MANOSTAT 72-310-000, 72-310-230, 72-312-000, 72-312-230, 72-315-000 Instruction Manual

...

VARISTALTIC ®

OPERATING MANUAL

MANOSTAT® VARISTALTIC®

PUMPS

NOTICE D’UTILISATION

POMPES MANOSTAT®

VARISTALTIC®

BEDIENUNGSANLEITUNG

MANOSTAT®

VARISTALTIC® PUMPEN

MANUAL DE OPERACIÓN

BOMBAS MANOSTAT®

VARISTALTIC®

72-315-000 VERA

Model Nos. Modèles n° Modellnummern Números de modelo

|

115V |

230V |

SIMON |

72-310-000 |

72-310-230 |

|

72-312-000* |

72-312-230* |

VERA |

72-315-000 |

72-315-230 |

|

72-317-000* |

72-317-230* |

PRESTON |

72-370-000 |

72-370-230 |

|

72-372-000* |

72-372-230* |

*These models have remote Inputs and Outputs. *Ces modèles ont des entrées et sorties à distance. *Diese Modelle haben externe Einund Ausgänge. *Estos modelos tiener entradas y salidas a distancia.

Division of Barnant Company

Division of Barnant Company

28W092 Commercial Avenue, Barrington, IL U.S.A. 60010-2392 |

|

1-800-637-3739 (U.S. and Canada only) 847-381-7050 (Local) |

11-847-381-7050 (outside U.S.) |

847-381-7053 (Local Fax) 11-847-381-7053 (Fax outside U.S.) |

A-1299-5045 |

www.barnant.com e-mail: barnant@barnant.com |

Edition 06 |

VARISTALTIC ®

EU Declaration of Conformity

Name of Apparatus: MANOSTAT® Variable Speed Peristaltic Pump

Model Numbers: 72-310-230 |

(Simon), |

72-312-230 |

(Simon w/remote), |

72-315-230 |

(Vera), |

72-317-230 |

(Vera w/remote), |

72-370-230 |

(Preston), |

72-372-230 |

(Preston w/remote) |

Description of Apparatus: Variable speed peristaltic pump to pump fluids.

Barnant Company declares that the above models are in conformity to the following harmonized standards and directives:

Applicable |

Applicable |

Manufacturer’s |

Directives |

Specifications |

Report Number |

|

|

|

73/23/EEC |

EN61010-1/A2: 1995 |

TR9862 |

93/68/EEC |

|

|

|

|

|

89/336/EEC |

EN61326-1/A1: 1998 |

TR9863 |

92/31/EEC |

|

|

93/68/EEC |

|

|

|

|

|

The last two digits of the year in which the current configuration of the above models was assessed per the Low Voltage Directive is: 00.

Manufacturer: Barnant Company Division

Cole-Parmer Instrument Company

28W092 Commercial Avenue

Barrington, IL 60010-2392

USA

Tel.: 847-381-7050

Manufacturer’s Signature:

|

|

15 August, 2000 |

|

|

|

|

|

James W. Doll |

|

Date |

|

Vice President, Engineering |

|

|

|

TABLE OF CONTENTS |

|

Title |

Page |

SAFETY PRECAUTIONS ..................................................................................................................................... |

4 |

Safety ................................................................................................................................................................ |

4 |

INTRODUCTION AND GENERAL DESCRIPTION .............................................................................................. |

5 |

CONTROLS, INDICATORS AND CONNECTORS ................................................................................................ |

5 |

SETUP .................................................................................................................................................................. |

6 |

Tubing Size Selection ........................................................................................................................................ |

6 |

OPERATION ......................................................................................................................................................... |

7 |

Inserting Tubing ................................................................................................................................................. |

7 |

For Optimum Tubing Life ................................................................................................................................... |

7 |

Pump Controls .................................................................................................................................................. |

7 |

REMOTE OPERATION ......................................................................................................................................... |

