Mannhart HCO100E Installation Manual

Operator & Installation

HYBRID CONVECTION OVEN

Manual

HCO100E ML-132502

Model Number: ___________

Serial Number: ___________

Date of Installation: ___________

Baxter Mfg, a Division of ITW FEG, LLC • 19220 State Route 162 East • Orting, WA 98360-9236

Phone: (360) 893-5554 • Fax: (360) 893-1337

www.baxterbakery.com

FORM 36714 Rev. A (January 2010)

TABLE OF CONTENTS

GENERAL ............................................................................................................................................. 3

INSTALLATION ..................................................................................................................................... 3

Installation Codes and Standards .................................................................................................... 4

Location ........................................................................................................................................... 4

Assembly ......................................................................................................................................... 4

Water Requirements ........................................................................................................................ 4

Plumbing Connections ..................................................................................................................... 5

Drain Connections ........................................................................................................................... 5

Electrical Connections ..................................................................................................................... 5

Vent Hood ........................................................................................................................................ 5

Dimensions Diagram ....................................................................................................................... 6

OPERATION .......................................................................................................................................... 8

Door Opening and Closing .............................................................................................................. 8

Controls ........................................................................................................................................... 8

Setting the Clock ........................................................................................................................... 10

Setting the Bake Temperature ....................................................................................................... 10

Setting the Bake Timer .................................................................................................................. 10

Setting the Steam Timer .................................................................................................................11

Setting the Fan Delay .....................................................................................................................11

Cool Down Mode ............................................................................................................................11

Recipe Designations ...................................................................................................................... 12

Entering Recipes ........................................................................................................................... 12

Using and Reviewing Recipes ....................................................................................................... 12

Customized Operation ................................................................................................................... 12

Basic Operation ............................................................................................................................. 15

CLEANING .......................................................................................................................................... 16

Daily Cleaning ............................................................................................................................... 16

Glass Cleaning .............................................................................................................................. 16

MAINTENANCE .................................................................................................................................. 17

Light Replacement ......................................................................................................................... 17

Service and Parts Information ....................................................................................................... 17

Schematic ...................................................................................................................................... 18

©BAXTER MFG, 2010

– 2 –

INSTALLATION, OPERATION AND CARE OF

HCO HYBRID CONVECTION OVENS

SAVE THESE INSTRUCTIONS

GENERAL

HCO Series Hybrid Convection Ovens (Fig. 1) are designed for your baking needs. There is one size

available, but it is stackable to provide a bank of two independent units. They are produced with quality

workmanship and material. Proper installation, usage and maintenance of the ovens will result in years

of satisfactory performance.

It is suggested that you thoroughly read this manual and carefully follow the instructions provided.

Fig. 1

INSTALLATION

The HCO100E Hybrid Convection Oven comes pre-assembled, but requires qualifi ed personnel to install

and make connections.

UNPACKING

This oven was inspected before leaving the factory. The transportation company assumes full responsibility

for safe delivery upon acceptance of the shipment. Immediately after unpacking, check for possible shipping

damage. If the oven is found to be damaged, save the packaging material and contact the carrier within

15 days of delivery.

Carefully unpack the oven and place in a work-accessible area as near to its fi nal installed position as

possible. Remove protective covering from exterior surfaces prior to placing oven in its fi nal location.

Prior to installation, verify that the electrical and the water service agree with the specifi cations on the

oven data plate and in this manual.

– 3 –

INSTALLATION CODES AND STANDARDS

In the United States, the HCO Series Hybrid Convection Oven must be installed in accordance with:

1. State and local codes.

2. National Electrical Code (ANSI/NFPA No.70, latest edition) available from the National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269.

In Canada, the HCO Series Hybrid Convection Oven must be installed in accordance with:

1. Local codes.

2. Canadian Electrical Code (CSA C22.2 No.3, latest edition) available from the Canadian Standards

Association, 5060 Spectrum Way, Mississauga, Ontario, Canada L4W 5N6.

