• If the system is to be moved to another

room or transported a longer distance,

ensure mounted accessories are securely

attached to the system.

• The C40 system is intended for transport

inside the operation room only when

undocked from the ceiling pendant.

Transportation to other locations requires

the use of a suitable cart or trolley

according to hospital routines.

CAUTION: Make sure extra equipment and

accessories, e.g. support arm and

additional table, are folded close to the

system during transport to minimize the risk

of tipping. The display arm should be

positioned as shown in the illustration.

3.10.2 During transport

• Move the system using the handles on the

main unit and not those on the control panel

or patient monitor. This will reduce the risk

of tipping and/or system damage.

• If the optional extra table is installed, make

sure it is folded into a vertical position.

• Be careful when moving the system down

a slope.

38

FLOW-i 4.2, User's Manual

Page 39

3.10.3 Storage

• During storage keep the system connected

to the mains power supply so that the

batteries maintain a full charge.

• If the system is disconnected from a power

source, ensure the batteries are fully

charged before storage to avoid

deterioration of battery performance.

• When the system is disconnected from a

mains power supply, a fully charged battery

can be stored in the FLOW-i system for up

to six weeks at temperatures between +5°C

(+40°F) and +40°C (+105°F). At

temperatures between +50°C (+125°F) and

60°C (+140°F) storage time is one week. If

these limits are exceeded, battery

performance can no longer can be

guaranteed.

• MAQUET recommends that the vaporizers

are emptied before long term storage (>30

days).

• For fire safety purposes, the system

requires functional batteries for system

Startup.

• Ensure the system is not exposed to

temperatures below -25oC (-13oF) or above

+60oC (140oF).

• For information on CO2 absorber storage,

see Chapter 7, page 128.

• Ensure the system is not exposed to a

relative humidity above 95%.

| System overview |

3 |

FLOW-i 4.2, User's Manual

39

Page 40

1

2

1

2

1

2

| System overview |

| 3

3.11 System models

The anesthesia system is available in different

models:

• C20

• C30

• C40

The following table shows the standard

equipment for these different models (main

components):

C40C30C20

• Working surface/writing table

• Reading lamp

• Two drawers, one lockable

• Battery for approx. 90 minutes

support (fully charged)

• Vertical shafts for optional

horizontal rails

• Four wheels with individual

locking brake

40

• Height adjustable

• Working surface/writing table

• Reading lamp

• One lockable drawer

• Battery for approx. 90 minutes

support (fully charged)

• Vertical shafts for optional

horizontal rails

• Four wheels with individual

locking brake

• Ceiling pendant

• Working surface/writing table

• Reading lamp

• One lockable drawer

• Battery for approx. 90 minutes

support (fully charged)

• Vertical shafts for optional

horizontal rails

FLOW-i 4.2, User's Manual

Page 41

| System overview |

3 |

3.12 Optional equipment

Not all listed optional equipment may be

available in your country, contact your local

MAQUET representative for more information.

3.12.1 Vaporizer holder

The vaporizer holder provides easy access to

an additional vaporizer during surgical

procedures.

The vaporizer holder may only be installed or

moved by a service technician trained and

authorized by Maquet.

FLOW-i 4.2, User's Manual

Attaching a vaporizer

A

Slide the vaporizer into the slot until the front

locks into place (A).

To remove the vaporizer, lift up the front and

gently pull outwards.

41

Page 42

| System overview |

| 3

3.12.2 Universal bracket for C20

The universal bracket for C20 is intended for

use with the FLOW-i C20 model only. It

provides additional space for mounting

accessory equipment.

3.12.3 Manual breathing bag support arm

The support arm provides a static and secure

support for the manual breathing bag and

associated tubings.

The support arm shall only be used to secure

the manual breathing bag and associated

tubings.

The universal bracket is permanently attached

to the core unit, and shall only be removed by

a service technician trained and authorized by

MAQUET.

Maximum dimensions of mounted equipment

is approximately 430x340x180 mm (WxHxD).

Always ensure mounted equipment is properly

secured before starting a patient case.

42

Connection

A

The support arm is fastened to the vertical

railing on the core unit by turning the fastening

knob (A).

