Page 1

E-SERIES

®

OPERATING MANUAL

E-SERIES® PUMPS

NOTICE D’UTILISATION

POMPES E-SERIES

BEDIENUNGSANLEITUNG

®

E-SERIES® PUMPEN

MANUAL DE OPERACIÓN

BOMBAS E-SERIES

®

Model Nos.

Modèles n°

Modellnummern

Números de modelo

72-410-014

72-410-028

72-410-049

72-410-108

72-415-014

72-415-028

72-415-049

72-415-108

Division of Barnant Company

28W092 Commercial Avenue, Barrington, IL U.S.A. 60010-2392

1-800-637-3739 (U.S. and Canada only) 847-381-7050 (Local) 11-847-381-7050 (outside U.S.)

847-381-7053 (Local Fax) 11-847-381-7053 (Fax outside U.S.)

www.barnant.com e-mail: barnant@barnant.com

A-1299-5078

Edition 03

Page 2

®

E-SERIES

EU Declaration of Conformity

Name of Apparatus: MANOSTAT® V ARISTALTIC E-SERIES® Fixed Speed Drive

Model Numbers: 72-415-014, 72-415-028, 72-415-049, 72-415-108

Description of Apparatus: Peristaltic pump head and drive. Used with tubing links to pump fluids.

72-415-014 (14 rpm), 72-415-028 (28 r pm),

72-415-049 (49 rpm), 72-415-108 (108 r pm)

Barnant Company declares that the above models are in conformity to the following

harmonized standards and directives:

Applicable Applicable Manufacturer’s

Directives Specifications Report Number

73/23/EEC EN61010-1/A2: 1995 TR9530

93/68/EEC

89/336/EEC EN61326-1/A1: 1998 TR9531

92/31/EEC

93/68/EEC

The last two digits of the year in which the current configuration of the above models was

assessed per the Low Voltage Directive is: 00.

Manufacturer: Barnant Company Division

Cole-Parmer Instrument Company

28W092 Commercial Avenue

Barrington, IL 60010-2392

USA

Tel.: 847-381-7050

Manufacturer’s Signature:

16 August, 2000

James W. Doll Date

Vice President, Engineering

2

Page 3

TABLE OF CONTENTS

Title Page

SAFETY PRECAUTIONS ........................................................................................................................................... 4

Safety...................................................................................................................................................................... 4

INTRODUCTION AND GENERAL DESCRIPTION .................................................................................................... 5

SETUP ........................................................................................................................................................................ 5

Tubing Size Selection.............................................................................................................................................. 5

Chemical Compatibility............................................................................................................................................ 5

OPERATION ............................................................................................................................................................... 6

Inserting T ubing Links ............................................................................................................................................. 6

Inserting T ubing Links—Alternate Method .............................................................................................................. 6

Pump Controls ........................................................................................................................................................ 6

TROUBLESHOOTING ................................................................................................................................................ 7

MAINTENANCE .......................................................................................................................................................... 7

Cleaning .................................................................................................................................................................. 7

Replacement Parts ................................................................................................................................................. 7

ACCESSORIES .......................................................................................................................................................... 8

SPECIFICATIONS ...................................................................................................................................................... 9

WARRANTY...............................................................................................................................................................10

PRODUCT RETURN ..................................................................................................................................................10

TECHNICAL ASSISTANCE .......................................................................................................................................10

3

Page 4

SAFETY PRECAUTIONS

DANGER: Remove power from the pump before any cleaning operation is started.

WARNING: Remove power from the pump before attempting any maintenance.

WARNINGS:Tubing breakage may result in fluid being sprayed from pump. Use appropriate measures to

protect operator and equipment.

Turn pump off before removing or installing tubing. Fingers or loose clothing could be caught in

the pump mechanism.

Pinched Finger Hazard — TURN OFF and UNPLUG the PUMP before removing or loading tubing.

CAUTIONS: When changing flow direction, allow the pump to come to a complete stop before starting again.

Failure to do so could cause permanent damage to the motor.

Replace the fuse only with one of the same type and rating. The fuse rating and type are stated on

the rear panel.

WARNING: PRODUCT USE LIMITATION

These products are not designed for, nor intended for use in, patient-connected applications, including, but not

limited to, medical and dental use and, accordingly, have not been submitted for FDA approval.

SAFETY

1. Read instructions before operating the unit.

2. Observe safety precautions at all times, especially when pumping dangerous liquids. Always have the pump head

cover properly mounted on the pump head and, in general, protect the pump area from accidental spillage of liquid.

3. Pump should not be used in outdoor or hazardous locations.

4. The MANOSTAT E-SERIES pumps should be well-grounded at all times.

NOTE: Use only MANOSTAT Silicone Tubing Links.

E-SERIES — Reg TM Chemtronics, Inc.

Trademarks bearing the ® symbol in this publication are registered in the U.S. and in other countries.

4

Page 5

INTRODUCTION AND GENERAL DESCRIPTION

The VARISTAL TIC® E-SERIES® pump is a fixed-speed, self-priming peristaltic pump. The peristaltic pump roller pressure squeezes fluid through the tubing. The flow is proportional to the speed of the rollers (rpm) and the inside diameter

of the tubing.

The VARISTALTIC E-SERIES pump can be used to pump fluid or gas without contaminating the pump; the pumped

material contacts the tubing only.

SETUP

TUBING SIZE SELECTION

Flexible tubing with a 55 ±5 Durometer (Shore A) with a 3/32 in. wall and an inside diameter from 1/16 in. to 1/4 in. can

be used in this pump.

Flow rate is determined by the tubing size in the pump head. Best perf ormance will be achiev ed when input and output

tubing connected to the link are the same ID as the link. All tubing inside the pump head m ust be surface-printed

MANOSTAT silicone tubing links.

MANOSTAT E-SERIES pumps are supplied with a silicone 3/16 in. ID tubing link. MANOSTAT offers silicone tubing links

in a range of sizes.

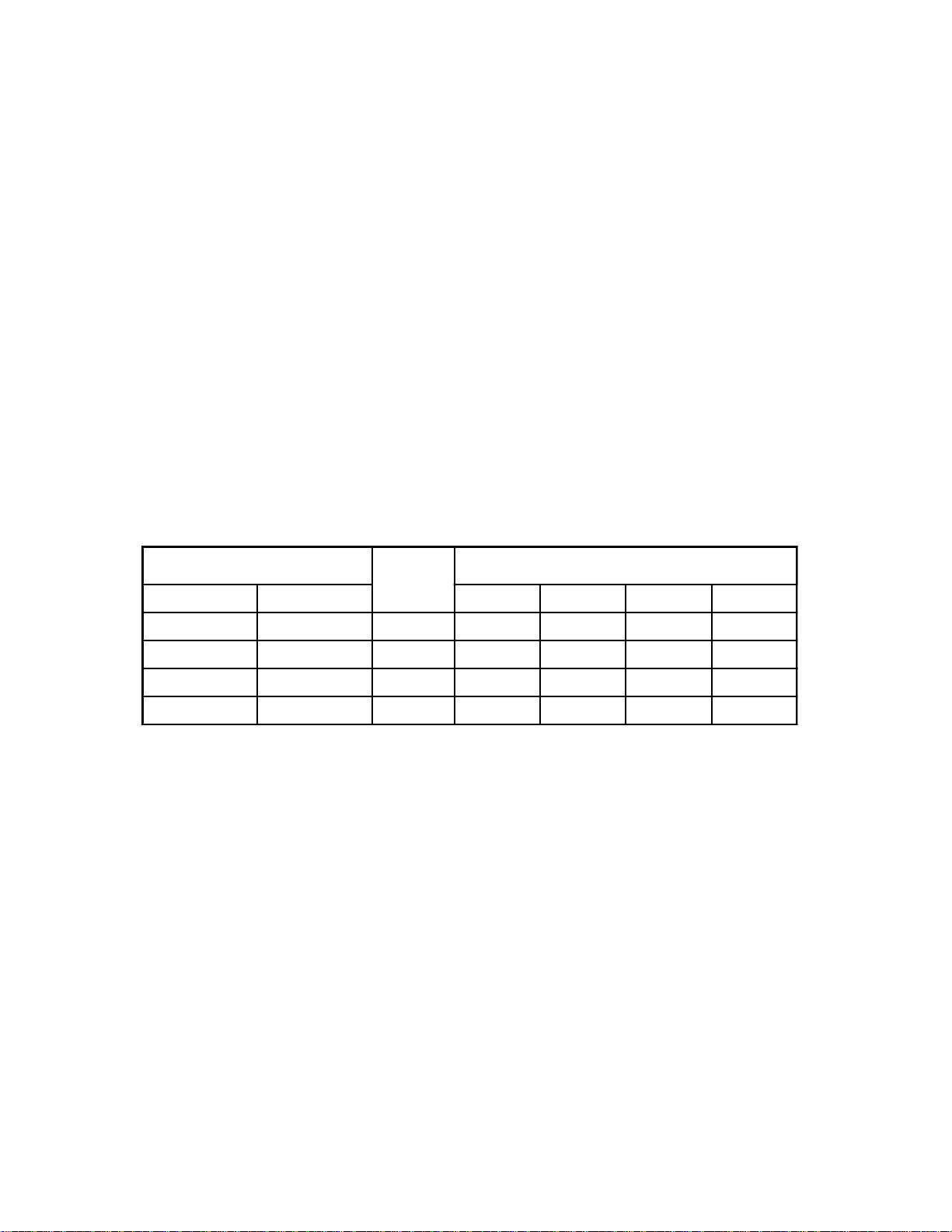

Refer to the flow rate chart below to select the correct tubing size.

TUBING SIZE SELECTION

Catalog No.

115 VAC 230 VAC 1/16* 1/8 3/16 1/4

72-410-014 72-415-014 14 3 12 27 45

72-410-028 72-415-028 28 6.5 25 55 90

72-410-049 72-415-049 49 11 44 100 150

72-410-108 72-415-108 108 26 104 228 375

* Requires shim

** At 50 Hz, flow rate will be 16% lower

*** Flow rate accuracy: ±8%

CHEMICAL COMPATIBILITY

Selection of tubing material depends on the chemical being pumped. Ref er to the enclosed MANOSTAT Tubing Guide

(part no. A-1299-5075) to select appropriate type of tubing links for the liquid in use.

rpm**

60 Hz

Flow Rate (mL/ min) ** *

Tu be Size (ID ⫻ 3/32 in. Wal l)

5

Page 6

OPERATION

Use only MANOSTAT precision tubing links with MANOSTAT pumps to ensure optimum performance. Use of

other tubing may void applicable warranties.

WARNINGS:Tubing breakage may result in fluid being sprayed from pump. Use appropriate measures to

protect operator and equipment.

Turn pump off before removing or installing tubing. Fingers or loose clothing could be caught in

the pump mechanism.

Pinched Finger Hazard — TURN OFF and UNPLUG the PUMP before removing or loading tubing.

