Page 1

Q Model Flake/Chiplet

Manitowoc

S Model Flake/Nugget

Technician’s

Handbook

This manual is updated as new information and models are

released. Visit our website for the latest manual.

America’s #1 Selling Ice Machine

Part Number 80-1230-9 10/10

www.manitowocice.com

Page 2

Page 3

Safety Notices

!

Warning

!

Caution

Important

As you work on Manitowoc equipment, be sure to pay

close attention to the safety notices in this handbook.

Disregarding the notices may lead to serious injury

and/or damage to the equipment.

Throughout this handbook, you will see the following

types of safety notices:

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement before proceeding, and work

carefully.

Text in a Caution box alerts you to a situation in

which you could damage the equipment. Be sure

to read the Caution statement before proceeding,

and work carefully.

Procedural Notices

As you work on Manitowoc equipment, be sure to read

the procedural notices in this handbook. These notices

supply helpful information which may assist you as

you work.

Throughout this handbook, you will see the following

types of procedural notices:

Text in an Important box provides you with

information that may help you perform a

procedure more efficiently. Disregarding this

information will not cause damage or injury, but it

may slow you down as you work.

Page 4

NOTE: T ext set off as a Note provides you with simple,

!

Caution

Important

! Warning

We reserve the right to make product

improvements at any time. S pecifications and

design are subject to change without notice.

but useful, extra information about the procedure you

are performing.

Read These Before Proceeding:

Proper installation, care and maintenance are

essential for maximum performance and troublefree operation of your Manitowoc equipment. If

you encounter problems not covered by this

handbook, do not proceed, contact Manitowoc

Foodservice Group. We will be happy to provide

assistance.

Routine adjustments and maintenance

procedures outlined in this handbook are not

covered by the warranty.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been

misused, abused, neglected, damaged, or

altered/modified from that of original

manufactured specifications.

