Page 1

MapleSim User's Guide

Copyright © Maplesoft, a division of Waterloo Maple Inc.

2008-2010

Page 2

MapleSim User's Guide

Copyright

Maplesoft, MapleSim, and Maple are all trademarks of Waterloo Maple Inc.

© Maplesoft, a division of Waterloo Maple Inc. 2001-2010. All rights reserved.

No part of this book may be reproduced, stored in a retrieval system, ortranscribed, in any form or by anymeans

— electronic,mechanical, photocopying,recording,or otherwise.Informationin thisdocumentis subjecttochange

without notice and does not represent a commitment on the part of the vendor. The software described in this

document isfurnished underalicense agreementandmay beusedor copiedonlyin accordancewiththe agreement.

It is against the law to copy the software on any medium except as specically allowed in the agreement.

Java and all Java-based marks are trademarks or registered trademarks of Sun Microsystems, Inc. in the United

States and other countries. Maplesoft is independent of Sun Microsystems, Inc.

Linux is a registered trademark of Linus Torvalds.

Macintosh is a trademark of Apple Inc., registered in the U.S. and other countries.

Microsoft, Excel, and Windows are registered trademarks of Microsoft Corporation.

Modelica is a registered trademark of the Modelica Association.

All other trademarks are the property of their respective owners.

This document was produced using a special version of Maple and DocBook.

Printed in Canada

ISBN 978-1-897310-90-8

Page 3

Contents

Introduction .................................................................................................. vii

1 Getting Started with MapleSim ........................................................................ 1

1.1 Physical Modeling in MapleSim ................................................................ 1

Acausal and Causal Modeling ................................................................... 2

1.2 The MapleSim Window ........................................................................... 5

1.3 Basic Tutorial: Modeling an RLC Circuit and DC Motor ................................ 7

Building an RLC Circuit Model .................................................................. 7

Specifying Component Properties ............................................................. 11

Adding a Probe ..................................................................................... 11

Simulating the RLC Circuit Model ............................................................ 12

Building a Simple DC Motor Model .......................................................... 13

Simulating the DC Motor Model ............................................................... 15

2 Building a Model ........................................................................................ 17

2.1 The MapleSim Component Library .......................................................... 17

Viewing Help Topics for Components ........................................................ 18

2.2 Browsing a Model ................................................................................ 18

Model Tree ........................................................................................... 18

Model Navigation Controls ...................................................................... 19

2.3 Dening How Components Interact in a System ......................................... 20

2.4 Specifying Component Properties ............................................................ 21

Specifying Parameter Units ...................................................................... 21

Specifying Initial Conditions ................................................................... 22

2.5 Creating and Managing Subsystems ......................................................... 23

Example: Creating a Subsystem ................................................................ 23

Viewing the Contents of a Subsystem ........................................................ 25

Adding Multiple Copies of a Subsystem to a Model ...................................... 26

Editing Subsystem Denitions and Shared Subsystems ................................. 28

Working with Stand-alone Subsystems ....................................................... 32

2.6 Global and Subsystem Parameters ............................................................ 34

Global Parameters .................................................................................. 34

Subsystem Parameters ............................................................................ 36

Creating Parameter Blocks ...................................................................... 38

2.7 Attaching Files to a Model ...................................................................... 42

2.8 Creating and Managing Custom Libraries .................................................. 43

Example: Adding Subsystems and Attachments to a Custom Library ............... 43

2.9 Annotating a Model ............................................................................... 45

Example: Adding a Text Annotation to a Model ........................................... 46

2.10 Entering Text in 2-D Math Notation ........................................................ 47

2.11 Creating a Data Set for an Interpolation Table Component ........................... 48

Example: Creating a Data Set in Maple ...................................................... 48

2.12 Best Practices: Building a Model ........................................................... 49

iii

Page 4

iv • Contents

Best Practices: Laying Out and Creating Subsystems .................................... 49

Best Practices: Building Electrical Models .................................................. 50

Best Practices: Building 1-D Translational Models ....................................... 52

Best Practices: Building Multibody Models ................................................. 53

Best Practices: Building Hydraulic Models ................................................. 53

3 Creating Custom Modeling Components .......................................................... 55

3.1 Overview ............................................................................................ 55

3.2 Opening Custom Component Examples .................................................... 56

3.3 Example: Nonlinear Spring-Damper Component ......................................... 56

Opening the Custom Component Template ................................................. 58

Dening the Component Name and Equations ............................................. 58

Dening Component Ports ....................................................................... 59

Generating the Custom Component ........................................................... 60

3.4 Working with Custom Components in MapleSim ........................................ 61

3.5 Editing a Custom Component .................................................................. 62

4 Simulating and Visualizing a Model ................................................................ 63

4.1 How MapleSim Simulates a Model .......................................................... 63

4.2 Simulating a Model .............................................................................. 66

Simulation Parameters ............................................................................ 66

Editing Probe Values .............................................................................. 70

Storing Parameter Sets to Compare Simulation Results ................................. 70

4.3 Simulation Progress Messages ................................................................. 71

4.4 Managing Simulation Results ................................................................. 71

4.5 Customizing Plot Windows .................................................................... 72

Example: Plotting Multiple Quantities in Individual Graphs ........................... 73

Example: Plotting One Quantity Versus Another ......................................... 76

4.6 Plot Window Toolbar and Menus ............................................................. 78

4.7 Visualizing a Multibody Model ................................................................ 78

The 3-D Workspace ................................................................................ 79

Viewing and Browsing 3-D Models ........................................................... 80

Adding Shapes to a 3-D Model ................................................................. 81

Building a Model in the 3-D Workspace ..................................................... 85

Example: Building a Double Pendulum Model in the 3-D Workspace ............... 88

4.8 Best Practices: Simulating and Visualizing a Model .................................... 96

5 Analyzing and Manipulating a Model ............................................................. 97

5.1 Overview ............................................................................................ 97

5.2 Retrieving Equations and Properties from a Model ..................................... 99

5.3 Analyzing Linear Systems .................................................................... 100

5.4 Optimizing Parameters ......................................................................... 101

5.5 Generating C Code from a Model ........................................................... 102

5.6 Working with Maple Embedded Components ........................................... 103

6 MapleSim Tutorials .................................................................................... 105

6.1 Tutorial 1: Modeling a DC Motor with a Gearbox ...................................... 105

Page 5

Contents • v

Adding a Gearbox to a DC Motor Model .................................................. 105

Simulating the DC Motor with Gearbox Model .......................................... 106

Grouping the DC Motor Components into a Subsystem ............................... 107

Assigning Global Parameters to a Model ................................................... 108

Changing Input and Output Values .......................................................... 109

6.2 Tutorial 2: Modeling a Cable Tension Controller ....................................... 111

Building a Cable Tension Controller Model ............................................... 111

Specifying Component Properties ............................................................ 113

Simulating the Cable Tension Controller ................................................... 113

6.3 Tutorial 3: Modeling a Nonlinear Damper ................................................ 114

Generating a Custom Spring Damper ....................................................... 114

Providing Damping Coefcient Values ..................................................... 115

Building the Nonlinear Damper Model .................................................... 116

Assigning a Parameter to a Subsystem ..................................................... 118

Simulating the Nonlinear Damper with Linear Spring Model ........................ 119

6.4 Tutorial 4: Modeling a Planar Slider-Crank Mechanism .............................. 120

Creating a Planar Link Subsystem ........................................................... 121

Dening and Assigning Parameters ......................................................... 124

Creating the Crank and Connecting Rod Elements ...................................... 124

Adding the Fixed Frame, Sliding Mass, and Joint Elements .......................... 125

Specifying Initial Conditions .................................................................. 126

Simulating the Planar Slider-Crank Mechanism .......................................... 126

7 Reference: MapleSim Keyboard Shortcuts ...................................................... 129

Glossary ..................................................................................................... 131

Index ......................................................................................................... 133

Page 6

vi • Contents

Page 7

Introduction

MapleSim Overview

MapleSimTMis amodeling environment forcreating andsimulating complexmulti-domain

physical systems.It allowsyou tobuild component diagrams that represent physical systems

in a graphicalform. Usingboth symbolic andnumeric approaches,MapleSim automatically

generates model equations from a component diagram and runs high-delity simulations.

Build Complex Multi-domain Models

You can use MapleSimto buildmodels thatintegrate componentsfrom variousengineering

elds intoa completesystem. MapleSimfeatures alibrary ofover 300modeling components,

including electrical, hydraulic, mechanical, and thermal devices; sensors and sources; and

signal blocks.You can also createcustom componentsto suityour modelingand simulation

needs.

Advanced Symbolic and Numeric Capabilities

MapleSim uses the advanced symbolic and numeric capabilities of MapleTMto generate

the mathematicalmodels thatsimulate thebehavior ofa physical system. Youcan, therefore,

apply simplication techniques to equations to create concise and numerically efcient

models.

Pre-built Analysis Tools and Templates

MapleSim providesvarious pre-builttemplates inthe formof Mapleworksheets for viewing

model equations and performing advanced analysis tasks, such as parameter optimization.

To analyze your model and present your simulation results in an interactive format, you

can useMaple featuressuch asembedded components,plotting tools,and documentcreation

tools. You can also translate your models into C code and work with them in other applications and tools, including applications that allow you to perform real-time simulation.

Interactive 3-D Visualization Tools

The MapleSim 3-D visualization environment allows you to build and animate 3-D graphical representations of your multibody mechanical system models. You can use this environment to validate the 3-D conguration of your model and visually analyze the behavior

of your system under different conditions.

vii

Page 8

viii • Introduction

Related Products

MapleSim requires the latest version of Maple 14.

MaplesoftTMalso offers a suite of toolboxes, add-ons, and other applications that extend

the capabilities of Maple and MapleSim for engineering design projects.

For a complete list of products, visit http://www.maplesoft.com/products.

Related Resources

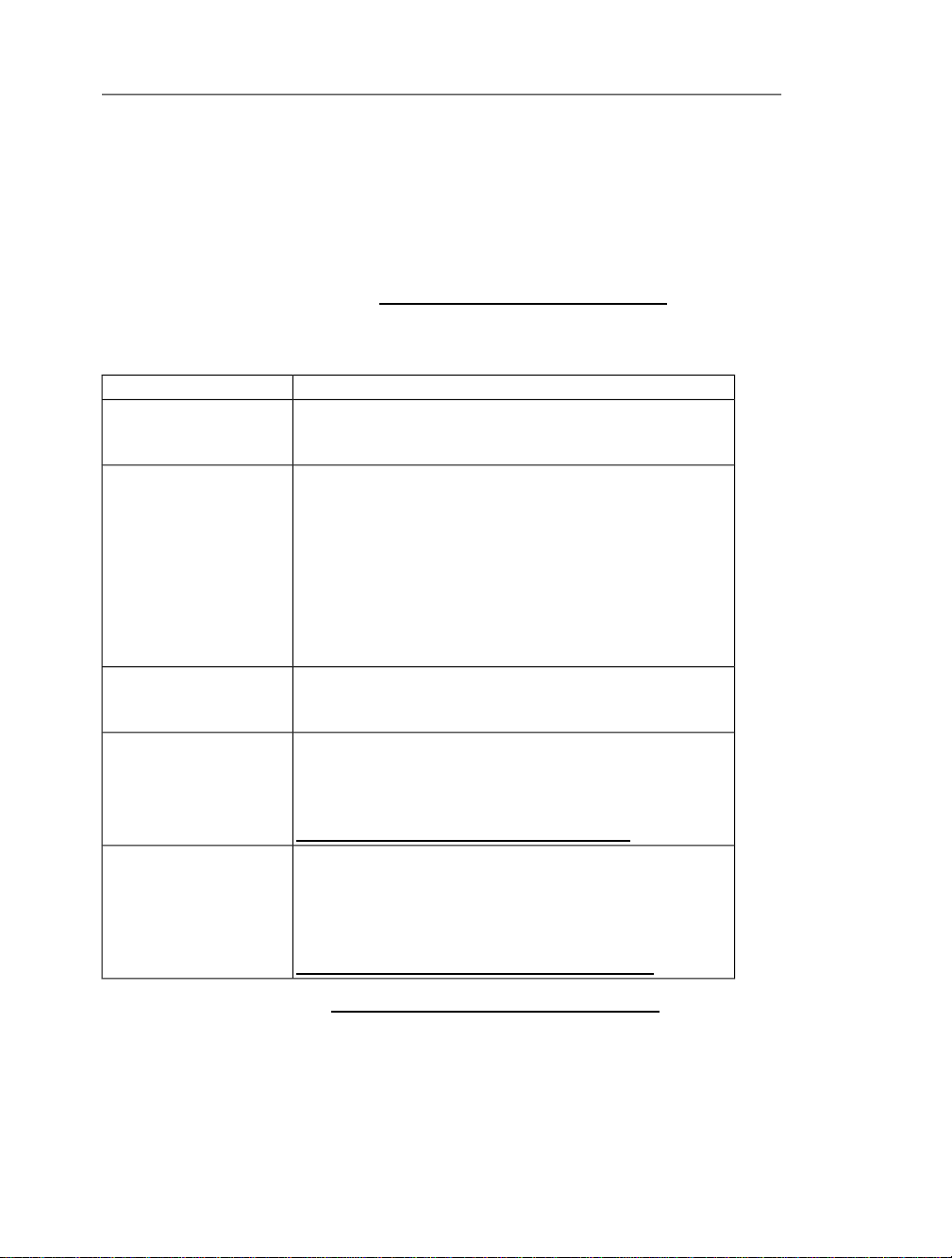

DescriptionResource

MapleSim Installation

Guide

MapleSim Help System

System requirements and installation instructionsfor MapleSim.

The MapleSimInstallation Guide is available inthe Install.html

le on your MapleSim installation DVD.

Provides the following information:

• MapleSim User's Guide: conceptual information about

MapleSim, an overview of MapleSim features, and tutorials

to help you get started.

• Using MapleSim: help topics for model building, simulation,

and analysis tasks.

• MapleSim Library Reference Guide: descriptions of the

modeling components available in MapleSim.

Sample modelsfrom variousengineering domains. Thesemodels

MapleSim Examples

MapleSim Online Resources

MapleSim Application

Center

are available in the Examples palette in theLibraries tab on the

left side of the MapleSim window.

Training webinars, product demonstrations, videos, sample applications, and more.

For more information, visit

http://www.maplesoft.com/products/maplesim.

A collectionofsample models,customcomponents, andanalysis

templates that youcan download anduse in your MapleSimprojects.

For more information, visit

http://www.maplesoft.com/applications/maplesim.

For additional resources, visit http://www.maplesoft.com/site_resources.

Page 9

Introduction • ix

Getting Help

To requestcustomer supportor technicalsupport, visithttp://www.maplesoft.com/support.

Customer Feedback

Maplesoft welcomes your feedback. For comments related to the MapleSim product documentation, contact doc@maplesoft.com.

Page 10

x • Introduction

Page 11

1 Getting Started with MapleSim

In this chapter:

• Physical Modeling in MapleSim (page 1)

• The MapleSim Window (page 5)

• Basic Tutorial: Modeling an RLC Circuit and DC Motor (page 7)

1.1 Physical Modeling in MapleSim

Physical modeling,or physics-basedmodeling, incorporatesmathematics andphysical laws

to describe the behavior of an engineering component or a system of interconnected components. Sincemost engineeringsystems haveassociated dynamics,the behavioris typically

dened with ordinary differential equations (ODEs).

To help youdevelop models quicklyand easily, MapleSim providesthe following features:

Topological or “Acausal” System Representation

The signal-ow approach used by traditional modeling tools requires system inputs and

outputs to be dened explicitly. In contrast, MapleSim allows you to use a topological

representation to connect interrelated components without having to consider how signals

ow between them.

Mathematical Model Formulation and Simplification

A topological representation maps readily to its mathematical representation and the symbolic capability of MapleSim automates the generation of system equations.

When MapleSimformulates thesystem equations,several mathematicalsimplication tools

are applied to remove any redundant equations and multiplication by zero or one.The simplication tools then combine and reduce the expressions to get a minimal set of equations

required to represent a system without losing delity.

Advanced Differential Algebraic Equation Solvers

Algebraic constraints areintroduced in the topologicalapproach to model denition.Problems that combine ODEs with these algebraic constraints are called Differential Algebraic

Equations (DAEs).Depending onthe natureof theseconstraints, the complexity of the DAE

problem can vary. An index of the DAEs provides a measure of the complexity of the

problem. Complexity increases with the index of the DAEs.

The development ofgeneralized solvers for complex DAEs is the subject of much research

in the symbolic computation eld. With Maple as its computation engine, MapleSim uses

1

Page 12

2 • 1 Getting Started with MapleSim

advanced DAE solvers that incorporate leading-edge symbolic and numeric techniques for

solving high-index DAEs.

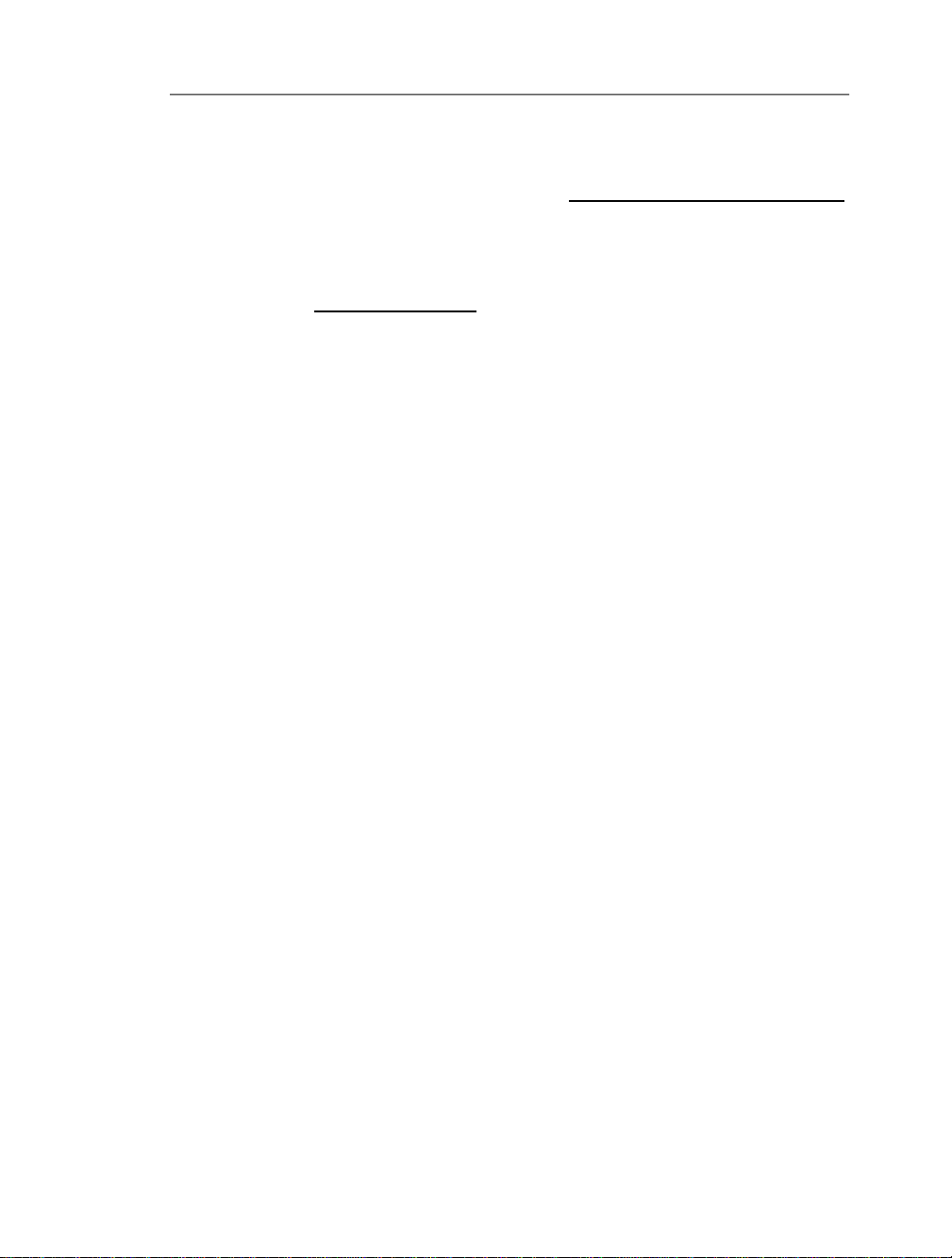

Acausal and Causal Modeling

Real engineered assemblies, such as motors and powertrains, consist of a network of interacting physical components. They are commonly modeled in software by block diagrams.

