Page 1

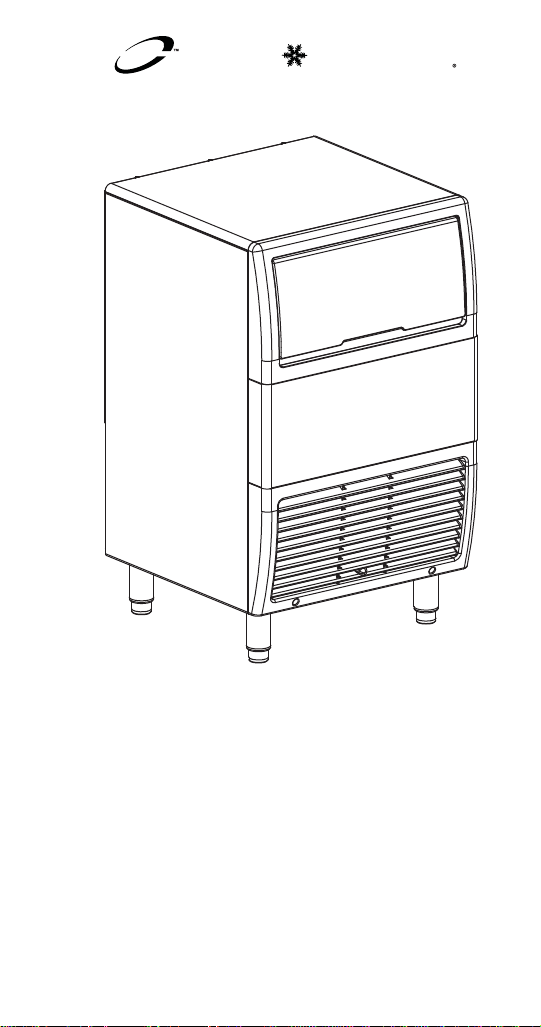

Manitowoc

UG Models

Technician’s Handbook

This manual is updated as new information and models

are released. Visit our website for the latest manual.

America’s #1 Selling Ice Machine

Manitowoc Ice P/N 040004390 11/14

www.manitowocice.com

Page 2

Page 3

Safety Notices

!

Warning

!

Caution

When using or servicing these Ice Machines, be sure

to pay close attention to the safety notices in this

handbook. Disregarding the notices may lead to

serious injury and/or damage to the ice machine.

Throughout this handbook, you will see the following

types of safety notices:

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement before proceeding, and work

carefully.

Text in a Caution box alerts you to a situation in

which you could damage the ice machine. Be sure

to read the Caution statement before proceeding,

and work carefully.

Page 4

Procedural Notices

Important

When using or servicing these Ice Machines, be sure

to read the procedural notices in this handbook. These

notices supply helpful information that may assist you

as you work.

Throughout this handbook, you will see the following

types of procedural notices:

Text in an Important box provides you with

information that may help you perform a procedure

more efficiently. Disregarding this information will not

cause damage or injury, but may slow you down as

you work.

NOTE:

simple, but useful extra information about the

procedure you are performing.

Text set off as a Note provides you with

Page 5

Read These Before Proceeding:

!

Caution

Important

!

Warning

!

Warning

Proper installation, care and maintenance are

essential for maximum ice production and trouble

free operation of your Manitowoc Ice Machine. If you

encounter problems not covered by this manual, do

not proceed, contact Manitowoc Ice, Inc. We will be

happy to provide assistance.

Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

We reserve the right to make product improvements at

any time. Specifications and design are subject to

change without notice.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

POTENTIAL PERSONAL INJURY SITUATION

This ice machine contains refrigerant charge.

Installation and Servicing must be performed by a

properly trained refrigeration technician aware of the

Dangers of dealing with refrigerant charged

equipment.

Page 6

This Page Intentionally Left Blank

Page 7

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General Information 1

Model Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Installation 3

Location of Ice Machine. . . . . . . . . . . . . . . . . . . . . 3

Water Service/Drains . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Requirements . . . . . . . . . . . . . . . . . . . . 5

Electrical Specifications . . . . . . . . . . . . . . . . . . . . 6

Power Consumption - kwh per 24 hours . . . . . . . 7

Ice Machine Heat of Rejection . . . . . . . . . . . . . . . 8

Component Identification 9

Component Removal . . . . . . . . . . . . . . . . . . . . . 11

Spray Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance 17

Cleaning & Sanitizing Procedure . . . . . . . . . . . . 18

Operation 23

Sequence Of Operation . . . . . . . . . . . . . . . . . . . . 23

Cube Shape . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Troubleshooting 29

All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Ice Machine Will Not Run. . . . . . . . . . . . . . . . . . 29

Compressor Won’t Run . . . . . . . . . . . . . . . . . . . 30

Compressor Electrical Diagnostics. . . . . . . . . . . 31

Diagnosing Start Components . . . . . . . . . . . . . . 33

Water Pump Won’t Run . . . . . . . . . . . . . . . . . . . 34

Hot Gas Valve Won’t Energize. . . . . . . . . . . . . . 34

Water Inlet Valve Won’t Energize. . . . . . . . . . . . 34

Ice Machine Prematurely Harvests . . . . . . . . . . 35

ce Machine Will Not Harvest . . . . . . . . . . . . . . . 36

Evaporator Thermostat. . . . . . . . . . . . . . . . . . . . 37

Water System Checklist. . . . . . . . . . . . . . . . . . . . 44

Ice Production Check. . . . . . . . . . . . . . . . . . . . . . 45

Analyzing Discharge Pressure . . . . . . . . . . . . . . 46

Discharge Pressure High Checklist . . . . . . . . . . 47

Freeze Cycle Discharge Pressure Low Checklist 48

Analyzing Suction Pressure. . . . . . . . . . . . . . . . . 49

Suction Pressure High Checklist . . . . . . . . . . . . 51

Page 8

Suction Pressure Low Checklist . . . . . . . . . . . . . 52

Discharge Line Temperature Analysis. . . . . . . . .53

Component Check Procedures 55

On/Off/Wash-Fill Toggle Switch . . . . . . . . . . . . . 55

Bin thermistor (T3). . . . . . . . . . . . . . . . . . . . . . . . 56

SUMP WATER THERMiSTOR (T1)& LIQUID LINE

THERMiSToR(T2). . . . . . . . . . . . . . . . . . . . . . . 58

high Pressure Cutout (HPCO) Control . . . . . . . . 65

Hot Gas Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Recover/Evacuation/Charging. . . . . . . . . . . . . . . 71

System Contamination Cleanup . . . . . . . . . . . . . 74

Mild System Contamination Cleanup . . . . . . . . . 76

Severe System Contamination Cleanup Procedure

77

Filter-Driers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Total System Refrigeration Charge . . . . . . . . . . 80

Cycle Times/24 Hour Ice Production and

Refrigerant Pressure Charts 81

ug18A Self-Contained Air-Cooled — Standard

Cube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

ug18A Self-Contained Air-Cooled — Standard

Cube (Continued) . . . . . . . . . . . . . . . . . . . . . . . 83

ug18A Self-Contained Air-Cooled — Standard

Cube (Continued) . . . . . . . . . . . . . . . . . . . . . . . 84

UG020A

Cube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

UG020A

Cube (Continued) . . . . . . . . . . . . . . . . . . . . . . . 86

UG020A

Cube (Continued) . . . . . . . . . . . . . . . . . . . . . . . 87

UG030A-251 Self-Contained Air-Cooled — Stan-

dard Cube . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

UG030A-251 Self-Contained Air-Cooled — Stan-

dard Cube . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

UG030A-251 Self-Contained Air-Cooled — Stan-

dard Cube (Continued) . . . . . . . . . . . . . . . . . . . 90

UG030A-261 Self-Contained Air-Cooled — Stan-

dard Cube . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

UG030A-261 Self-Contained Air-Cooled — Stan-

dard Cube . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

UG030A-261 Self-Contained Air-Cooled — Stan-

Self-Contained Air-Cooled — Standard

Self-Contained Air-Cooled — Standard

Self-Contained Air-Cooled — Standard

Page 9

dard Cube (Continued) . . . . . . . . . . . . . . . . . . 93

UG030A-161 Self-Contained Air-Cooled — Stan-

dard Cube . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

UG030A-161 Self-Contained Air-Cooled — Stan-

dard Cube . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

UG030A-161 Self-Contained Air-Cooled — Stan-

dard Cube (Continued) . . . . . . . . . . . . . . . . . . 96

UG030W

Standard Cube. . . . . . . . . . . . . . . . . . . . . . . . . 97

UG030W

Standard Cube. . . . . . . . . . . . . . . . . . . . . . . . . 98

UG030W

Standard Cube (Continued). . . . . . . . . . . . . . . 99

UG040A-251 Self-Contained Air-Cooled — Stan-

dard Cube . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

UG040A-251 Self-Contained Air-Cooled — Stan-

dard Cube (Continued) . . . . . . . . . . . . . . . . . 101

UG040A-251 Self-Contained Air-Cooled — Stan-

dard Cube (Continued) . . . . . . . . . . . . . . . . . 102

UG040A-261 Self-Contained Air-Cooled — Stan-

dard Cube . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

UG040A-261 Self-Contained Air-Cooled — Stan-

dard Cube (Continued) . . . . . . . . . . . . . . . . . 104

UG040A-261 Self-Contained Air-Cooled — Stan-

dard Cube (Continued) . . . . . . . . . . . . . . . . . 105

UG050A-251 Self-Contained Air-Cooled — Stan-

dard Cube . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

UG050A-251 Self-Contained Air-Cooled — Stan-

dard Cube (Continued) . . . . . . . . . . . . . . . . . 107

UG050A-251 Self-Contained Air-Cooled — Stan-

dard Cube (Continued) . . . . . . . . . . . . . . . . . 108

UG050W Self-Contained water-Cooled . . . . . . 109

UG050W Self-Contained water-Cooled . . . . . . 110

UG050W Self-Contained water-Cooled . . . . . . 111

UG065AG-251G Self-Contained Air-Cooled —

Standard Cube. . . . . . . . . . . . . . . . . . . . . . . . 112

UG065 Self-Contained Air-Cooled — Standard

Cube (Continued) . . . . . . . . . . . . . . . . . . . . . 113

UG065 Self-Contained Air-Cooled — Standard

Cube (Continued) . . . . . . . . . . . . . . . . . . . . . 114

UG080A Self-Contained Air-Cooled — Standard

Cube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

UG080A Self-Contained Air-Cooled — Standard

Cube (Continued) . . . . . . . . . . . . . . . . . . . . . 116

UG080A Self-Contained Air-Cooled — Standard

Self-Contained WATER--Cooled —

Self-Contained WATER--Cooled —

Self-Contained WATER--Cooled —

Page 10

Cube (Continued) . . . . . . . . . . . . . . . . . . . . . . 117

Diagrams 119

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . .119

UG18/UG20 air-cooled . . . . . . . . . . . . . . . . . . . 119

UG30/UG50/UG65 air-cooled . . . . . . . . . . . . . . 120

UG30/UG50 water-cooled . . . . . . . . . . . . . . . . 122

Tubing Schematics . . . . . . . . . . . . . . . . . . . . . . .123

ug18/UG20/UG30/UG40/UG65 Tubing Schematic .