Page 5

Table of Contents

General Information

Model Numbers . . . . . . . . . . . . . . . . . . . . .13

How to Read a Model Number . . . . . . 14

Model/Serial Number Location . . . . . . 15

Manitowoc Cleaner and Sanitizer . . . .15

Ice Machine Warranty Information . . . 15

Q Model & S Model Flake/Chiplet/Nugget

Commercial Warranty . . . . . . . . . . . . . . .16

Q Model & S Model Flake/Chiplet/Nugget Res-

idential Warranty . . . . . . . . . . . . . . . . . . .18

Installation

Location of Ice Machine . . . . . . . . . . . . . .23

Ice Machine Clearance Requirements . .24

Ice Machine Heat of Rejection . . . . . . . . .25

Location of Traditional Remote Units and Re-

mote condensing units . . . . . . . . . . . . . .26

Electrical Service . . . . . . . . . . . . . . . . . . .27

Circuit Ampacity . . . . . . . . . . . . . . . . .28

Ice Machine Head Section Water

Supply and Drains . . . . . . . . . . . . . . . . . .31

Potable Water Supply . . . . . . . . . . . . .31

Potable Water Inlet Lines . . . . . . . . . .31

Drain Connections . . . . . . . . . . . . . . . .32

Cooling Tower Applications

(Water-Cooled Models) . . . . . . . . . . . .32

Installing on a Dispenser . . . . . . . . . . . 33

Line Set Requirements . . . . . . . . . . . .34

Component Identification

QF400 Air-cooled . . . . . . . . . . . . . . . . . . .37

QF800/QC700 Air & Water-cooled . . . . . .38

SF0400/SN0450/SF0600/SN0650/SF0900/

SN0950/SF1200/SN1250 Air & Water-cooled

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

SF0600/SN0650/SF0900/SN0950/SF1200/

SN1250 Remote & QuietQube Model . . . 41

Part Number 80-1230-9 10/10 5

Page 6

Maintenance

Manitowoc’s Cleaning Technology . . . . 44

Exterior Cleaning . . . . . . . . . . . . . . . . 45

Preventative Maintenance Procedure . . 46

QF0400 . . . . . . . . . . . . . . . . . . . . . . . 46

QC0700/QF0800/QF2200/QF2300 . . 48

SN012/SN020/SF0400/SN0450/SF0600/

SN0650/SF0900/SN0950/SF1200/SN1250

50

Heavily Scaled Procedure . . . . . . . . . . . . 53

QF0400 . . . . . . . . . . . . . . . . . . . . . . . 53

QC0700/QF0800/QF2200/QF2300 . . 54

SN012/SN020/SF0400/SN0450/SF0600/

SN0650/SF0900/SN0950/SF1200/SN1250

55

Cleaning And Sanitizing Procedure . . . . 57

QF0400 . . . . . . . . . . . . . . . . . . . . . . . 57

QC0700/QF0800/QF2200/QF2300 . . 60

SN012/SN020/SF0400/SN0450/SF0600/

SN0650/SF0900/SN0950/SF1200/SN1250

62

Component Disassembly For Cleaning And

Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . 65

General Information . . . . . . . . . . . . . . 65

QF400 . . . . . . . . . . . . . . . . . . . . . . . . 66

QC0700/QF0800/QF2200/QF2300 . . 71

SN012/SN020 . . . . . . . . . . . . . . . . . . 84

Water Dump Valve - All Models . . . . . 98

Cleaning the Condenser . . . . . . . . . . . 100

Removal from Service/Winterization . . . 102

General . . . . . . . . . . . . . . . . . . . . . . . . 102

Self-Contained Air-Cooled or Remote Air-

Cooled Ice Machines . . . . . . . . . . . . . 102

Water-Cooled Ice Machines . . . . . . . . 103

Remote Ice Machines . . . . . . . . . . . . . 103

6 Part Number 80-1230-9 10/10

Page 7

Operation

Ice Making Sequence of Operation . . . . .105

QF0400/QC0700/QF0800 . . . . . . . . . . 105

QF2200 . . . . . . . . . . . . . . . . . . . . . . . .107

QF2300 . . . . . . . . . . . . . . . . . . . . . . . .112

SN012/SN020/SF0400/SN0450/SF0600/

SN0650/SF0900/SN0950/SF1200/SN1250

Nugget/Flake Machines . . . . . . . . . . .116

Energized Parts . . . . . . . . . . . . . . . . . .119

Troubleshooting

SafeGuard Feature . . . . . . . . . . . . . . . . . .121

QF0400/QC0700/QF0800/QF2200/QF2300 123

No Water SafeGuard . . . . . . . . . . . . . .123

Gear Motor Speed . . . . . . . . . . . . . . . .125

Temperature Is Too high Or Too Low .127

QF2200 Only - Temperature Is Too High or

Low . . . . . . . . . . . . . . . . . . . . . . . . . . .130

SN012/SN020/SF0400/SN0450/SF0600/

SN0650/SF0900/SN0950/SF1200/SN1250 132

No Water . . . . . . . . . . . . . . . . . . . . . . .132

No Ice Production . . . . . . . . . . . . . . . .133

Diagnosing an Ice Machine That Will Not Run

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

QF0400/QC0700/QF0800/QF2200/QF2300

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

RFC0985/RFC1285/RFC2085/RFC2385

Diagnosing A Condensing Unit That Will Not

Run . . . . . . . . . . . . . . . . . . . . . . . . . . .136

QF0400/QC0700/QF0800/QF2200/QF2300

Operational Problem Checklist . . . . . . 137

SN012/SN020/SF0400/SN0450/SF0600/

SN0650/SF0900/SN0950/SF1200/SN1250

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

Refrigeration Diagnostics . . . . . . . . . . . .146

Before Beginning Service . . . . . . . . . .146

Installation/Visual Inspection Checklist 146

Water System Checklist . . . . . . . . . . .147

Ice Production/Quality Check . . . . . . . 148

Analyzing Discharge Pressure . . . . . .149

Analyzing Suction Pressure . . . . . . . . 151

Part Number 80-1230-9 10/10 7

Page 8

Component Check Procedures

QF0400/QC0700/QF0800/QF2200/QF2300 153

Main Fuse . . . . . . . . . . . . . . . . . . . . . . 153

ICE/OFF/CLEAN Toggle Switch . . . . . 154

Water Float Valve . . . . . . . . . . . . . . . . 155

Water Level Check . . . . . . . . . . . . . . . 156

Bin Level Probe Diagnostics . . . . . . . . 157

Water Level Probes . . . . . . . . . . . . . . 161

Motor Speed Sensor . . . . . . . . . . . . . 165

Temperature Sensor . . . . . . . . . . . . . . 167

QF2200 Only . . . . . . . . . . . . . . . . . . . . . . . 169

Low Pressure Cut-Out Control . . . . . . 169

QF2300 Only . . . . . . . . . . . . . . . . . . . . . . . 170

Equalization Valve . . . . . . . . . . . . . . . 170

Electronic Bin Thermostat . . . . . . . . . 171

S Model Nugget/Flake . . . . . . . . . . . . . . . 176

Main Fuse . . . . . . . . . . . . . . . . . . . . . . 176

ICE/OFF/CLEAN Toggle Switch . . . . . 177

Float Switch . . . . . . . . . . . . . . . . . . . . 178

Ice Damper and Hall Effect Switches . 179

SN012/SN020 Only . . . . . . . . . . . . . . . . . . 182

Selector Switch . . . . . . . . . . . . . . . . . . 182

Dispense Switch . . . . . . . . . . . . . . . . . 183

Touchless Sensor . . . . . . . . . . . . . . . . 184

All Models . . . . . . . . . . . . . . . . . . . . . . . . . 185

High Pressure Cutout Control . . . . . . . 185

Compressor Electrical Diagnostics . . . 187

Diagnosing Start Components . . . . . . 189

Self Contained Air Cooled Models . . . . . 191

Fan Cycle Control . . . . . . . . . . . . . . . . 191

Self Contained Water-cooled Models . . 192

Water Regulating Valve . . . . . . . . . . . 192

Headmaster Control Valve . . . . . . . . . . . 193

Refrigerant Recovery/Evacuation . . . . . 195

Normal Self-Contained Procedures . . 195

Remote Air-Cooled Models . . . . . . . . 199

System Contamination Clean-Up . . . . . . 202

Determining Severity Of Contamination 202

Cleanup Procedure . . . . . . . . . . . . . . 204

Replacing Pressure Controls Wi th ou t Re-

moving Refrigerant Charge . . . . . . . . 207

8 Part Number 80-1230-9 10/10

Page 9

Gear Box Removal . . . . . . . . . . . . . . . . . .210

QF0400 . . . . . . . . . . . . . . . . . . . . . . . .210

QC0700/QF0800 . . . . . . . . . . . . . . . . .212

QF2200/QF2300 . . . . . . . . . . . . . . . . .214

Evaporator Re-Build Kits . . . . . . . . . . . . .216

Identifying Correct Kit: . . . . . . . . . . . . .216

Cleaning Evaporator after Disassembly 219

Evaporator Reassembly . . . . . . . . . . .220

EVAPORATOR REMOVAL . . . . . . . . . . . .222

QF0400 . . . . . . . . . . . . . . . . . . . . . . . .222

QC0700/QF0800 . . . . . . . . . . . . . . . . .224

QF2200/QF2300 . . . . . . . . . . . . . . . . .226

Component Specifications

Main Fuse . . . . . . . . . . . . . . . . . . . . . .229

ICE/OFF/CLEAN Toggle Switch . . . . .229

Fan Cycle Control . . . . . . . . . . . . . . . .229

High Pressure Cutout (HPCO) Control 229

Torque Values . . . . . . . . . . . . . . . . . . .229

Gearmotor RPMs . . . . . . . . . . . . . . . .230

Filter-Driers . . . . . . . . . . . . . . . . . . . . .230

Suction Line Filter . . . . . . . . . . . . . . . .231

Suction Cleanup Filter-Drier . . . . . . . . 231

Total System Refrigerant Charge . . . . . . 232

Part Number 80-1230-9 10/10 9

Page 10

Charts

Cycle Times/24-Hour Ice Production/

Refrigerant Pressure Charts . . . . . . . . . . 233

SN012A/SN020A . . . . . . . . . . . . . . . . 234

QF0400A Stainless Steel Evaporator . 235

QF0400A Bronze Evaporator . . . . . . . 236

SF0400A . . . . . . . . . . . . . . . . . . . . . . 237

SF0400W . . . . . . . . . . . . . . . . . . . . . . 238

SN0450A . . . . . . . . . . . . . . . . . . . . . . 239

SN0450W . . . . . . . . . . . . . . . . . . . . . . 240

SF0600A . . . . . . . . . . . . . . . . . . . . . . 241

SF0600W . . . . . . . . . . . . . . . . . . . . . . 242

SF0600N . . . . . . . . . . . . . . . . . . . . . . 243

SN0650A . . . . . . . . . . . . . . . . . . . . . . 244

SN0650W . . . . . . . . . . . . . . . . . . . . . . 245

SN0650N . . . . . . . . . . . . . . . . . . . . . . 246

QC0700A . . . . . . . . . . . . . . . . . . . . . . 247

QC0700W . . . . . . . . . . . . . . . . . . . . . . 248

QF0800A . . . . . . . . . . . . . . . . . . . . . . 249

QF0800W . . . . . . . . . . . . . . . . . . . . . . 250

SF900A . . . . . . . . . . . . . . . . . . . . . . . 251

SF900W . . . . . . . . . . . . . . . . . . . . . . . 252

SF900C/RFC985 . . . . . . . . . . . . . . . . 253

SN950A . . . . . . . . . . . . . . . . . . . . . . . 254

SN950W . . . . . . . . . . . . . . . . . . . . . . . 255

SN950C/RFC985 . . . . . . . . . . . . . . . . 256

SF1200A . . . . . . . . . . . . . . . . . . . . . . 257

SF1200W . . . . . . . . . . . . . . . . . . . . . . 258

SF1200C/RFC1285 . . . . . . . . . . . . . . 259

SN1250A . . . . . . . . . . . . . . . . . . . . . . 260

SN1250W . . . . . . . . . . . . . . . . . . . . . . 261

SN1250C/RFC1285 . . . . . . . . . . . . . . 262

QF2200/RFC2085 . . . . . . . . . . . . . . . 263

QF2300/RFC2385 . . . . . . . . . . . . . . . 264

10 Part Number 80-1230-9 10/10

Page 11

Diagrams

Wiring Diagrams . . . . . . . . . . . . . . . . . . . .265

QF0400 115/60/1 – 230/50/1 . . . . . . . 266

QC0700/QF0800 115/60/1 – 230/50/1 267

QC0700/QF0800 115/60/1 – 230/50/1 268

QC0700/QF0800 Compressor Section 269

QF2200 115/60/1 – 230/50/1 . . . . . . . 270

RFC2085 Condensing Unit 230/60/1 – 230/

50/1 . . . . . . . . . . . . . . . . . . . . . . . . . . .271

RFC2085 Condensing Unit 208 - 230/60/3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .272

QF2300 . . . . . . . . . . . . . . . . . . . . . . . .273

RFC2385 Condensing Unit . . . . . . . . . 274

RFC0985/RFC1285/RFC2385 Condensing

Unit . . . . . . . . . . . . . . . . . . . . . . . . . . .275

SN012/SN020 115/60/1 – 230/50/1 . . 276

S Model Flake / Nugget Head Sections 277

Electronic Control Boards . . . . . . . . . . . .278

S Model Flake/Nugget Control Boards 278

Q Model Flake/Chiplet Control Boards 280

Refrigeration Tubing Schematics . . . . . . 281

QF0400/QC0700/QF0800 . . . . . . . . . . 281

RFC2085 . . . . . . . . . . . . . . . . . . . . . . .282

RFC985/RFC1285/RFC2185/RFC2385 283

SN012/SN020 . . . . . . . . . . . . . . . . . . .284

SF0400/SN0450/SF0600/SN0650 . . .285

SF0900/SN0950/SF1200/SN1250 . . .286

SF0600/SN0650 . . . . . . . . . . . . . . . . . 287

Part Number 80-1230-9 10/10 11

Page 12

12 Part Number 80-1230-9 10/10

This Page Intentionally Left Blan k

Page 13

General Information

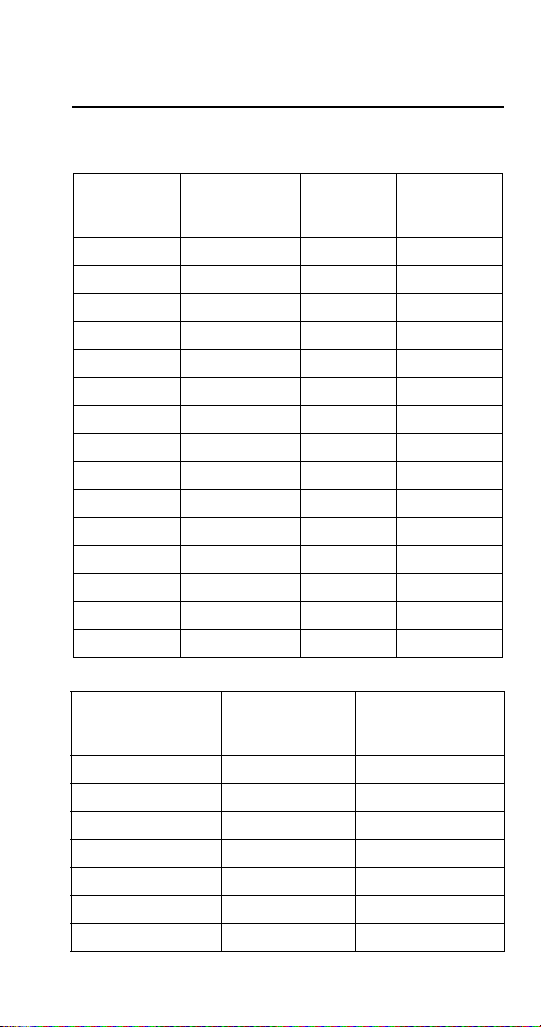

Model Numbers

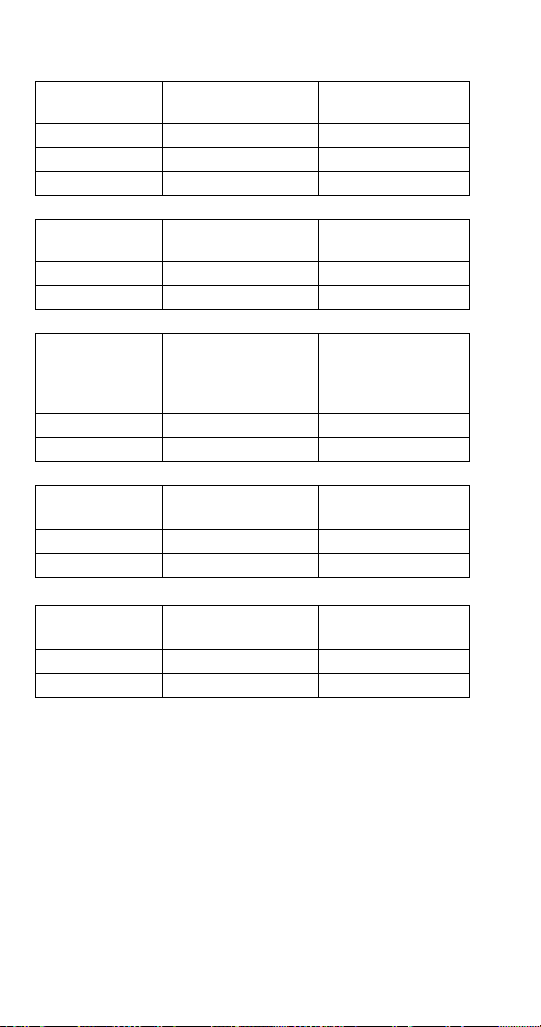

Head Section Models

Self-

Contained

Air-Cooled

SN012A (T) NA NA NA

SN020A (T) NA N/A NA

QF0406A NA NA NA

SF0406A SN0407W NA NA

SN0458A SN0459W NA NA

SF0606A SF0607W SF0696N NA

SN0658A SN0659W SN0698N NA

QC0708A QC0709W NA NA

QF0806A QF0807W NA NA

SF0906A SF0907W NA SF0976C

SN0958A SN0959W NA SN0978C

SF1206A SF1207W NA SF1276C

SN1258A SN1259W NA SN1278C

NA NA NA QF2296N

NA NA NA QF2396N

Remote Condenser Models

Head Section

SN0650 JC0495 NA

SF0976C NA RFC0985

SN0978C NA RFC0985

SF1276C NA RFC1285

SN1278C NA RFC1285

QF2296N NA RFC2085

QF2396N NA RFC2385

Self-

Contained

Water-Cooled

Traditional

Remote

Condenser

Traditional

Remote

Condenser

Condensing Unit

Remote

Condensing

Remote

Unit

Part Number 80-1230-9 10/10 13

Page 14

NOTE: Model numbers ending in 3 indicate a 3-phase

!

