Page 1

Getting Started with the

MapleSim Connector

Copyright © Maplesoft, a division of Waterloo Maple Inc

Maplesoft, a division of Waterloo Maple Inc

Page 2

Getting Started with the MapleSim Connector

Copyright

Maplesoft, Maple, and MapleSim are all trademarks of Waterloo Maple Inc.

© Maplesoft, a division of Waterloo Maple Inc. 1996-2009. All rights reserved. No part of this book may be reproduced, stored in a retrieval system, or transcribed, in any form or by any means — electronic, mechanical,

photocopying, recording, or otherwise. Information in this document is subject to change without notice and does

not represent a commitment on the part of the vendor. The software described in this document is furnished under

a license agreement and may be used or copied only in accordance with the agreement. It is against the law to

copy the software on any medium except as specifically allowed in the agreement.

Macintosh is a trademark of Apple Inc., registered in the U.S. and other countries.

MATLAB and Simulink are registered trademarks of The MathWorks, Inc.

All other trademarks are the property of their respective owners.

This document was produced using a special version of Maple and DocBook.

Printed in Canada

Page 3

Contents

Introduction ................................................................................................... v

1 Getting Started ............................................................................................. 1

1.1 Setting Up the MapleSim Connector ........................................................... 1

Establishing a Connection with MATLAB .................................................... 1

1.2 Getting Help .......................................................................................... 1

1.3 Using the Simulink Block Generation Template ............................................ 2

Viewing MapleSim Connector Examples ..................................................... 2

1.4 Example: RLC Circuit Model ................................................................... 3

1.5 Preparing a Model for Export .................................................................... 5

Converting the Model to a Subsystem .......................................................... 6

Defining Subsystem Inputs and Outputs ...................................................... 7

Define and Assign Subsystem Parameters . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 11

Exporting Your Model Using the Simulink Block Generation Template ............ 13

Implement the S-Function Block in Simulink .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 15

2 Creating and Exporting Mathematical Models in Maple ..................................... 17

2.1 Using a Template to Generate an S-Function Block ..................................... 17

2.2 Creating and Exporting a DynamicSystems Object Programmatically ............. 19

2.3 Example: DC Motor .............................................................................. 20

Index ........................................................................................................... 23

iii

Page 4

iv • Contents

Page 5

Introduction

The MapleSim™ Connector provides all of the tools you need to prepare and export your

dynamic systems models to Simulink® as S-function blocks. You can create a model in

MapleSim, simplify it in Maple™ by using an extensive range of analytical tools, and then

generate an S-function block that you can incorporate into your Simulink toolchain.

You can also use these tools for exporting mathematical models that you have created from

first principles in Maple as S-functions.

Furthermore, various options allow you to use the C code generation feature in Maple to

create code libraries of your MapleSim models for implementation in other applications.

Features of this toolbox include:

• Maple templates, which provide an intuitive user interface for optimizing your

MapleSim model, and then generate an S-function in Simulink.

• A range of examples illustrating how to prepare and export your models.

• A direct interface between Maple and Simulink allows you to generate and test an Sfunction block as you develop the model.

• Commands for developing S-functions of mathematical models from first principles in

the Maple environment and examples to illustrate how to do it.

• Access to commands in the SimulinkConnector and DynamicSystems packages for

developing automated applications to generate S-functions.

Scope of Model Support

MapleSim is a very comprehensive modeling tool where it is possible to create models that

could go beyond the scope of this MapleSim Connector release. In general, the MapleSim

Connector supports systems of any complexity, including systems of DAEs of any index,

in any mix of domains, as long as they exhibit continuous behavior. Systems that contain

any type of discontinuity, including discrete transforms, switches, logic gates, relational

and Boolean operations are not supported by the current release of this product.

Apart from all of the engineering and signal components that are continuous, this product

also supports lookup tables, and custom components that do not use discontinuous operations

such as piecewise functions.

v

Page 6

vi • Introduction

System Requirements

The MapleSim Connector requires the following:

• MATLAB® 2008b, 2009a or 2009b

• Simulink 7.0 or later

• The latest versions of Maple and MapleSim

For installation instructions and a complete list of system requirements, see the Install.html

file on the product CD.

Page 7

1 Getting Started

1.1 Setting Up the MapleSim Connector

Establishing a Connection with MATLAB

To generate an S-function block, you must set up Maple to communicate with MATLAB.

Start Maple and enter the following command to establish a connection with MATLAB.

>

A MATLAB command window is opened and the connection is established. If the window

does not open, follow the instructions in the ?Matlab[setup] help page to configure the

connection.

Next, set up the MATLAB mex compiler. Go to the MATLAB command window and enter

the setup command.

Follow the instructions to choose a local C compiler that supports ANSI (American National

Standards Institute) C code.

See the ?SimulinkConnector,setup help page for more information.

You are now ready to use the MapleSim Connector.

1.2 Getting Help

In Maple, enter ?SimulinkConnector at a prompt in a worksheet.

1

Page 8

2 • 1 Getting Started

1.3 Using the Simulink Block Generation Template

The MapleSim Connector provides a Simulink Block Generation template in the form of

a Maple worksheet for manipulating and exporting MapleSim subsystems. This template

contains pre-built embedded components that allow you to generate S-function or C code

from a MapleSim subsystem, export the subsystem as a Simulink block, and save the source

code.

Using this template, you can define inputs and outputs for the system, choose the format of

the resulting S-function, and generate the source code, library code, block script, or Simulink

block. You can also assign the model equations to a variable and use any Maple commands

to perform analysis tasks.

Viewing MapleSim Connector Examples

Toolbox examples are available in the Simulink Connector Examples palette in MapleSim.

Each example includes a code generation template in its document folder.

To view an example:

1. In the Simulink Connector Examples palette at the left side of the MapleSim window,

expand one of the submenus, and then click the entry for the model that you want to view.

2. Click the document folder button in the top toolbar.

3. From the document list, select Simulink Block Generation.

4. Click Open Selected. The code generation template is opened in Maple.

Some models include additional documents, such as templates that display model equations

or define custom components. You can open any of these documents by selecting its entry

in the list and clicking Open Selected.

Page 9

1.4 Example: RLC Circuit Model • 3

1.4 Example: RLC Circuit Model

In this example, you will generate a Simulink block from an RLC circuit model that was

created in MapleSim.

Before starting this tutorial, you must set up MATLAB and the mex compiler. For more

information, see Establishing a Connection with MATLAB (page 1).

