Page 1

MANNHART, INC.

651 Industrial Boulevard

Grapevine, Texas 76051

Tel.: (817) 421-0100

Fax: (817) 421-0246

www.mannhart.com

MANNHART

MANNHART

OPERATING / TECHNICAL MANUAL

Made in U.S.A.

COMPLETE RANGE OF SLICERS,

DICING GRIDS AND SHREDDERS

AVAILABLE.

EACH ACCESSORY SUPPLIED

WITH STORAGE SYSTEM.

PRINTED IN U.S.A. ©2001 MANNHART, INC.

Rev.01/2005

Vegetable Cutters

Model M2000 - 115V-1/2 HP

Model M3000 - 115V-3/4 HP

Page 2

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

INDEX:

PAGE 1 TECHNICAL INFORMATION

PAGE 2 ACCESSORIES: SLICERS & SHREDDERS

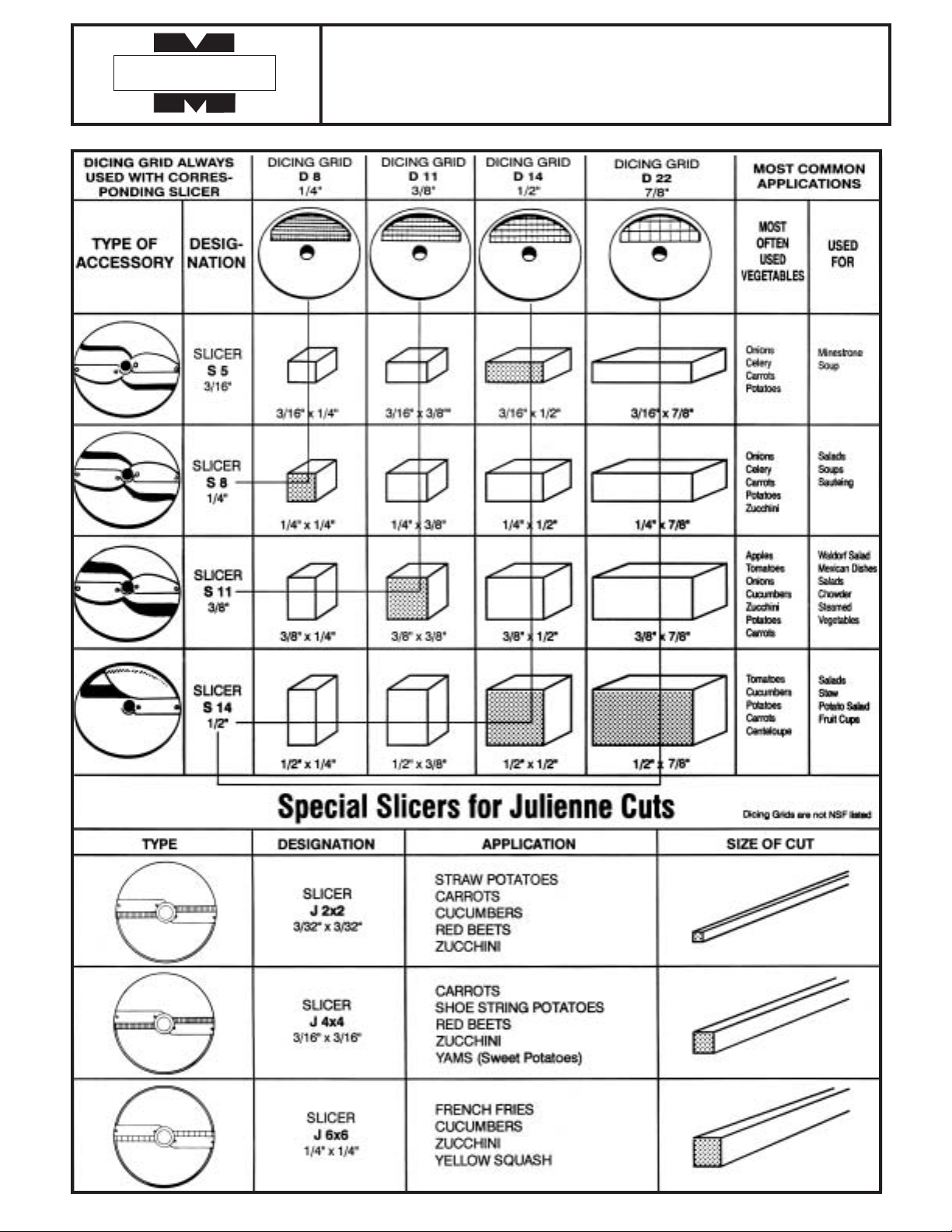

PAGE 3 DICING ACCESSORIES

SPECIAL SLICER FOR JULIENNE CUTS

OPERATING INSTRUCTIONS

PAGE 4 OPERATING INSTRUCTIONS INDEX

PAGE 5 SAFETY NOTES/VIDEO TRAINING TAPE

PAGE 6 INSTALLING & REMOVING FEED HOPPER LID

PAGE 7 INSTALLING & REMOVING SLICERS & SHREDDERS

PAGE 8 INSTRUCTIONS: INSTALLING & REMOVING DICING GRIDS

& CORRESPONDING SLICERS

PAGE 9 DIAGRAM: INSTALLING & REMOVING DICING GRIDS

& CORRESPONDING SLICERS

PAGE 10 CLEANING

PREVENTATIVE MAINTENANCE

PAGE 11 TROUBLE SHOOTING GUIDE

PAGE 12 WORK STATION - MACHINE DIMENSIONS

(Cruise Ship and Navy Vessel Mounting)

