Maquet CS300 Service Manual

SERVICE MANUAL

CS300™ is a U.S. trademark of Datascope Corp.

Copyright © Datascope Corp., 2015. Printed in U.S.A. All rights reserved. Contents of this publication may not be

reproduced in any form without permission of Datascope Corp.

Datascope

®

Mini Dopplex

is a U.S. registered trademark of Datascope Corp.

®

is a U.S. registered trademark of Huntleigh Healthcare, Inc.

0070-10-0689 CS300™ Service Manual

Table of Contents

Foreword....................................................................................................................................................... v

Warnings, Precautions and Notes.....................................................................................................................v

Warning........................................................................................................................................................v

Precautions ....................................................................................................................................................v

Notes ............................................................................................................................................................vi

Theory of Operation ......................................................................................................... 1 - 1

System Block Diagrams.................................................................................................................................... 1 - 2

Circuit Descriptions ......................................................................................................................................... 1 - 6

Power Supply for CS300.......................................................................................................................... 1 - 6

Sensor Module........................................................................................................................................ 1 - 6

Repair Information ........................................................................................................... 2 - 1

Introduction.................................................................................................................................................... 2 - 1

Safety Precautions........................................................................................................................................... 2 - 1

Troubleshooting Guidelines .............................................................................................................................. 2 - 1

Test Equipment and Special Tools Required........................................................................................................ 2 - 3

Troubleshooting Code Numbers........................................................................................................................ 2 - 4

Configuration DIP Switch (S2) Set-up on the Main Board ..................................................................................... 2 - 7

System Configuration ...................................................................................................................................... 2 - 8

Service Diagnostics ......................................................................................................................................... 2 - 8

Introduction............................................................................................................................................. 2 - 8

User Interface.......................................................................................................................................... 2 - 9

Main Menu............................................................................................................................................. 2 - 10

Pneumatic System Test ..................................................................................................................... 2 - 11

Display Test .................................................................................................................................... 2 - 14

Keypad / Switch Test ...................................................................................................................... 2 - 15

External RS-232 Port Test .................................................................................................................. 2 - 16

Modem Test .................................................................................................................................... 2 - 17

Recorder Test .................................................................................................................................. 2 - 18

Functional Tests ............................................................................................................................... 2 - 18

Diagnostic Support .......................................................................................................................... 2 - 25

Pneumatic Instructions...................................................................................................................................... 2 - 32

Removal ................................................................................................................................................. 2 - 32

Disassembly............................................................................................................................................ 2 - 33

Re-Assembly............................................................................................................................................ 2 - 34

Helium Regulator Yoke Extension Removal ......................................................................................................... 2 - 35

Pre-Removal Helium Leak Check ................................................................................................................ 2 - 35

Rear Panel Cover Removal........................................................................................................................ 2 - 35

Yoke Removal ......................................................................................................................................... 2 - 35

Replacement Parts ............................................................................................................ 3 - 1

Introduction.................................................................................................................................................... 3 - 1

Available Replacement Parts and Sub-Assemblies ............................................................................................... 3 - 1

Product Variations and Options................................................................................................................. 3 - 1

Exchange Program .................................................................................................................................. 3 - 1

Replacement Parts Pricing Information ........................................................................................................ 3 - 2

Ordering Information ............................................................................................................................... 3 - 2

Abbreviations.......................................................................................................................................... 3 - 3

Isometric Drawing and Parts Lists ...................................................................................................................... 3 - 10

Chassis .................................................................................................................................................. 3 - 10

Chassis International Parts List ................................................................................................................... 3 - 17

Monitor Module ...................................................................................................................................... 3 - 20

Monitor Module International Parts List ....................................................................................................... 3 - 22

Compressor Assembly .............................................................................................................................. 3 - 24

CS300™ Service Manual 0070-10-0689 i

Table of Contents

Cart Assembly......................................................................................................................................... 3 - 26

Cart Assembly International Parts List ......................................................................................................... 3 - 27

Calibration Procedure ....................................................................................................... 4 - 1

Introduction.................................................................................................................................................... 4 - 1

Warnings And General Guidelines ................................................................................................................... 4 - 2

Test Equipment and Special Tools Required................................................................................................. 4 - 2

Calibration..................................................................................................................................................... 4 - 4

Preliminary Steps..................................................................................................................................... 4 - 4

Initial Set-up for Calibration ...................................................................................................................... 4 - 4

Power-Up Test Routine .............................................................................................................................. 4 - 4

Service Diagnostics.................................................................................................................................. 4 - 5

User Interface ................................................................................................................................. 4 - 5

Power Supply Checks............................................................................................................................... 4 - 6

Record Time............................................................................................................................................ 4 - 7

Reference Voltage Check.......................................................................................................................... 4 - 7

Internal Transducer Check ........................................................................................................................ 4 - 7

Balloon (Shuttle) Transducer Calibration ..................................................................................................... 4 - 8

Atmospheric Transducer Calibration .......................................................................................................... 4 - 9

Drive Transducer Calibration..................................................................................................................... 4 - 9

Safety Disk Leak Test................................................................................................................................ 4 - 10

K6, K6A, K7, K8 Leak Test ....................................................................................................................... 4 - 11

Pressure Regulator and Vacuum Check....................................................................................................... 4 - 12

Autofill Calibration .................................................................................................................................. 4 - 12

Solenoid Driver Board Checks................................................................................................................... 4 - 14

Fiber Optic Test Instructions ...................................................................................................................... 4 - 15

ECG Gain Calibration ............................................................................................................................. 4 - 16

Blood Pressure Gain Calibration................................................................................................................ 4 - 17

Functional Tests .............................................................................................................................................. 4 - 18

Keypad / Switch Test............................................................................................................................... 4 - 18

External RS-232 Port Test .......................................................................................................................... 4 - 18

Modem Test ............................................................................................................................................ 4 - 20

Recorder Test .......................................................................................................................................... 4 - 21

Motor Calibration/Test............................................................................................................................. 4 - 21

Helium Tank Calibration........................................................................................................................... 4 - 22

Pneumatic Performance Tests..................................................................................................................... 4 - 22

Blood Pressure Channel Checks................................................................................................................. 4 - 23

ECG Channel Checks .............................................................................................................................. 4 - 24

Preference and Printer Menu Checks.......................................................................................................... 4 - 25

Pumping Checks...................................................................................................................................... 4 - 25

Portable Operation Check ........................................................................................................................ 4 - 26

Manual Fill Valve..................................................................................................................................... 4 - 26

Timer Check............................................................................................................................................ 4 - 26

Helium Checks ........................................................................................................................................ 4 - 26

Fan Check .............................................................................................................................................. 4 - 27

