VARISTALTIC

72-315-000 VERA

®

OPERATING MANUAL

MANOSTAT® VARISTALTIC

®

PUMPS

NOTICE D’UTILISATION

POMPES MANOSTAT

VARISTALTIC

BEDIENUNGSANLEITUNG

MANOSTAT

®

®

®

VARISTALTIC® PUMPEN

MANUAL DE OPERACIÓN

BOMBAS MANOSTAT

VARISTALTIC

®

®

Model Nos. Modèles n° Modellnummern Números de modelo

115V 230V

SIMON 72-310-000 72-310-230

72-312-000* 72-312-230*

VERA 72-315-000 72-315-230

72-317-000* 72-317-230*

PRESTON 72-370-000 72-370-230

72-372-000* 72-372-230*

*These models have remote Inputs and Outputs.

*Ces modèles ont des entrées et sorties à distance.

*Diese Modelle haben externe Ein- und Ausgänge.

*Estos modelos tiener entradas y salidas a distancia.

Division of Barnant Company

28W092 Commercial Avenue, Barrington, IL U.S.A. 60010-2392

1-800-637-3739 (U.S. and Canada only) 847-381-7050 (Local) 11-847-381-7050 (outside U.S.)

847-381-7053 (Local Fax) 11-847-381-7053 (Fax outside U.S.)

www.barnant.com e-mail: barnant@barnant.com

A-1299-5045

Edition 06

®

VARISTALTIC

EU Declaration of Conformity

Name of Apparatus: MANOSTAT® Var iable Speed Peristaltic Pump

Model Numbers: 72-310-230 (Simon), 72-312-230 (Simon w/remote),

72-315-230 (Vera), 72-317-230 (Vera w/remote),

72-370-230 (Preston), 72-372-230 (Preston w/remote)

Description of Apparatus: Var iable speed peristaltic pump to pump fluids.

Barnant Company declares that the above models are in confor mity to the following

harmonized standards and directives:

Applicable Applicable Manufacturer’s

Directives Specifications Report Number

73/23/EEC EN61010-1/A2: 1995 TR9862

93/68/EEC

89/336/EEC EN61326-1/A1: 1998 TR9863

92/31/EEC

93/68/EEC

The last two digits of the year in which the current configuration of the above models was

assessed per the Low Voltage Directive is: 00.

Manufacturer: Barnant Company Division

Cole-Parmer Instrument Company

28W092 Commercial Avenue

Barrington, IL 60010-2392

USA

Tel.: 847-381-7050

Manufacturer’s Signature:

15 August, 2000

James W. Doll Date

Vice President, Engineering

TABLE OF CONTENTS

Title Page

SAFETY PRECAUTIONS ..................................................................................................................................... 4

Safety................................................................................................................................................................ 4

INTRODUCTION AND GENERAL DESCRIPTION .............................................................................................. 5

CONTROLS, INDICATORS AND CONNECTORS ................................................................................................ 5

SETUP .................................................................................................................................................................. 6

Tubing Size Selection........................................................................................................................................ 6

OPERATION ......................................................................................................................................................... 7

Inserting T ubing................................................................................................................................................. 7

For Optimum Tubing Life ................................................................................................................................... 7

Pump Controls .................................................................................................................................................. 7

REMOTE OPERATION ......................................................................................................................................... 8

Description ........................................................................................................................................................ 8

Remote Inputs................................................................................................................................................... 8

MAINTENANCE .................................................................................................................................................. 10

Cleaning ..........................................................................................................................................................10

Replacement Parts ......................................................................................................................................... 10

ACCESSORIES .................................................................................................................................................. 11

SPECIFICATIONS .............................................................................................................................................. 12

WARRANTY........................................................................................................................................................ 13

PRODUCT RETURN ........................................................................................................................................... 13

TECHNICAL ASSISTANCE ................................................................................................................................ 13

3

SAFETY PRECAUTIONS

DANGER: Remove power from the pump before any cleaning operation is started.

WARNING: Remove power from the pump before attempting any maintenance.

WARNINGS: Tubing breakage may result in fluid being sprayed from pump. Use appropriate measures to

protect operator and equipment.

Turn pump off before removing or installing tubing. Fingers or loose clothing could be caught

in the pump mechanism.

CAUTIONS: When changing flow direction, allow the pump to come to a complete stop before starting

again. Failure to do so could cause permanent damage to the motor.

Replace the fuse only with one of the same type and rating. The fuse rating and type are stated

on the rear panel.

WARNING: PRODUCT USE LIMITATION

These products are not designed for, nor intended for use in, patient-connected applications, including, but not

limited to, medical and dental use, and, accordingly have not been submitted for FDA approval.

SAFETY

1. Read instructions before operating the unit.

2. Observe safety precautions at all times, especially when pumping dangerous liquids. Always have the clear plastic

cover properly mounted on the pump head and, in general, protect the pump area from accidental spillage of liquid.

3. If the pump runs unusually noisily or if bunching of the tubing in the pump can be observed, make sure the tubing is

clamped down tightly and/or replace it with a new piece of tubing.

4. The MANOSTAT VARISTALTIC pumps should be well-grounded at all times.

5. The pump is equipped with a current-limiting circuit that will slow the motor down if any of the following conditions

exist:

a. Tubing that is too hard is loaded in the pump.

b. Incorrect tubing size or wall thickness is loaded in the pump.

c. Tubing is improperly loaded into the pump head.

Note: Use only MANOSTAT tubing.

6. The unit is fused and grounded to protect the operator in the event of short circuits that could be caused by liquid

entering the case.

CAUTION: Replace the fuse only with one of the same type and rating. The fuse rating and type are stated

on the rear panel.

7. Pump should not be used in outdoor or hazardous locations.

NORPRENE, PHARMED, TYGON — Reg TM Norton Co.

Trademarks bearing the ® symbol in this publication are registered in the U.S. and in other countries.

4

INTRODUCTION AND GENERAL DESCRIPTION

The MANOSTAT variable speed pumps provide continuous pumping of fluids while power is supplied. 115 V pumps are

UL and cUL listed. 230 V pumps are CE certified. The pump speed range for all models is 24–720 rpm.

Model No. Description

72-310-000 SIMON, Analog speed pot, 115 V

72-312-000 SIMON, with remote option and Analog speed pot, 115 V

72-310-230 SIMON, Analog speed pot, 230 V

72-312-230 SIMON, with remote option and Analog speed pot, 230 V

72-315-000 VERA, Digital speed pot,115 V

72-317-000 VERA, with remote option and Digital speed pot, 115 V

72-315-230 VERA, Digital speed pot, 230 V

72-317-230 VERA, with remote option and Digital speed pot, 230 V

72-370-000 PRESTON, Digital speed pot, 115 V

72-372-000 PRESTON, with remote option and Digital speed pot, 115 V

72-370-230 PRESTON, Digital speed pot, 230 V

72-372-230 PRESTON, with remote option and Digital speed pot, 230 V

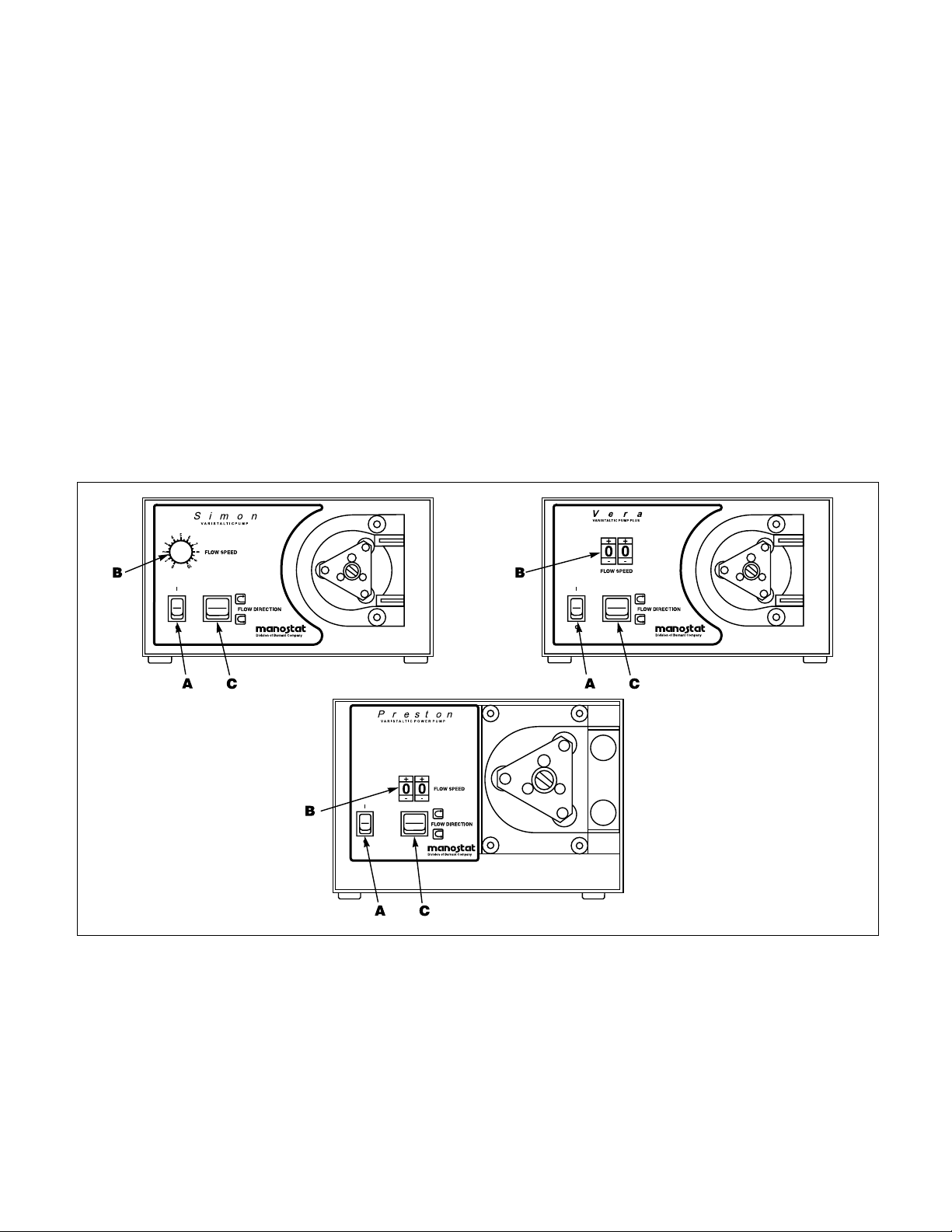

CONTROLS, INDICATORS AND CONNECTORS

Figure 1.

CONTROLS

A. POWER (ON/OFF) SWITCH: Turns the unit ON or OFF. Glows green when power is ON.

B. FLOW SPEED CONTROL KNOB (Simon) or SWITCH (Vera and Preston): Sets the speed of the pump. The

higher the number, the faster the speed of the pump.

C. FLOW DIRECTION SWITCH: Sets the direction of the rotation of the pump Clockwise/Off/Counterclockwise.

5

SETUP

Unpack the pump and retain all packing material until proper product operation has been verified. Select the tubing

according to the flow desired, while considering chemical compatibility and tubing life. Refer to the enclosed Chemical

Resistance Chart (part no. A-1299-5030) to select appropriate type of tubing for the liquid in use.

TUBING SIZE SELECTION

Flow rate is determined by the size of the tubing in the pump head. When tubing links are used, best performance will

be achieved when input and output tubing connected to the link are the same ID as the link. All tubing inside the

pump head must be surface-printed MANOSTAT tubing.