The lines connecting two blocks indicate that they are coupled by physical laws.

When simulatedby software,block diagramscan eitherbe causalor acausal.Many simulation

tools arerestricted tocausal (or signal-ow) modeling. Inthese tools,a unidirectionalsignal,

which is essentially a time-varying number, ows into a block. The block then performs a

well-dened mathematicaloperation on the signal andthe resultows out of the otherside.

This approach is useful for modeling systems that are dened purely by signals that ow

in a single direction, such as control systems and digital lters.

This approach isanalogous to an assignment,where a calculation isperformed on a known

variable orset ofvariables on the right handside andthe result is assigned toanother variable

on the left:

Modeling how real physical components interact requires a different approach. In acausal

modeling, a signalfrom two connected blocks travels in both directions. The programming

analogy would be a simple equality statement:

The signalincludes informationabout whichphysical quantities(for example,energy, current,

torque, heat and mass ows) must be conserved. The blocks contain information about

which physical laws(represented by equations) they must obey and, hence, which physical

quantities must be conserved.

Page 13

1.1 Physical Modeling in MapleSim • 3

MapleSim allows you to use both approaches. You can simulate a physical system (with

acausal modeling)together with the associated logic or controlloop (with causal modeling)

in a manner that suits either task best.

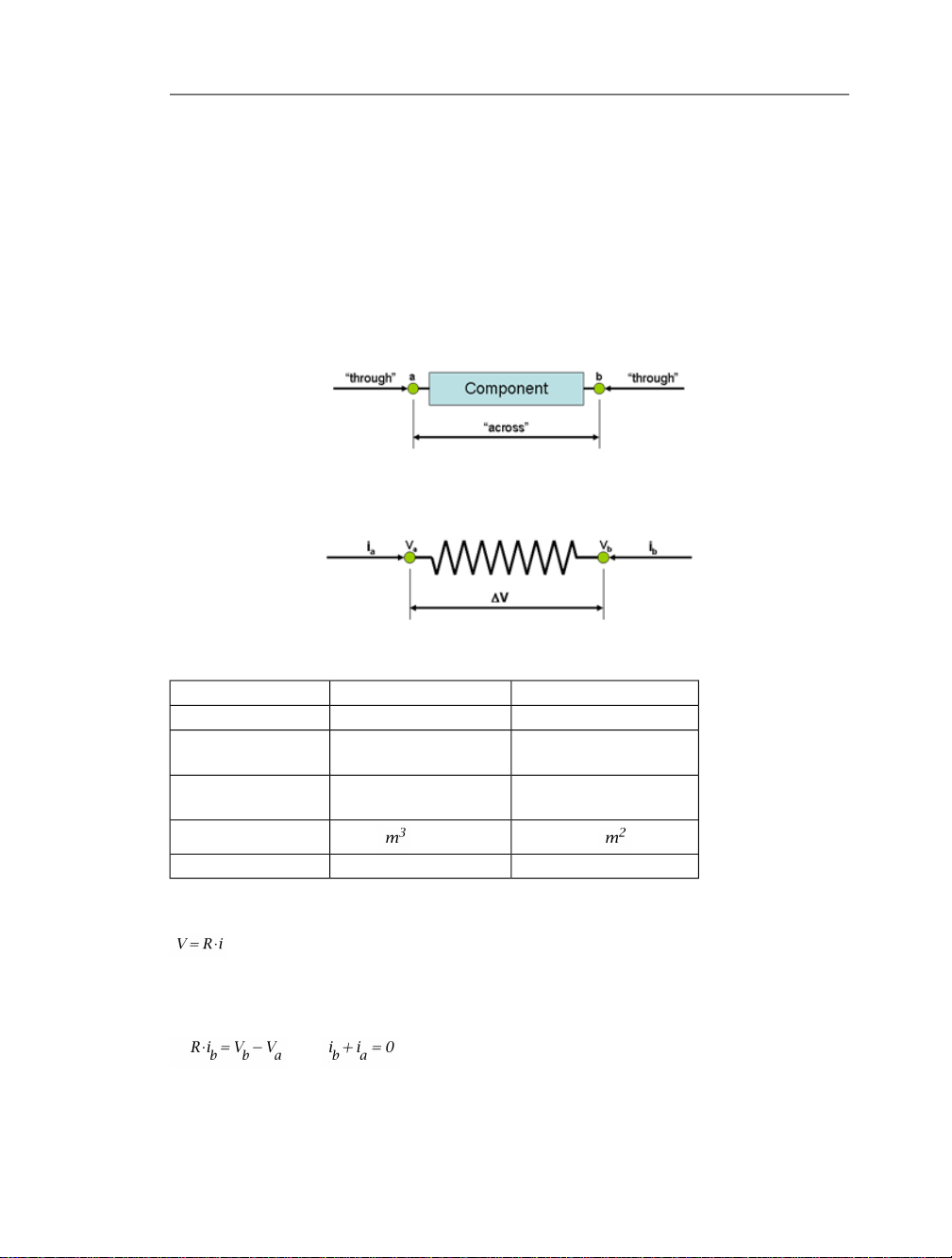

Through and Across Variables

When using the acausal modeling approach, it is useful to identify the through and across

variables ofthe componentyou aremodeling. In general terms, anacross variablerepresents

the driving force in a system and a through variable represents the ow of a conserved

quantity:

For example, in an electrical circuit, the through variable, i, is the current and the across

variable, V, is the voltage drop:

The following table lists some examples of through and across variablesfor other domains:

AcrossThroughDomain

Electrical

Mechanical (transla-

tional)

Mechanical (rotation-

al)

Hydraulic

Heat ow

Voltage (V)Current (A)

Velocity (m/s)Force (N)

Angular Velocity (rad/s)Torque (N.m)

Pressure (N/ )Flow ( /s)

Temperature (K)Heat ow (W)

As a simple example, the form of the governing equation for a resistor is

This equation,in conjunctionwith Kirchhoff’sconservation ofcurrent law,allows acomplete

representation of a circuit.

and

Page 14

4 • 1 Getting Started with MapleSim

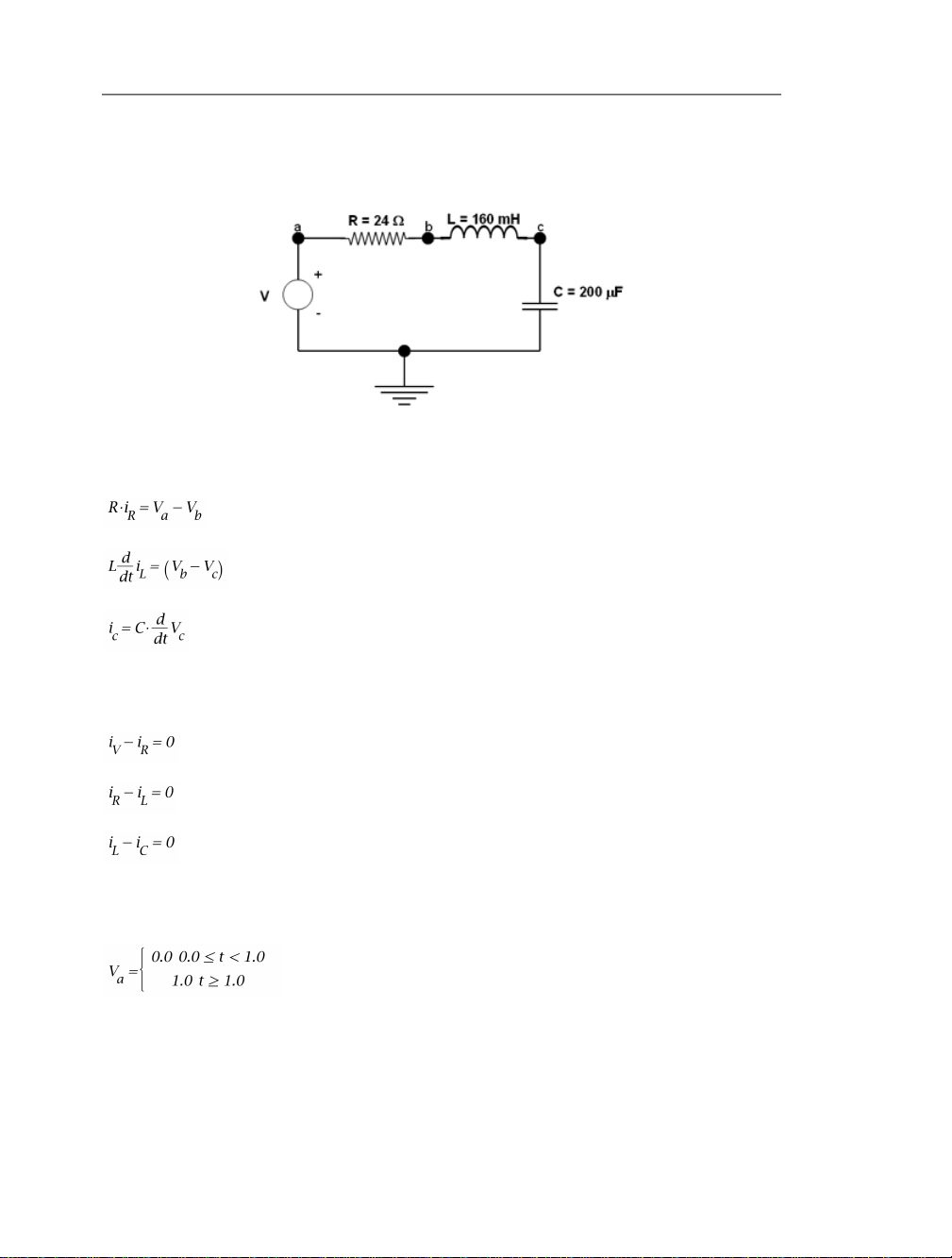

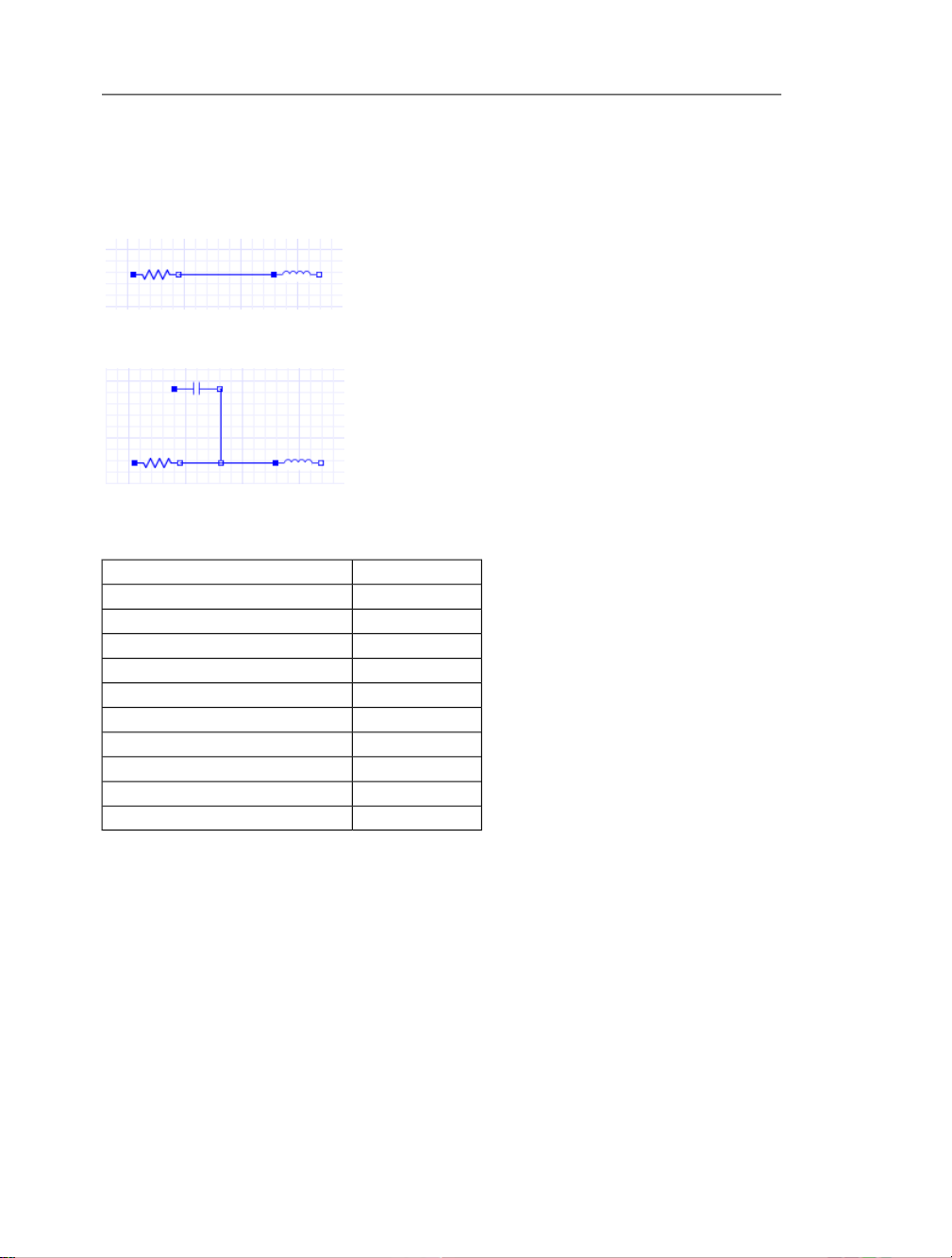

To extend this example, the following schematic diagram describes an RLC circuit, an

electrical circuit consisting of a resistor, inductor, and a capacitor connected in series:

If you wanted to model this circuit manually, it can be represented with the following

characteristic equations for the resistor, inductor, and capacitor respectively:

By applying Kirchhoff's current law, the following conservation equations are at points a,

b, and c:

These equations, along with a denition of the input voltage (dened as a transient going

from 0 to 1 volt, 1 second after the simulation starts)

provide enough information to dene the model and solve for the voltages and currents

through the circuit.

In MapleSim, all of these calculations are performed automatically; you only need to draw

the circuit and provide the component parameters. These principles can be applied equally

Page 15

1.2 The MapleSim Window • 5

to allengineering domainsin MapleSimand allowyou toconnect componentsin onedomain

with components in others easily.

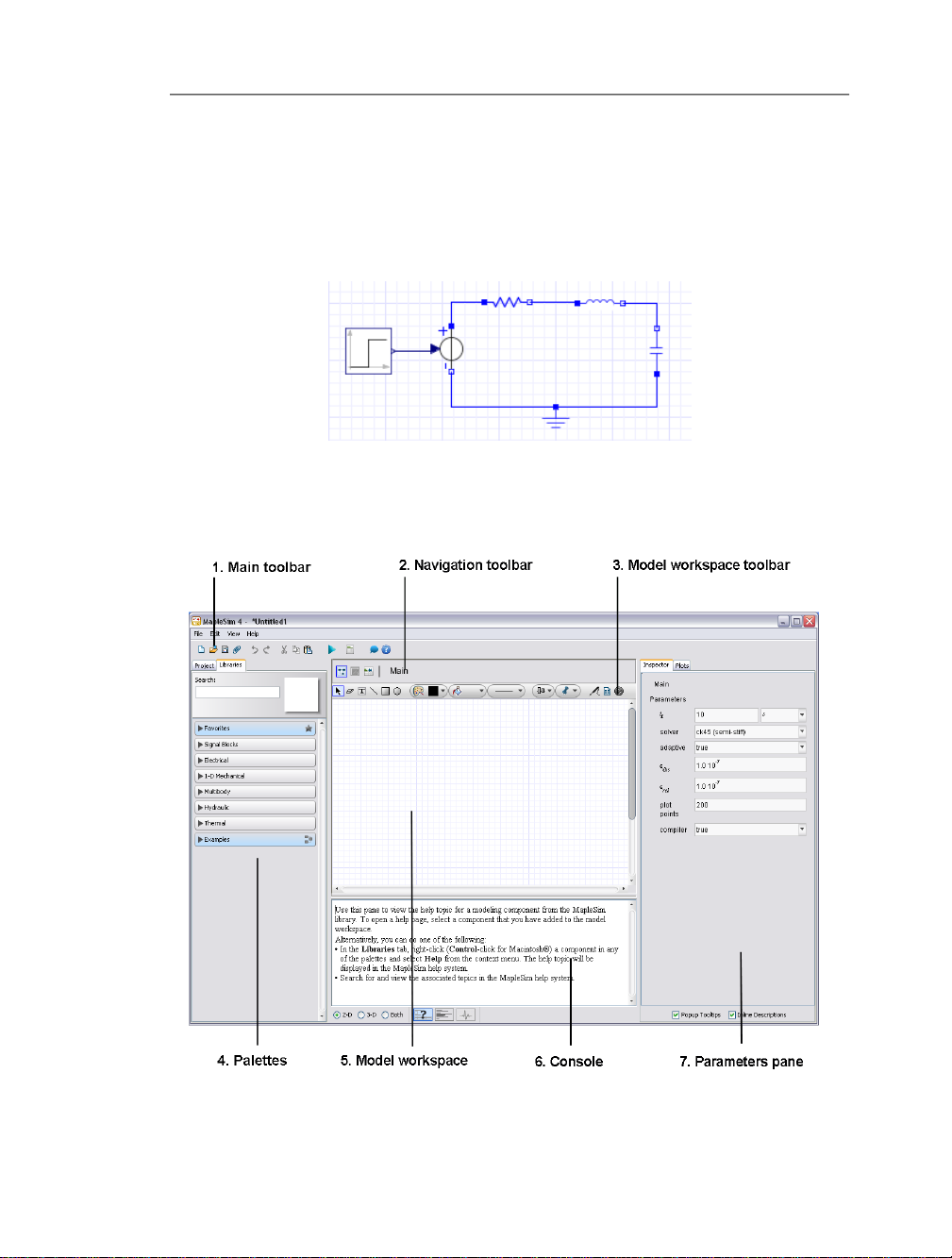

In the Basic Tutorial: Modeling an RLC Circuit and DC Motor (page 7) section of this