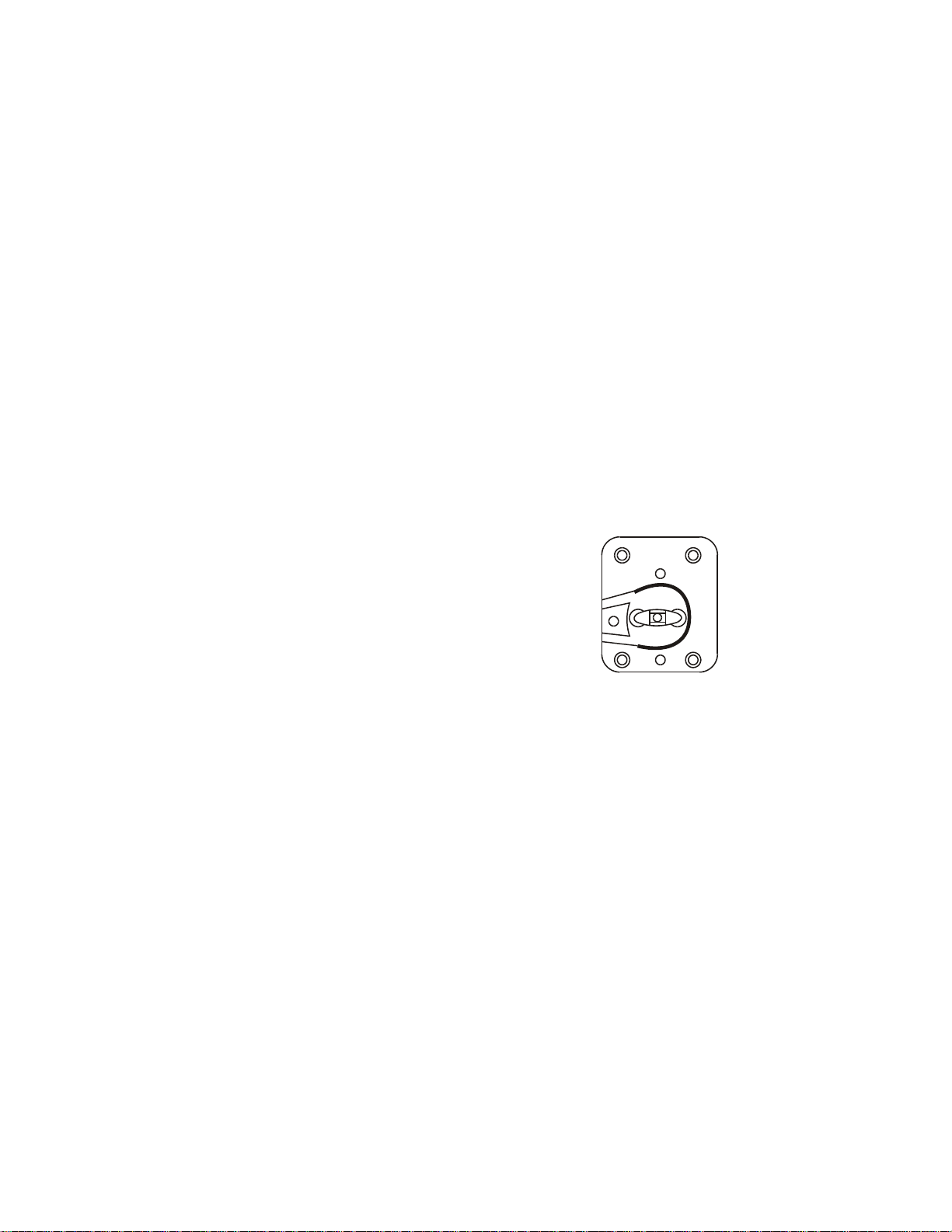

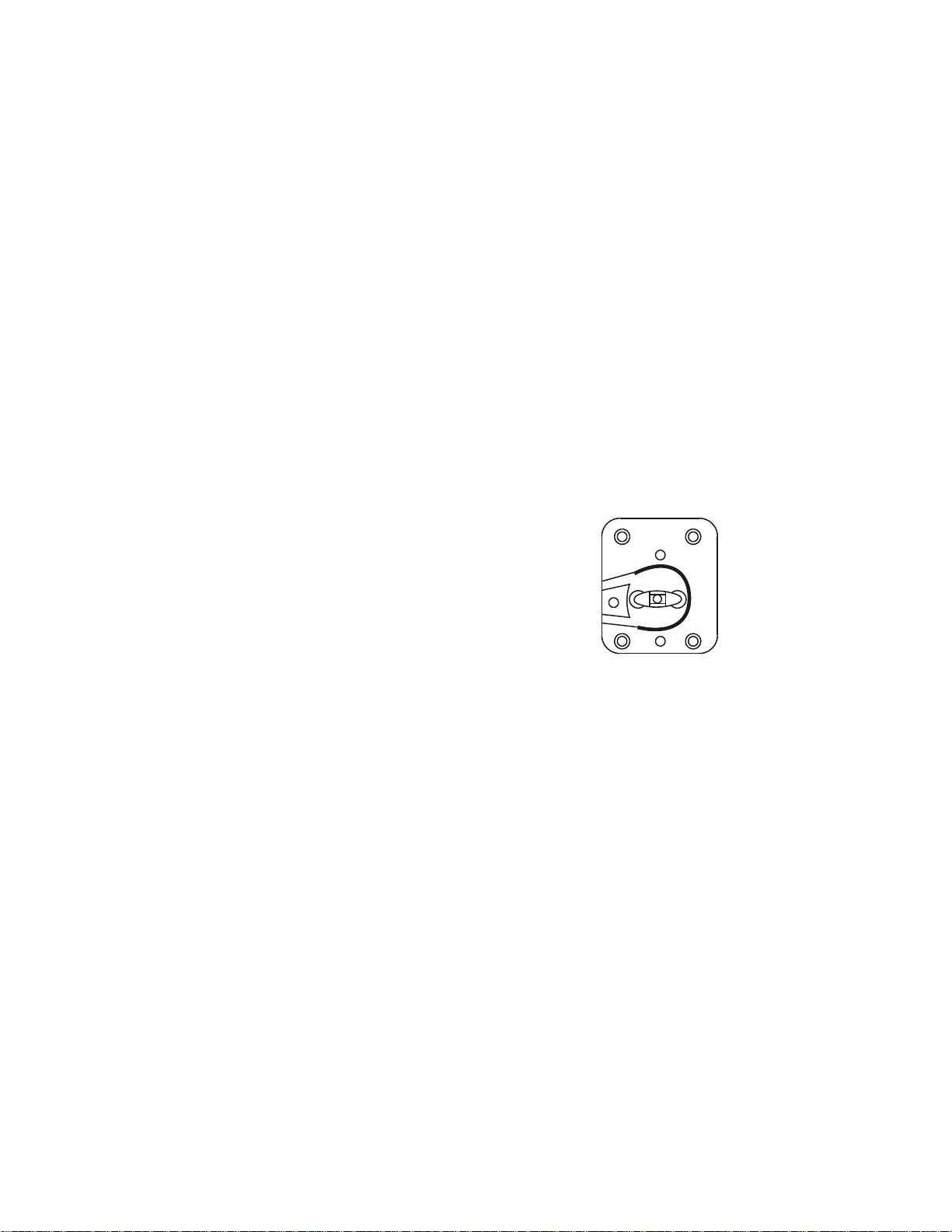

INSERTING TUBING LINKS (REFER TO FIGURES 1–4)

1. Ensure power switch is turned OFF and unit is unplugged.

2. Remove the two nuts and pump head cover from the pump head.

3. Position the roller bracket assembly as shown in Figure 1.

4. Push tubing into inlet port. Anchor tubing in grippers while rotating

the roller bracket assembly (see Figure 2).

5. Continue to rotate the roller bracket assembly, pushing tubing into

the curved pump head housing wall (see Figure 3).

6. Insert tubing connector into the tubing (see Figure 4).

7. Replace the cover and two nuts.

Figure 1

Figure 2

INSERTING TUBING LINKS — ALTERNATE METHOD

Figure 3

Figure 4

WARNING: Pinched Finger Hazard — TURN OFF and UNPLUG the PUMP before removing or loading tubing.

NOTE: Roller bracket assembly of the low r pm pump (Catalog #72-410-014) may be hard to rotate. It may be easier

to insert the tubing using this alternate method.

1. Remove one of the connectors from the tubing link.

NOTE: DO NOT remove the pump head cover!

2. Plug in the power cord and set the power switch to ON.

3. While the pump is running, carefully feed the tube (the end without the connector) into the inlet port. Continue

feeding the tube 1/4 in (6.3 mm) at a time, allowing the roller assemb ly to pull the tubing until the tube e xtends from

the outlet port, as shown in Figure 4.

4. Reconnect the connector to the tubing.

PUMP CONTROLS

1. Insert the tubing link to be used into the pump head.

2. Connect the inlet tubing, which originates from the reservoir, to the inlet port (on top), and the outlet tubing to the

outlet port.

3. Plug the power cord into a grounded AC socket.

4. Start the pump by setting the power switch to ON. Prime the tubing by letting the pump run for 5 to 10 minutes. The

pump will then be ready for use.

6

Page 7

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE ACTION

Power on, motor does not run. Line cord not connected properly in outlet. Check line cord connection.

Tubing has incorrect wall thickness. Refer to TUBING SIZE

SELECTION chart.

Fuse has blown. Check fuse on back of the pump.

CAUTION: Replace the fuse only with one

of the same type and rating. The

fuse rating and type are stated

on the rear panel.

Power on, motor running, pump Tubing inserted incorrectly. Make sure inlet and outlet tubing

head does not prime tubing. are inserted and connected

properly.

Not enough squeeze on tubing. Check tubing for backflow and

insert a shim, if necessar y.

Power on, motor making noise, Tubing is too hard or there is too Use MANOSTAT tubing with

roller does not rotate. much head pressure. 3/32 in. wall thickness only.

Fluctuation in output. Tubing is too hard or there is too Use MANOSTAT tubing with

much head pressure. 3/32 in. wall thickness only.

Tubing link is worn out. Replace tubing link.

IMPORTANT: Inspect tubing link (tubing inside the pump head) regularly and replace if deterioration occurs.

MAINTENANCE

WARNING: Remove power from the pump before attempting any maintenance.

The rear motor bearing should be given two drops of #20 non-detergent oil ev ery three months. Do not over-oil. Clean

off any accumulated dust or dirt.

CLEANING

DANGER: Remove power from the pump before any cleaning operation is started.

Keep the pump enclosure clean by using a mild detergent solution. Never immerse nor use excessive fluid when

cleaning the pump.

REPLACEMENT PARTS

Description Part Number Qty.

Fuse, Model 72-410-014 (0.5A STD, 250V, 3AG) B-1115-0047 1

Fuse, Models 72-415-014, 72-415-049 and 72-415-028 (T0.5A, 250V, 5 ⫻ 20 mm) B-1115-0062 1

Fuse, Model 72-410-028 (0.75A STD, 250V, 3AG) B-1115-0049 1

Fuse, Model 72-410-049 (1.5A STD, 250V, 3AG) B-1115-0032 1

Fuse, Model 72-415-108 (T1.0A, 250V, 5 ⫻ 20 mm) B-1115-0056 1

Fuse, Model 72-410-108 (2.0A SLO-BLO, 250V, 3AG) B-1115-0013 1

Rubber Foot—Large A-1390-0002 4

Knob Nickel Plt 8-32 UNC B-1083-0064 2

7

Page 8

ACCESSORIES

Description Part Number

TUBING LINKS (Sold in packages of 5 links)

Silicone tubing link — 1/16 in. ID 72-420-250

Silicone tubing link — 1/8 in. ID 72-420-350

Silicone tubing link — 3/16 in. ID 72-420-450

Silicone tubing link — 1/4 in. ID 72-420-550

Sinkers

PTFE sinkers keep tubing at the bottom of any container, eliminating the possibility of adhering to the reser voir wall.

