Page 1

ALPHAMAXX 1133.12B1/B3/

F1/F3

Operating instructions

Universal

operating table

English

GA113312EN02

Page 2

1133.12B1/B3/F1/F3

9

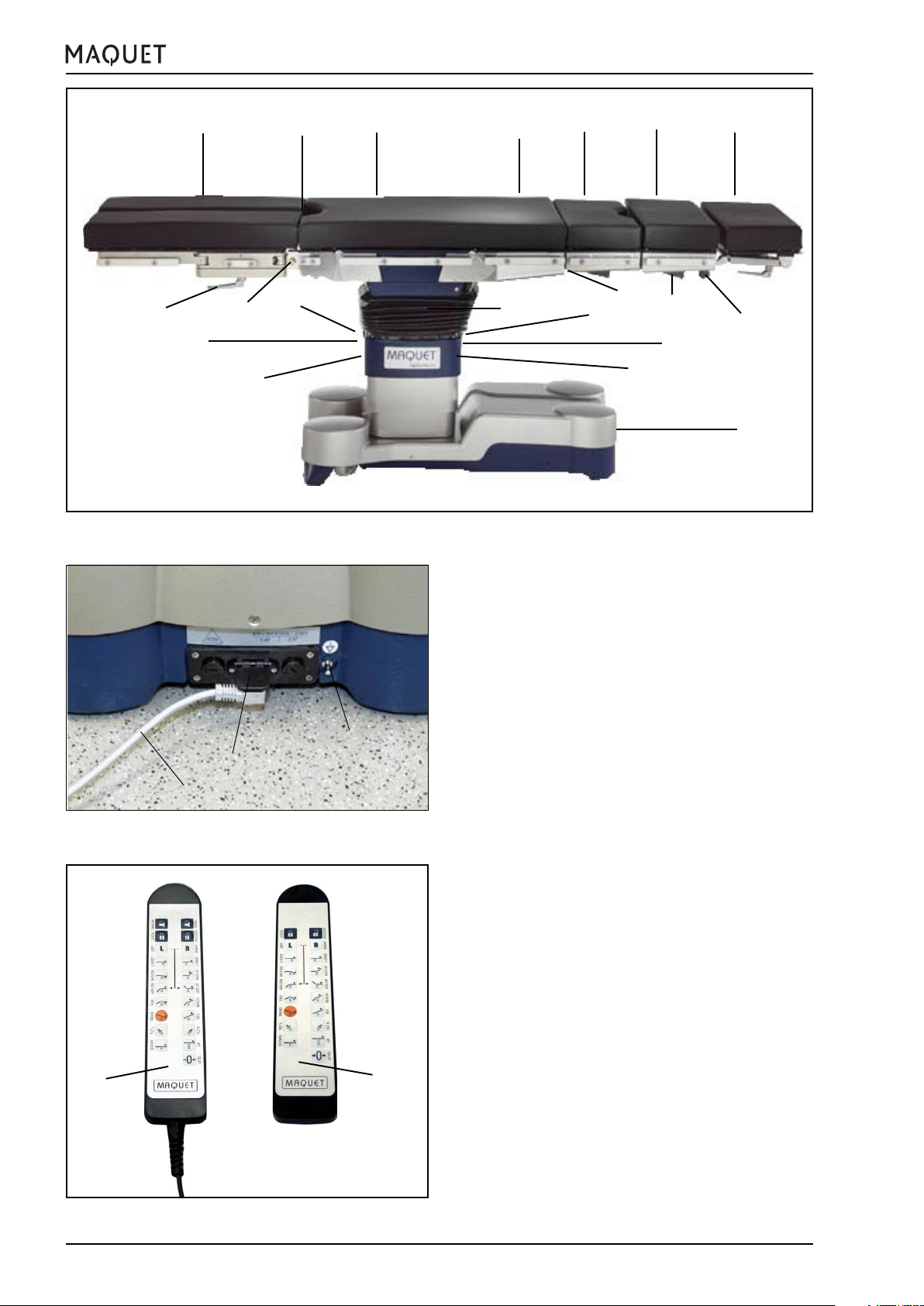

Pictorial guide

14

8

10

13

22

12

11

6

7

21

12

4

5

3

14

20

1

2

15

1. Head plate (e.g. 1130.64)

2. Fastening screws for head plate

16

15

3. Locking lever for extension segment

1131.31XX

4. Locking lever for extension segment

1131.31XX

(optional)

5. Mounting point for back plates

6. Lower back plate

17

7. Bellows

8. Leg plates 1133.53XX (optional)

9. Locking lever for leg plate abduction

10. Unlocking of leg plates

11. Seat plate

12. Infrared receiver and transmitter

13. Override system with status indicators

for operating table (on the rear)

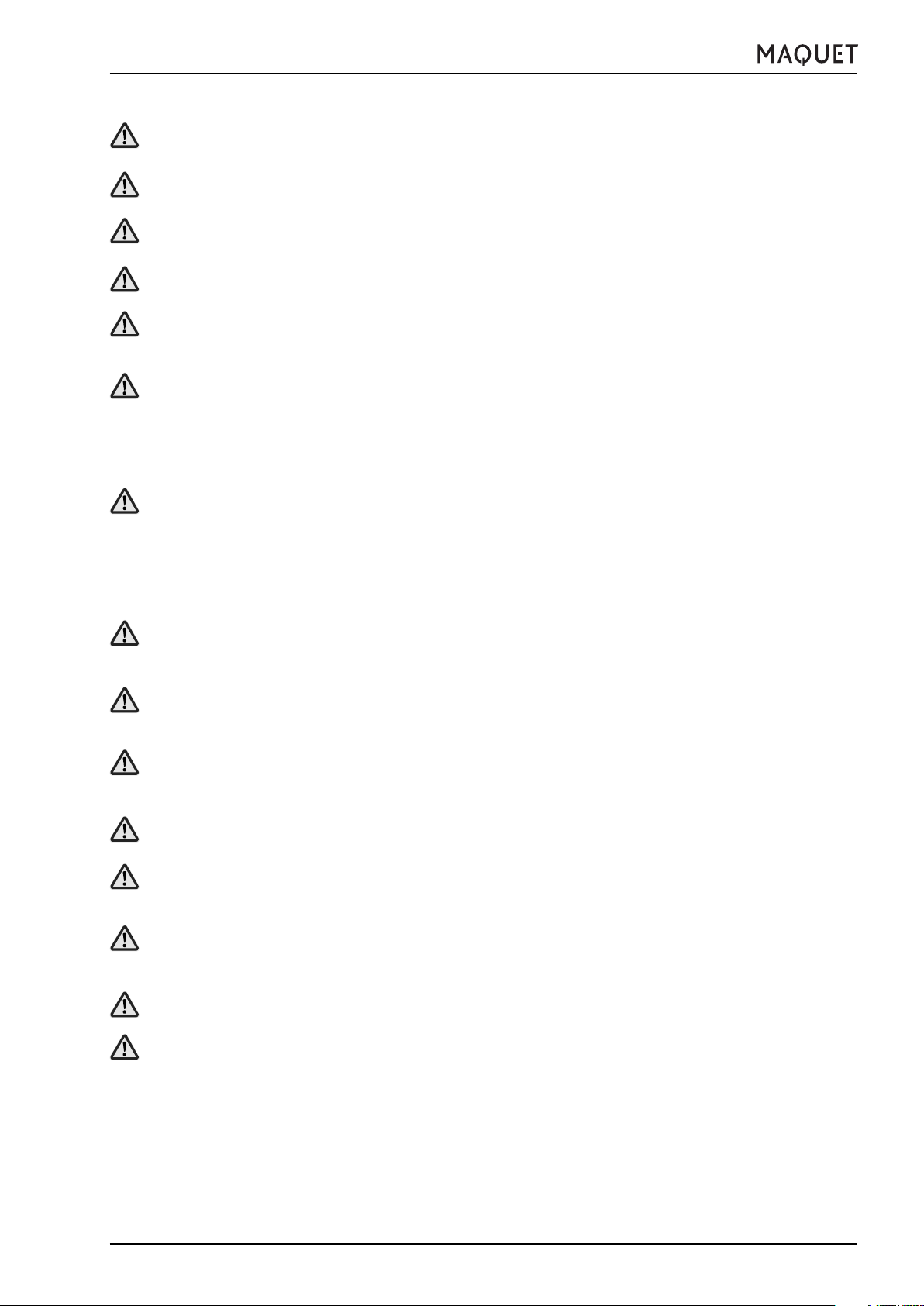

14. Sockets for corded hand control and

foot switch

15. Socket for mains cable

16. Mains cable

18

19

17. Potential equalization

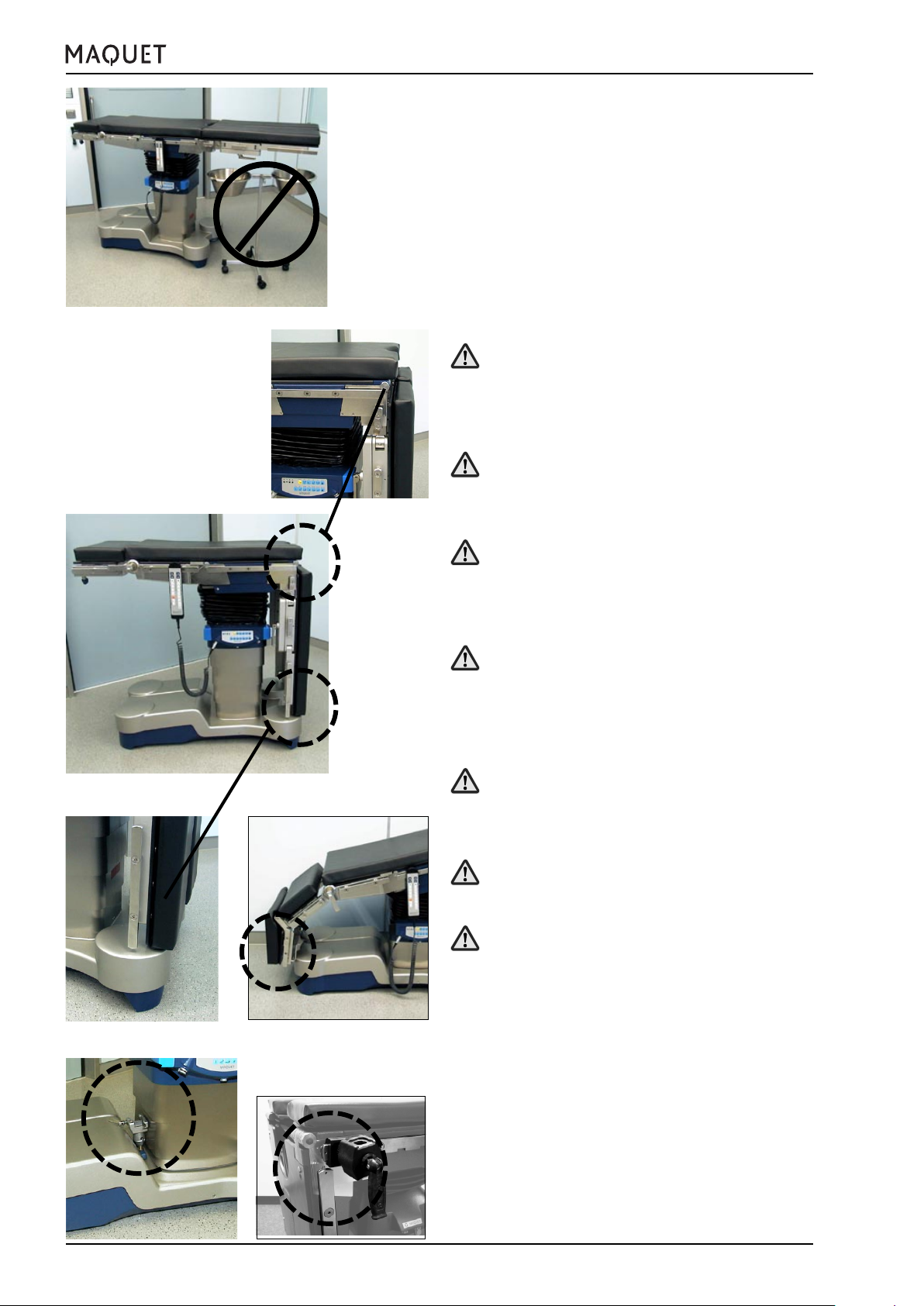

18. Corded hand control (optional)

19. IR remote control (optional)

20. Interface for servicing (on the rear)

21. Seat plate extension 1131.55XX

(optional)

22. Mounting point for leg plates

2

GA113312EN02

Page 3

1133.12B1/B3/F1/F3

Table of contents

Pictorial guide ..................................................................................................................................... 2

I. Important safety notes.................................................................................................................. 5

II. Important information .................................................................................................................. 7

1. Important information on these operating instructions: .............................................................. 7

2. Intended use of an operating table ............................................................................................7

3. Intended purpose: .................................................................................................................... 7

4. Fundamental safety aspects ....................................................................................................7

III. General description...................................................................................................................... 8

1. General features ....................................................................................................................... 8

2. Control of functions .................................................................................................................. 9

2.1 Corded hand control ...................................................................................................... 10

2.2 Override system = emergency operation ........................................................................ 11

2.3 IR remote control (optional) ........................................................................................... 13

2.3.1 IR system code ................................................................................................... 14

2.3.2 Charging station ................................................................................................... 15

2.4 Control via IR wall control panel ..................................................................................... 15

2.5 Control via foot switch 1009.81DX (optional) .................................................................. 16

2.6 „Neurolock“ function ...................................................................................................... 16

3. Table top ................................................................................................................................17

3.1 General features ........................................................................................................... 17

3.2 Mechanical adjustments .............................................................................................. 18

3.2.1 Mount / remove the head plate ............................................................................. 18

3.2.2 Extension segment 1131.31B0/F0 ....................................................................... 23

3.3 Collision protection at the leg plate mounting point ....................................................... 24

3.3.1 Seat plate extensions ......................................................................................... 25

3.3.2 Leg plates ............................................................................................................ 26

3.4 Table top padding .......................................................................................................... 27

3.5 Accessories..................................................................................................................27

4. Autodrive in the base.............................................................................................................. 28

IV. Use of the operating table ......................................................................................................... 29

1. General .................................................................................................................................. 29

2. Operation on battery power .................................................................................................... 29

3. Operation on mains power...................................................................................................... 30

4. HF surgery, use of defibrillators .............................................................................................. 30

V. Patient positioning ..................................................................................................................... 31

1. General .................................................................................................................................. 31