FLOW-i 4.2, User's Manual

Page 43

| System overview |

3 |

3.12.4 EVAC Restrictor

The EVAC restrictor acts to reduce the

pressure difference between high vacuum

evacuation systems and the FLOW-i AGS

outlet. This ensures proper gas evacuation

without adverse side effects.

The EVAC restrictor may only be installed by

a service technician trained and authorized by

Maquet.

AGS hose assemblies connected to the

system shall comply with ISO 80601-2-13.

If equipped with alternate connector systems,

the connectors shall comply with DISS:

CGA-V5:2008 (WAGD), SS 875 24 30:2004

(UTS).

Restrictor unit

3.12.5 Cable support arm

To organize and manage cables connecting

the patient to the patient monitor, a cable

support arm can be attached to any of the

system's four vertical shafts.

The arm can be bent and angled to provide

the most suitable cable arrangement. Ensure

that the emergency ventilation hatch is not

obscured by the cable support arm.

A

The apropriate evacuation flow is achieved by

turning the adjusting knob (A), so that the

evacuation floater in the AGS flow meter

hovers above the dashed area. This ensures

sufficient evacuation flow.

FLOW-i 4.2, User's Manual

The cable support arm is to be used for

electrical cables only. It shall not be used for

patient tubings or any other equipment.

The maximum load is 1.1 lbs.

43

Page 44

| System overview |

| 3

3.12.6 Top shelf

The top shelf is attached to the display

column. Various types of equipment, e.g.

parameter box and patient monitor, can be

used in combination with the shelf.

20”

CAUTIONS:

• The maximum load of the top shelf is 20

kg. Applies to all system models.

• The size and placement of equipment

mounted on the top shelf must be

constrained to the following dimensions:

- Height: 20 in.

- Width: 14 in.

- Depth: 18 in.

• Ensure that equipment mounted on the

top shelf is properly fastened.

• Be aware of equipment mounted on the

top shelf when moving the display arm.

The top shelf, along with any associated

equipment, shall be assembled by a hospital

technician.

44

FLOW-i 4.2, User's Manual

Page 45

| System overview |

3 |

3.12.7 Vaporizer slot cover

The vaporizer slot cover is intended to protect

the gas and electrical connections inside the

vaporizer slot when no vaporizer is connected.

1 2

Slide the cover at a slight angle into the vacant

vaporizer slot until it locks into place..

3.12.8 Backup gas system

The backup gas rack and backup gas cylinder

holder are described in Chapter 10, page 204.

FLOW-i 4.2, User's Manual

45

Page 46

| System overview |

| 3

46

FLOW-i 4.2, User's Manual

Page 47

4 Startup and system checkout Table of contents

| Startup and system checkout |

48|System startup4.1

49|System checkout4.2

59|Leakage check4.3

60|Vaporizer check4.4

61|Understanding results4.5

62|Standby mode4.6

63|Start case4.7

64|Emergency ventilation4.8

4 |

FLOW-i 4.2, User's Manual

47

Page 48

| Startup and system checkout |

| 4

4.1 System startup

• Start the system by means of the Power

button found directly above the Emergency

ventilation system.

48

FLOW-i 4.2, User's Manual

Page 49

| Startup and system checkout |

4 |

4.2 System checkout

01-01 13 00

1 2

A prompt to start the System checkout

procedure is automatically displayed at system

startup:

1. Bypass the System checkout

2. Start the System checkout

To ensure correct system functionality, optimal

performance and patient safety, the System

checkout procedure must be performed as

follows:

• Once a day, or before connecting the first

patient within a running 24 hour period.

• After replacing the patient cassette.

• After the system has been transported.

If the system needs to be used immediately,

i.e. during an emergency, values and results

from the last successful System checkout

remain in effect.

Press the Start touch pad in the System

checkout window to begin the procedure.

The System checkout can also be initiated via

the Menu membrane button during Standby,

see Chapter 9, page 166.

The procedure includes the following main

areas:

• Preparations

• Checks requiring user interaction

• Automatic checks

FLOW-i 4.2, User's Manual

49

Page 50

| Startup and system checkout |

| 4

4.2.1 Preparations

01-01 13 00

1

2

3

The first part of the System checkout

procedure ensures that the system is correctly

prepared for use.

