Page 1

HCM450 CUTTER MIXER

MODEL

HCM450 Cutter Mixer

HCM450 ML-134207

ML-134208

ML-134209

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

F-34772 Rev. E (May 2014)

Page 2

INSTALLATION, OPERATION AND CARE OF

Model HCM450 Cutter Mixer

SAVE THESE INSTRUCTIONS

GENERAL

The HCM450 Cutter Mixer cuts, mixes or blends foods quickly and effi ciently. A transparent lid allows

the operator to inspect the product during the mix-cut-blend process. The unit operates continuously,

momentarily or with a timer control which shuts off the machine automatically after the set time has elapsed.

The HCM450 bowl has a liquid capacity of 45 quarts.

The motor on HCM450 is rated 5 HP, 1140 RPM and has thermal overload protection. The motor is totally

enclosed with external fan cooling.

The cut mix shaft assembly is used for cutting meat products, vegetables, cheese, pastry, cake products

and some doughs that require both cutting and mixing.

The knead mix shaft assembly is used for applications where cutting is not required. It is especially good

for kneading yeast doughs.

The strainer basket may be used when cutting vegetables in water. After cutting, the strainer basket is

raised to allow the water to drain away from the food.

The bowl is locked in its vertical position during processing with the lock arm on HOLD. After processing,

when you move the lock arm from HOLD to TILT, the bowl can pivot to allow easy pouring.

When cutting certain products, a hand-operated mixing baffl e may be used to stir or move the product

into the knives. The mixing baffl e may be removed when it is not needed.

© HOBART, 1980, 1987, 2002, 2010

– 2 –

Page 3

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the cutter mixer is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, verify that the electrical service agrees with the specifi cations on the machine data

plate located on the frame behind the control box.

ASSEMBLY

Remove the cutter mixer from the skid and install rubber feet as follows: Apply a bead of silicon sealant

(not provided) around the edge of each leg. Insert a rubber foot onto each leg and fasten with bolts and

washers provided. Match the shape of the foot to conform to the shape of the leg. Two of each style are

included.

NOTE: Optional right and left casters (with rubber caster pads) are available for installation on the two

legs on the control panel side. Assemble with the bolts and washers provided for the rubber feet.

Place cutter mixer in the desired location.

ELECTRICAL CONNECTIONS

Electrical and grounding connections must comply with applicable portions of the

national electrical code and/or other local electrical codes.

Disconnect electrical power supply and place a tag at the disconnect switch,

indicating that the circuit is being worked on.

Machines are shipped from the factory with a 6-foot cord and plug. A mating receptacle is furnished with

the machine as standard equipment.

– 3 –

Page 4

ASSEMBLING BOWL SEAL AND ATTACHMENTS

Refer to the handbook accompanying the cutter mixer for recipe guidelines and advice regarding the

appropriate selection of attachments for the desired application.

Before installing bowl seal and attachments, be sure the power cord is unplugged.