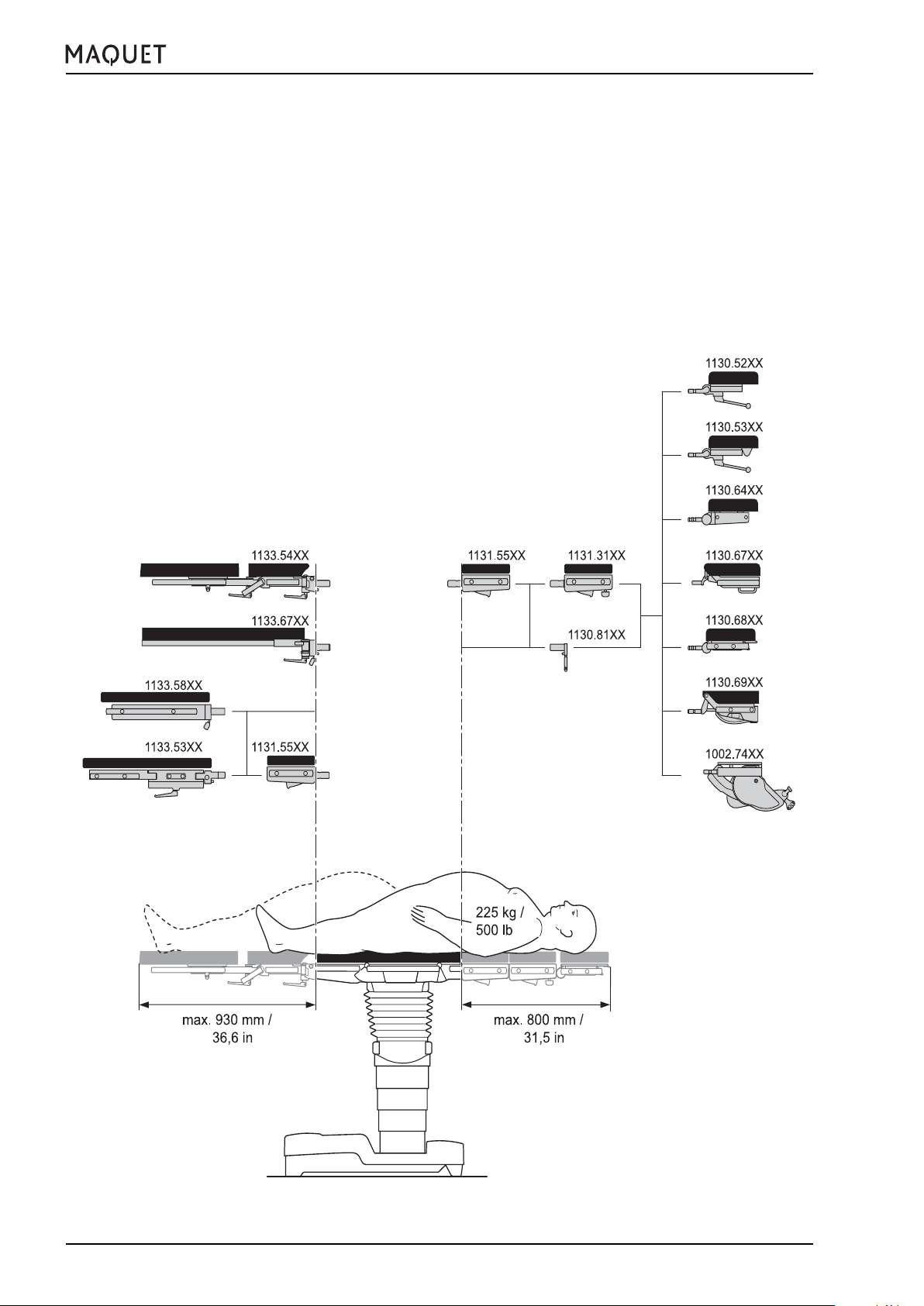

2. Positioning a patient weighing between 225 kg and 450 kg (500 lb - 1000 lb) ......................... 33

2.1 Approved accessories ................................................................................................... 33

2.2 Operating table immobilized (LOCK) ............................................................................. 33

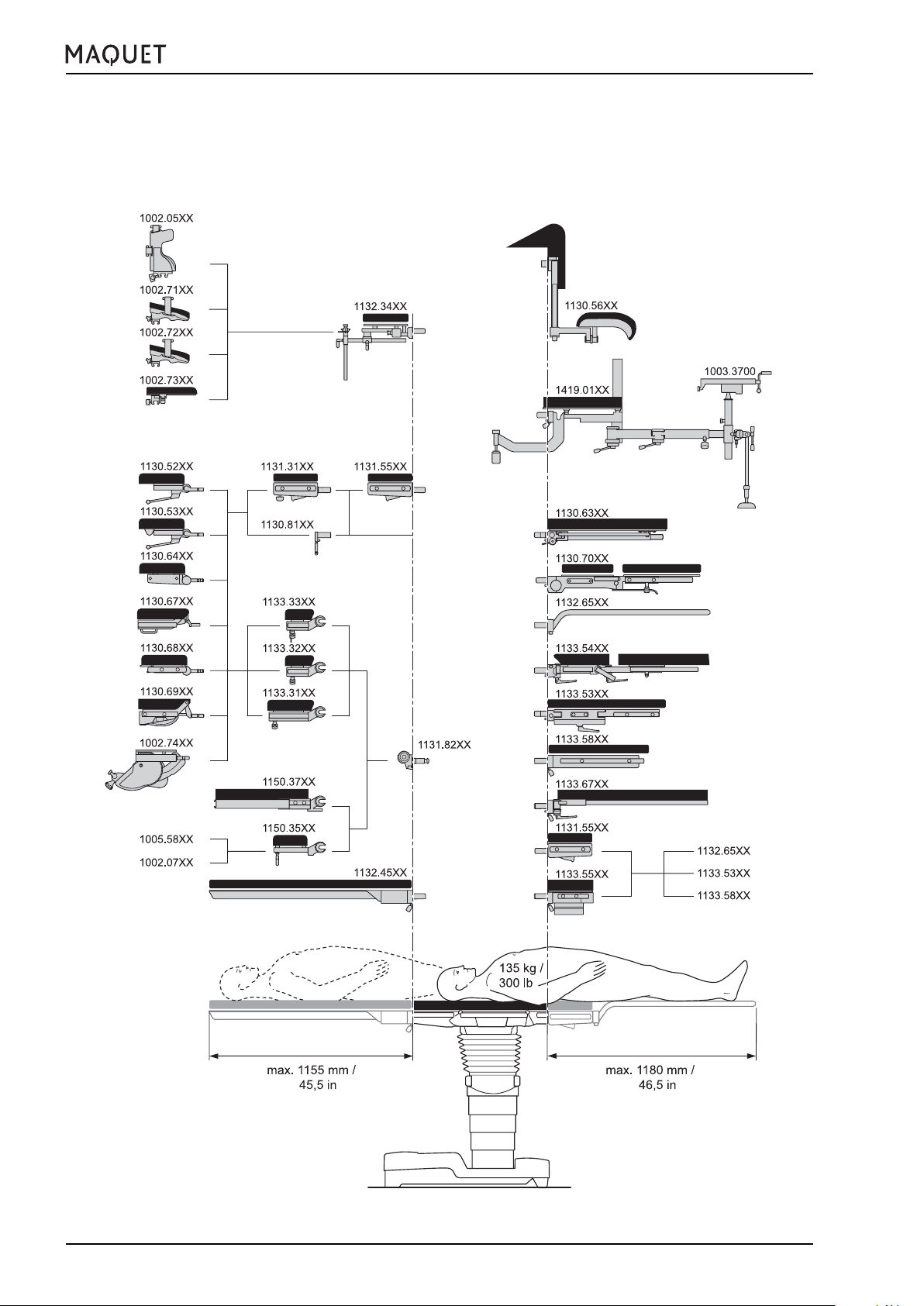

3. Positioning a patient weighing between 135 kg and 225 kg (300 lb - 500 lb) ........................... 34

3.1 Approved accessories ................................................................................................... 34

3.2 Operating table not immobilized (UNLOCK) .................................................................. 34

3.2.1 NORMAL patient orientation / operating table not immobilized (UNLOCK)............ 35

3.2.2 REVERSE patient orientation / operating table not immobilized (UNLOCK) ........ 36

3.3 Operating table immobilized (LOCK) ............................................................................. 37

3.3.1 NORMAL patient orientation / operating table immobilized (LOCK) ...................... 37

3.3.2 REVERSE patient orientation / operating table immobilized (LOCK) .................... 38

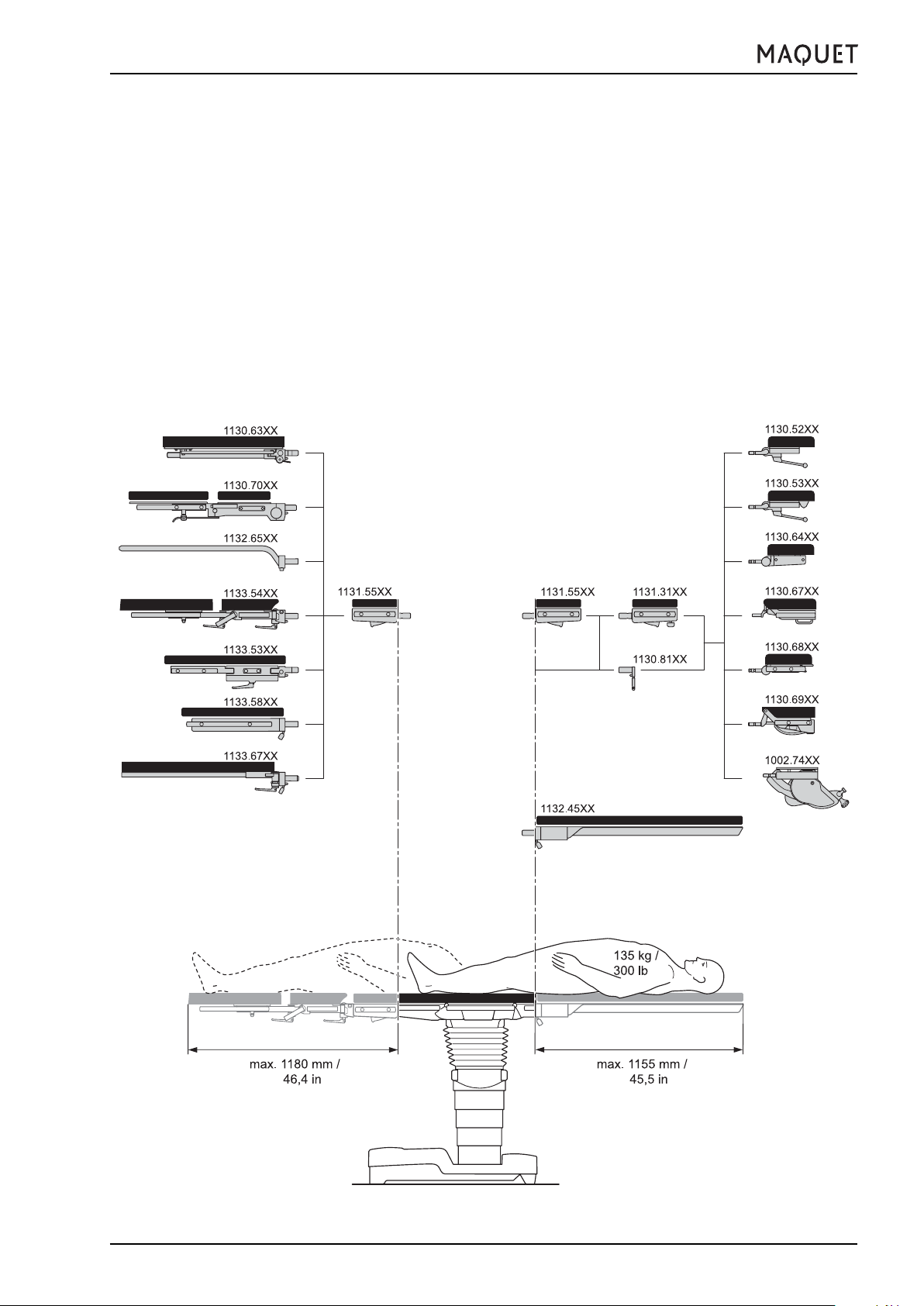

4. Positioning a patient weighing up to 135 kg (300 lb) ............................................................... 39

4.1 Approved accessories ................................................................................................... 39

4.2 Operating table not immobilized (UNLOCK) .................................................................. 39

4.2.1 General ................................................................................................................ 39

4.2.2 NORMAL patient orientation / operating table not immobilized (UNLOCK)............ 40

4.2.3 REVERSE patient orientation / operating table not immobilized (UNLOCK) ......... 41

4.3 Operating table immobilized (LOCK) ............................................................................. 42

4.3.1 NORMAL patient orientation / operating table immobilized (LOCK) ...................... 42

4.2.2 REVERSE patient orientation / operating table immobilized (LOCK) .................... 43

GA113312EN02

3

Page 4

1133.12B1/B3/F1/F3

VI. Care and maintenance .............................................................................................................. 44

1. Cleaning ................................................................................................................................. 44

2. Disinfection ............................................................................................................................ 44

3. Maintenance .......................................................................................................................... 45

4. Malfunctions .......................................................................................................................... 45

5. Environmental protection ........................................................................................................ 46

VII. Technical specifications ............................................................................................................. 47

1. Operating table adjustments .................................................................................................. 47

2. Electrical specifications ......................................................................................................... 47

VIII.List of accessories ...................................................................................................................... 48

1. Accessories for head-side mounting point: .............................................................................. 51

1.1 For patients weighing up to 450 kg (1000 lb) .......................................................................... 51

1.2 For patients weighing up to 225 kg (500 lb) ............................................................................ 51

1.3 For patients weighing up to 135 kg (300 lb) ............................................................................ 51

2. Accessories for the back plate mounting point........................................................................ 52

2.1 For patients weighing up to 450 kg (1000 lb) .......................................................................... 52

2.2 For patients weighing up to 225 kg (500 lb) ............................................................................ 52

2.3 For patients weighing up to 135 kg (300 lb) ............................................................................ 52

3. Accessories for leg plate mounting point................................................................................. 52

3.1 For patients weighing up to 450 kg (1000 lb) .......................................................................... 52

3.2 For patients weighing up to 225 kg (500 lb) ............................................................................ 52

3.3 For patients weighing up to 135 kg (300 lb) ............................................................................ 52

4. Accessories for side rails ........................................................................................................... 53

5. Special-purpose accessories ..................................................................................................... 54

6. Control units ................................................................................................................................54

IX. Spare parts list............................................................................................................................ 55

4

GA113312EN02

Page 5

1133.12B1/B3/F1/F3

I. Important safety notes

I. Important safety notes

Mount only the accessories listed in chapter VIII.

Make sure the operating table is set up horizontally and that it is stable.

Immobilize the operating table prior to use! Press the LOCK button!

Immobilize the operating table prior to transferring the patient! Press the LOCK button!

The patient may be transferred only from the side of the operating table. If the patient is transferred from

head or foot end, there is a danger of tipping over!

Injury hazard!

If the patient is not secured during transportation, when adjusting the operating table or when positioning the

patient (particularly when the slope feature is used), then the patient could slip, uncontrolled, off the operating table. Always secure the patient and maintain continuous observation.

Hazard of burns to the patient!

When using HF surgical equipment, defibrillators and defibrillation monitors, make sure to avoid that the

patient comes into contact with metal parts of the operating table, the table tops or the accessories. Also

make sure to avoid that the patient is lying on moist underlays or sheets on the conductive pads.

Be absolutely sure to comply with the manufacturers operating instructions!

Hazard of damage!

Avoid any collisions between the accessories and the operating table during adjustment procedures!

Consult MAQUET prior to using accessories produced by other manufacturers if they affect the longitudinal

geometry of the table top.

There is no explosion protection while recharging the batteries or when the operating table is on mains

power.

When connecting or removing the mains cable, observe the correct order of the procedure! (See page 22)

Avoid endangering the patient’s respiratory system, nerve pathways and circulatory system by ensuring the

patient is properly positioned and observing the patient’s condition.

The operating table’s electrical conductivity has to be checked once a year! This check should be performed only by trained servicing personnel.

Before opening the equipment, disconnect the mains plug.

Electrical devices (e. g. cellphones, radios, magnetic resonance tomographs) can interfere with the functioning of the operating table when used near the operating table.

Please observe the Technical Description for the operating table.

It contains imformation on electromagnetic compatibility (EMC) for the operating table (both radiation and

resistance to interference).

Adhere to those specifications when using electrical devices and respond properly in the event of effects on

your operating table.

GA113312EN02

5

Page 6

I. Important safety notes

Injury hazard!

Before aligning the leg plates horizontally, check

the patient’s position carfully, particularly when

using knee crutches.