Ideal for use with pumps and dispensers, these sinkers have hose barb ends for simple insertion into flexible tubing.

PTFE composition offers solvent resistance and can be autoclaved.

Sets of two (2): small (for use with 1/16 in. to 1/8 in. ID tubing)

and large (for use with 3/16 in. to 1/4 in. ID tubing)

Sinkers, set of 2 (one each size) 75-250-100

Sinkers 1/16 in. — 1/8 in. each 75-250-102

Sinkers 3/16 in. — 1/4 in. each 75-250-104

Shims

Shim for pump (required for 1/16 in. ID tubing links)* 72-420-100

*Flow shim installation: Remove paper covering to expose

adhesive before installing shim.

NOTE: Shim may also be used on 1/8 in. tubing link.

8

Page 9

SPECIFICATIONS

Output:

Pump Speed:

Model 72-410-014 14 rpm

Model 72-410-028 28 rpm

Model 72-410-049 49 rpm

Model 72-410-108 108 rpm

Model 72-415-014 14 × (5/6)* rpm

Model 72-415-028 28 × (5/6)* rpm

Model 72-415-049 49 × (5/6)* rpm

Model 72-415-108 108 × (5/6)* rpm

*NOTE: Speed for the 72-415-XXX Series Drives is 5/6 that

of the 72-410-XXX series due to operation at 50 Hz.

Torque:

Model 72-410-014 8 in-lbs (9.22 kg•cm)

Model 72-410-028 8 in-lbs (9.22 kg•cm)

Model 72-410-049 7 in-lbs (8.06 kg•cm)

Model 72-410-108 6 in-lbs (6.91 kg•cm)

Model 72-415-014 9.5 in-lbs (10.94 kg•cm)

Model 72-415-028 8 in-lbs (9.22 kg•cm)

Model 72-415-049 8.5 in-lbs (9.79 kg•cm)

Model 72-415-108 6 in-lbs (6.91 kg•cm)

Input:

Operating Voltage/Frequency/max. current:

Model 72-410-014 115 VAC ±10% @ 60 Hz, 0.33 A

Model 72-415-014 230 VAC ±10% @ 50 Hz, 0.13 A

Model 72-410-028 115 VAC ±10% @ 60 Hz, 0.60 A

Model 72-415-028 230 VAC ±10% @ 50 Hz, 0.23 A

Model 72-410-049 115 VAC ±10% @ 60 Hz, 0.77 A

Model 72-415-049 230 VAC ±10% @ 50 Hz, 0.31 A

Model 72-410-108 115 VAC ±10% @ 60 Hz, 1.24 A

Model 72-415-108 230 VAC ±10% @ 50 Hz, 0.47 A

Installation Category: Installation category II per IEC 664 (local level—appliances,

portable equipment, etc.)

Environment:

Operating Temperature: 32 to 104°F (0 to 40°C)

Storage Temperature: −49 to 149°F (−45 to 65°C)

Humidity: 10% to 90% non-condensing

Altitude: Less than 6562 ft (2000 m)

Pollution Degree: Pollution degree 2 per IEC 664 (indoor use—lab, office)

Construction:

Dimensions (L × W × H): 5 in × 6-9/16 in × 5-5/16 in (13 cm × 17 cm × 13.5 cm)

Weight: 4 lbs (1.8 kg)

Color: White

Material: Painted steel housing

Enclosure Rating: IP21 per IEC 529

Compliance: 115V: UL508, CSA C22.2, No. 14-M91

230V (For CE Mark):

EN61010-1/A2: 1995

(EU Low Voltage Directive) and

EN61326-1/A1: 1998

(EU EMC Directive)

9

Page 10

WARRANTY

Use only MANOSTAT precision tubing links with MANOSTAT pumps to ensure optimum performance. Use of

other tubing may void applicable warranties.

The Manufacturer warrants this product to be free from significant deviations from published specifications. If repair or

adjustment is necessary within the warranty period, the problem will be corrected at no charge if it is not due to misuse

or abuse on your part, as determined by the manufacturer . Repair costs outside the warranty period, or those resulting

from product misuse or abuse, may be invoiced to you.

The warranty period for this product is noted on the Warranty Card.

PRODUCT RETURN

T o limit charges and dela ys, contact the seller or Man ufacturer f or authorization and shipping instructions before returning the product, either within or outside of the warranty period. When returning the product, please state the reason for

the return. For y our protection, pac k the product carefully and insure it against possib le damage or loss. Any damages

resulting from improper packaging are your responsibility.

TECHNICAL ASSISTANCE

If you have any questions about the use of this product, contact the Manufacturer or authorized seller.

10

Printed in U.S.A.

030701

Page 11

TABLE DES MA TIÈRES

Intitulé Page

MESURES DE SÉCURITÉ .................................................................................................................................... 12

Sécurité.............................................................................................................................................................. 12

INTRODUCTION ET DESCRIPTION GÉNÉRALE................................................................................................ 13

INSTALLATION ...................................................................................................................................................... 13

Sélection du diamètre de tube ........................................................................................................................... 13

Compatibilité chimique ....................................................................................................................................... 13

FONCTIONNEMENT ............................................................................................................................................. 14

Insertion des sections de raccordement de tubes.............................................................................................. 14

Insertion des sections de raccordement de tubes—Méthode de remplacement................................................ 14

Commandes de la pompe .................................................................................................................................. 14

DÉPANNAGE ......................................................................................................................................................... 15

ENTRETIEN........................................................................................................................................................... 15

Nettoyage........................................................................................................................................................... 15

Pièces de rechange ........................................................................................................................................... 15

ACCESSOIRES ..................................................................................................................................................... 16

CARACTÉRISTIQUES TECHNIQUES .................................................................................................................. 17

GARANTIE............................................................................................................................................................. 18

RETOUR DE MARCHANDISES ......................................................................................................... ................... 18

ASSISTANCE TECHNIQUE................................................................................................................................... 18

FRANÇAIS

11

Page 12

MESURES DE SÉCURITÉ

DANGER : Mettre la pompe hors tension avant de procéder à toute opération de nettoyage.

AVERTISSEMENT : Mettre la pompe hors tension avant de procéder à toute opération d’entretien.

AVERTISSEMENTS : Une rupture de tube risque d’entraîner une pulvérisation de fluide hors de la pompe.

Prendre des mesures appropriées pour protéger l’opérateur et le matériel.

Mettre la pompe hors tension avant de débrancher ou de raccorder un tube. Les doigts

ou les vêtements amples risquent de se prendre dans le mécanisme de pompage.

Risque de pincement de doigts — METTRE la POMPE HORS TENSION et la DÉBRANCHER

de la prise de courant avant de débrancher ou de raccorder un tube.

CONSEILS

DE PRUDENCE : Lors de l’inversion du sens de circulation, laisser la pompe s’arrêter complètement a vant

de la remettre en marche. Sinon, le moteur risque d’être endommagé définitivement.

Remplacer le fusible par un neuf de mêmes type et intensité nominale uniquement.

L’intensité nominale et le type du fusible sont indiqués sur le panneau arrière.

AVERTISSEMENT : LIMITES D’UTILISATION DES PRODUITS

Ces produits ne sont pas conçus pour, ni destinés à, être utilisés dans des applications avec patients , y compris,

entre autres, les applications médicales et dentaires, et n’ont par conséquent pas été soumis à l’agrément de

la FDA.

SÉCURITÉ

1. Lire les instructions avant de se servir de l’appareil.

2. Toujours prendre des mesures de sécurité, en particulier lors du pompage de liquides dangereux. T oujours monter

correctement le couvercle de tête de pompe sur la tête et, de façon générale, protéger la zone dans laquelle se

trouve la pompe contre tout renversement accidentel de liquide.

3. La pompe ne doit pas être utilisée à l’extérieur ni dans des endroits dangereux.

4. Les pompes MANOSTAT E-SERIES doivent toujours être correctement mises à la terre.

REMARQUE : N’utiliser que des sections de raccordement de tubes en silicone MANOSTAT.

E-SERIES — Marque déposée de Chemtronics, Inc.

Les marques accompagnées du symbole ® qui apparaissent dans cette publication sont déposées aux États-Unis et dans d’autres pays.

12

Page 13

INTRODUCTION ET DESCRIPTION GÉNÉRALE

La pompe VARISTALTIC® E-SERIES® est une pompe péristaltique à vitesse fixe et autoamorçage. La pression des

rouleaux de la pompe force le fluide à circuler dans les tubes. Le débit est propor tionnel à la vitesse des rouleaux

(tr/mn) et au diamètre intérieur des tubes.

La pompe VARISTALTIC E-SERIES peut être utilisée pour pomper un fluide ou un gaz sans être contaminée ; le

produit pompé ne touche que les tubes.

INSTALLATION

SÉLECTION DU DIAMÈTRE DE TUBE

Il est possible d’utiliser des tubes flexibles à indice de dureté de 55 ± 5 (Shore A), paroi de 3/32 po et diamètre intérieur

compris entre 1/16 et 1/4 po dans cette pompe.

Le débit est déterminé par le diamètre du tube raccordé dans la tête de pompe. Les meilleures perfor mances sont

obtenues lorsque les tubes d’entrée et de sortie raccordés à l’élément de liaison ont le même diamètre intérieur que ce

dernier. Tous les tubes qui se trouvent à l’intérieur de la tête de pompe doivent être des sections de raccordement

de tubes en silicone MANOSTAT à impression en relief.

Les pompes MANOSTAT E-SERIES sont fournies avec un élément de liaison de tubes en silicone de 3/16 po de

diamètre intérieur. MANOSTAT offre des tubes en silicone de différents diamètres.

Se reporter au tableau de débits ci-dessous pour sélectionner le diamètre de tube correct.

SÉLECTION DU DIAMÈTRE DE TUBE

N° catalogue

115 V c.a. 230 V c.a. 1/16 po* 1/8 po 3/16 po 1/4 po

72-410-014 72-415-014 14 3 12 27 45

72-410-028 72-415-028 28 6,5 25 55 90

72-410-049 72-415-049 49 11 44 100 150

72-410-108 72-415-108 108 26 104 228 375

* Exige cale d’épaisseur

**À 50 Hz, le débit sera inférieur de 16 %

***Précision du débit : ± 8 %

COMPATIBILITÉ CHIMIQUE

La sélection de la matière dont sont fabriqués les tubes dépend du produit chimique à pomper. Se reporter au guide de

tubes MANOSTAT fourni (pièce n° A-1299-5075) pour sélectionner le type des sections de raccordement de tubes

adapté au liquide à pomper.