Leakage Current Test - Safety Checks ................................................................................................................ 4 - 28

Source Current, Chassis Case to Ground Leakage ....................................................................................... 4 - 28

Lead to Ground....................................................................................................................................... 4 - 29

Ground Resistance................................................................................................................................... 4 - 29

Calibration Test Point Locations ................................................................................................................. 4 - 30

Preventive Maintenance.................................................................................................... 5 - 1

Introduction.................................................................................................................................................... 5 - 1

Required Parts ................................................................................................................................................ 5 - 2

ii 0070-10-0689 CS300™ Service Manual

Table of Contents

System Log Book............................................................................................................................................. 5 - 3

Preventive Maintenance Schedules.................................................................................................................... 5 - 4

Visual Inspection Checklists .............................................................................................................................. 5 - 6

Weekly or Before Each Use ...................................................................................................................... 5 - 6

Every 6 Months or 2500 Hours of Use ....................................................................................................... 5 - 6

Access and Replacement Instructions ................................................................................................................. 5 - 8

Pump Maintenance Instructions.................................................................................................................. 5 - 8

Pump Muffler Replacement........................................................................................................................ 5 - 11

Pneumatic Filter Replacement Instructions .................................................................................................... 5 - 11

Shock Mounts and Hoses ......................................................................................................................... 5 - 12

Battery Replacement ................................................................................................................................ 5 - 12

Purge Line Filter Replacement .................................................................................................................... 5 - 14

Power Supply.......................................................................................................................................... 5 - 15

Clean Fiber Optic Assembly ..................................................................................................................... 5 - 15

Fiber Optic Lamp Replacement.................................................................................................................. 5 - 17

CS300™ Service Manual 0070-10-0689 iii

Table of Contents

This page intentionally left blank.

iv 0070-10-0689 CS300™ Service Manual

Foreword Introduction

Foreword

This manual is intended to provide information required to properly service the Datascope

CS300 Intra-Aortic Balloon Pump.

Warnings, Precautions and Notes

Please read and adhere to the following list of warnings, precautions and notes; some of

which are repeated in the appropriate areas throughout this manual.

A WARNING is provided if there is reasonable evidence of an association of a serious

hazard with the misuse of this device or when special attention is required for the safety of

the patient.

A PRECAUTION is provided when any special care is to be exercised by the practitioner to

avoid causing damage to this device or other property. They may also include actions to be

taken to avoid effects on patients or users that may not be potentially life threatening or result

in serious injury, but about which the user should be aware.

A NOTE is provided when extra general information is applicable. Notes appear in the

appropriate areas throughout the manual.

Warning

WARNING: Compressed gasses (helium cylinders) are considered

Dangerous Goods/Hazardous Materials per I.A.T.A. and

D.O.T. Regulations.

It is a violation of federal and international law to offer any

package or over pack of dangerous goods for

transportation without the package being appropriately

identified, packed, marked, classified, labeled and

documented according to D.O.T. and I.A.T.A. regulations.

Please refer to the applicable I.A.T.A. Dangerous Goods

Regulations and / or the Code of Federal Regulations 49

(Transportation, Parts 171-180) for further information.

WARNING: Preventive Maintenance should not be performed when the

IABP is attached to a patient.

Precautions

CAUTION: Do not short component leads together.

CAUTION: The troubleshooting charts are not intended as a rapid

course on how to repair devices of this type. Rather, they

are intended as a guide for qualified technical personnel

only. The instrument covers should only be removed by

technically qualified personnel who have received

supplementary instructions regarding maintenance of

medical electronic equipment or have had equivalent

experience in this area.

CS300™ Service Manual 0070-10-0689 v

Introduction Notes

CAUTION: The accidental shorting of component leads can easily over

CAUTION: To avoid damage, do not use the high powered iron to

stress components, resulting in a second unnecessary failure

(aside from creating a possible safety risk).

repair printed wiring boards as the conductors will lift from

the surface under the extreme heat.

Notes

NOTE: Datascope maintains a policy of continual product

improvement and reserves the right to change materials

and specifications without notice.