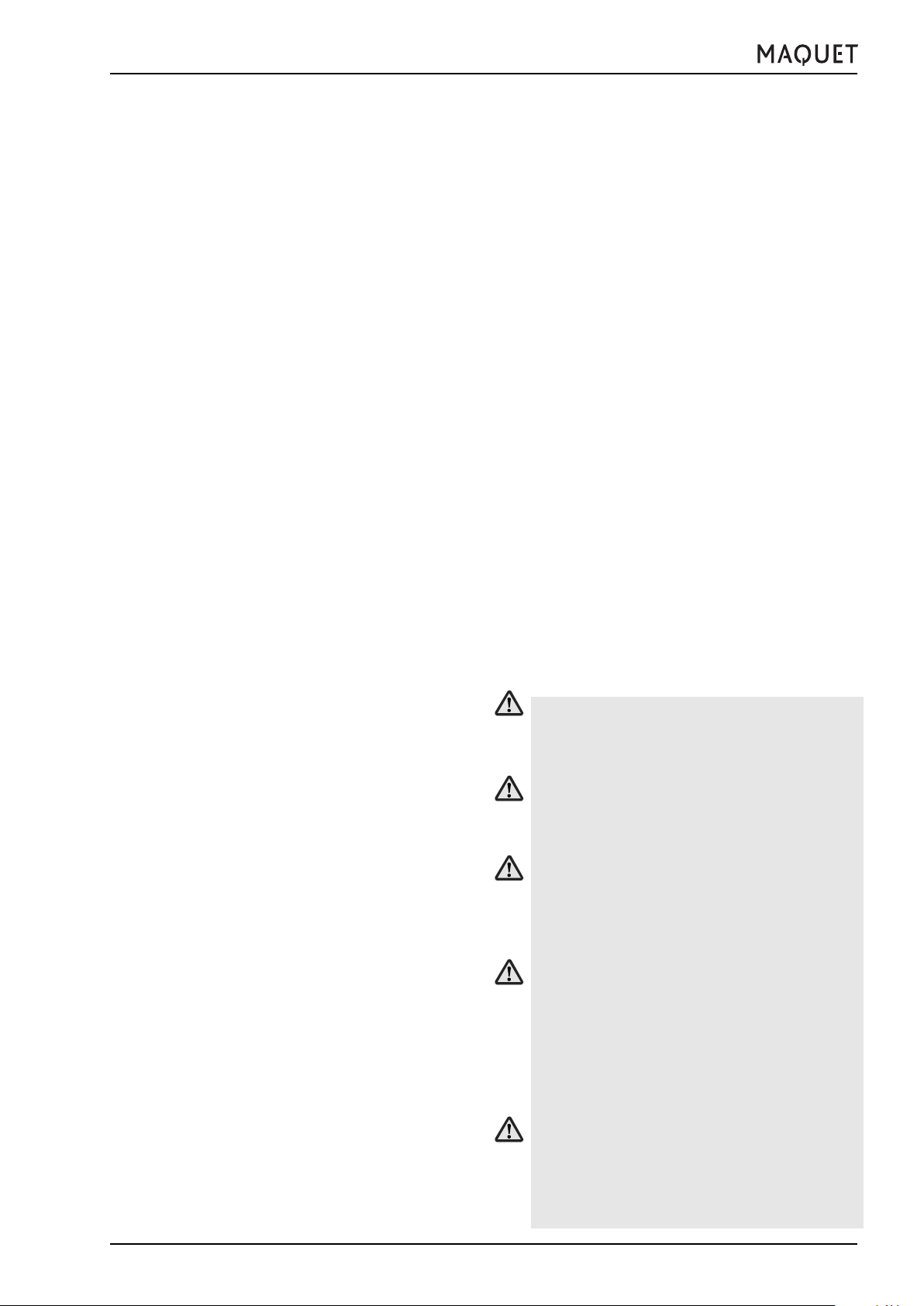

Hazard of pinching and crushing!

Do not touch the side rails in the area of the joints

when adjusting the table top.

1133.12B1/B3/F1/F3

Hazard of pinching and crushing!

Hazard of pinching!

Do not reach under the table top or between the

table top components during adjustment procedures.

Hazard of pinching and crushing!

When immobilizing the operating table (LOCK),

the operator’s feet may be crushed or shorn.

When setting the operating table, keep enough

distance from the table base.

Hazard of damage!

Do not place any objects on the operating table

base.

Hazard of damage!

Do not press or pull on the covers of the joints.

Hazard of damage!

Make sure the cable of the hand control does not

get jammed when adjusting the operating table.

6

Collision hazard!

GA113312EN02

Page 7

1133.12B1/B3/F1/F3

II. Important information

II. Important information

Your hospital has opted for the 1133.12 operating table. We appreciate the confidence you have placed in us.

1. Important information on these operating instructions:

• Please read these operating instructions completely and carefully. They were written to familiarize you with

the features of this operating table.

• Be sure to always follow the instructions given here.

• Always store these operating instructions near the unit.

• In these operating instructions we have used the following symbols:

This symbol identifies information which is critical for safety as described in the international

standard applicable to the field of medicine.

Note

This symbol precedes all notes which will help to avoid operational difficulties.

X An “X” in the order number (e.g. 1133.53XX) stands in place of the different versions.

2. Intended use of an operating table

The operating tables distributed by MAQUET are to be used exclusively in the field of human medicine. Before the

equipment is used, all users must be instructed in its proper use. This familiarization session is confirmed in an

acceptance log. The location selected for the table must conform to the applicable standards and guidelines.

Before using the equipment, you must be absolutely certain that it is properly installed and maintained.

3. Intended purpose:

The operating table 1133.12 is used to support and position a patient for surgical treatment

• immediately before, during and after the operative phase,

• in rooms used for medical purposes which fulfil the following requirements:

- equipment to protect against electric shocks

- additional potential equalization

- electrically conductive floor (corresponding to Group 1 or 2 as per VDE 0100 Part 710)

• under medical supervision.

• A max. patient weight of 450 kg (1000 lb.) is permissible in certain circumstances.

Avoid excentric patient positions, i.e. the patient’s centre of gravity (near the navel) must be as close as

possible to the centre of the column.

The design of the table top makes the operating table suitable for every surgical discipline. The positioning options

are listed in the operating instructions.

The adjustments are made electrohydraulically using the corded hand control, the IR remote control, the IR wall

control panel or a foot switch.

Side rails are used to mount accessories, in accordance with the manufacturer’s instructions.

The radiotranslucent operating table top allows for intraoperative use of X-ray equipment.

Note:

In accordance with generally accepted hygiene standards, the operating table top is to be covered with

surgical drapes during use.

4. Fundamental safety aspects

This operating table meets the requirements set forth in the IEC 60601-1 international standard which is equivalent

to DIN VDE 0750, Part 1.

The operating table is classified as a Class I equipment according to the Medical Device Directive.

Whenever maintenance work is required, remember that the MAQUET Service Department is the right address in

terms of quality and maintaining guarantee protection. You will certainly understand that MAQUET can be held

responsable for the safety technology features only if assembly, enhancements, readjustment, modifications and

repairs are made exclusively by our service department or by an authorized agent and if the unit is full in full

compliance with the operating instructions.

GA113312EN02

7

Page 8

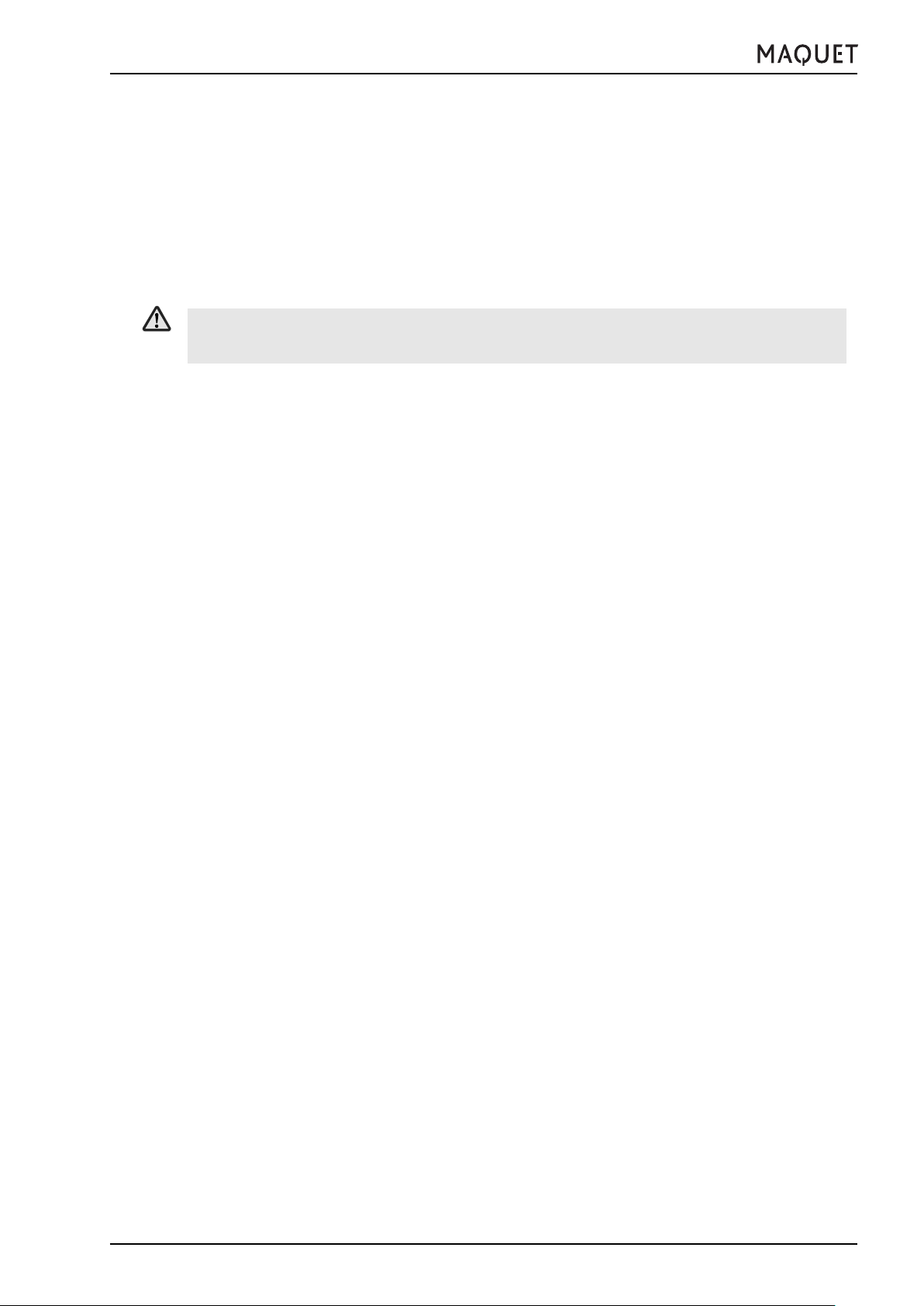

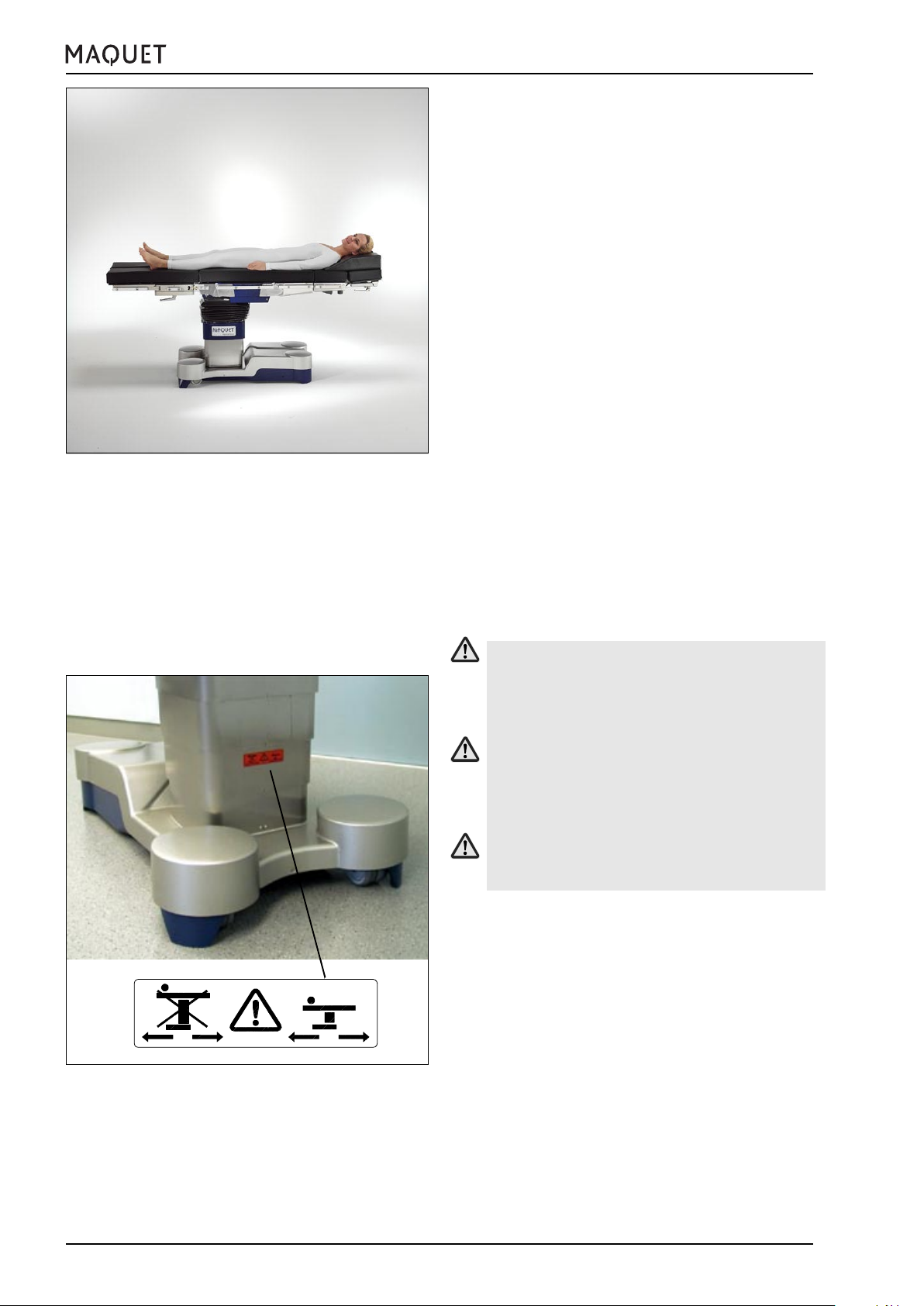

Fig.III-1: The preferred patient orientation

III. General description

III. General description

1. General features

In princliple, the operating table 1133.12 ALPHAMAXX

is suitable for the following surgical procedures:

• in the thorax and abdominal areas

• in the head area

• in gynaecology

• in urology

• in orthopaedics

If required, separate accessories can be attached to

the operating table.

The table top is subdivided into 6 sections:

• head plate (removable)

• upper back plate (removable)

• lower back plate

• seat plate

• split leg plates

The lower back, seat and leg plates are adjusted under

motor power.

The head plate and the upper back plate are adjusted

manually.

X-ray cassettes can be inserted underneath the back

plate.

The side rails are used to attach accessories.

1133.12B1/B3/F1/F3

NO

YES

Fig.III-2: Warning sign for table top height

For patients weighing up to 135 kg (300 lb), place

the operating table on its castors (UNLOCK) only

up to the maximum table top height of 940 mm

(37 in)! The warning sign is not seen!

For patients weighing between 135 kg and max.

225 kg (300 - 500 lb), place the operating table

on its castors (UNLOCK) only when the table top

is in its lowest position.

Using the UNLOCK function for patient weights

exceeding 225 kg (500 lb) is not permissible.

1.1 Versions

Various versions of the operating table 1133.12 are available.