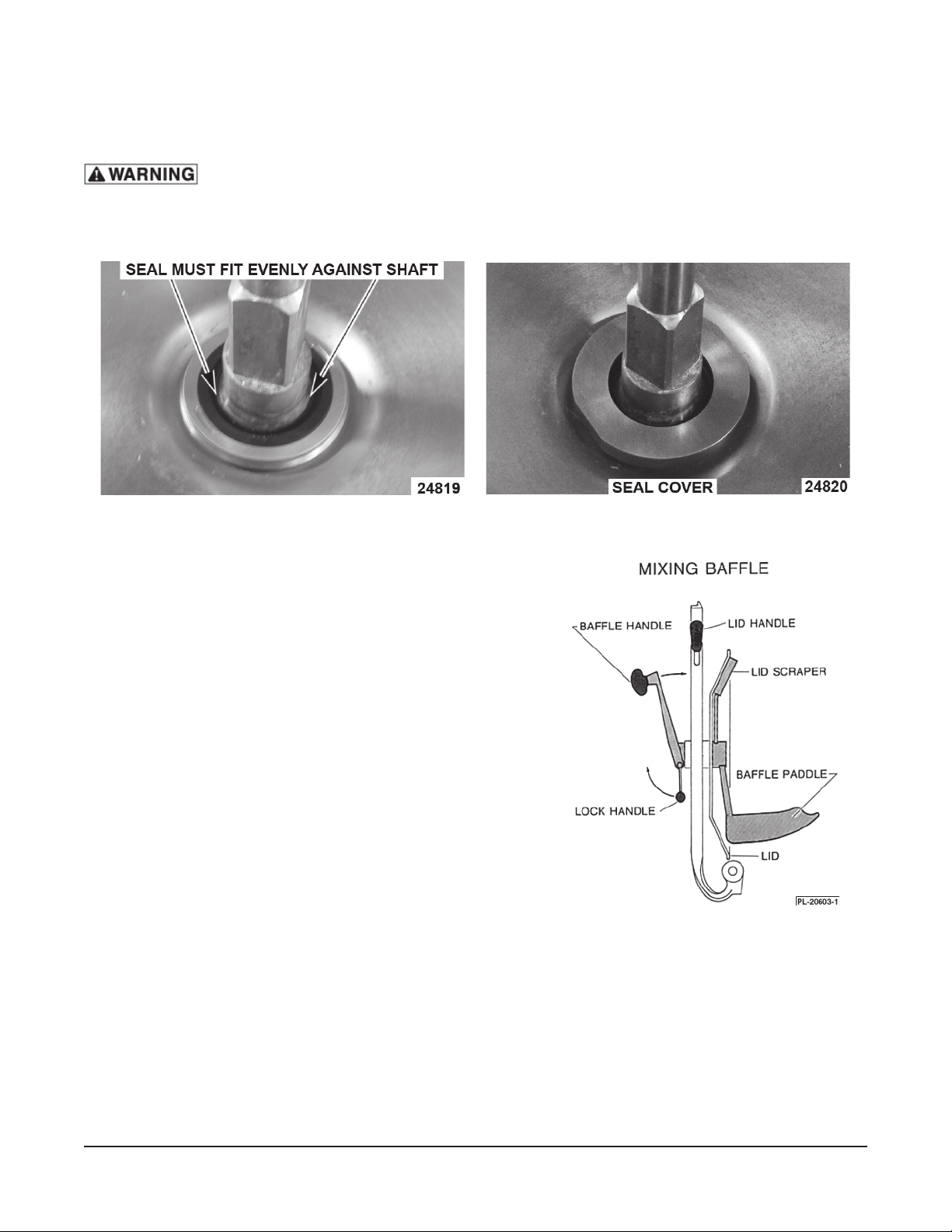

Bowl Seal: Insert rubber seal into the lower seal housing (Fig. 1). Press the seal down fully into housing.

Screw seal cover onto housing fi nger tight (Fig. 2).

Fig. 1 Fig. 2

Strainer Basket: If needed, insert basket in bowl over the

motor shaft.

NOTE: Never use strainer basket and mixing baffl e at the

same time.

Cut Mix Shaft Assembly or Knead Mix Shaft Assembly: Place

on motor shaft, seat square drive at base and tighten hand

knob by turning counterclockwise.

Lid Scraper: Insert on bar opposite mixing baffl e. Lid scraper

is used to clean the inside of the bowl cover.

Mixing Baffl e: Insert shaft of mixing baffl e into hole in the

center of the lid. With baffl e paddle down, hold baffl e handle

at an angle so lock handle hangs down and insert onto shaft.

Then tighten lock handle (Fig. 3).

Fig. 3

– 4 –

Page 5

OPERATION

Move bowl tilt handle to HOLD to lock bowl in vertical position (Fig. 4).

Close and latch the lid by grasping the lid handle with the left hand. Press lid handle down while turning

the latch until lid lock is engaged (Fig. 4).

CONTROLS (FIG. 4)

The Timer has three mode settings: Run, Jog or Timer.

RUN – Machine runs continuously after START is pushed until STOP is pressed.

JOG – Machine jogs momentarily while START is held down; the machine turns off

when you release START.