Warning

Q F 0807 W

ICE MACHINE

MODEL

ICE CUBE SIZE

F FLAKE

C CHIPLET

# CUBE SIZE

6 FLAKE

7 FLAKE

8 CHIPLET

9 CHIPLET

CONDENSER TYPE

AIR-COOLED

WATER-COOLED

AIR-COOLED

WATER-COOLED

A SELF-CONTAINED AIR-COOLED

W SELF-CONTAINED WAT ER-COOLED

N REMOTE AIR-COOLED

9 REMOTE

AIR-COOLED

CONDENSER TYPE

ICE MACHINE

SERIES

unit. Example: RFC12853

* Traditional Remotes - condenser is outside,

compressor is inside. The heat is rejected outside.

Line set consists of a hi gh pressure d ischarge li ne and

a high pressure liquid line. Only models ending in “N”

use Traditional Remote Condensers.

** RFC Remote Condensing Unit - compressor,

condenser, accumulator and head pressure control

valve outside. Line set consists of a low pressure

suction line and a high pressure liquid line. Only

models ending in “C” use RFC Remote Condensing

Units.

HOW TO READ A MODEL NUMBER

Personal Injury Potential

The ice machine must be attached to the adapter

and dispenser to prevent the ice machine from

falling. Mounting brackets are provided with all

Nugget ice machines.

14 Part Number 80-1230-9 10/10

Page 15

MODEL/SERIAL NUMBER LOCATION

!

Caution

Important

These numbers are required when requesting

information from your local Manitowoc Distributor,

service representative, or Manitowoc Ice, Inc. The

model and serial number are listed on the OWNER

WARRANTY REGISTRATION CARD. They are also

listed on the MODEL/SERIAL NUMBER DECAL

affixed to the ice machine.

MANITOWOC CLEANER AND SANITIZER

Manitowoc Ice Machine Cleaner and Sanitizer are

available in 16 oz. (473 ml) bottles. These are the only

cleaners and sanitizer approved for use with

Manitowoc products.

Flake/Chiplet/Nugget models must use cleaner part

number 000000084 ONLY

to the evaporator will result with repeated use or

high concentrations of standard (green) cleaner.

This damage is not covered by the warranty.

Cleaner Part Number Sanitizer Part Number

16 oz. 000000084 16 oz. 94-0565-3

1 gal N/A 1 gal. 94-0581-3

ICE MACHINE WARRANTY INFORMATION

Owner Warranty Registration Card

Warranty coverage begins the day the ice machine is

installed.

Complete and mail the OWNER WARRANTY

REGISTRATION CARD as soon as possible to

validate the installation date.

If the OWNER WARRANTY REGISTRA TION CARD is

not returned, Manitowoc will use the date of sale to the

Manitowoc Distributor as the first day of warranty

coverage for your new ice machine.

(clear cleaner). Damage

Part Number 80-1230-9 10/10 15

Page 16

Q Model & S Model Flake/Chiplet/Nugget Commercial Warranty

Manitowoc Ice, Inc. (hereinafter referred to as the

"COMPANY") warrants for a period of twenty four

months from the installation date (except as limited

below) that new Flake/Chiplet ice machines

manufactured by the COMPANY shall be free of

defects in material or workmanship under normal and

proper use and maintenance as specified by the

COMPANY and upon proper installation and start-up

in accordance with the instruction manual supplied

with the ice machine. The COMPANY'S warranty

hereunder with respect to the compressor shall apply

for an additional thirty-six months, excludi n g al l labo r

charges.

The obligation of the COMPANY under this warranty is

limited to the repair or replacement of parts,

components, or assemblies that in the opinion of the

COMPANY are defective. This warranty is further

limited to the cost of parts, components or assemblies

and standard straight time labor charges at the

servicing location.

Time and hourly rate schedules, as published from

time to time by the COMPANY, apply to all service

procedures. Additional expenses including without

limitation, travel time, overtime premium, material cost,

accessing or removal of the ice machine, or shipping

are the responsibility of the owner, along with all

maintenance, adjustments, cleaning, and ice

purchases. Labor covered under this warranty must be

performed by a COMPANY Contracted Service

Representative or a refrigeration service agency as

qualified and authorized by the COMPANY'S local

Distributor. The COMPANY'S liability under this

warranty shall in no event be greater than the actual

purchase price paid by customer for the ice machine.

16 Part Number 80-1230-9 10/10

Page 17

The foregoing warranty shall not apply to (1) any part

or assembly that has been altered, modified, or

changed; (2) any part or assembly that has been

subjected to misuse, abuse, neglect, or accidents; (3)

any ice machine that has been installed and/or

maintained inconsistent with the technical instructions

provided by the COMPANY; or (4) any ice machine

initially installed more than five years from the serial

number production date. This warranty shall not apply

if the Ice Machine's refrigeration system is modified

with a condenser, heat reclaim device, or parts and

assemblies other than those manufactured by the

COMPANY, unless the COMPANY approves these

modifications for specific locations in writing.

THIS WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES OR GUARANTEES OF ANY KIND,

EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITYOR

FITNESS FOR A PARTICULAR PURPOSE. In no

event shall the COMPANY be liable for any special,

indirect, incidental or consequential damages. Upon

the expiration of the warranty period, the COMPANY'S

liability under this warranty shall terminate. The

foregoing warranty shall constitute the sole liability of

the COMPANY and the exclusive remedy of the

customer or user.

To secure prompt and continuing warranty service, the

warranty registration card must be completed and sent

to the COMPANY within five (5) days from the

installation date.

Complete the following and retain for your record:

Distributor/Dealer

Model Number Serial Number

Installation Date

MANITOWOC ICE

2110 So. 26th St., P.O. Box 1720, Manitowoc, WI 54220

Telephone: 920-682-0161 Fax: 920-683-7585

Web Site - www.manitowocice.com

Part Number 80-1230-9 10/10 17

Page 18

Q Model & S Model Flake/Chiplet/Nugget Residential Warranty

WHAT DOES THIS LIMITED WARRANTY COVER?

Subject to the exclusions and limitations below,

Manitowoc Ice, Inc. (“Manitowoc”) warrants to the

original consumer that any new ice machine

manufactured by Manitowoc (the “Product”) shall be

free of defects in material or workmanship for the

warranty period outlined below under normal use and

maintenance, and upon proper installation and startup in accordance with the instruction manual supplied

with the Product.

HOW LONG DOES THIS LIMITED WARRANTY

LAST?

Product Covered Warranty Period

Ice Machine

WHO IS COVERED BY THIS LIMITED WARRANTY?

This limited warranty only applies to the original

consumer of the Product and is not transferable.

Twelve months from the

sale date

18 Part Number 80-1230-9 10/10

Page 19

WHAT ARE MANITOWOC ICE’S OBLIGATIONS

UNDER THIS LIMITED WARRANTY?

If a defect arises and Manitowoc receives a valid

warranty claim prior to the expiration of the warranty

period, Manitowoc shall, at its option: (1) repair the

Product at Manitowoc’s cost, including standard

straight time labor charges, (2) replace the Product

with one that is new or at least as functionally

equivalent as the original, or (3) refund the purchase

price for the Product. Replacement parts are

warranted for 90 days or the balance of the original

warranty period, whichever is longer. The foregoing

constitutes Manitowoc’s sole obligation and the

consumer’s exclusive remedy for any breach of this

limited warranty. Manitowoc’ s liability under this limited

warranty is limited to the purchase price of Product.

Additional expenses including, without limitation,

service travel time, overtime or premium labor

charges, accessing or removing the Product, or

shipping are the responsibility of the consumer.

HOW TO OBTAIN WARRANTY SERVICE

To obtain warranty service or information regarding

your Product, please contact us at:

MANITOWOC ICE

2110 So. 26th St. P.O. Box 1720, Manitowoc, WI

54221-1720

Telephone: 920-682-0161 Fax: 920-683-7585

www.manitowocice.com

Part Number 80-1230-9 10/10 19

Page 20

WHAT IS NOT COVERED?

This limited warranty does not cover, and you are

solely responsible for the costs of: (1) periodic or

routine maintenance, (2) repair or replacement of the

Product or parts due to normal wear and tear, (3)

defects or damage to the Product or parts resulting

from misuse, abuse, neglect, or accidents, (4) defects

or damage to the Product or parts resulting from

improper or unauthorized alterations, modifications, or

changes; and (5) defects or damage to any Product

that has not been installed and/or maintained in

accordance with the instruction manual or technical

instructions provided by Manitowoc. To the extent that

warranty exclusions are not permitted under some

state laws, these exclusions may not apply to you.

E

XCEPT AS STATED IN THE FOLLOWING SENTENCE, THIS

IMITED WARRANTY IS THE SOLE AND EXCLUSIVE

L

W

ARRANTY OF MANITOWOC WITH REGARD TO THE

P

RODUCT. ALL IMPLIED WARRANTIES ARE STRICTLY

IMITED TO THE DURATION OF THE LIMITED WARRANTY

L

A

PPLICABLE TO THE PRODUCTS AS STATED ABOVE,

I

NCLUDING BUT NOT LIMITED TO, ANY WARRANTY OF

ERCHANTABILITY OR OF FITNESS FOR A PARTICULAR

M

P

URPOSE.

Some states do not allow limitations on how long an

implied warranty lasts, so the above limitation may not

apply to you.

20 Part Number 80-1230-9 10/10

Page 21

IN NO EVENT SHALL MANITOWOC OR ANY OF ITS

A

FFILIATES BE LIABLE TO THE CONSUMER OR ANY

THER PERSON FOR ANY INCIDENTAL, CONSEQUENTIAL

O

O

R SPECIAL DAMAGES OF ANY KIND (INCLUDING,

W

ITHOUT LIMITATION, LOSS OF PROFITS, REVENUE OR

USINESS) ARISING FROM OR IN ANY MANNER

B

C

ONNECTED WITH THE PRODUCT, ANY BREACH OF THIS

L

IMITED WARRANTY, OR ANY OTHER CAUSE

HATSOEVER, WHETHER BASED ON CONTRACT, TORT

W

O

R ANY OTHER THEORY OF LIABILITY.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

HOW STATE LAW APPLIES

This limited warranty gives you specific legal rights,

and you may also have rights that vary from state to

state or from one jurisdiction to another.

REGISTRATION CARD

T o secure prompt and continuing warranty service, this

warranty registration card must be completed and sent

to Manitowoc within thirty (30) days from the sale date.

Complete the registration card and send it to

Manitowoc.

Part Number 80-1230-9 10/10 21

Page 22

22 Part Number 80-1230-9 10/10

This Page Intentionally Left Blan k

Page 23

Installation

!

Warning

PERSONAL INJURY POTENTIAL

Remove all ice machine panels before lifting and

installing.

Location of Ice Machine

The location selected for the ice machine must meet

the following criteria. If any of these criteria are not

met, select another location.

• The location must be indoors.

• The location must be free of airborne and other

contaminants.