8 |

Description ........................................................................................................................................................ |

8 |

Remote Inputs ................................................................................................................................................... |

8 |

MAINTENANCE .................................................................................................................................................. |

10 |

Cleaning .......................................................................................................................................................... |

10 |

Replacement Parts ......................................................................................................................................... |

10 |

ACCESSORIES .................................................................................................................................................. |

11 |

SPECIFICATIONS .............................................................................................................................................. |

12 |

WARRANTY ........................................................................................................................................................ |

13 |

PRODUCT RETURN ........................................................................................................................................... |

13 |

TECHNICAL ASSISTANCE ................................................................................................................................ |

13 |

3

SAFETY PRECAUTIONS

DANGER: Remove power from the pump before any cleaning operation is started.

WARNING: Remove power from the pump before attempting any maintenance.

WARNINGS: Tubing breakage may result in fluid being sprayed from pump. Use appropriate measures to protect operator and equipment.

Turn pump off before removing or installing tubing. Fingers or loose clothing could be caught in the pump mechanism.

CAUTIONS: When changing flow direction, allow the pump to come to a complete stop before starting  again. Failure to do so could cause permanent damage to the motor.

again. Failure to do so could cause permanent damage to the motor.

Replace the fuse only with one of the same type and rating. The fuse rating and type are stated on the rear panel.

WARNING: PRODUCT USE LIMITATION

WARNING: PRODUCT USE LIMITATION

These products are not designed for, nor intended for use in, patient-connected applications, including, but not limited to, medical and dental use, and, accordingly have not been submitted for FDA approval.

SAFETY

1.Read instructions before operating the unit.

2.Observe safety precautions at all times, especially when pumping dangerous liquids. Always have the clear plastic cover properly mounted on the pump head and, in general, protect the pump area from accidental spillage of liquid.

3.If the pump runs unusually noisily or if bunching of the tubing in the pump can be observed, make sure the tubing is clamped down tightly and/or replace it with a new piece of tubing.

4.The MANOSTAT VARISTALTIC pumps should be well-grounded at all times.

5.The pump is equipped with a current-limiting circuit that will slow the motor down if any of the following conditions exist:

a.Tubing that is too hard is loaded in the pump.

b.Incorrect tubing size or wall thickness is loaded in the pump.

c.Tubing is improperly loaded into the pump head.

Note: Use only MANOSTAT tubing.

6.The unit is fused and grounded to protect the operator in the event of short circuits that could be caused by liquid entering the case.

CAUTION: Replace the fuse only with one of the same type and rating. The fuse rating and type are stated on the rear panel.

7. Pump should not be used in outdoor or hazardous locations.

NORPRENE, PHARMED, TYGON — Reg TM Norton Co.

Trademarks bearing the ® symbol in this publication are registered in the U.S. and in other countries.

4

INTRODUCTION AND GENERAL DESCRIPTION

The MANOSTAT variable speed pumps provide continuous pumping of fluids while power is supplied. 115 V pumps are UL and cUL listed. 230 V pumps are CE certified. The pump speed range for all models is 24–720 rpm.

Model No. |

Description |

72-310-000 |

SIMON, Analog speed pot, 115 V |

72-312-000 |

SIMON, with remote option and Analog speed pot, 115 V |

72-310-230 |

SIMON, Analog speed pot, 230 V |

72-312-230 |

SIMON, with remote option and Analog speed pot, 230 V |

72-315-000 |

VERA, Digital speed pot,115 V |

72-317-000 |

VERA, with remote option and Digital speed pot, 115 V |

72-315-230 |

VERA, Digital speed pot, 230 V |

72-317-230 |

VERA, with remote option and Digital speed pot, 230 V |

72-370-000 |

PRESTON, Digital speed pot, 115 V |

72-372-000 |

PRESTON, with remote option and Digital speed pot, 115 V |

72-370-230 |

PRESTON, Digital speed pot, 230 V |

72-372-230 |

PRESTON, with remote option and Digital speed pot, 230 V |

CONTROLS, INDICATORS AND CONNECTORS

Figure 1.