LOCATION

The HCO100E Hybrid Convection Oven must have the following minimum clearances to combustibles:

• Top and Sides: 0"

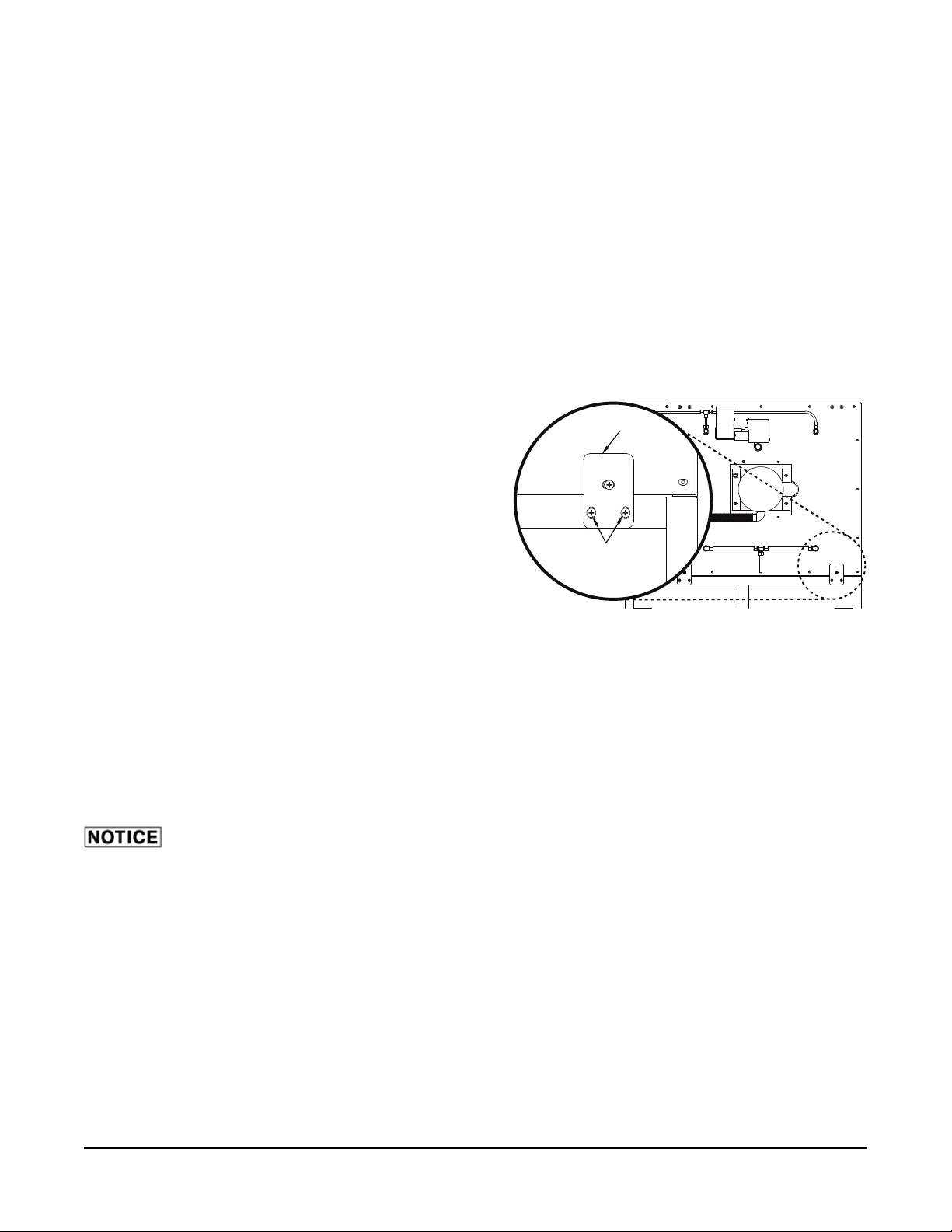

BRACKET

• Back 1" from motor

The oven must be installed on a noncombustible

surface and combustibles may not be stored beneath

the mounting surface.