• The air temperature must be at least 45°F (7°C),

but must not exceed 110°F (43°C).

• The water temperature must be at least 45°F

(7°C), but must not exceed 90°F (32°C).

• The location must not be near heat-generating

equipment or in direct sunlight.

• The location must be capable of supporting the

weight of the ice machine and a full bin of ice.

• The location must allow enough clearance for

water, drain and electrical connections in the rear

of the ice machine.

• The location must not obstruct airflow through or

around the ice machine. Refer to the chart below

for clearance requirements.

• RFC Condensing Units ONLY - Interconnecting

wiring (115/60/1 or 230/50/1) is required between

the ice machine and condensing unit to energize

the contactor coil.

• The ice machine must be protected if it will be

subjected to temperatures below 32°F (0°C).

Failure caused by exposure to freezing

temperatures is not covered by the warranty. See

“Removal from Service/Winterization”

Part Number 80-1230-9 10/10 23

Page 24

Ice Machine Clearance Requirements

SN12/SN20

Top 24" (61.0 cm) NA

Sides 8" (20.3 cm) NA

Back 5" (12.7 cm) NA

Self-Contained

Air-Cooled

Water-Cooled*

QF400

Self-Contained

Air-Cooled

Water-Cooled

and Remote*

Top/Sides 5" (12.7 cm) NA

Back 5" (12.7 cm) NA

SF400/SN450

SF600/SN650

SF900/SN950

Self-Contained

Air-Cooled

Water-Cooled

and Remote*

S1200/SN1250

Top/Sides 8" (20.3 cm) 8" (20.3 cm)*

Back 5" (12.7 cm) 5" (12.7 cm)*

QF800

QC700

Self-Contained

Air-Cooled

Water-Cooled

and Remote*

Top/Sides 8" (20.3 cm) 5" (12.7 cm)*

Back 5" (12.7 cm) 5" (12.7 cm)*

QF2200

QF2300

Self-Contained

Air-Cooled

Water-Cooled

and Remote*

Top/Sides NA 5" (12.7 cm)*

Back NA 5" (12.7 cm)*

* Water-Cooled and Remotes Only - There is no minimum clearance

required. This value is recommended for efficient operation and

servicing only.

NOTE: SN12/SN20 airflow is in the left side and out the top.

QF400 is in and out the front of the ice machine.

24 Part Number 80-1230-9 10/10

Page 25

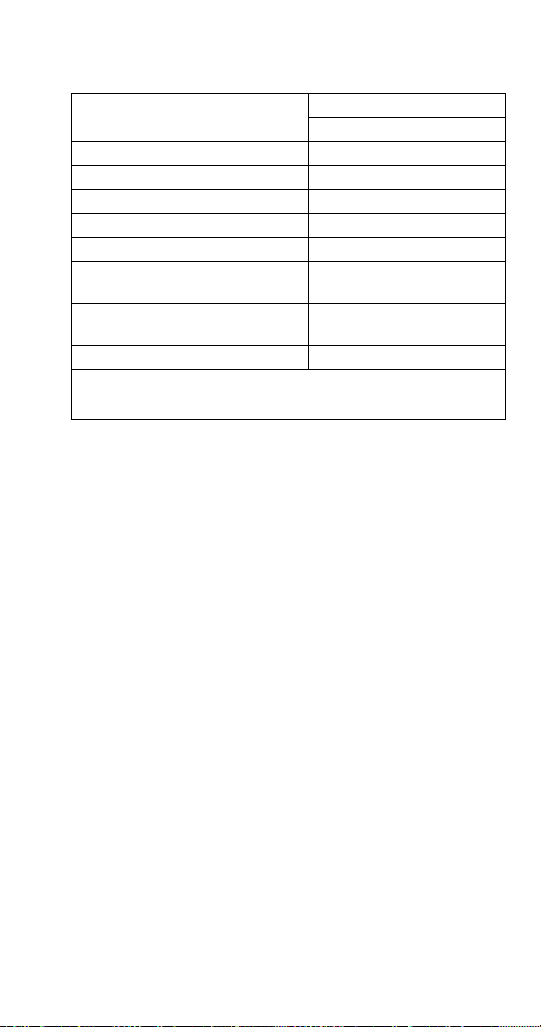

Ice Machine Heat of Rejection

Series

Ice Machine

SN12/SN20 2,300

QF400 4,000

SF400/SN450 3,400

SF600/SN650 5,300

QF800/QC700 7,800

SF900/SN950

SF900C/SN950C

SF1200/SN1250

SF1200C/SN1250C

QF2200/QF2300 21,000

BTU/Hour

*

Because the heat of rejection varies during the ice making cycle,

the figure shown is an average.

Heat of Rejection*

Air Conditioning

9,000

16,000

Ice machines, like other refrigeration equipment, reject

heat through the condenser. It is helpful to know the

amount of heat rejected by the ice machine when

sizing air conditioning equipment where self-contained

air-cooled ice machines are installed.

This information is also necessary when evaluating

the benefits of using water-cooled or remote

condensers to reduce air conditioning loads. The

amount of heat added to an air conditioned

environment by an ice machine using a water-cooled

or remote condenser is negligible.

Knowing the amount of heat rejected is also important

when sizing a cooling tower for a water-cooled

condenser. Use the peak figure for sizing the cooling

tower.

Part Number 80-1230-9 10/10 25

Page 26

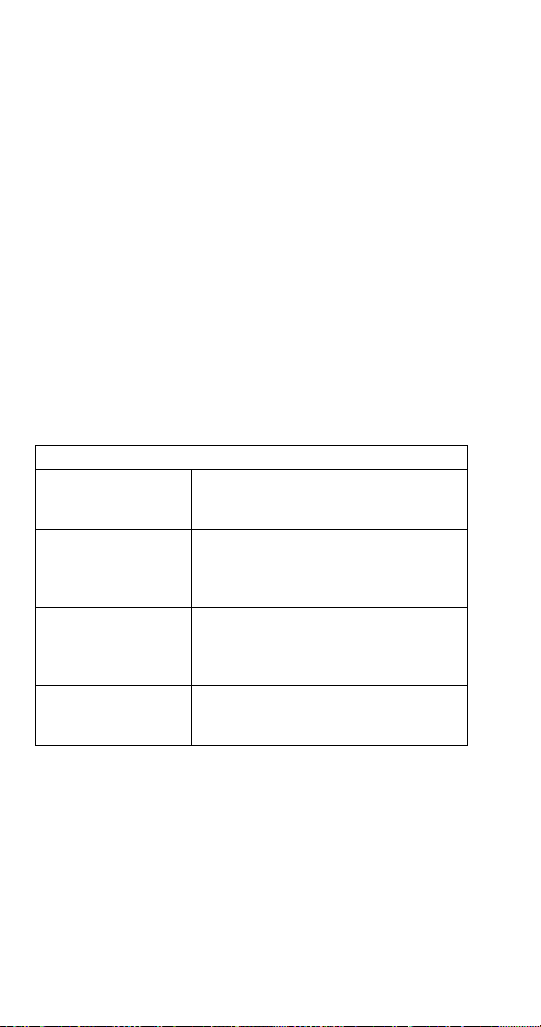

Location of Tr aditional Remote Uni t s and Remote condensing units

The location selected for the Remote Units must meet

the following criteria. If any of these criteria are not

met, select another location.

• The air temperature must be at least -20°F

(-28.9°C) but must not exceed 120°F (49°C).

• The location must not allow exhaust fan heat and/

or grease to enter the condenser.

• The location must not obstruct airflow through or

around the condensing unit. Refer to the chart

below for clearance requirements.

• RFC Condensing Units ONLY - Interconnecting

wiring (115/60/1) is required between the ice

machine and condensing unit to energize the

contactor coil.

Traditional Remote/Condensing Unit Clearances

Traditional Remote

JC0495

Top/Bottom

Traditional Remote

JC0495

Sides

Remote

Condensing Unit

RFC - Top/Sides

Remote

Condensing Unit

RFC - Front/Back

Bottom clearance is 12" (31 cm)

Top clearance is 4’ (1.2 m)

There is no minimum clearance

required, although 6" (15 cm) is

recommended for efficient operation

and servicing only.

There is no minimum clearance

required, although 6" (15 cm) is

recommended for efficient operation

and servicing only.

4’ (1.2 m)

26 Part Number 80-1230-9 10/10

Page 27

Electrical Service

!

Warning

!

Warning

General

All wiring must conform to local, state and national

codes.

Voltage

The maximum allowable voltage variation is ± 10% of

the rated voltage on the ice machine model/serial

number plate at start-up (when the electrical load is

highest).

Fuse/Circuit Breaker

A separate fuse/circuit breaker must be provided for

each ice machine. Circuit breakers must be H.A.C.R.

rated (does not apply in Canada).

The ice machine must be grounded in accordance

with national and local electrical codes.

SN012/SN020/QF0400 115/60/1 ice machines are

factory pre-wired with a power cord and 5-15P plug

confirmation.

SN012/SN020/QF0400 230/50/1 ice machines are

factory pre-wired with a power cord, no plug is

supplied.

SF0400/SN0450/SF0600/SN0650/SF0900/SN0950/

SF1200/SN1250 ice machines are not supplied with a

power cord.