123

UG50/UG80 Tubing Schematic. . . . . . . . . . . . . 124

Page 11

General Information

Model Numbers

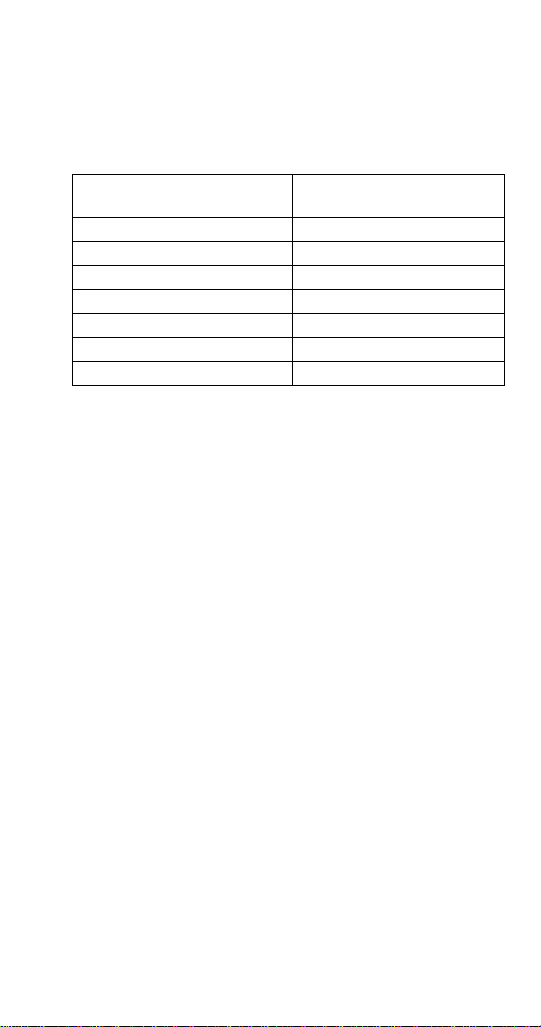

This manual covers the following models:

Self-Contained

Air-Cooled

UG018A N/A

UG020A N/A

UG030A UG030W

UG040A N/A

UG050A UG050W

UG065A N/A

UG080A N/A

Water-Cooled

–1–

Page 12

This Page Intentionally Left Blank

–2–

Page 13

Installation

Location of Ice Machine

The location selected for the ice machine must meet

the following criteria. If any of these criteria are not

met, select another location.

• The location must be indoors.

• The location must be free of airborne and other

contaminants.

• The air temperature must be at least 10ºC but must

not exceed 43.4ºC.

• The location must not be near heat-generating

equipment or in direct sunlight.

• The location must be capable of supporting the

weight of the ice machine and a full bin of ice.

• The location must allow enough clearance for water,

drain, and electrical connections in the rear of the

ice machine.

• The location must not obstruct airflow through or

around the ice machine (condenser airflow is in and

out the front). Refer to the chart below f or clearance

requirements.

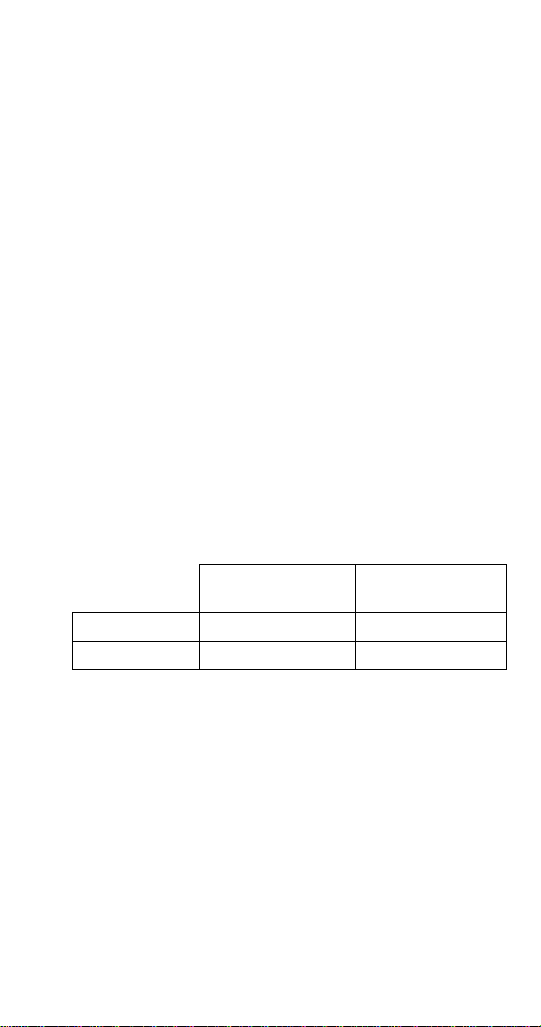

Self-Contained

Air-Cooled

Top/Sides 203 mm (8")* 127 mm (5")*

Back 127 mm (5")* 127 mm (5")*

*NOTE:

There is no minimum clearance requirement for the

top or left and right sides of the ice machine. The listed

values are recommended for efficient operation and

servicing only.

The ice machine may be built into a cabinet.

Self-Contained

Water-Cooled

3

Page 14

WATER SERVICE/DRAINS

!

Caution

Water Supply

Local water conditions may require treatment of the

water to inhibit scale formation, filter sediment, and

remove chlorine odor and taste.

Water Inlet Lines

• Do not connect the ice machine to a hot water

supply. Be sure all hot water restrictors installed for

other equipment are working. (Check valves on sink

faucets, dishwashers, etc.)

• If water pressure exceeds the maximum

recommended pressure, 5 bar (500 kPA), install a

water pressure regulator.

• Install a water shut-off valve.

Drain Connections

• Drain lines must have a 2.5 cm per meter drop, and

must not create traps.

• The floor drain must be large enough to

accommodate drainage from all drains.

The ice machine must be protected if it will be

subjected to temperatures below 0°C. Failure

caused by exposure to freezing temperatures is not

covered by the warranty.

4

Page 15

ELECTRICAL REQUIREMENTS

Voltage

The maximum allowable voltage variation is ±6% of

the rated voltage on the ice machine model/serial

number plate at start-up (when the electrical load is

highest).

All ice machines are factory pre-wired with a power

cord only, no plug is supplied.

Fuse/Circuit Breaker

A separate fuse/circuit breaker must be provided for

each ice machine. An electrical disconnect switch

must be provided if the ice machine is hard wired

(wired without a plug).

Total Circuit Ampacity

The total circuit ampacity is used to help select the

wire size of the electrical supply.

The wire size (or gauge) is also dependent upon

location, materials used, length of run, etc., so a

qualified electrician must make the determination.

5

Page 16

6

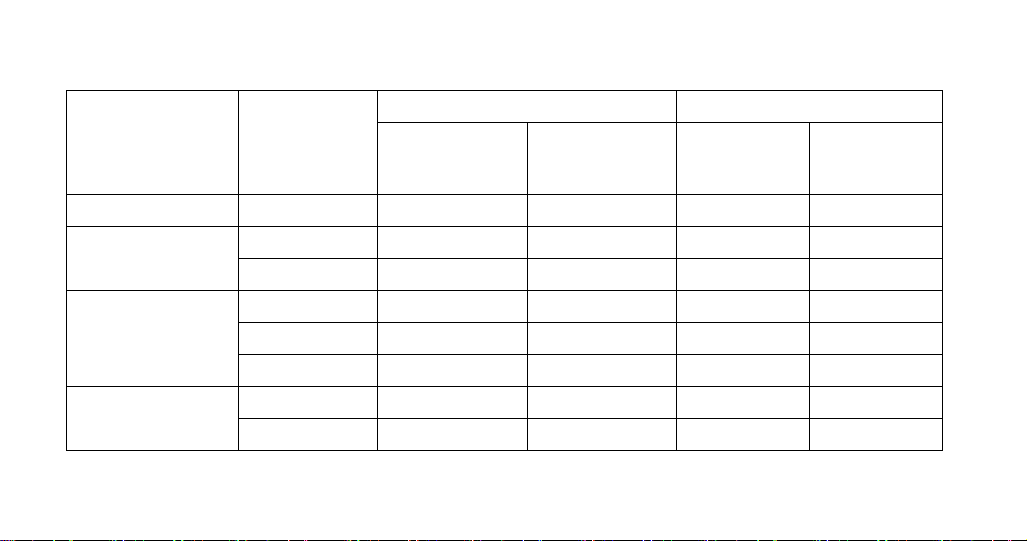

ELECTRICAL SPECIFICATIONS

Ice Machine

UG018 230/1/50 10 2.0 N/A N/A

UG020

UG030

UG040

Voltage/Phase/

Air-Cooled Water-Cooled

m Fuse/

Cyc

le

230/1/50 10 2.3 N/A N/A

230/1/60 10 2.3 N/A N/A

230/1/50 15 2.8 15 2.5

230/1/60 15 2.8 N/A N/A

115/1/60 15 5.5 N/A N/A

230/1/50 15 3.0 N/A N/A

230/1/60 15 3.0 N/A N/A

Maximu

Circuit Breaker

Total Am ps

Maximum

Fuse/Circuit

Breaker

Tot a l Amps

Page 17

230/1/50 15 4.0 15 2.8

UG050

UG065

UG080

7

230/1/60 15 4.0 N/A N/A

115/1/60 15 6.8 N/A N/A

230/1/50 15 4.5 N/A N/A

230/1/60 15 4.5 N/A N/A

230/1/50 15 5.5 N/A N/A

230/1/60 15 5.5 N/A N/A

Page 18

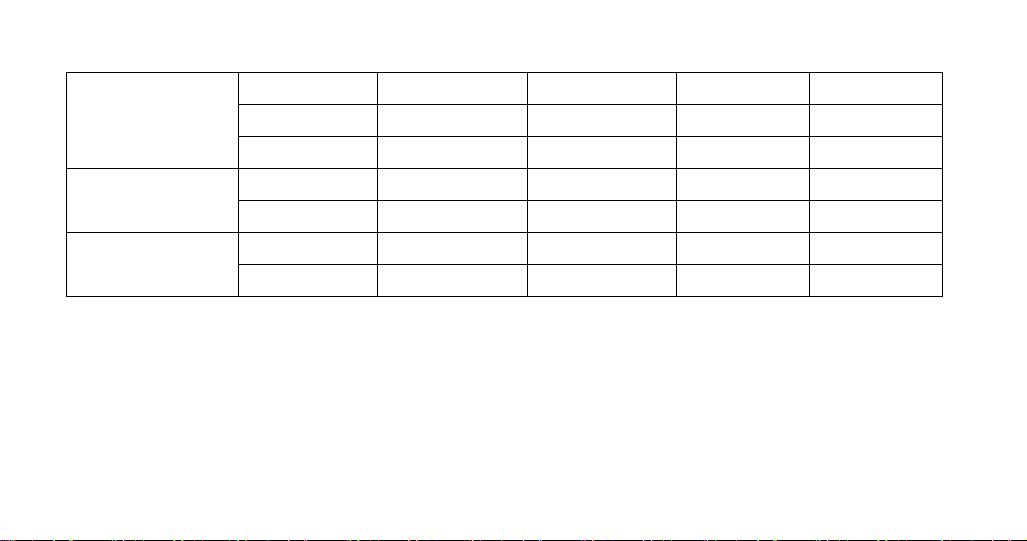

ICE MACHINE HEAT OF REJECTION

Series Ice

Machine

Air Conditioning Peak

Heat of Rejection

UG18 1,150 2,300

UG20 1,400 2,600

UG30 1,900 3,300

UG40 2,100 4,100

UG50 2,600 5,000

UG65 2,900 5,000

UG80 4,300 7,400

BTU/Hour

Because the heat of reje ction varies during the ice

making cycle, the figure sho wn is an average.