1133.12B1 Operating table incl. SFC padding and

standard side rails

1133.12B3 Operating table incl. SFC padding, standard side rails and autodrive in the base

1133.12F1 Operating table incl. SFC padding and US

side rails

1133.12F3 Operating table incl. SFC padding, US side

rails and autodrive in the base

The corded hand control, the IR transmitter, the charging station for the IR transmitter as well as head plates,

upper back plates and leg plates are to be ordered separately. The order numbers are listed in chapters VIII and

IX.

8

GA113312EN02

Page 9

1133.12B1/B3/F1/F3

III. General description

2. Control of functions

The electrohydraulic functions of the operating table can

be activated using one of the following control elements:

• Corded hand control (see 2.1)

• Override system = emergency operation(see 2.2)

or optionally via:

• IR remote control (see 2.3)

• Wall control panel (see 2.4)

• Foot switch (see 2.5)

The corded hand control and the IR remote control have

almost the same function buttons.

The override system is used only for emergency operation of the operating table.

The foot switch functions are: operating table height,

Trendelenburg/reverse Trendelenburg and another function (lateral tilt, longitudinal shift, back plate or leg plate

adjustment)

Note:

For safety reasons, only the following functions can

be used when the UNLOCK function is activated:

TRENDELENBURG and REVERSE TRENDELENBURG.

The sockets (14) for the corded hand control and

the foot switch are located on the override panel.

Note:

If the functions are controlled simulataneously by

more than one operating element, each movement

of the operating table is stopped immediately.

Hazard of operating table tipping over!

Make sure to remove any potential hindrances

before adjusting the operating table!

Hazard of damage during adjustments!

Do not place any objects on the operating table

base.

Hazard of pinching!

Do not reach under the table top or between the

table top components during adjustment procedures.

Injury hazard!

If the patient is not secured during transportation, when adjusting the operating table or when

positioning the patient (particularly when the slope

feature is used), then the patient could slip, uncontrolled, off the operating table. Always secure

the patient and maintain continuous observation.

GA113312EN02

Hazard of damage!

When not in use, hang up the corded hand control at the side rail of the operating table.

Make sure the cable of the hand control does not

get jammed when adjusting the operating table.

9

Page 10

III. General description

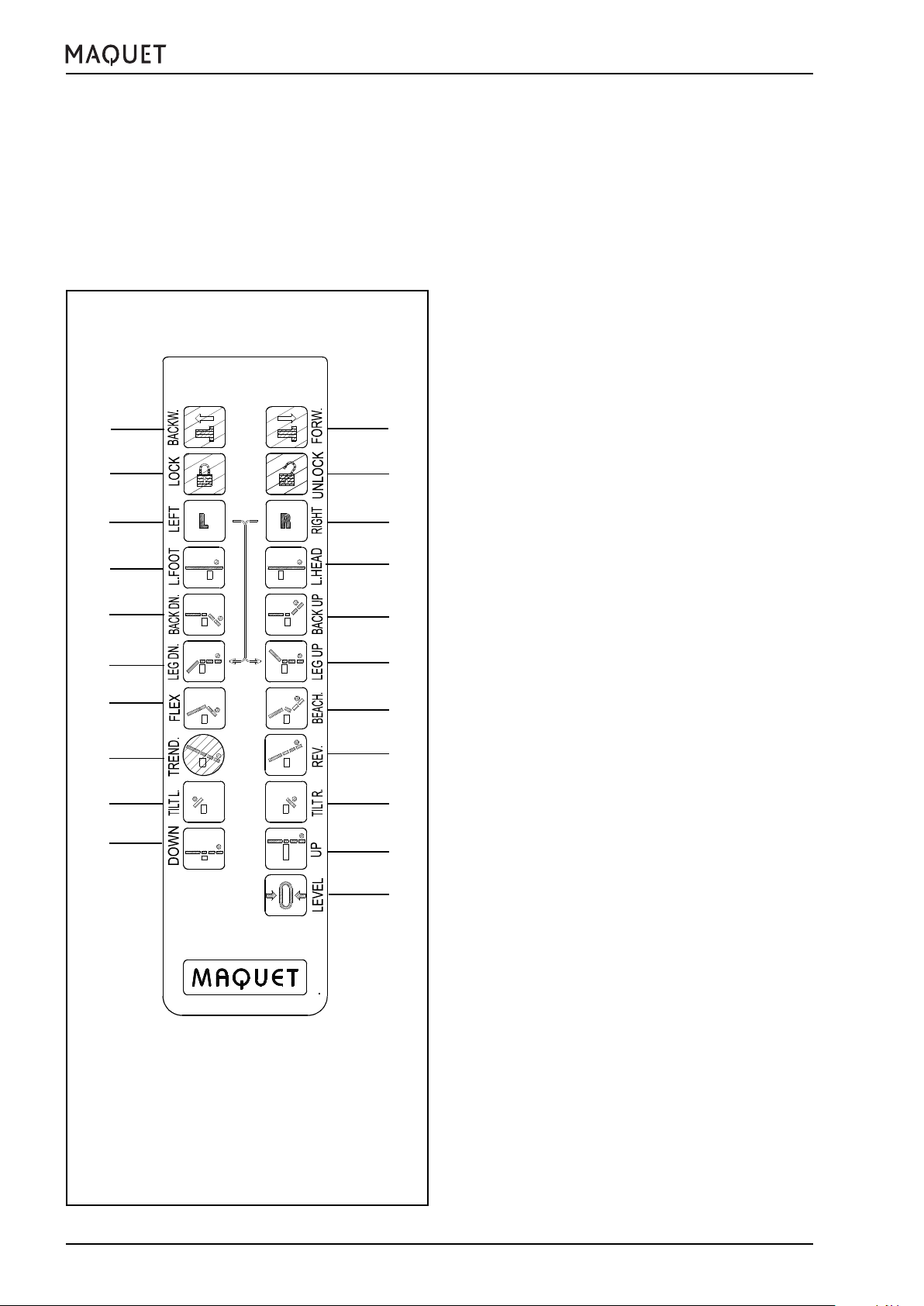

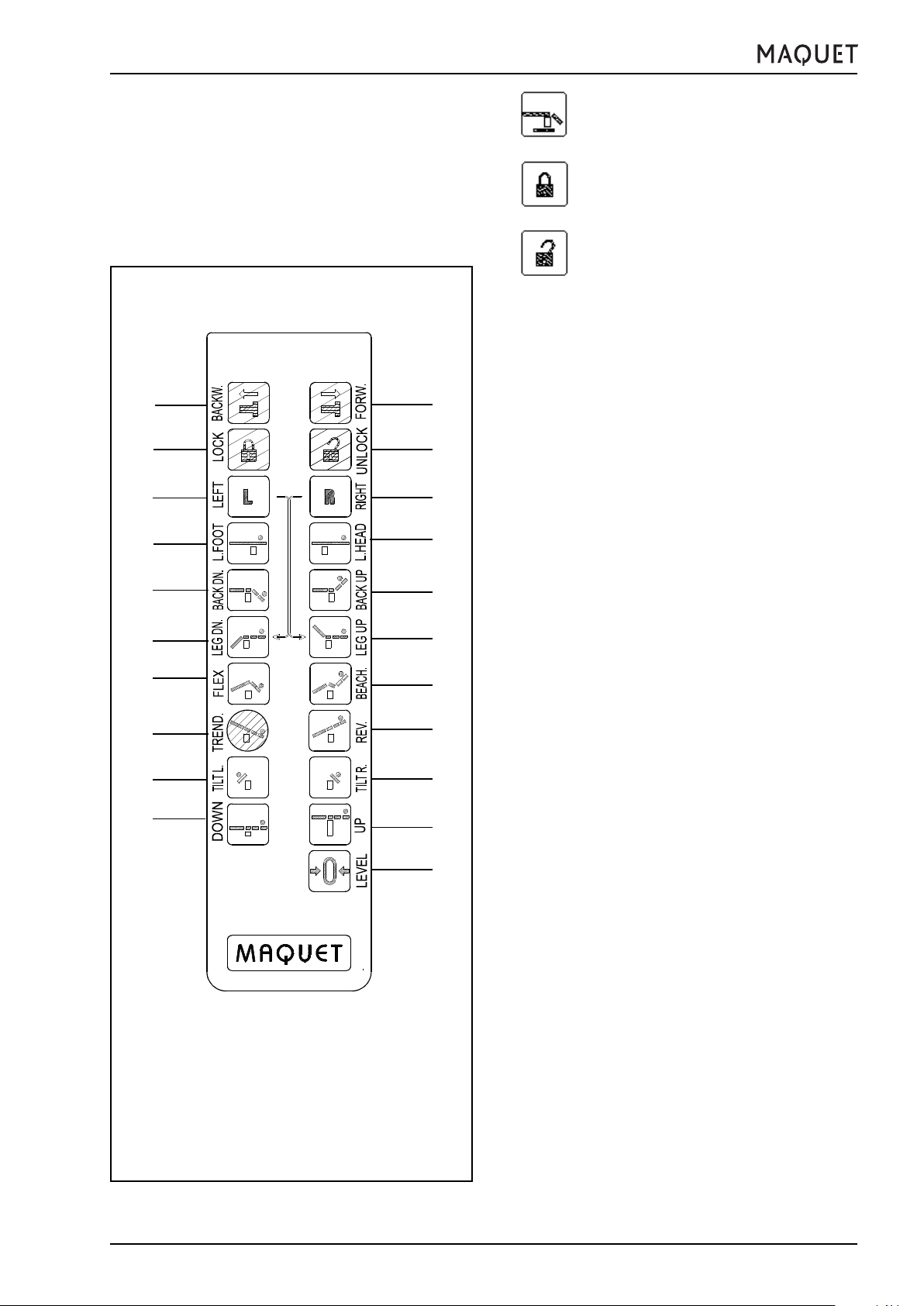

2.1 Corded hand control

The corded hand control is connected to the operating

table at one of the two sockets (14) (for simultaneous

connection of corded hand control and foot switch) on

the override panel (13). The electric motor-powered adjustments of the operating table can be made immediately by pressing down the corresponding function button.

1133.12B1/B3/F1/F3

v w

t

r

p

l

j

g

e

c

a

m

a) Table top

b) Table top

c) Tilt

d) Tilt

e) Trendelenburg position

f) Reverse Trendelenburg position

g)

Flex

Activates the functions

and

u

s

q

k

h

f

d

b

z

m) Slope (lower) back plate

w) Displace the operating table

reached to force the surgical field upward.

h)

Beach chair

Raises the back plate, moves the entire table

top into the Trendelenburg position and lowers the leg plates. The patient is moved into a

seated position.

j) Slope (both) leg plates

k) Slope (both) leg plates

l) Slope (lower) back plate

p) Shift table top

q) Shift table top

r) Adjust the left leg plate individually

The left leg plate can be controlled individually only in conjunction with the appropriate

function button for the desired movement, either downward (r+ j) or upward (r + k), under

two-button control.

s) Adjust the right leg plate individually

Analogous to the control for the left leg plate,

individually downward (s + j) or upward (s +

k), under two-button control.

t)

Lock

Press the LOCK button for at least 1 second:

the table will be immobilized automatically.

u)

UNLOCK

To unlock the operating table, press the UNLOCK button for at least 1 second, then the

castors will be extended automatically and

the table can be displaced.

v)

Autodrive in the base

Displace the operating table

ward the head end).

the foot end).

When displacing the operating table under

motor power, it must be guided with one hand.

down

up

to the left

to the right

position

(view from head end)

(view from head end)

back plate down

toward the foot end

toward head end

reverse Trendelenburg

until a flex position is

downward

upward

downward

upward

1133.12B2 (optional)

backward

forward

(to-

(toward

10

GA113312EN02

Page 11

1133.12B1/B3/F1/F3

III. General description

z) 0-position

Resets the lateral tilt, Trendelenburg/reverse

Trendelenburg, back plate and leg plate adjustments to the horizontal position. If the

function button z is pressed, the operating

table top will first reset the adjustments in the

following order: lateral tilt, Trendelenburg/reverse Trendelenburg, back plate. An acoustic

signal will indicate that these adjustments have

been reset. Release the function button z and

press once again to reset the leg plates to

the horizontal position; if the leg plates have

been adjusted individually, they will be positioned in parallel to one another.

Notes:

Manual adjustment functions such as those for the

upper back plate, head plate and leg plate abduction will not be affected by the IR remote control

(and, as a consequence, neither by the automatic

0-position function).

The transmission power for the IR remote control

ist sufficient to operate the draped operating table

even from a greater distance. If the desired adjustment is not executed by the operating table, even

though a function button is depressed completely,

then you should re-aim the hand control or move to

another position in the OR. In such cases the receiver is probably being blocked by a person’s body.

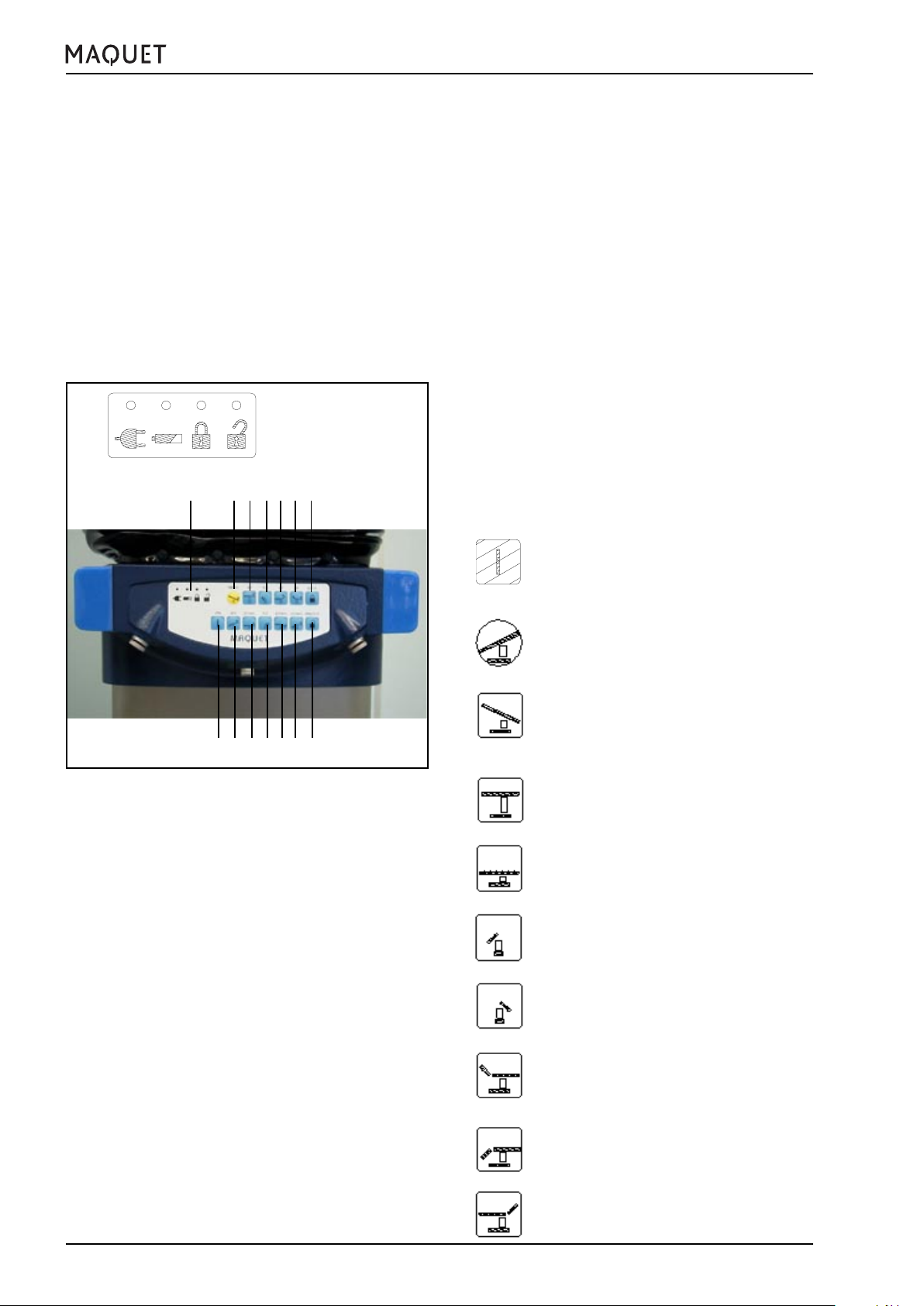

Fig.III-4: Override control panel

13

2.2 Override system = emergency operation

2.2.1 Override control panel

In case of a malfunction or if the hand control is defective, you can control the operating table functions via

the control panel (13) on the upper column casing (emergency operation).