Simon, Vera and Preston pumps accept tubing ID sizes of 1/32 in. to 5/16 in.

For best results, select a tubing size with a mid-r ange at the desired flow rate to be pumped. The table below gives an

average of flow rates measured with water at standard pressure and temperature. No lift or discharge pressure is

represented.

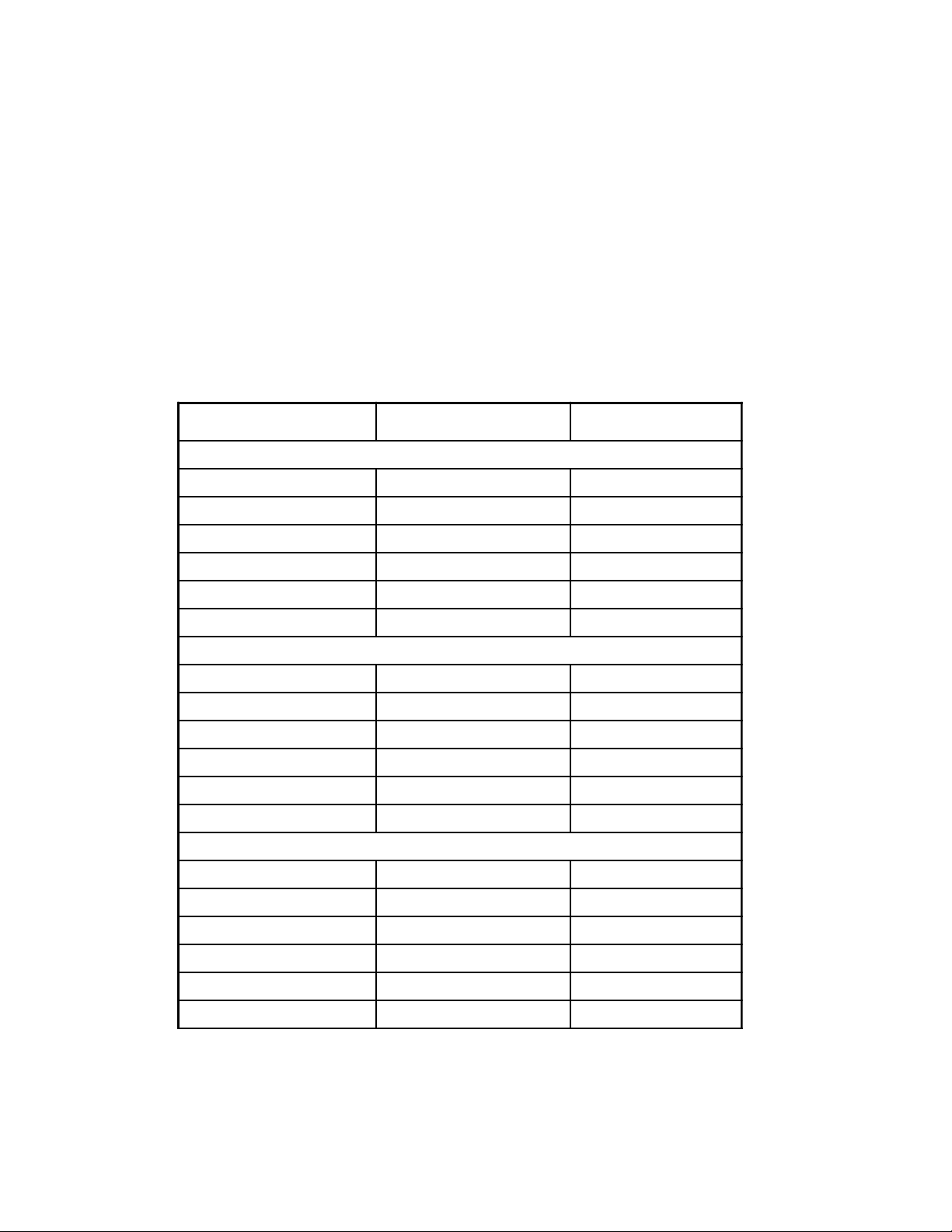

TUBING SELECTION CHART

Simon and Vera Pumps

(mL/min )

1–37 1/32 in ID (13)* 2–40

6–170 1/16 in ID (14)* 11–29

25–700 1/8 in ID (16) 44–1200

57–1700 3/16 in ID (25) 93–2490

91–2650 1/4 in ID (17) 170–4200

137–3475 5/16 in ID (18) 246–4950

NORPRENE

1–40 1/32 in ID (13)* 2–77

8–210 1/16 in ID (14)* 13–350

28–780 1/8 in ID (16) 46–1250

60–1740 3/16 in ID (25) 103–2800

96–2600 1/4 in ID (17) 168–4200

121–3400 5/16 in ID (18) 245–5500

Silicone Tubing Size

®

and PHARMED® Tubing Siz e

TYGON

®

Tubing Siz e

Preston Pumps

(mL/min )

1–25 1/32 in ID (13)* 2–55

6–185 1/16 in ID (14)* 9–320

25–770 1/8 in ID (16) 45–1250

60–1720 3/16 in ID (25) 105–2850

96–2800 1/4 in ID (17) 174–4800

120–3500 5/16 in ID (18) 236–5400

* Requires tubing links.

6

OPERATION

Use only MANOSTAT precision tubing with MANOSTAT pumps to ensure optimum performance. Use of other

tubing may void applicable warranties.

INSERTING TUBING

WARNINGS: Tubing breakage may result in fluid being sprayed from pump. Use appropriate measures to

protect operator and equipment.

Turn pump off before removing or installing tubing. Fingers or loose clothing could be caught

in the pump mechanism.

1. Make sure that the power switch is turned OFF.

2. Remove the two thumb nuts, and then remove the clear plastic cover from the pump head.

3. For T ubing Links: Attach input and output ends of the transfer tubing to the connectors of the tubing link. Insert the

tubing link so that the tie wraps or the flanges of the link are as close as possible to the outside of the pump head.

Manually rotate the roller assembly and guide the tubing between the rollers and the pump head wall.

For T ubing: Insert tubing between the rollers and the pump head housing in the center of the channel (i.e., midway

between the clear plastic pump head cover and the pump head housing bottom). This ensures that the rollers

depress the entire width of the tubing as they turn. Manually rotate the roller assemb ly and guide the tubing between

the rollers and the pump head wall. When using tubing (not links), there should be a small but visible gap between

the tubing and the pump head housing for about 1/3 to 1/2 of the contact surface at an y time. Pull gently on the input

and output sides of the tubing to create a gap between the tubing and the curved pump head housing wall.

4. Replace the clear plastic cover ov er the pump head, being sure to tighten down the thumb nuts to pre vent the tubing

from moving during operation.

The clear plastic pump head cover is re versib le on Simon and Ver a models, with diff erent siz e tubing retainers on each

face. If the tubing is smaller than 3/16 in. ID, place the cover so that the larger tubing retainers hold the tubing. If the

tubing is 3/16 in. ID (Size 25) or larger, reverse the cover.

On Preston models, adjust the two screws on the retainer clamp to hold the tubing in place after attaching the clear

plastic cover to the pump head. If the tubing is smaller than 3/16 in. ID (Size 25) and a tubing link is not used, do one of

the following to prevent the tubing from creeping in the pump head:

• Cover the tubing at the clamping points with a small section of a larger tubing to increase the grip.

• Use a tubing connector on the input of the pump head.

FOR OPTIMUM TUBING LIFE

Periodically move the tubing so that a different segment is in the pump head, or change the tubing link. This will avoid

excessive tubing wear at any specific point. Always move the worn tubing to the suction side of the pump.

PUMP CONTROLS

CAUTION: When changing flow direction, allow the pump to come to a complete stop before starting

again. Failure to do so could cause permanent damage to the motor.

1. Make sure the flow speed control is set to the minimum setting.

2. Tur n the power switch ON. Increase the flow speed setting to star t the pump action. The higher the number

selected, the faster the speed of the pump.

3. VARIST ALTIC pumps are self-priming. To begin pumping, select a flow direction with the flow direction switch, insert

the intake and output tubing into a reservoir , and turn the unit ON. Prime the tubing for at least 5 min utes. If accurate

flow control is important, allow the pump to prime for approximately 20 minutes for more stable flow conditions.

7

REMOTE OPERATION

DESCRIPTION

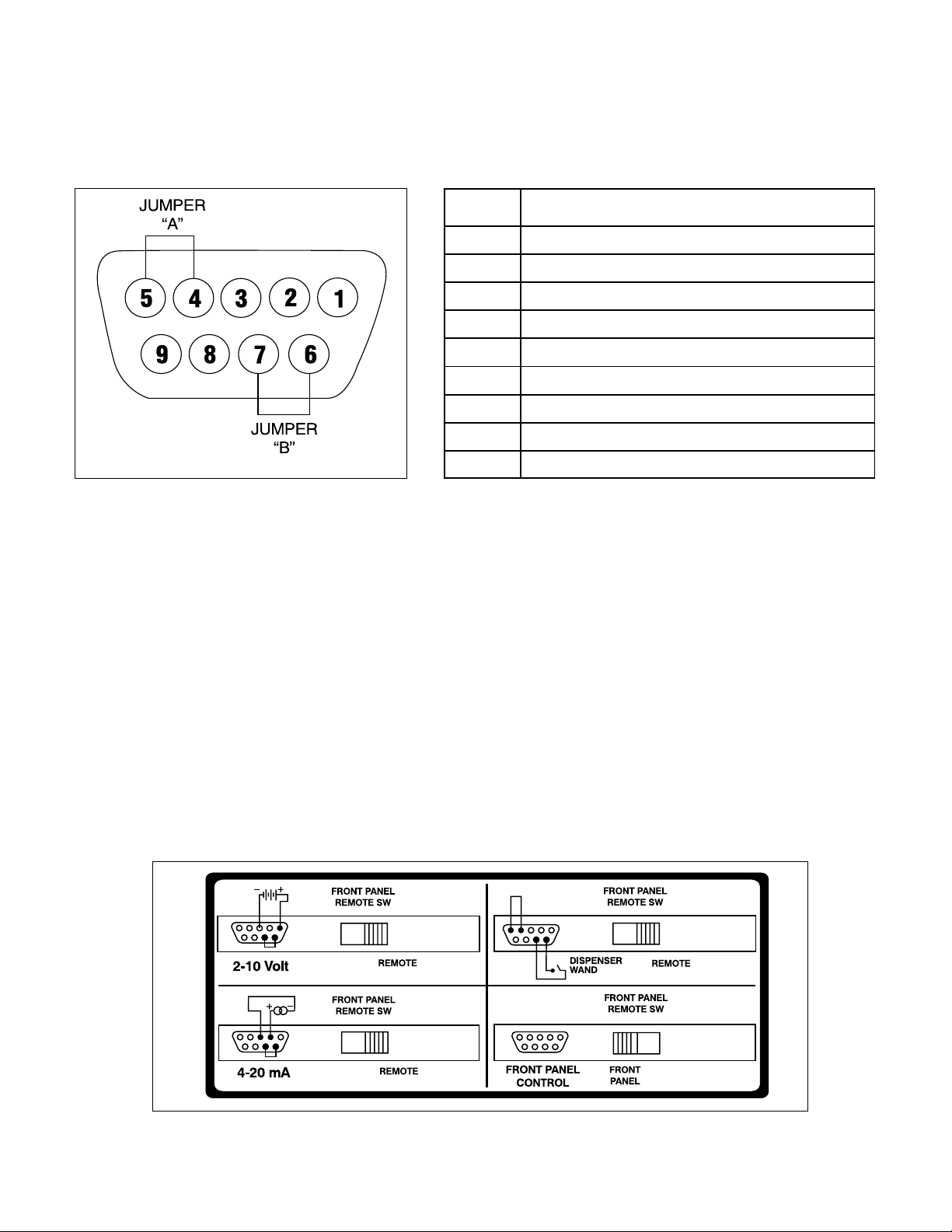

Models equipped with remote inputs and outputs can be controlled by external signals connected at the rear panel 9-pin

“D” shell connector. The Remote inputs permit control of the pump by remote equipment or accessories. Figure 2

shows the signal locations of the connector.