SF0900C/SN0950C/SF1200C/SN1250C/

QF2200/QF2300 with Remote Condensing Unit the

ice machine head section and remote condensing unit

are wired independent of each other. A separate

dedicated fuse/circuit breaker must be provided

each condensing unit. Circuit breakers must be

H.A.C.R. rated (does not apply in Canada).

for

Part Number 80-1230-9 10/10 27

Page 28

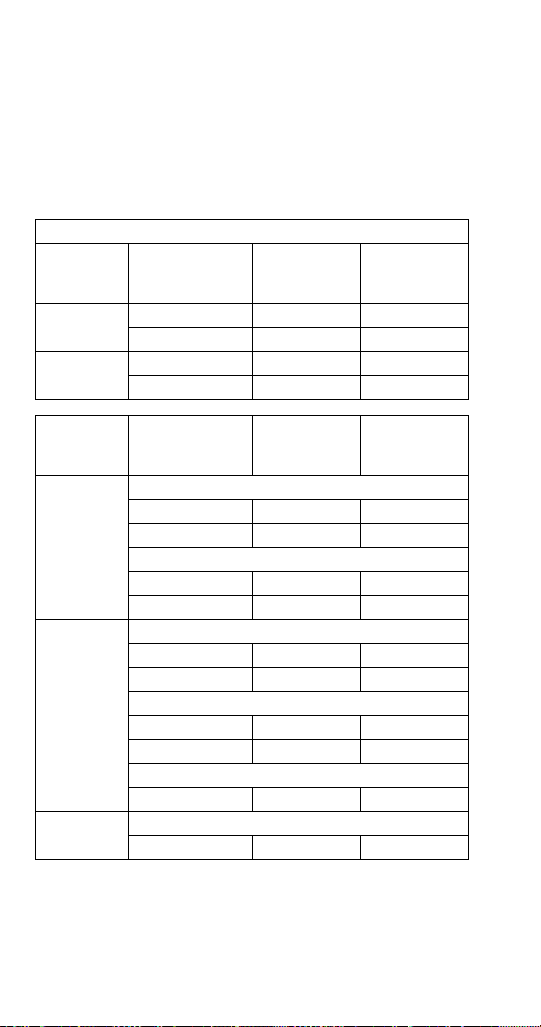

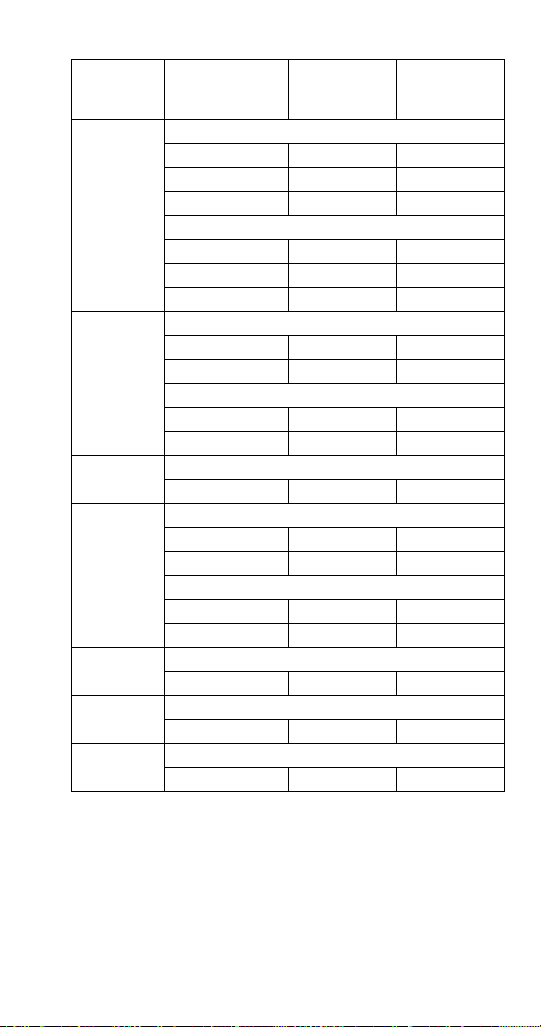

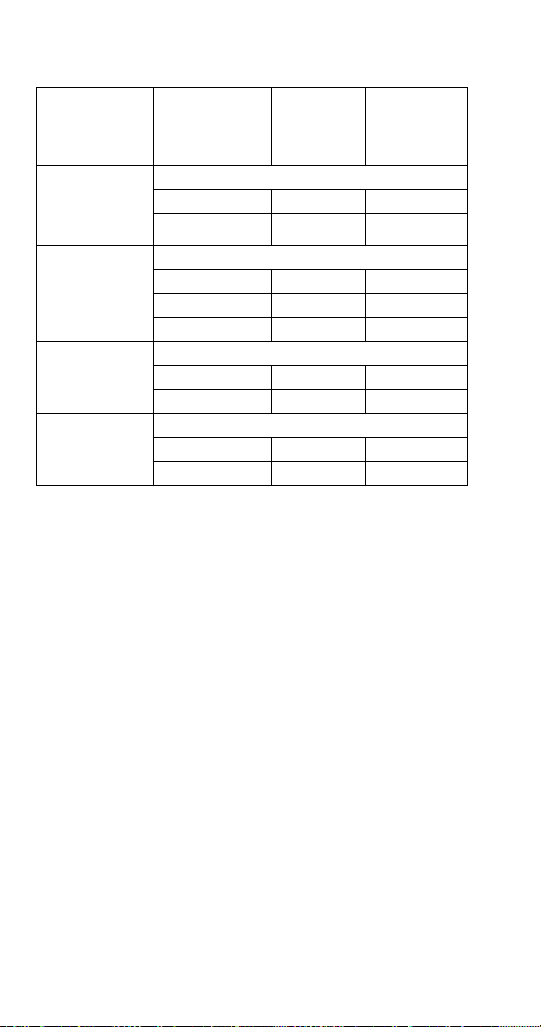

CIRCUIT AMPACITY

The minimum circuit ampacity is used to help select

the wire size of the electrical supply. (Minimum circuit

ampacity is not the ice machine’s running amp load.)

The wire size (or gauge) is also dependent upon

location, materials used, length of run, etc., so it must

be determined by a qualified electrician.

Self Contained Air-Cooled

Ice

Machine

SN012

SN020

QF0400

Voltage

Phase Cycle

115/1/60 15 10.3

230/1/50 15 4.6

115/1/60 15 9.8

230/1/50 15 4.2

Max. Fuse/

Circuit

Breaker

Total

Amps

Ice

Machine

SF0400/

SN0450

SF0600/

SN0650

JC0495

28 Part Number 80-1230-9 10/10

Voltage

Phase

Cycle

115/1/60 20 13.7

230/1/50 15 7.2

115/1/60 20 12.9

230/1/50 15 6.6

115/1/60 20 16.2

230/1/50 15 7.0

115/1/60 20 15.5

230/1/50 15 6.7

115/1/60 20 17.9

Traditional Remote Condenser

115/60/1 NA 2.3

Max. Fuse/

Circuit

Breaker

Air-Cooled

Water-Cooled

Air-Cooled

Water-Cooled

Remote Air-Cooled

Minimum

Circuit

Amps

Page 29

Ice

Machine

QC0700/

QF0800

SF0900/

SN0950

SF0900C/

SN0950C

SF1200/

SN1250

SF1200C/

SN1250C

QF2200

QF2300

Voltage

Phase

Cycle

115/1/60 30 18.9

230/1/50 20 8.8

230/1/60 15 8.7

115/1/60 30 17.9

230/1/50 20 8.4

230/1/60 15 8.3

230/1/50 15 7.0

230/1/60 15 8.0

230/1/50 15 6.7

230/1/60 15 7.7

Air-Cooled Head Section

115/1/60 15 1.7

230/1/50 15 8.0

230/1/60 15 9.8

230/1/50 15 7.7

230/1/60 15 9.0

Air-Cooled Head Section

115/1/60 15 2.1

Remote Air-Cooled Head Section

115/1/60 15 4.3

Remote Air-Cooled Head Section

115/1/60 15 5.5

Max. Fuse/

Circuit

Breaker

Air-Cooled

Water-Cooled

Air-Cooled

Water-Cooled

Air-Cooled

Water-Cooled

Minimum

Circuit

Amps

Part Number 80-1230-9 10/10 29

Page 30

Condensing

Unit

RFC0985

used with

SF0900C/

SN0950C

RFC1285

used with

SF1200C/

SN1250C

RFC2085

used with

QF2200

RFC2385

used with

QF2300

Voltage

Phase

Cycle

Max.

Fuse/

Circuit

Breaker

Minimum

Circuit

Amps

Remote Condensing Unit

208-230/1/60 15 8.6

208-230/1/50 15 8.0

Remote Condensing Unit

208-230/1/60 15 9.2

208-230/3/60 15 6.8

208-230/1/50 15 12.0

Remote Condensing Unit

208-230/1/60 30 15.6

208-230/3/60 20 11.2

Remote Condensing Unit

208-230/1/60 30 18.5

208-230/3/60 20 12.8

30 Part Number 80-1230-9 10/10

Page 31

Ice Machine Head Section Water

Important

Supply and Drains

POTABLE WATER SUPPLY

Local water conditions may require treatment of the

water to inhibit scale formation, filter sediment, remove

chlorine, and improve taste and clarity.

If you are installing a Manitowoc water filter system,

refer to the Installation Instructions supplied with the

filter system for ice making water inlet connections.

POTABLE WATER INLET LINES

Follow these guidelines to install water inlet lines:

• Do not connect the ice machine to a hot water

supply. Be sure all hot water restrictors inst alled for

other equipment are working. (Check valves on

sink faucets, dishwashers, etc.)

• If water pressure exceeds the maximum

recommended pressure of 80 psig (5.5 Bar),

obtain a water pressure regulator from your

Manitowoc Distributor.

• Install a water shut-of f valve and union for both the

ice making and condenser water lines.

• Insulate water inlet lines to prevent condensation.

Part Number 80-1230-9 10/10 31

Page 32

DRAIN CONNECTIONS

Follow these guidelines when installing drain lines to

prevent drain water from flowing back into the ice

machine and storage bin:

• Drain lines must have a 1.5 in. (3.8 cm) drop per 5

ft. of run (2.5 cm per meter), and must not create

traps.

• The floor drain must be large enough to

accommodate drainage from all drains.

• Run separate bin and water-cooled condenser

drain lines. Insulate them to prevent condensation.

• Vent the bin drain to the atmosphere. Do not vent

the condenser drain on water-cooled models.

• Drains must have a union or other suitable means

to allow a place of disconnection from the ice

machine when servicing is required.

COOLING TOWER APPLICATIONS (WATER-COOLED MODELS)

A water cooling tower installation does not require

modification of the ice machine. The water regulator

valve for the condenser continues to control the

refrigeration discharge pressure.

It is necessary to know the amount of heat rejection,

(refer to page 25) and the pressure drop through the

condenser and water valves (inlet and outlet) when

using a cooling tower on an ice machine.

• Water entering the condenser must not exceed

90°F (32°C).

• Water flow through the condenser must not

exceed 5 gal. (19 L) per minute.

• Allow for a pressure drop of 7 psi (48 kPa)

between the condenser water inlet and the outlet

of the ice machine.

• Water exiting the condenser must not exceed

110°F (43°C).

32 Part Number 80-1230-9 10/10

Page 33

INSTALLING ON A DISPENSER

!

Warning

!

Caution

Nugget ice is soft and chewable. This characteristic

makes this ice more difficult to dispense. All dispenser

manufacturers require a kit be installed for Nugget

type ice. Contact the dispenser manufacturer for the

correct adapter and nugget dispensing kit for your

specific model dispenser. The required kit can vary by

dispenser size from the same manufacturer.

Failure to install the correct kit and make the

necessary modifications on the dispenser will result in:

• Congealed ice which will not dispense and will

damage the ice machine and dispenser

• Insufficient ice contact with the cold plate which

will result in an inferior product

• A safety issue if ice lifts the adapter or ice machine

Nugget Dispensing Kit Installation Procedure

1. Follow the dispenser manufacturers instructions

for installation of the adapter (if required) and

nugget ice kit.