NOTE: Minimum 24" clearance needed for service

SCREWS

access on the right side.

ASSEMBLY

Fig. 2

The oven must be installed on a stand or a non-combustible surface.

The oven must be sealed to the stand or surface with an NSF-approved sealant, such as Dow Corning

732 or GE RTV 108.

Secure the oven to the stand using the provided tie down brackets, which mount on the rear of the oven

(Fig. 2). If there are two units that need to be stacked with a stand, see instructions included with stacking

kit.

WATER REQUIREMENTS

As with all steam related products, water fi ltration and regular fi lter replacements, coupled with

routine deliming, are required. Your local Hobart Service offi ce can recommend a water treatment system

to meet the needs of your local water conditions. Contact your local Hobart Service representative for

water treatment offerings.

Proper water quality can improve the taste of the food prepared in the oven, reduce liming and extend

equipment life. Local water conditions vary from one location to another. The recommended proper water

treatment for effective and effi cient use of this equipment will also vary depending on the local water conditions.

Ask your municipal water supplier for details about your local water supply prior to installation.

Recommended water hardness is 2.0 to 6.0 grains of hardness per gallon with pH from 7.0 to 8.0. Chlorides

must not exceed 30 parts per million. Water hardness above 6.0 grains per gallon should be treated by

a water conditioner (water softener and/or in-line water treatment). Water hardness below 4.0 grains per

gallon may also require a water treatment system to reduce potential corrosion. Water treatment has

been shown to reduce costs associated with machine cleaning, reduce deliming and reduce corrosion of

metallic surfaces.

– 4 –

PLUMBING CONNECTIONS

Water and waste piping and connections shall comply with the International Plumbing

Code 2003, International Code Council (ICC), or to the Uniform Plumbing Code 2003, International

Association of Plumbing and Mechanical Offi cials (IAPMO). Plumbing connections must comply

with applicable sanitary, safety and plumbing codes and provide adequate backfl ow protection to

comply with applicable federal, state and local codes.

Connect the cold water supply to the

3

/8" NPT connection located at the rear of the oven. Water supply

should have a pressure of 20 to 80 psi. The oven is supplied with a fl ow regulator which must remain on

the oven.

DRAIN CONNECTIONS

In order to avoid any back pressure in the oven, do not connect solidly to any drain.

Route the drain line to a fl oor drain, allowing a minimum

1" air gap between the drain line outlet and fl oor

drain.