Pin

No.

1 Speed Control Voltage Input (2–10V) (+) input

2 Speed Contr ol Curr ent Input (4–20 mA) (+) input

3 Speed Contr ol I nput Reference Common

4 Remote/Local Speed (+) Control

5 Remote/Local Reference Speed (–) Return

6 St art/Stop Reference (–) Return

7 St art/Stop (+) Contr ol

8 Chassi s (Earth) Ground

9 Chassi s (Earth) Ground

Figure 2. DB9 Pin Configuration

with Wiring Scheme

REMOTE INPUTS

The FRONT PANEL/REMOTE switch enables remote functions. Switching to FRONT PANEL disables the remote

functions, allowing the front panel controls to operate the pump.

When the FRONT PANEL/REMOTE switch is in the REMOTE position, starting and stopping the pump is controlled by

an external contact closure between pins 6 and 7 (Jumper B), and the pump speed is determined by an externally

supplied 2–10 V or 4–20 mA source. Connection must be made between pins 6 and 7 and a control voltage greater

than 2 V or a control current greater than 4 mA must be applied for the pump to run.

Description

If setting the speed from the front panel is desired with remote Start/Stop contact operation, the FRONT PANEL/

REMOTE must again be in the REMOTE position. In addition, Jumper A should be in place. Jumper A connects pin 5

of the “D” shell connector (REMOTE/LOCAL SPEED) to pin 6 (RETURN). Start/Stop will then be controlled from the

rear panel (Jumper B), and the pump speed will be controlled from the front panel. The accessory Footswitch (part no.

73-750-000) and Dispenser Wand (part no. 73-055-590) are connected internally in this way.

Figure 3 shows four typical wiring configurations: 2–10 V follower, 4–20 mA follower, accessory dispenser wand (or

footswitch), and full front panel control.

Figure 3. Back Panel Connectors

8

NOTE: The signal common for the speed control voltage and current inputs is referenced to earth ground.

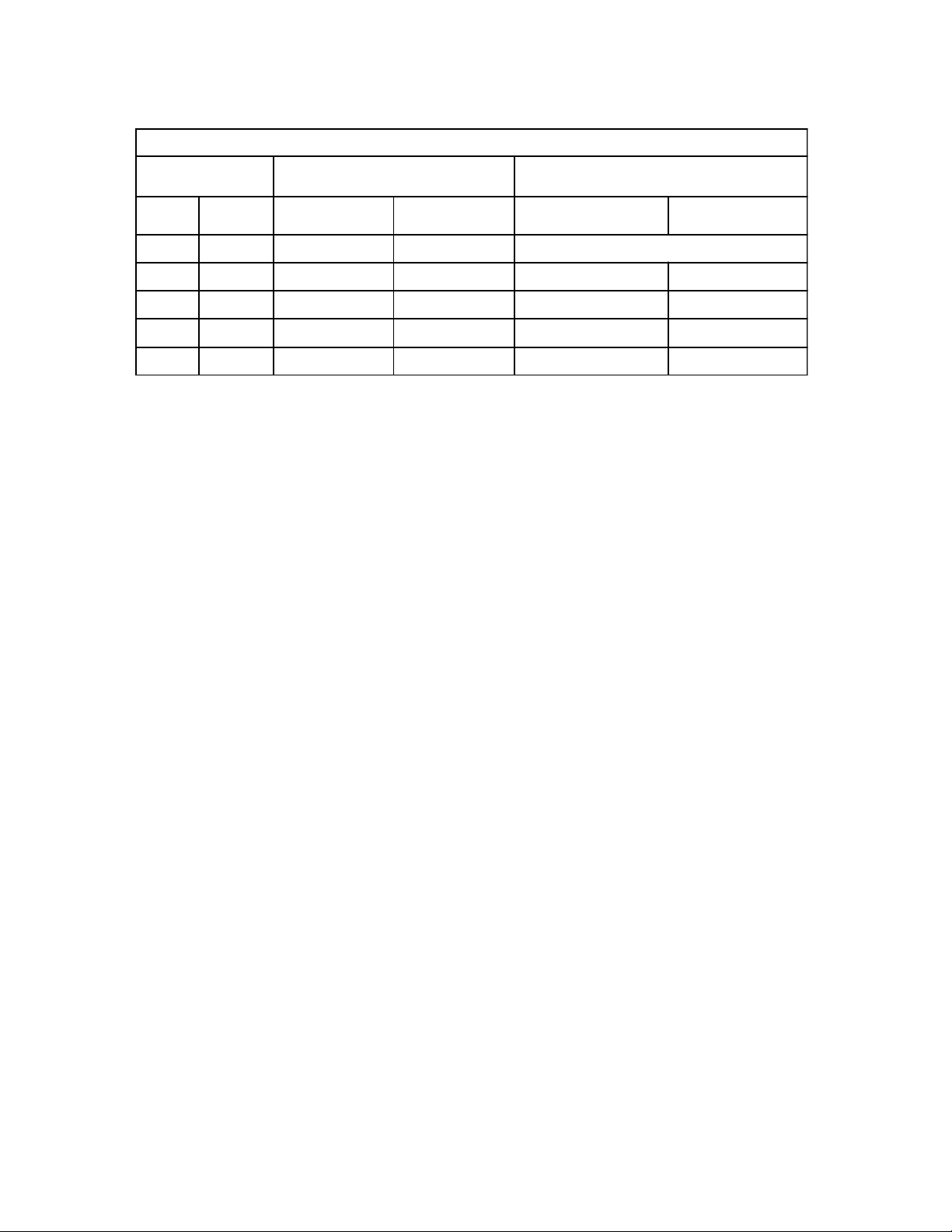

The table Operation Summary for the Feature Inputs summarizes the remote input operation.

Operation Summary for the Feature Inputs

Rear Panel Mode

Select Switch

Front

Panel

On Off X X Front Panel Control Only

Off On In In Front Panel Remote Start

Off On In Out Front Panel Remote Stop

Off On Out In Remote Remote Start

Off On Out Out Remote Remote Stop

KEY: X = N/A

The START/ST OP (pin 7) input and REMO TE/LOCAL SPEED (pin 4) input are digital inputs . The y are internally pulled

up to +15 V with respect to logic common (RETURNS). They can alternately be driven with open collector logic. For

increased noise immunity, use of contact closures is recommended.

Remote

Off = Not selected

On = Selected

Shorting Jumper

or Contact Clos ure

Jumper “A”

(Pins 4 to 5)

Jumper “B”

(Pins 6 to 7)

Functions Activated

Speed Start/Stop

9

MAINTENANCE

WARNING: Remove power from the pump before attempting any maintenance.

The speed control circuit has solid-state components that do not require service. An e xcessive load on the system ma y,

howev er, cause the fuse to blow . An indication of an excessive load is a s witch that does not light with po wer applied to

the pump and when the ON-OFF switch is in the ON position. If this condition occurs, remove power from the unit and

remove the fuse from the fuse holder located on the rear of the pump . Replace the fuse with a fuse of the same type and

rating. This information is printed on the rear of the unit.

CAUTION: Replace the fuse only with one of the same type and rating. The fuse rating and type are stated

on the rear panel.

Motor brush and commutator life depend on duty cycle and operating speed. Brushes should be inspected every six

months or 2000 hours of operation, whichever occurs first, or if erratic operation occurs. Replace when less than

7.6 mm (0.300 in) long. The commutator should be inspected periodically and cleaned if necessary. If pre v entiv e maintenance is not performed, excessive commutator wear or “bridging” between commutator segments will cause exces-

sive current through the controller circuit.

These models are equipped with a toothed-belt and should be inspected for belt wear at the same interval as the

brushes. The presence of some belt dust at or inside the pump is normal and has no effect on the operation of the pump.

If the belt is slipping, adjust the tension by loosening the motor nuts that secure it to the motor bracket and swing the

motor away from the PC board. Once adjusted, tighten the nut. Do not over-tighten the belt, as this will cause e xcessive

drive belt wear, bearing wear and noise. Replace the belt if frayed or torn. (See REPLACEMENT PARTS.)

CLEANING

DANGER: Remove power from the pump before any cleaning operation is started.

Keep the pump enclosure clean by using a mild detergent solution. Never immerse nor use excessive fluid when

cleaning the pump.

REPLACEMENT PARTS

Description Part Number Qty.

Motor brushes (2) A-4343-CR 2

Brush Cap (1) A-3190-CR 1

Motor 90 V Assembly D-3080-0001 1

Motor 180 V Assembly D-3080-0002 1

Pump Pulley B-3901 1

Motor Pulley A-3166 1

Drive Belt (Simon and Vera) A-1341-0005 1

Drive Belt (Preston) A-1341-0006 1

Rubber Foot A-1390-0004 1

Knob for speed pot (Simon) B-1083-0035 1

Fan (plastic) B-1247-0027 1

Fan (metal) B-1247-0032 1

Fuse (115 V) (T3.15A, 250V, 5 ⫻ 20 mm) B-1115-0057 1

Fuse (230 V) (T1.6A, 250V, 5 ⫻ 20 mm) B-1115-0042 1

Pump Head Cover (Simon and Vera) 91-055-075 1

Pump Head Cover (Preston) 91-065-110 1

Knob (pump cover) B-1083-0063 1

Tubing Clamp (Preston pump only) 91-065-130 1

Line Cord 115 V B-3115 1

Line Cord 230 V (Euro) B-2938 1

10

ACCESSORIES

Tubing Links Simon and Vera Preston

1/32 in. Tubing Link—NORPRENE, pk of 5 72-305-135 75-305-135

1/16 in. Tubing Link—NORPRENE, pk of 5 72-305-145 75-305-145

1/8 in. Tubing Link—NORPRENE, pk of 5 72-305-165 75-305-165

3/16 in. Tubing Link—NORPRENE, pk of 5 72-305-255 75-305-255

1/4 in. Tubing Link—NORPRENE, pk of 5 72-305-175 75-305-175

1/32 in. Tubing Link—PHARMED, pk of 5 72-301-135 75-301-135

1/16 in. Tubing Link—PHARMED, pk of 5 72-301-145 75-301-145

1/8 in. Tubing Link—PHARMED, pk of 5 72-301-165 75-301-165

3/16 in. Tubing Link—PHARMED, pk of 5 72-301-255 75-301-255

1/4 in. Tubing Link—PHARMED, pk of 5 72-301-175 75-301-175

1/32 in. Tubing Link—Silicone, pk of 5 72-300-135 75-300-135

1/16 in. Tubing Link—Silicone, pk of 5 72-300-145 75-300-145

1/8 in. Tubing Link—Silicone, pk of 5 72-300-165 75-300-165

3/16 in. Tubing Link—Silicone, pk of 5 72-300-255 75-300-255

1/4 in. Tubing Link—Silicone, pk of 5 72-300-175 75-300-175

1/32 in. Tubing Link—TYGON, pk of 5 72-310-135 75-310-135

1/16 in. Tubing Link—TYGON, pk of 5 72-310-145 75-310-145

1/8 in. Tubing Link—TYGON, pk of 5 72-310-165 75-310-165

3/16 in. Tubing Link—TYGON, pk of 5 72-310-255 75-310-255

1/4 in. Tubing Link—TYGON, pk of 5 72-310-175 75-310-175

PTFE Sinkers — keep intake tube at bottom of reservoir for

1/16 in. – 5/16 in. ID tubing (set of 2) 75-250-100

Footswitch (115 V or 230 V) 73-750-000

Autoclavable Dispensing Tips—Glass tip with Luer Lock

for 3/16 in. and 1/4 in. ID tubing 72-648-000

Polypropylene tip with Luer Lock for 1/16 in. and 1/8 in. ID tubing 72-648-020

Autoclav able Stainless Steel Cannulae

for use with Luer Lock Dispensing tip:

Cannula 16 Gauge 91-015-210

Cannula 13 Gauge 91-015-220

Dispenser Wand 73-055-590

11

SPECIFICATIONS

Output:

Speed: 24–720 rpm

Torque: 120 in-oz (8.6 kg•cm)

Input:

Operating V oltage/F requency:

Models 72-310-000, 72-312-000, 72-315-000,

72-317-000, 72-370-000, 72-372-000 100–130 VAC, 60 Hz, 2.1 A

Models 72-310-230, 72-312-230, 72-315-230,

72-317-230, 72-370-230, 72-372-230 190–260 VAC, 50 Hz, 1.3 A

Start/Stop—Local Control:

Input V oltage:

Function Disable 15 VDC Typ.