TECHNICAL DATA AND PARTS LIST

PAGE 14 OVERALL SIDE VIEW

PAGE 15 FEED HOPPER LID

PAGE 16-17 INTERNAL VIEWS

PAGE 18 ELECTRICAL WIRING DIAGRAM

PAGE 19 ELECTRICAL WIRING DIAGRAM WITH TRIAC ASSEMBLY

PART S LIST

PAGE 20-23 PARTS LIST

ACCESSORIES AND ACCESSORIES PARTS LIST

PAGE 26 SLICERS & SHREDDERS

PAGE 27 DICING ACCESSORIES

SPECIAL SLICERS FOR JULIENNE CUTS

PAGE 28 REPLACEMENT CUTTING EDGES & SHREDDER PLATES

PAGE 29 REPLACEMENT CUTTING EDGES & JULIENNE BARS

PAGE 30 EJECTORS

STORAGE RACK

PAGE 31-32 ACCESSORIES AND PARTS LIST FOR M2000/M3000

Page 3

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

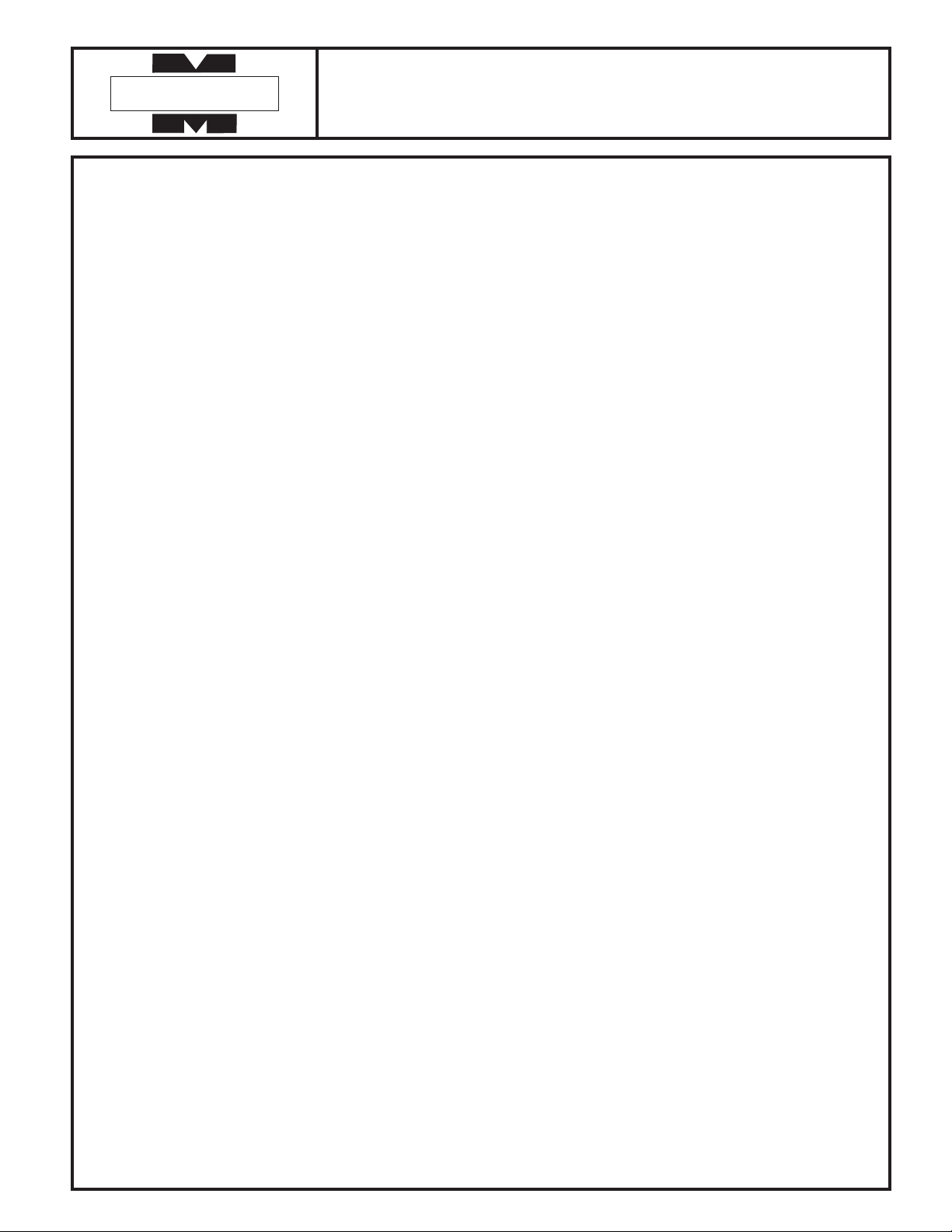

CAPACITY

MODEL SLICING DICING MOTOR DIMENSIONS WEIGHT TRANSMISSION

lbs/hr

1/2 HP A 20.375" (520mm)

41 lbs.

M2000 600-650 650-800 115/60/1 B 18.25" (465mm) Poly V-Belt

(18kg)

7.5 AMPS C 8.5" (216mm)

3/4 HP A 23.25" (590mm)

56 lbs.

M3000 800-900 1400-1500 115/60/1 B 18.25" (465mm) Poly V-Belt

(25.5kg)

10.8 AMPS C 8.5" (216mm)

WARRANTY: One Year, Parts and Labor. (Cutting edges and dicing grids not included.)

1

● COMPACT AND STURDY DESIGN

ALL CAST ALUMINUM AND STAINLESS STEEL

● AT TACHMENTS ARE FULLY INTERCHANGEABLE

WITHOUT TOOLS

● HIGH OUTPUT, SAVES TIME AND LABOR COST

● SIMPLE TO OPERATE AND EASY TO CLEAN

● SAFE - UL LISTED, NSF

● MADE IN U.S.A.