8

Page 19

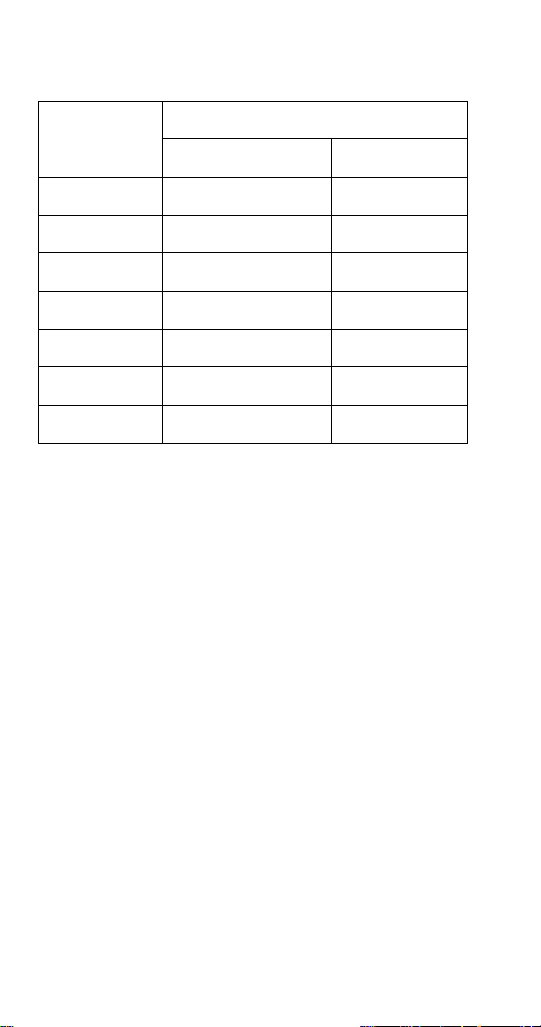

Component Identification

Water

Curtains

Water

Trough

Control

board

On/Off/Wash-Fill

Tog g l e S w it c h

Air Cooled

Condenser

9

Page 20

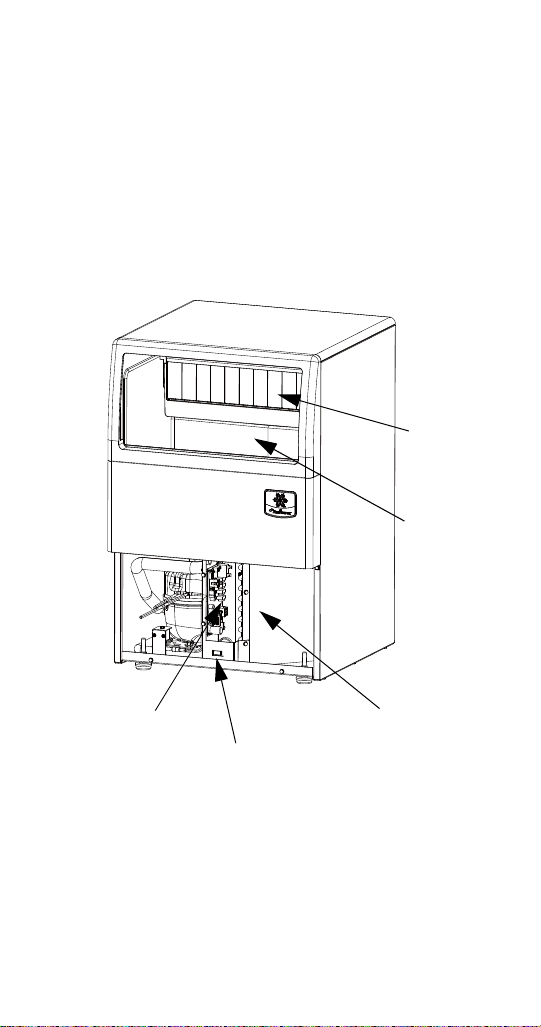

Evaporator

Spra y

Nozzles

Toggle Switch

Spra y B ar

Ice Chute

10

Page 21

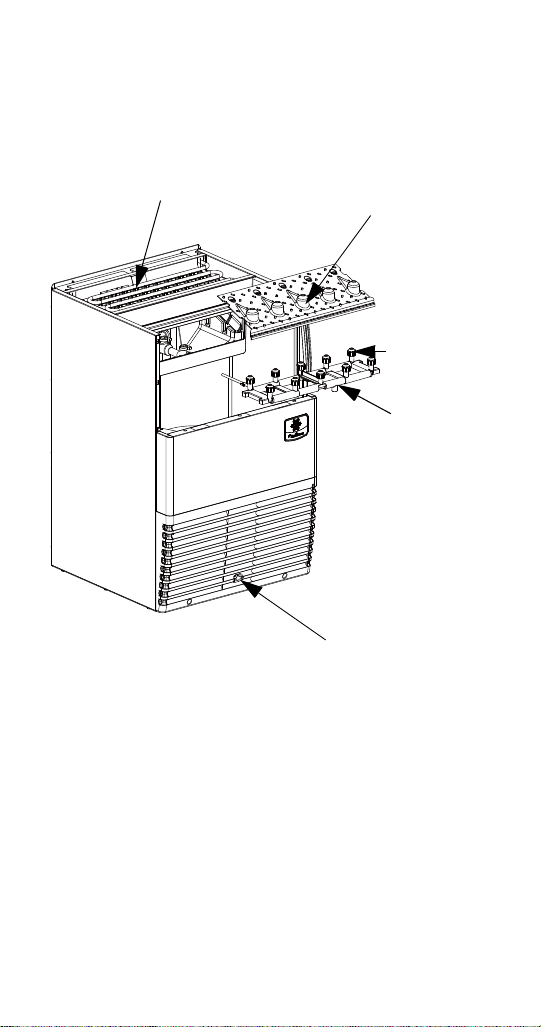

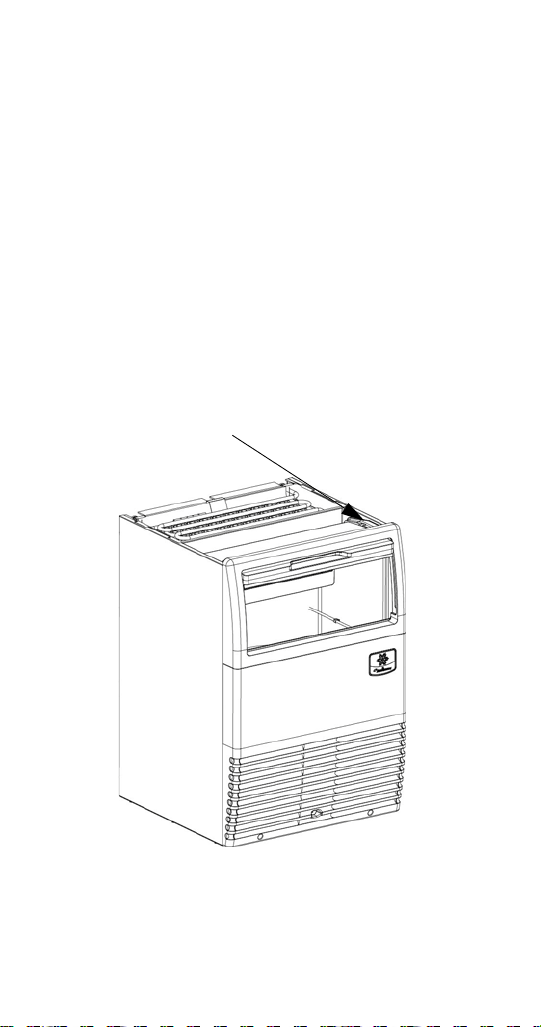

COMPONENT REMOVAL

Remove 2 Screws and

Slide Cover Back

T op Cove r

For easiest access to the evaporator compartment, the

top cover can be removed.

1. Remove two screws on the rear of the ice

machine.

2. Slide top cover back to disengage the three pins

from the front panel

11

Page 22

Bin Door

Align Door Pins With

Track Slots, Then Lift

Door Out Of Track

Allows access to the storage bin.

1. Remove top cover.

2. Slide door up until rear pins align with slot in door

tracks.

3. Lift rear door pins out and slide door up until front

door pins align with slot.

4. Lift door out of door track

12

Page 23

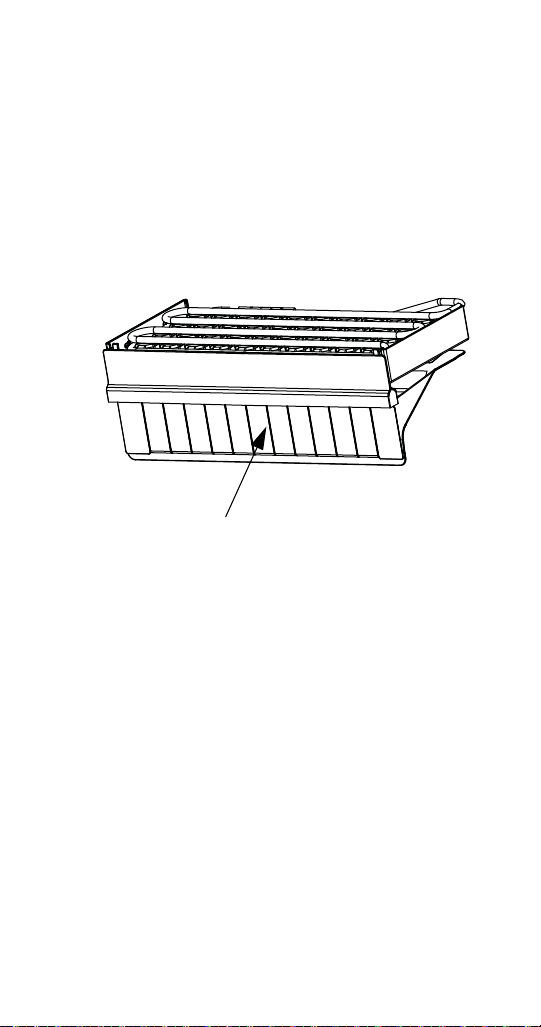

Water Curtain

Water Curtain

The water curtain is designed to keep the spraying

water from escaping the evaporator compartment.

Removal of the bin door is not required, but enhances

access.

1. Grasp the ice curtain and lift up.

2. To re-install into ice machine, pivot the water

curtain and pull down into position. Make sure

tabs are secure in grooves.

13

Page 24

Ice Chute

Ice Chute

The ice chute is positioned over the spray nozzles and

allows the ice to easily fall into the bin. It must be firmly

positioned over the Spray Bar Assembly, with the front

edge inside the water trough or the spray nozzles will

not be aligned with the spray holes, and spray water

will fall into bin.

1. Grab protruding spray holes on one end and lift

up.

2. Pivot ice chute and remove.

3. To re-install ice chute, grasp protruding spray

holes and position over Spray Bar Assembly.