vi 0070-10-0689 CS300™ Service Manual

1.0

Theory of Operation

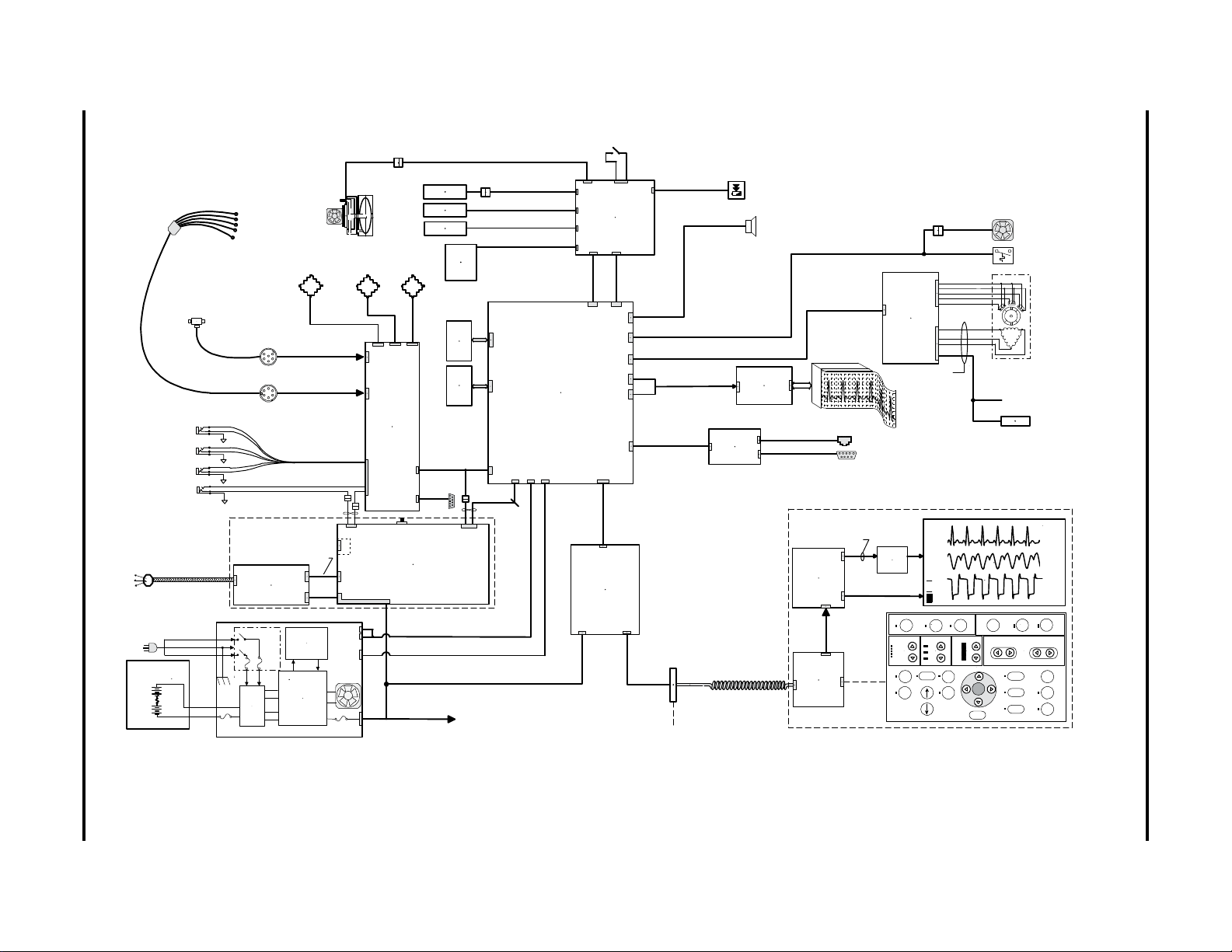

The Theory of Operation is divided into two parts. The first part contains block diagrams for

the entire system, including cabling, and pneumatics. It should be used by service personnel

to become familiar with the internal organization of the instrument. The second part contains

PCB drawings, the related block diagrams, and a brief circuit description.

CS300™ Service Manual 0070-10-0689 1 - 1

System Block Diagrams Theory of Operation

1.1 System Block Diagrams

The Block Diagrams indicate the internal organization of the instrument. They are used to

gain familiarity with the instrument and to locate malfunctioning PC boards as readily as

possible. To avoid clutter, the number of PC board interconnects is minimized. The

interconnects shown represent major or essential signal flow and clock connections.

Block Diagrams Page

System Block Diagram 1-3

Cable Block Diagram 1-4

Pneumatic Block Diagram 1-5

1 - 2 0070-10-0689 CS300™ Service Manual

Safety

Disk

RA

LA

LL

Patient

Balloon

Pres sur e

Transducer

ECG

Cathet er

Extender

Patient Inputs

Recorder

AR-42

Main Board

ECG

Pressure

9

Tel e - co m

Output

RS-23 2

Exter nal

Monitor

Inputs

ECG

Pressure

Trainer

Auto Fill tubing

Drain

tubing

FAN

Peltiercooler

&heatsink

Pelti er & f an

LVDS0,1,2,C(2 ea)

RxMAIN(2)

TxMAIN(2)

BULK-RT N(2)

BUF-RxMAI N

TxMAIN

HD0- 15

ToMotor control Bd.

S

S

Motor A

Motor B

Motor C

HALL A

HALLB

HALL C

HALL+

HALL-

FromPower Supply

DC Brushless Motor

BULK20-32VDC

Shared

RAM

68HC11

Communication

Processor

6809 Micro processor

IABP Sub-system

68020 Microprocessor

Display Sub-system

0670-00-1152 or

0670-00-0788

ECG-EXT-SEL*

ECG-EX T-IN

BP-EXT-SEL*

BP-EXT-IN

SOLND-STATE

BALLOON - E XC +, -

DRIVE-EXC+,-

DRIVE-X OUT +, -

BALLOON- XOUT +, -

0670-00-0668

1mV

5uV/V/1mmHg

1VOLT/mV

1VOLT/100mmHg

FE-TX

FE-RX

FE-CLK

TRIG- PULSE *

SOLND-STATE

BATT-VOLT

BATT-CURR

To Test

Connector

REMOTE-ON*

LED-ANODE,LED-CATH

Status-FAN-FAIL*,BATT-FLT*,BATT-LOW*,BATT-OP*

BATT-GND, BATT-CUR, BATT-VOLT

+12VRecorder, -12V,+5V Vcc, +24V Sol. Driver

Power Swit ch

ON/ OF F

DGND

BD 0-7

+24V,+ -12, +5

CHARGE L ED +, -

XXXX_SOL *

K1*, K2*, K4* Fil l

K6 , K7 ,K 8 D ri ve

K3,K5Purge

FULL*,EMPTY*,K6A

J1

J4 J5

J2J3

J6

JP5

JP19 JP18

JP16

JP22

JP21

JP17

JP1

JP3

JP20

ON/OFF

JP25

JP1

JP2

JP11

JP8

JP7

JP5

JP6

JP3

0670-00-0639

Solenoid Driver

Board

Pneumatics

(solenoids, switches

andpressuret ransducers)

Front End

Board

Displ ay Boa rd

0670-00-0640

MODEM

BOARD

JP2

JP1

JP3

JP30

SystemTimer (hours)

101.3

BULK

BULK-RET

SPKR(+)

DGND

JP1

JP3

0671-00-0004

Motor

Control

Board

JP1

JP2

0670-00-0647

RECORDER

INTERFACE

BOARD

J1

J2

20

MTR-ENABL E*, MOTO R-DRIVE

MOTO R- TACH , D IG -TA CH

+5V,12V-RCD,12VRET-RCD

AR42-TXD,AR42-RTS, AR42-RES*

AR42-RXD,AR42-CTS,A R42-SYNC

0670-00-0736

Video

Board

JP23

PUMP ASSEMBLY

COOLING FAN

CMPRS-FAN-FAIL*

24V

J7

JP2

BULK(2)

Receive r

0670-00-0786

Datase tte

(FLASH)

IAB

DriveManif old

0104-00-0018

FillManifold

0104-00-0023

Dual-Head

Compressor

2

Helium

pressure

regulator

Helium

Ta n k

To S a l i ne B ag

J2

CS*,OE*

J1

0670-00-0787

Datase tte

(FLASH)

DSS

CS*,OE*

J1

Pressure

Vaccuum

0670- 00-0 763

+5V

J2

J2

Keypad

Controller

0670-00-1145

LVDS0,1,2,C(2 ea)

+5V(2),+12V(2)

RTN(4), RATE0,

RATE1

Board-to-board

Connection

J4

Dual Re ser voi r

Press ure

Transducer

PSIG

J8

ECG-EXT-OUT

BP-EXT-OUT

ECG/Press.