2. Make all necessary beverage, electrical and drain

connections to the dispenser.

3. Level the dispenser front to back and side to side.

4. Install ice machine on dispenser and secure ice

machine, dispenser and adapter with provided

brackets.

5. Complete water, drain and electrical connections

to the ice machine.

The ice machine and adapter must be attached to the

dispenser to prevent the ice machine from falling.

Ice machines in low volume locations may experience

congealing. Thermostat kit K00364 must be added in these

locations to prevent damage to the ice machine and dispenser.

Part Number 80-1230-9 10/10 33

PERSONAL INJURY POTENTIAL

Page 34

LINE SET REQUIREMENTS

Traditional Remote Units Only

Ice Machine

Head Section

SN0650 JC0495

Line Set

RM20/35/50

Discharge

Condenser Line Set

Line

5/16 in

(7.9 mm)

Liquid

Line

1/4 in

(7 mm)

RM-20

RM-35

RM-50

Insulation

Thickness

12.7 mm

QuietQube Remote Condensing Units Only

Ice Machine

Head Section

SF0900C

SN0950C

SF1200C

SN1250C

QF2200/QF2300

Line Set

RC-21

RC-31

RC-51

RC-20

RC-30

RC-50

(15.9 mm)

(19.1 mm)

Suction

Line

5/8 in

3/4 in.

Condensing

Unit

RFC0985

RFC1285

RFC2085

RFC2385

Liquid

Line

3/8 in

(9.5 mm)

1/2 in.

(12.7 mm)

Line Set

RC-21

RC-31

RC-51

RC-21

RC-31

RC-51

RC-20

RC-30

RC-50

Insulation

Thickness

1/2 in

(12.7 mm)

Suction Line

1/2" (13 mm)

Liquid Line

1/4" (7 mm)

1/2 in

34 Part Number 80-1230-9 10/10

Page 35

• Maximum total amount of tubing is 100’ (30.5 M)

Important

• Maximum height condenser or condensing unit

can be above ice machine is 35’ (10.7 M)

• Maximum distance condenser or condensing unit

can be below the ice machine 15’ (4.5 M)

• Condensing units only - Suction line oil trap is

required for any rise that is 20’ (6 M) or greater.

• Refer to Installation Use and Care Manual for

complete installation information.

Manitowoc remote systems are only approved

and warranted as a complete new package.

Warranty on the refrigeration system will be

void if a new ice machine head section is

connected to pre-existing (used) tubing or

remote condensers.

Part Number 80-1230-9 10/10 35

Page 36

36 Part Number 80-1230-9 10/10

This Page Intentionally Left Blan k

Page 37

Component Identification

WATER LEVEL PROBES

WATER FLOAT VALVE

COIL

EVAPORATOR

GEAR MOTOR /

GEAR BOX

ASSEMBLY

ICE/OFF/CLEAN

TOGGLE SWITCH

CONDESER

FAN/ MOTOR

POTABLE

WATER

DRAIN

CONTROL BOX

QF400 Air-cooled

Part Number 80-1230-9 10/10 37

Page 38

QF800/QC700 Air & Water-cooled

CONDENSER

FAN MOTOR

ICE/OFF/CLEAN

TOGGLE SWITCH

ICE CHUTE

CLEANING

SOLUTION FILL

HOLE

WATER LEVEL

PROBE

DUMP

VALVE

38 Part Number 80-1230-9 10/10

Page 39

SF0400/SN0450/SF0600/SN0650/SF0900/

R

CONDENSER FAN

MOTOR

ICE CHUTE

GEAR BOX

AIR-COOLED

CONDENSER

EVAPORATOR

WATER

RESERVOIR

DRAIN FITTING

WATER INLET

DUMP VALVE

SN0950/SF1200/SN1250 Air & Watercooled

AIR BAFFLE

ELECTRICAL

ENTRANCE

GEAR

MOTOR

COMPRESSO

Part Number 80-1230-9 10/10 39

Page 40

GEAR

MOTOR

ICE CHUTE

COVER

HALL EFFECT

SWITCH

WATER

RESERVOIR

CONTROL BOX

CONTROL

BOARD

TOGGLE

SWITCH

40 Part Number 80-1230-9 10/10

Page 41

SF0600/SN0650/SF0900/SN0950/SF1200/

EVAPORATOR

WATER

RESERVOIR

WATER

DUMP VALVE

GEAR

MOTOR

RECEIVER

DRIER

WATER

INLET

CONTROL

BOX

HALL EFFECT

SWITCH

COOL VAPOR

VALV E

EXPANSION

VALV E

QuietQube Only

SUCTION

LINE

&

LIQUID

LINE

SN1250 Remote & QuietQube Model

Part Number 80-1230-9 10/10 41

Page 42

42 Part Number 80-1230-9 10/10

This Page Intentionally Left Blan k

Page 43

Maintenance

!

Caution

!

Caution

!

Warning

!

Warning

Maintenance procedures or failures due to a lack of

maintenance are not covered by the warranty.

Manitowoc Ice Machine Cleaner and Sanitizer are the

only products approved for use in Manitowoc ice

machines.

Use the correct Manitowoc approved metal safe Ice

Machine Cleaner (part number 000000084) and

Sanitizer (part number 94-0565-3). It is a violation of

Federal law to use these solutions in a manner

inconsistent with their labeling. Read and

understand all labels printed on bottles before use.

Do not mix Cleaner and Sanitizer solutions toge ther.

It is a violation of Federal law to use these solutions

in a manner inconsistent with their labeling.

Wear rubber gloves and safety goggles (and/or face

shield) when handling ice machine Cleaner or

Sanitizer.

If you do not understand the procedures or the

safety precautions that must be followed, call your

local Manitowoc Distributor or Manitowoc Ice.

Part Number 80-1230-9 10/10 43

Page 44

Manitowoc’s Cleaning Technology

Manitowoc Flake/Nugget Ice Machines allow the

initiation and completion of a cleaning cycle at the flip

of a switch. This cycle will permit cleaning of all

surfaces that come in contact with the water

distribution system. Periodic maintenance must be

performed that includes sanitizing the bin and adjacent

surface areas, which are not contacted by the water

distribution system.

Depending on local water conditions Manitowoc

recommends initiating preventative maintenance

cleaning procedures between the 6 month cleanings.

This preventive maintenance removes mineral buildup from the evaporator, which results in peak

efficiency and lower operating costs.

This technology allows initiation and completion of a

clean cycle, after which the ice machine automatically

starts ice making again.

There are three separate cleaning procedures.

Heavily Scaled Cleaning Procedure

Perform this procedure if you have some or all of these

symptoms.

• Grinding, popping or squealing noises from the

evaporator.

• Grinding noise from gearbox.

• Ice machine trips speed sensor.

A Cleaning/Sanitizing Procedure must be performed

after this procedure.

Cleaning/Sanitizing Procedure

This procedure must be performed a minimum of once

every six months:

• All ice must be removed from the bin/dispenser.

• The ice machine and bin/dispenser must be

disassembled, cleaned and sanitized.

• The ice machine produces ice with the cleaner and

sanitizer solutions.

• All ice produced during the cleaning and sanitizing

procedure must be discarded

44 Part Number 80-1230-9 10/10

Page 45

Preventative Maintenance Cleaning Procedure

Perform this procedure as often as required for your

water conditions:

• Allows cleaning the ice machine without removing

all of the ice from the bin/dispenser.

• Removes mineral deposits from areas that are in

direct contact with water during the Freeze cycle

(reservoir, evaporator, auger, drain lines).

.

EXTERIOR CLEANING

Clean the area around the ice machine as often as

necessary to maintain cleanliness and efficient

operation. Use cleaners designed for use with

stainless steel products.

Sponge any dust and dirt off the outside of the ice

machine with mild soap and water. Wipe dry with a

clean, soft cloth.

Heavy stains should be removed with stainless steel

wool. Never use plain steel wool or abrasive pads.

They will scratch the panels.

SN012/SN020 Only

WEEKLY

Remove grill from scrap ice tray and wipe splash

panel, scrap ice tray and grill with sanitizer & water

solution. Pour excess solution in scrap ice tray to clear

drain.

TOUCHLESS SENSOR ONLY

Wipe sensor window with a soft cloth and mild

detergent. Rinse with clear water and dry with a clean

soft cloth.

Dust and dirt can be removed from exterior surfaces

with mild household dish-washing detergent and warm

water. Wipe dry with a clean, soft cloth.

Part Number 80-1230-9 10/10 45

Page 46

Preventative Maintenance Procedure

!

Caution

QF0400

Preventative Maintenance Cleaning Procedure

Step 1 Set the toggle switch to the OFF position.

Open bin door and remove the 2 thumbscrews and

back evaporator panel.

Step 2 To start a cleaning cycle, move the toggle

switch to the CLEAN position. Water will flow through

the water dump valve and down the drain. The flush,

gear motor, speed, dump valve and water solenoid

lights will energize to indicate the ice machine is in the

cleaning mode.

Step 3 Wait about 1 minute or until the dump valve

light de-energizes. Lift the front cover on the reservoir

and add the proper amount of Manitowoc Ice Machine

Cleaner

.

Use Manitowoc clear (P/N 000000084) Ice

Machine Cleaner only. It is a violation of Federal

law to use these solutions in a manner

inconsistent with their labeling. Read and

understand all labels printed on bottles before

use.

Model

QF0400 2 oz. (60 ml)

Step 4 The ice machine will automatically time out

four Flush and Rinse cycles, and then stop. The Flush

light remains energized until the toggle switch is

moved to the OFF position. This entire cycle lasts

approximately 11 minutes.

46 Part Number 80-1230-9 10/10

Amount of Cleaner Part

Number 000000084

Page 47

NOTE: Periodic cleaning must be performed on

adjacent surface areas not contacted by the water

distribution system.

Manitowoc recommends disassembling, cleaning and

sanitizing the ice machine and bin/dispenser a

minimum of once every six months.

Step 5

A. The ice machine may be set to start and

finish a cleaning procedure, and then

automatically start ice making again.

B. Wait about one minute into the cleaning cycle

(until the Dump Valve light de-energizes),

then move the switch from CLEAN to ICE

position.

When the cleaning cycle is complete, the Flush light

will turn off and ice making will start automatically.

Part Number 80-1230-9 10/10 47

Page 48

QC0700/QF0800/QF2200/QF2300

!

Caution

Preventative Maintenance Cleaning Procedure

Step 1 Remove front and top covers and set the

toggle switch to the OFF position.