Page 4

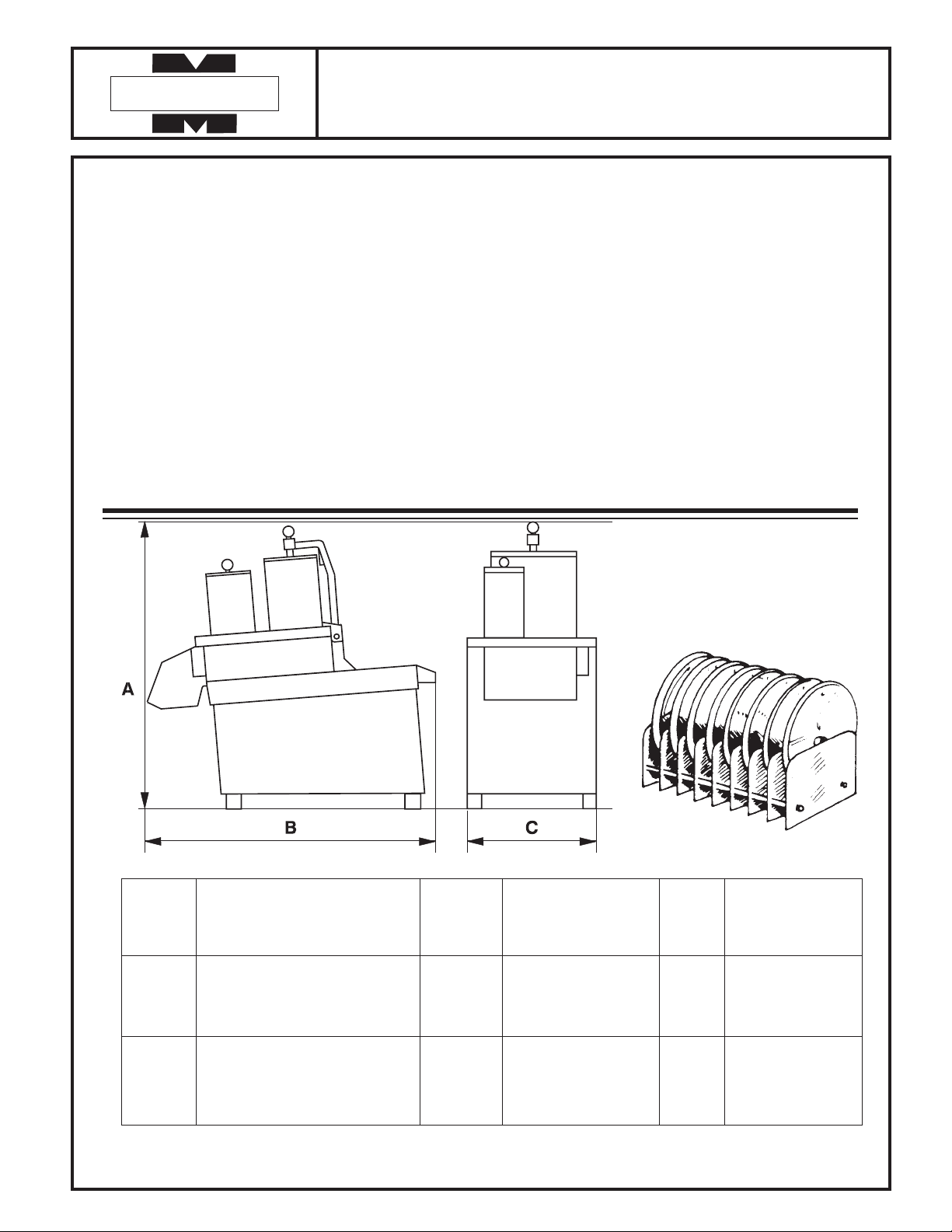

2

TYPE DESIGNATION SOME APPLICATIONS SIZE OF CUT

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

SLICER S2

2 mm (1/16")

SLICER S3

3 mm (1/8")

SLICER S5

5 mm (3/16")

SLICER S5C

CRINKLE CUT

5 mm (1/4")

SHREDDER SH2

Extra Fine

2 mm (1/32")

SHREDDER SH3

3 mm (1/8")

SHREDDER SH4

4 mm (3/16")

SHREDDER SH7

7 mm (7/32")

SHREDDER SHP

Fine

Coleslaw

Radishes

Onions

Cucumbers

Carrots, Celery

Cucumbers

Zucchini, Mushrooms

Lettuce for Tacos

Scalloped Potatoes

Cucumbers, Carrots

Zucchini/Squash

Tomatoes

Carrots

Potatoes

Cucumbers

Carrot Salad Raw

Root Celery Salad

Parmesan Cheese

Carrots Julienne

Cheese for Tacos

and Salads

Carrots

Cheese

Hash Browns

Carrots

Cheese for Pizza

Hash Browns

Parmesan Cheese

Bread Crumbs

Page 5

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

3

Page 6

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

4

OPERATING INSTRUCTIONS

● SAFETY NOTES

● VIDEO TRAINING TAPE OR CD-ROM

● INSTALLING OF SLICERS & SHREDDERS

● INSTALLING OF DICING GRIDS WITH

CORRESPONDING SLICERS

● CLEANING

● PREVENTATIVE MAINTENANCE OF

MACHINE AND ACCESSORIES

● TROUBLE SHOOTING GUIDE

● WORK STATION RECOMMENDATIONS

(Cruise Ship and Navy Vessel mounting)

Page 7

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

5

OPERATING INSTRUCTIONS

SAFETY

WARNING: Injury to the operator and damage to the machine can

result from incorrect use of this vegetable cutter. Read these instructions

carefully and be sure that all users of the Mannhart Begetable Cutter are

trained before being allowed to use the vegetable cutter.

CAUTION: Always use large and small SAFETY PUSHERS when

operating the Mannhart Vegetable Cutter. Do not insert hands or fingers

into the feed hopper openings while machine is operating.

The Mannhart Vegetable Cutter is equipped with a magnetic interlock

between the feed hopper lid and the power base. The interlock prevents

the machine from operating unless the feed hopper lid is in the proper

position.

ALWAYS unplug the power cord before CLEANING the machine or at

any time while the machine is not in use.

VIDEO TRAINING TAPE OR CD-ROM FOR

MANNHART VEGETABLE CUTTER

Every Mannhart Vegetable Cutter is supplied with a VIDEO TRAINING

TAPE OR CD-ROM.

Ensure that the operator reviews the training tape/CD-Rom before

operating the machine. The training tape/CD-Rom demonstrates the

proper use and SAFETY procedures to be followed.