CONTROLS

A.POWER (ON/OFF) SWITCH: Turns the unit ON or OFF. Glows green when power is ON.

B.FLOW SPEED CONTROL KNOB (Simon) or SWITCH (Vera and Preston): Sets the speed of the pump. The higher the number, the faster the speed of the pump.

C.FLOW DIRECTION SWITCH: Sets the direction of the rotation of the pump Clockwise/Off/Counterclockwise.

5

SETUP

Unpack the pump and retain all packing material until proper product operation has been verified. Select the tubing according to the flow desired, while considering chemical compatibility and tubing life. Refer to the enclosed Chemical Resistance Chart (part no. A-1299-5030) to select appropriate type of tubing for the liquid in use.

TUBING SIZE SELECTION

Flow rate is determined by the size of the tubing in the pump head. When tubing links are used, best performance will be achieved when input and output tubing connected to the link are the same ID as the link. All tubing inside the pump head must be surface-printed MANOSTAT tubing.

Simon, Vera and Preston pumps accept tubing ID sizes of 1/32 in. to 5/16 in.

For best results, select a tubing size with a mid-range at the desired flow rate to be pumped. The table below gives an average of flow rates measured with water at standard pressure and temperature. No lift or discharge pressure is represented.

TUBING SELECTION CHART

Simon and Vera Pumps |

|

Preston Pumps |

(mL/min) |

|

(mL/min) |

|

Silicone Tubing Size |

|

|

|

|

1–37 |

1/32 in ID (13)* |

2–40 |

|

|

|

6–170 |

1/16 in ID (14)* |

11–29 |

|

|

|

25–700 |

1/8 in ID (16) |

44–1200 |

|

|

|

57–1700 |

3/16 in ID (25) |

93–2490 |

|

|

|

91–2650 |

1/4 in ID (17) |

170–4200 |

|

|

|

137–3475 |

5/16 in ID (18) |

246–4950 |

|

|

|

NORPRENE® and PHARMED® Tubing Size |

||

1–40 |

1/32 in ID (13)* |

2–77 |

|

|

|

8–210 |

1/16 in ID (14)* |

13–350 |

|

|

|

28–780 |

1/8 in ID (16) |

46–1250 |

|

|

|

60–1740 |

3/16 in ID (25) |

103–2800 |

|

|

|

96–2600 |

1/4 in ID (17) |

168–4200 |

|

|

|

121–3400 |

5/16 in ID (18) |

245–5500 |

|

|

|

|

TYGON® Tubing Size |

|

1–25 |

1/32 in ID (13)* |

2–55 |

|

|

|

6–185 |

1/16 in ID (14)* |

9–320 |

|

|

|

25–770 |

1/8 in ID (16) |

45–1250 |

|

|

|

60–1720 |

3/16 in ID (25) |

105–2850 |

|

|

|

96–2800 |

1/4 in ID (17) |

174–4800 |

|

|

|

120–3500 |

5/16 in ID (18) |

236–5400 |

|

|

|

* Requires tubing links.

6

OPERATION

Use only MANOSTAT precision tubing with MANOSTAT pumps to ensure optimum performance. Use of other tubing may void applicable warranties.

INSERTING TUBING

WARNINGS: Tubing breakage may result in fluid being sprayed from pump. Use appropriate measures to  protect operator and equipment.

protect operator and equipment.

Turn pump off before removing or installing tubing. Fingers or loose clothing could be caught in the pump mechanism.

1.Make sure that the power switch is turned OFF.

2.Remove the two thumb nuts, and then remove the clear plastic cover from the pump head.

3.For Tubing Links: Attach input and output ends of the transfer tubing to the connectors of the tubing link. Insert the tubing link so that the tie wraps or the flanges of the link are as close as possible to the outside of the pump head. Manually rotate the roller assembly and guide the tubing between the rollers and the pump head wall.