TIMER – After you set the time and push START, the machine will run for the

amount of time on the timer. After the set time has lapsed, the machine

automatically stops.

START – Turns the machine on.

STOP – Turns the machine off.

UNLOADING

Push the STOP switch. After the shaft has stopped, open the cover. NOTE: When the baffl e is not in

place, the lid opens a few inches upon release.

Remove the cut mix shaft assembly before emptying bowl. The knead mix shaft assembly may stay in

place while emptying the bowl.

Scrape lid (when necessary) before tipping bowl.

For products cut in water, lift out the strainer basket while the bowl is in the vertical position. Allow water

to strain through holes in bottom of strainer basket.

Move the bowl tilt handle to TILT.

The bowl may be tilted to any desired position, depending upon the type of product. Grasp the lid handle

and cautiously tilt the bowl by pulling toward you as the contents empty into a container.

After product has been removed, return bowl to vertical position. Return bowl tilt handle to HOLD position

and proceed to run another load or clean the machine.

– 5 –

Page 6

BAFFLE HANDLE

BAFFLE HANDLE

LOCK HANDLE

LID HANDLE

LID LATCH

START

STOP

LOCK HANDLE

CUT MIX SHAFT ASSEMBLY

BOWL TILT HANDLE

HAND KNOB

5-MINUTE TIMER

WITH JOG, RUN,

AND TIMED SETTINGS

KNEAD MIX SHAFT ASSEMBLY

LID SCRAPER

MIXING BAFFLE

STRAINER BASKET

PL-41654-1

Fig. 4

– 6 –

Page 7

CLEANING

Damage to the lid can result if it is exposed to certain chemicals. Do not use harsh abrasives,

such as powdered or liquid cleansers, steel wool or other abrasive pads; cleaners containing ammonia,

such as window sprays; cleaners containing chlorine, solvents, chemical adhesives; and highly caustic

chemicals, such as drain cleaners or commercial dishwasher detergents.

PREWASH

Before disassembling, put 1gallon of warm water and 1or 2 tablespoons of a mild liquid household

dishwashing detergent, such as Joy, Ivory or Palmolive Green in the bowl. Close and latch the lid. Turn

the timer to JOG and run for three bursts of 3 seconds each so the solution is thoroughly mixed.

WASH BOWL AND COMPONENTS

Unplug unit before cleaning.

Remove cut mix shaft assembly or knead mix shaft assembly and, if necessary, the mixing baffl e. Do not

leave attachments on motor shaft for storage.

Wash the inside of the bowl and the underneath side of the lid using a soft, clean cloth or sponge. Use a

soft, plastic spatula to scrape the inside of the bowl if food soil adheres to the side of the bowl.

Hand wash the attachments.

Remove the wash water from the bowl.

RINSE

Pour 1 gallon of warm rinse water into the bowl.

Rinse attachments and mixing baffl e with water in bowl

and remove them to dry. Thoroughly rinse the inside

of the lid and bowl.

Remove the rinse water from the bowl and dry with a

clean cloth.

REMOVE BOWL SEAL

Remove the bowl seal by unscrewing the seal cover

(Fig. 5) and pulling out the rubber seal. There are detents

(Fig. 6) in the lower seal housing to allow gripping the

seal. Wash, rinse and dry both parts.

Reassemble seal and seal cover (Figs. 1 and 2). Be

sure bowl area is properly cleaned before reinstalling

seal. Push seal into lower housing then install seal

cover fi nger tight.

Fig. 5

NOTE: The bowl seal should be cleaned at least once

per day or once per shift.

Leave the lid unlatched when machine is not in use.

NOTE: It is recommended that you do not store extra accessories in the bowl to prevent damage in case

the unit gets turned on.

– 7 –

Fig. 6

Page 8

MAINTENANCE

The prelubricated motor bearings should be checked by a Hobart service technician every 3 to 4 years

under normal use. No other lubrication is required.

TROUBLESHOOTING

SERVICE

Contact your local Hobart-authorized Service Offi ce for any repairs or adjustments needed on this

equipment.

Symptom Possible Cause

Cutter mixer won't operate.