Page 8

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

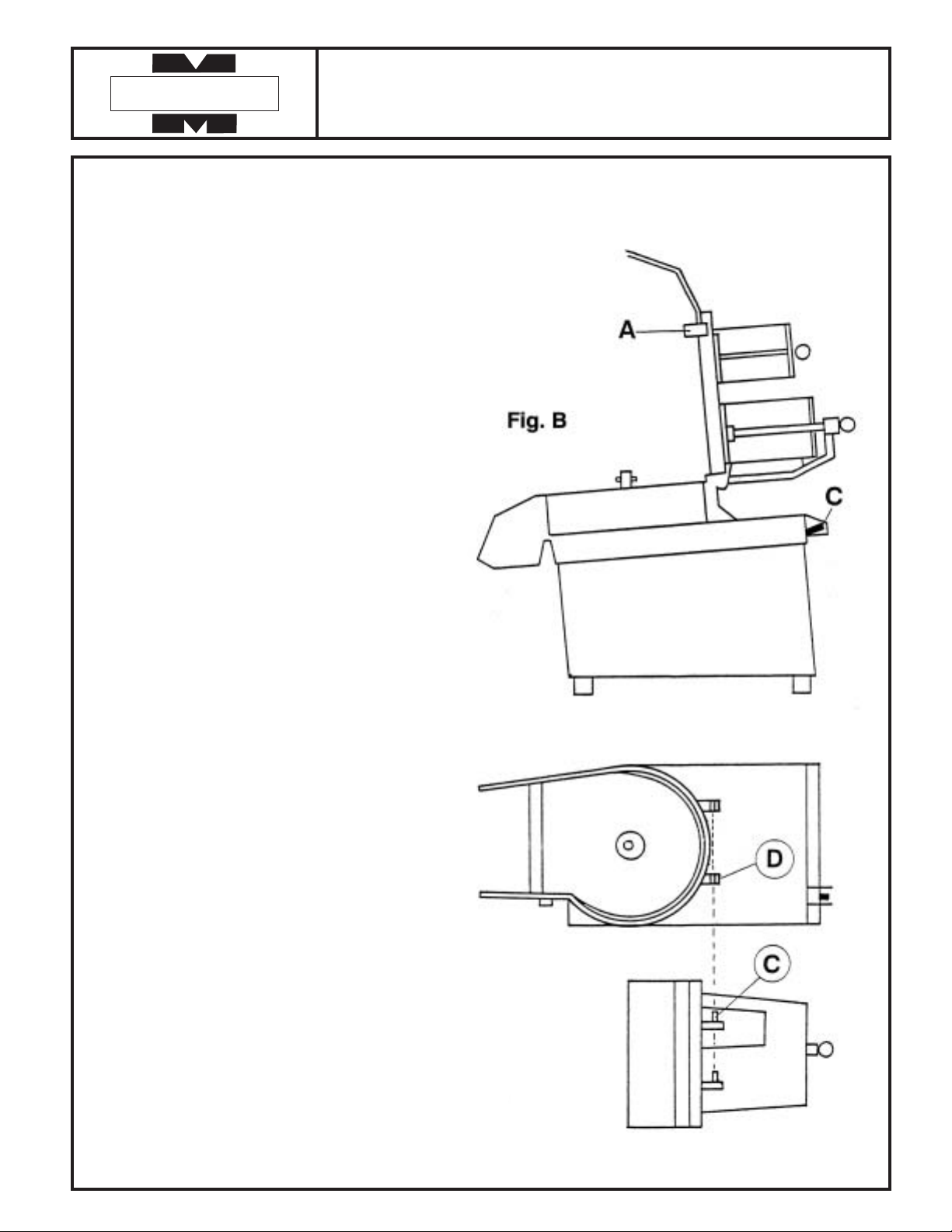

INSTALLING & REMOVING

FEED HOPPER LID

REVIEW THE MANNHART VIDEO

TRAINING TAPE PRIOR TO USING

YOUR NEW MANNHART VEGETABLE

CUTTER. READ THE OPERATING

INSTRUCTIONS CAREFULLY.

WARNING: Always ensure that the

ON/OFF switch (C) is in the OFF

POSITION prior to installing or removing

accessories.

REMOVING THE FEED HOPPER LID

Disengage the magnetic toggle lock (A) and

open the feed hopper lid to the upright

position (B). Slide feed hopper lid away

from the vegetable cutter body.

INSTALLING THE FEED HOPPER LID

To install the feed hopper lid, hold the feed

hopper lid in the upright position and line

up the long hinge pin (C) with the pin hole

(D). Slide feed hopper lid towards the

vegetable cutter base until both hinge pins

are fully engaged. Close feed hopper lid.