For Tubing: Insert tubing between the rollers and the pump head housing in the center of the channel (i.e., midway between the clear plastic pump head cover and the pump head housing bottom). This ensures that the rollers depress the entire width of the tubing as they turn. Manually rotate the roller assembly and guide the tubing between the rollers and the pump head wall. When using tubing (not links), there should be a small but visible gap between the tubing and the pump head housing for about 1/3 to 1/2 of the contact surface at any time. Pull gently on the input and output sides of the tubing to create a gap between the tubing and the curved pump head housing wall.

4.Replace the clear plastic cover over the pump head, being sure to tighten down the thumb nuts to prevent the tubing from moving during operation.

The clear plastic pump head cover is reversible on Simon and Vera models, with different size tubing retainers on each face. If the tubing is smaller than 3/16 in. ID, place the cover so that the larger tubing retainers hold the tubing. If the tubing is 3/16 in. ID (Size 25) or larger, reverse the cover.

On Preston models, adjust the two screws on the retainer clamp to hold the tubing in place after attaching the clear plastic cover to the pump head. If the tubing is smaller than 3/16 in. ID (Size 25) and a tubing link is not used, do one of the following to prevent the tubing from creeping in the pump head:

•Cover the tubing at the clamping points with a small section of a larger tubing to increase the grip.

•Use a tubing connector on the input of the pump head.

FOR OPTIMUM TUBING LIFE

Periodically move the tubing so that a different segment is in the pump head, or change the tubing link. This will avoid excessive tubing wear at any specific point. Always move the worn tubing to the suction side of the pump.

PUMP CONTROLS

CAUTION: When changing flow direction, allow the pump to come to a complete stop before starting  again. Failure to do so could cause permanent damage to the motor.

again. Failure to do so could cause permanent damage to the motor.

1.Make sure the flow speed control is set to the minimum setting.

2.Turn the power switch ON. Increase the flow speed setting to start the pump action. The higher the number selected, the faster the speed of the pump.

3.VARISTALTIC pumps are self-priming.To begin pumping, select a flow direction with the flow direction switch, insert the intake and output tubing into a reservoir, and turn the unit ON. Prime the tubing for at least 5 minutes. If accurate flow control is important, allow the pump to prime for approximately 20 minutes for more stable flow conditions.

7

REMOTE OPERATION

DESCRIPTION

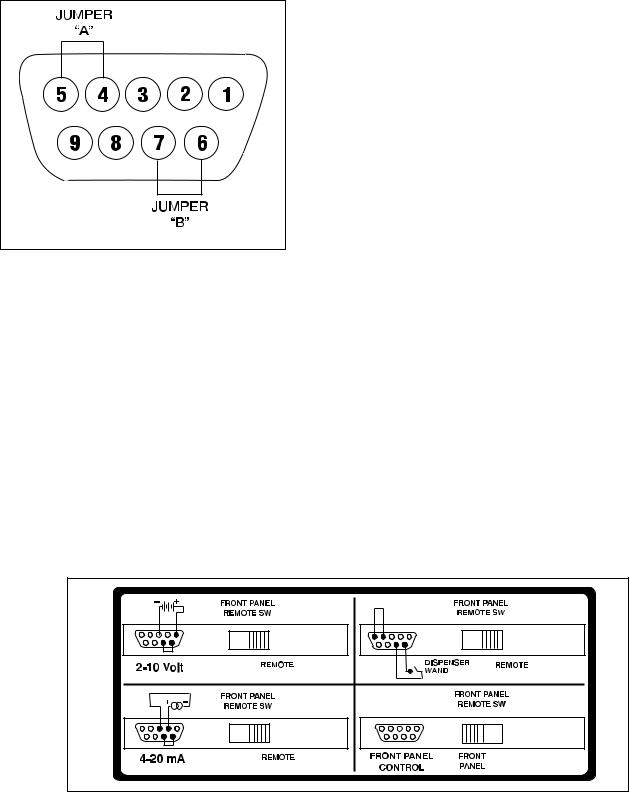

Models equipped with remote inputs and outputs can be controlled by external signals connected at the rear panel 9-pin “D” shell connector. The Remote inputs permit control of the pump by remote equipment or accessories. Figure 2 shows the signal locations of the connector.