Vitesse

(tr/mn)**

60 Hz

Débit (ml/mn)*** Diam. de tub

(diam. int. × paroi 3/32 po)

13

Page 14

FONCTIONNEMENT

N’utiliser que des sections de raccordement de tubes de précision MANOSTAT avec les pompes MANOSTAT

pour garantir des performances optimales. L’utilisation d’autres tubes peut ann uler les garanties applicables.

AVERTISSEMENTS : Risque de pincement de doigts — METTRE la POMPE HORS TENSION et la DÉBRANCHER

de la prise de courant avant de débrancher ou de raccorder un tube.

Une rupture de tube risque d’entraîner une pulvérisation de fluide hors de la pompe.

Prendre des mesures appropriées pour protéger l’opérateur et le matériel.

Mettre la pompe hors tension avant de débrancher ou de raccorder un tube. Les doigts

ou les vêtements amples risquent de se prendre dans le mécanisme de pompage.

INSERTION DES SECTIONS DE RACCORDEMENT DE TUBES

(VOIR FIGURES 1–4)

1. S’assurer que le commutateur de marche-arrêt est tourné en position

d’arrêt et que l’appareil est débranché.

2. Retirer les deux écrous et le couvercle de tête de pompe de la tête.

3. Positionner le support de rouleaux comme indiqué sur la Figure 1.

4. Enfoncer le tube dans l’orifice d’arrivée. Serrer le tube dans les pinces

tout en faisant tourner le support de rouleaux (voir la Figure 2).

5. Continuer à faire tourner le suppor t de rouleaux en enfonçant le

tube dans la paroi incurvée du carter de tête de pompe (voir la

Figure 3).

6. Enfoncer le connecteur de tube dans le tube (voir la Figure 4).

7. Remettre le couvercle et les deux écrous en place.

Figure 1

Figure 3

Figure 2

Figure 4

INSERTION DES SECTIONS DE RACCORDEMENT DE TUBES — MÉTHODE DE REMPLACEMENT

AVERTISSEMENT : Risque de pincement de doigts — METTRE la POMPE HORS TENSION et la DÉBRANCHER

de la prise de courant avant de débrancher ou de raccorder un tube.

REMARQUE : Il se peut que le suppor t de rouleaux de la pompe à basse vitesse (n° catalogue 72-410-014) soit

difficile à faire tourner et qu’il soit plus facile d’enfoncer le tube en employant cette méthode de

remplacement.

1. Enlever l’un des raccords de l’élément de liaison de tubes.

REMARQUE : NE PAS retirer le couvercle de tête de pompe !

2. Brancher le cordon d’alimentation et placer le commutateur de marche-arrêt en position de marche.

3. La pompe étant en marche, enfiler le tube (du côté sans raccord) av ec précaution dans l’orifice d’arrivér. Continuer

à enfiler le tube de 6,3 mm à la fois, en laissant les rouleaux tirer le tube jusqu’à ce qu’il dépasse de l’orifice de

sortie, comme indiqué sur la Figure 4.

4. Reposer le raccord sur le tube.

COMMANDES DE LA POMPE

1. Enfoncer l’élément de liaison de tubes à utiliser dans la tête de pompe.

2. Raccorder le tube d’arrivée en provenance du réservoir à l’orifice d’arrivée (sur le dessus) et le tube de sortie à

l’orifice correspondant.

3. Brancher le cordon d’alimentation dans une prise secteur 2 pôles + terre.

4. Mettre la pompe en marche en plaçant le commutateur de marche arrêt en position de marche. Amorcer les tubes

en laissant la pompe tourner pendant 5 à 10 minutes. La pompe est alors prête à l’emploi.

14

Page 15

DÉPANNAGE

PROBLÈME CAUSE POSSIBLE MESURE CORRECTRICE

La pompe est sous

tension mais le moteur

ne tourne pas.

La pompe est sous

tension et le moteur

tourne mais la tête de

pompe n’amorce pas

les tubes.

La pompe est sous

tension, le moteur ronfle

mais le rouleau ne

tourne pas.

Fluctuations dans le

débit de refoulement.

Le cordon d’alimentation est mal branché dans

la prise.

L’épaisseur de la paroi des tubes est incorrecte.

Le fusible a sauté.

ATTENTION : Remplacer le fusible par un

neuf de mêmes type et

intensité nominale uniquement. L’intensité nominale et le

type du fusible sont indiqués

sur le panneau arrière.

Les tubes ne sont pas enfoncés

correctement.

Pression insuffisante sur le tube.

Le tube est trop dur ou la pression de

refoulement est trop élevée.

Le tube est trop dur ou la pression de

refoulement est trop élevée.

L’élément de liaison de tubes est usé.

Vérifier le branchement du cordon

d’alimentation.

Voir le Tableau de SÉLECTION DU

DIAMÈTRE DE TUBE.

Vérifier le fusible au dos de la pompe.

S’assurer que les tubes d’arrivée et de

sortie sont enfoncés et raccordés

correctement.

Vérifier le tube pour voir s’il y a contrecourant et insérer une cale d’épaisseur

si nécessaire.

Utiliser uniquement des tubes

MANOSTAT dont la paroi est épaisse

de 3/32 po.

Utiliser uniquement des tubes

MANOSTAT dont la paroi est épaisse

de 3/32 po.

Remplacer l’élément de liaison de tubes.

IMPORTANT : Examiner régulièrement l’élément de liaison de tubes (celui qui se trouve à l’intérieur de la tête de

pompe) et le remplacer s’il est détérioré.

ENTRETIEN

AVERTISSEMENT : Mettre la pompe hors tension avant de proc éder à toute opération d’entretien.

Appliquer deux gouttes d’huile non détergente n° 20 sur le roulement arrière du moteur tous les trois mois. Ne pas trop

le huiler. Enlever toute poussière ou crasse accumulée.

NETTOYAGE

DANGER : Mettre la pompe hors tension avant de procéder à toute opération de nettoyage.

Maintenir la propreté du carter de la pompe avec une solution de détergent doux. Ne jamais plonger complètement la

pompe dans du liquide ni utiliser trop de liquide pour la nettoyer.

PIÈCES DE RECHANGE

Description Numéro de pièce Qté

Fusible, modèle 72-410-014 (0,5 A STD, 250 V, 3 AG) B-1115-0047 1

Fusible, modèles 72-415-014, 72-415-049 et 72-415-028 (T0,5 A, 250 V, 5 ⫻ 20 mm) B-1115-0062 1

Fusible, modèle 72-410-028 (0,75 A STD, 250 V, 3 AG) B-1115-0049 1

Fusible, modèle 72-410-049 (1,5 A STD, 250 V, 3 AG) B-1115-0032 1

Fusible, modèle 72-415-108 (T1.0 A, 250 V, 5 ⫻ 20 mm) B-1115-0056 1

Fusible, modèle 72-410-108 (2,0 A SLO-BLO, 250 V, 3 AG) B-1115-0013 1

Pied en caoutchouc—grande taille A-1390-0002 4

Bouton nickelé 8-32 UNC B-1083-0064 2

15

Page 16

ACCESSOIRES

Description Numéro de pièce

ÉLÉMENTS DE LIAISON DE TUBES (vendus en paquets de 5)

Élément de liaison de tubes en silicone — 1/16 po diam. int. 72-420-250

Élément de liaison de tubes en silicone — 1/8 po diam. int. 72-420-350

Élément de liaison de tubes en silicone — 3/16 po diam. int. 72-420-450

Élément de liaison de tubes en silicone — 1/4 po diam. int. 72-420-550

Lests

Les lests en polytétrafluoroéthylène maintiennent le tube au fond de tout récipient pour l’empêcher d’adhérer à la

paroi du réservoir. Ces lests, qui sont parfaitement adaptés à une utilisation avec les pompes et les distributeurs, ont

des embouts cannelés qui simplifient leur insertion dans les tubes flexibles. Leur fabrication en

polytétrafluoroéthylène leur permet de résister aux solvants et d’être stérilisés en autoclave.

Jeux de deux (2) : petite taille (pour utilisation avec des tubes de

1/16 à 1/8 po de diam. int.) et grande taille

(pour utilisation avec des tubes de 3/16 à 1/4 po de diam. int.)

Jeu de 2 lests (un de chaque taille) 75-250-100

Lests individuels 1/16 po — 1/8 po 75-250-102

Lests individuels 3/16 po — 1/4 po 75-250-104

Cales d’épaisseur

Cale d’épaisseur pour pompe (nécessaire pour les éléments de

liaison de tubes de 1/16 po de diam. int.)* 72-420-100

*Pose de la cale d’épaisseur : décoller le papier pour mettre

l’adhésif à nu avant de poser la cale d’épaisseur.

REMARQUE : Il est également possible de poser une cale d’épaisseur

sur un élément de liaison de tubes de 1/8 po.

16

Page 17

CARACTÉRISTIQUES TECHNIQUES

Sortie :

Vitesse de la pompe :

Modèle 72-410-014 14 tr/mn

Modèle 72-410-028 28 tr/mn

Modèle 72-410-049 49 tr/mn

Modèle 72-410-108 108 tr/mn

Modèle 72-415-014 14 ⫻ (5/6)* tr/mn

Modèle 72-415-028 28 ⫻ (5/6)* tr/mn

Modèle 72-415-049 49 ⫻ (5/6)* tr/mn

Modèle 72-415-108 108 ⫻ (5/6)* tr/mn

*REMARQUE : La vitesse des entraînements de la série

72-415-XXX est égale aux 5/6 de celle de la série

72-410-XXX par suite du fonctionnement à 50 Hz.

Couple :

Modèle 72-410-014 9,22 kg•cm

Modèle 72-410-028 9,22 kg•cm

Modèle 72-410-049 8,06 kg•cm

Modèle 72-410-108 6,91 kg•cm

Modele 72-415-014 10,94 kg•cm

Modele 72-415-028 9,22 kg•cm

Modele 72-415-049 9,79 kg•cm

Modèle 72-415-108 6,91 kg•cm

Entrée :

Tension/fréquence/intensité max. de fonctionnement :

Modèle 72-410-014 115 V c.a. ± 10 % à 60 Hz, 0,33 A

Modèle 72-415-014 230 V c.a. ± 10 % à 50 Hz, 0,13 A

Modèle 72-410-028 115 V c.a. ± 10 % à 60 Hz, 0,60 A

Modèle 72-415-028 230 V c.a. ± 10 % à 50 Hz, 0,23 A

Modèle 72-410-049 115 V c.a. ± 10 % à 60 Hz, 0,77 A

Modèle 72-415-049 230 V c.a. ± 10 % à 50 Hz, 0,31 A

Modèle 72-410-108 115 V c.a. ± 10 % à 60 Hz, 1,24 A

Modèle 72-415-108 230 V c.a. ± 10 % à 50 Hz, 0,47 A

Catégorie d’installation : Catégorie II d’après la norme IEC 664

(installation locale — appareillage, matériel portatif, etc.)