6

Page 9

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

7

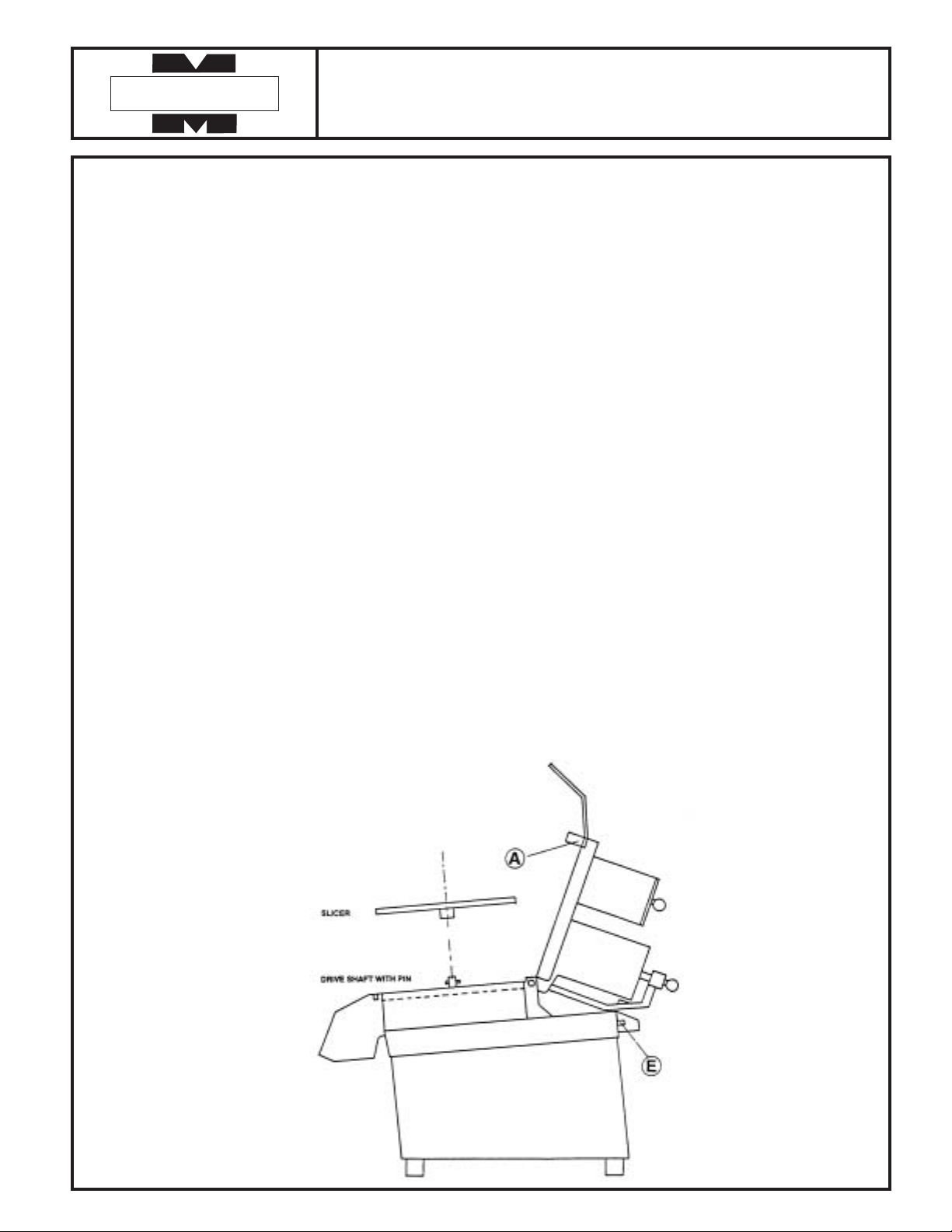

INSTALLING & REMOVING SLICERS

& SHREDDERS

OPERATING INSTRUCTIONS

INSTALLING OF SLICERS, JULIENNE SLICERS AND SHREDDERS

Disengage the magnetic toggle lock (A) and open the feed hopper lid until it rests on the back of

the base.

Select the desired SLICER and place it onto the drive shaft until the top of the slicer is flush with

the top end of the drive shaft. Close the feed hopper lid and engage the magnetic toggle switch.

Turn the ON/OFF SWITCH into the ON POSITION and start slicing your vegetables, either using

the small or large feed hopper tube.

REMOVING OF SLICING ACCESSORIES

Turn ON/OFF SWITCH to OFF POSITION (E). Disengage magnetic toggle lock (A) and open feed

hopper lid until it rests on the back of the base.

Hold SLICER with both hands and rotate counter clockwise until the slicer bushing is disengaged

from the drive shaft pin. Lift SLICER off the drive shaft, clean it and place the SLICER back into

the storage rack which is automatically supplied with your new MANNHART Vegetable Cutter.

Clean your MANNHART Vegetable Cutter - SEE CLEANING - and close feed hopper lid. Unplug

the power supply cord while the MANNHART Vegetable Cutter is not in use.

Page 10

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

8

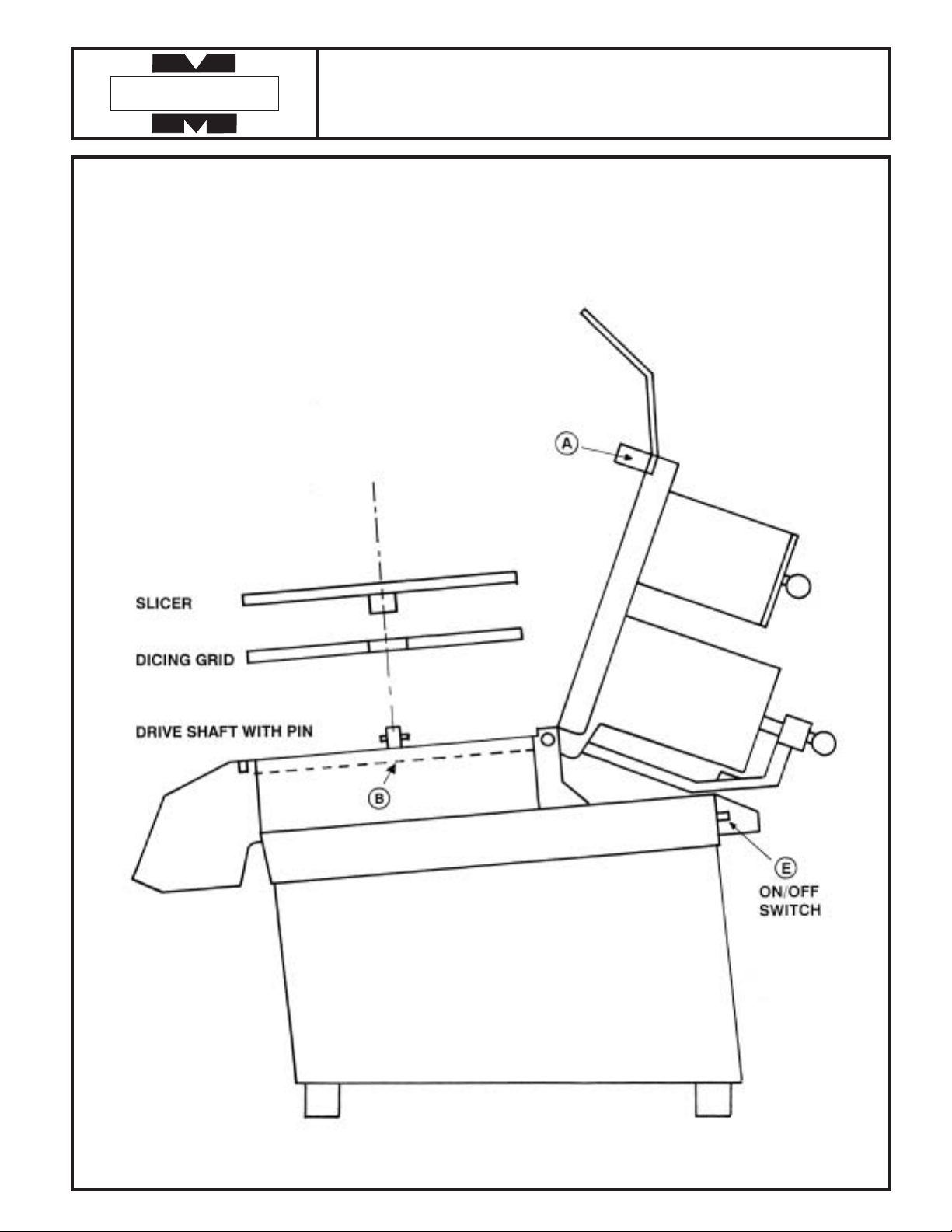

INSTALLING & REMOVING DICING GRIDS

& CORRESPONDING SLICERS

REVIEW THE MANNHART VIDEO TRAINING TAPE PRIOR TO USING YOUR NEW

MANNHART VEGETABLE CUTTER. READ THE OPERATING INSTRUCTIONS

CAREFULLY.