Note:

Always press the ON button together with the desired function button.

Note:

If the operating table batteries are discharged, the

override system will only work when the operating

table is connected to the mains.

Note:

When using the override control panel, the collision

protection feature is not activated. Avoid extreme

adjustments - the combination of maximum Trendelenburg/reverse Trendelenburg position and maximum lateral tilt.

GA113312EN02

11

Page 12

AC

EGILN

III. General description

The functions of the override control panel are shown in

the following:

A) LED-Status indicators of the operating table

Note:

The status indicators are only active when the

corded hand control or the IR remote control is

switched on.

Description of the symbols from left to right:

• Mains connection: the green LED lights up

when the operating table is connected to the

mains.

• Battery charge level: the red LED flashes when

the operating table batteries have to be recharged as soon as possible.

• Operating table is immobilized: the green LED

lights up when the operating table is immobilized, i.e.

• Operating table castors are extended:

the red LED lights up when the operating table is on its castors and can be displaced, i.e.

UNLOCK

LOCK

activated.

activated.

1133.12B1/B3/F1/F3

DFHK

B

Fig.III-5: Override control panel buttons

MO

B) ON

switches the motor on and must be

pressed in addition to each function but-

ton

C) TREND

Table top into Trendelenburg position

D) REV.

Table top into reverse Trendelenburg

position

E) UP

Table top up

F) DOWN

Table top down

G) TILT

Lateral tilt to the left

12

H) TILT

Lateral tilt to the right

I) UP

Slope back plate upward

K) DOWN

Slope back plate downward

L) UP

Slope leg plate upward

GA113312EN02

Page 13

1133.12B1/B3/F1/F3

v w

t

r

III. General description

M) DOWN

N) LOCK

O) UNLOCK

2.3 IR remote control (optional)

The operating table can be equipped with an IR remote

control, as desired.

u

s

The required charging station for the IR remote control

is not included with the order no. 1133.91A0.

The layout of the function buttons for the operating table adjustments is the same on the corded hand control and the IR remote control apart from one exception:

Slope leg plate downward

Operating table immobilized

Operating table on its castors, can be displaced

m

q

k

h

f

d

b

z

There are no function buttons for the autodrive in the

base. For safety reasons, you can only activate this

function via the corded hand control.

Note:

When switching on the IR remote control, the LED

status indicators on the control panel on the operating table column are active (see chapter „Override

system“).

Note:

When using the IR remote control or the corded

hand control, the electronics generally avoid collisions with the floor or parts of the operating table.

If accessories with manual adjustment functions are

mounted, then it is not always possible to avoid

collisions.

p

l

j

g

e

c

a

Fig.III-6: IR remote control

GA113312EN02

13

Page 14

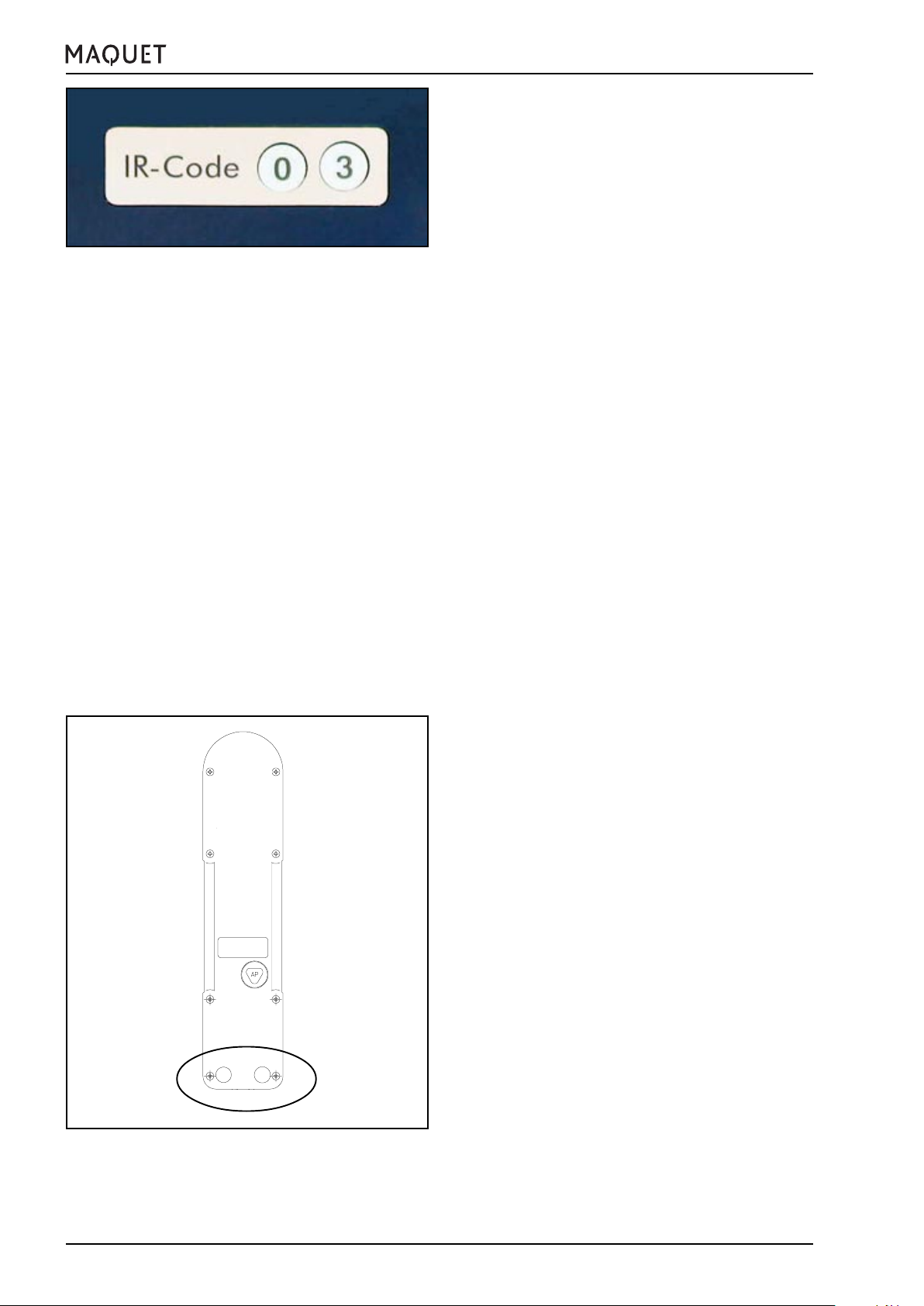

Fig.III-7: IR code

III. General description

2.3.1 IR system code

Every IR remote control is unequivocally assigned to an

operating table by way of the electronic encoding. The

operating table has the same system code as the associated IR remote control.

You can see from the label at the operating table column whether IR reception has been activated for this

operating table. If the IR code is crossed out, then the

infrared reception is blocked for the operating table.

The encoding for the operating table and the IR remote

control as well as activating/blocking the IR reception

are performed by authorized personnel.

The operating table and the associated IR remote control are marked by adhesive labels bearing the system

code which has been set:

• The adhesive labels are affixed to the operating table column next to the IR receiver.

• The adhesive labels are affixed to the back of the IR

remote control.

The two dot-shaped adhesive labels bear a number from

0 to 9 or a letter from A to F :

• left 0,1,2,...,A,B,...,F

• right 0,1,2,...,A,B,...,F

1133.12B1/B3/F1/F3

Fig.III-8: IR code

Examples of IR system codes which have been set:

Identification: 1 5

3A

C2

DA

Note:

The order of the identification letters/numbers is

singificant, i.e. the IR system code 4 B does not

equal B 4.

Note:

Always leave the IR remote control at the working

location for the associated operating table, since

the operating table can be adjusted only by using

this particular IR remote control.

Of course, the operating table can be adjusted via a

corded hand control or the override system at any

time, regardless of the IR remote control.

Note:

The transmission power of the IR remote control ist

0

3

sufficient to operate the draped operating table even

from a greater distance. If the desired adjustment is

not executed by the operating table, even though a

function button is depressed completely, then you

should re-aim the IR remote control or move to another position in the OR. In such cases the receiver

is probably being blocked by a person’s body.

14

GA113312EN02

Page 15

1133.12B1/B3/F1/F3

Fig.III-9: Charging station

III. General description

2.3.2 Charging station

Recharging the IR remote control:

• Connect the mobile charging station to the mains.

The green LED in the charging station indicates whether

the required supply voltage is available or not.

• Place the IR remote control in the charging station

as follows:

– Keypad visible, in the position for normal use,

i.e. the 0-position button (x) is located at the

bottom right

– the base of the hand control is in contact with

the lower limit stop of the holder.

Note:

The capacity of the rechargeable battery for the IR

remote control is sufficient to ensure several day’s

use of the operating table. Nevertheless, we recommend that you insert the hand control into the holder

of the charging station so that the battery is recharged overnight.

Fig.III-10: Charging station

Fig.III-11: IR wall control panel

2.4 Control via IR wall control panel

The desired adjustment functions of the operating table

can be controlled by means of the function buttons (1)

at the wall control panel or the separate IR hand control

(2).

Note:

The IR wall control panel can be mounted to the

wall at a later date.

For further information please refer to the operating

instructions GA115095GBxx.

GA113312EN02

15

Page 16

14

Fig.III-12: Foot switch

III. General description

2.5 Control via foot switch 1009.81DX (optional)

14

Connect the foot switch to one of the two sockets (14)

at the column head.

Three functions each can be activated using the following foot switch versions:

1009.81D0 Foot switch with the functions:

1009.81D1 Foot switch with the functions:

1009.81D2 Foot switch with the functions:

1009.81D3 Foot switch with the functions:

Note:

Observe the operating instructions for the foot

switch.

1133.12B1/B3/F1/F3

height, Trendelenburg/rev. Trendelenburg, back plate

height, Trendelenburg/rev. Trendelenburg, lateral tilt

height, Trendelenburg/rev. Trendelenburg, leg plates

height, Trendelenburg/rev. Trendelenburg, longitudinal shift

Fig.III-13: „Neurolock“ function

2.6 „Neurolock“ function

If requested, the MAQUET service personnel can set

the „Neurolock“ function at the operating table.

This function avoids adjustments of the table position

due to unintentional actuation of the buttons on the hand

control.

a+b) The „Neurolock“ function can be unlocked by

pressing simultaneously the buttons „table top

down“ (a) and „table top up“ (b) on the control

module. The operating table can now be adjusted.

If no further buttons on the control module are

actuated for approx. 8 seconds, then the

„Neurolock“ function will be activated again. Adjusting the operating table again is only possible

after actuating simultaneously the „table top

down“ (a) and „table top up“ (b) function buttons.

Note:

The „table top down“ and „table top up“ functions

cannot be actuated simultaneously using the foot

switch 1009.81X0.

Use an IR hand control or a corded hand control to

unlock the „Neurolock“ function.

16

GA113312EN02

Page 17

1133.12B1/B3/F1/F3

III. General description

3. Table top

3.1 General features

The table top 1133.12 has been designed to meet the

requirements of various surgical disciplines. Selecting

from a variety of modules lets you adapt the geometry

of the table top to accommodate the individual patient

height.

The table top is divided into a maximum of 6 sections,

depending on the type of leg plate and upper back plate

module selected.

• Head plate

• Upper back plate (extension segment)

• Lower back plate

• Seat plate

• Leg plates

The table top is equipped with a motor-powered

longitudinal shift feature through 230 mm, and motorpowered adjustment functions for the back plate and leg

plates. Furthermore the mounting sockets for the leg

plates automatically detect whether one-piece

components have been installed, thus increasing

reliability and safety in use. Depending on the application,

the adjustment ranges for the accessories mounted at

the leg plate mounting point may be restricted. Please

refer to the operating instructions for the accessory in

question.

Attaching different back plate modules at the lower/

upper back plate mounting point enables positions

perfectly suited to the patient and more favourable

functional working conditions for the surgical team and

the procedure. Guide rails for X-ray cassettes are

located underneath the back plate. The side rails are

used to attach accessories. Various head positioning

accessories can be mounted at the head end of the back

plate modules instead of the head plate (see chapter V,

Patient positioning).

GA113312EN02

Note:

According to the IEC 60601-1 international standard, the operating table is designed for safe handling of a patient weight of 450 kg (1000 lb). When

using accessories, the maximum load may be restricted. Please observe chapter VIII List of accessories.

17

Page 18

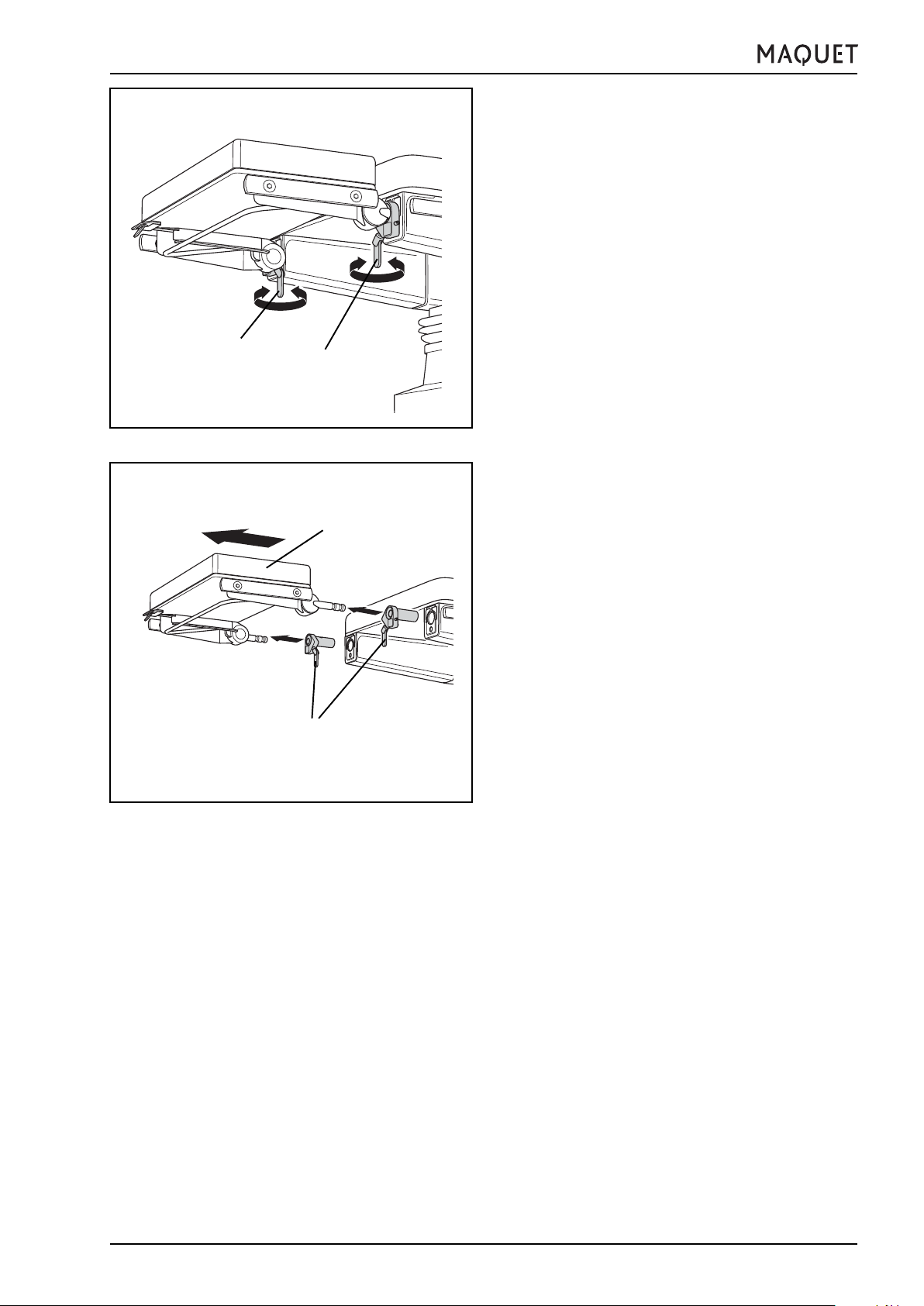

III. General description

3.2 Mechanical adjustments

3.2.1 Mount / remove the head plate

Note

Use and handling are described in detail in the operating instructions for this product.