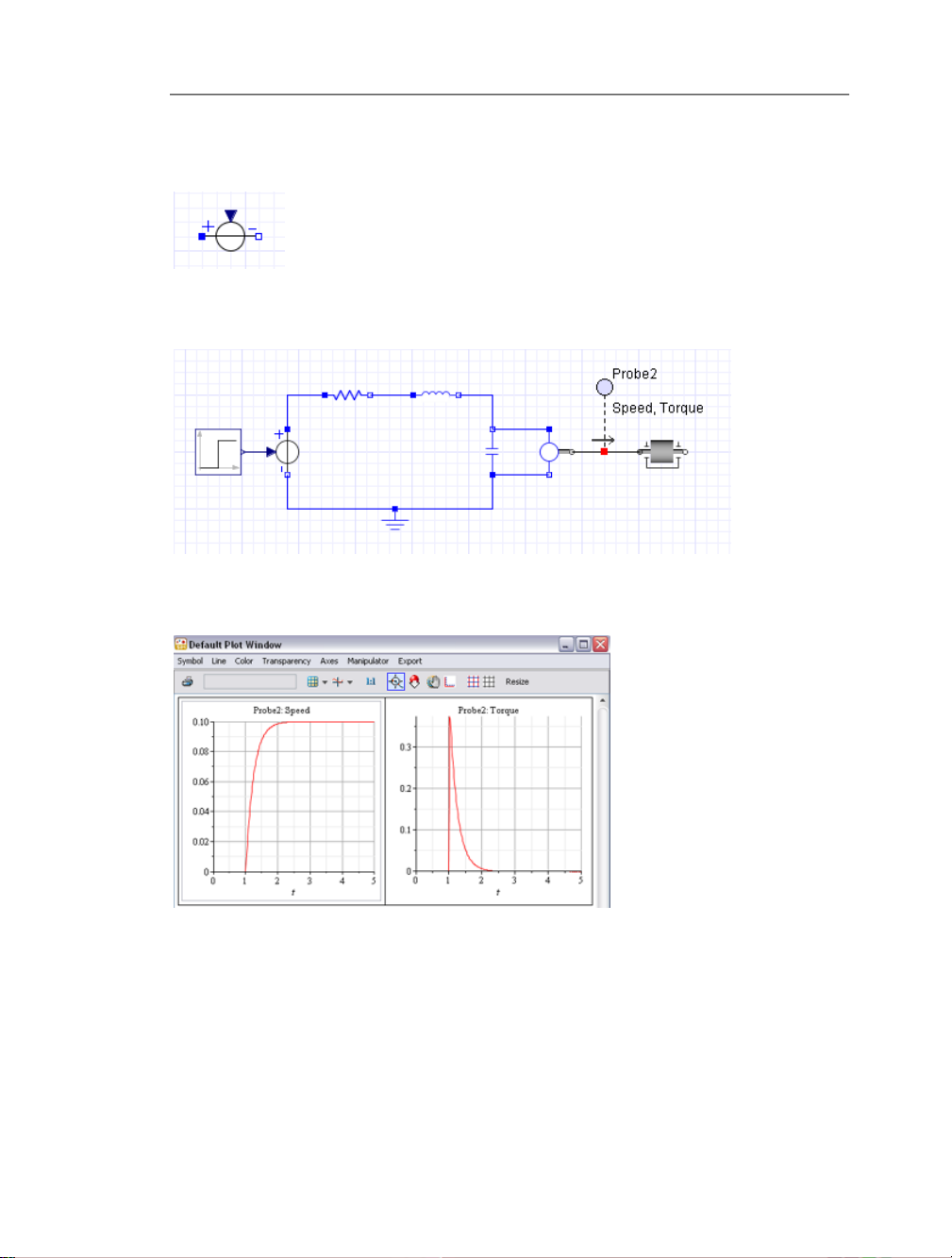

chapter, you will model the RLC circuit described above. The following image shows how

the RLC circuit diagram appears when it is built in MapleSim.

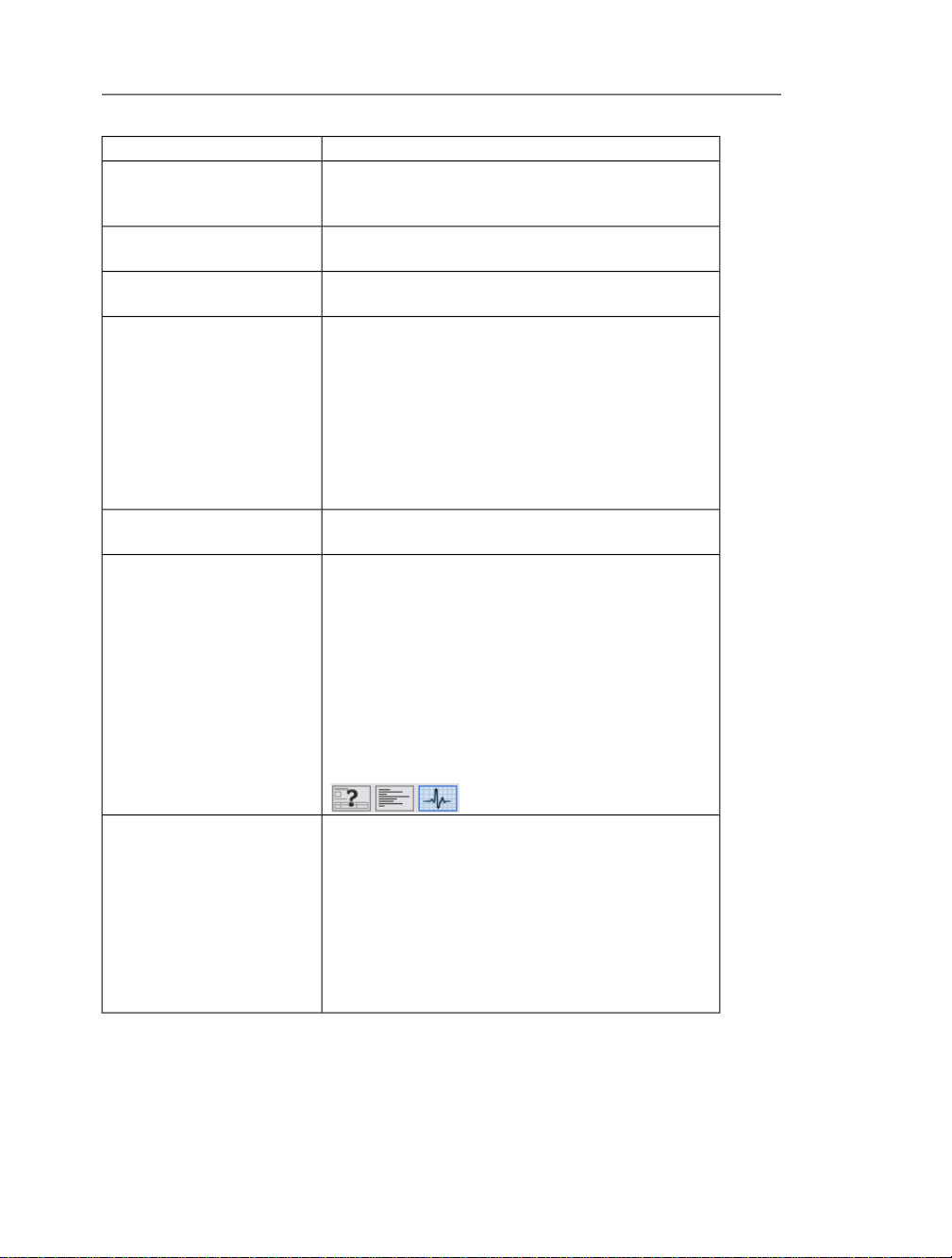

1.2 The MapleSim Window

In the default view, the MapleSim window contains the following panes and components:

Page 16

6 • 1 Getting Started with MapleSim

DescriptionComponent

Contains tools for running a simulation, attaching

1. Main toolbar

2. Navigation toolbar

3. Model workspace toolbar

4. Palettes pane

MapleSim analysistemplates toyour model, and performing other common tasks.

Contains tools for browsing your model and subsystems

hierarchically, and changing the model view.

Contains tools for laying out and selecting objects, and

adding elements such as annotations and probes.

Contains expandable menus withtools that you can use to

build a model and manage your MapleSim project. This

pane contains two tabs:

• Libraries tab: containspalettes withsample modelsand

domain-specic componentsthat youcanadd tomodels.

• Project tab: contains palettes with tools to help you

browse and build a model, and manage simulation results, probes, and documents that you attach to a model.

5. Model workspace

6. Console

7. Parameters pane

The area in which you build and edit a model in a block

diagram view.

Contains the following panes:

• Help pane: displays the help topic associated with a

modeling component.

• Message Console pane: displaysprogress messages in-

dicating the status of the MapleSim engine during a

simulation.

• Debugging pane: displays diagnostic messages as you

build your model.

You can use the buttons below the console

( ) to display each pane.

Contains the following tabs:

• Inspector tab: allows you to view and edit modeling

component properties, such as names and parameter

values, andspecify simulationoptions andprobe values.

• Plots tab: allowsyou todene customlayouts forsimu-

lation graphs and plot windows.

The contentsof thispane changedepending onyour selec-

tion in the model workspace.

MapleSim alsoprovides a3-D workspacethat youcan use to build, animate,and manipulate

3-D multibodymodels. Formore information,see Visualizinga Multibody Model (page 78)

in Chapter 4.

Page 17

1.3 Basic Tutorial: Modeling an RLC Circuit and DC Motor • 7

1.3 Basic Tutorial: Modeling an RLC Circuit and DC Motor

This tutorial introduces you to the modeling components and basic tools in MapleSim. It

illustrates the ability to mix causal models with acausal models.

In this tutorial, you will perform the following tasks:

1. Build an RLC circuit model.

2. Set parameter values to specify component properties.

3. Add probes to identify values of interest for the simulation.

4. Simulate the RLC circuit model.

5. Modify the RLC circuit diagram to create a simple DC motor model.

6. Simulate the DC motor model using different parameters.

Building an RLC Circuit Model

To buildthe RLC circuitdiagram, youadd componentsin the modelworkspace andconnect

them ina system.In this example, the RLCcircuit modelcontains ground,resistor, inductor,

capacitor, and signal voltage source components from the Electrical component library. It

also contains a step input source, which is a signal generator that drives the input voltage

level in the circuit.

Page 18

8 • 1 Getting Started with MapleSim

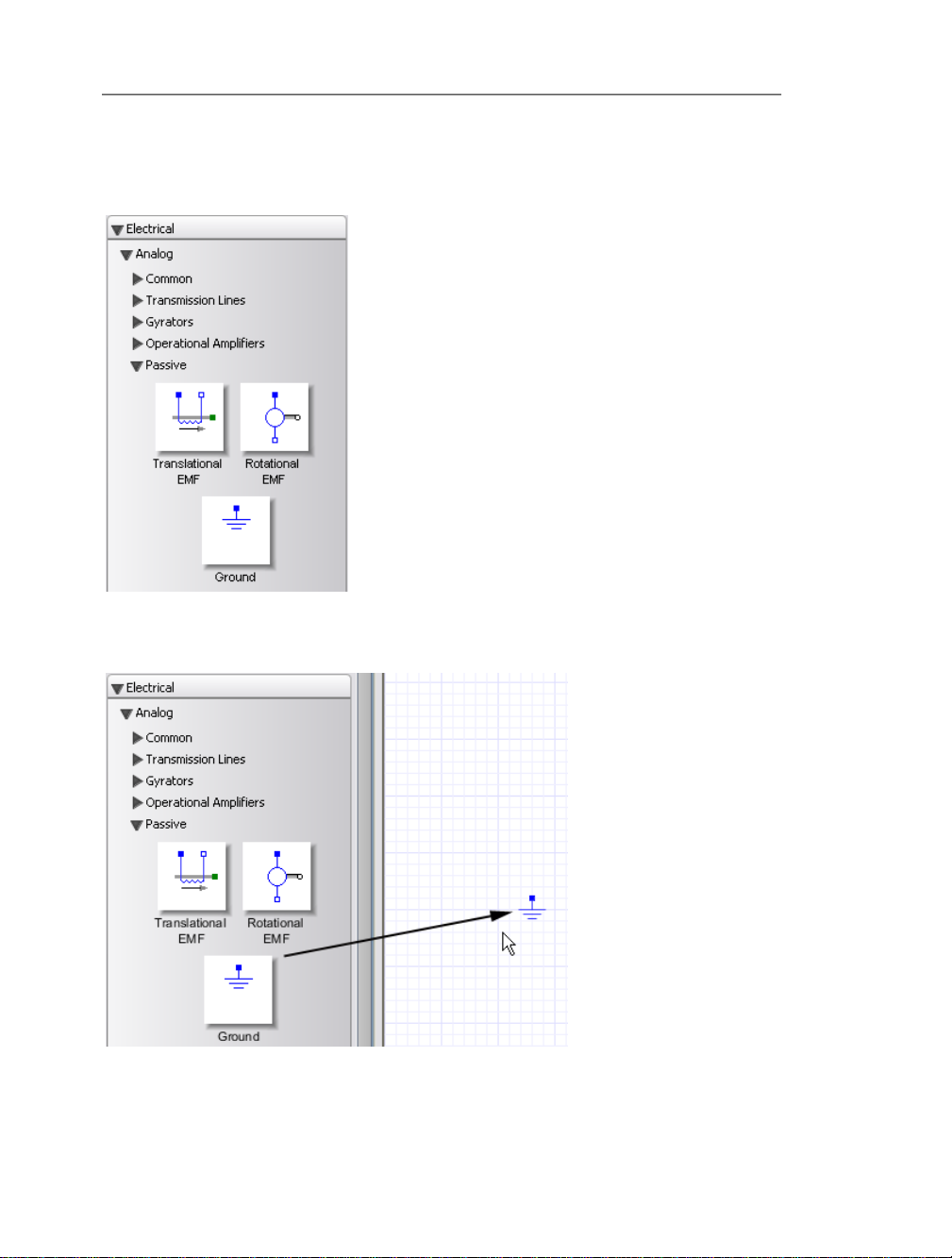

1. Inthe Librariestab at theleft ofthe modelworkspace, click the triangle besideElectrical

to expand the palette. In the same way, expand the Analog menu, and then expand the

Passive submenu.

2. From the Electrical → Analog → Passive menu, drag the Ground component to the

model workspace.

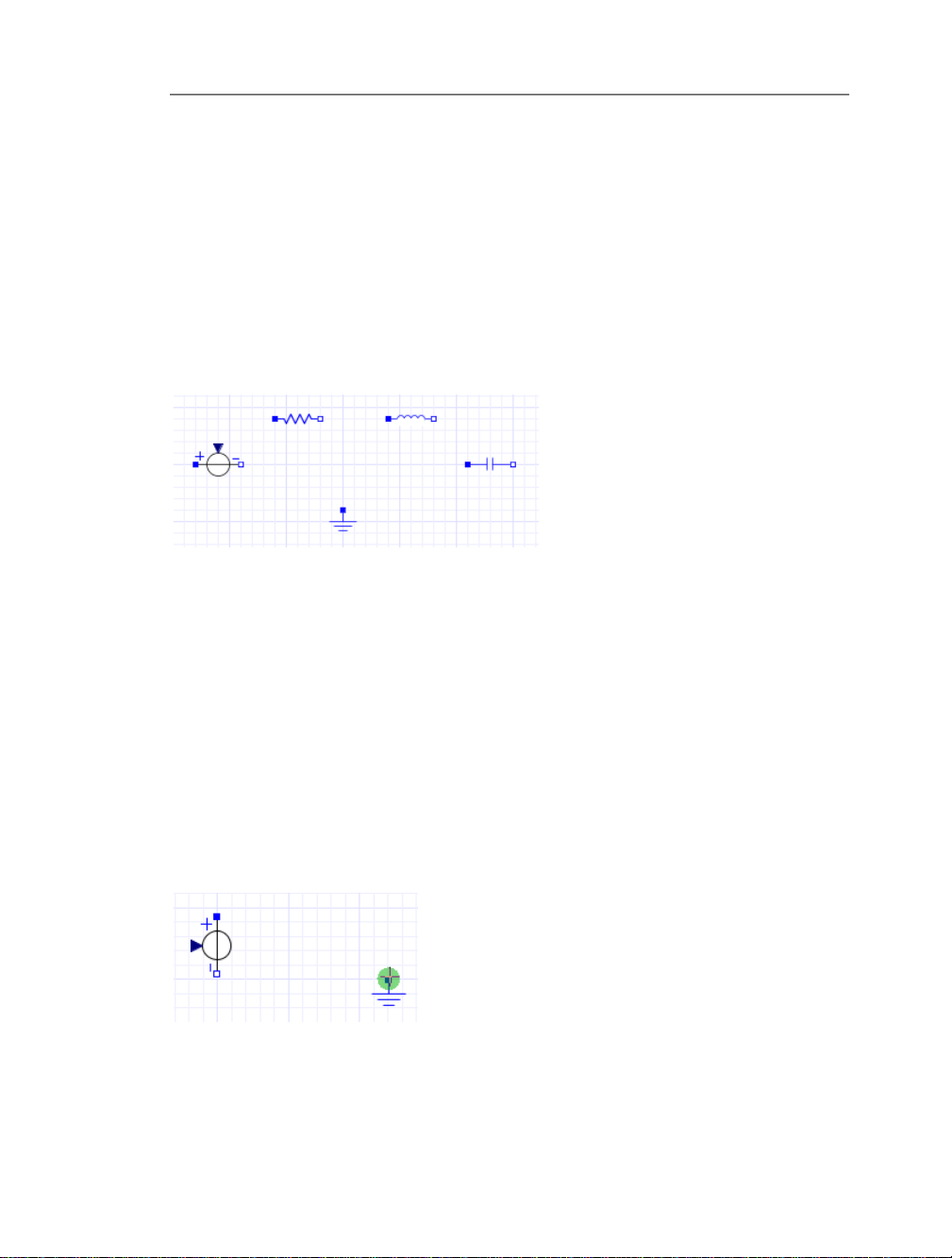

3. Add the remaining electrical components to the model workspace.

Page 19

1.3 Basic Tutorial: Modeling an RLC Circuit and DC Motor • 9

• From the Electrical → Analog → Passive→ Resistors menu, addthe Resistorcompon-

ent.

• From the Electrical → Analog → Passive → Inductors menu, add the Inductor com-

ponent.

• From the Electrical → Analog → Passive → Capacitors menu, add the Capacitor

component.

• From the Electrical → Analog → Sources → Voltage menu, add the Signal Voltage

component.