Conditions d’utilisation :

Température de fonctionnement : 0 à 40 °C

Température d’entreposage : –45 à 65 °C

Humidité : 10 à 90 % sans condensation

Altitude : Inférieure à 2000 m

Degré de pollution : Degré 2 d’après la norme IEC 664

(utilisation intérieure — laboratoire, bureau)

Fabrication :

Dimensions (L ⫻ l ⫻ H) : 13 cm ⫻ 17 cm ⫻ 13,5 cm

Poids : 1,8 kg

Couleur : Blanc

Matière : Carter en acier peint

Homologation du boîtier : IP21 (IEC 529)

Conformités : 115 V : UL 508, ACNOR C22.2, n° 14-M91

230 V (pour estampillage CE) :

EN61010-1/A2 : 1995

(Directive européenne sur les basses tensions) et

EN61326-1/A1 : 1998

(Directive européenne sur la compatibilité électromagnétique)

17

Page 18

GARANTIE

N’utiliser que des sections de raccordement de tubes de précision MANOSTAT avec les pompes MANOSTAT

pour garantir des performances optimales. L’utilisation d’autres tubes peut ann uler les garanties applicables.

Nous garantissons que ce produit est conforme aux descriptifs. Si une réparation ou un réglage s’avère nécessaire

durant la période de garantie, le problème sera corrigé gratuitement s’il n’est pas dû à une utilisation par le client dont

nous avons déterminé qu’elle est incorrecte ou abusive . Les réparations effectuées en dehors de la période de garantie

ou rendues nécessaires par une utilisation incorrecte ou abusive seront à la charge du client.

La période de garantie pour ce produit est indiquée sur la carte de garantie.

RETOUR DE MARCHANDISES

Pour limiter les frais et délais, le produit ne peut être retour né sans notre autorisation préalable et nos instructions

d’expédition ou celles du revendeur. Lors du renv oi du produit, bien vouloir en indiquer la r aison. pour se protéger, nous

recommandons au client d’emballer soigneusement le produit et de l’assurer contre les risques de dommages ou de

perte. Nous ne serons pas responsable des dommages résultant d’un emballage incorrect.

ASSIST ANCE TECHNIQUE

Pour toute question concernant l’utilisation de ce produit, prendre contact avec nous ou avec un revendeur agréé.

18

Imprimé aux États-Unis

030701

Page 19

INHALTSVERZEICHNIS

Titel Seite

SICHERHEITSMASSNAHMEN ............................................................................................................................. 20

Sicherheit ........................................................................................................................................................... 20

EINFÜHRUNG UND ALLGEMEINE BESCHREIBUNG......................................................................................... 21

VORBEREITUNG................................................................................................................................................... 21

Auswahl der Schlauchgröße............................................................................................................................... 21

Chemische Beständigkeit................................................................................................................................... 21

BETRIEB................................................................................................................................................................ 22

Einlegen der Pumpenschläuche......................................................................................................................... 22

Einlegen der Pumpenschläuche – Alternativmethode........................................................................................ 22

Bedienelemente der Pumpe............................................................................................................................... 22

STÖRUNGSBESEITIGUNG .................................................................................................................................. 23

WARTUNG............................................................................................................................................................. 23

Reinigen ............................................................................................................................................................. 23

Ersatzteile .......................................................................................................................................................... 23

ZUBEHÖR.............................................................................................................................................................. 24

TECHNISCHE DATEN ........................................................................................................................................... 25

GARANTIE............................................................................................................................................................. 26

WARENRÜCKSENDUNGEN................................................................................................................................. 26

TECHNISCHE BERATUNG ............................................................................................................ ....................... 26

DEUTSCH

19

Page 20

SICHERHEITSMASSNAHMEN

VORSICHT,

LEBENSGEFAHR: Vor allen Reinigungsarbeiten zuerst die Stromzufuhr zur Pumpe unterbrechen.

VORSICHT: Vor allen War tungsarbeiten zuerst die Stromzufuhr zur Pumpe unterbrechen.

WARNHINWEISE: Bei Schlauchbruch wird u. U. Flüssigkeit von der Pumpe verspritzt. Geeignete Maßnahmen

zum Schutz von Bediener und Geräten ergreifen.

Vor dem Herausnehmen oder Einlegen von Schläuchen die Pumpe ausschalten, da sich

andernfalls Finger oder lose Kleidung im Antriebsmechanismus verfangen könnten.

Risiko von Fingerquetschungen – v or Herausnehmen oder Einlegen von Schläuchen die

PUMPE AUSSCHALTEN und NETZSTECKER ZIEHEN.

ACHTUNG: Beim Ändern der Flussrichtung vor dem Neustart warten, bis die Pumpe v ollständig zum

Stillstand gekommen ist, da es andernfalls zu einer permanenten Beschädigung des

Motors kommen kann.

Die Sicherung nur gegen eine Sicherung des gleichen T yps und der gleichen Nennleistung

auswechseln. Die Nennleistung der Sicherung und der Sicherungstyp sind auf der

Rückwand angegeben.

ACHTUNG: ANWENDUNGSEINSCHRÄNKUNGEN

Dieses Gerät ist nicht für den Einsatz am Patienten vorgesehen und auch nicht für diesen Zweck bestimmt (z.B.

medizinischen oder zahnmedizinischen Bereich) und entspricht demgemäß auch keinen FDA (Food & Drug Ad-

ministration) Normen.

SICHERHEIT

1. Vor Inbetriebnahme des Geräts die Anleitungen lesen.

2. Die Sicherheitsmaßnahmen sind zu allen Zeiten zu beachten. Beim Pumpen gefährlicher Flüssigkeiten ist besondere

Vorsicht geboten. Die Abdeckung des Pumpenkopfs muss immer einwandfrei auf dem Pumpenkopf angebracht

sein, und der gesamte Pumpenbereich ist vor einem versehentlichen Verschütten von Flüssigkeit zu schützen.

3. Die Pumpe darf nicht im Freien oder in risikoreichen Bereichen verwendet werden.

4. Die E-SERIES-Pumpen von MANOSTAT müssen zu allen Zeiten einwandfrei geerdet sein.

HINWEIS: Nur MANOSTAT-Silikon-Pumpenschläuche verwenden!

E-SERIES — eingetragen Marke der Chemtronics, Inc.

Marken mit dem Symbol ® in dieser Veröffentlichung sind in den USA und in anderen Ländern eingetragen.

20

Page 21

EINFÜHRUNG UND ALLGEMEINE BESCHREIBUNG

Die E-SERIES®-Pumpe der VARISTALTIC® ist eine selbstansaugende Schlauchpumpe mit fester Drehzahl. Die

peristaltische Pumpenrolle drückt die Flüssigkeit durch den Schlauch. Die Fördermenge ist proportional zur Rollendrehzahl

(U/min) und dem Innendurchmesser des Schlauchs.

Die E-SERIES-Pumpe der VARISTAL TIC kann zum Pumpen von Flüssigk eit oder Gas ohne Kontamination der Pumpe

verwendet werden; das gepumpte Mater ial kommt nur mit dem Schlauch in Berührung.

VORBEREITUNG

AUSWAHL DER SCHLAUCHGRÖSSE

In dieser Pumpe kann ein 55 ±5 Durometer (Shore A) flexibler Schlauch mit einer W andstärke v on 3/32 Zoll und einem

Innendurchmesser von 1/16 bis 1/4 Zoll verwendet werden.

Die Fördermenge richtet sich nach der Größe des Schlauchs im Pumpenkopf. Die beste Leistung erzielt, wenn der mit

dem Pumpenschlauch verbundene Ansaug- und Auslassschlauch denselben Innendurchmesser hat wie der

Pumpenschlauch. Alle Schläuche im Inneren des Pumpenkopfes müssen durch ihren Aufdruck eindeutig als

MANOSTAT-Silikon-Pumpenschläuche gekennzeichnet sein.

Die E-SERIES-Pumpen von MANOSTAT werden mit einem Silikon-Pumpenschlauch mit 3/16 Zoll Innendurchmesser

geliefert. MANOSTAT bietet Silikon-Pumpenschläuche in verschiedenen Größen an.

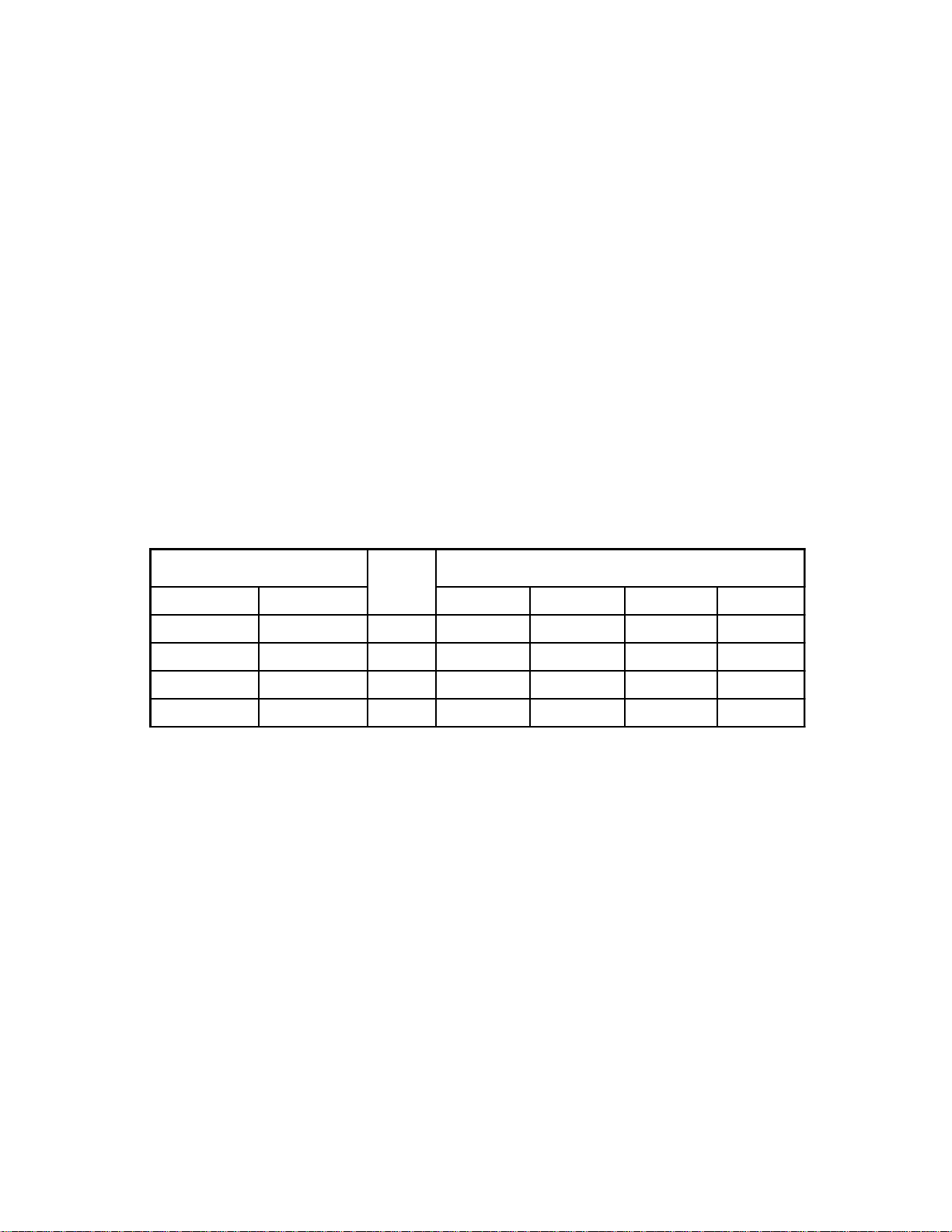

Wählen Sie die geeignete Schlauchgröße anhand der nachstehenden Fördermengentabelle aus.