Note

The head plate adapter 1130.81A0 is required to

mount head plates at the back plate mounting point.

3.2.1.1 Mount the head plate using the head plate

adapter 1130.81A0.

Note

The head plate adapter consists of a left and a right

part. Please observe the markings L and R.

If the adapters are mixed up, the distance of the

mounting sockets is not correct.

1133.12B1/B3/F1/F3

A

B

Fig.III-14: Mount the head plate adapter

C

A

B

Mount the head plate

⌧ Insert the pins of the two head plate adpaters

1130.81A0 (A) in the sockets (B) at the back plate

mounting point, up to the stop.

⌧ Insert the head plate pins (C) into the mounting

sockets (D) at the front of the table top, up to the

stop.

D

Fig.III-15: Mount the head plate

18

D

GA113312EN02

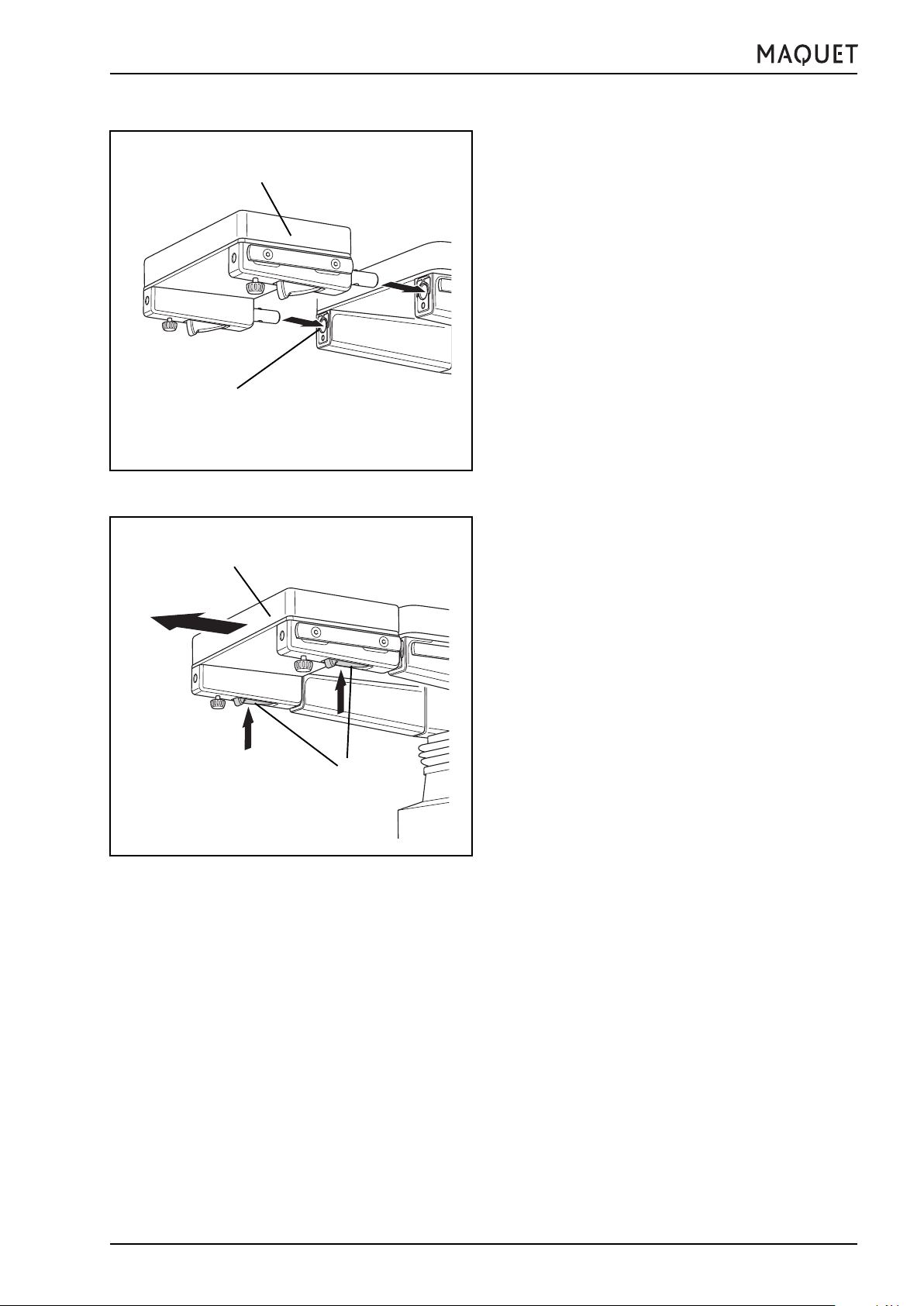

Page 19

1133.12B1/B3/F1/F3

III. General description

⌧ Tighten the locking screws (E).

⌧ Pull on either side of the seat plate extension to

ensure that it is properly secured.

E

Fig.III-16: Mount and secure the head plate

E

C

E

Remove the head plate

⌧ Loosen the locking screws (E).

⌧ Remove the head plate (C).

⌧ Remove the two head plate adapters 1130.81A0.

Fig.III-17: Remove the head plate

GA113312EN02

19

Page 20

III. General description

3.2.1.2 Mount / remove the joint adapters 1131.82A0

Note

The joint adapter consists of a left and a right part.

Please observe the markings L and R.

If the joint adapters are mixed up, they cannot be

used since the eccentric levers will point to the middle of the table top.

Mount the joint adapter

⌧ Insert the left joint adapter 1131.82A0 (L) and the

right joint adapter 1131.82A0 (R) with their pins fully

L

1

R

in the sockets (A) of the back plate mounting point,

at the front of the table top.

1133.12B1/B3/F1/F3

A

Fig.III-18: Insert the joint adapter

L

Fig.III-19: Swivel the joint adapters downward

R

⌧ Swivel the joint adapters (L) and (R) downward in the

direction of the arrows, up to the stop.

20

GA113312EN02

Page 21

1133.12B1/B3/F1/F3

Fig.III-20: Check to ensure proper attachment

III. General description

⌧ Pull on the adapter to ensure that it is properly

secured.

Remove the joint adapters

R

L

Fig.III-21: Remove the joint adapters

⌧ Swivel the joint adapters (L) and (R) upward in the

direction of the arrows, up to the stop.

⌧ Pull out the joint adapters (L) and (R).

GA113312EN02

21

Page 22

A

B

C

1

Fig.III-22: Remove the back plate

III. General description

3.2.1.3 Change out accessories at the joint adapter

1131.82A0

⌧ If a back plate (A) is already mounted: Hold the back

plate.

⌧ On either side:

Press on the safety push-button (B) and open the

eccentric lever (C).

⌧ Raise the back plate (A) until it is in an almost vertical

position (approx. 75°) and remove it from the joint

adapter mounting point.

1133.12B1/B3/F1/F3

Fig.III-23: Mount the back plate

⌧ Insert the other back plate (D) from above, in an

almost vertical position (approx. 75°), in the joint

D

E

adapter mounting point, lower it until it is in the

desired position and hold it.

⌧ On either side:

Retighten the eccentric lever (E).

22

GA113312EN02

Page 23

1133.12B1/B3/F1/F3

A

B

Fig.III-24: Mount the extension segment

III. General description

3.2.2 Extension segment 1131.31B0/F0

The table top is extended to position taller patients or

to optimize the patient position.

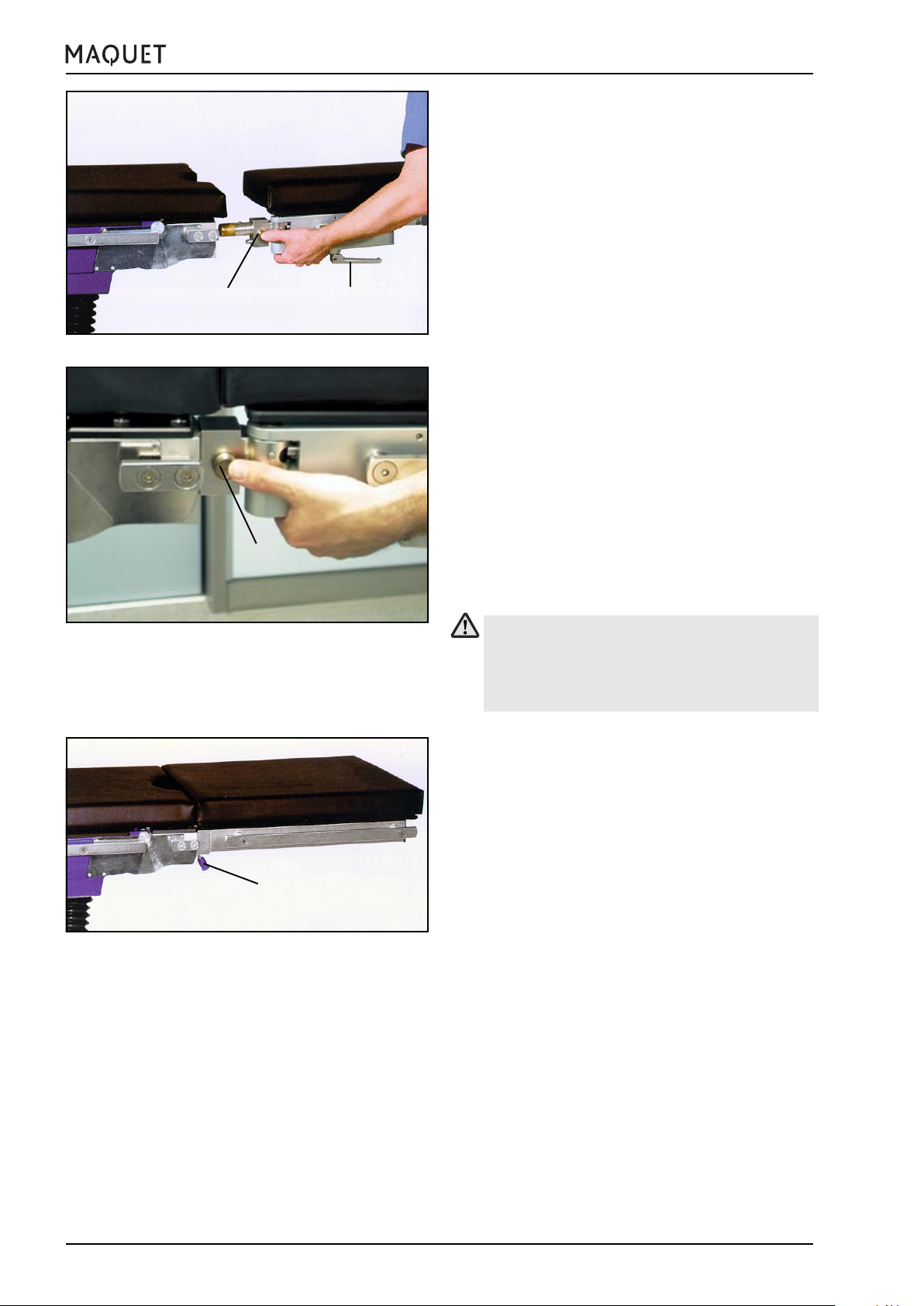

Mount the extension segment

⌧ If necessary, remove the head plate

⌧ Insert the pins of the extension segment (A) in the

mounting sockets (B) at the front of the table top, up

to the stop.

The extension segment is locked automatically.

⌧ Pull on either side of the seat plate extension to

ensure that it is properly secured.

A

C

Fig.III-25: Remove the extension segment

Remove the extension segment

⌧ Press the two levers (C) against the extension

segment.

⌧ Remove the extension segment (A) without binding.

GA113312EN02

23

Page 24

A

Fig.III-26: Accessory recognition feature

III. General description

3.3 Collision protection at the leg plate mounting point

The table top is fitted with an accessory recognition

feature at the leg plate mounting point. When using

encoded leg plate accessories, this feature recognizes

the accessories and avoids collision with the operating

table or the floor during leg plate adjustment.

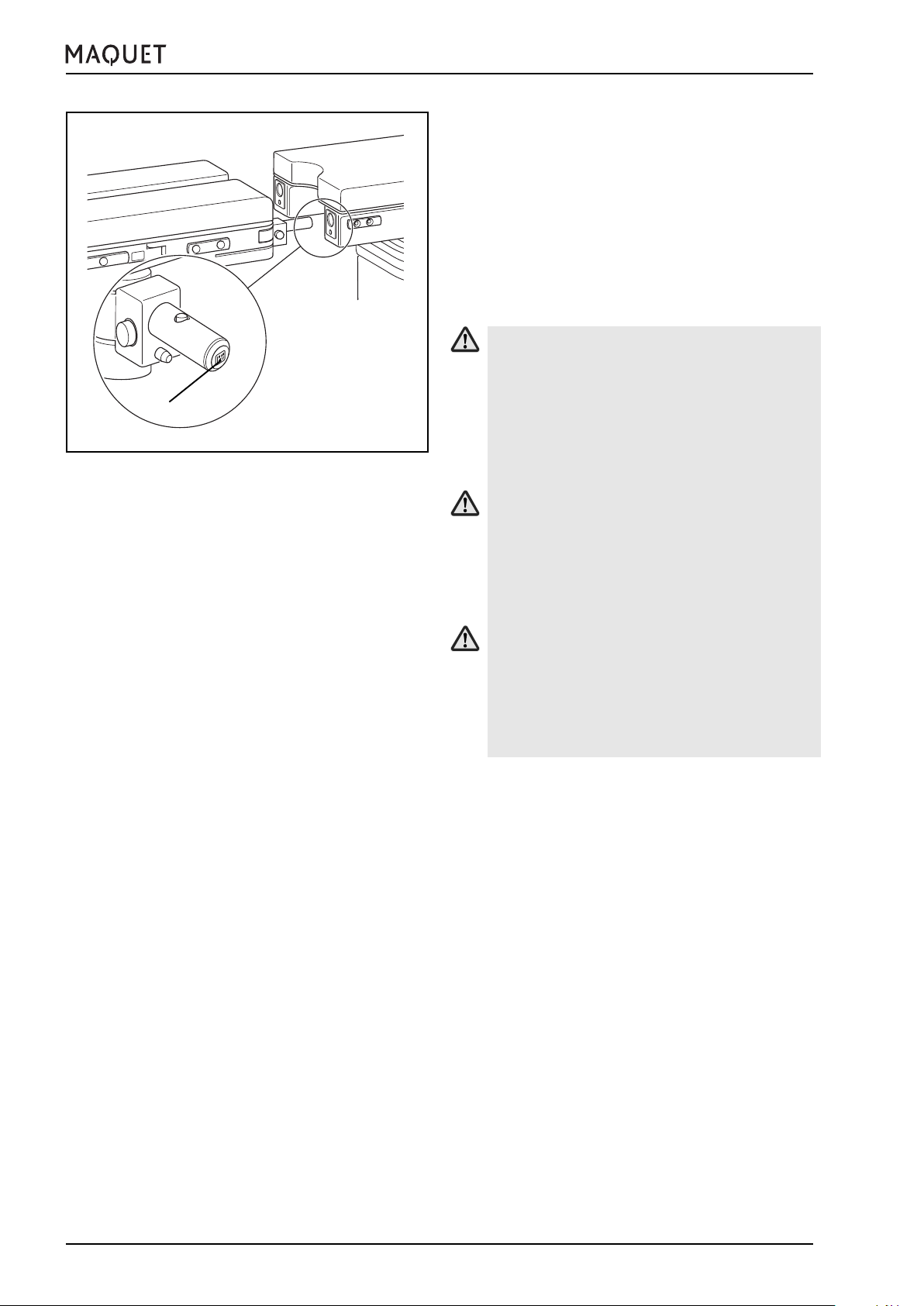

Encoded accessories are fitted with a “code plug” (A) at

the front of the mounting pin.