ELECTRICAL CONNECTIONS

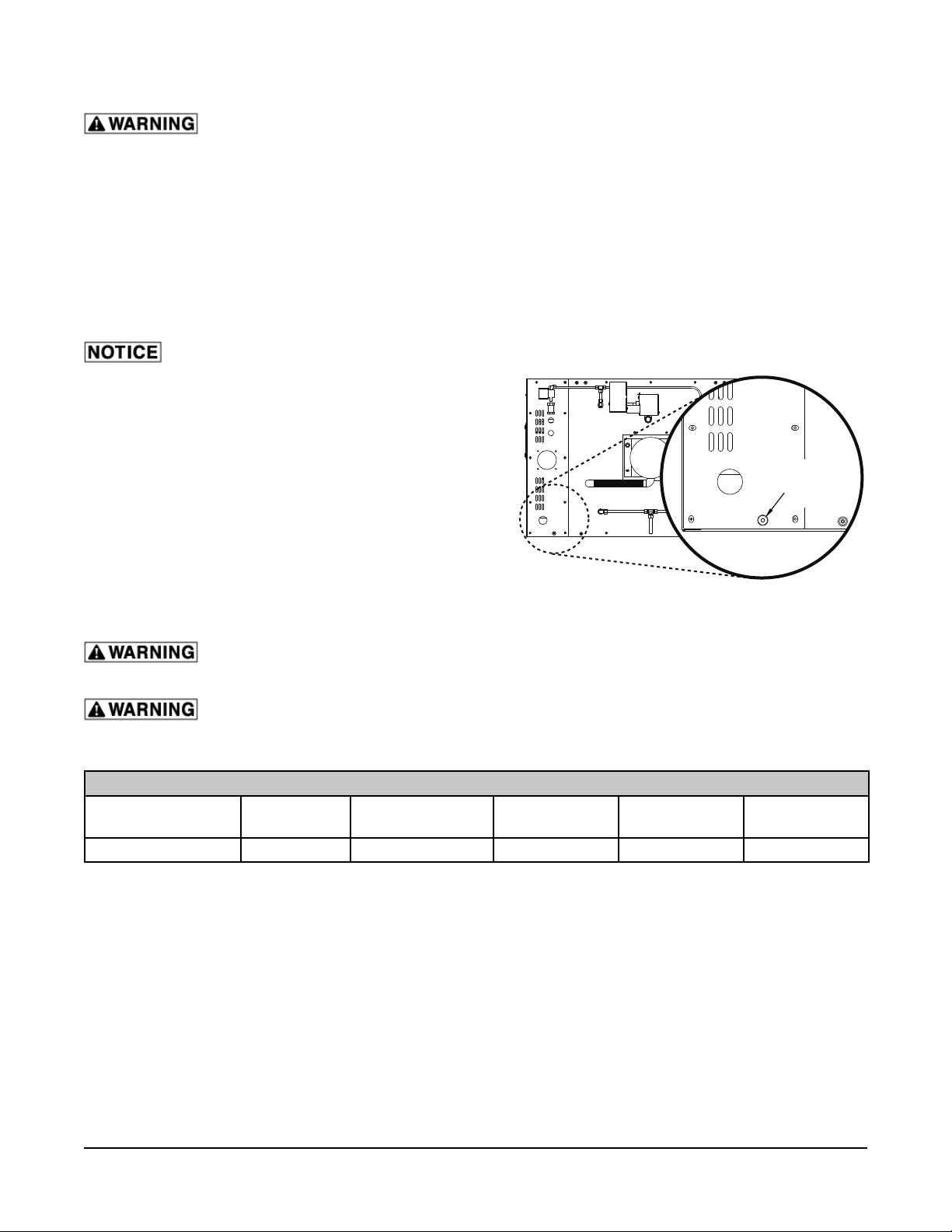

NOTE: The oven must be installed with the provided

LANYARD

CONNECTION

POINT

lanyard securely attached to the oven (Fig. 3) and to

the wall. Verify that all connections are long enough

so that the oven can be pulled forward to the extent of

the lanyard without straining any connections. Optional

30A plug is not available for Canadian installations.

Fig. 3

Refer to Canadian standards for requirements.

Electrical and grounding connections must comply with the applicable portions of

the National Electrical Code and/or other local electrical codes.

Disconnect the electrical power to the unit and follow lockout / tagout

procedures.

ELECTRICAL DATA (Per Unit)

Model Voltage Phase Amps Heating

Elements kW

HCO100E 208-240 3 24.7 to 27 7.8 to 10.3

Motor

1

/2 Hp.*

* 2.8 amp included in rating.

VENT HOOD

Some local codes may require the oven to be located under an exhaust hood. Information on the construction

and installation of ventilating hoods may be obtained from Vapor Removal from Cooking Equipment, NFPA

Standard No. 96 (latest edition).