Outputs

RL

C

JP9

Battery

Charge

LED

Bloo d

Detec t

Sensor

(p/o

Sol Dr v)

Backlight

Inverter

J4

0671-00-0230

Speaker

JP31

CS100 Keypad

J5

Coiledcable

Te st Connector

FromFront EndBoard

1-ECG-VAR-TEST

2-BP-TEST

3-BALLOON-PRESS-TEST

4-DRIVE-PRESS-TEST

5-PCR-PLS-TEST

6-TRIG-PLS-TEST

7-SOLND-STAT-TEST

8-GND_A

9-GND_D

ECG

AUTO

AUTO

100

76

94

112

80

II

2

20

LCD Display 640X 480

105

0160-00-0071-02 or

0160-00-0113*

ECG

PRESSURE

Pacer V/ AV

Pacer A

Internal

OPEN

MENU

1:1

1:2

1:3

MAX

OFF

IABINFLATION

Earlier Later

HELP

IABDEFLATION

LaterEarlier

AUTO

START

STANDBY

TRIGGERSOURCE IAB FREQUENCY

AUGMENTATION

SEMI

AUTO

MANUAL

ZERO

PRESSURE

ALARM

MUTE

IAB

FILL

REF

LINE

AUG

ALARM

BACK

ECG/AP

SOURCES

PUMP

OPTIONS

USER

PREFERENCES

INFLATION

INTERVAL

FREEZE

DISPLAY

PRINT

STRIP

OPERATION MODE

16

3Ring

4Tip

1,2,5,6 n/ c

RJ11 Connector

Power Supply Assembly

DC Fan

AC

Power E ntr y

Module

AC IN

Fusib le l ink

24VBattery

Input

filters

Control

Board

-Power factor

correction

-Battery charger

-Regulatedsuppl ies

PowerBoard

J100

J101

J102

J103

30A

10A

10A

0014-00-0033-05

FOS Assy

Fiber-Optic

Intfc Board

0997-00-1161

p/o J2

JP15

J3

J3

J1

J2

V-BULK, B ULK-RTN

V-B U LK

BULK-RTN

V-B UL K

BULK-RT N

TxD, RxD

Rst, Sy nc

J1

TxD,RxD

FE-CLK

p/o J2

J5

S1

BedsideBP

ZeroPB-SW

Lo-Lvl

Out

iso-zone

Fiber-Optic Sensor

p/o Sensor IAB

PurgeManifold

0104-00-0026

0161-00-0022

Bat te ry A ss y

0146-00-0047-XX ( non UTS)

0146-00-0051( UTS)

Fiber Optic Sensor

Assembly

MOTOR

COMPRESSOR

ASSEMBLY

0102-00-0001

ATM

Xducer

0331-00-0119

CS300 Block Diagram

0012- 00-1 429 o r

0012- 00-1 747*

* For use with NEC64E dis play.

CS300

™

Service Manual 0070-10-0689 1 - 3

FIGURE 1-1 System Block Diagram

Theory of Operation System Block Diagrams

1 - 4 0070-10-0689 CS300

Safety Disk /

C R M Asse mb l y

Pressure

Transducer

ECG

Pat ient I np uts

Recorder

AR-42

Main Board

ECG

Pressu re

Tele-com

Output

RS-232

Exter nal

Monitor

Inputs

ECG

Pre ssu r e

Trai ne r

FA N

Pel t i er co o l e r

&heatsink

To Motor Cont roll er Bd.

S

S

MotorA

MotorB

MotorC

HALL A

HALL B

HALL C

HALL +

HALL-

DC Br u shl ess M ot or

0670-00-1152

0670-00-0668

Power Swit ch

J1

J5J4

J2

J3

J1

JP5

JP19 JP18

JP16

JP 2 2

JP23

JP17

JP1

JP3

JP20

JP25

JP1 JP 2

JP11JP8

JP7

JP3

JP5

JP6

0670-00-0639

Solenoid D r iver

Board

Front End

Board

Display Board

0670-00-0640

MODEM

BOARD

JP2

JP1

JP3

JP 3 0

0671-00- 0004

Motor

Control

Board

JP1

JP3

0670-00-0647

RECORDER

INTERFACE

BOARD

J1

J2

0670-00-0736

JP 2 1

J7

JP2

Video

Boar d

Receiver

0670-00-0786

D a t a set t e

(FLASH)

IAB

J2

J1

0670-00-0787

Datasette

(FLASH)

DSS

J1

0670-0 0-076 3

J2

J2

Keypad

Controller

PCB

0670-00-1145

Boar d- to- b oar d

Connecti on

J4

J8

ECG/Pres.

Outputs

JP9

Batt ery

Charge

LED

Backlight

Inverter

J4

0671-00-0230

Speaker

JP31

CS100 K e y pad

0331-00-0119

J5

Coi l ed cabl e

ECG

AUTO

AUTO

100

76

94

112

80

II

2

20

LCDDisplay640 X480

105

0160- 00- 00 71- 02 o r

0160- 00- 01 13*

ECG

PRESSURE

PacerV/AV

PacerA

Internal

OPEN

MENU

1:1

1:2

1:3

MAX

OFF

IABINFLATION

Earlier Later

HELP

IABDEFLATION

LaterEarlier

AUTO START

STANDBY

TRIGGER SOURCE IAB FREQUENCY

AUGMENTATION

SEMI

AUTO

MANUAL

ZERO

PRESSURE

ALARM

MUTE

IAB

FILL

REF

LINE

AUG

ALARM

BACK

ECG/AP

SOURCES

PUMP

OPTIONS

USER

PREFERENC ES

INFLATION

INTERVAL

FREEZE

DISPLAY

PRINT

STR I P

OPERATIONMODE

Po w e r S u p p l y A ssem b l y

DCFan

AC

Pow er En t ry

Module

AC IN

Fusiblelink

24V Battery

Input

fil ters

Control

Board

-Power factor

correct ion

-Batterycharger

-Regul ated suppl ies

Pow er Bo ar d

J100

J101

J102

J1 0 3

30A

10A

10A

0014-00-0033-05

FOS Assy

Fiber-Opt ic

InterfaceBoard

p/o J2

JP15

J3

J3

J1

J2

J1

p/o J2

J5

S1

Fiber -Opti c Sensor

p/o Sensor I AB

Battery Assy

0146-00-0047-X X ( non UTS)

0146-00-0051 ( U TS)

0997- 00- 1161

Fiber Optic Sensor

Assembly

0012-00-0977

FillM anifold

0104-0 0-002 3

Purge M anifold

0104-00 -0026

DriveManifold

0104-00-0018

Saf e t y V en t

Sol en o i d K 6A

Sensor s

-Empty

-Full

0012-00-0976

Helium

Tran sduc er

Ball oon

Transducer

Dri ve

Trans duc er

0012-00-0834

0012- 00- 1062

2

/

0012- 00- 1104

6

/

6

/

6

/

8

/

0012- 00- 0767

4

/

0012- 00- 1096-0 1

0012- 00-1 097-01

10/26

/

0012-00-1061

14

/

0012- 00- 1196-01

20

/

20

/

20

/

0012-00-0784-02

0012-00-0761-02

0012-00-0874-02

2

/

0012-00-0893-02

4

/

0012- 00- 0759-0 2

4

/

Compressor

Fan

Thermal

Swi t c h

0012-00-1056

From Power Suppl y

101.3

Sys t em T i mer

(hours)

4

/

2

/

0012- 00- 14 29 or

0012- 00- 17 47*

0012- 00-142 8

0012-00-1059

Chassi s

0012- 00-1 056

0012- 00-1 060

0012- 00-1 875-02

0012-00-0766

0012- 00- 1537

part of

0012- 00- 153 9

0012- 00- 1538

0012- 00- 1765

0012- 00-105 8

0012- 00- 0745

JP2

0012- 00- 0888

0012- 00- 1536

par t of

0012- 00- 1539

par t of

0012-00-1539

* For usewi th NEC64E display.