1. Electrical power not connected.

2. Circuit breaker tripped or fuse blown.

F-34772 Rev. E (May 2014) PRINTED IN U.S.A.

– 8 –

Page 9

COUPEUR/MÉLANGEUR HCM 450

MODÈLE

HCM450 ML - 134207

ML - 134208

ML - 134209

F-34772 RÉV. E (Mai 2014)

Page 10

INSTALLATION, FONCTIONNEMENT ET ENTRETIEN DU

Coupeur mélangeur – Modèle HCM450

CONSERVEZ CE MODE D’EMPLOI

INFORMATIONS GÉNÉRALES

Le coupeur mélangeur HCM450 peut couper, mélanger ou incorporer des aliments rapidement et efcacement.

Le couvercle transparent permet à l’opérateur d’observer le produit pendant le processus de mélange, coupage et

incorporation. L’appareil peut fonctionner en continu, par a-coups sporadiquement ou par l’entremise d’un contrôle

minuté qui éteint automatiquement la machine lorsque le temps réglé s’est écoulé. La cuve du HCM450 a une capacité liquide de 45 pte américaines (42,6 l).

Le moteur de l’appareil HCM450 a une puissance nominale de 5 HP, tourne à 1140 t/min et est doté d’une protection

contre les surcharges thermiques. Ce moteur est entièrement fermé à ventilation extérieure.

L’arbre à couper/mélanger sert à couper des produits de viande, des légumes, du fromage, de la pâtisserie, des

gâteaux et certaines pâtes qui exigent à la fois d’être coupées et mélangées.

L’arbre pétrisseur/mélangeur est utilisé pour les applications où il n’est pas nécessaire de couper. Il est particulièrement efcace pour pétrir les pâtes levées.

Le panier ltre peut être utilisé lorsque l’on coupe des légumes dans l’eau. Après la coupe le panier ltre est relevé

pour laisser l’eau s’écouler hors des aliments.

Pendant le fonctionnement, la cuve est verrouillée en position verticale, le bras de verrou placé à la position de

BLOCAGE (HOLD). À la n d’un processus, lorsque vous déplacez le bras de verrou de BLOCAGE (HOLD) à PEN-

CHER (TILT), la cuve peut pivoter pour la vider facilement.

Lors de la coupe de certains produits, un déecteur de mélange manuel peut être utilisé pour remuer ou diriger le

produit vers les lames. S’il n’est pas requis, le déecteur de mélange peut être retiré.

© HOBART, 1980, 1987, 2002, 2010

– 2 –

Page 11

DÉBALLAGE

Aussitôt le déballage terminé, assurez-vous que l’appareil n’a pas subi de dommages pendant l’expédition.

Si vous décelez des dommages à la machine après son déballage, conservez le matériel d’emballage et

contactez le transporteur dans les 15 jours suivant la livraison.

Avant de commencer l’installation, assurez-vous que votre entrée électrique est conforme aux données

de la plaque signalétique de l’appareil.

ASSEMBLAGE

Retirez le coupeur mélangeur de la palette et installez les pieds de caoutchouc comme suit: appliquez un

cordon de silicone (non livré) autour des bords de chacune des pattes. Insérez un pied de caoutchouc au

bout de chaque patte et fi xez-le avec les boulons et les rondelles livrées. Appariez la forme du pied pour

se marier à la forme de la patte. Deux types de pieds sont livrés.

REMARQUE: des roulettes droite et gauche (avec coussins de caoutchouc pour roulettes), offertes en

option, sont disponibles pour installation sur les deux pattes situées du côté du poste de commande.

Fixez-les avec les boulons et les rondelles livrés avec les pieds de caoutchouc.

Placez le coupeur mélangeur à l’endroit désiré.

CONNEXIONS ÉLECTRIQUES

Les connexions électriques et de mise à la terre doivent être faites en conformité

avec les portions applicables du code national de l’électricité et/ou en conformité avec les autres

codes électriques locaux.

Coupez l’alimentation électrique de l’appareil et attachez une étiquette sur le

sectionneur pour indiquer que vous êtes en train de travailler sur le circuit.