Accessories which are not encoded at the mounting pin

can be used at the leg plate mounting point; however,

there is no collision protection when making adjustments.

Injury hazard!

It is possible to use accessories which are not

encoded at the leg plate mounting point: this may,

however, result in collisions during certain adjustment procedures.

Observe the movement during the adjustment

procedure and be sure to avoid any collision.

1133.12B1/B3/F1/F3

Injury hazard!

Additional accessories mounted at the side rails

will not be recognized by the collision protection

feature.

Observe the movement during the adjustment

procedure and be sure to avoid any collision.

Injury hazard!

A leg plate which is mounted in addition at the

seat plate extension will not be recognized by

the collision protection feature.

Observe the movement during the adjustment

procedure and be sure to avoid any collision.

Functional sequence

⌧ Press and hold any button.

The collision protection is activated and will stop

the downward movement in time.

⌧ Release the button.

24

GA113312EN02

Page 25

1133.12B1/B3/F1/F3

III. General description

3.3.1 Seat plate extensions

The seat plate extension is suitable for use during procedures in gynaecology and urology.

Seat plate extension 1133.55BC

• To mount or remove the seat plate extension, actuate the release lever (A) and insert the seat plate

extension in the mounting sockets up to the stop or

remove it.

• The seat plate extension cannot be adjusted.

A

Fig.III-27:Seat plate extension 1133.55BC

A

B

Fig.III-28: Mount the seat plate extension

Seat plate extension 1131.55B0/F0

Mount the seat plate extension

⌧ If necessary, remove the leg plate.

⌧ Insert the pins of the seat plate extension (A) in the

mounting sockets (B) at the front of the table top, up

to the stop.

The seat plate extension is locked automatically.

⌧ Pull on either side of the seat plate extension to

ensure that it is properly secured.

The seat plate extension can be adjusted.

Remove the seat plate extension

A

C

Fig.III-29: Remove the seat plate extension

GA113312EN02

⌧ Press the two levers (C) against the seat plate

extension.

⌧ Remove the seat plate extension (A) without binding.

25

Page 26

10

Fig.III-30: Mount the split leg plate

III. General description

3.3.2 Leg plates Split leg plate 1133.53BC

• To mount the split leg plates, press the push-button

(10) and insert the leg plate pins in the mounting

sockets, up to the stop (Abb. III-30).

• The leg plate is locked as soon as the push-button

is released (10) (Fig.III-31).

• The slope of the leg plate is adjusted

electrohydraulically by means of the control mod-

9

ule.

• To abduct the leg plate, open the eccentric lever (9)

and set the desired abduction angle.

• Retighten the eccentric lever after making the adjustment.

• A dual-pivot joint is used to abduct the leg plates

1133.53 so that on the one hand the surgeon has

access to the patient’s body from the foot end while

at the same time the patient’s leg is given sufficient support.

1133.12B1/B3/F1/F3

10

Fig.III-31: Unlock the leg plates

A

Fig.III-32: Mount / remove the single-section leg plate

• To remove the leg plate, press the push-button (10)

and pull the leg plate out of the mounting sockets.

Before setting the leg plates in the flat and horizontal position (0-position), be sure to observe

that they are not positioned one on top of the

other.

Collision hazard! Injury hazard!

Single-section leg plate 1133.58BC

• To mount or remove the single-section leg plate,

acuate the release lever (A) and insert the leg plate

in the mounting sockets up to the stop or remove it.

The single-section leg plate is suitable for surgical

procedures in orthopaedics ans vascular surgery

where the patient’s legs are to be X-rayed. The slope

of the leg plate is adjusted electrohydraulically by

means of the control mudule.

26

GA113312EN02

Page 27

1133.12B1/B3/F1/F3

III. General description

3.4 Table top padding

The operating table top is supplied with table top plates

and SFC pads secured with Velcro straps.

3.5 Accessories

Mount only the accessories listed in chapter VIII.

Do not use non-original accessories which affect the

longitudinal geometry of the table top without first consulting with MAQUET.

Accessories which are mounted on the side rails of the

operating table provided for this purpose should also be

drawn exclusively from the MAQUET line of accessories. When developing MAQUET accessories, close

attention is paid to careful harmonization with the

MAQUET operating tables. This means that when the

accessory is used for its intended purpose, the maximum possible safety for patients and staff will be attained.

Accessories (to be mounted on the side rails) which

are made by other manufacturers must be particularly

carefully examined to ensure that they do not represent

a hazard to the patient and the staff or to the operating

table (due to possible collisions). Particularly accessory units with high weights or long lever arms (such as

hand operating tables, retractor systems etc.) must be

expressly permitted by MAQUET.

Injury hazard!

Do not use worn or damaged accessories!

Injury hazard!

Make sure to fasten the table top accessories

properly!

Injury hazard!

Collisions between accessories, the operating

table and the patient can occur when adjusting

or displacing the operating table.

Observe the adjustment procedure and avoid collisions.

GA113312EN02

27

Page 28

III. General description

4. Autodrive in the base

The operating table version 1133.12B3/F3 is equipped

with an autodrive in the base. The operating table will

start moving slowly and will slow down softly after releasing the function button (i or k).

i) BACKW.

k) FORW.

To move the operating table, proceed as follows:

• Remove the mains cable from the operating table

• Fully extend the operating table castors (press UN-

LOCK button)

• Guide the operating table with at least one hand

• Press function button (v or w) and the operating ta-

ble will move in the selected direction.

• Release function button (v or w) and the operating

table will gently brake until it stops.

1133.12B1/B3/F1/F3

Move the table backward in the longitudinal

direction

Move the table forward in the longitudinal

direction

Fig.III-33:Overide control panel

Note:

If the LEDs for the LOCK and UNLOCK functions

are flashing, press the UNLOCK button.

Guide the operating table with at least one hand

during displacement.

Note:

When moving the operating table, do not press the

override system buttons since this will cause several functions to be activated simultaneously and

involve the hazard of injury or collision with potential

hindrances.

Note:

The operating table can only be moved laterally if

you have not activated the BACKW. or

FORW.functions!

28

GA113312EN02

Page 29

1133.12B1/B3/F1/F3

IV. Use of the operating table

IV. Use of the operating table

1. General

The operating table’s electrical conductivity has

to be checked once a year! This check should

be performed only by trained servicing personnel.

Note:

Connect the operating table to the potential equalization system in the OR during the surgical procedure (see DIN VDE 0100 standard, Part 1).

For this purpose, connect the potential equalization pin with the cable to a potential equalization

point in the OR, next to the patient.

A potential euqlization cable (5 m) with connectors

at both ends is included in the scope of supply of

the operating table.

2. Operation on battery power

When operating the table with the integrated batteries

with no connection to the mains supply, the operating

table meets the requirements of the Class AP Test for

Anaesthesiological Operation. It may be used in areas

subject to explosion hazard, zone M.

Battery operation of the table is always preferable to

operation on mains power.

Th capacity of the fully charged batteries allow approx.

one week’s use of the operating table, depending on

how often adjustments are made.

If the charge level of the batteries drops below a minimum permissible value, this is indicated by the red operating table status indicator LED when the operating

table is switched on.

Note:

At less than 10% charge the operating table will

shut down automatically.

Recharge the batteries

Discharged batteries will attain 90% of their charging

capacity after approx. 5 hours (100% after approx. 10

hours).

The batteries are automatically recharged as soon as

the operating table is connected to the mains by means

of the mains cable.

GA113312EN02

29

Page 30

IV. Use of the operating table

Note:

We recommend to recharge the batteries overnight,

but at least every 2 days, even if „low charge level“

of the batteries has not been indicated yet.

Regular recharging of the batteries will ensure sufficient battery power for the daily OR programme. It

will also serve to prolong the useful life of the batteries.

1133.12B1/B3/F1/F3

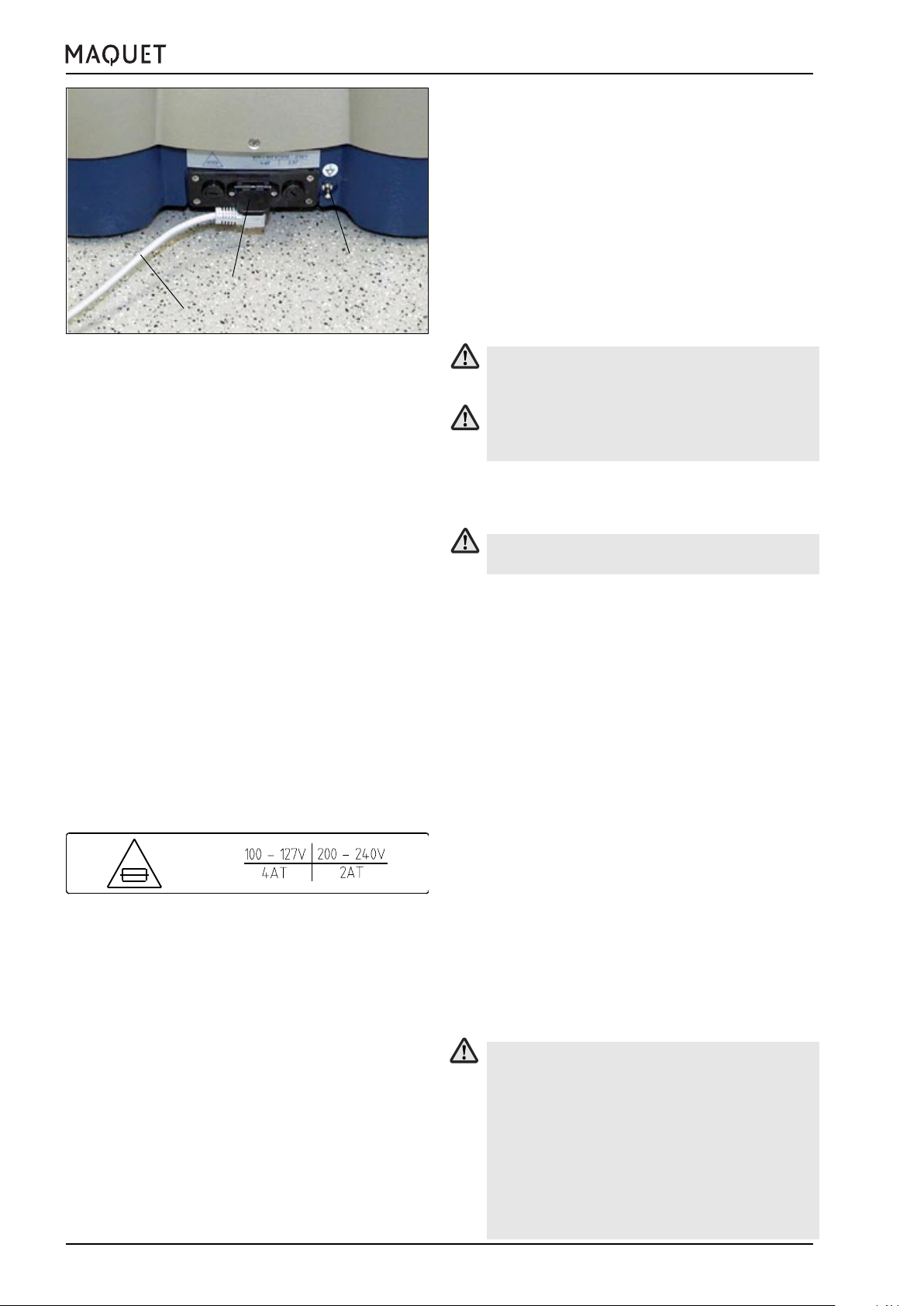

Potential equalization

Socket for mains cable

Mains cable

Fig.IV-1: Operating table connections

3. Operation on mains power

The batteries are automatically recharged as soon as

the operating table is connected to the mains by means

of the mains cable.

There is no explosion protection while recharging the batteries or when the operating table is

on mains power.

The operating table is disconnected from the

mains by means of the mains plug.

Connect the operating table to the mains by means of

the mains cable.

When connecting or removing the mains cable,

observe the correct order of the procedure!

• When connecting the mains cable, first of all

connect the operating table and then connect

the plug to the mains.

• When disconnecting the mains cable, first of

all pull the plug out of the socket and then

remove the cable from the operating table.

Fig.IV-2: Fuses

Note:

Damaged cables must be replaced immediately.

When replacing fuses, please note:

1. Unplug the operating table

2. Unscrew the two fuse holders located on the right

and left next to the socket for the mains connection using a coin or a large screw driver.

3. Insert the appropriate fuse according the the table

opposite

4. Reinsert the fuse holders

4. HF surgery, use of defibrillators

In the field of HF surgery and when using defibrillators,

be absolutely sure to observe the following safety instructions:

Hazard of burns!

When using HF surgical equipment, defibrillators

and defibrillation monitors, make sure to avoid

that the patient comes into contact with metal

parts of the operating table, the table tops or the

accessories. Also make sure to avoid that the

patient is lying on moist underlays or sheets on

the conductive pads.

Be absolutely sure to comply with the manufacturers operating instructions!

30

GA113312EN02

Page 31

1133.12B1/B3/F1/F3

V. Patient positioning

V. Patient positioning

1. General

The 1133.12 modular operating table offers the possibility to use various modules as the back plate, thus providing advantages for adaptation of the patient position

to different surgical disciplines.

Note:

The NORMAL patient orientation is preferable to

the REVERSE patient orientation. In the NORMAL

patient orientation the patient’s head is lying above

the long end of the operating table base (see

sketch).

In accordance with generally accepted hygiene

standards, the operating table top is to be covered with surgical drapes during use.

Observe the prescribed orientation for the patient.

Never position the patient’s upper part of the body

on the leg plate.

Fig.V-1: The preferred patient orientation

Injury hazard!

Risk of injury due to the operating table tipping

over or material breaks when using non-approved

accessories. The patient positions vary, depending on the patient weight (see sketches in chapter V, Patient positioning) and the operating table accessories which may be employed (see

Accessories list, chapter VIII).

Observe the specifications for positioning the

patient according to his/her weight.

Injury hazard!

If the patient is not secured during transportation, when adjusting the operating table or when

positioning the patient (particularly when the slope

feature is used), then the patient could slip, uncontrolled, off the operating table. Always secure

the patient and maintain continuous observation.

GA113312EN02

31

Page 32

Fig.V-2: Patient position

V. Patient positioning

Injury hazard!

If the operating table is not wide enough to enable an ergonomic patient position, then the patient may be injured.

The table width extenders (1001.75A0 / 76A0)

may be mounted on the side rails of the operating table to enable ergonomic patient positioning.

Only one infusion stand (1009.01C0), one anaesthesia screen (1002.57A0), one wristlet

(1002.24C0) and one arm protector (1002.25A0)

may be mounted to the table width extenders

(1001.75A0 / 76A0).

When positioning the patient, be sure to observe

that the patient is lying above the centre of the

column in the lateral direction (see sketch).

Injury hazard!