4. Drag the components in the arrangement shown below.

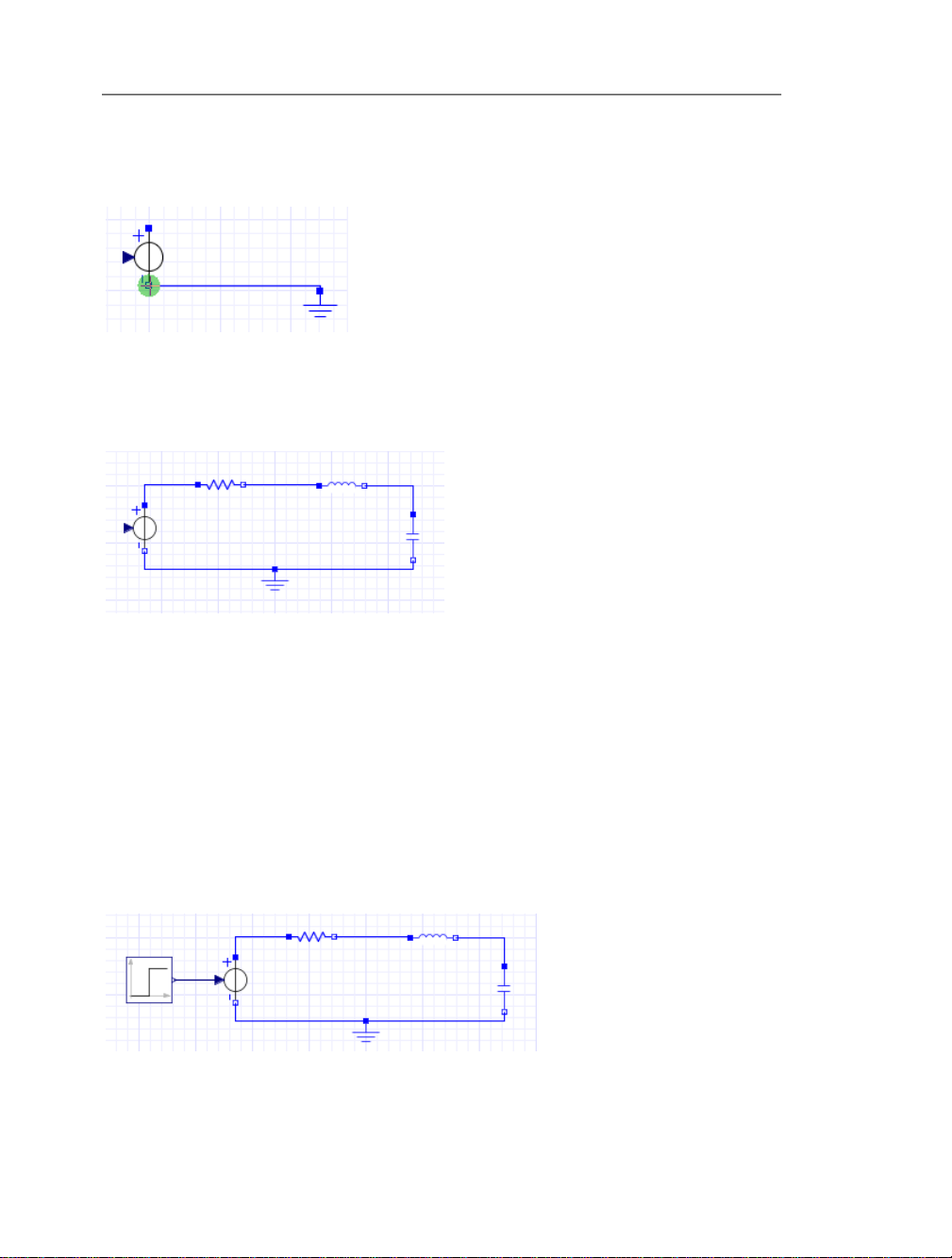

5. To rotate the Signal Voltage component clockwise, right-click (Control-click for

Macintosh®) the Signal Voltage component in the model workspace and select Rotate

Clockwise.

6. To ip the component horizontally, right-click (Control-click for Macintosh) the component again and select Flip Horizontal. Make sure that the positive (blue) port is at the

top.

7. Torotate theCapacitor component clockwise,right-click (Control-click forMacintosh)

the Capacitor icon in the model workspace and select Rotate Clockwise.

You can now connect the modeling components to dene interactions in your system.

8. Hover your mouse pointer over the Ground component port. The port is highlighted in

green.

Page 20

10 • 1 Getting Started with MapleSim

9. Click the Ground input port to start the connection line.

10. Hover your mouse pointer over the negative port of the Signal Voltage component.

11. Click the port once. The Ground component is connected to the Signal Voltage com-

ponent.

12. Connect the remaining components in the arrangement shown below.

You can now add a source to your model.

13. Expand theSignal Blocks palette. Expand theSources menu and then expand the Real

submenu.

14. From the palette, drag the Step source and place it to the left of the Signal Voltage

component in the model workspace.

The step source has a specic signal ow, which is represented by the arrows on the connections. This ow causes the circuit to respond to the input signal.

15. Connect the Step source to the Signal Voltage component. The complete RLC circuit

model is displayed below.

Page 21

1.3 Basic Tutorial: Modeling an RLC Circuit and DC Motor • 11

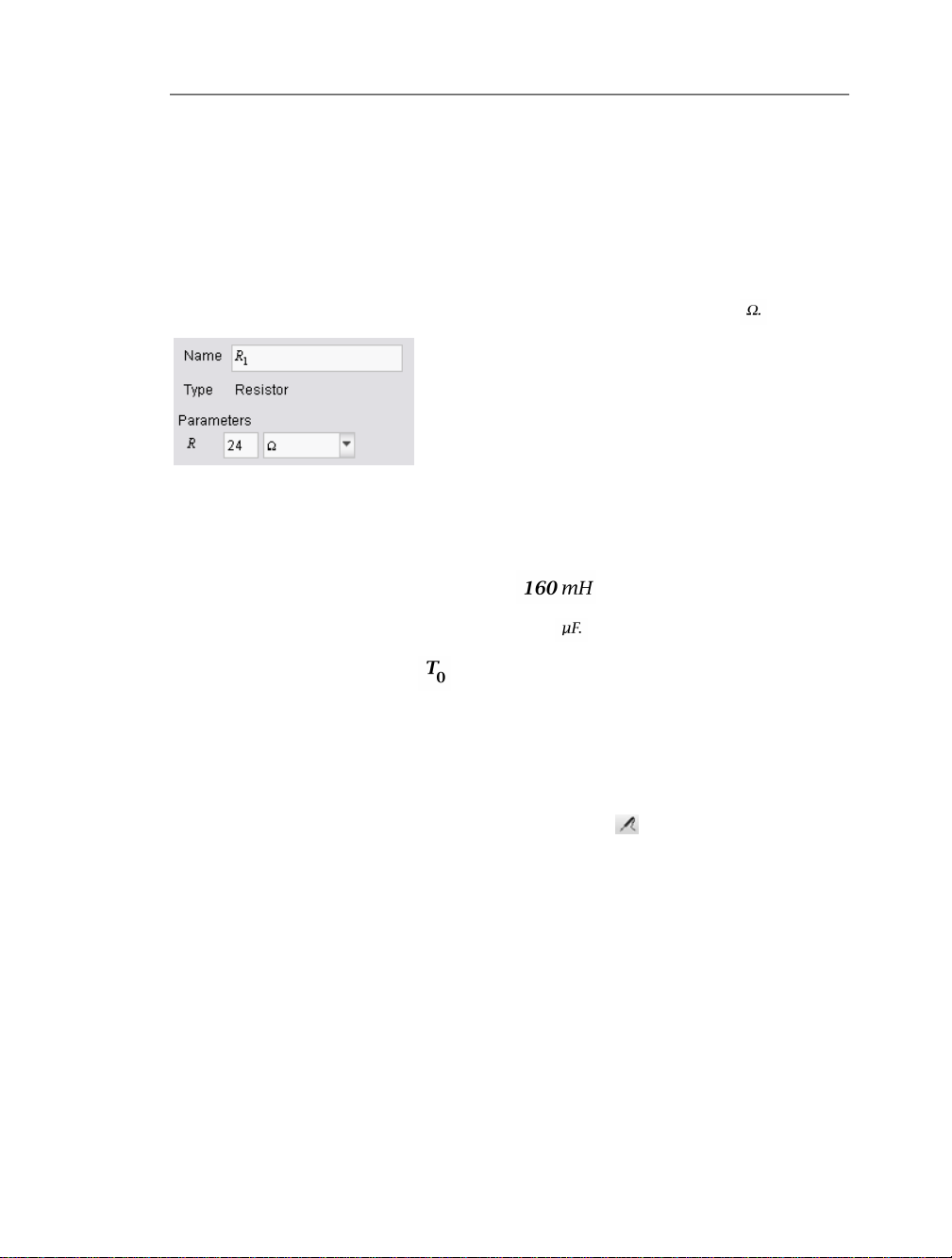

Specifying Component Properties

To specify component properties, you can set parameter values for components in your

model.

1. In the model workspace, click the Resistor component. The Inspector tab at the right of

the model workspace displays the name and parameter values of the resistor.

2. In the R eld, enter 24, and press Enter. The resistance is changed to 24

3. Specify the following parameter values for the other components. You can specify units

for a parameter by selecting a value from the drop-down menu found beside the parameter

value eld.

• For the Inductor, specify an inductance of .

• For the Capacitor, specify a capacitance of 200

• For the Step source, specify a value of 0.1 s.

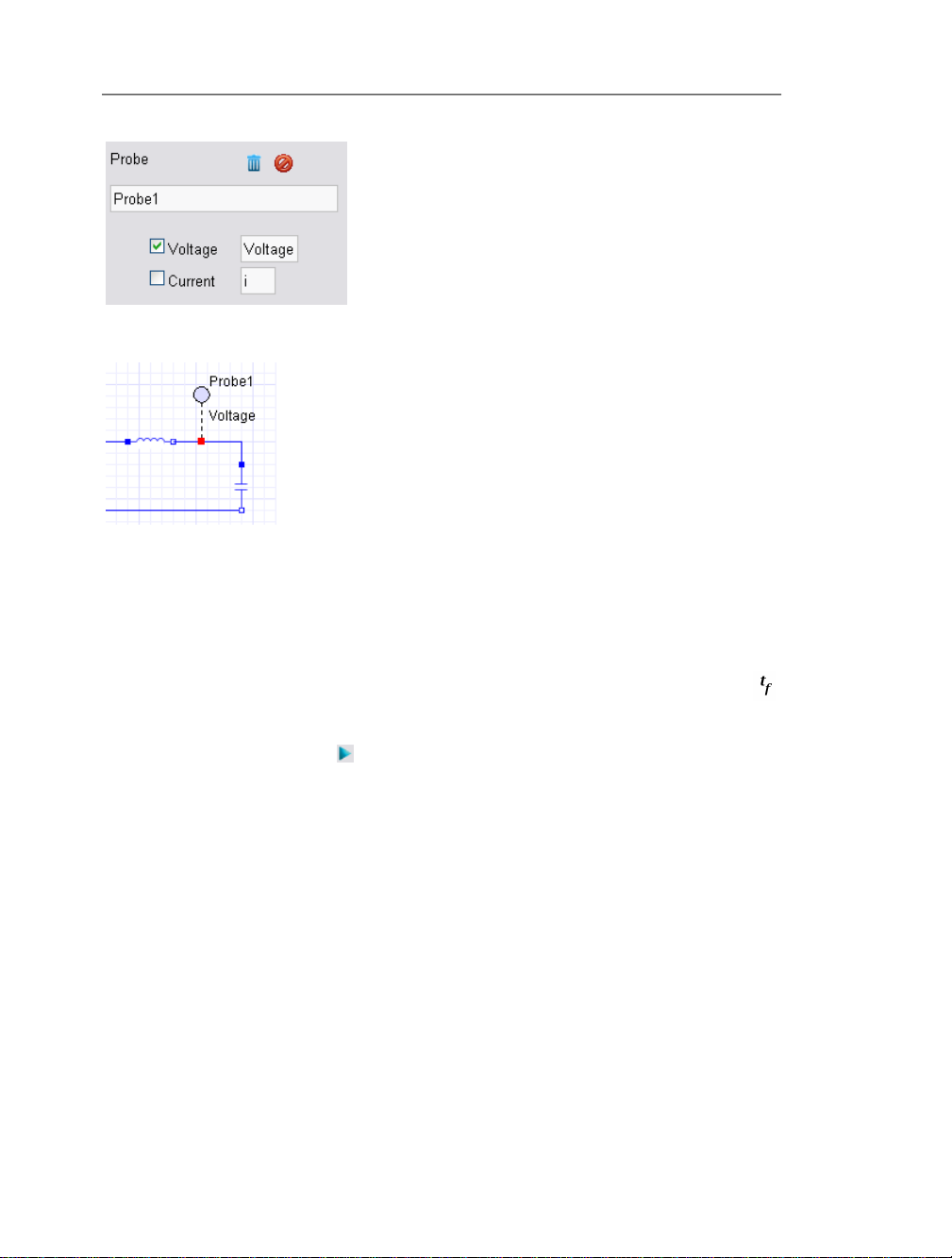

Adding a Probe

To specify data values for a simulation, you must attach probes to lines or ports to the

model. In this example, you will measure the voltage of the RLC circuit.

1. In the model workspace toolbar, click the probe button ( ).

2. Hover your mouse pointer over the line that connects the Inductor and Capacitor

components. The line is highlighted.

3. Left-click the line once. The probe is displayed in the model workspace.

4. Drag the probe to position it and then click the probe once to place it on the line.

5. Select the probe. The probe properties are displayed in the Inspector tab at the right of

the model workspace.

6. Select the Voltage check box to include the voltage quantity in the simulation graph.

7. To display a custom name for this quantity in the model workspace, enter Voltage as

shown below and press Enter.

Page 22

12 • 1 Getting Started with MapleSim

The probe is added to the connection line.

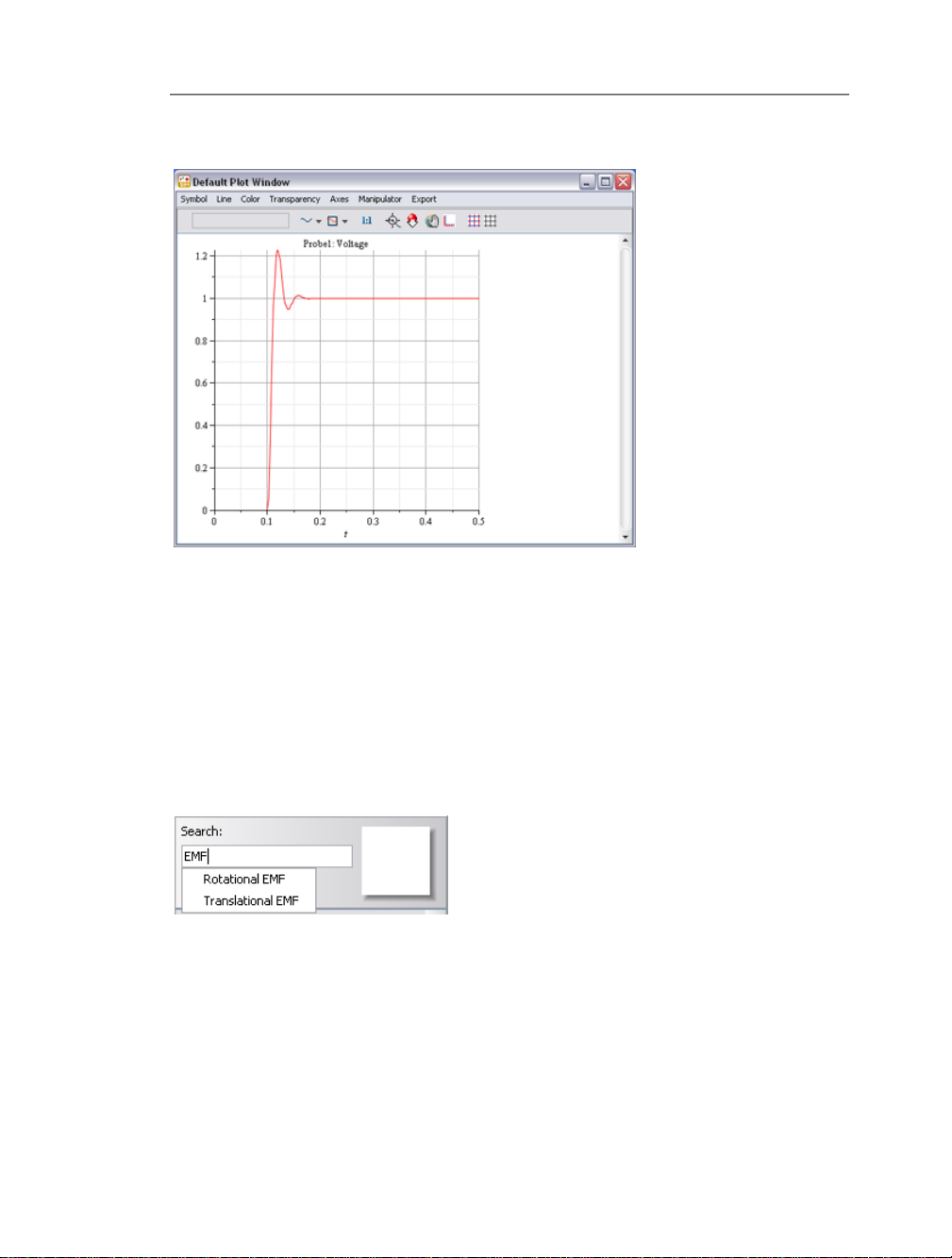

Simulating the RLC Circuit Model

Before simulatingyour model,you canspecify theduration for which to run the simulation.

1. Click a blank area in the model workspace.

2. Inthe Inspector tab at theright of the model workspace,set the simulation end time( )

to 0.5 seconds and press Enter.

3. Click the simulation button ( ) in the main toolbar. MapleSim generates the system

equations and simulates the response to the step input.

Page 23

1.3 Basic Tutorial: Modeling an RLC Circuit and DC Motor • 13

When the simulation is complete, the voltage response is plotted in a graph.

4. Save the modelas RLC_Circuit1.msim. The probes and modied parameter values are

saved as part of the model.

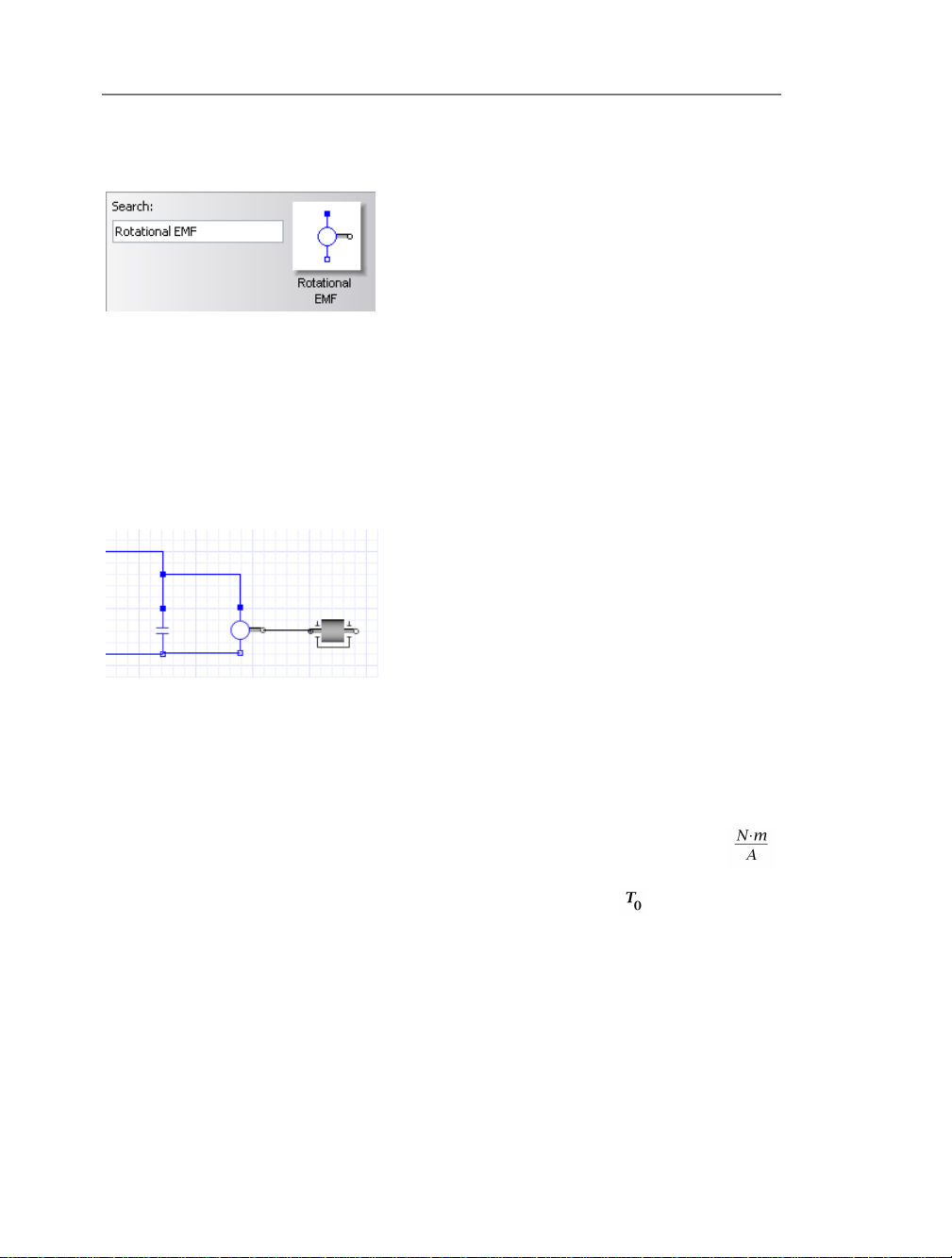

Building a Simple DC Motor Model

You will now add an electromotive force (EMF) component and a mechanical inertia

component to the RLC circuit modelto create a DC motor model. Inthis example, you will

add components to the RLC circuit model using the search feature.