Pin |

Description |

|

No. |

||

|

||

1 |

Speed Control Voltage Input (2–10V) (+) input |

|

|

|

|

2 |

Speed Control Current Input (4–20 mA) (+) input |

|

|

|

|

3 |

Speed Control Input Reference Common |

|

|

|

|

4 |

Remote/Local Speed (+) Control |

|

|

|

|

5 |

Remote/Local Reference Speed (–) Return |

|

|

|

|

6 |

Start/Stop Reference (–) Return |

|

|

|

|

7 |

Start/Stop (+) Control |

|

|

|

|

8 |

Chassis (Earth) Ground |

|

|

|

|

9 |

Chassis (Earth) Ground |

|

|

|

Figure 2. DB9 Pin Configuration

with Wiring Scheme

REMOTE INPUTS

The FRONT PANEL/REMOTE switch enables remote functions. Switching to FRONT PANEL disables the remote functions, allowing the front panel controls to operate the pump.

When the FRONT PANEL/REMOTE switch is in the REMOTE position, starting and stopping the pump is controlled by an external contact closure between pins 6 and 7 (Jumper B), and the pump speed is determined by an externally supplied 2–10 V or 4–20 mA source. Connection must be made between pins 6 and 7 and a control voltage greater than 2 V or a control current greater than 4 mA must be applied for the pump to run.

If setting the speed from the front panel is desired with remote Start/Stop contact operation, the FRONT PANEL/ REMOTE must again be in the REMOTE position. In addition, Jumper A should be in place. Jumper A connects pin 5 of the “D” shell connector (REMOTE/LOCAL SPEED) to pin 6 (RETURN). Start/Stop will then be controlled from the rear panel (Jumper B), and the pump speed will be controlled from the front panel. The accessory Footswitch (part no. 73-750-000) and Dispenser Wand (part no. 73-055-590) are connected internally in this way.

Figure 3 shows four typical wiring configurations: 2–10 V follower, 4–20 mA follower, accessory dispenser wand (or footswitch), and full front panel control.

Figure 3. Back Panel Connectors

8

NOTE: The signal common for the speed control voltage and current inputs is referenced to earth ground.

The table Operation Summary for the Feature Inputs summarizes the remote input operation.

|

|

|

|

Operation Summary for the Feature Inputs |

|

||

|

|

|

|

|

|

|

|

|

Rear Panel Mode |

Shorting Jumper |

Functions Activated |

||||

|

Select Switch |

or Contact Closure |

|||||

|

|

|

|||||

|

Front |

|

Remote |

Jumper “A” |

Jumper “B” |

Speed |

Start/Stop |

|

Panel |

|

(Pins 4 to 5) |

(Pins 6 to 7) |

|||

|

|

|

|

|

|||

|

On |

|

Off |

X |

X |

Front Panel Control Only |

|

|

|

|

|

|

|

|

|

|

Off |

|

On |

In |

In |

Front Panel |

Remote Start |

|

|

|

|

|

|

|

|

|

Off |

|

On |

In |

Out |

Front Panel |

Remote Stop |

|

|

|

|

|

|

|

|

|

Off |

|

On |

Out |

In |

Remote |

Remote Start |

|

|

|

|

|

|

|

|

|

Off |

|

On |

Out |

Out |

Remote |

Remote Stop |

|

|

|

|

|

|

|

|

KEY: |

X = N/A |

|

|

|

|

||

Off = Not selected

On = Selected

The START/STOP (pin 7) input and REMOTE/LOCAL SPEED (pin 4) input are digital inputs. They are internally pulled up to +15 V with respect to logic common (RETURNS). They can alternately be driven with open collector logic. For increased noise immunity, use of contact closures is recommended.