Function Enable: 0.8 VDC Max.

Input Current:

Function Disable: 100 µA Max. leakage

Function Enable: 1.5mA Max.

Installation Category: Installation category II per IEC 664

(local level—appliances, portable equipment, etc.)

Environment:

Operating Temperature: 32 to 104°F (0 to 40°C)

Storage Temperature: –49 to 149°F (–45 to 65°C)

Humidity: 10% to 90% non-condensing

Altitude: Less than 6562 ft (2000 m)

Pollution Degree: Pollution degree 2 per IEC 664

(indoor use — lab, office)

Construction:

Dimensions (L W H):

Models 72-310-000, 72-312-000, 72-315-000, 12 in 9 in 6 in (30.5 cm 22.9 cm 15.2 cm)

72-317-000, 72-310-230, 72-312-230,

72-315-230, 72-317-230

Models 72-370-000, 72-372-000, 72-370-230, 12 in 10 in 7 in (30.5 cm 25.4 cm 17.8 cm)

72-372-230

Weight:

Models 72-310-000, 72-312-000, 72-315-000, 14.9 lbs (6.8 kg)

72-317-000, 72-310-230, 72-312-230,

72-315-230, 72-317-230

Models 72-370-000, 72-372-000, 72-370-230, 17.4 lbs (7.9 kg)

72-372-230

Color: Black

Material: Painted steel housing

Enclosure Rating: IP22 per IEC 529

Compliance: 115V: UL508, CSA C22.2, No. 14-M91

230V (For CE Mark):

EN61010-1/A2: 1995 (EU Low Voltage Directive) and

EN61326-1/A1: 1998 (EU EMC Directive)

12

WARRANTY

Use only MANOSTAT precision tubing with MANOSTAT pumps to ensure optimum performance. Use of other

tubing may void applicable warranties.

The Manufacturer warrants this product to be free from significant deviations from published specifications. If repair or

adjustment is necessary within the warranty period, the problem will be corrected at no charge if it is not due to misuse

or abuse on your part, as determined by the manufacturer . Repair costs outside the warranty period, or those resulting

from product misuse or abuse, may be invoiced to you.

The warranty period for this product is noted on the Warranty Card.

PRODUCT RETURN

T o limit charges and dela ys, contact the seller or Man ufacturer f or authorization and shipping instructions before returning the product, either within or outside of the warranty period. When returning the product, please state the reason for

the return. For y our protection, pac k the product carefully and insure it against possib le damage or loss. Any damages

resulting from improper packaging are your responsibility.

TECHNICAL ASSISTANCE

If you have any questions about the use of this product, contact the Manufacturer or authorized seller.

13

Printed in U.S.A.

060701

TABLE DES MATIÈRES

Intitulé Page

MESURES DE SÉCURITÉ...................................................................................................................................................... 15

Sécurité ............................................................................................................................................................................... 15

INTRODUCTION ET DESCRIPTION GÉNÉRALE ................................................................................................................. 16

COMMANDES, TÉMOINS ET CONNECTEURS.................................................................................................................... 16

INSTALLATION ........................................................................................................................................................................ 17

Sélection du diamètre de tube............................................................................................................................................ 17

FONCTIONNEMENT............................................................................................................................................................... 18

Insertion du tube ................................................................................................................................................................. 18

Optimisation de la durée de service des tubes .................................................................................................................. 18

Commandes de la pompe .................................................................................................................................................. 18

TÉLÉCOMMANDE .................................................................................................................................................................. 19

Description .......................................................................................................................................................................... 19

Entrées pour télécommande .............................................................................................................................................. 19

ENTRETIEN............................................................................................................................................................................. 21

Nettoyage............................................................................................................................................................................ 21

Pièces de rechange ............................................................................................................................................................ 21

ACCESSOIRES ....................................................................................................................................................................... 22

CARACTÉRISTIQUES TECHNIQUES.................................................................................................................................... 23

GARANTIE............................................................................................................................................................................... 24

RETOUR DE MARCHANDISES.............................................................................................................................................. 24

ASSISTANCE TECHNIQUE .................................................................................................................................................... 24

14

MESURES DE SÉCURITÉ

DANGER : Mettre la pompe hors tension avant de procéder à toute opération de nettoyage .

AVERTISSEMENT : Mettre la pompe hors tension avant de procéder à toute opération d’entretien.

AVERTISSEMENTS : Une rupture de tube risque d’entraîner une pulvérisation de fluide hors de la pompe. Prendre

des mesures appropriées pour protéger l’opérateur et le matériel.

Mettre la pompe hors tension avant de débrancher ou de raccorder un tube . Les doigts ou les

vêtements amples risquent de se prendre dans le mécanisme de pompage.

CONSEILS

DE PRUDENCE : Lors de l’inversion du sens de circulation, laisser la pompe s’arrêter complètement avant de la

remettre en marche. Sinon, le moteur risque d’être endommagé définitivement.

Remplacer le fusible par un neuf de mêmes type et intensité nominale uniquement. L’intensité

nominale et le type du fusible sont indiqués sur le panneau arrière.

AVERTISSEMENT : LIMITES D’UTILISATION DU PRODUIT

Ces produits ne sont pas conçus, ni destinés à, être utilisés dans des applications avec patients, y compris, entre autres,

les applications médicales et dentaires et n’ont par conséquent pas été soumis à l’agrément de la FDA.

FRANÇAIS

SÉCURITÉ

1. Lire les instructions avant de se servir de l’appareil.

2. T oujours prendre des mesures de sécurité, en particulier lors du pompage de liquides dangereux. Toujours monter correctement

le couvercle en plastique transparent sur la tête et, de façon générale, protéger la zone dans laquelle se trouve la pompe

contre tout renversement accidentel de liquide.

3. Si la pompe est anormalement bruyante ou si un tassement du tube peut être observé dans celle-ci, s’assurer que le tube

est bien serré et/ou le remplacer par une section de tube neuf.

4. Les pompes MANOSTAT VARISTALTIC doivent toujours être correctement mises à la terre.

5. La pompe est équipée d’un circuit limiteur de courant qui ralentit le moteur dans l’une quelconque des situations suivantes :

a. Un tube trop dur est raccordé à la pompe.

b. Un tube d’un diamètre ou d’une épaisseur de paroi incorrect est raccordé à la pompe.

c. Le tube n’est pas raccordé correctement à la tête de pompe.

Remarque : N’utiliser que des tubes MANOSTAT.

6. L’appareil est protégé par fusible et mis à la terre pour protéger l’opérateur en cas de court-circuit pouvant être provoqué par

la pénétration de liquide dans le carter.

ATTENTION : Remplacer le fusible par un neuf de mêmes type et intensité nominale uniquement. L’intensité

nominale et le type du fusible sont indiqués sur le panneau arrière.

7. La pompe ne doit pas être utilisée à l’extérieur ni dans des endroits dangereux.

NORPRENE, PHARMED, TYGON — Marques déposées de Norton Co.

Les marques accompagnées du symbole ® qui apparaissent dans cette publication sont déposées aux États-Unis et dans d’autres pays.

15

INTRODUCTION ET DESCRIPTION GÉNÉRALE

Les pompes MANOSTAT à vitesse variable permettent le pompage ininterrompu de fluides tant qu’elles sont sous tension. Les

pompes 115 V ont reçu les agréments UL et cUL. Celles de 230 V sont estampillées CE. La plage de vitesse de pompage de tous

les modèles va de 24 à 720 tr/mn.

N° de modèle Description

72-310-000 SIMON, potentiomètre analogique de vitesse, 115 V

72-312-000 SIMON, avec commande à distance en option et potentiomètre analogique de vitesse, 115 V

72-310-230 SIMON, potentiomètre analogique de vitesse, 230 V

72-312-230 SIMON, avec commande à distance en option et potentiomètre analogique de vitesse, 230 V

72-315-000 VERA, potentiomètre numérique de vitesse, 115 V

72-317-000 VERA, avec commande à distance en option et potentiomètre numérique de vitesse, 115V

72-315-230 VERA, potentiomètre numérique de vitesse, 230 V

72-317-230 VERA, avec commande à distance en option et potentiomètre numérique de vitesse, 230 V

72-370-000 PRESTON, potentiomètre numérique de vitesse, 115 V

72-372-000 PRESTON, avec commande à distance en option et potentiomètre numérique de vitesse, 115 V

72-370-230 PRESTON, potentiomètre numérique de vitesse, 230 V

72-372-230 PRESTON, avec commande à distance en option et potentiomètre numérique de vitesse, 230 V

COMMANDES, TÉMOINS ET CONNECTEURS

Figure 1.

COMMANDES

A. COMMUTATEUR DE MARCHE-ARRÊT : Il met l’appareil SOUS et HORS TENSION. Il s’allume en vert lorsque l’appareil est

SOUS TENSION.

B. BOUTON DE COMMANDE (Simon) ou SÉLECTEUR (Vera et Preston) DE VITESSE : Il permet de sélectionner la vitesse

de la pompe. Plus le chiffre est élevé, plus la pompe tourne vite.

C. SÉLECTEUR DE SENS DE CIRCULATION : Il permet de sélectionner le sens de rotation (horaire/arrêt/antihoraire) de la

pompe.

16

INSTALLATION

Déballer la pompe et conserver le matériau d’emballage jusqu’à ce que le fonctionnement correct du produit ait été vérifié.

Sélectionner les tubes en fonction du débit désiré, en tenant compte également de la compatibilité chimique et de la durée de

service des tubes. Se reporter au tableau de résistance aux attaques chimiques fourni (pièce n° A-1299-5030) pour sélectionner

le type de tube adapté au liquide à pomper.