1. In the Libraries tab, in the Search eld located above the palettes, type EMF. A drop-

down list displays your search results.

Page 24

14 • 1 Getting Started with MapleSim

2. Select Rotational EMF from the drop-down list. The Rotational EMF component is

displayed in the square beside the search eld.

3. From the square beside the search eld, drag the Rotational EMF component to the

modeling workspace and place it to the right of the Capacitor component.

4. In the search pane, search for Inertia.

5. Add theInertia component to the model workspace and placeit to the right of the Rota-

tional EMF component.

6. Connect the components as shown below.

Note: To connect the positive blue port of the Rotational EMF component, click the port

once, drag your mouse pointer to the line connecting the capacitor and inductor, and click

the line.

7. In the model workspace, click the Rotational EMF component.

8. In the Inspectortab, change the value of the transformation coefcient (k) to 10 .

9. Click the Step component and change the value of the parameter, , to 1.

Page 25

1.3 Basic Tutorial: Modeling an RLC Circuit and DC Motor • 15

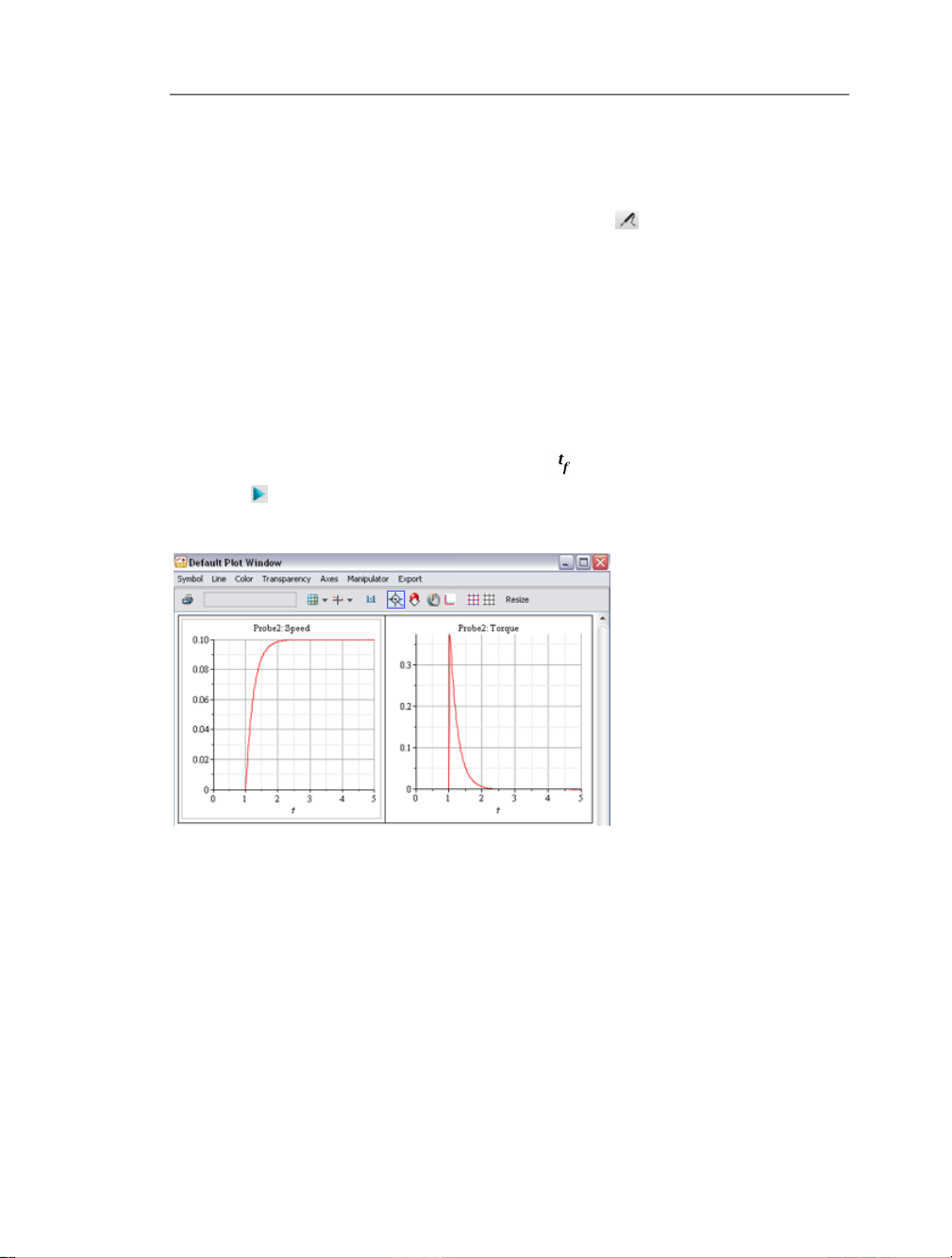

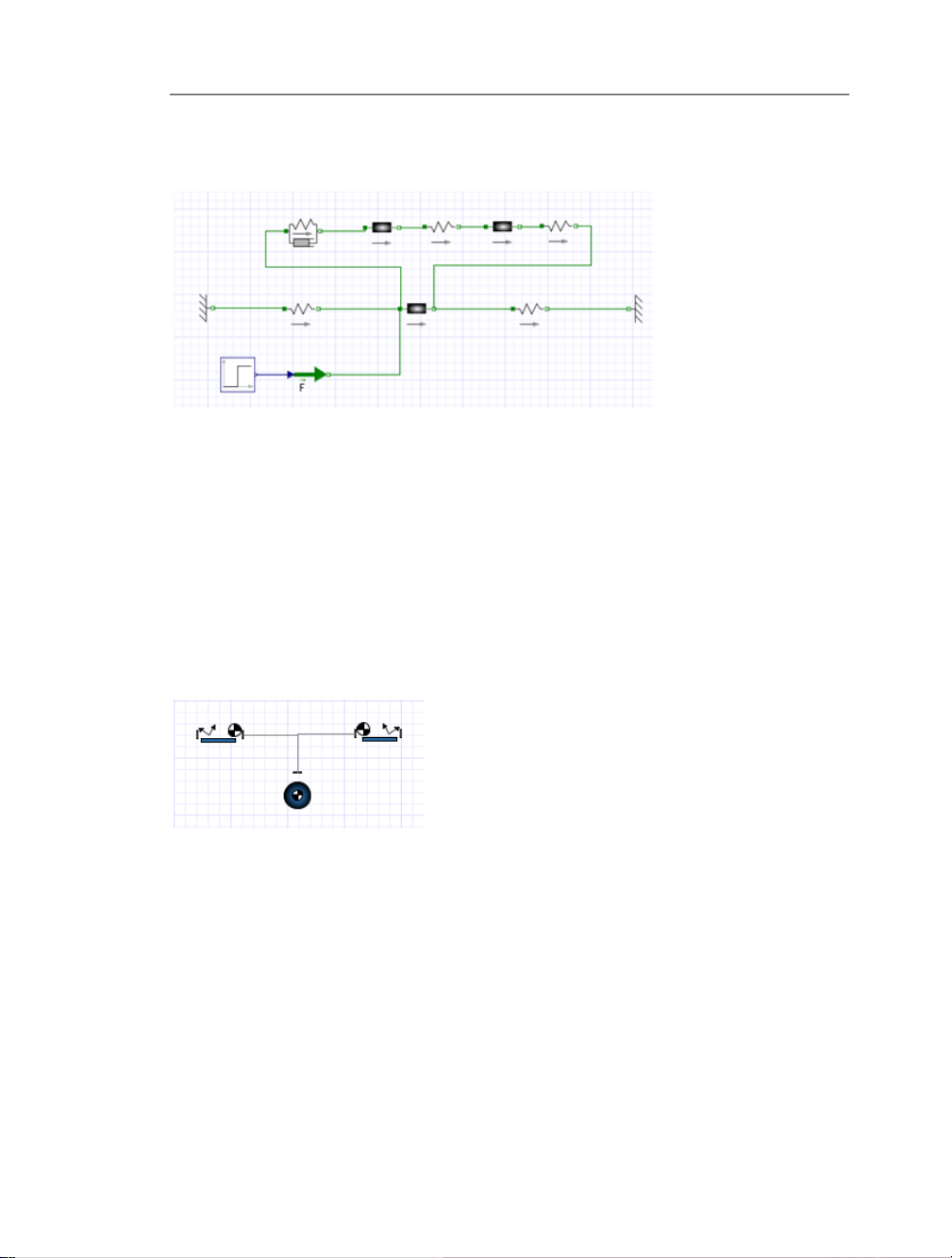

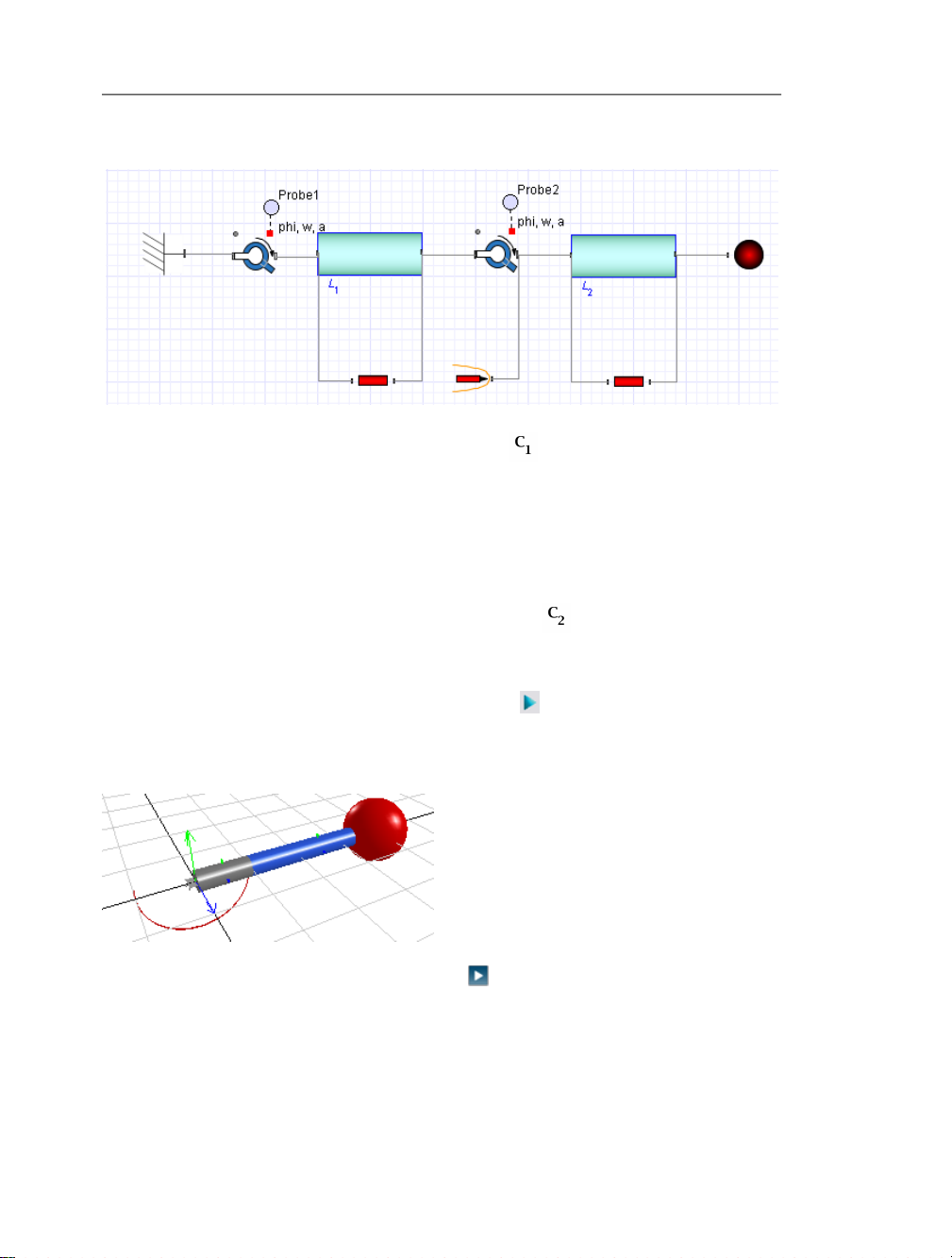

Simulating the DC Motor Model

1. In the model workspace, delete Probe1.

2. In the model workspace toolbar, click the probe button ( ).

3. Hover your mouse pointer over the line that connects the Rotational EMF and Inertia

components.

4. Left-click the line and then left-click the probe once to position it.

5. Select the probe.

6. In the Inspectortab, selectthe Speedand Torque check boxes.The probe,with anarrow

indicating the direction of the conserved quantity ow, is added to the model.

7. Click a blank area in the model workspace.

8. In the Inspectortab, setthe simulationend time ( )to 5 seconds and clickthe simulation

button ( ) in the main toolbar.

The following graphs are displayed.

9. Save the model as DC_Motor1.msim.

Page 26

16 • 1 Getting Started with MapleSim

Page 27

2 Building a Model

In this chapter:

• The MapleSim Component Library (page 17)

• Browsing a Model (page 18)

• Dening How Components Interact in a System (page 20)

• Specifying Component Properties (page 21)

• Creating and Managing Subsystems (page 23)

• Global and Subsystem Parameters (page 34)

• Attaching Files to a Model (page 42)

• Creating and Managing Custom Libraries (page 43)

• Annotating a Model (page 45)

• Entering Text in 2-D Math Notation (page 47)

• Creating a Data Set for an Interpolation Table Component (page 48)

• Best Practices: Building a Model (page 49)

2.1 The MapleSim Component Library

The MapleSim component library contains over 300 components that you can use to build

models. All of thesecomponents are organized in palettes according to their respective domains: electrical, hydraulic, 1-D and multibody mechanical, thermal, and signal blocks.

Most of these components are based on the Modelica® Standard Library.

DescriptionLibrary

Electrical

Hydraulic

1-D Mechanical

Multibody Mechanical

Signal Blocks

Components to modelelectrical analog circuits,singlephase and multiphase systems, and electric machines.

Components to model hydraulic systems such as uid

power systems, cylinders, and actuators.

Components to model 1-D translational and rotational

systems.

Components to model multibody mechanical systems,

including force, motion, and joint components.

Components tomanipulateor generateinput andoutput

signals.

Components to model heat ow and heat transfer.Thermal

The library also contains sample models that you can view and simulate, for example,

complete electrical circuits and lters. For more information about the MapleSim library

17

Page 28

18 • 2 Building a Model

structure and modeling components, see the MapleSim Library Reference Guide in the

MapleSim help system.

To extendthe defaultlibrary,you cancreate acustom modelingcomponent froma mathematical model and add it to a custom library. For more information, see Creating Custom

Modeling Components (page 55).

Viewing Help Topics for Components

In thehelp panebelow themodel workspace,you canview thehelp topic for each component

from the MapleSimcomponent library. To display the help pane, click the help pane button

( ) at the bottom of the MapleSim window. You can then select a component that you

have addedto the modelworkspace toview itshelp topic.Alternatively, toview help topics,

you can perform one of the following tasks:

• Right-click (Control-clickfor Macintosh®)a modelingcomponent in any of thepalettes

and select Help from the context menu.

• Search for the help pages for components in the MapleSim help system.

2.2 Browsing a Model

Using the Model Tree palette or model navigation controls, you can browse your model to

view hierarchical levels of components in the modelworkspace. You can browse to the top

level for an overall view of your system. The top level is the highest level of your model:

it represents the complete system, which can include individual modeling components and

subsystem blocks that represent groups of components. You can also browse to sublevels

in your model to view the contents of individual subsystems or components.

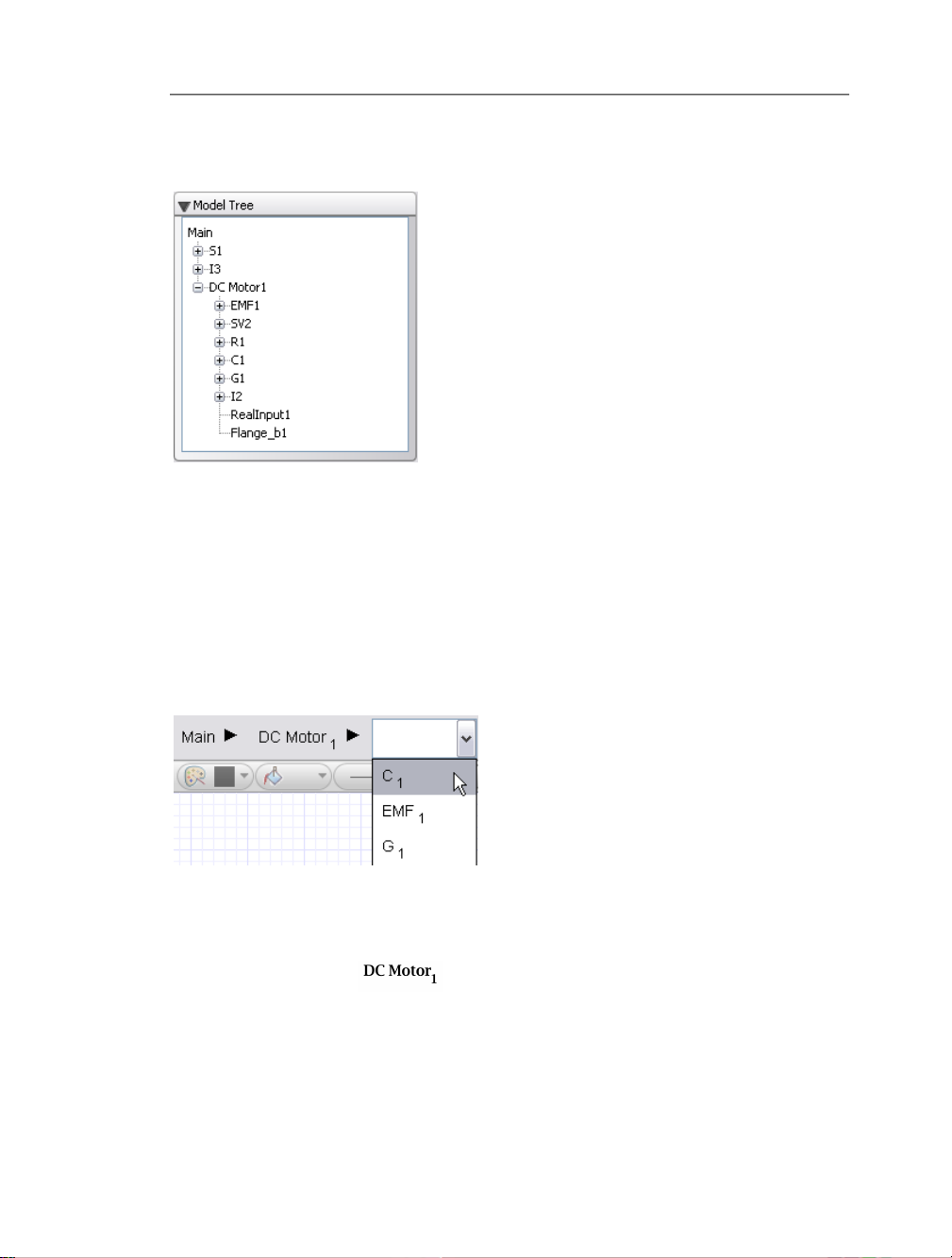

Model Tree

To browse your model, you can use the Model Tree palette in the Project tab located on

the left side of the MapleSim window. Each node in the model tree represents a modeling

Page 29

2.2 Browsing a Model • 19

component, subsystem, or connection port in your model. For example, the model tree of

a DC motor is shown below.