9

MAINTENANCE

WARNING: Remove power from the pump before attempting any maintenance.

The speed control circuit has solid-state components that do not require service. An excessive load on the system may, however, cause the fuse to blow. An indication of an excessive load is a switch that does not light with power applied to the pump and when the ON-OFF switch is in the ON position. If this condition occurs, remove power from the unit and remove the fuse from the fuse holder located on the rear of the pump. Replace the fuse with a fuse of the same type and rating. This information is printed on the rear of the unit.

CAUTION: Replace the fuse only with one of the same type and rating. The fuse rating and type are stated on the rear panel.

Motor brush and commutator life depend on duty cycle and operating speed. Brushes should be inspected every six months or 2000 hours of operation, whichever occurs first, or if erratic operation occurs. Replace when less than 7.6 mm (0.300 in) long. The commutator should be inspected periodically and cleaned if necessary. If preventive maintenance is not performed, excessive commutator wear or “bridging” between commutator segments will cause excessive current through the controller circuit.

These models are equipped with a toothed-belt and should be inspected for belt wear at the same interval as the brushes.The presence of some belt dust at or inside the pump is normal and has no effect on the operation of the pump. If the belt is slipping, adjust the tension by loosening the motor nuts that secure it to the motor bracket and swing the motor away from the PC board. Once adjusted, tighten the nut. Do not over-tighten the belt, as this will cause excessive drive belt wear, bearing wear and noise. Replace the belt if frayed or torn. (See REPLACEMENT PARTS.)

CLEANING

DANGER: Remove power from the pump before any cleaning operation is started.

Keep the pump enclosure clean by using a mild detergent solution. Never immerse nor use excessive fluid when cleaning the pump.