Make sure rear supports are over Spray Bar

Assembly, and front edge is inside of water trough

14

Page 25

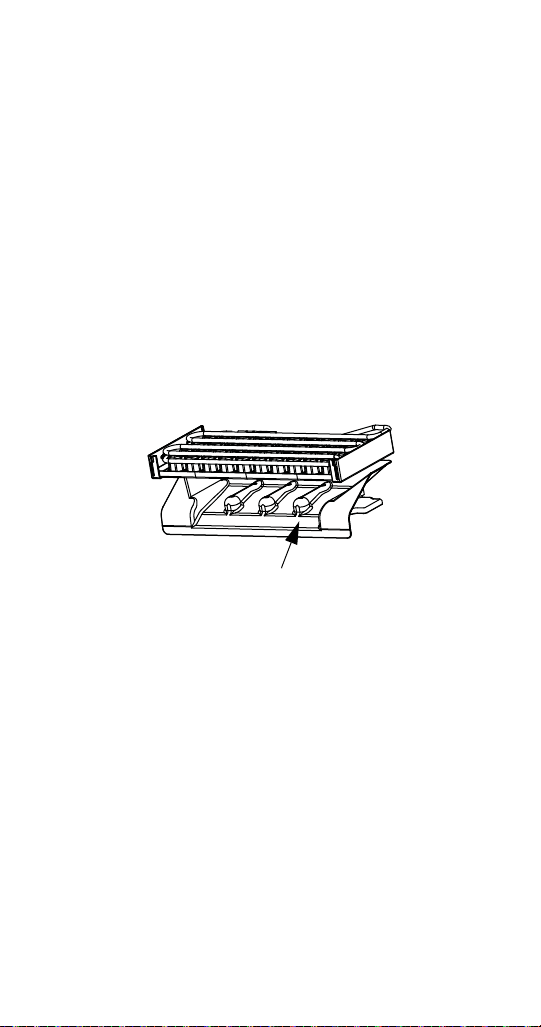

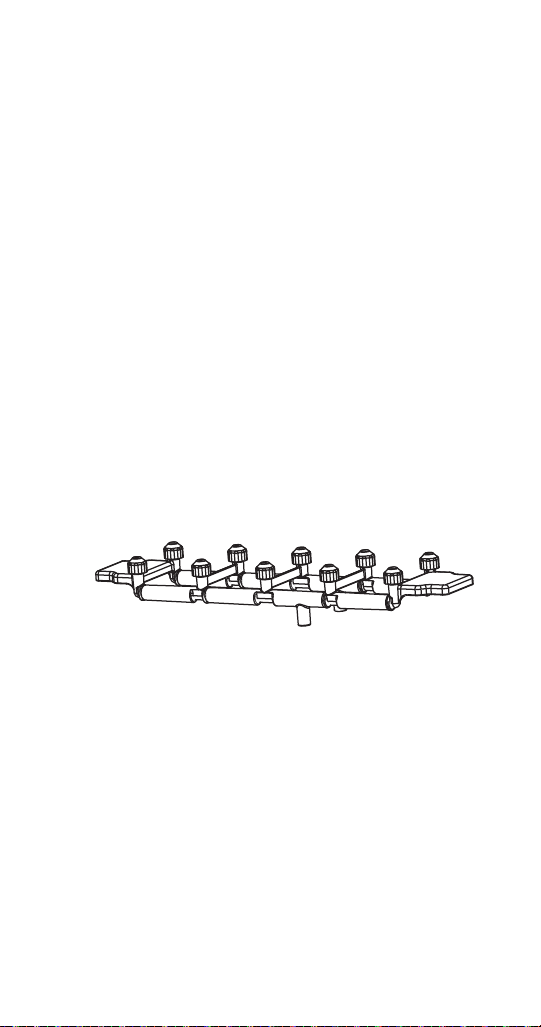

SPRAY BAR

The spray bar supplies water to the individual icemaking cups. Water from the Water Pump sprays

through the nozzles, located on the upper portion of

the tubes.

1. Grasp one end of the spray bar, lift up and remove

from seat formed in water trough.

2. Remove both plastic clips on water inlet tubing by

grasping both ears on clip and separating.

3. Apply food grade lubricate to ease re-assembly of

spray bar components when necessary.

4. To re-install spray bar, position water inlet tubing

on inlet ports, and squeeze clips until tight.

5. Reposition assembly on water trough seat.

NOTE:

Nozzles and inserts can be removed for

cleaning by unscrewing nozzles. Inserts are located

inside the spray bar ports. The spray bar also

disassembles for easy cleaning

15

Page 26

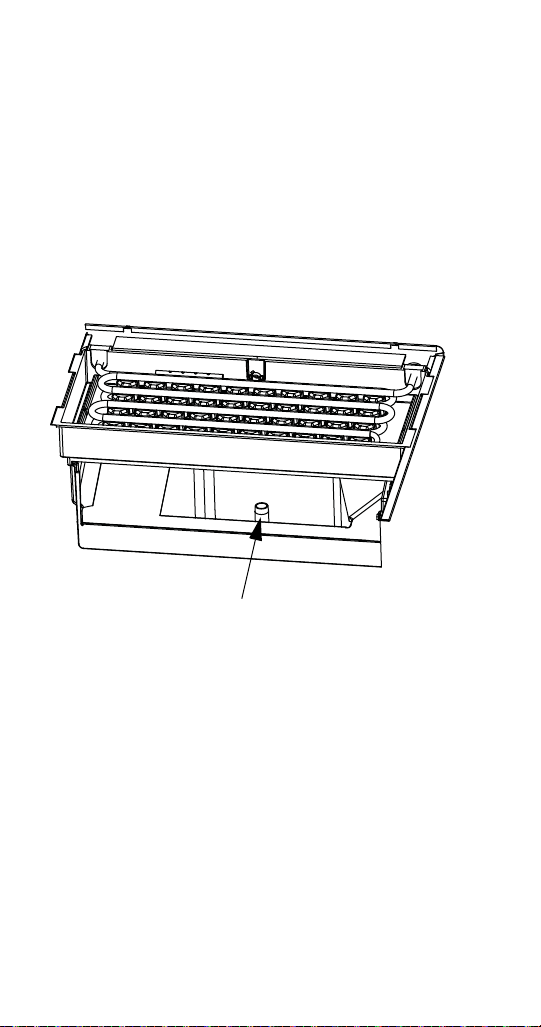

Sump Drain Overflow Tube

Overflow Tube

The sump drain overflow tube is located in the

evaporator water sump.

1. Remove shutters and ice chute.

2. Lift spray bar or disconnect and remove for

easiest access.

3. Pull up on over flow tube to remove.

To replace plug, insert in hole, and push with force to

make a tight seal

16

Page 27

Maintenance

!

Caution

!

Warning

INTERIOR CLEANING AND SANITIZING

GENERAL

Clean and sanitize the ice machine every six months

for efficient operation. If the ice machine requires more

frequent cleaning and sanitizing, consult a qualified

service company to test the water quality and

recommend appropriate water treatment.

An extremely dirty ice machine must be taken apart for

cleaning and sanitizing.

Use only approved Ice Machine Cleaner and

Sanitizer. Read and understand all labels printed on

bottles before use. Do not mix Ice Machine Cleaner

and Sanitizer solutions together

Wear rubber gloves and safety goggles (and/or face

shield) when handling Ice Machine Cleaner or

Sanitizer.

17

Page 28

CLEANING & SANITIZING PROCEDURE

!

Caution

Ice machine cleaner is used to remove lime scale or

other mineral deposits. Sanitizer is used to remove

algae or slime.

Mix 4 liters of water with 500 ml of cleaner in a plastic

or stainless container.

Cleaner Water

500 ml (16 oz) 4 l (1 gal)

Step 1 Set the toggle switch to the OFF position at the

end of a Harvest Cycle, after ice releases from the

evaporator. Or, set the switch to the OFF position and

allow the ice to melt off the evaporator.

Never use anything to force ice from the

evaporator. Damage may result.

Step 2 Remove all ice from the bin.

Step 3 Remove all parts as described in Section 3,

Component Identification & Removal.

Step 4 Take all components to sink and with 2 liters

Cleaner/Water mixture clean all components with a

soft nylon brush. Disassemble spray bar, remove

nozzles and inserts and soak for 5 minutes. For

heavily scaled parts, soak in solution for 15–20

minutes. Rinse all components with clean water.

Step 5 While components are soaking; use nylon

brush to scrub inside of ice bin. Scrub inside of door,

door track, bin, sump trough, and evaporator

moldings. With clean water, rinse all of these areas

thoroughly.

Step 6 Replace sump overflow tube and pour

remaining 2 liters of mixture into the water sump.

Replace all parts.

Step 7 To start a cleaning cycle, set the toggle switch

to the WASH position.

18

Page 29

Step 8 After 13.5 minutes, set the toggle switch to the

OFF position. Remove water curtain, ice chute and

over flow tube from the water sump. Allow all water to

drain from the sump. Replace drain plug . Set toggle

switch to WASH and circulate for 12minutes.

Step 9 Wait until the cleaning cycle(12 minutes) is

complete then place the toggle switch in the OFF

position.Remove water curtain, ice chute, water sump

over flow tube. Drain water from sump and replace

tube.

Step 10 Mix 60 ml of sanitizer with 12 l of water in a

plastic or stainless steel container.

Sanitizer Water

60 ml (2 oz) 12 l (3 gal)

Step 11 Remove Water Curtain and Ice Chute as

described in Section 3, Component Identification &

Removal.

Step 12 Take all components to sink and with 10 liters

Sanitizer/Water mixture sanitize all components with a

soft nylon brush or cloth. Do not rinse components.

Step 13 Use brush or cloth to sanitize the inside of ice

bin. Scrub inside of door, door track, bin, water sump,

water distribution assembly and evaporator moldings.

Do not rinse.

Step 14 Replace sump drain over flow tube, and

transfer remaining 2 liters of solution to the sump

trough. Replace all components.

Step 15 To start a sanitizing cycle, set the toggle

switch to the WASH position.

Step 16 After 13.5 minutes, set the toggle switch to

the OFF position. Remove water curtain and ice chute

Remove over flow tube from water sump and allow all

water to drain from sump. Replace drain plug. Set

toggle switch to WASH and circulate for 12

minutes.

Step 17 Wait until the cleaning cycle (12 minutes) is

complete then place the toggle switch in the OFF

19

Page 30

position. Remove water curtain, ice chute, water sump

over flow tube. Drain water from sump and replace tub

Step 18 Replace all parts.

Step 19 Place toggle switch to ON position,ice

machine will go into ice making cycle.

20

Page 31

EXTERIOR CLEANING

!

Caution

Clean the area around the ice machine as often as

necessary to maintain cleanliness and efficient

operation.

Sponge any dust and dirt off the outside of the ice

machine with mild soap and water. Wipe dry with a

clean, soft cloth.

A commercial grade stainless steel cleaner and polish

may be used.

REMOVAL FROM SERVICE/WINTERIZATION

GENERAL

Special precautions must be taken if the ice machine is

to be removed from service for an extended period of

time or exposed to ambient temperatures of 0°C

(32°F) or below.

If water is allowed to remain in the ice machine in

freezing temperatures, severe damage to some

components could result. Damage of this nature is

not covered by the warranty.

Follow the applicable procedure below.

AIR-COOLED ICE MACHINES

1. Disconnect the electric power at the circuit

breaker or the electric service switch.

2. Turn off the water supply.

3. Drain the water from the water sump and water

pump by disconnecting the water pump tubing.

4. Disconnect and drain the incoming ice-making

water line and disconnect the tubing from the

water inlet valve outlet and allow water to drain.

5. Blow compressed air in the drain opening and

water valve outlet hose, then reattach.

6. Make sure water is not trapped in any of the water

or drain lines.

21

Page 32

WATER-COOLED ICE MACHINES

1. Perform steps 1-6 under “Air-Cooled Ice

Machines.”

2. Disconnect the incoming water and drain lines

from the water-cooled condenser.

3. Insert a large screwdriver between the bottom

spring coils of the water regulating valve. Pry

upward to open the valve.

4. Hold the valve open and blow compressed air

through the condenser until water no longer exits.

22

Page 33

Operation

Sequence Of Operation

I

NITIAL START-UP

1. Water Inlet and Pressure Equalization

Turn the toggle switch to”ON” positon,the water fill

valve and harvest valve are energized, 300 seconds

, the water fill valve is de-energized. 20seconds

later

after the harvest valve solenoid is energized, the

compressor is energized. 300seconds after the

compressor is energized, the harvest valve solenoid is

de-energized, the water pumpand the fan motor are

energized,machine goes into freeze cycle.