0012-00-0746

0012-00

-0785

0012-00-1422

0012-00

-0964

(UT S)

0012-00-0886- 01 - 110V

0012-00-0886- 02 - 220V

0012-00-0886- 03 - 220V ( Chinese)

0012- 00- 1682

System Block Diagrams Theory of Operation

™

Service Manual

FIGURE 1-2 Cable Block Diagram

CS300

Helium

Gauge

0

2K

4K

Helium

Cylinder

Volume Cylinder

K5

K1

K2

Fill Solenoid

Patient I.A.B.

Helium

Solenoid

RG1

C

C

21

2

Legend: Solenoids shown in normal position ( non-activated )

Solenoid (open )

Solenoid (closed)

Relief Valve

Transducer

Regulator

C - common

1 -- normally open

2 -- normally closed

3Way

Solenoid

Pump

To Solenoid

Driver PCB

Purge

Solenoids

Empty

S2

Full

Blood Back

Sensor

2 Stage

regulator

FP1

Safety Disk

Brushless

DC Motor

Filter

Pressure

Head

Muffler

Vacuum

Head

K4

Isolation

Solenoid

Muffler

To Front End PCB

Muffler

CV2

4.5 P.S.I.

Relief

Valve

1

Hall Effect

Sensors

PRESSURE

RESERVOIR

X2

Drive

Transducer

X1

Balloon

FAN

Peltier cooler

& heatsink

Manual

Fill Port

FILL MANIFOLD

DRIVE MANIFOLD

To Motor

Control PCB

To Solenoid

Driver PCB

S1

CV1

K8

K7

Pressure

Solenoid

Vacuum

Solenoid

RG2

8 P.S.I.

Back Pressure

Regulator

9 P.S.I.

Relief Valve

K6

Vent

Solenoid

REF.

SIGNAL

TUBE

SIGNAL

LED

Transducer

VACUUM

RESERVOIR

Safety

Vent

Solenoid

K3

PURGEASSEMBLY

X4

Helium

Tank

Transducer

To Front End PCB

K6A

Muffler

™

Service Manual 0070-10-0689 1 - 5

Theory of Operation System Block Diagrams

FIGURE 1-3 Pneumatic Block Diagram

Circuit Descriptions Theory of Operation

1.2 Circuit Descriptions

1.2.1 Power Supply for CS300

P/N INPUTS OUTPUTS

0014-00-0033-05 AC Mains, Battery 18 - 32 volts (main or bulk supply)

24 V (solenoid supply) +/-12 volts, +5 volts,

Battery charger, charge LED drive

1.2.2 Sensor Module

P/N DESCRIPTION

0992-00-0202 The Fiber Optic Sensor Assembly accepts an optical signal that

communicates blood pressure information from a sensor placed in

the intra-aortic balloon.