4

5

6

7

8

9

An in-depth description of the different steps

is presented in the table on page 52.

Check the components listed on the screen

and press the 'Continue' touch pad located

in the bottom right of the screen when

finished.

50

FLOW-i 4.2, User's Manual

Page 51

| Startup and system checkout |

4 |

If an external Patient Gas Analyzer is used (not

the one in FLOW-i), the sampling has to be

switched off in order not to remove gas from

the system. The Leakage check may otherwise

fail.

If the system has backup cylinders installed,

an extra check point appears on the screen.

Make sure these cylinders are open for the

duration of the System checkout.

If only the O

backup gas cylinder is used, the

2

Air and/or N2O backup gas cylinder pressure

check can be disabled in Service and Settings

– Startup configuration, see Chapter 9, page

178.

If any of the connected vaporizers contain

<5% of the total agent volume, the automatic

vaporizer test will not be initiated for that

vaporizer. A prompt window appears. Pressing

'bypass test' will exclude that vaporizer from

the check. Pressing 'redo test' will repeat the

test.

4.2.2 Gas sampling leakage

The 'sampling leakage alarm' responds to

amounts of leakage sufficient to interfere with

the gas sampling precision.

If the alarm is activated, perform any or all of

the following actions before contacting Maquet

service:

• Check the sampling line connections

• Check the patient tubing connections

• Replace the patient cassette

FLOW-i 4.2, User's Manual

51

Page 52

| Startup and system checkout |

| 4

Additional descriptionPreparatory steps

Step 1

Check that the breathing circuit is correctly

mounted and connected to the test plug (A).

Step 2

Check the water trap and sampling line.

Discard/empty any water present in the water trap.

A

Step 3

Check that the absorber is correctly mounted and

unsaturated. Also check that the switch is in the

'locked' position.

52

FLOW-i 4.2, User's Manual

Page 53

Step 4

Check that the vaporizer(s) contains sufficient

agent.

| Startup and system checkout |

4 |

Additional descriptionPreparatory steps

max

max

Step 5

Check that the Anesthesia Gas Scavenging (AGS)

flow indicator is above the dashed area.

CAUTION: Ensure that the AGS is correctly

connected. Running the system with a poor AGS

connection may result in anesthetic agent being

emitted into the operation environment.

Step 6

Check that the central gas supplies are connected.

min

min

FLOW-i 4.2, User's Manual

53

Page 54

| Startup and system checkout |

| 4

Step 7 (only if backup cylinders are installed)

Check that the Backup cylinders are opened. Close

the cylinders after completing System checkout.

The system checkout will not initiate if the system

is not connected to the central gas supply.

WARNING! If the backup gas supply pressure

is higher than the central gas supply pressure,

the backup cylinder gas will be used during the

System checkout. Make a note of the backup

cylinder pressure presented on the Control Panel

screen during the System checkout.

Additional descriptionPreparatory steps

Step 8

Check that the manual resuscitator is readily

available and is working correctly.

Step 9

Check for adequate suction pressure in the suction

unit and that the auxiliary O

flow is functioning

2

properly, refer to Chapter 7, page 129, for

instructions.

54

FLOW-i 4.2, User's Manual

Page 55

4.2.3 Checks requiring user interaction

A

B

| Startup and system checkout |

01-01 13 00

3

2

1

2

1

4 |

The second part of the System checkout

procedure requires the user to perform a few

actions before proceeding to the next step:

A. Manually test the O2 flush:

• Press the 'Start check' touch pad.

• Fully depress the O2 flush button for

approx. 3 seconds. If the test is

successful, 'Passed' appears on the

panel screen. Continue to the next step

(B). Otherwise repeat the test.

FLOW-i 4.2, User's Manual

B. Inspect the function of the inspiratory and

expiratory unidirectional valves (some

systems may be fitted with a patient

cassette lid that needs to be opened to

see the valves):

• If necessary, open the patient cassette

lid.

• Press 'Start check' and ensure that the

unidirectional valves are moving up and

down.

• Confirm by pressing 'Yes' on the panel

screen prompt.

• If necessary, close the patient cassette

lid and press 'Continue' or simply press

'Continue' to move on to the next step.