2. Freeze Cycle

The pump sprays water into the inverted cups. The

water freezes layer by layer, until an ice cube forms in

each cup.

When the”water temperature”is equal to or less than 2

? for more than 5 seconds, control will read the” liquid

line temperature” and dip switch setting , get the”

freeze postpone time” and “fan shut off time”.Board

will shut the Fan before the end of the freeze cycle to

assist harvest. When the ” freeze postpone time” has

elapsed, the harvest cycle is initiated.

23

Page 34

3. Harvest Cycle

The compressor continues to operate and the water

pump is de-energized. The hot gas valve energizes,

allowing hot gas to enter and warm the evaporator.

The water valve is also energized, aiding with harvest,

as well as filling up the sump with fresh water for a

new freeze cycle.

at the point of 2 minutes to freeze end , board will read

the ” liquid line temperature”again and calculate the

“harvest time”

The ice falls from the cups and is directed into the bin

by the ice chute. The harvest cycle continues until the

harvest time has elapsed,then machine goes into a

new freeze cycle

4. Automatic Shut-Off

When the storage bin is full, the ice will come in

contact with the bin thermostat which is located inside

the bin. The machine will stop after approximately

45seconds of continuous ice contact with the bin

thermostat probe.

The ice machine remains off until a 3 minutes delay

has elapsed and enough ice has been removed from

the storage bin to allow the ice to fall clear of the bin

thermostat probe. As the ice clears the probe, the bin

thermostat warms up and the machine starts another

freeze cycle.

NOTE:

Be Careful not to turn the ice machine to WASH by

mistake. If so then you will need to follow the

WASH procedure until finished. Or, to bypass the

WASH lock-in, press the Test Button

3 times in 10 seconds and then set the

board)

toggle switch to the OFF position.

(in control

24

Page 35

I

ICE CUBE THICKNESS CHECK

The ice cube thickness is factory-set to maintain the

ice cube thickness at the proper size and weight.

1. Allow the ice machine to operate for three

complete cycles. The cubes should have a small

dimple in the center.

2. Cycle times vary, according to surrounding air and

water inlet temperatures.

3. If cubes are not full (large dimple), raise the “dip

switch” level to increase cube size. Allow ice

machine to complete three cycles, then check

cube.

4. If cubes are too full, ( no dimple), lower the “dip

switch” level to decrease cube size.Allow ice

machine to operate three complete cycles.

5. The “dip switch” can be adjusted to five levels: -2/

+1/+

-1/0/

2, and ensure that only one level switch

is pressed

25

Page 36

.

dip switch

Decrease

Cube Size

Factory

Default

Setting

Increase

Cube Size

test button

26

Page 37

CUBE SHAPE

The standard cube has an average weight of 19

Notice the normal dimple in the center of the cube.

27

Page 38

28

Page 39

Troubleshooting

All Models

ICE MACHINE WILL NOT RUN

Nothing on the ice machine will operate (compressor,

water pump, condenser fan motor). If any component

runs this procedure can be skipped, move on to the

next diagnostics (water pump won’t run, compressor

won’t run, etc).

1. Place the toggle switch in the clean position. If the

water pump runs begin with toggle switch

diagnostics. If water pump does not run place

toggle switch in ice position.

2. Verify correct voltage is present and matches

nameplate voltage.

3. High pressure switch must be closed on water

cooled ice machines

4. Bin thermostat must be closed before any

components can be energized.

29

Page 40

COMPRESSOR WON’T RUN

If the water pump is running and the compressor is

not, it may be tripping on overload or tripping the

breaker/fuse. Check for grounded winding if breaker

keeps tripping.

1. Compressor Relay LED lit?

2. Start capacitor and relay function?

3. Compressor windings closed?

4. Refer to compressor diagnostics.

30

Page 41

COMPRESSOR ELECTRICAL DIAGNOSTICS

The compressor does not start or will trip repeatedly

on overload.

Check Resistance (OHM) Values

NOTE:

Compressor windings can have very low ohm

values. Use a properly calibrated meter.

Perform the resistance test after the compressor

cools. The compressor dome should be cool enough

to touch (below 49°C) to assure that the overload is

closed and the resistance readings will be accurate.

Single Phase Compressors

1. Disconnect power from the condensing unit and

remove the wires from the compressor terminals.

2. The resistance values between C and S and

between C and R, when added together should

equal the resistance value between S and R.

3. If the overload is open, there will be a resistance

reading between S and R, and open readings

between C and S and between C and R. Allow the

compressor to cool, then check the readings again.

Check Motor Windings to Ground

Check continuity between all three terminals and the

compressor shell or copper refrigeration line. Scrape

metal surface to get good contact. If continuity is

present, the compressor windings are grounded and

the compressor should be replaced.

To determine if the Compressor is seized check the

amp draw while the compressor is trying to start.

31

Page 42

Compressor Drawing High Amps

The continuous amperage draw on start-up should not

be near the maximum fuse size indicated on the serial

tag.

The wiring must be correctly sized to minimize voltage

drop at compressor start-up. The voltage when the

compressor is trying to start must be within (6% of the

nameplate voltage).

Compressor Drawing Locked Rotor

The three likely causes of this are:

• Low voltage supply (check voltage while

compressor is trying to start)

• Defective starting component

• Mechanically seized compressor

To determine which you have:

• Install high and low side gauges.

• Try to start the compressor.

• Watch the pressures closely.

If the pressures do not move, the compressor is

seized. Replace the compressor.

If the pressures move, the compressor is turning

slowly and is not seized. Check the capacitors and

relay.

32

Page 43

DIAGNOSING START COMPONENTS

If the compressor attempts to start, or hums and trips

the overload protector, check the start components

before replacing the compressor.

Capacitor

Visual evidence of capacitor failure can include a

bulged terminal end or a ruptured membrane. Do not

assume a capacitor is good if no visual evidence is

present. A good test is to install a known good

substitute capacitor. Use a capacitor tester when

checking a suspect capacitor. Clip the bleed resistor

off the capacitor terminals before testing.

Current Relay

The relay has a set of contacts that energize and deenergize the compressor start winding. The contacts

on the relay are normally open (start winding deenergized). When power is applied the run winding will

be at LRA. The relay coil will become an

electromagnet and close the contacts (start winding

energized). As the compressor motor RPM increases,

the run winding current draw and relay coil magnetism

decrease allowing the contacts to open. Replace a

suspect relay with a known good relay, or use a

momentary switch and start capacitor to mimic relay

operation.

33

Page 44

WATER PUMP WON’T RUN

1. Water pump winding closed?

• Yes-rebulid or replace water pump.

• No-Water Pump Relay LED on control board lit?

∗ Yes:repair wiring

∗ No: rebulid or replace control board

HOT GAS VALVE WON’T ENERGIZE

1. Line voltage at hot gas valve?

• Yes - Replace hot gas valve coil.

• No - Hot gas valve Relay LED on control board lit?

∗ Yes:repair wiring

No:rebulid or replace control board

WATER INLET VALVE WON’T ENERGIZE

1. Line voltage at water inlet valve?

• Yes - Replace water inlet valve coil.

• No - water inlet valve Relay LED on control board

lit?

∗ Yes:repair wiring

No:rebulid or replace control board

34

Page 45

ICE MACHINE PREMATURELY HARVESTS

1. Line voltage at hot gas valve?

> No - Replace hot gas valve.

2. had set the "dip switch"?

>Yes - Refer to"ice cube thickness check"

djusting increase cube size(increase Increased

a

ice freeze time)

Refer to" thermistor diagnostics.” test the Water

Thermistor and the Liquid Line Thermistor .

35

Page 46

CE MACHINE WILL NOT HARVEST

1. Liquid Line Thermistor temperature below

setpoint?

2. Liquid Line Thermistor sensor installation

correctly?

3. Refer to" thermistor diagnostics.” test the Liquid

Line Thermistor.

Line voltage at hot gas valve and water inlet Solenoid?

36

Page 47

EVAPORATOR THERMOSTAT

Function

Thermistor resistance values change with

temperature.The value supplied to the control board is

used to Initiates and terminates freeze cycle?harvest

cycle and automatic shutdown?

Three thermistors are located on the ice machine.

are labeled T1, T2, T3?

They

T1- Water thermistor located at the water trough.

T2- Liquid line thermistor sensor located at outlet of

the condenser.

T3-Bin full thermistor sensor located at top of

the bin.

SPECIFICATIONS

TI &T3

Temperatur

e of

Thermistor

°C

-50 344.6 26 4.771

-49 320.5 27 4.567

-48 298.2 28 4.375

-47 277.6 29 4.190

-46 258.7 30 4.016

-45 241.1 31 3.849

-44 224.8 32 3.690

-43 209.8 33 3.538

-42 195.9 34 3.394

-41 183.0 35 3.256

Resistance

K Ohms (x

1000)

Temperatur

e of

Thermistor

Resistance

K Ohms (x

1000)

37

Page 48

Temperatur

e of

Thermistor

°C

Resistance

K Ohms (x

1000)

Temperatur

e of

Thermistor

-40 171.0 36 3.124

-39 159.9 37 2.999

-38 149.5 38 2.879

-37 140.0 39 2.764

-36 131.1 40 2.656

-35 122.8 41 2.551

-34 115.1 42 2.452

-33 108.0 43 2.356

-32 101.2 44 2.266

-31 95.03 45 2.179

-30 89.24 46 2.095

-29 83.83 47 2.016

-28 78.79 48 1.940

-27 74.09 49 1.867

-26 69.70 50 1.797

-25 65.58 51 1.731

-24 61.75 52 1.667

-23 58.16 53 1.606

-22 54.81 54 1.547

-21 51.66 55 1.491

-20 48.72 56 1.437

-19 45.97 57 1.385

-18 43.39 58 1.336

-17 40.96 59 1.289

-16 38.69 60 1.243

-15 36.56 61 1.200

-14 34.56 62 1.158

-13 32.68 63 1.117

-12 30.92 64 1.079

-11 29.25 65 1.041

-10 27.70 66 1.006

Resistance

K Ohms (x

1000)

38

Page 49

Temperatur

e of

Thermistor

°C

Resistance

K Ohms (x

1000)

Temperatur

e of

Thermistor

-9 26.24 67 0.9715

-8 24.85 68 0.9386

-7 23.55 69 0.9069

-6 22.33 70 0.8766

-5 21.18 71 0.8173

-4 20.09 72 0.8192

-3 19.07 73 0.7922

-2 18.10 74 0.7662

-1 17.19 75 0.7411

0 16.33 76 0.7170

1 15.52 77 0.6939

2 14.75 78 0.6715

3 14.02 79 0.6501

4 13.33 80 0.6293

5 12.69 81 0.6094

6 12.07 82 0.5902

7 11.49 83 0.5717

8 10.94 84 0.5538

9 10.43 85 0.5367

10 9.932 86 0.5201

11 9.466 87 0.5041

12 9.025 88 0.4887

13 8.608 89 0.4739

14 8.211 90 0.4595

15 7.836 91 0.4457

16 7.480 92 0.4323

17 7.142 93 0.4194

18 6.821 94 0.4069

19 6.516 95 0.3950

20 6.228 96 0.3833

21 5.953 97 0.3722

Resistance

K Ohms (x

1000)

39

Page 50

Temperatur

e of

Thermistor

°C

22 5.692 98 0.3613

23 5.444 99 0.3508

24 5.208 100 0.3407

25 4.984

Resistance

K Ohms (x

1000)

Temperatur

e of

Thermistor

T2

Resistance

K Ohms (x

1000)