To browse your model and view the parameters associated with a component or subsystem,

expand and double-click the nodes in the model tree. You can double-click the Main node

to viewthe top levelof your model and thechild nodes to view thecontents of a component

or subsystem.

Model Navigation Controls

Alternatively, youcan usethe model navigation controls located above the model workspace

toolbar to browse between modeling components, subsystems, and hierarchical levels in a

diagram displayed in the model workspace.

From the drop-down menu, select the name of the subsystem or modeling component that

you want to view in the model workspace. You can click the Main button to browse to the

top level of your model. You can also browse directly to subsystems in your model. For

example, by clicking the button in the example shown above, you can view the

DC motor subsystem contents in the model workspace.

Page 30

20 • 2 Building a Model

2.3 Defining How Components Interact in a System

To dene interactions between modelingcomponents, you connectthem in a system. In the

model workspace, you can draw a connection line between two connection ports.

You can also draw a connection line between a port and another connection line.

MapleSim permits connections between compatible domains only. By default, each line

type is displayed in a domain-specic color.

Line ColorDomain

BlackMechanical 1-D rotational

GreenMechanical 1-D translational

BlackMechanical multibody

BlueElectrical analog

BlueElectrical multiphase

PurpleDigital logic

PinkBoolean signal

Navy blueCausal signal

OrangeInteger signal

RedThermal

The connection ports for each domain are also displayed in specic colors and shapes. For

more information about connection ports, see the MapleSim Library Reference → Con-

nectors Overview topic in the MapleSim help system.

Page 31

2.4 Specifying Component Properties • 21

2.4 Specifying Component Properties

To specify component properties, you can set parameter values for components in your

model. When you select a component in the model workspace, the congurable parameter

values for that component are displayed in the Inspector tab located on the right side of

the MapleSim window.

Note: Not all components provide editable parameter values.

You enter parameter values in 2-D math notation, which is a formatting option that allows

you to add mathematical text such as superscripts, subscripts, and Greek characters. For

more information, see Entering Text in 2-D Math Notation (page 47).

Specifying Parameter Units

You can use thedrop-down menus besideparameter elds withdimensions to specify units

for parameter values. For example, the image below displays the congurable parameter

elds for a Sliding Mass component. You can optionally specify the mass in kg, , ,

or slug, and the length in m, cm, mm, ft, or in.

When you simulate a model, MapleSim automatically converts all parameter units to the

International System of Units (SI). Youcan, therefore, selectmore than one system of units

for parameter values throughout a model.

If you want to convert the units of a signal, use the Unit Conversion Block component

from the Signal Converters menu in the Signal Blocks palette. This component allows

you to perform conversions in dimensions such as time, temperature, velocity, pressure,

and volume. In the following example, a Unit Conversion Block component is connected

Page 32

22 • 2 Building a Model

between a translational Position Sensor and Feedback component to convert the units of

an output signal.

If you include an electrical, 1-D mechanical, hydraulic, or thermal sensor in your model,

you can also select the units in which to generate an output signal.

Specifying Initial Conditions

You can set parameter values to specify initial conditions for many electrical, hydraulic,

and 1-D mechanical components, including capacitors, hydraulic pipes, and mechanical

springs and dampers. When you select a component that contains state variables in the

model workspace, the available initial condition elds are displayed in the Inspector tab,

along with the other congurable parameter values for that component.

For example, the image below displays the initial velocity and position elds that you can

set for a Sliding Mass component.

Page 33

2.5 Creating and Managing Subsystems • 23

2.5 Creating and Managing Subsystems

A subsystem (or compound component) is a set of modeling components that are grouped

in a single block component. A sample DC motor subsystem is shown below.

You can createa subsystemto groupcomponents thatform acomplete system,for example,

a tire or DC motor. You can also create a subsystem to improve the layout of a diagram in

the model workspace, add multiple copies of a system to a model, or analyze a component

group in Maple. You can organize your model hierarchicallyby creating subsystemswithin

other subsystems.

For bestpractices on creating subsystems in MapleSim, seeBest Practices: Laying Out and

Creating Subsystems (page 49).

Example: Creating a Subsystem

In the following example, you will group the electrical components of a DC motor model

into a subsystem.

1. In the Libraries tab on the left side of the MapleSim window, expand the Examples

palette, expand the Tutorial menu, and then open the Simple DC Motor example.

Page 34

24 • 2 Building a Model

2. Using the selection tool( ) located above the modelworkspace, draw abox around the

electrical components.

3. From the Edit menu, select Create Subsystem.

4. In the dialog box, enter DC Motor.

5. Click OK. A white block, which represents the DC motor, is displayed in the model

workspace.

In thisexample, you created a stand-alonesubsystem, which can be editedand manipulated

independently of other subsystems in your model. If you wantto add multiple copies of the

same subsystem to your model and edit those subsystems as a group, you can create a sub-

system denition. For more information, see Adding Multiple Copies of a Subsystem to a

Model (page 26).

Page 35

2.5 Creating and Managing Subsystems • 25

Viewing the Contents of a Subsystem

To view the contents of a subsystem, double-click the subsystem icon in the model workspace. The detailed view of a subsystem is displayed.

In this view, a broken line indicates the subsystem boundary. You can edit the connection

lines and components within the boundary, add and connect components outside of the

boundary, and add subsystem ports to connect the subsystem to other components. If you

want toresize theboundary,click thebroken line and drag oneof thesizing handlesdisplayed

around the box.

To browse to the top level of the model or to other subsystems, use the controls in the navigation toolbar.

Page 36

26 • 2 Building a Model

Adding Multiple Copies of a Subsystem to a Model

If you plan to add multiple copies of a subsystem to a model and want all of the copies to

have the same conguration, you cancreate a subsystemdenition. A subsystem denition

is the base subsystem that denes the attributes and conguration that you want a series of

subsystems to share.

For example,if you want to add three DCmotor subsystemsthat all have identical components and resistance values in your model, you would perform the following tasks:

1. Build a DC motor subsystem with the desired conguration in the model workspace

2. Use that subsystem conguration to create a subsystem denition and and add it to the

Denitions palette, and

3. Add copies of the DC motor subsystem to your model using the subsystem denition as

a source.

To add copies of the DC motor subsystem to your model, you can drag the DC Motor sub-

system denition icon from the Denitions palette and place it in the model workspace.

The copies that you add to the model workspace will then share a conguration that is

identical to the subsystem denition in the Denitions palette; the copies in the model

workspace are called shared subsystems because they share and refer to the conguration

specied in their corresponding subsystem denition.

Shared subsystems that are copied from the same subsystem denition are linked, which

means that changes that you make to one shared subsystem will be reected in all of the

other shared subsystemsthat werecreated from thesame subsystemdenition. The changes

are also reected in the subsystem denition entry in the Denitions palette.

Using the example shown above, if you change the resistance parameter of the Resistor

component in the shared subsystem from 24 to 10 , the resistance value

Page 37

2.5 Creating and Managing Subsystems • 27

of the Resistor component in the and shared subsystems and the

DC Motor subsystem denition in the Denitions palette will also be changed to 10 .

For moreinformation, see EditingSubsystem Denitions and SharedSubsystems (page 28).

Example: Adding Subsystem Definitions and Shared Subsystems to a Model

In thefollowing example,you willcreate aDC Motor subsystem denition and add multiple

shared subsystems to your model.

Adding a Subsystem Definition to the Definitions Palette

1. In the model workspace, right-click (Control-click for Macintosh) the stand-alone DC

motor subsystem that you created in Example: Creating a Subsystem (page 23).

2. From the context menu, select Convert to Shared Subsystem.

3. Enter DC Motor as the name for the subsystem denition and click OK.

4. Inthe Projecttab on the left sideof themodel workspace, expand the Denitionspalette

and then expand the Subsystems menu.

The subsystem denition is added to the Denitions palette and the subsystem in the

model workspace is converted into a shared subsystem called . This shared

subsystem is linked to the DC Motor subsystem denition.

You can now use this subsystem denition to add multiple DC motor shared subsystems

to your MapleSim model.

Page 38

28 • 2 Building a Model

Tip: If you wantto usea subsystemdenition inanother model,add thesubsystem denition

to a custom library. For more information, see Creating and Managing Custom Librar-

ies (page 43).

Adding Multiple DC Motor Shared Subsystems to a Model

To add multiple DC Motor shared subsystems to a model, drag the DC Motor subsystem

denition icon from the Denitions palette and place it in the model workspace.

When you create a new stand-alone subsystem or add shared subsystems to a model, a

unique subscript number is appended to the subsystem name displayed in the model workspace. As shown in the image above, subscript numbers are appended to the namesof each

DC Motor shared subsystem. These numbers can help you to identify multiple subsystem

copies in your model.

Editing Subsystem Definitions and Shared Subsystems

If you edit a shared subsystem in the model workspace, your changes will be reected in

the subsystem denition that is linked to the shared subsystem, as well as other shared

subsystems that were copied from the same subsystem denition.

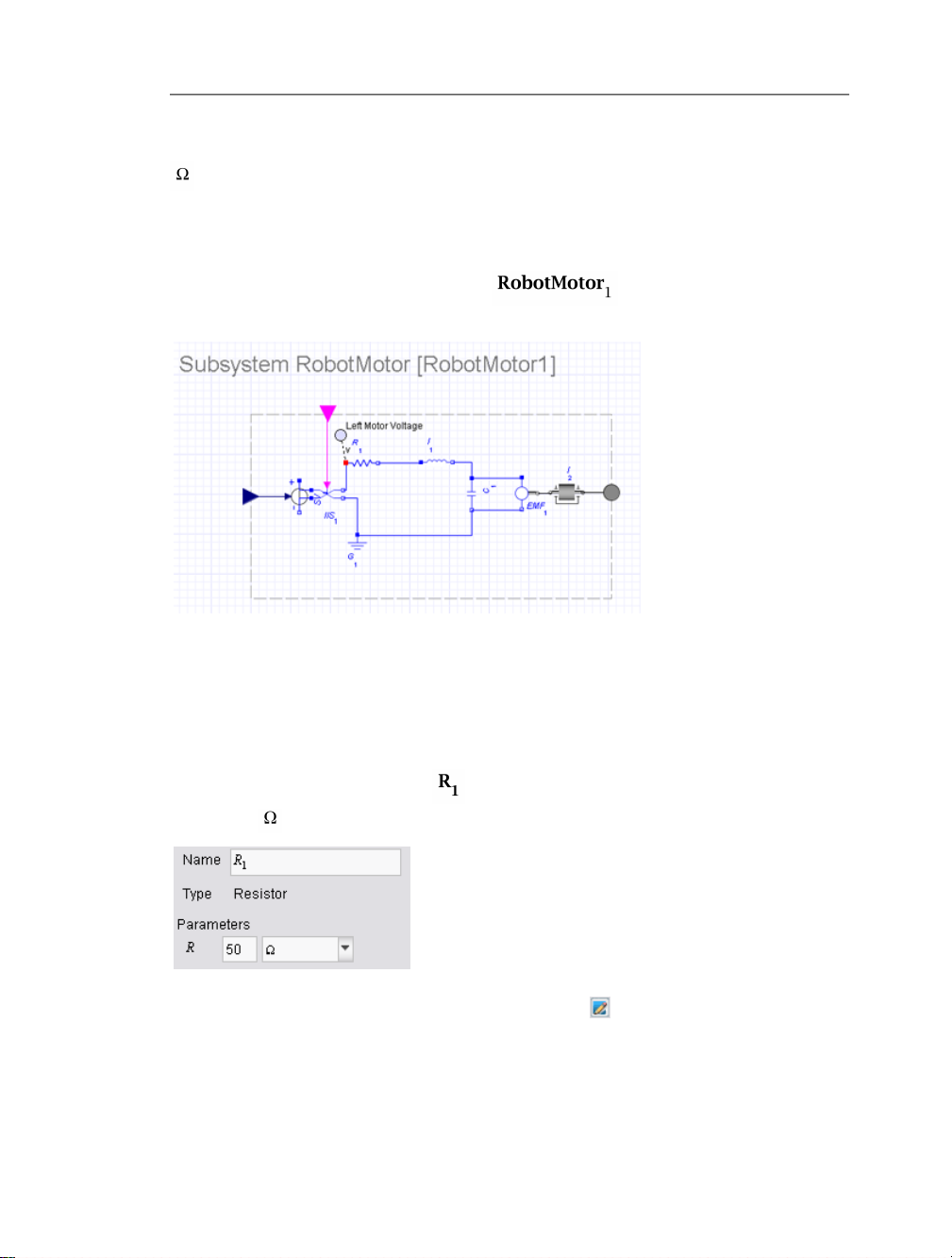

Example: Editing Shared Subsystems that are Linked to the Same Subsystem Definition

In this example, you will edit the resistance values and subsystem icons in a model that

contains two DC motor shared subsystems called and .

These shared subsystems are linked to a subsystem denition called RobotMotor. When

you changethe resistancevalue inone RobotMotorshared subsystem,the otherRobotMot-

or shared subsystem and RobotMotor shared subsystems that you add in the future will

contain the changes.

Page 39

2.5 Creating and Managing Subsystems • 29

To start, both RobotMotor shared subsystems in this model have a resistance value of 30

.

1. In the Libraries tab on the left side of the MapleSim window, expand the Examples

palette, expand the Multidomain menu, and then open the Sumobot example.

2. Inthe model workspace,double-click the shared subsystem.The detailed

view of the shared subsystem is displayed.

Note that a heading with the subsystem denition name (RobotMotor) followed by the

shared subsystem name (RobotMotor1) is displayed at the top of the model workspace.In

the detailed view of all shared subsystems, this heading is displayed to help you identify

multiple subsystem copies in your model. Also, when you select a shared subsystem, its

subsystem denition name is displayed in the Type eld in the Inspector tab.

3. Select the Resistor component ( ) and, in the Inspector tab, change the resistance

value to 50 .

4. In the navigation toolbar, click the icon view button ( ).

Page 40

30 • 2 Building a Model

5. Using the rectangle tool( ) in themodel workspace toolbar, click and dragyour mouse

pointer to draw a shape in the box.

6. In the navigation toolbar, click the diagram view button ( ).

7. Click Main in the navigation toolbar to browse to the top level of the model. Both of the

RobotMotor shared subsystems now display the square that you drew.

8. In the Project tab on the left side of the MapleSim window, expand the Denitions

palette, and thenexpand theSubsystems menu. As shown inthe imagebelow,your changes

are also reected in the RobotMotor entry displayed in this palette.

Page 41

2.5 Creating and Managing Subsystems • 31

If you double-click the RobotMotor subsystems in the model workspace and select their

Resistor components, you will also see that both of the shared subsystems now have a res-

istance value of 50

9. From the Denitions palette, drag a new copy of the RobotMotor subsystem and place

it anywhere in the model workspace. The new copy displays the square that you drew and

its resistance value is also 50

Example: Removing the Link Between a Shared Subsystem and its Subsystem Definition

If your model contains multiple shared subsystems that are linked and youwant to edit one

copy only, you canremove thelink betweena sharedsubsystem andits subsystem denition,

and edit that subsystem without affecting others in the model workspace.

1. In the Libraries tab on the left side of the MapleSim window, expand the Examples

palette, expand the Multidomain menu, and then open the Sumobot example.

2. In the model workspace, right-click (Control-click for Macintosh) the

shared subsystem.

3. Select Convertto Stand-alone Subsystem. The subsystem isno longer

linked to the RobotMotor subsystem denition in the Denitions palette; it is now called

copy of

4. Double-click the shared subsystem.

5. Click the icon view button ( ).

6. Using the rectangle tool ( ), click and drag your mouse pointer to draw a shape in the

box in the model workspace.

7. Click the diagram view button ( ) and click Main to browse to the top level of the

model. Your change is shown in the shared subsystem in the model

workspace and the RobotMotor subsystem denition in the Denitions palette. Note that

your changeis notshown inthe copyof subsystem thatis nolonger linked

to the RobotMotor subsystem denition.

Page 42

32 • 2 Building a Model

Tip: When you converta shared subsystem to astand-alone subsystem,it is a good practice

to assign the stand-alone subsystem a meaningful name that clearly distinguishes it from

existing shared subsystems and subsystem denitions.

Working with Stand-alone Subsystems

Stand-alone subsystems are subsystems that are not linked to a subsystem denition. You

can create a stand-alone subsystem in two ways: by creating a new subsystem as shown in

Example: Creating a Subsystem (page 23) or by converting a shared subsystem to a standalone subsystem as shown in Example: Removing the Link Between a Shared Subsystem

and its Subsystem Denition (page 31). Stand-alone subsystems can be edited independently

without affecting other subsystems in the model workspace.

To identify a subsystem as a stand-alone subsystem, select a subsystem in the model

workspace and examine the Inspector tab. If that subsystem is a stand-alone subsystem,

the Type eld reads Standalone Subsystem.

Also, ifyou double-clicka stand-alonesubsystem tobrowse toits detailedview,no heading

is displayed for the subsystem in the model workspace.

When youcopy andpaste astand-alone subsystem in the model workspace, you can optionally convert that subsystem into a shared subsystem and createa new subsystem denition.

For more information, see Example: Copying and Pasting a Stand-alone Subsys-

tem (page 33).

Example: Resolving Warning Messages in the Debugging Console

When you convert a shared subsystem into a stand-alone subsystem, a warning message

appears to inform you that the link to the subsystem denition has been removed.

Note: This example is an extension of Example: Removing the Link Between a Shared

Subsystem and its Subsystem Denition (page 31).

1. Click the debugging button ( ) at the bottom of the MapleSim window todisplay the

debugging console. The following warning message appears in the console.

Page 43

2.5 Creating and Managing Subsystems • 33

2. To work with the copy of subsystem as a stand-alone subsystem, rightclick (Control-click for Macintosh) the warning message and select Ignore duplication

warnings for “copy for RobotMotor1”.

Alternatively, if you want to link the copy of stand-alone subsystem to the

RobotMotor subsystem denition again,you canright-click (Control-clickfor Macintosh)

the warning message and select Update “copy of RobotMotor1” to use the shared sub-

system “RobotMotor”.