55

Page 56

| Startup and system checkout |

| 4

4.2.4 Automatic checks

01-01 13 00

1

The third part of the System checkout

procedure contains a number of tests that the

system automatically performs. These are as

follows:

• Internal tests

• Barometer

• Gas supply pressure

• Pressure transducers

• Safety valve

• Vaporizer inlet/outlet valve

• Flow transducer

• AUTO ventilation leakage

• MAN ventilation leakage

• Gas analyzer

• Battery

• Vaporizer 1

• Vaporizer 2

• Technical alarms

Components listed on the screen are

individually tested. 'Passed' (in green text) or

'Failed' (in red text) is displayed after each test

depending on the outcome. 'Running'

indicates the test currently being performed.

If the gas analyzer test fails, the vaporizer tests

will not be performed. A dialog box will appear

to inform the user of this.

The automatic check procedure ends when

all tests are performed. This procedure can at

any time be bypassed by pressing the Bypass

touch pad located in the lower left area of the

panel screen (1).

The current leakage for manual and automatic

ventilation is displayed separately in ml/min.

A maximum leakage of up to 150 ml/min is

allowed for each of the ventilation modes. The

leakage tests are performed using a pressure

of 50 cmH2O and 30 cmH2O for AUTO and

MAN ventilation mode respectively.

Some automatic tests can be repeated after

the automatic test sequence has finished; a

prompt to check the relevant part and redo

check appears on the screen.

56

FLOW-i 4.2, User's Manual

Page 57

| Startup and system checkout |

4 |

If only the O2 backup gas cylinder is used, the

Air and/or N

O backup gas cylinder pressure

2

check can be disabled in Service and Settings

– Startup configuration, see Chapter 9, page

178.

Circuit compliance compensation is calculated

during the leakage tests and presented with

the test results.

If N2O central gas supply pressure is

connected while the N2O function is

deactivated, the system checkout will fail.

WARNING! If the System checkout is

unsuccessful, the system must not be

connected to the patient until the

malfunction is corrected. If the malfunction

cannot be corrected by the operator, the

system must be turned Off, taken out of

operation and serviced by personnel trained

and authorized by MAQUET.

4.2.5 Finalization

01-01 13 00

1 2 3

Once all checks are completed, a summary is

displayed on the screen. Press the Standby

touch pad located at the bottom right of the

screen to enter Standby mode.

Checks can be repeated by pressing any of

the touch pad buttons located in the bottom

left area of the panel screen:

FLOW-i 4.2, User's Manual

1. Redo System checkout

2. Redo leakage check

3. Redo vaporizer check

57

Page 58

| Startup and system checkout |

| 4

These checks can also be initiated in Standby

mode via the Menu membrane button.

The results of each test in the System

checkout procedure can also be viewed by

pressing the 'Results' touch pad in the

Standby mode main screen, or by accessing

the System checkout sub-menu via the Menu

membrane button.

CAUTION: Close the backup cylinders after

completing the System checkout to avoid

unintentional use or leakage of the backup

gas.

4.2.6 Bypassing System checkout

In emergencies, the System checkout can be

bypassed at any stage of the procedure. This,

however, is not recommended.

With an emergency startup situation, Manual

ventilation and fresh gas dosage are ready for

use within 15 seconds. Monitored parameters

have full accuracy after a maximum of 15

minutes. However, pressure, flow and volume

displays will be 90-95% accurate after approx.

two minutes.

If the system is still warm, full accuracy is

obtained much more quickly.

If the System checkout is bypassed, the

default system value (without patient tubing)

for circuit compliance compensation will be

used.

58

FLOW-i 4.2, User's Manual

Page 59

| Startup and system checkout |

4 |

4.3 Leakage check

Performs a Leakage check of the manual and

automatic breathing circuits. It shall be

performed after each change of tubings,

breathing bags or filters.

01-01 13 00

1 3

2 4

Leakage check preparatory phase contains

four steps, equivalent to steps 1, 2, 3 and 6

performed during the Full system check, see

section 4.2.1.

The automatic check sequence includes

automatic and manual breathing circuit

leakage checks.

01-01 13 00

1 2 3

A summary of the results is displayed after the

automatic check. Press the Standby touch

pad to enter Standby mode or press any of

the touch pads marked 1-3 to repeat any of

the checks.