Temperatur

e of

Thermistor

°C

-40 225.1 36 6.623

-39 212.8 37 6.387

-38 200.6 38 6.162

-37 189.3 39 5.945

-36 178.7 40 5.738

-35 168.8 41 5.538

-34 159.4 42 5.347

-33 150.6 43 5.163

-32 142.4 44 4.987

-31 134.7 45 4.817

-30 127.5 46 4.655

-29 120.6 47 4.498

-28 114.2 48 4.348

-27 108.2 49 4.203

-26 102.5 50 4.064

-25 97.20 51 3.931

-24 92.17 52 3.803

-23 87.44 53 3.680

40

Resistance

K Ohms (x

1000)

Temperatur

e of

Thermistor

Resistance

K Ohms (x

1000)

Page 51

Temperatur

e of

Thermistor

°C

Resistance

K Ohms (x

1000)

Temperatur

e of

Thermistor

-22 82.97 54 3.561

-21 78.77 55 3.446

-20 74.80 56 3.336

-19 71.05 57 3.230

-18 67.52 58 3.127

-17 64.19 59 3.028

-16 61.03 60 2.933

-15 58.06 61 2.841

-14 55.24 62 2.753

-13 52.58 63 2.667

-12 50.07 64 2.585

-11 47.68 65 2.505

-10 45.43 66 2.428

-9 43.30 67 2.354

-8 41.27 68 2.283

-7 39.36 69 2.214

-6 37.55 70 2.147

-5 35.83 71 2.082

-4 34.19 72 2.020

-3 32.65 73 1.960

-2 31.18 74 1.902

-1 29.78 75 1.846

0 28.49 76 1.791

1 27.20 77 1.739

2 26.01 78 1.688

3 24.88 79 1.639

4 23.80 80 1.592

5 22.78 81 1.546

6 21.81 82 1.502

7 20.88 83 1.459

8 20.00 84 1.417

Resistance

K Ohms (x

1000)

41

Page 52

Temperatur

e of

Thermistor

°C

Resistance

K Ohms (x

1000)

Temperatur

e of

Thermistor

9 19.16 85 1.377

10 18.36 86 1.338

11 17.60 87 1.300

12 16.88 88 1.264

13 16.19 89 1.229

14 15.53 90 1.195

15 14.90 91 1.162

16 14.30 92 1.129

17 13.73 93 1.098

18 13.19 94 1.068

19 12.67 95 1.039

20 12.17 96 1.011

21 11.70 97 0.9838

22 11.24 98 0.9572

23 10.81 99 0.9316

24 10.40 100 0.9066

25 10.00 101 0.8832

26 9.622 102 0.8604

27 9.260 103 0.8384

28 8.913 104 0.8170

29 8.582 105 0.7964

30 8.265 106 0.7762

31 7.961 107 0.7564

32 7.670 108 0.7374

33 7.391 109 0.7190

34 7.124 11 0 0.7010

35 6.868

Resistance

K Ohms (x

1000)

42

Page 53

Check Procedure

1. Make sure the thermistor sensors installation

correctly

2. Disconnect thermistor from control board and

measure resistance.

3. Measure temperature at the thermistor.

4. Compare measured resistance/

temperature.Creadings to resistance/temperature

relationship

• Within 10% of the published resistance value-

Thermistor is good

• Not within 10% of the published resistancevalue -

Thermistor is defective.

43

Page 54

Water System Checklist

A water-related problem often causes the same

symptoms as a refrigeration system component

malfunction.

Water system problems must be identified and

eliminated prior to replacing refrigeration components.

Water area (evaporator) is dirty

• Clean as needed

Water inlet pressure not between 1.4 and 5.5 bar

• Install a water regulator valve or increase the water

pressure

Incoming water temperature is not between

1.7°C and 32.2°C

• If too hot, check the hot water line check valves in

other store equipment

Water filtration is plugged (if used)

• Install a new water filter

Hoses, fittings, etc., are leaking water

• Repair/replace as needed

Water inlet valve is stuck open or closed

• Clean/replace as needed

Water is spraying out of the sump trough area

• Stop the water spray

Uneven water flow across the evaporator

• Clean the ice machine

44

Page 55

Ice Production Check

The amount of ice a machine produces directly relates

to the operating water and air temperatures. This

means an ice machine with a 20°C outdoor ambient

temperature and 10.0°C water produces more ice than

the same model ice machine with a 32°C outdoor

ambient and 21°C water.

1. Determine the ice machine operating conditions:

Air temp entering condenser: ____°

Air temp around ice machine: ____°

Water temp entering sump trough: ____°

2. Refer to the appropriate 24-Hour Ice Production

Chart.

3. Use the operating conditions determined in Step 1

to find published 24 hr. ice production: ____

• Times are in minutes.

Example: 1 min., 15 sec. converts to 1.25 min.

(15 seconds ÷ 60 seconds = .25 minutes)

• Weights are in grams.

4. Perform an ice production check using the formula

below.

1. _________

Freeze Time

2. 1440

_________

Minutes in

24 Hrs.

3. _________

Weight of One

Harvest

+ _________

Harvest Time

_________

Total Cycle

Time

× _________

Cycles per Day

= _________

To t a l C y cl e

Time

_________

Cycles per Day

= _________

Actual 24-Hour

Production

Weighing the ice is the only 100% accurate check.

Compare the results of Step 3 with Step 2. Ice

production is normal when these numbers match

closely. If they match closely, determine if:

• Another ice machine is required.

Relocating the existing equipment to lower the load

conditions is required.

45

Page 56

Analyzing Discharge Pressure

1. Determine the ice machine operating conditions:

Air temp. entering condenser ______

Air temp. around ice machine ______

Water temp. entering sump trough ______

2. Refer to Cycle Times/24 Hour Ice Production/

Refrigeration Pressure Chart for ice machine being

checked.

3. Use the operating conditions determined in Step 1

to find the published normal discharge pressures.

Freeze Cycle ______

Harvest Cycle ______

Perform an actual discharge pressure check.

Freeze Cycle

PSIG

Beginning

of Cycle

Middle

of Cycle

End

of Cycle

__________ __________

__________ __________

__________ __________

Compare the actual discharge pressure (Step 3) with

the published discharge pressure (Step 2).

The discharge pressure is normal when the actual

pressure falls within the published pressure range for

the ice machine’s operating conditions. It is normal for

the discharge pressure to be higher at the beginning of

the freeze cycle (when load is greatest), then drop

throughout the freeze cycle.

Harvest Cycle

PSIG

46

Page 57

DISCHARGE PRESSURE HIGH CHECKLIST

Improper Installation

• Refer to “Installation/Visual Inspection Checklist”

Restricted Condenser Air Flow

• High inlet air temperature

• Condenser discharge air re-circulation

• Dirty condenser fins

• Defective fan motor

Improper Refrigerant Charge

• Overcharged

• Non-condensable in system

• Wrong type of refrigerant

Other

• High side refrigerant lines/component restricted

(before mid-condenser)

47

Page 58

FREEZE CYCLE DISCHARGE PRESSURE LOW

CHECKLIST

Improper Installation

• Refer to “Installation/Visual Inspection Checklist”

Improper Refrigerant Charge

• Undercharged

• Wrong type of refrigerant

Other

• High side refrigerant lines/component restricted

(before mid-condenser)

NOTE:

Do not limit your diagnosis to only the items

listed in the checklists.

48

Page 59

Analyzing Suction Pressure

The suction pressure gradually drops throughout the

freeze cycle. The actual suction pressure (and drop

rate) changes as the air and water temperature

entering the ice machine changes. These variables

also determine the freeze cycle times.

To analyze and identify the proper suction pressure

drop throughout the freeze cycle, compare the

published suction pressure to the published freeze

cycle time.

NOTE:

suction pressure. High or low discharge pressure may

be causing high or low suction pressure.

Analyze discharge pressure before analyzing

49

Page 60

Procedure

20

2.56

140

2.92

2.2

Step

1. Determine the ice

machine operating

conditions.

2A. Refer to “Cycle Time” and

“Operating Pressure”

charts for ice machine

model being checked.

Using operating

conditions from Step 1,

determine published

freeze cycle time and

published freeze cycle

suction pressure.

2B. Compare the published

freeze cycle time and

published freeze cycle

suction pressure. Develop

a chart.

3. Perform an actual suction

pressure check at the

beginning, middle and end

of the freeze cycle. Note

the times at which the

readings are taken.

4. Compare the actual

freeze cycle suction

pressure (Step 3) to the

published freeze cycle

time and pressure

comparison (Step 2B).

Determine if the suction

pressure is high, low or

acceptabl e.

Example Using UG040A Model Ice

Air temp. entering condenser:

32°C

Water temp. entering water fill valve:

21°C

39.28 minutes

Published Freeze cycle time:

2.92 to2.2 bar

Published Freeze cycle suction pressure:

Published Freeze Cycle Suction

In the example, the proper suction pressure

should be approximate ly 2.92 bar at 1 min ute;

Manifold gauges were connected to the

example ice machine and suction pressure

readings taken as follows:

Beginning of Freeze cycle:5bar (at 1 min.)

Middle of Freeze cycle:4 bar (at 20 min.)

End of Freeze cycle:3 bar (at 40 min.)

In this example, the suction pressure is

considered high throughout the freeze cycle.

It should have been:

Approximately 2.92 bar

(at 1 minute) – not 5 bar

Approximately 2.56 bar

(at 20 minutes) – not 4 bar

Approximately 2.2 bar

(at 40 minutes) – not 3 bar

Machine

Published Freeze Cycle Time

(minutes)

Pressure (bar)

2.56bar at 20 minutes; etc.

50

Page 61

SUCTION PRESSURE HIGH CHECKLIST

Improper Installation

• Refer to “Installation/Visual Inspection Checklist”

Discharge Pressure

• Discharge pressure is too high, and is affecting

suction pressure, refer to “Freeze Cycle Discharge

Pressure High Checklist”

Improper Refrigerant Charge

• Overcharged

• Wrong type of refrigerant

• Non Condensable in system

Other

• Hot gas valve leaking

• TXV flooding (check bulb mounting)

Defective compressor

51

Page 62

SUCTION PRESSURE LOW CHECKLIST

Improper Installation

• Refer to “Installation/Visual Inspection Checklist”

Discharge Pressure

• Discharge pressure is too low, and is affecting

suction pressure, refer to “Freeze Cycle Discharge

Pressure Low Checklist”

Improper Refrigerant Charge

• Undercharged

• Wrong type of refrigerant

Other

• Improper water supply over evaporator, refer to

“Water System Checklist”

• Loss of heat transfer from tubing on back side of

evaporator

• Restricted/plugged liquid line drier

• Restricted/plugged tubing or capillary tube in suction

side of refrigeration system

• TXV starving

• Moisture in refrigeration system

NOTE:

Do not limit your diagnosis to only the items

listed in the checklists.

52

Page 63

Discharge Line Temperature Analysis

General

Compressor discharge line temperature on a normally

operating ice machine steadily increases throughout

the freeze cycle. Comparing the temperatures over

several cycles will result in a consistent maximum

discharge line temperature.

Ambient air temperatures affect the maximum

discharge line temperature.

Higher ambient air temperatures at the condenser =

higher discharge line temperatures at the compressor.

Lower ambient air temperatures at the condenser =

lower discharge line temperatures at the compressor.

Regardless of ambient temperature, the freeze cycle

discharge line temperature will be higher than 71°C on

a normally operating ice machine.

Procedure

Connect a temperature probe on the compressor

discharge line within 6" of the compressor.

Observe the discharge line temperature for the last ten

minutes of the freeze cycle and record the maximum

discharge line temperature.