REPLACEMENT PARTS |

|

|

Description |

Part Number |

Qty. |

Motor brushes (2) |

A-4343-CR |

2 |

Brush Cap (1) |

A-3190-CR |

1 |

Motor 90 V Assembly |

D-3080-0001 |

1 |

Motor 180 V Assembly |

D-3080-0002 |

1 |

Pump Pulley |

B-3901 |

1 |

Motor Pulley |

A-3166 |

1 |

Drive Belt (Simon and Vera) |

A-1341-0005 |

1 |

Drive Belt (Preston) |

A-1341-0006 |

1 |

Rubber Foot |

A-1390-0004 |

1 |

Knob for speed pot (Simon) |

B-1083-0035 |

1 |

Fan (plastic) |

B-1247-0027 |

1 |

Fan (metal) |

B-1247-0032 |

1 |

Fuse (115 V) (T3.15A, 250V, 5 20 mm) |

B-1115-0057 |

1 |

Fuse (230 V) (T1.6A, 250V, 5 20 mm) |

B-1115-0042 |

1 |

Pump Head Cover (Simon and Vera) |

91-055-075 |

1 |

Pump Head Cover (Preston) |

91-065-110 |

1 |

Knob (pump cover) |

B-1083-0063 |

1 |

Tubing Clamp (Preston pump only) |

91-065-130 |

1 |

Line Cord 115 V |

B-3115 |

1 |

Line Cord 230 V (Euro) |

B-2938 |

1 |

10

ACCESSORIES

Tubing Links |

Simon and Vera |

Preston |

1/32 in. Tubing Link— NORPRENE, pk of 5 |

72-305-135 |

75-305-135 |

1/16 in. Tubing Link— NORPRENE, pk of 5 |

72-305-145 |

75-305-145 |

1/8 in. Tubing Link— NORPRENE, pk of 5 |

72-305-165 |

75-305-165 |

3/16 in. Tubing Link— NORPRENE, pk of 5 |

72-305-255 |

75-305-255 |

1/4 in. Tubing Link— NORPRENE, pk of 5 |

72-305-175 |

75-305-175 |

1/32 in. Tubing Link— PHARMED, pk of 5 |

72-301-135 |

75-301-135 |

1/16 in. Tubing Link— PHARMED, pk of 5 |

72-301-145 |

75-301-145 |

1/8 in. Tubing Link— PHARMED, pk of 5 |

72-301-165 |

75-301-165 |

3/16 in. Tubing Link— PHARMED, pk of 5 |

72-301-255 |

75-301-255 |

1/4 in. Tubing Link— PHARMED, pk of 5 |

72-301-175 |

75-301-175 |

1/32 in. Tubing Link— Silicone, pk of 5 |

72-300-135 |

75-300-135 |

1/16 in. Tubing Link— Silicone, pk of 5 |

72-300-145 |

75-300-145 |

1/8 in. Tubing Link— Silicone, pk of 5 |

72-300-165 |

75-300-165 |

3/16 in. Tubing Link— Silicone, pk of 5 |

72-300-255 |

75-300-255 |

1/4 in. Tubing Link— Silicone, pk of 5 |

72-300-175 |

75-300-175 |

1/32 in. Tubing Link— TYGON, pk of 5 |

72-310-135 |

75-310-135 |

1/16 in. Tubing Link— TYGON, pk of 5 |

72-310-145 |

75-310-145 |

1/8 in. Tubing Link— TYGON, pk of 5 |

72-310-165 |

75-310-165 |

3/16 in. Tubing Link— TYGON, pk of 5 |

72-310-255 |

75-310-255 |

1/4 in. Tubing Link— TYGON, pk of 5 |

72-310-175 |

75-310-175 |

PTFE Sinkers — keep intake tube at bottom of reservoir for |

|

|

1/16 in. – 5/16 in. ID tubing (set of 2) |

|

75-250-100 |

Footswitch (115 V or 230 V) |

|

73-750-000 |

Autoclavable Dispensing Tips— Glass tip with Luer Lock |

|

|

for 3/16 in. and 1/4 in. ID tubing |

|

72-648-000 |

Polypropylene tip with Luer Lock for 1/16 in. and 1/8 in. ID tubing |

72-648-020 |

|

Autoclavable Stainless Steel Cannulae |

|

|

for use with Luer Lock Dispensing tip: |

|

|

Cannula 16 Gauge |

|

91-015-210 |

Cannula 13 Gauge |

|

91-015-220 |

Dispenser Wand |

|

73-055-590 |

11

SPECIFICATIONS |

|

Output: |

|

Speed: |

24–720 rpm |

Torque: |

120 in-oz (8.6 kg•cm) |

Input: |

|

Operating Voltage/Frequency: |

|

Models 72-310-000, 72-312-000, 72-315-000, |

|

72-317-000, 72-370-000, 72-372-000 |

100–130 VAC, 60 Hz, 2.1 A |

Models 72-310-230, 72-312-230, 72-315-230, |

|

72-317-230, 72-370-230, 72-372-230 |

190–260 VAC, 50 Hz, 1.3 A |

Start/Stop— Local Control: |

|

|

Input Voltage: |

Function Disable |

15 VDC Typ. |

Function Enable: |

0.8 VDC Max. |

|

Input Current: |

Function Disable: |

100 A Max. leakage |

Function Enable: |

1.5mA Max. |

Installation Category: |

Installation category II per IEC 664 |

|

(local level— appliances, portable equipment, etc.) |

Environment: |

|

Operating Temperature: |

32 to 104°F (0 to 40°C) |

Storage Temperature: |

–49 to 149°F (–45 to 65°C) |

Humidity: |

10% to 90% non-condensing |

Altitude: |

Less than 6562 ft (2000 m) |

Pollution Degree: |

Pollution degree 2 per IEC 664 |

|

(indoor use — lab, office) |

Construction: |

|

Dimensions (L W H): |

|

Models 72-310-000, 72-312-000, 72-315-000, |

12 in 9 in 6 in (30.5 cm 22.9 cm 15.2 cm) |

72-317-000, 72-310-230, 72-312-230, |

|

72-315-230, 72-317-230 |

|

Models 72-370-000, 72-372-000, 72-370-230, |

12 in 10 in 7 in (30.5 cm 25.4 cm 17.8 cm) |

72-372-230 |

|

Weight: |

|

Models 72-310-000, 72-312-000, 72-315-000, |

14.9 lbs (6.8 kg) |

72-317-000, 72-310-230, 72-312-230, |

|

72-315-230, 72-317-230 |

|

Models 72-370-000, 72-372-000, 72-370-230, |

17.4 lbs (7.9 kg) |

72-372-230 |

|

Color: |

Black |

Material: |

Painted steel housing |

Enclosure Rating: |

IP22 per IEC 529 |

Compliance: |

115V: UL508, CSA C22.2, No. 14-M91 |

|

230V (For CE Mark): |

|

EN61010-1/A2: 1995 (EU Low Voltage Directive) and |

|

EN61326-1/A1: 1998 (EU EMC Directive) |

12

WARRANTY

Use only MANOSTAT precision tubing with MANOSTAT pumps to ensure optimum performance. Use of other tubing may void applicable warranties.