WARNING: Always ensure that the ON/OFF switch is in the OFF position prior to

installing or removing accessories.

INSTALLING OF DICING GRIDS WITH DICING SLICERS

Disengage the magnetic toggle lock (A) and open the feed hopper lid until it rests on the back

of the base.

Select the desired DICING GRID and install it INTO THE TOP SEAT of the cutting compartment (B), top surface of DICING GRID facing up. (Size mark is located on top surface of grid D8, D11, D14, D22). DICING GRID MUST BE FLUSH with the top rim of the cutting

compartment.

Install the corresponding DICING SLICER (S8 with D8, S11 with D11, S14 with D14 or D22)

by placing the SLICER onto the drive shaft above the DICING GRID. Top surface of slicer

must be flush with top of drive shaft.

Close the feed hopper lid and engage the magnetic toggle lock. Turn the ON/OFF switch to the ON

position.

IMPORTANT: Dice vegetables through the large feed hopper tube only!

REMOVING OF SLICING AND DICING ACCESSORIES

Turn ON/OFF SWITCH to OFF POSITION (E). Disengage magnetic toggle lock (A) and open feed

hopper lid until it rests on the back of the base.

Hold SLICER with both hands and rotate counter clockwise until the slicer bushing is

disengaged from the drive shaft pin. Lift SLICER off the drive shaft, clean it and place the

SLICER back into the storage rack which is automatically supplied with your new

MANNHART Vegetable Cutter.

CLEAN THE DICING GRID WITH A CARROT WHILE THE GRID IS STILL LOCATED

in the cutting compartment. We recommend the use of a carrot to push the remaining vegetables

through the grid - SEE VIDEO TAPE DEMONSTRATION.

Place DICING GRID into the storage rack and CLEAN your MANNHART Vegetable Cutter SEE CLEANING - and close feed hopper lid. Unplug the power supply cord while storing the

MANNHART Vegetable Cutter in between uses.

Page 11

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

9

INSTALLING & REMOVING DICING GRIDS

& CORRESPONDING SLICERS

Page 12

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

10

CLEANING

WARNING: Unplug unit from power supply prior to cleaning.

REMOVE FEED HOPPER LID and rinse thoroughly under running water.

NEVER USE DISHWASHER. Feed hopper lid may be soaked in sanitizing

lotion if desired.

HAND WIPING or RINSING of the cutting compartment of the Mannhart

Vebetable Cutter is recommended. Do not use pressure washer inside the

cutting compartment.

WARNING: The SLICING AND DICING ACCESSORIES are

equipped with SHARP KNIVES. Use caution when rinsing the accessories

or when sanitizing. NEVER PLACE ACCESSORIES INTO THE DISHWASHER and NEVER LEAVE ACCESSORIES submerged in sanitizing

lotion unless attended by operator. IMMEDIATELY REMOVE accessories

from sanitizing lotion after soaking and store in accessories storage rack in

safe and visible place.

REVIEW THE MANNHART VIDEO TRAINING TAPE FOR

ADDITIONAL CLEANING AND HANDLING INSTRUCTIONS

PREVENTATIVE MAINTENANCE

WARNING: The power cord must be disconnected prior to the start of

any inspection or check-up.

ALWAYS REMOVE ANY ACCESSORIES from the Mannhart Vegetable

Cutter prior to any maintenance or inspection.

The Mannhart Vegetable Cutter does not require periodic maintenance. All

moving internal parts are quipped with DOUBLE SEALED BALL

BEARINGS which are maintenance free. NO LUBRICATION REQUIRED.

DO NOT DIRECT water pressure or steam directly to the housing or

bottom of the vegetable cutter.

Page 13

11

TROUBLE SHOOTING GUIDE

MACHINE DOES NOT START

— Check power supply cord and outlet.

— Check whether feed hopper is properly installed and locked in place.

— Check whether magnet in toggle lock is intact. (Part #2110)

VEGETABLES WHEN DICING ARE NOT CONSISTENTLY

DICED

— Ensure, when dicing, that you use large feed opening only.

(See operating instructions)

— Place vegetables in hopper while machine is in OFF position.

Place pusher on vegetables and exert sufficient pressure so that

vegetables are in contact with slicer.

— When dicing celery and onions, while machine is running, feed one

onion at a time and use pusher to hold onion or celery onto knife.

— Cutting edges on slicer or dicing grid are not sharp.

NOTE: It is important that constant pressure be applied on

the vegetables.

VEGETABLE CUTTER STALLS WHEN DICING OR

SHREDDING CHEESE

— Check tension of Poly-V-Belt. (Consult parts manual and service

technician)

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

Page 14

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

12

MODEL MOTOR DIMENSIONS WEIGHT

MANNHART 1/2 HP A 20.375" (520mm) 41 lbs.

2000 115/60/1 B 18.25" (465mm) (17.5 kg)

C 8.5" (216mm)

MANNHART 3/4 HP A 23.25" (533mm) 56 lbs.

M3000 115/60/1 B 18.25" (465mm) (25.5kg)

C 8.5" (216mm)

MODEL MOTOR DIMENSIONS WEIGHT

MANNHART 1/2 HP A 10.375" (260mm) 41 lbs.

2000 115/60/1 B 7.2" (183mm) (18.5 kg)

7.5 Amps

MANNHART 3/4 HP A 10.375" (260mm) 58 lbs.

M3000 115/60/1 B 7.2" (183mm) (26kg)

10.8 Amps

MODEL MOTOR DIMENSIONS WEIGHT

MANNHART 1/2 HP A 24.375" (572mm) 41 lbs.

2000 115/60/1 B 18.25" (465mm) (17.5 kg)

C 8.5" (216mm)

Navy Legs

Extension D 4.0" (102mm)

MANNHART 3/4 HP A 27.25" (635mm) 58 lbs.