SÉLECTION DU DIAMÈTRE DE TUBE

Le débit est déterminé par le diamètre du tube raccordé dans la tête de pompe. En cas d’utilisation d’éléments de liaison de tubes,

les meilleures performances sont obtenues lorsque les tubes d’entrée et de sortie raccordés à l’élément de liaison ont le même

diamètre intérieur que ce dernier. Tous les tubes qui se trouvent à l’intérieur de la tête de pompe doivent être des tubes

MANOSTAT à impression en relief.

Les pompes Simon, Vera et Preston acceptent des tubes de 1/32 à 5/16 po de diamètre intérieur.

Pour obtenir les meilleurs résultats, sélectionner des tubes d’un diamètre permettant d’obtenir un débit correspondant à la moy enne

de la plage de débit à laquelle on désire pomper. Le tableau ci-dessous donne une moyenne des débits mesurés avec de l’eau à

la pression et à la température standard. Aucune pression d’aspiration ni de refoulement n’est indiquée.

TABLEAU DE SÉLECTION DE TUBE

Pompes Simon et Vera

(ml/mn)

Diamètre de tube en silicone

1–37 1/32 po diam. int. (13)* 2–40

6–170 1/16 po diam. int. (14)* 11–29

25–700 1/8 po diam. int. (16) 44–1200

57–1700 3/16 po diam. int. (25) 93–2490

91–2650 1/4 po diam. int. (17) 170–4200

137–3475 5/16 po diam. int. (18) 246–4950

®

Diamètre de tubes NORPRENE

et PHARMED

1–40 1/32 po diam. int. (13)* 2–77

8–210 1/16 po diam. int. (14)* 13–350

28–780 1/8 po diam. int. (16) 46–1250

60–1740 3/16 po diam. int. (25) 103–2800

96–2600 1/4 po diam. int. (17) 168–4200

121–3400 5/16 po diam. int. (18) 245–5500

Diamètre de tube TYGON

®

Pompes Preston

(ml/mn)

®

1–25 1/32 po diam. int. (13)* 2–55

6–185 1/16 po diam. int. (14)* 9–320

25–770 1/8 po diam. int. (16) 45–1250

60–1720 3/16 po diam. int. (25) 105–2850

96–2800 1/4 po diam. int. (17) 174–4800

120–3500 5/16 po diam. int. (18) 236–5400

* Exige des éléments de liaison de tubes.

17

FONCTIONNEMENT

Utiliser uniquement des tubes MANOSTAT extrudés avec précision avec les pompes MANOSTAT pour garantir des

performances optimales. L’utilisation d’autres tubes peut annuler les garanties applicables.

INSERTION DU TUBE

AVERTISSEMENTS : Une rupture de tube risque d’entraîner une pulvérisation de fluide hors de la pompe. Prendre des

mesures appropriées pour protéger l’opérateur et le matériel.

Mettre la pompe hors tension avant de débrancher ou de raccorder un tube. Les doigts ou les

vêtements amples risquent de se prendre dans le mécanisme de pompage.

1. S’assurer que le commutateur de marche-arrêt est en position d’arrêt.

2. Retirer les deux écrous à oreilles, puis enlever le couvercle en plastique transparent de la tête de pompe.

3. Éléments de liaison de tubes : Fixer les côtés arrivée et sortie du tube de transfer t aux raccords de l’élément de liaison.

Enfoncer ce dernier de façon à ce que ses attaches ou brides soient aussi rapprochées que possible de l’extér ieur de la tête

de pompe. Faire tourner l’ensemble de rouleaux à la main et guider le tube entre les rouleaux et la paroi de la tête de pompe.

Tube : Enfoncer le tube entre les rouleaux et le carter de la tête de pompe au milieu de la rainure (c’est-à-dire à mi-distance

entre le couvercle en plastique transparent de la tête de pompe et le bas du carter de la tête). Cela garantit que les rouleaux

appuient sur toute la largeur du tube lorsqu’ils tournent. Faire tour ner l’ensemble de rouleaux à la main et guider le tube entre

les rouleaux et la paroi de la tête de pompe. Lorsqu’on utilise des tubes (pas des éléments de liaison), il doit toujours y a v oir un

espace réduit mais visible entre le tube et le carter de la tête de pompe sur une distance qui doit être comprise entre le tiers

et la moitié de la surface de contact. Tirer doucement sur les côtés arrivée et sortie du tube pour créer un espace entre le tube

et la paroi incurvée du carter de tête de pompe.

4. Remettre le couvercle en plastique transparent en place sur la tête de pompe, en veillant à serrer les écrous à oreilles pour

empêcher le tube de bouger en cours de fonctionnement.

Le couvercle en plastique transparent de la tête de pompe est réversible sur les modèles Simon et Vera, avec des dispositifs de

retenue de tubes de différents diamètres sur chaque face. Si les tubes sont d’un diamètre intérieur inférieur à 3/16 po, placer le

couvercle de façon à ce que les plus gros dispositifs de retenue les maintiennent. Si les tubes sont d’un diamètre intérieur d’au

moins 3/16 po (calibre 25), retourner le couvercle.

Sur les modèles Preston, régler les deux vis du collier de serrage pour maintenir le tube en place après avoir fixé le couvercle en

plastique transparent à la tête de pompe. Si le diamètre intérieur du tube est inférieur à 3/16 po (calibre 25) et qu’un élément de

liaison de tubes n’est pas utilisé, prendre l’une des mesures suivantes pour empêcher le tube de glisser dans la tête de pompe :

• Couvrir le tube aux points de raccordement avec un petit morceau de tube de plus grand diamètre pour améliorer le serrage.

• Poser un raccord sur l’entrée de la tête de pompe.

OPTIMISATION DE LA DURÉE DE SERVICE DES TUBES

Déplacer régulièrement les tubes de façon à ce qu’un segment différent soit dans la pompe ou remplacer l’élément de liaison de

tubes. Cela évite une usure excessive des tubes en n’importe quel point précis. Toujours transférer le tube usé du côté aspiration

de la pompe.

COMMANDES DE LA POMPE

ATTENTION : Lors de l’inversion du sens de circulation, laisser la pompe s’arrêter complètement avant de la

remettre en marche. Sinon, le moteur risque d’être endommagé définitivement.

1. S’assurer que la commande de vitesse de circulation est réglée à la position de vitesse minimum.

2. Tourner le commutateur de marche/arrêt en position de marche. Augmenter la vitesse de circulation pour lancer le pompage.

Plus le chiffre sélectionné est élevé, plus la pompe tourne vite.

3. Les pompes VARIST ALTIC sont à autoamorçage. P our commencer à pomper , choisir le sens de circulation à l’aide du sélecteur

correspondant, enfoncer les tubes d’aspiration et de refoulement dans un réservoir et mettre la pompe en marche. Amorcer

les tubes pendant au moins 5 minutes. Si un débit précis est impor tant, laisser la pompe s’amorcer pendant 20 minutes

environ pour obtenir une ciculation plus stable.

18

TÉLÉCOMMANDE

DESCRIPTION

Les modèles équipés d’entrées et de sorties pour télécommande peuvent être commandés à l’aide de signaux externes acheminés

via le connecteur à 9 broches et coquille en D qui se trouve sur le panneau arrière. Les entrées pour télécommande permettent de

commander la pompe à l’aide d’un appareillage ou d’accessoires à distance. La Figure 2 indique l’affectation des broches du

connecteur à la transmission des différents signaux.

Broche

Figure 2. Configuration des broches du

Description

n°

Entrée de tension à l’entrée de réglage de vi tesse

1

(2–10 V) (+)

Entrée d’intensité à l’entrée de réglage de vitesse

2

(4–20 mA) (+)

3 Commun de référence d’entrée de réglage de vitesse

4 Commande à distance/locale de vitesse (+)

Retour de signal de référence de vitesse (–) à la

5

commande à distance/lo cal e

6 Retour de signal de r éférence de marche/arrêt (–)

7 Commande de marche/arrêt (+)

8Mise à la terre du châssis

9Mise à la terre du châssis

connecteur DB9 et câblage

ENTRÉES POUR TÉLÉCOMMANDE

Le sélecteur FRONT PANEL / REMOTE (Panneau avant/télécommande) permet d’activer les fonctions de télécommande. Sa

mise en position FRONT PANEL désactive les fonctions de télécommande pour permettre de commander la pompe à par tir du

panneau avant.

Lorsque le sélecteur FRONT PANEL/REMOTE est en position REMOTE, la mise en marche et l’arrêt de la pompe sont commandés

par la fermeture d’un contact extérieur entre les broches 6 et 7 (cavalier B) et la vitesse de la pompe est déterminée par la tension

(2–10 V) ou l’intensité (4–20 mA) du courant fourni par une source d’alimentation extérieure. Une liaison doit être établie entre les

broches 6 et 7 et la pompe doit recevoir une tension de commande supérieure à 2 V ou une intensité de commande supérieure à

4 mA pour fonctionner.

Si on souhaite régler la vitesse depuis le panneau avant et télécommander la mise en marche et l’arrêt, le sélecteur FRONT

PANEL/REMOTE doit être remis en position REMOTE. En outre, le cavalier A doit être en place. Il relie la broche 5 du connecteur

à coquille en D (COMMANDE À DIST ANCE/LOCALE DE VITESSE) à la broche 6 (RET OUR). La marche/arrêt ser a alors commandée

à partir du panneau arrière (cavalier B) et la vitesse de la pompe à partir du panneau avant. La connexion interne de l’interrupteur

à pédale (pièce n° 73-750-000) et du tube distributeur (pièce n° 73-055-590) disponibles comme accessoires s’effectue de la

même façon.

La Figure 3 fait apparaître quatre configurations types de câblage : asservissement 2–10 V, asservissement 4–20 mA, tube

distributeur (ou interrupteur à pédale) et commande complète à partir du panneau avant.

Figure 3. Connecteurs du panneau arrière

19

REMARQUE : le signal du commun pour les entrées de tension et d’intensité de réglage de vitesse est mesuré par rapport à

celui de mise à la terre.

Le tableau Sommaire du fonctionnement des entrées de fonctions résume les informations concernant les entrées pour

télécommande.

Sommaire du foncti onnement de s e ntr ées de fonct ions

Sélecteur de mode de

tableau arrière

Panneau avant Télécommande

Sélectionné No n sélectionné S/O S/O Commande sur panneau avant uniquement

Non sélectionné Sélectionnée Branché Branché Panneau avant Marche télécomm andé

Non sélectionné Sélectionnée Branché Débranché Panneau avant Arrêt télécommandé

Non sélectionné SélectionnéeDébranché Branché Télécommande Marche télécommandé

Non sélectionné SélectionnéeDébranché Débranché Télécommande Arrêt télécommandé

CLÉ : S/O = Sans objet

L’entrée de MARCHE/ARRÊT (broche 7) et celle de COMMANDE À DISTANCE/LOCALE DE VITESSE (broche 4) sont des entrées

numériques. Le commun logique (RETOURS) les relève par voie interne jusqu’à + 15 V. Elles peuvent également être pilotées à

l’aide d’une logique à collecteur ouvert. Pour améliorer la protection antibruit, il est recommandé d’utiliser des fermetures de

contacts.

Court-circuit de cavalier ou

fermeture de contact

Cavalier « A »

(entre broches

4 et 5)

Cavalier « B »

(entre broches

6 et 7)

Fonctions activées

Vitesse Marche/arrêt

20

ENTRETIEN

AVERTISSEMENT : Mettre la pompe hors tension avant de procéder à toute opération d’entretien.