Les appareils sont expédiés de l’usine équipés d’un cordon de 6 pi (1 500 mm) et d’une fi che. Un connecteur

homologue est livré de série avec la machine.

– 3 –

Page 12

MISE EN PLACE DU JOINT DE CUVE ET DES OUTILS

Référez-vous au manuel qui accompagne le coupeur mélangeur pour un guide de recettes et des conseils à

l’égard de la bonne sélection des outils à utiliser pour effectuer le travail souhaité.

Avant la mise en place du joint de cuve et des outils, assurez-vous que le cordon

d’alimentation a été débranché.

Joint de cuve: insérez le joint de caoutchouc dans le logement du joint inférieur (Fig. 1). Pressez le joint complètement dans le logement. Vissez solidement le couvre-joint avec les mains dans le logement (Fig. 2).

Panier ltre: si nécessaire, insérez le panier ltre par dessus l’arbre

du moteur.

REMARQUE: ne jamais utiliser le panier ltre en même temps que

le déecteur de mélange.

Le bras couper/mélanger ou celui pour pétrir/mélanger: posez-les

sur l’arbre du moteur, insérez-les sur l’entraînement carré à la base

et serrez le bouton à la main en le faisant pivoter dans le sens antihoraire.

Le grattoir du couvercle: Insérez-le sur la barre du côté opposé du

déecteur de mélange. Ce grattoir sert à nettoyer l’intérieur du couvercle de la cuve.

Le déecteur de mélange: insérez l’arbre du déecteur de mélange

dans l’orice au centre du couvercle. La palette du déecteur tournée vers le bas, tenez la poignée du déecteur à un angle tel que le

levier de verrouillage soit dirigé vers le bas et s’insère dans l’arbre.

Serrez alors le levier de verrouillage (Fig.3).

– 4 –

Page 13

FONCTIONNEMENT

Amenez le levier d’inclinaison de la cuve en position de blocage (HOLD) pour la verrouiller en position

verticale.

Fermez et verrouillez le couvercle en saisissant la poignée de la main gauche. Appuyez sur la poignée

du couvercle tout en tournant le loquet jusqu’à ce qu’il s’enclenche (Fig. 4).

CONTRÔLES (FIG. 4)

La minuterie comporte trois modes de fonctionnement: Marche (Run), À-coups (Jog), ou Minuterie (Timer).

MARCHE (RUN) – Après avoir appuyé sur MARCHE (RUN), l’appareil tourne continuellement

jusqu’à ce qu’on ait appuyé sur STOP.

À-COUPS (JOG) – La machine marche par à-coups lorsque vous maintenez le bouton de

MARCHE (START) enfoncé; elle s’arrête lorsque vous relâchez le bouton

de MARCHE (START).

MINUTERIE (TIMER) – Après avoir réglé le temps et appuyé sur MARCHE (RUN), l’appareil

fonctionnera pendant la durée de temps que vous avez demandé

à la minuterie. Une fois le temps écoulé, la machine s’arrêtera

automatiquement.

MARCHE (START) – Fait démarrer l’appareil.

STOP – Arrête l’appareil.

DÉCHARGEMENT

Appuyez sur le commutateur STOP. Après que l’arbre se soit arrêté, ouvrez le couvercle. REMARQUE:

lorsque le défl ecteur n’est pas utilisé, le couvercle s’entrouvre de quelques pouces une fois relâché.

Avant de vider la cuve, retirez l’arbre à couper mélanger. L’arbre à pétrir mélanger peut demeurer dans

la cuve pendant que vous la videz.

Raclez le couvercle (si nécessaire) avant d’incliner la cuve.

Pour ce qui est des produits coupés dans l’eau, relevez le panier fi ltre pendant que la cuve est en position

verticale. Laissez l’eau s’écouler par les trous au fond du panier.

Déplacez le levier d’inclinaison à INCLINER (TILT).

La cuve peut être penchée à n’importe quelle position souhaitée selon le type de produit. Agrippez la

poignée du couvercle et inclinez la cuve avec précaution en tirant vers vous à mesure que le contenu se

décharge dans un récipient.