53

Page 64

DISCHARGE LINE TEMPERATURE ABOVE 71°C AT

END OF FREEZE CYCLE:

Ice machines that are operating normally will have

consistent maximum discharge line temperatures

above 71°C.

DISCHARGE LINE TEMPERATURE BELOW 71°C AT

END OF FREEZE CYCLE:

Ice machines that have a flooding expansion valve will

have a maximum discharge line temperature that

decreases each cycle.

Verify the expansion valve sensing bulb is 100%

insulated and sealed airtight. Condenser air contacting

an incorrectly insulated sensing bulb will cause

overfeeding of the expansion valve.

Verify the expansion valve sensing bulb is positioned

and secured correctly.

54

Page 65

Component Check Procedures

ON/OFF/WASH-FILL T OGGLE SWITCH

Function

The switch is used to place the ice machine in ON,

OFF or WASH mode of operation.

Specifications

Double-pole, Double-throw switch.

Check Procedure

1. Inspect the toggle switch for correct wiring.

2. Isolate the toggle switch by disconnecting all wires

from the switch.

3. Check across the toggle switch terminals using a

calibrated ohmmeter. Note where the wire numbers

are connected to the switch terminals, or refer to

the wiring diagram to take proper readings.

Switch

Setting

ON

WASH

OFF

Terminals Ohm Reading

5-6 Open

5-4 Closed

2-1 Closed

2-3 Open

5-4 Open

5-6 Closed

2-3 Closed

2-1 Open

2-3 Open

2-1 Open

5-6 Open

5-4 Open

Replace the toggle switch if ohm readings do not

match all three-switch settings.

55

Page 66

BIN THERMISTOR (T3)

Function

The bin thermistor stops the ice machine when the bin

is full. When ice cubes contact the bin thermistor bulb

holder, the bin thermistor opens and stops the ice

machine. When ice cubes no longer contact the bin

thermistor bulb holder, the bin thermistor closes and

the ice machine starts.

The bin thermistor “temperature setting” determined

by the point of T2(liquid line thermistor) of when T1

(sump water thermistor) come down 2 °C, refer to the

Specifications Charts below for clearance.

Specifications

UG40/UG50/YG65

T1 (°C) T2 (°C)

≤2.0 T2≤28 ≤1.5 ≥2.0

≤2.0 28<T2≤56 ≤2.0 ≥3.5

≤2.0 56<T2 ≤3.0 ≥4.5

Shut down

(T3)

Go back

(T3)

UG18/UG20/UG30

T1 (°C) T2 (°C)

≤2.0 T2≤32 ≤1.7 ≥2.2

≤2.0 32<T2≤51 ≤2.2 ≥3.7

≤2.0 51<T2 ≤3.0 ≥4.5

Shut down

(T3)

Go back

(T3)

UG80

T1 (°C) T2 (°C)

≤2.0 T2≤37 ≤1.5 ≥2.0

≤2.0 37<T2≤56 ≤2.0 ≥3.5

≤2.0 56<T2 ≤3.0 ≥4.5

56

Shut down

(T3)

Go back

(T3)

Page 67

Check Procedure

!

Warning

Disconnect electrical power to the entire ice

machine before proceeding.

Make sure bulb is inserted correctly 35.5 cm in the

bulb well. Disconnect the wires from the bin thermostat

and check the resistance across the terminals.

No Ice on Bulb Ice on Bulb Result

Closed (O) Open (OL) Thermostat good

Open (OL) Closed (O)

Replace

thermostat

NOTE:

After covering/uncovering the bulb holder with

ice, wait at least three minutes to allow the thermostat

to react. (Open/Close)

57

Page 68

SUMP WATER THERMISTOR (T1)& LIQUID LINE

THERMISTOR(T2)

Function

The sump water thermistor sensor immersed in water

to detect sump temperature.The value supplied to the

control board is

used to Initiates freeze cycle

The liquid line thermistor senses the refrigeration

system liquid line temperature. This is used in

conjunction with the control board to determine the

length of the freeze and harvest cycles

.

Specifications

The sump water thermostor :

R2.0°C ±0.5°C = 14.75Kohm ±1%

The liquid line thermistor:

R25°C±0.5°C = 10Kohm ±1%

Check Procedure

1. Make sure the thermistor sensors installation

correctly

2. Disconnect thermistor from control board and

measure resistance.

3. Measure temperature at the thermistor.

4. Compare measured resistance/

temperature.Creadings to resistance/temperature

relationship

Within 10% of the published resistance valueThermistor is good

58

Page 69

Temperature/Resistance Chart

Important

If the ohmmeter reads “OL,” check the scale setting

on the meter before assuming the thermistor is bad.

TI &T3

Temperatur

e of

Thermistor

°C

-50 344.6 26 4.771

-49 320.5 27 4.567

-48 298.2 28 4.375

-47 277.6 29 4.190

-46 258.7 30 4.016

-45 241.1 31 3.849

-44 224.8 32 3.690

-43 209.8 33 3.538

-42 195.9 34 3.394

-41 183.0 35 3.256

-40 171.0 36 3.124

-39 159.9 37 2.999

-38 149.5 38 2.879

-37 140.0 39 2.764

-36 131.1 40 2.656

-35 122.8 41 2.551

-34 115.1 42 2.452

-33 108.0 43 2.356

-32 101.2 44 2.266

-31 95.03 45 2.179

-30 89.24 46 2.095

-29 83.83 47 2.016

-28 78.79 48 1.940

-27 74.09 49 1.867

Resistance

K Ohms (x

1000)

Temperatur

e of

Thermistor

Resistance

K Ohms (x

1000)

59

Page 70

Temperatur

e of

Thermistor

°C

Resistance

K Ohms (x

1000)

Temperatur

e of

Thermistor

-26 69.70 50 1.797

-25 65.58 51 1.731

-24 61.75 52 1.667

-23 58.16 53 1.606

-22 54.81 54 1.547

-21 51.66 55 1.491

-20 48.72 56 1.437

-19 45.97 57 1.385

-18 43.39 58 1.336

-17 40.96 59 1.289

-16 38.69 60 1.243

-15 36.56 61 1.200

-14 34.56 62 1.158

-13 32.68 63 1.117

-12 30.92 64 1.079

-11 29.25 65 1.041

-10 27.70 66 1.006

-9 26.24 67 0.9715

-8 24.85 68 0.9386

-7 23.55 69 0.9069

-6 22.33 70 0.8766

-5 21.18 71 0.8173

-4 20.09 72 0.8192

-3 19.07 73 0.7922

-2 18.10 74 0.7662

-1 17.19 75 0.7411

0 16.33 76 0.7170

1 15.52 77 0.6939

2 14.75 78 0.6715

3 14.02 79 0.6501

4 13.33 80 0.6293

Resistance

K Ohms (x

1000)

60

Page 71

Temperatur

e of

Thermistor

°C

5 12.69 81 0.6094

6 12.07 82 0.5902

7 11.49 83 0.5717

8 10.94 84 0.5538

9 10.43 85 0.5367

10 9.932 86 0.5201

11 9.466 87 0.5041

12 9.025 88 0.4887

13 8.608 89 0.4739

14 8.211 90 0.4595

15 7.836 91 0.4457

16 7.480 92 0.4323

17 7.142 93 0.4194

18 6.821 94 0.4069

19 6.516 95 0.3950

20 6.228 96 0.3833

21 5.953 97 0.3722

22 5.692 98 0.3613

23 5.444 99 0.3508

24 5.208 100 0.3407

25 4.984

Resistance

K Ohms (x

1000)

Temperatur

e of

Thermistor

Resistance

K Ohms (x

1000)

T2

Temperatur

e of

Thermistor

°C

-40 225.1 36 6.623

-39 212.8 37 6.387

Resistance

K Ohms (x

1000)

Temperatur

e of

Thermistor

Resistance

K Ohms (x

1000)

61

Page 72

Temperatur

e of

Thermistor

°C

Resistance

K Ohms (x

1000)

Temperatur

e of

Thermistor

-38 200.6 38 6.162

-37 189.3 39 5.945

-36 178.7 40 5.738

-35 168.8 41 5.538

-34 159.4 42 5.347

-33 150.6 43 5.163

-32 142.4 44 4.987

-31 134.7 45 4.817

-30 127.5 46 4.655

-29 120.6 47 4.498

-28 114.2 48 4.348

-27 108.2 49 4.203

-26 102.5 50 4.064

-25 97.20 51 3.931

-24 92.17 52 3.803

-23 87.44 53 3.680

-22 82.97 54 3.561

-21 78.77 55 3.446

-20 74.80 56 3.336

-19 71.05 57 3.230

-18 67.52 58 3.127

-17 64.19 59 3.028

-16 61.03 60 2.933

-15 58.06 61 2.841

-14 55.24 62 2.753

-13 52.58 63 2.667

-12 50.07 64 2.585

-11 47.68 65 2.505

-10 45.43 66 2.428

-9 43.30 67 2.354

-8 41.27 68 2.283

Resistance

K Ohms (x

1000)

62

Page 73

Temperatur

e of

Thermistor

°C

Resistance

K Ohms (x

1000)

Temperatur

e of

Thermistor

-7 39.36 69 2.214

-6 37.55 70 2.147

-5 35.83 71 2.082

-4 34.19 72 2.020

-3 32.65 73 1.960

-2 31.18 74 1.902

-1 29.78 75 1.846

0 28.49 76 1.791

1 27.20 77 1.739

2 26.01 78 1.688

3 24.88 79 1.639

4 23.80 80 1.592

5 22.78 81 1.546

6 21.81 82 1.502

7 20.88 83 1.459

8 20.00 84 1.417

9 19.16 85 1.377

10 18.36 86 1.338

11 17.60 87 1.300

12 16.88 88 1.264

13 16.19 89 1.229

14 15.53 90 1.195

15 14.90 91 1.162

16 14.30 92 1.129

17 13.73 93 1.098

18 13.19 94 1.068

19 12.67 95 1.039

20 12.17 96 1.011

21 11.70 97 0.9838

22 11.24 98 0.9572

23 10.81 99 0.9316

Resistance

K Ohms (x

1000)

63

Page 74

Temperatur

e of

Thermistor

°C

Resistance

K Ohms (x

1000)

Temperatur

e of

Thermistor

24 10.40 100 0.9066

25 10.00 101 0.8832

26 9.622 102 0.8604

27 9.260 103 0.8384

28 8.913 104 0.8170

29 8.582 105 0.7964

30 8.265 106 0.7762

31 7.961 107 0.7564

32 7.670 108 0.7374

33 7.391 109 0.7190

34 7.124 11 0 0.7010

35 6.868

Resistance

K Ohms (x

1000)

64

Page 75

HIGH PRESSURE CUTOUT (HPCO) CONTROL

!

Warning

Water Cooled Only

FUNCTION

Stops the ice machine if subjected to excessive highside pressure.

The HPCO control is normally closed, and opens on a

rise in discharge pressure.

SPECIFICATIONS

Model Cut-out Cut-in:

UG030W 300 psig ± 10 150 psig ± 10

UG050W 450 psig± 10 300 psig± 10

CHECK PROCEDURE

1. Set ON/OFF/WASH switch to OFF.

2. Connect manifold gauges.

3. Hook voltmeter in parallel across the HPCO,

leaving wires attached.

4. Close the valve to the water condenser inlet.

5. Set ON/OFF/WASH switch to ON.

6. No water flowing through the condenser will cause

the HPCO control to open because of excessive

pressure. Watch the pressure gauge and record the

cut-out pressure.

If discharge pressure exceeds 310 psig (UG030) or

460psig(UG050) and the HPCO control does not cut

out, set ON/OFF/WASH switch to OFF to stop ice

machine operation.