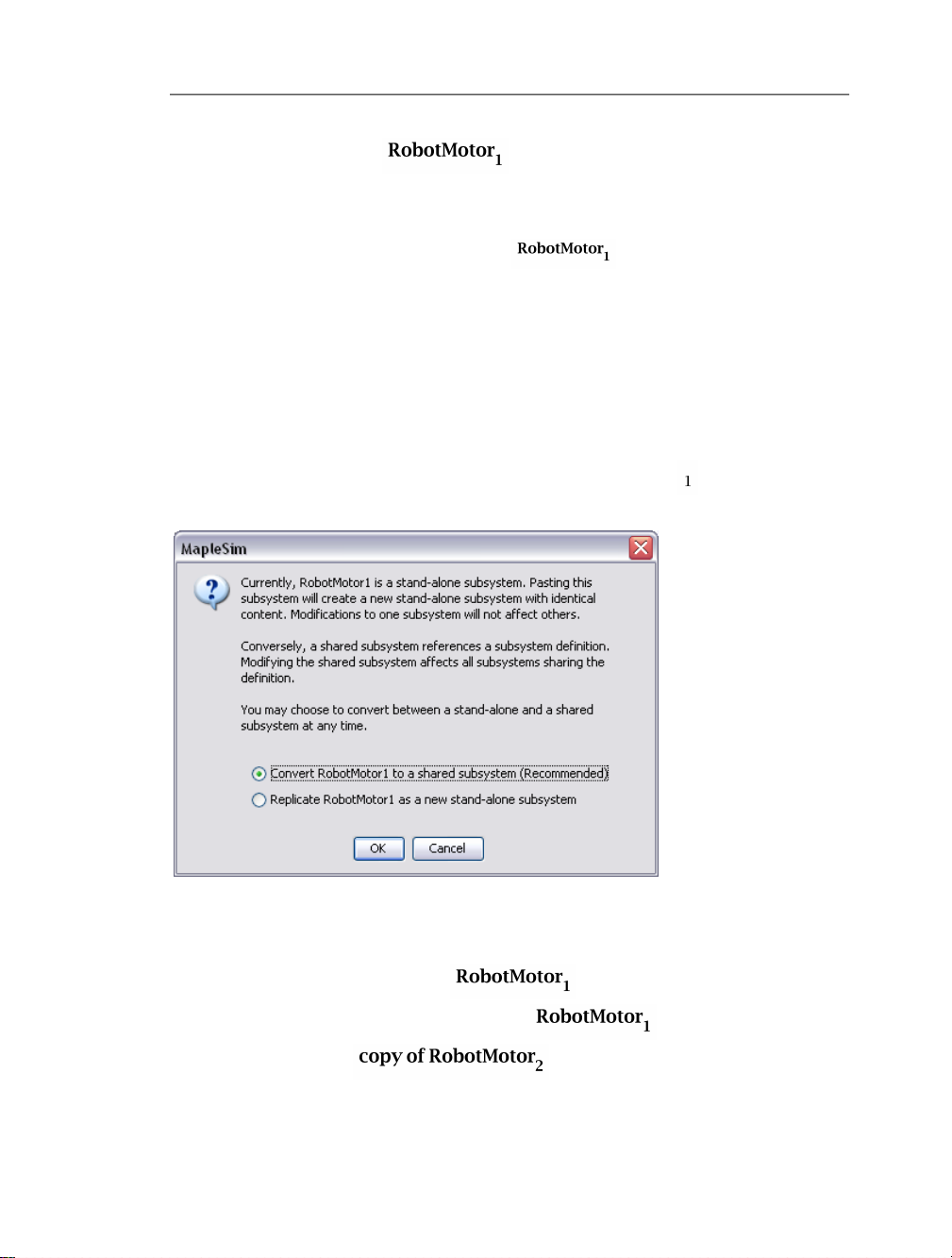

Example: Copying and Pasting a Stand-alone Subsystem

Note: This example is an extension of Example: Removing the Link Between a Shared

Subsystem and its Subsystem Denition (page 31).

1. Inthe model workspace,copy and paste the copyof RobotMotor stand-alone subsystem. The following dialog box is displayed:

2. SelectConvert RobotMotor 1 to shared subsystem (Recommended). Anew subsystem

denition called RobotMotor 1 is added to the Denitions palette.

In the model workspace, the copy of stand-alone subsystem has been

converted to a shared subsystem called copy of and another copy of that

shared subsystemcalled has beenadded to themodel workspace.

Page 44

34 • 2 Building a Model

Both the copy of and shared subsystems are

linked to the new RobotMotor 1 subsystem denition. Therefore, if you edit either

or in the model workspace, your

changes will not be reected in subsystems that are linked to the original RobotMotor

subsystem denition.

Note: Alternatively, you can select Replicate RobotMotor 1 as a new stand-alone subsystem to add another stand-alone subsystem that can be edited independently without af-

fecting other subsystems in the model workspace.

2.6 Global and Subsystem Parameters

Global Parameters

If yourmodel contains multiplecomponents thatshare a commonparameter value, you can

create a global parameter. A global parameter allows you to dene a common parameter

value in one location and then assign that common value to multiple components in your

model.

The example described below illustrates how to dene and assign a global parameter. To

view a more detailed example, see Tutorial 1: Modeling a DC Motor with a Gear-

box (page 105) in Chapter 6 of this guide.

Example: Defining and Assigning a Global Parameter

If yourmodel containsmultiple Resistorcomponents thathave acommon resistancevalue,

you can dene a global parameter for the resistance value in the parameter editor view.

1. In the Libraries tab, expand the Electrical palette, expand the Analog menu, expand

the Passive menu, and then expand the Resistors menu.

2. Fromthe palette, drag three copiesof the Resistor component into the model workspace.

Page 45

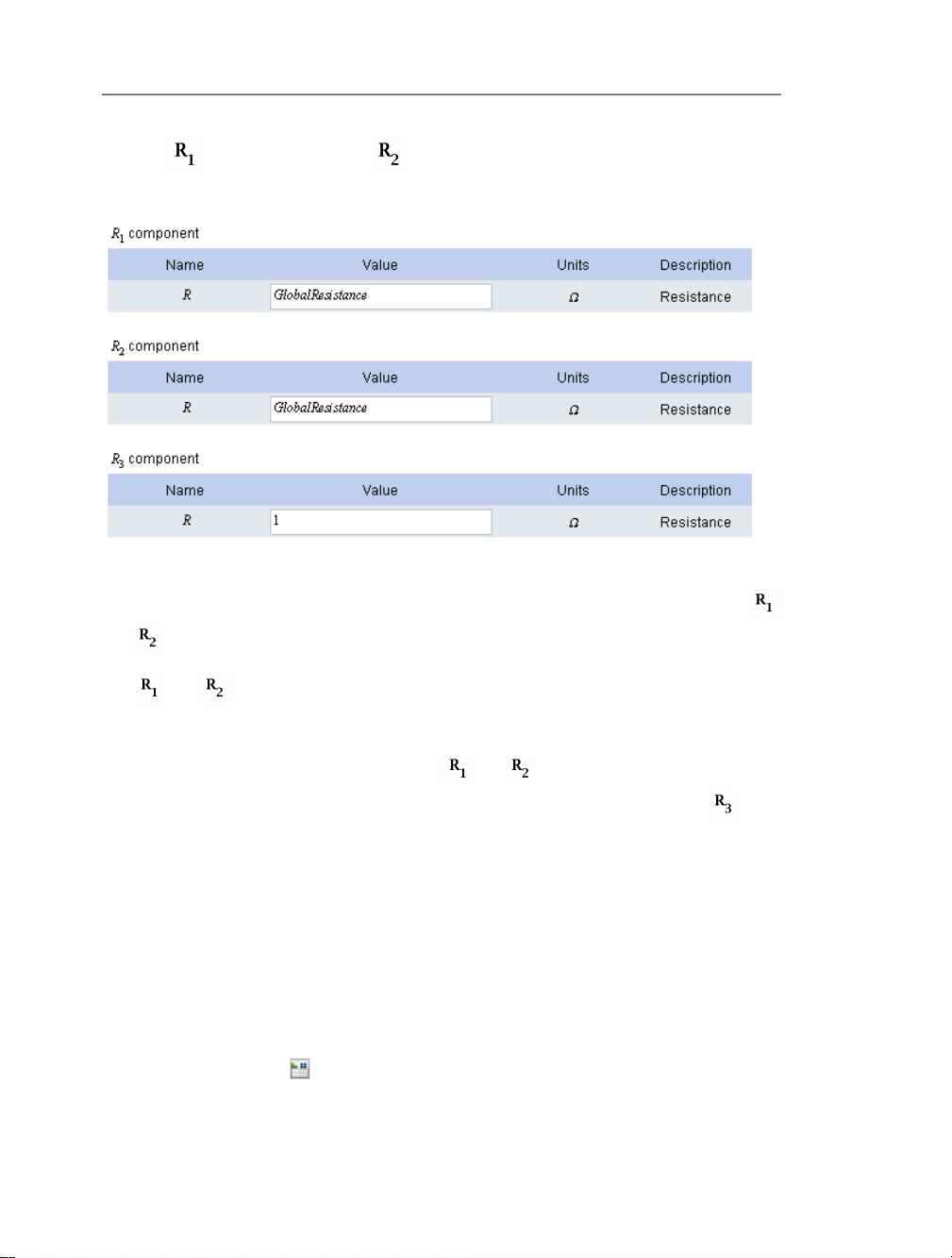

2.6 Global and Subsystem Parameters • 35

3. In the navigation toolbar, click the parameter editor button ( ). You will use this screen

to dene the global parameter and assign it to the Resistor components in your model.

4. Click the rst eld in the Main subsystem default settings table.

5. Enter GlobalResistance as the global parameter name and press Enter.

6. Specify a default value of 2 and enter Global resistance variable as the description.

The global parameter for the resistance value is now dened. You can now assign the

common GlobalResistance parameter value to the individual Resistor components that

you added to the model workspace.

Page 46

36 • 2 Building a Model

7. In the component table and component table, enter GlobalResistance as the

resistance value.

The resistancevalue of the parameter GlobalResistance (2, as dened in theMain subsys-

tem default settings table) has now been assigned to the resistance parameters of the

and components.

The and components will now inherit any changes made to the GlobalResistance

parameter value in the Main subsystem default settings table. For example, if you change

the default value of the GlobalResistance parameter to 5 in the Main subsystem default

settings table, the resistanceparameters ofthe and componentswill alsobe changed

to 5. Any change to the GlobalResistance parameter value will not apply to the component because it has not been assigned GlobalResistance as a parameter value.

Subsystem Parameters

You can create asubsystem parameter ifyou want to create a common parameter value that

will be shared by multiple components in a subsystem. Similar to global parameters, a

subsystem parameter is a common value that you dene in the parameter editor view and

assign to components.

Subsystem parameters, however, can only be assigned to components in the subsystem in

which they are dened. If you double-click a subsystem in the model workspace, click the

parameter editor button ( ), and dene a parameter in the parameter editor view, the

Page 47

2.6 Global and Subsystem Parameters • 37

parameter that you dene can only be assigned to components in the subsystem that you

double-clicked and any nested subsystems.

To view an example, see Tutorial 3: Modeling a Nonlinear Damper (page 114) in Chapter

6 of this guide.

Note: If you create a parameter within a subsystem and assign its value to a component at

the top level, the component at the top level will not inherit the parameter value.

Example: Assigning a Subsystem Parameter to a Shared Subsystem

If you assign a subsystem parameter to a shared subsystem in your model, the default subsystem parameter will also be assigned to other shared subsystems that are linked to it.

However, after the default subsystem parameter is assigned, you can edit the subsystem

parameter value for each shared subsystem separately without affecting other parameter

values in the model.

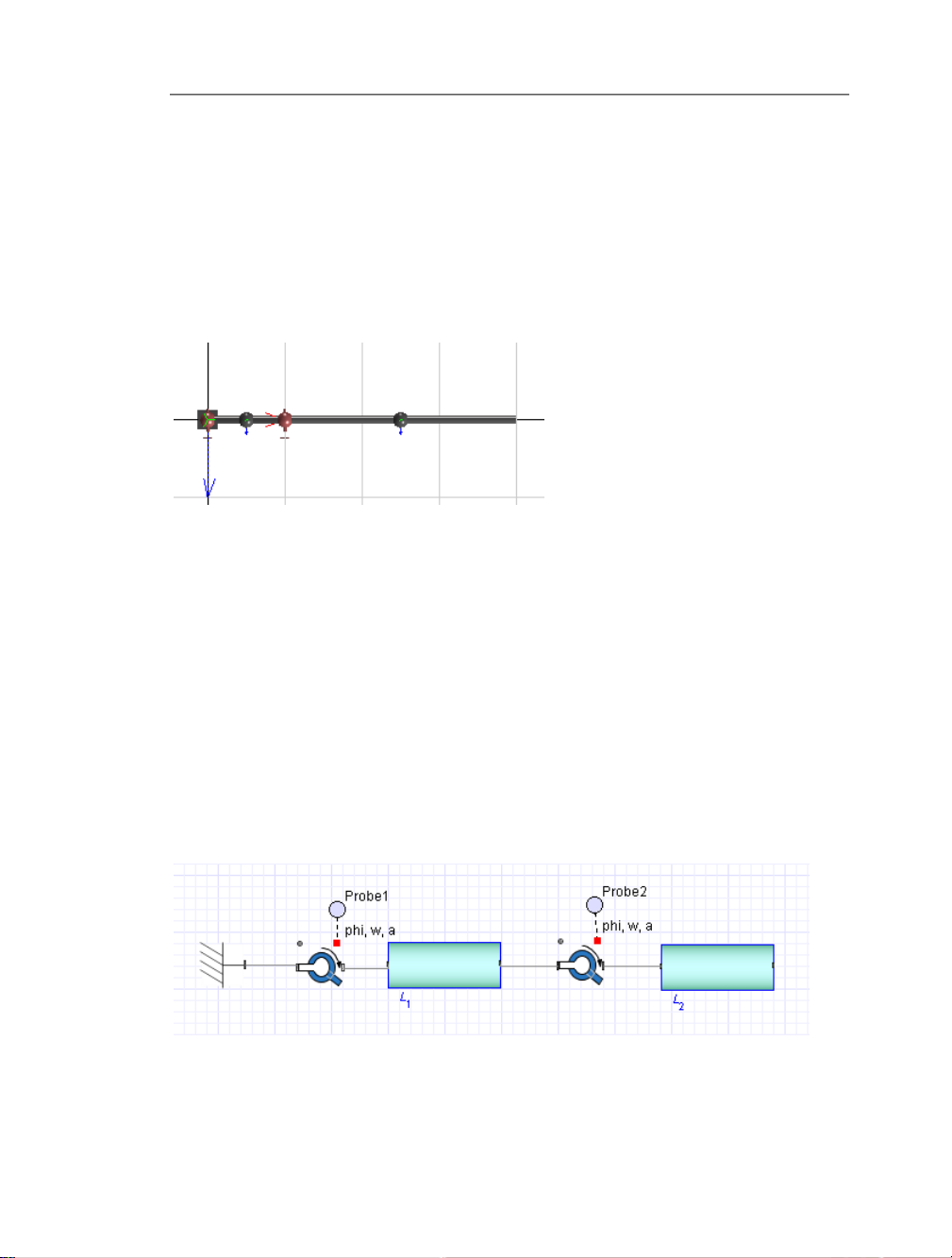

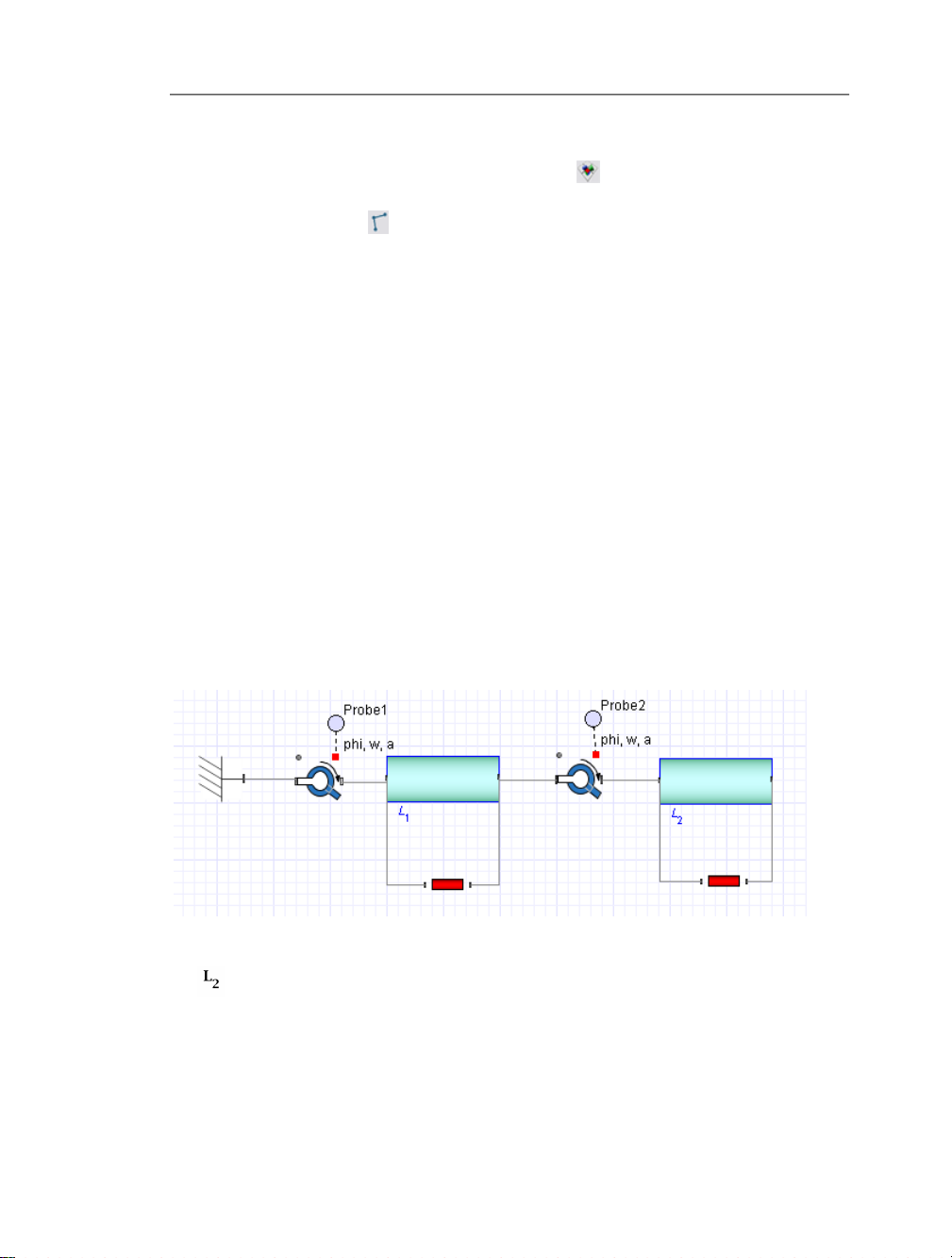

1. Inthe Examplespalette, expandthe Multibodysubmenu, andopen theDouble Pendulum

model. This model contains two shared subsystems, and , which are linked to a

subsystem denition called L.

2. Double-click the shared subsystem.

3. Click the parameter editor button ( ).

4. In the L subsystem default settings table, click the empty eld at the bottom of the

table.

5. Type c as the parameter name, keep the default value as 1, and press Enter.

6. Click thediagram view button ( ). The new subsystem parameter, c, is displayed in the

Inspector tab for the shared subsystem.

7. In the top view of the model, select the subsystem and examine the Inspector tab.

The new subsystem parameter is also displayed for the shared subsystem.