To generate an S-function block:

1. In the Simulink Connector Examples palette, select the RLC Parallel Circuit example.

2. Click the document folder button in the top toolbar.

3. From the drop-down menu, select Simulink Block Generation.

4. Click New.

5. Enter RLC Circuit as the worksheet name and click OK.

6. In the document list at the left side of the dialog box, select RLC Circuit and click Open

Selected. Your MapleSim model is opened in the Simulink Block Generation for

MapleSim Template in Maple.

7. In the Model Summary section of the template, from the Subsystem drop-down menu,

select the RLC_Parallel subsystem. This list box displays all of the subsystems in your

MapleSim model.

8. Click System Update. All of the template fields are populated with information specific

to the subsystem.

9. In the S-Function block name field, enter RLC_Circuit. This is the name that will be

displayed for the block in Simulink.

Page 10

4 • 1 Getting Started

You can now specify which subsystem parameters will be kept as configurable parameters

in the generated Simulink block. In this example, the resistance parameter will be kept as

a configurable parameter.

10. In the Setting Parameters section, select the R1.R parameter entry in the Substituted

Parameters list.

11. Click the > button. The entry is added to the Simulink Parameters list. The resistance

parameter will be kept as a configurable parameter in the generated Simulink block and the

parameters remaining in the Substituted Parameters list will be assigned to values during

the code generation process.

12. To change the default value of the resistance parameter, select R1.R from the Simulink

Parameters list and enter 5 in the Parameter Value field and click anywhere outside of

the field.

13. In the Advanced Code Generation Settings section, set the Code Optimization option

to Full. This option specifies the degree of simplification applied to the model equations

during the code generation process. This option eliminates redundant variables and equations

in the system.

14. In the Generate Simulink Block section, click the Model radio button.

15. Click Generate to Simulink to generate the S-function code and create the block.

Note: Generating a block may require a few minutes.

A MATLAB command window is opened and the block with the specified parameters is

generated in Simulink.

Page 11

1.5 Preparing a Model for Export • 5

Double-clicking the block opens the mask that contains the symbolic parameters from the

original model. This block can now be connected with any compatible Simulink blocks.

1.5 Preparing a Model for Export

In this example, you will perform the steps required to prepare a slider-crank mechanism

model and export it as an S-function block:

1. Convert the slider-crank mechanism model to a subsystem.

2. Define subsystem inputs and outputs.

3. Define and assign subsystem parameters.

4. Export the model using the Simulink Block Generation template.

5. Implement the S-function block in Simulink.

The following tutorial will take you through these steps in detail. Before starting this tutorial,

you must set up MATLAB and the mex compiler. For more information, see Establishing

a Connection with MATLAB (page 1).

To open the slider-crank mechanism example:

1. In MapleSim, expand the Examples palette and then expand the Multibody submenu.

2. Open the Slider Crank Mechanism example.

Page 12

6 • 1 Getting Started

Converting the Model to a Subsystem

By converting your entire model or part of your model into a subsystem, you identify which

parts of the model that you want to export. In this example, you will prepare the system for

export by grouping all of the components into a subsystem.

1. Using the selection tool ( ) located above the model workspace, draw a box around all

of the components in the model.

2. From the Edit menu, select Create Subsystem.

3. In the Create Subsystem dialog box, enter SliderCrank as the subsystem name.

Page 13

1.5 Preparing a Model for Export • 7

4. Click OK. A SliderCrank subsystem block is displayed in the model workspace.

Defining Subsystem Inputs and Outputs

Simulink only supports data signals. Properties on acausal ports, such as mechanical flanges

and electrical pins, must be converted to signals using the appropriate components. The

resulting signals can then be directed as inputs and outputs for the subsystem in MapleSim

and for the S-function block.

In this example, you will convert the displacements of the slider and the joint between the

crank and connecting rod to output signals. The input signal needs to be converted to a

torque that is applied to the revolute joint that represents the crank shaft.

1. Double-click the subsystem block to view its contents. The broken line surrounding the

components indicates the subsystem boundary, which can be resized by clicking and dragging

its sizing handles.

2. Delete the probes that are attached to the model.

3. On the left side of the MapleSim window, expand the Multibody palette and then expand

the Sensors submenu.

4. Drag the Absolute Translation component to the model workspace and place it below

the Prismatic Joint component.

5. Right-click (Control-click for Macintosh®) the Absolute Translation component and

select Rotate Counterclockwise.

6. From the Signal Blocks → Routing → Demultiplexers menu, drag a 3-port Demulti-

plexer component to the model workspace and place it to the right of the Absolute Trans-

lation component.