Replace the HPCO control if it:

• Will not reset (below 150 psig [UG030];below 300

psig [UG050])

• Does not open at the specified cut-out point

65

Page 76

HOT GAS VALVE

General

The hot gas valve is an electrically operated valve that

opens when energized, and closes when deenergized.

Normal Operation

The valve is de-energized (closed) during the freeze

cycle and energized (open) during the harvest cycle.

The valve is positioned between the compressor and

the evaporator and performs two functions:

7. Prevents refrigerant from entering the evaporator

during the freeze cycle.

The hot gas valve is de-energized (closed)

preventing refrigerant flow from the receiver into

the evaporator.

8. Allows refrigerant vapor to enter the evaporator in

the harvest cycle.

During the harvest cycle, the hot gas valve is

energized (open) allowing refrigerant gas from the

discharge line of the compressor to flow into the

evaporator. The heat is absorbed by the evaporator

and allows release of the ice slab.

Exact pressures vary according to ambient

temperature and ice machine model. Harvest

pressures can be found in the “Cycle Time/24 Hour Ice

Production/Refrigerant Pressure Charts in this book.

66

Page 77

Hot Gas Valve Analysis

The valve can fail in two positions:

• Valve will not open in the harvest cycle.

• Valve remains open during the freeze cycle.

VALVE WILL NOT OPEN IN THE HARVEST CYCLE:

Although the coil is energized in the harvest cycle, the

evaporator temperature/pressure remains unchanged

from the freeze cycle.

VALVE REMAINS OPEN IN THE FREEZE CYCLE:

Symptoms of a hot gas valve remaining partially open

during the freeze cycle can be similar to symptoms of

an expansion valve, Capillary tube or compressor

problem. Symptoms are dependent on the amount of

leakage in the freeze cycle.

A small amount of leakage will cause increased freeze

times. As the amount of leakage increases, the length

of the freeze cycle increases.

Refer to the Parts Manual for proper valve application.

If replacement is necessary, use only “original”

Manitowoc replacement parts.

67

Page 78

Use the following procedure and table to help

Important

!

Warning

determine if a hot gas valve is remaining partially open

during the freeze cycle.

1. Wait five minutes into the freeze cycle.

2. Feel the inlet of the hot gas valve.

Feeling the hot gas valve outlet or across the hot

gas valve itself will not work for this comparison. The

hot gas valve outlet is on the suction side (cool

refrigerant). It may be cool enough to touch even if

the valve is leaking.

3. Feel the compressor discharge line.

The inlet of the hot gas valve and the compressor

discharge line could be hot enough to burn your

hand. Just touch them momentarily.

4. Compare the temperature of the inlet of the hot gas

valves to the temperature of the compressor

discharge line.

68

Page 79

Examples of hot gas valve inlet/compressor

discharge line temperature comparison

Findings Comments

The inlet of the hot gas

valve is cool enough to

touch and the

compressor discharge

line is hot.

The inlet of the hot gas

valve is hot and

approaches the

temperature of a hot

compressor discharge

line.

Both the inlet of the hot

gas valve and the

compressor discharge

line are cool enough to

touch.

This is normal as the discharge

line should always be too hot to

touch and the hot gas valve inlet,

although too hot to touch during

harvest, should be cool enough

to touch after 5 minutes into the

freeze cycle.

This is an indication something is

wrong, as the hot gas valve inlet

did not cool down during the

freeze cycle. If the compressor

dome is also entirely hot, the

problem is not a hot gas valve

leaking, but rather something

causing the compressor (and the

entire ice machine) to get hot.

This is an indication something is

wrong, causing the compressor

discharge line to be cool to the

touch. This is not caused by a hot

gas valve leaking.

69

Page 80

This Page Intentionally Left Blank

70

Page 81

Refrigerant

Important

Important

RECOVER/EVACUATION/CHARGING

Normal Procedures

Do not purge refrigerant to the atmosphere. Capture

refrigerant using recovery equipment. Follow the

manufacturer’s recommendations.

Manitowoc Ice, Inc. assumes no responsibility for

the use of contaminated refrigerant. Damage

resulting from the use of contaminated refrigerant is

the sole responsibility of the servicing company.

Replace the liquid line drier before evacuating and

recharging. Use only a Manitowoc (O.E.M.) liquid

line filter drier to prevent voiding the warranty.

Connections

1. Suction side of the compressor through the suction

service valve.

2. Discharge side of the compressor through the

discharge service valve.

–71–

Page 82

Self-Contained Recovery/Evacuation

Place the toggle switch in the OFF position.

Install manifold gauges (with low loss fittings), scale,

and recovery unit or two-stage vacuum pump.

Open (backseat) the high and low side on manifold

gauges.

Perform recovery or evacuation:

A. Recovery: Operate the recovery unit as directed by

the manufacturer’s instructions.

B. Evacuation prior to recharging: Pull the system

down to 500 microns. Then, allow the pump to run

for an additional half hour. Turn off the pump and

perform a standing vacuum leak check.

NOTE: Check for leaks using a halide or electronic

leak detector after charging the ice machine.

Follow the Charging Procedures on the next page.

–72–

Page 83

Charging Procedures

Important

The charge is critical on all Manitowoc ice machines.

Use a scale to ensure the proper charge is installed.

1. Be sure the toggle switch is in the OFF position.

2. Close the vacuum pump valve and the low side

manifold gauge valve.

3. Open the high side manifold gauge valve.

4. Open the refrigerant cylinder and add the proper

refrigerant charge (shown on nameplate) through

the discharge service valve.

5. Let the system “settle” for 2 to 3 minutes.

6. Place the toggle switch in the ICE position.

7. Close the high side on the manifold gauge set. Add

any remaining vapor charge through the suction

service valve (if necessary).

NOTE: Manifold gauges must be removed properly to

ensure that no refrigerant contamination or loss

occurs.

8. Make sure all vapor in the charging hoses is drawn

into the ice machine before disconnecting.

a. Run the ice machine in freeze cycle.

b. Disconnect the high side service valve at the ice

machine.

c. Open the high and low side valves on the

manifold gauge set. Any refrigerant in the lines

will be pulled into the low side of the system.

d. Allow the pressures to equalize while the ice

machine is in the freeze cycle.

e. Disconnect the low side service valve at the ice

machine.

9. Install the caps on the refrigeration access valves.

–73–

Page 84

SYSTEM CONTAMINATION CLEANUP

Important

General

This section describes the basic requirements for

restoring contaminated systems to reliable service.

Manitowoc Ice, Inc. assumes no responsibility for

the use of contaminated refrigerant. Damage

resulting from the use of contaminated refrigerant is

the sole responsibility of the servicing company.

DETERMINING SEVERITY OF CONTAMINATION

System contamination is generally caused by either

moisture or residue from compressor burnout entering

the refrigeration system.

Inspection of the refrigerant usually provides the first

indication of system contamination. Obvious moisture

or an acrid odor in the refrigerant indicates

contamination.

If either condition is found, or if contamination is

suspected, use a Total Test Kit from Totaline or a

similar diagnostic tool. These devices sample

refrigerant, eliminating the need to take an oil sample.

Follow the manufacturer’s directions.

If a refrigerant test kit indicates harmful levels of

contamination, or if a test kit is not available, inspect

the compressor oil.

1. Remove the refrigerant charge from the ice

machine.

2. Remove the compressor from the system.

3. Check the odor and appearance of the oil.

4. Inspect open suction and discharge lines at the

compressor for burnout deposits.

5. If no signs of contamination are present, perform an

acid oil test to determine the type of cleanup

required.

–74–

Page 85

Contamination/Cleanup Chart

Symptoms/Findings

No symptoms or suspicion of

contamination.

Moisture/Air Contamination

symptoms. Refrigeration

system open to atmosphere for

longer than 15 minutes.

Refrigeration test kit and/or acid

oil test shows contamination.

No burnout deposits in open

compressor lines.

Mild Compressor Burnout

symptoms. Oil appears clean

but smells acrid. Refrigeration

test kit or acid oil test shows

harmful acid content. No

burnout deposits in open

compressor lines.

Severe Compressor Burnout

symptoms. Oil is discolored,

acidic, and smells acrid.

Burnout deposits found in the

compressor, lines, and other

components.

Required Cleanup

Procedure

Normal evacuation/

recharging procedure

Mild contamination

cleanup procedure

Mild contamination

cleanup procedure

Severe contamination

cleanup procedure

–75–

Page 86

MILD SYSTEM CONTAMINATION CLEANUP

Important

Procedure

1. Replace any failed components.

2. If the compressor is good, change the oil.

3. Replace the liquid line drier.

NOTE: If the contamination is from moisture, use heat

lamps during evacuation. Position them at the

compressor, condenser and evaporator prior to

evacuation. Do not position heat lamps too close to

plastic components, or they may melt or warp.

Dry nitrogen is recommended for this procedure.

This will prevent CFC release.

Follow the normal evacuation procedure, except

replace the evacuation step with the following:

A. Pull vacuum to 1000 microns. Break the vacuum

with dry nitrogen and sweep the system. Pressurize

to a minimum of .35 bar.

B. Pull vacuum to 500 microns. Break the vacuum

with dry nitrogen and sweep the system. Pressurize

to a minimum of .35 bar.

C. Change the vacuum pump oil.

D. Pull vacuum to 500 microns. Run the vacuum pump

for 1/2 hour on self-contained models, 1 hour on

remotes.

NOTE: Perform a pressure test to be sure there are no

leaks.

Charge the system with the proper refrigerant to the

nameplate charge.

Operate the ice machine.

–76–

Page 87

SEVERE SYSTEM CONTAMINATION CLEANUP

Important

PROCEDURE

1. Remove the refrigerant charge.

2. Remove the compressor.

3. Wipe away any burnout deposits from suction and

discharge lines at compressor.

4. Sweep through the open system with dry nitrogen.

Refrigerant sweeps are not recommended, as they

release CFC’s into the atmosphere.

5. Install a new compressor and new start

components.

6. Install suction line filter-drier in front of compressor.

7. Install a new liquid line drier.

–77–

Page 88

Important

Dry nitrogen is recommended for this procedure.

This will prevent CFC release.

A. Pull vacuum to 1000 microns. Break the vacuum

with dry nitrogen and sweep the system. Pressurize

to a minimum of .35 bar.

B. Change the vacuum pump oil.

C. Pull vacuum to 500 microns. Break the vacuum

with dry nitrogen and sweep the system. Pressurize

to a minimum of .35 bar.

D. Change the vacuum pump oil.

E. Pull vacuum to 500 microns. Run the vacuum pump

for 1 hour additional hour.

Charge the system with the proper refrigerant to the

nameplate charge.

Operate the ice machine for one hour. Then, check

the pressure drop across the suction line filter-drier.

F. If the pressure drop is less than .14 bar, the filter-

drier should be adequate for complete cleanup.

G. If the pressure drop exceeds .14 bar, change the

suction line filter-drier and the liquid line drier.

Repeat until the pressure drop is acceptable.

Operate the ice machine for 48-72 hours. Replace

the suction line and liquid line drier if necessary.

–78–

Page 89

FILTER-DRIERS

Important

Liquid Line Filter Drier

The filter-drier used on Manitowoc ice machines are

manufactured to Manitowoc specifications.

The difference between a Manitowoc drier and an offthe-shelf drier is in filtration. A Manitowoc drier has

dirt-retaining filtration, with fiberglass filters on both the

inlet and outlet ends. This is very important because

ice machines have a back-flushing action that takes

place during every harvest cycle.

A Manitowoc filter-drier has a very high moisture

removal capability and a good acid removal capacity.

The liquid line drier is covered as a warranty part.