M3000 115/60/1 B 18.25" (465mm) (26kg)

C 8.5" (216mm)

Navy Legs

Extension D 4.0" (102mm)

WORK STATION - MACHINE DIMENSIONS

(Cruise Ship and Navy Vessel Mounting)

TABLE TOP (Freestanding)

TABLE TOP (Permanent Installation) - Cruise Ship and Navy

MOUNTING DIMENSIONS FOR PERMANENT TABLE TOP

INSTALLATION

D

Page 15

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

13

TECHNICAL DATA

AND

PARTS LIST

Page 16

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

14

OVERALL SIDE VIEW

Page 17

15

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

Page 18

16

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

Page 19

17

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

Page 20

18

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

MODEL M2000 and M3000

MOTOR

White

Black

ON/OFF SWITCH

Black

Ground

WHITE

ELECTRICAL WIRING DIAGRAM

CONTACT NORMALLY OPEN

REED SWITCH

RELAY

4

B

3

A

NOTE: The Reed Switch is a magnetically operated safety switch. It is not a fuse.

The contact closes when the Magnet in the toggle lock locates above the Reed Switch.

REED SWITCH ASSEMBLY WITH WIRES FOR M2000 (PART #2322-B)

REED SWITCH ASSEMBLY WITH WIRES FOR M3000 (PART #2322-C)

Page 21

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

19

MODEL M2000 and M3000

MOTOR

White

Black

ON/OFF SWITCH

Black

Ground

WHITE

ELECTRICAL WIRING DIAGRAM

PUSHER SAFETY

REED SWITCH

CONTACT NORMALLY OPEN

REED SWITCH

TRIAC

RELAY

4B

3A

NOTE: The Reed Switch is a magnetically operated safety switch. It is not a fuse.

The contact closes when the Magnet in the toggle lock locates above the Reed Switch.

REED SWITCH / TRIAC ASSEMBLY FOR MAGNETIC SAFETY PUSHER (PART #2322-A)