Le circuit de réglage de vitesse inclut des composants à semiconducteurs qui ne demandent aucun entretien. Si toutefois le circuit

est soumis à une charge excessive, le fusible risque de sauter. Lorsqu’il y a charge excessive, le commutateur de marche-arrêt ne

s’allume pas lorsque la pompe est mise sous tension et qu’il est en position de marche. En pareil cas, mettre la pompe sous

tension et retirer le fusible du porte-fusible qui se trouve sur l’arrière de la pompe. Remplacer le fusible par un neuf de mêmes type

et intensité nominale. Ces informations sont imprimées sur l’arrière de la pompe.

ATTENTION : Remplacer le fusible par un neuf de mêmes type et intensité nominale uniquement. L’intensité

nominale et le type du fusible sont indiqués sur le panneau arrière.

La durée de service des balais et du collecteur du moteur dépend du coefficient d’utilisation et de la vitesse de fonctionnement. Il

convient d’examiner les balais tous les six mois ou toutes les 2000 heures de fonctionnement, suivant le premier terme échu, ou

en cas de fonctionnement irrégulier. Les remplacer lorsqu’ils sont longs de moins de 7,6 mm. Il convient d’examiner le collecteur

régulièrement et de ne nettoyer si nécessaire. Si un entretien préventif n’est pas effectué, une usure excessive du collecteur ou un

« pontage » des segments du collecteur provoque une intensité excessive dans le circuit du contrôleur.

Ces modèles sont équipés d’une courroie crantée et il convient de les examiner pour voir si cette der nière est usée aux mêmes

intervalles que les balais. La présence d’une petite quantité de débris de courroie à l’intérieur de la pompe est normale et n’a aucun

effet sur le fonctionnement de cette dernière. Si la courroie patine, régler sa tension en desserrant les écrous qui fixent le moteur

à son support et faire pivoter le moteur pour l’écarter de la carte de circuits impr imés. Une fois le réglage effectué, resserrer les

écrous. Ne pas trop tendre la courroie, ce qui entraînerait son usure excessive, ainsi qu’une usure des roulements et un

fonctionnement bruyant. Remplacer la courroie si elle est effilochée ou déchirée. (Voir PIÈCES DE RECHANGE.)

NETTOYAGE

DANGER : Mettre la pompe hors tension avant de procéder à toute opération de nettoyage.

Maintenir la propreté du carter de la pompe avec une solution de détergent doux. Ne jamais plonger complètement la pompe dans

du liquide ni utiliser trop de liquide pour la nettoyer.

PIÈCES DE RECHANGE

Description Numéro de pièce Qté

Balais de moteur (2) A-4343-CR 2

Capuchon de balai (1) A-3190-CR 1

Moteur 90 V D-3080-0001 1

Moteur 180 V D-3080-0002 1

Poulie de pompe B-3901 1

Poulie de moteur A-3166 1

Courroie d’entraînement (Simon et Vera) A-1341-0005 1

Courroie d’entraînement (Preston) A-1341-0006 1

Pied en caoutchouc A-1390-0004 1

Bouton pour potentiomètre de vitesse (Simon) B-1083-0035 1

Ventilateur (plastique) B-1247-0027 1

Ventilateur (métal) B-1247-0032 1

Fusible (115 V) (T3.15 A, 250 V, 5 ⫻ 20 mm) B-1115-0057 1

Fusible (230 V) (T1.6 A, 250 V, 5 ⫻ 20 mm) B-1115-0042 1

Couvercle de tête de pompe (Simon et Vera) 91-055-075 1

Couvercle de tête de pompe (Preston) 91-065-110 1

Bouton (couvercle de pompe) B-1083-0063 1

Collier de tube (pompe Preston uniquement) 91-065-130 1

Cordon d’alimentation 115 V B-3115 1

Cordon d’alimentation 230 V (Europe) B-2938 1

21

ACCESSOIRES

Éléments de liaison de tubes Simon et Vera Preston

Élément de liaison 1/32 po—NORPRENE, paquet de 5 72-305-135 75-305-135

Élément de liaison 1/16 po—NORPRENE, paquet de 5 72-305-145 75-305-145

Élément de liaison 1/8 po—NORPRENE, paquet de 5 72-305-165 75-305-165

Élément de liaison 3/16 po—NORPRENE, paquet de 5 72-305-255 75-305-255

Élément de liaison 1/4 po—NORPRENE, paquet de 5 72-305-175 75-305-175

Élément de liaison 1/32 po—PHARMED, paquet de 5 72-301-135 75-301-135

Élément de liaison 1/16 po—PHARMED, paquet de 5 72-301-145 75-301-145

Élément de liaison 1/8 po—PHARMED, paquet de 5 72-301-165 75-301-165

Élément de liaison 3/16 po—PHARMED, paquet de 5 72-301-255 75-301-255

Élément de liaison 1/4 po—PHARMED, paquet de 5 72-301-175 75-301-175

Élément de liaison 1/32 po—Silicone, paquet de 5 72-300-135 75-300-135

Élément de liaison 1/16 po—Silicone, paquet de 5 72-300-145 75-300-145

Élément de liaison 1/8 po—Silicone, paquet de 5 72-300-165 75-300-165

Élément de liaison 3/16 po—Silicone, paquet de 5 72-300-255 75-300-255

Élément de liaison 1/4 po—Silicone, paquet de 5 72-300-175 75-300-175

Élément de liaison 1/32 po—TYGON, paquet de 5 72-310-135 75-310-135

Élément de liaison 1/16 po—TYGON, paquet de 5 72-310-145 75-310-145

Élément de liaison 1/8 po—TYGON, paquet de 5 72-310-165 75-310-165

Élément de liaison 3/16 po—TYGON, paquet de 5 72-310-255 75-310-255

Élément de liaison 1/4 po—TYGON, paquet de 5 72-310-175 75-310-175

Lests en polytétrafluoroéthylène — maintiennent le tube d’aspiration au

fond du réservoir pour tubes de 1/16 à 5/16 po

de diam. int. (jeu de 2) 75-250-100

Interrupteur à pédale (115 ou 230 V) 73-750-000

Buse distributrice autoclavable en verre avec Luer Lock

pour tubes de 3/16 et 1/4 po 72-648-000

Buse en polypropylène avec Luer Lock pour tubes

de 1/16 et 1/8 po de diam. int. 72-648-020

Cannule autoclavable en acier inoxydable

pour utilisation avec buse distributrice à Luer Lock :

Cannule calibre 16 91-015-210

Cannule calibre 13 91-015-220

Tube distributeur 73-055-590

22

CARACTÉRISTIQUES TECHNIQUES

Sortie :

Vitesse : 24–720 tr/mn

Couple : 8,6 kg•cm

Entrée :

Tension/fréquence de fonctionnement :

Modèles 72-310-000, 72-312-000, 72-315-000,

72-317-000, 72-370-000, 72-372-000 100–130 V c.a., 60 Hz, 2,1 A

Modèles 72-310-230, 72-312-230, 72-315-230,

72-317-230, 72-370-230, 72-372-230 190–260 V c.a., 50 Hz, 1,3 A

Marche/arrêt—Commande locale :

Tension à l’entrée :

Désactivation de fonction : 15 V c.c. norm.

Activation de fonction : 0,8 V c.c. max.

Intensité à l’entrée :

Désactivation de fonction : Fuite de 100 µA max.

Activation de fonction : 1,5 mA max.

Catégorie d’installation : Catégorie II d’après la norme IEC 664

(installation locale—appareillage, matériel portatif, etc.)

Conditions d’utilisation :

Température de fonctionnement : 0 à 40 °C

Température d’entreposage : –45 à 65 °C

Humidité : 10 à 90 % sans condensation

Altitude : Inférieure à 2000 m

Degré de pollution : Degré 2 (IEC 664)

(utilisation intérieure — laboratoire, bureau)

Fabrication:

Dimensions (L ⫻ l ⫻ H) :

Modèles 72-310-000, 72-312-000, 72-315-000, 30,5 ⫻ 22,9 ⫻ 15,2 cm

72-317-000, 72-310-230, 72-312-230,

72-315-230, 72-317-230

Modèles 72-370-000, 72-372-000, 72-370-230, 30,5 ⫻ 25,4 ⫻ 17,8 cm

72-372-230

Poids :

Modèles 72-310-000, 72-312-000, 72-315-000, 6,8 kg

72-317-000, 72-310-230, 72-312-230,

72-315-230, 72-317-230

Modèles 72-370-000, 72-372-000, 72-370-230, 7,9 kg

72-372-230

Couleur : Noir

Matière : Carter en acier peint

Homologation du carter : IP22 (IEC 529)

Conformités : 115 V : UL508, ACNOR C22.2, n° 14-M91

230 V (pour estampillage CE) :

EN61010-1/A2 : 1995

(Directive européenne sur les basses tensions)

et EN61326-1/A1 : 1998 (Directive européenne

sur la compatibilité électromagnétique)

23

GARANTIE

Utiliser uniquement des tubes MANOSTAT extrudés avec précision avec les pompes MANOSTAT pour garantir des

performances optimales. L’utilisation d’autres tubes peut annuler les garanties applicables.

Nous garantissons que ce produit est conforme aux descriptifs. Si une réparation ou un réglage s’avère nécessaire durant la

période de garantie, le problème sera corrigé gratuitement s’il n’est pas dû à une utilisation par le client dont nous a vons déterminé

qu’elle est incorrecte ou abusive. Les réparations effectuées en dehors de la période de garantie ou rendues nécessaires par une

utilisation incorrecte ou abusive seront à la charge du client.

La période de garantie pour ce produit est indiquée sur la carte de garantie.

RETOUR DE MARCHANDISES

Pour limiter les frais et délais, le produit ne peut être retour né sans notre autor isation préalable et nos instructions d’expédition ou

celles du revendeur. Lors du renvoi du produit, bien vouloir en indiquer la raison. Pour se protéger, nous recommandons au client

d’emballer soigneusement le produit et de l’assurer contre les risques de dommages ou de perte. Nous ne serons pas responsable

des dommages résultant d’un emballage incorrect.

ASSIST ANCE TECHNIQUE

Pour toute question concernant l’utilisation de ce produit, prendre contact avec nous ou avec un revendeur agréé.

24

Imprimé aux États-Unis

060701

INHALTSVERZEICHNIS

Titel Seite

SICHERHEITSMASSNAHMEN............................................................................................................................................26

Sicherheit .........................................................................................................................................................................26

EINFÜHRUNG UND ALLGEMEINE BESCHREIBUNG.......................................................................................................27

BEDIENELEMENTE, ANZEIGEN UND ANSCHLÜSSE ......................................................................................................27

VORBEREITUNG .................................................................................................................................................................28

Auswahl der Schlauchgröße ............................................................................................................................................28

BETRIEB...............................................................................................................................................................................29

Einlegen des Schlauchs................................................................................................................................................... 29

Optimierung der Schlauchhaltbarkeit ..............................................................................................................................29

Bedienelemente der Pumpe ............................................................................................................................................29

FERNBETRIEB.....................................................................................................................................................................30

Beschreibung ...................................................................................................................................................................30

Externe Eingänge ............................................................................................................................................................30

WARTUNG............................................................................................................................................................................32

Reinigen ...........................................................................................................................................................................32

Ersatzteile ........................................................................................................................................................................32

ZUBEHÖR ............................................................................................................................................................................ 33

TECHNISCHE DATEN..........................................................................................................................................................34

GARANTIE............................................................................................................................................................................35

WARENRÜCKSENDUNGEN................................................................................................................................................ 35

TECHNISCHE BERATUNG ..................................................................................................................................................35

DEUTSCH

25

SICHERHEITSMASSNAHMEN

VORSICHT,

LEBENSGEFAHR: Vor allen Reinigungsarbeiten zuerst die Stromzufuhr zur Pumpe unterbrechen.