Page 14

8 • 1 Getting Started

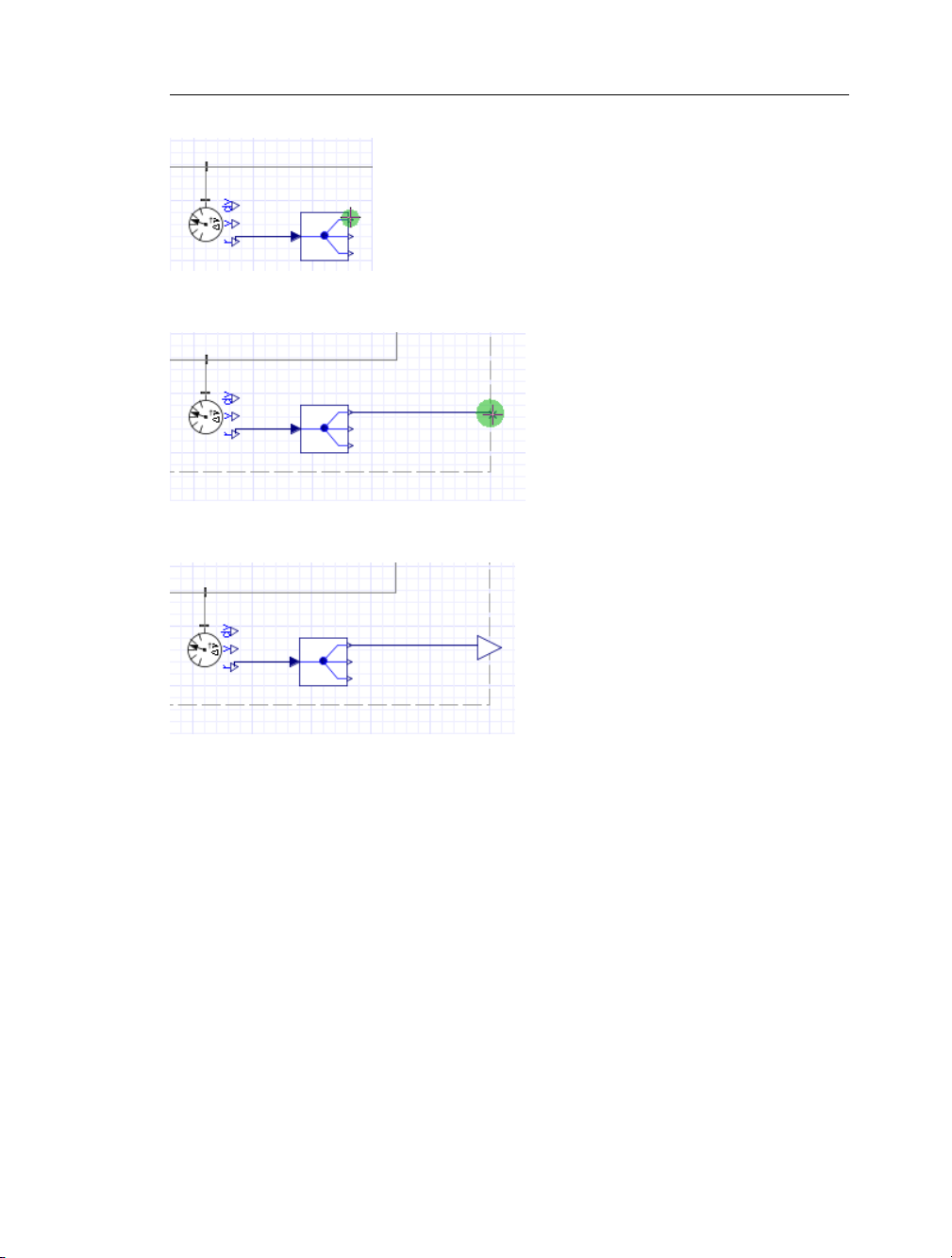

7. To connect the Absolute Translation component to the model, click the frame (the white

square connector). The frame is highlighted in green when you hover your pointer over it.

8. Draw a vertical line and click the connection line directly above the component. The

sensor is connected to the rest of the diagram.

9. In the same way, connect the r output port of the Absolute Translation component to

the navy blue input port of the demultiplexer. This is the displacement signal from the sensor

in x, y, and z coordinates. Since the slider only moves along the x axis, you need to output

the first coordinate as a signal.

10. Hover your pointer over the first demultiplexer port and click your mouse button once.

Page 15

1.5 Preparing a Model for Export • 9

11. Drag your pointer to the subsystem boundary.

12. Click the boundary once. A real output port is added to your subsystem.

13. Add another Absolute Translation component above the Connecting Rod subsystem.

14. Right-click (Control-click for Macintosh) this Absolute Translation component and

select Flip Vertically.

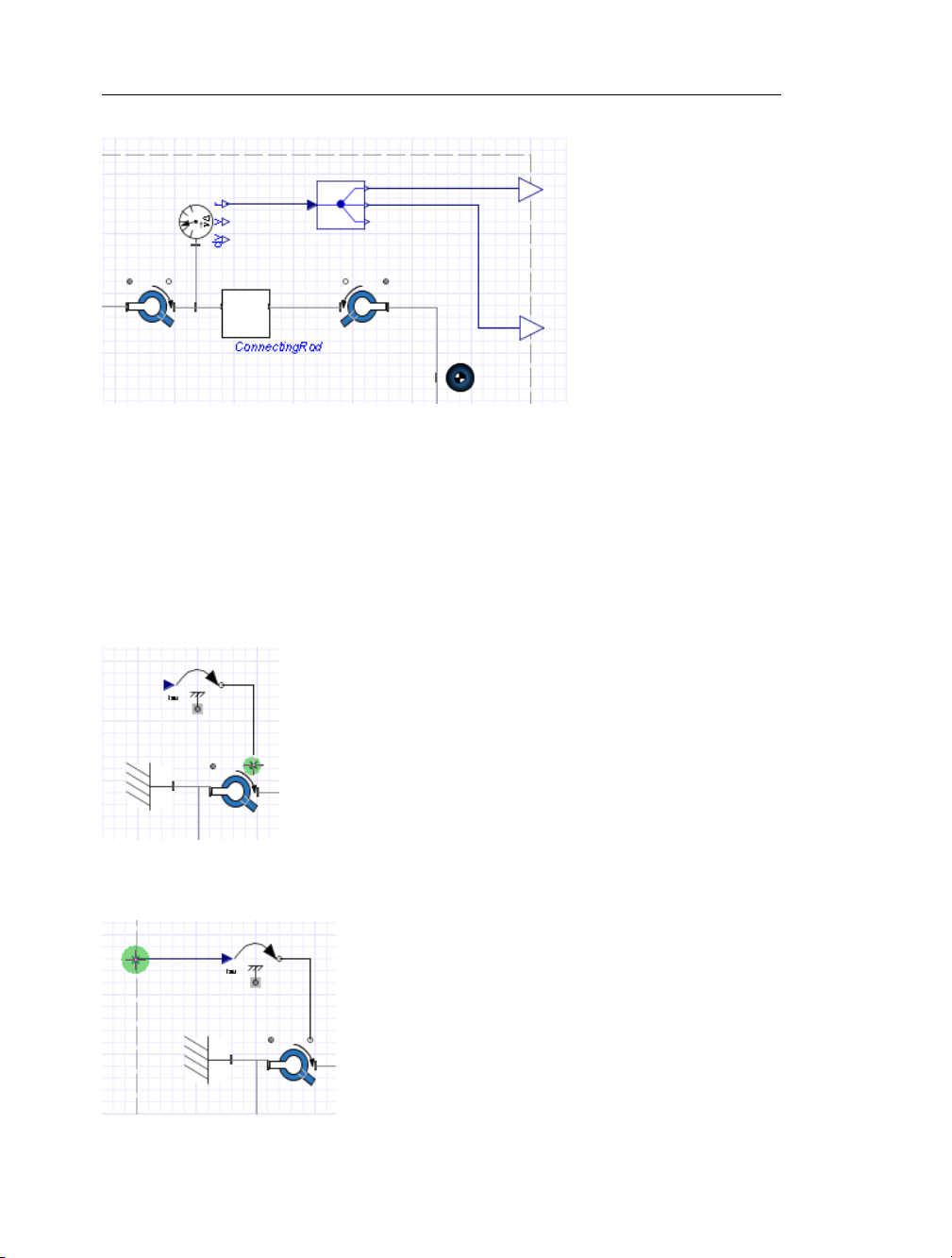

15. Add a 3-port Demultiplexer component to the right of the sensor and connect the

components as shown below.