The circuit compliance compensation is

re-calculated during the Leakage check and

the log is updated with the new measured

values for leakage.

FLOW-i 4.2, User's Manual

59

Page 60

| Startup and system checkout |

| 4

4.4 Vaporizer check

Performs a leakage check of the manual and

automatic breathing circuits and a check of

vaporizer functionality. It shall be performed

after a vaporizer has been connected to the

system.

The first part is identical to the Leakage check

and is made to ensure that no agents leak out

into the operating room during Run mode.

01-01 13 00

1

4

5

2

6

3

01-01 13 00

1 2 3

The automatic check sequence includes

vaporizer checks in addition to the automatic

and manual breathing circuit leakage checks.

A summary of the Leakage check and the

Vaporizer check results is displayed after the

automatic check. Press the Standby touch

pad to enter Standby mode or press any of

the touch pads marked 1-3 to repeat any of

the checks.

Vaporizer check preparatory phase contains

six steps, equivalent to steps 1 to 6 performed

during the Full system check, see section

4.2.1.

If any of the connected vaporizers contain

<5% of the total agent volume, the automatic

vaporizer test will not be initiated for that

vaporizer. A prompt window appears. Pressing

'bypass test' will exclude that vaporizer from

the check. Pressing 'redo test' will repeat the

test.

60

When the vaporizer is connected and active,

the Agent concentration touch pad displays

the name of the agent, and the agent

concentration is by default set to OFF.

FLOW-i 4.2, User's Manual

Page 61

| Startup and system checkout |

4 |

4.5 Understanding results

01-01 13 00

1

32

In Standby mode, the central area of the

screen displays the result of performed system

checks, along with date, time and outcome.

The symbol (1) can be either green, yellow or

red, depending on the current status of system

checkouts. A detailed view is obtained by

pressing 'View results' (2). A full system

checkout, leakage check or vaporizer check

is initiated by pressing the corresponding

touch pad (3).

Patient cases should not be started if only

Leakage or Vaporizer checks have been

performed since system startup or during the

last 24 hours period.

Press the 'Results' touch pad to display a

window describing the system checkout

results in more detail.

Symbol color codes correspond to the

following:

Passed. A patient case can be

started.

FLOW-i 4.2, User's Manual

More than 24 hours since a

successful full system checkout

was performed. Perform a System

checkout.

Not performed. A patient case

can be started, but this is not

recommended. Perform a System

checkout.

Red symbolYellow symbolGreen symbol

Failed. One or several checks

failed during the System

checkout/Leakage

check/Vaporizer check. Make

appropriate adjustments and redo

check.

61

Page 62

| Startup and system checkout |

| 4

4.6 Standby mode

01-01 13 00

The Standby screen provides a summary of

the System status, the current gas/ventilation

settings and the selected ventilation mode. If

a vaporizer is connected and selected, the

name of the agent is presented on the screen.

Listed below are examples of functions that

can be performed in Standby mode either by

pressing the active touch pads, or by

accessing the menu using the Menu button.

If the System checkout was bypassed, or if

the System checkout failed, a corresponding

system message will be displayed in the

message area.

When a patient case is started using AUTO

ventilation or a switch is made during Run

mode to AUTO ventilation, the preset gas and

ventilation settings are activated.

• The gas and ventilation settings can be

preset before starting a patient case.

• Define patient settings.

• Any or all system checks can be started;

System checkout, Leakage test and

Vaporizer test.

• The Service and settings menu can be

accessed.

• A patient case can be started.

• Alarm limits can be preset before starting

a patient case.

• Test results of the latest performed checks

can be reviewed by pressing the results

touch pad.

62

FLOW-i 4.2, User's Manual

Page 63

| Startup and system checkout |

4 |

4.7 Start case

Once a successful system checkout has been

performed, the system is ready to start a

patient case. Customize the case by defining

patient category, ventilation mode, ventilation

mode settings, and alarm limits. Press the

'start case' membrane button to start the case.

See Chapter 9, page 157, for more information.

Patient category selection is described in

Chapter 5, page 75.

Ventilation mode selection and parameter

settings are described in Chapter 5.

Alarm limit settings are described in Chapter

9, page 187.