Une fois le produit retiré, ramenez la cuve en position verticale. Replacez le levier en position de BLOCAGE

(HOLD) et passez à une autre charge ou nettoyez l’appareil.

– 5 –

Page 14

– 6 –

Page 15

NETTOYAGE

AVIS Le couvercle peut être endommagé s’il est exposé à certains produits chimiques. N’employez pas d’abrasifs

forts tels que les poudres à nettoyer solides ou liquides, la laine d’acier ou autres tampons abrasifs; les nettoyants

contenant de l’ammoniaque comme les nettoie-vitres; les nettoyants contenant du chlore, les solvants, les adhésifs

chimiques; et les produits chimiques hautement caustiques, comme les produits de débouchage ou les détergents

de lave-vaisselle commerciaux.

AVANT LE LAVAGE

Avant le démontage, versez 1 gal d’eau chaude (3,8 l) dans la cuve et ajoutez-y 1 ou 2 cuillerées à soupe (30 ml)

de savon domestique doux tel que Joy, Ivory ou Palmolive vert. Fermez et verrouillez le couvercle. Réglez la minuterie à À-COUPS (JOG) et faites fonctionner la machine en trois coups de 3 secondes chacun pour mélanger la

solution à fond.

LAVAGE DE LA CUVE ET DES COMPOSANTS

Débranchez l’appareil avant de le nettoyer.

Retirez les ensembles à couper mélanger ou à pétrir mélanger et si nécessaire, le déecteur de mélange. Ne laissez pas les outils sur l’arbre du moteur pour l’entreposage.

Lavez l’intérieur de la cuve ainsi que le côté intérieur du couvercle à l’aide d’un chiffon propre et doux ou d’une

éponge. Servez-vous d’une spatule en plastique mou pour récurer l’intérieur de la cuve si des résidus d’aliments

sont restés collés sur les parois.

Lavez les outils à la main.

Vidangez l’eau du lavage de la cuve.

RINÇAGE

Pour le rinçage, versez 1 gallon d’eau chaude dans la

cuve.

Rincez les outils et le déecteur dans l’eau de la cuve et

retirez-les pour les faire sécher. Rincez soigneusement

l’intérieur du couvercle et de la cuve.

Vidangez l’eau de rinçage de la cuve et asséchez celleci avec un chiffon propre.

RETRAIT DU JOINT DE CUVE

Retirez le joint de cuve en dévissant le couvre-joint (Fig.

5) et en tirant sur le joint en caoutchouc. Il y a des crans

de détente dans le logement inférieur du joint pour vous

permettre de le soulever. Lavez, rincez et asséchez les

deux parties.

Remettez le joint et le couvre-joint en place (Fig. 1 et

2). Assurez-vous que les alentours de la cuve sont bien

nettoyés avant de réinstaller le joint. Poussez le joint

dans son logement inférieur pour ensuite remettre le

couvre-joint en place fermement à la main.

REMARQUE: le joint de cuve devrait être nettoyé au

moins une fois par jour ou par quart de travail.

Lorsque l’appareil n’est pas utilisé, laissez le couvercle

non verrouillé.

REMARQUE: Il est recommandé de ne pas ranger d’outils ou d’accessoires dans la cuve pour prévenir des dommages au cas où l’appareil serait mis en marche inopinément.

– 7 –

Page 16

ENTRETIEN

Les roulements du moteur prélubriés devraient être vériés par un technicien d’entretien de Hobart à tous les 3 ou

4 ans dans des conditions d’utilisations normales. Aucune autre lubrication n’est nécessaire.

DÉPANNAGE

SERVICE TECHNIQUE

Pour toute réparation ou réglage de cet équipement, contactez le bureau du service de l’entretien autorisé par

Hobart dans votre région.

Symptôme Cause possible

Le coupeur mélangeur ne veut pas

fonctionner.

1. Le courant électrique n’est pas branché.

2. Le disjoncteur s’est déclenché ou un fusible est brûlé.

F-34772 Rév. E (Mai 2014)

– 8 –

IMPRIMÉ AUX É.-U.

Loading...

Loading...