– 5 –

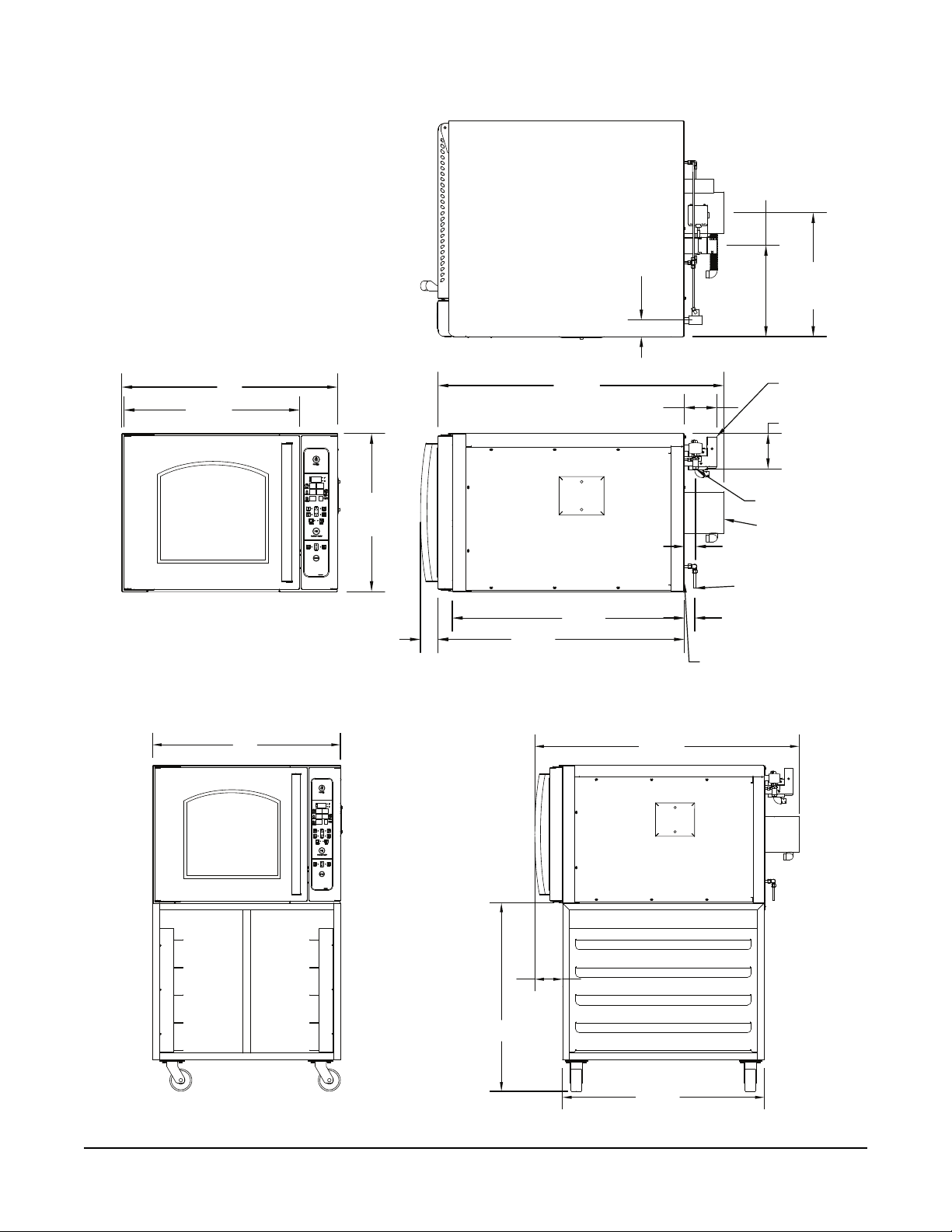

DIMENSIONS DIAGRAM

34”

27 5/8”

45 1/8”

2 5/8”

5 1/8”

CL WATER IN

14 3/8”

CL VENT

19 1/2”

CL DRAIN

STEAM

VENT

5 5/8”

WATER INLET

(3/8” NPT)

24 7/8”

MUST BE MOUNTED ON STAND (OPTIONAL)

OR NON-COMBUSTIBLE SURFACE

2 3/4”

HCO100E Without Stand Base

34”

MOTOR

1 3/4”

DRAIN

(3/8” OD TUBING)

36 5/8”

1 5/8”

38 7/8”

6' CORD

(WITH NEMA 15-30A PLUG - U.S. INSTALLATIONS ONLY)

47 7/8”

5”

34”

HCO100E With Stand Base

– 6 –

36 1/2”

Loading...

Loading...