Page 16

10 • 1 Getting Started

Since the crank is moving in the x, y plane, you only need to output the first two signals.

You will now add a real input port to your subsystem to control the torque on the crank

shaft.

16. From the 1-D Mechanical → Rotational → Torque Drivers menu, add a Torque

component to the model workspace and place it above the Fixed Frame component.

17. Connect the white flange of the Torque component to the white flange of the leftmost

Revolute Joint.

18. Click the input port of the Torque component and drag your pointer to the subsystem

boundary.

Page 17

1.5 Preparing a Model for Export • 11

19. Click the boundary once. A real input port is added to your subsystem.

The complete subsystem is displayed below.

Define and Assign Subsystem Parameters

You can define custom parameters that can be used in expressions in your model to edit

values more easily. To do so, you define a parameter with a numeric value in the parameter

editor. You can then assign that parameter as a variable to the parameters of other components; those individual components will then inherit the numeric value of the parameter

defined in the parameter editor. By using this approach, you only need to change the value

in the parameter editor to change the parameter values for multiple components.

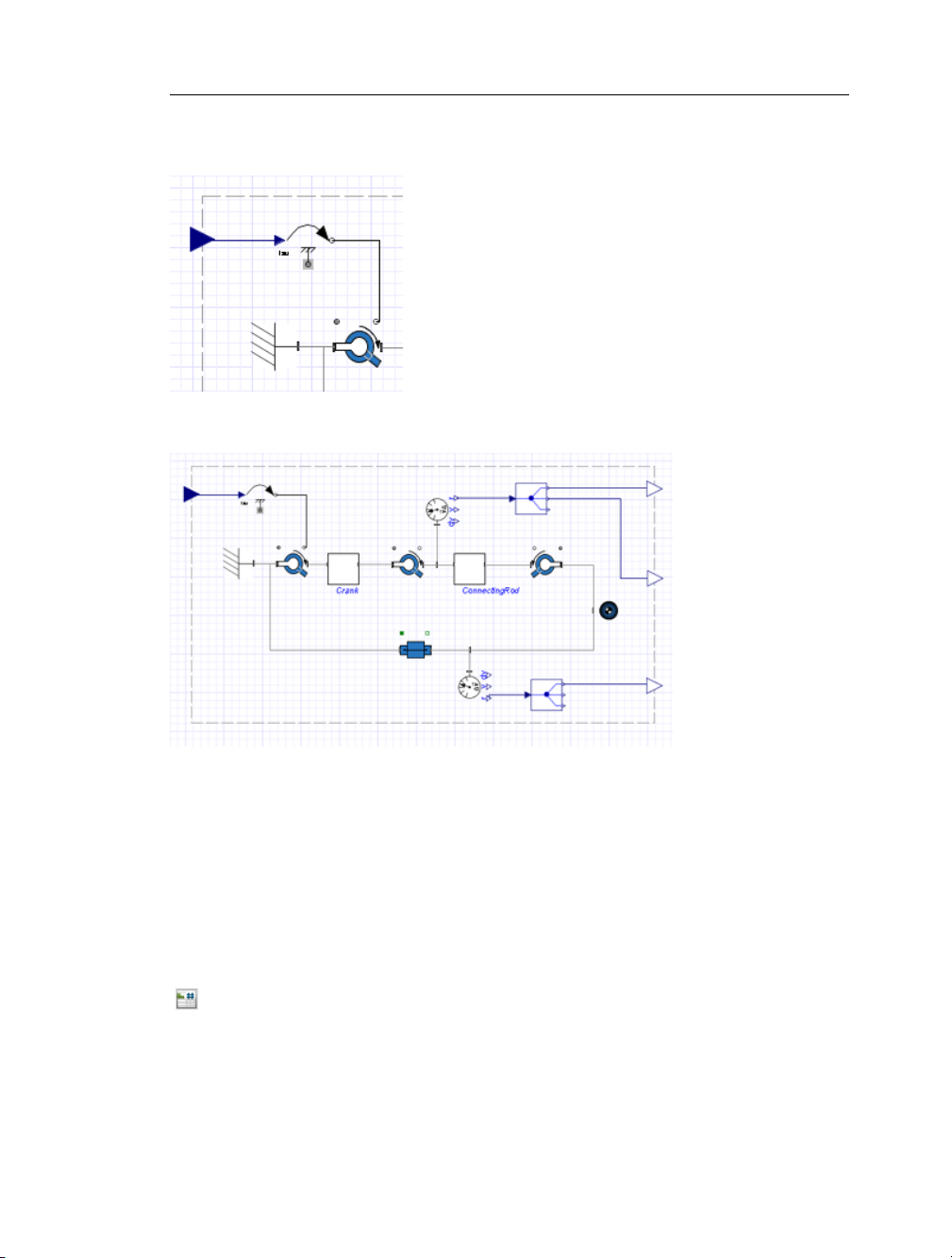

1. While in the detailed view of the SliderCrank subsystem, click the parameters button

( ) above the model workspace. The parameter editor is displayed.