Step 2 To start a cleaning cycle, move the toggle

switch to the CLEAN position. Water will flow through

the water dump valve and down the drain. The flush,

gear motor, speed, dump valve and water solenoid

lights will energize to indicate the ice machine is in the

cleaning mode.

Step 3 Remove the 1-1/2 in. plug from the top cover

of the water reservoir. Wait about one minute or until

the Dump Valve light de-energizes, then add the

proper amount of Manitowoc Ice Machine Cleaner and

reinstall the plug.

Use Manitowoc clear (P/N 000000084) Ice

Machine Cleaner only. It is a violation of Federal

law to use these solutions in a manner

inconsistent with their labeling. Read and

understand all labels printed on bottles before

use.

Model

QF0800/QC0700 3 oz. (90 ml)

QF2200/QF2300 3 oz. (90 ml)

Amount of Cleaner

(Part # 000000084)

Step 4 The ice machine will automatically time out

four Flush and Rinse cycles, and then stop. The Flush

light remains energized until the toggle switch is

moved to the OFF position. This entire cycle lasts

approximately 11 minutes.

48 Part Number 80-1230-9 10/10

Page 49

NOTE: Periodic cleaning must be performed on

adjacent surface areas not contacted by the water

distribution system.

Manitowoc recommends disassembling, cleaning and

sanitizing the ice machine and bin/dispenser a

minimum of once every six months.

Step 5

A. The ice machine may be set to start and

finish a cleaning procedure, and then

automatically start ice making again.

B. Wait about one minute into the cleaning cycle

(until the Dump Valve light de-energizes),

then move the switch from CLEAN to ICE

position.

C. When the cleaning cycle is complete, the

Flush light will turn off and ice making will

start automatically.

Part Number 80-1230-9 10/10 49

Page 50

SN012/SN020/SF0400/SN0450/SF0600/SN0650/

!

Caution

SF0900/SN0950/SF1200/SN1250

Preventative Maintenance

Ice machine cleaner is used to remove lime scale or

other mineral deposits. It is not used to remove algae

or slime. Refer to “Sanitizing Procedure” for removal of

algae and slime. To initiate a cleaning cycle using

Manitowoc’s Cleaning Technology use the following

procedure.

Step 1 To start a cleaning cycle, move the toggle

switch to the CLEAN position. Water will flow through

the water dump valve and down the drain.

Step 2 Remove the cover from the top of the ice

chute. Wait about one minute then add the proper

amount of Manitowoc Ice Machine Cleaner and reinstall cover.

Use only Manitowoc approved Ice Machine

Cleaner part number 000000084. It is a violation

of Federal law to use these solutions in a manner

inconsistent with their labeling. Read and

understand all labels printed on bottles before

use.

Model

SN12 SN20 2 ounces (60 ml)

SF0400 SN0450 2 ounces (60 ml)

SF0600 SN0650 3 ounces (90 ml)

SF0900 SN0950 6 ounces (180 ml)

SF1200 SN1250 8 ounces (240 ml)

SF2000 SN2050 12 ounces (360 ml)

50 Part Number 80-1230-9 10/10

Amount of Cleaner

Part Number 000000084

Page 51

Step 3 The ice machine will automatically time out a

ADD SOLUTION HERE

series of flush and rinse cycles, and then stops. This

entire cycle lasts approximately 30 minutes.

NOTE: Periodic cleaning must be performed on

adjacent surface areas not contacted by the water

distribution system.

NOTE: The ice machine may be set to start and finish

a cleaning procedure, and then automatically start ice

making again.

A. After cleaner is added move the switch from

CLEAN to ICE position.

B. When the cleaning cycle is complete ice

making will start automatically.

Part Number 80-1230-9 10/10 51

Page 52

Changing toggle switch position during clean

cycle:

1. Less than 60 seconds into Clean cycle - The

Clean cycle will end when the toggle switch is

moved to the OFF position.

2. More than 60 seconds into Clean cycle - The ice

machine will complete the clean cycle. Toggle

switch position will determine the next cycle after

the Clean cycle is completed.

• CLEAN POSITION - The ice machine will wait for

a change in toggle switch position.

• OFF POSITION - The ice machine will wait for a

change in toggle switch position.

• ICE POSITION - The ice machine will start making

ice automatically.

3. To abort the clean cycle move the toggle switch

from CLEAN to OFF to CLEAN and back to OFF

within a 15 second time period.

Manitowoc recommends disassembling, cleaning and

sanitizing the ice machine and dispenser every six

months.

52 Part Number 80-1230-9 10/10

Page 53

Heavily Scaled Procedure

QF0400

Procedure to Clean Heavily Scaled Ice Machines

Step 1 Remove all ice from the bin.

Step 2 Remove front and top covers and set the

toggle switch to the OFF position.

Step 3 Disconnect water supply line at float valve

quick disconnect by depressing stainless steel lever.

Step 4 Refer to chart below:

Pre-mix cleaner with lukewarm water in a non-

metallic container.

Amount of Cleaner

Part Number 000000084

Cleaner Water

32 oz

(0.94 L)

16 oz (0.5

L)

Model

QF0400

Water

Reservoir

Capacity

48 oz

(1.4 L)

Step 5 Remove all water from the evaporator and

water reservoir. Start an ice making cycle by moving

the toggle switch to the ICE position. Water will flow

through the water dump valve and down the drain for

45 seconds. After 45 seconds move the toggle switch

to the OFF position. Remove the plug from the top

cover of the water reservoir. Add the entire cleaner/

water solution and re-install the plug. Leave the

cleaner/water solution in the evaporator for a

minimum of 4 hours.

Step 6 Move the toggle switch from OFF to ICE. The

cleaner/water solution will flow through the water

dump valve and down the drain for 45 seconds.

Step 7 Move the toggle switch to the OFF position,

then follow the standard cleaning and

sanitizing procedures for the model ice machine you

are cleaning.

Part Number 80-1230-9 10/10 53

Page 54

QC0700/QF0800/QF2200/QF2300

Procedure to Clean Heavily Scaled Ice Machines

Step 1 Remove all ice from the bin.

Step 2 Remove front and top covers and set the

toggle switch to the OFF position.

Step 3 Disconnect water supply line at float valve

quick disconnect by depressing stainless steel lever.

Step 4 Refer to chart below:

Premix cleaner with lukewarm water in a

non-metallic container.

Amount of Cleaner

Part Number 000000084

Cleaner Water

Model

QF0800/

QC0700

QF2200/

QF2300

Water

Reservoir

Capacity

48 oz (1.4 L) 32 oz (0.94 L) 16 oz (0.5 L)

72 oz (2.1 L) 48 oz (1.4 L) 24 oz (0.7 L)

Step 5 Remove all water from the evaporator and

water reservoir. Start an ice making cycle by moving

the toggle switch to the ICE position. Water will flow

through the water dump valve and down the drain for

45 seconds. After 45 seconds move the toggle switch

to the OFF position. Remove the plug from the top

cover of the water reservoir. Add the entire cleaner/

water solution and re-install the plug. Leave the

cleaner/water solution in the evaporator for a

minimum of 4 hours.

Step 6 Move the toggle switch from OFF to ICE. The

cleaner/water solution will flow through the water

dump valve and down the drain for 45 seconds.

Move the toggle switch to the OFF position, then

follow the standard cleaning and

sanitizing procedures for the model ice machine you

are cleaning.

54 Part Number 80-1230-9 10/10

Page 55

SN012/SN020/SF0400/SN0450/SF0600/SN0650/ SF0900/SN0950/SF1200/SN1250

Procedure to Clean Heavily Scaled Flake/Nugget Ice Machines

Ice machines that are heavily scaled or have not been

cleaned on a regular basis will need to run this

Procedure. Failure to do so may result in binding of the

auger as the lime scale releases from the auger and

evaporator barrel.

Step 1 Remove panels and set the ICE/OFF/CLEAN

toggle switch to the OFF position.

Step 2 Remove all ice from the bin.

Step 3 Turn off the water supply to the ice machine.

Step 4 Place ICE/OFF/CLEAN toggle switch in the

CLEAN position. The dump valve will open and drain

the water from the evaporator and reservoir.

Step 5 Wait approximately 30 seconds (or until the

evaporator is drained) and place the toggle switch in

the OFF position.

Step 6 Refer to chart and add the correct amount of

cleaner for your model ice machine.

Model

SN12 SN20

SF0400 SN0450

SF0600 SN0650

SF0900 SN0950

SF1200 SN1250

SF2000 SN2050

Amount of Cleaner

Part Number 000000084

16 ounces (473 ml)

32 ounces (950 ml)

Part Number 80-1230-9 10/10 55

Page 56

Step 1 Turn on the water supply to the ice machine.

Important

ADD SOLUTION HERE

Leave the cleaner/water solution in the

evaporator for a minimum of 4 hours.

Step 2 Move the toggle switch to the ICE position.

The compressor will energize and produce ice with the

cleaning solution. Continue the freeze cycle for 15

minutes.

Step 3 Move the toggle switch to the OFF position,

then follow the standard cleaning and sanitizing

procedures.

56 Part Number 80-1230-9 10/10

Page 57

Cleaning And Sanitizing Procedure

QF0400

Cleaning and Sanitizing Procedure

Step 1 Set the toggle switch to the OFF position.

Open bin door and remove the 2 thumbscrews and

back evaporator panel.

Step 2 To start a cleaning cycle, move the toggle

switch to the CLEAN position. Water will flow through

the water dump valve and down the drain. The flush,

gear motor, speed, dump valve and water solenoid

lights will energize to indicate the ice machine is in the

cleaning mode.

Step 3 Wait about 1 minute or until the dump valve

light de-energizes. Lift the front cover on the reservoir

and add the proper amount of Manitowoc Ice Machine

Cleaner

Step 4 The ice machine will automatically time out

four Flush and Rinse cycles, and then stop. The Flush

light remains energized until the toggle switch is

moved to the OFF position. This entire cycle lasts

approximately 11 minutes.

NOTE: The ice machine may be set to start and finish

a cleaning procedure, and then automatically start ice

making again.

.

Model

QF0400 2 oz. (60 ml)

A. Wait about one minute into the cleaning cycle

(until the Dump Valve light de-energizes),

then move the switch from CLEAN to ICE

position.

B. When the cleaning cycle is complete, the

Flush light will turn off and ice making will

start automatically.

Amount of Cleaner

Part Number 000000084

Part Number 80-1230-9 10/10 57

Page 58

Step 5 Disconnect water supply line at float valve

quick disconnect by depressing stainless steel lever.

Step 6 Mix 2 oz. (60 ml) of Manitowoc Ice Machine

Sanitizer with 3 gal. (11 L) of cool water.

Model

QF0400

Amount of

Sanitizer/Water

2 oz. (60 ml)

mixed with 3 gal.