1 - 6 0070-10-0689 CS300™ Service Manual

Theory of Operation Circuit Descriptions

Circuit Descriptions Page

Power Supply Assembly Block Diagram P/N 0014-00-0033-05 1-8

Front End Description 1-9

Front End PCB Drawing P/N 0670-00-0668 1-10

Front End PCB Block Diagram P/N 0670-00-0668 1-11

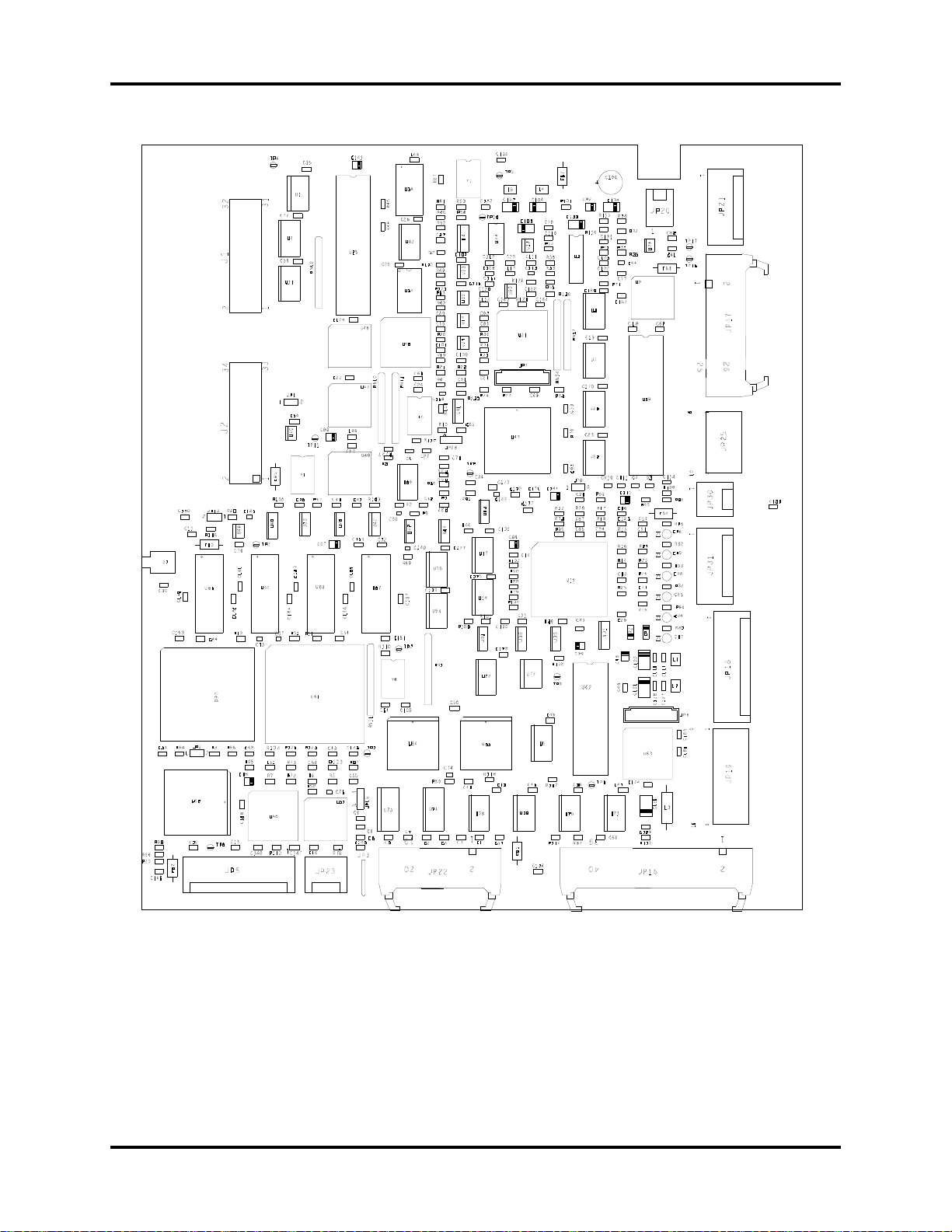

Main Board Description 1-12

Main PCB Drawing P/N 0670-00-1152 / 0670-00-0788 1-13

Main Board Block Diagram P/N 0670-00-1152 / 0670-00-0788 1-15

Display Controller Description 1-16

Display Controller PCB Drawing P/N 0670-00-0640 1-17

Display Controller Block Diagram P/N 0670-00-0640 1-18

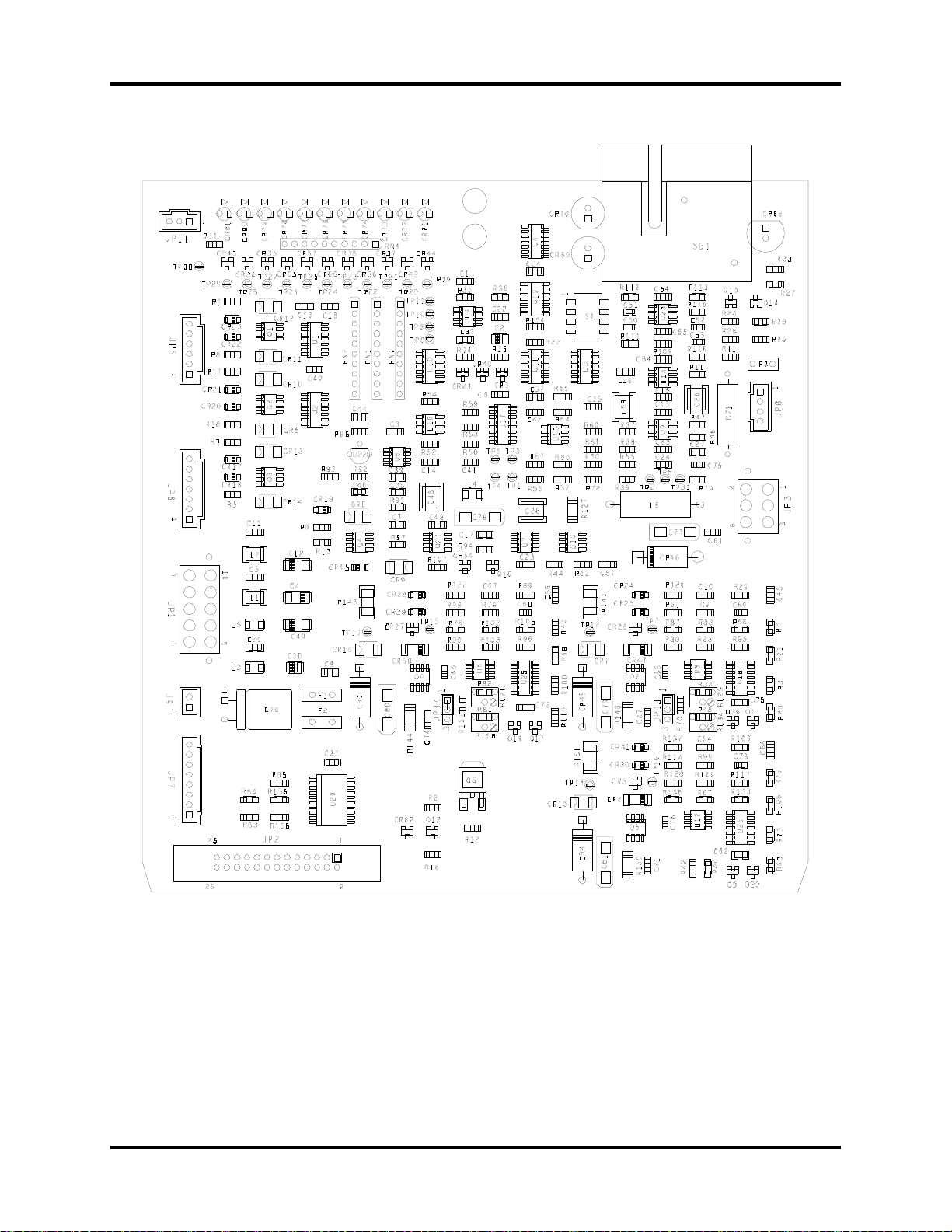

Solenoid Driver Description 1-19

Solenoid Driver PCB Diagram P/N 0670-00-0639 1-20

Solenoid Driver PCB Block Diagram P/N 0670-00-0639 1-21

Keypad Controller Description 1-22

Keypad Controller PCB Diagram P/N 0670-00-1145 1-23

Keypad Controller Block Diagram P/N 0670-00-1145 1-24

Video Receiver Description 1-25

Video Receiver Board Diagram P/N 0670-00-0736 1-26

Video Receiver Block Diagram P/N 0670-00-0736 1-27

Sensor Module Description 1-28

Sensor Module Board Diagram P/N 0997-00-1161 1-29

Sensor Module Block Diagram P/N 0997-00-1161 1-30

CS300™ Service Manual 0070-10-0689 1 - 7

1 - 8 0070-10-0689 CS300

1

2

3

AC

ACN

GND

EMI

FILTER

DC

FAN

POWER

FACTOR

CORRECTION

CONVERTER

(PFC)