Page 18

12 • 1 Getting Started

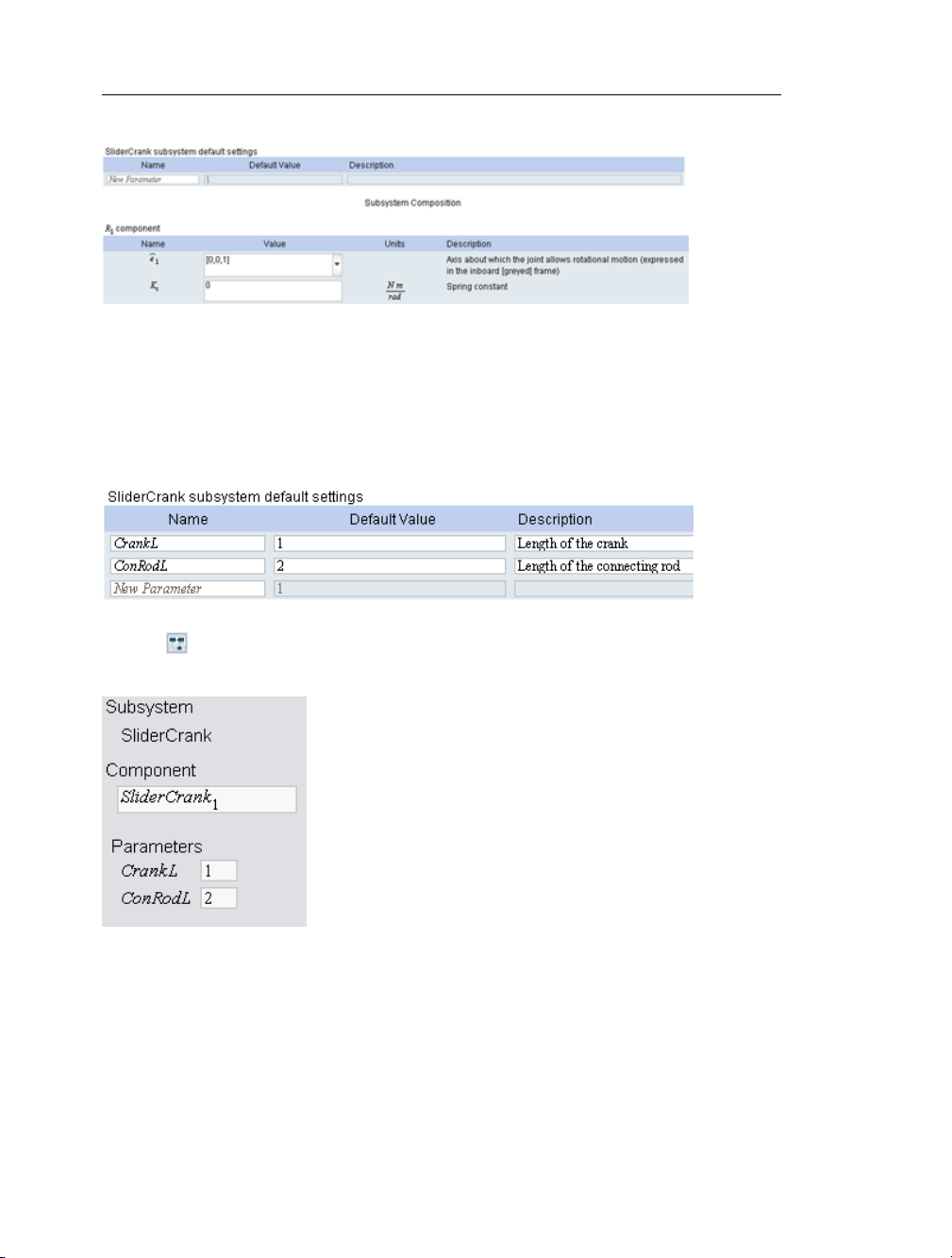

2. In the New Parameter field, define a parameter called CrankL and press Enter.

3. Specify a default value of 1 and enter Length of the crank as the description.

4. In the second row of the table, define a parameter called ConRodL and press Enter.

5. Specify a default value of 2 and enter Length of the connecting rod as the description.

6. Click to switch to the diagram view. The parameters are defined in the Parameters

pane.

7. In the model workspace, select the Crank subsystem.

8. In the Parameters pane, change the length value (L) to CrankL.

Page 19

1.5 Preparing a Model for Export • 13

The Crank subsystem now inherts the numeric value of CrankL that you defined.

9. Select the ConnectingRod subsystem and change its length value to ConRodL.

10. Click the Main button above the model workspace to navigate to the top level of the

model.

You will include these parameter values in the model that you export. You are now ready

to convert your model to an S-function block.

Exporting Your Model Using the Simulink Block Generation Template

After preparing the model, you can use the Simulink Block Generation template to set export

options and convert the model to an S-function block.