VORSICHT: Vor allen Wartungsarbeiten zuerst die Stromzufuhr zur Pumpe unterbrechen.

WARNHINWEISE: Bei Schlauchbruch wird u. U . Flüssigkeit v on der Pumpe verspritzt. Geeignete Maßnahmen zum Schutz

von Bediener und Geräten ergreifen.

Vor dem Herausnehmen oder Einlegen von Schläuchen die Pumpe ausschalten, da sich andernfalls

Finger oder lose Kleidung im Antriebsmechanismus verfangen könnten.

ACHTUNG: Beim Ändern der Flussrichtung vor dem Neustart warten, bis die Pumpe vollständig zum Stillstand

gekommen ist, da es andernfalls zu einer permanenten Beschädigung des Motors kommen kann.

Die Sicherung nur gegen eine Sicherung des gleichen T yps und der gleichen Nennleistung aus wechseln.

Die Nennleistung der Sicherung und der Sicherungstyp sind auf der Rückwand angegeben.

ACHTUNG: ANWENDUNGSEINSCHRÄNKUNGEN

Dieses Gerät ist nicht für den Einsatz am Patienten vorgesehen und auch nicht für diesen Zwec k bestimmt (z.B. medizinischen

oder zahnmedizinischen Bereich) und entspricht demgemäß auch keinen FDA (Food & Drug Administration) Normen.

SICHERHEIT

1. Vor Inbetriebnahme des Geräts die Anleitungen lesen.

2. Die Sicherheitsmaßnahmen sind zu allen Zeiten zu beachten. Beim Pumpen gefährlicher Flüssigkeiten ist besondere Vorsicht

geboten. Die durchsichtige Kunststoffabdeckung des Pumpenkopfs muss immer einwandfrei auf dem Pumpenkopf montiert

sein, und der gesamte Pumpenbereich ist vor einem versehentlichen Verschütten von Flüssigkeit zu schützen.

3. Wenn die Pumpe ungewöhnliche Geräusche erzeugt oder wenn sich der Schlauch in der Pumpe verwürgt, sicherstellen, dass

der Schlauch sicher festgeklemmt ist und/oder den Schlauch gegen ein neues Schlauchstück auswechseln.

4. Die VARISTALTIC-Pumpen von MANOSTAT müssen zu allen Zeiten einwandfrei geerdet sein.

5. Die Pumpe ist mit einer Strombegrenzungsschaltung ausgestattet, die den Motor verlangsamt, wenn eine der folgenden

Bedingungen vorliegt:

a. Der Schlauch in der Pumpe ist zu hart.

b. Der Schlauch in der Pumpe hat die falsche Größe oder Wandstärke.

c. Der Schlauch ist nicht einwandfrei in den Pumpenkopf eingeführt.

Hinweis: Nur MANOSTAT-Schläuche verwenden!

6. Das Gerät hat eine Sicherung und ist geerdet, um den Bediener im Fall von Kurzschlüssen zu schütz en, die bei Eindringen von

Flüssigkeit in das Gehäuse auftreten können.

ACHTUNG: Die Sicherung nur gegen eine Sicherung des gleichen Typs und der gleichen Nennleistung auswechseln.

Die Nennleistung der Sicherung und der Sicherungstyp sind auf der Rückwand angegeben.

7. Die Pumpe darf nicht im Freien oder in gefährdeten Bereichen verwendet werden.

NORPRENE, PHARMED, TYGON — eingetragenen Marken der Norton Co.

Marken mit dem Symbol ® in dieser Veröffentlichung sind in den USA und in anderen Ländern eingetragen.

26

EINFÜHRUNG UND ALLGEMEINE BESCHREIBUNG

Die MANOSTAT Regelpumpen sind im eingeschalteten Zustand für das kontinuierliche Pumpen von Flüssigkeiten vorgesehen. Die

115 V-Pumpen haben die UL- und cUL-Zulassung. Die 230 V-Pumpen sind CE-zer tifiziert. Der Pumpendrehzahlbereich für alle

Modelle liegt bei 24 – 720 U/min.

Modellnr. Beschreibung

72-310-000 SIMON, analoger Drehzahlpotenziometer, 115 V

72-312-000 SIMON, mit Fernbetriebsoption und analogem Drehzahlpotenziometer, 115 V

72-310-230 SIMON, analoger Drehzahlpotenziometer, 230 V

72-312-230 SIMON, mit Fernbetriebsoption und analogem Drehzahlpotenziometer, 230 V

72-315-000 VERA, digitaler Drehzahlpotenziometer, 115 V

72-317-000 VERA, mit Fernbetriebsoption und digitalem Drehzahlpotenziometer, 115 V

72-315-230 VERA, digitaler Drehzahlpotenziometer, 230 V

72-317-230 VERA, mit Fernbetriebsoption und digitalem Drehzahlpotenziometer, 230 V

72-370-000 PRESTON, digitaler Drehzahlpotenziometer, 115 V

72-372-000 PRESTON, mit Fernbetriebsoption und digitalem Drehzahlpotenziometer, 115 V

72-370-230 PRESTON, digitaler Drehzahlpotenziometer, 230 V

72-372-230 PRESTON, mit Fernbetriebsoption und digitalem Drehzahlpotenziometer, 230 V

BEDIENELEMENTE, ANZEIGEN UND ANSCHLÜSSE

Abbildung 1

BEDIENELEMENTE

A. NETZSCHALTER (EIN/AUS): Schaltet das Gerät ein bzw. aus. Leuchtet grün, wenn das Gerät eingeschaltet ist.

B. FLOW SPEED — FÖRDERLEISTUNGSREGLER (Simon) oder -SCHAL TER (Vera und Preston): Stellt die Pumpendrehzahl

ein. Je höher die Zahl, desto höher die Pumpendrehzahl.

C. FLOW DIRECTION — FLUSSRICHTUNGSSCHAL TER: Stellt die Drehrichtung der Pumpe ein: im Uhrzeigersinn/A us/entgegen

dem Uhrzeigersinn.

27

VORBEREITUNG

Packen Sie die Pumpe aus und heben Sie die gesamte Ver packung auf, bis Sie das Gerät auf einwandfreien Betrieb über prüft

haben. Wählen Sie den Schlauch entsprechend der gewünschten Fördermenge aus. Berücksichtigen Sie dabei die chemische

Beständigkeit und die Lebensdauer des Schlauchs. Zur Auswahl des geeigneten Schlauchtyps für die verwendete Flüssigkeit

lesen Sie bitte in der mitgelieferten Chemical Resistance Chart (Tabelle mit chemischen Beständigkeitsdaten) nach (Artikelnr.

A-1299-5030).

AUSWAHL DER SCHLAUCHGRÖSSE

Die Fördermenge richtet sich nach der Größe des Schlauchs im Pumpenkopf. Bei Verwendung von Pumpenschläuchen wird die

beste Leistung erzielt, wenn der mit dem Pumpenschlauch verbundene Ansaug- und A uslassschlauch denselben Innendurchmesser

hat wie der Pumpenschlauch. Alle Schläuche im Inneren des Pumpenkopfes müssen durch ihren Aufdruck eindeutig als

MANOSTAT-Schläuche gekennzeichnet sein.

Für Simon, Vera- und Preston-Pumpen können Schläuche mit einem Innendurchmesser von 1/32 bis 5/16 Zoll verwendet werden.

Beste Ergebnisse werden erzielt, wenn eine Schlauchgröße im Mittelbereich der zu pumpenden Fördermenge gewählt wird. Die

nachstehende Tabelle enthält Durchschnittswerte für Fördermengen, die mit Wasser bei Standarddruck und -temperatur gemessen

wurden. Werte für Ansaug- oder Förderdruck werden nicht angegeben.

TABELLE FÜR DIE SCHLAUCHAUSWAHL

Simon- und Vera-Pumpen

(ml/min)

Silikonschlau c hg röße

1–37 1/32 Zoll ID (13)* 2–40

Preston-Pumpen

(ml/min)

6–170 1/16 Zoll I D ( 14) * 11–29

25–700 1/8 Zoll ID (16) 44–1200

57–1700 3/16 Zoll ID (25) 93–2490

91–2650 1/4 Zoll ID (17) 170–4200

137–3475 5/16 Zoll ID (18) 246–4950

®

NORPRENE

1–40 1/32 Zoll ID (13)* 2–77

8–210 1/16 Zoll I D ( 14) * 13–350

28–780 1/8 Zoll ID (16) 46–1250

60–1740 3/16 Zoll ID (25) 103–2800

96–2600 1/4 Zoll ID (17) 168–4200

121–3400 5/16 Zoll ID (18) 245–5500

1–25 1/32 Zoll ID (13)* 2–55

6–185 1/16 Zoll I D ( 14) * 9–320

25–770 1/8 Zoll ID (16) 45–1250

60–1720 3/16 Zoll ID (25) 105–2850

- und PHARMED®-Schlauchgröße

TYGON®-Schlauchgröße

96–2800 1/4 Zoll ID (17) 174–4800

120–3500 5/16 Zoll ID (18) 236–5400

* Erforder t Pumpenschläuche. ID = Innendurchmesser

28

BETRIEB

Um optimale Anwendungsergebnisse zu gewährleisten, sind für MANOSTAT-Pumpen ausschließlich MANOSTATPräzisionsschläuche zu verwenden. Der Einsatz anderer Schläuche kann eine Verweigerung der Garantieleistung nach

sich ziehen.

EINLEGEN DES SCHLAUCHS

WARNHINWEISE: Bei Schlauchbruch wird u. U . Flüssigkeit v on der Pumpe ver spritzt. Geeignete Maßnahmen zum Schutz

von Bediener und Geräten ergreifen.

Vor dem Herausnehmen oder Einlegen von Schläuchen die Pumpe ausschalten, da sich andernfalls

Finger oder lose Kleidung im Antriebsmechanismus verfangen könnten.

1. Sicherstellen, dass der Netzschalter auf AUS steht.

2. Die beiden Flügelmuttern entfernen und dann die durchsichtige Kunststoffabdeckung vom Pumpenkopf abnehmen.

3. Pumpenschläuche: Das Ansaug- und A uslassende des T ransf erschlauchs an die V erbinder des Pumpenschlauchs anschließen.

Den Pumpenschlauch so einführen, dass die Stege oder Flansche des Pumpenschlauchs möglichst nahe an der Außenseite

des Pumpenkopfs liegen. Die Rolleneinheit von Hand drehen und den Schlauch zwischen den Rollen und der Pumpenkopfw and

einführen.

Fortlaufender Schlauch: Den Schlauch zwischen den Rollen und dem Gehäuse des Pumpenkopfs in der Mitte des Kanals

einführen (d.h. in der Mitte zwischen der durchsichtigen Kunststoffabdeckung des Pumpenkopfes und dem Boden des

Pumpenkopfgehäuses). Dadurch wird sichergestellt, dass die Rollen beim Drehen auf die gesamte Schlauchbreite Druck

ausüben. Die Rolleneinheit v on Hand drehen und den Schlauch zwischen den Rollen und der Pumpenkopfwand hindurchführen.

Bei V erwendung v on fortlaufendem Schlauch (keinen Pumpenschlauchstüc ken) sollte zwischen dem Schlauch und dem Gehäuse

des Pumpenkopfes über ca. 1/3 bis 1/2 der Berührungsfläche jederzeit ein kleiner, aber sichtbarer Spalt vorhanden sein.