J1

1

2

3

BATT

BATT

BATT-RET

J3

4

BATT-RET

90-264

VAC

20-32 VDC

BATTERY

CHARGER

MULTIPLE

OUTPUT

FLYBACK

CONVERTER

1

2

3

4

BULK

BULK

BULK-RET

BULK-RET

1

2

3

4

BATT-VOLT

BATT-CURR

AGND

REMOTE-ON*

5

6

7

8

BATT-LOW *

BATT-HRT*

BATT-FLT*

BATT-OP*

P/O J100

J103

J101 J102

INPUT PCBA

POWER PCBA

STATUS CONNECTOR

POWER

CONNECTORS

CONTROL

PCBA

SELV

BARRIER

SELV

BARRIER

CHASSIS

GROUND

PFC

CONTROL

ISO

CONVERTER

CONTROL

CHARGER CONTROL

FAN DRIVE

STATUS LINES

FLYBACK

CONVERTER

CONTROL

INTERNAL BULK

MAINS

ON/OFF

MAINS

FUSES

BATTERY

FUSE

BULK

FUSE

EMI

FILTER

BULK

SWITCH

RECTIFIER

BRIDGE

HOUSEKEEPING

SUPPLY

CONTROL

LOGIC

1

2

3

4

+12V

12RET

-12V

5RET

5

6

7

8

+5RET

+24V

24RET

+5V

1

2

3

4

+12V

12RET

-12V

5RET

5

6

7

8

+5RET

+24V

24RET

+5V

9

10

11

12

FF_SD_DISABLE

REDUCED_AIR

13

14

15

LED-CATH

DGND

LED-ANODE

P/O J100

18-32 VDC

POWER ENTRY MODULE

MAINS

ISOLATION

CONVERTER

NOT USED

NOT USED

Service Manual

™

FIGURE 1-4 Power Supply Assembly Block Diagram

P/N 0014-00-0033-05

Circuit Descriptions Theory of Operation

Theory of Operation Circuit Descriptions

Front End Description

ECG Pressure

• Patient isolation • Patient isolation

• ESU filters • Pressure scaling

• Lead selection • Auto zero circuit

• Reference lead drive • Pressure gain adjustment

• External ECG signal selection • External pressure signal selection

• Pacer detection • Pressure ESD protection

• ECG trigger signal conditioning

• ECG size

• ECG ESD protection

• ECG defibrillator protection

Data Acquisition Microcontroller

• Pneumatic transducer amplifiers • Serial interface to Main Board

• A/D converter for display signals • ECG circuit control latches

• 12-Bit A/D converter • Pressure circuit control latches

• Transducer excitation voltages • Controls A/D conversion

• Pacer blanking

• ESU detect and time-out

• Auto zero control

CS300™ Service Manual 0070-10-0689 1 - 9

1 - 10 0070-10-0689 CS300

Circuit Descriptions Theory of Operation

FIGURE 1-5 Front End PCB Drawing

P/N 0670-00-0668

™

Service Manual

CS300

CSD

Circuitry

Amp

ESU Flt

Lead Sel

Lead Drv

Diff Amp

Mod

De-Mod

De-Mod

Amp

&

Lead

Fault

Var Ga in

DAC

Pacer Det

&

ESU Det

Mux

A/D

Conv

68HC711

Micro-

controller

Gain Adj

&

Zero Ofst

He tank-Pres

ECG-Trig

BP-Trig

ECG-Disp

BP-Disp

Drive-Pres

Bal-Pres

Atmos-Pres

2.5V Ref

Batt-Volt

Batt-Cur

Tem p

A-Gnd

Pwr

Conv

Iso Pwr

Supply

Iso-Barrier

BP-Trig

BP-Disp

ECG-Trig

ECG-Disp

BP

ECG

To Comm Proc.

on Main Board

Ext BP In

Ext ECG In

Trigg er

Processing

Pressure

ECG

Patient

Inputs

5uV/V/1mmHg

1mV

Mod

Display

Gain

Balloon-Exc(+)

Balloon-Exc(-)

Balloon-Xout(+)

Balloon-Xout(-)

Drive-Exc(+)

Drive-Exc(-)

Drive-Xout(+)

Drive-Xout(-)

J4

J5

Excit.

Voltage

Reg.

2.5VRef

+5V -5V

+5V Ref

Scaling

Amp

On board

transducer

Offset

Atmospheric Pressure Channel

Instrumentation Amp

Offset

Balloon Pressure Channel

Instrumentation Amp

Offset

Drive Pressure Channel

2.5V

Reg.

Independent

Reference

Buffer

Buffer

4mV / mmHg

4mV / mmHg

Balloon-Press

Tes t ( to P6)

Drive-PressTes t ( to P6)

Tan k -E x c

Tan k -S i g

Tan k -G n d

Buffer

+5V Ref.

Scaling

Amp

Helium Tank

Pressure Channel

Tem p

Sensor

Solnd-state

Trig-pulse*

Batt-volt

Batt-curr

FE-TX

FE-RX

FE-Clk

Scaling

Amp

BattCurr

BattVolt

Buffer

Buffer

Solnd-Stat-Test (To P6)

Trig-Pls-Test (To P6)

Buffers

68HC711

Micro-Controller

125mV/V

250mV/A

Temperature

Channel

12 MHz

Xtal

Divide-

by-48

Clk-62.5 KHz

3.00 MHz

ESU-Present*

Pacer-Blanking*

LD-Flt-Detect

Trai ner*

Slew-rate-exceeded

HW-ESU-exceeded

Xducer*

60Hz / 50Hz*

ECG-Ext-Sel*

BP-Ext-Sel*

1 Volt / mV

1 Volt / 100mmHg

External Monitor Inputs

ECG-Ext-In

ECG-Ext-Sel*

BP-Ext-In

BP-Ext-Sel*

ECG-Ext-Out

BP-Ext-Out

Solnd-State

50/60 HZ

Notch

60 Hz / 50 Hz*

J3

Trainer

ECG

Pressure

6 - Trig-Pls-Test

7 - Solnd-Stat-Test

8 - Gnd_A

9 - Gnd_D

1 - ECG-Var-Test

2 - BP-Test

3 - Balloon-Press-Test

4 - Drive-Press-Test

5 - Pcr-Pls-Test

Diagnostic Output

P6

Service Manual 0070-10-0689 1 - 11

™

FIGURE 1-6 Front End PCB Block Diagram

P/N 0670-00-0668

Theory of Operation Circuit Descriptions

Circuit Descriptions Theory of Operation

Main Board Description

6809 Microprocessor (2 MHz) 68020 Microprocessor (33 MHz)

• 50 k EPROM (Datasette) • 2 M EPROM (Datasette)

• 12 k RAM • 2 M RAM

• Solenoid control signals • Real time clock and NVRAM

• Watchdog timer • Display interface

• Alarm processing • Recorder control

• Pneumatic switch status • Recorder interface

• IABP control status • RS-232 interface

• Motor speed D/A converter • Modem interface

• Configuration DIP switch

68HC711 Microprocessor

Serial interface to the Front End, Solenoid Driver and Keypad Controller boards

• Shared RAM interface

Shared RAM

• Port 1 interfaces with the 68020 sub-system

• Port 2 interfaces with the 6809 sub-system

• Port 3 interfaces with the 68HC711 (communications processor)