1. Click the document folder icon in the main toolbar.

2. From the drop-down menu, select Simulink Block Generation.

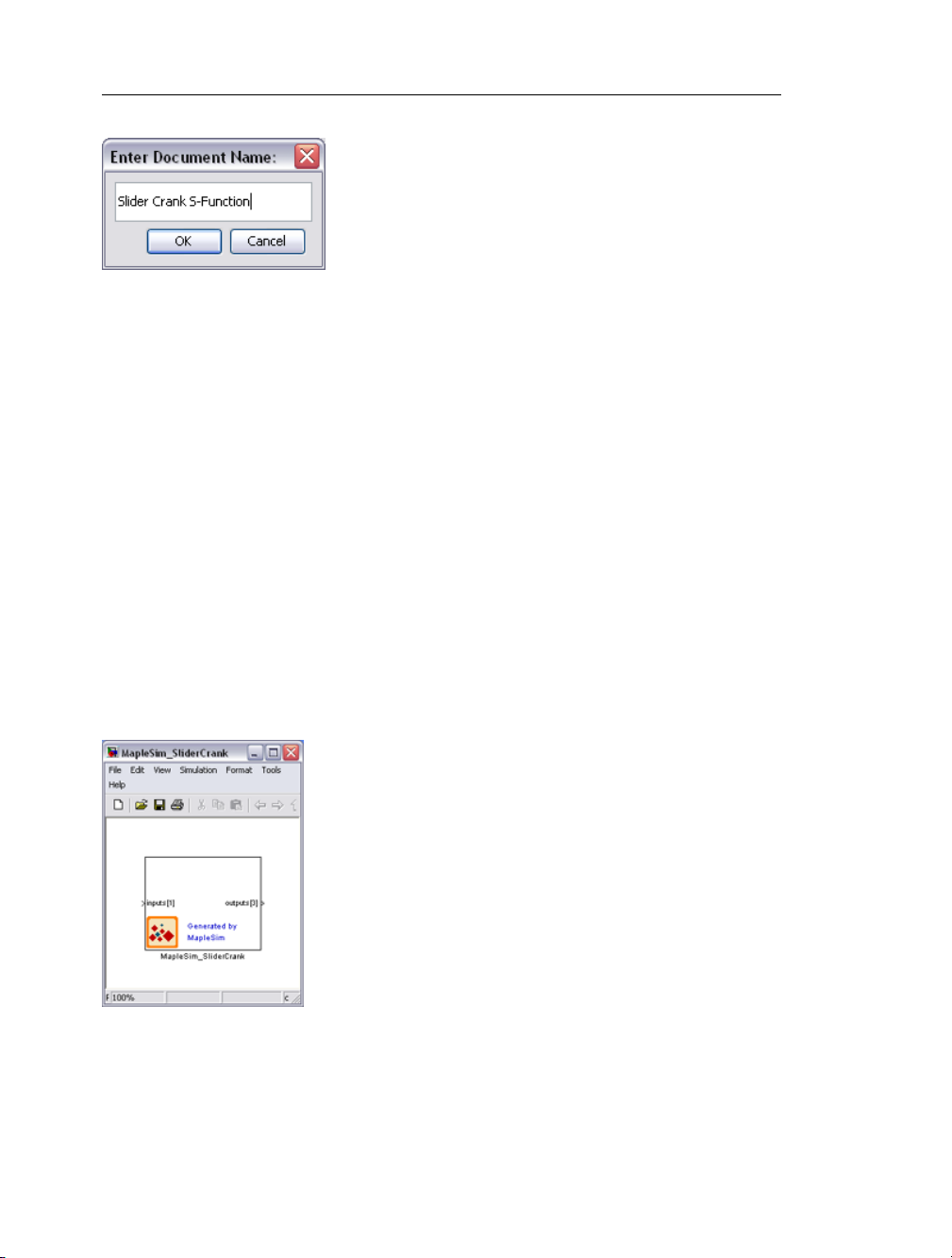

3. Click New.

4. Enter Slider Crank S-Function as the worksheet name and click OK.

Page 20

14 • 1 Getting Started

5. In the document list at the left side of the dialog box, select Slider Crank S-Function

and click Open Selected. The slider-crank subsystem is opened in the Simulink Block

Generation for MapleSim Template in Maple.

6. From the Subsystem drop-down menu, select SliderCrank and click System Update.

All of the template fields are populated with information specific to the subsystem.

7. In the Setting Parameters section, click the >> button. The ConRodL and CrankL

parameters, which you defined in the previous section, are added to the Simulink Parameters

list. These parameters will be kept as configurable parameters in the generated Simulink

block.

8. In the Generate Simulink Block section, select the Model radio button to place the

generated block into a new Simulink model instead of the Simulink block library.

9. Click Generate to Simulink to generate the S-function code and create the block.

Note: Generating a block may require a few minutes.

A MATLAB command window is opened and the block with the specified parameters is

generated in Simulink.

Page 21

1.5 Preparing a Model for Export • 15

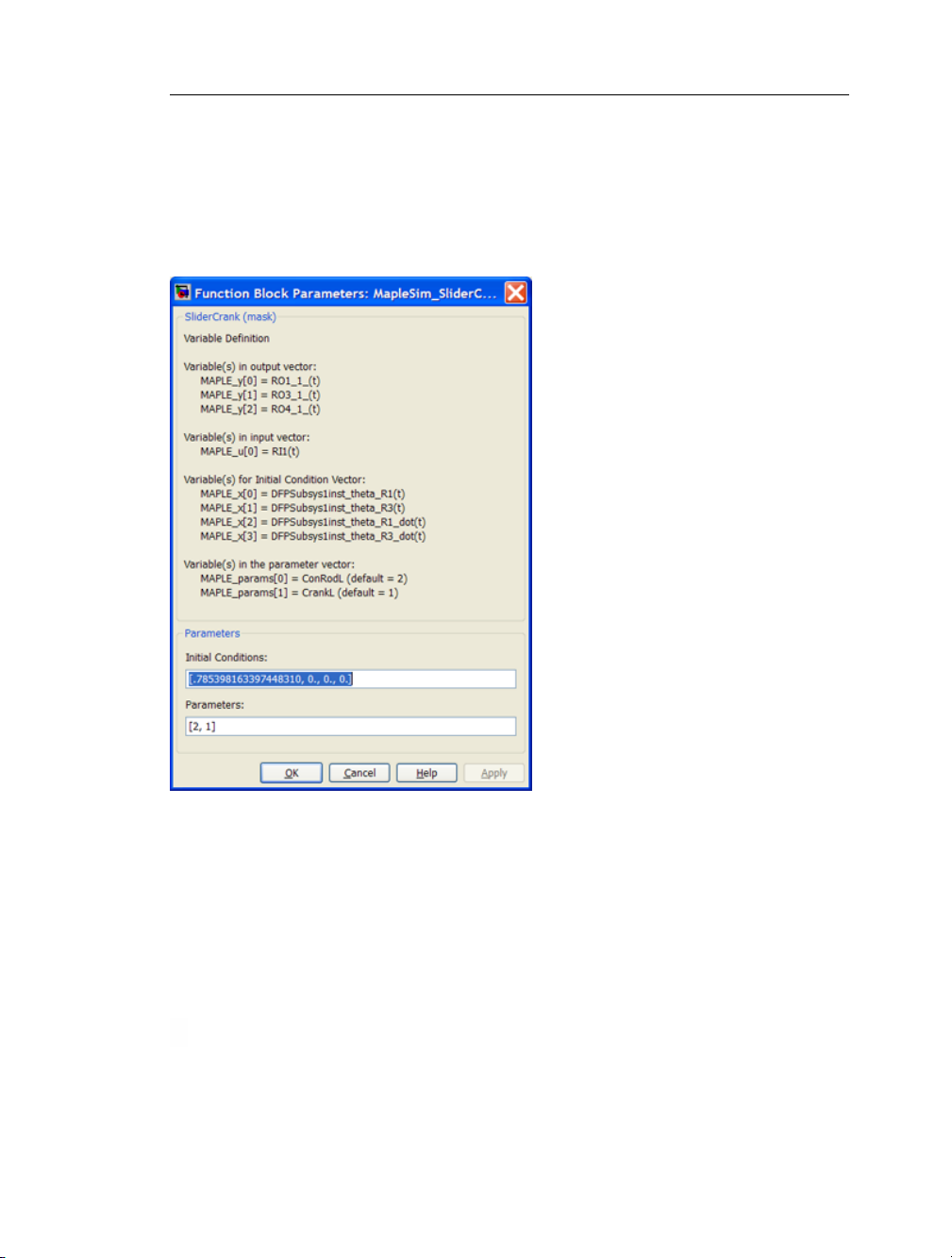

Implement the S-Function Block in Simulink

In Simulink, you can connect your block to other compatible blocks, specify initial conditions,

and edit the component parameter values.

1. In Simulink, double-click the block. The Parameter Mask dialog box is displayed.

This dialog box displays the ConRodL and CrankL parameters that you defined in

MapleSim as a vector. The text in the dialog describes each parameter in the order they

appear in the vector. Initial conditions can also be changed in this dialog box.