AUSWAHL DER SCHLAUCHGRÖSSE

Katalognr.

115 V~ 230 V~ 1/16* 1/8 3/16 1/4

72-410-014 72-415-014 14 3 12 27 45

72-410-028 72-415-028 28 6,5 25 55 90

72-410-049 72-415-049 49 11 44 100 150

72-410-108 72-415-108 108 26 104 228 375

* Erfordert Beilagscheibe

** Bei 50 Hz verringert sich die Fördermenge um 16 %

*** Genauigkeit der Förder menge: ±8 %

CHEMISCHE BESTÄNDIGKEIT

Die Auswahl des Schlauchmaterials richtet sich nach der zu pumpenden Chemikalie. Zur Auswahl des geeigneten

Pumpenschlauchtyps für die verwendete Flüssigkeit lessen Sie bitte in der mitgeliefer ten Anleitung zur Wahl von

MANOSTAT-Schläuchen (MANOSTAT Tubing Guide, Artikelnr. A-1299-5075) nach.

U/min**

60 Hz

Schlauchgröße (I nnendu rchm. × 3/32 Wand)

Fördermenge ( ml/min)***

21

Page 22

BETRIEB

Um optimale Anwendungsergebnisse zu gewährleisten, sind für MANOSTAT-Pumpen ausschließlich

MANOSTAT-Präzisions-Pumpenschläuche zu verwenden. Der Einsatz anderer Schläuche kann eine

Verweigerung der Garantieleistung nach sich ziehen.

WARNHINWEISE: Bei Schlauchbruch wird u. U. Flüssigkeit von der Pumpe verspritzt. Geeignete Maßnahmen

zum Schutz von Bediener und Geräten ergreifen.

Vor dem Herausnehmen oder Einlegen von Schläuchen die Pumpe ausschalten, da sich

andernfalls Finger oder lose Kleidung im Antriebsmechanismus verfangen könnten.

Risiko von Fingerquetschungen – v or dem Herausnehmen oder Einlegen von Schläuchen

die PUMPE AUSSCHALTEN und NETZSTECKER ZIEHEN.

EINLEGEN DER PUMPENSCHLÄUCHE

(SIEHE ABBILDUNGEN 1 – 4)

1. Sicherstellen, dass der Netzschalter auf AUS steht und der

Netzstecker gezogen ist.

2. Die beiden Muttern und die Pumpenkopfabdeckung vom Pumpenk opf

abnehmen.

3. Die Rollenhalterungseinheit wie in Abbildung 1 gezeigt positionieren.

4. Den Schlauch in die Einlassöffnung einführen. Den Schlauch in den

Greifern verankern und dabei die Rollenhalterungseinheit drehen

(siehe Abbildung 2).

5. Die Rollenhalterungseinheit weiterhin drehen und den Schlauch in

die gebogene Gehäusewand des Pumpenkopfs schieben (siehe

Abbildung 3).

6. Das Schlauchverbindungsstück in den Schlauch einsetzen (siehe

Abbildung 4)

7. Die Abdeckung und die beiden Muttern wieder anbringen.

Abbildung 1

Abbildung 3

Abbildung 2

Abbildung 4

EINLEGEN DER PUMPENSCHLÄUCHE — ALTERNATIVMETHODE

VORSICHT : Risiko von Fingerquetsc hungen – vor Herausnehmen oder Einlegen von Sc hläuchen die PUMPE

AUSSCHALTEN und NETZSTECKER ZIEHEN.

HINWEIS: Die Rollenhalterungseinheit der Pumpe mit niedriger Drehzahl (Katalognr. 72-410-014) lässt sich u. U. nur

schwer drehen. In diesem Fall ist es einfacher, den Schlauch mit dieser Alternativmethode einzulegen.

1. Einen der Verbinder vom Pumpenschlauch entfernen.

HINWEIS: Die Pumpenkopfabdeckung NICHT abnehmen!

2. Netzstecker einstecken und den Netzschalter auf EIN stellen.

3. Den Schlauch am Ende ohne Verbinder bei laufender Pumpe in die Einlassöffnung einführen. Den Schlauch jeweils

um ca. 6,35 mm einführen, so dass die Rolleneinheit den Schlauch aufziehen kann, bis der Schlauch aus der

Auslassöffnung austritt (siehe Abbildung 4).

4. Den Verbinder wieder am Schlauch anbringen.

BEDIENELEMENTE DER PUMPE

1. Den zu verwendenden Pumpenschlauch in den Pumpenkopf einlegen.

2. Den vom Behälter kommenden Ansaugschlauch an die Einlassöffnung (oben) und den Auslassschlauch an die

Auslassöffnung anschließen.

3. Das Netzkabel in eine geerdete Netzsteckdose einstecken.

4. Zum Starten der Pumpe den Netzschalter auf EIN stellen. Die Pumpe zum V orfüllen 5 bis 10 Minuten lauf en lassen.

Danach ist die Pumpe betriebsbereit.

22

Page 23

STÖRUNGSBESEITIGUNG

PROBLEM MÖGLICHE URSACHE VORGEHENSWEISE

Einheit ist eingeschaltet,

Motor läuft nicht.

Einheit ist eingeschaltet,

Motor läuft,

Pumpenkopf füllt den

Schlauch nicht.

Gerät ist eingeschaltet,

Motor ist hörbar, Rolle

dreht sich nicht.

Leistungsschwankungen

Netzkabel nicht einwandfrei an die Steckdose

angeschlossen.

Schlauch hat falsche Wandstärke.

Sicherung durchgebrannt.

ACHTUNG: Die Sicherung nur gegen eine

Sicherung des gleichen Typs

und der gleichen Nennleistung

auswechseln. Die Nennleistung der Sicherung und der

Sicherungstyp sind auf der

Rückwand angegeben.

Schlauch falsch eingelegt.

Nicht genügend Anpressdruck am Schlauch.

Schlauch ist zu hart oder der Kopfdruck ist zu

hoch.

Schlauch ist zu steif oder der Kopfdruck ist zu

hoch.

Pumpenschlauch ist abgenutzt.

Netzkabelanschluss prüfen.

Siehe Tabelle zur AUSWAHL DER

SCHLAUCHGRÖSSE.

Sicherung an der Rückwand der Pumpe

prüfen.

Sicherstellen, dass der Ansaug- und

Auslassschlauch einwandfrei eingelegt

und angeschlossen ist.

Schlauch auf Rückfluss prüfen und ggf .

eine Beilagscheibe einlegen.

Nur einen MANOSTAT-Schlauch mit

einer Wandstärke von 3/32 Zoll

verwenden.

Nur einen MANOSTAT-Schlauch mit

einer Wandstärke von 3/32 Zoll

verwenden.

Pumpenschlauch auswechseln.

WICHTIG: Pumpenschlauch (das Schlauchstück im Pumpenkopf) regelmäßig über prüfen und bei

Verschleißerscheinungen auswechseln.

WARTUNG

VORSICHT: Vor allen War tungsarbeiten zuerst die Stromzufuhr zur Pumpe unterbrechen.

Das hintere Motorlager muss alle drei Monate mit zwei Tropfen #20 Öl ohne Detergentzusätze geschmiert werden.

Nicht zu stark schmieren. Staub- und Schmutzansammlungen entfernen.

REINIGEN

VORSICHT,

LEBENSGEFAHR: Vor allen Reinigungsarbeiten zuerst die Stromzufuhr zur Pumpe unterbrechen.

Das Pumpengehäuse mit einem milden Reinigungsmittel sauber halten. Beim Reinigen die Pumpe niemals eintauchen

oder zu viel Flüssigkeit verwenden.

ERSATZTEILE

Beschreibung Artikelnummer Stckz.

Sicherung, Modell 72-410-014 (0,5 A STD, 250 V, 3 AG) B-1115-0047 1

Sicherung, Modelle 72-415-014, 72-415-049 und 72-415-028 (T0.5 A, 250 V, 5 ⫻ 20 mm) B-1115-0062 1

Sicherung, Modell 72-410-028 (0,75 A STD, 250 V, 3 AG) B-1115-0049 1

Sicherung, Modell 72-410-049 (1,5 A STD, 250V, 3 AG) B-1115-0032 1

Sicherung, Modell 72-415-108 (T1.0 A, 250 V, 5 ⫻ 20 mm) B-1115-0056 1

Sicherung, Modell 72-410-108 (2,0 A SLO-BLO, 250 V, 3 AG) B-1115-0013 1

Gummifuß – groß A-1390-0002 4

Knopf, vernickelt 8-32 UNC B-1083-0064 2

23

Page 24

ZUBEHÖR

Beschreibung Artikelnummer

PUMPENSCHLÄUCHE (in Packungen mit je 5 Pumpenschläuchen)

Silikonpumpenschlauch — 1/16 Zoll Innendurchmesser 72-420-250

Silikonpumpenschlauch — 1/8 Zoll Innendurchmesser 72-420-350

Silikonpumpenschlauch — 3/16 Zoll Innendurchmesser 72-420-450

Silikonpumpenschlauch — 1/4 Zoll Innendurchmesser 72-420-550

Senkkörper

Die PTFE-Senkkörper halten den Schlauch am Boden des Behälters fest, so dass er nicht an der Behälterwand

haften kann. Diese Senkkörper sind mit Schlaucholiven zum einfachen Einführen in flexible Schläuche versehen und

eignen sich ideal für den Einsatz mit Pumpen und Dosiergeräten. Die PTFE-Zusammensetzung ist gegen

Reinigungsmittel beständig und autoklavierbar.

Sätze mit je zwei (2): klein (für Schläuche mit 1/16 bis 1/8 Zoll Innendurchmesser)

und groß (für Schläuche mit 3/16 bis 1/4 Zoll Innendurchmesser)

Senkkörpersatz mit je zwei Stück (einer je Größe) 75-250-100

Senkkörper je einer 1/16 – 1/8 Zoll 75-250-102

Senkkörper je einer 3/16 – 1/4 Zoll 75-250-104

Beilagscheiben

Beilagscheibe für Pumpe (für Pumpenschläuche

mit 1/16 Zoll Innendurchmesser erforderlich)* 72-420-100

*Einsetzen der Flussbeilagscheiben: Vor Einsetz en der Beilagescheibe

die Papierabdeckung von der Haftfläche abziehen.

HINWEIS: Die Beilagscheibe kann auch für 1/8-Zoll-Pumpenschläuche

verwendet werden.

24

Page 25

TECHNISCHE DATEN

Ausgangsleistung:

Pumpendrehzahl:

Modell 72-410-014 14 U/min

Modell 72-410-028 28 U/min

Modell 72-410-049 49 U/min

Modell 72-410-108 108 U/min

Modell 72-415-014 14 ⫻ (5/6)* U/min

Modell 72-415-028 28 ⫻ (5/6)* U/min

Modell 72-415-049 49 ⫻ (5/6)* U/min

Modell 72-415-108 108 ⫻ (5/6)* U/min

*ANMERKUNG: Auf Grund des Betriebs mit 50 Hz beträgt die

Drehzahl der Antriebe der Serie 72-415-XXX 5/6 der Drehzahl

der Serie 72-410-XXX.