8. In the Inspector tab, change the value of c to 50.

9. Click the shared subsystem in the model workspace and examine the Inspector tab.

Note that the value of its parameter, c, remains the same.

Page 48

38 • 2 Building a Model

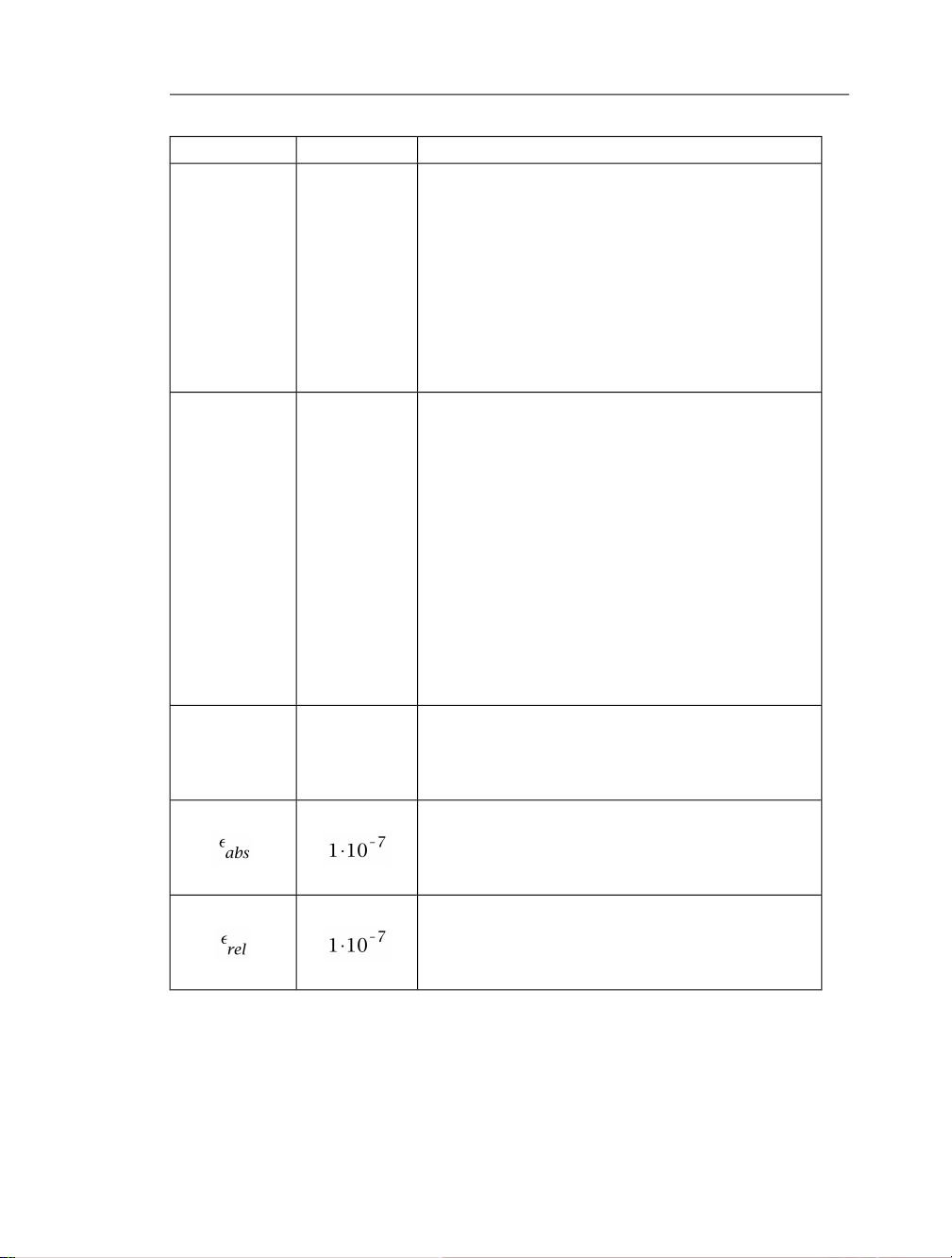

Creating Parameter Blocks

As analternative todening subsystemparameters usingthe methodsdescribed above,you

can create a parameter block to dene a set of subsystem parameters and assign them to

components in your model. Parameter blocks allow you to reuse sets of parameter values

in multiple models.

The followingimage shows a parameter blockthat hasbeen added tothe modelworkspace.

When youdouble-click this block, the parametereditor view is displayed. Thisview allows

you to dene parameter values for the block.

After dening parameter values, you can assign those values to the component parameters

in your model.

To useparameter valuesin another model, you can add aparameter blockto acustom library.

For more information about custom libraries, see Creating and Managing Custom Librar-

ies (page 43).

Notes:

• Parameter blocks must be placed in thesame subsystem as the components to whichyou

want to assign the parameter value.

• Parameter blocks atthe samehierarchical levelin amodel cannothave thesame parameter

names. For example, two separate parameter blocks in the same subsystem cannot each

contain a parameter called mass.

Example: Creating and Using a Parameter Block

In thisexample, youwill createa setof parameters that can be shared bymultiple components

in your model. By creating a parameter block, you only need to edit parameter values in

one location to compare results when you run multiple simulations.

Page 49

2.6 Global and Subsystem Parameters • 39

1. In the Libraries tab on the left side of the MapleSim window, expand the Examples

palette, expand the Mechanical menu, and then open the PreLoad example.

2. From the model workspace toolbar, click the parameter block button ( ).

3. Click a blank area in the model workspace. The Create Parameter Block dialog box is

displayed.

4. Specify a parameter block name SlidingMassParams and click OK.

5. Double-click the SlidingMassParams parameter block in the model workspace. The

parameter editor view is displayed.

6. Click the rst eld in the table and dene a new parameter called MASS.

7. Press Enter.

8. Specify a default value of 5 and enter the description Mass of the sliding mass.

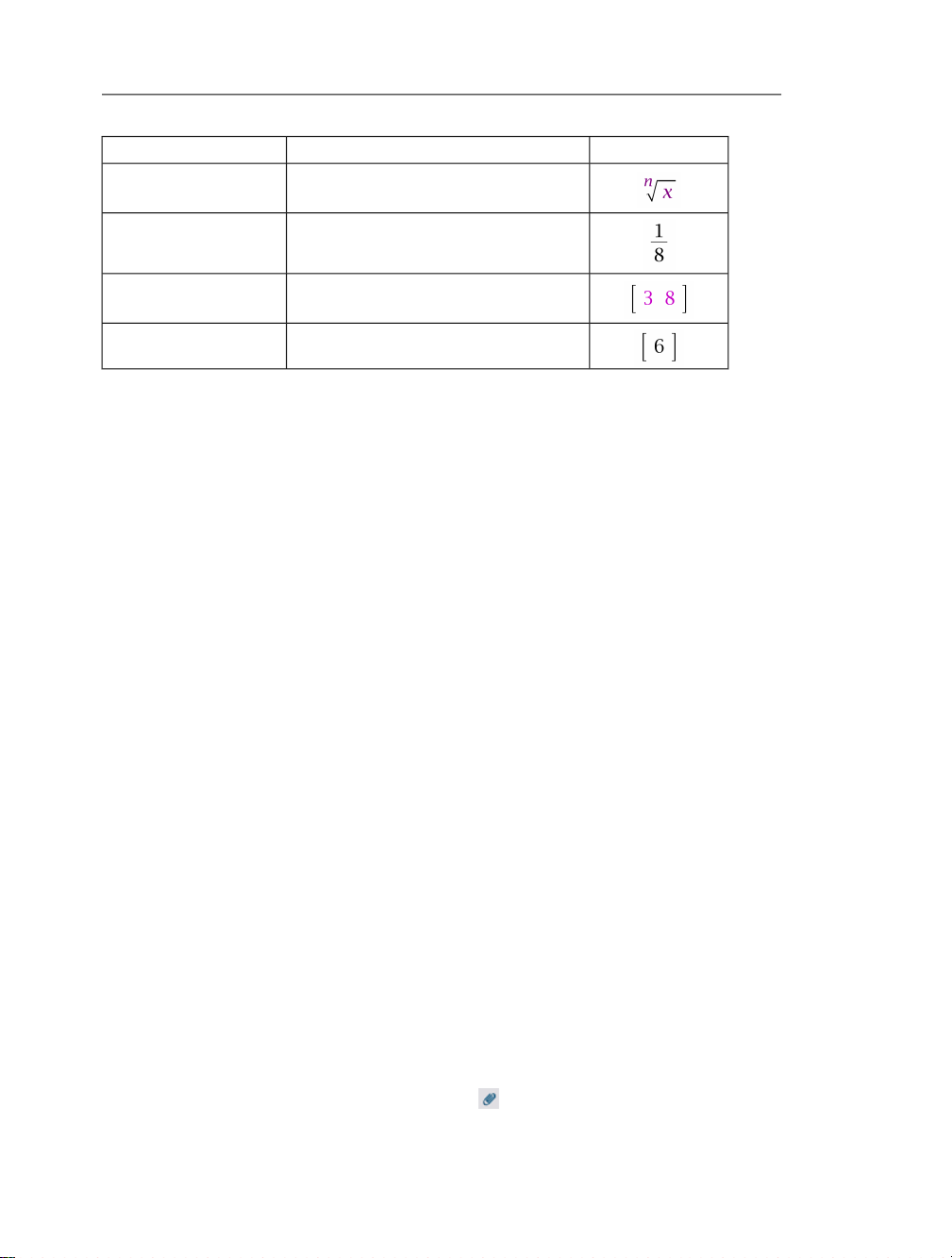

9. In thesame way, dene the following parameters andvalues in the SlidingMassParams

subsystem default settings table.

Name

Value

DescriptionDefault

Length of the sliding mass.2LENGTH

Initial velocity of the sliding mass.1

Initial position of the sliding mass.1

Tip: To enter a subscript, press Ctrl + Shift + the underscorekey (Windows® andLinux®)

or Command + Shift + the underscore key (Macintosh®) and type the valueto include in

Page 50

40 • 2 Building a Model

the subscript. To move the cursor outof the subscript position, press the right arrow key on

your keyboard.

The parameter editor view appears as follows when the values are dened.

10. Clickthe diagram view button ( ) andthen clickMain in the navigationtoolbar.When

you select the parameter blockin the modelworkspace, the parametersthat you denedare

displayed in the Inspector tab on the right side of the MapleSim window.

11. In the model workspace, select one of the Sliding Mass components in the diagram.

12. In the Inspector tab, assign the following values.

Page 51

2.6 Global and Subsystem Parameters • 41

The parameters of this Sliding Mass component now inherit the numeric values that you

dened in the parameter block.

13. In the same way, assign the same values to the parameters of the other Sliding Mass

components in the model.

14. In the model workspace, delete Probe1.

15. Select Probe2.

16. In the Inspector tab, clear the check box beside Speed.

17. To simulate themodel, clickthe simulationbutton ( ) in themain toolbar. Thefollowing

graph is displayed.

18. In the model workspace, click the parameter block.

19. In the Inspector tab, change the mass to 25, the length to 10, and the initial velocity to

5. These changes apply to all of the Sliding Mass components to which you assigned the

symbolic parameter values.

Page 52

42 • 2 Building a Model

20. Simulate the model again. Another simulation graph, which you can compare to your

rst rst graph, is displayed. In this example, the curve shifts vertically after you run a

simulation with the new parameter values.

2.7 Attaching Files to a Model

You can use the Attachments palette in the Project tab to attach les of any format to a

model (for example, spreadsheets or design documents created in external applications).

You can save les attached in the Attachments palette as part of the current model and

refer to them when you work with that model in a future MapleSim session. To save a le,

right-click (Control-click forMacintosh) thecategory in whichyou wantto savethe attachment in the palette and select Attach File.

The following is an image of an Attachments palette that contains les called Damper-

Curve.csv and Data Generation.mw.

You can alsouse the Attachments palette to open MapleSim templates to perform analysis

tasks in Maple, create custom modeling components, and generate data sets for a model.

Page 53

2.8 Creating and Managing Custom Libraries • 43

For more information about performing analysis tasks, see Analyzing and Manipulating a

Model (page 97) in this guide.

2.8 Creating and Managing Custom Libraries

You can create a custom library to save a collection of subsystems, custom modeling components, orattachments thatyou planto reusein multipleles or MapleSim sessions. Custom

libraries are displayed in custom palettes below the Examples palette, in theLibraries tab,

on the left side of the MapleSim window and saved as .msimlib les on your computer.

A sample custom palette with a subsystem is shown below.

Example: Adding Subsystems and Attachments to a Custom Library

In this example, you will add a subsystem and an .mw attachment to a custom library to

make them available in a future MapleSim session.

1. In the Libraries tab, expand the Examples palette, expand the Multidomain menu, and

then open the Sliding Table example.

2. From the File menu, select Create Library...

Page 54

44 • 2 Building a Model

3. Select a path and specify the le name Sliding Table.msimlib.

Note: This le will store the custom library and the le name that you specify will appear

as the custom palette name in the MapleSim interface.

4. Click Save. The Add to User Library dialog box displays all of the subsystems in your

model and les attached in the Attachments palette.

5. Select the check box beside Motor to add the subsystem to the custom library.

6. Select the check box besideAdvancedAnalysis.mw to add theattachment to the custom

library.

7. Click OK. A new custom library palette is added in the Libraries tab on the left side of

the MapleSim window.

Page 55

2.9 Annotating a Model • 45

This palette and its contents are displayed in the Libraries tab. They can be used in a

model the next time you start MapleSim.

8. In the Sliding Table palette, click Attachments. The Library Attachments dialog box

is displayed. This dialog box lists all of the attachments that you have added to the custom

library.

You can also use this dialog box to add attachments to the Attachments palette of another

model and open attachments in their associated applications.

9. Close the dialog box.

2.9 Annotating a Model

You can use the tools in the model workspace toolbar to draw lines, arrows, and shapes.

MapleSim also provides many tools for customizing the colors, line styles, and shape lls.

You can use the text tool ( ) in the model workspace toolbar to add text annotations to

your model. In text annotations, you can enter mathematical text in 2-D math notation and

Page 56

46 • 2 Building a Model

modify the style, color, and font of the text. For more information about 2-D math notation,

see Entering Text in 2-D Math Notation (page 47).

Example: Adding a Text Annotation to a Model

1. In the Libraries tab, expand the Examples palette, expand the Tutorial menu and then

open the Simple DC Motor example.

2. From the model workspace toolbar, click the text tool button ( ).

3. In the model workspace, draw a text box for an annotation below the Step component.

When you releaseyour left mouse button, the toolbar above the model workspace switches

to the text formatting toolbar.

4. Enter the following text: This block generates a step signal with a height of 1.

5. Select the text that you entered and change the font to Arial.

6. Click anywhere outside of the text box.

7. Draw another text box below the Inertia component.

8. Enter the following text: Inertia with a value of 0 rad.

Tip: To enter the omega character ( ), press F5 to switch to the 2-D math mode, type

omega, and then press Ctrl + Space (Windows), Ctrl + Shift + Space (Linux), or Esc

(Macintosh). To enter the subscript, press Ctrl + Shift + the underscore key (Windows

and Linux) or Command + Shift + the underscore key (Macintosh) followed by 0. Press

the right arrow key to move the cursor from the subscript position.

9. Click anywhere outside of the text box.

Page 57

2.10 Entering Text in 2-D Math Notation • 47

10. Select the text that you entered and change the font to Arial.

11. Click anywhere outside of the text box to complete the annotation.

2.10 Entering Text in 2-D Math Notation

In parameter values and annotations, you can enter text in 2-D math notation, which is a

formatting option for adding mathematical elements such as subscripts, superscripts, and

Greek characters. As you enter a phrase in 2-D math notation, you can use the command

and symbol completion feature to display a list of possible Maple commandsor mathematical symbols that you can insert.

The following table lists common key combinations for 2-D math notation:

ExampleKey CombinationTask

Switch between text and

2-D math mode (annotations only)

Command and symbol

completion (parameter

values and annotations

only)

Enter a subscript for a

variable

1. Enter the rst few characters of a symbol

name, Greek character, or Maple command.

2. Enter the key combination for your platform:

• Ctrl + Space (Windows)

• Ctrl + Shift + Space (Linux)

• Esc (Macintosh)

3. From the menu, select the symbol or

command that you want to insert.

Ctrl (or Command) + Shift + underscore

( _ )

-F5

-

Enter a square root

caret (^)Enter a superscript

Enter sqrtand pressCtrl (or Command for

Macintosh) + Space.

Page 58

48 • 2 Building a Model

Enter a root

Enter nthroot and press Ctrl(or Command)

+ Space.

forward slash (/)Enter a fraction

ExampleKey CombinationTask

Enter a piecewise, matrix,

or vector row

For more information, see the Using MapleSim → Building a Model → Annotating a

Model → Key Combinations for 2-D Math Notation topic in theMapleSim help system.

Ctrl (or Command) + Shift + R

Ctrl (or Command) + Shift + CEnter a table column

2.11 Creating a Data Set for an Interpolation Table

Component

You can create a data set to provide values for an interpolation table component in your

model. Forexample, youcan providecustom values for input signals, and electricalCurrent

Table and Voltage Table sources. To create a data set, you can either attach a Microsoft®

Excel® spreadsheet (.xls) or comma-separated values (.csv) le that contains the custom

values, or youcan createa dataset in Mapleusing theData Generation Template or Random

Data Template provided in the MapleSim templates dialog box.

Note: The Microsoft Excel 2007 le format (.xlsx) is not supported.

For more information about interpolation table components, see the MapleSim Library

Reference →Signal Blocks → Interpolation Tables→ Overview topic in the MapleSim

help system.

Example: Creating a Data Set in Maple

In this example, you will use the Data Generation Template to create a data set for a

MapleSim 1DLookup Tablecomponent. Inthis template,you canuse anyMaple commands

to create a data set; however, for demonstration purposes, you will create a data set using

a computation that has already been dened.

1. Open a new MapleSim document.

2. Inthe Librariestab, expandthe Signal Blocks palette, andthen expandthe Interpolation

Tables menu.

3. Add a 1D Lookup Table component to the model workspace.

4. In the main toolbar, click the templates button ( ).

Page 59

2.12 Best Practices: Building a Model • 49

5. From the templates list, select Data Generation.

6. In the Attachment eld, enter My First Data Set and click Create Attachment. The

Data Generation Template is opened in Maple.

7. To execute the entire worksheet, click at the top of the Maple window.

8. At the bottom of the template, in the Data set name eld, enter TestDataSet.

9. To make the data set availablein MapleSim, clickthe Attach Data in MapleSim button.

10. In MapleSim, in the Project tab, expand the Attachmentspalette, and then expand the

Data Sets category. The data set le is displayed in the list.

You can nowassign thisdata set to the interpolation table component in themodel workspace.

11. In the model workspace, select the 1D Lookup Table component.

12. Inthe Inspectortab, from the data drop-down menu, selectthe TestDataSet.mpld le.

The data set is now assigned to the 1D Lookup Table component.

13. Save the Data Generation Template in Maple and then save your model in MapleSim.

2.12 Best Practices: Building a Model

This section describes best practices to consider when laying out and building a MapleSim

model.

Best Practices: Laying Out and Creating Subsystems

To start building your model, drag components from the palettes to the center of the model

workspace. Dragthe componentsinto thearrangement thatyou wantin themodel workspace

and then, if necessary, change their orientation so that the components are facing in the

direction that you want. When you have established the position and orientation of the

components, connect them in the model workspace.

When groupingcomponents intosubsystems, makesure thatyou includelogical component