2. Click the Help button. This window provides a model description and information about

the inputs, outputs, parameters, and initial conditions.

3. All inputs and outputs are implemented as vector signals. To access individual signals

in Simulink, use a Mux block for inputs and a Demux block for outputs.

Page 22

16 • 1 Getting Started

Page 23

2 Creating and Exporting Mathematical Models in Maple

In Maple, you can use commands from the DynamicSystems package to create a system

from first principles. Maple contains a data structure called a system object that encapsulates

the properties of a dynamic system. This data structure contains information, for example,

the description of the system, and the description of the inputs. Five different types of systems

can be created.

• Differential equation or difference equation

• Transfer function as an expression

• Transfer function as a list of numerator and denominator coefficients

• State-space

• Zero, pole, gain

You can use the Simulink Block Generation for DynamicSystems template, which provides

embedded components for generating source code and exporting a DynamicSystems object

to Simulink. To open this template, enter ?MapleSimSimulinkConnector,DynamicSys-

temsBlockGeneration at a prompt in a Maple worksheet.

Alternatively, you can create a DynamicSystems object in a new worksheet and use commands from the SimulinkConnector package to generate source code and save it as a

MATLAB .m file.

2.1 Using a Template to Generate an S-Function Block

In this tutorial, you will use the Simulink Block Generation for DynamicSystems template

to generate a Simulink block from a dynamic system defined in Maple.

Before starting this tutorial, you must set up MATLAB and the mex compiler. For more

information, see Establishing a Connection with MATLAB.

To generate an S-function block from a dynamic system:

1. In a Maple worksheet, enter ?MapleSimSimulinkConnector,DynamicSystemsBlock-

Generation. The template is opened.

2. If prompted to execute the entire worksheet, click Yes.

In the Component Equations section, you would normally define variables to store component equations and parameters.

17

Page 24

18 • 2 Creating and Exporting Mathematical Models in Maple

These variables are referenced in the equations that define the system object. For demonstration purposes, the equations and parameters of a DC Motor have been defined for you.

3. In the Generate Simulink Block section, select the Model radio button. This option

places the S-function into a new Simulink model instead of a Simulink block library.

4. Click Code Generation. The generated C code is displayed in the View Code section.

5. Click Generate to Simulink.

6. In the Select File dialog box, specify the path and name of the .m and .c files to which

to save the generated code.

7. Click Save. Maple generates the Simulink block.

Note: Generating a block may require a few minutes.

A MATLAB command window is opened and the block with the specified parameters is

generated in Simulink. Double-clicking the block opens the mask that contains the symbolic

parameters from the original model. This block can now be connected with any compatible

Simulink blocks.

Page 25

2.2 Creating and Exporting a DynamicSystems Object Programmatically • 19

2.2 Creating and Exporting a DynamicSystems Object

Programmatically

First, load the DynamicSystems and SimulinkConnector packages in the Maple worksheet.

>

>

To create a system object from the transfer function , use the following

command:

>

(2.1)

To view the details of the system, use the PrintSystem command.

>

(2.2)

The default values for the input names ( and output names have been used.

Alternatively, during creation of the system, different input and output names can be specified.

Page 26

20 • 2 Creating and Exporting Mathematical Models in Maple

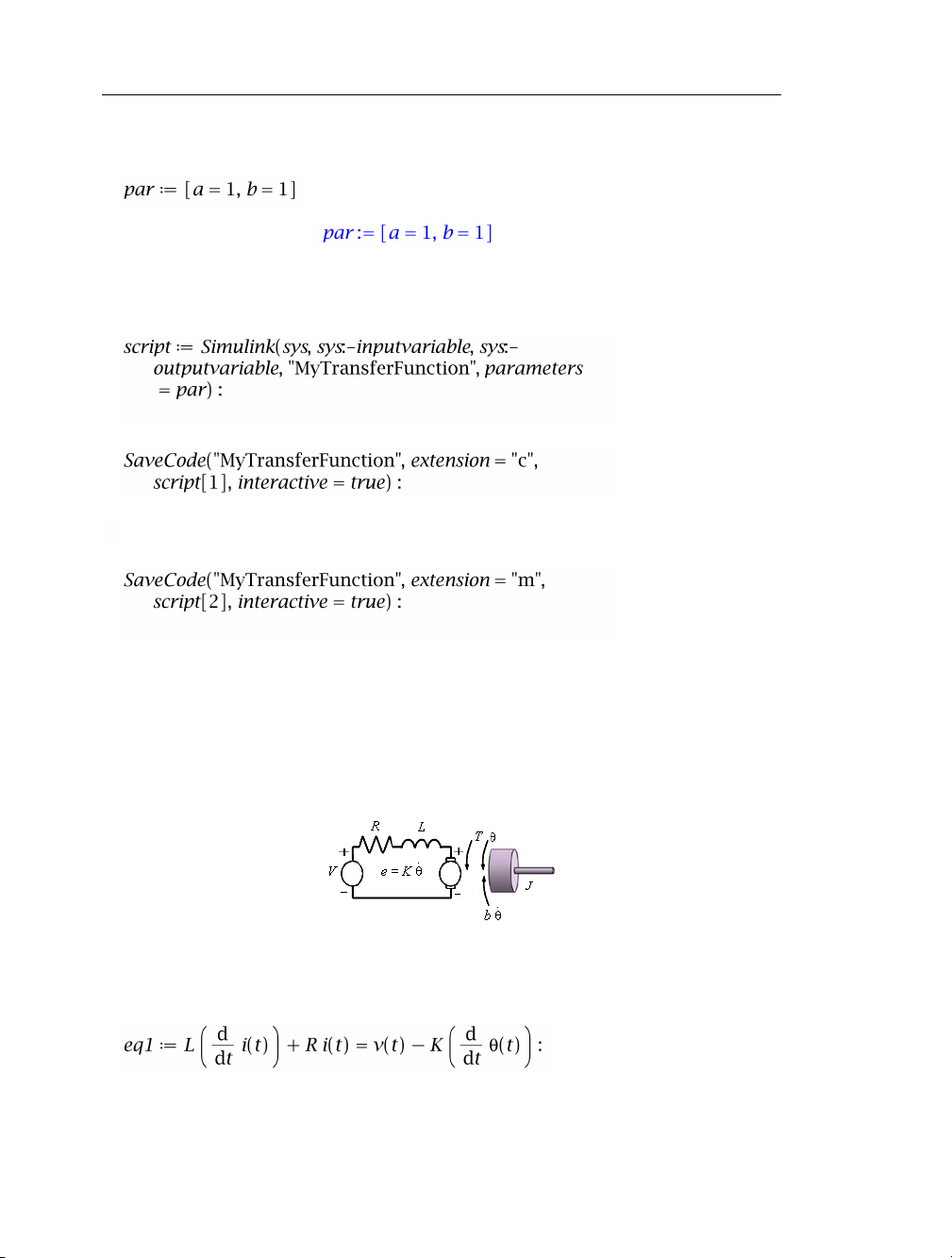

To define parameters values, use the following command:

>

(2.3)

Finally, use the Simulink command to generate the source code and the SaveCode command

to save the code as a .c file and MATLAB .m file.