(11 L) cool water

Step 7 To start the sanitizing procedure, move the

toggle switch to the ICE position. The gear motor will

start and the water dump valve will energize. Water

will flow through the water dump valve and down the

drain. The control board light for the dump valve, gear

motor, and speed will energize to indicate the ice

machine is starting the ice making sequence.

Step 8 Wait 45 seconds until the Dump Valve light

de-energizes and the Water Level Probe light

energizes. Fill the water reservoir with the pre-mixed

solution of sanitizer/water. When water contacts the

water level probe, the compressor will energize.

The ice machine will freeze and discharge the

sanitizing solution into the bin. Add the remaining

sanitizer/water solution when the water level in the

reservoir drops.

NOTE: Do not allow the water level to drop below the

water level probes. The ice machine will discontinue

the cycle when the water level probes open (lose

water contact) for more than 90 seconds (30 seconds

on replacement boards).

58 Part Number 80-1230-9 10/10

Page 59

Step 9 After the entire sanitizer/water solution has

been added to the reservoir, reconnect the water

supply line at the float valve quick disconnect.

The ice machine will continue to freeze and discharge

the sanitizing solution into the bin.

Allow the cycle to run for ten minutes to remove all

sanitizing solution from the water reservoir.

Step 10 Place the toggle switch in the OFF position,

discard all ice produced and refer to disassembly for

cleaning and sanitizing.

Part Number 80-1230-9 10/10 59

Page 60

QC0700/QF0800/QF2200/QF2300

Cleaning and Sanitizing Procedure

Step 1 Remove front and top cover and set the

toggle switch to the OFF position.

Step 2 Remove all ice from the bin/dispenser.

Step 3 Disconnect water supply line at float valve

quick disconnect by depressing stainless steel lever.

Step 4 Remove the top cover from the water

reservoir.

Step 5 Remove the water level probes from the top

cover and with wires attached, place the water level

probes (stand upright) inside the water reservoir.

Step 6 To start the cleaning procedure, move the

toggle switch to the ICE position. The gear motor will

start and the water dump valve will energize. Water

will flow through the water dump valve and down the

drain. The control board light for the dump valve, gear

motor, and speed will energize to indicate the ice

machine is starting the ice making sequence.

Step 7 Wait 45 seconds until the Dump Valve light

de-energizes and the Water Level Probe light

energizes. Add the proper amount of Manitowoc Ice

Machine Cleaner to the water reservoir.

Model

QF0800/QC0700 3 oz. (90 ml)

QF2200/QF2300 3 oz. (90 ml)

Amount of Cleaner

Part Number 000000084

Step 8 Reconnect the water supply line to the float

valve. When water contacts the water level probe, the

compressor will energize. The ice machine will freeze

and discharge the cleaning solution into the bin.

Continue the Freeze cycle for ten minutes to remove

all cleaning solution from the water reservoir.

Step 9 Discard all ice produced during the cleaning

process.

Step 10 Disconnect water supply line at float valve

quick disconnect by depressing stainless steel lever.

60 Part Number 80-1230-9 10/10

Page 61

Step 11 Mix 2 oz. (60 ml) of Manitowoc Ice Machine

Sanitizer with 3 gal. (11 L) of cool water.

Model

QF0800/QC0700/QF2200/

QF2300

Amount of

Sanitizer/Water

2 oz. (60 ml)

mixed with 3 gal. (11 L)

cool water

Step 12 To start the sanitizing procedure, move the

toggle switch to the ICE position. The gear motor will

start and the water dump valve will energize. Water

will flow through the water dump valve and down the

drain. The control board light for the dump valve, gear

motor, and speed will energiz0e to indicate the ice

machine is starting the ice making sequence.

Step 13 Wait 45 seconds until the Dump Valve light

de-energizes and the Water Level Probe light

energizes. Fill the water reservoir with the pre-mixed

solution of sanitizer/water. When water contacts the

water level probe, the compressor will energize.

The ice machine will freeze and discharge the

sanitizing solution into the bin. Add the remaining

sanitizer/water solution when the water level in the

reservoir drops.

NOTE: Do not allow the water level to drop below the

water level probes. The ice machine will discontinue

the cycle when the water level probes open (lose

water contact) for more than 90 seconds (30 seconds

on replacement boards).

Step 14 After the entire sanitizer/water solution has

been added to the reservoir, reconnect the water

supply line at the float valve quick disconnect.

The ice machine will continue to freeze and discharge

the sanitizing solution into the bin.

Allow the cycle to run for ten minutes to remove all

sanitizing solution from the water reservoir.

Step 15 Place the toggle switch in the OFF position,

discard all ice produced and refer to disassembly for

cleaning and sanitizing.

Part Number 80-1230-9 10/10 61

Page 62

SN012/SN020/SF0400/SN0450/SF0600/SN0650/

!

Caution

SF0900/SN0950/SF1200/SN1250

Cleaning & Sanitizing Procedure

Ice machines that are heavily scaled or have not been

cleaned on a regular basis will need to run the Heavily

Scaled Cleaning Procedure before this one. Failure to

do so may result in binding of the auger as the lime

scale releases from the auger and evaporator barrel.

Ice machine cleaner is used to remove lime scale or

other mineral deposits. Ice machine sanitizer is used

to remove algae or slime.

Step 1 Remove panels and set the ICE/OFF/CLEAN

toggle switch to the OFF position.

Step 2 Turn off the water supply to the ice machine.

Step 3 Remove all ice from the bin.

Step 4 Place ICE/OFF/CLEAN toggle switch in the

CLEAN position. The dump valve will open and drain

the water from the evaporator and reservoir.

Step 5 Wait approximately 30 seconds (or until the

evaporator is drained) and place the toggle switch in

the OFF position.

Use only Manitowoc approved Ice Machine

Cleaner part number 000000084. It is a violation

of Federal law to use these solutions in a manner

inconsistent with their labeling. Read and

understand all labels printed on bottles before

use.

62 Part Number 80-1230-9 10/10

Page 63

Step 6 Refer to chart and premix the correct solution

of cleaner and cool water for your model ice machine.

Amount of

Model

SN12 SN20 2 oz (60 ml) 32 oz (1 liter)

SF0400 SN0450 2 oz (60 ml) 32 oz (1 liter)

SF0600 SN0650 3 oz (90 ml) 32 oz (1 liter)

SF0900 SN0950 4 oz (120 ml) 32 oz (1 liter)

SF1200 SN1250 8 oz (235 ml) 64 oz (2 liter)

SF2000 SN2050 8 oz (235 ml) 64 oz (2 liter)

Cleaner

Part Number

000000084

Amount of

Water

Step 7 Remove the top cover from the ice chute and

pour the cleaner/water solution into the evaporator.

Add the entire amount of premixed solution (excess

solution will exit through the overflow tube in the water

reservoir).

Step 8 Replace the ice chute cover and allow the ice

machine to stand for 30 minutes.

Step 9 Turn on the water supply to the ice machine.

Step 10 Move the toggle switch to the ICE positi on.

The compressor will energize and produce ice with the

cleaning solution.

Step 11 The ice machine will freeze and discharge

the cleaning solution into the bin. Allow the cycle to run

for 15 minutes.

Step 12 Place the toggle switch in the OFF position

and discard all ice produced during the cleaning

process.

Step 13 Turn off the water supply to the ice machine.

Step 14 Place ICE/OFF/CLEAN toggle switch in the

CLEAN position. The dump valve will open and drain

the water from the evaporator and reservoir.

Step 15 Wait approximately 30 seconds (or until the

evaporator is drained) and place the toggle switch in

the OFF position.

Part Number 80-1230-9 10/10 63

Page 64

Step 16 Refer to chart and premix the correct

solution of sanitizer and cool water for your model ice

machine.

Amount of Sanitizer

Model

SN12

SN20

SF0400

SN0450

SF0600

SN0650

SF0900

SN0950

SF1200

SN1250

Part Number

94-0565-3

2 ounces (60 ml) 3 gallons (11.4L)

Amount of Water

Step 17 Remove the top cover from the ice chute and

pour the sanitizer/water solution into the evaporator.

Add the entire amount of premixed solution (excess

solution will exit through the overflow tube in the water

reservoir).

Step 18 Replace the ice chute cover and allow the

ice machine to stand for 30 minutes.

Step 19 Turn on the water supply to the ice machine.

Step 20 Move the toggle switch to the ICE position.

The compressor will energize and produce ice with the

sanitizing solution.

Step 21 The ice machine will freeze and discharge

the sanitizing solution into the bin. Allow the cycle to

run for 15 minutes.

Step 22 Discard all ice produced during the sanitizing

process.

Step 23 Place the toggle switch in the CLEAN

position. The ice machine will automatically time out a

series of flush and rinse cycles, and then stops. This

entire cycle lasts approximately 30 minutes.

Step 24 Refer to Disassembly For Cleaning/

Sanitizing for your specific model and remove, clean

and sanitize all parts listed.

64 Part Number 80-1230-9 10/10

Page 65

Component Disassembly For Cleaning

!

Warning

!

Warning

!

Caution

And Sanitizing

Disconnect electric power to the ice machine at the

electric switch box before proceeding.

Wear rubber gloves and safety goggles (and/or face

shield) when handling Ice Machine Cleaner or

Sanitizer.

Do not mix Cleaner and Sanitizer solutions toge ther.

It is a violation of Federal law to use these solutions

in a manner inconsistent with their labeling.

GENERAL INFORMATION

1. Turn off the water supply to the ice machine at the

water service valve, or disconnect water supply

line at float valve quick disconnect by depressing

stainless steel lever.

2. Remove the components you want to clean or

sanitize. See the pages specific to the model you

are working on for removal procedures.

3. Soak the removed parts to clean and sanitize.

Solution

Type

Cleaner 1 gal. (4 L) 16 oz. (500 ml) cleaner

Sanitizer 3 gal. (11 L) 2 oz. (60 ml) sanitizer

Water Mixed With

4. Use a soft-bristle brush or sponge (NOT a wire

brush) to carefully clean the parts.

5. Use the solution and a brush to clean all

disassembled components and the inside of the

bin.

6. Re-install the removed parts and turn on the water

and electrical supply.

Part Number 80-1230-9 10/10 65

Page 66

QF400

WATER LEVEL

PROBES

Removal of Parts for Cleaning and Sanitizing

Water Level Probe Removal

1. Place the toggle switch in the OFF position, turn

off the water supply and disconnect electrical

power to the ice machine.

2. Disconnect water supply line at float valve quick

disconnect by depressing stainless steel lever.

3. Pull up on water level probes to remove.

4. Disconnect wires from water level probes or

control board.