1 - 12 0070-10-0689 CS300™ Service Manual

Theory of Operation Circuit Descriptions

FIGURE 1-7 Main PCB Drawing

P/N 0670-00-1152

CS300™ Service Manual 0070-10-0689 1 - 13

Circuit Descriptions Theory of Operation

FIGURE 1-8 Main PCB Drawing

P/N 0670-00-0788

1 - 14 0070-10-0689 CS300™ Service Manual

CS300

68020 (DSS)

Processor

Circuit

Group

6809 (IAB)

Processor

Circuit

Group

68HC11

(Comm)

Processor

Circuit

Group

RAM

Datasette

VIA

D/A Conv

Audio

Synth

& Amp

Shared

RAM

RAM

Datasette

QUAD

UART

To Modem

To Thermal Printer

& RS232

spare

To D is p l a y

Controller

To F r o n t

End

To K ey p ad

Control

To Solenoid

Driver

To Motor

Control

To Speaker

RTC /

NVRAM

JP5

p/o JP16

p/oJP17JP21JP20JP22JP31p/oJP1

6

JP19

+5V

+12V

-12

+24

From

Power

Supply

JP18

To

Power

Supply

Status

Remote On

p/o JP17

From

Solenoid

Driver

Status

™

Service Manual 0070-10-0689 1 - 15

Theory of Operation Circuit Descriptions

FIGURE 1-9 Main Board Block Diagram

P/N 0670-00-1152 / 0670-00-0788

Circuit Descriptions Theory of Operation

Display Controller Description

• Generates system display via Hitachi ACRTC device

• Acts as peripheral to 68020 (DSS) processor

• Transmits video data and control signals to display head via LVDS transmitter

• Provides serial communications link between Comm Proc and Keypad Controller

• Provides V-Bulk supply voltage to Display Head assembly with soft-start circuit

1 - 16 0070-10-0689 CS300™ Service Manual

CS300

™

Service Manual 0070-10-0689 1 - 17

Theory of Operation Circuit Descriptions

FIGURE 1-10 Display Controller PCB Drawing

P/N 0670-00-0640

1 - 18 0070-10-0689 CS300

XILINX

FPGA

Clock

Gen

Frame

Buffer

Hitachi

Graphics

Processor

Osc

Bidir

Buff

Data

CS,WE

DTACK

MAD

ADDR

DATA

LD,UD

FLM,LP

DISP-OFF

7.5M HZ

3.75MHZ

(Frame Buffer

&

LCD

Controller)

30MHz

Config.

PROMs

CS,CLK

LVDS

Driver

30MHz

VS,MRD

DRW,AS

CS,WS(2)

Data

CP

JP1

JP2

JP3

SoftStart

Ckt

KCTxD

KCRxD

Diff

DrvRcv

IRQ

To M ai n Board

To D i spl ay Head

V-Bulk,

Rtn

CP-EN

OE*

T/R*

Circuit Descriptions Theory of Operation

™

Service Manual

FIGURE 1-11 Display Controller Block Diagram

P/N 0670-00-0640

Theory of Operation Circuit Descriptions

Solenoid Driver Description

• Receives solenoid control signals (11) from Main Board

• Energizes fill solenoids (K1, K2, K3, K4 and K5)

• Energizes drive solenoids (K6, K6A, K7 and K8)

• Provides prolonged inflation watch-dog timer

• De-energizes drive solenoids if watch-dog timer expires and sends signal to Main Board

• Energizes Peltier devices in Safety Disk

• Incorporates blood detection circuitry

CS300™ Service Manual 0070-10-0689 1 - 19

Circuit Descriptions Theory of Operation

FIGURE 1-12 Solenoid Driver PCB Diagram

P/N 0670-00-0639

1 - 20 0070-10-0689 CS300™ Service Manual

MAIN BOARD

JP2

JP7

BD0 - 8

6809 DATA BUS

SWITCH

STATUS

FET CONTROL

FILL

SOLENOIDS

DRIVE

SOLENOIDS

FET CONTROL

(K1,K2,K4)

(K6,K7,K8)

PROLONGED

INFLATION

FAIL SAFE

LED

INDICATORS

WDOG*

RD_SOL_STATE*

JP5

JP3

FILL

SOLENOIDS

DRIVE

SOLENOIDS

SOL_WATCHDOG*

K7*, K8*

XXXX_SOL*

SOL_WDOG*

JP9

CHRG-LED-, +

CHRG-LED -, +

K1*,K2*,K4*

K6*,K7*,K8*

PELT_ON/OFF*

SOL_WDOG*

JP11

JP1

ON/OFF

DGND

POWER

SWITCH

ON/OFF

+5v-PELT

+24v,+12v,+5V-12V

JP6

PURGE

SOLENOIDS

PURGE

SOLENOIDS

FET CONTROL

(K3 , K5)

FULL*

EMPTY*

K6A*

DRAIN TUBING

240HZ

LED

DRIVE

BB_LED+, -

CLOCK

TUBE_SGN

REF_SGN

DEMOD

DEMOD*

SYNCHRONOUS

DETECTOR

LOW PASS

FILTER

LOW PASS

FILTER

COMPARATOR

SENSOR

BLOCK

REF_SIGNAL

TUBE_SIGNAL

2.5V

REFERENCE

2.5V

+12VF

PELT_ON/OFF*

AMBIENT

TEMP.

PELTIER

CONTROL

JP8

CONDENSATE

REMOVAL

MODULE

PELT_CONTROL

PELT-PWR

+12VP (FAN)

SAFETY VENT

SOLENOID

VOLUME

CYLINDER

SENSORS

LED

CHARGE

INDICATOR

MAIN BOARD

K3*,K5*

BBALARM*

CS300

Service Manual 0070-10-0689 1 - 21

™

FIGURE 1-13 Solenoid Driver PCB Block Diagram

P/N 0670-00-0639

Theory of Operation Circuit Descriptions

Circuit Descriptions Theory of Operation

Keypad Controller Description

• 68HC11 micro-controller continually scans key matrix of 7 Rows X 6 Columns (42 keys

max)

• Micro-controller controls LEDs via serial input LED driver chip

• Micro-controller communicates switch closures and receives LED data via serial

communications link to Comm Processor on Main Board

• Passes video interface (LVDS) through to Video Receiver PCBA

• Provides DC/DC converters from V-Bulk to +5V and +12V to power this PCBA, Video

Receiver and LCD display panel

1 - 22 0070-10-0689 CS300™ Service Manual

Loading...

Loading...