>

>

>

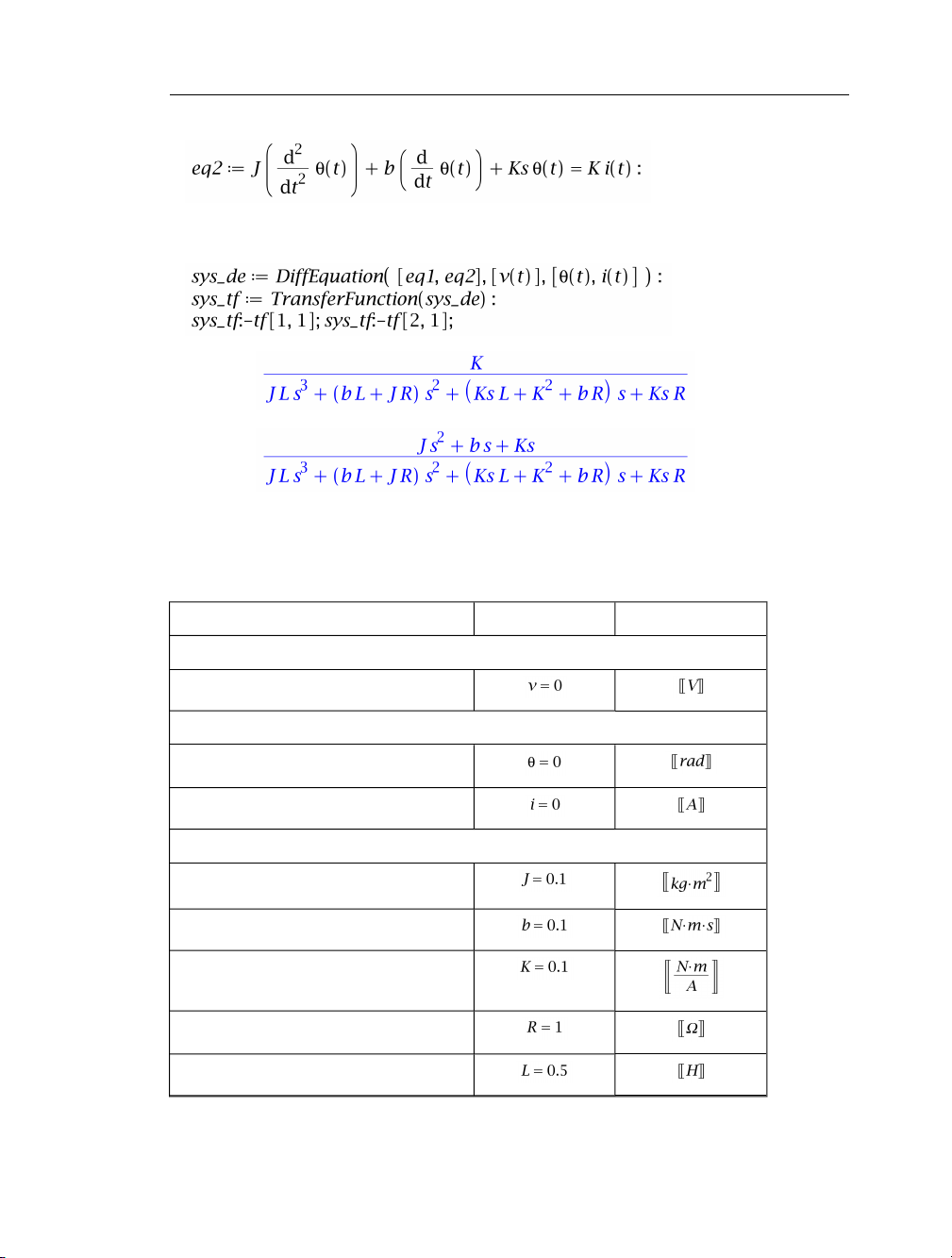

2.3 Example: DC Motor

Consider the classic example of the simplified DC motor. Using the built-in functionality

of the DynamicSystems package in Maple, you can define the system model, and then

visualize and simulate it before saving the code.

This example demonstrates how to define, analyze, and export a system programmatically.

1. In a new Maple worksheet, define the system model.

Differential Equation Model:

>

Page 27

2.3 Example: DC Motor • 21

>

Transfer Function Model:

>

(2.4)

In place of the above commands, you could use the PrintSystem command to display each

part of the model.

2. Specify the parameters in the model.

Units(Initial) ValueDescription

Input Variables

Applied voltage

Output Variables

Motor shaft angular position

Motor current

Parameters

Moment of inertia of the motor

Damping of the mechanical system

Electromotive force constant

Motor coil resistance

Motor coil inductance

Page 28

22 • 2 Creating and Exporting Mathematical Models in Maple

Units(Initial) ValueDescription

External Spring Load Constant

>

>

3. Generate and save the source code as a .c file and MATLAB .m file.

>

>

>

With the basic tools shown in this guide, you are now ready to use the MapleSim Connector

to solve many system design problems. Enter ?DynamicSystems and ?SimulinkConnector

at a prompt in a Maple worksheet for more information about the commands used in this

guide.

Page 29

Index

D

DynamicSystems object, 17

Creating and Exporting Programmatically, 19

Transfer function, 19

I

Inputs and outputs, 7

M

MapleSim Connector Examples Palette, 2

Mathematical model, 17

MATLAB

Setup, 1

S

Simulink, 15

Subsystem

Creating, 6

Subsystem parameters, 11

System object, 17

T

Templates

DynamicSystems, 17

Simulink Block Generation, 2, 13

23

Page 30

24 • Index

Loading...

Loading...