Page 22

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

20

QUANTITY

PART# DESCRIPTION PER MACHINE

2100 FEED HOPPER LID (STANDARD) WITH MOUNTING 1

PINS BUT WITHOUT TOGGLE LOCK AND FIXED

PUSHER ASSEMBLY

2100-A FEED HOPPER LID COMPLETE WITH MOUNTING 1

PINS, TOGGLE LOCK AND FIXED PUSHER

ASSEMBLY

2105 PUSHER, SMALL 1

2106 PUSHER, LARGE (LOOSE) 1

2107 KNOB FOR PUSHERS #2105 & 2106 1

2108 FIXED PUSHER ASSEMBLY, COMPLETE 1

WITH MOUNTING PIN

2108-A FIXED PUSHER ARM WITH NYLON BUSHING 1

2108-B PUSHER PLATE WITH HEXAGON ROD 1

2108-C KNOB ASSEMBLY FOR FIXED PUSHER ONLY 1

2108-D MOUNTING PUSHER PIN 1

2108-H FIXED PUSHER ARM WITH NYLON BUSHING 1

AND MAGNET FOR SAFETY PUSHER

2108-MP FIXED PUSHER ASSEMBLY COMPLETE WITH 1

2 MAGNETS AND MOUNTING PIN

2110 TOGGLE LOCK WITH MAGNET 1

2110-A MAGNET ONLY FOR TOGGLE LOCK #2110 1

2110-B MAGNET ONLY FOR MAGNETIC SAFETY PUSHER 1

2111 SHOULDER BOLT FOR TOGGLE 1

2111-A STAINLESS STEEL SCREW FOR ROLLER 1

2112 ROLLER FOR TOGGLE LOCK 1

2113 HOPPER HINGE PIN (LONG) 1

2114 HOPPER HINGE PIN (SHORT) 1

2200 BODY - POLISHED CAST ALUMINUM 1

2207 DRIVE SHAFT COMPLETE WITH DRIVE PIN 1

Page 23

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

21

QUANTITY

PART# DESCRIPTION PER MACHINE

2208 DRIVE PIN (FOR SLICERS) 1

2208-A DRIVE PIN (FOR EJECTOR) 1

2209 KEY FOR DRIVE SHAFT 1

2209-A HEXAGON BOLT WITH WASHERS TO FASTEN 1

LARGE PULLEY

2210 WIPER BLADE FOR NSF EJECTOR 1

2210-A SCREW FOR WIPER BLADE 2

2211-NSF NSF EJECTOR WITH WIPER BLADE 1

2211-ED EJECTOR DISC 1

2212 SEAL G 30 X 40 X 4 1

2213 BALL BEARING - Upper #6203 LLB 1

2214 BALL BEARING - Lower #6303 LLB 1

2215 RETAINING RING FOR DRIVE SHAFT 1

2301 MOTOR MOUNTING BOLT M6 WITH 4

LOCKWASHER FOR M2000

3301 MOTOR MOUNTING BOLT WITH 4

LOCKWASHER FOR M3000

2303 MOTOR 115/60/1 - 1/3 HP M2000 1

2303-A MOTOR 115/60/1 - 1/2 HP M2000 1

2304 MOTOR EXPORT 230/50/1 1

1/3 HP M2000

3305 MOTOR 115/60/1 - 3/4 HP M3000 1

3305-A MOTOR EXPORT 230/60/1 - 3/4 HP M3000 1

3306 MOTOR EXPORT 230/50/1 - 3/4 HP M3000 1

2310 ON/OFF TOGGLE SWITCH 1

2311 POWER SUPPLY CORD WITH MOLDED PLUG 1

FOR M2000

3311 POWER SUPPLY CORD WITH MOLDED PLUG 1

FOR M3000

2311-E POWER SUPPLY CORD FOR M2000 - EXPORT 1

Page 24

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

22

QUANTITY

PART# DESCRIPTION PER MACHINE

3311-E POWER SUPPLY CORD FOR M3000 - EXPORT 1

2312 CABLE RELIEF BUSHING 1

2313 SUPPORT LEG REAR WITH NUT/LOCKNUT FOR M2000 2

2313-A SUPPORT LEG FRONT WITH NUT/LOCKNUT FOR M2000 2

3314 SUPPORT LEG REAR WITH NUT/LOCKNUT FOR M3000 2

3314-A SUPPORT LEG FRONT WITH NUT/LOCKNUT FOR M3000 2

2316 RUBBER FOOT WITH THREADED INSERTS 4

2317 UL ROD WITH NUT/LOCKNUT FOR M2000 1

3317 UL ROD WITH NUT/LOCKNUT FOR M3000 1

3317-D ACORN NUT SS FOR UL ROD 1

2318 MIDTEX RELAY - 115V/60/1 FOR M2000 / M3000 1

2318-A MIDTEX RELAY - 115V/60/1 FOR M2000 1/2 HP 1

2318-E MIDTEX RELAY - 230/50/1 FOR EXPORT 1

2319 MOUNTING BAR FOR UL ROD AND RELAY 1

2320 RELAY MOUNTING SCREW WITH LOCKWASHER 2

2322-A REED SWITCH / TRIAC ASSEMBLY FOR MAGNETIC 1

SAFETY PUSHER

2322-B REED SWITCH ASSEMBLY WITH WIRES FOR M2000 1

2322-C REED SWITCH ASSEMBLY WITH WIRES FOR M3000 1

2323 REED SWITCH MOUNTING BRACKET WITH 1

SCREW AND LOCKWASHER

2325 PULLEY LARGE 1

2325-E PULLEY LARGE, EXPORT 1

2326 POLY-V-BELT 240J6 1

2327 MOTOR PULLEY FOR M2000 1

2327-A HEXAGON BOLTS M5 WITH WASHERS FOR 1

M2000 MOTOR PULLEY

Page 25

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

23

QUANTITY

PART# DESCRIPTION PER MACHINE

2327-D KEY FOR M2000 MOTOR PULLEY 1

2327-E MOTOR PULLEY FOR M2000 EXPORT 230/50/1 1

3327 MOTOR PULLEY WITH SET SCREW FOR M3000 1

3327-D KEY FOR M3000 MOTOR PULLEY 1

3327-E MOTOR PULLEY WITH SET SCREW FOR M3000 1

EXPORT

2328 BELT TENSION BOLT WITH LOCKWASHER 1

FOR M2000

3328 BELT TENSION BOLT WITH LOCKWASHER 1

FOR M3000

2331 MOTOR MOUNTING FLANGE FOR M2000 1

2333 FASTENING BOLT WITH WASHERS FOR MOTOR 2

FLANGE TO M2000 BODY

2334 SPLIT LOCKWASHER FOR MOTOR FLANGE BOLTS 1

M2000

2335 WASHER FOR MOTOR FLANGE BOLTS FOR M2000 1

3332 MOTOR MOUNTING FLANGE FOR M3000 1

3332-E MOTOR MOUNTING FLANGE FOR M3000 EXPORT 1

3333 FASTENING BOLT WITH WASHERS FOR MOTOR 4

FLANGE TO M3000 BODY

3334 SPLIT LOCKWASHER FOR MOTOR FLANGE BOLTS 1

M3000 1

3335 WASHER FOR MOTOR FLANGE BOLTS FOR M3000 1

2349 HOUSING SS FOR M2000 1

3350 HOUSING SS FOR M3000 1

SPECIAL ACCESSORIES

2500 DIAMOND FILE TO SHARPEN CUTTING EDGES 1

AND DICING GRIDS

Page 26

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

24

Page 27

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

25

ACCESSORIES

AND

ACCESSORIES

PARTS LIST

Page 28

26

TYPE DESIGNATION SOME APPLICATIONS SIZE OF CUT

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

SLICER S2

2 mm (1/16")

SLICER S3

3 mm (1/8")

SLICER S5

5 mm (3/16")

SLICER S5C

CRINKLE CUT

5 mm (1/4")

SHREDDER SH2

Extra Fine

2 mm (1/32")

SHREDDER SH3

3 mm (1/8")

SHREDDER SH4

4 mm (3/16")

SHREDDER SH7

7 mm (7/32")

SHREDDER SHP

Fine

Part # 2401

Part # 2402

Part # 2403

Part # 2403CC

Part # 2410

Part # 2411

Part # 2412

Part # 2413

Part # 2415

Page 29

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

27

Page 30

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

28

Page 31

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

29

Page 32

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

30

Page 33

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

31

ACCESSORIES AND PARTS LIST FOR M2000 / M3000

Slicers, Julienne Slicers, Shredders & Dicing Grids

Part # Description

2400 SLICER S1

2401 SLICER S2

2402 SLICER S3

2403 SLICER S5

2403-CC SLICER S5C (Crinkle Cut)

2404 SLICER S8

2405 SLICER S11

2406 SLICER S14

2407 JULIENNE SLICER J2X2

2408 JULIENNE SLICER J4X4

2409 JULIENNE SLICER J6X6

2410 SHREDDER SH2

2411 SHREDDER SH3

2412 SHREDDER SH4

2413 SHREDDER SH7

2415 SHREDDER SHP

2416 DICING GRID D8

2417 DICING GRID D11

2418 DICING GRID D14

2419 DICING GRID D22

2421 SPECIAL GRIDS

Page 34

Vegetable Cutters

Mannhart M2000 / M3000

MANNHART

32

ACCESSORIES AND PARTS LIST FOR M2000 / M3000

Shredder Frames and Plates only (unassembled)

Part # Description

2422 SHREDDER FRAME FOR SH2, SH3

2423 SHREDDER FRAME FOR SH4, SH7, SHP

2475 SHREDDER PLATE ONLY FOR SH2

2476 SHREDDER PLATE ONLY FOR SH3

2477 SHREDDER PLATE ONLY FOR SH4

2478 SHREDDER PLATE ONLY FOR SH7

2479 SHREDDER PLATE ONLY FOR SHP

Cutting Edges and Cutting Bars for Slicers and Julienne Slicers

Part # Description

2431 CUTTING EDGE FOR SLICERS S2, S3, S5, S8, S11

2432 CUTTING EDGE FOR SLICER S14

2433 CUTTING EDGE FOR JULIENNE SLICERS J2X2, J4X4, J6X6

2434 SCREWS FOR CUTTING EDGES

2435 SCREWS FOR CUTTING BARS

2435-A SCREWS FOR SHREDDER PLATES

2436 CUTTING BAR FOR JULIENNE SLICER J2X2

2437 CUTTING BAR FOR JULIENNE SLICER J4X4

2438 CUTTING BAR FOR JULIENNE SLICER J6X6

Page 35

MANNHART

MANNHART, INC.

651 INDUSTRIAL BOULEVARD

GRAPEVINE, TEXAS 76051

TELEPHONE: (817) 421-0100

FAX: (817) 421-0246

www.mannhart.com

Loading...

Loading...