Drehmoment:

Modell 72-410-014 9,22 kg•cm

Modell 72-410-028 9,22 kg•cm

Modell 72-410-049 8,06 kg•cm

Modell 72-410-108 6,91 kg•cm

Modell 72-415-014 10,94 kg•cm

Modell 72-415-028 9,22 kg•cm

Modell 72-415-049 9,79 kg•cm

Modell 72-415-108 6,91 kg•cm

Eingangsleistung:

Betriebsspannung/Frequenz/max. Stromstärke:

Modell 72-410-014 115 V~ ±10 % bei 60 Hz, 0,33 A

Modell 72-415-014 230 V~ ±10 % bei 50 Hz, 0,13 A

Modell 72-410-028 115 V~ ±10 % bei 60 Hz, 0,60 A

Modell 72-415-028 230 V~ ±10 % bei 50 Hz, 0,23 A

Modell 72-410-049 115 V~ ±10 % bei 60 Hz, 0,77 A

Modell 72-415-049 230 V~ ±10 % bei 50 Hz, 0,31 A

Modell 72-410-108 115 V~ ±10 % bei 60 Hz, 1,24 A

Modell 72-415-108 230 V~ ±10 % bei 50 Hz, 0,47 A

Installationsklasse: Installationsklasse II nach IEC 664 (Lokale Anwendungen —

Haushaltsgeräte, tragbare Geräte usw.)

Umgebungsbedingungen:

Betriebstemperatur: 0 bis 40 °C

Lagertemperatur: –45 bis 65 °C

Luftfeuchtigkeit: 10 % bis 90 %, nicht kondensierend

Höhe ü. M.: Unter 2000 m

Umweltverschmutzungsgrad: Umweltverschmutzungsgrad 2 nach IEC 664

(Innengebrauch —Labor , Büro)

Bauweise:

Abmessungen (L ⫻ B ⫻ H): 13 cm ⫻ 17 cm ⫻ 13,5 cm

Gewicht: 1,8 kg

Farbe: Weiß

Material: Lackiertes Stahlgehäuse

Schutzart Gehäuse: IP21 nach IEC 529

Entspricht den Normen: 115 V: UL508, CSA C22.2, Nr. 14-M91

230 V (für CE-Kennzeichen):

EN61010-1/A2: 1995

(Niederspannungsrichtlinie der EU) und

EN61326-1/A1: 1998

(EMV-Richtlinie der EU)

25

Page 26

GARANTIE

Um optimale Anwendungsergebnisse zu gewährleisten, sind für MANOSTAT-Pumpen ausschließlich

MANOSTAT-Präzisions-Pumpenschläuche zu verwenden. Der Einsatz anderer Schläuche kann eine

Verweigerung der Garantieleistung nach sich ziehen.

Der Hersteller garantiert, dass dieses Produkt keine nennenswerten Abweichungen von den veröffentlichten

Spezifikationen aufweist. Falls während der Garantiezeit eine Repar atur oder Nachbesserung erforderlich werden sollte,

wird dies kostenlos vorgenommen, vorausgesetzt, es liegt kein vom Hersteller feststellbarer fehlerhafter oder

unsachgemäßer Einsatz seitens des Kunden vor. Reparaturkosten außerhalb der Garantiezeit oder auf Grund von

fehlerhaftem oder unsachgemäßem Gebrauch des Produktes werden Ihnen in Rechnung gestellt.

Die Garantiefrist für dieses Produkt ist auf der Garantiekarte vermerkt.

W ARENRÜCKSENDUNGEN

Um Kosten und Verzögerungen so gering wie möglich zu halten, lassen Sie sich in jedem Fall von Ihrem Fachhändler

oder dem Hersteller eine Rücksendegenehmigung und die V ersandanweisungen geben, bevor Sie Ware zurückschicken.

Geben Sie bitte den Rücksendegrund mit an. Verpacken Sie die W are sorgfältig und versichern Sie die Sendung gegen

Beschädigung bzw. Verlust. Für Transportschäden auf Gr und unsachgemäßer Verpackung haften Sie.

TECHNISCHE BERATUNG

Wenn Sie Fragen zur Anwendung diese Produktes haben, wenden Sie sich bitte an den Hersteller oder autorisierten

Fachhändler.

26

Printed in U.S.A.

030701

Page 27

ÍNDICE GENERAL

Título Página

PRECAUCIONES DE SEGURIDAD ...................................................................................................................... 28

Seguridad........................................................................................................................................................... 28

INTRODUCCIÓN Y DESCRIPCIÓN GENERAL .................................................................................................... 29

CONFIGURACIÓN................................................................................................................................................. 29

Selección del tamaño del tubo ........................................................................................................................... 29

Compatibilidad química...................................................................................................................................... 29

OPERACIÓN.......................................................................................................................................................... 30

Inserción de uniones de tubo ............................................................................................................................. 30

Inserción de uniones de tubo— Método alternativo ........................................................................................... 30

Controles de la bomba ....................................................................................................................................... 30

LOCALIZACIÓN Y RESOLUCIÓN DE PROBLEMAS............................................................................................ 31

MANTENIMIENTO ................................................................................................................................................. 31

Limpieza............................................................................................................................................................. 31

Piezas de repuesto ............................................................................................................................................ 31

ACCESORIOS ....................................................................................................................................................... 32

ESPECIFICACIONES ............................................................................................................................................ 33

GARANTÍA............................................................................................................................................................. 34

DEVOLUCIÓN DEL PRODUCTO .......................................................................................................................... 34

ASISTENCIA TÉCNICA ............................................................................................................. ............................ 34

ESPAÑOL

27

Page 28

PRECAUCIONES DE SEGURIDAD

PELIGRO: Desconecte la corriente de la bomba antes de empezar una operación de limpieza.

ADVERTENCIA: Desconecte la corriente de la bomba antes de tratar de efectuar el mantenimiento.

ADVERTENCIAS: La rotura de los tubos puede hacer que la bomba rocíe fluido. T ome las medidas necesarias

para proteger al operador y los equipos.

Desconecte la bomba antes de quitar o instalar tubos. El mecanismo de la bomba puede

enganchar los dedos o la ropa holgada.

Peligro de pellizcarse los dedos — DESCONECTE y DESENCHUFE la BOMBA antes de

quitar o cargar un tubo.

PRECAUCIONES: Al cambiar el sentido del flujo, deje que la bomba se pare completamente antes de volver

a funcionar. De no hacer esto se pueden producir daños permanentes en el motor.

Reemplace el fusible solamente por otro del mismo tipo y características. Las características

y tipo de fusible se indican en el panel trasero.

ADVERTENCIA: LIMITACIÓN DEL USO DEL PRODUCTO

Estos productos no están diseñados ni tienen como finalidad ser usados en aplicaciones conectadas al paciente,

incluidas aplicaciones médicas o dentales, pero sin limitarse a las mismas, y en consecuencia no se han enviado

a la FDA para su aprobación.

SEGURIDAD

1. Lea las instrucciones antes de operar la unidad.

2. Observe las precauciones de seguridad en todo momento, especialmente al bombear líquidos peligrosos. Mantenga

siempre la tapa de la cabeza de la bomba bien montada en la cabeza de la bomba y , en gener al, proteja el área de

la bomba contra los derrames de líquido por accidente.

3. La bomba no debe usarse en lugares exteriores o peligrosos.

4. Las bombas MANOSTAT E-SERIES deben estar bien conectadas a tierra en todo momento.

NOTA: Use sólo uniones de tubo de silicona MANOSTAT.

E-SERIES — Marca comercial registrada de Chemtronics, Inc.

Las marcas comerciales de esta publicación que tengan el símbolo ® están registradas en EE.UU. y otros países.

28

Page 29

INTRODUCCIÓN Y DESCRIPCIÓN GENERAL

La bomba VARISTALTIC® E-SERIES® es una bomba peristáltica de velocidad fija y cebado automático. La presión de

los rodillos de la bomba peristáltica aprieta el fluido por el tubo. El caudal es proporcional a la velocidad de los rodillos

(rpm) y al diámetro interior del tubo.

La bomba VARISTALTIC E-SERIES puede usarse para bombear fluido o gas sin contaminar la bomba; el material

bombeado hace contacto con el tubo solamente.

CONFIGURACIÓN

SELECCIÓN DEL TAMAÑO DEL TUBO

Con esta bomba se puede usar un tubo flexible con un valor de durómetro de 55 ±5 (Shore A) con una pared de

3/32 pulg y un diámetro interior de 1/16 pulg a 1/4 pulg.

El caudal viene determinado por el tamaño del tubo de la cabeza de la bomba. El máximo rendimiento se logra cuando

el tubo de entrada y el tubo de salida conectados a la unión tienen el mismo diámetro interior que la unión. Todos los

tubos dentro de la bomba deben ser uniones de tubo de silicona MANOSTAT impresos en la superficie.

Las bombas MANOSTAT E-SERIES vienen con una unión de tubo de silicona de 3/16 pulg de diámetro interior.

MANOSTAT ofrece uniones de tubo de silicona de varios tamaños.

Consulte la tabla de caudales siguiente para escoger el tamaño correcto del tubo.

SELECCIÓN DE TAMAÑOS DE TUBOS

Catálogo No.

115 VCA 230 VCA 1/16* 1/8 3/16 1/4

72-410-014 72-415-014 14 3 12 27 45

72-410-028 72-415-028 28 6,5 25 55 90

72-410-049 72-415-049 49 11 44 100 150

72-410-108 72-415-108 108 26 104 228 375

* Requiere calzo

** A 50 Hz, el caudal será un 16% menor

*** Precisión del caudal: ±8%

COMPATIBILIDAD QUÍMICA

La selección del material de los tubos depende del producto químico que se bombee. Consulte la quía de tubos

MANOST AT (No . de pieza A-1299-5075) para seleccionar el tipo de unión de tubo apropiado para el líquido que se esté

usando.

rpm**

60 Hz

Tamaño del tubo (diám. int. × pared de 3/32 pul g)

Caudal (mL/min)** *

29

Page 30

OPERACIÓN

Use solamente uniones de tubos de precisión MANOSTAT con las bombas MANOSTAT para asegurar un

rendimiento óptimo. El uso de otros tubos puede anular las garantías correspondientes.

ADVERTENCIAS: Peligro de pellizcarse los dedos — DESCONECTE y DESENCHUFE la BOMBA antes de

quitar o cargar un tubo.

La rotura de los tubos puede hacer que la bomba rocíe fluido. Tome las medidas necesarias

para proteger al operador y los equipos.

Desconecte la bomba antes de quitar o instalar tubos. El mecanismo de la bomba puede

enganchar los dedos o la ropa holgada.

INSERCIÓN DE UNIONES DE TUBO

(CONSULTE LAS FIGURAS 1–4)

1. Asegúrese de que el interruptor de alimentación esté en la posición

de apagado y la unidad esté desenchufada.

2. Quite de la cabeza de la bomba las dos tuercas y la tapa de la

cabeza de la bomba.

3. Coloque el conjunto de soporte de los rodillos según se muestra en

la Figura 1.