Vorsichtig am Ansaug- und Auslassende des Schlauchs ziehen, so dass zwischen dem Schlauch und der gebogenen

Gehäusewand des Pumpenkopfs ein Spalt entsteht.

4. Die durchsichtige Kunststoffabdeckung wieder auf den Pumpenkopf aufsetzen und die Flügelmuttern fest anziehen, damit

sich der Schlauch während des Betriebs nicht verschiebt.

An Simon- und Vera-Modellen hat die durchsichtige Kunststoffabdeckung des Pumpenkopfs verschiedene Schlauchhalterungen

auf jeder Seite und kann umgedreht werden. Wenn der Innendurchmesser des Schlauchs weniger als 3/16 Zoll beträgt, die

Abdeckung so platzieren, dass der Schlauch von den größeren Schlauchhalterungen gehalten wird. Wenn der Innendurchmesser

des Schlauchs 3/16 Zoll (Größe 25) oder mehr beträgt, die Abdeckung umdrehen.

Nach Anbringen der durchsichtigen Kunstoffabdeckung auf dem Pumpenk opf von Preston-Modellen die beiden Schrauben auf der

Halteklemme so einstellen, dass sie den Schlauch arretieren. Wenn der Innendurchmesser des Schlauchs weniger als 3/16 Zoll

(Größe 25) beträgt und kein Pumpenschlauch verwendet wird, einen der folgenden Schritte ausführen, um zu verhindern, dass

der Schlauch in den Pumpenkopf wandert:

• den Schlauch an den Klemmpunkten zur Erhöhung der Griffigkeit mit einem kleinen Stück größeren Schlauch abdecken.

• am Einlass des Pumpenkopfes einen Schlauchverbinder verwenden.

OPTIMIERUNG DER SCHLAUCHHALTBARKEIT

Den Schlauch regelmäßig verschieben, so dass sich jeweils eine andere Schlauchlänge im Pumpenkopf befindet, oder den

Pumpenschlauch auswechseln. Dadurch wird vermieden, dass sich der Schlauch an einer Stelle frühzeitig abnutzt. Den abgenutzten

Schlauch immer zur Ansaugseite der Pumpe hin bewegen.

BEDIENELEMENTE DER PUMPE

ACHTUNG: Beim Ändern der Flussrichtung vor dem Neustart warten, bis die Pumpe vollständig zum Stillstand

gekommen ist, da es andernfalls zu einer permanenten Beschädigung des Motors kommen kann.

1. Sicherstellen, dass der Förderleistungsregler auf den niedrigsten Wert eingestellt ist.

2. Die Pumpe einschalten. Den Förderleistungsregler höher stellen, um den Pumpvorgang zu starten. Je höher die gewählte

Zahl, desto höher die Pumpendrehzahl.

3. VARISTALTIC-Pumpen sind selbstansaugend. Um mit dem Pumpen zu beginnen, mit dem Flussrichtungsschalter eine

Flussrichtung auswählen, den Ansaug- und Auslassschlauch in einen Behälter legen und die Pumpe einschalten. Den Schlauch

mindestens 5 Minuten lang vorfüllen. W enn eine genaue Regelung der Fördermenge wichtig ist, die Pumpe bis zu ca. 20 Minuten

vorfüllen, um stabilere Fließbedingungen zu schaffen.

29

FERNBETRIEB

BESCHREIBUNG

Modelle mit externen Ein- und Ausgängen können durch externe Signale gesteuert werden, die an den 9-poligen Steckverbinder

mit „D“-Gehäuse an der Rückwand angeschlossen werden. Die exter nen Eingänge erlauben die Steuerung der Pumpe durch

externe Geräte oder Zubehörteile. Abbildung 2 zeigt die Signalbelegung des Steckverbinders.

Pin-Nr. Beschreibung

Drehzahlregelung Spannungseingang (2 – 10 V) (+)

1

Eingang

2 Drehzahlregelung Stromeingang (4 – 20 mA) (+) Eingang

3 Drehzahlregelung Eingang Bezugsleiter

4 Extern/Lokal Drehzahl (+) Regelung

5 Extern/Lokal Bezugsdrehzahl (–) Rücklauf

6 Star t/Stopp Bezug (–) Rücklauf

7 Start/Stopp (+) Steuerung

8 Gestellerde

9 Gestellerde

Abbildung 2. DB9-Stiftbelegung mit

Verdrahtungsplan

EXTERNE EINGÄNGE

Die Fernbetriebsfunktionen werden über den Schalter FRONT PANEL/REMOTE (Frontplatte/Extern) aktiviert. Beim Schalten auf

FRONT PANEL werden die Fernbetr iebsfunktionen deaktivier t, und die Pumpe kann über die Bedienelemente an der Frontplatte

gesteuert werden.

Wenn der Schalter FRONT PANEL/REMOTE auf REMOTE steht, wird das Starten und Stoppen der Pumpe über eine externe

Kontaktschließung zwischen den Stiften 6 und 7 (Steckbrüche B) gesteuert, und die Pumpendrehzahl wird durch eine extern

bereitgestellte 2 – 10 V oder 4 – 20 mA Quelle bestimmt. Für den Betrieb der Pumpe muss zwischen den Stiften 6 und 7 eine

Verbindung hergestellt und eine Steuerspannung von mehr als 2 V bzw. ein Steuerstrom von mehr als 4 mA angelegt werden.

Wenn die Einstellung der Drehzahl von der Frontplatte aus über einen externen Star t/Stopp-Kontakt erfolgen soll, muss sich der

Schalter FRONT PANEL/REMOTE wieder in der Stellung REMOTE befinden. Ferner muss Steckbrücke A vorhanden sein.

Steckbrücke A verbindet Stift 5 des „D“-Gehäuse-Steckverbinders (REMOTE/LOCAL SPEED — Drehzahl extern/lokal) mit Stift 6

(RETURN — Rücklauf). Die Start/Stopp-Funktion wird dann von der Rückwand (Steckbrücke B) aus gesteuert, und die

Pumpendrehzahl wird von der Frontplatte aus gesteuert Der als Zubehör erhältliche Fußschalter (Artikelnr. 73-750-000) und der

Dosierstab (Artikelnr. 73-055-590) werden auf diese Weise intern verbunden.

Abbildung 3 zeigt vier typische Verdrahtungskonfigurationen: 2 – 10 V Folgeregler, 4 – 20 mA Folgeregler, als Zubehör erhältlicher

Dosierstab (oder Fußschalter) und die komplette Steuerung über die Frontplatte.

Abbildung 3. Anschlüsse an der Rückwand

30

HINWEIS: Das gemeinsame Bezugspotenzial für die Drehzahlreglerspannung und Stromeingänge ist geerdet.

In der Tabelle Übersicht über den Betrieb der Eingangsfunktionen wird der Betrieb der externen Eingänge zusammenfassend

dargestellt.

Übersicht über den Betrieb de r Ei ngangs funk ti onen

Betriebsartwahlschalter an

der Rückwand (MODE)

Front Panel

(Frontplatte)

Ein Aus X X Steuer ung nur über die Frontplatte

Aus Ein Vorhanden Vorhanden Frontplatte Externer Star t

Aus Ein Vorhanden Nicht vorhanden Frontplatte Externer Stopp

Aus Ein Nicht vorhanden Vorhanden Extern Externer Start

Aus Ein Nicht vorhanden Nicht vorhanden Extern Externer Stopp

Remote

(Extern)

Kurzschlussbrücke oder

Kontaktschluss

Steckbrücke „A“

(Stifte 4 und 5)

Steckbrücke „B“

(Stifte 6 und 7)

Aktivierte Funktionen

Drehzahl Start/Stopp

ERKLÄRUNG: X = nicht zutreffend

Der Eingang START/STOPP (Stift 7) und der Eingang REMOTE/LOCAL SPEED (Drehzahl extern/lokal) (Stift 4) sind digitale

Eingänge. Sie werden intern in Bezug auf die logische Masse (RETURNS) auf 15 V hochgesetzt. Alternativ können sie mit offener

Kollektorlogik betrieben werden. Für eine erhöhte Störfestigkeit wird die Verwendung von Kontaktschließungen empfohlen.

Aus = Nicht ausgewählt

Ein = Ausgewählt

31

WARTUNG

VORSICHT: Vor allen Wartungsarbeiten zuerst die Stromzufuhr zur Pumpe unterbrechen.

Die Schaltung für die Drehzahlregelung enthält wartungsfreie Halbleiterkomponenten. Bei einer übermäßigen Belastung des Systems kann jedoch die Sicherung durchbrennen. Ein Anzeichen für eine übermäßige Belastung ist ein Schalter , der nicht aufleuchtet,

wenn die Pumpe mit Strom versorgt wird und der Netzschalter auf EIN steht. In diesem F all die Stromzufuhr zum Gerät unterbrechen

und die Sicherung aus dem Sicherungshalter an der Rückwand der Pumpe nehmen. Die Sicherung gegen eine Sicherung des

gleichen Typs und der gleichen Nennleistung auswechseln. Diese Daten sind auf der Rückseite des Geräts vermer kt.

ACHTUNG: Die Sicherung nur gegen eine Sicherung des gleichen Typs und der gleichen Nennleistung auswechseln.

Die Nennleistung der Sicherung und der Sicherungstyp sind auf der Rückwand angegeben.

Die Lebensdauer der Kohlebürsten und des K ommutators hängt vom Einschaltzyklus und der Betriebsdrehzahl ab. Die K ohlebürsten

müssen alle 6 Monate oder nach jeweils 2000 Betriebsstunden geprüft werden, wobei der jeweils frühere Termin gilt, oder wenn

sich Fehler in der Anwendung bemerkbar machen. Auswechseln, wenn eine Bürste bis auf weniger als 7,6 mm abgenutzt ist. Der

Kommutator muss regelmäßig geprüft und ggf. gereinigt werden. Wenn keine vorbeugende Wartung durchgeführt wird, wird durch

übermäßigen Kommutatorverschleiß oder eine „Überbrückung“ zwischen den Kommutatorsegmenten ein zu hoher Strom durch

die Steuerungschaltung geführt.

Diese Modelle haben einen Zahnriemen, der nach dem gleichen Zeitplan wie die Bürsten auf Verschleiß geprüft werden muss. Das

V orhandensein von etwas Riemenstaub an oder im Inneren der Pumpe ist normal und beeinträchtigt den Betrieb der Pumpe nicht.

Bei Riemenschlupf die Spannung nachstellen. Hierzu die Motormuttern, mit denen der Motor an der Motorhalterung befestigt ist,

lösen und den Motor von der Platine weg kippen. Nach der Einstellung die Mutter wieder anziehen. Den Riemen nicht zu stark

spannen, da dies zu vorzeitigem Verschleiß von Antriebsriemen und Lager und zu Geräuschentwicklung führen kann. Ein

durchgescheuerter oder Risse aufweisender Riemen muss ausgewechselt werden. (Siehe ERSATZTEILE.)

REINIGEN

VORSICHT,

LEBENSGEFAHR: Vor allen Reinigungsarbeiten zuerst die Stromzufuhr unterbrechen.

Das Pumpengehäuse mit einem milden Reinigungsmittel sauber halten. Beim Reinigen die Pumpe niemals eintauchen oder zu

viel Flüssigkeit verwenden.

ERSATZTEILE

Beschreibung Artikelnummer Stckz.

Kohlebürsten (2) A-4343-CR 2

Kohlebürstenkappe (1) A-3190-CR 1

Motorbaugruppe 90 V D-3080-0001 1