The Manufacturer warrants this product to be free from significant deviations from published specifications. If repair or adjustment is necessary within the warranty period, the problem will be corrected at no charge if it is not due to misuse or abuse on your part, as determined by the manufacturer. Repair costs outside the warranty period, or those resulting from product misuse or abuse, may be invoiced to you.

The warranty period for this product is noted on the Warranty Card.

PRODUCT RETURN

To limit charges and delays, contact the seller or Manufacturer for authorization and shipping instructions before returning the product, either within or outside of the warranty period. When returning the product, please state the reason for the return. For your protection, pack the product carefully and insure it against possible damage or loss. Any damages resulting from improper packaging are your responsibility.

TECHNICAL ASSISTANCE

If you have any questions about the use of this product, contact the Manufacturer or authorized seller.

Printed in U.S.A.

060701

13

TABLE DES MATIÈRES |

|

Intitulé |

Page |

MESURES DE SÉCURITÉ ............................................................................................................ |

.......................................... 15 |

Sécurité ....................................................................................................................... ........................................................ |

15 |

INTRODUCTION ET DESCRIPTION GÉNÉRALE ........................................................................................... ...................... |

16 |

COMMANDES, TÉMOINS ET CONNECTEURS .............................................................................................. ...................... |

16 |

INSTALLATION ........................................................................................................................................................................ |

17 |

Sélection du diamètre de tube .................................................................................................. .......................................... |

17 |

FONCTIONNEMENT ............................................................................................................................................................... |

18 |

Insertion du tube ................................................................................................................................................................. |

18 |

Optimisation de la durée de service des tubes .................................................................................................................. |

18 |

Commandes de la pompe .................................................................................................................................................. |

18 |

TÉLÉCOMMANDE ................................................................................................................... ............................................... |

19 |

Description .......................................................................................................................................................................... |

19 |

Entrées pour télécommande ...................................................................................................... ........................................ |

19 |

ENTRETIEN ............................................................................................................................................................................. |

21 |

Nettoyage ............................................................................................................................................................................ |

21 |

Pièces de rechange ............................................................................................................................................................ |

21 |

ACCESSOIRES ....................................................................................................................................................................... |

22 |

CARACTÉRISTIQUES TECHNIQUES .................................................................................................... ................................ |

23 |

GARANTIE ............................................................................................................................................................................... |

24 |

RETOUR DE MARCHANDISES .............................................................................................................................................. |

24 |

ASSISTANCE TECHNIQUE .................................................................................................................................................... |

24 |

14

Loading...

Loading...