WARNING! Ensure that all alarm limits and

ventilator settings are appropriately set

before connecting the system to the patient.

4.7.1 Compliance compensation

Part of the volume of each inspiration will not

reach the patient because of gas compression

in the anesthesia system and expansion of the

tubing. All components in the patient circuit

affect such losses.

When compliance compensation is calculated,

the delivered and measured volume and flow

values are automatically compensated for

these losses. The leakage test must be passed

in order for the system to calculate correct

compliance compensation. If the leakage test

is not passed, the default system value

(without patient tubing) for circuit compliance

compensation will be used.

The compliance compensation calculations

are made based on the current set-up of the

system, and are subject to changes to the

breathing system volume.

FLOW-i 4.2, User's Manual

These calculations become obsolete when,

for example, patient tubings are changed (e.g.

from adult to infant), or if additional equipment

is installed which increases the breathing

system volume.

Update the system by performing a new

leakage check to ensure correct delivery of

gas flow.

63

Page 64

| Startup and system checkout |

| 4

4.8 Emergency ventilation

4.8.1 Manual check of Emergency

ventilation system

To test its operation, perform the following:

1. Activate the Emergency ventilation system

using the activation switch for emergency

ventilation.

2. Set the O2 flow to 10 l/min - the current

flow is indicated on the flowmeter when

the center of the ball is aligned with the

printed scale.

3. Check at various APL settings that the

test lung can be ventilated using the

Manual breathing bag.

O

2

10

8

mbar / cmH2O

6

4

2

I/min

APL

If the emergency ventilation is activated, either

during a patient case or when testing the

system, the emergency ventilation APL valve

must be set to minimum before resuming

normal ventilation (AUTO or MAN) or starting

a new patient case.

CAUTIONS:

• The emergency flow is always delivered

via the patient cassette outlet and thus

the patient tubings must always be

connected to patient cassette outlets

when emergency ventilation is used.

• Staff working with the system should

practise regularly using the emergency

ventilation system.

64

I/min

O

2

Not for use with AFGO

1 3

2

FLOW-i 4.2, User's Manual

Page 65

5 System functionality Table of contents

| System functionality |

66|FLOW-i Anesthesia system5.1

74|Patient settings5.2

79|Fresh gas flow settings5.3

83|Ventilation settings5.4

104|Measured values5.5

107|Waveform area5.6

114|Inspiratory and expiratory hold5.7

117|Miscellaneous5.8

5 |

FLOW-i 4.2, User's Manual

65

Page 66

| System functionality |

| 5

5.1 FLOW-i Anesthesia system

The FLOW-i is a software controlled circle

system for anesthesia. It features several

components distinguishing it from other

anesthesia systems; gas modules regulating

fresh gas flow, the volume reflector and the

injector based vaporizer.

The volume reflector replaces the 'bag in

bottle' used in many traditional systems. It has

a fixed volume of 1.2 liters and no moving

parts. Gas flow is regulated by the reflector

gas module. This facilitates precise control of

gas flow and pressure during automatic

ventilation.

The Vaporizer works with an electronic based

injector technology capable of operating at

low tidal volumes. This allows for fresh gas to

be led directly through the vaporizer chamber

and be mixed with the anesthetic agent.

Changes made in agent concentrations will

therefore be instantaneous. The vaporizer

technology also enables high agent

concentrations at high fresh gas flows, i.e. up

to 20 l/min.

5.1.1 Tidal volume delivery

The tidal volume delivered to the patient

comes from two sources: the fresh gas flow

and exhaled gas in the volume reflector

pushed back towards the patient by the

reflector gas module. Refer to page 72 for a

schematic view.

When the part of the tidal volume delivered

from the volume reflector exceeds one litre,

gas from the reflector gas module may pass

through the volume reflector and add oxygen

to the breathing system. This will trigger the

'Leakage' alarm.

In these situations, the oxygen concentration

will increase and the agent concentration will

decrease. However, ventilation will always be

maintained.

The situation can be corrected by increasing

the fresh gas flow.

Carefully monitor displayed gas measurements

when using low fresh gas flow settings and

high tidal volumes.