It is not permissible to mount another table width

extender to a table width extender 1001.75A0/

76A0.

1133.12B1/B3/F1/F3

Injury hazard!

The nursing staff must ensure the patient is properly positioned and observe the patient’s condition in order to avoid endangering the patient’s

respiratory system, nerve pathways and circulatory system.

Injury hazard!

Keep the patient under continuous observation

when adjusting the knee crutches.

Hazard of tipping over!

Immobilize the operating table prior to transferring the patient! Press the LOCK button!

Note:

After standstills, actuate the operating table functions to check proper functioning before positioning

the patient.

Press the function buttons height up/down, Trendelenburg/reverse Trendelenburg, lateral tilt right/left,

back palte up/down, leg plates up/down for two to

three seconds each. Finally, press the 0-position

button (z) to align the operating table horizontally.

The functions of the corded hand control are described on page 9.

32

Note:

Depending on the patient weight, the speed of the

motor-powered adjustment and displacement functions will change.

When lowering the table while a heavy patient is

lying on the table top, the speed of downward movements will slighly increase.

The adjustment speed will be reduced during upward movments.

GA113312EN02

Page 33

1133.12B1/B3/F1/F3

2. Positioning a patient weighing between 225 kg and 450 kg (500 lb - 1000 lb)

2.1 Approved accessories Injury hazard!

The accessories which are mounted may not exceed the maximum length as specified in the sketch below.

For further accessories, please refer to the accessories list in chapter VIII.

•

We recommend to use the extension segment 1131.31xx in conjunction with the head plate 1130.67xx to

extend the table top at the head end by 540 mm (21.3 in).

• Leg plates: The abductable leg plate 1133.53xx (max. length 675 mm) as well as the single-section leg plate

1133.58xx are approved.

• Accessories mounted on the side rails

1001.44D0 Arm posturing device 450 mm long

1001.75A0 Table width extender 100 x 300 mm

1001.76A0 Table width extender 100 x 200 mm

1002.25A0 Arm protector

1001.85B0 Foot plate

1001.86A0/B0 Split foot plate

2.2 Operating table immobilized (LOCK) Hazard of operating table tipping over!

Injury hazard due to the operating table tipping over when extending the operating table castors (UNLOCK).

The operating table must always be immobilized (LOCK) for patient weights exceeding 225 kg.

V. Patient positioning

Injury hazard!!

Injury hazard due to the patient slipping off the operating table during unrestricted use of adjustment functions.

Therefore, restrict the adjustment functions as follows for patient weights exceeding 225 kg:

• Longitudinal shift not permissible

• maximum slope (Trendelenburg/reverse Trendelenburg) ±10°

• maximum tilt (left/right) ±5°

• maximum back plate slope ±10°

• maximum leg plate slope ±10°

The adjustment functions are restricted in the interest of patient safety.

Injury hazard!!

If the patient is not positioned correctly, then the operating table may tip over.

Patients weighing more than 225 kg may be positioned in the NORMAL patient orientation only.

GA113312EN02

33

Page 34

V. Patient positioning

1133.12B1/B3/F1/F3

Fig. V-3: NORMAL patient orientation 450 kg (1000 lb) max. patient weight LOCK

3. Positioning a patient weighing between 135 kg and 225 kg (300 lb - 500 lb)

3.1 Approved accessories

Injury hazard!

The accessories which are mounted may not exceed the maximum length as specified in the following

sketch.

For further accessories, please refer to the accessories list in chapter VIII.

• We recommend to use the extension segment 1131.31xx in conjunction with the head plate 1130.67xx to

extend the table top at the head end by 540 mm (21.3 in).

• Accessories mounted on the side rails

1001.44D0 Arm posturing device 450 mm long

1001.75A0 Table width extender 100 x 300 mm

1001.76A0 Table width extender 100 x 200 mm

1002.25A0 Arm protector

1001.85B0 Foot plate

1001.86A0/B0 Split foot plate

3.2 Operating table not immobilized (UNLOCK)

Hazard of operating table tipping over!

If the patient is not positioned correctly, then the operating table may tip over when extending the operating

table castors (UNLOCK).

The patient must be positioned according to Fig. V-4 and Fig. V-5 and the operating table must be set to its

lowest position before extending the operating table castors (UNLOCK).

34

GA113312EN02

Page 35

1133.12B1/B3/F1/F3

3.2.1 NORMAL patient orientation / operating table not immobilized (UNLOCK)

V. Patient positioning

Fig. V-4: NORMAL patient orientation 225 kg (500 lb) max. patient weight UNLOCK

GA113312EN02

35

Page 36

V. Patient positioning

3.2.2 REVERSE patient orientation / operating table not immobilized (UNLOCK)

1133.12B1/B3/F1/F3

Fig. V-5: REVERSE patient orientation 225 kg (500 lb) max. patient weight UNLOCK

36

GA113312EN02

Page 37

1133.12B1/B3/F1/F3

3.3 Operating table immobilized (LOCK)

3.3.1 NORMAL patient orientation / operating table immobilized (LOCK)

V. Patient positioning

Fig. V-6: NORMAL patient orientation 225 kg (500 lb) max. patient weight LOCK

GA113312EN02

37

Page 38

V. Patient positioning

3.3.2 REVERSE patient orientation / operating table immobilized (LOCK)

1133.12B1/B3/F1/F3

Fig. V-7: REVERSE patient orientation 225 kg (500 lb) max. patient weight LOCK

38

GA113312EN02

Page 39

1133.12B1/B3/F1/F3

V. Patient positioning

4. Positioning a patient weighing up to 135 kg (300 lb)

4.1 Approved accessories

Injury hazard!

The accessories which are mounted may not exceed the maximum length as specified in the sketch.

For further accessories, please refer to the accessories list in chapter VIII.

4.2 Operating table not immobilized (UNLOCK)

4.2.1 General

Hazard of operating table tipping over!

If the patient is not positioned correctly, then the

operating table may tip over when extending the

operating table castors (UNLOCK).

The patient must be positioned according to Fig.

V-1 and the operating must be set to a height

less than 940 mm before extending the operating table castors (UNLOCK). The position below

940 mm is attained when the warning sign is not

seen.

NO

YES

Fig. V-8: Marking for moving patients weighing up to

135 kg

GA113312EN02

39

Page 40

V. Patient positioning

4.2.2 NORMAL patient orientation / operating table not immobilized (UNLOCK)

1133.12B1/B3/F1/F3

Fig. V-9: NORMAL patient orientation 135 kg (300 lb) max. patient weight UNLOCK

40

GA113312EN02

Page 41

1133.12B1/B3/F1/F3

4.2.3 REVERSE patient orientation / operating table not immobilized (UNLOCK)

V. Patient positioning

Fig. V-10: REVERSE patient orientation 135 kg (300 lb) max. patient weight UNLOCK

GA113312EN02

41

Page 42

V. Patient positioning

4.3 Operating table immobilized (LOCK)

4.3.1 NORMAL patient orientation / operating table immobilized (LOCK)

1133.12B1/B3/F1/F3

Fig. V-11: NORMAL patient orientation 135 kg (300 lb) max. patient weight LOCK

42

GA113312EN02

Page 43

1133.12B1/B3/F1/F3

4.2.2 REVERSE patient orientation / operating table immobilized (LOCK)

V. Patient positioning

Fig. V-12: REVERSE patient orientation 135 kg (300 lb) max. patient weight LOCK

GA113312EN02

43

Page 44

VI. Care and maintenance

VI. Care and maintenance

Cover the operating table with surgical drapes when not

in use.

1. Cleaning

Use a slightly alkaline general detergent (soap suds)

containing tensides and phosphates as the active cleaning agents to clean the operating table and the accessories.

If the surfaces are extremely dirty, then the cleaner

should be used in concentrated form. Wipe down the

surfaces with clear water.

Note:

Only use as much water as is absolutely necessary and immediately remove any excess water with

a dry cloth.

Note:

Do not use water or detergent jets sprayed out under high pressure. High-pressure cleaning can cause

the liquid to penetrate the gaps required for technical reasons and cause corrosion.

1133.12B1/B3/F1/F3

2. Disinfection

Use a standard commercially available, aldehyde-based

surface disinfectant in a dilute aqueous solution for

manual disinfection of the operating table. This agent

should be included in the list published by the German

DGHM* (German Association for Hygiene and Microbiology). There you will find further information on the

individual components of the disinfectant

Note:

The disinfectant may not contain the following components:

• Chlorine or compounds which would liberate chlorine.

These agents are corrosive to metallic surfaces.

• Alcohol or compounds containing alcohol.

Disinfectant solutions for the skin contain

alcohol!

These compounds will damage plastic components, e.g. table top pads, operating levers.

These agents will create explosive gas-air mixtures.

Note:

Never spray the disinfectant directly into the gaps

of the operating table.

* Deutsche Gesellschaft für Hygiene und Mikrobiologie DGHM

c/o Institut für Hygiene und Mikrobiologie

Universität Würzburg

Josef-Schneider-Str. 2

97080 Würzburg / Germany

http://www.dghm.org

44

GA113312EN02

Page 45

1133.12B1/B3/F1/F3

VI. Care and maintenance

3. Maintenance

The operating table requires annual servicing by MAQUET

Customer Service or by a MAQUET-authorized service

technician.

Please adhere to prescribed maintenance intervals as

otherwise guarantee coverage will lapse.

In so doing you also make a contribution to patient safety

and extend the useful life of your costly equipment.

We recommend concluding a maintenance contract with

MAQUET.

Outside Germany please contact your local representative in all matters relating to service.

4. Malfunctions

If your operating table is defective, we recommend proceeding as follows in order to place the operating table

on its castors:

1. Use the ‘UNLOCK’ function on the override panel:

Press the ‘ON’ and the ‘UNLOCK’ buttons simultaneously until the table is standing on its castors.

2. If there is no battery capacity: Use the mains cable

to connect the operating table to the mains and repeat step 1.

3. If the castors have to be extended manually:

• Remove the sealing cap at the base using a widebladed screw driver or a coin.

• Insert the ratchet (Ref. no. 3113.3649, included in

the delivery) into the opening.

• Turn the ratchet (A) clockwise until the castors

are extended (visual check). When the castors are

fully extended, it will be very difficult or impossible

to turn the ratchet (A).

• Screw in the sealing cap without tightening.

• Move the defective operating table to the desired

location and park it on its castors (secure it, if

required).

• Inform the service department.

Caution:

• If the castors have been extended using the manual

pump, then the UNLOCk function must not be actu-

A

ated, otherwise the base will be lowered and cannot

be mobilized again.

GA113312EN02

If there is a malfunction, please inform the local MAQUET

representative or the factory. Please give an accurate

description of the symptoms and quote the serial number

to facilitate our response and make it possible to rectify

the problem more quickly.

Note:

Never attempt to repair a malfunction yourself and

never use force!

45

Page 46

VI. Care and maintenance

5. Environmental protection

Packaging materials:

The packaging used for MAQUET products is made of

materials compatible with the environment. They are

made of untreated wood, cardboard, recyclable plastics or other reusable materials. MAQUET will dispose

of the packaging materials upon request.

MAQUET products:

MAQUET will take back any used products, or component parts thereof, which are no longer usable and reuse the components in a way which is not damaging

the environment. Please ring your local MAQUET service centre for more details.

Plastic components:

large plastic components have a symbol to indicate what

type of plastic they are made of in order to make recycling easier.

Padding can be disposed of as normal household

wastes.

1133.12B1/B3/F1/F3

Batteries / Rechargeable batteries:

can be disposed of through the local waste system.

Your local MAQUET representative may supply further

information. MAQUET is an affiliate of the “Unified Battery Return System,” a foundation established to ensure proper and environmentally benign battery recycling or, where appropriate, to provide for a means of

disposal compatible with the public interest.

46

GA113312EN02

Page 47

1133.12B1/B3/F1/F3

VII. Technical specifications

VII. Technical specifications

1. Operating table adjustments

Length without accessories: 866 mm (34.1 in.)

Length incl. accessories

1130.67xx / 1131.31xx / 1133.53xx: 2090 mm (82.3 in.)

Width: 530 mm (20.9 in.)

Width across side rails: max. 580 mm (22.8 in.)

Height (without pad) 1133.02.12XX 594 - 1056 mm (23.4 - 41.6 in.)

Weight: approx. 312 kg (688 lb.)

Trendelenburg: 30°

Reverse Trendelenburg: 30°

Lateral tilt left/right: 20°

Back plate up: 80°

Back plate down: 40°

Upper back plate up: 90° (manual adjustment)

Upper back plate down: 45° (manual adjustment)

Leg plate up: 10°

Leg plate down: 90°

Longitudinal shift: 230 mm

Flex position: 40°

Reverse Trendelenburg 20°

Back plate down 20°

Beach chair:

Trendelenburg 25°

Back plate up 80°

Leg plate down 70°

Max. patient weight: 450 kg (1000 lb.)

2. Electrical specifications

Nominal voltage: AC 100/110-115/127

200/220/230-240V

Frequency: 50/60 Hz

Power consumption: 400 VA max.

Class:II.

Applied part: Type B

The enclosure leakage current meets the requirements of the patient leakage current for CF conditions

according to IEC 60601-1, IP X4* IPS ** SELV*** DC 24V

Operating mode: int. 10 min ON / 20 min OFF

For patient weights from 225 kg to 450 kg: 2 min ON / 120 min OFF

Explosion protection AP for operation on battery power

When connected to the mains, the operating table is not

approved for use in areas subject to explosion hazard

(AP-M)!

Rechargeable batteries: Type A512C / 15SR

2 Batteriens 12 V / 15 Ah

* IPX 4 = protection against ingress of liquids ** IPS = internal power source *** SELV = safety extra low voltage

GA113312EN02

47

Page 48

VIII. List of accessories

VIII. List of accessories

1133.12B1/B3/F1/F3

Fig. VIII-1: Accessories for patients weighing up to 450 kg (1000 lb).

For further approved accessories, please refer to the accessories list in chapter VIII.

48

GA113312EN02

Page 49

1133.12B1/B3/F1/F3

VIII. List of accessories

Fig. VIII-2: Accessories for patients weighing up to 225 kg (500 lb).

For further approved accessories, please refer to the accessories list in chapter VIII.

GA113312EN02

49

Page 50

VIII. List of accessories

1133.12B1/B3/F1/F3

Fig. VIII-3: Accessories for patients weighing up to 135 kg (300 lb).

For further approved accessories, please refer to the accessories list in chapter VIII.

50

GA113312EN02

Page 51

1133.12B1/B3/F1/F3

1. Accessories for head-side mounting point:

1.1 For patients weighing up to 450 kg (1000 lb)

1130.67X0 Head plate with gas strut assisted adjustment, washable

1.2 For patients weighing up to 225 kg (500 lb)

1130.52X0 Head plate, simple version

1130.53X0 Head plate with double articulation

1130.54B0 Connection bracket

1002.07A0 Head plate adapter

1002.71A0 Horseshoe-shaped head rest

1002.73A0 Head plate, flat

1002.6200 Head plate, flat

1002.72A0 Horseshoe-shaped head rest, split

1003.4700 Head support plate

1002.65A0 Connection fixture

1002.71A0 Horseshoe-shaped head rest

1002.73A0 Head plate, flat

1002.6200 Head plate, flat

1002.72A0 Horseshoe-shaped head rest, split

1003.4700 Head support plate

1005.3600 Special clamp for skull clamp

1005.5800 Supporting arm

1002.5800 Adapter

1130.64X0 Head plate

1130.67X0 Head plate with gas strut assisted adjustment, washable

1130.68B0 Head plate, long, folding down with gas strut, SFC padding, with side rails, Europe

1130.69X0 Head plate with double articulation

1002.74A0 Motor-powered head plate

1002.71A0 Horseshoe-shaped head rest

1002.73A0 Head plate, flat

1002.6200 Head plate, flat

1002.72A0 Horseshoe-shaped head rest, split