4. Introduzca el tubo en el orificio de entrada empujándolo. Fije el tubo

con los dispositivos de agarre a la vez que gira el conjunto del soporte

de los rodillos (vea la Figura 2).

5. Siga girando el conjunto de soporte de los rodillos, empujando el

tubo por la pared curvada de la caja de la bomba (vea la Figura 3).

6. Inserte el conector del tubo en el tubo (vea la Figura 4).

7. Vuelva a colocar la tapa y las dos tuercas.

Figura 1

Figura 3

Figura 2

Figura 4

INSERCIÓN DE UNIONES DE TUBO — MÉTODO ALTERNATIVO

ADVERTENCIA: Peligro de pellizcarse los dedos — DESCONECTE y DESENCHUFE la BOMBA antes de

quitar o cargar un tubo.

NOTA: Tal vez resulte difícil girar el conjunto de soporte de los rodillos de la bomba de bajas rpm (No. de catálogo

72-410-014). Es posible que sea más fácil insertar el tubo usando este método alternativo.

1. Quite uno de los conectores de la unión del tubo.

NOTA: ¡NO quite la tapa de la cabeza de la bomba!

2. Enchufe el cordón de alimentación y ponga el interruptor de alimentación en la posición de encendido.

3. Con la bomba en funcionamiento, inserte el tubo con cuidado (el extremo sin el conector) en el orificio de entrada.

Siga insertando el tubo en tramos de 6,3 mm, dejando que el conjunto de rodillos tire del tubo hasta que el tubo se

extienda desde el orificio de salida, según se muestra en la Figura 4.

4. Vuelva a conectar el conector al tubo.

CONTROLES DE LA BOMBA

1. Inserte la unión del tubo que se vaya a usar en la cabeza de la bomba.

2. Conecte el tubo de entrada, que se origina en el depósito, al orificio de entrada (arriba), y el tubo de salida al orificio

de salida.

3. Enchufe el cordón de alimentación a la fuente de CA puesta a tierra.

4. Ponga la bomba en marcha poniendo el interruptor de alimentación en la posición de encendido. Cebe el tubo

dejando que la bomba funcione durante 5 a 10 minutos. Después de esto la bomba estará lista para su uso.

30

Page 31

LOCALIZACIÓN Y RESOLUCIÓN DE PROBLEMAS

PROBLEMA CAUSA POSIBLE ACCIÓN

Corriente conectada, el

motor no funciona.

Corriente conectada,

motor en funcionamiento, la cabeza de la

bomba no ceba el tubo.

Corriente conectada,

ruido en el motor, el

rodillo no gira.

Fluctuación en la salida.

El cordón de alimentación no está bien

conectado a la toma de corriente.

El tubo tiene un espesor de pared incorrecto.

Fusible fundido.

PRECAUCIÓN : Reemplace el fusible

solamente por otro del

mismo tipo y características. Las características

y tipo de fusible se indican

en el panel trasero.

Tubo mal insertado.

El tubo no se aprieta suficiente.

El tubo está demasiado duro o hay

demasiada presión piezométrica.

El tubo está demasiado duro o hay demasiada

presión piezométrica.

La unión del tubo está desgastada.

Compruebe la conexión del cordón de

alimentación.

Consulte la tabla de SELECCIÓN DE

TAMAÑOS DEL TUBO.

Compruebe el fusible de la parte de

atrás de la bomba.

Asegúrese de que el tubo de entrada y

salida estén bien insertados y

conectados.

Compruebe el tubo para ver si hay un

flujo de retroceso e inserte un calzo, si

es necesario.

Use sólo tubos MANOSTAT con

paredes de un espesor de 3/32 pulg.

Use sólo tubos MANOSTAT con

paredes de un espesor de 3/32 pulg.

Reemplace la unión del tubo.

IMPORTANTE: Inspeccione con regularidad la unión del tubo (tubo dentro de la cabeza de la bomba) y reemplácela

si está deteriorada.

MANTENIMIENTO

ADVERTENCIA: Desconecte la corriente de la bomba antes de tratar de efectuar el mantenimiento.

Se deben echar dos gotas de aceite No. 20 no detergente en el cojinete trasero del motor cada tres meses . No lubrique

excesivamente . Limpie el polvo o suciedad acumulada.

LIMPIEZA

PELIGRO: Desconecte la corriente de la bomba antes de empezar una operación de limpieza.

Mantenga limpio el recinto de la bomba usando un detergente suave. No sumerja nunca ni use una cantidad excesiva

de fluido al limpiar la bomba.

PIEZAS DE REPUESTO

Descripción Número de pieza Cdad.

Fusible modelo 72-410-014 (0,5 A STD, 250 V, 3 AG) B-1115-0047 1

Fusible modelos 72-415-014, 72-415-049 y 72-415-028 (T0.5 A, 250 V, 5 ⫻ 20 mm) B-1115-0062 1

Fusible modelo 72-410-028 (0,75 A STD, 250 V, 3 AG) B-1115-0049 1

Fusible modelo 72-410-049 (1,5 A STD, 250 V, 3 AG) B-1115-0032 1

Fusible modelo 72-415-108 (T1.0 A, 250 V, 5 ⫻ 20 mm) B-1115-0056 1

Fusible modelo 72-410-108 (2,0 A SLO-BLO, 250 V, 3 AG) B-1115-0013 1

Pata de caucho—Grande A-1390-0002 4

Perilla de níquel platino 8-32 UNC B-1083-0064 2

31

Page 32

ACCESORIOS

DescripciónNúmero de pieza

UNIONES DE TUBOS (vendidas en paquetes de 5 uniones)

Unión de tubo de silicona — 1/16 pulg de diám. int. 72-420-250

Unión de tubo de silicona — 1/8 pulg de diám. int. 72-420-350

Unión de tubo de silicona — 3/16 pulg de diám. int. 72-420-450

Unión de tubo de silicona — 1/4 pulg de diám. int. 72-420-550

Lastres

Los lastres de PTFE mantienen el tubo en el fondo de cualquier recipiente, eliminando la posibilidad de que

adhieran a la pared del depósito. Estos lastres, ideales para usar con bombas y distribuidores, tienen extremos en

forma de arpón de manguera para poder insertarlos simplemente en el tubo flexible. La composición de PTFE

ofrece resistencia a los disolventes y esterilizarse en un autoclave.

Juego de dos (2): pequeño (para usar con tubos de 1/16 pulg a 1/8 pulg de diám. int.)

y grande (para usar con tubos de 3/16 pulg a 1/4 pulg de diám. int.)

Lastres, juego de 2 (uno de cada tamaño) 75-250-100

Lastres de 1/16 pulg — 1/8 pulg cada uno 75-250-102

Lastres de 3/16 pulg — 1/4 pulg cada uno 75-250-104

Calzos

Calzo para bomba (necesario para uniones de tubo

de 1/16 pulg de diám. int.)* 72-420-100

*Instalación del calzo de caudal: Quite la cubierta de papel para dejar el

adhesivo al descubierto antes de instalar el calzo.

NOTA: El calzo también puede usarse en una unión de tubo de 1/8 pulg.

32

Page 33

ESPECIFICACIONES

Salida:

Velocidad de la bomba:

Modelo 72-410-014 14 rpm

Modelo 72-410-028 28 rpm

Modelo 72-410-049 49 rpm

Modelo 72-410-108 108 rpm

Modelo 72-415-014 14 ⫻ (5/6)* rpm

Modelo 72-415-028 28 ⫻ (5/6)* rpm

Modelo 72-415-049 49 ⫻ (5/6)* rpm

Modelo 72-415-108 108 ⫻ (5/6)* r pm

*NOTA: La velocidad para los mandos de serie 72-415-XXX es 5/6

de la de los de la serie 72-410-XXX debido a la operación a 50 Hz.

Par:

Modelo 72-410-014 9,22 kg•cm

Modelo 72-410-028 9,22 kg•cm

Modelo 72-410-049 8,06 kg•cm

Modelo 72-410-108 6,91 kg•cm

Modelo 72-415-014 10,94 kg•cm

Modelo 72-415-028 9,22 kg•cm

Modelo 72-415-049 9,79 kg•cm

Modelo 72-415-108 6,91 kg•cm

Entrada:

Voltaje/Frecuencia/Corriente máxima de operación:

Modelo 72-410-014 115 VCA ±10% a 60 Hz, 0,33 A

Modelo 72-415-014 230 VCA ±10% a 50 Hz, 0,13 A

Modelo 72-410-028 115 VCA ±10% a 60 Hz, 0,60 A

Modelo 72-415-028 230 VCA ±10% a 50 Hz, 0,23 A

Modelo 72-410-049 115 VCA ±10% a 60 Hz, 0,77 A

Modelo 72-415-049 230 VCA ±10% a 50 Hz, 0,31 A

Modelo 72-410-108 115 VCA ±10% a 60 Hz, 1,24 A

Modelo 72-415-108 230 VCA ±10% a 50 Hz, 0,47 A

Categoría de la instalación: Categoría de instalación II según IEC 664

(nivel local — aparatos, equipos portátiles, etc.)

Ambiente:

Temperatura de operación: 0 a 40°C

Temperatura de almacenamiento: −45 a 65°C

Humedad: 10% a 90% sin condensación

Altitud: Menos de 2000 m

Nivel de contaminación: Nivel de contaminación 2 según IEC 664

(uso interior — laboratorio, oficina)

Construcción:

Dimensiones (L ⫻ A ⫻ H): 13 cm ⫻ 17 cm ⫻ 13,5 cm

Peso: 1,8 kg

Color: Blanco

Material: Caja de acero pintada

Valores nominales del recinto: IP21 según IEC 529

Cumple con las siguientes normas: 115V: UL508, CSA C22.2, No. 14-M91

230V (para la marca CE):

EN61010-1/A2: 1995

(Directiva de bajo voltaje de la UE) y

EN61326-1/A1: 1998

(Directiva EMC de la UE)

33

Page 34

GARANTÍA

Use solamente uniones de tubos de precisión MANOSTAT con las bombas MANOSTAT para asegurar un

rendimiento óptimo. El uso de otros tubos puede anular las garantías correspondientes.

El Fabricante garantiza que este producto no se desvía significativamente de las especificaciones publicadas. Si es

necesario efectuar reparaciones o ajustes en el período de garantía, el problema se corregirá de f orma gratuita si no es

debido al uso indebido o maltrato por su parte, según lo determine el Fabricante. Es posible que le facturemos los

costos de reparación fuera del período de garantía, o los costos resultantes del uso indebido o maltrato del producto.

El período de garantía para este producto se incluye en la tarjeta de garantía.

DEVOLUCIÓN DEL PRODUCTO

Para limitar los cargos y demoras , póngase en contacto con el vendedor o F abricante para obtener la autorización y las

instrucciones de envío antes de devolver este producto, ya sea durante el período de garantía o fuera del mismo. Al

devolver el producto, indique la razón de la devolución. Para su protección, empaquete el producto con cuidado y

asegúrelo contra posibles daños o pérdidas. Usted es responsable de los daños que sean consecuencia de un

empaquetado indebido.

ASISTENCIA TÉCNICA

Si tiene alguna duda sobre el uso de este producto, póngase en contacto con el Fabricante o vendedor autorizado.

34

Impreso en EE.UU.

030701

Loading...

Loading...