66

FLOW-i 4.2, User's Manual

Page 67

5.1.2 Low flow anesthesia

The use of oxygen as the drive gas in the

volume reflector diminishes the risk for hypoxia

should a leakage occur during low, or minimal

flow anesthesia. However, should a leakage

occur (the source of which is either known of

unknown), then the volume reflector always

ensures ventilation (it will never collapse like

a bellows).

A leakage moves the borderline between

exhaled gas and oxygen towards the breathing

circuit, see illustration below. During a leakage

the volume reflector adds oxygen to the

breathing circuit. The leakage is obvious to

the anesthetist as there is a simultaneous slow

increase of oxygen concentration and a slow

decrease of agent concentration at the

y-piece. A leakage alarm will also be activated.

| System functionality |

A

B

5 |

3

2

1

3

The illustration shows the relative positioning

of oxygen to exhaled gas during three different

situations; Inhalation (A), Exhalation (B) and

Leakage (C).

C

3

1. Exhaled gas

2. Oxygen from the reflector module

3. Oxygen/exhaled gas border

FLOW-i 4.2, User's Manual

67

Page 68

| System functionality |

| 5

5.1.3 Safety functions in FLOW-i to avoid potential hypoxia

To prevent the oxygen concentration in the

breathing circuit from becoming too low and

potentially causing hypoxia, the system has

two features; O2Guard and the Safety Flush.

O2Guard

During a patient case, exhaled gas from the

volume reflector and fresh gas from the

system are mixed in the breathing circuit. This

results in an oxygen concentration in the

breathing circuit that is lower than the set

oxygen concentration.

During low flow anesthesia the oxygen

concentration in the total inspiratory flow may

decrease over time. This may result in a

situation whereby the inspiratory oxygen

concentration becomes so low that the patient

experiences hypoxia.

Safety flush

If the inspiratory oxygen concentration falls

even lower, possibly due to gas delivery

malfunction, then the system performs a safety

flush replacing the entire breathing circuit

volume with gas containing a high oxygen

concentration. In addition, the fresh gas flow

and O2 concentration are increased to

predefined values. These actions are

accompanied by a dialog window informing

of the changes.

If the system detects an inspiratory oxygen

concentration below a certain level (see image

below), it will initiate several actions to mitigate

the situation. The gas mix is set to Air/O2, the

fresh gas flow and oxygen concentration are

both adjusted. A dialog window appears

informing of the alterations. These changes

remain in effect until new settings are made.

The trigger level is always lower than the

relevant alarm, 'FiO2: low, thus avoiding

interference.

68

FLOW-i 4.2, User's Manual

Page 69

Inspiratory oxygen concentration and alarm

limits

[O

2

]%

| System functionality |

21%

5 |

The illustration opposite shows how the

settings for the 'FiO2: Low' alarm affect the

activation thresholds for O2Guard and the

Safety Flush. At lower alarm settings, the

respective thresholds for O2Guard and Safety

Flush decrease accordingly to avoid

interference between the functions. At higher

alarm settings, these thresholds remain at

20.5% and 17.5% for O2Guard and the Safety

Flush respectively.

Each shaded area corresponds to a system

action that is dependant on the current

inspiratory oxygen concentration (Y-axis), and

current alarm limit settings (X-axis). A vertical

line can be drawn from the X-axis (21% in the

illustration), representing the current alarm

level setting. In this case, as long as the

inspiratory oxygen level remains above 21%,

no O2-alarm is triggered.

However, if at an alarm setting of 21%, the

inspiratory oxygen falls below 21%, the 'FiO2:

Low'-alarm is triggered. If the inspiratory

oxygen decreases even further, then O2Guard

is activated at 20,5%, and the Safety Flush at

16,5% respectively.

The O2Guard and Safety Flush are only

activated after the trigger requirements have

been met for more than 20 consecutive

seconds.

99

1

30

25

2

21

3

17.5

4

13.5

0

18% 99%

Inspiratory oxygen concentration i listed on the Y-axis, and

inspiratory oxygen alarm level on the X-axis.

1. Normal operation (no alarm)

2. Activation of the low inspiratory oxygen

alarm

3. Activation of O2Guard

4. Activation of the Safety Flush

FLOW-i 4.2, User's Manual

69

Page 70

| System functionality |

| 5

5.1.4 Manual ventilation